Page 1

KERN & Sohn GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@kern-sohn.com

Phone: +49-[0]7433- 9933-0

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

Installation Instructions

Weighing beams

KERN KFA V20

Version 1.2

08/2013

GB

KFA V20-IA-e-1312

Page 2

GB

KERN KFA V20

Version 1.2 08/2013

Installation Instructions Weighing beams

Contents

1 Technical data ................................................................................................ 3

2 Appliance overview ....................................................................................... 5

3 Basic Information (General) .......................................................................... 6

3.1 Documentation ........................................................................................................................... 6

3.2 Proper use .................................................................................................................................. 6

3.3 Improper Use .............................................................................................................................. 6

3.4 Warranty ..................................................................................................................................... 6

3.5 Monitoring of Test Resources ..................................................................................................... 7

4 Basic Safety Precautions .............................................................................. 7

4.1 Pay attention to the instructions in the Operation Manual .......................................................... 7

4.2 Personnel training ....................................................................................................................... 7

5 Transport and storage ................................................................................... 7

5.1 Testing upon acceptance ........................................................................................................... 7

5.2 Packaging / return transport ....................................................................................................... 7

6 Unpacking, Setup and Commissioning ....................................................... 8

6.1 Installation Site, Location of Use ................................................................................................ 8

6.2 Unpacking and placing ............................................................................................................... 9

6.3 Connecting a display screen ..................................................................................................... 10

7 Operation ................................................................ ................................ ...... 10

7.1 Load/unload weighing beams ................................................................................................... 11

8 Service, maintenance, disposal .................................................................. 12

8.1 Daily check ............................................................................................................................... 12

8.2 Cleaning .................................................................................................................................... 12

8.3 Service, maintenance ............................................................................................................... 12

8.4 Disposal .................................................................................................................................... 12

8.5 Instant help ............................................................................................................................... 13

9 Service documentation ............................................................................... 14

9.1 Overview, setting regulation, tolerances ................................................................................... 14

9.2 Check and adjustment of the corner load ................................................................................. 15

10 Preload / Deadload settings ........................................................................ 16

2 KFA V20-IA-e-1312

Page 3

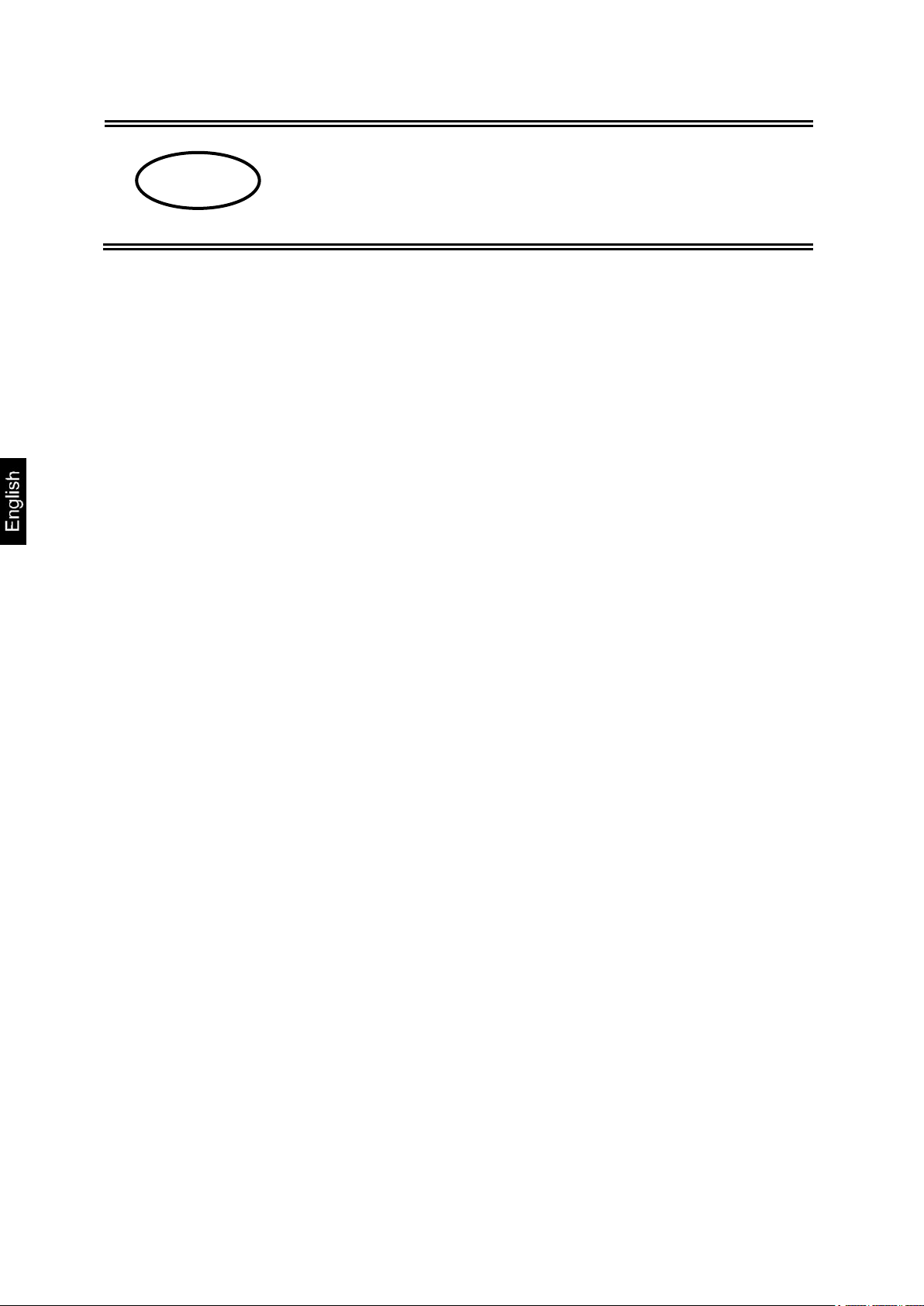

1 Technical data

Model

Weighing

range

Max

Readability

d

Preload

additive

Cable length

display

screen

approx.

Connecting

cable

weighing

beams

approx.

Net weight

approx.

kg

kg

kg m m

kg

KFA 1500V20

1500

0.5

300 5 2.5

42

KFA 3000V20

3000

1

500 5 2.5

42

KFA

3000V20L

3000

1

500 5 1.5

42

KFA 6000V20

6000

2

1000

5

1.5

35

KFA

6000V20L

6000

2

1000

5

1.5

42

KFA V20-IA-e-1312 3

Page 4

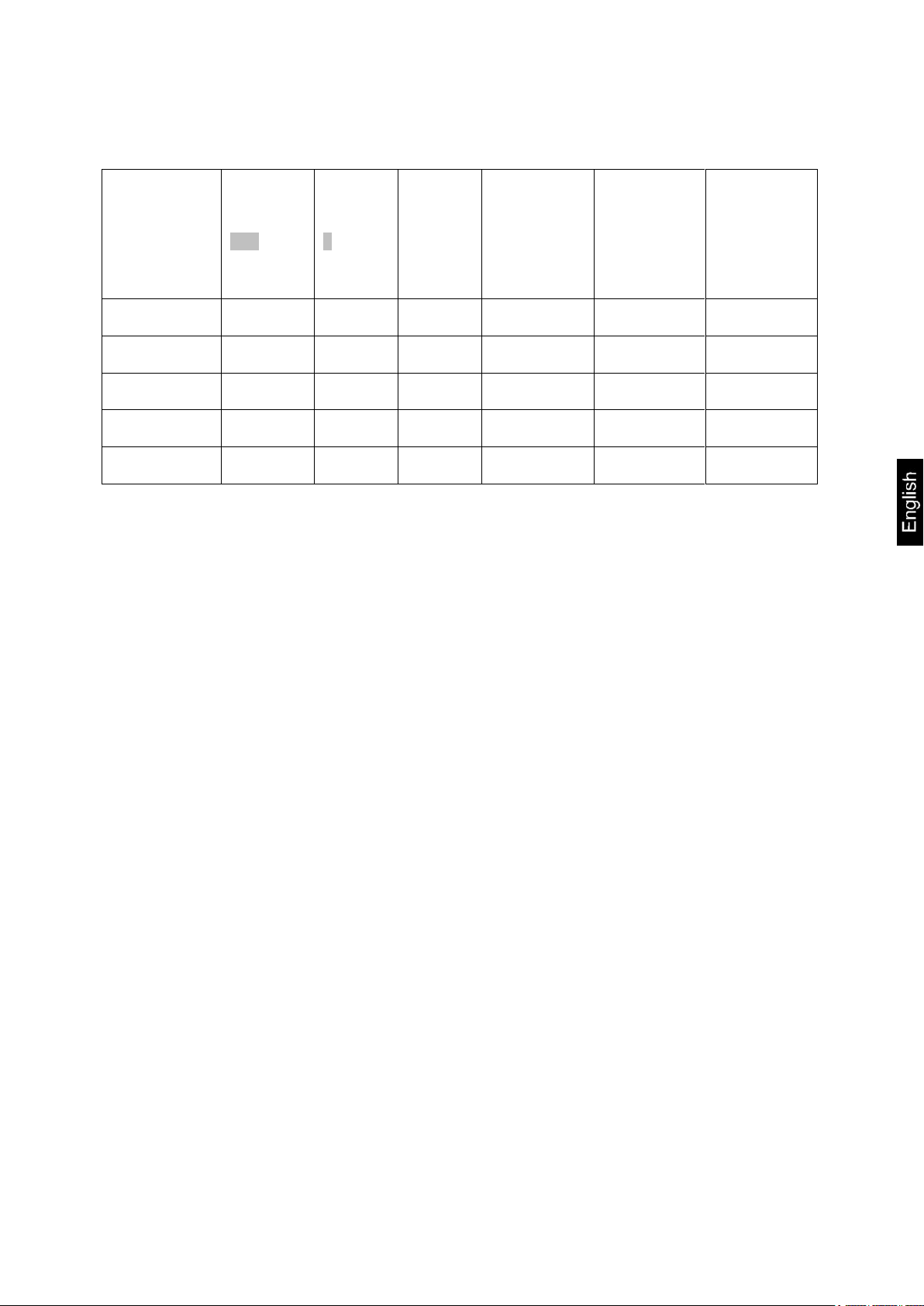

„L“-models length 2000 mm

Dimensions:

4 KFA V20-IA-e-1312

Page 5

2 Appliance overview

Mains lead display screen

Connecting cable weighing beams

Handle for easy transport

Weighing cell feet and weighing cells

Cover adjusting screw for weighing cell feet

Illustrative example weighing system KERN KFA V20 + KFB-TM

KFA V20-IA-e-1312 5

Page 6

3 Basic Information (General)

3.1 Documentation

These installation instruction contain all data necessary for placing and

commissioning the weighing beams KERN KFA V20.

In combination with a display unit, described below as weighing system, for operation

configuration, please refer to the operating instructions of the display unit.

3.2 Proper use

The weighing beams are designed for weighing of large, voluminous or long loads.

They are designed to be used as “non-automatic scales“ As soon as a stable

weighing value is reached the weighing value can be read.

3.3 Improper Use

Do not leave loads permanently on the weighing beams. This may damage the

measuring system.

Impacts and overloading exceeding the stated maximum load (max) of the weighing

beams, minus a possibly existing tare load, must be strictly avoided. This may

damage the weighing beams.

Never operate in an explosive environment. The serial version is not explosion

protected.

Do not modify the construction of the weighing beams. This may lead to incorrect

weighing results, safety-related faults and destruction of the weighing beams.

The weighing beams may only be used according to the described conditions. Other

areas of use must be released by KERN in writing.

3.4 Warranty

Warranty claims shall be voided in case

Our conditions in the operation manual are ignored

The appliance is used outside the described uses

Structural changes of the device

Mechanical damage and damage caused by media, liquids

Natural wear and tear

The appliance is improperly set up or incorrectly electrically connected

Overload of the measuring system

6 KFA V20-IA-e-1312

Page 7

3.5 Monitoring of Test Resources

Carefully read this operation manual before setup and commissioning,

even if you are already familiar with KERN balances.

Versions in other languages are non-binding translations.

The only binding version is the original document in German.

Keep all parts of the original packaging for a possibly

required return.

Only use original packaging for returning.

Prior to dispatch disconnect all cables and remove

loose/mobile parts.

Reattach possibly supplied transport securing devices.

Secure all parts against shifting and damage.

In the framework of quality assurance the measuring-related properties of the

weighing system and, if applicable, the testing weight, must be checked regularly.

The responsible user must define a suitable interval as well as type and scope of this

test. Information is available on KERN’s home page (www.kern-sohn.com with

regard to the monitoring of weighing system test substances and the test weights

required for this. In KERN's accredited DKD calibration laboratory test weights and

weighing systems may be calibrated (return to the national standard) fast and at

moderate cost.

4 Basic Safety Precautions

4.1 Pay attention to the instructions in the Operation Manual

4.2 Personnel training

The appliance may only be operated and maintained by trained personnel.

The installation of a display unit must only be carried out by a well acquainted

specialist with the workings of weighing balances.

5 Transport and storage

5.1 Testing upon acceptance

When receiving the appliance, please check packaging immediately, and the

appliance itself when unpacking for possible visible damage.

5.2 Packaging / return transport

KFA V20-IA-e-1312 7

Page 8

6 Unpacking, Setup and Commissioning

6.1 Installation Site, Location of Use

The weighing beams are designed in a way that reliable weighing results are

achieved in common conditions of use.

To enable exact and fast work, select the right site.

On the installation site observe the following:

Place the weigh beam on a level and stable surface.

The foundations at the site must be able to bear the weight of the weighing

beams as well as the weight of the maximum weight.

Avoid extreme heat as well as temperature fluctuation caused by installing

next to a radiator or in the direct sunlight

Protect the weighing system against direct draughts due to open windows and

doors

Avoid jarring during weighing

Protect the weighing beams against high humidity, vapours and dust

Do not expose weighing beams to moisture over a long period of time. Non-

permitted condensation (condensation of air humidity on the appliance) may

occur if a cold appliance is taken to a considerably warmer environment. In

this case, acclimatize the disconnected appliance for ca. 2 hours at room

temperature

Avoid static charge of goods to be weighed or weighing container

Do not lean weighing beams against a wall

Do not move weighing beams whilst loaded

Keep away chemicals (such as liquids or gasses), which could attack and

damage the weighing beams inside or from outside

Keep IP protection of the device

Major display deviations (incorrect weighing results) may be experienced should

electromagnetic fields (e.g. due to mobile phones or radio equipment), static

electricity accumulations or instable power supply occur. Change location or remove

source of interference.

8 KFA V20-IA-e-1312

Page 9

6.2 Unpacking and placing

Unpacking:

Remove weighing beams and accessories carefully from packaging, remove

packaging material and place device at the planned work place. Verify that there has

been no damage and that all packing items are present.

Scope of delivery:

2 Weighing beams with fitted “mains lead display screen“ and “connecting cable

weighing beams”.

4 weighing cell feet

Operating instructions

Placing:

Prior to the final placing, install the four weighing cell feet.

Ensure a level surface on the installation site, particularly around the weighing

cell feet.

Put down the weighing beams and check whether they are positioned level and

that all four feet reach the floor. Adjust minor height differences by adjusting the

weighing cell feet.

For this purpose remove the cap head screw (See chapter 2, item ) and adjust

the height of the 4 weighing cells by turning the adjusting screw. For this purpose

use an external levelling appliance, e.g. a water level.

Make sure not to crimp or damage the mains lead and connecting cable when

lifting or placing.

KFA V20-IA-e-1312 9

Page 10

6.3 Connecting a display screen

terminal

Color

State

EXC+ [IN+]

red

voltage +

SIG + [OUT+]

green

signal +

SIG -[OUT-]

white

signal -

EXC -[IN- ]

black

voltage -

Attention

Put the connecting cable to the display unit in a manner that it is protected against

damage.

Description of the connection cable:

7 Operation

Information about

Network connection

Power is supplied via the connecting cable of the display unit

Initial Commissioning

Connection of peripheral devices

and the correct operation you will in the operating instructions included in the scope

of delivery of the display unit.

10 KFA V20-IA-e-1312

Page 11

7.1 Load/unload weighing beams

The weighing beams are designed for an evenly spread load

Avoid falling load, shock loads and impacts from the side.

Weighing beams must not be moved when loaded.

Place the load onto both weighing beams by using a pallet truck, crane or fork lift.

Ensure that the load is not swinging when it is placed onto the weighing beams.

Lift the load first vertically at least 10 cm above the weighing beams before it is

removed or newly placed.

KFA V20-IA-e-1312 11

Page 12

8 Service, maintenance, disposal

Before any maintenance, cleaning and repair work disconnect the

appliance from the operating voltage.

8.1 Daily check

Ensure that all four feet are in contact with the floor.

Ensure that cables are not damaged.

Ensure that the weighing beams are free of soiling, in particular underneath the

edges.

8.2 Cleaning

! Remove regularly corrosive substances.

! Keep IP protection.

! Do not aim water or steam jet at the weigh cells.

Clean weighing beams using a soft cloth soaked in a mild detergent. Take care

that the device is not penetrated by fluids and polish it with a dry soft cloth.

8.3 Service, maintenance

The appliance may only be opened by trained service technicians who are

authorized by KERN.

Ensure that the weighing system is regularly calibrated, see chap. 3.5 Testing

instruments control.

8.4 Disposal

Disposal of packaging and appliance must be carried out by operator according

to valid national or regional law of the location where the appliance is used.

12 KFA V20-IA-e-1312

Page 13

8.5 Instant help

Fault

Possible cause

The displayed weight is permanently

changing

Draught/air movement

Floor vibrations

Weighing beams come into contact with

foreign substances.

Electromagnetic fields / static charging

(choose different location/switch off

interfering device if possible)

The weighing result is obviously

incorrect

No zero display for unloaded weighing

beams.

Adjustment is no longer correct.

Great fluctuations in temperature.

The weighing beams are not level.

Electromagnetic fields / static charging

(choose different location/switch off

interfering device if possible)

In case of an error in the program process, briefly turn off the weighing system and

disconnect from power supply. The weighing process must then be restarted from

the beginning.

Help:

Should other error messages occur, switch balance off and then on again. If the error

message remains inform manufacturer.

KFA V20-IA-e-1312 13

Page 14

9 Service documentation

This chapter is only intended for a balance specialist!

The weighing beams are fitted with a DMS weigh cell at each corner.

The analogue-digital transformation occurs in the display unit. Also all

the balance and country-specific data are stored there.

Capacity

600 kg

1500 kg

Readability

200 g

500 g

Min

4 kg

10 kg

Max

600 kg

1500 kg

1/3 corner load

200 kg

500 kg

Tolerance

200 g

500 g

-1

-0,75

-0,5

-0,25

0

0,25

0,5

0,75

1

0 500 1000 1500

[kg]

[g]

-0,4

-0,3

-0,2

-0,1

0

0,1

0,2

0,3

0,4

0 100 200 300 400 500 600

[kg]

[g]

600kg

1500kg

9.1 Overview, setting regulation, tolerances

Testing and setting regulations:

Verification data and tolerances as per OIML:

14 KFA V20-IA-e-1312

Page 15

9.2 Check and adjustment of the corner load

Check of the corner load:

Place a suitable aid such as a pallet on both weighing

beams. Make sure that the aid is designed to bear

the weight of the test weight.

Place the test weights in the centre of the load plate

and tare.

The balance displays -0-.

Place the test weights successively on all four

corners.

Now the deviations are displayed with sign, write

down the values. If there are deviations out of the

tolerances (see chap. 9.1), an adjustment will be

necessary.

Adjustment of corner load:

Preparation:

For a better control of the modifications which occur

during adjustment, select in the configuration menu

the highest readability for control purposes.

Open connection box

Adjustment rule:

The corner (weighing cell) with the biggest negative

deviation must be set to zero. Do not re-adjust this

corner even after several adjustment sequences.

Adjustment on the analogue print

Adjustment of weighing cell J2 takes place at the potentiometer VR1.

Adjustment of weighing cell J3 takes place at the potentiometer VR2.

Adjustment of weighing cell J4 takes place at the potentiometer VR3.

Adjustment of weighing cell J5 takes place at the potentiometer VR4.

Increase the value turning to the right, reduce the value turning to the left.

KFA V20-IA-e-1312 15

Page 16

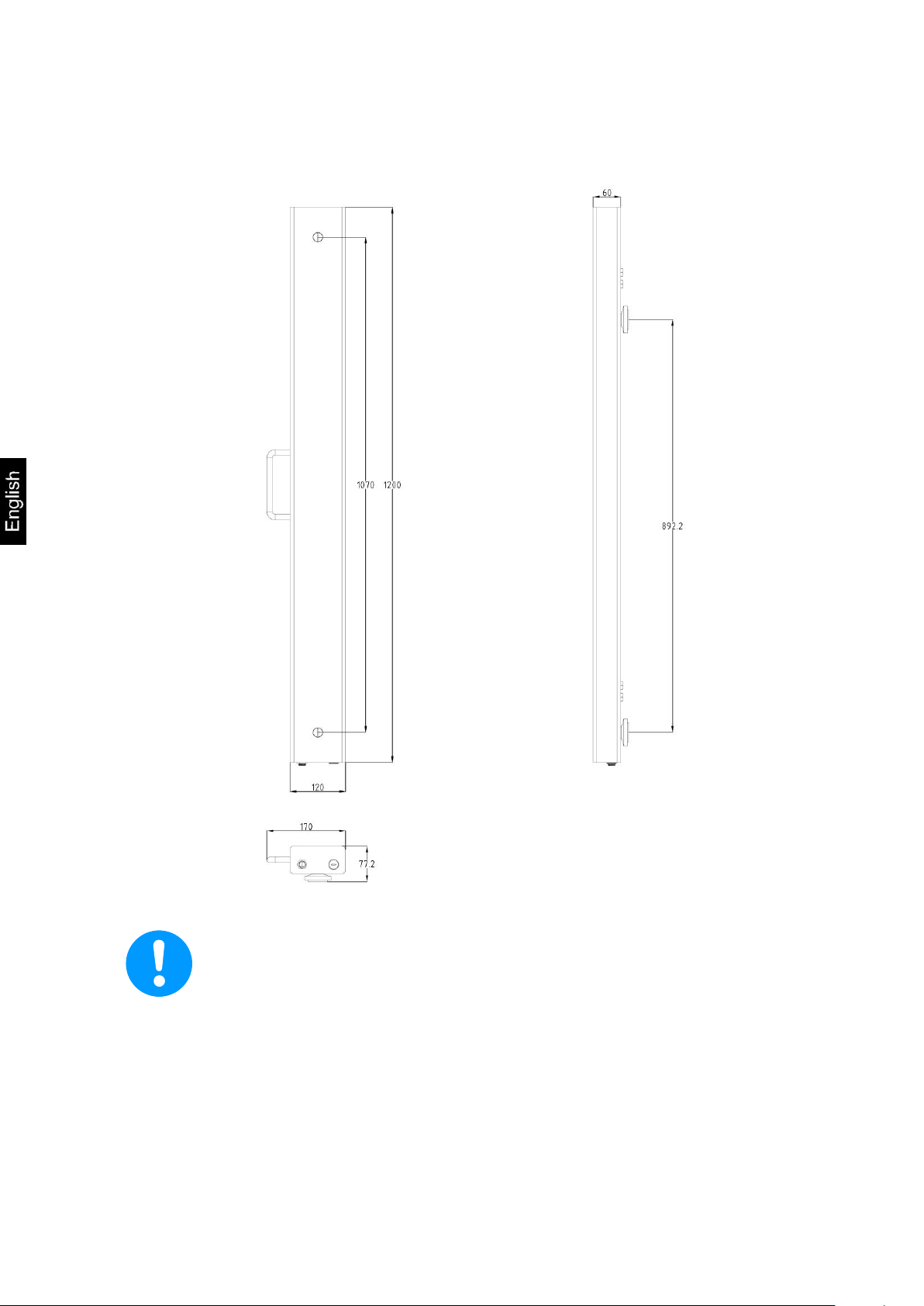

Kern model

Max. preload* (kg)

* = additive preload

Deadload** (kg)

**= already applied

preload

Center Overload

Protection circa

(kg)

Corner Overload

Protection circa

(kg)

Loadcell

Capacity (kg)

KFA 1500V20

0

39

NA

NA

1000kg

KFA 3000V20

0

39

NA

NA

1500kg

KFA 3000V20L

0

55

NA

NA

1500kg

KFA 6000V20

0

85

NA

NA

3000kg

KFA 6000V20L

0

95

NA

NA

3000kg

Platform

type

Platform

dimension

(mm)

Load

cell

TC

Class

Max

E

max

E

mi

n

Y

n

Deadload

T

min

T

max

Type

No.

Pre

load

-1

-4 -3

(kg) -5 -6

(kg)

(kg)

(g)

KFA 1500V20

1200x120

SQB

TC6911

C3 0 1000

0

10000

3000

36

-10

40

KFA 3000V20

1200x120

SQB

TC6911

C3 0 1500

0

10000

3000

36

-10

40

KFA 3000V20L

2000x120

SQB

TC6911

C3 0 1500

0

10000

3000

55

-10

40

KFA 6000V20

1200x120

SQB

TC6911

C3 0 3000

0

10000

3000

85

-10

40

KFA 6000V20L

2000x120

SQB

TC6911

C3 0 3000

0

10000

3000

95

-10

40

10 Preload / Deadload settings

16 KFA V20-IA-e-1312

Loading...

Loading...