Kerr OPTILUX 501 User manual

OPERATING

INSTRUCTIONS

OPERATING

ds

SYBRON

21

Commerce

TEL.

FAX

(800)

(800)

CE

European

Kerr

Italia

Via

Passanti,

1-84018

ITALIA

+39-081-850-8311

Scafati

Drive,

537-7123 + International

537-7345 = International

Optflux

products

Union

Representative

S.p.A.

332

(SA)

Kerr

DENTAL

Danbury,

@:

are

SPECIALTIES

CT

06810-4153,

internationally

distributed

TEL.

FAX

Kerr

1

Mallard

Mallard

Peterborough,

PE3

ENGLAND

+44-1733-260-998

through

UK

Road,

8YP

USA

(714)

516-7669

(714)

516-7581

Kerr

Corporation

Limited

Business

Bretton

Cambridgeshire

Centre

INSTRUCTIONS

“OPERATING

INSTRUCTIONS

TIONS

OPERATING

INSTRUCTIONS

OPERATING

INSTRUCTIONS

OPERATING

INSTRUCTIONS

OPERATING

INSTRUCTIONS

OPERATING

INSTRUCTIONS

OPERATING

INSTRUCTIO

OPERATING

INSTRUCTIO

OPER

INSTRUCTIO

OPERATING

INSTRUCTIO

Kerr

GmbH

Liststrasse

D76185

GERMANY

+49-721-95567-0

Kerr

Unit

112-118

North

New

AUSTRALIA

+61-29-870-7500

28

Karisruhe

Australia

11

Talavera

Ryde

2113

South

Wales

Pty,

Limited

Road

Kerr

Italia

S.p.A.

Succ.

Francaise

7-9 rue

93100

FRANCE

+33-1-48-51-18-50/60

Sybron

Kitamura

29-24

Bunkyo-Ku,

113-0021

JAPAN

+81-3-5977-3126

du

Sergent

Montreuil

Dental

Bldg.

Honkomagome

Sous

Specialties

Tokyo

960681

Bobillot

2-chome

REV.

Bois

Japan,

D

Inc.

OPTILUX

+

OPERATOR'S

+

MANUEL

MANUAL

D'UTILISATION

501 - CURING

+

MANUAL

+

MANUAL

DEL

DO

LIGHT

USUARIO

OPERADOR

TECHNICAL

1.

DESCRIPTION

2.

ERGONOMIC

3.

SPECIFICATIONS

4.

LAMP

REPLACEMENT

5.

FUSE

REPLACEMENT

6.

TROUBLESHOOTING

DESCRIPTION

FEATURES

AND

EQUIPMENT

CLASS

+

ENGLISH

*

INSTRUCTIONS

7.

SAFETY

8.

ASSEMBLY/MOUNTING

9.

OPERATION

10.

MAINTENANCE

11.

CLEANING/DISINFECTING/STERILIZING

12.

LIABILITY

13.

WARRANTY

14.

ACCESSORIES

15.

FIGURES/PHOTOGRAPHS

—DECLARATION

PRECAUTIONS

FOR

AND

OF

CONFORMITY

USE

REPLACEMENT

PARTS

10

11

16

18

20

21

93

back

TECHNICAL

1.

DESCRIPTION

The

Optilux 501

cured

materials

2.

ERGONOMIC

Many

ergonomic

is a visible

by

dental

features

below:

a)

Carrying

to

handpiece

and

b)

Ventilation

of

handle:

be

used

in

gripping

the

control

as a carrying

place,

the

openings:

unit

openings.

c)

Handpiece

and

prevent

carried.

breakage.

d)

Handpiece

pointing

compromising

e)

Easy

positioned

hand

can

handpiece

of

the

f)

Keypad:

depressed,

g)

Smooth

surfaces

DISINFECTING/STERILIZING

In

in

grip:

away

slip

by

hanger.

The

equipment

for

hanger:

it

from

addition,

placement:

either

the

With

from

around

rotating

raised

with

audio and

easy

curing

professionals.

FEATURES

are

The

recessed

handle.

can

be

top

of

the

The

to

help

The

becoming

the

The

direction

secure

fit.

the

handplece

the

front

the

handle

the

keys

surfaces:

cleaning.

DESCRIPTION

unit

incorporated

back

The

easily

unit.

handle

visual

openings

avoid

hanger

accidentally

hanger

handpiece

for

left

resting

surface

and

forward

of

the

confirmation

The

Refer

for

details.

carried

liquids

is

material

or

keypad

intended

at

unit

are

into

the

is

by

placing

hidden

for

the

top

well

of

from

designed

to

dislodged

is

durable

can

be placed in

right

handed

in

Its

of

the

control

grip

it

comfortably.

while

lifting

provide a tactile

of

Optilux

SECTION

to

is

polymerization

Optilux

balanced

on

entering.

501

the

unit

fingers

the top

secure

when

and

was

and,

in

and

Do

the

resistant

the

operators,

hanger,

unit

so

the

that a gloved

Remove

the

handpiece

the

selection.

designed

with

CLEANING/

11,

of

light

as

defined

designed

with

the

the

recess

bottom

not

cover

handpiece

the

unit

is

to

hanger,

without

handle

feel

smooth

is

the

out

when

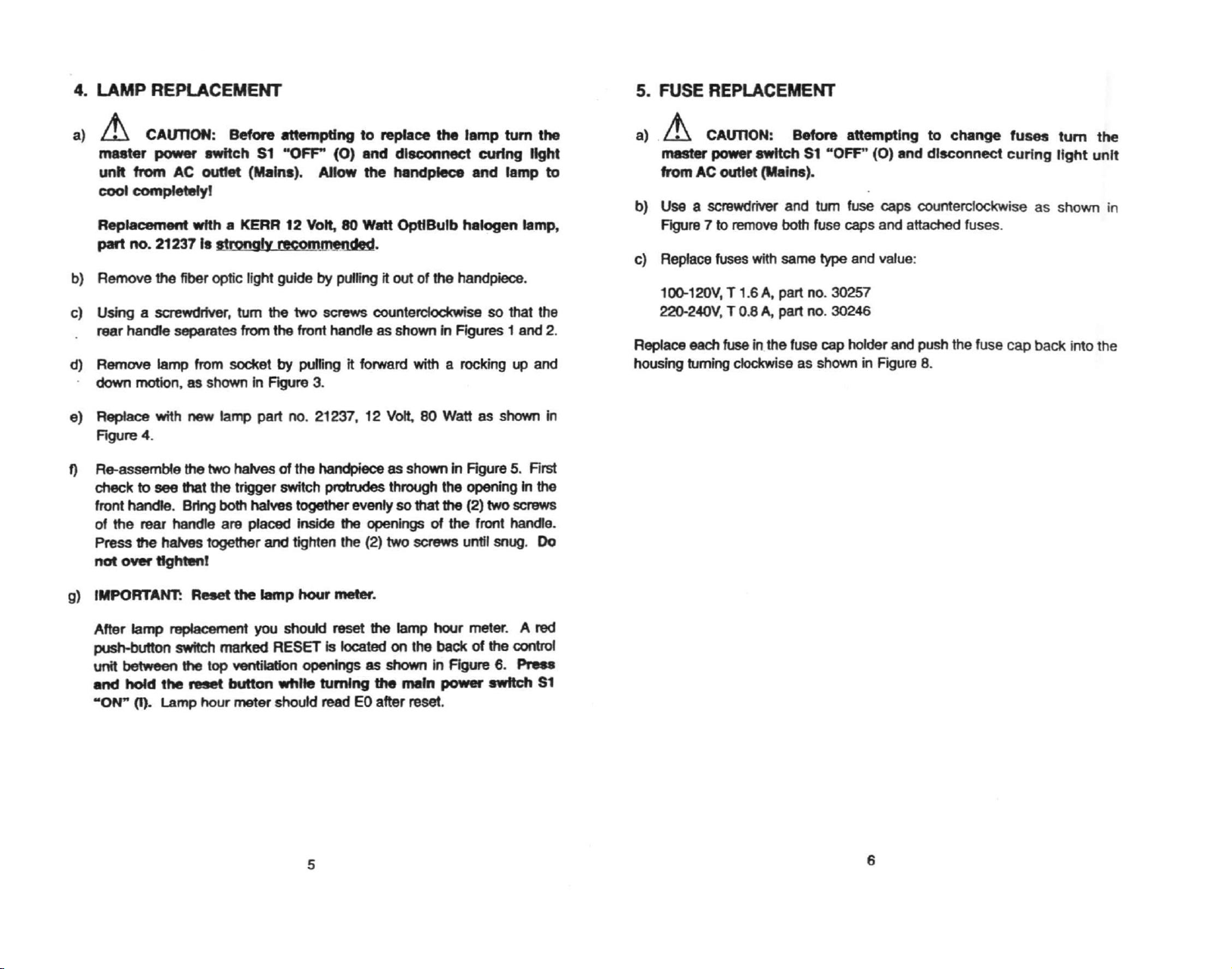

SPECIFICATIONS

AC

supply

connection:

Power

input:

Equipment

9)

Output

n

o)

P)

9)

Protection

electric

Protection

Transport

Fuses

Output

class:

from

shock:

from

ingress

of

liquids:

Environment:

and

*

Ambient

+

Relative

+

Atmospheric

(2

per

unit):

wavelength

fight

Intensity:

+

10,

20,

*

R,

B,

BLEACH

storage:

30,

temperature

humidity

pressure

range:

40,

C

AND

EQUIPMENT

100-120V-/2.0A,

220-240V-/1.0A,

160

VA,

+

Type

None

Equipment

of a fiammable

nitrous

-40*F

10%

to

-5

atm

Continuous

duty

100-120V, T 1.6

220-240V, T 0.8

12

Volt,

400-505

850

mW/cm*

1000

(mWicr? = milliwatts

400-510

100-1999

100

mW/om

11mm

8mm

turbo+

8.0"

(20.5

7.5"

(19.0

6.25"

10

oz.

6

Ib. 6 oz.

Handpiece

-

nominal

BF

[X]

not

oxide

to

158*F

100%,

to

1.0

operation

cycle

of 1 minute

80

Watt

nm

(nanometers)

mW/cm*

nm

mW/cm*

curved

curved

cm)

cm)

(16.0

cm)

(300

g.)

(2.9 kg.)

thermostat

o

50/60

50/60

D

suitable

anaesthetic

(-40°C

including

atm

(501

with

A,

part

A,

part

OptiBub,

minimum

minimum

per

light

quide,

light

CLASS

Hz

Hz

for

use

In

mixture

to

+70°C)

condensation

hPa

to

1060

intermittent

ON/4

minutes

no.

30257.

no.

30246

part

no.

using

8mm

using

8mm

centimeter

part

no.

guide,

part

protection

O

the

presence

with

hPa)

loading,

OFF

E

21237

curved

curved

square)

20898

no.

air

or

turbo+

turbo+

952213

light

light

guide

guide

3

LAMP

REPLACEMENT

5.

FUSE

REPLACEMENT

A

master

unit

cool

CAUTION:

power

from

completely!

Replacement

part

no.

21237

Remove

b)

Using a screwdriver,

c)

rear

Remove

down

Replace

e)

Figure

Re-assemble

check

front

of

the

Press

not

the

handle

lamp

motion,

with

4.

to

see

handle.

rear

the

over

tighten!

separates

handle

halves

Before

switch

AC

outiet

with a KERR

is

strongly

fiber

optic

from

from

socket

as

shown

new

lamp

the

two

halves

that

the

trigger

Bring

both

are

together

attempting

S1

“OFF”

(Mains).

12 Volt,

recommended.

light

guide

tum

the two

the

front

by

pulling

in

Figure

3.

part

no.

of

the

switch

halves

placed

and

together

inside

tighten

to

(0)

and

Allow

by

screws

21237,

handpiece

the

80

Watt

pulling

counterclockwise

handle

it

forward

12

protrudes

evenly

the

openings

the

(2)

replace

disconnect

handpiece

OptiBulb

it

out

of

as

shown

with a rocking

Volt,

80

as

shown

through

so

that

of the

two

screws

the

lamp

curing

and

halogen

the

handpiece.

so

in

Figures 1 and

Watt

as

in

Figure

the

opening

the

(2)

two

front

until

turn

light

lamp

that

up

shown

5.

in

screws

handle.

snug.

the

to

lamp,

the

2.

and

in

First

the

Do

a)

A

CAUTION:

master

from

b)

Use a screwdriver

Figure 7 to

c)

Replace

power

AC

fuses

outlet

remove

100-120V, T 1.6

220-240V, T 0.8

Replace

housing

each

fuse

tuming

switch

(Mains).

and tum

both

with

same

A,

part

A,

part

in

the

clockwise

Before

S1

fuse

type

no.

no.

fuse

cap

as

shown

attempting

“OFF”

fuse

caps

and

30257

30246

holder

in

to

(0)

and

disconnect

caps

counterclockwise

and

attached

value:

and

push

Figure

8.

change

fuses.

the

fuse

fuses

curing

as

cap

back

turn

light

shown

into

the

unit

in

the

IMPORTANT:

9)

After

push-button

unit

between

and

hold

“ON”

lamp

replacement

switch

the

(I).

Lamp

Reset

the

reset

the

marked

top

ventilation

button

hour

meter

lamp

you

hour

should

RESET

openings

while

should

meter.

reset

is

located

turning

read

EO

the

as

the

after

lamp

on

the

shown

main

reset.

hour

meter. A red

back

of

in Figure

power

the

control

6.

Press

switch

S1

Loading...

Loading...