Page 1

Alarmline II Digital Linear

Heat Sensor Cable

Technical Manual

P/N 20-8501-509-DL03-04 • ISS 09APR18

Page 2

Copyright

©

2018 UTC Fire & Security. All rights reserved.

Trademarks and

patents

Alarmline and

Technical Manual

UTC

Other trade names used in this document may be trademarks or

registered trademarks of the manufacturers or vendors of the

respective products.

Manufacturer

Thermocable Flexible Elements Ltd.,

Pasture

Authorized EU manufacturing representative:

UTC Fire & Security B.V.

Kelvinstraat 7, 6003 DH Weert, Netherlands

Revision

04

20

cannot be disposed of as unsorted municip al was te in the Europ ean

Union. For proper recycling, return this product to your local supplier

upon the purchase of equivalent new equipment, or dispose of it at

designated collection points. For more

www.recyclethis.info.

Contact information

For contact information, see:

Technical helpline:

Sales enquiries:

e

Alarmline II Digital Linear Heat Sensor Cable

name and logo are trademarks of

Fire & Security.

Lane, Clayton, Bradf or d BD14 6LU.

.

.

12/19/EU (WEEE directive): Products marked with this symbol

information see:

firesecurityproducts.com.

+44 (0) 1908 281981

+44 (0) 1908 281981

-mail: kidde_airsense_techsupport@kiddeuk.co.uk

Page 3

Content

Important information ii

Chapter 1 Introduction 1

Overview 2

Regulatory information 4

Technical specifications 5

Chapter 2 Design and installation 9

Design guidelines 10

Installation 12

Chapter 3 Commissioning 19

Passive checks 20

Functional testing 20

Chapter 4 Application guidelines 23

Overview 24

Conveyor belts 25

Escalators and moving walkways 27

Cable trays and racks 28

Floating roof storage tanks and bund areas 29

Cold storage and freez er war ehous es 31

Index 33

Alarmline II Digital Linear Heat Sensor Cable Technical Manual i

Page 4

Important information

Limitation of liability

To the maximum extent permitted by applicable law, in no event will UTCFS be

liable for any lost profits or business opportunities, loss of use, business

interruption, loss of data, or any other indirect, special, incidental, or

consequential damages under any theory of liability, whether based in contract,

tort, negligence, product liability, or otherwise. Because some jurisdictions do not

allow the exclusion or limitation of liability for consequential or incidental

damages the preceding limitation may not apply to you. In any event the total

liability of UTCFS shall not exceed the purchase price of the product. The

foregoing limitation will apply to the maximum extent permitted by applicable law,

regardless of whether UTCFS has been advised of the possibility of such

damages and regardless of whether any remedy fails of its essential purpose.

Installation in accordance with this manual, applicable codes, and the instructions

of the authority having jurisdiction is mandatory.

While every precaution has been taken during the prepar ati on of this man ual to

ensure the accuracy of its contents, UTCFS assumes no responsibility for errors

or omissions.

Product warnings and disclaimers

THESE PRODUCTS ARE INTENDE D FOR SALE TO AND INSTALLATION BY

QUALIFIED PROFESSIONALS. UTC FIRE & SECURITY CANNOT PROVIDE

ANY ASSURANCE THAT ANY PERSON OR ENTITY BUYING ITS

PRODUCTS, INCLUDING ANY “AUTHO RIZED DEALER” OR “AUTHORIZED

RESELLER”, IS PROPERLY TRAINED OR EXPERIENCED TO CORRECTLY

INSTALL FIRE AND SECURITY RELATED PRODUCTS.

For more information on warranty disclaimers and product safety information,

please check https://firesecurityproducts.com/policy/product-warning/ or scan the

QR code:

ii Alarmline II Digital Linear Heat Sensor Cable Technical Manual

Page 5

Advisory messages

Advisory messages alert you to conditions or practices that can cause unwanted

results. The advisory messages used in this document are shown and described

below.

WARNING: Warning messages advise you of hazards that could result in injury

or loss of life. They tell you which actions to take or to avoid in order to prevent

the injury or loss of life.

Caution: Caution messages advise you of possible equipment damage. They tell

you which actions to take or to avoid in order to prevent the damage.

Note: Note messages advise you of the possible loss of time or effort. They

describe how to avoid the loss. Notes are also used to point out important

information that you should read.

Note: Kidde Products Ltd. has taken every care to ensure that Alarmline II Digital

Linear Heat Detection systems are as simple to install as possible but in case of

difficulty, please contact our Help Line to ensure trouble free installation and

operation. Kidde Produ c ts Ltd. takes no responsibility for damage or injury

occasioned as a result of failing to install or operate the equipment in accordance

with these instructions.

Alarmline II Digital Linear Heat Sensor Cable Technical Manual iii

Page 6

iv Alarmline II Digital Linear Heat Sensor Cable Technical Manual

Page 7

Chapter 1

Introduction

Summary

This chapter provides an introduction to the product.

Content

Overview 2

Operation 2

Product range 3

Regulatory information 4

UL/ULC listings 4

FM approvals 5

Technical specifications 5

Alarmline II Digital Linear Heat Sensor Cable Technical Manual 1

Page 8

Chapter 1: Introduction

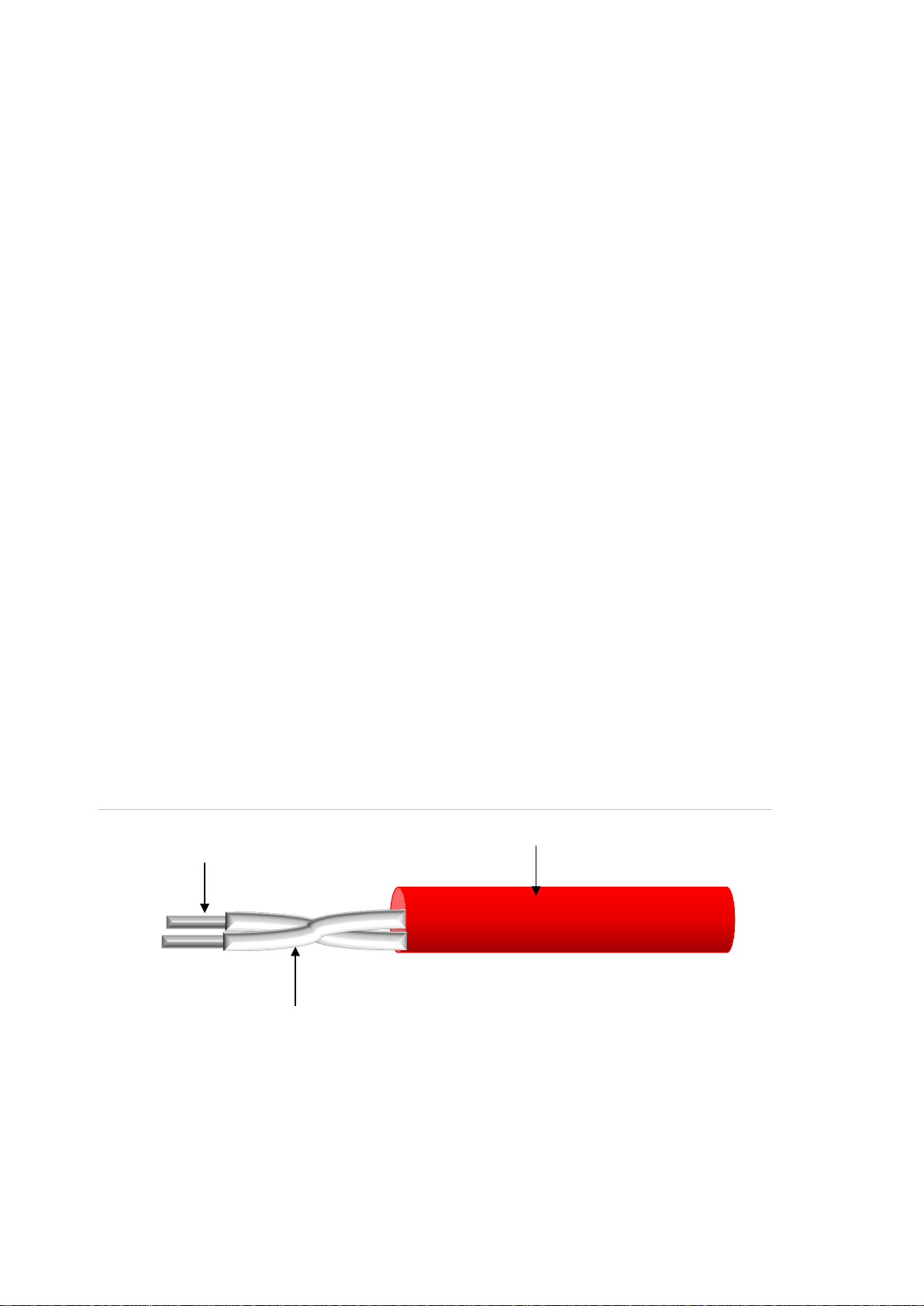

Tri-metallic cores

Protective coating

Advanced temperature-sensitive polymer

Overview

Alarmline II Digital Sensor Cables are a flexible durable and cost-effective form of

fire detection, suitable for protecting a wide range of commercial and industrial

applications.

They provide flexibility in installation enabling them to be used for general area

protection or proximity detection close to a specific point of risk. A wide range of

alarm temperatures, protective coatings, and installation fixings ensure system

design and installation is specific to the risk. Alarmline II Digital Sensor Cables

are especially suited for use in confined areas or areas with harsh environmental

conditions where the use of other forms of detection is limited.

Alarmline II Digital Sensor Cables can be easily integrated to any fire control

panel through a moni to r ed inp ut (a conventional detection zone, zone monitor

unit, or switch monitor unit, etc.). The Digital Location Control Unit provides

additional functionality to the Alarmline II Digital Sensor Cable system by being

able to determine the alarm location along extended lengths of digital sensor

cable (up to 3000 m).

This manual provides technical information, installation guidelines, and design

recommendations for a selection of typical applications (it does not cover all

possible applications – contact Kidde Prod uc t s Ltd. technical support for further

design and installation advice).

Operation

Alarmline II Digital Sensor Cables are constructed from a twisted pair of trimetallic conductors covered with an advanced temperature-sensitive polymer. A

protective outer coating is then extruded over the twisted pair.

Figure 1: Cable construction

2 Alarm l i ne II Digital Li near Heat Sensor Cable T echnical Manual

Page 9

Chapter 1: Introduction

Part

AD68

AD68N

AD68P

AD68SS

AD88

AD88N

AD88P

AD88SS

AD105

AD105N

AD105P

AD105SS

AD185N

AD185SS

The two inner cores of the sensor cable are tightly twisted together to provide a

mechanical tension bet ween them. When the temperature-sensi ti ve polymer

reaches a specified temperature it begins to soften, the tension between the two

inner cores forces the two conductors together creating a short circuit.

The simplistic operation of the Alarmline II Digital Sensor Cable makes it

compatible with any control equipment capable of accepting contact closure type

initiating devices.

Product range

The Alarmline II Digital S ensor Cable range consists of five fixed-temperature

alarm cables, each with a range of protective coatings.

Table 1: Alarmline II Digital Sensor Cable product range

number Description Comments

Alarmline II Digital Sensor Cable – 68°C

(155°F) PVC

Alarmline II Digital Sensor Cable – 68°C

(155°F) Nylon

Alarmline II Digital Sensor Cable – 68°C

(155°F) Polypropylene

Alarmline II Digital Sensor Cable – 68°C

(155°F) Stainless Steel over PVC

Alarmline II Digital Sensor Cable – 88°C

(190°F) PVC

Alarmline II Digital Sensor Cable – 88°C

(190°F) Nylon

Alarmline II Digital Sensor Cable – 88°C

(190°F) Polypropylene

Alarmline II Digital Sensor Cable – 88°C

(190°F) Stainless Steel over PVC

Alarmline II Digital Sensor Cable – 105°C

(221°F) PVC

Alarmline II Digital Sensor Cable – 105°C

(221°F) Nylon

Interior applications, general area

coverage

Chemical/UV protection, exterior

applications

Increased chemical protection in

caustic environments

Increased mechanical protection

Interior applications, general area

coverage

Chemical/UV protection, exterior

applications

Increased chemical protection in

caustic environments

Increased mechanical protection

Interior applications, general area

coverage

Chemical/UV protection, exterior

applications

Alarmline II Digital Sensor Cable – 105°C

(221°F) Polypropylene

Alarmline II Digital Sensor Cable – 105°C

(221°F) Stainless Steel over PVC

Alarmline II Digital Sensor Cable – 185°C

(365°F) Nylon

Alarmline II Digital Sensor Cable – 185°C

(365°F) Stainless steel over Nylon

Alarmline II Digital Linear Heat Sensor Cable Technical Manual 3

Increased chemical protection in

caustic environments

Increased mechanical protection

Chemical/UV protection, exterior

applications

Chemical/UV and mechanical

protection

Page 10

Chapter 1: Introduction

Part

AD2

AD2

Cable

AD68

AD68N

AD88

AD88N

AD105

number Description Comments

18 Alarmline II Digital Sensor Cable – 218°C

(424°F) Silicon e

18SS Alarmline II Digital Sensor Cable – 218°C

(424°F) Stainless steel over Silicone

Chemical/UV protection, exterior

applications

Chemical/UV and mechanical

protection

Additional coated cables are available for special applications:

• Polypropylene outer coating: Provides increased chemical protection within

caustic environments.

• Stainless steel outer braid: Provides increased mechanical protection.

For further information regarding the specialist coatings, contact your local sales

representative.

Regulatory information

UL/ULC listings

The sensor cables listed below have been tested and approved by UL and ULC

to UTHV Heat actuated devices for special application and UQGS Heatautomatic fire detectors.

UL and ULC listed, file number S35630. Categories UTHV, UTHV7, UQGS, and

UQGS7: "Heat activated devices for Special applications”.

Table 2: UL/ULC listings

Alarm temperature Outer coating Spacing

68°C (155°F) PVC Maximum spacing 10.6 m (35 ft.)

between sensor cable runs for

general area coverage

68°C (155°F) Nylon Maximum spacing 4.5 m (15 ft.)

between sensor cable runs for

general area coverage

88°C (191°F) PVC Maximum spacing 10.6 m (35 ft.)

between sensor cable runs for

general area coverage

88°C (191°F) Nylon Maximum spacing 4.5 m (15 ft.)

between sensor cable runs for

general area coverage

105°C (221°F) PVC Maximum spacing 10.6 m (35 ft.)

between sensor cable runs for

general area coverage

4 Alarm l i ne II Digital Li near Heat Sensor Cable T echnical Manual

Page 11

Chapter 1: Introduction

Cable

AD105N

AD185N

AD2

Cable

AD68

AD88

AD105

AD218

Alarm

temperature

Outer coating

Outer colour

Outer diameter

Ambient

temperature

Installation

temperature

Alarm temperature Outer coating Spacing

105°C (221°F) Nylon Maximum spacing 4.5 m (15 ft.)

between sensor cable runs for

general area coverage

185°C (365°F) Nylon Proximity detection only

18 218°C (424°F) Silicone Proximity detection only

FM approvals

The sensor cables listed below have been tested and approved by FM (Fire

Detection, Heat Activated).

Table 3: FM approvals

Alarm temperature Outer coating Spacing

68°C (155°F) PVC Maximum spacing 9 m (30 ft.)

between sensor cable runs for

general area coverage

88°C (191°F) PVC Maximum spacing 9 m (30 ft.)

between sensor cable runs for

general area coverage

105°C (221°F) PVC Maximum spacing 7.6 m (25 ft.)

between sensor cable runs for

general area coverage

235°C (455°F) Silicone Proximity detection only

Technical specifications

Table 4: AD68 range

AD68 AD68N AD68P AD68SS

Red Black Red Red

PVC Nylon Polypropylene

68°C (155°F)

Stainless steel

over PVC

3.6 mm

(±0.12 mm)

0.142 in.

(±0.005 in.)

2 × tri-metallic conductors Ø 0.912 mm (0.036 in.)

Alarmline II Digital Linear Heat Sensor Cable Technical Manual 5

4.44 mm

(±0.12 mm)

(0.175 in.

(±0.005 in.)

45°C (113°F) max.

−10°C (14°F) min.

4.5 mm

(±0.12 mm)

(0.177 in.

(±0.005 in.)

4.1 mm

(±0.12 mm)

(0.161 in.

(±0.005 in.)

Page 12

Chapter 1: Introduction

Operating

temperature

Bend radius

Voltage rating

Insulation rating

Resistance

Capacitance

Inductance

Alarm

temperature

Outer coating

Outer colour

Outer diameter

Ambient

temperature

Installation

temperature

Operating

temperature

Bend radius

Voltage rating

Insulation rating

Resistance

Capacitance

Inductance

AD68 AD68N AD68P AD68SS

50 mm (2 in.) min., extended to 100 mm (4 in.) for low temperature

30 VAC, 42 VDC max.

1 kV tested protective outer coat

90.5 Ω/km (27.6 Ω/1000 ft.) max. per conductor at 20°C

<120 pF/m (<37 pF/ft.)

<1.6 µH/m (<0.49 µH/ft.)

Table 5: AD88 range

White Black White White

3.6 mm

−40°C (−40°F) min.

environments

AD88 AD88N AD88P AD88SS

88°C (190°F)

PVC Nylon Polypropylene

(±0.12 mm)

0.142 in.

(±0.005 in.)

4.44 mm

(±0.12 mm)

(0.175 in.

(±0.005 in.)

4.5 mm

(±0.12 mm)

(0.177 in.

(±0.005 in.)

Stainless steel

over PVC

4.1 mm

(±0.12 mm)

(0.161 in.

(±0.005 in.)

2 × tri-metallic conductors Ø 0.912 mm (0.036 in.)

69°C (156°F) max.

−10°C (14°F) min.

−40°C (−40°F) min.

50 mm (2 in.) min., extended to 100 mm (4 in.) for low temperature

environments

30 VAC, 42 VDC max.

1 kV tested protective outer coat

89.5 Ω/km (27.3 Ω/1000 ft.) max. per conductor at 20°C

<85 pF/m (<26 pF/ft.)

<1.72 µH/m (<0.52 µH/ft.)

6 Alarm l i ne II Digital Li near Heat Sensor Cable T echnical Manual

Page 13

Chapter 1: Introduction

Alarm

temperature

Outer coating

Outer colour

Outer diameter

Ambient

temperature

Installation

temperature

Operating

temperature

Bend radius

Voltage rating

Insulation rating

Resistance

Capacitance

Inductance

Alarm

temperature

Outer coating

Outer colour

Outer diameter

Ambient

temperature

Installation

temperature

Operating

temperature

Bend radius

Table 6: AD105 range

AD105 AD105N AD105P AD105SS

PVC Nylon Polypropylene

105°C (221°F)

Stainless steel

over PVC

White Black White White

3.6 mm

(±0.12 mm)

0.142 in.

(±0.005 in.)

4.44 mm

(±0.12 mm)

(0.175 in.

(±0.005 in.)

4.5 mm

(±0.12 mm)

(0.177 in.

(±0.005 in.)

4.1 mm

(±0.12 mm)

(0.161 in.

(±0.005 in.)

2 × tri-metallic conductors Ø 0.912 mm (0.036 in.)

69°C (156°F) max.

−10°C (14°F) min.

−40°C (−40°F) min.

50 mm (2 in.) min., extended to 100 mm (4 in.) for low temperature

environments

30 VAC, 42 VDC max.

1 kV tested protective outer coat

91 Ω/km (27.7 Ω/1000 ft.) max. per conductor at 20°C

<73 pF/m (<22 pF/ft.)

<1.65 µH/m (<0.5 µH/ft.)

Table 7: AD185 range

Nylon Stainless steel over PVC

Red White

4.44 mm (±0.12 mm)

AD185N AD185SS

185°C (365°F)

5 mm (±0.12 mm)

(0.175 in. (±0.005 in.)

(0.197 in. (±0.005 in.)

2 × tri-metallic conductors Ø 0.912 mm (0.036 in.)

125°C (257°F) max.

−10°C (14°F) min.

−40°C (−40°F) min.

50 mm (2 in.) min., extended to 100 mm (4 in.) for low temperature

environments

Alarmline II Digital Linear Heat Sensor Cable Technical Manual 7

Page 14

Chapter 1: Introduction

Voltage rating

Insulation rating

Resistance

Capacitance

Inductance

Alarm

temperature

Outer coating

Outer colour

Outer diameter

Ambient

temperature

Installation

temperature

Operating

temperature

Bend radius

Voltage rating

Insulation rating

Resistance

Capacitance

Inductance

30 VAC, 42 VDC max.

1 kV tested protective outer coat

91 Ω/km (27.7 Ω/1000 ft.) max. per conductor at 20°C

<90 pF/m (<27 pF/ft.)

<1.62 µH/m (<0.49 µH/ft.)

Table 8: AD218 range

Silicone rubber Stainless steel over silicone

Green Green

AD185N AD185SS

AD218 AD218SS

UL/ULC approval at 2 18° C ( 424°F)

FM approval at 235°C (455°F)

5 mm (±0.1 mm)

(0.196 in. (±0.004 in.)

5.5 mm (±0.11 mm)

(0.216 in. (±0.04 in.)

2 × tri-metallic conductors Ø 0.912 mm (0.036 in.)

170°C (338°F) max.

−10°C (14°F) min.

−40°C (−40°F) min.

63.5 mm (2.5 in.) min., extended to 127 mm (5 in.) for low temperature

environments

70 VAC, 100 VDC max.

5 kV tested protective outer coat

90 Ω/km (27.4 Ω/1000 ft.) max. per conductor at 20°C

<85 pF/m (<26 pF/ft.)

<2.00 µH/m (<0.61 µH/ft.)

8 Alarm l i ne II Digital Li near Heat Sensor Cable T echnical Manual

Page 15

Chapter 2

Design and installation

Summary

This chapter provides design guidelines and installation information for your

product.

Content

Design guidelines 10

Proximity detection 10

Area coverage 11

Installation 12

Jointing 14

Connecting sensor cable to a monitored input 14

Interposing or leader cable 16

Digital Location Control Unit 16

Hazardous area installation 17

Alarmline II Digital Linear Heat Sensor Cable Technical Manual 9

Page 16

Chapter 2: Design and installation

Design guidelines

The design and installation of an Alarmline II Digital Linear Heat Detection

system is unique to every site and application, therefore it is recommended that

this work is only undertaken by trained and competent persons following the

guidelines in this chapter.

There are two main types of protection that can be provided by the Alarmline II

Digital Sensor Cable:

Proximity detection: The sensor cable is installed close to the point of risk,

generally around the equipment to be protected. There is no specific design

criteria for these applications but there are guidelines to be considered.

Area coverage: The sensor cable is distributed throughout the risk area allowing

protection of the general area as opposed to specific points. Alarmline II Digital

Sensor Cable offers an alternative to point type heat detectors in this type of

application.

Proximity detection

• Selection of the appropriate sensor cable type is critical to ensure correct

performance of the system. The cable selection will be based on the

maximum possible ambient temperature within the risk area and the required

alarm temperature.

• The sensor cable should be installed close enough to the point of risk to give

an acceptable response, but not in a position where it can be damaged or

obstruct any moving parts. The location of the sensor cable should not restrict

access to any parts of the equipment which require maintenance.

• The thermal path to the sensor cable should not be obstructed an d a

minimum distance of 25 mm should be left between the sensor cable and any

surface it is being mounted to.

• In outdoor applications, shield the sensor cable from direct sunlight to control

the ambient temperature around the cable and to prevent the risk of false

alarms.

• In hazardous areas, galvanic isolators or intrinsically safe (IS) barriers are

required to provide an IS circuit.

• Fixing of the cable will be determined by the application and the location at

which the cable is installed. Support the cable to prevent sagging. The

environmental conditions and clips to be used must considered.

10 Alarmline II Digital Linear Heat Sensor Cable Technical Manual

Page 17

Chapter 2: Design and installation

Standard

BS

UL/ULC

FM

d2

d1

Area coverage

In applications where the sensor cable is installed for general area coverage (as

an alternative to point type heat detectors), the positioning of the sensor cable

typically follows the applicable local standards or approvals. The sensor cable is

typically installed at ceiling height and laid out so that sufficient coverage is

provided (see Figure 2 below).

Maximum spacing between cable runs typically follows the same limits as normal

point type heat detectors and as defined by applicable local standards, as shown

in the table below.

Table 9: Maximum spacing between cable runs

Maximum spacing

5839 7.5 m (24.5 ft.)

9 m (30 ft.)

9 m (30 ft.)

Figure 2: Distributed sensor cable for general area coverage

d1 – Spacing of sensor cable from the wall (d1 = (d2/2))

2

– Spacing between sensor cable runs

d

Other design recommendations for general area coverage systems:

• Selection of the appropriate sensor cable type is critical to ensure correct

performance. The selection of the cable will be based on the maximum

possible ambient temperature within the risk area and the alarm temperature

of the cabl e.

• The recommended total area coverage for a single Alarmline II Digital

detection zone shall be no more than 2000 m2 (21,528 ft2).

Alarmline II Digital Linear Heat Sensor Cable Technical Manual 11

Page 18

Chapter 2: Design and installation

• The cable should be installed no closer than 25 mm and no further than

150 mm from the fixing sur face.

• Fixing of the cable will be determined by the application and the installation

location. The cable must be supported at 1 m intervals (min.), with additional

supports where there are bends in the cable. The environmental conditions

and clips to be used must considered.

• The minimum bend radius when installing AD68, AD88, AD105, and AD185

sensor cables in ambient conditions of 0°C (32°F) and above is 50 mm (2 in.)

or 63.5 mm (2.5 in.) for AD218 sensor cables.

For areas where ambient conditions are likely to be less than 0°C (32°F) the

minimum bend radius for AD68, AD88, AD105, and AD185 sensor cables is

100 mm (4 in.) or 127 mm (5 in.) for AD218 sensor cables.

In hazardous areas, galvanic isolators or intrinsically safe (IS) barriers are

required to provide an IS circuit.

Installation

Caution: This product must be installed and maintained by qualified personnel

adhering to all local or national installation requirements and any other applicable

regulations.

As well as the installation of the sensor cable within the risk area this section also

provides details on interfacing the sensor cable into the fire alarm monitoring

equipment.

Installation guidelines

Note: Perform a continuity test on the reeled cable prior to installation to ensure

that no damage has occurr ed dur ing transit.

It is not possible to provide definitive installation instructions as each application

will be uniquely different. The following points outline general requirements for

installation.

• Sensor cable must only be installed in the area to be protected. If the

equipment monitoring the sensor cable is not installed within the risk area

then a suitable interposing/leader cable can be connected between the

sensor cable and the monitoring equipment.

• Sensor cables can be provided with various outer sheaths to suit the

environment (PVC, nylon, polypropylene, and stainless steel braid). Be sure

to select the correct protective outer sheath to suit the environment.

• Sensor cables should be terminated in junction boxes that are suitable to the

environment.

12 Alarmline II Digital Linear Heat Sensor Cable Technical Manual

Page 19

Chapter 2: Design and installation

Ammonia liquid

Butane

Copper nitrate

Fuel oils

Gasoline

Hydrofluoric acid

Kerosene

Diesel fuel

Acetic acid

• Sensor cable fixing clips should be suitable for the environment and the

surface they are being fitted to. There is no requirement for the sensor cable

to be tensioned, however on straight runs it is recommended to support the

cable at a distance of 1 m to prevent sagging.

• When using metal fixing clips, protect the cable at the fixing points by using

the silicone sleeve around the sensor cable.

• The minimum bend radius for AD68, AD88, AD105, and AD185 sensor cables

is 50 mm (2 in.) or 63.5 mm (2.5 in.) for AD218 sensor cables.

For areas where ambient conditions are likely to be less than 0°C (32°F) the

minimum bend radius for AD68, AD88, AD105, and AD185 sensor cables is

100 mm (4 in.) or 127 mm (5 in.) for AD218 sensor cables.

• Sensor cable is supplied on drums o f 100 m, 500 m, and 1000 m and can be

easily jointed to create the required sensor cable length.

• Do not paint the sensor cable.

• Where possible, fixing of the sensor cable should be the last stage in the

installation to prevent any damage to the cable during other installation tasks.

• Pull the sensor cable from the reel using a reel stand. D o not pull the cable off

the reel vertically as this may damage the cable.

Chemical resistance

Table 10: Chemical resistance comparison

PVC coating Nylon coating Polypropylene

coating

∗∗∗∗∗ ∗∗∗ ∗∗∗∗∗ ***

∗∗∗∗∗ ∗∗∗∗∗ ∗ **

∗∗∗∗∗ ∗∗∗∗∗ *****

∗∗∗∗∗ ∗∗∗∗∗ ∗∗∗ ***

∗∗ ∗∗∗∗∗ ∗∗ ***

∗ ∗ ∗∗∗∗∗ *

∗∗∗∗∗ ∗∗∗∗∗ ∗ ***

∗∗∗∗∗ ∗∗∗∗∗ ∗∗∗∗ ***

∗∗ ∗ ∗∗∗∗∗ ****

Silicone coating

Alarmline II Digital Linear Heat Sensor Cable Technical Manual 13

Page 20

Chapter 2: Design and installation

Jointing

One of the advantages of the Alarmline II Digital Sensor Cable is that damaged

sections of cable can be cut out and replaced without having to replace the entire

cable run. When a cable has been acti v at ed or has been damaged, the section of

the cable can be cut away and a new section of cable can be jointed into the

existing cable run.

Joint the cable using suitable junction boxes and ensure that it is jointed correctly

to prevent any problems from bad connections, etc.

Connecting sensor cable to a monitored input

Caution: Before connecting the sensor cable to any control equipment, consult

the technical documentation provided by the equipment manufacturer.

The sensor cable can be connected directly to any control equipment with a

monitored input which can detect the operation of a switch changeover. The most

common types of system would be either a conventional fire alarm control panel

or an addressable fire alar m contr ol panel.

For a conventional fire alarm panel, the sensor cable can be connected directly

to a detection zone input. Any detection zone used would be specific to the

Alarmline II Digital Sensor Cable with no other detection devices attached to the

zone.

For an addressable fire alarm panel, the sensor cable can be connected to the

control panel:

• Via the control panel monitored inputs (if available), or

• As a device on the addressable loop using a suitable loop interface (for

example, a Zone Monitor Unit or Switch Monitor Unit)

Regardless of whether the sensor cable is fitted to a conventional detection zone

or a loop interface on an addressable fire alarm control panel, the configuration is

the same (see Figure 3 on page 15).

14 Alarmline II Digital Linear Heat Sensor Cable Technical Manual

Page 21

Chapter 2: Design and installation

1

2

3

4

5

6

Figure 3: Connecting to a fire alarm contro l panel

1. Connection terminals for monitored input (whether this is a conventional

detection zone or a loop interface two terminals are provided). This input will

monitor for changes in the resistance of the circuit to determine the presence

of an open circuit or an alarm condition (short circuit).

2. Interposing or leader cable (the sensor cable must be installed only in the

area that it is to prot ect). If the control equipment or interface is to be mounted

remotely to the protected area, then a suitable two-core fire-rated cable can

be used to make the connection between the two locations (“Interposing or

leader cable” on page 16).

3. Suitable junction boxes should be used when terminating the sensor cable

(for example, Ex junction boxes for hazardous areas). The diameter of the

sensor cables range from 3.6 to 4.5 mm – be sure to select the correct size

glands for junction boxes.

4. Alarm resistor. Monitored inputs will monitor for changes in the resistance of

the circuit connected to it and different resistance values will indicate different

events.

Conventional fire alarm panels and loop interfaces will have a specified alarm

resistor value which must be fitted in series with the sensor ca bl e for the

system to activate an alarm condition. The alarm resistor value will vary

dependent on the control equipment/interface and will be specified by the

equipment manufacturer.

Alarmline II Digital Linear Heat Sensor Cable Technical Manual 15

Page 22

Chapter 2: Design and installation

C

0.8

1.3

2.0

3.3

The position of the alarm resistor in the circuit is critical – it must be located at

the start of the sensor cable. If using an interposing cable this allows the

interposing cable to be monitored for open and short circuit faults only. Only

when the sensor cable operates (short circuits) will the alarm resistor be

introduced to the circuit activating an alarm at the control equipment.

5. The sensor cable must be installed only in the protected area and will be

monitored for open circui t faul ts (short circuit on the sensor cable indicates an

alarm). The correct temperature sensor cable must be selected for the

application to prevent false alarms.

6. End-of-line monitoring device. This allows the control panel to monitor the

integrity of the circuit completing the circuit and allowing sufficient current flow

from the positive to negati ve terminals. The end-of-line monitoring device

must be located at the end of the sensor cable and the value will be specified

by the control equipment manufacturer. In the majority of cases the end-ofline devices will be supplied with the control panel.

Interposing or leader cable

The sensor cable must be installed only in the area that it is protecting. In some

applications, you’ll need to use an interposing or leader cable to connect the

sensor cable to the monitoring equipment.

An approved fire-rated interposing or leader cable should be used and, when

connecting the interposing or leader cable to the sensor cable, an IP66/67 rated

junction box should be used. The maximum length of the interposing/leader cable

will vary based on the cross-sectional area, as shown below.

The following maximum lengths of interposing or leader cable are bas ed on the

maximum length of sensor cable (3000 m or 9842 ft.).

Table 11: Maximum length of interposing or leader cable

able cross section Maximum length

mm2 (18 AWG) 2,500 m (8,200 ft.)

mm2 (16 AWG) 3,500 m (11,500 ft.)

mm2 (14 AWG) 6,000 m (20,000 ft.)

mm2 (12 AWG) 9,500 m (31,000 ft.)

Digital Location Control Unit

For applications where long lengths of sensor cable are installed such as cable

tunnels, road tunnels, and conveyor belts use a Digital Location Control Unit to

detect the location of the al ar m acti vation along a length of cable. A max i mum of

3 km of Alarmline II Digital Sensor Cable can be attached to the Digital Location

Control Unit.

16 Alarmline II Digital Linear Heat Sensor Cable Technical Manual

Page 23

Chapter 2: Design and installation

Hazardous area installation

Note: When installing equipment in hazardous areas close liaison with the

responsible site perso nnel is ess ential.

Alarmline II Digital Sensor Cable is classified as “simple apparatus” when it

comes to Hazardous areas and does not require certification. The sensor cable

can be installed within a hazardous area provided suitable safety barriers are

used between the sensor cable and the control equipment.

The type of safety barrier shall be determined by the control equipment and

therefore close liaison with the control equipment manufacturer is required to

ensure the correct safety barrier is used. The safety barrier will be installed along

with the control equipment in a safe area.

The relevant manufacturer’s documentation should be consulted for wiring details

of barriers, configuration of monitoring equipment, etc.

To ensure that the system complies with hazardous area requirements, it is

important to consider t he el ectrical characteristics. Each safety barrier specifies

the maximum resistance, capacitance, inductance, and L/R ratio of any

device/cable that is attached to it (these details are provided in the specification

tables in “Technical specifications” on page 5).

These characteristics may have a significant impact on the design of the system

and may limit the length of sensor cable that can be used dependent on the

safety barrier.

All terminations and connections on a hazardous area installation must be done

in suitably approved junction boxes for the type of area.

Alarmline II Digital Linear Heat Sensor Cable Technical Manual 17

Page 24

Chapter 2: Design and installation

18 Alarmline II Digital Linear Heat Sensor Cable Technical Manual

Page 25

Chapter 3

Commissioning

Summary

This chapter provides information on commissioning.

Content

Passive checks 20

Functional testing 20

Alarmline II Digital Linear Heat Sensor Cable Technical Manual 19

Page 26

Chapter 3: Commissioning

Ensure that the installed sensor cable is fully tested and inspected prior to

handover. Use the following guidelines to ensure that this is done correctly.

Passive checks

• Visually inspect the cable to ensure correct installation in accordance with the

specification and system design.

• Check that the correct cable (alarm temperature) has bee n installed.

• Check each cable for mechanical damage, that all clips are securely held in

place, and that the cable is correctly installed within the clips.

• Inspect all joints and terminations to ensure that they are correctly installed

and appropriate for the application and environment .

• Ensure that the correct end-of-line device is fitted for the monitoring

equipment used.

• Ensure that the correct value alarm resistor is installed and that it is in the

correct location.

• Check that insulation resistance between conductors (excluding end-of-line

devices) is 1000 MΩ per km (minimum).

• Check that the conductor resistance per km/ft. does not exceed that listed in

“Technical specifications” on page 5.

Functional testing

Alarmline II Digital Sensor Cable is non-restorable and it is ther e fore not pos si bl e

to test the cable by applying heat without damaging it. Simulated tests are

recommended.

Simulated fault tes t

The sensor cable is monitored for open circ uit fault only.

To perform the test:

1. To trigger a fault condition, remove any connection between the monitoring

equipment and the sensor cable.

2. Confirm that the monitoring equipment registers a fault condition for the

sensor cable.

20 Alarmline II Digital Linear Heat Sensor Cable Technical Manual

Page 27

Chapter 3: Commissioning

Simulated alarm test

Testing of the cable will trigger an alarm at the monitoring equipment – isolate

the monitoring equipment outputs as required.

To perform the test:

1. Ensure that the cable is connected to the monitoring equipment and that no

faults are present.

2. Place a short circuit across the end of the sensor cable.

3. Hold the short circuit in place until the relevant alarm condition appears on the

control panel.

4. Once the test has bee n completed, remove the short circuit and return all

control units to normal status.

Functional alarm test

If required a functional alarm test can be performed by attaching a spare length

of sensor cable to the end of the installed cable. This can then be heated to

generate an alarm conditi on.

Testing of the cable will trigger an alarm at the monitoring equipment – isolate

the monitoring equipment outputs as required.

To perform the test:

1. Fix a short length of cable (1 m, 3 ft.) between the end of the installed sensor

cable and the end-of-line device.

2. Using a suitable heat source subject the cable to sufficient heat to reach the

alarm temperature.

3. Confirm that the cable indicates the relevant alarm condition.

4. Remove the length of test cable and connect the end-of-line device to the

sensor cable before resetting the monitoring equipment.

Alarmline II Digital Linear Heat Sensor Cable Technical Manual 21

Page 28

Chapter 3: Commissioning

22 Alarmline II Digital Linear Heat Sensor Cable Technical Manual

Page 29

Chapter 4

Application guidelines

Summary

This chapter provides g ui deli nes for typical applications.

Content

Overview 24

Conveyor belts 25

Escalators and moving walkways 27

Cable trays and racks 28

Floating roof storage tanks and bund areas 29

Cold storage and freezer w ar ehous es 31

Alarmline II Digital Linear Heat Sensor Cable Technical Manual 23

Page 30

Chapter 4: Application guidelines

Overview

Alarmline Digital Sensor Cables have been successfully installed in a wide range

of applications. Each application is different and a thorough risk assessment

must be carried out to determine the best type of system and design. This

section of the manual provides guidance on typi cal applic ati ons.

The following list includes applications where sensor cables have been used:

• Cable trays and risers

• Boilers

• Conveyors

• Transformers

• Control room and computer

suites – floor voids

• Cooling towers

• Alternator pits

• Control cubicle protection

• Ducting and pipework

• Radar

• Missile storage

• Engine bay protection

• Chemical and fuel storage tanks

– fixed roof

• Fuel storage tanks – floating roof

• Well heads

• Power units and pumps

• Cold-storage warehousing

• Service ducts

• Rolling stock

• Road and rail tunnels

• Dust extraction ducts

• Storage racking

• Grain silos and dryers

• Switchgear

• Cottages – thatched roof

• Paint spray booths

• Paint storage

• Reactor vessels

• Extraction and ventilation

systems

• Wet bench application s

• Food processing and preparation

areas

• Car parks

• Passenger walkways

• Distilleries

• Baggage conveyors

• Escalators

• Industrial kitchens – canopy

protection

This list is for guidance only and other applications may exist which have not

been included.

24 Alarmline II Digital Linear Heat Sensor Cable Technical Manual

Page 31

Chapter 4: Application guidelines

Assessment

Location

Accessibility

then a system which requires little or

Key risk areas

Fuel type

reas. The fuel

Interaction

Conveyor belts

Conveyor belts are used on many sites to transport materials/product around the

facility which can be anything ranging from coal, chemicals, luggage, minerals, or

grain, etc.

The main causes of fires on conveyor belts are as follows:

• Friction (misaligned belts or seized rollers)

• Overheating (drive motors)

• Burning material (combustible material being carried on conveyor)

The effect of a fire on a conveyor can be significant as a moving conveyor could

assist with the spread of fire over a larger area.

A number of important issues need to be considered when carrying out the risk

assessment of the conveyor belt:

Table 12: Conveyor belt risk assessment

Considerations

If the conveyor belt is located outdoors and is not covered, then the

detection system must be able to withstand being exposed to the

elements without any effect on performance or causing false alarms.

If accessibility is likely to be an issue,

no maintenance once installed is a signif icant adv ant a ge. Acc es sibi lity will

become more of an issue on covered conveyors.

Many of the key risk areas may be out of sight (roller bearings underneath

the belt, drive motor, cabinets, etc.).

The type of material being carried on the conveyor – is it combustible, is

there the potential for a dust explosion, etc. It may be necessary to

provide a detection system which is suitable for hazardous a

type would also help determine the requirement for any automatic firefighting equipment and which type.

Should the detection system trigger an alarm, what actions are to be

taken (automatic shutdowns, visual/aud ib le warni ngs , ac tivati on of

automatic firefighting equipment, etc.).

Alarmline II Digital Sensor Cable can provide a highly effective detection solution

for the protection of conveyor belts. The flexibility of the sensor cable allows it to

be installed very close to the point of risk (in close proximity to the belt and the

rollers). Once installed the cable should require no maintenance unless it has

been activated (and then only the damaged section of cable needs to be

replaced). As it is a heat sensor, the cable is unaffected by the potential harsh

environmental conditions providing the correct temperature cable is selected

based on the maximum ambient.

Figure 4 on page 26 shows the recommended areas for installing Alarmline II

Digital Sensor Cable on a conveyor belt.

Alarmline II Digital Linear Heat Sensor Cable Technical Manual 25

Page 32

Chapter 4: Application guidelines

Location

Roller bearings

Above the belt

Underneath

underneath

Three locations are recom me nde d for the sen sor cable t o provide complete

detection on the conveyor belt.

Table 13: Recommended locations

Problems with friction from a misaligned belt or a seized bearing will

cause an overheat – by placing the sensor cable as close as possible to

the roller bearings the earlier a potential incident can be detected. A

controlled shutdown can be implemented preventing a potential fire

incident. It is recommended that cable is run down both sides of the

conveyor.

If the conveyor is covered it is recommended that sensor cable is fixed to

the canopy above the conveyor belt to detect for any fires on the belt,

enabling a controlled shutdown preventing potential fire spread by the

moving escalator.

It is a recommendation that sensor cable can also be installed

the conveyor to detect any fires that may occur due to trash or

combustible fuel that may have fallen from the conveyor belt.

Figure 4: Sensor cable installation for covered conveyor

The sensor cable should be installed in such a way as to not interfere with

maintenance and to prevent mechanical damage. Fixing clips should be selected

based upon fixing location and available fixing surfaces (most commonly edge

clips have been used to fit to the metal framework of the conveyor).

26 Alarmline II Digital Linear Heat Sensor Cable Technical Manual

Page 33

Chapter 4: Application guidelines

Escalators and mov ing walkways

Escalators and moving walkways can be found in many buildings such as

shopping centres, airports, train stations, etc. Underneath the escalator there are

many mechanical moving parts which can overheat due to friction i f t hey become

seized or damaged. Due to the confined space under the escalator and the harsh

operating conditions (dust, oil, grease), it is a very difficult environment to install

any fire detection equipment.

Alarmline II Digital Sensor Cable is flexible enough to be installed close to the

main points of risk and be unaffected by the environment. Once the cable has

been installed there is no need to access it for maintenance pur p os e s .

Due to the number of moving parts within the escalator, it may be advantag eous

to use the stainless steel braided version of the cable which provides additional

mechanical protection. The recommended clip type for this application is the

edge clip (making installation easier and quicker).

There are three key areas of an escalator that should be considered when

providing detection:

• Bearings

• Trash collector tray s

• Drive motor housings

Sensor cable can be used to protect all of these areas.

Figure 5 below shows the principle of protecting an escalator or moving walkway

with sensor cable. A co ntinuous run of cable around the bearings and the trash

collecting trays at either end provides significant coverage.

Figure 5: Sensor cable installation for escalators and moving walkways

Alarmline II Digital Linear Heat Sensor Cable Technical Manual 27

Page 34

Chapter 4: Application guidelines

Cable trays and racks

In applications such as petrochemical plants, pow er gener at ion pl an ts, etc., miles

and miles of cables are used transporting high voltages around the plant. These

can be external cable trays exposed to the elements or can be underground

cable trays hidden out of sight either way overheating in a high voltage cable

can cause significant damage. Alarmline II Digital Sensor Cable is a recognised

solution for being able to protect these cables close to the point of risk.

As shown in Figure 6 on page 29, sensor cable is run above the cable tray to be

able to detect an increase in temperature from the cables being protected.

Generally one length of sensor cable is run down the cable tray but this may

depend on the width of the cable tray. Where multiple cable trays exist it is

recommended that sensor cable is run above each cable tray.

In power generation plants and large industrial installations the general principle

of applying sensor cable to cable tray and racks follows the recommendations of

the electricity generation companies in the United King dom.

• A single sensor cable can be used to protect cable trays up to 600 mm wide.

• Cable trays over 600 mm wide will require multiple runs of sensor cable to

provide adequate coverage (cable trays up to 1200 mm wide requir e two

sensor cable runs, cable trays up to 1800 mm wide would require three

sensor cable runs, etc.)

• Sensor cable should be installed between 150 and 250 mm above the cable

tray it’s protecting.

The sensor cable is supported at 1 m spacing at a height of between 150 and

250 mm above each tray. This provides maximum operating sensitivity without

obstructing access to power cables, etc. mounted on tray work. It is

recommended to install sensor cable on the underside of the bottom tray or rack

to further protect again s t "rub bis h" fir es.

28 Alarmline II Digital Linear Heat Sensor Cable Technical Manual

Page 35

Chapter 4: Application guidelines

Figure 6: Sensor cable installation for cable trays

‘V’ clips are designed to support cables underneath layers of cable trays (this is a

spring steel clip designed to fit the standard holes on a cable tray).

Floating roof storage tanks and bund areas

Floating roof storage tanks are a high risk application and liaison with

experienced site personnel with regards to the design and installation

requirements is essential.

Floating roof storage tanks are specifically designed for the safe storage of

petroleum products such as crude oil or concentrates and the roof is designed to

move up and down as the liquid content of the tank changes so there is no

vapour space. A rim seal system is provided between the tank shell and the roof

which prevents rim evaporation.

Alarmline II Digital Sensor Cable can be installed to detect an overheat condition

or fire around the rim seal and can be used to provide a control signal to an

automatic firefighting system (such as a foam system).

Sensor cable is installed close to the upper edge of the weather seal, using the

roof’s steel straps or the edge of the foam dam, where provided, as anchor

points. Alternatively, support clips may be provided to suit. Sensor cable (or its

interconnection wire) should be installed with consideration for the rise and fall of

the floating roof, preferably using an approved retractable cable system (see

Figure 8 on page 30).

Alarmline II Digital Sensor Cable is classified as a simple device and therefore

requires no certificat ion for use in hazardous areas, al though suitable safety

Alarmline II Digital Linear Heat Sensor Cable Technical Manual 29

Page 36

Chapter 4: Application guidelines

barriers MUST be installed between the sensor cable and the control equipment

located in a safe area of the site. The type of safety barrier will be determined by

the monitoring equipment – this information should be readily available from the

manufacturer of the monitoring equipment (see Figure 7 and Figure 8 below).

Figure 7: Sensor cable installation for floating roof tank

Figure 8: Detail of floating roof tank installation

30 Alarmline II Digital Linear Heat Sensor Cable Technical Manual

Page 37

Chapter 4: Application guidelines

Cold storage and freezer warehouses

Cold storage areas and freezer warehouses provide a difficult environment for

many types of fire detection due to the sub-zero operating temperatures of such

areas. With its minimum operating temperature of −40°C (−40°F) Alarmline II

Digital Sensor Cable can provide an acceptable solution, allowing it to be

installed in the risk area without being effected by the environment.

There are two ways the sensor cable c a n be used t o pr ov i de fir e det ec ti on in

such an application:

• General area coverage, or

• In-rack detection

General area coverage follows the requirements detailed in “Area coverage” on

page 11.

The alternative type of installation for these applications is storage rack

detection. As with other applications, a significant advantage of using sensor

cable is the flexibility to install it close to the point of risk. In storage areas by

being able to install the cable within the storage racking itself it is closer to the

risk and therefore able to detect an overheat or fire condition considerably

quicker than general area heat sensors. This system also allows more accurate

location of where the condition occurs.

Installation of the sensor cable can be done quickly and easily by using edge

clips to fix the cable to the framew or k of the racking. Ensure that the cable is

installed in a position where it is not likely to be damaged by loading and

unloading of the storage racks.

The following precautionary measures must be considered when installing the

sensor cable:

• Installation should not occur in temperatures lower than −11°C (12°F) as this

can make the cable less flexible and more prone to damage. It may be

necessary to raise the temperature of the area during installation an d then

return to the normal operating temperature after installation.

• Electronic interfaces and monitoring equipment must be installed outside the

low temperature area – therefore interposing/leader cables and IP66/67

junction boxes will be required.

• The minimum bend radius at low temperatures is increased to 100 mm.

Alarmline II Digital Linear Heat Sensor Cable Technical Manual 31

Page 38

Chapter 4: Application guidelines

32 Alarmline II Digital Linear Heat Sensor Cable Technical Manual

Page 39

Index

A

applications

cable trays and racks, 28

cold storage and freezer warehouses, 31

conveyer belts, 25

escalators and moving walkways, 27

floating roof storage tanks and bund areas,

29

approvals

FM, 4

UL/ULC, 4

C

chemical resistance, 13

commissioning

functional alarm test, 21

passive checks, 20

simulated alarm test, 21

simulated fault test, 20

G

guidelines

area coverage, 11

design, 10

installation, 12

proximity detection, 10

typical applications, 24

S

sensor cable

operation, 2

product range, 3

T

technical specifications

AD105 range, 7

AD185 range, 7

AD218 range, 8

AD68 range, 5

AD88 range, 6

testing

functional alarm test, 21

simulated alarm test, 21

simulated fault test, 20

I

installation

connecting to a monitored input, 14

hazardous area, 17

interposing or leader cable, 16

jointing, 14

maximum length of interposing or leader

cable, 16

maximum spacing between cable runs, 11

R

regulatory information, 4

Alarmline II Digital Linear Heat Sensor Cable Technical Manual 33

Page 40

Index

34 Alarmline II Digital Linear Heat Sensor Cable Technical Manual

Page 41

Index

Alarmline II Digital Linear Heat Sensor Cable Technical Manual 35

Page 42

Loading...

Loading...