Page 1

HART XL

INSTALLATION

OPERATION &

COMMISSIONING

MANUAL

MANUAL NO. TM0042

Page 2

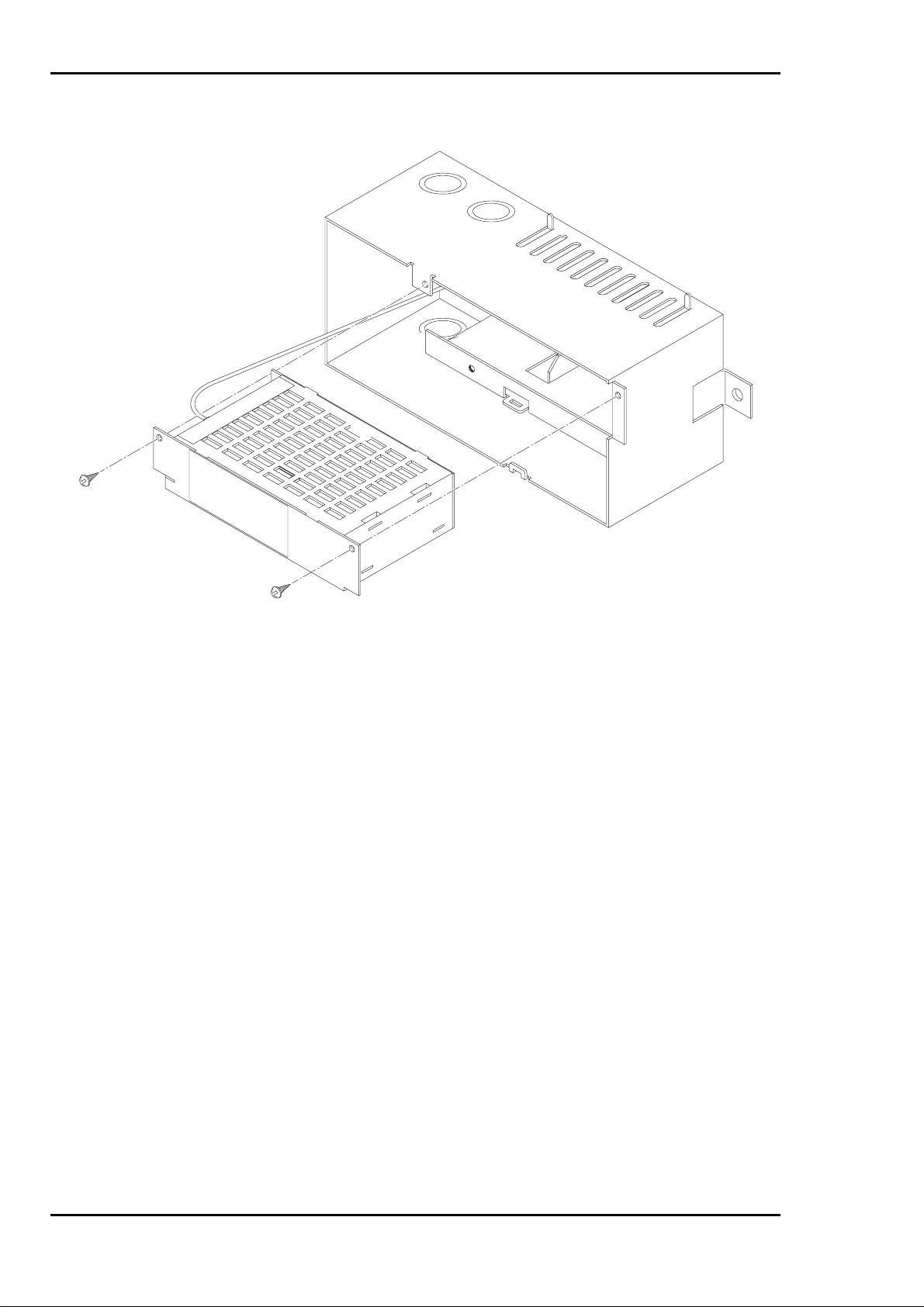

Installation, Operation and Maintenance Manual

FOREWORD

This manual is intended to clearly and accu rately reflect the High-Sensitivity Smoke Detector system with

the Modular Control Equipment. This manual is to be used by trained distributors only. This publication

describes the installation, operation and maintenance for the High-Sensitivity Smoke Detector system.

TERMS AND ABBREVIATIONS

AC/a.c.- Alternating Current

AH Amperes per Hour

CPU- Central Processing Unit

DC/d.c.- Direct Current

DIA- Diameter

ESC- Escape

ESP- Extended Sampling Point

FT- Feet or Foot

FT/S- Feet per Second

GND- Ground

HSSD®- High Sensitivity Smoke Detector

HVAC- Heat, Ventilation and Air-Conditioning

IIM- Intelligent Interface Module

ISOL- Isolate

Km Kilometre

LCD- Liquid Crystal Display

LED- Light Emitting Diode

mA- Milliamperes

mm Millimetres

m/s Metres per Second

PC- Personnel Computer

PCB Printed Circuit Board

P/N - Part Number

Sq. Ft.- Square Feet

TBA To Be Advised

VVolts

VAC- Voltage Alternating Current

VDC - Voltage Direct Current

VS.- Versus

%/m Percent Per Metr e

%/ft Percent per Feet

Issue 1 Page i

February 2001

Page 3

Installation, Operation and Maintenance Manual

TABLE OF CONTENTS

Para Page

1 INTRODUCTION........................................................................................................................1-1

1.1 Features ................................................................................................................................1-1

2 SYSTEM FUNCTIONAL DESCRIPTION...................................................................................2-1

2.1 General..................................................................................................................................2-1

2.2 Overall Functional Description ..............................................................................................2-1

2.3 Detector.................................................................................................................................2-5

2.3.1 Detector Head ..................................................................................................................2-7

2.3.2 Termination Board............................................................................................................2-9

2.3.3 Fan Module ....................................................................................................................2-11

2.4 Display Module....................................................................................................................2-11

2.5 Intelligent Interface Module.................................................................................................2-12

2.5.1 PC Port...........................................................................................................................2-13

2.5.2 RS-485 Connection........................................................................................................2-13

2.5.3 Telephone Port (with optional modem) ..........................................................................2-13

2.6 Power Su pplies ..............................................................................................................2-14

2.6.1 Self Contained Power Supply ........................................................................................2-14

2.6.2 Battery Calculation .........................................................................................................2-14

2.7 Use of the Elutriator.............................................................................................................2-16

3 CONTROLS AND INDICATORS................................................................................................3-1

3.1 Status Indicator......................................................................................................................3-1

3.2 Termination Board Indicator..................................................................................................3-1

3.3 Display Module......................................................................................................................3-1

3.4 Sounder.................................................................................................................................3-6

3.5 LaserNET Software...............................................................................................................3-7

4 INSTALLATION..........................................................................................................................4-1

4.1 Introduction............................................................................................................................4-1

4.2 Locating the Detector ............................................................................................................4-1

4.3 Installing the Detector............................................................................................................4-2

4.4 Termination Board Field Wiring.............................................................................................4-5

4.5 Installing the Display Module.................................................................................................4-6

4.5.1 Installing the Remote Display Module..............................................................................4-7

4.6 Installing Self Contained Power Supply ................................................................................4-9

4.7 Installing the Intelligent Interface Module............................................................................4-12

4.7.1 Wiring the RS-485 Network............................................................................................4-12

4.7.2 Installing the Stand Alone Intelligent Interface Module.................................................4-12

4.7.3 Setting Detector Address ...............................................................................................4-16

4.7.4 Installation Checks .........................................................................................................4-17

4.7.5 Installing Telephone Line to the Intelligent Interface Module.........................................4-17

4.7.6 Software Configuration...................................................................................................4-17

4.8 Programming.......................................................................................................................4-17

4.9 Installation Method for the Elutriator....................................................................................4-17

Page ii Issue 1

February 2001

Page 4

Installation, Operation and Maintenance Manual

TABLE OF CONTENTS (Continued)

Para Page

5 SYSTEM DESIGN ......................................................................................................................5-1

5.1 Introduction ............................................................................................................................5-1

5.2 Selecting the Correct Detector...............................................................................................5-1

5.2.1 Ultra Detector....................................................................................................................5-1

5.2.2 Standard Detector.............................................................................................................5-2

5.3 Air Sampling Pipe Network Design........................................................................................5-2

5.4 Pipe Network Design Terms and Details...............................................................................5-2

5.5 Air Velocity.............................................................................................................................5-3

5.6 Branch Point ..........................................................................................................................5-3

5.7 Elutriator.................................................................................................................. ...............5-3

5.8 Elbow, Standard 90 degree ...................................................................................................5-3

5.9 Sweep Elbow......................................................................................................................... 5-3

5.9.1 Equivalent Feet.................................................................................................................5-4

5.9.2 Extended Sampling Point (ESP).......................................................................................5-4

5.9.3 Sampling Point (SP) .........................................................................................................5-4

5.10 Pipe Segment ........................................................................................................................5-4

5.11 Sampling Hole........................................................................................................................5-4

5.12 System Transport Time..........................................................................................................5-5

5.13 Suction Pressure ....................................................................................................................5-7

5.14 Zones of Varying Static Press ure ..........................................................................................5-7

5.15 Distributed Pipe Network Sampling -

Symmetrical and Non-Symmetrical Balanced Systems ........................................................5-7

5.16 Return Air Grill Sampling .......................................................................................................5-7

5.17 Return Air Duct Sampling ......................................................................................................5-7

5.18 Selecting a Sampling Method................................................................................................5-7

5.18.1 Telephone Central Offices................................................................................................5-8

5.18.2 Computer Rooms..............................................................................................................5-8

5.18.3 Clean Rooms....................................................................................................................5-8

5.18.4 Atriums..............................................................................................................................5-8

5.18.5 Office Areas......................................................................................................................5-8

5.18.6 Warehous e Stora ge..........................................................................................................5-8

5.19 Computer Balanced System Design using “SNIFF“ Version 3.0 Software............................5-9

5.19.1 Parameters for Computer Balanced Systems..................................................................5-9

5.20 Using the “SNIFF“ Version 3.0 Software ...............................................................................5-9

5.21 Return Air Duct Detection Design........................................................................................5-10

5.22 Sampling Pipe Requirements ..............................................................................................5-11

5.23 Return Air Grill Sampling Design.........................................................................................5-12

5.24 Installing the Air-Sampling Pipe Network.............................................................................5-13

5.25 Final touches........................................................................................................................5-14

5.25.1 Air-Samp li ng Pipe Labe ls ...............................................................................................5-14

5.25.2 Sample Port Labels ........................................................................................................5-14

5.25.3 Sample Point Labels.......................................................................................................5-14

5.25.4 Mini Sample Point Labels ...............................................................................................5-14

6 SYSTEM COMMISSIONING ......................................................................................................6-1

6.1 Introduction ............................................................................................................................6-1

6.2 System Checkout...................................................................................................................6-1

6.3 Monitoring and Testing Systems ...........................................................................................6-1

6.4 Transport-Time Testing..........................................................................................................6-2

6.4.1 Commissioning Sheet.......................................................................................................6-2

6.5 Suction Pressure Testing.......................................................................................................6-2

6.6 Gross Smoke Test .................................................................................................................6-3

6.6.1 Burning Wire Test.............................................................................................................6-3

Issue 1 Page iii

February 2001

Page 5

Installation, Operation and Maintenance Manual

TABLE OF CONTENTS (Continued)

Para Page

7 ROUTINE MAINTENANCE ........................................................................................................7-1

7.1 Introduction............................................................................................................................7-1

7.2 Scheduled Maintenance........................................................................................................7-1

7.3 Maintenance Procedures ......................................................................................................7-1

7.3.1 Visual Check ....................................................................................................................7-1

7.3.2 Battery-Status Check .......................................................................................................7-1

7.3.3 Gross Smoke Test............................................................................................................7-1

7.3.4 Sampe-Hole Airflow Verificat ion Test...............................................................................7-2

7.3.5 Detector Sensitivity Test...................................................................................................7-2

7.3.6 Clean Detector .................................................................................................................7-2

7.3.7 Clean Elutriator.................................................................................................................7-3

8 TROUBLE SHOOTING AND CORRECTIVE MAINTENANCE..................................................8-1

8.1 Introduction............................................................................................................................8-1

8.2 Standard Fault Isolation Techniques.....................................................................................8-1

8.2.1 Visual Inspection ...................................................................................................................8-1

8.2.2 Power Checks .......................................................................................................................8-1

8.3 Troubleshooting.....................................................................................................................8-2

8.4 Replacement .........................................................................................................................8-8

8.4.1 Replacing the Detector.....................................................................................................8-8

8.4.2 Replacing the Detector Head...........................................................................................8-9

8.4.3 Replacing the Termination Board...................................................................................8-11

8.4.4 Replacing the Fan Module .............................................................................................8-14

8.4.5 Replacing the Display Module........................................................................................8-15

8.4.6 Replacing the Intelligent Interface Module.....................................................................8-17

8.4.7 Replacing the Single Zone Power Supply......................................................................8-17

9 PARTS LIST...............................................................................................................................9-1

APPENDIX...................................................................................................................................A1

LIST OF ILLUSTRATIONS

Figure Page

1.1

2.1

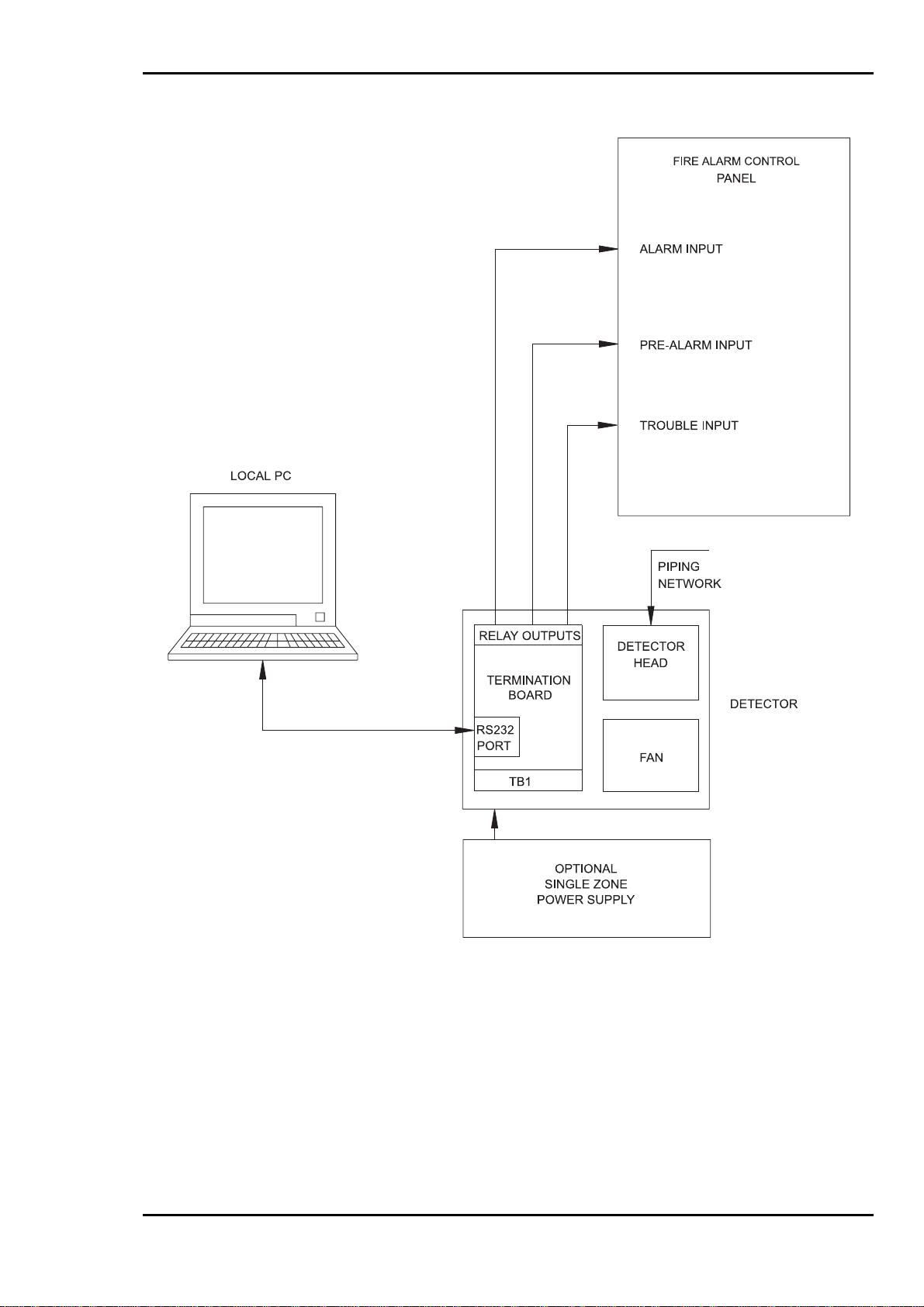

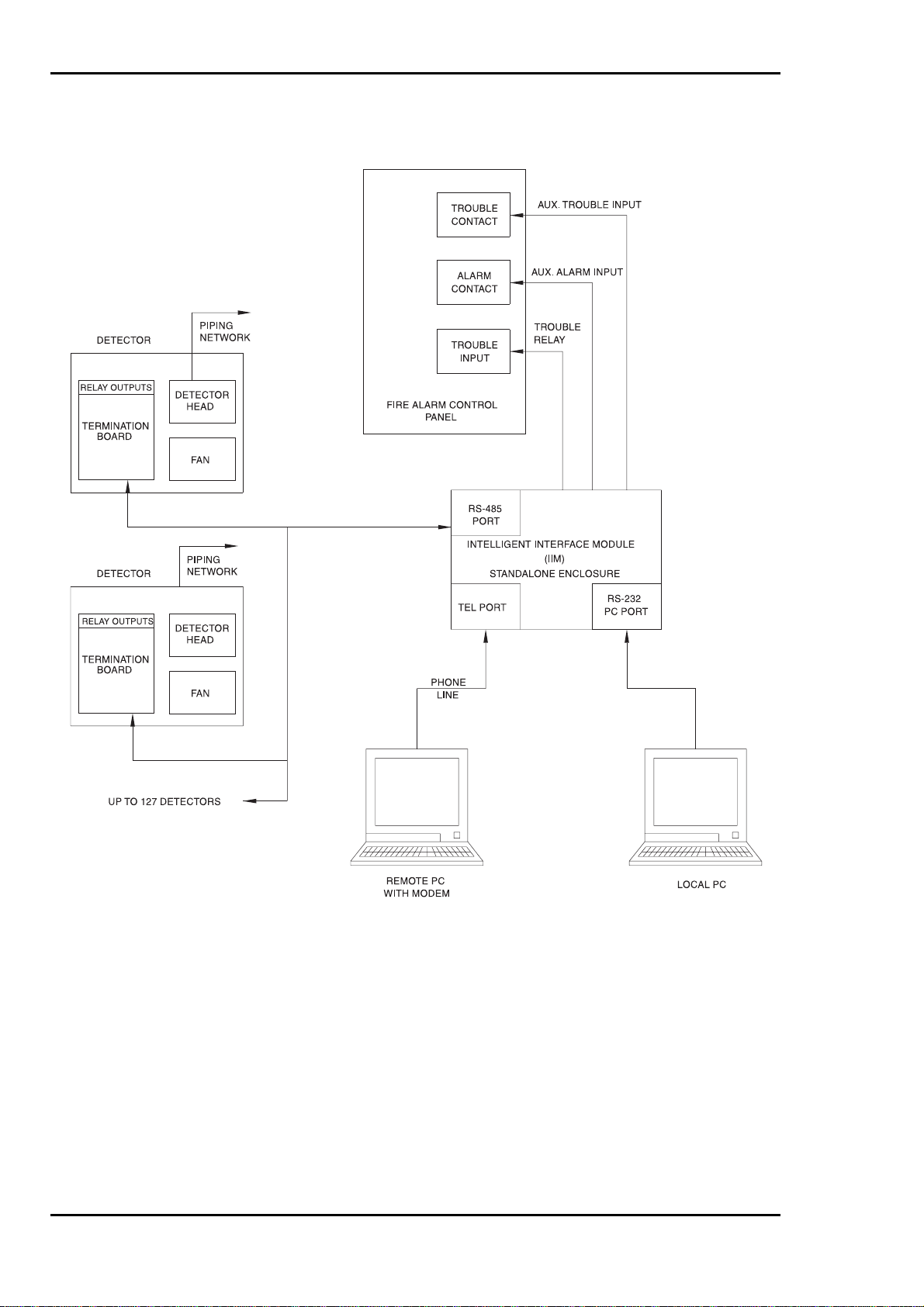

2.2 Typical System with Stand Alone Intelligent Interface Module...................................................2-4

2.3 Detector Block Diagram..............................................................................................................2-6

2.4 Detector Head Views..................................................................................................................2-8

2.5 Termination Board Internal Wiring Diagram.............................................................................2-10

2.6 Self Contained Power Supply Diagram....................................................................................2-15

2.7 Elutriator Cut-Away View..........................................................................................................2-16

4.1

4.2

4.3

4.4

4.5a Connecting the Internal Power Supply.....................................................................................4-10

4.5b Installing the Single Zone Power Supply..................................................................................4-11

4.6 Intelligent Interface Module Stand Alone Mounted (4-Wire) ....................................................4-14

4.7 Intelligent Interface Module Stand Alone Mounted (2-Wire) ....................................................4-15

Detector......................................................................................................................................1-3

Typical Stand Alone System.......................................................................................................2-3

Detector Installation Diagram.....................................................................................................4-4

Termination Board External Wirin g Diagra m..............................................................................4-5

Installing the Display Module......................................................................................................4-6

Installing the Remote Display Module........................................................................................4-8

Page iv Issue 1

February 2001

Page 6

Installation, Operation and Maintenance Manual

LIST OF ILLUSTRATIONS (continued)

Figure Page

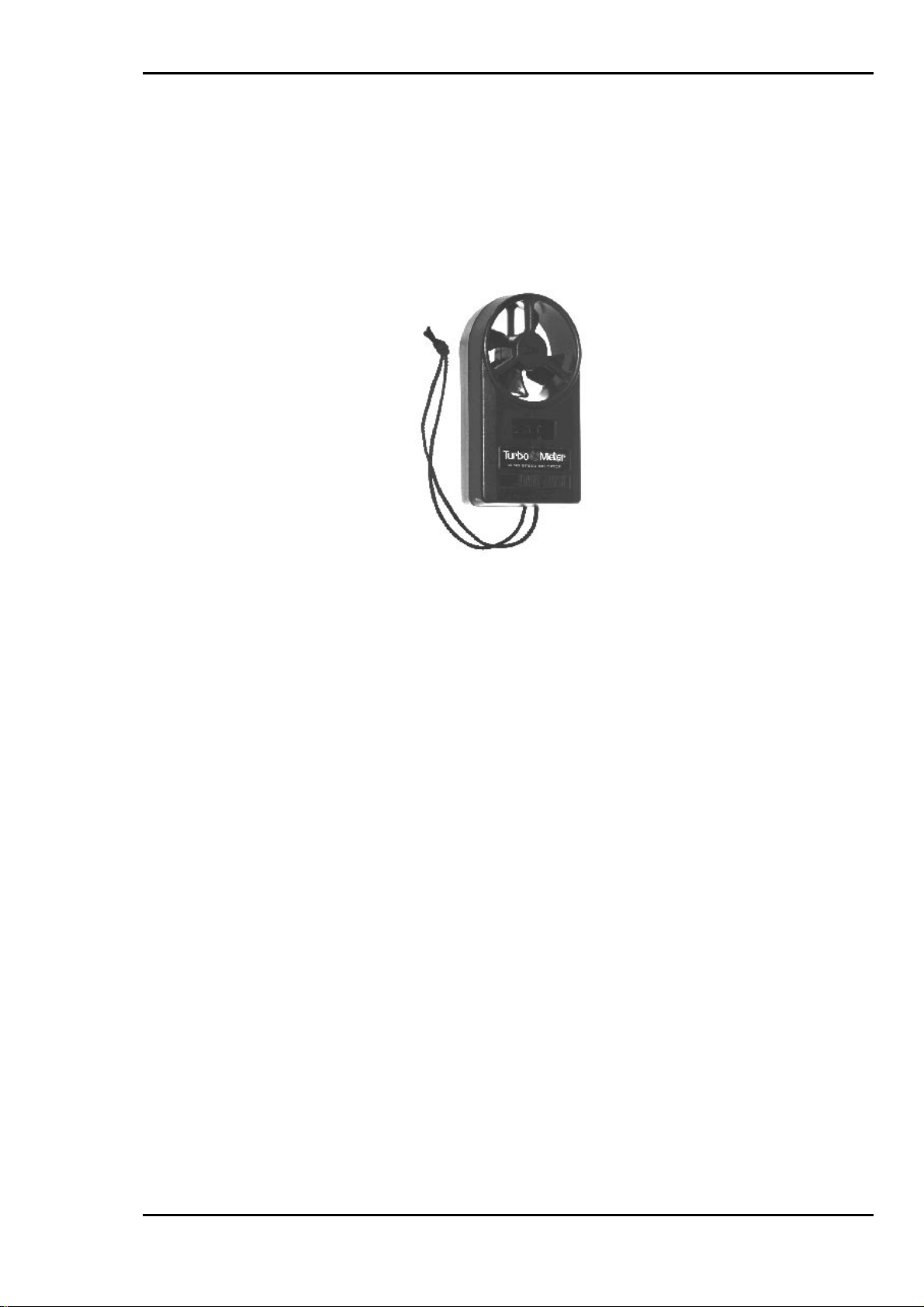

5.1 Anemometer................................................................................................................................5-3

5.2 Return Air Grill Sampling Method .............................................................................................5-12

5.3 Mini Sample Point Kit................................................................................................................5-13

6.1 Magnehelic Test Set-Up .............................................................................................................6-3

8.1 Paddle Lever...............................................................................................................................8-9

8.2 Replacing the Detector Head....................................................................................................8-10

8.3 Replacing the Termination Board .............................................................................................8-12

8.4 Termination Board Internal Wiring Diagram .............................................................................8-13

8.5 Replacing the Fan Module........................................................................................................8-14

8.6 Replacing the Display Module ..................................................................................................8-15

8.7 Replacing the Remote Display Module.....................................................................................8-16

8.8 Replacing the Single Zone Power Supply ................................................................................8-18

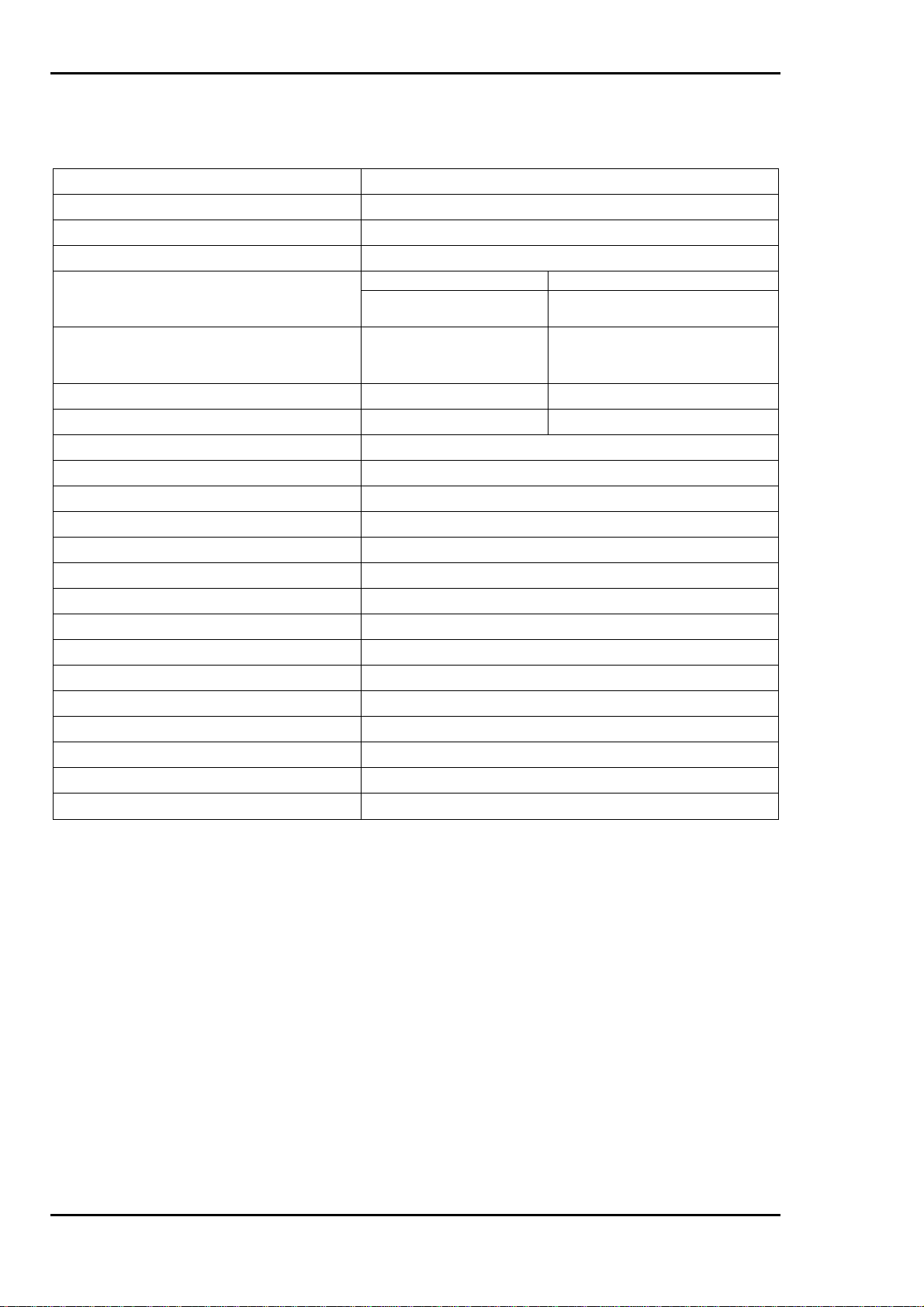

LIST OF TABLES

Table Page

1.1 Detector Technical Specifications...............................................................................................1-2

2.1 Detector Specifications ...............................................................................................................2-5

2.2 Display Module Specifications..................................................................................................2-12

2.3 Intelligent Interface Module Specifications ...............................................................................2-13

2.4 Self Contained Power Supply Assembly ..................................................................................2-14

4.1 Detector Address Switch Settings ............................................................................................4-16

5.1 Elbow Equivalent Measurements ...............................................................................................5-4

5.2 Minimum Detector Sensitivity Se tti ng .........................................................................................5-6

8.1 Troubleshooting Guide................................................................................................................8-2

8.2 Intelligent Interface Module to Computer Com mun ic at ions Faults.............................................8- 3

8.3 General System Faults ...............................................................................................................8-4

8.4 Intelligent Interface Module to Termination Board Communications Problems..........................8-5

8.5 Faults Indicated on the Display Module or LaserNET Graphic Display......................................8-6

Issue 1 Page v

February 2001

Page 7

Installation, Operation and Maintenance Manual

SAFETY SUMMARY

Installation Precautions

reliability:

Several different sources of power can be connected to this High Sensitivity Smoke Detection system.

Disconnect all sources of power before servicing. The High Sensitivity Smoke Detector (HSSD) system and

associated equipment may be damaged by removing and/or inserting cards, modules, or interconnecting cables while

the unit is energised. Do not attempt to install, service, or operate this unit until this manual is read and understood.

Application of the system:

the HSSD system must be monitored before final commissioning. Special attention should be given to systems

installed where elevated levels of background ambient smoke or particulate concentrations are present within the

protected area. Examples of such applications would be: kitchens, boiler rooms, manufacturing or other processes

where open flames or unprotected heating surfaces are present.

This monitoring must be conducted for a minimum of two weeks and be conducted during all normal

situations which may cause an elevated level of smoke or particulate to occur in the protected area. This

monitoring process will determine the most appropriate detector sensitivity, alarm threshold and delay

settings for the application.

Use with fire suppression systems:

-

the release of a fire suppression system

should provide one initiation signal of a cross zo ned detection system.

Static Electricity:

-

When handling these components or modules, wear an antistatic wrist strap or grounding device.

Electronic components and modules can be damaged by small amounts of static electricity.

To reduce the possibility of inadvertent alarms caused by “normal” ambient conditions,

GENERAL SAFETY NOTICES

The following general safety notices supplement specific warnings and cautions appearing in the manual. The safety

precautions in this section must be underst ood and app lied during operation and maintenance.

Adherence to the following will aid in problem-free installation with long-term

Under no circumstances should the detector be used to directly initiate

. When used as detection for a fire suppression system, the detector

The following must be observed to maintain personnel safety.

TEST EQUIPMENT

Make certain test equipment is in good operating condition. Do not touch live equipment or personnel working on live

equipment while holding a test meter. Some types of measuring devices should not be grounded; these devices

should not be held when taking measurements.

FIRST AID

Any injury, no matter how slight, should never go unattended. Always obtain first aid or medical attention

immediately.

GENERAL PRECAUTIONS

The following general safety precautions are to be observed at all times:

1. All electrical components associated with equipment shall be installed and grounded in accordance with local

regulation requirements.

2. Special precautionary measures are essential to prevent applying power to equipment at any time maintenance

work is in progress.

3. Before working on electrical equipment, use a voltmeter to ensure that system is not energised.

4. When working near electricity, do not use metal rules, flashlights, metallic pencils, or any other objects having

exposed conductive material.

5. When connecting a meter to terminals for measurement, use range higher than expected voltage.

Page vi Issue 1

February 2001

Page 8

Page 9

Installation, Operation and Maintenance Manual

1 INTRODUCTION

This manual contains operation, installation, maintenance, trouble shooting and parts list information for

the High Sensitivity Smoke Detection (HSSD) system.

The HSSD system is designed to provide high sensitivity smoke detection for an area up to 2000 sq/m

(20,000 sq/ft). Detection of smoke is achieved by using a fan to draw air from the protected area through

sampling pipe network back to a Detector. The Detector will analyse the air for the presence of smoke.

The Detector uses laser based particle counting technology to achieve the highest levels of performance.

The unique design ensures that only smoke particles that pass through a focused laser beam are

detected. Consequently, the Detector’s performance will not be affected by the build up of dirt within the

detection head chamber. Therefore no filters are required and system maintenance is minim al.

Air is continuously sampled from risk areas along a pipe network to the Detector. The standard Detector

has a dynamic sensitivity range from 0.005%/m to 1%/m (0.0015% to 0.3%/ft) obscuration. Alternatively

an ultra Detector has an increased sensitivity range 0.001%/m to 0.1% to (0.0003% to 0.03%/ft) for use

in very clean applications. The Detector sensitivity can be set to accommodate varying background

levels.

A Display Module provides a visual indication of the system status, smoke level, alarm and trouble

conditions of the Detector. Software conditions in the Display Module are condition specific i.e. when the

system is in quiescent “Normal” is displayed with the company logo and time and date information.

Should an alarm or trouble condition be activated then the relevant condition will be displayed. The

Display Module can be fitted into the Detector or remotely mounted.

A termination board located within the Detector provides micro processor control of the HSSD system.

The termination board provides the inter fac e betw een the det ec tor head, the RS4 85 network, the Display

Module and the PC Port. An on board memory stores configuration details, history events and system

information.

1.1 Features

The following is a list of major features of the HSSD system.

Laser based particle counting technology.

No particle filters required.

Service port located on the side of the Detector to allow ease of commissioning.

Attachable 1 amp Self Contained Power Supply and battery back up unit.

On site sensitivity selection, to meet specific application requirements.

Four individual alarm levels (Pre-Alarm levels 1 and 2/Alarm levels 1 and 2).

Lasernet network options, 1 to 127 Detectors per system. Using RS485 communications.

Modular design for fast and easy servicing.

Smoke history and event log storage and battery back-up.

Issue 1 Page 1-1

February 2001

Page 10

Installation, Operation and Maintenance Manual

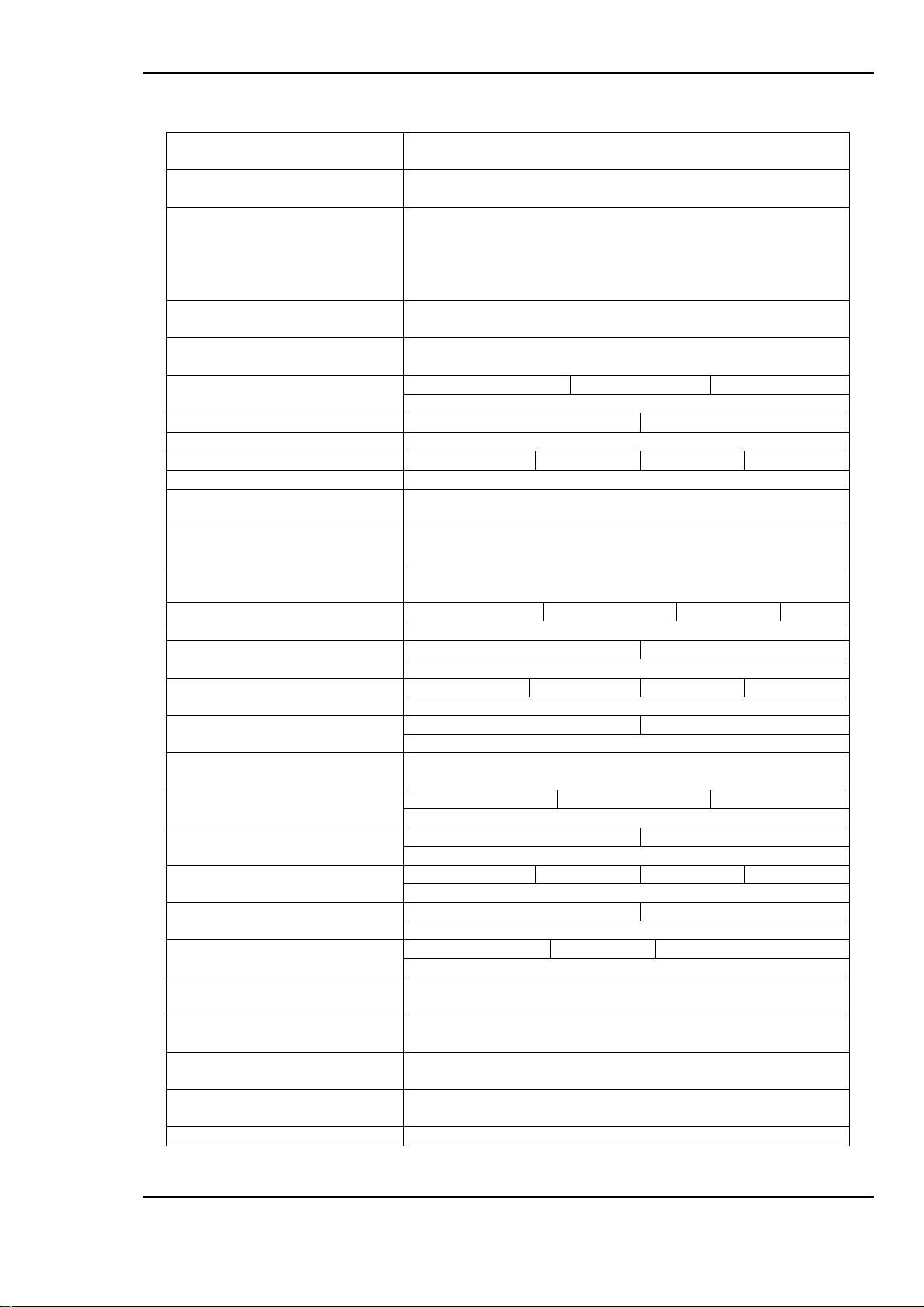

Table 1.1 Detector Technical Specification

DESCRIPTION SPECIFICATION

Weight 3.4 kg (7.5 lbs)

Finish Polycarbonate Light Grey Material

Input Voltage 18 to 30 V DC (24 V DC nominal)

Standard Detector Ultra D etect or

Detector Sensitivity Range

Input Current (With Standard Head) 315 mA 345/445 mA *

Input Current (With Ultra Head) 395 mA 425/525 mA *

Operating Temperature

Operating Humidity (With Standard Head) 10 to 95% non condensing

Operating Humidity (With Ultra Head) TBA

Enclosure IP31

Dimensions 320 mm wide by 228 mm high by 108 mm deep

Alarm Relay(s) Normally open contacts, 2 Amp @ 28 V DC, resistive

Pre-Alarm Relay(s) Normally open contacts, 2 Amp @ 28 V DC, resistive

Isolate Relay Normally open contacts, 2 Amp @ 28 V DC, resistive

Trouble Relay Normally closed contacts, 2 Amp @ 28 V DC, resistive

Electrical Connection Up to 18 GA field wiring to removeable terminal blocks

Service Port Connection RJ12 – RS232 communications

Network Connection 2 pair – RS485 communications

Remote Display Connection RS485 communications ( 4 core including power)

Air Inlet Port 0.75 inch threaded

Exhaust Port 1 inch

0.005%/m to 1%/m

(0.0015% to 0.3%/ft)

Stand Alone With Display Module

0° to 52° C (32° to 125° F)

0.001%/m to 0.1%/m

(0.0003% to 0.03%/ft)

* Back-light off/Back-light on

Page 1-2 Issue 1

February 2001

Page 11

Installation, Operation and Maintenance Manual

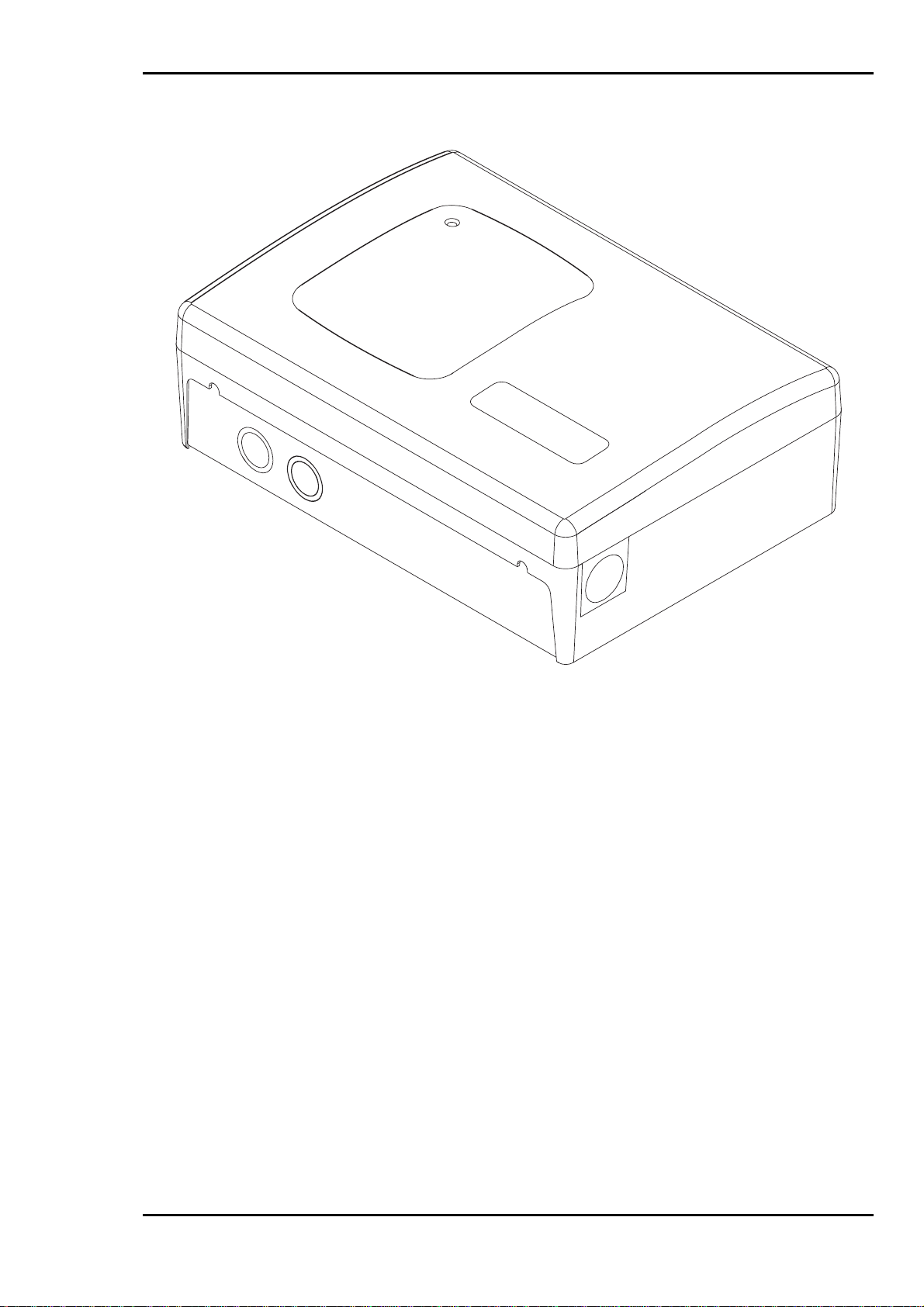

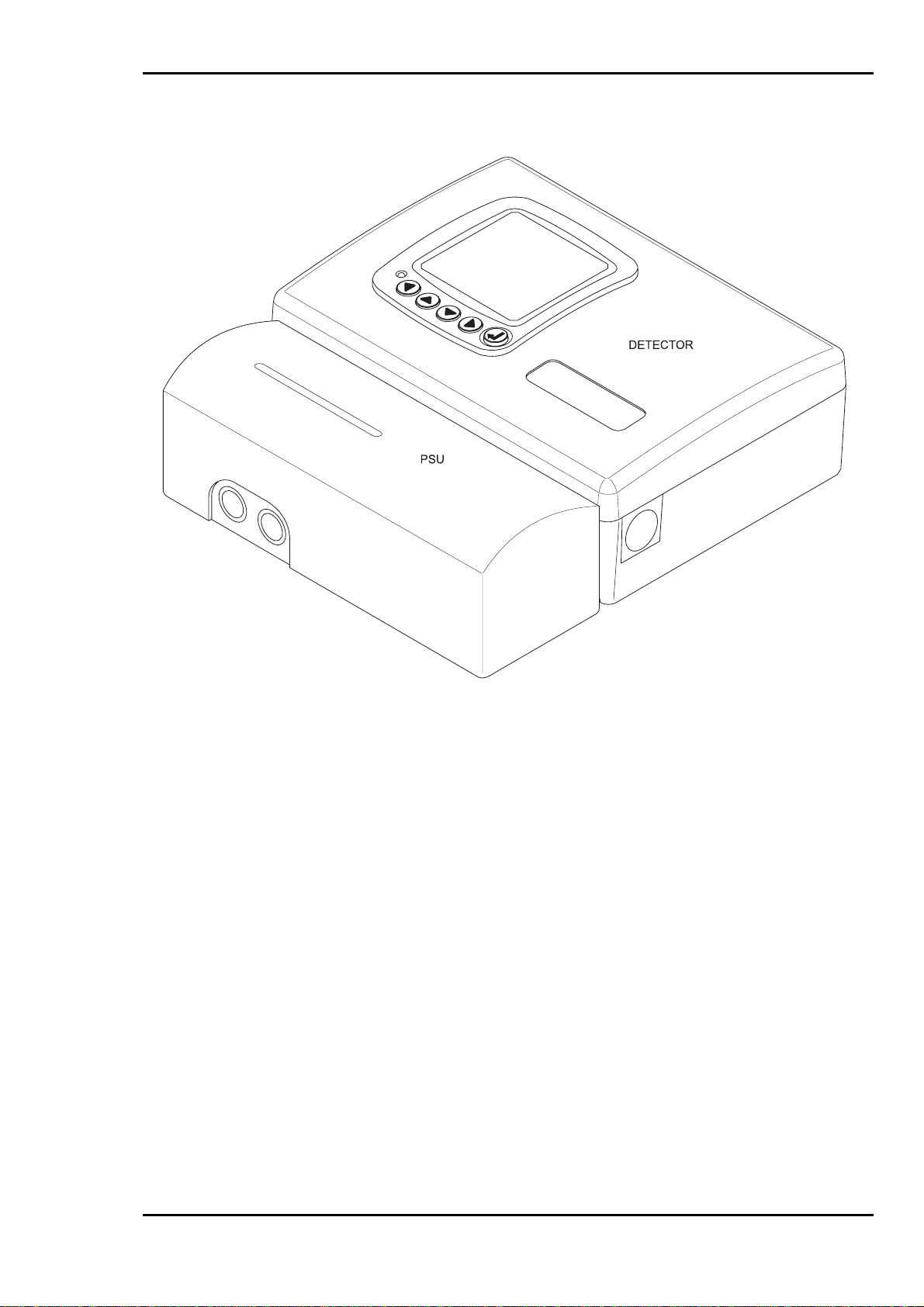

Figure 1.1 Detector

Issue 1 Page 1-3

February 2001

Page 12

Installation, Operation and Maintenance Manual

This Page Intentionally Left Blank

Page 1-4 Issue 1

February 2001

Page 13

Installation, Operation and Maintenance Manual

2 SYSTEM FUNCTIONAL DESCRIPTION

2.1 General

The following paragraphs pr ovide a functional description of the overall operation of the system, as well

as functional descriptions of the major components that together make up the High Sensitivity Smoke

Detection (HSSD) system.

2.2 Overall Functional Description

The High Sensitivity Smoke Detection system comprises a number of major components. Figures 2.1 to

2.2, show how these components are interconnected. These Figures also show the options available for

configuring the system depending on the application in which it i s to be used. The options available are

connecting the Detector via an Intelligent Interface. The system will support up to 127 Detectors. Each

Detector contains the following items:

termination board

detector head

fan module

Display module (optional)

This system is designed to provide high sensitivity smoke detection for an area up to 2000 sq-m (20,000

sq.ft). Smoke detection is accomplished by using a fan, mounted in the Detector, to draw in air from a

protected area through sampling pipe network back to the detector where the air is analysed for the

presence of smoke. The sensitivity of the Detector is programmable over a wide range to meet virtually

any application. In addition, an “Ultra” version of the detector is available with even higher sensitivity,

exclusively for clean room applications.

A three-colour light emitting diode (LED) mounted in the fascia plate of the Detector provides a visual

indication of the current status of the system. Current system conditions are indicated by this LED as

follows:

Continuous Green Normal

Flashing Green Auto Setup

Continuous Yellow Fault/Isolate

Flashing Red Pre-Alarm

Continuous Red Alarm

System status data collated on the termination board is transmitted via an RS-485 serial communications

link to the Display Module. The Display Module is an optional user interface which provides a display on

a back-lit mono LCD. The display provides a visual indication of the system status, smoke level, alarm

and trouble conditions of the Detector. By use of the control keys (4 cursor and 1 enter) an operator is

capable of viewing the information via a password protected menu function. The system status is also

indicated by a three colour LED providing the same functionality as described above.

Connections to a PC via an RS-232 network allow site-specific settings such as pre-alarm and alarm

levels to be loaded into a non-volatile RAM fitted on the termination board. The termination board

connects to the RS-485 network at an address set on a 7 way DIL switch. The Intelligent Interface

Module (IIM) is an optional user interface which serves as a communications controller, networking up to

127 termination boards. The IIM is linked via the RS-232 to a computer, running LaserNET version 3.0

software, situated on site. Alternatively, the IIM can be connected via a modem to a computer, which is

located at a remote site. Connection of the PC to the termination boards allows the system to be

configured and monitored from either a local or remote location. The IIM can also be programmed to dial

out to a remote PC should any alarm or trouble condition occur.

Issue 1 Page 2-1

February 2001

Page 14

Installation, Operation and Maintenance Manual

In addition to the detector, a sampling pipe network is required to carry the sampled air from the protected

area to the detector. Overall perf ormance of the High Sensitivity Smoke Detection system is dependent

upon the layout of the air sampling pipe network. Use of the “SNIFF” computerised program balances the

piping network to provide for an equal intake of air at each sampling hole. For a detailed description on

how to design a pipe network reference should be made to the SNIFF Manual (Version 3.0).

The sampling pipe network is normally constructed from ½ inch, ¾ inch, or 1-inch internal-diameter

smooth bore pipe. The type of pipe is not critical because of the low operating pressures. Any smooth

bore pipe will be satisfactory provided it is rigid enough so that it does not sag between supports and it

meets all code requirements. Some commonly used types are PVC, ABS, CPVC, EMT and copper

tubing. Flexible tubing can be used for sampling hole drops.

Page 2-2 Issue 1

February 2001

Page 15

Installation, Operation and Maintenance Manual

Figure 2.1 Typical Stand Alone System

Issue 1 Page 2-3

February 2001

Page 16

Installation, Operation and Maintenance Manual

Figure 2.2 Typical System with Stand Alone Intelligent Interface Module

Page 2-4 Issue 1

February 2001

Page 17

Installation, Operation and Maintenance Manual

2.3 Detector

The Detector consists of a backbox with a removable cover, incorporated within the Detector are a

detector head, termination board and a fan. These three items are the major elements of the Detector,

refer to Figure 2.3 detailing the detector block diagram. The design of the Detector allows surface

mounting, thus providing ease of installation and maintenance. Replacement of any of the detector’s

main elements can be achieved without the need to remove the backbox, conduit, inlet or exhaust pipe.

The fan is mounted in a plenum within the Detector and is controlled via the termination board, thus

ensuring optimal fan speed. An LED located on the front panel of the Detector provides a visual

indication of the current system status. Two types of Detector are available; standard and ultra sensitive.

The ultra sensitive version is recommended for use in clean room applications only.

Table 2.1 Detector Specifications

DESCRIPTION SPECIFICATION

Part Number (With Standard Head) 53836-K183

Part Number(With Ultra Head) 53836-K186

Weight 3.4 kg (7.5 lbs)

Finish Polycarbonate Light Grey Material

Input Voltage 18 to 30 V DC (24 V DC nominal)

Stand Alone With Display Module

Input Current (With Standard Head) 315 mA 345/445 mA *

Input Current (With Ultra Head) 395 mA 425/525 mA *

Operating Temperature

Operating Humidity (With Standard Head) 10 to 95% non condensing

Operating Humidity (With Ultra Head) 10 to 70% non condensing

Alarm Relay Normally open contacts, 2 Amp @ 28 V DC, resistive

Pre-Alarm Relay Normally open contacts, 2 Amp @ 28 V DC, resistive

Isolate Relay Normally open contacts, 2 Amp @ 28 V DC, resistive

Trouble Relay Normally closed contacts, 2 Amp @ 28 V DC, resistive

Electrical Connection Up to 18 GA field wiring to removable terminal blocks

Service Port Connection RJ12 – RS232 communications

Network Connection 2 pair – RS485 communications

Remote Display Connection RS485 communications (4 core including power)

Air Inlet Port 0.75 inch threaded

Exhaust Port 1 inch

0° to 52° C (32° to 125° F)

* Back-light off/Back-light on

Issue 1 Page 2-5

February 2001

Page 18

Installation, Operation and Maintenance Manual

Figure 2.3 Detector Block Diagram

Page 2-6 Issue 1

February 2001

Page 19

Installation, Operation and Maintenance Manual

2.3.1 Detector Head

Located within the Detector, the detector head is a highly sensitive detector utilising a laser, focussed to a

narrow beam. The laser beam exits a sample chamber into an attached beam dump area which monitors

the laser intensity. A receive optics assembly is mounted on the sample chamber with its optical axis

normal to the laser beam axis (see Figure 2.4).

A particle-size discriminator inhibits the detector from responding to large particles, thus preventing

occasional large particles (dust, pollen, soot, etc.) from generating an alarm. As the smoke particulate

passes into the sampling element a sensor electronically counts each particle. Particle counting HSSD

devices are much more sensitive to the prevailing concentration of small particulate (the tell tale sign of

early combustion) than conventional devices. Although larger particulate such as dust does not

significantly affect the signal recorded (number of particles) from either a background or a prevailing

smoke environment. Most particulate with a diameter greater than 10Pm is electronically recognised and

thus not added to the smoke count register. This ensures a true and clear measurement of the absolute

real time concentration. Electronic circuitry within the detector head ensures that no change in sensitivity

occurs with changes in air flow. The Detector is calibrated so that it will not respond to particle sizes

smaller than 0.01 or greater than 10 microns. The intensity of the laser is monitored by a photocell. If the

intensity of the laser begins to vary from the factory set level, a feedback circuit automatically

compensates the laser drive circuit accordingly. This circuit arrangement virtually eliminates any change

in laser energy output which in turn keeps the detector sensitivity stable.

An airflow measuring circuit monitors the flow of air through the detector. Should the air flow vary or stop,

a status signal is transmitted to the termination board.

One of the features of the detector head signal processing that provides the dynamic sensitivity range.

The sensitivity range can be adjusted via LaserNET software to meet with system requirements. A

processor located on the signal processing board controls communications between the detector head

and the termination board. Information recorded by the detector head is continually communicated to the

termination board.

Two types of detector head are available; the standard detector head which has a dynamic sensitivity

range of 0.005% to 1%/m (0. 0015% to 0.3%/ft) and an ultra sensitive detector head specifically designed

for the clean-room applications. The ultra sensitive detector head incorporates an avalanche photon

detector and has a dynamic sensitivity range of 0.001% to 0.1%m (0.0003% to 0.03%/ft) for use in very

clean applications. Detector sensitivity can be programmed to accommodate varying background levels.

Issue 1 Page 2-7

February 2001

Page 20

Installation, Operation and Maintenance Manual

Figure 2.4 Detector Head Views

Page 2-8 Issue 1

February 2001

Page 21

Installation, Operation and Maintenance Manual

2.3.2 Termination Board

The termination board is micro processor controlled providing the interface between the detector head,

the RS-485 network, the Display module and the PC Port. A seven position DIP switch on the termination

board allows the network address to be set, enabling 127 Detectors to be connected. An on board

memory stores configuration details, history events and system information. In the event of a power

failure, information can be retained for up to a period of approximately 90 days by a battery back-up. An

on board LED, when lit, provides indication of power.

An adjustable switching regulator, located on the termination board, ensuring optimal supply voltage to

the fan.

The termination board provides 6 relays with volt free change-over contact rated at 2 amp, 30 V DC. Each

relay has its own operation as detailed below:

Pre-alarm level 1

Pre-alarm level 2

Alarm level 1

Alarm level 2

Trouble

Isolated

It should be noted that the Trouble relay is energised in its normal condition so it will transfer when power

is lost.

The termination board can communicate to an external PC, running LaserNET software, via an RS-232

output. Connection will be by a standard RJ12 connector. Communications will allow for the up/down

load of configuration and history data. Both configuration and history data are stored within an on board

non-volatile memory. The system will retain the configuration and history data following a CPU reset or

extended periods of power down only when the termination board battery link LK3 is installed.

The termination board provides connections for a supervised power supply unit, Intelligent Interface

Module (IIM) and a remotely mounted Display Module (optional). Ease of installation and maintenance is

achieved by using the removable terminals.

Issue 1 Page 2-9

February 2001

Page 22

Installation, Operation and Maintenance Manual

CABLE ASSEMBLY

TERM BOARD / TRI-COLOUR LED

BLANKING PLATE

C/W STATUSLED

FRONT PANEL OPTIONS

(LCD DISPLAY OR STATUS LED)

DISPLAY

MODULE

43682-K157

ANALASER

INTERFACEMODULE

(OPTIONAL)

CABLE ASSEMBLY

TERM BOARD / LCD DISPLAY

43682-K156

INTERNAL WIRING

PRE PREALARM1 ALARM2 ALARM 2ALARM 1 TROUBLE ISOLATE

CM CMNO NO CM NO CM NO NCCM NO CM NC NO

1

ALARM1

TROUBLE

CM NC NO

RL4

RL5

PROGRAM

LK2

P2

++++

PSU

STATUS POWER OUT

-

+

ISOLATE

POWERON

TB2

CM NC NO

LED

RL6

LK4

BAT1

REG1

TB1

1

---

POWERIN

+

--

-

-

++

PRE 2PRE ALARM2ALARM1ALARM

NO CM NO

CM NO CM NO

CM

1

RL1

RL2 RL3

P6

IC5

RELAYEXP/LOCALASER

LK1

P1

STATUSLED

P4

INTERFACE

P9

INTERNALDISPLAY

M/TERM

ON

1

SW2

HSSD

++

MAINLOOP

0V +24V

-

TERMINATION

CARD

P3

0V

IC9

IC7

+24V

EXTERNALDISPLAY

-

-+-

+

1

+

P5

LK3

P7

IC4

F2

-+

TB2

CHASSIS

GROUND

PC

CABLE ASSEMBLY

TERM BOARD / DETECTOR

43682-K155

MAINLOOP ADDRESS

SW1

DET.HEAD RESET

FAN AD J

FAN

1

CABLE SUPPLIED

F1

WITH FAN ASSEMBLY

TB1

1

+

CABLE ASSEMBLY

RJ12 / RJ12

43682-K158

RJ12 SOCKET

LOCATED ON LHS

OF UNIT

DETECTOR

H300/UHSSD

FAN

MAIN LOOP

PSU

STATUSEXTERNAL DISPLAY

POWER OUT

POWER IN

Figure 2.5 Termination Board Internal Wiring Diagram

Page 2-10 Issue 1

February 2001

Page 23

Installation, Operation and Maintenance Manual

2.3.3 Fan M odule

The fan module contains a highly efficient radial fan that has been specifically designed for use within the

Detector. The fan draws air from the sampling pipe network through the detector head and then exhausts

the air through a port on the side of the unit or by an alternative optional rear exhaust port. In addition, an

adapter port returns the sampled air to the protected area. A regulated voltage is supplied to the fan

module from the termination board.

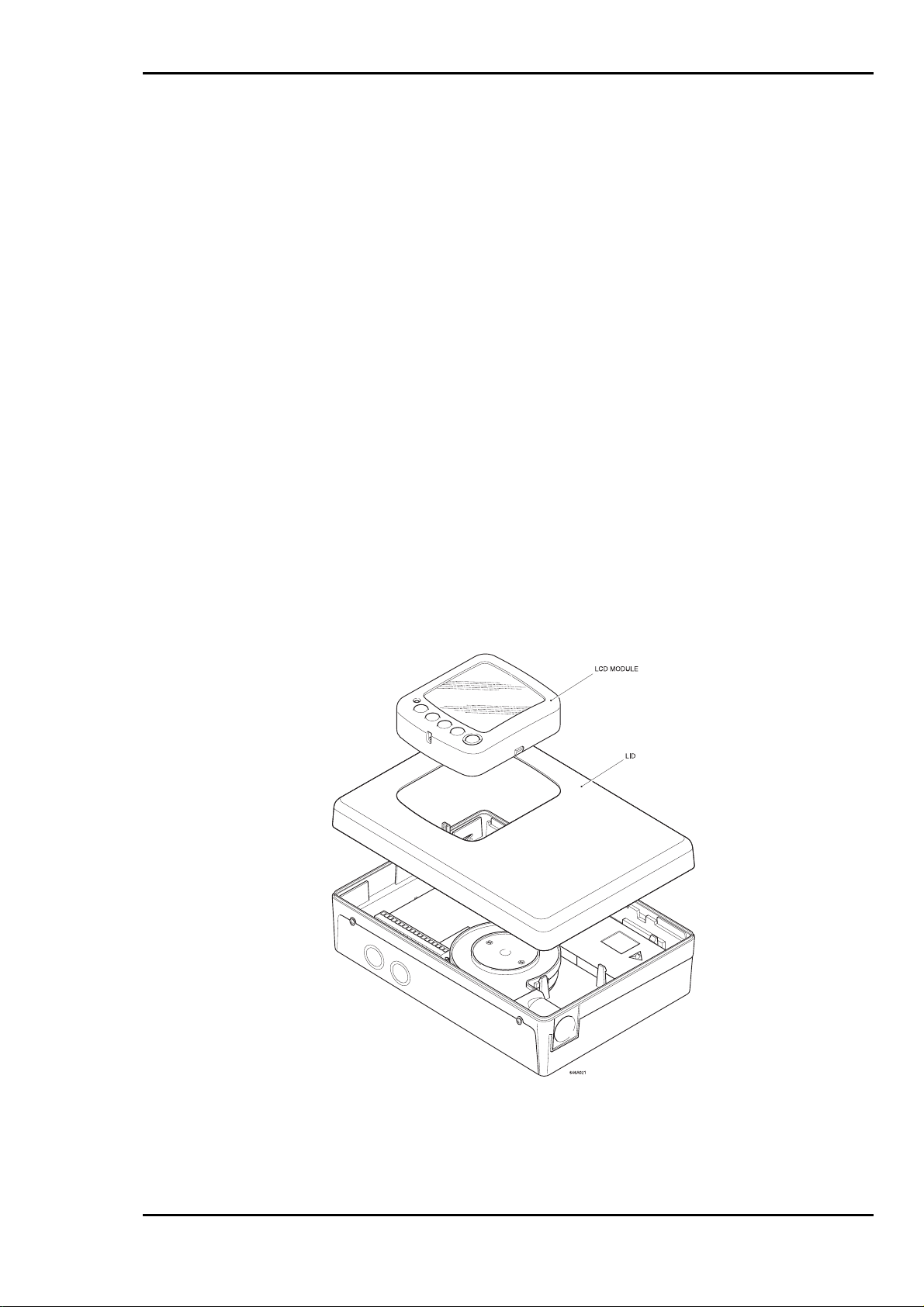

2.4 Display Module

The Display Module is an optional item that can be either mounted within the Detector or alternatively, it is

possible to mount remotely. Remote mount can be achieved by use of a back box or a rack mount

option. Maximum distance of up to 1 km from the Detector to the remote Display Module is allowed. In

either application, RS-485 communication and 28 V DC is supplied via terminals located upon the

termination board. Recommended cable type being Mineral Insulated Copper Cable (MICC).

Various facilities are provided by the Display Module that include the following:

Operator Visual Interface

Internal Audible Sounder alar m

Status LED

Control Keys (4 cursor and 1 enter)

The cursor control keys allow an operator to navigate through the displayed menu and password screens

by operating the Up, Down, Left or Right keys and the Enter key.

Real time system data is displayed which includes the current smoke level and airflow, all alarm

conditions, all trouble conditions and the current system status.

An internal sounder provides an audible indication that an alarm or trouble condition exists on the system.

If a trouble condition exists the sounder alarm operates intermittently. Upon the activation of an event the

sounder will provide an audible indication. The audible indication will continue until the operator silences

the sounder using the control keys.

The conditions that activate the sounder are:

Any Alarm Condition

Any Pre-Alarm Condition

Any Trouble Condition

A multi coloured LED that is controlled via the Display Module provides a visual indication of the current

system status.

Continuous Green Normal

Flashing Green Auto Setup

Continuous Yellow Fault/Isolate

Flashing Red Pre-Alarm

Continuous Red Alarm

Control keys are used to navigate through the menu selections.

Issue 1 Page 2-11

February 2001

Page 24

Installation, Operation and Maintenance Manual

The Display Module incorporates a removable adapter plate, which permits the module to be mounted to

the wall.

Table 2.2 Display Module Specifications

DESCRIPTION SPECIFICATION

Part Number 53836-K182

Input Voltage 18 to 36 V DC (24 V DC nominal)

Maximum Input Current 30 mA (normal); 104 mA with Back-light ON

Operating Temperature 0° to 52° C (32° to 125° F)

Operating Humidity 10 to 95% non-condensing

2.5 Intelligent Interface Module

The Intelligent Interface Module (IIM) is an optional item, which can be mounted in a stand alone

enclosure. The IIM allows service and maintenance functions to be undertaken on the Detectors. The

IIM is a communications link networking up to 127 Detectors. A computer running LaserNET software

Version 3.0 can communicate with the IIM either with a local PC or remote PC connected by an optional

modem. This allows the Detectors to be completely configured and monitored from a central location with

the connection of an optional modem, allowing interrogation of the system with a remote PC.

The IIM stores all field-programmed parameters in non-volatile memory, thus ensuring that no

programming will be lost during a complete power failure. Field programmable parameters consist of the

following:

Three telephone numbers for auto-dial sequence

Twenty character owner location mess ag e

Installation engineer’s password

Owner’s password

Dial tone supervision enable/disable

FenwalNET interface port enab le/ dis ab le

AutoDial function enable and disable

Configuration of RS485 Network for style 6 or style 4

Trouble report delay

Security call back scheme enable/disable

Call back phone number

Page 2-12 Issue 1

February 2001

Page 25

Installation, Operation and Maintenance Manual

2.5.1 PC Port

The PC Port is used for programming and may be used to provide ancillary on premises one way

communication of alarms and troubles to a PC (using LaserNET software).

2.5.2 RS485 Connection

Up to 127 Detectors can be connected via the RS-485 network with the maximum bus length of 1 kM

(4000 feet). This connection is capable of being wired for either Style 4 (Class B) or Style 6 (Class A)

supervised operation.

2.5.3 Telephone Port (with optional modem)

For a HSSD system using a PC running LaserNET software, located at a remote site, a telephone port on

the IIM allows off premises communication through a standard telephone line. The Telephone Port

provides communication via a modem and standard telephone line, and will provide ancillary off-premises

transmittal of Detector alarms and troubles.

Table 2.3 Intelligent Interface Module Specifications

DESCRIPTION SPECIFICATION

IIM with Modem Part Number 53836-K189

IIM without Modem Part Number 53836-K190

Input Voltage 20.4 V DC to 28 V (24 V DC Nominal)

Maximum Input Current

Operating Temperature 0° to 52° C (32° to 125° F)

Operating Humidity 10 – 95% non-condensing

70 mA (Max) Standby

80 mA (Max) Alarm

Issue 1 Page 2-13

February 2001

Page 26

Installation, Operation and Maintenance Manual

2.6 Power Supplies

An optional self-contained assembly supplies power to a single HSSD system.

2.6.1 Self Contained Power Supply

The self contained power supply powers a single Detector, with or without a Display Module including 4

hours of battery backup.

Table 2.4 Self Contained Power Supply Assembly

DESCRIPTION SPECIFICATION

Part Number 53836-K185

Weight (including batteries) 3.1 kg (7 lbs)

Finish Polycarbonate Material Light Grey Cover with painted steel backbox

Input Voltage 90 to 260 V AC 50/60 Hz

Maximum Input Current 1 A

Operating Temperature

Operating Humidity 10 to 95% non condensing

Output Voltage 28.75 V DC

Output Current Maximum 1 A

Battery Charging Voltage 27.3 V DC

Battery Charge Circuit Fuses 500 mA

Trouble Relay Normally closed contacts, 1 Amp @ 28 V DC., resistive

Batteries Yuasa NP2-12 (12V 2.0 AH) x2

0°C to 52°C with no de-rating

2.6.2 Battery Calculation

The calculation used for determining the battery requirements for the Detector is detailed as follows:

Minimum Battery Capacity (Amps Per Hour) = 1.25 x ((S x A) + (1.75 x ((A + B)/2)))

Where S = standby period in hours.

A = quiescent current in amps.

B = alarm current in amps.

Page 2-14 Issue 1

February 2001

Page 27

Installation, Operation and Maintenance Manual

Figure 2.6 Self Contained Power Supply Diagram

Issue 1 Page 2-15

February 2001

Page 28

Installation, Operation and Maintenance Manual

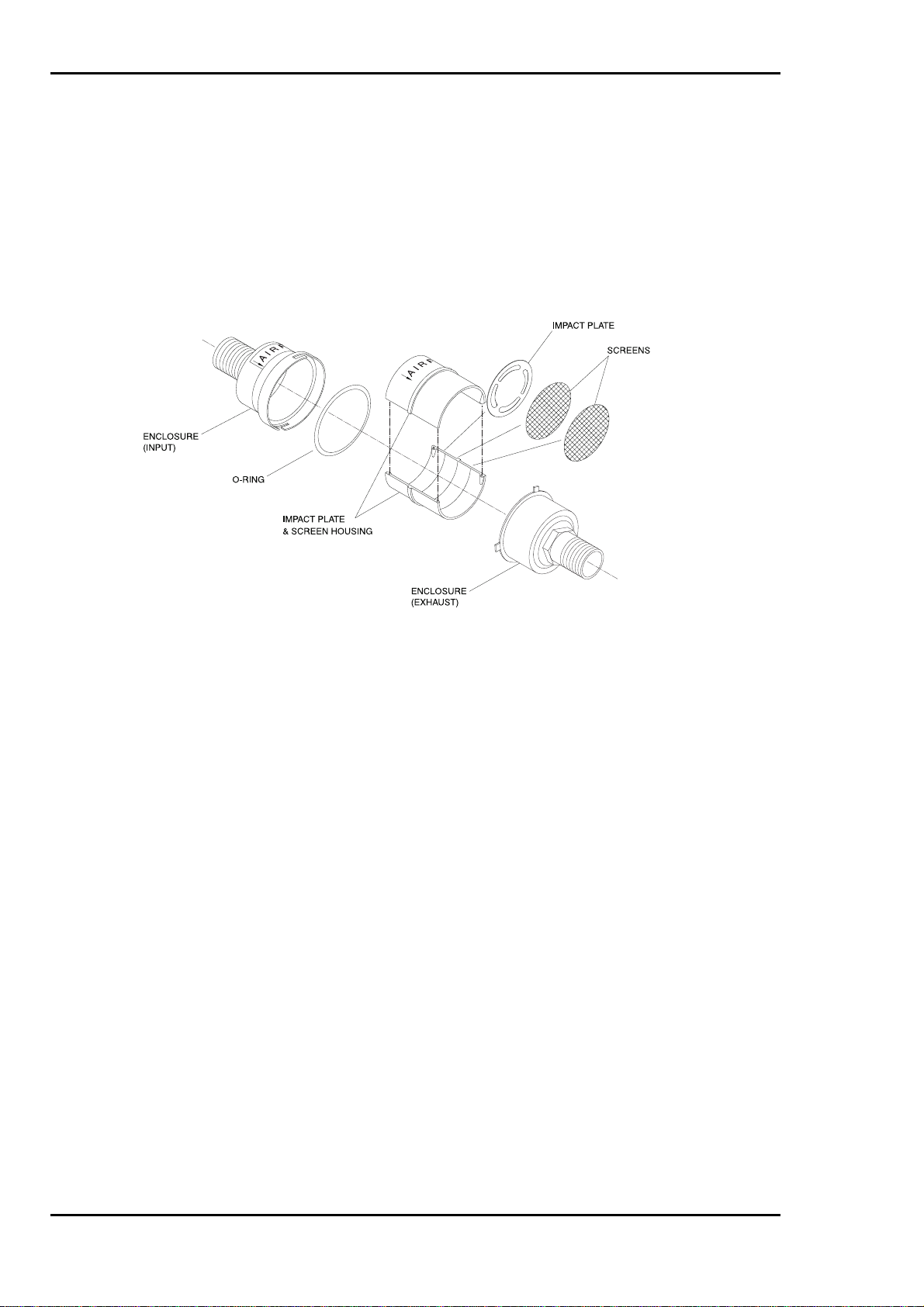

2.7 Use of the Elutriator

The Elutriator is an optional item and can be used if the protected area is expected to have heavy

amounts of non-combustion part icula te. An Elutr iator sho uld be inst al led to pr event bui ld- up of mat erial

within the Detector. The elutriator is an inertial particle separator that allows air to flow freely through it

while separating out large particulates by allowing them to accumulate on an impact plate. Refer to

Figure 2.8

Figure 2.7 Elutriator Cut-Away View

Page 2-16 Issue 1

February 2001

Page 29

Installation, Operation and Maintenance Manual

3 CONTROLS AND INDICATORS

3.1 Status Indicator

A three-colour light emitting diode (LED) mounted in the fascia plate of the Detector provides a visual

indication of the current status of the system. A similar LED is also provided on the Display Module. The

LED changes colour to indicate the system status. System conditions that are indicated by this LED, are

as follows:

Continuous Green Normal

Flashing Green Auto Setup

Continuous Yellow Fault/Isolate

Flashing Red Pre-Alarm

Continuous Red Alarm

3.2

The termination board provides a Power On LED indicator. This is located in the top right corner of the

board and displays, when lit, that power is present.

3.3 Display Module

The Display Module is an optional item, which provides a back-lit mono Liquid Crystal Display (LCD).

The main functi on is to provide a visual indication of the system status, these being smoke level, airflow,

alarm and trouble conditions of the Detector. The back-light of the Display Module operates upon

activation of any condition or by use of the control keys. If there are no further activations or operation of

any control key for one minute, the back-light will return to its normal state.

The Display Module allows an operator to request certain functions to be performed by selecting options

from a displayed menu list. The functions are as follows:

The above functions are available to an operator and are dependent upon the current status of the

system. Selected functions are only accessed provided a password is correctly entered.

Termination Board Indicator

Silence Cancels the internal audible sounder.

Reset Reset the Detector.

Status Allows viewing of the current status of the unit.

Smoke Allows viewing of Alarm sensitivity settings, Pre-Alarm settings and current

smoke levels.

Airflow Allows viewing of the airflow thresholds and settings.

Isolate Allows the Detector to be isolated and De-isolated.

Start Test Enables the Sensitivity Test of the detector head.

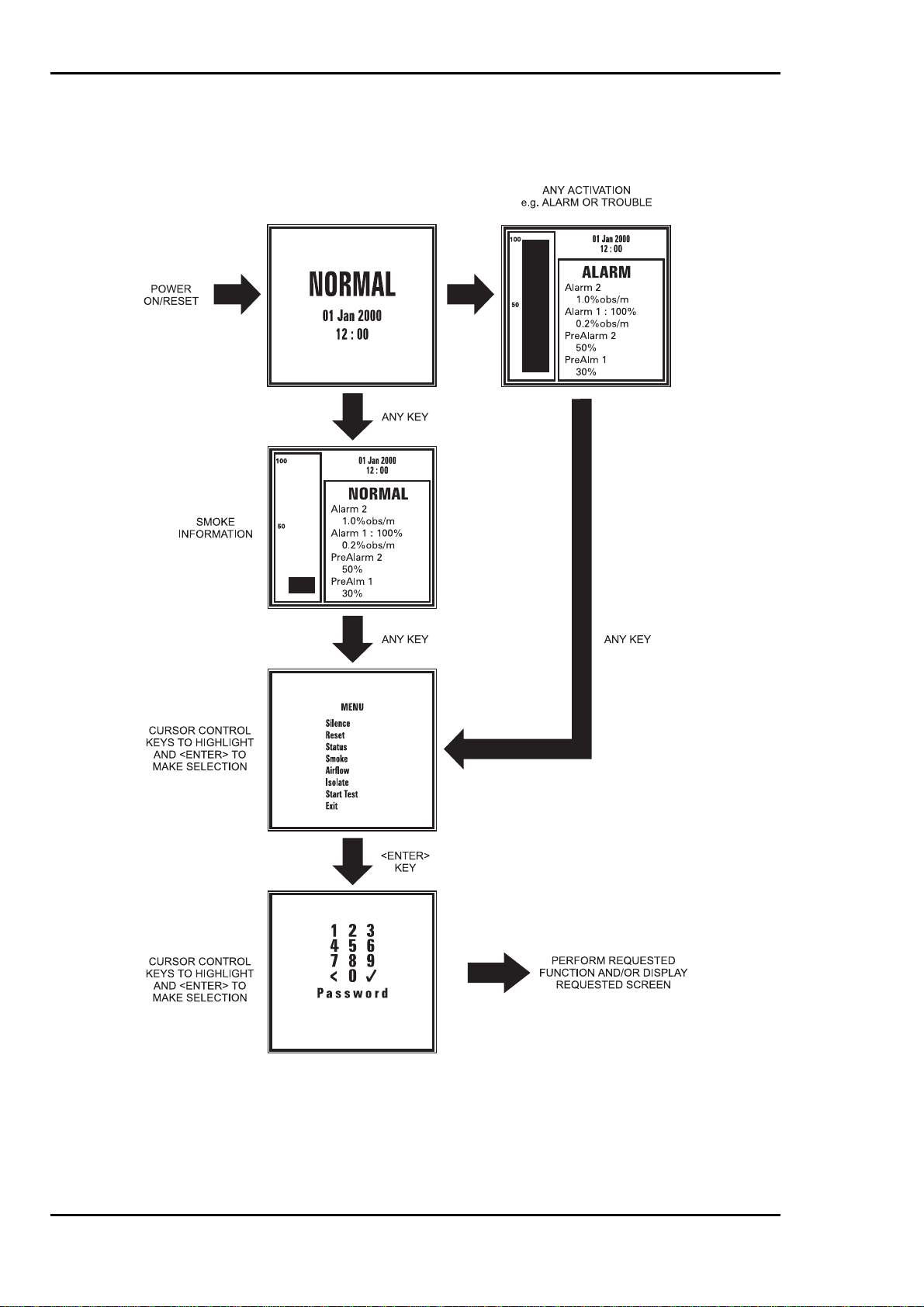

The following is an illustration showing the hierarchy of the display structure. Additionally the key presses

needed to access the required screen are also shown. Subsequent paragraphs in this part of the manual

provide detail information on each screen.

Issue 1 Page 3-1

February 2001

Page 30

Installation, Operation and Maintenance Manual

Page 3-2 Issue 1

February 2001

Page 31

Installation, Operation and Maintenance Manual

On system power up the System Status Screen is displayed.

This display is shown during the system’s “quiescent state”.

If the status of the system is anything other than Normal then the respective status will be displayed

instead, e.g. TROUBLE or ALARM.

The Display Module shows, in textual form, the current system status: -

PRE-ALARM 1

PRE-ALARM 2 These system status conditions indicate that the current smoke

ALARM 1 level has reached one of the pre-configured alarm levels.

ALARM 2

TROUBLE This indicates that a trouble condition exists i.e. Airflow, Power

Supply Unit (PSU), CPU or Detector.

ISOLATE This status condition indicates tha t the system is disabled in

communicating Alarm, Pre-Alarm or Trouble conditions.

TEST Test will be displayed whenever the system is set into test by an

operator.

From the Normal display screen the operator is able to access the smoke display (only when the status

display is showing NORMAL) by pressing any key (any cursor control or ENTER (↵) key).

The smoke display indicates by means of a bar graph the smok e

level currently being detected. Additionally both the current

Alarms and Pre-Alar ms settings are disp layed. The smoke level

displayed is a value in the range 0% to 100%.

Issue 1 Page 3-3

February 2001

Page 32

Installation, Operation and Maintenance Manual

Operation of any of the control keys on the Display Module will cause the Menu screen to be displayed.

The Menu screen displays the allowable system functions via a

scrollable menu. Highlighting is used to indicate the current

selection.

However, prior to the system functions being performed, the Password Entry screen is displayed and the

operator is required to enter the relevant password.

The password is enter ed by highlighting the r equired digit (using

the cursor control keys) and then pressing the enter key to

accept. As each dig it of th e pas sword is se lected a * is d ispl ayed

on the screen. By selectin g ‘←’ (b ackspace) , the oper ator is ab le

to delete previously incor rectly enter ed d igits. The pass word fie ld

is a maximum of eight digits and a min imum of three. Once the

required number of dig its for the password h as been entere d the

9

can be highlighted and selected by pressing the enter key.

Once operated the password selection will be verified.

Once verified, the requested system function can be performed. It should be noted that only the TEST,

ISOLATE, RESET and SILENCE functions require a password to be entered before they can be

performed. The menu options available to the user are dependent on the current system status.

If the system is NORMAL then the following options are avail able, scrollable in the following order:

STATUS

SMOKE

AIRFLOW

ISOLATE

START TEST

EXIT

Page 3-4 Issue 1

February 2001

Page 33

Installation, Operation and Maintenance Manual

If the system i s in any state other then NORMAL (i.e. Ala rm and Trouble) the following options are

available scrollable in the fol low ing or der:

SILENCE

RESET

STATUS

SMOKE

AIRFLOW

ISOLATE

START TEST

EXIT

The control keys are detailed below with a description of their operation.

LEFT UP DOWN RIGHT ENTER

The <RIGHT> and <DOWN> cursor control keys perform the same function, namely to scroll to the next

menu option. The <LEFT> and <UP> cursor control keys perform the same function, namely to scroll to

the previous menu option.

Pressing the enter key whilst a menu option is displayed causes that system function to be performed

(provided a valid password is entered). Any number of functions can be performed without the need to

re-enter the password.

If, after entering the password the operator does not press any key for 1 minute then the validity

of the password will time-out and will need to be re-entered.

The EXIT system function is used to exit the menu display and return to the STATUS screen. This

effectively terminates this session and any further function requests from the menu screen will require the

password to be entered again.

From the system STATUS screen if a fault condition exists on the system then the Smoke Information is

automatically displayed without any operator input required. The operator can then have access to the

menu in the normal manner as outlined above.

Detailed below are examples of the various types of information that can be detailed on the Display.

The Status Information screen appears as shown.

Issue 1 Page 3-5

February 2001

Page 34

Installation, Operation and Maintenance Manual

The Smoke Information screen appears as shown.

The Airflow information screen appears as shown.

The Test information screen appears as shown.

3.4

Sounder

The Display Module provides an audible indication by use of an internal sounder. Upon activation of an

event the internal sounder will provide an audible indication that an alarm or trouble condition exists on

the system. If a trouble condition exists the sounder alarm operates intermittently and continuous for an

Alarm. The audible indication will continue until the operator silences the sounder using the control keys.

Page 3-6 Issue 1

February 2001

Page 35

Installation, Operation and Maintenance Manual

The conditions that activate the sounder are as follows:

Alarm condition Continuous operation

Pre-Alarm condition Continuous operation

Trouble condition Intermittent operation

3.5 LaserNET software

Details of the LaserNET software are contained in the LaserNET Software Manual Version 3.

Issue 1 Page 3-7

February 2001

Page 36

Installation, Operation and Maintenance Manual

This Page is Intentionally Left Blank

Page 3-8 Issue 1

February 2001

Page 37

Installation, Operation and Maintenance Manual

4 INSTALLATION

4.1 Introduction

The following paragraphs provide information needed to carry out an installation of a High Sensitivity

Smoke Detection (HSSD) system. Installation consists of mounting the Detector and its various optional

items. These items include the Display Module, the Intelligent Interface Module (IIM) andthe stand alone

power supply. Installation should only be carried out by factory trained technicians in accordance with

applicable installation requirements. These being as follows:

(1) British Standard BS6266 : 1992 (Code of practice for Fire protection for electronic data

and processing).

(2) British Standard BS 5839 Pt 1 – Fire Detection & Alarm systems for Buildings – Code of

Practice for System Design, Insta llation & Service.

(3) British Fire Protection Systems Association – BFPSA Code of Practice for Category 1

Aspirating Smoke Detection Systems.

(4) Any other local installation requirements.

4.2 Locating the Detector

Mount the Detector as close as possible to the protected areas. This minimises transportation time and

air resistance in the air sampling pipe network.

The Detector should be located in an area where the air pressure surrounding the unit is the same, or

lower than the atmospheric pressure around all the sampling ports in the sampling pipe network. A

building’s HVAC fans may positively pressurise a space creating a pressure differential within the

building. If the detector is located in an area where the pressure is greater than the sampling pipe, a

resistance to the normal airflow through the pipe will occur. Also, if individual sampling holes are exposed

to different static pressures air may not flow properly, resulting in uneven sampling.

If the detector must be located in a higher-pressure area than the entire sampling network, or if the

sampled air must be returned to the protected area, an exhaust port adapter must be used. The exhaust

port adapter allows a return pipe to be fitted on to the exhaust port of the Detector.

To reduce the possibility of condensation the Detector must always be at approximately the same (or

higher) temperature than the air-sampling pipe network. If the Detector is protecting ducts it is

reccomended that the exhaust air from the Detector be returned to the duct by use of the exhaust port

adapter and associated piping. This requirement assures positive airflow through the Detector.

When installing a flush mounted unit the option is available to have the exhaust port and cable entry

through the rear. Should this method of mounting the Detector be employed then the self contained

Power Supply cannot be used. A flush mount Bezel kit is available for this type of installation.

The Detector can also be mounted upside down to allow the pipe inlet to come from below the unit to

meet with application requirements. Should this method of installation be employed the Display Module

can be reversed allowing correct orientation of the display.

Should the Detector be mounted in an area which is not easily accessible to a user, then the Display

Module can be situated remotely in a more accessible location.

To enable the Display Module to be monitored by the user, it is a requirement when installing the unit to

use the optimum viewing angle. Therefore it is recommended that the unit be mounted at a height which

can be easily observed.

Issue 1 Page 4-1

February 2001

Page 38

Installation, Operation and Maintenance Manual

An optional Self Contained Power Supply unit can be installed directly below the Detector. This unit will

provide a supervised supply with the addition of battery back-up in case of mains failure. The Self

Contained Power Supply cannot be used when the Detector is either mounted upside down or when flush

mounted into the wall.

Electrical connections to the Detector are possible by using the provided pre-formed conduit knock-outs.

The conduit knock-outs are located top, bottom or rear of the Detector back box. The Self Contained

Power Supply also provides similar conduit knock-outs for use when it is mounted below.

4.3 Installing the Detector

CAUTION

ANTI-STATIC PRECAUTIONS

WHEN HANDLING ANY ELECTRIC COMPONENTS OR

CIRCUIT BOARDS ANTI-STATIC PRECAUTIONS MUST

BE CARRIED OUT. FAILURE TO DO SO MAY RESULT IN

COMPONENT DAMAGE.

Static discharge can be reduced by adhering to the following guide lines.

(1) Always use conductive or anti-static containers for transportation and storage, if returning

any item.

(2) Wear an earthed wrist strap while handling devices and ensure a good earth is

maintained throughout.

(3) Never subject a static sensitive device to sliding movement over an unearthed surface

and avoid any direct contact with the pins or connections.

(4) Avoid placing sensitive devices onto plastic or vinyl surfaces.

(5) Minimise the handling of sensitive devices and Printed Circuit Boards (PCBs).

Page 4-2 Issue 1

February 2001

Page 39

Installation, Operation and Maintenance Manual

CAUTION

!

LASER HAZARD

The detector in the enclosure is a factory-sealed unit

containing a Class-3B laser product with invisible

radiation.

!

Extended exposure to a Class-3B laser directly or indirectly

may cause severe damage to the human eye.

The Detector is designed for surface mounting. It is also capable of being mounted in different

orientations to meet with the requirements of different applications. The Detector can be mounted

normally with the inlet pipe at the top of the unit. Alternatively the Detector can be mounted upside down

or recessed into the wall. The Detector incorporates conduit knockouts (concentric 0.5 inch and 0.75

inch) two each on the top, bottom, and rear.

The assembly should be mounted in a manner to minimise the number of 90 degree bends needed to

connect the Detector to the piping network. The system drawings should accurately depict the Detector

location and all piping distances and bends required for the connection to the unit. The Detector provides

an exhaust port to which can be either positioned at the side or by an optional rear exhaust port. An

exhaust port adapter can be attached. If the air must be returned from the Detector to the protected

space, then an optional adapter fits into the Detector’s exhaust port and provides a connection to a 1.0

inch threaded pipe.

The Detector is designed with 4-corner mounting holes. Installation must be in accordance with good

electrical and safety practices, although 0.25 inch mounting hardware is recommended. To mount the

assembly proceed as follows:

WARNING

AVOID EXPOSURE TO BEAM

(1) Remove the Detector from its carton and carry out a visual inspection of the unit to

ensure that no damage has occurred during transit.

(2) Remove the lid of the Detector by turning each of the two locking screws, situated on the

bottom side of the Detector, a quarter turn anti-clockwise and lift the lid clear. Exercise

care during this procedure, as at this point the lid is still connected to the Detector.

(3) Unplug the plastic tether attached between the Detector and the lid.

(4) Unplug the status LED harness connection from the termination board, the lid is now

detached from the Detector

(5) Place the Detector in the selected location ensuring it is in the correct orientation (Display

Module reads correctly). Mark and drill the wall with the appropriate hardware and

secure into position.

Issue 1 Page 4-3

February 2001

Page 40

Installation, Operation and Maintenance Manual

Reference should be made to Chapter 5, System Design, for information on the design of the sampling

pipe system. The sample inlet port of the Detector provides a 0.75 inch threaded interface section to the

sampling pipe network. Once installed this will provide an airtight connection.

Before connecting the piping network to the Detector, the piping must be connected to a vacuum cleaner

for several minutes (at the Detector end of the network). This will ensure that any loose debris is

removed from the piping network. While the vacuum is connected, the pipe should be tapped lightly

starting from the furthest pipe segment and moving back towards the vacuum.

If the sampled air must be returned from the Detector to the protected space, an exhaust port adapter

must be used. The optional adapter will push fit into the Detector's exhaust port and provides a threaded

connection to a 1 inch pipe.

Figure 4.1 Detector Installation Diagram

Page 4-4 Issue 1

February 2001

Page 41

Installation, Operation and Maintenance Manual

4.4 Termination Board Field Wiring

The following illustration shows the external connections for the termination board. Cable entries are

from the top, bottom or rear via the conduit knock-outs on the Detector.

EXTERNAL WIRING

8A8B9A9B9C

7A7B6B

6A

5B

5A

PRE

PRENOALARM1NOALARM2

CM

CM

1

RELAYEXP/LOCALASER

PRE 2PRE ALARM2ALARM1ALARM

NO CM NO

CM

1

RL1

P1

P9

IC5

LK1

HSSD

++

MAINLOOP

RL2 RL3

TERMINATION

-

P6

STATUSLED

P4

INTERFACE

INTERNALDISPLAY

M/TERM

NO

5B

CM

5A

6B

6A

7B

7A

8B

8A

9C

9A

9B

10C

10A

10B

PRE-ALARM VFCO CONTACTS

RATED AT2 AMP 30V DC

NO

CM

NO

CM

ALARM VFCO CONTACTS

RATED AT2 AMP 30V DC

NO

CM

NO

FAULTVFCO CONTACTS

CM

RATED AT2 AMP 30V DC

NORMALLY ENERGISED ON POWER UP

NC

NO

ISOLATE VFCO CONTACTS

CM

RATED AT2 AMP 30V DC

NC

NETWORK END OF

LINE SELECT

(SEE NOTE 4)

ALARM1

CM NO CM NO

CARD

P3

0V

CM NO

IC9

+24V

CM CM

IC7

-+-

EXTERNALDISPLAY

ALARM 2

NO

TROUBLE

CM NC NO

RL4

RL5

LK2

P2

++++

PSU

TROUBLE

ISOLATE

CM NC NO

PROGRAM

STATUS POWER OUT

10A

ISOLATEALARM 1

NONC CM NC NO

POWERON

TB2

LED

RL6

LK4

BAT1

REG1

TB1

1

---

POWERIN

10B

10C

TB2

TEMPORARY CONNECTIONS FOR

11A

SITE PROGRAMMING LEAD

VIA SERVICE PORT LOCATED

ON LHS OF UNIT

11A

PC

MAINLOOP ADDRESS

1

SW1

+

P5

LK3

P7

IC4

F2

RS485

NETWORK ADDRESS

DET.HEAD RESET

(SEE DETAIL 1)

FAN AD J

FAN

1

BATTERY/MEMORYLINK

(SEE DETAIL 3)

F1

FUSE 1A

DETAIL 1

NETWORK ADDRESS EXAMPLES

6

5

2

3

4

1

7

6

7

6

7

ADRESS 1

ON

5

2

3

4

1

ADRESS 20

ON

5

2

3

4

1

ADRESS 32

ON

SEE NOTE 1&2

LK1, LK2 & LK4

2

13

NORMAL OPERATING

DO NOT REMOVE

DETAIL 3

21

BACK-UP

BATTERYCONNECTED

LK3

21

BACK-UP

BATTERYDIS-CONNECTED

TB1

POWER IN

4A

1

+

4B

24v DC / 2A

RS485

NETWORK

-+-

1A1B1C

-

1A

+

1B

-

1C

+

1D

+

MAIN LOOP

1D

0V

2A

-+-

+24V

EXTERNALDISPLAY

2C

2B

2D

SPARE RS485

+

+

-+-

-

PSU

STATUS

POWER OUT

3A

SPARE 24v

DC / 0.5A

RS485

P2

2A

0v

2B

24v

--

2C

2D

++

44782-K155

REMOTE

DISPLAY

MODULE

NOTES:

1. DO NOT MOVE LK1, LK2 & LK4

2. ALL LINKS SHOWN IN NORMAL OPERATING POSITION

3. MAXIMUM CABLE SIZE OF TERMINALS 14 AWG

4. NETWORK NORMAL OPERATING POSITION.

POSITION IF TERMINATION BOARDAT END OF LASERNET NETWORK

Figure 4.2 Termination board External Wiring Diagram

4B

28V

4A

POWER

0V

SUPPLY UNIT

3A

FAULT

Issue 1 Page 4-5

February 2001

Page 42

Installation, Operation and Maintenance Manual

All external connections to the Detector should be earthed correctly. This is achieved by using the

provided earth stud located in the bottom left corner of the Detector.

4.5 Installing the Display Module

There are two options for installing the Display Module either within the Detector or remotely as a stand

alone item. The following procedures describe installation of the Display Module in the Detector

(1) Remove the Display Module from its carton and carry out a visual inspection of the unit to

ensure that no damage has occurred during transit.

(2) Remove the lid of the Detector by turning each of the two locking screws, situated on the

rear of the Detector, a quarter turn anti-clockwise, lift the lid clear. Exercise caution

during this procedure as at this point the lid is still not totally free from the Detector.

(3) Unplug the plastic tether attached to the lid.

(4) Unplug the status LED connection from the termination board, the lid is now detached

from the Detector