Page 1

KERN & Sohn GmbH

Ziegelei 1

E-Mail: info@kern-sohn.com

Phone: +49-[0]7433- 9933-0

Internet: www.kern-sohn.com

Operating manual

Pallet truck scale

KERN VHE-A

Version 1.1

01/2014

GB

D-72336 Balingen

Fax: +49-[0]7433-9933-149

VHE-A-BA-e-1411

Page 2

KERN VHE-A

Operating instructions Pallet truck scale

GB

Version 1.1 01/2014

Contents

1 Technical data ................................................................................................... 3

1.1 Dimensions ................................................................................................................ 4

2 Appliance overview ........................................................................................... 5

2.1 Overview of display .................................................................................................... 5

2.2 Keyboard overview .................................................................................................... 6

2.2.1 In weighing mode: ....................................................................................................................... 6

3 Basic instructions for scales ........................................................................... 7

3.1 Proper use ................................................................................................................. 7

3.2 Improper Use ............................................................................................................. 7

3.3 Warranty .................................................................................................................... 7

3.4 Monitoring of Test Resources .................................................................................... 8

4 Basic safety instructions for scales ................................................................ 8

4.1 Pay attention to the instructions in the Operat ion Manual .......................................... 8

4.2 Personnel training ...................................................................................................... 8

5 Transport and storage ...................................................................................... 8

5.1 Testing upon acceptance ........................................................................................... 8

5.2 Packaging / return t ransport ...................................................................................... 8

6 Unpacking and placing ..................................................................................... 9

6.1 Site of installation, place of operat ion for scales ........................................................ 9

6.2 Scope of delivery

......................................................................................................10

7 Adjustment ....................................................................................................... 11

7.1 Zero-setting ..............................................................................................................11

8 Commissioning ............................................................................................... 16

8.1 Switch on the pallet truck scale .................................................................................17

8.2 Switch off the pallet truck scale .................................................................................17

8.3 Weighing ..................................................................................................................18

8.4 Zero point correction .................................................................................................19

8.5 Taring .......................................................................................................................19

8.6 Totalization ...............................................................................................................20

8.7 Display stored weighing data ....................................................................................20

8.8 Delete the saved weighing data ................................................................................20

8.9 Battery operation ......................................................................................................21

9 Error messages ............................................................................................... 22

10 Servicing, maintenance, disposal .............................................................. 23

10.1 Clean ........................................................................................................................23

10.2 Ser vicing, m aint enanc e.............................................................................................23

10.3 Disposal ....................................................................................................................23

11 Instant help ................................................................................................... 24

2 VHE-A-BA-e-1411

Page 3

1 Technical data

KERN VHE 2T5A

Readability (d) 5 kg

Weighing range (max) 2000 kg

Reproducibility 20 kg

Linearity ± 30 kg

Stabilization time 3 sec.

Allowable ambient temperature -10° C .... + 40° C

Humidity of air

Weighing unit kg

Electric Supply 2 x 1.5V AA batteries

Operating period 100 h

Auto Off 3 min

Net weight 65 kg

max. 95 %

(not condensing)

VHE-A-BA-e-1411 3

Page 4

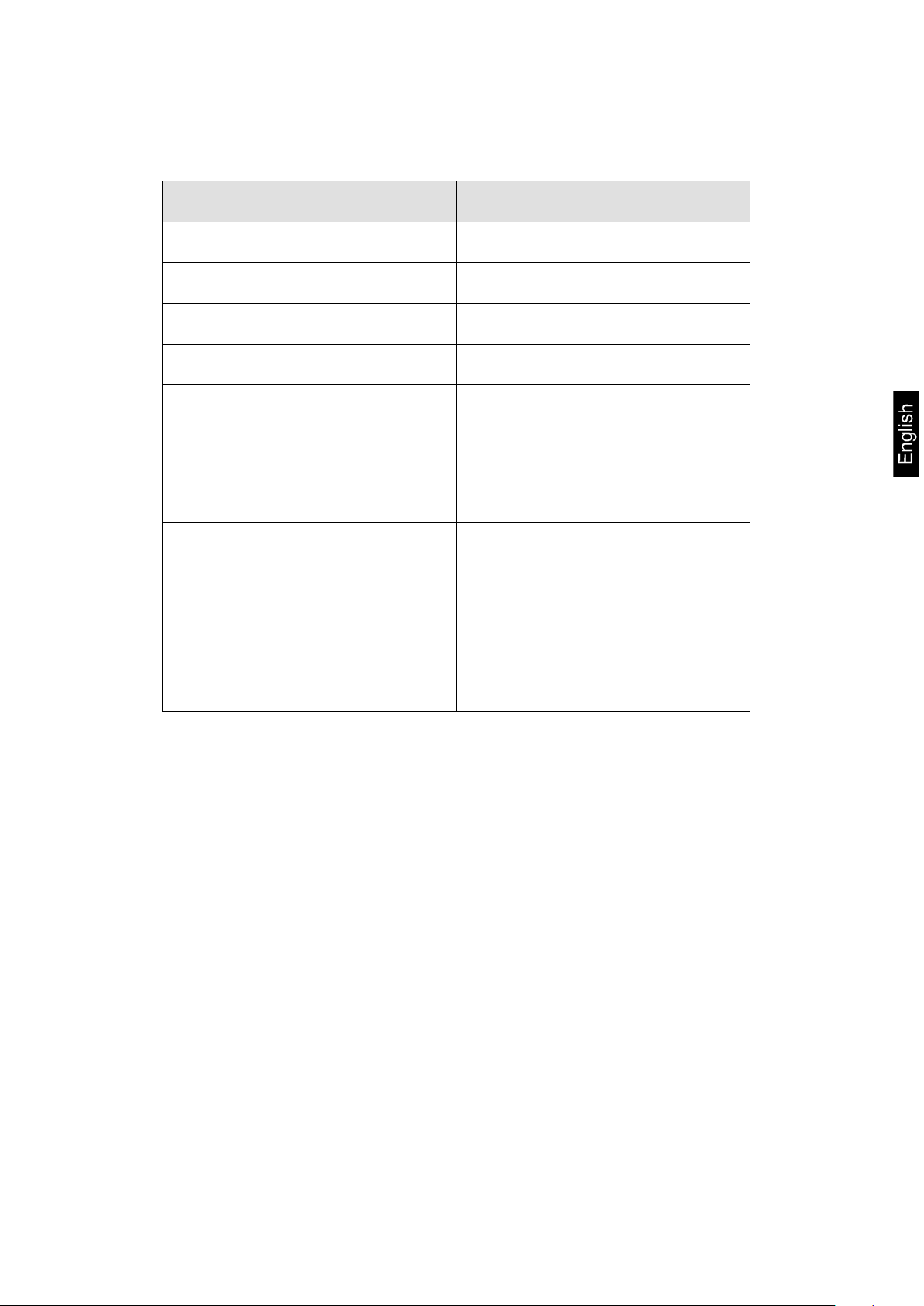

A

Fork length

1150 mm

B

Fork width

150 mm

A

F D C

E

B

102°

102°

1.1 Dimensions

C Minimum fork height 83 mm

Clearance 30 mm

D Maximum fork height 205 mm

Hoisting height 122 mm

E Width across forks 520 mm

F Height upper edge of display 575 mm

4 VHE-A-BA-e-1411

Page 5

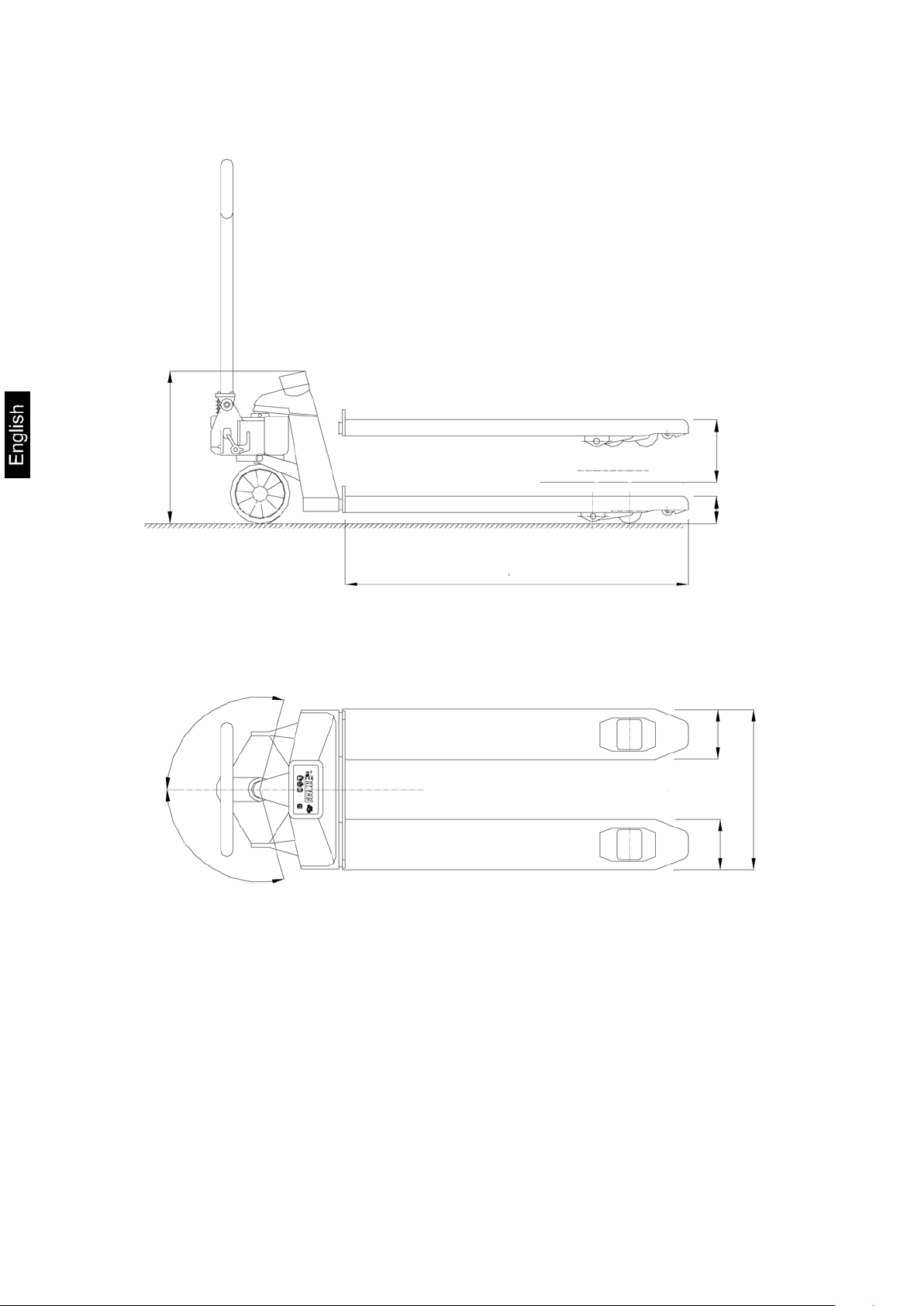

Load lifted too high; upper arrow is flashing

Reference height reached

Reference height almost reached, very slow lifting, 1 arrow lighting

Slowly lifting, 2 arrows lighting

Fast lifting, 3 arrows lighting

The displayed weight value is negative

M

Weight is stored

KG

Weight value in kg

Batteries of the display unit are empty; exchange batteries

2 Appliance overview

2.1 Overview of display

VHE-A-BA-e-1411 5

Page 6

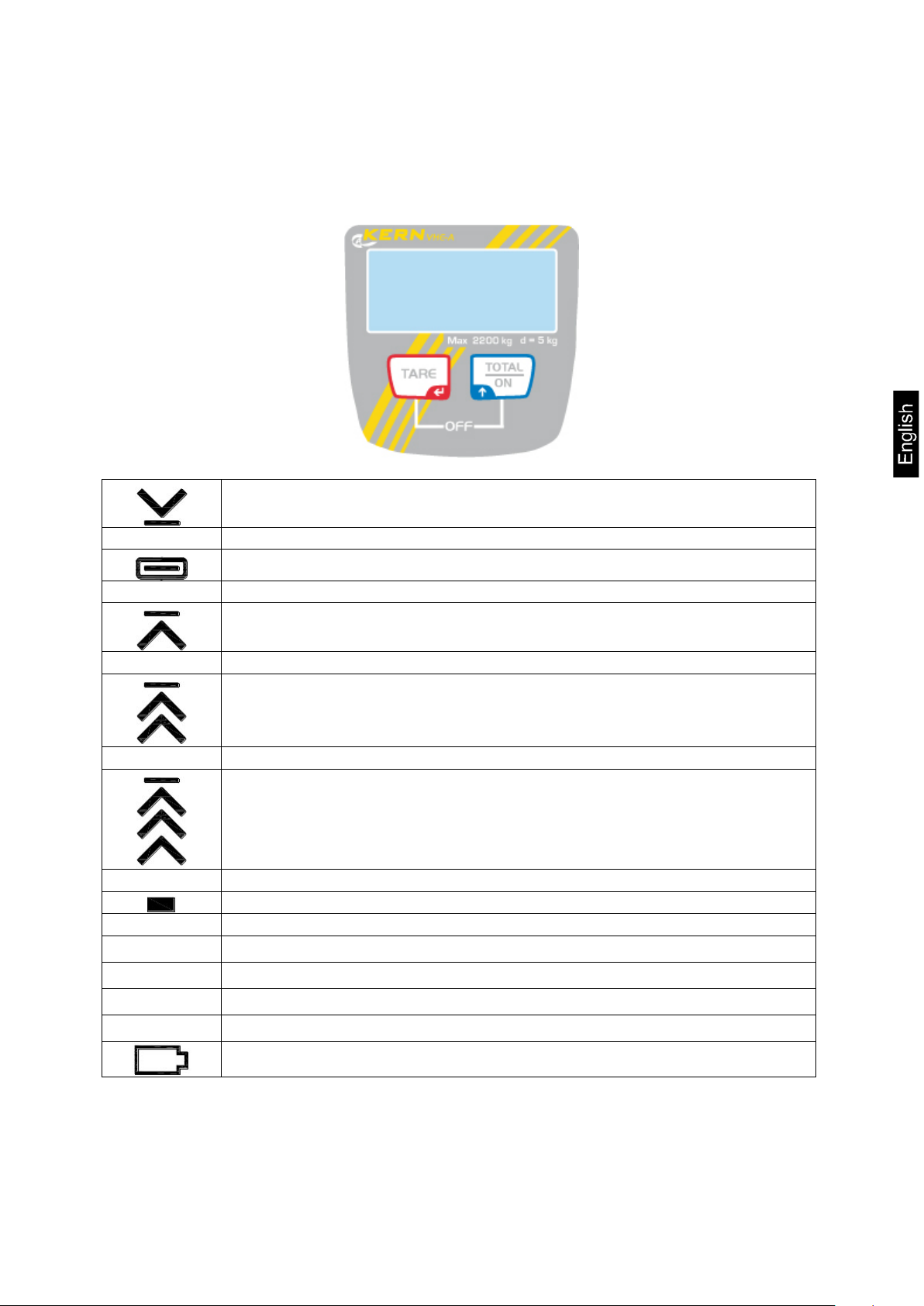

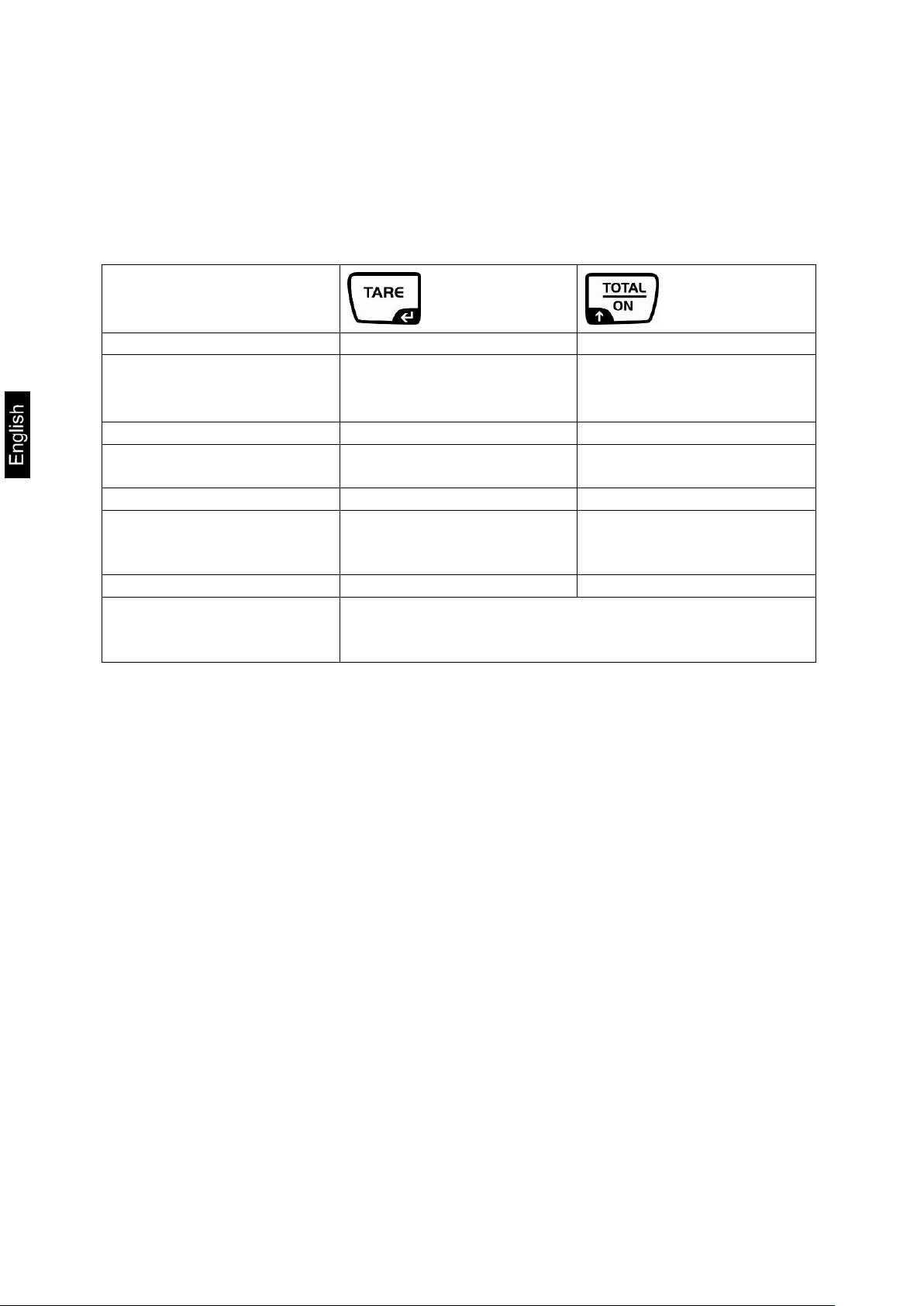

Short key pressing

• Zeroing

• Switch on balance

memory

long pressing of button

(>3 sec)

• Call up subtotal

very long pressing of

(>10 sec)

• Delete memory

Press both buttons at the

displayed.

2.2 Keyboard overview

2.2.1 In weighing mode:

Operation

• Add weight to sum

button

same time until OFF is

• Switch off system

6 VHE-A-BA-e-1411

Page 7

3 Basic instructions for scales

3.1 Proper use

The balance you purchased is intended to determine the weighing value of material

to be weighed. It is intended to be used as a “non-automatic balance”, i.e. the

material to be weighed is manually and carefully placed in the centre of the weighing

pan. As soon as a stable weighing value is reached the weighing value can be read.

3.2 Improper Use

Do not use balance for dynamic weighing. In the event that small quantities are

removed or added to the material to be weighed, incorrect weighing results can be

displayed due to the “stability compensation“. (Example: Slowly draining fluids from a

container on the balance.)

Do not leave permanent load on the weighing pan. This may damage the measuring

system.

Impacts and overloading exceeding the stated maximum load (max) of the balance,

minus a possibly existing tare load, must be strictly avoided. Balance may be

damage by this.

Never operate balance in explosive environment. The serial version is not explosion

protected.

The structure of the balance may not be modified. This may lead to incorrect

weighing results, safety-related faults and destruction of the balance.

The balance may only be used according to the described conditions. Other areas of

use must be released by KERN in writing.

3.3 Warranty

Warranty claims shall be voided in case

• Our conditions in the operation manual are ignored

• The appliance is used outside the described uses

• The appliance is modified or opened

• Mechanical damage and damage caused by media, liquids

• Natural wear and tear

• The appliance is improperly set up or incorrectly electrically connected

• The measuring system is overloaded

VHE-A-BA-e-1411 7

Page 8

3.4 Monitoring of Test Resources

In the framework of quality assurance the measuring-related properties of the

balance and, if applicable, the testing weight, must be checked regularly. The

responsible user must define a suitable interval as well as type and scope of this

test. Information is available on KERN’s home page (www.kern-sohn.com) with

regard to the monitoring of balance test substances and the test weights required for

this. In KERN’s accredited DKD calibration laboratory test weights and balances may

be calibrated (return to the national standard) fast and at moderate cost.

4 Basic safety instructions for scales

4.1 Pay attention to the instructions in the Operation Manual

Carefully read this operation manual before setup and

commissioning, even if you are already familiar with KERN

balances.

All language versions contain a non-binding translation.

The original German is binding.

4.2 Personnel training

The appliance may only be operated and maintained by trained personnel.

5 Transport and storage

5.1 Testing upon acceptance

When receiving the appliance, please check packaging immediately, and the

appliance itself when unpacking for possible visible damage.

5.2 Packaging / return transport

Keep all parts of the original packaging for a possibly

required return.

Only use original packaging for returning.

8 VHE-A-BA-e-1411

Page 9

Incorrect lifting of a load

Correct lifting of a load

6 Unpacking and placing

6.1 Site of installation, place of operation for scales

The balances are designed in a way that reliable weighing results are achieved in

common conditions of use.

You will work accurately and fast, if you select the right location for your balance.

On the installation site observe the following:

The load must be lifted clear of the display unit’s case and other pallets.

The load must be lifted evenly distributed, so that it has the lowest

measurement insecurity (deviations up to 0.8% of the capacity may occur).

Inclined position of the weighing system can falsify the weighing result. Holes

and unevenness, too, have this effect. A smooth floor is ideal.

VHE-A-BA-e-1411 9

Page 10

Optimum accuracy in weighing results is achieved if the load centre is

between the forks. The forks are easily bent and twisted when the load is offcentre. This may result in diminished accuracy.

Avoid jarring during weighing

Protect the balance against high humidity, vapours and dust

Do not expose the device to extreme dampness for longer periods of time.

Non-permitted condensation (condensation of air humidity on the appliance)

may occur if a cold appliance is taken to a considerably warmer environment.

In this case, acclimatize the disconnected appliance for ca. 2 hours at room

temperature.

Major display deviations (incorrect weighing results) may be experienced

should electromagnetic fields (e.g. due to mobile phones or radio equipment),

static electricity accumulations or instable power supply occur. Change

location or remove source of interference.

6.2 Scope of delivery

Serial accessories:

• Pallet truck scales

• 2 x 1.5V AA batteries

• Operating manual

10 VHE-A-BA-e-1411

Page 11

7 Adjustment

As the acceleration value due to gravity is not the same at every location on earth,

each balance must be coordinated - in compliance with the underlying physical

weighing principle - to the existing acceleration due to gravity at its place of

location (only if the balance has not already been adjusted to the location in the

factory). This adjustment process must be carried out for the first commissioning,

after each change of location as well as in case of fluctuating environment

temperature. To receive accurate measuring values it is also recommended to

adjust the balance periodically in weighing operation.

Observe stable environmental conditions. A warming up time (see chapter Fehler!

Verweisquelle konnte nicht gefunden werden.) is required for stabilization.

Ensure that the system is not loaded. The system should be lifted by

approximately 2 lifting index markings and stand absolutely free.

7.1 Zero-setting

Unload the weighing system and switch-on with TOTAL.

If the weighing system does not display „0“, press ZERO

VHE-A-BA-e-1411 11

Page 12

How to carry out adjustments

Switch off weighing system

Press for 30 sec., PAR is displayed

Press until CAL is displayed

Press , ZERO is displayed flashing, because the

reference height is not reached yet

Place a pallet and adjust the reference height, when the

reference height is reached, the display stops flashing and

only the right-hand bar above in the display continues to be

displayed.

Press for approx. 3 sec., the count down fur setting

the first adjustment point runs automatically.

The weight of 1000 kg for the first adjustment point is

displayed. One point (=1. adjustment point) is displayed

before the cipher.

Place 1000 kg

After placing the weight the weighing system leaves the

reference height, the display flashes

Bring the weighing system on reference height, the display

stops flashing

12 VHE-A-BA-e-1411

Page 13

displayed

procedure.

Press for approx. 3 sec., the count down for setting

the second adjustment point runs off automatically.

The weight for the second adjustment point is displayed.

Moreover two points appear in the display.

Place 2000 kg

After placing the weight the weighing system leaves the

reference height, the display flashes

Place the weighing system on reference height, the display

stops flashing.

Press for approx. 3 sec., the count down for setting

the third adjustment point runs off automatically, 0 is

Remove weight.

Press , vU004 is displayed, followed by PAr

Press for approx. 3 sec., SAVE is displayed,

followed by 0.

The balance is now in weighing mode.

Adjustment now has finished.

An adjusting error or incorrect adjusting weight will be

indicated by the error message; repeat adjustment

VHE-A-BA-e-1411 13

Page 14

Carry out adjustment by entering the adjustment weight

Switch off weighing system

Press for 30 sec., PAR is displayed

Press until CAL is displayed

Press , ZERO is displayed flashing, because the

reference height is not reached yet

Place a pallet and adjust the reference height, when the

reference height is reached, the display stops flashing and

only the righthand bar above in the display continues to be

displayed.

Press for approx. 3 sec., the count down runs off

automatically.

.1000 is displayed.

Press 2 x , 0 is displayed

Press shortly, the display for entering the

adjustment weight is displayed, the right digit flashes.

Use both keys to enter the desired adjustment weight:

Use to alter cipher, use to change the digit

(example)

INFO: when entering 1500 kg = enter 15000 (example). With the other values

proceed in the same way: the last zero will not be considered:

14 VHE-A-BA-e-1411

Page 15

the error

Acknowledge by .

Place the set weight and set the reference height

Press for approx. 3 sec., the count down runs off

automatically, followed by the program version and Save.

Then the balance returns automatically into the weighing mode.

Adjustment now has finished.

An adjusting error or incorrect adjusting weight will be indicated by

message; repeat adjustment procedure.

VHE-A-BA-e-1411 15

Page 16

8 Commissioning

Correct weighing only possible at „reference height “

(see fig. 1 and 2)

Actuate repeatedly the drawbar handle (hand lever 1 downwards. fig.1) until the

reference height is reached. In the display appears see fig.2.

Fig. 1

Fig. 2

If the pallet truck scale is not in reference height, the weight

value in the display appears flashing.

Place the pallet truck scale into reference height, the display

does not more flash.

16 VHE-A-BA-e-1411

Page 17

8.1 Switch on the pallet truck scale

Switch on the pallet truck scale using key,

the balance carries out a selftest and changes then

to the zero display

8.2 Switch off the pallet truck scale

Press the buttons and at the same

time until OFF appears.

After that the display extinguishes.

(example)

The display extinguishes automatically when the buttons have

not been pressed for two minutes or if the system is not used.

VHE-A-BA-e-1411 17

Page 18

8.3 Weighing

Switch on the pallet truck scale using key,

the balance carries out a selftest and changes then

to the zero display „0“ is displayed flashing.

If „0“ is not displayed, press

Let the pallet truck scale lower onto the lowest point.

Three arrows are lighting up when the lowest point is

reached.

Take up the load and lift till to reference height.

Three arrows are lighting up. The weight value is

displayed flashing. Continue lifting the load.

Two arrows are lighting up. Lift slowly

A arrow is lighting up. Lift slowly.

The reference height is reached. The symbol

displayed. The display of the weight value does not

more flash.

The upper arrow is lighting up, when a load has been

lifted too high up. Lower the pallet truck scale

completely till to the ground to start a new weighing.

is

18 VHE-A-BA-e-1411

Page 19

8.4 Zero point correction

Switch on pallet truck scale using button.

Check whether the forks of the pallet truck scale are

empty

Lift pallet truck scale till to the reference height (see

chap. 8, fig. 1).

If the display does not show zero, reset display using

8.5 Taring

Lift weighing container till to the reference height (see chap. 8, fig. 1).

Switch on pallet truck scale using button.

The weight of the weighing container is displayed.

Tare using button.

Fill material to be weighed in the container, the net

weight is displayed.

If the container is removed from the balance, the tare

weight is displayed as a negative value. The tare

weight remains stored until the button is

pressed anew or the balance is switched off.

VHE-A-BA-e-1411 19

Page 20

Total weight

8.6 Totalization

The display unit offers an option that allows the addition of weighing values and the

display of the total weight.

Pick up the load and bring it to reference height

Press . The value is stored and „M“ is

displayed.

The display alternately shows the consecutive

number (number of weighings) and the total weight.

After a few seconds the system automatically reverts

to standard weighing mode.

Add-up another load as described before. Observe

that the system must be unloaded between the

weighing procedures.

(example)

Number of weighing

procedures

8.7 Display stored weighing data

Press for approx. 3 sec, the number of weighing procedures

and the total weight are displayed alternately

8.8 Delete the saved weighing data

During display of the weighing data press shortly, data in the store

are deleted, the display changes automatically into weighing mode and the

„M“ extinguishes.

20 VHE-A-BA-e-1411

Page 21

8.9 Battery operation

Power is supplied via 2 x 1.5V AA batteries. At a regular use with full batteries,

approx. 1 year can be weighed.

If the battery symbol is displayed, this means that the batteries will soon be

flat.

Change the batteries immediately.

If the capacity of the batteries is completely exhausted, the display will switch-off

automatically.

In order to save the battery, the balance switches automatically off after 3 minutes

without load changing.

If the balance is not used for a longer time, take out the batteries and store them

separately. Leaking battery liquid could damage the balance.

Change the battery as follows:

VHE-A-BA-e-1411 21

Page 22

- O.L. -

The weighing system is overloaded. Remove the load

Err06

Load cell signal too high

Err07

Load cell signal too low

Err12

Calibration deleted

Err98

The calibration value must be higher than the former

value

Battery symbol flashes: The battery is almost empty

and has to be replaced (see chap. 8.9)

M

Flashing „M“: Memory is full, no more weights can be

added-up. Delete memory (see chap. 8.8)

9 Error messages

22 VHE-A-BA-e-1411

Page 23

10 Servici ng, mai ntenance, disposal

10.1 Clean

Please do not use aggressive cleaning agents (solvents or similar agents), but a

cloth dampened with mild soap suds. Take care that the device is not penetrated by

fluids and polish it with a dry soft cloth.

10.2 Servicing, maintenance

The appliance may only be opened by trained service technicians who are

authorized by KERN.

The same maintenance guidelines as for standard manual lift truck without loaddisplay system.

General rules:

Pulling instead of pushing allows an easier handling of the load (steering

wheels on the side of the drawbar)

If the lifting device is not used, the manual lever should be left in centre

position. This prolongs the life span of the seals.

The display unit should only be cleaned with a damp cloth. Chemical cleaning

agents and a pressurized water jet cause damage.

To prevent damages to the electronic system and weighing cells it is

necessary that welding work on the entire weighing system is carried out

exclusively by technical specialists.

The bearings of the wheels as well as the joints in the load roller section

should be regularly cleaned and greased.

10.3 Disposal

Disposal of packaging and appliance must be carried out by operator according to

valid national or regional law of the location where the appliance is used.

VHE-A-BA-e-1411 23

Page 24

The displayed weight is permanently

11 I ns tant help

In case of an error in the program process, briefly turn off the balance and

disconnect from power supply. The weighing process must then be restarted from

the beginning.

Help:

Fault Possible cause

The displayed weight does not glow.

changing

-

The weighing value is obviously

wrong

• The balance is not switched on.

• The batteries are empty

• Draught/air movement

• Sites with vibration.

• Loading fork is in contact with foreign

matter.

• Electromagnetic fields / static charging

(choose different location/switch off

interfering device if possible)

• The display of the balance is not at zero

• Adjustment is no longer correct.

• Great fluctuations in temperature.

• Electromagnetic fields / static charging

(choose different location/switch off

interfering device if possible)

• Load fork has not been pumped to

reference height

Should other error messages occur, switch balance off and then on again. If the error

message remains inform manufacturer.

24 VHE-A-BA-e-1411

• The control pin is not in position

„Reference height“.

Loading...

Loading...