Page 1

Kidde ADS

Actuation Assembly Kit for 225-lb and 395-lb.

Cylinders and Nitrogen Driver Manifolds

P/N: 06-129882-001

FEATURES

• Reduces the Number of Control Heads

• Allows Cylinders to Actuate Simultaneously

• Safe and Easy to Install

DESCRIPTION

Each Kidde ADS must be equipped with the actuation

assembly in order for the nitrogen driver to pneumatically

actuate the agent cylinder. The nitrogen driver is set up to

act as the master cylinder. Actuation of the nitrogen

driver is initiated by use of a control head; it initiates the

nitrogen system discharge by opening the pilot check on

the cylinder valves. This allows the nitrogen to pressurize

the discharge head piston, which opens the main check

in the valve and discharges the contents of nitrogen

through the transfer hose. From the transfer hose, the

nitrogen splits in two directions. The first path the nitrogen takes is through the orifice fitting were the nitrogen

pressure is regulated into the agent cylinder. At the same

time, the nitrogen travels through the actuation assembly

to the pressure operated control head. The pressure

operated control head actuates the FM-200 cylinder

valve by releasing the pressure off the top of the piston,

thereby allowing the FM-200 to be driven out by the nitrogen.

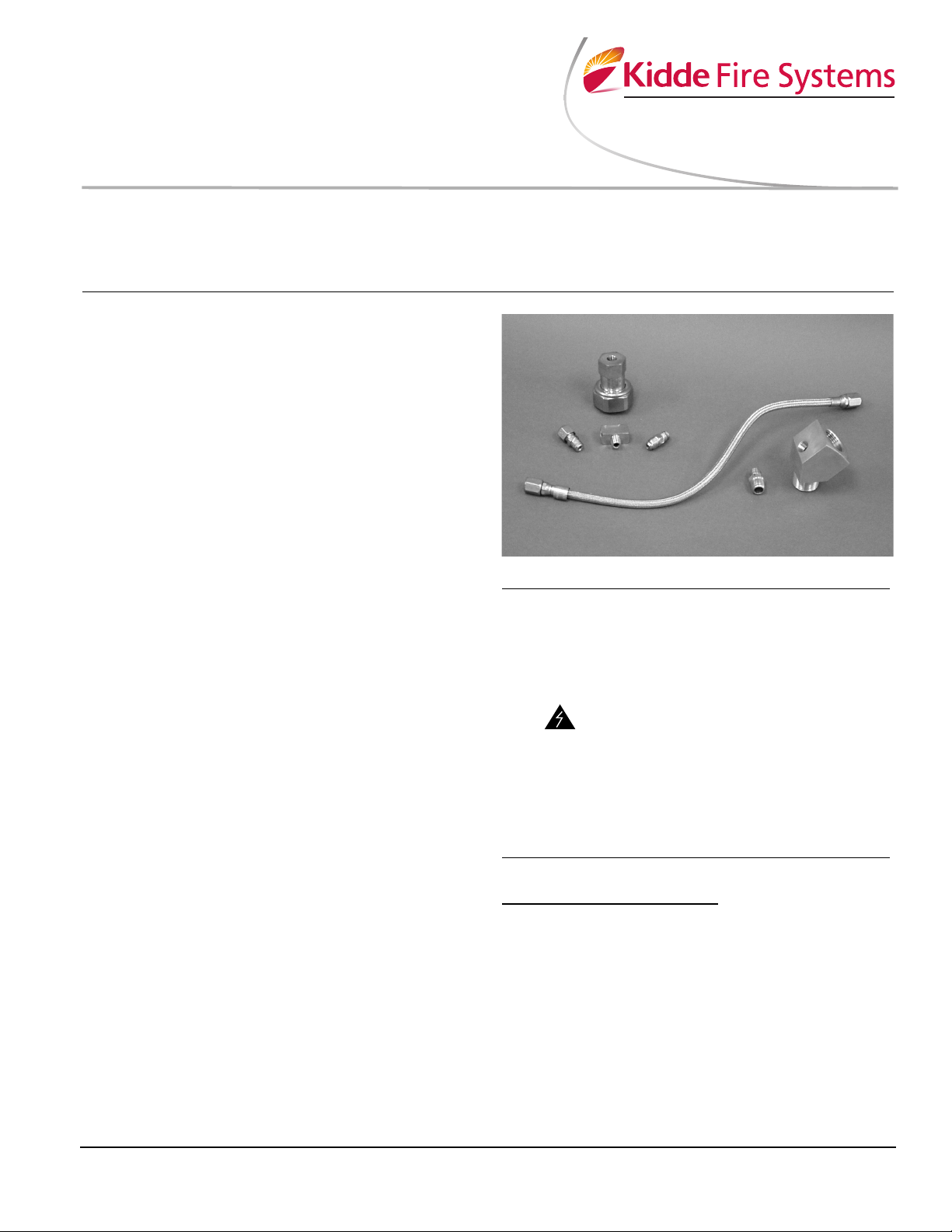

The actuation assembly kit for the 225-lb. and 395-lb.

ADS (P/N 06-129882-001) consists of seven parts (see

Table 1). The nitrogen fitting threads into the orifice fitting.

The 1/8-in. flare allows for the connection of the actuation

hose, which is then fitted into the 1/8-in. branch tee for

operation of the pressure operated control head. A

Schrader valve and cap is then added to the 1/8-in. tee

as a safety for venting off residual pressure after discharge and before decommissioning of the system.

INSTALLATION

Once the nitrogen driver cylinder and the agent storage

cylinder are safely secured and attached to system piping, the actuation assembly can be connected using the

following procedure. Inspect and assemble the kit components separately, prior to attaching to the agent storage cylinder.

A UTC Fire & Security Company

Effective: April 2007

K-90-103

• Pressure Relief Device Included for Safe Disassembly

• UL Listed

• FM Approved

The agent storage cylinder must be

permanently connected into the system piping. Never attach the control

head to the cylinder valve until the cylinders are secured in brackets or racking and the hose is attached to the

agent cylinder. Under no circumstances should the control head

WARNING

remain attached to the cylinder valve

after removal from service or during

shipment, handling, storage or filling.

In the event of inadvertent discharge,

failure to follow these instructions

could result in death, serious bodily

injury and/or property damage.

ASSEMBLY:

Assembly of Kit Components

1. Apply thread tape to male thread of nitrogen transfer

fitting.

2. Apply thread tape to the NPT male thread of the first

1/8-in. x 1/4-in. flared fitting, thread NPT male into

the nitrogen transfer fitting and tighten.

3. Take the two assembled components and thread

into orifice fitting already attached to the nitrogen diffuser assembly, then tighten.

4. Apply thread tape to the male end of 1/8-in. branch

tee and thread into the pressure operated control

head (P/N 878737). Tighten the branch tee.

Page 2

5. Apply thread tape to the NPT male thread of the

second 1/8-in. x 1/4-in. flared fitting and thread into

one side of the 1/8-in. branch tee. Tighten the flared

fitting.

6. Apply thread tape to the male end of the Schrader

valve. Securely threading the male end into the

open end of the 1/8-in. branch tee. Apply Schrader

cap to Schrader fitting.

7. Connect 1/4-in. actuation hose to flare fitting that

was applied to the 1/8-in. branch tee.

8. Connect the other end of the 1/4-in. actuation hose

into the flare fitting that was connected in the busing

in Step 3.

9. Remove the protection cap from the cylinder valve.

10. Using a suitable wrench, assemble control head to

cylinder valve and tighten swivel nut securely.

MAINTENANCE

MONTHLY:

Inspect components for cracks, corrosion, grime, etc.

Ensure that the assembled fittings are tightly secured at

each of their respective connections and to the agent cylinder. If any defects are found during the monthly inspection, immediately contact a Kidde Distributor to service

the systems. Please refer to the Design, Installation,

Operation and Maintenance Manual for more details (P/N

90-FM200M-030).

ORDERING INFORMATION

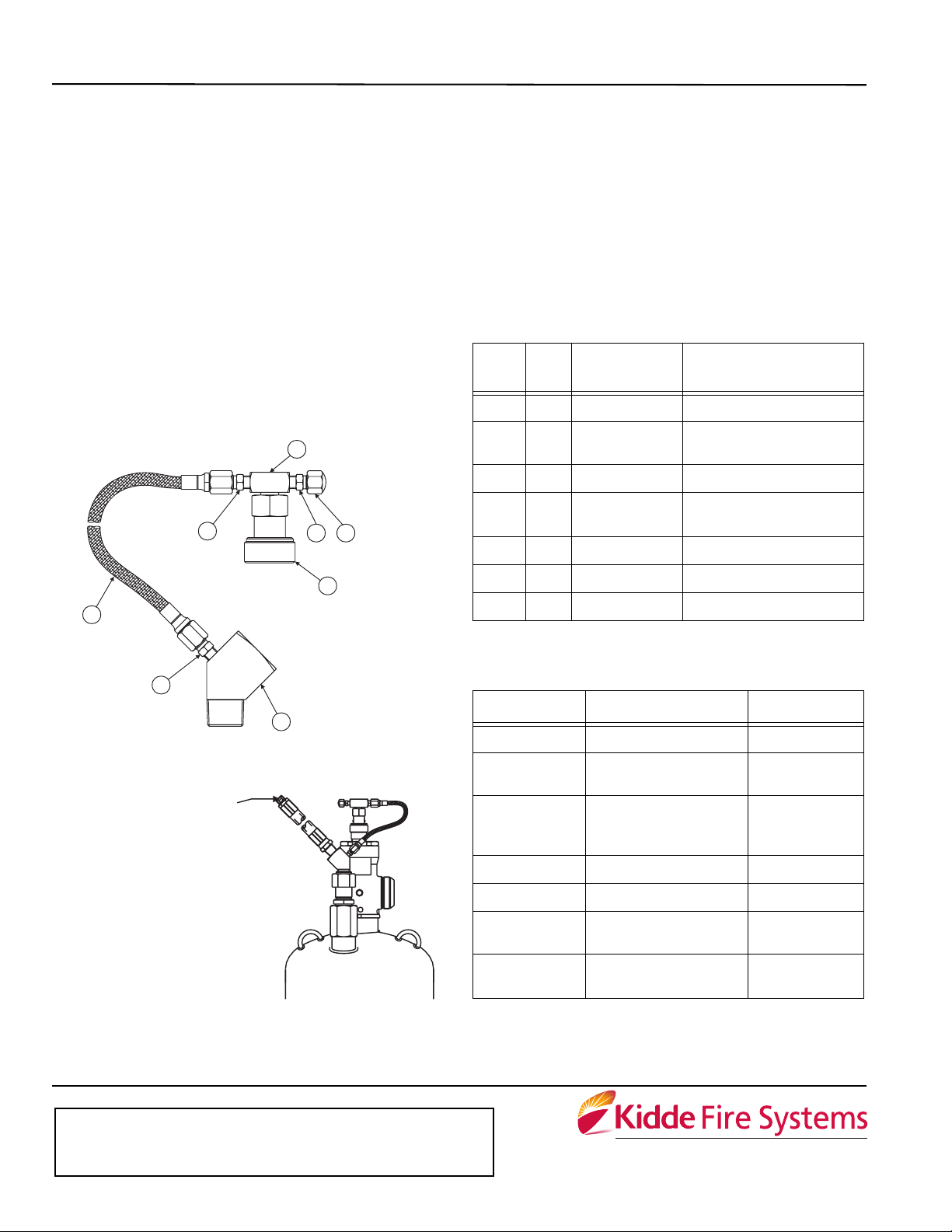

Table 1: Actuation Assembly Kit Part Numbers

Item

No.

Qty. Part Number Description

1 1 06-236124-001 NitrogenTransfer Fitting

3

4

3

Figure 1. Actuation Kit Assembly

CONNECT TO NITROGEN DRIVER

FOR NITROGEN MANIFOLD SYSTEMS,

USING P/N 06-118207-00X

USE HOSE P/N 06-118324-001*

PIPING MANIFOLD, REFER TO THE DESIGN,

MAINTENANCE MANUAL, P/N 90-FM200M-030.

*NOTE: TO CONNECT INTO

INSTALLATION,OPERATION AND

5

7

6

2

1. FITTING–NITROGEN TRANSFER

2. VALVE–PNEUMATIC ACTUATOR

3. FITTING–FLARED 1/8" x 1/4”

4. HOSE–FLEXIBLE 3/16”

5. TEE–1/8" BRANCH

6. VALVE–SCHRADER

7. CAP–SCHRADER VALVE

1

2 1 878737 Pressure Operated Control

Head

3 2 06-118191-001 Fitting flared 1/8-in. x 1/4-in.

4 1 06-118193-001 3/16-in. Flexible Actuation

Hose, 16-in. length

5 1 06-118192-001 1/8-in. Branch Tee

6 1 WK-263303-000 1/8-in. Schrader Valve

7 1 WK-263304-000 1/8-in. Schrader Valve Cap

SPECIFICATIONS

Table 2: Materials Specifications

Part Number Description Material

06-236124-001 Nitrogen Transfer Fitting Brass

06-118191-001 1/8-in. x 1/4-in.

Flared Fittings

06-118193-001 3/16-in. Flexible

Actuation Hose

06-118192-001 1/8-in. Branch Tee Brass

WK-263303-000 1/8-in. Schrader Valve Brass

Brass

Stainless Steel

Braiding, Brass

Fittings

Figure 2. Cylinder and Valve Assembly

with Assembled Actuation Components

This literature is provided for informational purposes only. KIDDE-FENWAL, INC.

assumes no responsibility for the product’s suitability for a particular application. The

product must be properly applied to work correctly.

If you need more information on this product, or if you have a particular problem or question, contact KIDDE-FENWAL, INC., Ashland, MA 01721. Telephone: (508) 881-2000.

K-90-103 Rev AB © 2007 Kidde-Fenwal Inc. Printed in USA

WK-263304-000 1/8-in. Schrader Valve

Cap

878737 Pressure Operated

Control Head

A UTC Fire & Security Company

400 Main Street

Ashland, MA 01721

Ph: 508.881.2000

Fax: 508.881.8920

www.kiddefiresystems.com

Brass

Brass

Loading...

Loading...