Page 1

Sauter GmbH

Tieringerstr. 11-15 Tel: +49-[0]7433- 9976-174

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

TC_car

DIGITAL COATING THICKNESS GAUGE

Model: TC 1250-0.1 FN- car

Table of contents

1. Features

2. Specifications

3. Front panel descriptions

4. Measuring procedure

5. Calibration

6. Battery replacement

7. Calibration foils

8. Trouble shooting

9. Declaration of conformity

Annotation: It is strongly recommended to calibrate

the new instrument before the first use, as

described in paragraph 5. By doing this it

will be achieved a much better measure ment result right from the start.

1. Features

»This instrument meets the standards of both ISO 2178,

ISO 2360 as well as DIN, ASTM and BS. It is suitable for

the laboratory and for use in “harsh field” conditions.

»The F- mode measures the thickness of nonmagnetic

materials, e.g. paint, plastic, porcelain enamel, copper,

zinc, aluminium, chrome, laquer layers etc. These layers

are located on magnetic materials e.g. steel, iron,

nickle etc. It is often used to measure the thickness of

galvanizing layer, laquer layer, porcelain enamel layer,

phosphide layer, copper tile, aluminium tile, some alloy

tile, paper etc.

»The N- mode measures the thickness of nonmagnetic

coatings on nonmagnetic materials.

It is used on anodizing, varnish, paint, enamel, plastic

coatings, powder etc. It can be applied on aluminium,

brass, nonmagnetic stainless steel etc.

»Automatic substrate recognition.

»Manual or automatically auto power off to conserve

batteries

»Two measurement modes:- single and continuous

»Date transfer to PC possible

2. Specifications

Display: 4 digits

Range: 0 to 1250 µm/ 0 to 50 mil

Resolution: 0.1µm (0 to 100 µm)

1 µm (over 100 µm)

Accuracy:

Standard:

Is valid within a tolerance range of ± 100 μm around the

individually measured range, if a two-point calibration was

performed within this tolerance range.

- Off-Set Accur Mode:

or min. ± 1.0 µm

Is valid within ± 50 μm around the Off-Set Accur point.

PC- interface: with RS-232C interface

Power supply: 4x 1.5V AAA (UM-4) battery

Operating conditions:

Temperature: 0 to 50°C

Humidity: <80%

Size: 126 x 65 x 27mm (5.0 x 2.6 x 1.1 inch)

Weight: about 81g (not including batteries)

Accessories: Carrying case

Operation manual

F-sensor (inbuilt)

FN-sensor (inbuilt)

Calibration foils

Base plate (iron)

Base plate (aluminium)

Optional accessories: Cable & software for RS-232C

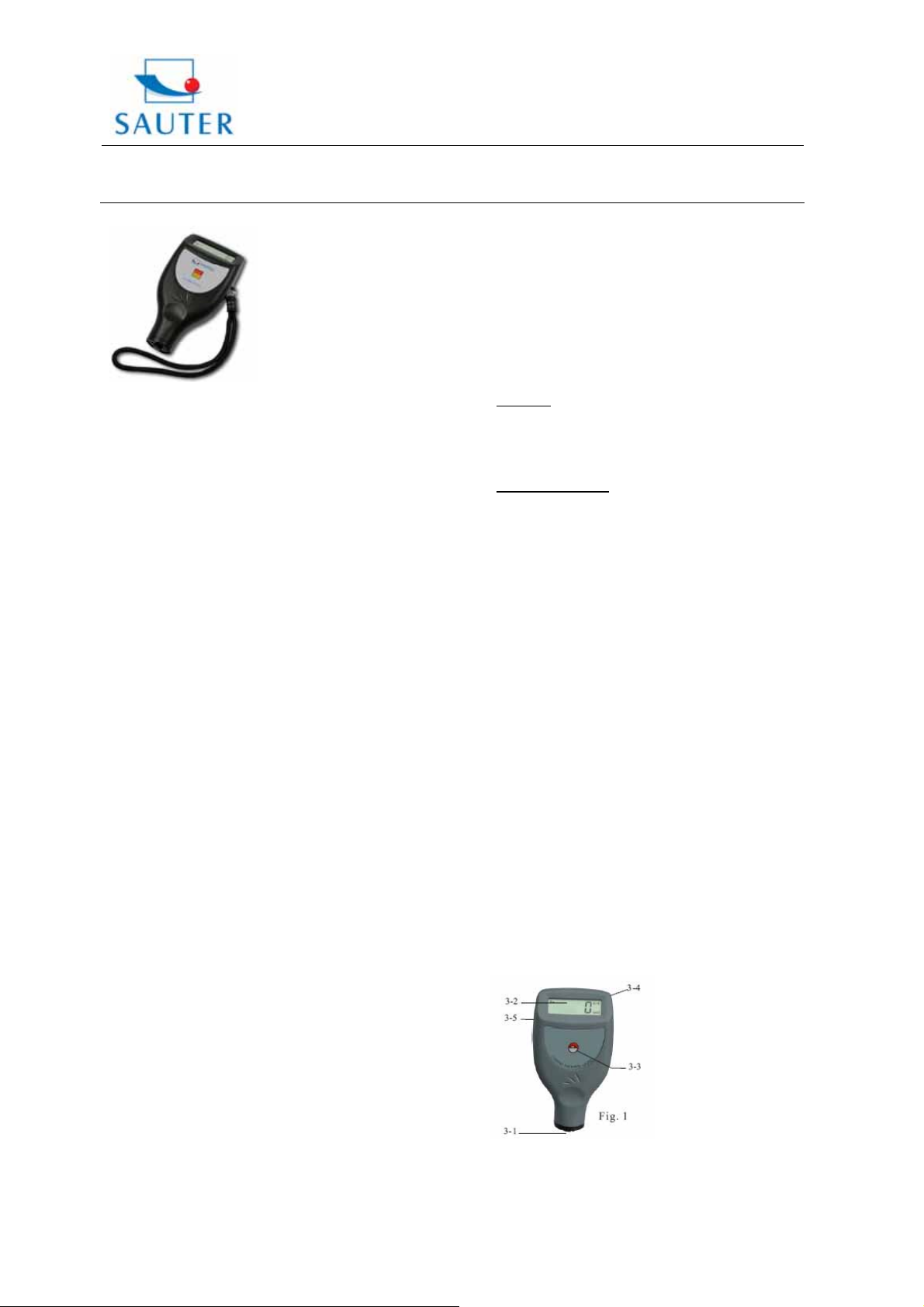

3. Front panel description

3-1 Sensors (inbuilt)

3-2 Display

3-3 Zero- key, Power- on/ Power- off key

3% of the measured value or min. ± 2.5 µm

Fax: +49-[0]7433-9976-285

Internet: www. sauter.eu

1% of the measured value

TC_car-BA-e-1110 1

Page 2

Sauter GmbH

Tieringerstr. 11-15 Tel: +49-[0]7433- 9976-174

D-72336 Balingen

E-Mail: info@sauter.eu

Instruction Manual

TC_car

3-4 Battery compartment/ cover

3-5 Jack for RS-232C interface

4. Measuring procedure

4.1 The Power- on/Power-off key 3-3 is to be pressed to

switch on the instrument.`0`appears on the display 3-2.

The instrument recognizes the sensor itself,by the

symbol `Fe` (= F) or `NFe` (= N) which is indicated

on the display. The instrument enters the auto mode

which can automatically recognize the base plate.

4.2 The sensor 3-1 is to be placed onto a coating layer to

be measured. The reading on the display is the thick ness of the coating layer.

4.3 For the next measurement the sensor 3-1 is to be

lifted for more than 1cm and step 4.2 is to be

repeated.

4.4 In case of inaccuracies to the measurement result it is

recommended to calibrate the instrument before

measuring as described in part 5.

4.5 The instrument can be switched off by pressing the

Power- on/ Power- off key 3-3. The power will switch

itself off 50 seconds after the last operation.

4.6 The measurement unit can be indicated with `µm` or

`mil`. To convert:

The Zero/ Power- on/ off key 3-3 has to be pressed

and not to be released until `UNIT` appears on the

display. The measurement unit changes by releasing.

All in all this operation lasts about 6 seconds (from

starting pressing the Zero-/ Power-on/ off key).

4.7 To change the measuring mode from `single` to `con tinuous or vice visa, the Zero/ Power- key 3-3

is to be pressed and not released until `SC` appears

on the display. The measuring mode changes into

the other one when the key is released. This lasts

about 8 seconds. The symbol ((•)) on the display

indicates the continuous mode.

5. Calibration

5.1 Zero adjustment:

Zero adjustment for `Fe` (=F) and `NFe` (=NF) should

be carried out separately.

The iron base plate is to be used if `Fe` is

shown on the display. The base plate of aluminium is

to be used if `NFe` is shown on the display.

The sensor 3-1 is to be placed carefully onto the base

plate and the Zero-/ Power key is to be pressed without

lifting the sensor. `0` appears on the display.

Attention: The calibration is invalid if the sensor is

not directly placed on the base plate or another un coated material.

6. Battery replacement

6.1 If the battery symbol ``+/-`` appears on the display, the

batteries should be replaced.

6.2 The battery cover 3-4 is to be removed and the

batteries are to be taken off.

6.3 The batteries (4x1.5V AAA/UM-4) are to be installed

Fax: +49-[0]7433-9976-285

Internet: www. sauter.eu

correctly into the case.

6.4 If the instrument is not to be used for an extended

period, batteries are to be extracted.

7. Calibration foils

As accessory there is included a foil set of different foils

and ranges, which is to be seen below.

Range

(µm)

0-200 X X X X

0-500 X X X X

01000

02000

8. Trouble shooting

8.1 The instrument should always be calibrated on the

uncoated base material to be measured instead of the

base plate included in the delivery. Then the

accuracy is more precise.

8.2 Sensors will eventually wear off. Life of the sensor will

depend on the number of measurements taken and

how abrasive the coating is.

9. Declaration of conformity

STANDARD FOIL INCLUDED

CM

CM

25

50

X X X X X

X X X X X

CM

100

CM

200

CM

500

CM

1000

TC_car-BA-e-1110 2

Page 3

Sauter GmbH

Tieringerstr. 11-15

D-72336 Balingen

E-Mail: info@sauter.eu

Tel: +49-[0]7433- 9976-174

Fax: +49-[0]7433-9976-285

Internet: www. sauter.eu

Instruction Manual

TC_car

TC_car-BA-e-1110 3

Loading...

Loading...