Page 1

KM

KMCOMPONENTSYSTEM

KM6250.2

English Version

Versión Español

Altavoz Componente KM

Manual del Propietario

Deutsche Version

KM Komponenten-System

Benutzerhandbuch

Version Française

Kits deux voies KM

Manuel d’utilisation

2009 KM Components Multilingual c01.indd 12009 KM Components Multilingual c01.indd 1 11/21/2008 3:37:53 PM11/21/2008 3:37:53 PM

Page 2

KMMarineComponentSystemOwner’sManual

Model: KM6250.2

Authorized KICKER Dealer:

Purchase Date:

Speaker Model Number:

Your KM component system speakers were specially designed for “Livin’ Loud” out in the harsh marine

environment. They are magnetically shielded and use advanced materials and construction techniques to

maintain optimal performance for years to come.

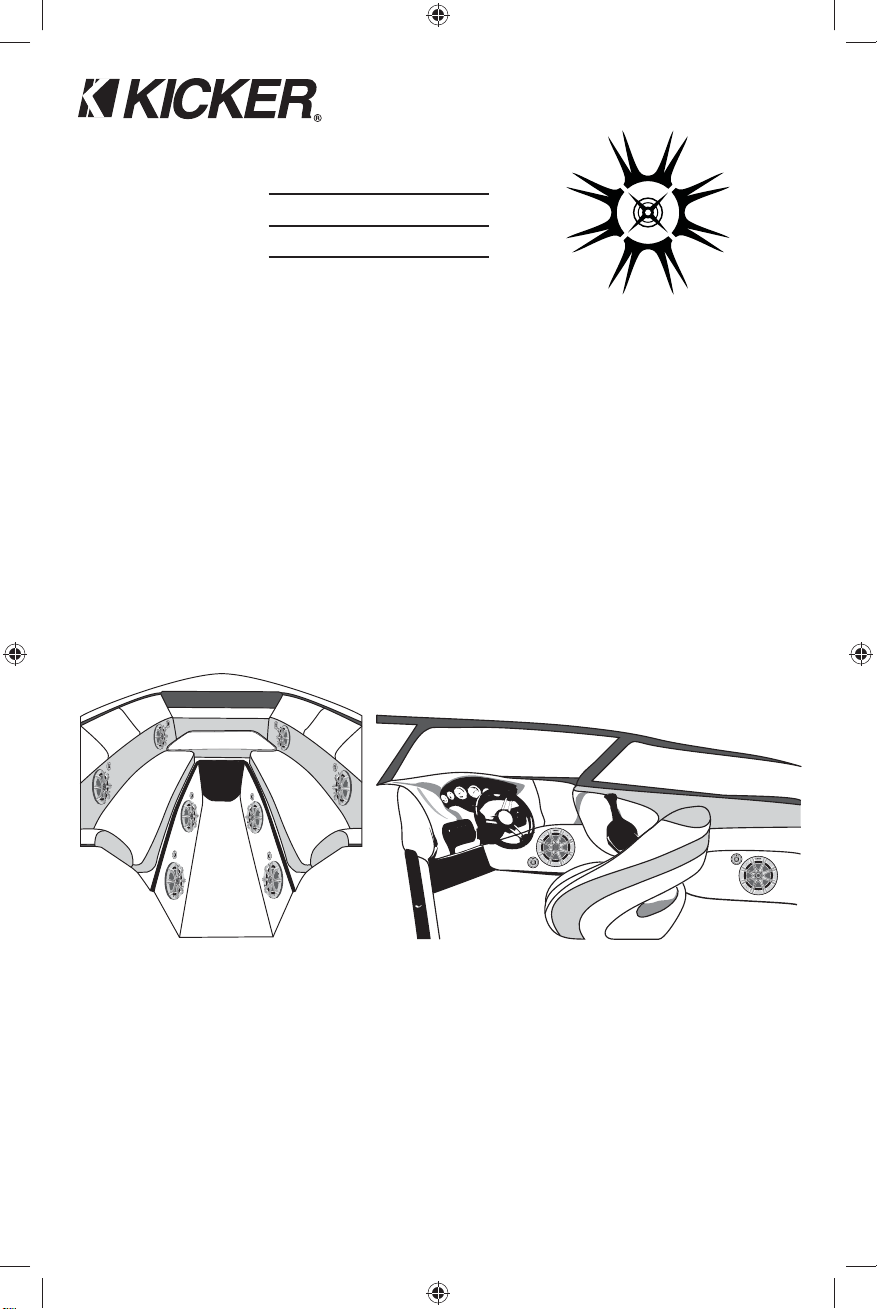

APPLICATION

The Kicker KM component system speakers are specifi cally designed for mounting in free-air applications.

The speakers do not require a sealed enclosure for optimum performance. It is important to isolate the

sound coming off the front of the driver from the sound radiating from the back of the driver. This isolation

is usually accomplished by using the driver in a factory speaker location, or in a location with a semiisolated rear chamber.

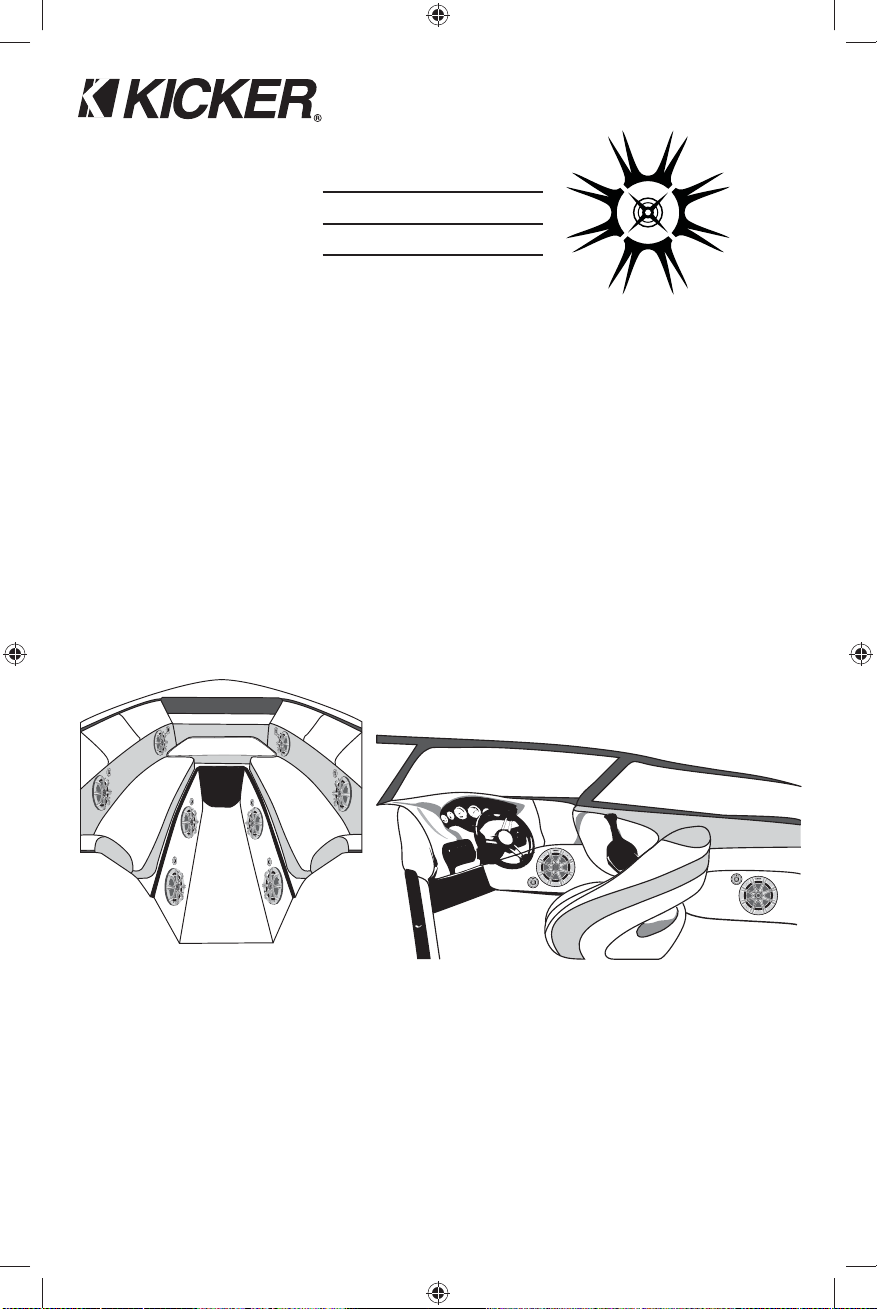

LOCATION

The sound produced by the KM component system is directional, particularly for the tweeter’s sonic

output. Find the best location for stereophonic sound. If necessary, add more KM component systems or

KM coaxial speakers (Kicker KM6200) to the system to help distribute and balance the sound-stage. After

determining the best mounting locations, carefully check the areas where the mounting hardware will be

placed.

KM6250.2

Possible locations for KM

Component Speaker Mounting

WOOFER MOUNTING

Make sure the stainless steel mounting screws and U-type speed clips will not puncture the fuel cell,

wiring, or interfere with any mechanical parts on the underside of the mounting surface. Use the woofer

“template” inside your KM component system speaker’s shipping carton to mark the woofer mounting

hole, then cut directly on the line. Pre-drill the mounting screw holes using a 7/64” (2.5mm) bit, and attach

the KM component system woofer to the boat, by fastening the supplied stainless steel course-threaded

screws to the boat’s structure. If applicable, utilize the enclosed stainless steel U-type speed clips. Mount

the speaker and grille right side-up to take advantage of the KM component woofer’s integrated moisture

draining system. The Grilles are removable for custom painting applications. If the supplied hardware is

not applicable to your installation, some other means of securely attaching the speakers to the vessel

must be used.

2

2009 KM Components Multilingual c01.indd 22009 KM Components Multilingual c01.indd 2 11/21/2008 3:38:05 PM11/21/2008 3:38:05 PM

KMCOMPONENTSYSTEM

Page 3

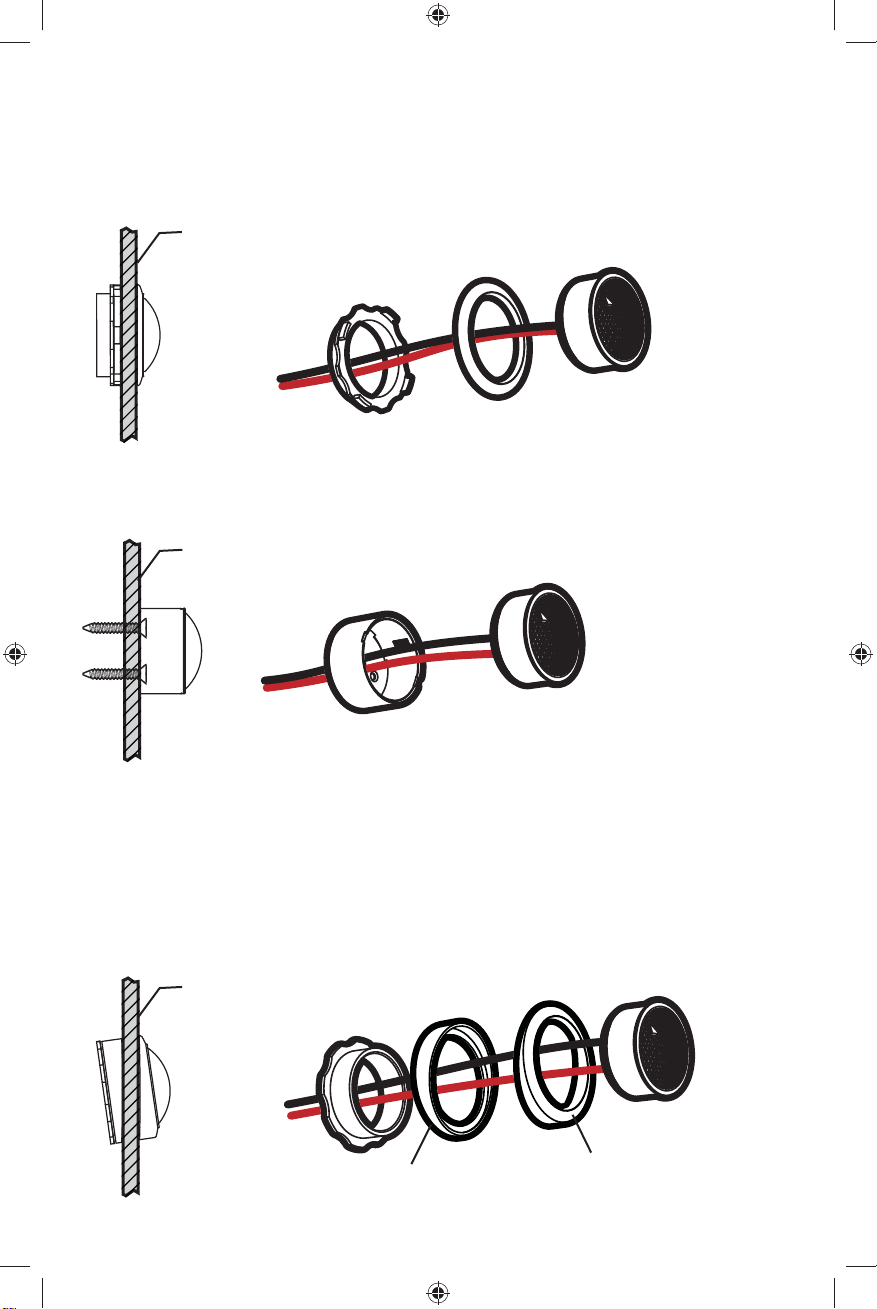

TWEETER MOUNTING

The tweeter can be mounted one of three ways: fl ush, surface and angled mounting. For fl ush

mounting applications, choose a fl at location on the panel with space behind the panel to allow room for

the mounting nut. After checking the clearances, cut the appropriate mounting hole diameter in the panel

(see the chart below). Place the shorter mounting nut behind the panel. Feed the wire through the hole in

the panel and the mounting nut. Mount the tweeter by screwing the mounting nut onto the tweeter.

panel

short

mounting nut

fl ush ring

tweeter

Flush Mounting the Tweeter

For surface mounting applications use the surface mount cup as a template and pre-drill two 7/64”

(2.5mm) screw holes for attaching the mounting cup to the panel, and a 5/16” (8mm) hole for the wires.

Two #8 fl athead stainless steel sheet metal screws are supplied to attach the mounting cup to the panel.

Position the tweeter over the mounting cup and press it into position.

panel

tweeter

surface mount

cup

Surface Mounting the Tweeter

For angled mounting applications choose a fl at location on the panel with space behind the panel to

allow room for the mounting nut and back angle ring. After checking the clearances, cut the appropriate

mounting hole diameter in the panel (see the chart below). Place the front angle ring (does not fi t through

the longer tweeter mounting nut) in front of the panel. Then place the wire and tweeter through the front

angle ring and into the panel. Next place the wire through the back angle ring (fi ts through the longer

tweeter mounting nut), place the back angle ring over the rear of the tweeter, and line-up the narrow

part of the front angle ring for the preferred angle of operation. Place the wire through the longer tweeter

mounting nut and loosely tighten the mounting nut around the tweeter. Rotate all the parts in unison until

the tweeter is angled in the desired direction. Secure the assembly by tightening the tweeter mounting

nut.

panel

long

mounting nut

back angle ring

front angle ring

Angle Mounting the Tweeter

3

2009 KM Components Multilingual c01.indd 32009 KM Components Multilingual c01.indd 3 11/21/2008 3:38:09 PM11/21/2008 3:38:09 PM

Page 4

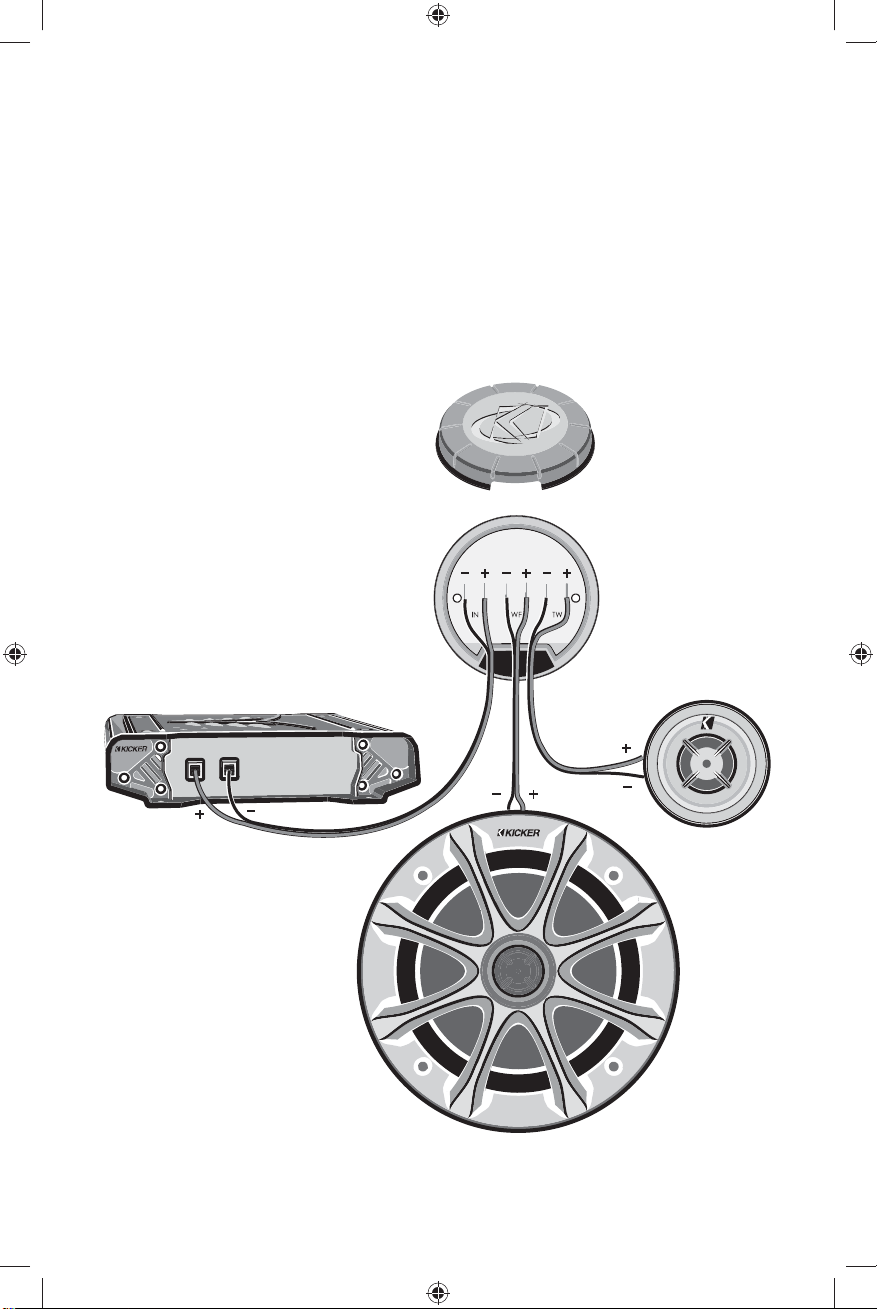

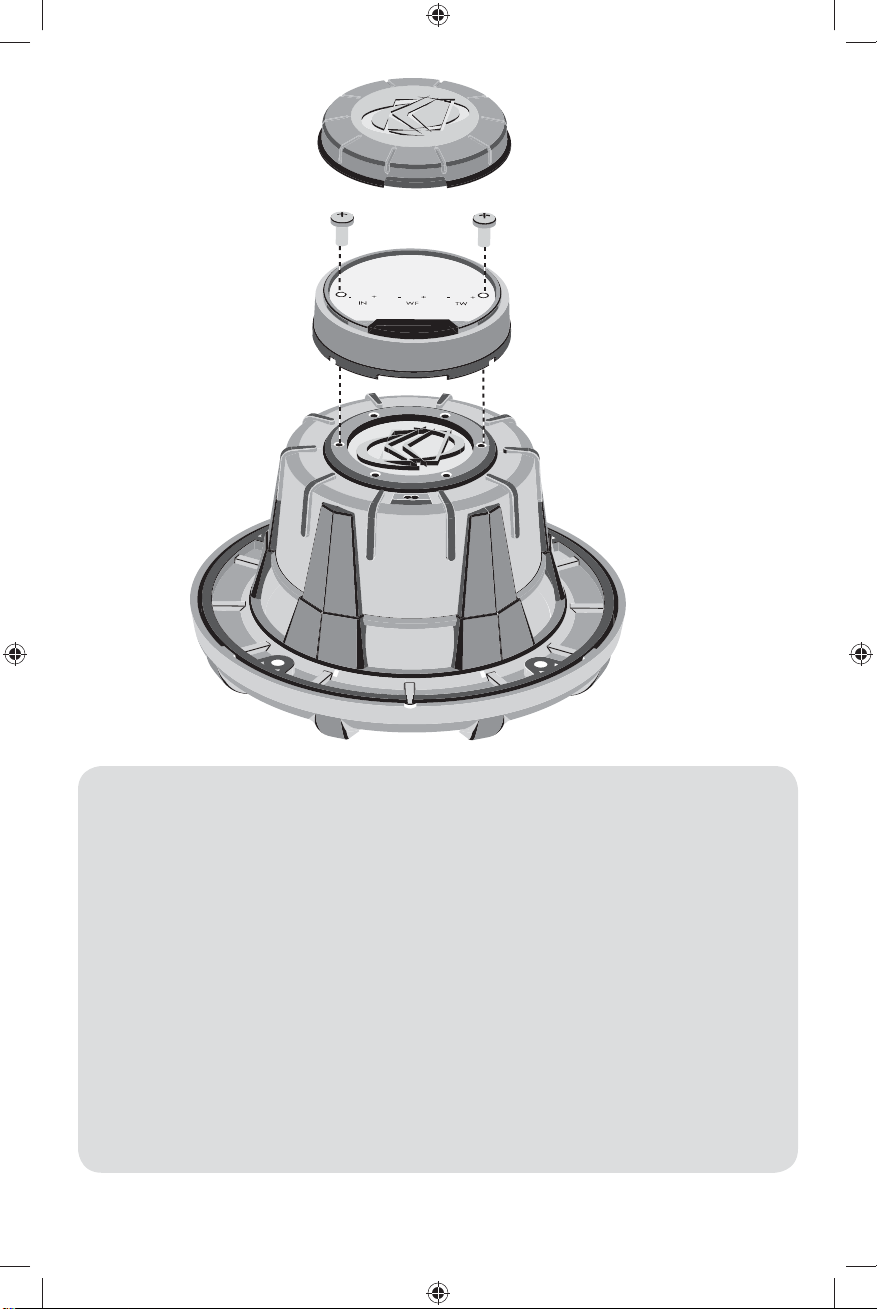

WIRING

Carefully place the speaker wire in a location that is clear of standing water and moving components of

the vessel. For reference, the Blue wire is Positive and the Grey wire is Negative. Mount the crossover to

the woofer’s back plate with the enclosed phillips-head M3 stainless steel machined screws, or mount

the crossover remotely in a location free and clear of standing water. The locking crossover cover with

water resistant gasket is removable for wiring installation; it helps prevent terminal corrosion and electrical

shorting. The positive and negative gold plated terminals are of different sizes and correspond to the

appropriate gold plated positive and negative wire connectors. Take off the crossover cover, and connect

the wire from the woofer to the “WF” terminal and the wire from the tweeter to the “TW” terminal. Connect

the supplied 15 feet (4.5m) of wire to “IN” terminal in the crossover. Carefully route the wires through the

slot between the crossover and crossover cover, and snap the crossover cover back on the crossover.

Connect the other end of the heavy gauge wire to your amplifi er in accordance with its owner’s manual.

Crossover Cover

Slot

Source Unit or Amplifi er

SPKR +

SPKR -

Integrated moisture draining system

4

KMCOMPONENTSYSTEM

2009 KM Components Multilingual c01.indd 42009 KM Components Multilingual c01.indd 4 11/21/2008 3:38:11 PM11/21/2008 3:38:11 PM

Page 5

Crossover Cover

Crossover mounted

to the KM Component

Woofer’s Back Plate

MODEL:

Woofer Size, in (cm) 6 (16)

Tweeter Size, in (mm) 1 (25)

Dome Material Titanium

Nominal Impedence [Zn], ohm 4

Power Handling* Watts, Peak (RMS) 225 (75)

Sensitivity [SPL0], db @ 1W, !m 88

Effective Frequency Range, Hz 35-21k

Woofer Mounting Hole Diameter, in (cm) 5 1/8 (13)

Woofer Mounting Depth w/o Crossover, in (cm) 2 7/8 (7.2)

Flush Mounting Tweeter Hole Diameter, in (cm) 1 13/16 (4.5)

High Pass, dB, at Frequency, Hz 18, 4000

Low Pass, dB, at Frequency, Hz 12, 4000

Bolt-Thru Grilles Yes

Kicker Marine speakers use the highest level of magnetic shielding available to minimize compass and gauge deviation

in your dash. Kicker Marine speakers meet or exceed industry standards for environmental humidity and corrosion,

and for material degradation due to UV exposure.

2009 KM Components Multilingual c01.indd 52009 KM Components Multilingual c01.indd 5 11/21/2008 3:38:13 PM11/21/2008 3:38:13 PM

KM6250.2

5

Page 6

KMSistemaComponenteManualdelPropietario

Modelo: KM6250.2

Distribuidor autorizado de Kicker:

Fecha de compra:

Número de modelo de altavoz:

Su KM sistemas de componentes se diseñó para “Livin’ Loud” en el ambiente marino duro. Se

protege magnéticamente y utiliza las técnicas avanzadas de materias y construcción para mantener el

desempeño que óptimo para años para venir.

APLICACIÓN

Sus sistemas de componentes de la serie KM de KICKER han sido diseñados específi camente para

montarlos en aplicaciones al aire libre. A pesar de que los altavoces no necesitan una caja sellada para

un rendimiento óptimo, es importante separar el sonido radiado por delante del sonido radiado por detrás

del altavoz. Esta separación se logra normalmente usando un excitador de tamaño correcto en un lugar

preestablecido de fábrica para el altavoz.

POSISITON

El sonido producido por los altavoces Componente del KM es direccional, especialmente para la

producción sónica de altavoz. Encuentre el mejor posisition para el sonido estereofónico. Si necesario,

agrega más altavoces Componente o Coax (Kicker KM6200) del KM al sistema para ayudar a distribuir y

equilibrar la sano-etapa. Después que determinar el mejor posistions que monta, verifi ca con cuidado las

áreas donde el hardware que monta irá.

Posistions posible para los altavoces

Componente del KM que Montan

MONTAJE

El acero inoxidable encerrado que monta los tornillos y clipes DE TIPO U de velocidad no deben romper

la célula del combustible, alambrar, ni intervenir con ninguna parte mecánica en la cara inferior de la

superfi cie que monta. Utilice el “plantilla” dentro de su altavoz Componente del KM es el cartón del envío

de marcar el hoyo que monta, entonces corte directamente en la línea. El pre-taladro los hoyos del tornillo

que montan que utiliza un 7/64” (2.5mm) el taladro, y conecta los altavoces Componente del KM al

barco, abrocha el acero inoxidable suministrado los tornillos curso-enhebrados a la estructura del barco.

Si aplicable, utiliza el acero inoxidable encerrado clipes DE TIPO U de velocidad. Monte el altavoz y

la rejilla para aprovecharse de boca arriba el sistema del altavoz ha integrado sistema de desaguar

de humedad. Las Rejillas son movibles para aplicaciones de pintar de costumbre. Si el hardware

suministrado no es aplicable a su instalación, algunos otros medios de conectar seguramente a los

oradores a la nave se debe utilizar.

6

KMCOMPONENTSYSTEM

2009 KM Components Multilingual c01.indd 62009 KM Components Multilingual c01.indd 6 11/21/2008 3:38:13 PM11/21/2008 3:38:13 PM

Page 7

TWEETER MONTAJE

El altavoz se puede montar uno de tres maneras: limpía, la superfi cie y montar angulado. Para

aplicaciones de montar de limpíe, se refi ere por favor a la ilustración. Escoja una ubicación plana en

el panel con el espacio detrás del panel para permitir el espacio para la tuerca que monta. Después que

verifi car los espacios libres, cortan el diámetro apropiado de hoyo que monta en el panel (ve el pie de

página). Coloque la tuerca más corta que monta detrás del panel. Alimente el cable del tweeter por el

hoyo en el panel y la tuerca que montan. Monte el tweeter enroscando la tuerca que monta en el tweeter.

Panel

Tuerca más

corta que monta

Reborde

de tweeter

Tweeter

Montar Limpíe

Para aplicaciones de montar de superfi cie utiliza la copa de superfi cie del monte como una plantilla y

pre-taladro dos 7/64” (2.5mm) hoyos de tornillo para conectar la copa de superfi cie del monte al panel,

y un 5/16” (8mm) hoyo para los cables del altavoz. Dos #8 tornillos inoxidables se suministran para

conectar la copa de superfi cie del monte al panel. Posicione el tweeter sobre la copa de superfi cie del

monte y lo aprieta en posición.

Panel

Copa de superfi cie

del monte

Tweeter

Superfi cie Montar

Para montar angulado las aplicaciones escogen una ubicación plana en el panel con el espacio detrás

del panel para permitir el espacio para la tuerca que monta y el anillo del ángulo de espalda. Después

que verifi car los espacios libres, cortan el diámetro apropiado de hoyo que monta en el panel (ve el pie

de página). Coloque el anillo anterior del ángulo (no queda por el tweeter más largo que monta tuerca)

delante del panel. Coloque el cable del altavoz y el tweeter por el anillo anterior del ángulo y en el panel.

Coloque el cable del altavoz por el anillo del ángulo de espalda (los ataques por el tweeter más largo

que monta tuerca), coloca el anillo del ángulo de espalda sobre el trasero del tweeter, y de la alineación

la parte estrecha del anillo anterior del ángulo para el ángulo preferido de la operación. Coloque el cable

del altavoz por el tweeter más largo que monta tuerca y aprieta fl ojamente la tuerca que monta alrededor

del tweeter. Gire todas las partes al unísono hasta que el tweeter esté angulado en la dirección deseada.

Asegure la asamblea apretando el tweeter que monta tuerca.

Panel

Tuerca más larga

que monta

Anillo del ángulo de espalda

Anillo anterior

del ángulo

Tweeter

7

Montar Angulado

2009 KM Components Multilingual c01.indd 72009 KM Components Multilingual c01.indd 7 11/21/2008 3:38:18 PM11/21/2008 3:38:18 PM

Page 8

CABLEADO

Coloque el cable del altavoz en un posistion vacía de agua parada y componentes móviles del barco.

Para la referencia, el cable azul es Positivo y el cable de gris es Negativo. Monte el crossover al plato de

la espalda del altavoz para sonidos graves con la phillips-M3 encerrada inoxidable los tornillos, o monta

el crossover remotamente en una posistion vacía de agua parada. El cerrar la cubierta terminal con agua

junta de culata resistente es movible para la instalación de cable. La junta de culata previene la corrosión

terminal y shorting eléctrico. Las terminales positivas y negativas de oro son de tamaño y corresponder

diferentes a los conectores apropiados, positivos y negativos del cable del altavoz. Tome de la cubierta

de crossover, y conecte el cable del altavoz del altavoz para sonidos graves al “WF” terminal y el cable

de altavoz del tweeter al “TW” terminal. Conecte el suministró 15 pies (4.5m) de cable de altavoz al

“EN” terminal en el crossover. Dirija con cuidado el cable del altavoz por la ranura entre el crossover y la

cubierta de crossover, y chasquée la espalda de la cubierta de crossover en el crossover. Conecte el

otro fi n del cable del altavoz a su amplifi cador de acuerdo con su manual.

Cubierta de

Crossover

Ranura

Unidad fuente o amplifi cador

SPKR +

SPKR -

Garantía Comuníquese con su concesionario o

distribuidor Kicker internacional para obtener infor

ación sobre procedimientos específi cos relacionados

con las normas de garantía de su país.

8

KMCOMPONENTSYSTEM

Integrado sistema de

desaguar de humedad

2009 KM Components Multilingual c01.indd 82009 KM Components Multilingual c01.indd 8 11/21/2008 3:38:20 PM11/21/2008 3:38:20 PM

Page 9

Cubierta de

Crossover

El crossover montó

al plato de la espalda

del Altavoz para

sonidos graves del

componente del KM

MODELO:

Tamaño del woofer, plg (cm) 6 (16)

Tamaño del tweeter, plg (cm) 1 (25)

Material del diafragma del tweeter Titanio

Impedancia nominal [Zn], ohmio 4

Procesamiento máximo de potencia, vatios (RMS) 225 (75)

Sensibilidad [SPLo], dB @ 1W, 1m 88

Gama de potencias, Hz 35-21k

Diámetro del agujero de montaje, plg (cm) 5 1/8 (13)

Profundidad de montaje superior sin crossover, plg (cm) 2 7/8 (7.2)

Limpíe Montar el Diámetro del agujero de tweeter, plg (cm) 1 13/16 (4.5)

Paso alto, dB por octava, en la Frecuencia, Hz 18, 4000

Paso bajo, dB por octava, en la Frecuencia, Hz 12, 4000

Cierre por rejillas Si

Los altavoces Kicker marinos tienen proteger magnético y aminoran la desviación de brújula y calibrador. Los

altavoces Kicker marinos encuentran o exceden los estándares de la industria para la humedad y la corrosión

ambientales, y para la degradación material debido a la exposición de ultravioleta.

2009 KM Components Multilingual c01.indd 92009 KM Components Multilingual c01.indd 9 11/21/2008 3:38:21 PM11/21/2008 3:38:21 PM

KM6250.2

9

Page 10

KMKomponenten-SystemeBenutzerHandBuch

Modelle: KM6250.2

Authorisierter KICKER Händler:

Einkaufsdatum:

Lautsprecher Modell Nummer:

Ihr KM Komponenten-System wurde besonders für “Livin’ Loud” in der harten Marineumwelt entworfen.

Es ist magnetisch beschützt. Es ist Materialien und Konstruktion fortgeschritten beizubehalten, dass ideale

Leistung jahrelang kommt.

EINBAU

Das Kicker Komponenten-System der KM-Serie ist speziell für den Einbau in nicht geschlossenen

Gehäusen gedacht. Die Lautsprecher benötigen für optimale Leistung kein geschlossenes Gehäuse.

Es ist wichtig, den vorne aus dem Lautsprecher austretenden Schall vom Schall zu trennen, der von der

Rückseite des Lautsprechers kommt. Diese Trennung wird meist durch die Verwendung der korrekten

Treibergröße und Einbau an einer isolierten hinteren Stelle erreicht. .

POSITION

Die Position und Ausrichtung Ihres KM Komponenten-Systems beeinfl usst die Qualität und Quantität

der Wiedergabe, besonders für die Schallausgabe des Hochtonlautsprechers. Finden Sie den besten

Ort für stereofonischen Klang. Installieren von mehr Lautsprechern (siehe auch das Kicker KM6200

Koax-System) zum Boot verteilt und gleicht die Räumlichkeit aus. Nachdem Sie die beste Einbauposition

gewählt haben, prüfen Sie sorgfältig die Stellen, an denen Montagehalterungen angebracht werden

sollen.

Orte für KM KomponentenSysteme installation

INSTALLATION

Vergewissern Sie sich, dass die Montageschrauben keine Benzintanks, Kabel usw. anbohren oder

Mechanismen an der Unterseite der Einbauoberfl äche stören würden. Die Pappschablone im Lieferkarton

des KM Komponenten-Systems kann als Vorlage für das Ausschneiden des Lautsprechermontagelochs

aus Ihrem Gehäuse verwendet werden. Nachdem Sie Ihre Schallwand mit der Schablone markiert haben,

müssen Sie direkt an der Linie ausschneiden. Bohren Sie die Löcher mit einem 2,5-mm-Bohrer vor, und

befestigen Sie das KM Komponenten-System an das Boot mit den beiliegenden Edelstähle-Schrauben

in die Struktur des Boots. Wenn zutreffend, verwenden Sie wenn die eingeschlossene Edelstahl “U-Type

Speed” Klammern. Installieren Sie das KM Komponenten-System und den Schutzgitter ordentlich, mit

dem Feuchtigkeit entwässernd Steckplatz am Boden. Wenn die beiliegenden Befestigungselemente

nicht für Ihre Installation passen, muss eine andere Methode zur sicheren Befestigung des Systems am

Fahrzeug verwendet werden.

10

2009 KM Components Multilingual c01.indd 102009 KM Components Multilingual c01.indd 10 11/21/2008 3:38:22 PM11/21/2008 3:38:22 PM

KMCOMPONENTSYSTEM

Page 11

HOCHTÖNER INSTALLATION

Der Hochtöner kann Ein von drei Wegen aufgestellt werden: fl ach mit der Oberfl äche, an der Oberfl äche

und mit Winkelringen an der Oberfl äche montiert werden. Für fl ach mit der Oberfl äche montiert werden.

Finden Sie einen fl achen Ort auf dem Unterausschuss mit Platz hinter dem Unterausschuss für die

Befestigungsmutter. Schneiden Sie den passenden Hochtöner Flach-Montageloch-Durchmesser im

Unterausschuss (siehe das Leistungsdiagramm unten). Stellen Sie die kürzere Befestigungsmutter

hinter den Unterausschuss. Führen Sie den Draht durch das Loch im Unterausschuss und der

Befestigungsmutter zu. Stellen Sie den Hochtöner durch Schrauben der Befestigungsmutter auf den

Hochtöner auf.

Unterausschuss

Kürzere

Befestigungsmutter

Hochtöner-Flansch

Hochtöner

Flach Mit Der Oberfl äche

Für Oberfl ächen Befestigungsanwendungen benutzt die Oberfl ächen-Untersatztasse als ein Modellrahmen

und vordrill zwei 2,5 mm Schraubenlöcher für die Oberfl ächen-Untersatztasse zum Unterausschuss, und

einem 8 mm Loch für die Drähte. Schrauben Sie die Oberfl ächen-Untersatztasse zum Unterausschuss

mit den zwei eingeschlossen #8 Edelstahl Flachkopfschrauben. Stellen Sie den Hochtöner über der

Oberfl ächen-Untersatztasse ein und drücken Sie ihn in Position.

Unterausschuss

Oberfl ächenUntersatztasse

Hochtöner

An Der Oberfl äche

Für mit Winkelringen an der Oberfl äche montiert werden, siehe Abbildung. Finden Sie einen fl achen

Ort auf dem Unterausschuss mit Platz hinter dem Unterausschuss für die Befestigungsmutter

und hinteren Winkelring. Schneiden Sie den passenden Hochtöner Flach-MontagelochDurchmesser im Unterausschuss (siehe das Leistungsdiagramm unten). Stellen Sie den vorderen

Winkelring (er passt durch die längere Befestigungsmutter nicht) vor dem Unterausschuss.

Stellen Sie dann den Draht und den Hochtöner durch den vorderen Winkelring und in den

Unterausschuss

längere

Befestigungsmutter

Hinterer Winkelring

vorderer Winkelring

Hochtöner

Mit Winkelringe An Der Oberfl äche

11

2009 KM Components Multilingual c01.indd 112009 KM Components Multilingual c01.indd 11 11/21/2008 3:38:26 PM11/21/2008 3:38:26 PM

Page 12

Unterausschuss. Stellen Sie den Draht durch den hinteren Winkelring (er passt durch die längere

Befestigungsmutter) auf. Stellen Sie den hinteren Winkelring über die Hinterseite vom Hochtöner, und

leinen Sie der enge Teil vom vorderen Winkelring für den bevorzugten Winkel des Betriebs auf. Stellen

Sie den Draht durch die längere Befestigungsmutter auf, und “locker” festziehen die Befestigungsmutter

um den Hochtöner. Drehen Sie alle Teile in Einklang, bis der Hochtöner in der gewünschten

Richtung umgebogen ist. Sichern Sie die Versammlung durch Festziehen den Hochtöner aufstellend

Befestigungsmutter.

VERKABELUNG

Stellen Sie die Verkabelung in einen Ort, der klar von Stehenwasser und Bewegenbauteilen vom Gefäß ist.

Das blaue Kabel ist positiv und das silberne Kabel ist negativ. Stellen Sie die Überkreuzung zur Rückwand

des Tieftonlautsprechers mit dem eingeschlossenen Kreuzschlitzkopf M3-Edelstahl Schrauben, oder

stellen Sie die Überkreuzung in einen Ort, der klar von Stehenwasser und Bewegenbauteilen vom Gefäß

ist. Die Überkreuzungbedeckung ist abnehmbar für Verkabelungsinstallation, und wenn verschlossenenin-Ort, unterstützt sie in Zündungsschutz und die Verhinderung von Korrosion. Die positive und negative

goldene Stecker sind von verschiedenen Größen und verbinden zu den positiven und negativen

Drahtverbindern. Nehmen Sie die Überkreuzungsbedeckung ab und verbinden Sie den Draht vom

Tieftonlautsprecher zum “WF” Terminal und der Draht vom Hochtonlautsprecher zum “TW” Terminal.

Verbinden Sie das versorgte 4,5 m von Draht zu “IN” Terminal in der Überkreuzung. Leiten Sie vorsichtig

die Drähte durch den Steckplatz zwischen der Überkreuzung und der Überkreuzungsbedeckung um und

schnappen Sie die Überkreuzungsbedeckung zurück auf der Überkreuzung. Verbinden Sie das andere

Ende vom schweren Messgerätdraht zu Ihrem Verstärker gemäß seinem Benutzerhandbuch.

Überkreuzungsbedeckung

Steckplatz

Autoradio oder Verstärker

SPKR +

SPKR -

Garantie Nehmen Sie mit Ihren

internationalen Kicker-Fachhändler oder

Vertrieb Kontakt auf, um Details über die

Garantieleistungen in Ihrem Land zu erfahren.

Feuchtigkeit entwässernd Steckplatz

12

2009 KM Components Multilingual c01.indd 122009 KM Components Multilingual c01.indd 12 11/21/2008 3:38:28 PM11/21/2008 3:38:28 PM

KMCOMPONENTSYSTEM

Page 13

Überkreuzungsbedeckung

Überkreuzung zur

Rückwand des KM

Komponenten-Systems

aufgestellt

MODEL:

KM6250.2

Tieftönergröße, Zoll (cm) 6 (16)

Hochtönergröße, Zoll (mm) 1 (25)

Material der Hochtönermembran Titan

Nennimpedanz [Zn], Ohm 4

Spitzenbelastbarkeit, Watt (RMS) 225 (75)

Empfi ndlichkeit [SPLo], dB bei 1 W, 1 m 88

Effektiver Frequenzbereich, Hz 35-21k

Tieftöner Montageloch-Durchmesser, Zoll (cm) 5 1/8 (13)

Tieftöner Montagetiefe ohne Überkreuzung, Zoll (cm) 2 7/8 (7,2)

Hochtöner Flach-Montageloch-Durchmesser, Zoll (cm) 1 13/16 (4,5)

Hoher Überkreuzungspunkt, dB, an Frequenz, Hz 18, 4000

Niedriger Überkreuzungspunkt, dB, an Frequenz, Hz 12, 4000

Schraube-durch Schutzgitter Ja

Änderungen an Spezifi kationen und Leistungswerten vorbehalten. Sie fi nden die aktuellsten Informationen

bei kicker.com. Anmerkung: Um die besten Ergebnisse zu erzielen, benutzen Sie nur Originalzubehörteile und

Kabel von KICKER.KM Marine-Lautsprecher benutzen magnetische Beschützung und minimieren Kompass

und Messgerätabweichung in Ihrem Marinefahrzeug. KM Marine-Lautsprecher treffen sich oder überschreiten

Industrienstandards für Umweltfeuchtigkeit und Korrosion, und für materiellen Abbau auf Grund Ultraviolett Aussetzung.

2009 KM Components Multilingual c01.indd 132009 KM Components Multilingual c01.indd 13 11/21/2008 3:38:30 PM11/21/2008 3:38:30 PM

13

Page 14

Manueld’utilisationdeskitsdeuxvoiesKM

Modèles : KM6250.2

Distributeur Kicker agréé :

Date d’achat :

Numéro de modèle du haut-parleur :

Votre KM kits deux voies a été conçu pour l’environnement marin dur. L’haut-parleur est

magnétiquement protégé et utilise des matériels avancés et les techniques de construction pour maintenir

l’exécution optimale pendant des années pour venir.

APPLICATION

Ces haut-parleurs kits deux voies Kicker KM ont été spécialement conçus pour un montage sans

enceinte. Leur fonctionnement optimal ne nécessite pas d’enceinte close, mais il est important d’isoler

le son sortant par l’avant du haut-parleur et le son diffusé à l’arrière du haut-parleur. En général, cette

isolation est obtenue en installant dans un emplacement standard un haut-parleur de taille adéquate, ou

dans un emplacement avec un demi-isolé la chambre postérieure.

EMPLACEMENT

Le son produit par l’haut-parleur kits deux voies de KM est directionnel, particulièrement pour la

production sonore du tweeter. Trouver le meilleur emplacement pour le son stéréophonique. Si

nécessaire, ajouter les haut-parleurs kits deux voies ou coaxiaux (Kicker KM6200) de KM au système

pour aider distribuent et équilibrent la son-étape. Après avoir déterminé les emplacements le mieux

montants, soigneusement vérifi er les secteurs où le matériel montant sera placé.

Emplacements possibles pour

monter kits deux voies KM

MONTER

Assurer que l’acier inoxydable enclos montant des vis et les trombones de vitesse de type d’ « U » ne

crèveront pas la cellule de carburant, l’installation éléctrique, ou interférer avec les parties mécaniques sur

le dessous de la surface montant. Utiliser le “le gabarit” dans la boîte de l’expédition de votre haut-parleur

pour marquer le trou montant, l’alors coupure directement sur la ligne. Pré-entraîner les trous montant

de vis utilisant un 7/64” (2,5mm) le morceau, et attacher les haut-parleurs au bateau, en attachant les

vis d’acier inoxydable fournies à la structure du bateau. Le cas échéant, utiliser les trombones enclos

de vitesse de type d’ « U » d’acier inoxydable. Monter l’haut-parleur et la grille à l’endroit pour profi ter de

l’haut-parleur s’humidité intégrée draine le système. Les grilles sont détachables pour les applications de

tableau de coutume. Si le matériel fourni n’est pas applicable à votre installation, quelques autres moyens

d’attachant assurément les haut-parleurs au bateau doivent être utilisés.

14

2009 KM Components Multilingual c01.indd 142009 KM Components Multilingual c01.indd 14 11/21/2008 3:38:30 PM11/21/2008 3:38:30 PM

KMCOMPONENTSYSTEM

Page 15

TWEETER MONTER

Le tweeter peut être monté un de trois façons : plat, la surface et monter incliné. Pour monter plates

les applications, s’il vous plaît se référer à l’illustration. Choisir un emplacement plat sur le panneau

avec l’espace derrière le panneau pour permettre la pièce pour le écrou montant. Après avoir vérifi é les

dégagements, couper le diamètre de trou montant approprié dans le panneau (voir ci-dessous). Placer le

écrou montant plus courte derrière le panneau. Nourrir le câble d’haut-parleur par le trou dans le panneau

et le écrou montant. Monter le tweeter en vissant le écrou montant sur le tweeter.

Pannea

Le écrou montant

plus courte

Enjoliveur de hautparleur d’aigus

Haut-parleur

d’aigus

Montage Plat

Pour surface monter les applications utilise la tasse de mont de surface comme un gabarit et entraîne

pré-deux 7/64” (2,5mm) les trous de vis pour attacher la surface montant la tasse au panneau, et un

5/16” (8 mm) le trou pour le câble d’haut-parleur. Deux #8 vis à tête plate d’acier inoxydable sont fournies

pour attacher la surface montant la tasse au panneau. Disposer le tweeter par-dessus la surface montant

la tasse et l’appuie en place.

Pannea

La tasse de

mont de surface

Haut-parleur

d’aigus

Surface Monter

Pour incliné montant des applications choisissent un emplacement plat sur le panneau avec l’espace

derrière le panneau pour permettre la pièce pour le écrou montant et l’anneau arrière d’angle. Après avoir

vérifi é les dégagements, couper le diamètre de trou montant approprié dans le panneau (voir ci-dessous).

Placer l’anneau d’angle de devant (pas capable par le écrou montant plus longue) devant le panneau.

Placer le câble d’haut-parleur et le tweeter par l’anneau d’angle de devant et dans le panneau. L’endroit

prochain le câble d’haut-parleur par l’anneau d’angle arrière (les crises par la noix montant plus longue),

placer l’anneau d’angle arrière par-dessus l’arrière du tweeter, et la fi le la partie étroite de l’anneau d’angle

de devant pour l’angle préféré d’opération. Placer le câble d’haut-parleur par le écrou montant plus longue

et resserrer lâchement le écrou montant autour du tweeter. Tourner toutes les parties dans l’unisson

jusqu’à ce que le tweeter est incliné dans la direction désirée. Obtenir l’assemblée en resserrant le écrou

montant plus longue.

Pannea

Le écrou montant

plus longue

L’anneau arrière d’angle

L’anneau d’angle

de devant

Monter Incliné

2009 KM Components Multilingual c01.indd 152009 KM Components Multilingual c01.indd 15 11/21/2008 3:38:35 PM11/21/2008 3:38:35 PM

Haut-parleur

d’aigus

15

Page 16

CÂBLAGE

Placer le câble dans un emplacement éclaircit d’eau permanente et de composants en mouvement du

vaisseau. Pour la référence, le câble d’haut-parleur bleu est positif et le câble d’haut-parleur argent est

négatif. Monter le croisé à la plaque arrière de woofer avec l’enclos M3 vis d’acier inoxydable, ou monter

le croisé vaguement dans un emplacement libère d’eau permanente. Le verrouiller la couverture croisée

avec l’eau joint résistant est détachable pour l’installation de câble d’haut-parleur ; il aide empêche

la corrosion délimitante et shorting électrique. Les terminaux positifs et négatifs en or sont de tailles

différentes et correspondent aux connecteurs de câble d’haut-parleur appropriés, en or, positifs et

négatifs. Partir la couverture croisée, et connecter le câble d’haut-parleur du woofer au “WF” le terminal

et le fi l du tweeter au “TW” le terminal. Connecter l’a fourni 15 pieds (4,5m) de fi l à “IN” le terminal dans le

croisé. Soigneusement la route le câble d’haut-parleur par l’entaille entre la couverture croisée et croisée,

et claquer la couverture croisée de retour sur le croisé. Connecter l’autre fi n du câble d’haut-parleur à

votre amplifi cateur conformément à son manuel du propriétaire.

Couverture croisée

Entaille

Appareil source ou amplifi cateur

SPKR +

SPKR -

Garantie Pour connaître les procédures

propres à la politique de garantie de

votre pays, contactez votre revendeur ou

distributeur International Kicker.

16

L’humidité intégrée draine le système

KMCOMPONENTSYSTEM

2009 KM Components Multilingual c01.indd 162009 KM Components Multilingual c01.indd 16 11/21/2008 3:38:37 PM11/21/2008 3:38:37 PM

Page 17

Couverture croisée

Croisé monté à

la plaque arrière

de woofer

MODEL:

Diamètre du haut-parleur de graves, in (cm) 6 (16)

Diamètre du haut-parleur d’aigus, in (mm) 1 (25)

Matériau de la membrane de haut-parleur d’aigus Titane

Impédance nominale [Zn], ohms 4

Puissance admissible, watts, crête (effi cace) 225 (75)

Sensibilité [SPLo], dB @ 1 W, 1 m 88

Plage de fréquence effective, Hz 35-21k

Dimensions découpe de woofer, in (cm) 5 1/8 (13)

Profondeur de montage sans croisé, in (cm) 2 7/8 (7,2)

Dimensions découpe de Tweeter Montant plat, in (cm) 1 13/16 (4,5)

L’haute passe, dB, à la Fréquence, Hz 18, 4000

La passe basse, dB, à la Fréquence, Hz 12, 4000

Visser aux grilles Oui

Les Kicker KM haut-parleurs utilisent le plus haut niveau de protéger magnétique disponible pour minimiser la déviation

de compas et jauge. Les Kicker KM haut-parleurs rencontrent ou dépassent les normes d’industrie pour l’humidité et

la corrosion écologique, et pour la dégradation matérielle en raison de l’exposition ULTRAVIOLETE.

2009 KM Components Multilingual c01.indd 172009 KM Components Multilingual c01.indd 17 11/21/2008 3:38:38 PM11/21/2008 3:38:38 PM

KM6250.2

17

Page 18

ElectronicsLimitedWarranty

Kicker warrants this product to be free from defects in material and workmanship under normal use for a period of

THREE (3) MONTHS from date of original purchase with receipt. When purchased from an Authorized KICKER Dealer it is

warranted for TWO (2) YEARS from date of original purchase with receipt. In all cases you must have the original receipt.

Should service be necessary under this warranty for any reason due to manufacturing defect or malfunction during the

warranty period, Kicker will repair or replace (at its discretion) the defective merchandise with equivalent merchandise at

no charge. Warranty replacements may have cosmetic scratches and blemishes. Discontinued products may be replaced

with more current equivalent products.

This warranty is valid only for the original purchaser and is not extended to owners of the product subsequent to

the original purchaser. Any applicable implied warranties are limited in duration to a period of the express warranty

as provided herein beginning with the date of the original purchase at retail, and no warranties, whether express or

implied, shall apply to this product thereafter. Some states do not allow limitations on implied warranties; therefore these

exclusions may not apply to you. This warranty gives you specifi c legal rights; however you may have other rights that

vary from state to state.

WHAT TO DO IF YOU NEED WARRANTY OR SERVICE

Defective merchandise should be returned to your local Authorized Stillwater Designs (Kicker) Dealer for warranty

service. Assistance in locating an Authorized Dealer can be found at www.kicker.com or by contacting Stillwater

Designs directly. You can confi rm that a dealer is authorized by asking to see a current authorized dealer window decal.

If it becomes necessary for you to return defective merchandise directly to Stillwater Designs (Kicker), call the Kicker

Customer Service Department at (405) 624-8510 for a Return Merchandise Authorization (RMA) number. Package all

defective items in the original container or in a package that will prevent shipping damage, and return to:

Stillwater Designs, 3100 North Husband, Stillwater, OK 74075

The RMA number must be clearly marked on the outside of the package. Please return-only defective components. The

return of functioning items increases your return freight charges. Non-defective items will be returned freight-collect to

you.

Include a copy of the original receipt with the purchase date clearly visible, and a “proof-of-purchase” statement listing

the Customer’s name, Dealer’s name and invoice number, and product purchased. Warranty expiration on items without

proof-of-purchase will be determined from the type of sale and manufacturing date code. Freight must be prepaid; items

sent freight-collect, or COD, will be refused.

WHAT IS NOT COVERED?

This warranty is valid only if the product is used for the purpose for which it was designed.

It does not cover:

o Damage due to improper installation

o Subsequent damage to other components

o Damage caused by exposure to moisture, excessive heat, chemical cleaners, and/or UV radiation

o Damage through negligence, misuse, accident or abuse. Repeated returns for the same damage may be considered

abuse

o Any cost or expense related to the removal or reinstallation of product

o Speakers damaged due to amplifi er clipping or distortion

o Items previously repaired or modifi ed by any unauthorized repair facility

o Return shipping on non-defective items

o Products with tampered or missing barcode labels

o Products returned without a Return Merchandise Authorization (RMA) number

o Freight Damage

o The cost of shipping product to Kicker

o Service performed by anyone other than Kicker

HOW LONG WILL IT TAKE?

Kicker strives to maintain a goal of 72-hour service for all electronics (amplifi ers, crossovers, equalizers, etc.) returns.

Delays may be incurred if lack of replacement inventory or parts is encountered.

Failure to follow these steps may void your warranty. Any questions can be directed to the Kicker Customer Service

Department at (405) 624-8510.

NOTE: All specifi cations and performance fi gures are subject to change. Please visit the www.kicker.com for the most current information.

18

KMCOMPONENTSYSTEM

2009 KM Components Multilingual c01.indd 182009 KM Components Multilingual c01.indd 18 11/21/2008 3:38:39 PM11/21/2008 3:38:39 PM

Page 19

InternationalWarranty

National Marine

Manufacturers Association

MEMBER OF

Contact your International Kicker dealer or distributor concerning specifi c procedures for your country’s warranty policies.

WARNING: KICKER products are capable of producing sound levels that can permanently damage your hearing! Turning

up a system to a level that has audible distortion is more damaging to your ears than listening to an undistorted system at

the same volume level. The threshold of pain is always an indicator that the sound level is too loud and may permanently

damage your hearing. Please use common sense when controlling volume.

GARANTÍA INTERNACIONAL VersiónEspañol

Comuníquese con su concesionario o distribuidor Kicker internacional para obtener infor ación sobre procedimientos

específi cos relacionados con las normas de garantía de su país.

ADVERTENCIA: Los excitadores Kicker son capaces de producir niveles de sonido que pueden dañar permanentemente

el oído. Subir el volumen del sistema hasta un nivel que produzca distorsión es más dañino para el oído que escuchar un

sistema sin distorsión al mismo volumen. El dolor es siempre una indicación de que el sonido es muy fuerte y que puede

dañar permanentemente el oído. Sea precavido cuando controle el volumen.

La frase “combustible para vivir la vida Livin’ Loud™ a todo volumen” se refi ere al entusiasmo por la vida que la marca

Kicker de estéreos de automóvil representa y a la recomendación a nuestros clientes de que vivan lo mejor posible (“a

todo volumen”) en todo sentido. La línea de altavoces y amplifi cadores Kicker es la mejor del mercado de audio de

automóviles y por lo tanto representa el “combustible” para vivir a todo volumen en el área de “estéreos de automóvil” de

la vida de nuestros clientes. Recomendamos a todos nuestros clientes que obedezcan todas las reglas y reglamentos

locales sobre ruido en cuanto a los niveles legales y apropiados de audición fuera del vehículo.

INTERNATIONALE GARANTIE DeutscheVersion

Nehmen Sie mit Ihren internationalen Kicker-Fachhändler oder Vertrieb Kontakt auf, um Details über die Garantieleistungen

in Ihrem Land zu erfahren.

WARNUNG: KICKER-Treiber können einen Schallpegel erzeugen, der zu permanenten Gehörschäden führen kann!

Wenn Sie ein System auf einen Pegel stellen, der hörbare Verzerrungen erzeugt, schadet das Ihren Ohren mehr, als ein

nicht verzerrtes System auf dem gleichen Lautstärkepegel. Die Schmerzschwelle ist immer eine Anzeige dafür, dass der

Schallpegel zu laut ist und zu permanenten Gehörschäden führen kann. Seien Sie bei der Lautstärkeeinstellung bitte

vernünftig!

Der Slogan “Treibstoff für Livin’ Loud” bezieht sich auf die mit den Kicker-Autostereosystemen assoziierte Lebensfreude

und die Tatsache, dass wir unsere Kunden ermutigen, in allen Aspekten ihres Lebens nach dem Besten (“Livin’ Loud”) zu

streben. Die Lautsprecher und Verstärker von Kicker sind auf dem Markt für Auto-Soundsysteme führend und stellen somit

den “Treibstoff” für das Autostereoerlebnis unserer Kunden dar. Wir empfehlen allen unseren Kunden, sich bezüglich der

zugelassenen und passenden Lautstärkepegel außerhalb des Autos an die örtlichen Lärmvorschriften zu halten.

GARANTIE INTERNATIONALE VersionFrançaise

Pour connaître les procédures propres à la politique de garantie de votre pays, contactez votre revendeur ou distributeur

International Kicker.

AVERTISSEMENT: Les haut-parleurs Kicker ont la capacité de produire des niveaux sonores pouvant endommager

l’ouïe de façon irréversible ! L’augmentation du volume d’un système jusqu’à un niveau présentant une distorsion audible

endommage davantage l’ouïe que l’écoute d’un système sans distorsion au même volume. Le seuil de la douleur est

toujours le signe que le niveau sonore est trop élevé et risque d’endommager l’ouïe de façon irréversible. Réglez le volume

en faisant prevue de bon sens !

L’expression “ carburant pour vivre plein pot “ fait référence au dynamisme de la marque Kicker d’équipements audio

pour véhicules et a pour but d’encourager nos clients à faire le maximum (“ vivre plein pot “) dans tous les aspects de leur

vie. Les haut-parleurs et amplifi cateurs Kicker sont les meilleurs dans le domaine des équipements audio et représentent

donc pour nos client le “ carburant pour vivre plein pot “ dans l’aspect “ installation audio de véhicule “ de leur vie.

Nous encourageons tous nos clients à respecter toutes les lois et réglementations locales relatives aux niveaux sonores

acceptables à l’extérieur des véhicules.

MEMBER OF

National Marine

Manufacturers Association

2009 KM Components Multilingual c01.indd 192009 KM Components Multilingual c01.indd 19 11/21/2008 3:38:39 PM11/21/2008 3:38:39 PM

P.O. Box 459 • Stillwater, Oklahoma 74076 • U.S.A. • (405) 624-8510

11212008-C+09KM

19

Page 20

©2008 Stillwater Designs

2009 KM Components Multilingual c01.indd 202009 KM Components Multilingual c01.indd 20 11/21/2008 3:38:40 PM11/21/2008 3:38:40 PM

Loading...

Loading...