User’s and Service Guide

Agilent Technologies 85056A

2.4 mm Precision Calibration Kit

Agilent Part Number: 85056-90020

Printed in USA

Print Date: January 2002

Supersedes: September 2000

© Copyright 1996, 2000, 2002 Agilent Technologies, Inc. All rights reserved.

Warranty

This product i s w arranted against defec ts i n m aterial and workmanship for a p er io d of one

year from date of shipment. During the warranty period, Agilent Technologies will, at its

option, either repair or replace products which prove to be defective.

For warranty service or re pai r, this product must b e r etu rned to a serv ice facility

designated by Agilent. Buyer shall prepay shipping charges to Agilent and Agilent shall

pay shipping char ges to return the product to Buy er. However, Buyer shall pay all shipp ing

charges, d uties, and taxes for products returned to Agilent from another country.

Agilent Technologies warrants that its s oftware and firmware designa t e d by Agilent for

use with an instrumen t will execute its pr ogramming i ns tructi ons w hen proper l y i ns tall ed

on that instrument. Agilent Te c hnolog ie s does not warrant that the operation of the

instrument, or software, or fir mwa re will be uninterrupted or error -free.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from improper or ina dequate

maintenance by Buyer, Buyer-supplied software or interfacing, unauthorized modification

or misuse, operation outside of the environmental specifications for the product, or

improper site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. AGILENT TECHNOLOGIES

SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE.

Exclusive Remedies

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE

REMEDIES. AGILENT TECHNOLOGIES SHALL NOT BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER

BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

Assistan ce

Product maintenance agreements and other customer assistance agreements are availa ble

for Agilent products.

For any assistance, contact Agilent Technolog ies. Refer to page 5-4 for a list of Agilent

contacts.

ii

Contents

1. General Information

Calibration Kit Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Broadband Loads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Offset Opens and Shorts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Sliding Loads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Compatible Network Analyzers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Equipment Required but Not Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Incoming Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Recording the Device Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Clarifying the Sex of a Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

2. Specific atio ns

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Temperature—What to Watch Out For . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Mechanical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Pin Depth. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Certification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

3. Use, Maintenance, and Care of the Devices

Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Look for Obvious Defects and Damage Firs t. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

What Causes Connector Wear? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Inspect the Mating Plane Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Inspect Female Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Cleaning Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Gaging Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Connector Gage Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

When to Gage Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Gaging Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Gaging 2.4 mm Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Gaging the 2.4 mm Sliding Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Adj us t ing the Sli ding L o a d Pin De p t h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1 2

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -14

How to Make a Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Preliminary Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Final Connection Using a Torque Wrench. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Connecting the Sliding Load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

How to Separate a Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Using the Sliding Loa d. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Handling and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

85056A iii

Contents

4. Performance Verification

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

How Agilent Verifies the Devices in Your Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Recertifi cation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

How Often to Recertify. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Where to Send a Kit for Recertification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

5. Troublesh ooting

Troubleshooting Proc ess . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Returning a Kit or Device to Agilent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Contacting Agilent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

6. Replaceable Parts

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

A. Standard Definitions

Standard Class Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

Blank Forms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

Nominal Standard Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-8

Setting the System Impedance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-8

Blank Form. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A -12

iv 85056A

1 General Information

1-1

General Information

Calibration Kit Overview

Calibration Kit Overview

The Agilent 85056A 2.4 mm calibration kit is used to calibrate Agilent network analyzers

up to 50 GHz for measurements of components with 2.4 mm connectors.

Kit Contents

The 85056A calibration kit includes the fol lowing items:

• offset opens and shorts

• broad band and sliding load t er minations

• 2.4 mm adapters

• 2.4 mm gage sets

• 5/16 in, 90 N-cm (8 in-lb) torque wrench

• 7 mm open-end wrench

• data disks that contain the calibration definitions of the devices in the calibration kit

Refer to Chapter 6, “Rep laceable Parts,” for a complete list of kit contents and their

associat ed p art n u mbers.

Broadband Loads

The broadband loads are metrology-grade, 50Ω terminations that have b een optimized for

performance up to 50 GHz. The rugged internal structure provides for hig hly repeatable

connections. A distributed resistive element on sapphire provides excellent s tability and

return loss.

Offset Opens and Shorts

The offset opens and shorts are built from parts that are machined to the current

state-of-the-art in precision machining.

The offset short’s inner conductors have a one-piece construction, common with the

shorting plane. T he construction provides for extremely repeatable connections.

The offset opens have inner conductors that are supported by a strong,

low-dielectric-constant plastic to m i nimize compensation values.

Both the opens and shorts a re constructed so that the pin depth can be controlled ver y

tightly, thereby minimizing phase error s. The lengths of the o ffsets i n the opens and shorts

are designed so tha t the difference in phase of their refl ec tion coefficients is approximately

180 degre e s at all frequencies.

Adapters

Like the other devices in the kit, the adapters are built to very tight tolerances to provide

good broadband performance and to ensure stable, repeatable connections .

The adapters are desig ned so that their nominal electrical lengths are the same, allowing

them to be used in calibration procedures for non-insertable devices.

1-2 85056A

General Information

Incoming Inspection

Sliding Loads

The sliding loads in thi s kit are designed to provide excellent performance from 4 GHz to

50 GHz. The inner and outer conductors of the air line portion are precision machined to

state-of-the-art toler ances. Although the sliding load has exceptional return loss, i ts

superior load stability qual ifies it as a hig h -pe rformance device.

The sliding load w a s d es igned w ith the a b il ity to extend the inne r conduc tor f or c onnec ti on

purposes and then pull it back to a prese t pi n de pt h . T his fe ature is cri tical since it

minimizes the possibility of damage during connecti on, while maintaining a minimum pin

depth to optimize performance.

Compatible Network Analyzers

The 85056A calibration kits are intended to be used with the following Agilent network

analyzers:

•872x Series

• 8753 family

•PNA Series

If this calibration kit is used with other analyzers, the calibration constants must be

manually entered into the analyzer. Refer to your network analyzer user’s guide or

embedded help system for instructions.

Options

The following option is available for the 85056A:

Option 910

This option adds an additional copy of the user’s and service guide (this manual).

Equipment Required but Not Supplied

Connector cleaning supplies and various electrostatic discharge (ESD) protection devices

are not supplied with the calibration kit but are required to ensure successful operation of

the kit. Refer to Ta ble 6-2 on pag e 6-3 for ordering information.

Incoming Inspection

Verify that the shipment is complete by referring to T able 6-1.

Check for damage . T he foam-lined storage c ase pr ovi d es p r otec tion d uring s hipp ing. Verify

that this case and its contents are not damaged.

If the case or any devi ce appears damaged, or if the shipment is incomplete, contact

Agilent Technologies. See page 5-4 for contact information. Agilent will arrange for repair

or replacement of incomplete or damaged shipments without waiting for a settlement from

the transportation company.

85056A 1-3

General Information

Incoming Inspection

When you send the kit or device to Agilent, in clude a service tag (found near the end of this

manual) with the following information:

• your company name and address

• the name of a technic al contact person within your company, and the person's complete

phone number

• the model number and serial number of the kit

• the part number and serial num ber of the device

• the type of service required

•a detailed description of the problem

1-4 85056A

General Information

Recording the Device Serial Numbers

Recording the Device Serial Numbers

In addition to the kit ser ial number, the devices in the kit are individua lly seri alized (seria l

numbers are labeled onto the b ody of each device). Record these serial numbers in

Table 1-1. Recording the serial numbers will prevent confusing the devices in this kit with

similar devices from other kits.

The adapters included in the kit are for measurement convenience only and are not

serialized.

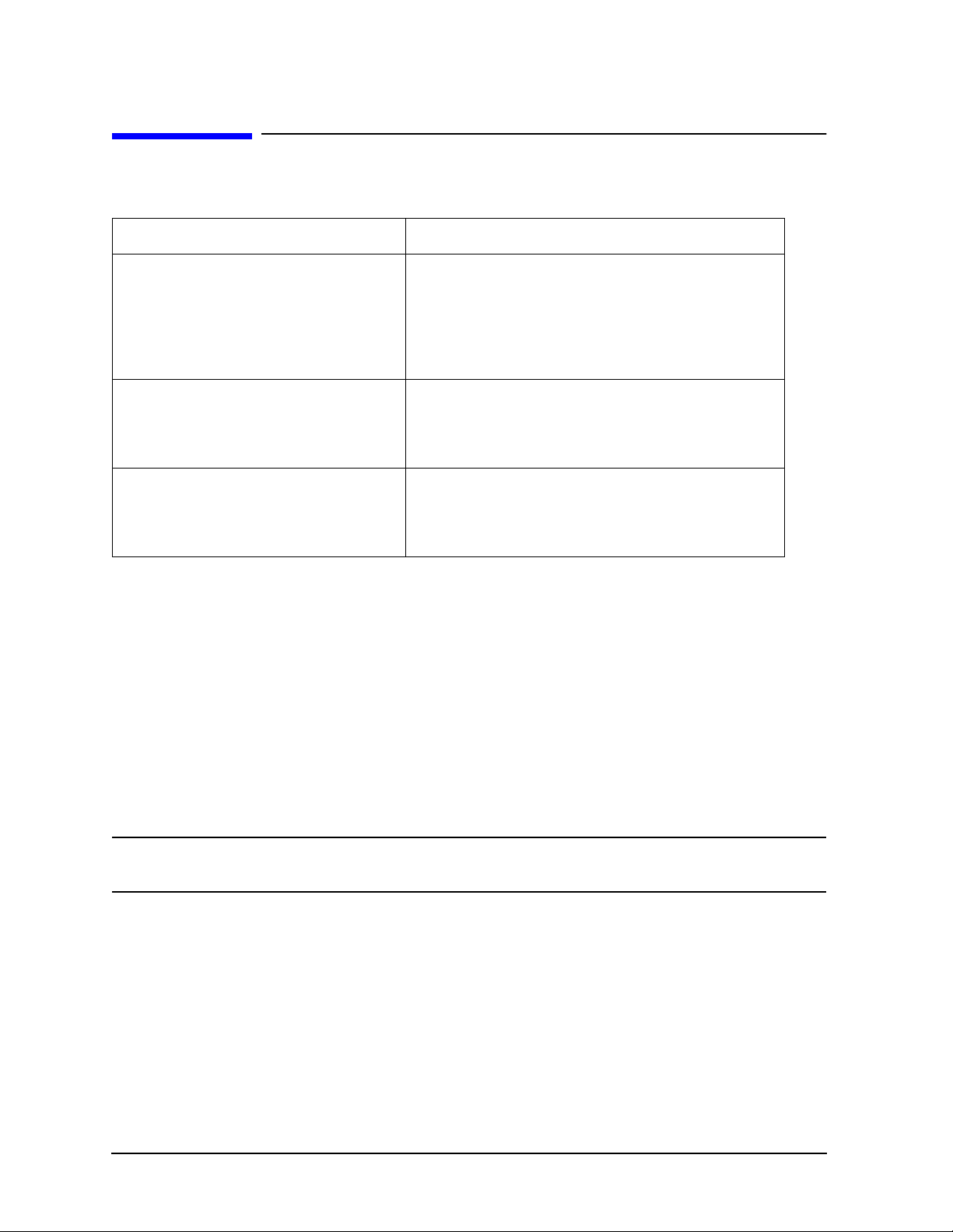

Table 1-1 Serial Number Record for the 85056A

Device Serial Number

Calibration kit

Male open

Female open

Male s hort

Female short

Male broadband load

Female broadband load

Male sliding load

Female sliding load

Male-to-male 2.4 mm adapter

Male-to-female 2.4 mm adap ter

Female-to-female 2.4 mm adapter

_______________________________

_______________________________

_______________________________

_______________________________

_______________________________

_______________________________

_______________________________

_______________________________

_______________________________

_______________________________

_______________________________

_______________________________

85056A 1-5

General Information

Clarifying the Sex of a Connector

Clarifying the Sex of a Connector

In this manual, c alib r ation devices and adapter s a r e r ef erred to in terms of their connector

interface. For example, a male open has a male connector.

However, during a measurement calibration, the network analyzer softkey menus label a

calibration device with reference to the sex of the analyzers test port connector—not the

calibration device connector. For example, the label SHORT(F) on the analyzers display

refers to the short that is to be connected to the female test port. This will be a male short

from the calibration kit.

A connector gages is referred to in terms of the connector that it measures. For instance, a

male connector gage has a female connector on the gage so that it can measure male

devices.

Preventive Maintenance

The best techniques for maintaining the integrity of the devices in the kit include:

• routine visual inspection

• cleaning

• proper g aging

• proper connection techniques

All of these are described in Chapter 3. Failure to detect and remove dirt or metallic

particles on a mating plane surfa ce can de grade re pe at ability an d accuracy an d can

damage any connector mated to it. Improper connections, resulting from pin depth values

being out of the ob served limits (see Table 2-2 on page 2-4), or from bad connection

techniques, can also damage these devices.

1-6 85056A

2 Specifications

2-1

Specifications

Environmenta l Requirements

Environmental Requirements

Table 2-1 Environmental Requirements

Parameter Limits

Temperature

Operating

Storage −40 °C to +75 °C

Error- corrected range

Altitude

Operating < 4,500 meters (≈15,000 fe et)

Storage < 15,000 meters (≈50,000 feet)

Relative humidity Always non-condensing

Operating 0 to 80% (26 °C maximum dry bulb)

Storage 0 to 90%

a. The temperatu re rang e over which the calibration standards maintain confor mance to their

b. The allowable network analyzer ambient tem perature drift during measurement calibration

a

b

specification s .

and during measurem ents when t he ne twor k analyzer er ror co rre cti on is t urne d on. Al so, the

range over which the network analyzer maintain s its specified pe rformance while correction

is turned on.

+20 °C to +26 °C

± 1 °C of measurement calibration temperature

Temperature—What to W atch Out For

Changes in temperature can affect electrica l characteristics. Therefore, the operating

temperature is a criti cal factor in performance. During a measurement calibration, the

temperature of the ca libration devices must be stable and within the range shown in

Table 2-1.

IMPORTANT Avoid unnecessary handling of the devices during calibration because your

fingers are a heat source.

2-2 85056A

Specifications

Mechanical Characteristics

Mechanical Characteristics

Mechanical characteristics such as center conductor protrusion a nd pin depth are not

performance specifications. They are, however, important supplemental characteristics

related to electrical performance. Agilent Technologies verifies the mechanical

characteristics of the devices in the kit with special gaging processes and electrica l testing.

This ensures that the device connectors do not ex hibit any center conductor protrusion or

improper pin depth when the kit leaves the fa ctory.

“Gaging Connectors” on page 3-6 explains how to use gages to determine if the kit devices

have maintained their mechanical integrity. Refer to Table 2-2 on page 2-4 for typic al and

observed pin depth limits.

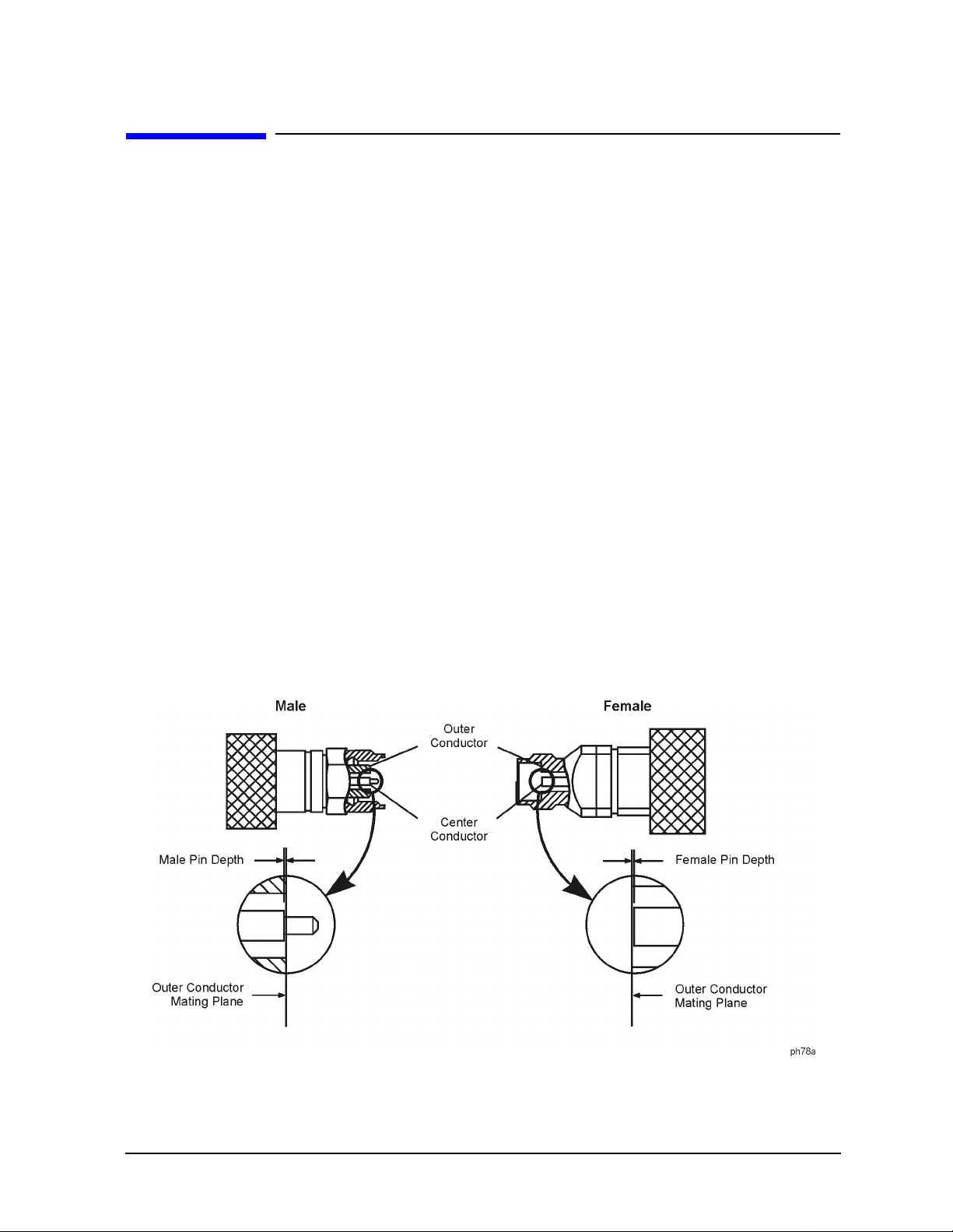

Pin Depth

Pin depth is the distance the center conductor mating plane differs from being flush with

the outer conductor mating plane. See Figure 2-1. The pin depth of a connector can be in

one of two states: either protruding or rec essed.

Protrusion is the condition in which the center conductor extends beyond the outer

conductor mating plane. This condition will indicate a p ositive value on the connector gage.

Recession is the condition in which the center conductor is set back from the outer

conductor mating plane. T his condition will indicate a negative value on the connector

gage.

Figure 2-1 Connector Pin Depth

85056A 2-3

Specifications

Mechanical Characteristics

The pin depth value of each calibration device in the kit is not specified, but is an

important mechanical parameter. The electrical performance of the device depends, to

some extent, on its pin depth. The electrical specifications for each device in the kit take

into account the effect of pin depth on the device’s performance. Table 2-2 lists the typical

pin depths and measurement uncerta inties, and pr ovid es observed pin depth limits for the

devices in the kit. If the pin depth of a device does not measure within the observed pin

depth limits, it may be an indication that the device fails to meet electrical specifi cations.

Refer to Figure 2-1 on pag e 2-3 for a visual representation of proper pin depth (slightly

recessed).

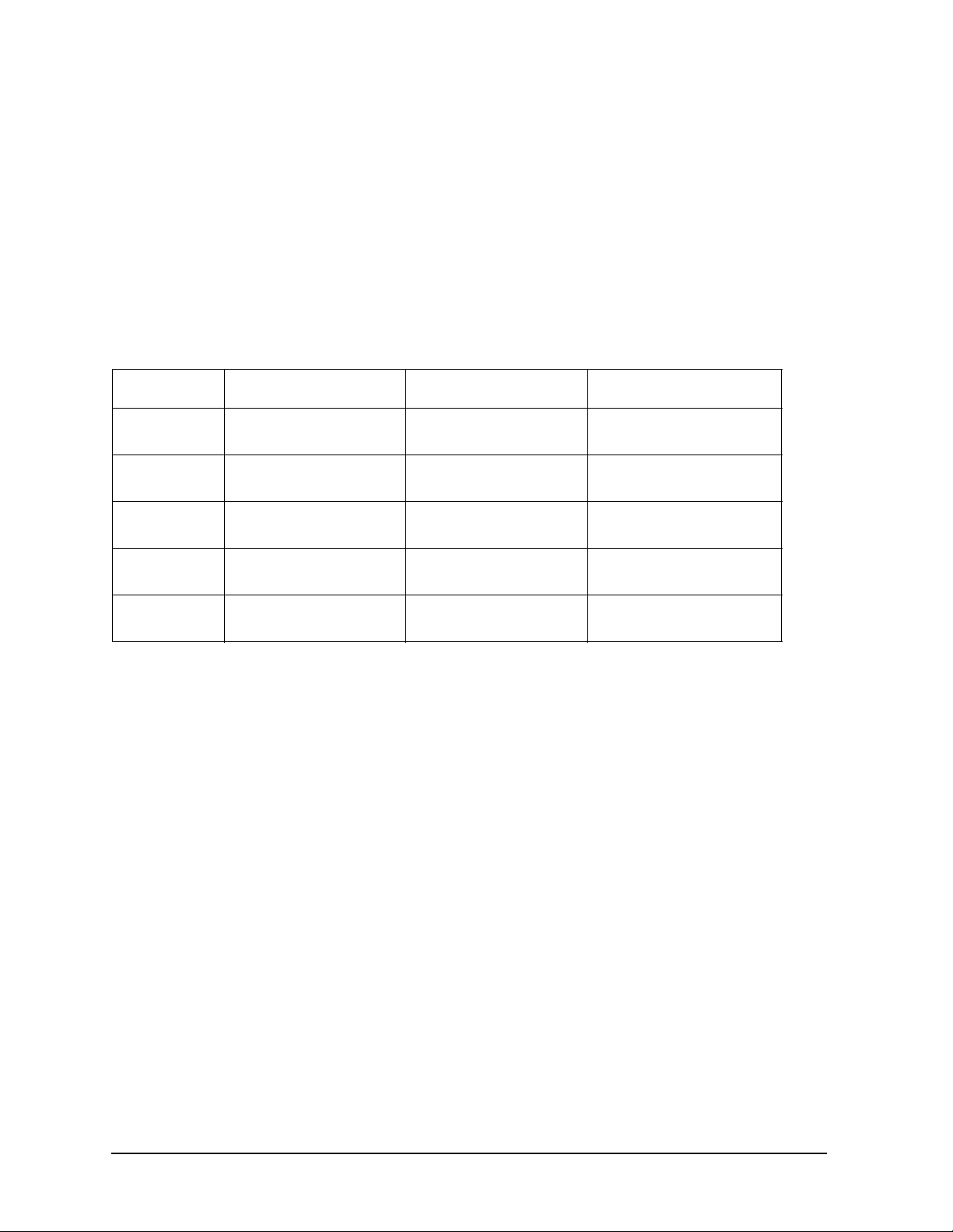

Table 2-2 Pin Depth Limits

Device

Opens 0 to −0.0127 mm

Shorts 0 to −0.0127 mm

Fixe d loads −0.0025 to −0.0203 mm

Sliding loads 0 to −0.0127 mm

Adapters 0 to −0.0381 mm

a. Approximately +2 sigma to −2 sigma of gage uncertainty based on stud ies done at the

factory according to recom m ended procedures.

b. Observed pin depth limits are the range of observation limit s seen on the gage reading due

to measurement uncert ainty. The depth could still be within specif ications.

Typical Pin Dept h

0 to −0.00050 in

0 to −0.00050 in

−0.00010 to −0.00080 in

0 to −0.00050 in

0 to −0.00150 in

Measu rem e n t U n certa in ty

+0.0030 to −0.0030 mm

+0.00012 to −0. 00012 in

+0.0015 to −0.0015 mm

+0.00006 to −0. 00006 in

+0.0030 to −0.0030 mm

+0.00012 to −0. 00012 in

+0.0015 to −0.0015 mm

+0.00006 to −0. 00006 in

+0.0030 to −0.0030 mm

+0.00012 to −0. 00012 in

a

Observed Pin Depth Limits

+0.0030 to −0.0157 mm

+0.00012 to −0.000 62 in

+0.0015 to −0.0142 mm

+0.00006 to −0.000 56 in

+0.0005 to −0.0234 mm

+0.00002 to −0.000 92 in

+0.0015 to −0.0142 mm

+0.00006 to −0.000 56 in

+0.0030 to −0.0411 mm

+0.00012 to −0.001 62 in

b

2-4 85056A

Specifications

Electrical Specifications

Electrical Specifications

The electrical specif ications in Table 2-3 apply to the devices in your calibration kit when

connected with an Agilent precision interface.

Table 2-3 Electrical Specifications for 85056 A 2.4 mm Devices

Device Specifi cation Frequency (GHz)

Broadband loads Return loss ≥ 42 dΒ (ρ ≤ 0.00794) dc to ≤ 4

(male and female) Return loss ≥ 34 dΒ (ρ ≤ 0.01995) > 4 to ≤ 20

Return loss ≥ 30 dB (ρ ≤ 0.0316 2) > 20 to ≤ 26.5

Return loss ≥ 26 dB (ρ ≤ 0.0501 9) > 26.5 to ≤ 50

a

Sliding loads

(male and female) Return loss ≥ 40 dΒ (ρ ≤ 0.01000) > 20 to ≤ 36

Adapters Return loss ≥ 32 dΒ (ρ ≤ 0.02512) dc to ≤ 4

Offset opens

(male and female) ± 1.25 ° devia tion from nominal > 2 to ≤ 20

Offset shorts

(male and female) ± 1.25 ° devia tion from nominal > 2 to ≤ 20

b

b

Return loss ≥ 42 dΒ (ρ ≤ 0.00794) 4 to ≤ 20

Return loss ≥ 38 dB (ρ ≤ 0.0125 9) > 36 to ≤ 40

Return loss ≥ 36 dB (ρ ≤ 0.0158 5) > 40 to ≤ 50

Return loss ≥ 30dΒ (ρ ≤ 0.03162) > 4 to ≤ 26.5

Return loss ≥ 25dB (ρ ≤ 0.05623) > 26.5 to ≤ 40

Return loss ≥ 20 dB (ρ ≤ 0.1000 0) > 40 to ≤ 50

± 0.5 ° deviation from nominal

± 1.75 ° devia tion from nominal > 20 to ≤ 40

± 2.25 ° devia tion from nominal > 40 to ≤ 50

± 0.50 ° devia tion from nominal

± 1.5 ° deviat ion from nominal > 20 to ≤ 40

dc to ≤ 2

dc to ≤ 2

± 2.0 ° deviat ion from nominal > 40 to ≤ 50

a. The specifications for t he sliding load termination incl ude the quality of the airline

portions within t he sliding load combined with the effective stability of the sliding

element.

b. The specifications for the opens and shorts are given as allowed deviation from the

nominal model as defined in the standard definitions (see “Nominal Standard

Definitions” on pageA-8).

85056A 2-5

Specifications

Electrical Specifications

Certification

Agilent Technologies certifies that this product met its p ub li shed s peci fic ations a t the time

of shipment from the factory. Agilent further certifies that its calibration measurements

are traceable to the United States National Institute of Standards and Technology (NIST)

to the extent allowed by the institute’s calibration facility, and to the calibration facilities

of other International Standards Organization m embers. See “How Agilent Verifies the

Devices in Your Kit” on page 4-2 for m o re information.

2-6 85056A

3 Use, Maintenance, and Care of the

Devices

3-1

Use, Maintenance, and Care of the Devices

Electrostatic Discharge

Electrostatic Discharge

Protection against electrostatic discharge (ESD) is essential while connecting, inspecting,

or cleaning connectors attached to a static-sensitive ci rcuit (such as those found in test

sets).

Static electricity can build up on y our body and can easily damage sensitive internal

circuit elements when discharged. Static discharges too small to be felt can cause

permanent damage. Devices such as calibration c omponents and devices under test (DUT),

can also carry an electrostatic charge. To prevent damage to the test set, components, and

devices:

• Always wear a grounded wrist stra p h avi ng a 1 MΩ resistor in series with it when

handling components and devices or when making connections to the test set.

• Always use a grounded antistatic mat in front of your test equipment.

• Always wear a heel strap when working in an area with a conductive floor. If you are

uncertain about the conductivity of your floor, wear a heel strap.

Figure 3-1 shows a typical ESD protection setup using a grounded mat and wrist strap.

Refer to Chapter 6, “Rep laceable Parts,” for information on ordering supplies for ESD

protection.

Figure 3-1 ESD Protection Setup

3-2 85056A

Use, Maintenance, and Care of the Devices

Visual Inspection

Visual Inspection

Visual inspection and, if necessary, cleaning should be done every time a connection is

made. Metal particles from the connector threads may fall into the connector when it is

disconnected. One connection made with a dirty or damaged connector can damage both

connectors beyond repair.

In some cases, m a gnification is necessary to see damage to a connector; a magnifying

device with a magnificati on of ≥ 10× is recommended. However, not all defects that are

visible only under magnification wi ll affect the elec trical per formance of the connector. Use

the following guidelines when evaluating the i ntegrity of a connector.

Look for Obvious Defects and Damage First

Examine the connectors first for obvious defects and damage: badly worn plating on the

connector interface, deformed threads, or bent, broken, or misaligned center conductors.

Connector nuts should move smoothly and be free of burrs, loose metal particles, and

rough spots.

What Causes Connector Wear?

Connector wear is caused by connecting and disconnecting the devices. The more use a

connector gets, the faster it wears and degrades. The wear is greatly accelerated when

connectors are not kept clean, or are not connected properly.

Connector wear eventually d egra des performance of the dev ice. Calibration devices should

have a long life if their use is on the order of a few times per week. Replace d evices with

worn connectors.

The test port connectors on the network analyzer test s et may have many connections each

day, and are therefore more subject to wear. It is recommended that an adapter be used as

a test port saver to m inimize the wear on the test set’s test port connectors.

Inspect the Mating Plane Surfaces

Flat contact between the connectors at a ll point s on their mating plane sur faces is required

for a good connection. See Figure 2-1 on pag e 2-3. Look especially for deep scratches or

dents, and for dirt and metal particles on the connector mating plane surfaces. Also look

for signs of damage due to excessive or uneven wear or misalignment.

Light burnishing of the mating plane surfaces is normal, and is evident as light scratches

or shallow circular marks distributed more or less uniformly over the mating plane

surface. Other small defects and cosmetic imperfections are also normal. None of these

affect electrical or mechanical performance.

If a connector shows deep scratches or dents, particles clinging to the mating plane

surfaces, or uneven wear, clean and inspect it again. Devices with d amaged connectors

should be discarded. Determine the cause of damage before connecting a new, undamaged

connector in the same configuration.

85056A 3-3

Use, Maintenance, and Care of the Devices

Cleaning Connectors

Inspect Female Connectors

Inspect the contact fingers in the female center conductor carefully. These can be bent or

broken, and damage to them is not always easy to see. A connector with damaged contact

fingers will not make good electrical contact and must be repla ced.

NOTE This is particularly important when mating nonprecision to precision devices.

The female 2.4 mm connectors in this calibration kit are metrology-grade, precision

slotless connector s (PSC) . Prec isi on s lotl ess conne cto rs are used to improve accuracy. With

PSCs on test ports and standards, the accuracy achieved when measuring at 50 dB return

loss levels is comparable to using conventi onal slotted connectors measuring devices

having only 30 dB ret urn loss. This represents an accuracy improvement of a bout 10 times.

Conventional female center conductors are slotted and, when mated, are flared by the

male pin. Because physical dimensions determine connector impedance, this change in

physical dimension affects electrical performance, making it very difficult to perform

precision measurements with c onventional slotted female connectors.

The precision slotless connector was developed to eliminate this problem. The PSC has a

center conductor with a solid cylindrical shell, the outside diameter of which does not

change when mated. Instead, this center conductor has an internal contact that flexes to

accept the male pin.

Cleaning Connectors

Clean connectors are essential for ensuring the integrity of RF and microwave coaxial

connections.

1. Use Compressed Air or Nitrogen

WARNING Always use protective eyewear when using compressed air or

nitrogen.

Use compressed air (or nitrogen) to loosen particles on the connector mating plane

surfaces. Clean ai r cannot damage a connector or leave particles or residues behind.

You can use any source of clean, dry, low-pressure compressed air or nitrogen that has

an effective oil-vapor filter and liquid condensation trap placed just before the outlet

hose.

Ground the hose nozzle to prevent electrostatic discharge, and set the air pressure to

less than 414 kP a (60 ps i) to con trol the vel ocity of th e air stream. High- velocity s treams

of compressed air can cause electrostatic effects when directed into a connector. These

electrostatic effects can damage the device. Refer to “Electrostatic Disch arge” on

page 3-2 earlier in this chapter for additional information.

3-4 85056A

Loading...

Loading...