Page 1

Sauter GmbH

Ziegelei 1

TF / TG

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

DIGITAL COATING THICKNESS GAUGE

Model: TF, F and NF, with sensor inside

Model: TG, F and NF, with sensor outside

Table of contents

1. Features

2. Specifications

3. Front panel description

4. Measuring procedure

5. Statistics

6. How to store and recall readings

7. How to delete readings

8. Transfer of readings to a PC

9. Calibration

10. Battery replacement

11. Correct handling of coating thickness

measurement with external sensors

12. Trouble shooting

13. Restaure factory settings

14. Notes

15. Declaration of conformity

Annotation: It is strongly recommended to calibrate

the new instrument before the first use, as

described in paragraph 9. By doing this it

will be achieved a much better measure ment result right from the start.

1. Features

* This instrument meets the standards of both, ISO 2178

and ISO 2361, and DIN as well as ASTM und BS.

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

It is suitable for the laboratory and for use in

`harsh field conditions.`

* The F mode measures the thickness of nonmagnetic

materials, e.g. paint, plastic, porcelain enamel, copper,

zinc, aluminium, chrome, laquer layers etc. These layers

are located on magnetic materials e.g. steel, iron,

nickle etc. It is often used to measure the thickness of

galvanizing layer, laquer layer, porcelain enamel layer,

phosphide layer, copper tile, aluminium tile, some alloy

tile, paper etc. Those layers are to be found on magnetic

base materials like iron, steel, nickel et c.

* The N mode measures the thickness of nonmagnetic

coatings, e.g. anodizing, varnish, paint, enamel, plastic

coatings, powder etc. These layers are located on non magnetic metals e.g. aluminium, brass, non magnetic

stainless steel etc.

* Automatically substrate recognition

* Manually or automatically “auto power off” to conserve

batteries.

* Two measurement modes: - single and continuous

* Wide measuring range and high resolution

* Metric/ imperial conversion

* Digital backlight display enables exact reading with no

guessing or errors

* Can communicate with PC for statistics and printing by

the optional cable.

* Can store up to 99 measurements

* Statistics available

1. Specifications

Display: 4 digits LCD, with backlight

Range: 0 up to 1250 µm/ 0 up to 50 mil

(another range may be specified)

Resolution: 0.1µm (0 up to 99.9µm)

1µm (over 100µm)

Accuracy:

-

Standard: 3% of the measured value or min. ± 2.5 µm

Is valid within a toleranc e range of ± 100 μm around the

individually measured range, if a two-point calibrat ion was

performed within this tolerance range.

-

Off-Set Accur Mode: 1% of the measured value

or min. ± 1.0 µm

Is valid within ± 50 μm around the Off-Set Accur point.

PC interface: mit RS-232C interface

TF_TG-BA-e-1311 1

Page 2

Sauter GmbH

Ziegelei 1

TF / TG

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

Power supply: 2 x 1.5V AAA(UM-4) batteri es

Operating conditions

Temperatures 0 up to 50°C

Humidity < 95 %

Dimensions: 126 x 65 x 35 mm (5.0 x 2.6 x 1.6 inch)

Weight: ca.81g (without batteries)

Accessories: - Carrying case

- Operation manual

- F-s ensor, (inbuilt at TF, at TG one sensor

for F and FN is extern, it has to be

plugged in)

- NF-sensor, (inbuilt at TF)

- Calibration foils

- Base plate (iron)

- Base plate (aluminium)

Optional accessories: Cable & software for RS-232C

USB adapter for RS-232C Software

3. Front panel description

3- 1 Sensor, inbuilt at model TF

3- 2 Display

3- 3 Power-key/Zero- key

3- 4 Plus - key

3- 5 Minus- key

3- 6 Reading key

3- 7 Deleting key

3- 8 Jack for RS-232C interface

3- 9 Battery cover

3-10 Wrist ring

3-11 Low battery indicator

3-12 Measuring symbol

3-13 Last reading/browsing value

3-14 Single measurement mode

3-15 Max. indicator value

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

3-16 Min. indicator value

3-17 Browsing state

3-18 Measuring state

3-19 Unit

3-20 Average indicator

3-21 Substrate indicator

3-22 Counter for storing

3-23 Counter for statistics

4. Measuring procedure

At model TG, the F-/NF- sensor (aut omat ically recogniti on)

has to be plugged in, to get into the F- or NF- mode.

4.1 The power key 3-3 has to be pressed to switch on the

instrument. `0` appears on the display 3-2.

With the Auto- Mode, the instrument recognizes the

mode itself by the symbol `Fe` (= F) or `NFe`(= N)

which is indicated on the display.

4.2 The sensor 3-1 is to be placed onto a coating layer to

be measured. The reading on the display is the thick ness of the coating layer. This can be corrected by

pressing the Plus- key 3-4 or the Minus- key 3-5

For doing this the sensor should be away from the

measured object or the base plate.

4.3 For the next measurement the sensor 3-1 has to be

lifted for more than 1cm and step 4.2 is to be repeated.

The instrument memorizes the continuous measured

value automatically with statistic measurement times.

Meanwhile, the Max, Min and average value will be

displayed.

4.4 To change the measurement unit from „µm“ to “mil” or

vice verse, the Power-key just has to be pressed and

not released until “UNIT” is shown on the display.

Then the same key 3-3 (this time Zero-key) has to be

pressed.

4.5 To change the measuring mode from `single` to

`continuous` or vice verse, the Power-key 3-3 has to

be pressed and not released until `SC` appears on

the display. Then the Zero- key 3-3 has to be pressed.

The symbol “STATS” represents the continuous

mode and `S` represents the single mode.

5. Statistics

This instrument calculates and displays a statistical

analysis of readings while the measurements are taken.

The statistics available are:

• Last value

• Mean value

• Highest reading marked by Max

• Lowest reading marked by Min

• Number of readings taken

To clear the statistical data before starting a new set of

data, the Zero-key just has to be pressed and releas ed. In

measurement mode, which is marked by SV , the last value

can be deleted by pressing the DEL-key. Restatistics is

calculated and displayed itself.

TF_TG-BA-e-1311 2

Page 3

Sauter GmbH

Ziegelei 1

TF / TG

D-72336 Balingen

E-Mail: info@sauter.eu

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

Instruction Manual

6. How to store and recall readings

6.1 The measurements taken are automatically saved in

the memory of the instrument. The m em ori zed dat a can be

browsed by pressing and releasing the READ-key to enter

into the browsing state, marked by “READ” on the display.

6.2 In browsing state, all the readi ngs memorized can be

recalled on the display by pressing the Plus-key 3-4 or the

Minus-key 3-5.

6.3 To delete only one memorized value in t he memory,

the reading to be deleted just has to be located on the

display by the Plus-key or the Minus-key. Then the DELkey has to be pressed and released. If there appears

“Err0” on the display, it is indicat ed that there i s no reading

to delete any more.

6.4 The Zero-key 3-3 has to be pressed to quit the

measurement state.

7. How to delete readings

7.1 To delete a reading on the display, the DEL-ke y has

to be pressed, no matter wheter you are located in

the measurement state marked “SV” or in browsing

state marked “RD”. Browsing state can be entered by

pressing the READ-key and measurement state is

entered by pressing the Zero-key.

7.2 To delete all readings in the memory, the DEL-key

has to be pressed in measurement state marked by

“SV” on the display for about 4 seconds until the

number of readings memorized becomes 0.

8. Transfer of readings to a PC

8.1 RS-232 software has to be installed on the PC.

During the installing process the “continue”-button

always has to be clicked.

8.2 The instrument has to be connected to the PC using

the optional cable.

8.3 The Thickness Gauge has to be switched on to

ensure that the reading screen is displayed.

8.4 The software has to be started and the instructions

included with the software Demo. EXE. have to be

followed.

9. Calibration

9.1 Zero adjustment:

Zero adjustment for `F` and `NF` should be carried

out separately. The iron base plate is to be used if

`F` is shown on the display. The base plate of

aluminium is to be used if `NF` is shown on the display.

The sensor 3-1 is to be placed carefully onto the base

plate and the Zero- key is to be pressed without lifting

the sensor. `0` appears on the display.

Attention: The calibratio n is invalid if the sensor is

not directly placed onto the base plate or another

uncoated material.

9.2 An appropriate calibration foil is to be selected accor ding to the measurement range.

9.3 The selected standard foil has to be placed onto the

base plate or the uncoated material.

9.4 The sensor 3-1 is to be pressed carefully onto the

calibration foil and then lifted.

The reading on the display is the value measured.

This can be corrected by pressing the Plus- key 3-4

or the Minus- key 3-5 while the sensor is removed

from the base plate or the measured object.

9.5 Repeat step 9.4 until the accuracy is achieved.

10. Battery replacement

10.1 If the battery symbol ``+/-`` appears on the display,

the batteries should be replaced.

10.2 The battery cover 3-9 has to be removed and the

batteries are to be taken off.

10.3 The batteries (2x1.5V AAA/UM-4) are to be inst al l ed

correctly into the case.

10.4 If the instrument is not to be used for an extended

period, batteries are to be extracted.

11. Correct handling of coating thickness

measurement with external sensors

The sensor has to be touched at the lower pole s egment

and it has to be pressed slightly onto the test object.

The black chequered pole segment is movably seated on a

spring. By means of the spring, the sensor tip presses onto

the test object with a defined force. This way,

measurement errors can be avoided.

It is recommendable to effect several test measurements

before the first use of the instrument. This way, further

measurement errors can be avoided.

12. Trouble shooting

12.1 The instrument should always be calibrated on the

uncoated base material to be measured instead of the

base plate included in the delivery. Then the

accuracy is more precise.

12.2 Sensors will eventually wear off. Life of the sensor will

TF_TG-BA-e-1311 3

Page 4

Sauter GmbH

Ziegelei 1

TF / TG

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

depend on the number of measurements taken and

how abrasive the coating is. Replacement of the sen sor should only be performed by qualified staff.

13. Restore factory settings

13.1 In the following cases it is recommended to restore

factory settings:

A. The instrument does not measure any more.

B. Measurement accuracy is degraded caused by the

abraded sensor or affected by environmental

conditions.

C. After the replacement of a new sensor.

13.2 How to restore?

`F` setting and `N` setting are to be done. It can be

done one or both of them. The procedure is as follows:

13.2.1 On the display the symbol `F` or `NF` appears.

If `F` is shown on the display, you have to restore factory

settings for `F`, as described below.

If `NF` appears, you have to follow factory settings for

`NF`.

13.2.2 The Power-on/ Power-off key 3-3 has to be pressed

until `CAL` appears on the display. This lasts about 12

seconds from starting pressing the Power-key.

13.2.3 If now F:H or NF:H is shown on the display, the

sensor has to be lifted for m ore than 5 cm. Then the Zerokey has to be pressed and the instrument returns into

measurement mode. With this, factory setting is restored.

Comment: This procedure should always be done withi n 6

seconds. Otherwise it will be automatically cancelled and

the restoration is invalid.

14. Notes

14.1 All settings, including restoring factory setting, unit

setting, S/C setting should be done within 6 seconds.

Otherwise the instrument will quit and k eep the status as

before.

14.2 The linearization of the instrument, which is given by

the calibration, can be changed with the Ln- function.

Any adjustment of the value of Ln will seriously affect

the accuracy. This value should onl y be adjusted by

professional persons.

Generally said:

The bigger the value of Ln, the smaller the reading on

the display for the same (coating) thickness. Only a small

change on the value of Ln causes a big change in the

reading of the upper measurement range

(at 500µm/20 mil).

The value of Ln is to adjust as follows:

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

Pressing the Power-key. It lasts about 14 seconds from

starting depressing this key. This value can be changed by

pressing the Plus- / Minus- key after `Ln` appears on the

display and the Power- key is released. This value is

stored and afterwards the Zero- key has to be pressed.

A. The reading at low end is to be adjusted by pressing

the Plus-/ or the Minus- key.

B. The value of Ln is enlarged if reading at low end

(e.g. 51µ m) is o.k., but reading at high end (e.g.

432µm) is too large.

In contrast with this the value of Ln is to be decreased

if the reading at low end (e.g. 51µm) is o.k. but at high

end (e.g. 432µm) it is too small.

C. Procedures from A to B are to be repeated until the

reading for every calibration foil is satisfactory in

its accuracy

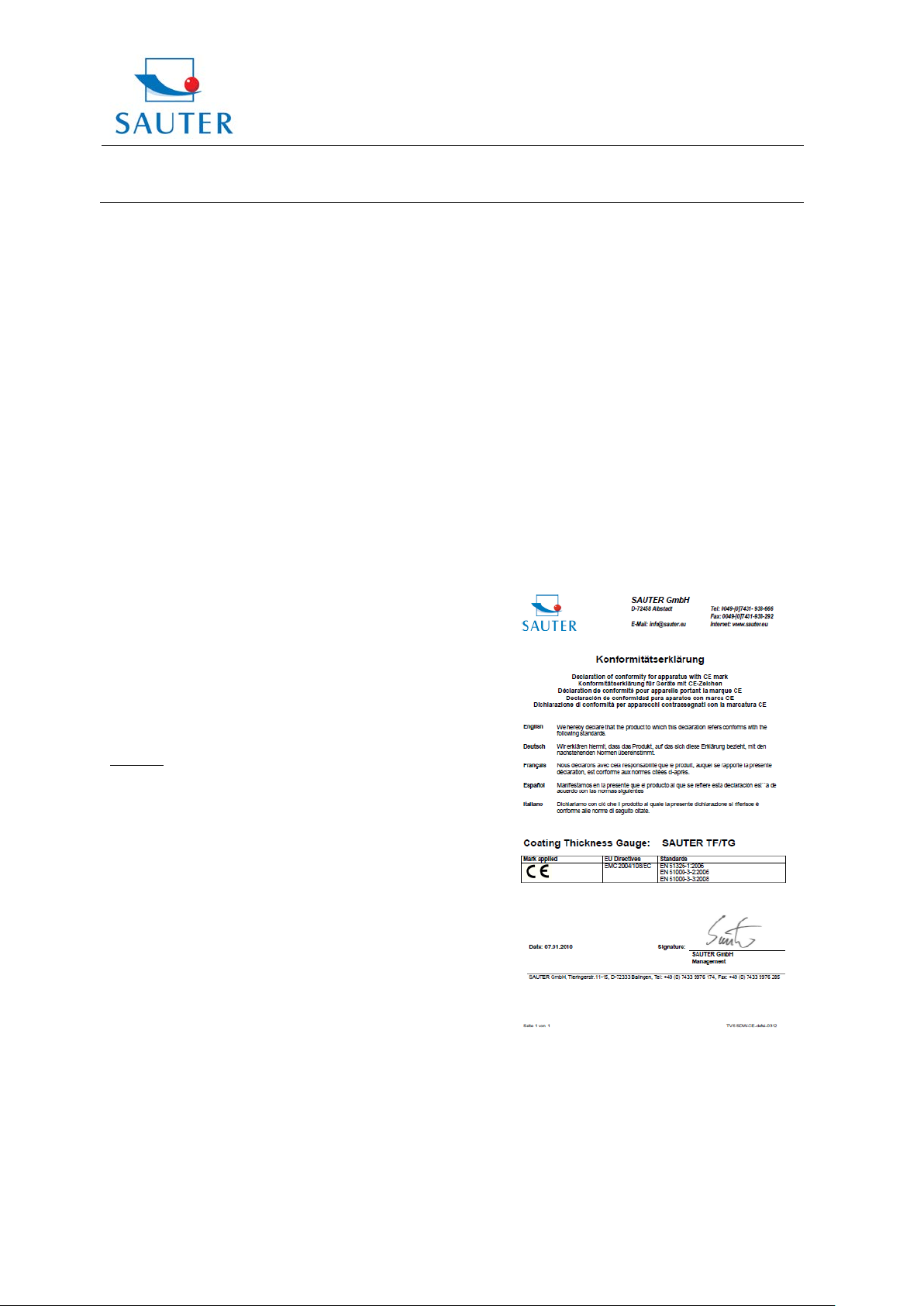

15. Declaration of conformity

TF_TG-BA-e-1311 4

Loading...

Loading...