Page 1

FC 1K-BT-BA-e-2020

Sauter GmbH

Ziegelei 1

D-72336 Balingen

e-mail: info@kern-sohn.com

Phone : +49- [0]7433- 9933-0

Fax: +49- [0]7433-9933-149

Internet: www.sauter.eu

Manual Concrete tester

SAUTER Concrete tester

Version 1.0

07/2020

GB

PROFESSIONAL MEASURING

Page 2

2 FC 1K-BT-BA-e-2020

GB

SAUTER Concrete tester

V. 1.0 04/2020

Manual Concrete tester

Congratulations on the purchase of a digital concrete measuring device with internal

measuring cell from SAUTER. We hope you will enjoy your quality measuring device

with a wide range of functions. Please do not hesitate to contact us if you have any

questions, requests or suggestions.

Table of contents:

1 Introduction .................................................................................................... 4

2 Scope of delivery ........................................................................................... 4

3 The Shotcrete Tester ...................................................................................... 5

4

Using

the Tester ............................................................................................. 5

4.1 EN ISO 14488-2 ......................................................................................................................... 5

4.2 Principle Method A ................................................................................................................... 5

4.3

Test

protocol

form ..................................................................................................................... 5

4.4 Test specimen ........................................................................................................................... 6

4.5 Conversion curves ................................................................................................................... 6

5 Test Procedure ............................................................................................... 6

5.1 Prepare the tester ..................................................................................................................... 7

5.2 Test the concrete at ten sample locations ............................................................................. 7

6 Expression of Results ................................................................................... 7

6.1 Calculation of compressive strength ..................................................................................... 7

7 Technical data ................................................................................................ 8

7.1 Technical data FC with internal loadcell 1kN ........................................................................ 8

8 Display indication .......................................................................................... 9

9 Control buttons ............................................................................................ 10

10 Menu items ................................................................................................... 11

10.1 Language ................................................................................................................................. 11

10.2 Display modes ........................................................................................................................ 11

10.3 Storing measured values ....................................................................................................... 11

10.4 Delete all records .................................................................................................................... 11

10.5 Browse Menu .......................................................................................................................... 12

10.6 Print.......................................................................................................................................... 13

10.7 System settings ...................................................................................................................... 13

10.8 USB/Loading ........................................................................................................................... 14

10.9 Multifunctional port ................................................................................................................ 14

11 Warnings ...................................................................................................... 15

12 Adjustment FC ............................................................................................. 18

Page 3

FC 1K-BT-BA-e-2020 3

13 Technical drawings ...................................................................................... 19

14 Appendix 1 ................................................................................................... 34

14.1 Test protocol ........................................................................................................................... 34

14.2 Diagram sheet ......................................................................................................................... 34

Page 4

4 FC 1K-BT-BA-e-2020

1 Introduction

Please read these operating instructions carefully before commissioning, even if you

already have experience with SAUTER measuring instruments.

After receipt of the concrete tester, it should be checked in advance that no transport

damage has occurred, that the outer packaging, the plastic housing, other parts or

even the gauge itself have not been damaged. If any damage is evident, please

notify SAUTER GmbH immediately.

The FC can measure tensile and compressive forces very accurately and it is easy to

operate. In this special version it is suitable to measure the resistance of young

sprayed concrete. It can be held in the hand for measurements. It is although suitable

to cover the procedure according to the EN ISO 14488-2 (Method A) for subsequent

calculation of the compressive strength of concrete.

SAUTER offers optional software and accessories to make the measuring instrument

more versatile in use. Please ask SAUTER or the SAUTER supplier or visit our

website www.sauter.eu.

2 Scope of delivery

SAUTER FC, incl. internal battery

Transport case

Battery charger

15 Steel needles, 3mm with a taper angle of 60°

Needle holder

Needle holder adapter

Knurled nut

T-shaped measuring instrument holder

User Manual German and English

Page 5

FC 1K-BT-BA-e-2020 5

3 The Shotcrete Tester

SAUTER shotcrete tester supports you to measure accurate readings of the forces

required to penetrate sprayed or poured concrete during the initial strength

development stage of curing. With the force readings you are able to convert the force

values to a compressive strength value. The best use on-site to measure and testing

shotcrete according to BS EN ISO 14488 (Method A).

4

Using

the Tester

4.1 EN ISO 14488-2

This part specifies two methods from which an estimate of the in situ compressive

strength of young hardened sprayed concrete can be made. The strength development

of young sprayed concrete is assessed in the ranges of 0,2 MPa to 1,2 MPa and 3

MPa to 16 MPa respectively with Method A and Method B. The SAUTER Shotcrete

Tester gives you the possibility to test the force values and convert them according to

the EN ISO 14488-2 and gives you an overview of your sprayed concrete quality.

4.2 Principle Method A

This method is used to measure the force required to push a needle of specified

dimensions to penetrate into the sprayed concrete to a depth of 15 mm +/- 2 mm. A

penetrometer indicates the resisting force, through compression of a calibrated spring

from which an estimated compressive strength can be derived from a conversion

curve, to be provided by the producer of the test equipment The tester indicates the

resisting force, from which an estimated compressive strength can be derived by

means of the appropriate example conversion curve, included with the product and

shown in Appendix A.

4.3

Test

protocol

form

The resulting strength calculation from the test data requires the measurement of

compressive force at multiple sample points. A test protocol form (see Appendix 2

Example) is needed to record these data;

Project – construction site address

Date

Test equip Serial No.

Time

Place – of the measuring points

Measurement values

Page 6

6 FC 1K-BT-BA-e-2020

4.4 Test specimen

No special test specimen is required. The testing procedure can be used for

measurements at any location without advance preparation. A sprayed concrete layer

of no less than 100 mm thickness is required for testing.

4.5 Conversion curves

Appendix A of this user guide contains a graph of conversion curves to enable the

calculation of the equivalent compressive strength (MPa) of the concrete from a tester

force reading (N).

This graph is derived from the example calibration curves provided in EN 14488-2

Annex A (informative) of the test standard.

Two linear curves and their associated formulae are reproduced for two typical

aggregate mixes of <8 mm and <=16 mm respectively. The compressive strength value

on the y-axis may be derived from a resistance force reading on the x-axis either by

direct extraction from the curve, or calculation via the appropriate formula, as indicated.

These curves are provided as reference examples based on data published in the

standard, however the individual concrete rnix will affect the accuracy of the

approximation. The user is at liberty to irnplement their own correlation function if this

would be more appropriate.

5 Test Procedure

Record time and place of completion of spraying and start of testing.

Ensure the force indicator is set to zero.

Apply the device perpendicularly to the surface of the sprayed concrete layer

and steadily push in the needle to a depth of 15 mm in a single continuous

movement. If this is prevented, for instance because of a large aggregate

particle or reinforcement, then discontinue the test and repeat in an adjacent

location.

Choose the aggregate size 8 or 16 mm.

Read the resistance force from the scale, record the value on the protocol form

and return indicator to original position.

Clean the needle if necessary.

Repeat the test ten times as quickly as possible (and within 1 min for strengths

below 0,5 MPa) in an area representative of the sprayed region.

Record the time at which the testing is finished (on protocol form).

Page 7

FC 1K-BT-BA-e-2020 7

5.1 Prepare the tester

Check the fit of the measuring tip

If it is worn out, please replace it

Switch on the FC.

Go to Menu choose Measurment an change Unit to “N” if it’s not already there.

Go to Test Menu and switch to Peak.

Go Back to Measurement screen

Perform your measurement.

5.2 Test the concrete at ten sample locations

Prepare the sample data row

To calculate the single representative value for the compressive strength of the

shotcrete at each test instance, 10 individual samples are taken with the tester.

The data are entered into a row on the test protocol form against the timestamp, for

example at 5, 20, 40, 60,120 minutes.

6 Expression of Results

6.1 Calculation of compressive strength

If you use the Excel file (www.kern-sohn.com), it will be calculate the values by itself

and mark the points in the diagram sheet. So you will get a proper clean protocol of

documentation of the quality of your sprayed concrete.

Page 8

8 FC 1K-BT-BA-e-2020

7 Technical data

7.1 Technical data FC with internal loadcell 1kN

Measuring

device

FC 1K

Capacity

1000N

Measurement

uncertainty

±0.3% of Max (measuring range)

Relative air

humidity

15% to 80% Humidity

Weight

(without

accessories)

Approx. 500g

Dimensions

Display unit

(LxWxH)

140x71x36mm

Thread

M6

Page 9

FC 1K-BT-BA-e-2020 9

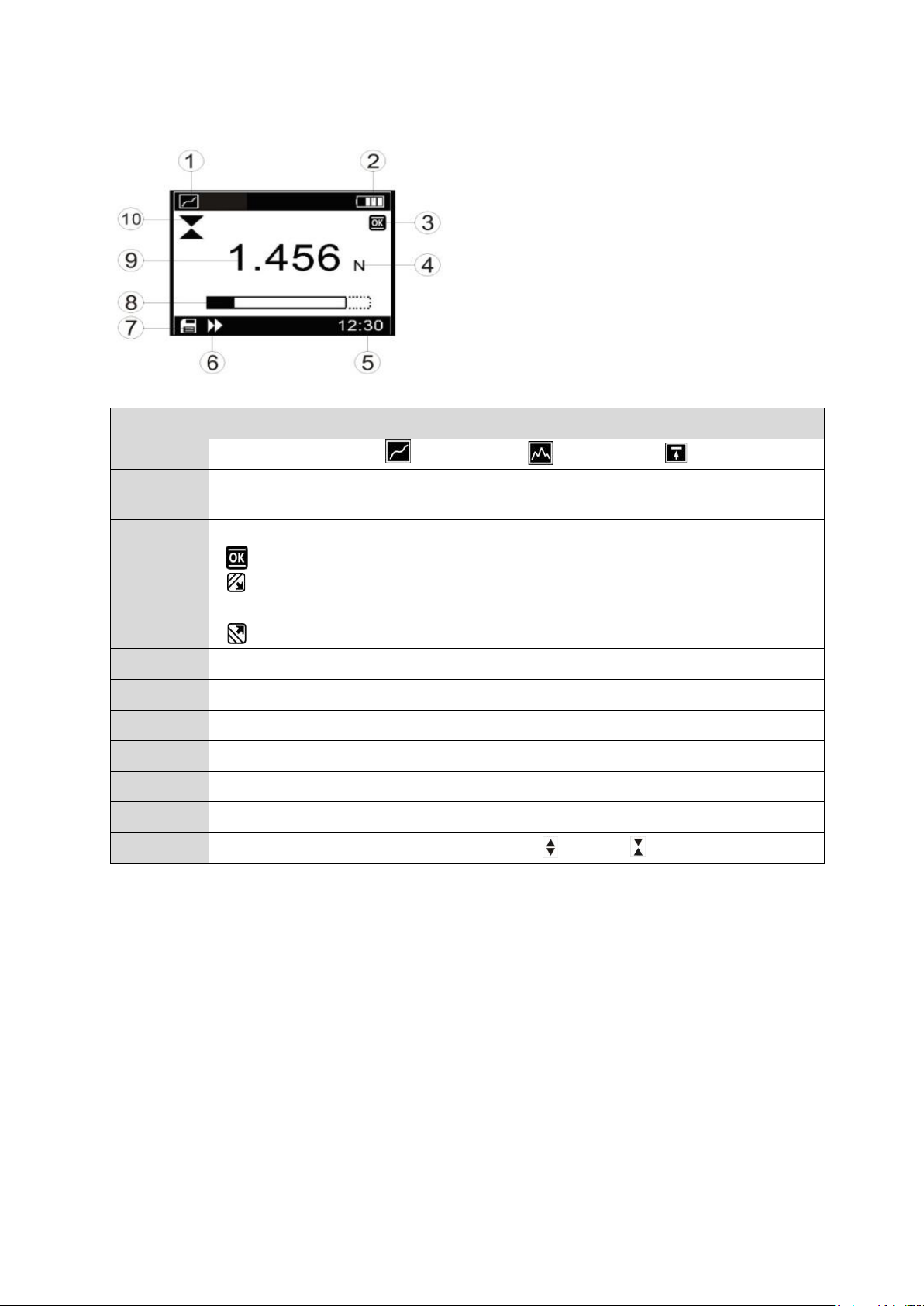

8 Display indication

Position

Description

1

Measuring mode: Track mode; Peak mode; Preset mode

2

Battery symbol: shows the current charge status; flashes when the

battery needs to be recharged

3

Default value status:

: the value is between the lower and upper limit and is OK

: the value is between the lower limit value and the value of 75% of

the lower limit value, i.e. the value falls below the lower limit value

: the value exceeds the upper limit value

4

Measuring units: the selected unit is displayed (N, kgf, ozf or lbf optional)

5

System Clock

6

Data transmission symbol

7

Data memory icon

8

Analogue load bar display

9

Current measured value

10

Direction of force (tension ( ) Pressure ( )

Page 10

10 FC 1K-BT-BA-e-2020

9 Control buttons

SAVE/ESC:

Saving the measured value

By pressing the SAVE/ESC button in the menu, you can return to the previous

page

ZERO (zeroing):

Zeroing the display

Arrow 'up' in the menu

ENTER:

Opening the menu

Confirm the selection in the menu

Mode (mode change):

Selecting the measuring mode

Arrow key 'down' in the menu

ON / OFF:

On / Off button (press button for approx. 1 s)

Page 11

FC 1K-BT-BA-e-2020 11

10 Menu items

10.1 Language

The display of the force gauge has several menu language versions. Select the desired

language setting.

10.2 Display modes

The force gauge has two display modes: force transducer oriented display and reverse

display. Select the desired display mode as required.

10.3 Storing measured values

The force gauge is equipped with the function for storing measured values. The stored

data can be searched or printed out.

During the measurement, press the key to save the respective value. The display

will show the data storage symbol ( ).

The stored data is displayed. In Track mode and Preset mode, the current force value

is measured, and in Peak mode, the maximum value.

10.4 Delete all records

To empty the memory, all data can be deleted at once. The display then shows a dialog

box with a corresponding security prompt.

Individual data can be deleted from the 'Browse' menu.

Page 12

12 FC 1K-BT-BA-e-2020

10.5 Browse Menu

With the menu 'Browse' you can browse the memory contents of the save order.

The keys or are used to navigate between the data records .

At the top of the list the last saved record is displayed.

After pressing the button, a small selection window appears on the display. In this

window you can choose between the 'Delete' or 'Print' option

If the 'Delete' option is selected, a dialog box with a corresponding security prompt is

displayed.

To exit the menu, press the key.

If the percentage drop is between 5% - 10%, please contact the supplier to have the

loadcell replaced. These values are given as a guide only. The actual need for

calibration/replacement of the loadcell varies with its individual characteristics.

Page 13

FC 1K-BT-BA-e-2020 13

10.6 Print

With the mini-printer the stored data can be printed out.

To do this, select the menu 'Print' and then the function 'Selected' or 'All'.

If the 'Selected' option is selected, the pressure range must be determined. If you

choose the 'All' option, a dialog box appears with a confirmation prompt

10.7 System settings

In the 'System' menu, settings for the display, automatic switch-off function, backlight,

key tone, etc. can be selected.

→

→

Fig 3-8

Page 14

14 FC 1K-BT-BA-e-2020

10.8 USB/Loading

Via this port, USB2.0 can be used to connect the force gauge to a PC computer for

data processing.

The Ni-MH battery can also be charged via this connection. To do this, connect the

mains adapter.

10.9 Multifunctional port

The PIN assignment is shown in the table.

Pin

Description

1

TX (RS232)

2

RX (RS232)

3

GND (RS232)

4

Default value output B

5 6

Default value output C (general)

7

Default value output A

8

10.9.1 RS-232

The RS232 interface is only used to connect a mini-printer to print out the data

received.

RS-232 specification:

- Hardware flow control: none

- Word length: 8 bits

- Stop bit: 1 bit

- Parity: none

- Data transmission rate: 38400

Fig 4-1

Page 15

FC 1K-BT-BA-e-2020 15

10.9.2 Default value outputs

Two preset value outputs form an open collector in the NPN version.

The circuit diagram below shows the inner default value circuit:

Pins 6 and 7 are switched on after the overload alarm is triggered.

In setting mode, pins 6 and 7 are switched on after the upper limit value has been

exceeded, and pins 4 to 6 - after the lower limit value has been fallen below.

Max. permissible voltage: for pins 7 to 6 and 4 to 6 the voltage must be below

35V, and for pins 6 to 7, pins 6 to 4 below 6V!

11 Warnings

Incorrectly performed force measurements can lead to serious injury to persons and

damage to objects and must therefore only be performed by trained and experienced

personnel.

In particular, it must be avoided that forces act on the purchased measuring

instrument which exceed the maximum load (Max) of the instrument or which do not

act axially via the external and internal load cell; or if high impulse forces act on the

measuring instrument.

Avoid twisting the loadcell, otherwise it could be damaged and the measuring

accuracy will decrease in any case.

Inappropriate use

Do not use the measuring instrument for medical weighing.

If small quantities of the material to be measured are removed or added, incorrect

measurement results may be displayed due to the "stability compensation" in the

measuring instrument! (Example: Slow flow of liquids out of a container suspended

from the measuring cell).

Page 16

16 FC 1K-BT-BA-e-2020

Do not apply a continuous load to measuring instruments with external measuring

cell.

Overloads

Please prevent the measuring instrument from being overloaded beyond the

specified maximum load (Max), minus any tare load that may already be present.

This can damage the measuring instrument (danger of breakage!)

Attention:

Make sure that never let people or objects

are under the load, as this could injure

or could be damaged!

The measuring instrument is not suitable for weighing people, do not use it as an

infant measuring instrument!

The measuring device does not comply with the German Medical Devices Act

(MPG).

Never operate the measuring instrument in rooms where there is a risk of

explosion. The standard version is not explosion-proof.

The design of the measuring instrument must not be changed. This can lead to

incorrect measurement results, safety-related defects and the destruction of the

measuring device.

The measuring instrument may only be operated or maintained by trained

personnel.

The measuring instrument may only be used in accordance with the described

specifications.

SAUTER must give written approval for any other areas of use / applications.

Warranty

The warranty is void if

Non-compliance with our guidelines of the operating instructions

Use outside the described field of application

Modifying or opening the device

mechanical damage and damage caused by agents such as liquids or liquids

have been caused

improper assembly or electrical installation

Overloading the measuring cell

Test equipment monitoring

As part of quality assurance, the metrological characteristics of the measuring

instrument and any test weight that may be present must be checked at regular

intervals. The user responsible must define a suitable interval for this purpose as well

as the type and scope of this inspection.

Page 17

FC 1K-BT-BA-e-2020 17

Information on the monitoring of measuring instruments and the necessary test

weights is available on the SAUTER homepage (www.sauter.eu). The weights and

measuring instruments can be checked and adjusted quickly and at favourable prices

in KERN's accredited DAkkS laboratory (traceability to the national standard).

Note:

To view the CE declaration, please click on the following link:

https://www.kern-sohn.com/shop/de/DOWNLOADS/

Page 18

18 FC 1K-BT-BA-e-2020

12 Adjustment FC

After a certain period of use, the force gauge may show deviations in a measuring

range which are due to the functioning of the device or other external influences.

In such a case, the device can be sent to our customer service for expert testing and

recalibration.

However, if you have standard force gauges and a measuring stand, you can perform

the calibration yourself according to the instructions below:

1. Fasten the force gauge to the measuring stand or to another holder

2. Zero the tare value by pressing the key.

3. Call up the calibration menu.

4. Load with test weight. The current measured value now equals the test weight

load. Wait until the measured value stabilizes before reading the measured

value.

5. Use the and keys to enter the test weight.

6. Press the key to initiate a new calibration procedure. The calibration process

can be interrupted by pressing the key.

If the calibration procedure is completed or interrupted three times, a message

window appears with the request to confirm the displayed message "Save and

Exit" (YES) or (NO).

Press the or key to select the desired option, then press the key .

If the "YES" option is selected, the display shows "Calibration complete!

❶Kalibrierungsdauer

❷Aktueller Measured value

❸Standardwert, entered

Page 19

FC 1K-BT-BA-e-2020 19

13 Technical drawings

Hole 4-M4P0.7

max. width 8

Unit

mm

Page 20

20 FC 1K-BT-BA-e-2020

14 Technical data

14.1 Technical data FL with internal loadcell up to 1kN

Measuring

device

FL 5

FL 10

FL 20

FL 50

FL 100

FL 200

FL 500

FL 1K

Capacity

5N

10N

20N

50N

100N

200N

500N

1000N

Measurement

uncertainty

±0.2% of Max (measuring range)

Work

temperature

15°C to 35°C

Relative air

humidity

15% to 80% Humidity

Weight

(without

accessories)

Approx. 500g

Dimensions

Display unit

(LxWxH)

160x75x30mm

Thread

M6

Page 21

FC 1K-BT-BA-e-2020 21

674

2 3 5 8 1

15 Battery indicator / power supply

Battery level > 4.8 V

4.8 V > Battery level > 4.7 V

4.7 V > Battery level > 4.4 V

4.4 V > Battery level > 4.0 V

Battery level < 4.0 V

If the battery voltage is less than 3.9V, a message appears that the battery

is exhausted and the device switches off automatically

The FL is equipped with four Nickel Metal Hybrid (NiMH) batteries type AAA. For

safety reasons during transport, the batteries are supplied uncharged. For maximum

battery life, we recommend that you charge the batteries only with the original

charger (supplied) for a period of 14-16 hours before using the meter for the first

time.

16 Display indication

Position

Description

1

Measurement result

2

Display mode (track, peak (pull), peak (push)

3

Display of the direction of force

4

battery charge indicator

5

Number of occupied memory locations

6

Activated pass-fail criterion

7

Display unit of the measurement result

8

Progress bar

Page 22

22 FC 1K-BT-BA-e-2020

17 Control buttons

MENU/ESC:

Opens the menu window with the individual submenus

By pressing the MENU/ESC button in the menu, you can return to the previous

page

ZERO (zeroing):

Zeroing the display in track mode (tare function)

ENTER:

Confirm the selection in the menu

Saving a measured value in PEAK mode

PRINT (print function):

Output of the memory contents to PC or printer

RESET (delete function):

Delete the current PEAK value

UNIT (units of measurement):

Press the key briefly: Switch between N, gf, kgf, ozf, lbf, mN

Mode (mode change):

Assignment with three functions:

Track mode (continuous measurement)

Peak Mode Train

Peak Mode Print

ON / OFF:

On / Off button (press button for approx. 1 s)

Page 23

FC 1K-BT-BA-e-2020 23

18 Functions

18.1 Limit value display Good / Bad

LED display for good / bad tests

Colour

Function

Red

Exceeding the upper limit value

Green

Indicates that the pass-fail criterion has been

reached

Yellow

Falling below the lower limit value

An upper and a lower limit value can be programmed. The measuring instrument

compares the measurement result with the limit values and outputs the result as a

signal in red or green light diodes.

Setting of the limit values see MENU PASS-FAIL

With the left arrow key the cursor is moved to the desired value. With the UP or

DOWN key the value can be changed. By pressing and holding one of these keys,

scrolling is possible. With the right arrow key the unit can be changed. With the

ENTER-key the settings are saved and you return to the main menu.

The display now shows a "PF".

The PASS-FAIL option is automatically disabled if the upper and lower limits are set

to 0 Newton. The lower value must also always be smaller than the upper one.

18.2 Invert display

The display can be rotated by 180°. To do this, do the following:

When the power is off, press and hold the "MENU/ESC" key. In addition, the "On/Off"

key is pressed and the unit switches on, thus rotating the display.

18.3 Store measured value in memory

Any measured value can be stored in the memory at any time by pressing the

ENTER key. A maximum of 500 readings can be stored.

Page 24

24 FC 1K-BT-BA-e-2020

18.4 Memory / Storage

The memory is used to view the stored data. It can store 500 readings. Currently,

individual entries or all entries can be deleted, or the measurement data of the

memory can be printed out.

To enter the MEMORY menu, the MENU/ESC button must be pressed. Use the UP

or DOWN button to move the cursor to MEMORY. Then confirm with the ENTER

button and you are on the memory page. Press the ESC button to return to the main

menu page.

With the arrow keys UP and DOWN the page can be changed within the memory and

by pressing and holding one of these two keys it is possible to scroll up or down.

By pressing the PRINT key, the memory contents can be printed out via the serial

port.

By pressing the ZERO button, the DELETE menu is accessed

Use the UP and DOWN arrow keys to select the desired delete option. If NO is

selected here and confirmed with the ENTER key, the meter returns to the memory

page.

When DELETE is selected and the ENTER button is pressed to confirm, the currently

stored measurement is deleted and the instrument returns to the memory page.

When DELETE ALL is selected and the ENTER button is pressed to confirm, all

stored measurements are deleted and the instrument returns to the memory page.

Page 25

FC 1K-BT-BA-e-2020 25

18.5 Diagnostics

This function is used to check the loadcell. If it is suspected that the loadcell has

been overloaded, the status can be determined immediately.

To do this, place the device in a horizontal position on a flat surface and call up the

main menu page. To enter the DIAGNOSTIC menu, the MENU/ESC button must be

pressed. Use the UP or DOWN button to move the cursor to DIAGNOSTIC and

confirm with the ENTER button. You are now on the DIAGNOSTIC page.

Press the ESC key to return to the main menu page.

If the percentage drop is between 5% - 10%, please contact the supplier to have the

loadcell replaced. These values are given as a guide only. The actual need for

calibration/replacement of the loadcell varies with its individual characteristics.

18.6 Select Output

With this option the used data output, RS 232 or USB is selected.

There is an analog output on the device. This generates a signal that goes from +2V

to -2V. This signal is a percentage of the maximum value of the force gauge. FOR

EXAMPLE..: FL100 50N is measured in the direction of pull, then a -1V signal is

applied to the analog output. 75N in compression direction, then + 1.5V is present at

the analog output. If the instrument is in PASS - Fail mode, 2V for PASS and 0V for

FAIL are present at the analog output.

Page 26

26 FC 1K-BT-BA-e-2020

19 Computer control of the force gauge

With the RS 232 interface a connection from the force gauge to the PC can be

established by sending RS232 commands.

RS232 command

Action

m

Change measuring mode

u

Change measuring unit

z

Set device to "zero

r

Perform reset on the device

20 RS232 output signal

The reading of the FL shown on the display can be transferred to the PC by pressing

the PRINT button or by issuing a command instruction to the force gauge from the

PC.

RS232

command

Action

l

Send the direct reading with unit

p

Send peak value (on pull) with unit

c

Send peak value (on pressure) with unit

x or pressing

PRINT KEY

- Send the direct reading with unit if the current mode is

the track mode

- Send peak value (on pull) with unit if the current mode

is peak mode

- Send peak value (on pressure) with unit if the current

mode is the peak value print mode

d

Send save

!

Send information about the device such as model,

capacity, serial number, firmware check, original offset,

current offset, overload counter

Page 27

FC 1K-BT-BA-e-2020 27

20.1 Interface protocol

RS-232 Parameters

- Baud rate: 9600

- Data bit: 8

- Parity: none

- Stop bit: 1

- Start bit 1

The measured value is requested by the ASCII character "9".

The returned measured value looks like this:

e.g. 0011.70 means -11.70 Newton if Newton is set

|_______ > first character describes the sign (0 = minus = pressure; 1 =

plus = pull)

| |____>-------- the remaining 6 digits describe the measured value as ASCII

character string

or: 1021.15 means +21.15 N (tractive force)

20.2 Assignment of the RS232 data interface

Pin

Signal

Illustration

2

TxD

Data output

3

GND

Ground

6

RxD

Input for control signal

Page 28

28 FC 1K-BT-BA-e-2020

21 Warnings

Incorrectly performed force measurements can lead to serious injury to persons and

damage to objects and must therefore only be performed by trained and experienced

personnel.

In particular, it must be avoided that forces act on the purchased measuring

instrument which exceed the maximum load (Max) of the instrument or which do not

act axially via the external and internal load cell; or if high impulse forces act on the

measuring instrument.

Avoid twisting the loadcell, otherwise it could be damaged and the measuring

accuracy will decrease in any case.

Inappropriate use

Do not use the measuring instrument for medical weighing.

If small quantities of the material to be measured are removed or added, incorrect

measurement results may be displayed due to the "stability compensation" in the

measuring instrument! (Example: Slow flow of liquids out of a container suspended

from the measuring cell).

Do not apply a continuous load to measuring instruments with external measuring

cell.

Overloads

Please prevent the measuring instrument from being overloaded beyond the

specified maximum load (Max), minus any tare load that may already be present.

This can damage the measuring instrument (danger of breakage!)

Page 29

FC 1K-BT-BA-e-2020 29

Attention:

Make sure that never let people or objects

are under the load, as it injures

or could be damaged!

The measuring instrument is not suitable for weighing people, do not use it as an

infant measuring instrument!

The measuring device does not comply with the German Medical Devices Act

(MPG).

Never operate the measuring instrument in rooms where there is a risk of

explosion. The standard version is not explosion-proof.

The design of the measuring instrument must not be changed. This can lead to

incorrect measurement results, safety-related defects and the destruction of the

measuring device.

The measuring instrument may only be operated or maintained by trained

personnel.

The measuring instrument may only be used in accordance with the described

specifications.

SAUTER must give written approval for any other areas of use / applications.

Warranty

The warranty is void if

Non-compliance with our guidelines of the operating instructions

Use outside the described field of application

Modifying or opening the device

mechanical damage and damage caused by agents such as liquids or liquids

have been caused

improper assembly or electrical installation

Overloading the measuring cell

Test equipment monitoring

As part of quality assurance, the metrological characteristics of the measuring

instrument and any test weight that may be present must be checked at regular

intervals. The user responsible must define a suitable interval for this purpose as well

as the type and scope of this inspection.

Information on the monitoring of measuring instruments and the necessary test

weights is available on the SAUTER homepage (www.sauter.eu). The weights and

measuring instruments can be checked and adjusted quickly and at favourable prices

in KERN's accredited DAkkS laboratory (traceability to the national standard).

Note:

To view the CE declaration, please click on the following link:

https://www.kern-sohn.com/shop/de/DOWNLOADS/

Page 30

30 FC 1K-BT-BA-e-2020

22 Adjustment instruction FL

Introduction:

This manual describes the adjustment procedure, although some programming

modes are password protected.

Important! During the adjustment procedure, all weights for loading the sensor should

be calibrated.

Tempering:

Before the measuring instrument is handed over to the calibration laboratory, the

respective instrument must be checked for possible damage and the order

specification.

Before starting adjustment, allow the measuring instrument to reach the working

temperature of the calibration laboratory for at least 2 hours.

Preparation:

Insert a full set of charged batteries in the battery compartment or connect a standard

power supply

Calibration:

1. Switch on the measuring instrument

2. Select the main menu by pressing the MENU key and select the menu function

CALIBRATION with the cursor keys UP and DOWN. Then press the ENTER key.

The ENTER PASSWORD window will appear on the screen.

ENTER PASSWORD [Enter password].

4 FIGURES

PASSWORD: 0000*

* Master password = 7780

Use the UP and DOWN arrow keys to scroll up and down. The left and right arrows

can be used to select the left and right positions. To change a digit, press and hold

for a moment.

Press the ENTER key to confirm the password. If the password is correct, the display

shows the calibration menu window.

Page 31

FC 1K-BT-BA-e-2020 31

CALIBRATION MENU

1) MAXIMUM LOAD

2) VOLTAGE INCREASE

3) COMPRESSION GAIN

4) SET NEW PASSWORD

3. Select the correct value of the weight for the respective measuring instrument. To

set the load, use the UP and DOWN arrow keys to select the MAX CAPACITY

menu function and press ENTER. The menu window for setting the maximum

load appears on the screen.

SETTING MAX. LOAD 1/2

SETTING MAX. LOAD 2/2

4. Use the UP and DOWN arrow keys to select the maximum load, press the

selected value and hold for a moment.

Press the ENTER key to save the selected value. Then return to the calibration

menu.

Page 32

32 FC 1K-BT-BA-e-2020

5. To calibrate in the voltage direction: use the UP and DOWN arrow keys to select

TENSION GAIN in the calibration menu and then press ENTER. The display

shows a menu window for voltage increase.

5.1. Zero voltage

Set up the measuring device together with the necessary accessories for

performing the voltage calibration

apply a force of 100% of the meter's power to the weight

Remove the load, leave the device standing

as soon as the display becomes stable, press the ZERO key to save the zero

display

5.2. maximum stress

apply the voltage force of 100% of the meter power

Calibrate the voltage increase with the UP and DOWN arrow keys and RIGHT

and LEFT until the meter displays the maximum voltage result

touch the ENTER key to save the results for the entire voltage scale.

6. Compression calibration: In the calibration menu, use the UP and DOWN arrow

keys to select the COMPRESSION GAIN menu function and then press ENTER.

The display will show a menu window for compression gain.

Page 33

FC 1K-BT-BA-e-2020 33

6.1. Zero Compression

Set up the measuring device and all necessary accessories for performing the

compression calibration

apply a force of 100% of the meter's power to the weight

Remove the load, leave the device standing

as soon as the display becomes stable, press the ZERO key to save the zero

display

6.2. maximum compression

apply the compression force of 100% of the gauge power

Calibrate the compression gain with the UP and DOWN arrow keys and

RIGHT and LEFT until the meter displays the maximum compression result

touch the ENTER key to save the results for the entire compression scale

7. After successful calibration, remove all accessories from the meter and place the

meter on a flat surface with its backside facing up.

Select the voltage increase menu window, press the ZERO key to obtain the

primary calibration offset, date and time and reset the overload counter.

Page 34

34 FC 1K-BT-BA-e-2020

23 Appendix 1

23.1 Test protocol

23.2 Diagram sheet

Loading...

Loading...