Keysight N5227A, N5290 Installation Manual

Keysight Technologies

PNA Series 2-Port and 4-Port

Microwave Network Analyzer System -

Banded Self-Configuration

(110 GHz and 120 GHz)

Use this manual in conjunction with the following documents:

-PNA Series Network Analyzer Embedded Help System

(Online at: http://na.support.keysight.com/pna)

-PNA Series Network Analyzer Installation and Quick Start

Guide Part Number E8356-90001

-N5227A PNA Series Microwave Network Analyzer Service

Guide Part Number N5227-90026

-N5290/1A Millimeter-Wave System Service Guide 90026

Operation and

Installation Guide

Notices

© Keysight Technologies, Inc.

2009-2021

No part of this manual may be

reproduced in any form or by any

means (including electronic storage

and retrieval or translation into a

foreign language) without prior

agreement and written consent from

Keysight Technologies, Inc. as

governed by United States and

international copyright laws.

Trademark Acknowledgments

Manual Part Number

N5292-90001

Edition

Edition 1, January 2021

Printed in USA/Malaysia

Published by:

Keysight Technologies

1400 Fountaingrove Parkway

Santa Rosa, CA 95403

Warranty

THE MATERIAL CONTAINED IN THIS

DOCUMENT IS PROVIDED “AS IS,”

AND IS SUBJECT TO BEING

CHANGED, WITHOUT NOTICE, IN

FUTURE EDITIONS. FURTHER, TO

THE MAXIMUM EXTENT PERMITTED

BY APPLICABLE LAW, KEYSIGHT

DISCLAIMS ALL WARRANTIES,

EITHER EXPRESS OR IMPLIED WITH

REGARD TO THIS MANUAL AND

ANY INFORMATION CONTAINED

HEREIN, INCLUDING BUT NOT

LIMITED TO THE IMPLIED

WARRANTIES OF

MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.

KEYSIGHT SHALL NOT BE LIABLE

FOR ERRORS OR FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES IN

CONNECTION WITH THE

FURNISHING, USE, OR

PERFORMANCE OF THIS

DOCUMENT OR ANY INFORMATION

CONTAINED HEREIN. SHOULD

KEYSIGHT AND THE USER HAVE A

SEPARATE WRITTEN AGREEMENT

WITH WARRANTY TERMS

COVERING THE MATERIAL IN THIS

DOCUMENT THAT CONFLICT WITH

THESE TERMS, THE WARRANTY

TERMS IN THE SEPARATE

AGREEMENT WILL CONTROL.

Technology Licenses

The hardware and/or software

described in this document are

furnished under a license and may be

used or copied only in accordance

with the terms of such license.

U.S. Government Rights

The Software is “commercial

computer software,” as defined

by Federal Acquisition Regulation

(“FAR”) 2.101. Pursuant to FAR

12.212 and 27.405-3 and

Department of Defense FAR

Supplement (“DFARS”) 227.7202,

the U.S. government acquires

commercial computer software

under the same terms by which

the software is customarily

provided to the public.

Accordingly, Keysight provides

the Software to U.S. government

customers under its standard

commercial license, which is

embodied in its End User License

Agreement (EULA), a copy of

which can be found at

http://www.keysight.com/find/sweula

The license set forth in the EULA

represents the exclusive authority

by which the U.S. government

may use, modify, distribute, or

disclose the Software. The EULA

and the license set forth therein,

does not require or permit,

among other things, that

Keysight: (1) Furnish technical

information related to

commercial computer software

or commercial computer

software documentation that is

not customarily provided to the

public; or (2) Relinquish to, or

otherwise provide, the

government rights in excess of

these rights customarily provided

to the public to use, modify,

reproduce, release, perform,

display, or disclose commercial

computer software or

commercial computer software

documentation. No additional

government requirements

beyond those set forth in the

EULA shall apply, except to the

extent that those terms, rights, or

licenses are explicitly required

from all providers of commercial

computer software pursuant to

the FAR and the DFARS and are

set forth specifically in writing

elsewhere in the EULA. Keysight

shall be under no obligation to

update, revise or otherwise

modify the Software. With

respect to any technical data as

defined by FAR 2.101, pursuant

to FAR 12.211 and 27.404.2 and

DFARS 227.7102, the U.S.

government acquires no greater

than Limited Rights as defined in

FAR 27.401 or DFAR 227.7103-5

(c), as applicable in any technical

data.

Safety Notices

A CAUTION notice denotes a hazard. It

calls attention to an operating

procedure, practice, or the like that,

if not correctly performed or adhered

to, could result in damage to the

product or loss of important data. Do

not proceed beyond a CAUTION

notice until the indicated conditions

are fully understood and met.

A WARNING notice denotes a hazard.

It calls attention to an operating

procedure, practice, or the like that,

if not correctly performed or adhered

to, could result in personal injury or

death. Do not proceed beyond a

WARNING notice until the indicated

conditions are fully understood and

met.

1. Safety and Regulatory Information

Information in This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Chapter One at-a-Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

General Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Safety Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Before Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Electrostatic Discharge Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

ESD Equipment Required for the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Regulatory Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Instrument Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Lithium Battery Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

EMC and Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

N5292A Test Set Equipment Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

System Heating and Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Required Conditions for Accuracy Enhanced Measurement. . . . . . . . . . . . . . . . . . . . . 1-13

Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

2. System Description

Information in This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Chapter Two at-a-Glance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Self-Configured Banded or Non-LFE Broadband Millimeter-Wave Network Analyzer System .

2-3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Network Analyzer Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

N5292A Test Set Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Front Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Rear Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Interconnect Kits, Rackmount Kits, and Optional Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Banded and Non-LFE Broadband N52xxB Millimeter System Interconnect Kits . . . . . 2-14

Millimeter System Rackmount Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Millimeter System Optional Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Compatible Millimeter-wave Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Basic System Measurement Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Coaxial Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Keysight Banded/Self-Configured System Installation Guide 3

3. System Installation

Information in This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Chapter Three at-a-Glance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Getting Prepared . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Tools Required for the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

About Installing the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Getting Assistance from Keysight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Contacting Keysight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Receiving the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Receiving the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Keysight Technologies Customer Engineering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Review the Principles of Connector Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

PNA, Controller, and Test Head Module Interconnections. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

System Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Rear Panel Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Front Panel Cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

OML/VDI Millimeter-wave Module Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Configuring the PNA Software for a Self Configured System. . . . . . . . . . . . . . . . . . . . . . . . 3-19

Configuring Non-LFE Broadband and LFE and Non-LFE Banded Systems . . . . . . . . . 3-19

OML/VDI and N5293A/5A Test Heads – Banded Configuration Calibration (Only) . . . . . . 3-21

Overview: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

System Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Required Calibration Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Overall Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Detailed Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Running the Calibrations (LO, RF, and IF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

LO Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

RF Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

IF Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

Initializing the Banded Millimeter-wave System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Running the Installation Calibration (Broadband Systems Only). . . . . . . . . . . . . . . . . . . . . 3-30

Troubleshooting the OML/VDI MiIlimeter Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

4. Performance Verification

Information in This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Chapter Four at-a-Glance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Preliminary Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

System Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

What the System Verification Verifies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Measurement Uncertainty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4 Keysight Banded/Self-Configured System Installation Guide

Measurement Traceability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Performing System Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

If the System Verification Fails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

5. Maintenance and Support

Information in This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Chapter Five at-a-Glance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Physical Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Electrical Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Caring for Waveguide (WG) Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Principles of Connector Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Keysight Support, Services, and Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Service and Support Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Contacting Keysight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Shipping an Item to Keysight for Service or Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Downloading the Online System Service Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Keysight Banded/Self-Configured System Installation Guide 5

6 Keysight Banded/Self-Configured System Installation Guide

Keysight PNA/PNA-X Series

2-Port and 4-Port Self-Configured Microwave Network Analyzer System

Installation Guide

1 Safety and Regulatory Information

This document is applicable to non-LFE broadband millimeter-wave

systems and banded millimeter-wave systems. Where the text applies to

both types of systems, "millimeter-wave system" is used. Where the

content is specific to one or the other types of systems, "non-LFE

broadband millimeter-wave system" or "banded millimeter-wave system"

is used. For N5290/91A LFE broadband millimeter-wave system

information refer to

http://literature.cdn.keysight.com/litweb/pdf/N5292-90002

Information in This Chapter

This chapter provides safety information that will help protect you and your system’s equipment. It also contains information that is required by various government regulatory agencies.

.

1-1

1-

Safety and Regulatory Information

Information in This Chapter

Chapter One at-a-Glance

Section Title Summary of Content

“Safety Symbols” on page 3 Descriptions of CAUTION and WARNING symbols used throughout this

manual.

“General Safety Considerations” on

A list of safety points to consider when servicing your network analyzer.

page 4

“Electrostatic Discharge Protection” on page 6

A discussion of electrostatic discharge (ESD) and related recommendations and requirements for ESD protection. Also, includes a table of ESD equipment part numbers.

“Regulatory Information” on page 8 Definitions of instrument markings.

Instructions for disposing of the analyzer’s lithium battery.

“N5292A Test Set Equipment Ratings” on page 11

“Environmental Requirements” on page 12

Describes the voltage, frequency, and power ratings of your N5292A test controller

Descriptions of the environmental requirements that are characteristic for a system based on the limitations of the PNA network analyzer

“Site Preparation” on page 13 Describes power requirement-related information for your millimeter-wave

system System.

1-2 Keysight Self-Configured System Installation Guide

Safety and Regulatory Information

Safety Symbols

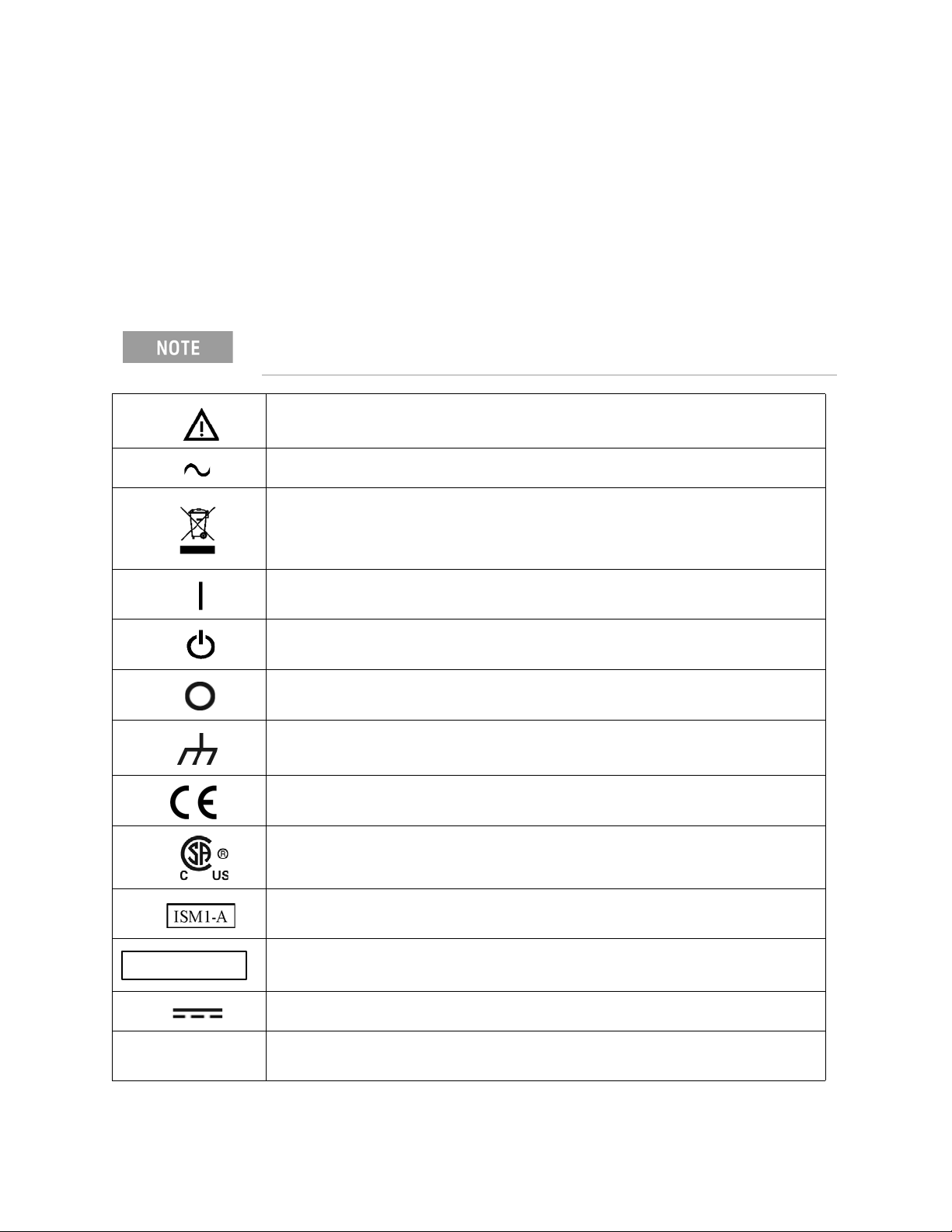

Safety Symbols

The following safety symbols are used throughout this manual. Familiarize yourself with each of the symbols and its meaning before operating this instrument.

Caution denotes a hazard. It calls attention to a procedure that, if not

correctly performed or adhered to, could result in damage to or

destruction of the instrument. Do not proceed beyond a caution note until

the indicated conditions are fully understood and met.

Warning denotes a hazard. It calls attention to a procedure which, if not correctly performed or adhered to, could result in injury or loss of life. Do not proceed beyond a warning note until the indicated conditions are fully understood and met.

Keysight Self-Configured System Installation Guide 1-3

1-

Safety and Regulatory Information

General Safety Considerations

General Safety Considerations

Safety Earth Ground

This is a Safety Class I product (provided with a protective earthing

ground incorporated in the power cord). The mains plug shall only

be inserted in a socket outlet provided with a protective earth

contact. Any interruption of the protective conductor, inside or

outside of the instrument, will make the instrument dangerous.

Intentional interruption is prohibited.

The Mains wiring and connectors shall be compatible with the connector used in the premise electrical system. Failure, to ensure adequate earth grounding by not using the correct components may cause product damage, and serious injury.

Always use the three-prong AC power cord supplied with this product. Failure to ensure adequate grounding by not using this cord may cause product damage.

Before Applying Power

This product has been designed and tested in accordance with

accepted industry standards, and has been supplied in a safe

condition. The documentation contains information and warnings

that must be followed by the user to ensure safe operation and to

maintain the product in a safe condition.

If this product is not used as specified, the protection provided by the equipment could be impaired. This product must be used in a normal condition (in which all means for protection are intact) only.

If an instrument handle is damaged, you should replace it immediately. Damaged handles can break while you are moving or lifting the instrument and cause personal injury or damage to the instrument.

Supply voltages which oscillate between the two normal input

ranges of the autoranging line voltage input will damage the power

supply. In rare cases, this damage has become a user safety

concern. If unstable power levels are expected, the analyzer input

power must be buffered by a line conditioner.

1-4 Keysight Self-Configured System Installation Guide

Safety and Regulatory Information

General Safety Considerations

Safety of any system incorporating the equipment is the responsibility of the assembler of the system.

This product is designed for use in Installation Category II and Pollution Degree 2 per IEC standards.

Before switching on this instrument, make sure

— the correct rating service breaker.

— the supply voltage is in the specified range

This instrument has auto-ranging line voltage input, be sure the supply voltage is within the specified range and voltage fluctuations do not to exceed 10 percent of the nominal supply voltage.

Do not operate the analyzer with the outer cover removed for more than 30 minutes, as this could cause the analyzer to overheat which could result in costly damage.

Servicing

Ventilation Requirements: When installing the product in a cabinet, the

convection into and out of the product must not be restricted. The ambient

temperature (outside the cabinet) must be less than the maximum

operating temperature of the instrument by 4 °C for every 100 watts

dissipated in the cabinet. If the total power dissipated in the cabinet is

greater than 800 watts, then forced convection must be used.

All of the service information for the banded and non-LFE broadband millimeter self-configurations can be found in the Service Guide. Refer to

http://literature.cdn.keysight.com/litweb/pdf/N5292-90026.

Keysight Self-Configured System Installation Guide 1-5

1-

Safety and Regulatory Information

Electrostatic Discharge Protection

Electrostatic Discharge Protection

This is important. If not properly protected against, electrostatic discharge can seriously damage your analyzer, resulting in costly repair.

Protection against electrostatic discharge (ESD) is essential while removing

assemblies from or connecting cables to the network analyzer. Static

electricity can build up on your body and can easily damage sensitive internal

circuit elements when discharged. Static discharges too small to be felt can

cause permanent damage. To prevent damage to the instrument:

— always have a grounded, conductive table mat in front of your test

equipment.

— always wear a grounded wrist strap, connected to a grounded conductive

table mat, having a 1 MΩ resistor in series with it, when handling

components and assemblies or when making connections.

— always wear a heel strap when working in an area with a conductive floor. If

you are uncertain about the conductivity of your floor, wear a heel strap.

— always ground yourself before you clean, inspect, or make a connection to

a static-sensitive device or test port. You can, for example, grasp the

grounded outer shell of the test port or cable connector briefly.

— always ground the center conductor of a test cable before making a

connection to the analyzer test port or other static-sensitive device. This

can be done as follows:

1. Connect a short (from your calibration kit) to one end of the cable to short the center conductor to the outer conductor.

2. While wearing a grounded wrist strap, grasp the outer shell of the cable connector.

3. Connect the other end of the cable to the test port and remove the short from the cable.

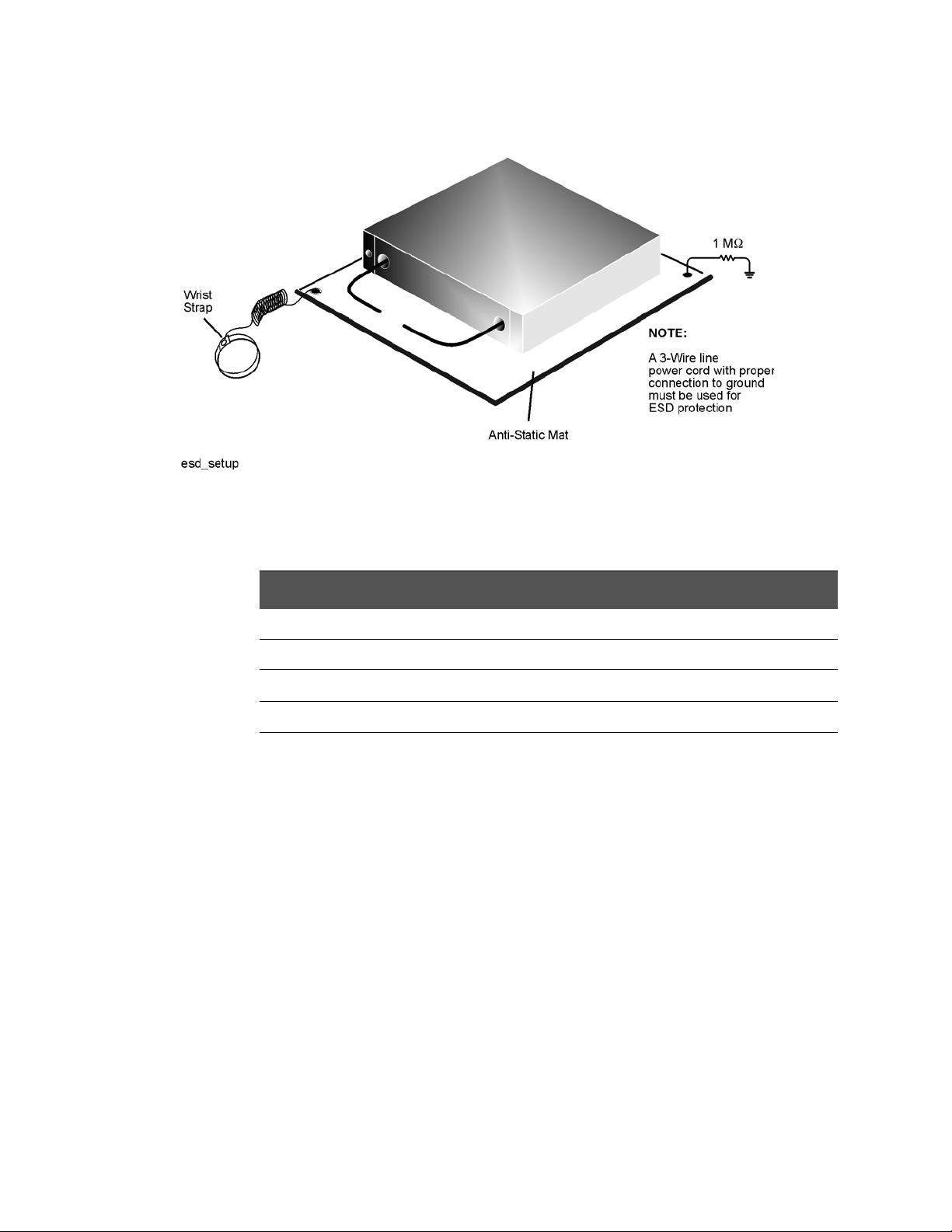

Figure 1-1 shows a typical ESD protection setup using a grounded mat and

wrist strap. Refer to “Electrostatic Discharge Protection” on page 1-6 for part

numbers.

1-6 Keysight Self-Configured System Installation Guide

Safety and Regulatory Information

Electrostatic Discharge Protection

Figure 1-1 ESD Protection Setup

ESD Equipment Required for the Installation

Description Keysight Part Number

ESD grounding wrist strap 9300-1367

5-ft grounding cord for wrist strap 9300-0980

2 x 4 ft conductive table mat and 15-ft grounding wire 9300-0797

ESD heel strap (for use with conductive floors) 9300-1308

Keysight Self-Configured System Installation Guide 1-7

1-

ICES/NMB-001

Safety and Regulatory Information

Regulatory Information

Regulatory Information

This section contains information that is required by various government regulatory agencies.

Instrument Markings

Familiarize yourself with these instrument markings and their meanings before operating the instrument.

Some instrument markings may not appear on your analyzer.

The instruction documentation symbol. The product is marked with this symbol when it is necessary for the user to refer to the instructions in the documentation.

The AC symbol indicates the required nature of the line module input power.

This symbol indicates separate collection for electrical and electronic equipment, mandated

under EU law as of August 13, 2005. All electric and electronic equipment are required to be

separated from normal waste for disposal (Reference WEEE Directive, 2002/96/EC).

This symbol indicates that the power line switch is ON.

This symbol indicates that the power line switch is in the STANDBY position.

This symbol indicates that the power line switch is in the OFF position.

This symbol is used to identify a terminal which is internally connected to the product frame or chassis.

The CE mark is a registered trademark of the European Community. (If accompanied by a year, it is when the design was proven.)

The CSA mark is a registered trademark of the CSA International.

This mark designates the product is an Industrial Scientific and Medical Group 1 Class A product (reference CISPR 11, Clause 5).

This is a marking to indicate product compliance with the Canadian Interference-Causing Equipment Standard (ICES-001).

Direct Current.

IP 2 0 The instrument has been designed to meet the requirements of IP 2 0 for egress and

operational environment.

1-8 Keysight Self-Configured System Installation Guide

Safety and Regulatory Information

Regulatory Information

The RCM mark is a registered trademark of the Australian Communications and Media Authority.

Indicates the time period during which no hazardous or toxic substance elements are expected to leak or deteriorate during normal use. Forty years is the expected useful life of the product.

This symbol on all primary or secondary packaging indicates compliance to China standard GB 18455-2001.

South Korean Certification (KC) mark; includes the marking's identifier code which follows the format: MSIP-REM-YYY-ZZZZZZZZZZZZZZ or KCC-REM-YYY-ZZZZZZZZZZZZ.

Lithium Battery Disposal

If the battery on your network analyzer’s CPU board needs to be disposed of, dispose of it in accordance with your country’s requirements. If required, you may return the battery to Keysight Technologies for disposal. Refer to

“Contacting Keysight” on page 5-4 for assistance.

EMC and Safety Information

EMC Information

Complies with European EMC Directive 2014/30/EU

— IEC/EN 61326-1

— CISPR Pub 11 Group 1, Class A

— AS/NZS CISPR 11

— ICES/NMB-001

This ISM device complies with Canadian ICES-001. Cet appareil ISM est conforme a la norme NMB-001 du Canada.

Keysight Self-Configured System Installation Guide 1-9

1-

Safety and Regulatory Information

Regulatory Information

South Korean Class A EMC declaration:

This equipment has been conformity assessed for use in business environments. In a residential environment this equipment may cause radio interference.

— This EMC statement applies to the equipment only for use in

business environment.

Safety:

Complies with the essential requirements of the European Low Voltage Directive as well as current editions of the following standards (dates and editions are cited in the Declaration of Conformity:

— IEC/EN 61010-1

— Canada: CSA C22.2 No. 61010-1

— USA: UL std no. 61010-1

Acoustic Statement: (European Machinery Directive)

Acoustic noise emission

LpA <70 dB

Operator position

Normal operation mode per ISO 7779

To find a current Declaration of Conformity for a specific Keysight product, go to:

http://www.keysight.com/go/conformity

1-10 Keysight Self-Configured System Installation Guide

Safety and Regulatory Information

N5292A Test Set Equipment Ratings

N5292A Test Set Equipment Ratings

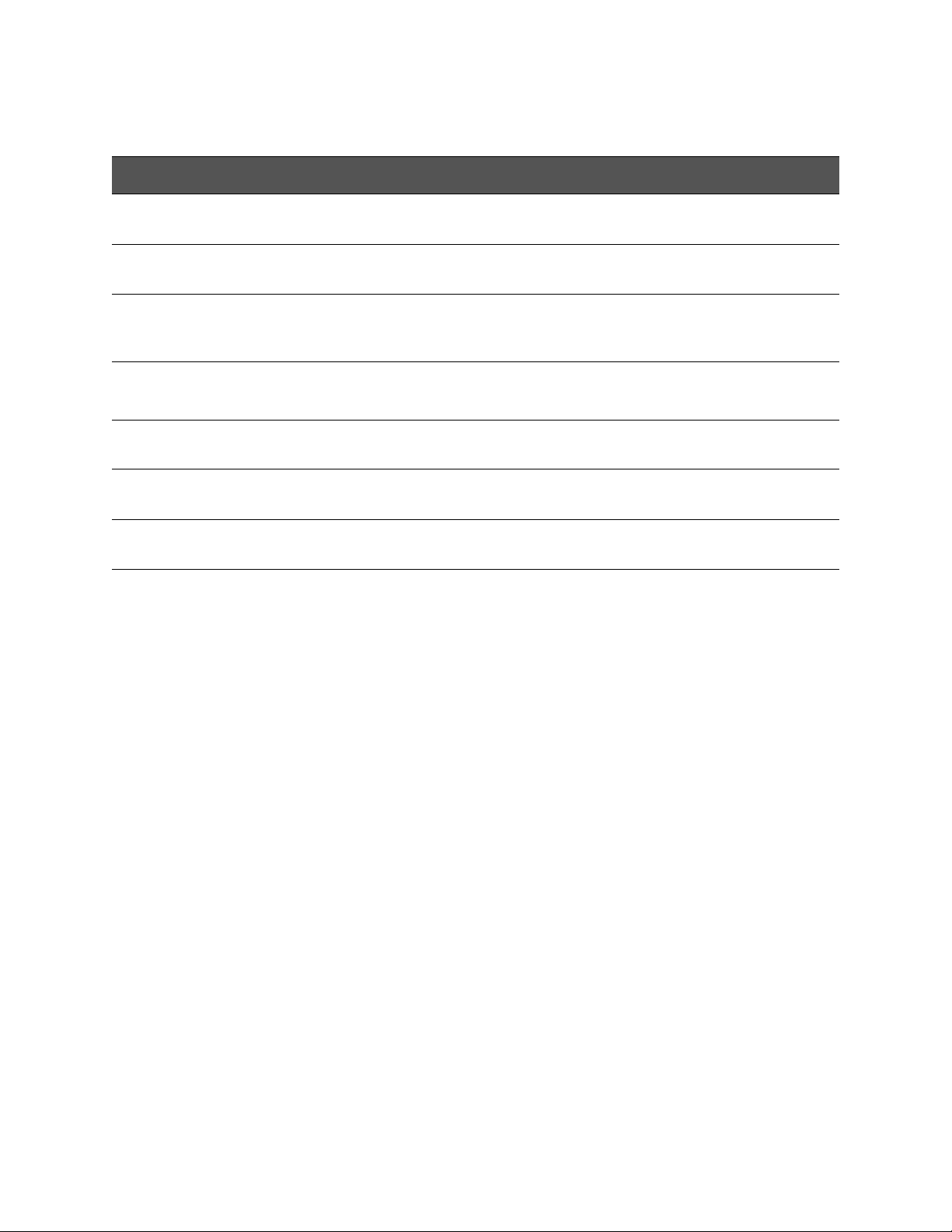

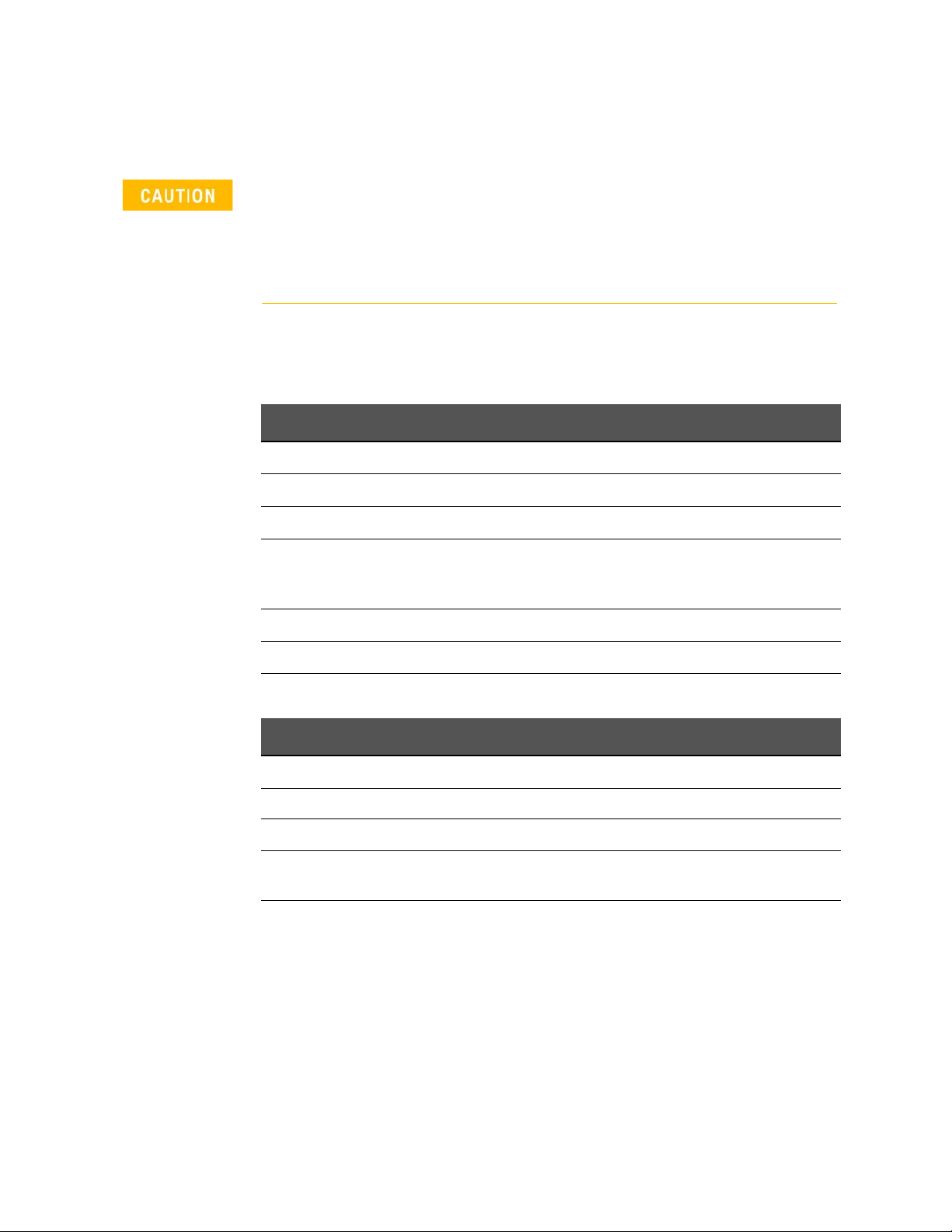

Table 1-1 N5292A Equipment Ratings

Nominal voltage and frequency or range 100/120V/220/240 Vac, 50/60 Hz

Power in watts, VA or current 210 W MAX

Keysight Self-Configured System Installation Guide 1-11

1-

Safety and Regulatory Information

Environmental Requirements

Environmental Requirements

Ventilation Requirements: When installing the product in a cabinet, the

convection into and out of the product must not be restricted. The ambient

temperature (outside the cabinet) must be less than the maximum

operating temperature of the instrument by 4 °C for every 100 watts

dissipated in the cabinet. If the total power dissipated in the cabinet is

greater than 800 watts, then forced convection must be used

The environmental requirements shown below are characteristic for the system and are based on the limitations of the PNA network analyzer used.

Table 1-2 Millimeter-wave System Environmental Conditions (Operating)

Environment Tem perat ure

.

Operation

Storage

Measurement Calibration

Performance Verification

Relative Humidity

Pressure Altitude Type tested 0 to 4600 meters (~15,000 feet)

0

°C to 40 °C (41 °F to 104 °F)

–40

°C to +65 °C (–40 °F to 158 °F)

20

°C to 26 °C (68 °F to 79 °F)

Temperature must be within 1

the temperature at which the measurement

calibration was performed.

Type tested at 95%, +40

Table 1-3 N5292/3/5A Environmental Conditions (Operating)

Environment Tem perat ure

for indoor use only (unless specified otherwise.)

Altitude up to 4,600 meters

Temperature 0 to 40 °C

Relative humidity Type tested, 0 to 95% relative humidity,

0

°C to 40 °C

non-condensing up to 40°C

°C (1.8 °F) of

°C (non-condensing)

System Heating and Cooling

Install air conditioning and heating, if necessary, to maintain the ambient temperature within the appropriate range (as given in the table above). Air conditioning capacity must be consistent with the BTU ratings given in Table

1-2 on page 1-12 and Table 1-3 on page 1-12.

1-12 Keysight Self-Configured System Installation Guide

Safety and Regulatory Information

Site Preparation

Required Conditions for Accuracy Enhanced Measurement

Accuracy-enhanced (error-corrected) measurements require the ambient temperature of the millimeter-wave system to be maintained within ± 1 °C of the ambient temperature at calibration.

Site Preparation

Install the instrument so that the detachable power cord is readily identifiable

and is easily reached by the operator. An externally installed switch or circuit

breaker (which is readily identifiable and is easily reached by the operator)

should be used as the disconnecting device.The detachable power cord can

also be used to disconnect the mains circuits from the mains supply before

other parts of the instrument. The front panel switch is only a standby switch

and is not a LINE switch.

Power Requirements

Before installing the system, be sure that the required ac power is available at all necessary locations.

— Three-wire power cables (which provide a safety ground) must be used with

all instruments.

— Air-conditioning equipment (or other motor-operated equipment) should

not be placed on the same ac line that powers the system.

— The table below lists the maximum VA ratings and BTU/hour ratings for all

instruments in the system. This table can be used to determine both the

electrical requirements and the air conditioning requirements of the system.

Keysight Self-Configured System Installation Guide 1-13

1-

Safety and Regulatory Information

Site Preparation

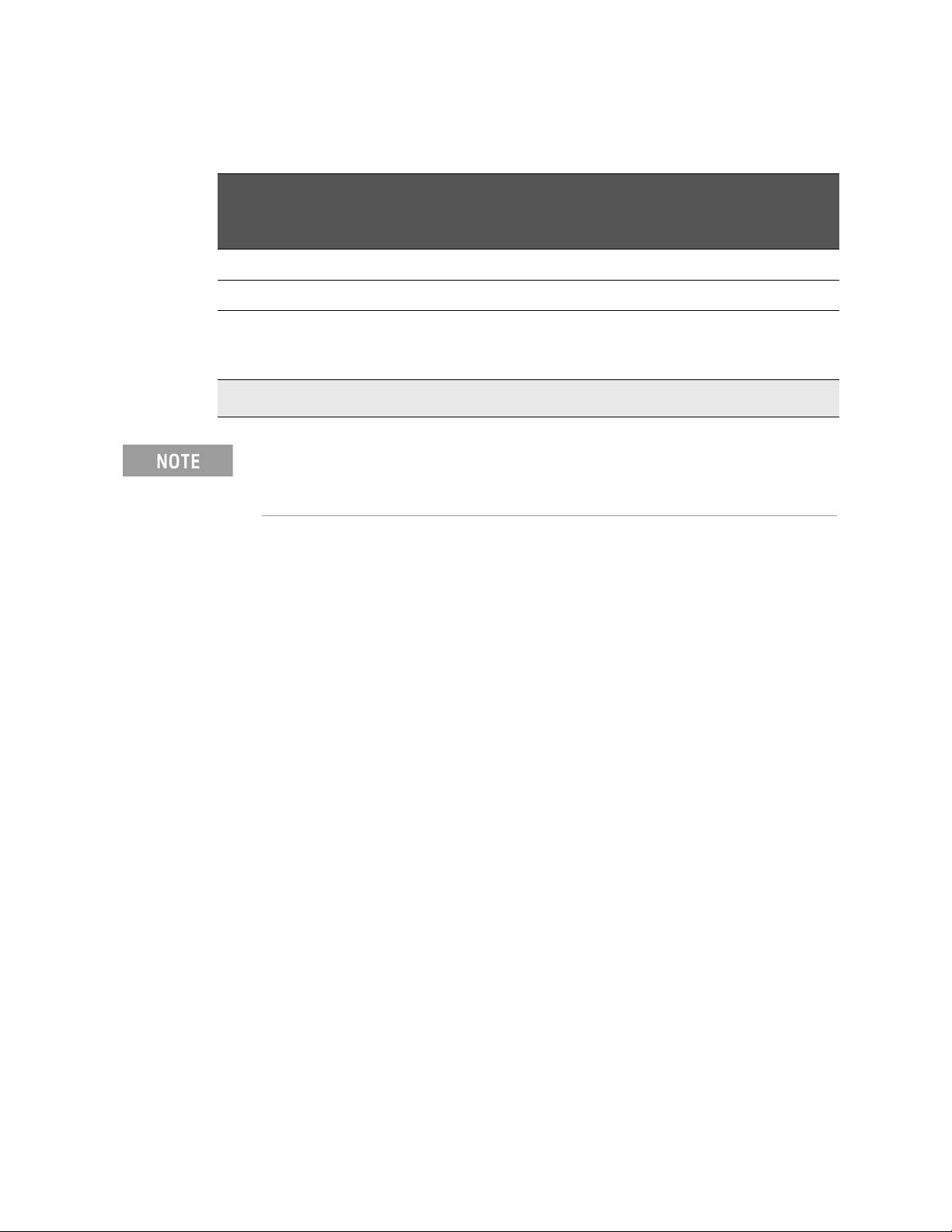

Table 1-4 Power Requirements of the System

Standard Equipment

Instrument Maximum VA Rating Maximum BTU/hour

N522xB and N524xB 350 1195

N5292A millimeter head controller 210 717

OML/VDI millimeter head (x1, x2, x3, or x4)

(Maximum VA rating includes any millimeter heads powered from controller)

(Maximum BTU/hour rating includes any millimeter heads powered from controller)

Tot al 560 1912

Values are verified with 120 Vac supplied to each instrument at 60 Hz.

The N5292A millimeter head controller supplies power to the test head modules.

1-14 Keysight Self-Configured System Installation Guide

Keysight PNA/PNA-X Series

2-Port and 4-Port Self-Configured Microwave Network Analyzer System

Installation Guide

2 System Description

The Low Frequency Extension (LFE) refers to the 900 Hz to 100 MHz

frequency range sold as option 205, 220, 405, and 420 in the N522xB and

option 205, 425, and 429 in the N524xB. All other configuration options are

considered to be "non-LFE". "Broadband" is defined as a system which

can sweep from 900 Hz or 10 MHz to 110/120 GHz.

This document is applicable to non-LFE broadband millimeter-wave

systems and non-LFE and LFE banded millimeter-wave systems. Where

the text applies to both types of systems, "millimeter-wave system" is

used. Where the content is specific to one or the other types of systems,

"non-LFE broadband millimeter-wave system" or "banded

millimeter-wave system" is used.

For N5290/91A LFE broadband millimeter-wave system information refer to

http://literature.cdn.keysight.com/litweb/pdf/N5292-90002.

2-1

2-

System Description

Information in This Chapter

Information in This Chapter

This chapter describes preparing to receiving your 2-port or 4-port self-configured banded or non-LFE broadband millimeter system and the system’s installation procedure(s).

Chapter Two at-a-Glance

Section Title Summary of Content

“Self-Configured Banded or Non-LFE Broadband Millimeter-Wave Network Analyzer System” on page 2-3

“Network Analyzer Requirements” on page 2-8

“N5292A Test Set Description” on page 2-11

“Interconnect Kits, Rackmount Kits, and Optional Parts” on page 2-14

“Compatible Millimeter-wave Modules” on page 2-21

“Basic System Measurement Configurations” on page 2-26

Overview of the banded or non-LFE broadband N52xxB millimeter-wave system.

Description of compatible PNA features.

N5292A test set controller description of front and rear panel features.

Description of the interconnect heads, rackmount kits, and optional parts.

Keysight N5293A/95A millimeter head and OML/VDI millimeter head descriptions of their features.

Millimeter-wave system basic measurement configurations.

2-2 Keysight Self-Configured System Installation Guide

System Description

Self-Configured Banded or Non-LFE Broadband Millimeter-Wave Network Analyzer

System

Self-Configured Banded or Non-LFE Broadband Millimeter-Wave Network Analyzer System

Non-LFE broadband millimeter-wave capability is only available with the

N5293/5A millimeter-wave modules and operates from 10 MHz to

110/120 GHz. For banded systems, the frequency range will vary from

60 GHz to 1.5 THz depending on the OML/VDI millimeter-wave heads

used in the system.

IMPORTANT! Only PNAs and PNA-X network analyzers with a frequency range equal to greater than 20 GHz are compatible with the N5292A test set controller.

IMPORTANT! For additional information on the OML/VDL heads, refer to

“OML/VDI and N5293A/5A Test Heads – Banded Configuration Calibration (Only)” on page 3-21.

Introduction

This section of this document describes system installation and operation for a

banded or non-LFE broadband millimeter-wave system using an N5292A

Millimeter Head Controller. Banded and non-LFE broadband millimeter-wave

systems are made up of three types of major components: a PNA or PNA-X, a

N5292A controller test set, and millimeter-wave heads. These components are

generally purchased separately and assembled by the customer into a system

at the customer's site. This section of the document focuses on receiving the

controller with accessories and then on system installation and operation.

IMPORTANT! For banded systems that are using the OML modules that require DC bias, a separate N5260AK91 power supply and adapter is required. See also, Table 2-9 on page 2-19. And, for VDI modules that require DC bias, use the VDI-175 power supply.

Each OML/VDI module requires a N5290A304 cable adapter to connect to the N5292A test set. See also Table 2-9 on page 2-19.

For additional information on the OML/VDL heads, refer to “OML/VDI and

N5293A/5A Test Heads – Banded Configuration Calibration (Only)” on

page 3-21.

Table 2-3 and Table 2 -4 list compatible PNA and PNA-X models with required

options. Figure 2-10 on page 22 and Figure 2-11 on page 23 list available millimeter-wave modules. Typical system configurations are pictured in Figure

2-1 on page 5, Figure 2-2 on page 5, Figure 2-3 on page 6, and Figure 2-4 on

page 7.

Keysight Self-Configured System Installation Guide 2-3

2-

System Description

Self-Configured Banded or Non-LFE Broadband Millimeter-Wave Network Analyzer

System

The N5292A Millimeter Head Controller is also used as part of the banded and non-LFE broadband analyzer system. Refer to “N5292A Test Set Description”

on page 2-11.

In this document the N5292A will be referred to as the test set.

— The self-configured Non-LFE broadband millimeter-wave system is a 2-port

or 4-port vector network analyzer system 10 MHz to 110 GHz or 10 MHz to

120 GHz.

— The self-configured banded millimeter-wave system is a 2-port or 4-port

vector network analyzer system. The bands are dependent on the type of

OML/VDI heads (60 GHz to 1.5 THz).

The illustration below shows the N52xxB configured for broadband coaxial measurement with Keysight’s N5293/5A millimeter-modules (refer to Figure

2-1 on page 5 and Figure 2-2 on page 5).

The illustrations below shows the third party OML/VDI modules (refer to Figure

2-3 on page 6 and Figure 2-4 on page 7).

2-4 Keysight Self-Configured System Installation Guide

System Description

2-Port N52xxB

PNA Network Analyzer

2-Port N5292A

Millimeter-head

Controller

N5293/5A Millimeter-heads

4-Port N52xxB

PNA Network Analyzer

4-Port N5292A

Millimeter-head

Controller

N5293/5A Millimeter-heads

Self-Configured Banded or Non-LFE Broadband Millimeter-Wave Network Analyzer

System

Figure 2-1 N52xxB 2-Port Non-LFE Broadband Test System – Coaxial Measurement

Configuration (using N5293/5A Millimeter Heads)

Figure 2-2 N52xxB 4-Port Non-LFE Broadband Test System – Coaxial Measurement

Configuration (using N5293/5A Millimeter Heads)

Keysight Self-Configured System Installation Guide 2-5

2-

System Description

Self-Configured Banded or Non-LFE Broadband Millimeter-Wave Network Analyzer

System

Figure 2-3 N52xxB 2-Port Banded Test System – Coaxial Measurement Configuration

(using OML/VDI Millimeter Heads)

2-6 Keysight Self-Configured System Installation Guide

System Description

Self-Configured Banded or Non-LFE Broadband Millimeter-Wave Network Analyzer

System

Figure 2-4 N52xxB 4-Port Banded Test System – Coaxial Measurement Configuration

(using OML/VDI Millimeter Heads)

Keysight Self-Configured System Installation Guide 2-7

2-

System Description

Network Analyzer Requirements

Network Analyzer Requirements

The required options for PNA models are indicated in the “PNA Option(s)” column of Table 2-3 on page 2-10. The required options for PNA-X models are indicated in the “PNA Option(s)” column of Table 2-4 on page 2-10.

The minimum firmware revision for PNA and PNA-X models is ≥A.12.80.

Space Requirements

Standard installation of the N52xxB with N5292A test set millimeter-wave system includes configuration and installation of the system on a customer provided lab bench or table top of adequate size and strength.

N52xxB with N5292A Test Set System Weight and Dimensions

Table 2-1 Stacked System Benchtop Dimensions

Model

2-Port 48 kg to 64 kg 37.5 cm (8U) 48.3 cm 57.8 cm or 65 cm

4-Port 51 kg to 70 kg

1. System benchtop dimensions are dependent on the number of ports, PNA model, and the style of the millimeter-head.

2. Minimum weights calculated with one VDI millimeter-head. Maximum weights calculated with four OML

millimeter-heads.

3. All heights include the height of a single set of instrument feet (1.3 cm).

Weight

2

Required Benchtop Dimensions for the System

3

Height

1

Width Depth

Component Weight and Dimensions

Table 2-1, “Stacked System Benchtop Dimensions,” shows the maximum

weight and dimensions of the N52xxB with N5292A test set millimeter-wave

system components. Refer also to Table 2-2 on page 2-9 for test head module

dimensions.

2-8 Keysight Self-Configured System Installation Guide

System Description

Network Analyzer Requirements

Table 2-2 N52xxB Banded and Non-LFE Broadband Millimeter-wave System

Components Weights and Dimensions

Model Weight

N5221B, N5222B, N5241B, N5242B, N5249B

36 kg to 37 kg,

depending on

Height

1

Width Depth

28.6 cm (6U) 48.3 cm 57.8 cm

hardware options

N5224B, N5225B, N5244B, N5245B

36 kg to 45 kg,

depending on

65 cm

hardware options

N5227B, N5247B 41 kg to 49 kg,

depending on

hardware options

N5292A 9 kg 10.2 cm (2U) 42.6 cm 60 cm

N5293/5A Millimeter-wave test

1.6 kg 9 cm 7.3 cm 16.7 cm

head modules

OML Millimeter-wave test head modules

VDI Millimeter-wave test head modules

1.3 kg to 3 kg

1 kg (Rx) to

1.8 kg (TxRx & TxRef)

6.9 cm (S & T/R)

6.9 cm (T)

3.8 cm (Rx)

3.8 cm (TxRx &

TxRef )

10.9 cm (S & T/R)

10.9 cm (T)

7.6 cm (Rx)

7.6 cm (TxRx &

TxRef )

33 cm (S & T/R)

11.9 cm (T)

8.9 cm (Rx)

21.6 cm (TxRx &

TxRef )

1. All heights include the height of a single set of instrument feet (1.3 cm).

Keysight Self-Configured System Installation Guide 2-9

2-

System Description

System Configurations

System Configurations

Table 2-3 and Table 2-4 on page 2-10 document all supported module

configurations for S-Parameter measurement capabilities for broadband and

banded mm-wave systems using the N5292A Option 200 and N5292A Option

400 test set. See also, Table 2-10 on page 2-22 through Table 2-11 on

page 2-23.

Table 2-3 PNA Based Configurations

PNA Model (s)

N5222B 201, 217, or 219 N5292A-200 N5292A-222

N5224B/5B/7B 201, 217, or 219 N5292A-200 N5292A-224

1. All PNA’s require Option 020.

PNA Options

401, 417, or 419 N5292A-200 N5292A-222

401, 417, or 419 N5292A-200 N5292A-224

1

Test Set Cable Interface

Kit

N5292A-222

N5292A-400 N5292A-442

N5292A-400 N5292A-444

Table 2-4 PNA-X Based Configurations

PNA-X Model (s) PNA

1

Option(s)

N5242B 201, 217, 219, 222, or 224 N5292A-200 N5292A-222

401, 417, 419, 422, or 423 N5292A-200 N5292A-222

Test Set Cable Interface

Kit

N5292A-400 N5292A-442

N5244/5B/47B 201, 217, 219, 222, or 224 N5292A-200 N5292A-224

401, 417, 419, 422, or 423 N5292A-200 N5292A-224

N5292A-400 N5292A-444

1. All PNA-X’s require Option 020.

2-10 Keysight Self-Configured System Installation Guide

Loading...

Loading...