Installation, Operation and

Service Manual

GEMINI 3T & 5T / ECLIPSE 3T

80% + EFFICIENCY

GAS FIRED LOWBOY FURNACE

KLR- FRONT KLR- REAR KLR- REAR KLF- FRONT

GEMINI 3T & 5T ECLIPSE 3T

INSTALLATIONS MUST MEET ALL LOCAL AND FEDERAL

CODES THAT MAY DIFFER FROM THIS MANUAL

Please read the manual in its entirety before beginning installation.

This manual must be kept with the furnace for future reference.

GRANBY FURNACES INC.

PO Box 637

12118 Hwy 209

Parrsboro Nova Scotia Canada

B0M 1S0

902-254-2543

www.granbyindustries.com 04-07-2015 G2014-E7 Rev. A

1

TABLE OF CONTENTS

Gemini & Eclipse

Gas

1.0 IMPORTANT SAFETY ADVICE 3

2.0 PRODUCT INFORMATION 5

3.0 FURNACE INSTALLATION 8

4.0 ACCESSORIES INSTALLATION 15

5.0 BURNER INSTALLATION AND SPECIFICATIONS 17

5.1 ASSEMBLY & INSTALLATION OF BURNER 17

5.2 GAS-FIRED FURNACE LIGHTING INSTRUCTIONS 18

5.3 TECHNICAL INFORMATION / SET-UP 19

6.0 FURNACE OPERATION AND SETTINGS 21

6.1 BLOWER SETTING 21

6.2 FAN TIMER CONTROL BOARD (ST9103 A 1028) 22

6.3 (ST9103 A 1028) CONTROL BOARD SEQUENCE 23

6.4 SERVICING – FAN TIMER (ST9103 A 1028) 24

7.0 SERVICE 26

8.0 ELECTRICAL / WIRING DIAGRAM 30

HEATING & COOLING – RIELLO BURNER 30

HEATING ONLY (2 WIRES THREMOSTAT 31

9.0 START-UP TEST RESULTS 32

10,0 TEST PROCEDURES 33

2

NOTE: THE BURNER INSTRUCTION MANUAL AND THE

BURNER USER’S INFORMATION MANUAL ARE

CONSIDERED PART OF THIS MANUAL AND THEIR

INSTRUCTIONS MUST BE FOLLOWED EXCEPT WHEN

SPECIFICALLY MENTIONNED IN THIS MANUAL.

WARNING: If the information in this

manual is not followed exactly, a fire or

explosion may result, causing property

damage, personal injury or death.

- Do not store or use gasoline or other

flammable vapors or liquid in the vicinity of

this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

o Do not try to light the appliance,

o Do not touch any electrical switch; do not

use any phone in your building,

o Immediately call your gas supplier from an

outside phone. Follow the gas supplier’s

instructions,

o If you cannot reach your gas supplier, call

the fire department.

- Installation and service must be performed

by a qualified installer, service agency or

the gas supplier.

3

1.0 IMPORTANT SAFETY ADVICE

Please read and understand this manual before installing, operating or servicing the

furnace. To ensure you have a clear understanding of the operating procedures of the unit

please take the time to read the IMPORTANT SAFETY ADVICE section of this manual.

• Use only with Natural gas or Propane gas. Refer to the furnace rating plate.

• Install this furnace only in a location and position as specified in Section 3 of

these instructions.

• Provide adequate combustion and ventilation air to the furnace space as

specified in Section 3 of these instructions.

WARNING

FIRE OR EXPLOSION HAZARD

Never test for gas leaks with an open flame. Use a commercially available soap

solution made specifically for the detection of leaks to check all connections, as

specified in Section 5 of these instructions.

• Always install furnace to operate within the furnace’s intended temperature-rise

range with a duct system that has an external static pressure within the allowable

range, as specified in Section 5 of these instructions. See furnace rating plate.

• When a furnace is installed so that supply ducts carry air circulated by the

furnace to areas outside the space containing the furnace, the return air shall also

be handled by duct(s) sealed to the furnace casing and terminating outside the

space containing the furnace.

• This gas-fired furnace is not intended for installation in a residential garage.

• This furnace is not factory approved for installation at altitude higher than 2000

feet.

• Excessive exposure to contaminated combustion air will result in safety and

performance related problems.

o Sample List of Contaminants to be Avoided

The recommended source of combustion air is to use the outdoor air

supply. However, the use of indoor air in most applications is

acceptable except as follows:

• 1. If the furnace is installed in a confined space it is

recommended that the necessary combustion air come from

the outdoors by way of attic, crawl space, air duct, or direct

opening.

• 2. If outdoor combustion air is used, there must be no

exposure to the installations or substances listed in “3” below.

• 3. The following types of installation may require OUTDOOR

AIR for combustion, due to chemical exposures:

o - Commercial buildings

o - Buildings with indoor pools

o - Furnaces installed in laundry rooms

4

o - Furnaces installed in hobby or craft rooms

o - Furnaces installed near chemical storage areas

o Exposure to the following substances in the combustion

air supply may also require OUTDOOR AIR for

combustion:

- Permanent wave solutions

- Chlorinated waxes and cleaners

- Chlorine based swimming pool chemicals

- Water softening chemicals

- De-icing salts or chemicals

- Carbon tetrachloride

- Halogen type refrigerants

- Cleaning solvents (such as perchloroethylene)

- Printing inks, paint removers, varnishes, etc.

- Hydrochloric acid

- Cements and glues

- Antistatic fabric softeners for clothes dryers

- Masonry acid washing materials

WARNINGS

NEVER burn garbage or paper in the unit.

NEVER store combustible material around it.

CAUTION

DO NOT START THE BURNER UNTIL ALL FITTINGS, COVERS AND DOORS ARE IN

PLACE. DO NOT TAMPER WITH THE FURNACE OR CONTROLS, CALL A QUALIFIED

BURNER TECHNICIAN. DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPOURS AND LIQUIDS IN THE VICINITY OF THIS UNIT OR ANY OTHER APPLIANCE.

DANGER

Do not use this furnace as a construction heater. Use of this furnace as a construction

heater exposes it to abnormal conditions, contaminated combustion air and lack of air

filtering. Failure to follow this warning can lead to premature furnace failure which could

result in a fire hazard and/or bodily harm and/or material damage.

IMPORTANT

This manual contains instructional and operational information for the GEMINI 3T & 5T/

ECLIPSE 3T OIL-FIRED FRONT / REAR FURNACE. Read the instructions thoroughly before

installing furnace or starting the burner. Consult local authorities about your local FIRE

SAFETY REGULATIONS. All installations must be in accordance with local state or provincial

codes. Improper installation will result in voiding of warranty.

THE INSTALLATION OF YOUR GAS-FIRED FURNACE MUST CONFORM TO THE

REQUIREMENT OF THE AUTHORITY HAVING JURISDICTION OR IN THE ABSENCE

OF SUCH REQUIREMENTS, TO THE NATIONAL FUEL GAS CODE ANDSI Z223.1/NFPA

54 AND/OR NATIONAL GAS AND PROPANE INSTALLATION CODE CAN/CSA B149.1

.

5

2.0 PRODUCT INFORMATION

CLEARANCE (minimum) TO COMBUSTIBLES

Top of Supply Plenum 1” (25 mm)

Front (Maintenance) 24” (610 mm)

Rear (Maintenance) 24” (610 mm)

Side – Non-Access 1” (25 mm)

Side – Access maintenance 24” (610 mm)

Flue Pipe 9” (229 mm)

Floor (Can be installed directly on combustible or non-combustible)

Furnaces for indoor installation on combustible flooring shall not be installed directly

on carpeting, tile or other combustible material other than wood flooring.

DRAFT PRESSURE

Breech draft pressure -0.01” wc minimum

AIR/BLOWER DATA

Maximum external static pressure 0.5” wc

Maximum cooling unit capacity 3.0 tons & 5.0 Tons

Maximum air temperature rise See pages 19,20 and 33

High Limit temperature 185°F

Thermostat anticipator See thermostat instructions

MOTOR/BLOWER

Gemini 3T / Eclipse 3T: 1/2 hp 4 Speed / G10-8 DD or 1/2 hp ECM / G10-8

Gemini 5T: ¾ hp / G12-10 DD or ¾ hp ECM / G12-10 DD

FAN/HIGH LIMIT CONTROL

Honeywell ST9103A1028 Fan Center & Thermo-Disk (7” stem)

THERMOSTAT

Any wall thermostat

ELECTRICAL – 120 Volts, 60 Hz

Canada Less than 12 amps. circuit protection 15 amps.

USA 13.3 amps, circuit protection 20 amps.

FLUE-PIPE CONNECTION

5” Chimney

AIR FILTERS

Gemini 3T / Eclipse 3T : 20” x 20” x 2” non pleated UL approved

Gemini 5T Rear: 20” x 20” x 2” & 15” x 20” non pleated UL approved

Gemini 5T Front: Two 15” x 20” non pleated UL approved

6

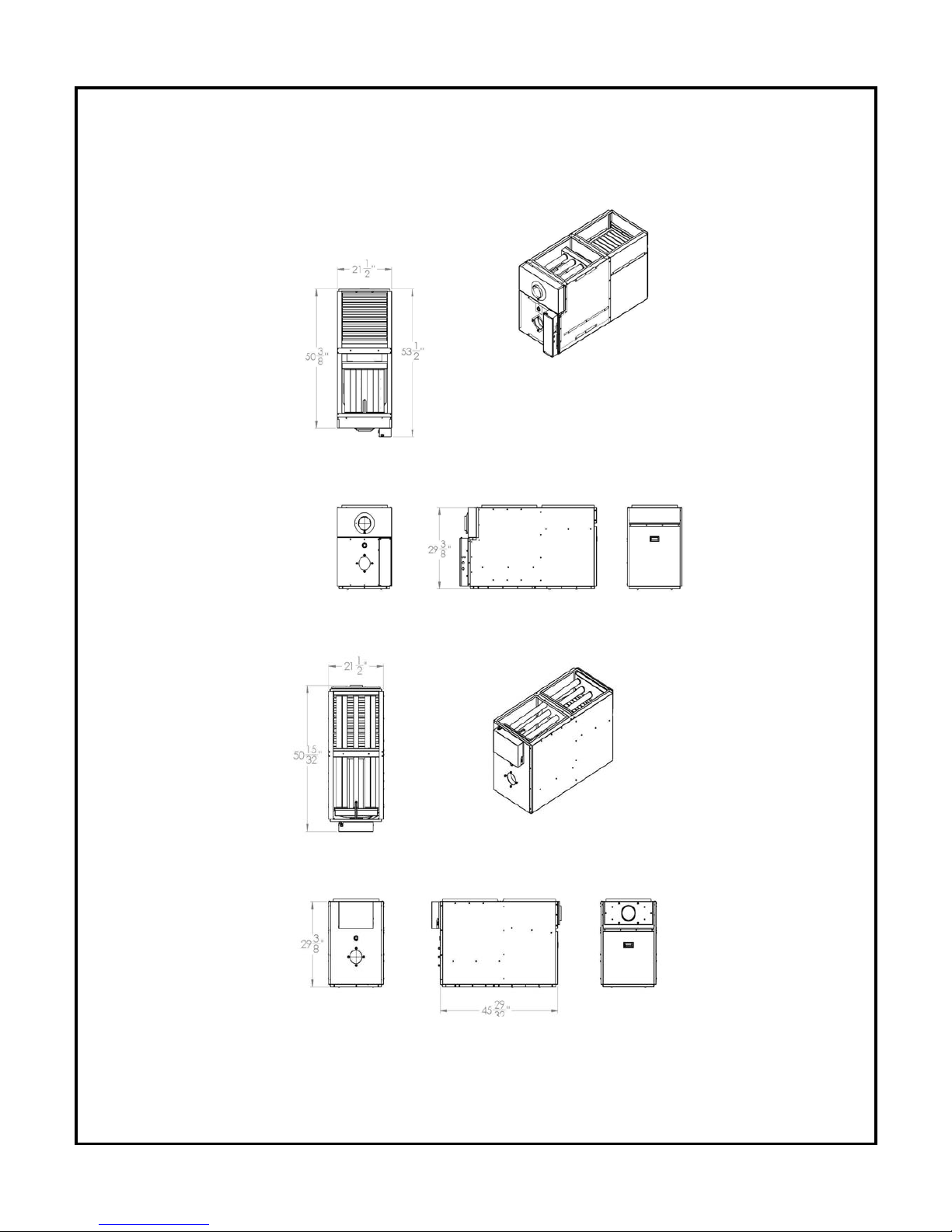

PLENUM (GEMINI 3T & 5T) REAR / FRONT

Cold air return 19” x 20” (483 x 508 mm)

Hot air supply 23-7/8” x 20” (606 x 508 mm)

Plenum spacing 3T: 1-3/4” (45mm)

5T: 2-3/4” (70mm)

GEMINI 3T/5T FRONT (KLF)

GEMINI 3T/5T REAR (KLR)

7

PLENUM (ECLIPSE 3T) REAR / FRONT

Cold air return 18” x 20-3/4” (457 x 527 mm)

Hot air supply 18” x 21-3/4” (457 x 552 mm)

Plenum spacing 2” (50mm)

ECLIPSE 3T FRONT (KLF)

ECLIPSE 3T REAR (KLR)

8

3.0 FURNACE INSTALLATION

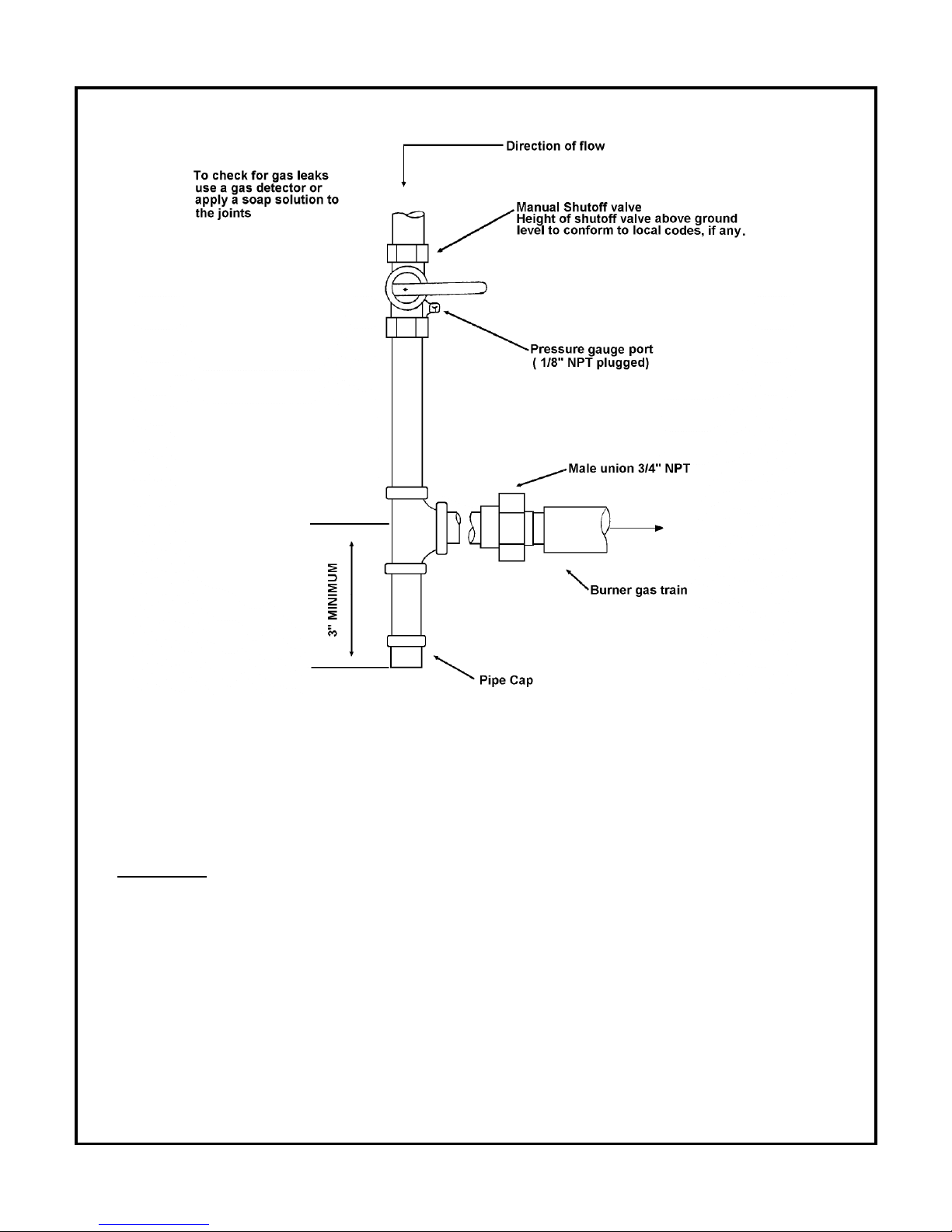

GAS PIPING

Gas piping must conform to local requirements.

Install according to the applicable code such as NATIONAL FUEL GAS CODE ANDSI

Z223.1/NFPA 54 AND/OR NATIONAL GAS AND PROPANE INSTALLATION CODE

CAN/CSA B149.1.

The gas piping must be installed between the gas meter and the combination gas valve

(located upstream of the Riello gas burner on the furnace. The gas valve has a knob acting as

a shut-off valve to stop gas flow. It is recommended to install a manual shut-off valve upstream

of the gas valve to facilitate service of the gas valve. The gas valve also has pressure tapping

for inlet pressure as well as outlet pressure. The outlet pressure of the gas valve is also

referred as manifold pressure in this manual.

If local codes allow the use of a flexible gas appliance connector, always use a new

listed connector. Do not use a connector which has previously serviced another gas

appliance

WARNING:

• Connect from the gas supply to the burner combination gas valve inlet using new, clean

black iron pipe and malleable iron fittings only. Do not use copper, brass, cast iron or

galvanized pipe or fittings.

• Provide support for gas piping. Do not rest weight of piping on burner gas valve.

• Apply pipe dope sparingly at all joints. Use only pipe dope listed for use with propane

gas. Do not use pipe sealing tape. In doubt consult CSA B149.1 or NFPA 54 or the

authorities having jurisdiction.

• Do not hold gas valve with a pipe wrench. Use crescent wrench or other smooth jawed

device. Do not over-tighten.

• Failure to comply with above could result in severe personal injury, death or

substantial property damage.

1. If possible, install a new gas line directly from the gas meter. If you are using an existing

gas line, verify it is clean and in good condition and verify it is large enough to handle the

load of all connected appliances. See the table below for guidance on pipe sizes.

2. When branching from a common gas line, do not tap from the bottom or horizontal sections,

only from the side or top.

3. Install a main manual shutoff valve, sediment trap a

nd ground joint union near the burner

combination gas valve connection as shown below.

9

GAS SUPPLY PRESSURE

• Maximum supply pressure: 13 inches W.C.

• Minimum supply pressure: 7” inches W.C.

•

WARNING:

• Do not expose the combination gas valve to gas pressures in excess of 14” W.C. The

valve has a safety mechanism that interrupt the flow of gas over 14” W.C. In any event

higher pressure could damage the valve seat, resulting in potentially hazardous

conditions. When pressure testing at higher pressures, disconnect burner from gas line

before testing.

10

• If the gas supply pressure can exceed 14 inches of water column at any time, you must

install a lockup type gas pressure regulator in the gas supply piping, ahead of the main

manual gas valve on the burner.

• The furnace and its gas connections must be leak tested before placing the boiler in

operation.

• Enough combustion air should be provided to the gas-fired furnace in accordance with

the section “Air for combustion and ventilation” of the National Fuel Gas Code ANSI

Z223.1/NFPA 54 or clause 8,2, 8,3 or 8.4 of Natural gas and Propane installation code

CAN/CSA B149.1, or applicable provisions of the local building codes.

TEST AND PURGE GAS LINE

1. Read warning above.

2. Pressure test and purge the line. Pressure testing should be done by the gas supplier or

utility, following all applicable codes.

11

PLACEMENT & VENTING

THE INSTALLATION OF YOUR GAS-FIRED FURNACE MUST CONFORM TO

THE REQUIREMENT OF THE AUTHORITY HAVING JURISDICTION OR IN

THE ABSENCE OF SUCH REQUIREMENTS, TO THE NATIONAL FUEL GAS

CODE ANDSI Z223.1/NFPA 54 AND/OR NATIONAL GAS AND PROPANE

INSTALLATION CODE CAN/CSA B149.1.

FLOOR SUPPORT COMBUSTIBLE – If required, support furnace on five (5) concrete

blocks. Make sure the center of the furnace base is supported. For a

furnace installed on a combustible floor, consult the applicable code and

authorities having jurisdiction on this application. The floor must support

the weight.

CHIMNEY/VENT Breech is certified for 5” vent pipe. Keep vent/flue pipe as short as

possible with min. 1/4” per foot upward slope. Vent/flue pipes MUST

NOT pass through a ceiling. Maximum flue gas temperature is 480°F.

ADDITIONAL CHIMNEY INFORMATIONS

WARNING

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each appliance connected to the venting

system being placed into operation could result in carbon monoxide poisoning or

death.

When an existing furnace is removed from a common venting system, the common venting

system is likely to be too large for proper venting of the appliances connected to it. At the time

of removal of the existing furnace, the following steps shall be followed with EACH appliance

remaining connected to the common venting system, while the other appliances remaining

connected to the common venting system are not in operation:

1. Seal any unused openings in the venting system.

2. Visually inspect the venting system for proper size and horizontal pitch and determine

there is no blockage or restriction, leakage, corrosion and other deficiencies which could

cause an unsafe operation.

3. Insofar as is practical, close all building doors and windows and all doors between the

space in which the appliances remaining connected to the common venting system are

located and other spaces of the building. Turn on clothes dryer and any appliance not

connected to the common venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will operate at maximum speed. Do not operate

a summer exhaust fan. Close fireplace dampers.

4. Place in operation the appliance being inspected. Follow the lighting instructions. Adjust

thermostat operation so appliance will operate continuously.

12

5. Test for spillage at the draft regulator outlet / draft hood opening after 5 minutes of main

burner operation. Use the flame of a match or candle, or smoke from a cigarette, cigar,

or pipe.

6. After it has been determined that each appliance remaining connected to the common

venting system properly vents when tested as outlined above, return doors, windows

exhaust fans, fireplace dampers and any other gas-burning appliance to their previous

condition of use.

7. Any improper operation of the common venting system should be corrected so the

installation conforms with the National fuel gas code ANSI Z223.1/NFPA 54 and/or the

Natural gas and propane installation code CAN/CSA B149.1. When resizing any portion

of the common venting system, the common venting system should be resized to

approach the minimum size as determined by the appropriate tables in chapter 13 of the

National fuel gas code ANSI Z223.1/NFPA 54 and/or the Natural gas and propane

installation code CAN/CSA B149.1.

• Vent installations shall be in accordance with Part 10, Venting of Equipment, and

Part 13, Sizing of Category I Venting Systems, CSA B199.1, of the National Fuel

Gas Code, ANSI Z223.1/NFPA 54 , and/or Section 7, Venting Systems and Air

Supply for Appliances, and Appendix C, Vent Sizing Tables for Category I Natural

Gas and Propane Appliances, of the Natural Gas and Propane Installation Code,

CSA B149.1, the local building codes, furnace and the vent manufacturer’s

instructions.

• Multistory common venting is not permitted for the KLR/KLF gas fired furnaces.

• KLR/KLF gas fired furnaces MUST be vented vertically.

• The furnace shall be connected to a factory built chimney or vent complying with

a recognized standard, or a masonry or concrete chimney lined with a lining

material acceptable to the authority having jurisdiction. Venting into an unlined

masonry chimney or concrete chimney is prohibited.

For furnaces for connection to gas vent or chimneys such as the KLR/KLF furnace, vent

installation must be in accordance with “Venting of equipment” of the National fuel gas code

ANSI Z223.1/NFPA 54 or “Venting systems and air supply for appliances” of the Natural gas

and propane installation code CAN/CSA B149.1, or applicable provisions of the local building

codes.

Vent connectors serving appliances vented by natural draft shall not be connected into any

portion of mechanical draft system operating under positive pressure.

Use of cellular core PVC (ASTM F*891), cellular core CPVC or Radel (Polyphenolsulfone) in

venting systems shall be prohibited.

Connecting non-metallic vent pipe and fittings with thermal insulation shall be prohibited.

13

Horizontal portions of the venting system shall be supported to prevent sagging by installing

support every 36 inches. The horizontal runs must be sloping upwards not less than ¼ inch per

foot from the boiler to the chimney connector.

A furnace shall not be connected to a chimney flue serving a separate appliance designed to

burn solid fuel.

Provisions for adequate combustion and ventilation air shall be in accordance with one of the

following:

1. Section 5.3, Air for Combustion and Ventilation, of the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 ,

2. Sections 7.2, 7.3 or 7.4 of Natural Gas and Propane Installation Code, CSA B149.1 ,

3. Applicable provisions of the local building code.

CONDENSATION If you have condensation in your chimney, make sure that the

chimney size is according to the tables in THE NATIONAL FUEL

GAS CODE ANDSI Z223.1/NFPA 54 AND/OR NATIONAL GAS AND

PROPANE INSTALLATION CODE CAN/CSA B149.1. The

temperature at the entrance of the chimney can be increased by

insulating the flue-pipe between the furnace and the chimney base.

If this is not sufficient, consider cutting or removing some flue

baffles in the furnace.

CHIMNEY VENT Furnace is approved for factory built chimney type “L” vents. Breech is

certified for 5” vent pipe. Keep vent/flue pipe as short as possible with a

minimum upward slope of ¼’’ per foot. Vent/flue pipes MUST NOT pass

through a ceiling. Maximum flue gas temperature is 575°F.

COMBUSTION & Install openings and ductwork to the furnace room providing fresh out-

VENTILATION AIR side combustion and circulation air for cooling the furnace casing, as

installation code requires. If installed in a closed room, provide two free

air ventilation openings of at least 8” x 12” (96 sq. in.) free flow area near

ceiling and floor. Gas burners must have sufficient air to allow vent

systems to operate properly.

14

DRAFT Use approved DOUBLE ACTING draft control supplied for 5” pipe. Set

specified draft minimum pressure of -0.01” wc. THE CHIMNEY MUST

BE EQUIPPED WITH A DOUBLE ACTING DRAFT REGULATOR.

FAILURE TO COMPLY WITH THIS MAY RESULT IN IMPROPER

OPERATION LEADING TO POTENTIAL DANGEROUS OPERATION

OF UNIT AND INJURIES TO PERSON AND LOSS OF LIFE.

ELECTRICAL Wire according to the National Electrical Code (Canadian Electrical

Code in Canada) or local codes. Use a separately fused #12 electrical

line directly from the service panel to the furnace junction box. Install a

manual shut-off switch at the door or stairway to furnace room so

furnace can be shut off remotely.

The furnace must be electrically grounded in accordance with local

codes or, in the absence of local codes, with the National Electrical

Code, ANSI/NFPA 70, and/or the Canadian Electrical Code , CSA

C22.1, Part 1, if an external electrical source is utilized

The wiring shall conform with the temperature limitations of 63°F

(35°C) rise.

The furnace shall be installed so the electrical components are

protected from water.

CLEARANCES Before placing unit, review installation clearances as shown on furnace

operating decal or section PRODUCT INFORMATION (page 5).

LOCATION Install the furnace close to chimney and central to ductwork.

15

4.0 ACCESSORIES INSTALLATION

BLOCKED VENT SWITCH (BVSO) FOR CANADIAN APPLICATION ONLY

Oil-fired appliances installed in Canada require a blocked vent switch system when installed on

a chimney. A safety switch is included with the furnace to perform this function. It is the

installer’s responsibility to install the switch in accordance with the instructions provided. Not

applicable for direct vent systems. Field Controls Model: WMO-1 (Manual Reset)

Switch Operation

Blocked vent switches are flue gas safety devices for detecting spillage of flue gases due to a

blocked flue or inadequate draft. After detecting a problem, the switch de-energizes the

system’s burner control.

NEVER reset the switch unless the cause of the blockage has been corrected.

Installation

1) Drill a 5/8” hole in to the flue vent pipe near the appliance breech connection.

2) This hole must be before the draft regulator, vertically or horizontally.

3) Remove one of the securing nuts from the threaded tube of the safety switch.

4) Tighten the other securing nut onto the pipe as far as possible (Figure 1).

5) Insert the threaded tube end into the pierced hole of the flue vent pipe.

6) Install the securing nut on the safety switch tube, which protrudes into the flue vent pipe.

Tighten the nut securely (Figure 1).

Figure 1 – Illustration Granby Industries Figure 2 - BVSO wiring diagram

Wiring Instructions (BVSO)

Caution: Disconnect the electrical power when wiring the unit.

Wire the blocked vent switch in accordance with The National Electrical Code and applicable

local codes. Wire the safety switch (BVSO) in series with the thermostat and the fan timer

relay control (Figure 2).

16

System Test Procedure (BVSO)

1) With the power re-established, block the chimney or vent pipe downstream of the switch.

2) Adjust the thermostat to call for heat.

3) Once the heating system has started the blocked vent switch should shut down the burner

within 10 minutes or sooner.

4) Once the system has cooled, the blocked vent switch can manually be reset.

5) This procedure should be tested a second time.

6) After testing the blocked vent switch the chimney should be cleared of obstruction and the

heating system should be tested over a long run cycle.

If the block vent switch shuts down the system, check to ensure there is enough draft in the

chimney and venting pipes.

AIR CONDITIONING

An air conditioning coil may be installed on the supply side only. Coils installed on the return

side will cause condensation on the heat exchanger; this will shorten the heat exchanger life

and may cause products of combustion to enter the house. Wire as per wiring label and

diagram. Height of the coil above the unit supply shall be at least 4” (102 mm) for the

ECLIPSE and 0’’ for the GEMINI.

00

KLF KLR KLR KLF

GEMINI 3T/5T ECLIPSE 3T

See A/C coil Manufacturers Requirements.

To check the AC coil total air flow resistance, see procedure at page 33

HUMIDIFIER

If a humidifier is installed ensure that no water can drip or run from it into the furnace. This

would cause deterioration and void the furnace warranty.

0’’

4 inch

17

5.0 BURNER INSTALLATION AND SPECIFICATIONS

5.1 ASSEMBLY & INSTALLATION OF BURNER

CONSULT THE BURNER INSTRUCTION MANUAL THAT IS INCLUDED IN THE BURNER

BOX. In case of differences between the instructions on the burner instruction manual

and this manual, the furnace instruction manual (this manual) must be followed. The

instructions in the gas burner instruction manuals are detailed mounting, wiring,

adjusting, testing and maintenance instructions that are specific to the burner used

(Riello or Carlin). The specific adjustments for the furnace are detailed in the following

pages. As a general guideline:

1) Use the burner instruction manual for general instructions.

2) Use this manual for specific instructions (such as for example, the initial air gate

adjustment for a specific size of furnace with a specific burner).

• RIELLO GAS BURNERS

o In the Section “Setting the burner”, disregard the table and use the initial

adjustments detailed for the appropriate unit with Riello burner in the section 5.2

of this manual below.

o In the section “Air gate adjustment”, disregard the table and use the information

in section 5.2 below.

o In the section “Combustion head settings”, disregard the table and use the

information in section 5.2 below.

o In the section “Manifold pressures”, disregard the table and use the information in

section 5.2 below.

o Disregard the “Pressure working chart” and the “Combustion chamber size”

sections as those sections apply only for conversion burners.

COMBUSTION CHECKS

All combustion checks must be performed with an instrument capable of reading at least CO2,

CO and temperature.

• RIELLO GAS BURNERS

o Natural Gas Maximum CO2 is 10%

o Propane Gas Maximum CO2 is 12%

o Maximum Air free PPM reading of CO is 200.

o If any of these readings exceed the values above, adjust the air gate to increase

the air intake to the burner.

AFTER PLACING THE FURNACE IN OPERATION, THE IGNITION SYSTEM MUST BE

TESTED. THE METHOD OF TESTING IS AS FOLLOWS:

• Place the furnace in operation, by raising the thermostat, and observe a normal

ignition of the burner.

• Lower the thermostat. This should shut off the burner.

• Close the manual shut-off gas valve that is upstream of the gas control.

• Place the furnace in operation again, by raising the thermostat.

• After a trial for ignition period, the burner control should go in lockout mode. A light

on the red button on the burner ignition control will indicate this.

18

• To restart the furnace, open again the manual gas shut-off valve that you closed a few

steps back..

• Press the red button on the ignition control. The burner should then retry its ignition and

light the burner. If this sequence is not respected, consult the burner manual

5.2 GAS-FIRED FURNACE LIGHTING INTRUCTIONS

19

5.3 TECHNICAL INFORMATION / SET-UP

KLR/KLF Series

(KLR) ECLIPSE 3T / GEMINI 3T REAR (KLF) ECLIPSE 3T / GEMINI 3T FRONT

Riello Burner

G-120 Gas G-120 Gas

Unit Model

KLR-E1-*087-03 (N/P) KLF-E1-*087-03 (N/P)

Input (BTU/h) 105,000 105,000

Output (BTU/h) 87,000 87,000

Manifold Pressure 3.7’’ W.C. Natural / 4.0’’ W.C. Propane 3.7’’ W.C. Natural / 4.0’’ W.C. Propane

Orifice size B5 Natural / B16 Propane B5 Natural / B16 Propane

Max. Inlet Pressure 11’’ W.C. Natural / 13’’ W.C. Propane 11’’ W.C. Natural / 13’’ W.C. Propane

Min. Inlet Pressure 7’’ W.C. 7’’ W.C.

Comb. Head Setting 3.0 3.0

Air Gate Adjustment 2.5 2.5

Desired CO2 (%) 9.3% Natural / 11.0% Propane 9.3% Natural / 11.0% Propane

Efficiency (%)

83.50 83.50

General Information

PSC motor info

Temperature Rise (°F) 55 – 85 55 – 85 55 – 85 55 – 85 55 – 85 55 – 85

Blower Speed (0.2’’ wc) M-LOW M-LOW M-LOW M-LOW M-LOW M-LOW

Blower Speed (0.5” wc)

M-HIGH M-HIGH HIGH M-HIGH HIGH HIGH

Energy Star ECM motor (0.2’’ wc to 0.5’’ wc static pressure)

Temperature Rise (°F) 40-70 45-75 55-85 55-85 55-85 60-85

Blower Speed M-LOW M-LOW M-LOW M-LOW M-LOW M-LOW

Static Pressure at 0.2'' WC / 0.5'' WC

(PSC MOTOR / ECM MOTOR)

Blower speed / CFM

Blower

GEMINI 3T (REAR)

PSC

GEMINI 3T (REAR)

ECM

Blower

GEMINI 3T (FRONT)

PSC

GEMINI 3T (FRONT)

ECM

Speed 0.2" wc 0.5" wc 0.2" wc 0.5" wc

Speed 0.2" wc 0.5" wc 0.2" wc 0.5" wc

HI 1500 1300 1500 1300

HI 1500 1300 1500 1300

MHI 1300 1200 1300 1200

MHI 1350 1300 1350 1300

MED --- --- 1200 1100

MED --- --- 1275 1200

MLO 1100 1000 1100 1000

MLO 1200 1100 1200 1100

LO

875

850

775

750

LO 875 850

775 775

Blower

ECLIPSE 3T (REAR)

PSC

ECLIPSE 3T (REAR)

ECM

Blower

ECLIPSE 3T (FRONT)

PSC

ECLIPSE 3T (FRONT)

ECM

Speed 0.2" wc 0.5" wc 0.2" wc 0.5" wc

Speed 0.2" wc 0.5" wc 0.2" wc 0.5" wc

HI 1400 1250 1400 1250

HI 1400 1250 1400 1250

MHI 1300 1200 1325 1225

MHI 1300 1200 1325 1225

MED --- --- 1275 1200

MED --- --- 1275 1200

MLO 1200 1150 1200 1125

MLO 1200 1150 1200 1125

LO

875

850 775

750

LO

875

850 775 750

20

KLR/KLF Series

GEMINI 5T REAR GEMINI 5T FRONT

Riello Burner

G-200 Gas G-200 Gas

Unit Model

KLR-E3-*131-05 (N/P) KLF-E3-*131-05 (N/P)

Input (BTU/h) 155,000 155,000

Output (BTU/h)

131,000

131,000

Manifold Pre

ssure

4.5’’ W.C. Natural /3.8’’ W.C. Propane

4.5’’ W.C. Natural /3.8’’ W.C. Propane

Orifice Size B5 Natural / B16 Propane B5 Natural / B16 Propane

Max. Inlet Pressure

11’’ W.C. Natural / 13’’ W.C. Propane

11’’ W.C. Natural / 13’’ W.C. Propane

Min. Inle

t Pressure

7’’ W.C.

7’’ W.C.

Comb. Head Setting 3.0 3.0

Air Gate Adjustment

2.5 2.5 Desired CO2 (%)

9,8% Natural / 11.6% Propane

9,8% Natural / 11.6% Propane

Efficiency (%)

83.50 83.50

General Information

PSC motor info

Temperature Rise (°F) 55 – 85 55 – 85 55 – 85 55 – 85 55 – 85 55 – 85

Blower Speed (0.2’’ wc) M-LOW M-HIGH M-HIGH M-LOW M-HIGH M-HIGH

Blower Speed (0.5” wc)

M-HIGH HIGH HIGH M-HIGH HIGH HIGH

Energy Star ECM motor (0.2’’ wc to 0.5’’ wc static pressure)

Temperature Rise (°F) 55-85 55-85 60-85 55-85 55-85 60-85

Blower Speed M-LOW MEDIUM M-HIGH M-LOW MEDIUM M-HIGH

Static Pressure at 0.2'' WC / 0.5'' WC

(PSC MOTOR / ECM MOTOR)

Blower speed / CFM

Blower

GEMINI 5T (REAR)

PSC

GEMINI 5T (REAR)

ECM

Blower

GEMINI 5T (FRONT)

PSC

GEMINI 5T (FRONT)

ECM

Speed 0.2" wc 0.5" wc 0.2" wc 0.5" wc

Speed 0.2" wc 0.5" wc 0.2" wc 0.5" wc

HI 1900 1800 2000 1910

HI 1900 1800 2000 1910

MHI 1800 1700 1900 1385

MHI 1800 1700 1900 1385

MED --- --- 1690 1660

MED --- --- 1690 1660

MLO 1550 1450 1610 1575

MLO 1550 1450 1610 1575

LO 1050

1000 1060

1010

LO

875 1050

1000

1010

21

6.0 FURNACE OPERATION AND SETTINGS

SHUTTING FURNACE DOWN

POWER OFF Turn off main power breaker or disconnect.

FUEL OFF Shut off manual gas supply valve.

Always keep manual gas supply valve shut off if the burner is shut down for an extended

period of time.

RESTARTING FURNACE

Follow this procedure before restarting a unit that has been shut down for an extended period

of time.

INSPECTION Have the furnace/system serviced and inspected by a qualified technician.

FUEL Turn on gas supply and check that there are no leaks.

POWER Turn on power and check that the furnace starts and operates as usual.

OPERATION If the furnace/system fails to operate or operates in an unusual manner, call

your service technician. If the burner fails to operate at any time, call a

qualified burner technician.

6.1 BLOWER SETTING

Ensure power is off when adjusting blower setting. For heating, use the blower speeds to

obtain a temperature rise of 75 degrees F. The Lo blower speed can be used for air circulation

when neither heating nor cooling are required. Set blower speeds to match the installation

requirements

FAN & LIMIT CONTROL

Limit 185°F – Factory set

Fan On 45 seconds after the burner starts

Fan Off Adjustable on board (see page 22)

THERMOSTAT ANTICIPATOR SETTING

Adjust to thermostat manufacturer’s instruction.

22

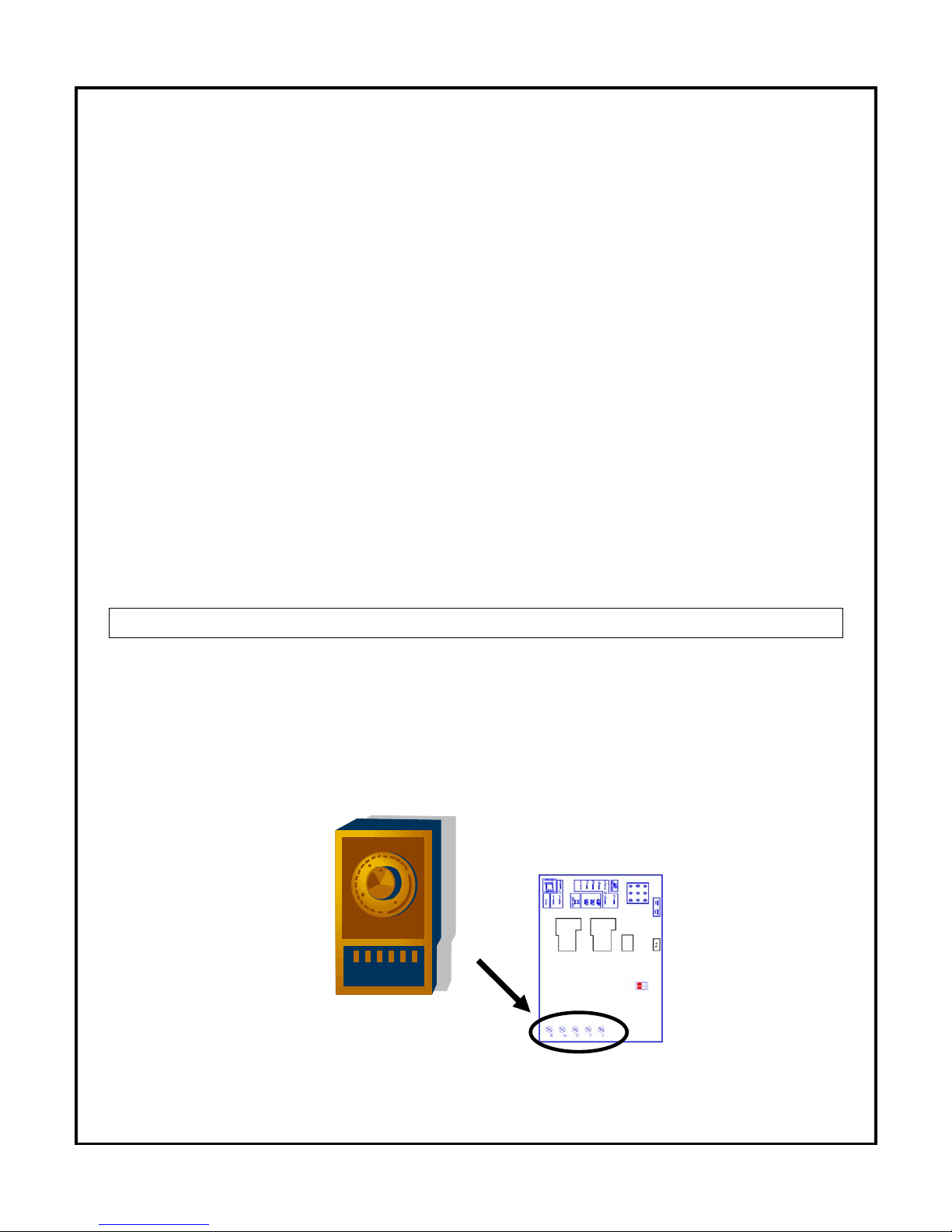

6.2 FAN TIMER CONTROL BOARD (ST9103A 1028)

o “FAN OFF” Dip Switches adjustment

COMFORT ADJUSTMENTS

o Outlet air consistently too warm or too cold - change the blower motor speed to give the

specified air temperature rise.

o Outlet air gets too warm and burner shuts down - increase air by changing the blower

motor speed to give the specified temperature rise.

o Outlet air is too cold or too warm at the end of the heating cycle after the burner has

turned off - adjust the “FAN OFF” dip switch on fan timer control board. Refer to the next

figure.

“FAN OFF” Dip Switch

OFF CYCLE AIR CIRCULATION (Factory settings)

LO SPEED All GEMINI and ECLIPSE models have the low speed switch for optional

constant air circulation during the furnace off cycle.

“FAN ON” When “FAN ON” is selected on the thermostat, the blower will run constantly

at the blower speed selected on the heating terminal. This is the equivalent of

jumping terminals R and G on the ST9103 board.

Dip Switches

23

6.3 ST9103A 1028 CONTROL BOARD SEQUENCE

ST9103 Heating Sequence

1) Thermostat calls for Heat.

2) Burner starts

3) Blower starts after 45 seconds

4) Burner shuts down after call for heat is satisfied

5) Blower stops according to adjusted (FAN OFF) Dip switch selection

ST9103 Cooling Sequence

1) Thermostat calls for cooling

2) Blower starts immediately

3) Cooling unit starts

4) Blower stops immediately after cooling demand is satisfied

5) Cooling unit stops

Honeywell ST9103A 1028 Electronic Board find in the electric box of each unit,

ECLIPSE / GEMINI

THERMOSTAT

Connect the thermostat wires

to the fan timer control board (ST9103).

24

6.4 Servicing - Fan Timer ST9103A 1028

Trouble shooting the Honeywell

electronic board ST9103

Before trouble shooting

the board,

check for the 5 amp. fuse

For accurate trouble shooting, follow step by step the Trouble Shooting Chart.

Step Possible Cause Check-out procedure Corrective action

No Heat

1 Incoming supply

Check for 120 Volts

between terminal S2 and 3

on electronic fan control

Yes - Move to next step

No -

Check breaker main power switch

2 Transformer

Check for 120 Volts between

terminal S3 and 4 on

electronic fan control.

Check for 24 Volts between

terminal X and C on

electronic fan control

Yes - Move to next step

No -

Check for bad connection

Yes - Move to next step

No -

Change Transformer

3

Electronic Fan

control

Check for 24 Volts between

R and C

Yes - Move to next step

No - Change the electronic board

Check for 24 Volts between

terminal W and C

Yes - Move to next step

No - Check thermostat and wiring

4

Warning: Make sure the quick connect cable is fully inserted on the board

Limit Control

Check for 120 Volts on each

terminal of the high limit

Yes - Move to step # 5

No - Move to next step

Check for 120 Volts coming

from the main plug-in of the

electronic fan control to the

limit control

Yes - Move to next step

No - Change the electronic fan control

Check for 120 Volts coming

out of the limit control

Yes

- Move to step # 5

No -

Failure on the limit control circuit

.

Temperature too high

. Bad limit control

25

Step Possible Cause

Check-out procedure Corrective action

No Heat

5

Riello burner

application

Check for 120 Volts on the

black wire, contact (COM)

on the burner activation

relay

Yes - Move to next step

No - Back to step # 4 or check for bad

connection

Check if oil primary control

is on reset

Yes - Press reset button

No - Move to the next step

Check for continuity

between the two wires

yellow and violet on the

burner activation relay

Yes - Move to next step

No - Change the electronic fan control

Check for 120 Volts on the

contact (No) of the burner

activation relay

Yes - Move to next step

No - Change the burner activation relay

Check for 120 volts on the

orange wire coming to the

burner (L)

Yes - Failure on the burner

No - Change the electronic fan control

6

Blower

. Low speed

Check if the

constant low

speed switch is

ON

Check for 120 Volts at the

''CONT'' terminal on the

electronic fan control

Yes - Move to next step

No - Change the electronic fan control

Check for 120 Volts on both

side of the constant low

speed switch

Yes - Check ''LOW'' speed on the

blower motor

No - Change the switch

(No) Cooling / Heating

7

Blower .

High speed

Cooling speed

Check for 24 Volts between G

and C on electronic fan

control

Check for 120 Volts at the

''COOL'' terminal of the

electronic fan control

Yes

- Move to next step

No - Check thermostat and wiring; if it's

OK, then change the electronic fan

control

Yes - Check ''COOL'' speed on the

blower motor

No - Change the electronic fan control

Heating speed

(45 sec. delay)

Check for 120 Volts at the

''HEAT'' terminal of the

electronic fan control

Yes - Check ''HEAT'' speed on the

b

lower motor

No - Change the electronic fan control

26

Step Possible Cause Check-out procedure Corrective action

Electronic air filter and Humidifier

8 Condensing unit

Check for 24 volts between

terminal Y and C on the

electronic fan control

Yes - Compressor ON

No - Check thermostat and wiring

9

Electronic air filter

Check for 120 Volts on

terminal ''EAC'' of the

electronic fan control

(thermostat must call a Heat,

Cool or Fan ON demand

Yes - Electronic filter failure

No - Change the electronic fan control

10 Humidifier

Check for 120 Volts on

terminal ''HUM'' of the

electronic fan control (burner

must be energized)

Yes -

Humidifier failure

No - Change the electronic fan control

7.0 SERVICE

WARNING

ELECTRICAL SHOCK, FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in dangerous

operation, serious injury, death or property damage.

Improper servicing could result in dangerous operation, serious

injury, death or property damage.

• Before servicing, disconnect all electrical power to furnace.

• When servicing controls, label all wires prior to disconnecting.

Reconnect wires correctly.

• Verify proper operation after servicing.

REGULAR MAINTENANCE

Check complete operation at least once a year. In Canada see B139, (Maintenance), for

recommended servicing procedure. Clean flue pipes on a regular basis. Replace flue pipes if

there is any sign of corrosion or other problems. Gaskets should be checked and may have to

be replaced.

27

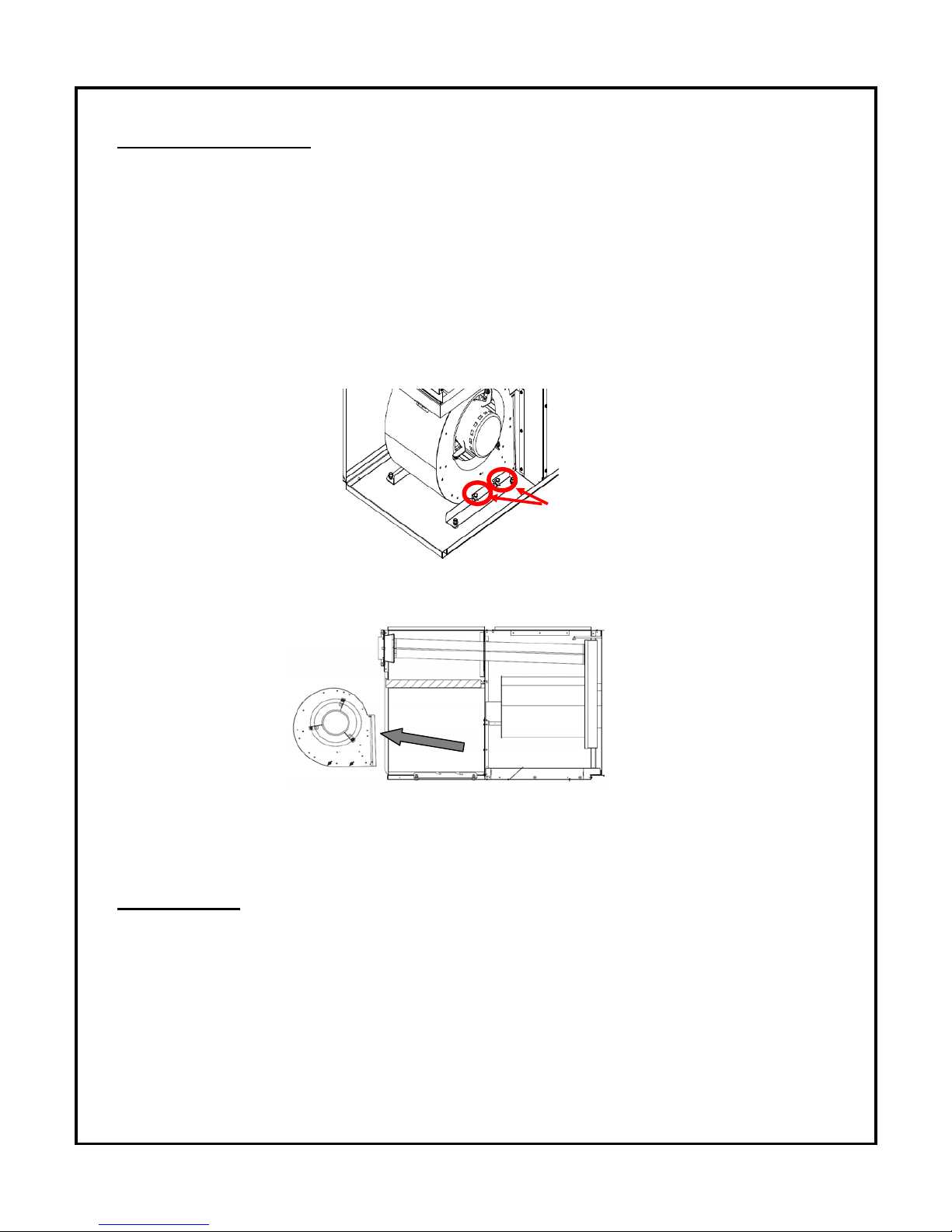

BLOWER REMOVAL

This furnace has a blower sealing system, which is designed to be tight and rattle free. Refer

to the instructions and pictures below.

1) Shut off oil and power to furnace.

2) Open blower compartment.

3) Remove air filter for easy maitenance.

4) Disconnect the wiring to the blower motor.

5) Remove the four (4) wing nuts securing the blower side to the base panel bracket.

6) Slide the blower toward you and then lift the blower straight up. Shift the blower out of the

furnace.

Put back the blower assembly using the reverse procedure. Ensure wiring and ground wires

are correctly reconnected.

AIR FILTERS

To maintain furnace performance and safety, replace dirty filters at least once every heating

season or as required. Use new approved disposable filters of the same size and type. Dirty,

clogged or wrong sized filters will impair the furnace performance and may cause the furnace

to shut down or overheat.

Wing Nuts

28

CLEANING HEAT EXCHANGER

Heat exchanger must be inspected every heating season. Refer to instructions and pictures

below.

GEMINI 3T/5T AND ECLIPSE 3T ( REAR) HEAT EXCHANGER

ECLIPSE 3T REAR ILLUSTRATION

(SAME STEPS for the GEMINI)

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------

GEMINI 3T/5T AND ECLIPSE 3T (FRONT) HEAT EXCHANGER

ECLIPSE 3T FRONT ILLUSTRATION

(SAME STEPS for the GEMINI)

Step 1:

Remove breech plate

Step 2:

Remove baffles

Step 3:

Clean the round tubes, if

needed (use a 2’’

diameter brush)

Step 4:

Remove burner

Step 5:

Clean combustion

chamber, if needed

Step 1:

Remove breech plate

Step 4:

Clean the transitions tubes if needed

Step 3:

Remove burner

St

ep 5:

Clean combustion chamber, if needed

Step 2:

Remove the baffles and clean

the round tubes, if needed

(use a 2’’ diameter brush)

Control

box in

front

29

BURNER CLEANING NOTES

Your burner manufacturer has supplied instructions for servicing and

maintenance should be performed as instructed.

Riello 40 G120 Gas Burner

Carlin EZGas PRO Burner Burner

PERFORM COMBUSTION TEST

Perform an annual combustion check on the gas burner.

Electronic

combustion

tester

30

8.0 ELECTRICAL / WIRING DIAGRAMS

HEATING & COOLING

Connection for Carlin

Burner, check the

Carlin burner

instruction manual

31

HEATING ONLY (2 WIRES THERMOSTAT)

Connection for Carlin

Burner, check the

Carlin burner

instruction manual

Riello burner

electrical

connection,

see page 30

32

10. START-UP TEST RESULTS

Model: Serial Number:

Lowboy KLR________ Lowboy KLF_______

Date of installation:

Installer (name & address):

START-UP TEST RESULTS

Size of unit (Btu/h):

Input: Manifold Pressure:

Chimney__________ DVSystem__________

Combustion Results:

CO2 %

Chimney draft: “ W.C.

Ambient temperature: °F

Gross flue temperature: °F

Temperature rise: °F (see page 33)

External total static pressure: “ W.C. (see page 33)

A/C Coil total resistance: “ W.C. (see page 33)

33

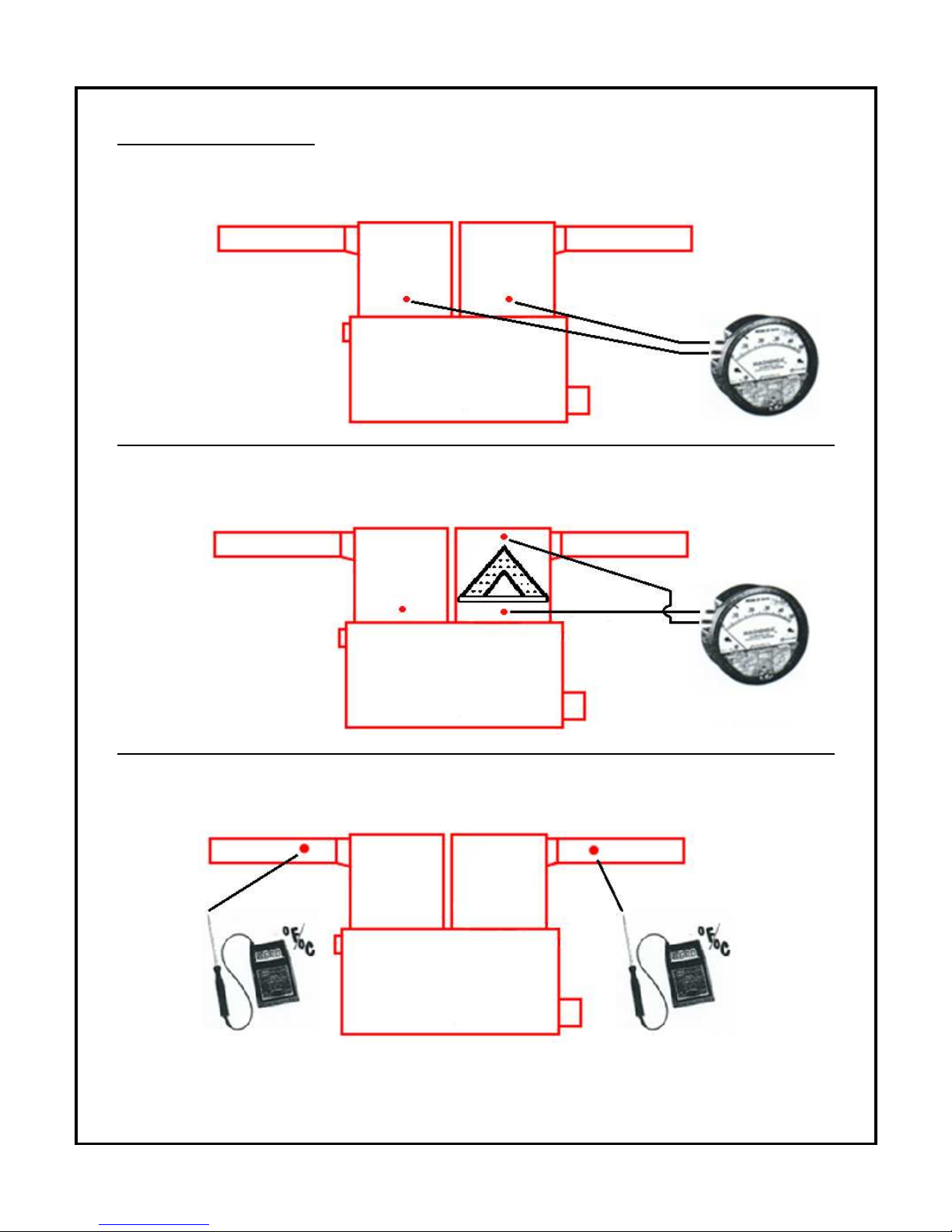

TEST PROCEDURES

External Total Static Pressure Reading

Total Static Pressure = Supply Pressure (Ps) + Return Pressure (Pr)

A/C Coil Total Resistance Reading

A/C coil total resistance = Coil Pressure (Pc) - Supply Pressure (Ps)

Temperature Rise Reading ***

Temperature rise = Supply Temp. (Ts) - Return Temp. (Tr)

*** Probe must not be in direct sight of heat exchanger.

Pr

Tr Ts

Pr

Ps

Pc

Ps

34

Kerr products manufactured by Granby Furnaces Inc. offer a full

line of furnaces and boilers built proudly in Parrsboro, NovaScotia, Canada at its 70,000 square feet facility. Kerr products are

sold across Canada through a wide distribution network.

Our team of engineers, designers and technicians continually

research and develop products to go beyond the demanding

specifications of today’s certifications.

Thank you

Thank youThank you

Thank you for

forfor

for choosing Ke

choosing Kechoosing Ke

choosing Kerrrrrrrr....

Loading...

Loading...