Page 1

KERN & Sohn GmbH

Ziegelei 1

E-Mail: info@kern-sohn.com

Phone: +49-[0]7433- 9933-0

Internet: www.kern-sohn.com

Operating and Inst allation

Display Unit

KERN KFS-TM

Version 1.0

12/2014

Instructions

GB

D-72336 Balingen

Fax: +49-[0]7433-9933-149

KFS-TM-BA_IA-e-1410

Page 2

KERN KFS-TM

Display unit

GB

Version 1.0 12/2014

Operating and installa t ion instructions

Contents

1 Technical data ................................................................................................... 4

2 Appliance overview ........................................................................................... 5

2.1 Overview of display .................................................................................................... 6

2.2 Keyboard overview .................................................................................................... 8

2.3 Audio signal ............................................................................................................... 9

3 Basic Information (Gen eral) ............................................................................. 9

3.1 Utilisation in accordance with specification. ............................................................... 9

3.2 Improper Use ............................................................................................................. 9

3.3 Warranty ...................................................................................................................10

3.4 Monitoring of Test Resources ...................................................................................10

4 Basic Safety Precauti o ns ................................................................................ 10

4.1 Pay attention to the instructions in the Operation Manual .........................................10

4.2 Personnel training .....................................................................................................10

5 Transport and storage .................................................................................... 11

5.1 Testing upon acceptance ..........................................................................................11

5.2 Packaging / return transport ......................................................................................11

6 Unpacking and placing ................................................................................... 11

6.1 Installation Site, Location of Use ...............................................................................11

6.2 Scope of delivery / standard accessories: .................................................................12

6.3 Unpacking/installation ...............................................................................................12

6.4 Mains connection ......................................................................................................14

6.5 Adjustment ................................................................................................................14

6.6 Linearization .............................................................................................................17

6.7 Verification ................................................................................................................19

2 KFS-TM-BA_IA-e-1410

Page 3

7 Operation ......................................................................................................... 21

7.1 Start-up .....................................................................................................................21

7.2 Switching Off ............................................................................................................21

7.3 Zeroing .....................................................................................................................21

7.4 Simple weighing ........................................................................................................21

7.5 Weighing with tare ....................................................................................................22

7.6 Counting ...................................................................................................................22

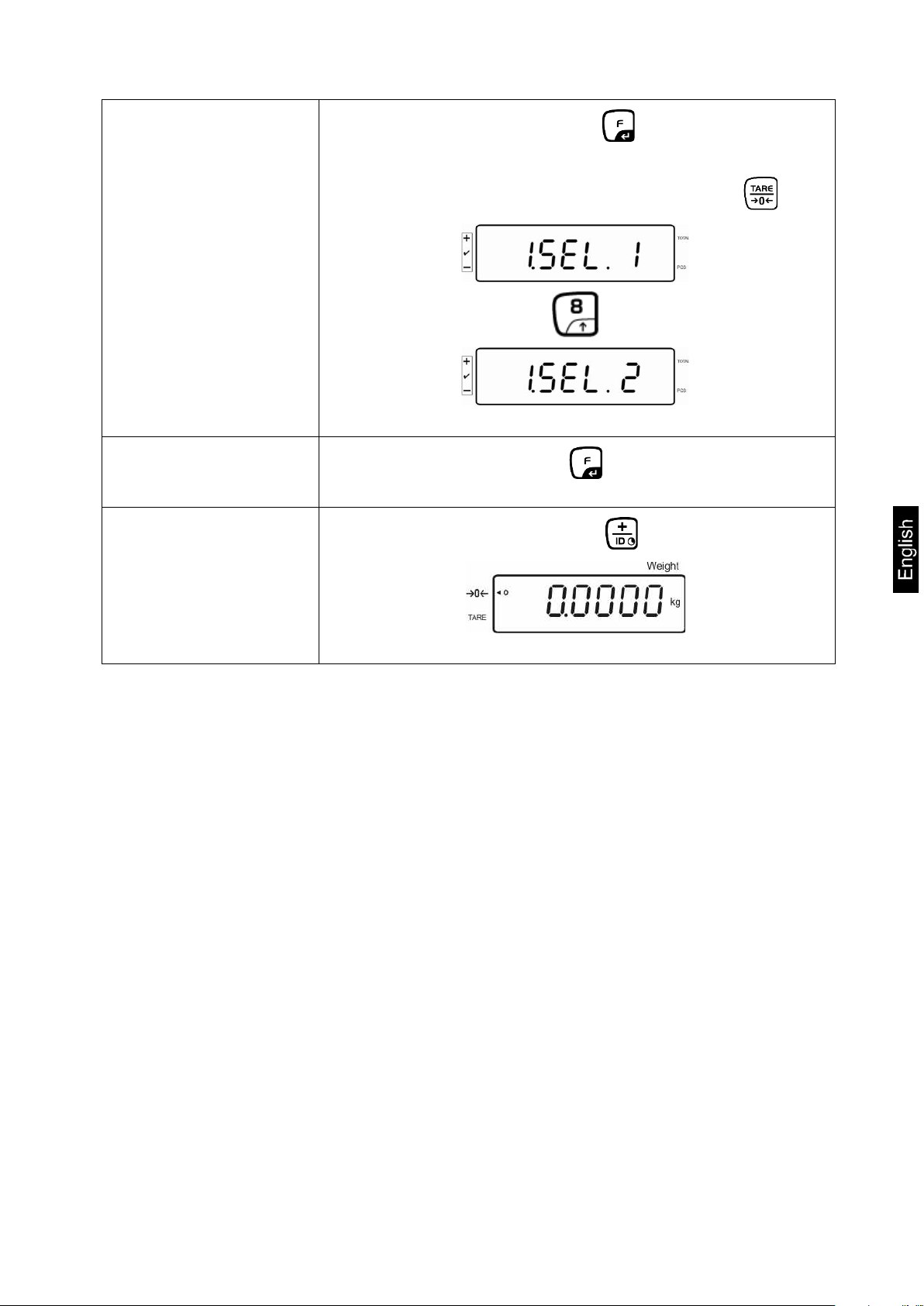

7.6.1 Determination of the average piece weight by weighing ................................................. 23

7.6.2 Numeric input of the average piece weight ..................................................................... 24

7.7 Totalization ...............................................................................................................25

7.7.1 Manual totalizing .............................................................................................................. 26

7.7.2 Automatic adding-up ........................................................................................................ 30

7.8 Tolerance check .......................................................................................................32

7.8.1 Tolerance check for target quantity ................................................................................. 35

7.8.2 Tolerance check for target weight.................................................................................... 37

8 Function menu ................................................................................................. 40

9 RS 232C interface ............................................................................................ 44

9.1 Technical data ..........................................................................................................44

9.2 Remote control instructions.......................................................................................45

10 Servicing, maintenance, disposal .............................................................. 46

10.1 Cleaning ...................................................................................................................46

10.2 Servicing, maintenance .............................................................................................46

10.3 Disposal ....................................................................................................................46

11 Error messages, troubleshooting guide .................................................... 47

12 Installing display unit / weighing bridge .................................................... 48

12.1 Technical data ..........................................................................................................48

12.2 Weighing system design ...........................................................................................48

12.3 Connecting a platform ...............................................................................................49

12.4 Configuring display devices ......................................................................................50

KFS-TM-BA_IA-e-1410 3

Page 4

1 Technical data

KERN KFS-TM

Display 6-digit

Weighing Units g, kg

Display LCD 16.5 mm digits with back lighting

DMS weighing cells

Range calibration We recommend ≥ 50 % max.

Electric Supply

Mains adapter secondary voltage 12V, 500 mA

Housing 260 x 150 x 65

Admissible

ambient temperature

Net weight 1.5 kg

Rechargeable battery

(optional)

Operating / charge time

Table leg

incl. wall fixture

80-100 Ω. Max. 4 item per 350 Ω;

Sensitivity 2-3 mV/V

Input voltage 220 V – 240 V, 50 Hz

0°C – 40°C

40 h / 12 h

Standard

Data output RS232

4 KFS-TM-BA_IA-e-1410

Page 5

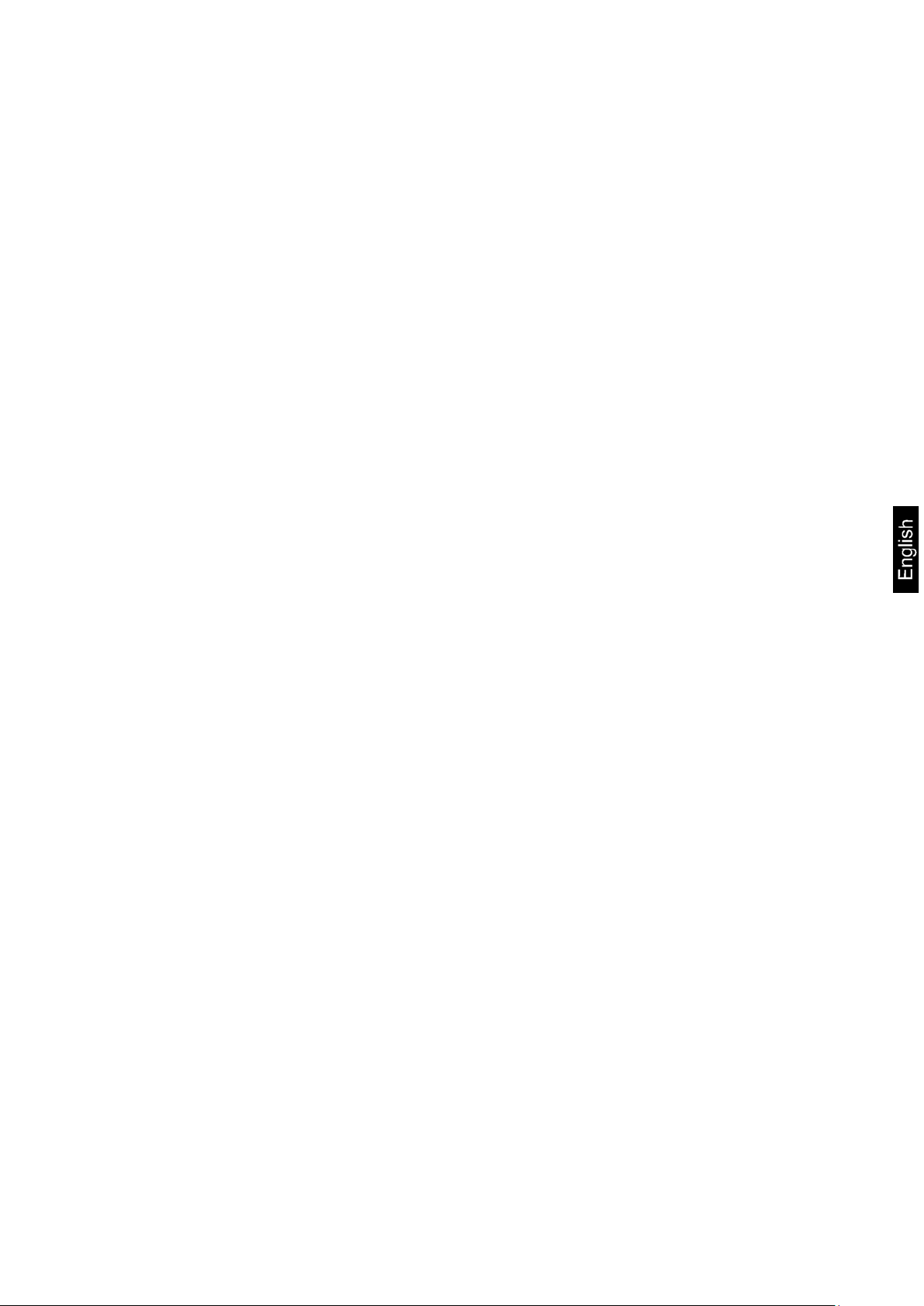

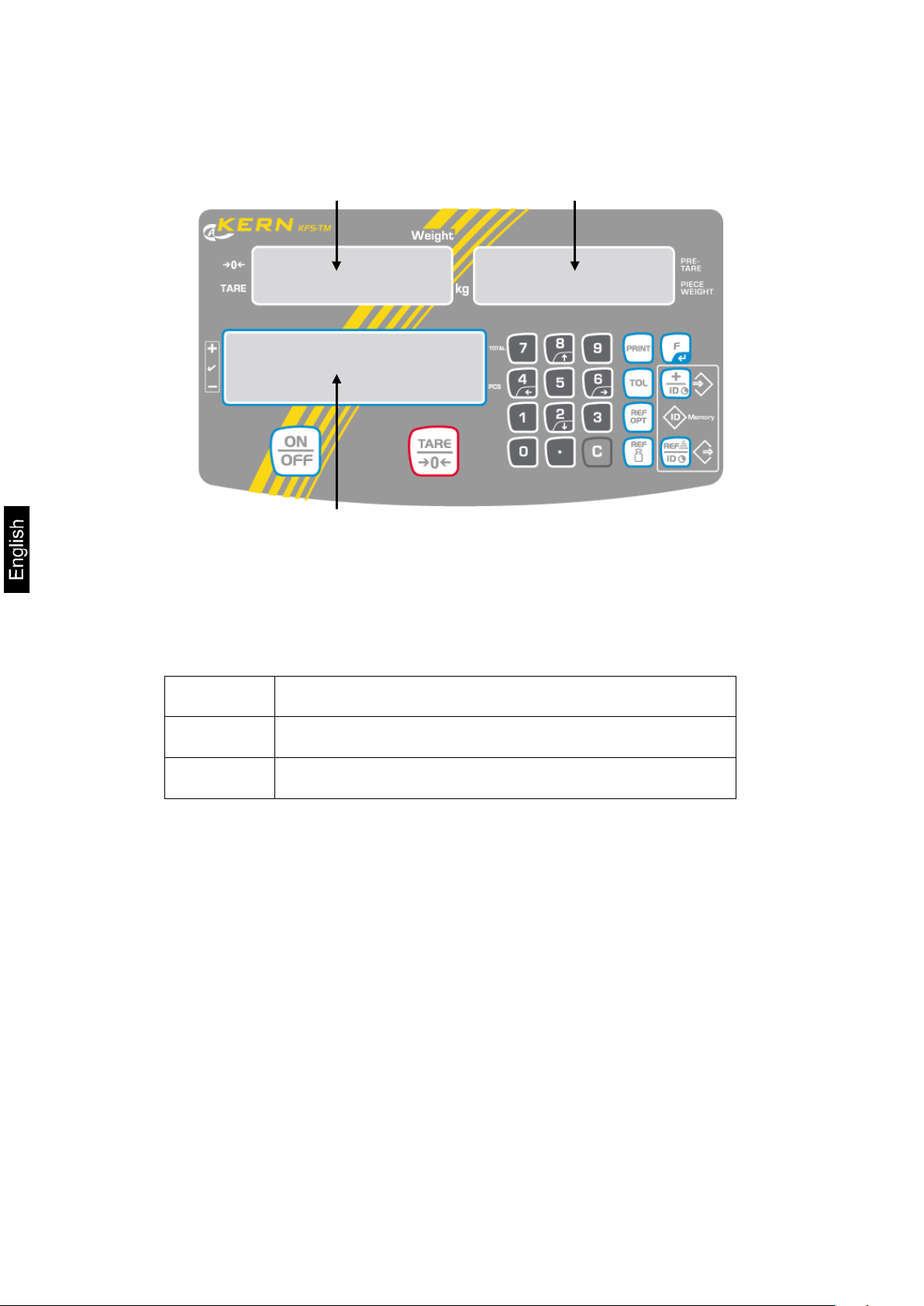

2 Appliance overview

1. Display “weight”

2. Display “average item weight“

3. Display “quantity”

4. Tolerance margin, see chap. 7.8

5. ON/OFF key

6. Tare and zero set key

7. Numeric keys

8. Function keys

9. RS-232

10. Input connection load cell cable

11. Table leg / wall unit

12. End stop table leg / tripod

13. Mains adapter connection

14. Adjustment switch

KFS-TM-BA_IA-e-1410 5

Page 6

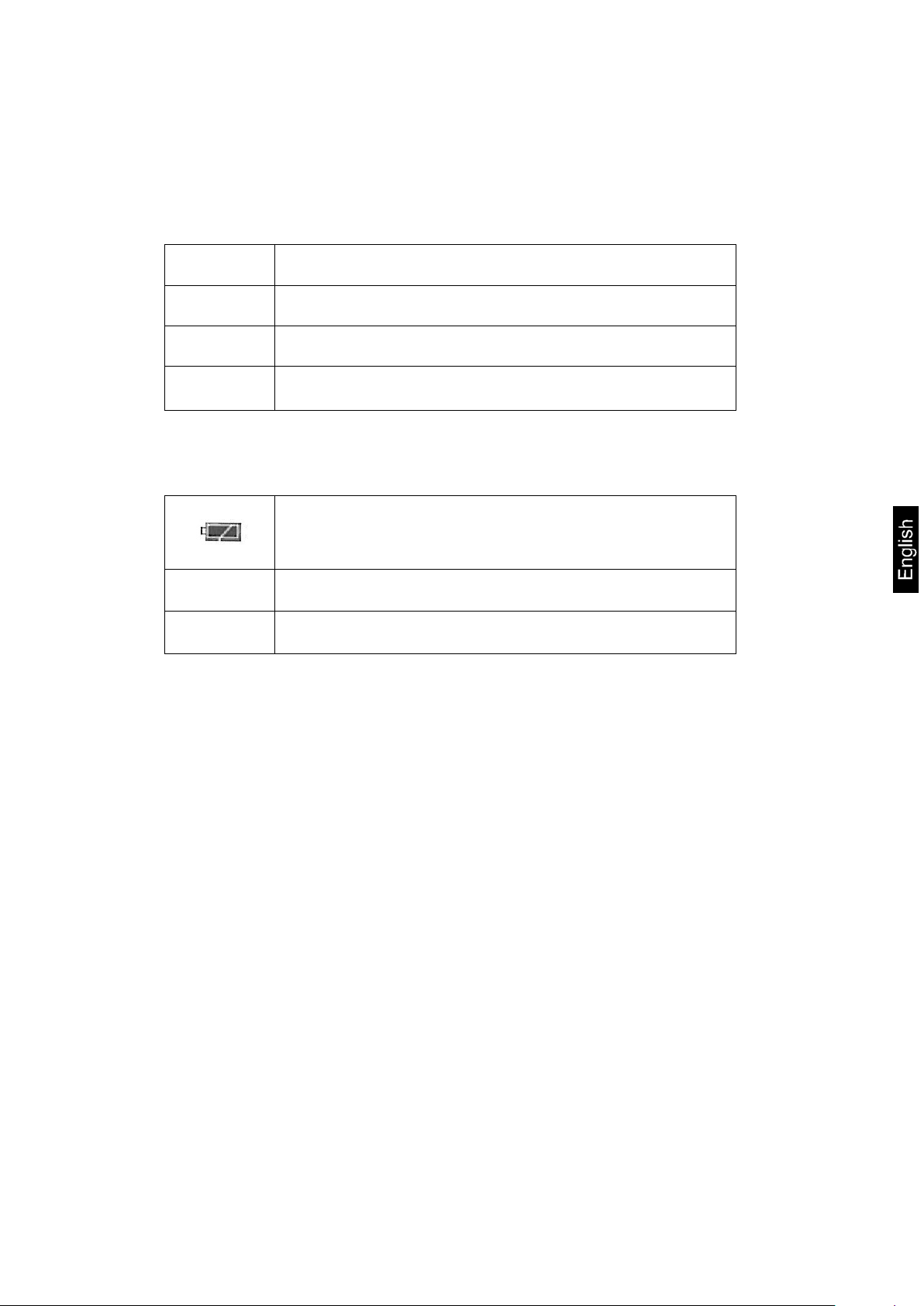

Weight display

Display average piece weight

2.1 Overview of display

Display quantity

• Weight dis play

Here the weight of your goods is displayed in [kg].

Indicator [] next to symbol displays:

TARE Net weight

a

• Display average piece weight

Here the average reference weight of a sample is displayed in [g]. This value is either

numerically entered by user or calculated by weighing on balance.

Stability display

Zeroing display

6 KFS-TM-BA_IA-e-1410

Page 7

• Display quantity

Here the current piece quantity (PCS = pieces) or in totalizing mode the sum

of the placed parts is displayed, see chapter 7.7.

Indicator [] next to symbol displays:

TOTAL Total number of pieces

+ Target quantity of items above upper tolerance limit

-

• Other displays

BUSY

LIGHT

Target quantity of items within tolerance limits

Target quantity of items below lower tolerance limit

• Power supply via line adapter

• Status display battery (optional)

• Saving / calculating weighing data

• Piece below minimum weight of piece

KFS-TM-BA_IA-e-1410 7

Page 8

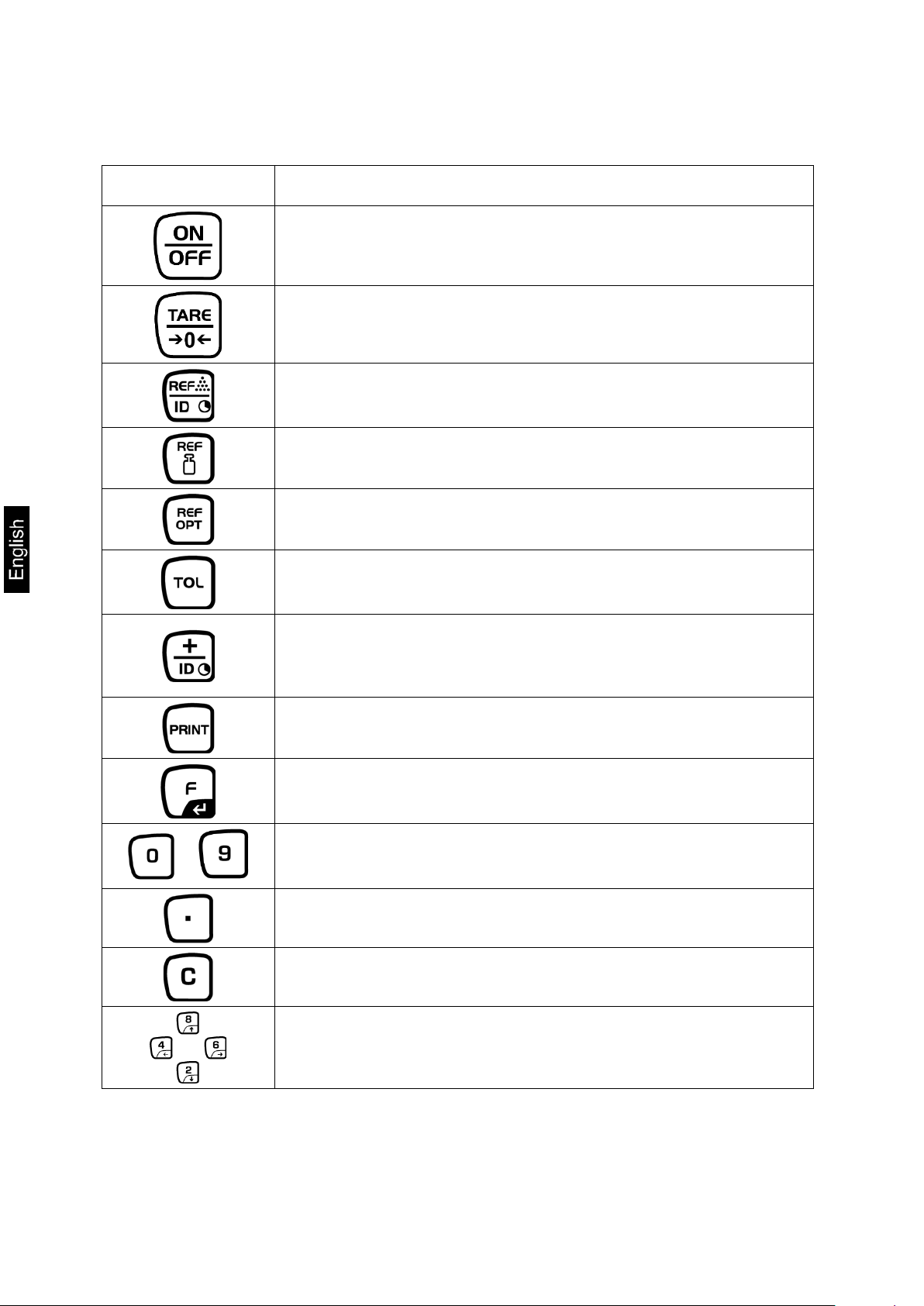

2.2 Keyboard overview

Button Function

Turn on/off

Taring (> 2 % Max)

Zero setting (< 2 % Max)

For entering of item weight by weighing see chap. 7.6.1

This value is saved to the weighing balance memory

For numeric entry of item weight see chap. 7.6.2

….

Reference optimisation

Set / call limits for tolerance control

Addition in sum memory

Exit menu, return to weighing mode

Call up total

Calculate weighing data via interface

Call function menu

Confirm selection in menu

Numeric keys

Decimal point

Delete key

Arrow keys for navigating around menu and for setting a

decimal place in numeric entries.

8 KFS-TM-BA_IA-e-1410

Page 9

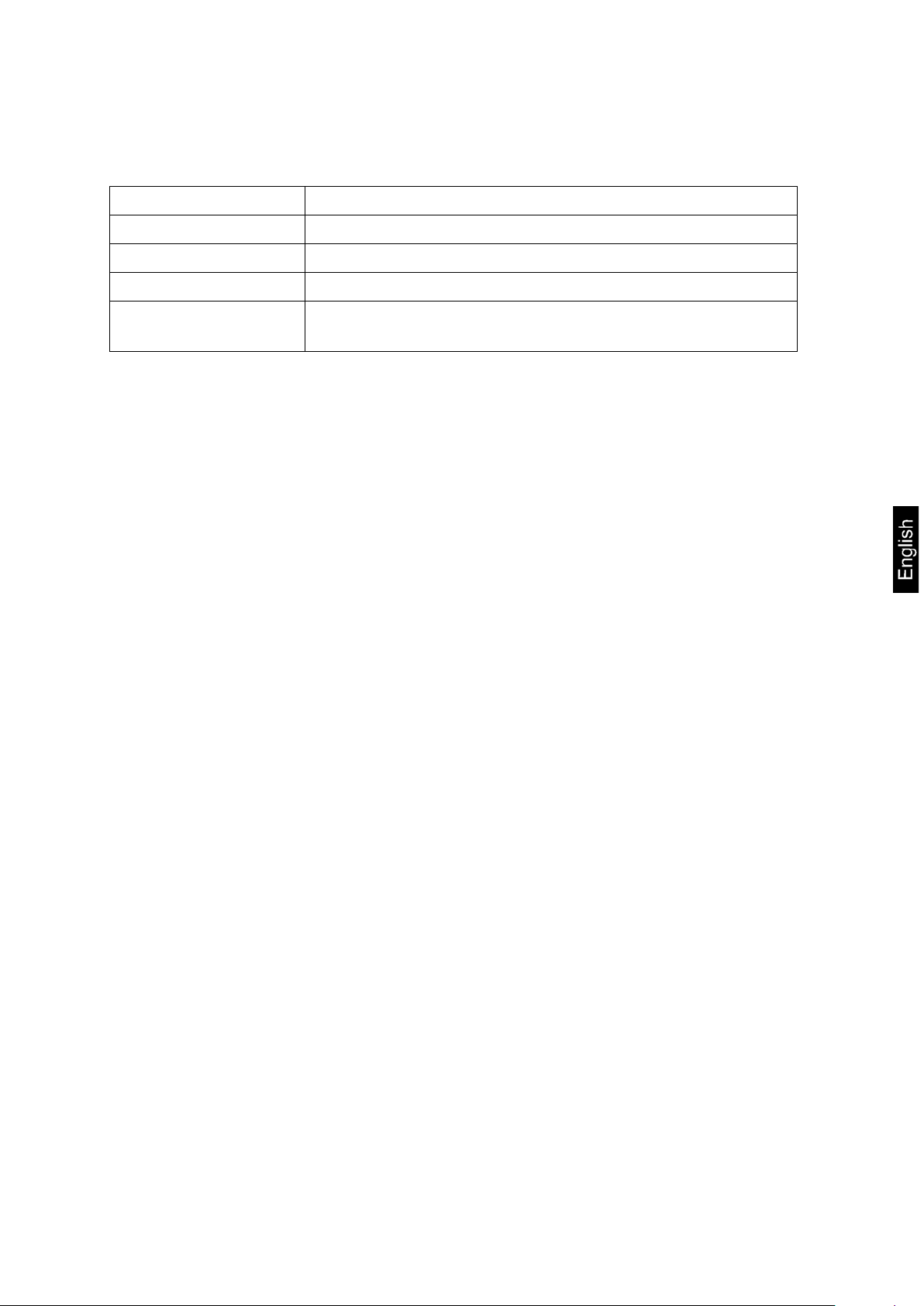

2.3 Audio signal

1 x briefly Confirm by pressing key

1 x longer Saving was successful

2 x briefly Invalid entry

3 x briefly Missing entry

continuous

Tolerance control depending on

menu setting ”F1 Co“, see chap. 8

3 Basic Information (General)

3.1 Utilisation in accord a n ce with sp ecif ication.

The display unit acquired by you is used in combination with a weighing plate and

serves to determine the weighing value of material to be weighed. I t i s inten ded t o be

used as a “non-automatic weighing system”, i.e. the material to be weighed is

manually and carefully placed in the centre of the weighing plate. As soon as a sta ble

weighing value is reached the weighing value can be read.

3.2 Improper Use

Do not use display unit for dynamic weighing. In the event that small quantities are

removed or added to the material to be weighed, incorrect weighing results can be

displayed due to the “stability compensation“ in the display unit. (Example: Slowly

draining fluids from a container on the balance.)

Do not leave permanent load on the weighing pan. This may damage the measuring

system.

Impacts and overloading exceeding the stated maximum load (max) of the weighing

plate, minus a possibly existing tare load, must be strictly avoided. Both, the weig hing

plate and the display unit may be damaged during this process.

Never operate display unit in explosive environment. The serial version is not

explosion protected.

Changes to the display unit's design are not permitted. This may lead to incorrect

weighing results, safety-related faul ts and des tr uct ion of the display unit.

The display unit may only be operated in accordance with the described default

settings. Other areas of use must be released by KERN in writing.

KFS-TM-BA_IA-e-1410 9

Page 10

3.3 Warranty

Warranty claims shall be voided in case

• Our conditions in the operation manual are ignored

• The appliance is used outside the described uses

• The appliance is modified or opened

• Mechanical damage or damage by media, liquids, natural wear and tear

• The appliance is improperly set up or incorrectly electrically connected

• The measuring system is overloaded

3.4 Monitoring of Test Resources

In the framework of quality assurance the measuring-related properties of the display

unit and, if applicable, the testing weight, must be checked regularly. The responsible

user must define a suitable interval as well as type and scope of this test. Information

is available on KERN’s home page (www.kern-sohn.com with regard to the

monitoring of display units’ test substances and the test weights required for this. In

KERN’s accredited DKD calibration laboratory test weights and display units may be

calibrated (return to the national standard) fast and at moderate cost.

4 Basic Safety Precautions

4.1 Pay attention to the instructions in the Operation Manual

Carefully read this operation manual before setup and commissioning, even if you

are already familiar with KERN balances.

4.2 Personnel training

The appliance may only be operated and maintained by trained personnel.

10 KFS-TM-BA_IA-e-1410

Page 11

5 T ransport and storage

5.1 Testing upon acceptance

When receiving the appliance, please check packaging immediately, and the

appliance itself when unpacking for possible visible damage.

5.2 Packaging / return transport

Keep all parts of the original packaging for a possibly

required return.

Only use original packaging for returning.

Prior to dispatch disconnect all cables and remove

loose/mobile parts.

Reattach possibly supplied transport securing devices.

Secure all parts such as the glass wind screen, the

weighing platform, power unit etc. against shifting and

damage.

6 Unpacking and placing

6.1 Installation Site, Location of Use

The display units are designed in a way that reliable weighing results are achieved in

common conditions of use.

Precise and fast work is achieved by selecting the right place for your display unit

and your weighing plate.

On the installation site observe the following:

• Place the display unit and the weighing plate on a stable, even surface.

• Avoid extreme heat as well as temperature fluctuation caused by installing

next to a radiator or in the direct sunlight;

• Protect the display unit and the weighing plate against direct draft from open

windows or doors.

• Avoid jarring during weighing;

• Protect the display unit and the weighing plate against high humidity, vapours

and dust.

• Do not expose the display unit to extreme dampness for longer periods of

time. Non-permitted condensation (condensation of air humidity on the

appliance) may occur if a cold appliance is taken to a considerably warmer

environment. In this case, acclimatize the disconnected appliance for ca. 2

hours at room temperature.

• Avoid static charge of goods to be weighed or weighing container.

KFS-TM-BA_IA-e-1410 11

Page 12

Wall fixture

• For display unit, see chapter 2

Major display deviations (incorrect weighing results) may be experienced should

electromagnetic fields (e.g. due to mobile phones or radio equipment), static

electricity accumulations or instable power supply occur. Change location or remove

source of interference.

6.2 Scope of delivery / standard accessories:

• Mains adapter

• Table leg incl. wall fixture

• Protective cover

• Operating manual

6.3 Unpacking/installation

Carefully remove the display unit from packaging, remove plastic cover and place it

in the designated work area.

Mount the display unit in a way that facilitates operation and where it is easy to see.

To be used with table leg and wall fixture

Push table leg in guide rail [11] up to end stop [12], see chap. 2.

Using with tripod (optional)

12 KFS-TM-BA_IA-e-1410

Page 13

(Example of illustration)

To position the display hig her up, the display unit may be mounted on an optionally

available tripod (KERN IFB-A01/A02).

KFS-TM-BA_IA-e-1410 13

Page 14

6.4 Mains connection

Power is supplied via the external mains adapter. The stated voltage value must be

the same as the local voltage.

Only use original KERN mains adapters. Using other makes requires consent by

KERN.

6.5 Adjustment

As the acceleration value due to gravity is not the same at every location on earth,

each display unit with connected weighing plate must be coordinated - in compliance

with the underlying physical weighing principle - to the existing acceleration due to

gravity at its place of location (only if the weighing system has not already been

adjusted to the location in the factory). This adjustment process must be carried out

for the first commissioning, after each change of location as well as in case of

fluctuating environment temperature. To receive accurate measuring values it is also

recommended to adjust the display unit periodically in weighing operation.

• Provide adjustment weight.

• The required adjustment wei g ht depends on the capacity of the

weighing system. Carry out adjustment as near as possible to the

scale’s maximum weight. Info about test weights can be found on the

Internet at: http://www.kern-sohn.com

• Observe stable environmental conditions. Stabilisation requires a certain

warm-up time.

14 KFS-TM-BA_IA-e-1410

Page 15

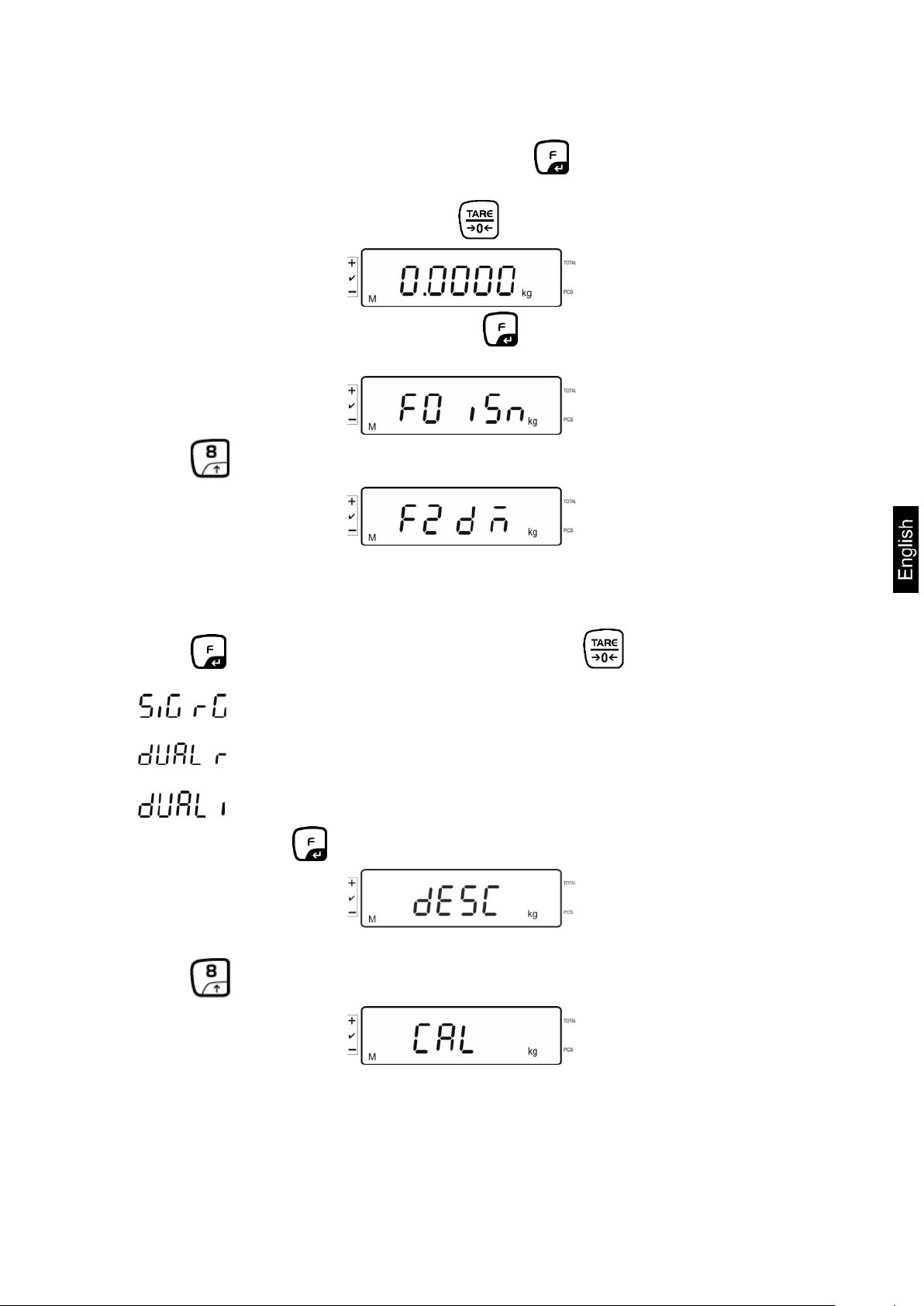

Call up menu:

Switch-on balance and during the selftest press .

Ensure that there are no objects on the weighing pan.

Reset to zero if necessary by pressing .

Go to weighing mode and press and hold for approx. 5-6 seconds until

FUNC followed by F0 iSn appears. Release button.

Press repeatedly until F2 dm is displayed.

On verified weighing systems press the adjustment switch!

Press and select the set weighing scales type by .

= Single-range balance

= Dual range balance

= Multi-interval balance

Acknowledge with .

Press repeatedly until „CAL“ will be displayed.

KFS-TM-BA_IA-e-1410 15

Page 16

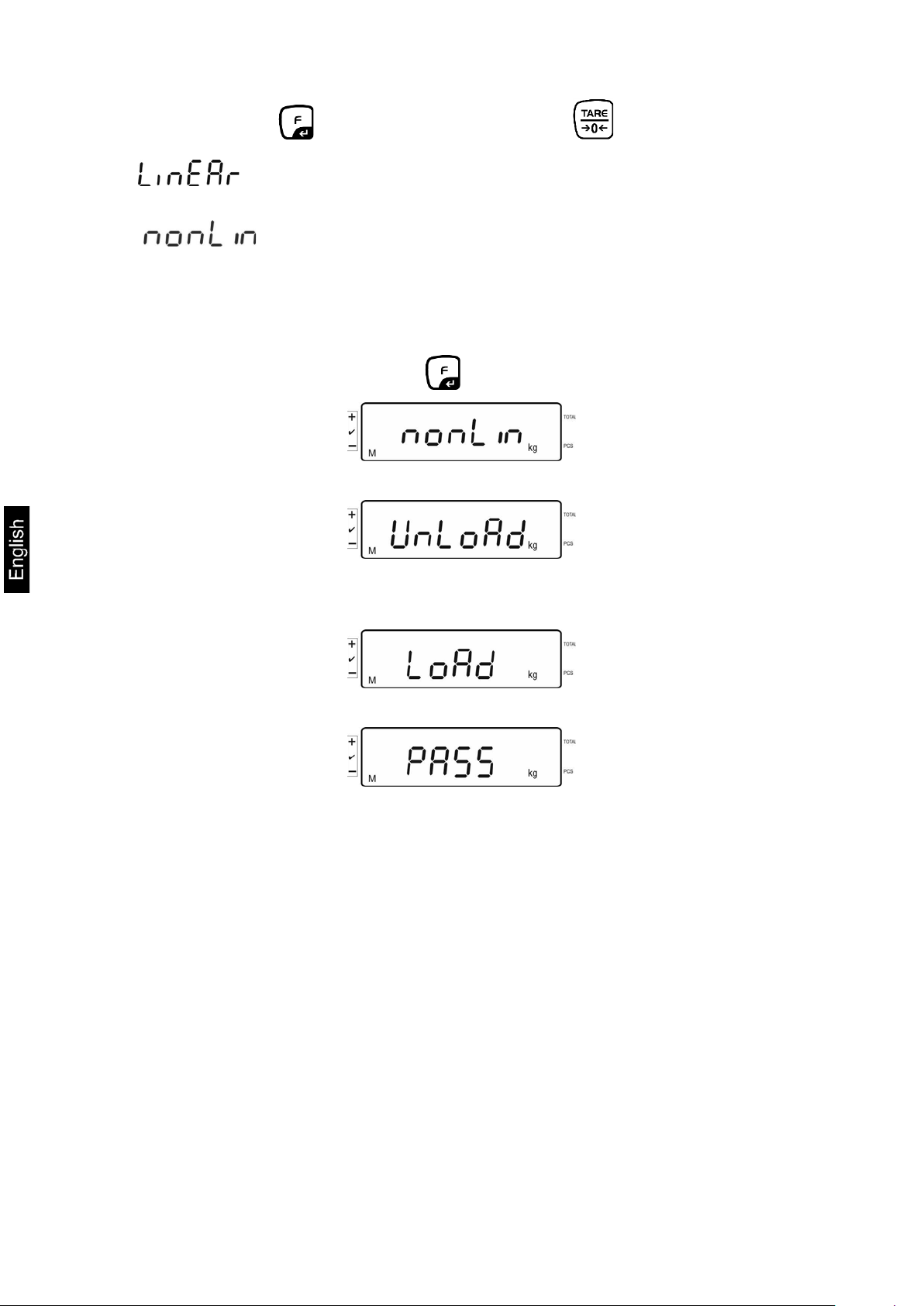

Acknowledge by and select desired setting with .

= Linearization

= Adjustment

How to carry out adjustment:

Confirm menu setting nonLin with .

Ensure that there are no objects on the weighing pan.

LoAd will be displayed after standstill control has been carried out.

Put the required adjustment weight carefully in the centre of the weighing pan.

After successful adjustment, the weighing scales will carry out a selftest.

During this selftest remove the adjustment weight and the weighing scales will

automatically return to weighing mode.

An adjusting error or incorrect adjusting weight will be indicated by the error

message; repeat adjustment procedure.

16 KFS-TM-BA_IA-e-1410

Page 17

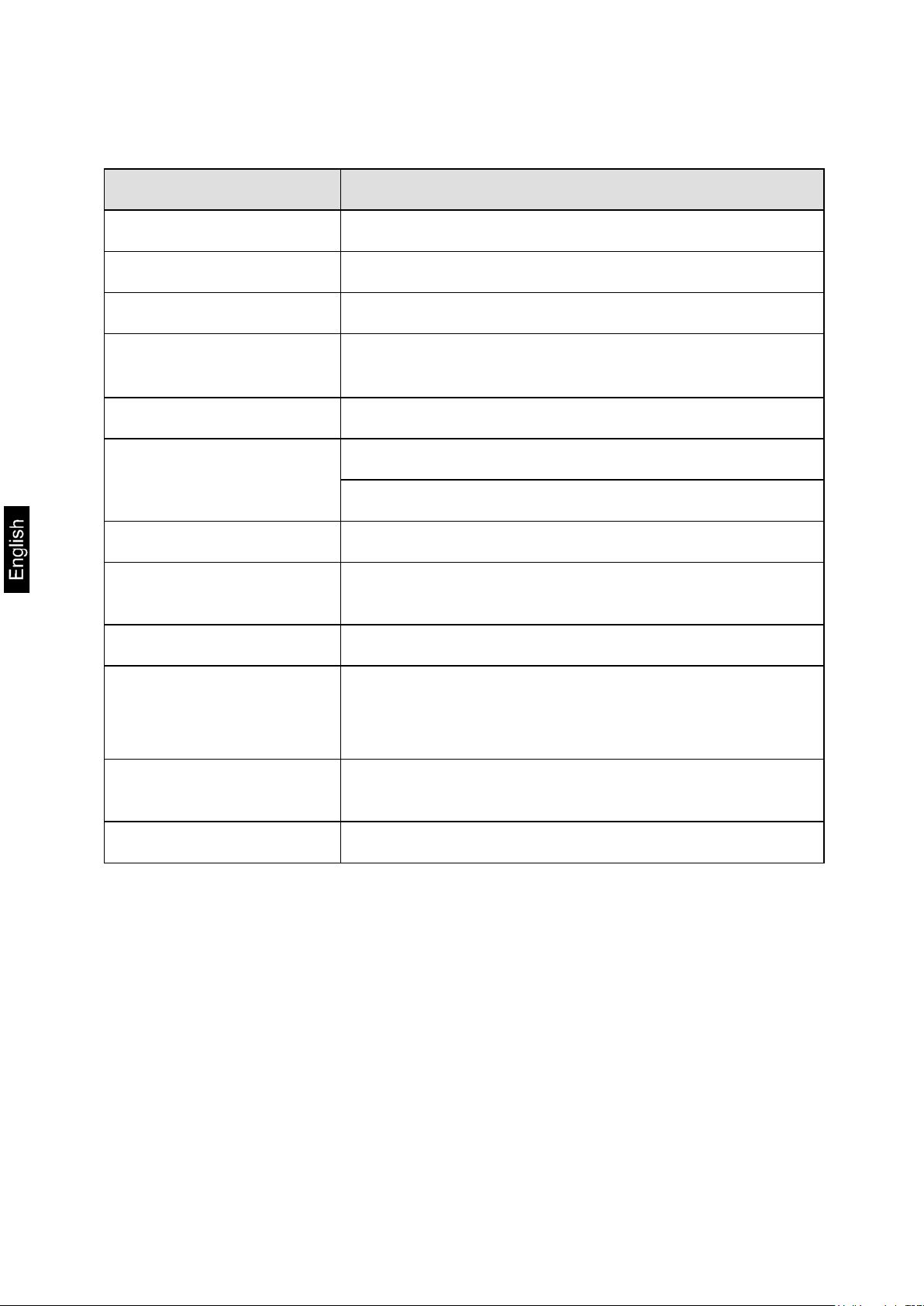

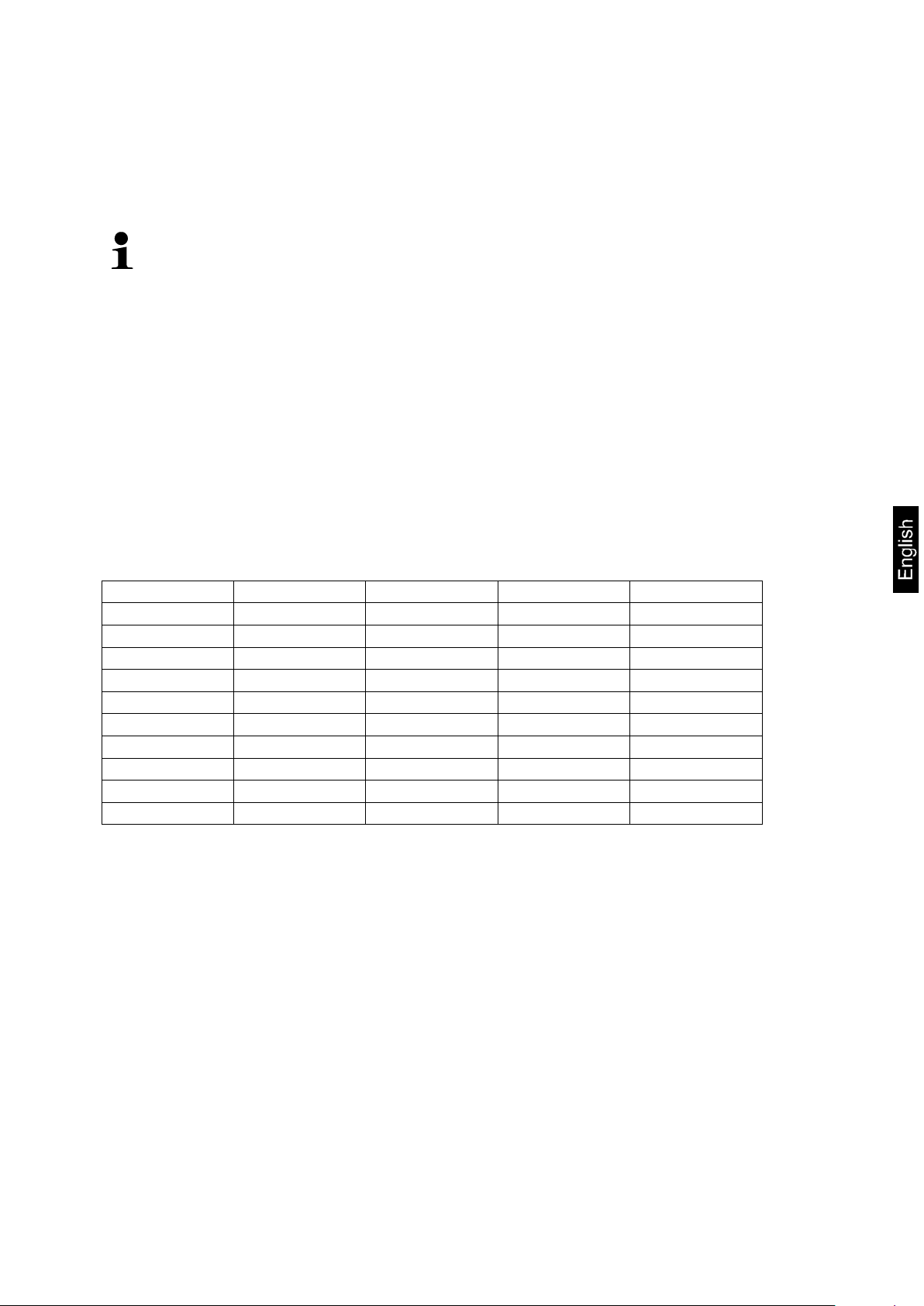

• Carrying out linearization is restricted to specialist staff possessing

see chapter “testing instruments control”.

MAX

LOAD 1

LOAD 2

LOAD 3

LOAD 4

3kg

0.5kg

1kg

2kg

3kg

6kg

1kg

2kg

4kg

6kg

15kg

3kg

5kg

10kg

15kg

30kg

10kg

15kg

20kg

30kg

60 kg

10kg

20kg

40kg

60kg

120 kg

30kg

60kg

60kg

150kg

300 kg

50kg

100kg

200kg

300kg

600 kg

100kg

200kg

400kg

600kg

1.5 t

3000kg

5000kg

1000kg

1500kg

3 t

5000kg

1000kg

2000kg

3000kg

6.6 Linearization

Linearity shows the greatest deviation of a weight display on the scale to the value of

the respective test weight according to plus and minus over the entire weighing

range. If linearity deviation is discovered during a monitoring of test resources, you

can improve this by means of linearization.

Tab. 1: Adjustment weights „LOAD1 – LOAD4“

well acquainted with the workings of weighing scales.

• The test weights to be used must be adapted to the weighing scale’s

specifications; see chapter “monitoring of test resources”.

• Observe stable environmental conditions. Stabilisation requires a

certain warm-up time.

• Do not remove the adjustment weight during linearization in step

LOAD 1 to LOAD 4, merely increase it instead. Conversely do not

remove the adjustment weight during step LOAD 4 to LOAD 1,

merely increase it instead.

• After successful linearisation you will have to carry out calibration;

KFS-TM-BA_IA-e-1410 17

Page 18

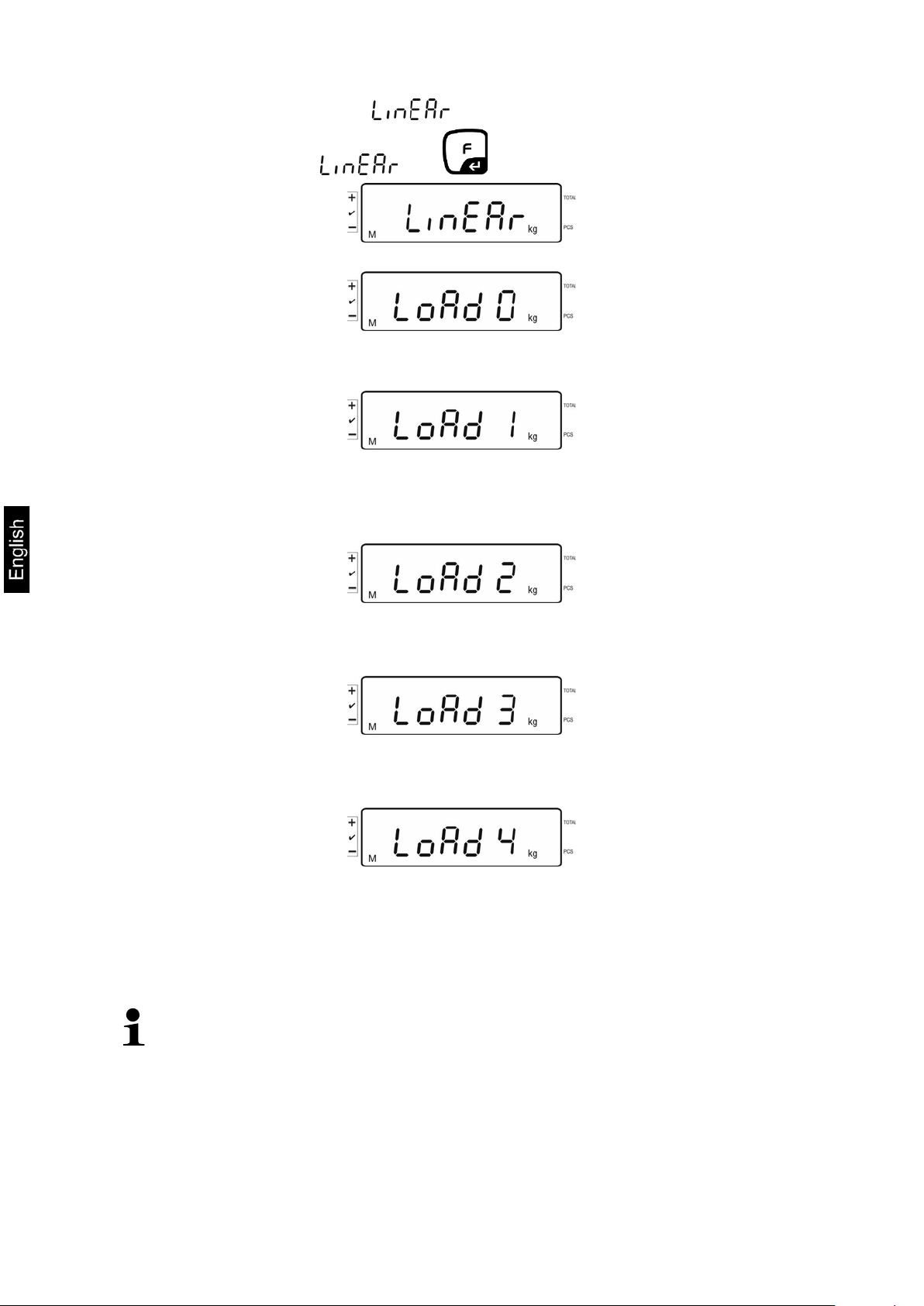

Call menu item lineariza tion , see chap. 6.6

Confirm menu setting with .

Ensure that there are no objects on the weighing plate.

“LoAd 1” will be displayed after standstill control has been carried out. Put the first

adjustment weight approx. 1/4 Max (see table 1) carefully in the centre of the

weighing pan.

“LoAd 2” will be displayed after standstill control has been carried out.

Put the second adjustment weight approx. 2/4 max (see table 1) carefully in the

centre of the weighing pan. “LoAd 3” will be displayed after standstill control has

been carried out.

Put the third adjustment weight approx. 3/4 max (see table 1) carefully in the

centre of the weighing pan. “LoAd 4” will be displayed after standstill control has

been carried out.

Put the forth adjustment weight approx. 4/4 max (see table 1) carefully in the

centre of the weighing pan.

After successful standstill control the balance carries out a selftest, then it

automatically returns to weighing mode.

• An adjusting error or incorrect adjusting weight will be indicated by the error

message; repeat adjustment procedure.

18 KFS-TM-BA_IA-e-1410

Page 19

6.7 Verification

General introduction:

According to EU directive 2009/23/EC balances must be officially verified if they are

used as follows (legally controlled area):

a) For commercial transactions if the price of goods is determined by weighing.

b) For the production of medicines in pharmacies as well as for analyses in the

medical and pharmaceutical laboratory.

c) For official purpose.

d) For manufacturing final packages.

In cases of doubt, please contact your local trade in standard.

Verification notes:

An EU Qualification Approval is in existence for verified weighing systems. If a

balance is used where obligation to verify exists as described above, it must be

verified and re-verified at regular intervals.

Reverification is carried out according to the relevant national statutory regulations.

The validity for verification of balances in Germany is e.g. 2 years.

The legal regulation of the country where the balance is used must be observed!

• Verification of the weighing system is invalid without the "seals".

KFS-TM-BA_IA-e-1410 19

Page 20

Notes on verified weighing systems

In verified weighing systems the access to menu items F1, F2, F3 of the configuration

menu will be blocked.

To cancel the access block, go to menu item F3 APP of the configuration menu (See

chap. 12.4) and change the setting to „on”.

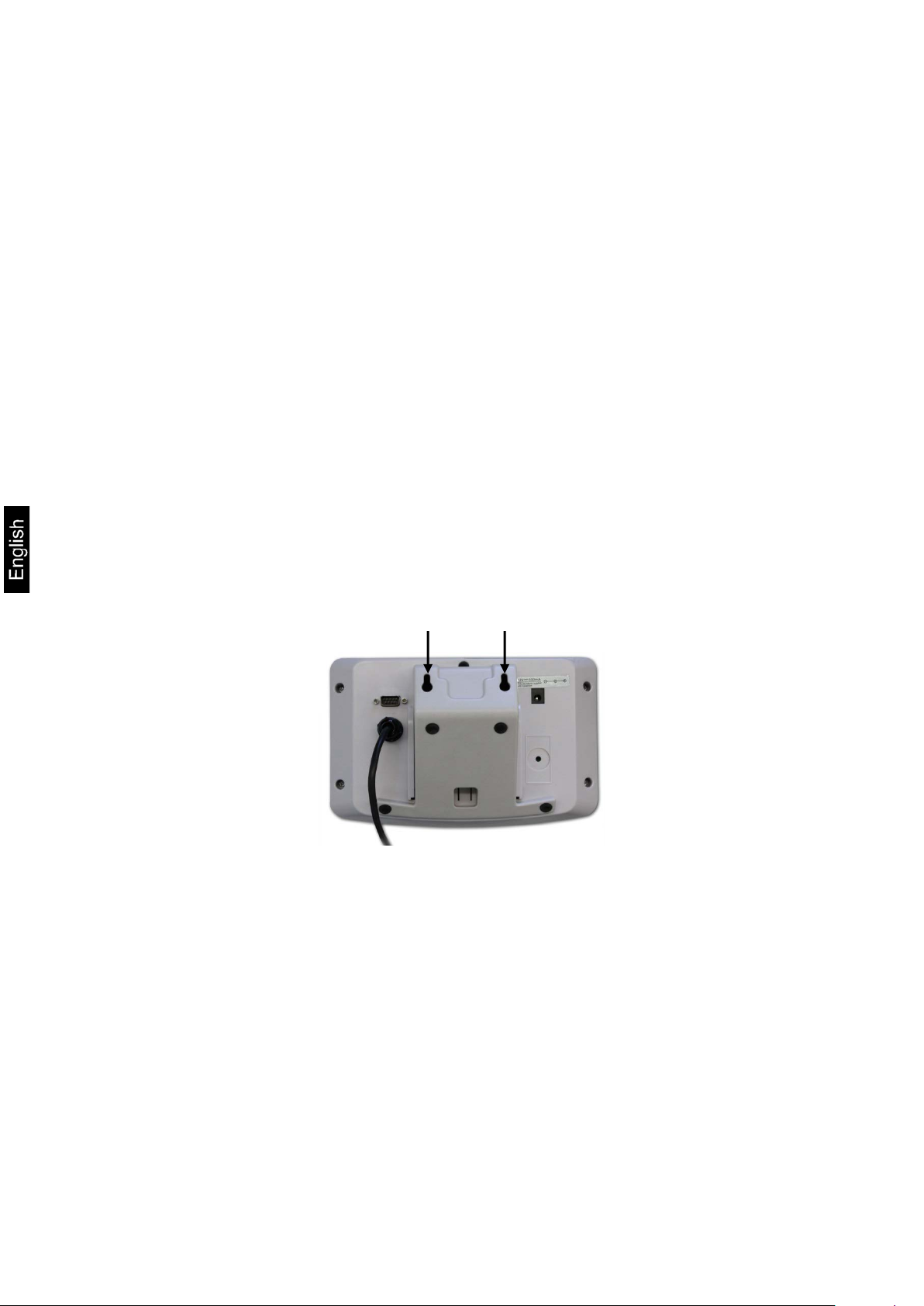

Position of seals and adjusting switch:

1. Self-destroying seal mark

2. Adjustment switch

3. Cover of adjustment switch

4. Self-destroying seal mark

20 KFS-TM-BA_IA-e-1410

Page 21

exceeding the stated maximum load (max) of the device, minus a

7 Operation

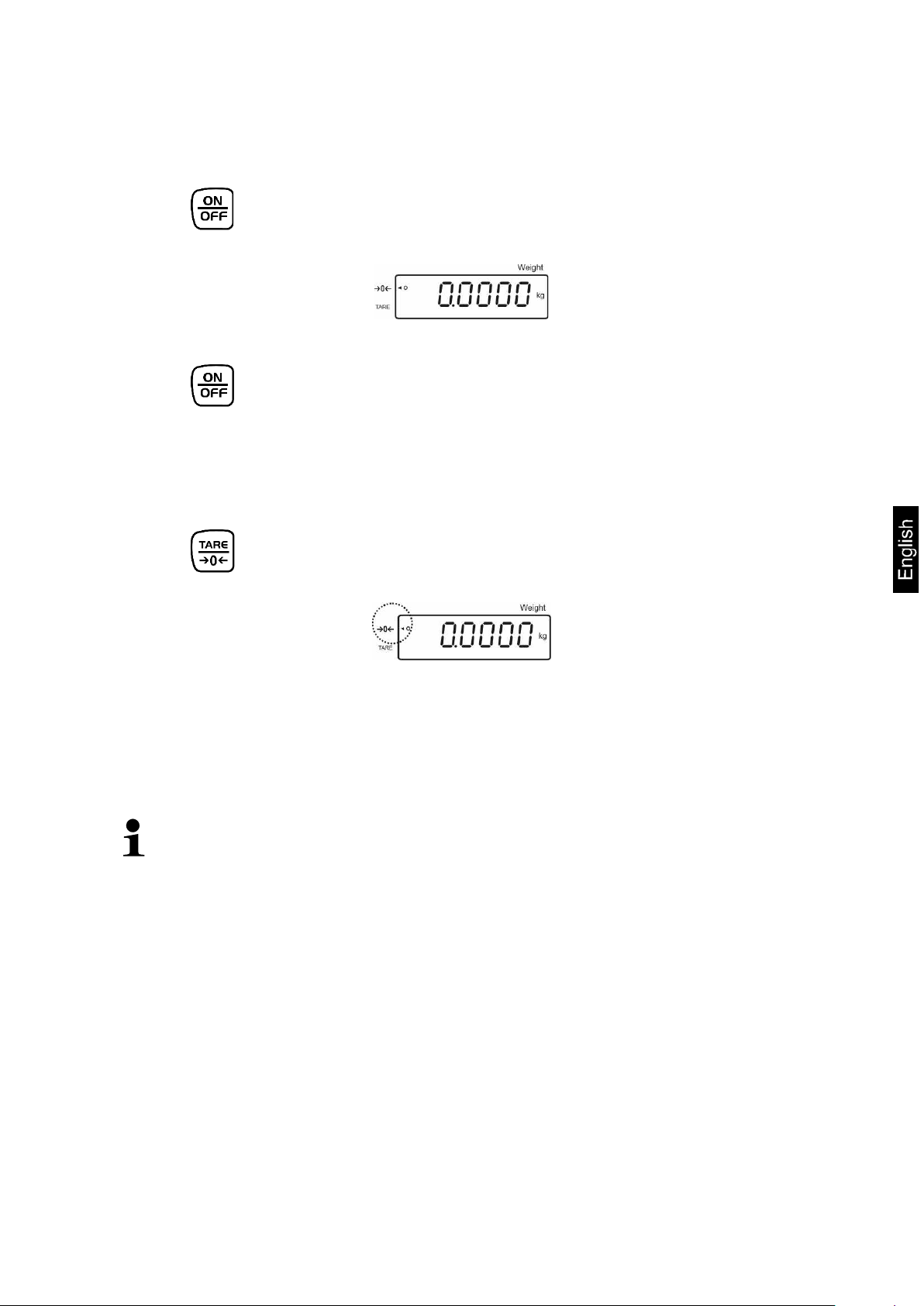

7.1 Start-up

Press , the appliance will carry out a self-test. As soon as the weight display

appears, the instrument will be ready to weigh.

7.2 Switching Off

Press , the display will disappear.

7.3 Zeroing

Resetting to zero corrects the influence of light soiling on the weighing plate.

Resetting range ± 2 % max.

To unload the weighing system

Press , the zero display as well as the indicator [] next to a will appear.

7.4 Simple weighing

Place goods to be weighed on balance.

Wait for stability display [].

Read weighing result.

Overload warning

Overloading

possibly existing tare load, must be strictly avoided. This could damage the

instrument.

Exceeding maximum loads is indicated by the display of “O-err“, and an audio

sound. Unload weighing system or reduce preload.

KFS-TM-BA_IA-e-1410 21

Page 22

7.5 Weighing with tare

Deposit weighing vessel. After successful standstill control press the button.

Zero display and the indicator [] next to TAR E appear. The weight of the

container is now internally saved.

Weigh the material, the net weight will be indicated.

After removing the weighing container, the weight of the weighing container

appears as negative display.

The tare procedure can be repeated as many times as necessary, for example

with initial weighing of several components for a mix (add-on weighing). The limit

is reached when the total weighing range capacity is full.

To delete the tare value, remove load from weighing plate and press .

7.6 Counting

During piece counting parts can either be counted into a container or out of a

container. To count a greater number of parts the average weight per part has to be

determined with a small quantity (reference quantity). The larger the reference

quantity, the higher the counting exactness.

High reference must be selected for small parts or parts with considerably different

sizes.

The average piece weight can only be determined by stable weighing

values.

If weighing values are under zero, the piece counter display shows a

negative number of items.

The message LIGHT appearing on the display indicates that load falls

below minimum weight value.

Delete incorrect entries by pressing .

The accuracy of an average item weight can be improved at any time

during additional counting processes. For this purpose add additional

items and press . After the reference optimization sounds a signal

tone. As the additional pi eces incr e ase t he base for the c al cul ati o n, t he

reference also becomes more exact.

22 KFS-TM-BA_IA-e-1410

Page 23

Count the items

7.6.1 Determination of the average piece weight by weighing Set reference

Reset balance to zero or tare the empty weighing container if necessary.

Place on the weighing plate a known number (e.g. 10 items) of individual pieces

as a reference.

Wait for the stability display, than enter the number of individual items via the

numeric keypad.

Acknowledge with .

The balance determines the average piece weight.

Tare if necessary, place weighing good and read off the number of items.

Delete reference

Press , the average unit weight will be deleted.

KFS-TM-BA_IA-e-1410 23

Page 24

7.6.2 Numeric input of the average piece weight

Set reference

Enter established item weight by pressing numeric keys and confirm by pressing

.

Count the items

Tare if necessary, place weighing good and read off the number of items.

Delete reference

Press , the average unit weight will be deleted.

24 KFS-TM-BA_IA-e-1410

Page 25

Currently placed weight

Selected item weight

Preview: currently placed quantity of

items + current total number of items

7.7 Totalization Adding-up during weight display:

Weight display: Currently placed weight

Item weight display: Selected item weight

Item quantity display: Currently placed quantity of items

Currently placed quantity of items

Adding-up during item display:

Press , the display changes to item display.

Weight display: Currently placed item quantity

Item weight display: Currently placed item quantity + total of added

display values

Item quantity display: Total of added-up display values

Currently placed quantity of items

Current total number of items

KFS-TM-BA_IA-e-1410 25

Page 26

Menu settings:

„F8 UA“ „4 UA 5“ see chap. 8

Currently placed weight

Selected item weight

-------------------------------------------

G 5.000kg

N:

5.000kg

C 0.000kg

PCS:

50pcs

UW

100.000g

-------------------------------------------

-

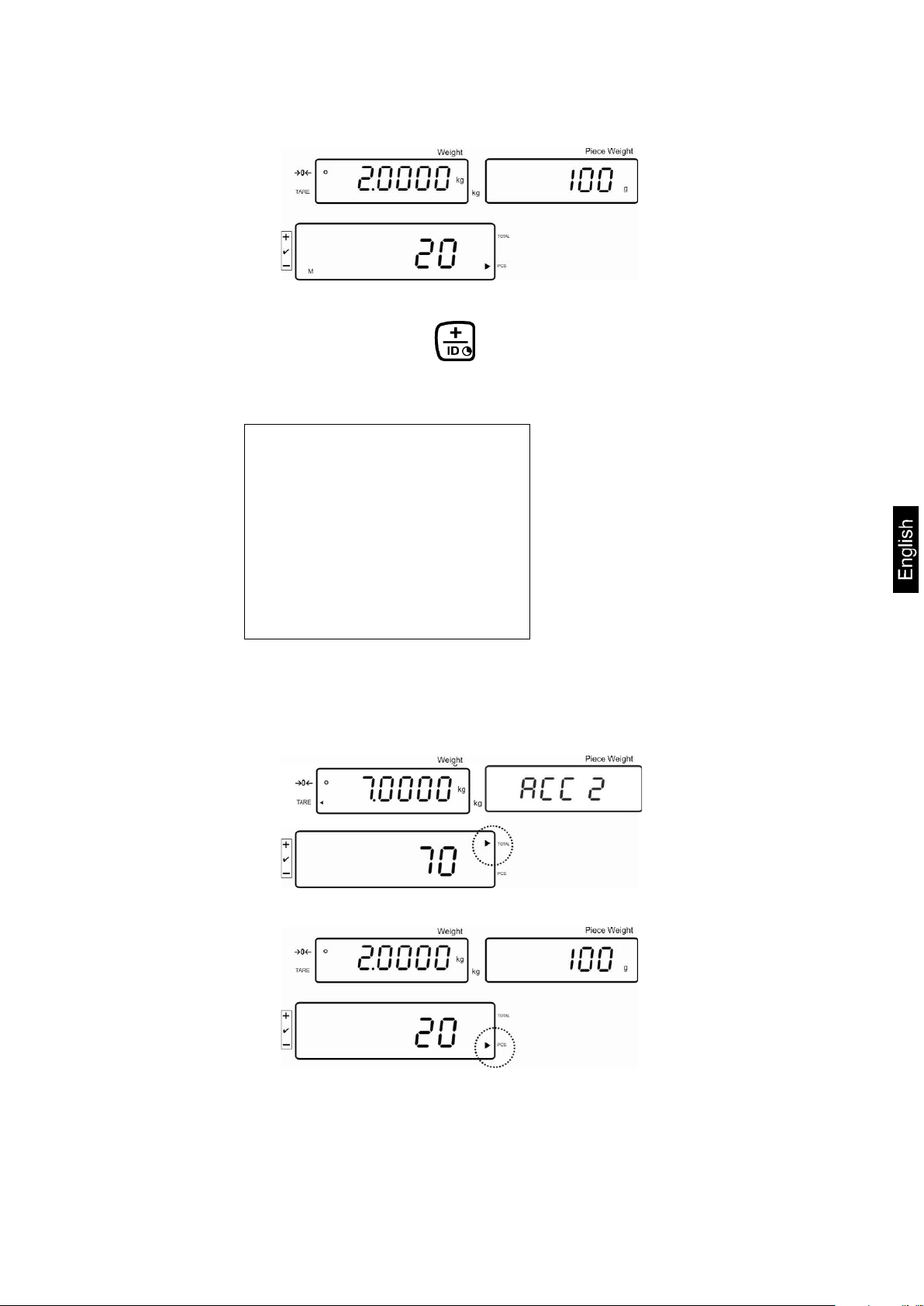

7.7.1 Manual totalizing

With this function the individual weighing values are added into the summation

memory by pressing and edited, when an optional printer is connected.

„F12 AC“ „5 AC 1“, see chap. 8

Calculate the average item weight (see chap. 7.6.1) or enter it manually (see

chap. 7.6.2).

Place weighing goods A.

Currently placed quantity of items

Wait for stability display, then press . The displayed value (e.g. 50 pieces)

will be added to the summation memory and printed if an optional printer is

connected.

Remove the weighed good. More weighed goods can only be added when the

display ≤ zero.

26 KFS-TM-BA_IA-e-1410

Page 27

-------------------------------------------

G 2.000kg

N:

2.000kg

C 0.000kg

PCS:

20pcs

UW

20.000g

-------------------------------------------

-

The total weight, the number of weighings as well as the total number of pieces

[] next to PCS)

Add more weighed goods as described before.

weighing system has been exhausted.

Place goods to be weighed B.

Wait for stability display, then press . The displayed value (e.g. 20 pieces)

will be added to the summation memory and printed if an optional printer is

connected.

will shortly appear (Indicator [] next to TOTAL).

Afterwards the display will change to the currently placed unit quantity (indicator

Please note that the weighing system must be unloaded between the individual

weighing procedures.

This process may be repeated 99 times or till such time as the capacity of the

KFS-TM-BA_IA-e-1410 27

Page 28

Total weight

Number weighing proces ses

-------------------------------------------

C 7.000kg

PCS:

70pcs

--------------------------------------------

Display and output sum „Total“:

Unload the weighing pan and press , the total weight, the number of

weighings, followed by the total number of pieces will be shown for 2 sec and

printed if an optional printer is connected.

Indicator:

Total number of pieces

Printout example:

28 KFS-TM-BA_IA-e-1410

Page 29

Delete weighing data:

Press to display the total weight, the number of weighing procedures and

the total quantity for 2 sec. During this display press .

KFS-TM-BA_IA-e-1410 29

Page 30

Menu settings:

„F8 UA“ „4 UA 5“ see chap. 8

Add up:

-------------------------------------------

G 0.000kg

N:

1.000kg

C 1.000kg

PCS:

10pcs

UW

100g

-------------------------------------------

-

-------------------------------------------

G 0.000kg

N:

2.000kg

C 3.000kg

PCS:

20pcs

UW

100g

-------------------------------------------

-

7.7.2 Automatic adding-up

With this function the individual weighing values are automatically added into the

summation memory when the balance is unloaded and edited, when an optional

printer is connected.

„F12 AC“ „5 AC 0“, see chap. 8

Calculate the average item weight (see chap. 7.6.1) or enter it manually

(see chap. 7.6.2).

Place weighing goods A.

After the standstill control sounds a signal tone, the weighing value will be

added into the summation memory.

Remove the weighed good. When an optional printer is connected, data

will be edited.

More weighed goods can only be added when the display ≤ zero.

Place goods to be weighed B.

After the standstill control sounds a signal tone, the weighing value will be added

into the summation memory.

Remove the weighed good.

The total weight, the number of weighings as well as the total number of pieces will

shortly appear (Indicator [] next to TOTAL).

When an optional printer is connected, data will be edited.

30 KFS-TM-BA_IA-e-1410

Page 31

-------------------------------------------

C 3.000kg

PCS:

30pcs

--------------------------------------------

Add more weighed goods as described before.

Please note that the weighing system must be unloaded between the individual

weighing procedures.

This process may be repeated 99 times or till such time as the capacity of the

weighing system has been exhausted.

Display and output sum „Total“:

Unload the weighing pan and press , the total weight, the number of

weighings, followed by the total number of pieces will be shown for 2 sec and

printed if an optional printer is connected.

Delete weighing data:

Press to display the total weight, the number of weighing procedures and

the total quantity for 2 sec. During this display press .

KFS-TM-BA_IA-e-1410 31

Page 32

14 bu0

Acoustic signal turned off

7.8 Tolerance check

The weighing scales allow weighing goods according to a target quantity or target

weight within specified tolerances. With this function one can also check if the

weighing good is within a defined tolerance range. Reaching target quantity is

indicated by an audio sound (if enabled in menu) and a visual signal

(Tolerance margin ) displayed.

For menu settings, see chapter 8:

Target quantity / target

weight with tolerances

Accurate target quantity /

accurate target weight

without tolerance

Audio signal:

The audio sound depends on the settings made in menu block “F4 bU“, see chap. 8.

Options:

14 bu 1 Audio signal will ring out when load is within tolerance range.

14 bu 2 Audio signal will ring out when load is beyond tolerance range.

Optical signal:

The triangular tolerance marker [ ] in the display of the display shows whether the

goods to be weighed are within the two tolerance limits.

Target quantity / target weight exceeds maximum tolerance limit

2 limits For menu setting, „F3 Pn ”

see chap. 8

1 limit For menu setting, „F3 Pn ”

see chap. 8

Target quantity / target weight within tolerance range

Target quantity / target weight below minimum tolerance limit

32 KFS-TM-BA_IA-e-1410

Page 33

Tolerance check „counting“

Activate function

For menu setting „F0 sel“, see chap. 8

long pressing:

Tolerance check „weighing“

KFS-TM-BA_IA-e-1410 33

Page 34

Display limits

1. Tolerance check for target weight

Press to display the lower limit for target weight including current setting.

Press to display the upper limit for target weight including current setting.

2. Tolerance check for target quantity

Press to display the lower limit for target quantity including current setting.

Press to display the upper limit for target quantity including current setting.

Return to weighing mode using

34 KFS-TM-BA_IA-e-1410

Page 35

If required, delete the current setting by pressing .

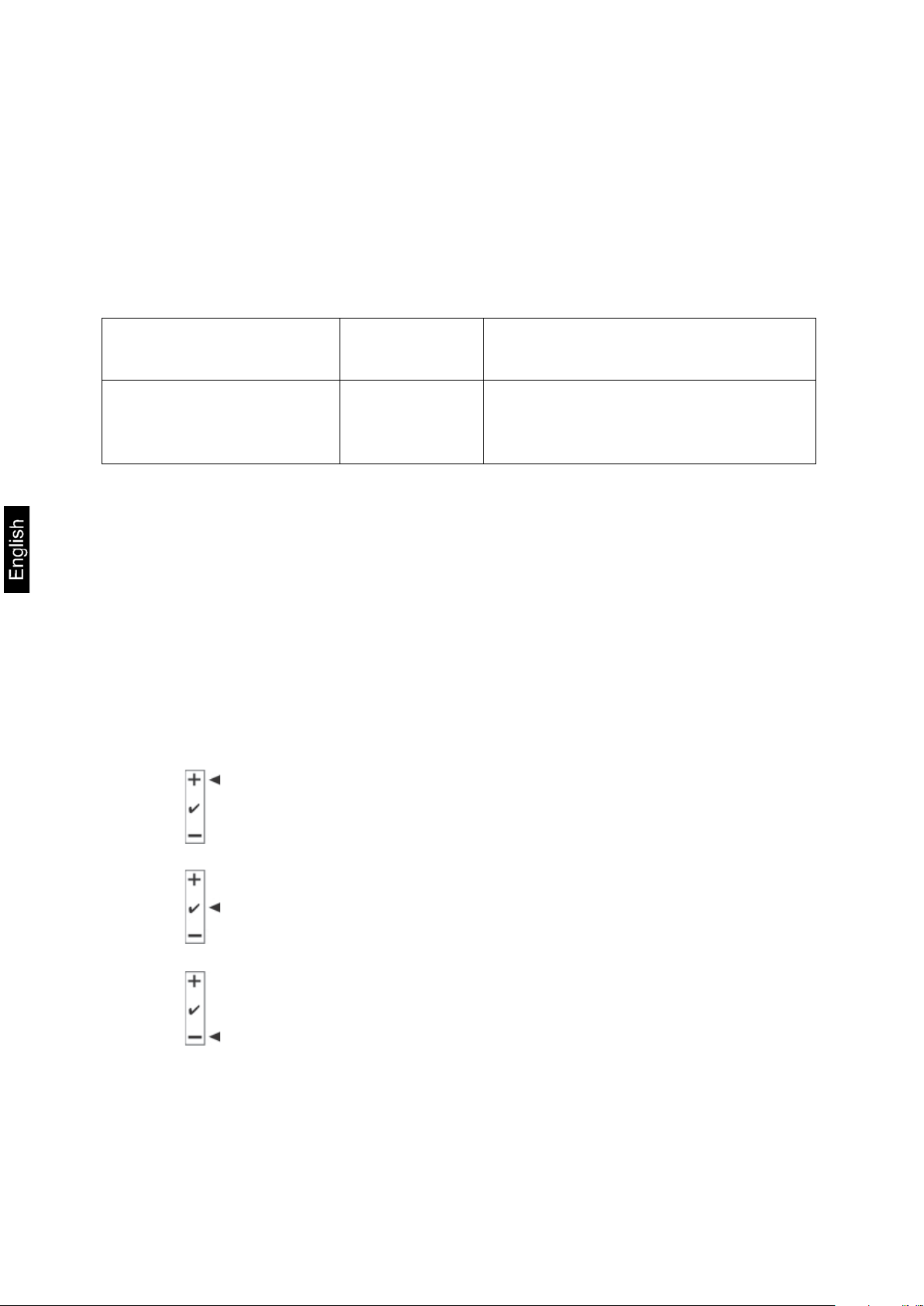

7.8.1 Tolerance check for target quantity

Activate menu setting „F0 sel / SEL 2“, see chap.7.8 „Activate function“.

Set limit values

Press to display the lower limit including current setting.

Use the numeric keys to enter the quantity for the lower limit (such as 70 units)

and confirm by pressing .

The upper limit will be displayed with the current setting.

Delete with if necessary.

Use the numeric keys to enter the quantity for the upper limit (such as 80 units)

and confirm by pressing .

KFS-TM-BA_IA-e-1410 35

Page 36

Start tolerance check

Specify unit weight, see chap. 7.6.1 or 7.6.2

Place load and wait until tolerance margin [] appears. With the help of the

tolerance indicator check if the weighed goods are under, inside or over the

default tolerance.

Depending on the setting in the menu an additional audio signal may be sounded.

Target quantity below tolerance:

Target quantity within tolerance:

Target quantity exceeds tolerance:

36 KFS-TM-BA_IA-e-1410

Page 37

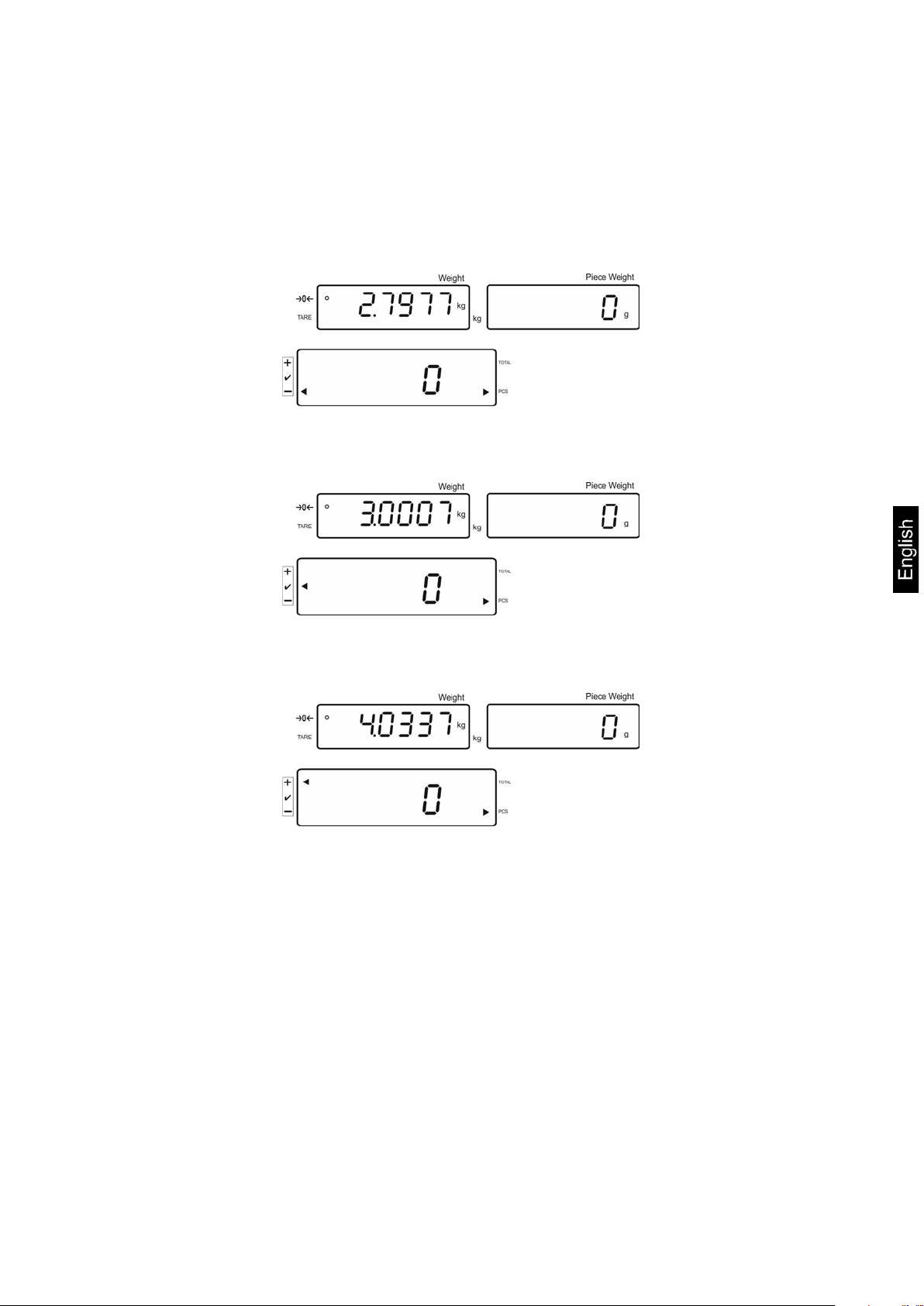

7.8.2 Tolerance check for target weight

Menu setting „F0 sel / SEL 1“, „Enable function“.

Set limit values

Press to display the lower limit including current setting.

Delete with if necessary.

Use the numeric keys to enter the weight for the lower limit value (such as 3 kg)

and confirm by pressing .

The upper limit for the target weight including current setting will be displayed.

Delete with if necessary.

KFS-TM-BA_IA-e-1410 37

Page 38

Use the numeric keys to enter the upper limit (such as 4 kg) and confirm by .

38 KFS-TM-BA_IA-e-1410

Page 39

Start tolerance check

Place load and wait until tolerance margin [] appears. With the hel p of the

tolerance indicator check if the weighed goods are under, inside or over the

default tolerance.

Depending on the setting in the menu an additional audio signal may be sounded.

Target weight below tolerance:

Target weight within tolerance:

Target weight exceeds tolerance:

KFS-TM-BA_IA-e-1410 39

Page 40

8 Function menu

Navigation in the menu:

Call up menu

Select menu items

In weighing mode keep pressed until FSEt appears.

Release button. The first menu item F0. SEL is displayed.

long pressing:

With help of , the individual menu items can be

selected one after the other.

and so on

40 KFS-TM-BA_IA-e-1410

Page 41

to the menu.

Change settings

Confirm setting

Return to weighing

mode

Confirm selected menu item with and the current

setting will be shown.

Change setting in selected menu item by pressing .

Confirm required setting with and the appliance returns

Press to return to weighing mode .

KFS-TM-BA_IA-e-1410 41

Page 42

1 SEL2*

Tolerance control for counting

standstill control is not yet displayed.

with standstill control.

Tolerance marker is only displayed above zero

range.

Tolerance marker is displayed for the whole

range.

13 Pn 0

13 Pn 1*

14 bu0*

14 bu1

14 bu2

2 Ao1

Automatic limiting point corr ec tion on, 0.5 d

2 Ao2*

Automatic limiting point correction on, 1 d

2 Ao3

Automatic limiting point correction on, 2 d

2 Ao4

Automatic limiting point correction on, 4 d

on

Automatic shut-off ON

3 Ap0*

AUTO OFF function disabled

4 UA0

Output via RS232C interface disabled

4 UA1*

Continuous data output

4 UA2

Continuous data output of stable weighing values

One output for stable weighing value. No output

stabilization.

see chap. 9.2.

Issue after pressing the PRINT ´button

4 UA5

Standard printer setting, output after pressing the

PRINT button

id on/off

Printout memory on/off

dt on/off

Printout date on/off

G on/off

Printout gross weight on/off

n on/off

Printout net weight on/off

C on/off

Printout total on/off

PCS on(off)

Printout parts counting on/off

4 UA6

Not documented

Overview:

Menu item Available settings

F0 SEL

Enable tolerance check

F1 Co

Display conditions of the tolerance

marker

F2 Li

Tolerance range

F3 Pn

Number of limiting points

F4 bU

Audio signal

F5 Ao

Automatic zero point correction

(zero tracking)

1 SEL0

1 SEL1

11 Co0

11 Co 1*

12 Li 0

12 Li 1*

2 Ao0

Tolerance control disabled

Tolerance control for weighing

Tolerance marker is always displayed, even if

Tolerance marker is only displayed in connection

1- Limiting point (OK/ -)

2- Limiting points (+/OK/-)

Audio sound during tolerance control disabled

Audio sound when load is within tolerance limits

Audio sound when load is beyond tolerance limits

Automatic zero tracking off

F6 At

Automatic cutout

F7 AP

Automatic shutdown for battery

operation

F8 UA

RS-232 mode

off

3 Ap1

4 UA3

4 UA4

Automatic shut-off OFF

Instrument will be switched off after 3 minutes of

inactivity of display unit or weighing bridge.

for stable weighing values. Renewed output after

For remote commands,

42 KFS-TM-BA_IA-e-1410

Page 43

For automatic totalizing see chap. 7.7.2

edited, when an optional printer is connected.

Manual totalizing, see chap. 7.7.1

printer is connected.

Automatic background illumination on when

weighing pate is loaded or key pressed.

F9 bl.

Baud rate

41 bl 0

41 bl1

41 bl 2

41 bl 3

F10 PA

Parity

42 Pr0*

42 Pr1

42 Pr2

F11 S0 Sd0 on*

Sd0 of

F12 AC 5 AC 0

5 AC 1*

1200 bps

2400 bps

4800 bps

9600 bps

No parity bit

Odd parity

Even parity

Autom. printout enabled on zero disp lay

Autom. printout disable d on zero display

With this function the individual weighing val ues

are automatically added into the summation

memory when the balance is unloaded and

With this function the individual weighing values

are added into the summation memory by

pressing and edited, when an optional

F13 bk

Display background illum inatio n

5 bkL0

5 bkL1

5 bkL2

F14 ti

Date format

Y m d

D m y

Factory settings are marked by *.

Background illumination off

Continuous background lighting

yyyy mm dd (JJJJ MM TT)

dd mm yyyy (TT MM JJJJ)

KFS-TM-BA_IA-e-1410 43

Page 44

Pin No.

Signal

Input/output

Functions

EXT.TARE

Input

External tare※2

RXD

Input

Receiving data

TXD

Output

Transmission data

DTR

Output

HIGH level with power “on”

GND ― Signal ground

― ―

―

― ―

―

― ―

―

GND ― Signal ground

1

2

3 4 5 6 7 8 9

9 pin d-subminiature bushing

9 RS 232C interface

You can print weighing data automatically via the RS 232C interface or manually by

pressing via the interface according to the setting in the menu.

This data exchange is asynchronous using ASCII - Code.

The following conditions must be met to provide successful communi cati on between

the weighing system and the printer.

• Use a suitable cable to connect the display unit to the interface of the printer.

Faultless operation requires an adequate KERN interface cable.

• Communic a ti on par a m eter s (baud ra t e, bi ts and parity) of display unit and

printer must match.

9.1 Technical data

1

2

3

4

5

6

7

8

9

44 KFS-TM-BA_IA-e-1410

Page 45

5

3

23

2

5

1

7

8

6

4

TXD

RX D

GND

DCO

RT S

CT S

DSR

DT R

RX D

TXD

GND

PC

Balance

Connection to PC:

D‐ SUB9 P

D‐ SUB9 P

9.2 Remote control instructions

Command Function

S Stable weighing value for the weight is sent via the RS232 interface

W Weighing value for the weight (stable or unstable) is sent via the

RS232 interface

T No data are sent, the balance carries out the tare function.

Z No data are sent, the zero-display appears.

P Quantity will be sent via the RS232-interface

KFS-TM-BA_IA-e-1410 45

Page 46

10 S e rvicing, maintenance, di s posal

10.1 Cleaning

Before cleaning, disconnect the appliance from the operating voltage.

Please do not use aggressive cleaning agents (solvents or similar agents), but a

cloth dampened with mild soap suds. Take care that the device is not penetrated by

fluids and polish it with a dry soft cloth.

Loose residue sample/powder can be removed carefully with a brush or manual

vacuum cleaner.

Spilled weighing goods must be removed immediately.

10.2 Servicing, maintenance

The appliance may only be opened by trained service technicians who are authorized

by KERN.

Before opening, disconnect from power supply.

10.3 Disposal

Disposal of packaging and appliance must be carried out by operator according to

valid national or regional law of the location where the appliance is used.

Should other error messages occur, switch balance off and then on again. If the error

message remains inform manufacturer.

46 KFS-TM-BA_IA-e-1410

Page 47

The displayed weight does

• The display unit is not switched on.

• Mains power supply interrupted (mains cable

defective).

• Power supply interrupted.

• (Rechargeable) batteries are inserted incorrectly or

empty

• No (rechargeable) batteries inserted.

The displayed weight is

• Table/floor vibrations

• Weighing pan has contact with other objects.

possible)

The weighing result is

• The display of the balance is not at zero

• Adjustment is no longer correct.

• The weighing pan is not level

• Great fluctuations in temperature.

possible)

11 E rror messages, troubleshoot ing guide

In case of an error in the program process, briefly turn off the appliance and

disconnect from power supply. The weighing process must then be restarted from the

beginning.

Fault Possible cause

not glow.

permanently changing

obviously incorrect

Error message Possible cause

o-Err

• Draught/air movement

• Electromagnetic fields / static charging (choose

different location/switch off interfering device if

• Warm-up time was ignored.

• Electromagnetic fields / static charging (choose

different location/switch off interfering device if

• Weighing range exceeded

u-Err

b-Err

1-Err

2-Err

l-Err

Err 3

Should other error messages occur, switch device off and then on again. If the error

message remains inform manufacturer.

KFS-TM-BA_IA-e-1410 47

• Insufficient preload, e. g. missing weighing pan

• Missing internal memory

• Incorr ect adj us ti ng w eight

• Incorr ect adj us t me nt

• Item weight too low

• Adjustment error

• Transport safety device has not been removed

Page 48

12 Installing display unit / weighing bridge

Installation / configuration of the weighing system must be carried out by a well

acquainted specialist with the workings of weighing balances.

12.1 Technical da ta

Supply voltage: 5 V/150mA

Sensitivity 2-3 mV/V

Resistance parameter 80 - 100 Ω, max 4 items per 350 Ω load cell

12.2 Weighing system design

The display unit is suitable for connection to any analogue platform in compliance

with the required specifications.

The following data must be established before selecting a weighing cell:

• Weighing balance capacity

This usually corresponds to the heaviest load to be weighed.

• Preload

This corresponds to the total weight of all parts that are to be placed on the

weighing cell such as upper part of platform, weighing pan etc.

• Total zero setting range

This is composed of the start-up zero setting range (± 2%) and the zero

setting range available to the user via the ZERO-key (2%). The total zero

setting range equals therefore 4 % of the scale’s capacity.

The addition of weighing scales capacity, preload and the total zero setting

range give the required capacity for the weighing cell.

To avoid overloading of the weighing cell, include an additional safety

margin.

• Smallest desired display division

48 KFS-TM-BA_IA-e-1410

Page 49

12.3 Connecting a platform

Disconnect the display unit from the power supply.

Weld the individual wires of the load cell cable to the printed circuit board.

Please see diagram below for plug allocation.

KFS-TM-BA_IA-e-1410 49

Page 50

and so on

12.4 Configuring display devices Navigation in the menu:

Call up menu

Switch-on balance and during the selftest press .

To call the firm menu item , press and hold for approx.

5-6 seconds until Func followed by F0 iSn appears.

Release button.

Select menu items

With help of , the individual menu items can be

selected one after the other.

50 KFS-TM-BA_IA-e-1410

Page 51

returns to the menu.

Change settings Confirm selected menu item such as F2 dm by pressing

and the current setting will be displayed.

Change setting in selected menu item by pressing .

Confirm setting

Reject setting

Return to weighing

mode

Confirm required setting with and the appliance

Press , the unit will return to the menu

Back to weighing mode press several times.

KFS-TM-BA_IA-e-1410 51

Page 52

Menu block

Main menu

Menu item

sub menu

Configuration menu overview:

Available settings / explanation

F0 iSn

F 1 Grv

F2 dm

-

-

Display internal resolution

Not documented

Single-range balance

Confirm by pressing , then the following menu items can

be selected by .

dESC Position decimal point available selection

0, 0.0, 0.00, 0.000, 0.0000, 0.00000

inC inC 1 Readability

inC 2

selectable 1, 2, 5, 10, 20, 50

inC 5

inC 10

inC 20

inC 50

CAP Balance capacity (max)

Adjust weighing system after configuration.

CAL nonLin Adjustment, see chap. 6.5

LinEAr For linearisation see chapter 6.6

52 KFS-TM-BA_IA-e-1410

Page 53

Dual range balance

Confirm with , then the following menu items can be

selected by .

dESC Position decimal point available

selection 0, 0.0, 0.00, 0.000, 0.0000,

0.00000

inC div 1 inC 1 Readability for

inC 2

inC 5

1. Weighing ra nge

Selectable 1, 2, 5, 10, 20,

50

inC 10

inC 20

inC 50

div 2 inC 1 Readability for

inC 2

inC 5

2. Weighing ra nge

Selectable 1, 2, 5, 10, 20,

50

inC 10

CAP CAP 1 Balance capacity (Max) 1st weighing

Adjust weighing system af ter configur ation.

CAL nonLin Adjustment, see chap. 6.5

inC 20

inC 50

range

CAP 2 Balance capacity (Max) 2nd weighing

range

LinEAr For linearisation see chapter 6.6

KFS-TM-BA_IA-e-1410 53

Page 54

Multi-interval balance

Confirm by , after that the following menu items are

available.

inC div 1 inC 1 Readability for

div 2 inC 1� Readability for

Position decimal point available

selection 0, 0.0, 0.00, 0.000, 0.0000

inC 2�

inC 5�

inC 10�

inC 20�

inC 50�

inC 2�

inC 5�

inC 10�

1. Weighing ra nge

Selectable 1, 2, 5, 10, 20,

50

2. Weighing ra nge

Selectable 1, 2, 5, 10, 20,

50

F3 APP

inC 20�

inC 50�

CAP CAP 1 Balance capacity (Max) 1st weighing

range

CAP 2 Balance capacity (Max) 2nd weighing

range

Adjust weighing system after configuration.

CAL nonLin Adjustment, see chap. 6.5

LinEAr For linearisation see chapter 6.6

Press adjustment switch

on In verified weighing systems the access to the

configuration menu is locked.

off Access to configuration menu enabled

(systems not appropriate for verification)

54 KFS-TM-BA_IA-e-1410

Loading...

Loading...