Page 1

KERN & Sohn GmbH

Ziegelei 1

D-72336 Balingen

email: info@kern-sohn.com

Phone: +49-[0]7433- 9933-0

Internet: www.kern-sohn.com

Operating instructions

Bottleweighing Balance

KERN SMT

Version 1.4

12/2014

GB

Fax: +49-[0]7433-9933-149

SMT-BA-e-1414

Page 2

KERN SMT

Bottleweighing Balance

GB

Version 1.4 12/2014

Operating instructions

Table of Contents

1 Technical Data ........................................................................................................... 3

2 Basic Information (General) ..................................................................................... 4

2.1 Proper use .............................................................................................................................................. 4

2.2 Improper Use ......................................................................................................................................... 4

2.3 Warranty ................................................................................................................................................. 4

2.4 Monitoring of Test Resources ............................................................................................................. 4

3 Basic Safety Precautions ......................................................................................... 5

3.1 Pay attention to the instructions in the Operation Manual ............................................................... 5

3.2 Personnel training ................................................................................................................................. 5

4 Transportation & Storage ......................................................................................... 5

4.1 Testing upon acceptance ..................................................................................................................... 5

4.2 Packaging / return transport ................................................................................................................ 5

5 Unpacking, Setup and Commissioning ................................................................... 6

5.1 Installation Site, Location of Use ......................................................................................................... 6

5.2 Unpacking .............................................................................................................................................. 6

5.3 Mains connection .................................................................................................................................. 6

5.4 Connection of peripheral devices ........................................................................................................ 6

5.5 Initial Commissioning ........................................................................................................................... 6

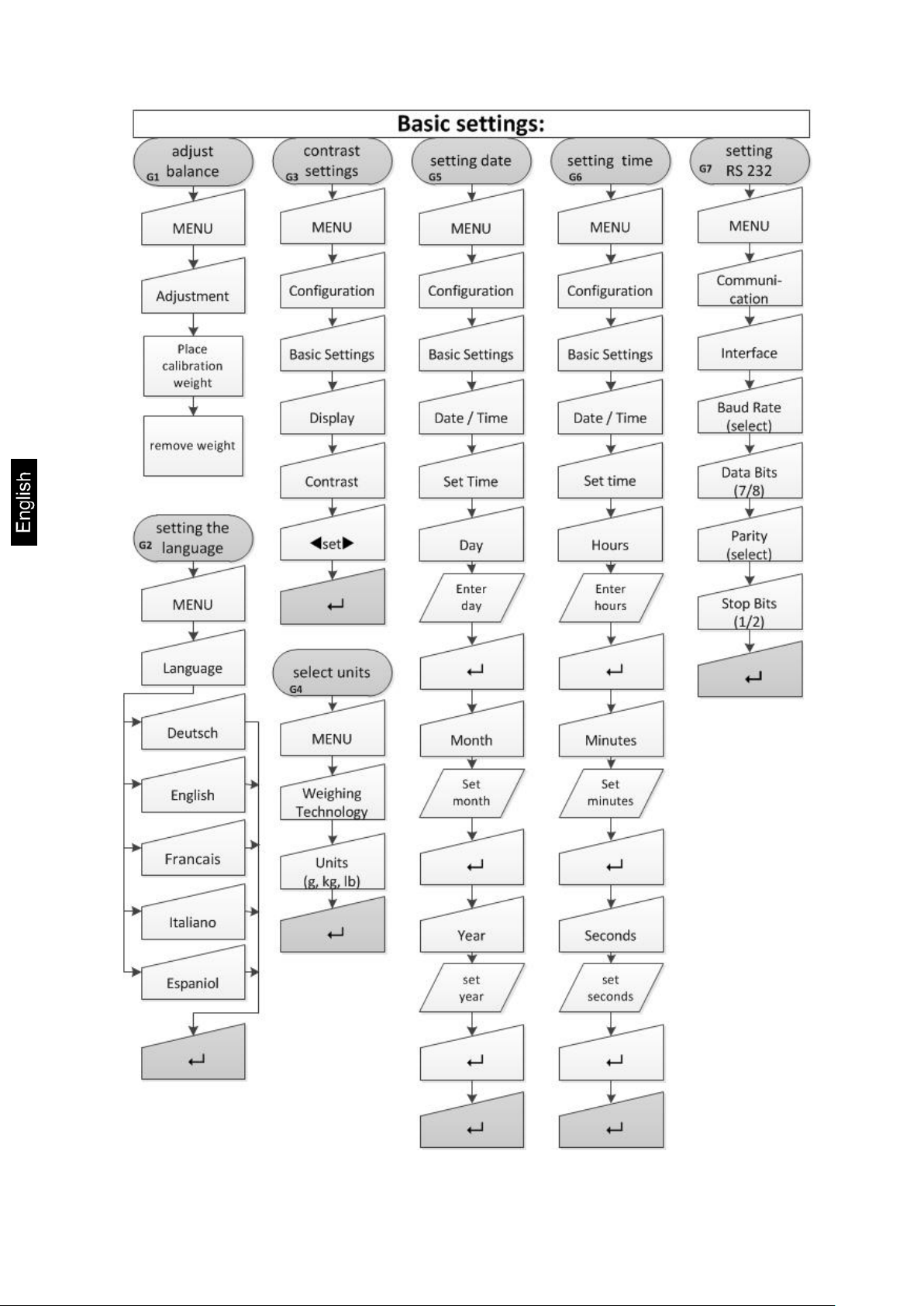

5.6 Adjustment ............................................................................................................................................. 7

5.7 Adjustment ............................................................................................................................................. 7

5.8 Verification ............................................................................................................................................. 7

6 Operation ................................................................................................................... 8

6.1 Starting balance by touch screen ........................................................................................................ 8

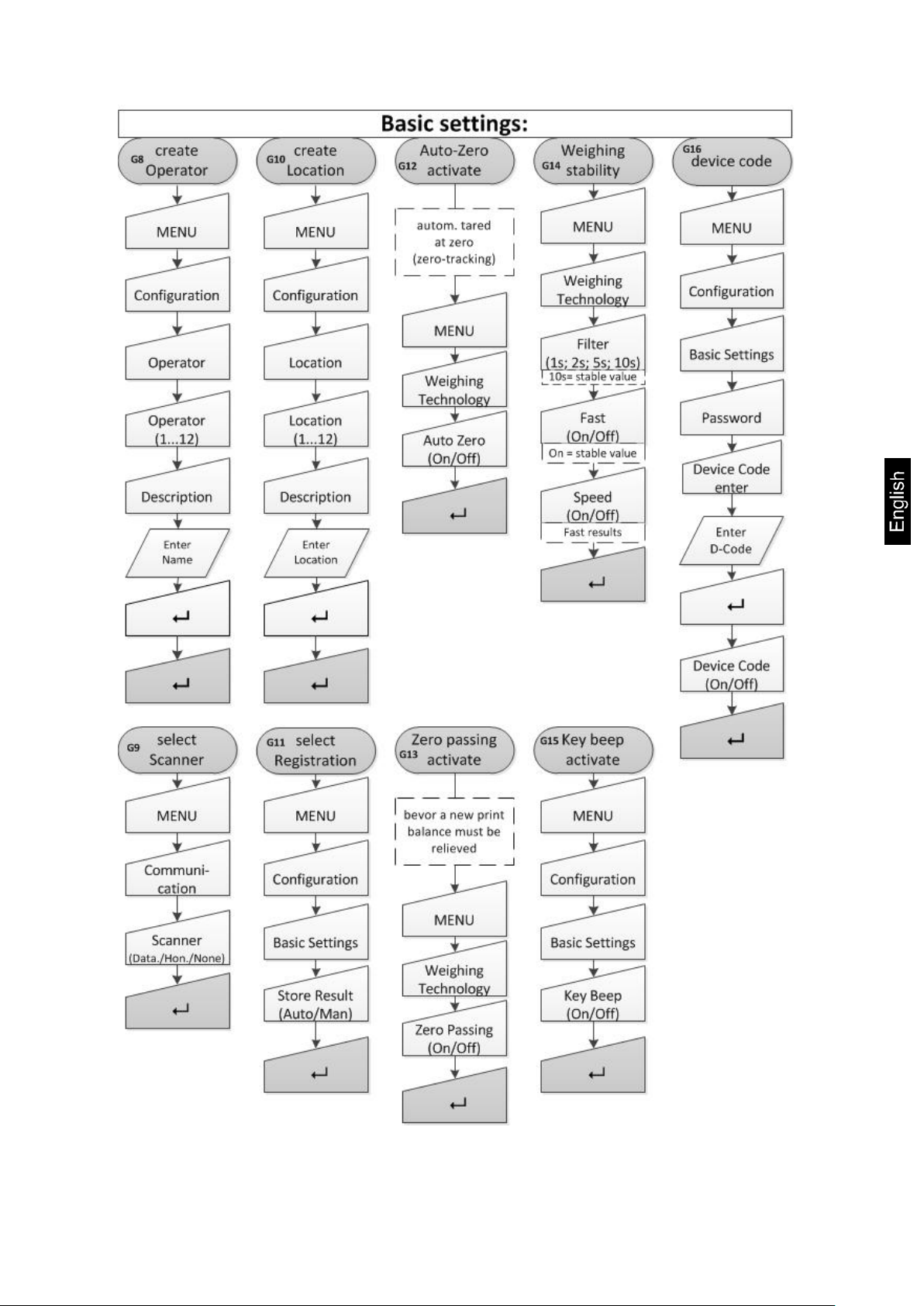

6.2 Select operator and location .............................................................................................................. 11

6.3 Start stocktaking: ................................................................................................................................ 12

6.4 Selecting the drink / Find out the ingredients and save: ................................................................ 13

6.5 Deleting a record: ................................................................................................................................ 15

6.6 Entry with autolist: .............................................................................................................................. 16

6.7 Scanner selection:............................................................................................................................... 18

6.8 Activate automatic storage results: .................................................................................................. 21

6.9 Input of operator and locations: ........................................................................................................ 22

6.10 Enabling / Disabling the zero passing: ............................................................................................. 25

6.11 Activation of the automatic switch-over to numeric entry .............................................................. 26

6.12 Data Transfer PC-SMT, SMT-PC ........................................................................................................ 28

7 Data output RS 232 C .............................................................................................. 34

7.1 Interface RS 232C ................................................................................................................................ 34

8 Service, maintenance, disposal ............................................................................. 35

8.1 Cleaning ............................................................................................................................................... 35

8.2 Service, maintenance .......................................................................................................................... 35

8.3 Disposal ................................................................................................................................................ 35

9 Instant help .............................................................................................................. 36

10 Declaration of c onform ity ....................................................................................... 37

SMT-BA-e-1414 2

Page 3

(max)

(subtractive)

(not supplied)

(typical)

mm

stainless steel mm

1 Technical Data

KERN SMT 10K-3

Readability (d) 1 g

Weighing range

Taring range

10 000 g

10 000 g

Reproducibility 1 g

Linearity ±0,5 g

Adjustment points 2 kg / 5 kg / 10 kg

Recommended

adjusting weight F1

10 kg

Humidity of air max. 80% rel. (non-condensing)

Stabilization time

Allowable ambient

temperature

+10 °C ... + 40 °C

3 sec.

Housing (B x D x H)

180 x 310 x 90

Vibration filter yes

Weighing plate

160 x 200

Units g, kg, lb

Weight kg (net) 2,7

Data interface yes (RS232)

3 SMT-BA-e-1414

Page 4

2 Basic Information (General)

It is absolutely necessary that you read and understand the operating instructions prior to

installation and commissioning and follow the instructions during the process!

2.1 Proper use

The balance you purchased is intended to determine the weighing value of material to be

weighed. It is intended to be used as a “non-automatic“ balance, i.e. the material to be

weighed is manually and carefully placed in the centre of the weighing plate. As soon as a

stable weighing value is reached the weighing value can be read.

2.2 Improper Use

Do not use balance for dynamic weighing. In the event that small quantities are removed or

added to the material to be weighed, incorrect weighing results can be displayed due to the

“stability compensation“ in the balance (Example: Slowly draining fluids from a container on

the balance.).

Do not leave permanent load on the weighing plate. This may damage the measuring

system.

Impacts and overloading exceeding the stated maximum load (max) of the balance, minus

a possibly existing tare load, must be strictly avoided. Balance may be damage by this.

Never operate balance in explosive environment. The serial version is not explosion

protected.

The structure of the balance may not be modified. This may lead to incorrect weighing

results, safety-related faults and destruction of the balance.

The balance may only be used according to the described conditions. Other areas of use

must be released by KERN in writing.

2.3 Warranty

Warranty claims shall be voided in case

- Our conditions in the operation manual are ignored

- The appliance is used outside the described uses

- The appliance is modified or opened

- mechanical damage and damage caused by media, liquids

- natural wear and tear

- The appliance is improperly set up or incorrectly electrically connected

- The measuring system is overloaded

2.4 Monitoring of Test Resources

In the framework of quality assurance the measuring-related properties of the balance and,

if applicable, the testing weight, must be checked regularly. The responsible user must

define a suitable interval as well as type and scope of this test. Information is available on

KERN’s home page (www.kern-sohn.com) with regard to the monitoring of balance test

substances and the test weights required for this. Our accredited DKD calibration laboratory

offers fast and inexpensive adjustment for test weights and weighing balances (reset to

national normal weight).

SMT-BA-e-1414 4

Page 5

3 Basic Safety Precautions

3.1 Pay attention to the instructions in the Operation Manual

Carefully read this operation manual before setup and

commissioning, even if you are already familiar with KERN

balances.

3.2 Personnel training

The appliance may only be operated and maintained by trained personnel.

4 Transportation & Storage

4.1 Testing upon acceptance

When receiving the appliance, please check packaging immediately, and the appliance

itself when unpacking for possible visible damage.

In case of visible damage have the damage verified by the messenger’s signature. Do not

alter goods or packaging and do not remove any parts of the delivery. Report the damage

immediately (within 24 hours) in writing to the parcel service.

4.2 Packaging / return transport

Keep all parts of the original packaging for a possibly required return.

Only use original packaging for returning.

Prior to dispatch disconnect all cables and remove loose/mobile parts.

Reattach possibly supplied transport securing devices.

Secure all parts such as the glass wind screen, the weighing platform,

power unit etc. against shifting and damage.

5 SMT-BA-e-1414

Page 6

5 Unpacking, Setup and Commissioning

5.1 Installation Site, Location of Use

The balances are designed in a way that reliable weighing results are achieved in common

conditions of use.

You will work accurately and fast, if you select the right location for your balance.

Therefore, observe the following for the installation site:

- Place the balance on a firm, level surface;

- Avoid extreme heat as well as temperature fluctuation caused by installing next to a

radiator or in the direct sunlight;

- Protect the balance against direct draughts due to open windows and doors;

- Avoid jarring during weighing;

- Protect the balance against high humidity, vapors and dust;

- Do not expose the device to extreme dampness for longer periods of time. Non-

permitted condensation (condensation of air humidity on the appliance) may occur if

a cold appliance is taken to a considerably warmer environment. In this case,

acclimatize the disconnected appliance for ca. 2 hours at room temperature.

- Avoid static charging of the material to be weighed, weighing container and

windshield.

If electro-magnetic fields or static charge occur, or if the power supply is unstable major

deviations on the display (incorrect weighing results) are possible. In that case, the location

must be changed.

5.2 Unpacking

Carefully remove the balance from the packaging, remove plastic cover and setup balance

at the intended workstation.

5.3 Mains connection

Power is supplied via the external mains adapter. The stated voltage value must be the

same as the local voltage.

Only use original KERN mains adapters. Using other makes requires consent by KERN.

5.4 Connection of peripheral devices

Before connecting or disconnecting of additional devices (printer, PC) to the data interface,

always disconnect the balance from the power supply. With your balance, only use

accessories and peripheral devices by KERN, as they are ideally tuned to your balance.

5.5 Initial Commissioning

A warming up time of 2 hours after switching on stabilizes the measuring values.

The accuracy of the balance depends on the local acceleration of gravity.

Strictly observe hints in chapter “Adjustment”.

SMT-BA-e-1414 6

Page 7

5.6 Adjustment

As the acceleration value due to gravity is not the same at every location on earth, each

balance must be coordinated - in compliance with the underlying physical weighing principle

- to the existing acceleration due to gravity at its place of location (only if the balance has

not already been adjusted to the location in the factory). This adjustment process must be

carried out during the initial start-up, after change in location and variation of surrounding

temperature. To receive accurate measuring values it is also recommended to adjust the

balance periodically in weighing operation.

5.7 Adjustment

With an adjustment weight, the weighing accuracy can be checked and re-adjusted at any

time.

Attention: In the verified balances the adjustment is not possible.

Procedure when a djusting:

Observe stable environmental conditions. A short warming up time of ca. 15 minutes is

recommended for stabilization.

5.8 Verification

General introduction:

According to EU directive 90/384/EEC balances must be verified if they are used as follows

(legally controlled area):

a) For commercial transactions if the price of goods is determined by weighing.

b) For the production of medicines in pharmacies as well as for analyses in the medical

and pharmaceutical laboratory.

c) For official purposes

d) For manufacturing final packages

In cases of doubt, please contact your local trade in standard.

Verification instructions

An EU type approval exists for balances described in their technical data as verifiable. If a

balance is used where obligation to verify exists as described above, it must verified and reverified in regular intervals.

Re-verification of a balance is carried out according to the respective national regulations.

The validity for verification of balances in Germany is e.g. 2 years.

The legal regulation of the country where the balance is used must be observed!

7 SMT-BA-e-1414

Page 8

After touching the touch

6 Operation

6.1 Starting balance by touch screen Welcome display:

screen and starting the

balance, this screen will

appear.

To start stocktaking, it is

obligatory to enter location

and operator.

Please press the inverted

buttons.

SMT-BA-e-1414 8

Page 9

9 SMT-BA-e-1414

Page 10

SMT-BA-e-1414 10

Page 11

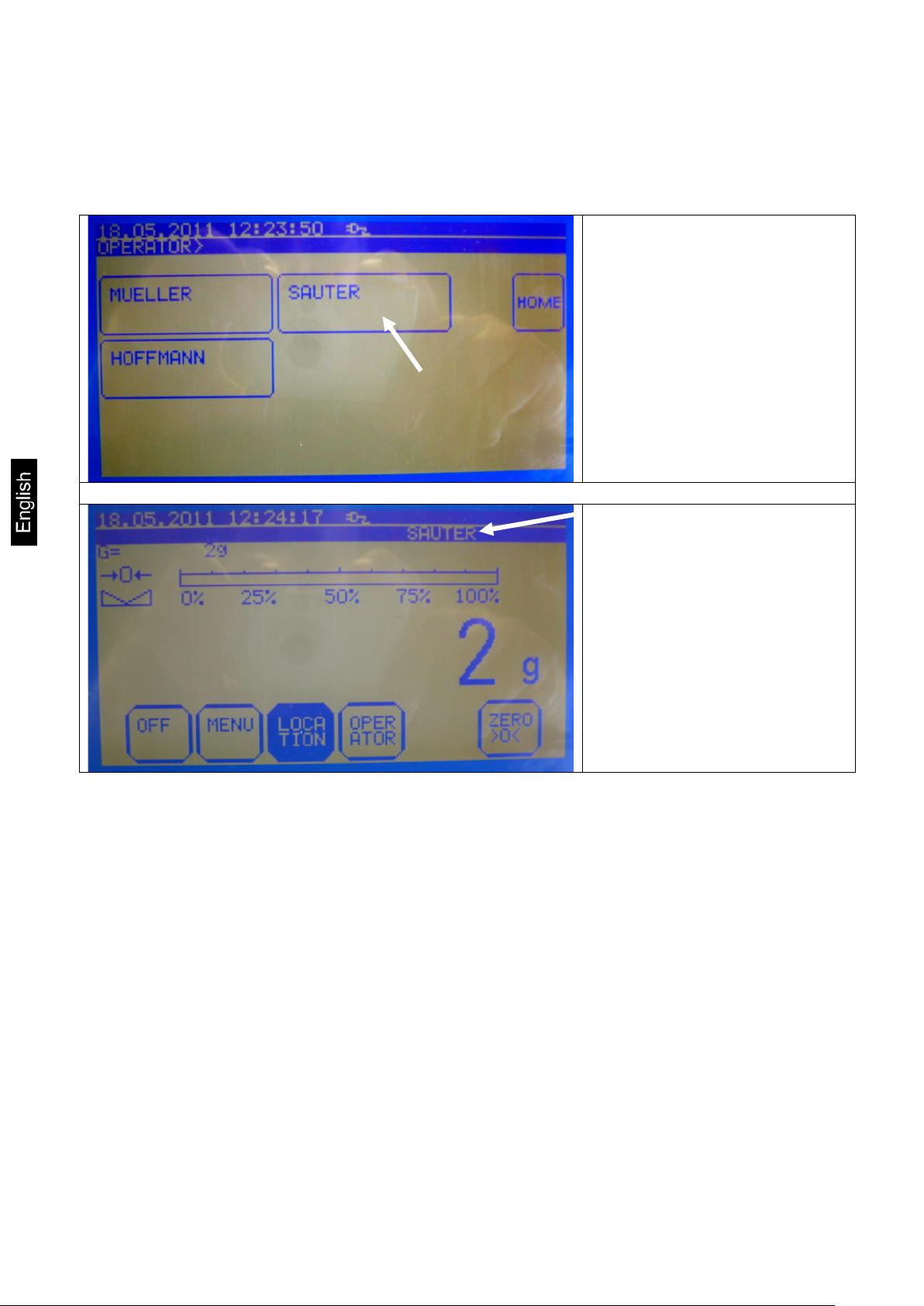

Press the operator button and

In the second information line

6.2 Select operator and location Select operator:

an option display for admitted

operators will appear.

Confirm them with selection.

If no operators are available,

these must be entered anew

via MENUE /

CONFIGURATION /

OPERATOR / DESCRIP TION.

appears now the selected

operator (see arrow).

11 SMT-BA-e-1414

Page 12

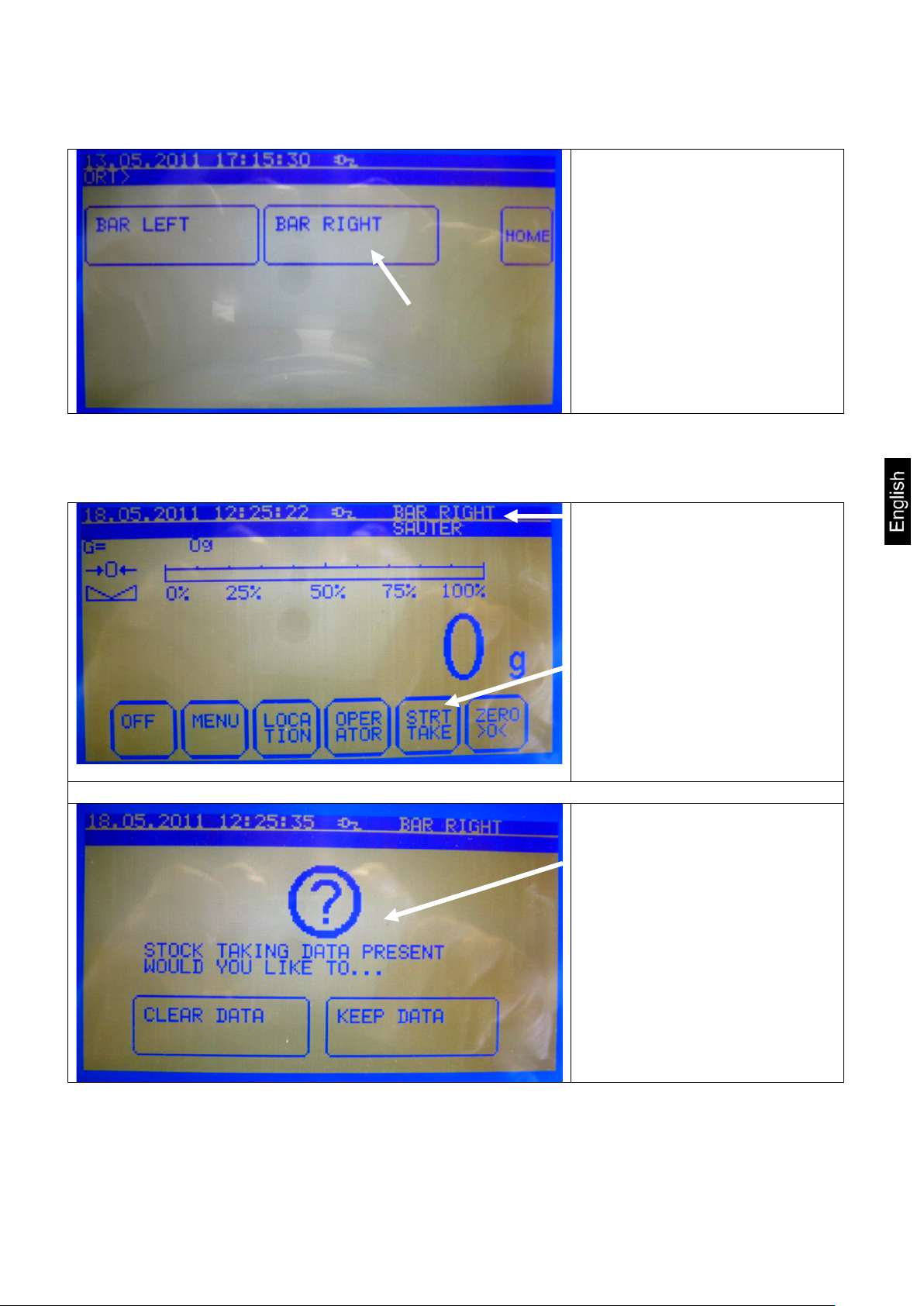

Press the Location button and

In the first information line

If there exist data of a former

Select location:

6.3 Start stocktaking:

the option displays of the

available locations will appear.

Confirm the correct location by

pressing the selection button.

If no selection fields can be

found, enter some of them via

MENU / CONFIGURATION /

LOCATION / DESCRIPTION.

appears now the selected

location of stocktaking.

In addition the

“STRT/TAKE “button will

appear on the display screen.

Pressing this button will allow

you to start your stocktaking.

stocktaking, a selection field

will appear if you want to keep

them or to delete them.

SMT-BA-e-1414 12

Page 13

Press the start button to

If selected via „SRCH-NAME“,

If selected via „SRCH-CODE“,

trigger this screen asking you

to select a drink.

Drink may be selected via

SRCH-CODE

SRCH-NAME

AUTO-LIST or

SCAN function may be carried

out.

6.4 Selecting the drink / Find out the ingredi ents and save: Input via keyboard:

this keyboard input field will

appear.

Enter the name of the drink

until a direct selection via

selecting fields will be

possible.

this keyboard input field will

appear.

Enter the code of the drink

until a direct selection via

selecting fields will be

possible.

13 SMT-BA-e-1414

Page 14

Enter the name of the drink.

Now a direct selection can

The selected drink now will

In the second information line

the information will appear if a

selection via selecting fields

will be available.

Please press the return button.

take location via the selecting

fields.

appear at the left in the

second information line.

SMT-BA-e-1414 14

Page 15

Put the selected drink on the

Press the “FRAC/VOL” button

Press the OK/Take button to

balance.

Now the contents of the bottle

will be displayed as a result in

cl.

and the proportional value for

the content will be displayed.

Save the bottle content using

the „OK/TAKE“ button.

6.5 Deleting a record:

trigger the second information

line asking you to select an

other drink.

If the last item of inventory is

to be deleted or the same

beverage put into another

bottle, then press the "CLR /

BACK" button. An overview of

the last drink records are

displayed in the same way.

15 SMT-BA-e-1414

Page 16

After pressing the "CLR /

For the selection of the

After that this screen will

6.6 Entry with autolist:

BACK" button, the last

inventory will be displayed.

To delete the last inventory

"Clear Registry" will be

pressed.

Should the same kind of

beverage be filed again then

press "Last beverage” button.

existing drink list from the

stocktaking screen

(STOP/TAKE) press the

„STRT/TAKE“ button.

appear.

Now press the „AUTO/LIST“

button.

SMT-BA-e-1414 16

Page 17

Now in the second information

Place the specified bottle.

For automatic storage of

line the first listed drink

appears.

The bottle content will be

displayed in „CL“.

results the result will be taken

over and in the second

information line the note „next

drink“ will ask you to remove

the bottle.

17 SMT-BA-e-1414

Page 18

When the bottle is removed,

The type of drink selection

Now press the

6.7 Scanner selection:

the following drink appears.

Use the „BACK/DRNK“ button

to register an other bottle of

the previous drink.

Use the „NEXT/DRNK“ button

to skip not existing drinks.

must be carried out from the

basic screen (STOP/TAKE)

via the menu button.

„Communication“ button.

SMT-BA-e-1414 18

Page 19

Now select the suitable

scanner.

When the desired scanner is

selected, confirm via the return

button.

Table

Scanner

Datalogic

19 SMT-BA-e-1414

Page 20

Handheld Scanner

Datalogic Quick Scan Mobile

SMT-BA-e-1414 20

Page 21

To determine the automatic

If the automatic storage of

6.8 Activate automatic storage results:

storage of results from the

basic screen, press the

„MENU“ button.

results has to be activated,

press the „Configuration“

button.

21 SMT-BA-e-1414

Page 22

Now press the „Basic settings“

Press the „Store Result:Auto“

Press the „MENU“ button from

button.

button and acknowledge with

Enter.

6.9 Input of operator and locations: Input of an operator:

the basic screen

(STOP/TAKE)

SMT-BA-e-1414 22

Page 23

Now press the „Configuration“

Now press the „Operator“

With the help of the operator

button.

button.

To enter a location press the

„Location“ button.

number the admitted operators

can be called up and edited.

23 SMT-BA-e-1414

Page 24

To enter a new operator,

Enter the name via the input

To enter a new location via the

overwrite no longer required

operators or call up empty

description fields by pressing

them.

keyboard field.

Save the correct name via the

Enter button.

Input of a location:

location number, call up a

previous location and

overwrite or write anew into an

empty field.

For this purpose press the

„Description“ button.

SMT-BA-e-1414 24

Page 25

Enter the location via the input

Press the „MENU“ button from

Subsequently trigger the

6.10 Enabling / Disabling the ze r o passing:

keyboard field.

Save the location via the Enter

button.

the basic screen

(STOP/TAKE).

„Weighing technology“ button.

25 SMT-BA-e-1414

Page 26

Now the selection may take

In order to shorten the time for

Now press the configuration

location via the zero-passing

button.

After that save with the enter

button.

6.11 Activation of the automatic switch-over to numeric entry

a serial input via SRCH /

CODE in time, so an

automatic switch-over

can be generated after saving.

To do this press the "MENU"

button.

button.

SMT-BA-e-1414 26

Page 27

Now press the „Basic settings“

Now press the arrow button

Set AUTO INPUT to "ON" and

button.

save.

27 SMT-BA-e-1414

Page 28

Bring back balance into the

Connect the PC to the balance

6.12 Data Transfer PC-SMT, SMT-PC

SETUP

Setup Balance

basic screen (STOP/TAKE).

via the RS 232 interface.

SMT-BA-e-1414 28

Page 29

Setup Application

Requirements:

• Windows XP or higher

• Microsoft Office 2003 or higher

• .Net Framework 2.0 or higher

1. Go to Settings Menu

2. Choose the SerialPort you connected your balance to

3. Select the Baudrate to same value as balance have(Default: 9600)

29 SMT-BA-e-1414

Page 30

UPLOAD DATA

1. Make sure balance is in basic Mode

2. Choose your File with File → Open

SMT-BA-e-1414 30

Page 31

3. Press „Upload from PC > balance“ Button to Upload the chosen File

Information: It will upload the same file everytime, till you select another one.

31 SMT-BA-e-1414

Page 32

DOWNLOAD DATA

1. Make sure balance is in basic Mode

2. Press „Download balance PC“ Button

3. You'll be asked for a filename

SMT-BA-e-1414 32

Page 33

4. Excel will automatically open containing the transfered Data

33 SMT-BA-e-1414

Page 34

5 1

9 6

7 Data output RS 232 C

Technical data:

8-bit ASCII Code

1 start bit, 8 data bits, 1 stop bit, no parity bit

Baud rate selectable from 2400, 4800, 9600 Baud (factory setting) and 19200 Baud.

Sub-D plug 9-channel required

For operation with interface faultless operation is only ensured with the correct KERN –

interface cable (max. 2m)

Pin allocation of the balance output socket (front view)

Sub-D jack 9-channel

Pin 2: Transmit data

Pin 3: Receive data

Pin 5: Signal ground

7.1 Interface RS 232C Data output via interface RS 232C

General

The previous condition for the data transfer between balance and a peripheral device (e.g.

printer, PC ...) is that the appliances are set to the same interface parameters (e.g. baud

rate, parity ...).

SMT-BA-e-1414 34

Page 35

8 Service, maintenance, disposal

8.1 Cleaning

Before cleaning, please disconnect the appliance from the operating voltage.

Please do not use aggressive cleaning agents (solvents or similar agents), but a cloth

dampened with mild soap suds. Ensure that no liquid penetrates into the device and wipe

with a dry soft cloth. Loose residue sample/powder can be removed carefully with a brush

or manual vacuum cleaner.

Spilled weighing goods m ust be removed immediately.

8.2 Service, maintenance

The appliance may only be opened by trained service technicians who are authorized by

KERN. Before opening, disconnect from power supply.

8.3 Disposal

Disposal of packaging and appliance must be carried out by operator according to valid

national or regional law of the location where the appliance is used.

35 SMT-BA-e-1414

Page 36

The displayed weight does not glow.

• The balance is not switched on.

interrupted (mains cable not plugged in/faulty).

• Power supply interrupted.

The displayed weight is permanently

changing

• Table/floor vibrations

arging (choose

possible)

The weighing value is obviously

• The display of the balance is not at zero

wrong

• Adjustment is no longer correct.

tatic charging (choose

possible)

9 Instant help

In case of an error in the program process, briefly turn off the balance and disconnect from

power supply. The weighing process must then be restarted from the beginning.

Help:

Fault Possible cause

• The mains supply connection has been

• Draught/air movement

• Weighing plate has contact with other objects.

• Electromagnetic fields / static ch

different location/switch off interfering device if

• Great fluctuations in temperature.

• Electromagnetic fields / s

different location/switch off interfering device if

Should other error messages occur, switch balance off and then on again. If the error

message remains inform manufacturer.

SMT-BA-e-1414 36

Page 37

KERN & Sohn GmbH

D-72322 Balingen-Frommern

E-Mail: info@kern-sohn.de

Tel: 0049-[0]7433- 9933-0

Internet: www.kern-sohn.de

D

Konformitätserklärung

Wir erk lären hiermit, dass das Produkt, auf das sich diese Erk lärung bezieht,

mit den nachstehenden Normen übereinstimmt.

GB

Declaration of

conformity

We hereby declare that the pr oduct to which this declaration refers conforms

with the following standards.

CZ

Prohlášení o

shode

Tímto prohlašujem e, že výrobek, kterého se toto prohlášení týká, je v souladu

s níže uvedenými normami.

E

Declaración de

conformidad

Manifestamos en la presente que el producto al que se refiere esta

declaración está de acuerdo con las normas siguientes

F

Déclaration de

conformité

Nous déclarons avec cela responsabilité que le produit, auquel se rapport e la

présente déclaration, est conforme aux normes citées ci-après.

I

Dichiarazione di

conformitá

Dichiariamo con ciò che il prodotto al quale la presente dichiarazione si

riferisce è conforme alle norme di seguito citate.

NL

Conformiteitverklaring

Wij verklaren hiermede dat het product, waarop deze verklaring betrekking

heeft, met de hierna vermelde normen overeenstemt.

P

Declaração de

conformidade

Declaramos por meio da presente que o produto no qual se refere esta

declaração, corresponde às normas seguintes.

PL

Deklaracja

zgodności

Niniejszym oświadczamy, że produkt, którego niniejsze oświadczenie dotyczy,

jest zgodny z poniższymi normami.

RUS

Заявление о

соответствии

Мы заявляем, что продукт, к которому относится данная декларация,

соответствует перечисленным ниже нормам.

EU Directive

Standards

2004/108/EC

EN55011:2009+A1:2010

EN 45501: 1992-10+AC: 1993-08

2006/95/EC

EN 60950

2011/65/EU

EN 50581:2012

Signature

Datum

17.07.2014

Ort der Ausstellung

Place of issue

72336 Balingen

Albert Sauter

KERN & Sohn GmbH

Geschäftsführer

Managing director

KERN & Sohn GmbH, Ziegelei 1, D-72336 Balingen, Tel. +49-[0]7433/9933-0

Fax +49-[0]7433/9933-149, E-Mail: info@kern-sohn.com, Internet: www.kern-sohn.com

10 Declar a t ion of conformity

Postfach 4052

Fax: 0049-[0]7433-9933-149

Declaration of conformity

EC-Konformitätserklärung EC-Declaration of -Conformity

Déclaration de conformité EC-Declaración de Conformidad

ECEC-Dichiarazione di conformità EC-Conformiteitverklaring

EC- Declaração de conformidade EC- Prohlášení o shode

EC-Deklaracja zgodności EC-Заявление о соответствии

Electronic Balan ce: KERN SMT

Date

EN 55022: 2010/AC:2011

EN 55024: 2010

OIML R 76-1: 2006

OIML R 76-2: 2006

Signatur

37 SMT-BA-e-1414

Loading...

Loading...