Page 1

KERN & Sohn GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@kern-sohn.com

Phone: +49-[0]7433- 9933-0

Internet: www.kern-sohn.com

Operating manual

KERN OEX

Version 1.1

10/2014

GB

Platform balance

Fax: +49-[0]7433-9933-149

Doc.No.OEX-BA-e-1411

Page 2

KERN OEX

Platform balance

GB

Version 1.1 10/2014

Operating manual

Contents

1 Pay attention to the instructions in the Operation Manual ............................. 3

2 Intended use for OEX balances ......................................................................... 4

3 Design of OEX balances with one weighing cell ............................................. 4

5 ATEX marking – meaning of icon ..................................................................... 7

6 Installation instruction for balance ................................................................... 9

7 Changing the installation site for the balance ............................................... 13

8 Cleaning and maintenance .............................................................................. 14

9 Technical examination ..................................................................................... 15

2 Doc.No.OEX-BA-e-1411

Page 3

1 Pay attention to the instructions in the Operation Manual

Carefully read this operation manual befor e setup and

commissioning, even if you are already familiar with

Conformity with these operating instructions is a precautionary measure for the safe

operation of IEX balances in ex-protected spaces.

Employees should familiarize themselves with the device’s components described in

the operating instructi o ns :

• Display KEX-TM

• Power unit IEX-A01-U, IEX-A01-E

These operating instru c ti ons should be freely available for consultation to the

employees.

The operating instructions contain the icons shown below:

• Continuously prescribed actions

• Actions prescribed under certain circumstances

KERN balances.

All language versions contain a non-binding

translation.

The original German is binding.

• Marking essential paragraphs dealing with explosion protec t ion

These operating instructions may be supplemented by additional warnings and safety

information provided by KERN.

All employees must be inform ed abo ut new supplements added to these oper ati ng

instructions.

Doc.No.OEX-BA-e-1411 3

Page 4

electrical part on the platform and the material used in zones 1

o

2 Intended use for OEX balances

Load in ex-protected spaces. It is possible to tare the balance over the entire working

range, thus allowing determination of the net weight.

The design of the balance (construction of non-electrical part of the platform balance

and material used) is in conformity with Directive 94/9/EE, applicable in countries of

the European Union.

• Due to their design, the balances of the IEX series can be used with

a nonand 2 where

o gasses, mixtures of gasses, vapour types IIA, IIB or IIC

o or explosive groups can develop,

as well as for temperature classes T1, T2, T3 or T4.

3 Design of OEX balances with one wei ghing cell

4 The construction of balances with one weighing cell of the IEX series is based on

the modular design principle and comprise:

• Display KEX-TM

• Power unit IEX-A01 by KERN, positioned outside the hazardous zone

• Weighing cell executed as ex-model

• Weighing platform, non-electric, mechanical balance component.

The display unit of the KEX-TM series is connected by a cable to the integrated

dynamometer (a weighing cell) of the platform. The platform bal a nc e compr is es a

weighing pan made of stainles s st eel pr oviding sufficient protecti on and al l owing

easy cleaning. The balances of the OEX series have a stainless steel weighing cell

providing advanced sturdiness against damaging influences in the ambient

conditions.

The cable used for connecting the weighing cell to the display unit is protected by a

rod or approx. 3 m long tube.

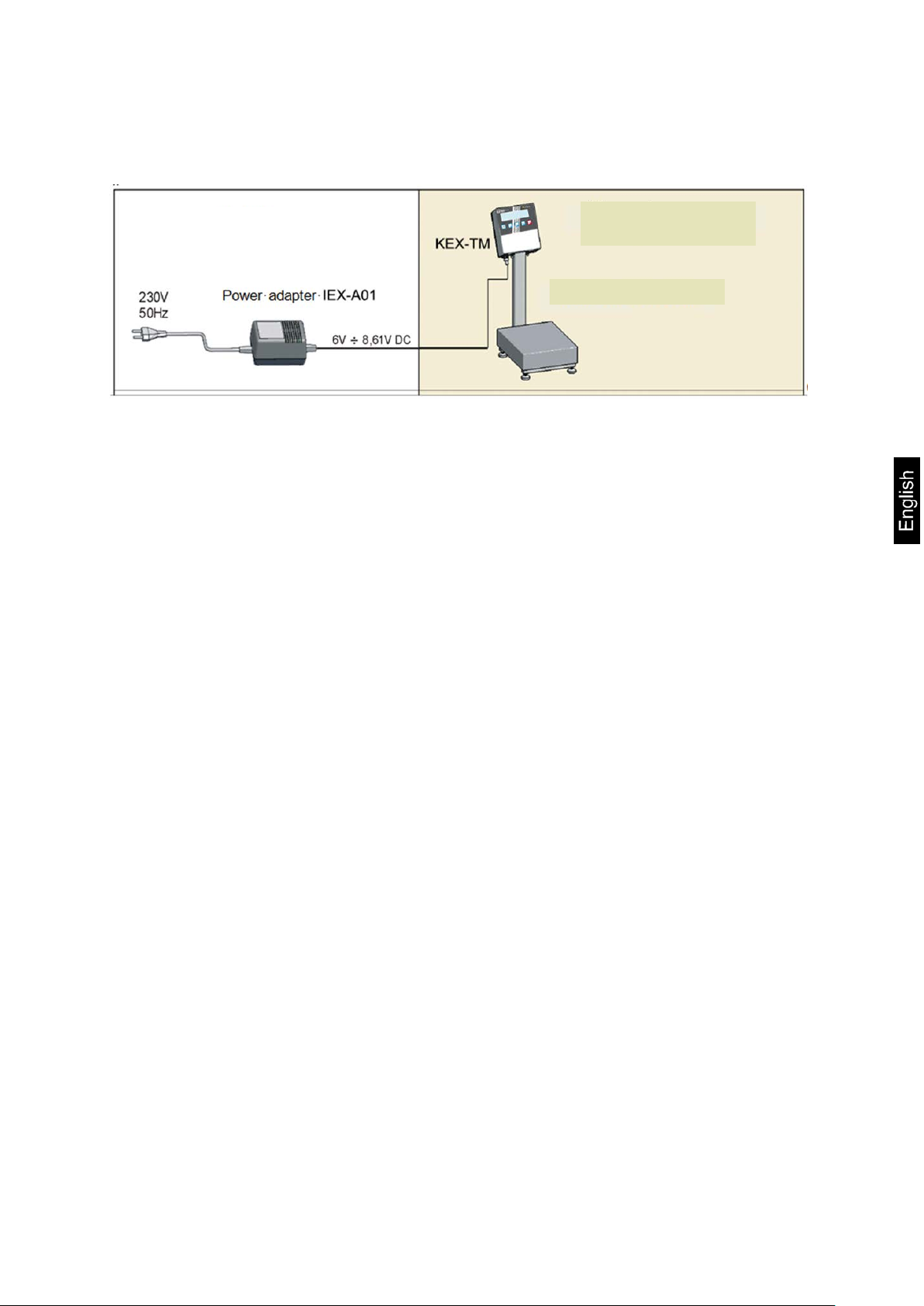

The display unit is supplied with energy by the KERN mains adapter IEX-A01

positioned outside the hazardous area. The mains adapter is plugged into the mains

power supply of 230V.

The housing of the display unit has a marked terminal for the PE conductor

(electrostatic disc harge). The housing is connected electrically to the platform

balance by a steel tube.

4 Doc.No.OEX-BA-e-1411

Page 5

Safe area

Ex-protected area

1 load cell balance

The balances of the OEX series are equipped with a KEX-TM display unit.

Doc.No.OEX-BA-e-1411 5

Page 6

Balance model

A1

A2 B C1

C2 D E

OEX 6K-3HM

306

246

103±3

268

208

~535

~485

OEX 10K-3HM

306

246

103±3

268

208

~535

~485

OEX 30K-2HM

410

410

98±2

370

370

~617

~613

OEX 60K-2HM

500

500

150±5

400

400

~790

~710

OEX 100K-1HM

500

500

150±5

400

400

~790

~710

Balances of the OEX series - dimensions

Balance model

A1

A2 B C1

C2

OEX 6K-3M

306

246

103±3

268

208

OEX 10K-3M

306

246

103±3

268

208

OEX 30K-2M

410

410

98±2

370

370

OEX 60K-2M

500

500

150±5

400

400

OEX 100K-1M

500

500

150±5

400

400

Balances of the OEX series - dimensions

Models with tripod:

Models without tripod:

6 Doc.No.OEX-BA-e-1411

Page 7

II 2 G IIC T4

Category for group II

devices:

1

2

3

Explosive atmosphere:

G

D

Icon for explosion

protection used

Construction

type:

o

p

q

d

e

ia

ib

Electrical

equipment

compatible with

one or few types

of explosion

protection

constructions

Gas explosivity group -

Examples:

-

-

,

Temperature class – max

surface temperature of device

parts exposed to explosive

mixtures:

T1: 4500C

of gas and vapour

Safety level

Gas atmosphere:

-

-

-

Dust atmosphere:

-

-

-

5 ATEX marking – meaning of icon

• The balances of the OEX series meet the requirements of group II,

Icon declaration as per Directive 94/9/EG:

class 2 for devices in as per Directive 94/9/EU and are marked as -

.

– The device

guarantees a very

high safety level,

- for operation in

areas 0,1,2

– The device

guarantees a very

high safety level,

- for operation in

areas 1,2

– The device

guarantees a normal

safety level,

- for operation in

Area 2

The balances of the OEX series are intended for indoor and outdoor use. However,

they should not be exposed to aggressive chemical vapours, critical temperatures

and high humidity. The platform balance construction is made of stainless steel.

Doc.No.OEX-BA-e-1411 7

– Caused by gas, steam

and mist.

– Caused by dust

–

– Oil protection

– Gas

protection

with

excessive

pressure

– Sand

protection

– Flameproof

protection

– Reinforced

construction

– Intrinsically

safe

construction

for operation

in areas

0,1,2,

– Intrinsically

safe

construction

for operation

in areas 1,2,

T2: 3000C

0

T3: 200

C

0

T4: 135

C

0

T5: 100

C

IIA: Propane (T1)

IIB: Ethylene (T2)

IIC: Acetylene (T2)

Benzene (T3)

Butane (T2)

Ethyl alcohol (T2)

Hydrogen (T1)

Ga

Gb

Gc

0

T6: 85

C

Temperature class

spontaneous ignition:

T1: > 450

T2: > 300

T3: > 200

T4: > 135

T5: > 100

T6: > 85

0

C

0

C

0

C

0

C

0

C

0

C

Da

Db

Dc

Page 8

The use of equipotential bonding is

explosive gasses can be

In the case of damage to the balance, unplug the plug, disconnect

the supply cable and take the device to a safe area for interim

storage so as to prevent any possible use of the balance before

result in loss of all rights to compensation under warranty.

• Ambient temperature d ur i ng operati o n -10°C to +40°C.

• The balance must be protected against mechanical shocks and

vibrations.

• The OEX balance must be installed and operated by expert staff.

• The balance should be serviced from time to time.

• Prevent electrostatic charge. Ensure t hat the ear th c ond uc tor

(equipotential) is connected to the KEX-TM display unit at all times.

• Do not disconnect PE conductor.

only admissible where the development of

completely ruled out.

•

repair.

• The display unit KEX-TM is designed intrinsically safe and is in

conformity with the following standards: PN-EN 60079-0 and PN-EN

60079-11 certified by KDB 14ATEX0110 certificate.

• The display unit is powered by mains adapter IEX-A01 made by

KERN and positioned outside the hazardous and is in conformity

with the standards: PN-EN 60079-0 and PN-EN 60079-11, certificate

KDB 14ATEX0109.

• The platform balance is used with weighing cells PC6, PC22, PC42,

PC60 and PCB supplied by Flintec which are certified for safe use in

hazardous areas - certi fica te BS V 09 ATE X E 086X.

• All non-electrical parts of the platform balance have been

manufactured in accordance with standard PN-EN 13463-1.

• All repair and maintenance work during which the housing of the

display unit needs to be opened should be carried out by KERN

customer services. Replace subassemblies with genuine parts. The

balance must not be opened by unauthorised persons as this will

Any installation or repair work deviating from those described in this manual will

inevitably result in loss of warranty.

8 Doc.No.OEX-BA-e-1411

Page 9

Weighing cell conductor

Transport Securing

Tripod

Washer

Nut

6 Installation instr uction for balance

• Prepare the installation site for the OEX balance in a professional manner.

• Ensure that the installation site is dry, level and firm.

• The permissible operating temperate range is from -10°C to +40°C

• The floor base for the installation of the platform balance must be firm enough

for supporting the maximum weight allowed for the load plus the platform

balance.

• Balances of the OEX series without tripod have a display unit that can be

connected to the wall via a cable with the help of a holder.

• The display unit is designed for attachment to a table or for installation on a

wall with the help of a holder.

o Unpack the balance outsi de the hazardous area.

o Remove all transport locking devices after unpacking:

o Attach tripod to platform.

o Feed excess cable into the tripod.

o Lift the weighing pan and remove the transport locking device.

Doc.No.OEX-BA-e-1411 9

Page 10

Transport Securing

Weighing pan

Safe area

Ex-protected area

CAUTION!

• To prevent electrostatic charge, connect the balance to earth.

• The contact slots for the wires are marked with the icon „ “.

• Prior to transport, prepare a PE conductor for electrostatic connection to earth of

the display unit.

• The PE conductor should end in a loop that is screwed to the display unit with the

help of nuts (M4).

• To ensure that the loop is fixed permanently and in contact with the display unit,

use a lock washer.

• The PE conductor should be of yellow and green colour and provide a sectional

surface of 4mm².

The diagram below shows the balance’s connection to earth:

Place the platform balance and the display unit on the intended installation site in the

ex-area and connect it to earth.

10 Doc.No.OEX-BA-e-1411

Page 11

atmosphere.

CAUTION!

• The assembly of the display unit, installation of the platform

balance and the connection to earth must be carried out within

a time frame that rules out the risk of developing an explosive

• Place the platform balance in a level, stable place as far away as possible from

heat sources and drafts.

• Level the balance with the help of the adjustable feet and a spirit level .

• Check, whether the adjustable feet stand on the balance base.

• Ensure that the weight is evenly distributed among the feet.

• Check once again that the installation site for the balance is level. Exact flat nes s

is established when the air bubble of the spirit level is in the centre of the spirit

level ring.

• If further levelling of the platform balance is required, turn the adjustable feet of

the balance in order to adjust the heig ht.

• Check the earth contact springs between the platform balance and the weighing

pan. This ensures that the electrostatic charge is discharged from the weighing

pan.

Doc.No.OEX-BA-e-1411 11

Page 12

power supply, secure it and contact KERN customer services.

• Put the weighing pan on the platform balance.

• Position the mains adapter outside the hazardous area in which an explosive

atmosphere may be expected to be present (that is in a safe place).

• Connect the connecting cable (max. 20 m) to the mains terminal marked DC IN

on the display unit.

1. Mains connection

2. Connection cable

3. Marking PE conductor

4. Shielded load cell cable

5. Sticker power connection

• Prior to initial start-up, make sure that there is no risk of explosion –

12 Doc.No.OEX-BA-e-1411

that no explosive atmospher e is pr ese nt . If it is obvious that the

balance is not working correctly, disconnect the balance from the

Page 13

• If the balance is to be taken to another installation site carry out all

operating instructions.

• Connect the adapter to a power supply of 230V AC.

• For prolonged periods of inactivity disconnect the balance from the power supply.

• Press the ON/OFF button and hold for approx . 1 second.

• After turning on the balance will carry out a self-test.

• Afterwards the balance will change to zero display, thus indicating readiness for

operation.

• The following icons will appear:

Zero indicator

kg

Stability display

Weighing mode / weighing unit

7 Changing the installation site for the balance

the precautionary measures described in chapter 6 of these

Doc.No.OEX-BA-e-1411 13

Page 14

8 Cleaning and maintenance

• Unplug the mains plug of power unit IEX-A01.

• Check, whether the electrostatic earth connection is plugged in correctly and

make sure it is in good working order.

• Clean the balance and the housing, using a slightly moistened cloth.

Simply apply any commercially available cleaning agent available for

domestic use.

• Do not use any agents for clea ning th at may scratch the sur face

mechanically. Among other thi ngs it i s c over ed i n a c onduc tiv e c oat tha t is

important for safe operation.

• The adjustable feet of the platform balance and the shock absorbers

are made of rubber. When they are inside the hazard area, you will

have to use a slightly moistened cloth for cleaning. Moistness

protects against electrostatic charges.

• Make sure that you do not damage the earth contact springs during

cleaning. They serve as a retainer of electrostatic charge on the

weighing pan. They should be approx. 5 mm above the shock

absorbers.

• Do not clean in the presence of explosive gasses.

• The use of concentrated acids, alkaline solutions or alcohols for

cleaning purposes is prohibited.

• The same applies to the use of compressed air and high pressure

cleaning equipment.

14 Doc.No.OEX-BA-e-1411

Page 15

9 Technical examination

• Technical examinati on by expert staff is required every three

months.

The examination should include the following:

• Condition of connection to earth for balance display unit, including:

o Fastening of display housing and electrical resistance - max. 100Ω,

o Fit a flexible steel tube for the protection of the conductor leading to the

platform balance and the display unit (regular balances with “cabled”

display).

• The quality of the connection between the platform and the display unit (flexible

steel tube connecting both subassemblies).

• Damage and loss of a connection is inacceptable.

• The electrical connection between the housing and the platform – the maximum

resistance between the weighing pan (put on) should be less than100Ω.

• Stability and levelling of the balance.

Doc.No.OEX-BA-e-1411 15

Loading...

Loading...