Page 1

KERN & Sohn GmbH

Ziegelei 1

E-Mail: info@kern-sohn.com

Phone: +49-[0]7433- 9933-0

Internet: www.kern-sohn.com

Operating and Installation

Instructions Display Unit

KERN KEN-TM / KET-TM

11/2014

GB

Version 2.0

D-72336 Balingen

Fax: +49-[0]7433-9933-149

KEN-TM / KET-TM-BA-e-1420

Page 2

KERN KEN-TM / KET-TM

Display unit

GB

Version 2.0 11/2014

Operating and installation instructions

Contents

1 TECHNICAL DATA ................................................................................................. 7

1.1 Dimensions .................................................................................................................................... 8

1.2 Anschlüsse / Schnittstellen .......................................................................................................... 9

1.2.1 KET-TM ....................................................................................................................................... 9

1.2.2 KEN-TM ..................................................................................................................................... 10

2 CONTROL ELEMENTS AND PROGRAM STRUCTURE ..................................... 12

2.1 Keyboard overview ...................................................................................................................... 12

2.2 Overview of display ..................................................................................................................... 14

2.3 Program structure ....................................................................................................................... 16

2.3.1 Menu overview .......................................................................................................................... 16

2.3.2 Navigation in the menu .............................................................................................................. 17

2.4 Authorisation levels .................................................................................................................... 19

3 BASIC INSTRUCTIONS ........................................................................................ 20

3.1 Proper use .................................................................................................................................... 20

3.2 Improper Use ................................................................................................................................ 21

3.3 Warranty ....................................................................................................................................... 21

3.4 Monitoring of Test Resources .................................................................................................... 21

4 BASIC SAFETY PRECAUTIONS ......................................................................... 22

4.1 Pay attention to the instructions in the Operation Manual ..................................................... 22

4.2 Personnel training ....................................................................................................................... 22

5 TRANSPORT AND STORAGE ............................................................................. 22

5.1 Testing upon acceptance ........................................................................................................... 22

5.2 Packaging / return transport ...................................................................................................... 22

6 UNPACKING, SETUP AND COMMISSIONING.................................................... 23

6.1 Installation Site, Location of Use ............................................................................................... 23

6.2 Unpacking and placing ............................................................................................................... 23

6.3 Scope of delivery / serial accessories ....................................................................................... 23

6.4 How to connect the platform ...................................................................................................... 24

6.5 Mains connection ........................................................................................................................ 24

6.6 Commissioning ............................................................................................................................ 24

6.7 Log out .......................................................................................................................................... 26

6.8 Putting out of service / Standby mode ...................................................................................... 26

6.9 Basic Operation ........................................................................................................................... 27

2 KEN-TM / KET_TM-BA-e-1420

Page 3

6.9.1 Simple weighing ........................................................................................................................ 27

6.9.2 Zeroing ...................................................................................................................................... 27

6.9.3 Selecting weighing unit ............................................................................................................. 28

6.9.4 Weighing with tare ..................................................................................................................... 29

6.10 Connection of peripheral devices .............................................................................................. 30

7 SYSTEM SETTINGS (MENU) ................................................................................ 31

7.1 Weighing ...................................................................................................................................... 32

7.1.1 Median filter ............................................................................................................................... 33

7.1.2 Filter .......................................................................................................................................... 33

7.1.3 Auto Zero................................................................................................................................... 34

7.1.4 LO threshold .............................................................................................................................. 34

7.1.5 Last digit display accuracy ........................................................................................................ 34

7.2 Communication parameters ....................................................................................................... 35

7.2.1 RS232 (1) / RS232 (2) .............................................................................................................. 35

7.2.2 Ethernet / IP .............................................................................................................................. 36

7.2.3 TCP ........................................................................................................................................... 36

7.3 Devices ......................................................................................................................................... 37

7.3.1 PC ............................................................................................................................................. 38

7.3.2 Printer ........................................................................................................................................ 41

7.3.3 Barcode scanner ....................................................................................................................... 43

7.3.4 Transponder card reader .......................................................................................................... 45

7.3.5 Additional display ...................................................................................................................... 46

7.4 Configure display ........................................................................................................................ 47

7.4.1 Select information texts ............................................................................................................. 47

7.4.2 Selecting function keys ............................................................................................................. 50

7.4.3 Display all platforms .................................................................................................................. 53

7.4.4 Select bargraph type ................................................................................................................. 54

7.5 I/O settings ................................................................................................................................... 59

7.5.1 Inputs ......................................................................................................................................... 60

7.5.2 Outputs ...................................................................................................................................... 61

7.6 Authorisations ............................................................................................................................. 62

7.7 Weighing Units ............................................................................................................................ 66

7.8 General parameters ..................................................................................................................... 68

7.8.1 User language ........................................................................................................................... 68

7.8.2 Enter date / time, select display format ..................................................................................... 69

7.8.3 Signal tone when pressing button ............................................................................................. 71

7.8.4 Set the touch screen alignment ................................................................................................ 72

7.8.5 Setting brightness of display ..................................................................................................... 73

7.8.6 Set mouse support .................................................................................................................... 73

7.8.7 Setting “Log on required“ .......................................................................................................... 74

7.8.8 Setting start logo ....................................................................................................................... 74

7.8.9 Setting viewing times for error messages ................................................................................. 75

7.9 Adjustment ................................................................................................................................... 76

7.10 Verification ................................................................................................................................... 76

7.11 Weighing scale info ..................................................................................................................... 78

KEN-TM / KET_TM-BA-e-1420 3

Page 4

8 APPLICATION SETTINGS ................................................................................... 79

8.1 Select application ........................................................................................................................ 79

8.2 Application specific settings ...................................................................................................... 82

9 WEIGHING ............................................................................................................ 85

9.1 Setting storage conditions for alibi memory ............................................................................ 86

9.2 Dispensing ................................................................................................................................... 88

9.3 Checkweighing ............................................................................................................................ 89

9.4 Tare mode ..................................................................................................................................... 92

9.5 Labelling ....................................................................................................................................... 93

9.6 Statistics ....................................................................................................................................... 94

9.7 Differential weighing ................................................................................................................... 95

9.8 Peak value function ..................................................................................................................... 96

9.9 Info about saved weighing activities ......................................................................................... 97

10 PARTS COUNTING ........................................................................................... 98

10.1 Select application ........................................................................................................................ 98

10.2 Application specific settings ...................................................................................................... 99

10.2.1 Automatic reference optimization........................................................................................ 100

10.2.2 Minimum reference single weight ....................................................................................... 102

10.3 Carry out parts counting ........................................................................................................... 103

10.3.1 Determination of the reference piece weight by weighing .................................................. 103

10.3.2 Enter reference single weight as numeric value ................................................................. 105

10.4.1 Load reference single weight from database. ..................................................................... 106

10.4.2 Allocating reference single weight in database to a product .............................................. 107

11 PERCENT DETERMINATION ......................................................................... 109

11.1 Select application ...................................................................................................................... 109

11.2 Application specific settings .................................................................................................... 110

11.3 How to carry out percentage calculation ................................................................................ 111

11.3.1 Determination of the reference weight by weighing ............................................................ 111

11.3.2 Enter reference weight as numeric value ........................................................................... 112

12 FORMULATION ............................................................................................... 114

12.1 Select application ...................................................................................................................... 114

12.2 Application specific settings .................................................................................................... 116

12.3 Defining recipe in database ...................................................................................................... 117

12.4 Process recipe from database ................................................................................................. 124

12.5 Log recipe ................................................................................................................................... 128

13 ANIMAL WEIGHING ........................................................................................ 131

13.1 Select application ...................................................................................................................... 131

13.2 Application specific settings .................................................................................................... 132

13.2.1 Average time ....................................................................................................................... 133

13.2.2 Auto start ............................................................................................................................. 133

13.3 Dynamic weighing using manual start .................................................................................... 134

4 KEN-TM / KET_TM-BA-e-1420

Page 5

13.4 Dynamic weighing with automatic start .................................................................................. 135

14 DATABASE ...................................................................................................... 136

14.1 Configuring database (administrator only) ............................................................................ 137

14.1.1 Accessibility of databases ................................................................................................... 138

14.1.2 Categories ........................................................................................................................... 138

14.1.3 Products / Operators / Clients ............................................................................................. 140

1.1.1 ..................................................................................................................................................... 140

1.1.1 ..................................................................................................................................................... 140

14.1.4 Extra variables .................................................................................................................... 141

14.1.5 Data record format .............................................................................................................. 141

14.1.6 Importing / exporting database file from USB storage medium .......................................... 142

14.2 Search for Data Record / Add Data Record ............................................................................ 143

14.4 Deleting data record (administrator only) ............................................................................... 145

14.5 Print data record ........................................................................................................................ 146

14.6 Basic data record operations via context menu .................................................................... 147

14.7 Edit databases (administrator only) ........................................................................................ 149

14.7.1 User database..................................................................................................................... 149

14.7.2 Product database ................................................................................................................ 150

14.7.3 Client database ................................................................................................................... 152

14.7.4 Database “Dosing Processes“ ............................................................................................ 152

14.7.5 Database “Recipes“ ............................................................................................................ 153

14.7.6 Database “Identification Processes“ ................................................................................... 153

14.7.7 Database “Packaging“ ........................................................................................................ 153

14.7.8 Database “Storage“ ............................................................................................................ 154

14.7.9 Database “Universal Variables“ .......................................................................................... 154

14.7.10 Database “Graphic“ ............................................................................................................ 154

15 LOGS ................................................................................................................ 155

15.1 Enabling accessibility to logs .................................................................................................. 156

15.2 Deleting older data (advanced users only) ............................................................................ 157

15.3 Weighing logs ............................................................................................................................ 158

15.3.1 Alibi memory ....................................................................................................................... 159

15.3.2 Filter .................................................................................................................................... 160

15.3.3 Record print out .................................................................................................................. 161

15.3.4 Display weighing procedures as a diagram ........................................................................ 163

15.3.5 Export weighing data to USB storage medium ................................................................... 164

15.3.6 Counter for weighing activities ............................................................................................ 165

16 COMMUNICATION ........................................................................................... 166

16.1 Overview interface commands ................................................................................................ 166

16.2 General response format .......................................................................................................... 167

16.3 Detailed information about interface logs .............................................................................. 168

16.3.1 Zeroing ................................................................................................................................ 168

16.3.2 Taring .................................................................................................................................. 168

16.3.3 Retrieve tare value .............................................................................................................. 169

16.3.4 Set tare value ...................................................................................................................... 169

16.3.5 Send stable weighing value in standard weighing unit ....................................................... 169

16.3.6 Send weighing value immediately in standard weighing unit ............................................. 170

KEN-TM / KET_TM-BA-e-1420 5

Page 6

16.3.7 Send weighing values for all platforms in default weighing unit immediately ..................... 171

16.3.8 Send stable weighing value in current weighing value ....................................................... 171

16.3.9 Send weighing value immediately in current weighing unit ................................................ 172

16.3.10 Start continuous output in standard weighing unit .............................................................. 172

16.3.11 Stop continuous output in standard weighing unit .............................................................. 172

16.3.12 Start continuous output in current weighing unit ................................................................. 173

16.3.13 Stop continuous output in current weighing unit ................................................................. 173

16.3.14 Set value for “Lower Threshold“.......................................................................................... 173

16.3.15 Set value for “Upper Threshold“.......................................................................................... 173

16.3.16 Retrieve value for “Lower Threshold“ ................................................................................. 174

16.3.17 Retrieve value for “Upper Threshold“ ................................................................................. 174

16.3.18 Press simulation “PRINT key“ ............................................................................................. 174

16.3.19 Send all implemented messages ........................................................................................ 174

16.4 Data format ................................................................................................................................. 175

17 SERVICING, MAINTENANCE, DISPOSAL ..................................................... 176

17.1 Cleaning ...................................................................................................................................... 176

17.2 Servicing, maintenance ............................................................................................................ 176

17.3 Disposal ...................................................................................................................................... 176

18 TROUBLESHOOTING GUIDE / ERROR MESSAGES ................................... 177

19 APPENDIX A – VARIABLES FOR PRINTOUTS ............................................ 178

19.1 List of variables ......................................................................................................................... 178

19.2 Format variables ........................................................................................................................ 184

20 APPENDIX B – LIST “FUNCTION KEYS“ ...................................................... 189

21 INSTALLATION DISPLAY UNIT / PLATFORM .............................................. 193

21.1 Technical data ............................................................................................................................ 193

21.2 Weighing system design .......................................................................................................... 193

21.3 How to connect the platform .................................................................................................... 194

21.4 Configure display unit ............................................................................................................... 196

21.4.1 Entering metrology / configuration data ............................................................................. 200

21.4.2 Adjusting a weighing system ............................................................................................... 202

21.4.3 How to linearize a weighing system .................................................................................... 204

21.4.4 Display configuration data ................................................................................................... 207

21.4.5 Reset to default settings ..................................................................................................... 207

21.4.6 Geo value ............................................................................................................................ 208

22 CONFORMITY EXPLANATION/ TEST CERTIFICATE ................................... 212

6 KEN-TM / KET_TM-BA-e-1420

Page 7

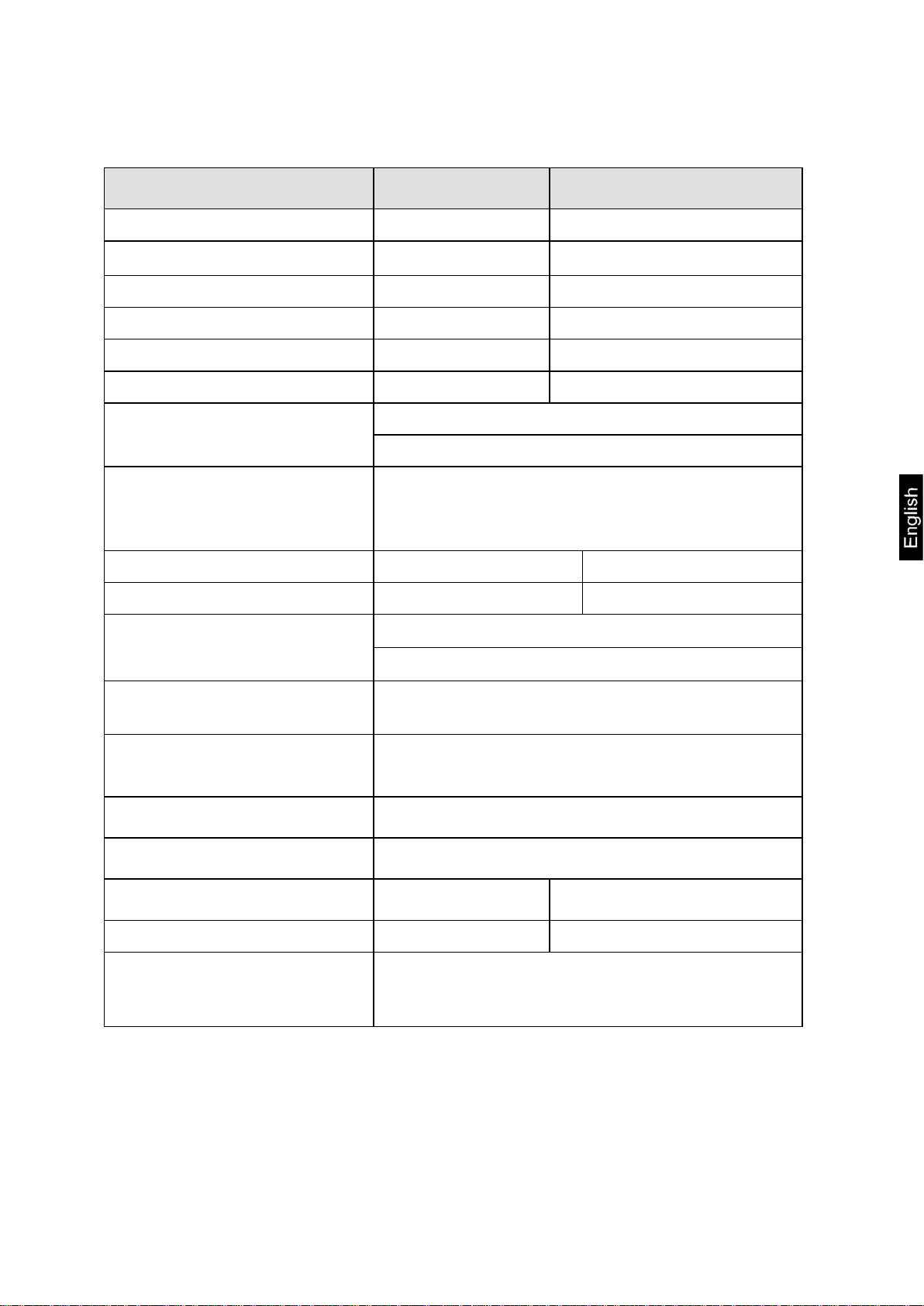

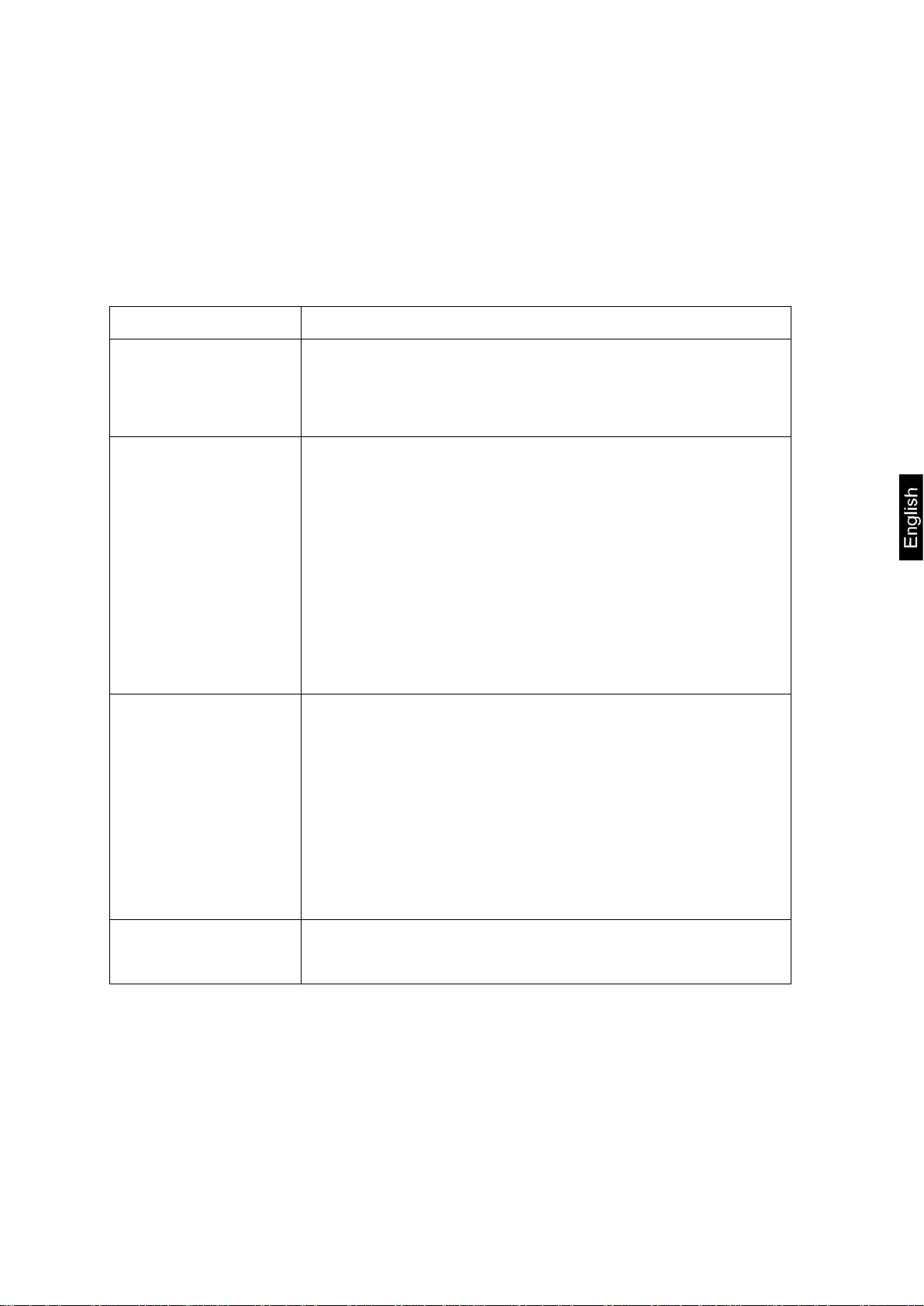

1 Technical data

KERN KET-TM KEN-TM

Display (segments) 7-digit 7-digit

Resolution (verified)

Resolution (non-verified) 100.000 d 100.000 d

Verification class III III

Weighing ranges 3 3

Divisions 1,2,5,…10n 1,2,5,…10n

Weighing Units

Display

Housing material Synthetic material Stainlees steel

Dimensions case [mm] 215 x 156 x 71 282 x 200 x 76

Load cell resistance

Recommended adjustment

weight

6000 e 6000 e

Models with type approval: g, kg

Models without type approval: g, kg, ct, lb, N, oz

Graphic LCD – Touch

Height of digit small 19 mm

Height of digit large 21 mm

min. 80 Ω

max. 1200 Ω

We recommend ≥ 50 % max.

Admissible

ambient temperature

Humidity of air 30 ~ 80 % relative (not condensing)

Input voltage – power unit 110 - 230 V AC

Input voltage - device 13.5 - 16 V 110- 240 V AC 65 – 150 mA

Net weight 650 g 4.5 kg

Languages

user interface

German, English, French, Italian, Polish,

Rumanian, Spanish, Turkish, Czech, Hungarian

see chap. 7.8.1

-10° C to +40° C

KEN-TM / KET_TM-BA-e-1420 7

Page 8

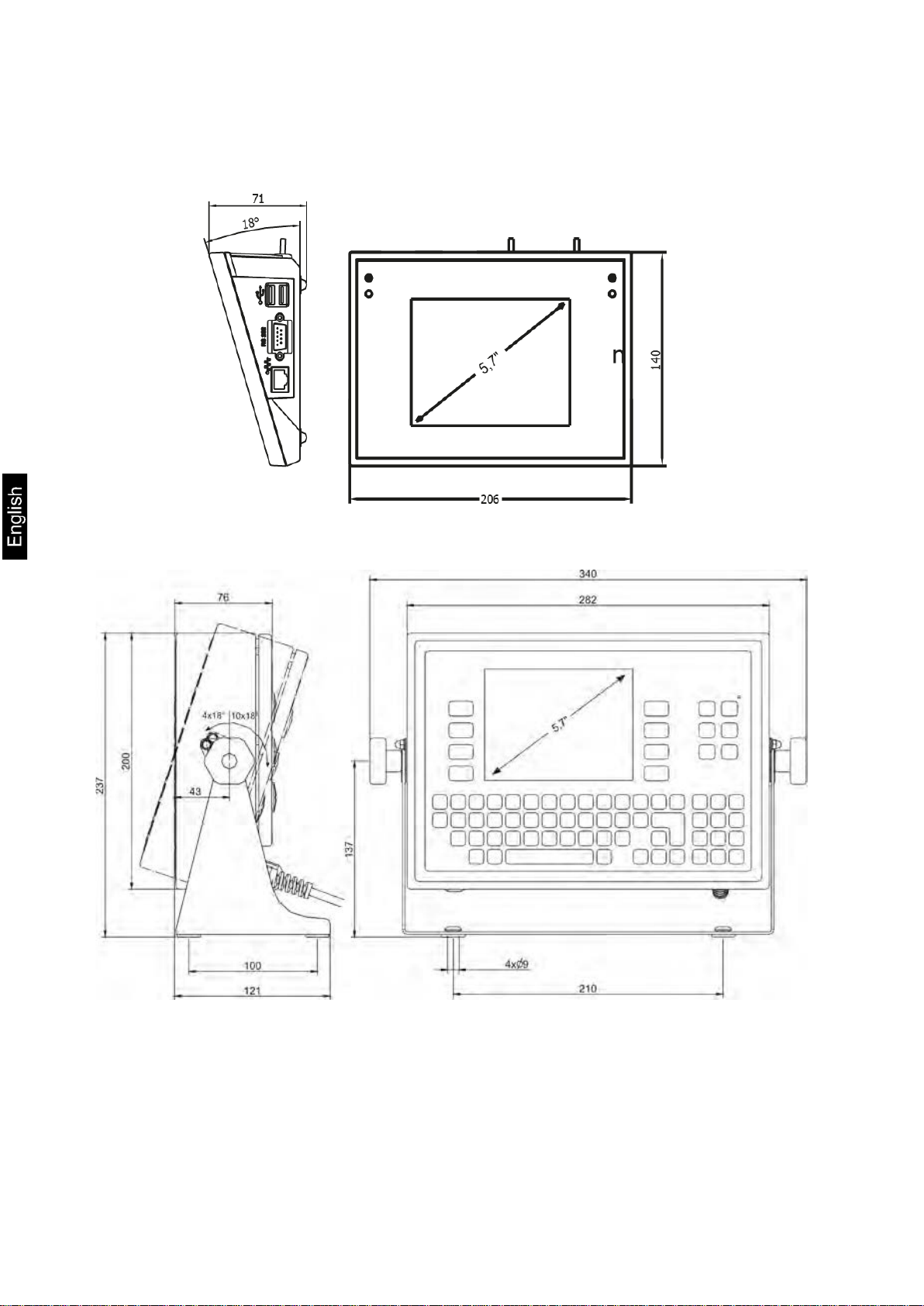

1.1 Dimensions

KET-TM:

KEN-TM:

8 KEN-TM / KET_TM-BA-e-1420

Page 9

3. USB port

Pin1 - GNDWE

Pin15 - OUT3

1.2 Anschlüsse / Schnittstellen

1.2.1 KET-TM

Pin allocation (front view):

1. Ethernet

2. RS232 (COM1)

RS232 DB9/M (9-pin plug)

Pin2 - RxD

Pin3 - TxD

Pin5 - GND

Digital I/O, RS232 DSUB15/F (15-pin socket)

Configuration IN1 – IN4 / OUT1 – OUT 4, see chap.7.5

Pin2 - OUT1

Pin3 - OUT2

Pin4 - COMM

Pin5 - 6÷9VDC

Pin6 - IN4

Pin7 - IN3

Pin8 - TxD2

Pin9 - 5VDC

Pin10 - GNDRS

Pin11 - IN2

Pin12 - IN1

Pin13 - RxD2

Pin14 - OUT4

4. Digital I/O, RS232 (COM2)

KEN-TM / KET_TM-BA-e-1420 9

Page 10

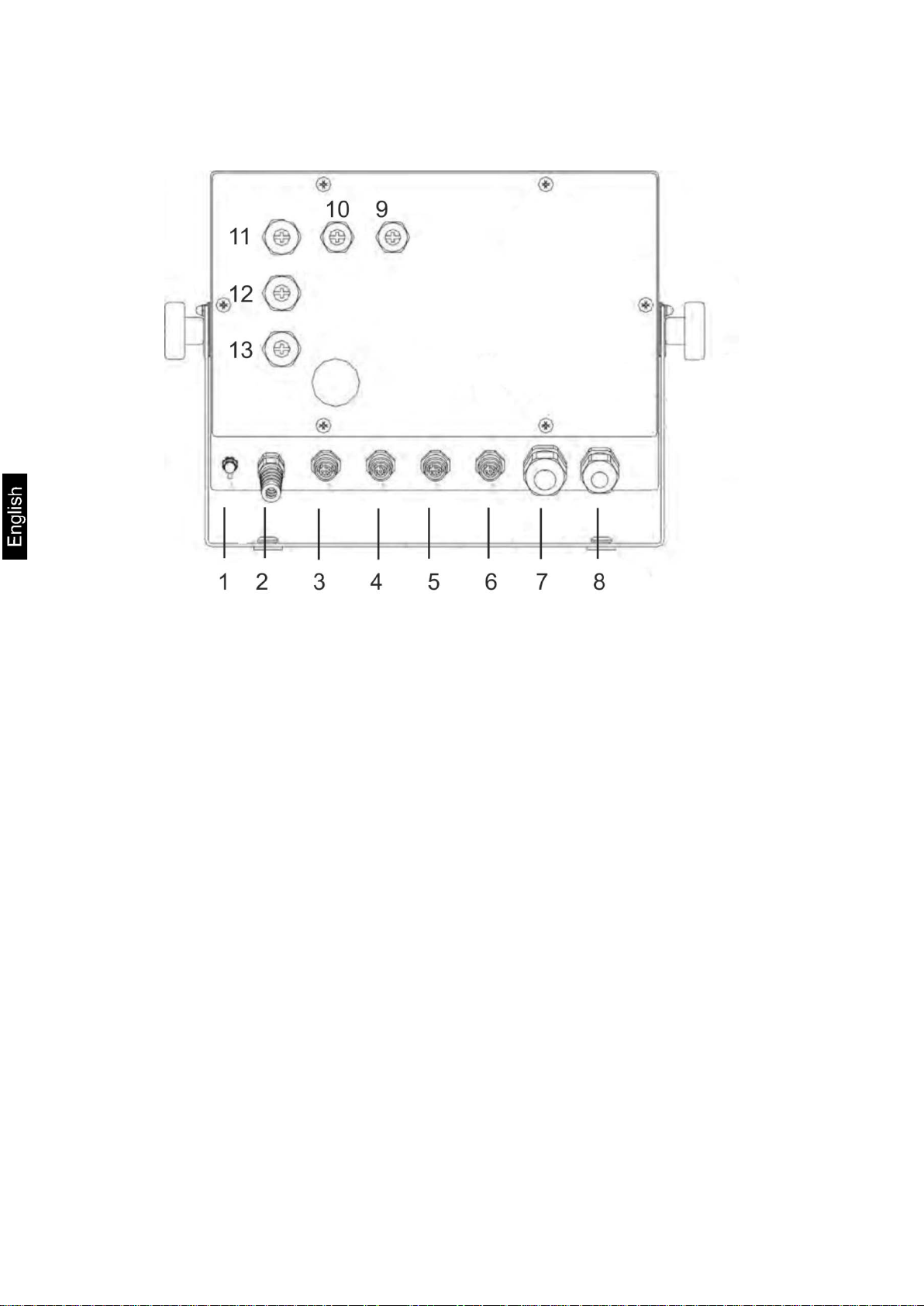

1.2.2 KEN-TM

1. Protective conductor

2. Electric Supply

3. Ethernet

4. 3IN/OUT

5. RS232

6. USB port

7. Peripherals (8IN/8OUT)

8. Platform 1

9. Add-on devices

10. Add-on devices

11. Platform 2

12. Platform 3

13. Platform 4

10 KEN-TM / KET_TM-BA-e-1420

Page 11

Pin1 – B

Pin6 – +5VDC

Pin1 – NC

Pin6 – +5VDC

Pin1 – OUT3

Pin8 – GNDWE

Pin1 – NC

Pin8 – IN4

Error-free operation is only guaranteed when using the optionally available

KERN interface cables.

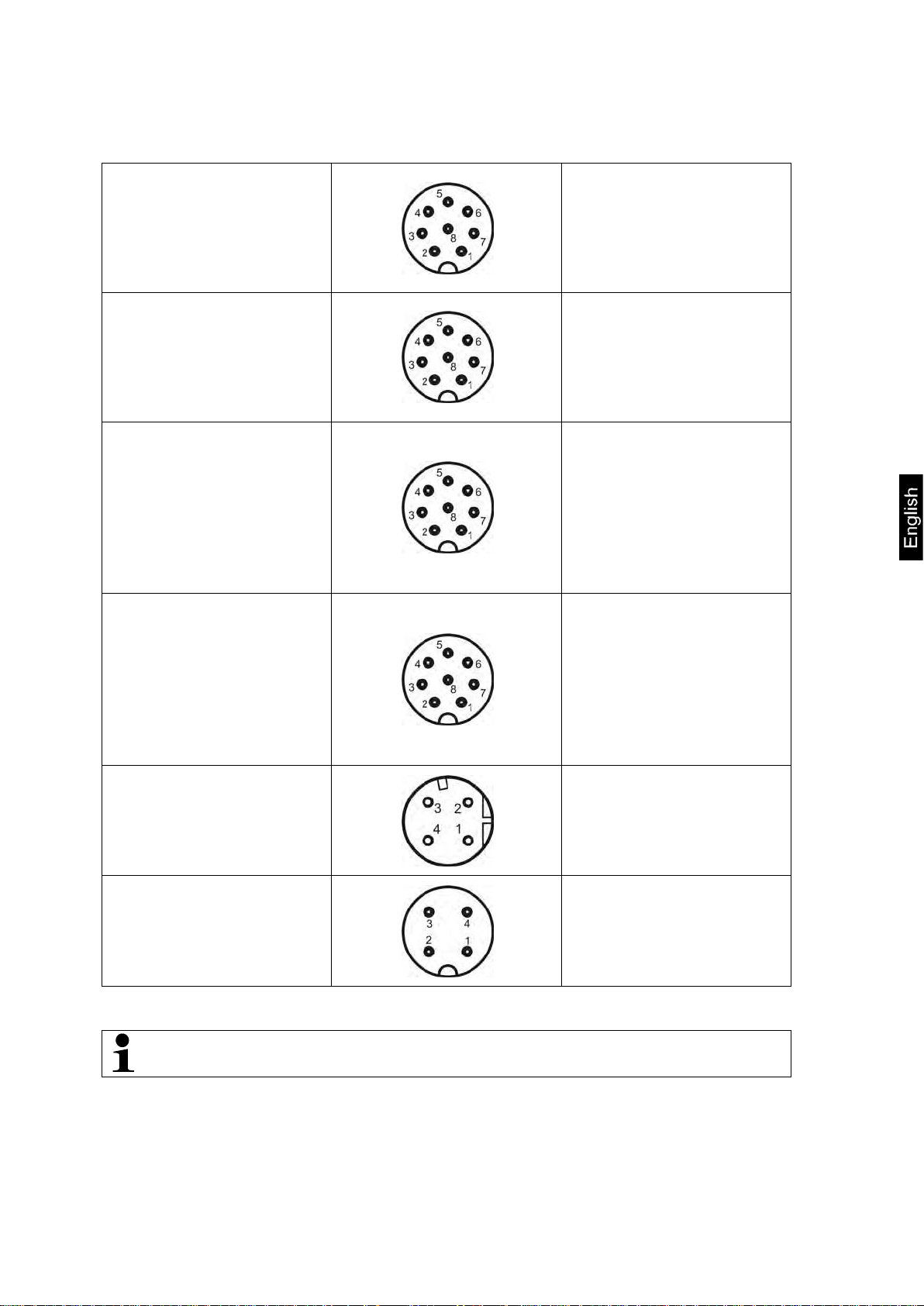

Pin allocation:

RS 232 / BUS Module

(option)

Addition RS 232

3IN/OUT

Pin2 – RxD

Pin3 – TxD

Pin4 – A

Pin5 – GND

Pin2 – RxD

Pin3 – TxD

Pin4 – NC

Pin5 – GND

Pin2 – OUT2

Pin3 – OUT1

Pin4 – COMM

Pin5 – IN3

Pin6 – IN2

Pin7 – IN1

4INPUTS

Ethernet

USB

Pin2 – NC

Pin3 – NC

Pin4 – +24VDC

Pin5 – IN3

Pin6 – IN2

Pin7 – IN1

Pin1 – Rx+

Pin2 – Tx+

Pin3 – RxPin4 – Tx-

Pin1 – Vcc

Pin2 – DPin3 – D+

Pin4 – GND

KEN-TM / KET_TM-BA-e-1420 11

Page 12

2 Control elements and program structure

2.1 Keyboard overview

Fig.: KET-TM

Fig.: KEN-TM

12 KEN-TM / KET_TM-BA-e-1420

Page 13

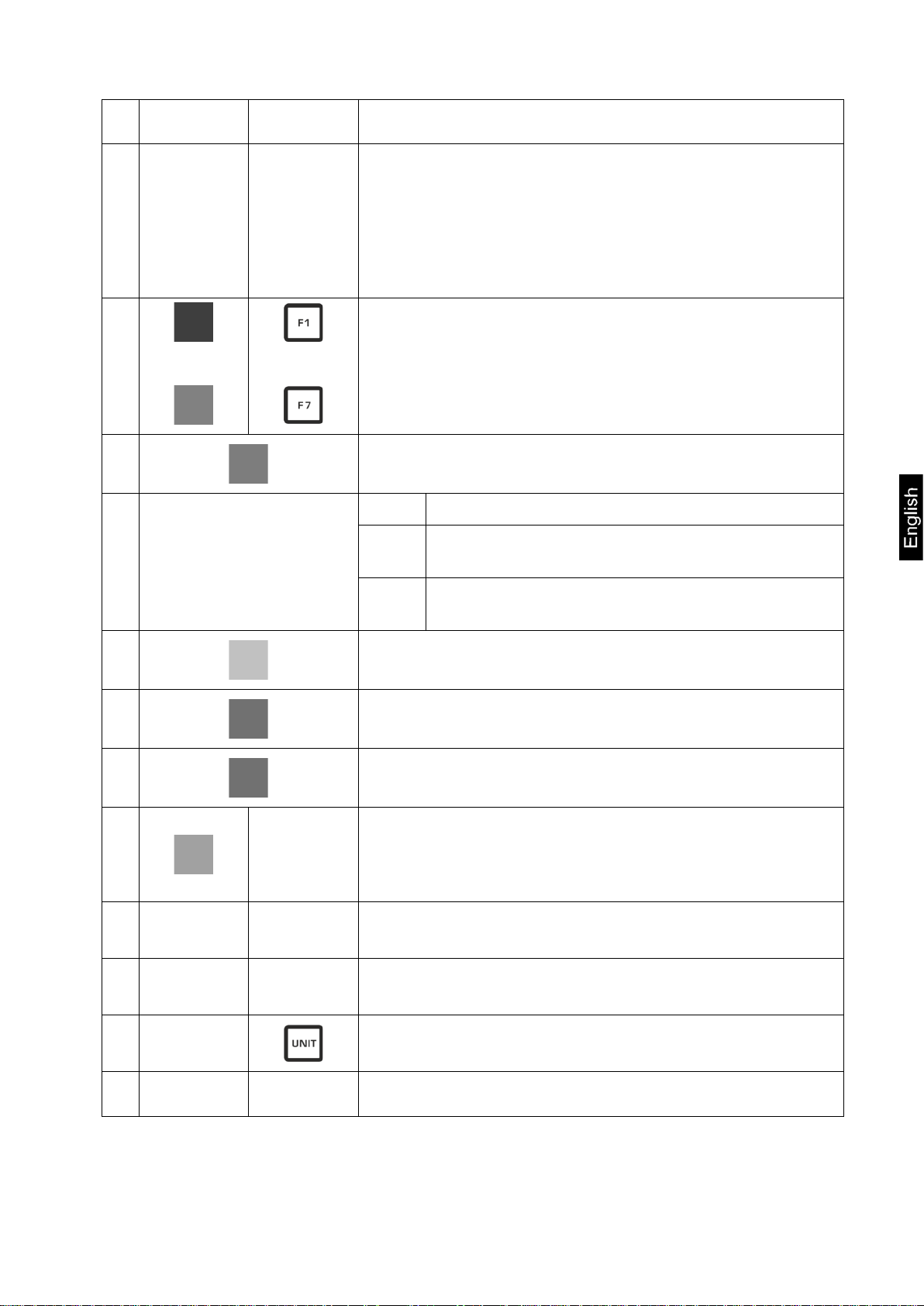

KET-TM KEN-TM

1

2

3

4

LED

Status display

Touch-free sensors.

Adjustable function, see chap. 7.4.2. Operate this function by

moving your hand across the respective sensor. The sensor

-

will confirm (if enabled in the menu see chap. 7.8.3) by

sounding an audio signal that it has detected and executed a

command.

The sensors are supplied disabled by default.

Shortcut key for frequently used applications, functions

and settings

Settings, see chap 7.4.2

Call up menu

OFF: when instrument ready for operation

ON:

Flashi

ng:

When weighing scale is connected to power

supply

When operating system is loading

5

6

7

8

9 -

10 -

11 -

12 -

Turn on/off

Zeroing

Taring

• Issue weighing data

• Confirm

Enter tare value numerically

Change platform

Switch-over weighing unit

Alphanumerical keyboard

KEN-TM / KET_TM-BA-e-1420 13

Page 14

Do not operate the touch screen with sharp or pointed objects!

This could damage the touch screen.

select the desired application.

2.2 Overview of display

The coloured touch screen is a touch-sensitive display. The touch screen does not only

display information, you can also enter orders, by tapping certain areas of the surface.

1. Range

1

Active application.

Tapping the control button will call up a menu where you can

2

Logged-in user

Tapping this control key will allow you to select additional users.

3

Active connection to PC

Active connection to a PC is indicated by an icon.

4

Current date/time

Tapping this button can be used to change date / time. For

setting of display format see chap. 7.8.2

The display has four areas:

14 KEN-TM / KET_TM-BA-e-1420

Page 15

calibrated part of weighing scales with type approval is

highlighted.

Settings, see chap 7.4.1

function keys see chap. 7.4.2

2. Range

5

Current measuring value.

The non-

6

Current weighing unit

To select an item from the menu, tap the button. (For definition

of selection see chap. 7.7).

7

Stability display

The stability display shows that the weighing value is stable.

8

Zero indicator

3. Range

9

Info field

This area shows additional information to the enabled

application.

Tap this button to select which info fields and function keys [0]

are to be shown, see chap.7.4.1.

The bar filled black at the upper margin shows the enabled info

field.

For instance when the field in the centre is enabled

4. Range

KEN-TM / KET_TM-BA-e-1420 15

0

Function keys

The function keys allow direct access to frequently required

functions and settings in the enabled application. For defining

Page 16

WEIGHING

see chap. 7.1.

DATABASES

see chap. 14.

REPORTS

see chap. 15.

WORKING MODES

see chap. 8.

COMMUNICATION

see chap. 7.2.

DEVICES

see chap. 7.3.

DISPLAY

see chap. 7.4

INPUTS / OUTPUTS

see chap. 7.5

ACCESS LEVELS

see chap. 7.6

UNITS

OTHERS

CALIBRATION

type approval

INFO

see chap. 7.11

UPDATE

Not documented

2.3 Program structure

2.3.1 Menu overview

The menu is split into the following blocks:

To call up individual menu blocks and change their settings, tap the icons.

16 KEN-TM / KET_TM-BA-e-1420

see chap. 7.7.

see chap. 7.8

see chap. 7.9

only available for models without

Page 17

2.3.2 Navigation in the menu

Call up menu

Scroll forward in menu

Scroll backwards in menu

Scroll „down“.

Confirm entry, back to previous view

Cancel entry, back to previous view

Add position in database

Search date in database

Search name in database

Search code in database

Print position from database

Delete editing field

Hide / show keyboard

Import data from USB storage medium

Display menu showing all available variables

Display returns one step to previous view

KEN-TM / KET_TM-BA-e-1420 17

Display returns directly to main window

Page 18

Exit menu / back to weighing mode.

The display returns one step to previous view by tapping

Press Back to Main Window repeatedly.

or

In the upper bar and press once and the device will return immediately

to the start screen.

After returning to the previous view or the start screen all the changes you entered

will be saved automatically.

18 KEN-TM / KET_TM-BA-e-1420

Page 19

Authorisation level

Available rights and functions

Administrator

The administrator is allowed to use all the functions and

Advanced user

Start and carry out weighing.

User Start and carry out weighing.

none

Carry out weighing.

2.4 Authorisation levels

The software is designed for users with different access rights:

Administrator and various users There is only one administrator.

The administrator is allowed to use all the functions and has all access rights.

A user, on the other hand, is not allowed to use all the functions and has limited

rights, see table 1 below.

Tab. 1:

has all access rights.

There is only one administrator.

Delete old data from database

Access the following functions:

<Operating modes>

<Profiles read-out>

<Communication>

<Devices>

<Other> except <date / time>

Define universal variables

Export weighing data

View data from database

Access the following functions:

<Profiles read-out>

<General parameters> except <date / time>

No access to menu and database.

KEN-TM / KET_TM-BA-e-1420 19

Page 20

3 Basic instructions

3.1 Proper use

The display unit acquired by you is used in combination with a load cell and serves to

determine the weighing value of material to be weighed. It is not intended for use as

non-automatic weighing system.

Place load manually but carefully on weighing platform.

Prevent loads from dropping.

Place load in centre.

Prevent lateral stress as well as pushing from the side.

As soon as a stable weighing value is reached the weighing value can be

read.

20 KEN-TM / KET_TM-BA-e-1420

Page 21

3.2 Improper Use

Do not use weighing system for dynamic weighing. In the event that small quantities are

removed or added to the material to be weighed, incorrect weighing results can be

displayed due to the “stability compensation“ in the unit. (Example: Slowly draining

fluids from a container on the balance.)

Do not leave permanent load on the weighing pan. This may damage the measuring

system.

Impacts and overloading exceeding the stated maximum load (max) of the weighing

plate, minus a possibly existing tare load, must be strictly avoided. Both, the weighing

plate and the display unit may be damaged during this process.

Never operate display unit in explosive environment. The serial version is not explosion

protected.

Changes to the display unit's design are not permitted. This may lead to incorrect

weighing results, safety-related faults and destruction of the display unit.

The display unit may only be operated in accordance with the described default

settings. Other areas of use must be released by KERN in writing.

3.3 Warranty

Warranty claims shall be voided in case

• Our conditions in the operation manual are ignored

• The appliance is used outside the described uses

• The appliance is modified or opened

• Mechanical damage or damage by media, liquids, natural wear and tear

• The appliance is improperly set up or incorrectly electrically connected

• The measuring system is overloaded

3.4 Monitoring of Test Resources

In the framework of quality assurance the measuring-related properties of the display

unit and, if applicable, the testing weight, must be checked regularly. The responsible

user must define a suitable interval as well as type and scope of this test. Information is

available on KERN’s home page (www.kern-sohn.com with regard to the monitoring of

display units’ test substances and the test weights required for this. In KERN’s

accredited DKD calibration laboratory test weights and display units may be calibrated

(return to the national standard) fast and at moderate cost.

KEN-TM / KET_TM-BA-e-1420 21

Page 22

4 Basic Safety Precautions

4.1 Pay attention to the instructions in the Operation Manual

Carefully read this operation manual before setup and

commissioning, even if you are already familiar with KERN balances.

All language versions contain a non-binding translation.

The original German is binding.

4.2 Personnel training

The appliance may only be operated and maintained by trained personnel.

5 Transport and storage

5.1 Testing upon acceptance

When receiving the appliance, please check packaging immediately, and the appliance

itself when unpacking for possible visible damage.

5.2 Packaging / return transport

Keep all parts of the original packaging for a possibly

required return.

Only use original packaging for returning.

Prior to dispatch disconnect all cables and remove

loose/mobile parts.

Reattach possibly supplied transport securing devices.

Secure all parts against shifting and damage.

22 KEN-TM / KET_TM-BA-e-1420

Page 23

KET-TM

KEN-TM

Display Unit

Display unit with integrated power unit

Protective cover

Operating and Installation Instructions

Mains adapter

IEC cable

Ferrite core for cable shielding

Operating and Installation Instructions

6 Unpacking, Setup and Commissioning

6.1 Installation Site, Location of Use

The display units are designed in a way that reliable weighing results are achieved in

common conditions of use.

Precise and fast work is achieved by selecting the right place for your display unit and

your weighing plate.

On the installation site observe the following:

• Place the weighing system on a firm, level surface;

• Avoid extreme heat as well as temperature fluctuation caused by installing next

to a radiator or in the direct sunlight;

• Protect the display unit and the weighing plate against direct draft from open

windows or doors.

• Avoid jarring during weighing;

• Protect the display unit and the weighing plate against high humidity, vapours

and dust.

• Do not expose the display unit to extreme dampness for longer periods of time.

Non-permitted condensation (condensation of air humidity on the appliance) may

occur if a cold appliance is taken to a considerably warmer environment. In this

case, acclimatize the disconnected appliance for ca. 2 hours at room

temperature.

• Avoid static charge of goods to be weighed or weighing container.

Major display deviations (incorrect weighing results) may be experienced should

electromagnetic fields (e.g. due to mobile phones or radio equipment), static electricity

accumulations or instable power supply occur. Change location or remove source of

interference.

6.2 Unpacking and placing

Take the display unit carefully out of its packaging, remove the plastic jacket and install

it at the designated work space. Mount the display unit in a way that facilitates operation

and where it is easy to see.

The display unit is not mounted rigidly on the weighing platform. If

required, it may be placed independently within the vicinity of the weighing

scale as long as the length of the cable allows such a setup.

6.3 Scope of delivery / serial accessories

KEN-TM / KET_TM-BA-e-1420 23

Page 24

6.4 How to connect the platform

See chap. 21 “Installing display unit / platform“.

Please also follow the instructions for installing a platform, as these contain all the

details for the set-up and first start-up.

6.5 Mains connection

Power supply is achieved via external power units (KET-TM only). The stated voltage

value must be the same as the local voltage.

Only use original KERN mains adapters. Using other makes requires consent by KERN.

6.6 Commissioning

+ Connect scale to power supply.

Connect display unit to power supply; the red status light will light up.

Press and the operating system will be loaded when the red status light is

flashing.

Wait until the start screen followed by the user interface is displayed.

As soon as the weight display appears, the balance is ready for weighing. On

delivery, the weighing scale will be in a logged-out status, that is, merely the

simplest functions such as Weigh or Tare are enabled, see chap. 6.9.

To obtain full access to the user parameters and to the editing functions of

databases, the user has to log on as administrator by following the steps below:

Later on, the last used user profile will be loaded on start-up.

24 KEN-TM / KET_TM-BA-e-1420

Page 25

+ Log in

,

Tap <Log in> button.

<Operators> window appears.

The weighing scale is supplied without

user profiles. To adjust all settings, the

user has to register as administrator.

Tap <Admin> button.

KEN-TM / KET_TM-BA-e-1420 25

Page 26

Initial Commissioning

In order to obtain exact results with the electronic balances, your balance

g temperature (see warming up time chap.

During this warming up time the weighing system must be connected to

hing system depends on the local acceleration of

Strictly observe hints in chapter Adjustment.

+ Setting user language

On delivery the display is set to German. For setting additional languages see

chap.7.8.1.

must have reached the operatin

1).

the power supply (mains, accumulator or battery).

To adapt the balance to ambient conditions, open wind screen doors.

The accuracy of the weig

gravity.

6.7 Log out

Tap logged-on user in the upper bar of the display.

This will bring up the <User> window.

Tap <log out> button

6.8 Putting out of service / Standby mode

Press and tap desired option.

When selecting <Stand by> the weighing scale will be ready for operation. It is ready

for operation immediately after start-up without requiring warm-up time.

When selecting <Off> you will have to restart the weighing scale as described in chap.

6.6 and observe the required warm-up time.

26 KEN-TM / KET_TM-BA-e-1420

Page 27

6.9 Basic Operation

+ Stabilisation requires a certain warm-up time.

+ For further information on specific setting options for the weighing

application please refer to chap.8.2

6.9.1 Simple weighing

Check zero display [ ] and set to zero with the help of .

Place goods to be weighed on balance.

Wait until the stability display appears ( ).

Read weighing result.

To save and print the weighing value if an optional printer is connected, press

For data format see chap. 16.4

6.9.2 Zeroing

In order to obtain optimal weighing results, reset to zero the balance before weighing.

Setting to zero requires a range ± 2% max. Values greater than ± 2% max will trigger

the error message “Err2“.

Unload the balance

Press and zero display as well as indicator will appear.

KEN-TM / KET_TM-BA-e-1420 27

Page 28

Unit

Designation

With type approval

Without type approval

Gram

[g]

yes

yes

Kilogram

[kg]

yes

yes

Carat

[ct]

yes

yes

Pound

[lb]

no

yes

Ounce

[oz]

no

yes

Newton

[N]

no

yes

6.9.3 Selecting weighing unit

Tap unit to select from the displayed

menu.

Not all weighing units are available for weighing scales with type approval.

For definition of start unit and user defined units see chap. 7.7.

28 KEN-TM / KET_TM-BA-e-1420

Page 29

Tare weight

displayed with

The attempt of taring negative

The limit is

6.9.4 Weighing with tare

Taring

The dead weight of any weighing container may be tared away by pressing a button, so

that the following weighing procedures show the net weight of the goods to be weighed.

Put weighing container on the weighing pan.

Wait until the stability display appears ( ), then press . Zero display and

indicator (Net) appear. The weight of the container is now internally saved.

Weigh the material.

Wait until the stability display appears ( ).

Read net weight.

• Tare weight can be allocated to a product in the database.

will be loaded automatically as soon as a product is selected.

• When the balance is unloaded the saved taring value is

negative sign.

• Taring negative values is prohibited.

values will result in error message “Err 3“

• The taring process can be repeated any number of times.

reached when the whole weighing range is exhausted.

Numeric entering of tara weight

Press or the the function key (allocating function key, see chap.

7.4.2) and the numeric input window will appear.

Enter known tare weight and confirm by tapping . The balance returns to

weighing mode.

The entered weight will be saved as tare weight whereupon the indicator [Net]

and the tare weight including minus sign will appear.

Place the filled weighing container.

Wait until the stability display appears [ ].

Read net weight.

KEN-TM / KET_TM-BA-e-1420 29

Page 30

Delete tare

1. Unload weighing plate and press .

The (Net) indicator turns off, the zero display shows.

2. When the weighing platform is loaded, you can only press if the zero setting

range is kept within 2% max (>2% max will generate error message “Err 2“).

The (Net) indicator turns off, the zero display shows.

3. Press function key <Turn off tare> when weighing platform is loaded (<2%

max) or unloaded (For allocation of function key see chap.7.4.2. The (Net)

indicator turns off, the zero display shows.

If there is a function key allocated to <Reset tare> , the most recently used

tare value will be called up. (Allocation of function key, see chap. 7.4.2).

6.10 Connection of peripheral devices

Before connecting or disconnecting of additional devices (printer, PC) to the data

interface, always disconnect the balance from the power supply.

With your balance, only use accessories and peripheral devices by KERN, as they are

ideally tuned to your balance.

30 KEN-TM / KET_TM-BA-e-1420

Page 31

7 System settings (menu)

The system settings are used to customise the behaviour of the weighing scales to your

requirements (such as ambient conditions, special weighing processes).

System settings apply to all user profiles and applications.

To change settings, you have to select <Administrator> as user.

Weighing scales with type approval offer access to all settings.

Call up system settings (menu):

+ To open system settings, press and the options for system settings will

appear, see chap. 2.3.1.

+ Navigation in menu see chap. 2.3.2

KEN-TM / KET_TM-BA-e-1420 31

Page 32

7.1 Weighing

This function is used to customise the behaviour of the weighing scale to the

ambient conditions of special requirements.

Filter

Confirm results

Autozero

Autozero: Dosing

Last digit

Tap <Weighing>.

To call up and change settings tap the

icons.

32 KEN-TM / KET_TM-BA-e-1420

Page 33

Please note that in general slowing down reaction times result in higher

influence on the stability deterioration.

7.1.1 Median filter

The median filter removes shocks such as mechanical vibrations.

Tap <Medianfilter>

The menu will appear.

Select desired setting.

7.1.2 Filter

This setting is used to customise the behaviour of the weighing scale to

the ambient conditions.

stability of the set data handling, while speeding up reaction times have an

<very fast> The balance reacts quickly and in a

<slow> The balance reacts slowly and in a robust

Tap <Filter>

The menu will appear.

sensitive manner, quiet set-up location.

manner, busy set-up location

KEN-TM / KET_TM-BA-e-1420 33

Page 34

below the net value set for the LO threshold.

Tap <LO threshold> and the numeric

7.1.3 Auto Zero

The automatic zero point adapter (auto zero) provides continuous

correction for minor weight variations such as contamination on the

weighing platform.

In the event that small quantities are removed or added to the material to

be weighed, incorrect weighing results can be displayed due to the

“stability compensation“. (e.g. slow flow of liquids from a container placed

on the balance, evaporating processes).

When apportioning involves small variations of weight, it is advisable to

switch off this function.

Available settings:

- Auto zero disabled

- Auto zero enabled

7.1.4 LO threshold

Entering threshold for automatic operation

The next measurement will not be saved until the weighing display falls

input window will appear.

Enter value and take over by .

7.1.5 Last digit display accuracy

Lower display accuracy results in faster display.

Tap < Last digit >

The menu will appear.

34 KEN-TM / KET_TM-BA-e-1420

Always All digits on

Never Last digit off

When stable Last digit on for

stable weighing value

Page 35

7.2 Communication parameters

Via the interfaces weighing data may be exchanged with connected peripheral devices.

Connect balance using a suitable cable with the interface of the peripheral device.

Error-free operation is only guaranteed when using the optionally available KERN

interface cables.

Available interfaces (See image chap. 1.2)

Ethernet

RS232 (COM1)

USB port

Digital I/O, RS232 (COM2)

All interfaces must be configured according to peripheral device and desired function.

7.2.1 RS232 (1) / RS232 (2)

Tap <Communication>.

Select interface to be configured.

Tap < RS232 (1) or RS232 (2)>

Configuration options will be displayed.

Select setting.

The communication parameters of

weighing scale and peripheral device must

match.

KEN-TM / KET_TM-BA-e-1420 35

Page 36

DHCP

IP-address

Mask

Gate

DNS

MAC address

Device specific (not editable)

Transfer parameters have to be set according to local network.

7.2.2 Ethernet / IP

Tap < Ethernet >

The configuration options below will be

displayed:

yes

no

Automatic manual

The import of changes requires that you restart the device by .

7.2.3 TCP

Tap <TCP>

Set TCP-Port in input window.

Default value for KERN devices is “4001“.

36 KEN-TM / KET_TM-BA-e-1420

Page 37

7.3 Devices

Tap <Devices>.

Select peripheral device to be

configured.

KEN-TM / KET_TM-BA-e-1420 37

Page 38

7.3.1 PC

Select / configure computer interface

1. Port

Tap < Computer >

Configuration options will be displayed.

Tap <Port>.

The display will show the interfaces

available for connecting the device to the

computer.

2. Address

Tap <Address>.

Enter the desired address in the input

window and confirm by tapping

38 KEN-TM / KET_TM-BA-e-1420

Page 39

3. Continuous transmission

Setting options:

no

yes

4. Default log

This is used to determine which information is to be issued to the PC.

Continuous data transmission disabled

Continuous data transmission enabled

Tap < Weighing Printout Template >

and the input window will appear. Enter

texts and variables (For table see chap.

19) and import by tapping .

Variables are to be presented in curly

brackets {x}.

Tap and the menu showing all

variables will appear.

To enter line break tap <Enter>.

To hide the keyboard / zoom out the

input window, tap

To import a complete draft from an

USB storage medium, tap

To import a complete draft from an

USB storage medium, tap

To delete the content in the editing

field, tap

KEN-TM / KET_TM-BA-e-1420 39

Page 40

System active.

The following icons are displayed on the upper screen bar when the

5. E2R system

Setting options:

Tap < E2R System >.

The settings

<System enabled> /

<Product selection blocked> are

blocked by default.

These settings may only be modified by

the manufacturer!

no

yes

System disabled

functions are enabled:

System active

Active connection to PC software

40 KEN-TM / KET_TM-BA-e-1420

Page 41

1. Port

7.3.2 Printer

Selecting / configuring printer interface

Tap < Printer >

Configuration options will be displayed.

2. Code

Tap <Port>.

The display will show the interfaces

available for connecting the device to the

computer.

Tap <Code>.

Enter desired value in input window and

confirm by tapping

KEN-TM / KET_TM-BA-e-1420 41

Page 42

3. Defining logs

Tap <Printouts>.

Select log type (such as weighing printout

sample), and the input window will

appear. Enter texts and variables (For

variables menu see chap. 19 ) and import

by tapping .

Variables are to be presented in curly

brackets {x}.

Finish each line by tapping “ Enter“

Display example:

Default log “Weighing“

4. Enabling printouts

Tap and the menu showing all

variables will appear.

To enter line break tap <Enter>.

To hide the keyboard / zoom out the

input window, tap

To import a complete draft from an

USB storage medium, tap

To delete the content in the editing

field, tap .

Tap < Printouts activation >.

enabled

disabled

42 KEN-TM / KET_TM-BA-e-1420

Page 43

Ensure that communication parameters of weighing scale (standard

9600 baud) and barcode scanner match.

7.3.3 Barcode scanner

Select / configure interface

The barcode scanner allows fast access to:

Product

Customer

Packaging

Bearing

Dispensing processes

Recipe

Components of recipe

Universal variables

Serial number

Batch number

1. Port

Tap < Bar Code Reader >

Configuration options will be displayed.

Tap <Port>.

The available interfaces will be displayed.

KEN-TM / KET_TM-BA-e-1420 43

Page 44

2. Prefix / suffix

3. Field selection

Tap < Prefix / Suffix >.

Enter values (hexadecimal) for prefix /

suffix in input window and import by

tapping .

Tap < Field selection >.

To call up and change settings tap the

icons.

44 KEN-TM / KET_TM-BA-e-1420

Page 45

Ensure that communication parameters of weighing scale

(standard 9600 baud) and transponder card reader match.

4. Test

Tap < Test >.

Check error-free functioning of barcode

scanner.

7.3.4 Transponder card reader

Select / configure interface

Tap < Transponder card reader >

Tap <Port>.

The available interfaces will be displayed.

KEN-TM / KET_TM-BA-e-1420 45

Page 46

1. Port

7.3.5 Additional display

Tap < Additional display >

2. Sample

Tap <Port>.

The available interfaces will be displayed.

Tap <Sample>.

The input window used to define the

communication log will appear.

Factory settings:

{141} KERN KET-A03

{142} KERN KET-A06

46 KEN-TM / KET_TM-BA-e-1420

Page 47

7.4 Configure display

This function allows the user to customise the terminal to his/her requirements.

Tap < Display >.

The available parameters will be

displayed.

7.4.1 Select information texts

Tap < Text information >.

To call up and change settings tap the

icons.

KEN-TM / KET_TM-BA-e-1420 47

Page 48

Main display sample

(middle)

Select information texts in info field

The info field is displayed in the application below

the weighing value in the form of a grey field. This

Left display sample

section also shows additional information to the

enabled application. It is possible to create 3

Right display sample

separate info fields. To change between fields, use

a swiping movement with your hand.

To enter the information text, tap the desired field and the input window

will appear. Enter texts and variables (For table see chap. 19.1) and

import by tapping . For default settings see table 2 below:

Variables are to be presented in curly brackets {x}.

Tap and the menu showing all variables will appear.

To enter line break tap <Enter>.

To hide the keyboard / zoom out the input window, tap

To import a complete draft from an USB storage medium, tap

To import a complete draft from an USB storage medium, tap

To delete the content in the editing field, tap .

Font

Font

Font style Character font available: Arial, Courier

Font size Font size options small, normal, large.

yes

Grease, lubricant Font style “Bold“

no

yes

Font tilt Font style “Italic“

no

Font colour

Background colour

Font colour for text information at the working area,

18 colour options

Colour display for display screen, 18 colour options

Set default

Reset to default setting

48 KEN-TM / KET_TM-BA-e-1420

Page 49

Weighing:

{40:Product:,-15}{50}

{40:Total:,-15}{16}{11}

Parts counting:

{40:Product:,-15}{50}

{40:Tare:,-15}{9}{11}

Percent

{40:Product:,-15}{50}

{40:Tare:,-15}{9}{11}

Dosing:

Dosiervorgang: {175}

Formulation:

{220}

{40:Designed:,-12}{225:F0}

Density:

Product: {50}

Animal

weighing:

{40:Tare:,-15}{9}{11}

{40:Gross:,-15}{8}{11}

FPVO

Product: {50} Code: {51}

Table 2: Default settings “information texts“

{40:Tare:,-15}{9}{11}

{40:Gross:,-15}{8}{11}

{40:Quantity:,-15}{15}

{40:Mass of reference weight:,-15}{35}{11}

{40:Net:,-15}{7}{11}

determination:

{40:Mass of reference weight:,-15}{36}{11}

{40:Net:,-15}{7}{11}

{40:Ingredient:,-12}{230}/{231}[{226}]

{40:Dose:,-12}{228}{11}/{227}{11}

{40:Batch:,-12}{232}/{233}

KEN-TM / KET_TM-BA-e-1420 49

Page 50

The menu will appear.

7.4.2 Selecting function keys

Function keys allow direct access to frequently used functions and settings of the

enabled application. They are displayed on the application at the lower margin of the

display.

Tap < Button functions >.

Menu will appear:

Keys F1 – F3

Display keys 1- 9

Touch free sensors,

left / right (KET-TM only)

Use the cursor to scroll forward or

backward.

The numbers of the display keys

determine the order on the display.

Tap desired key.

For default settings see table 3 below:

Use the cursor to scroll forward or

backward.

Selection is imported by tapping. The

display returns to the previous screen.

50 KEN-TM / KET_TM-BA-e-1420

Page 51

Set limit values MIN and MAX for control

Table 3: Default settings “function keys“

Weighing:

Parts counting:

F1-key Search product

F2-key Select customer

F3-key Set tare

Screen key 1 Application specific settings

Screen key 2

Screen key 3 Select packaging

Screen key 4 Edit serial number

Screen key 5 Edit batch number

Screen key 6 Statistics Z: Zeroing

F1-key Search product

F2-key Select customer

F3-key Set tare

Screen key 1 Application specific settings

weighing

Percent determination:

Dosing:

Screen key 2 Select packaging

Screen key 3 Enter reference single weight numerically

Screen key 4 Determine reference single weight by weighing

Screen key 5 Allocate reference single weight

F1-key Search product

F2-key Select customer

F3-key Set tare

Screen key 1 Application specific settings

Screen key 2 Select packaging

Screen key 3

Screen key 4

F1-key Select dispensing

F2-key Select customer

Enter reference weight (100%) as numeric

value

Determine reference weight (100%) by

weighing

KEN-TM / KET_TM-BA-e-1420 51

F3-key Set tare

Screen key 1 Application specific settings

Page 52

Determination of

density:

Formulation:

Screen key 2 Select dispensing

Screen key 3 Start

Screen key 4 Stop

Screen key 5 Failure

F1-key Select recipe

F2-key Select customer

F3-key Set tare

Screen key 1 Application specific settings

Screen key 2 Select recipe

Screen key 3 Start recipe

Screen key 4 Stop recipe

Screen key 5 Select component from recipe menu

Screen key 6 Select previous component of recipe

Screen key 7 Select next recipe

Animal weighing:

Screen key 8 Enter weight manually

Screen key 9 Edit serial number of component

F1-key Search product

F2-key Select customer

F3-key Set tare

Screen key 1 Application specific settings

Screen key 2 Determine density of liquid

Screen key 3 Determine density of solids

Screen key 4 Stop

F1-key

F2-key

F3-key

Screen key 1

Search product

Select customer

Set tare

Local parameters

52 KEN-TM / KET_TM-BA-e-1420

Screen key 2

Start

Page 53

7.4.3 Display all platforms

When used as weighing system with several platforms, the display for each platform

can be switched as follows:

For assigning switching option to function key or sensor, see chap. 7.4.2.

or

Enable function <Show all platforms> as described below:

Tap < Show all platforms >.

- no

- yes

All platforms will be displayed when this function is enabled.

To edit the desired platform, tap it.

KEN-TM / KET_TM-BA-e-1420 53

Page 54

7.4.4 Select bargraph type

1. Bargraph type

Tap < Bargraph >.

The available bargraph types will be

displayed:

None – bargraph is not displayed

Fast weighing

Pilot light settings

Linearity

Tap < Bargraph Type >.

Select type of your choice to be

displayed.

54 KEN-TM / KET_TM-BA-e-1420

Page 55

2. Fast weighing

Function:

Eight red and three green pilot lights indicate whether the load is within the tolerance

limits (MIN / MAX threshold).

The signal lights provide the following information:

The red pilot lights on the left

indicate that the target weight is

below the lower tolerance limit

(MIN threshold).

The lower the weight value

below the MIN threshold the

more red arrows will light up on

the left.

Settings:

The green pilot lights

indicate that the target

weight is within the

tolerance range (OK

threshold).

< 1/3 MIN-MAX

range

> 1/3 and 2/3

MIN-MAX range

> 2/3 MIN-MAX

range

Tap < Fast weighing >.

The menu will be displayed; see table 4

below.

The red pilot lights on the

right indicate that the target

weight is above the upper

tolerance limit (MAX

threshold).

The greater the weight value

above the MAX threshold, the

more red arrows will light up

on the right.

KEN-TM / KET_TM-BA-e-1420 55

Page 56

Tab. 4:

Operating mode for

thresholds

MIN, MAX

Operating mode of

OK threshold

Stable – pilot light for thresholds MIN, MAX

will be visible after exceeding the LO threshold and

after reaching a stable weighing result;

Unstable – pilot light for thresholds MIN / MAX will be

visible after exceeding the LO threshold.

Stable – pilot light for threshold OK will be visible after

exceeding the LO threshold and after reaching a stable

weighing result;

Unstable – pilot light for threshold OK will be visible

after exceeding the LO threshold

Pilot light colour for MIN

threshold

Pilot light threshold for OK

threshold

Pilot light colour for MAX

threshold

Gradient Turn on / turn off filling flow for type “Gradient“.

Background colour

Frame colour

Select pilot light colour for threshold MIN, 18 colour

options available

Select pilot light threshold for threshold OK, 18 colour

options available

Select pilot light threshold for threshold MAX, 18 colour

options available.

Select background colour for bargraph, 18 colour

options available.

Select frame colour for bargraph, 18 colour options

available.

3. Pilot light setting (checkweighing)

Three colour pilot lights indicate whether the load is within the tolerance limits (MIN /

MAX threshold).

The signal lights provide the following information:

Target weight below lower

tolerance limit

(MIN threshold)

Target weight within

tolerance range (OK

threshold)

Target weight above

upper tolerance limit

(MAX threshold)

56 KEN-TM / KET_TM-BA-e-1420

Page 57

Settings:

Tap < Signalling checkweighing

ranges >.

Menu will appear, see table. 4.

4. Linearity

Function:

The bargraph display moves from the left to the right and proceeds equally to the

weight loaded onto the weighing balance. Its full width is reached at maximum load.

For tolerance controls such as dosaging, apportioning or sorting the balance will

display violated upper or lower limits vie the bargraph display. The analogue

bargraph display (length of displayed bars) indicates where the weight of the

weighed goods comes in the tolerance range. The tolerance range is always

standardised between target value and limit values (Min / MAX threshold) so that it

corresponds to the bar length of the bargraph.

Target weight below lower tolerance limit (MIN threshold):

Target weight within tolerance range (OK threshold):

Target weight above upper tolerance limit (MAX threshold):

KEN-TM / KET_TM-BA-e-1420 57

Page 58

Settings:

Tab. 5:

Pilot light colour for MIN

threshold

Tap < Linear >.

Menu will appear, see table. 5.

Select pilot light colour for threshold MIN, 18 colour

options available

Pilot light threshold for OK

threshold

Pilot light colour for MAX

threshold

Gradient Turn on / turn off filling flow for type “Gradient“.

Background colour of OK

range

Frame colour

Select pilot light threshold for threshold OK, 18 colour

options available

Select pilot light threshold for threshold MAX, 18 colour

options available.

Select background colour for OK range on bargraph,

18 colour options available.

Select frame colour for bargraph, 18 colour options

available.

58 KEN-TM / KET_TM-BA-e-1420

Page 59

7.5 I/O settings

Tap < Inputs / Outputs >.

KEN-TM / KET_TM-BA-e-1420 59

Page 60

7.5.1 Inputs

For pin allocation IN1 – IN4, see chap. 1.2

Tap < Inputs >.

Select input to configure

(IN1 – IN4).

Default settings of all inputs: <none>.

Select action to be carried out on

enabling selected input.

60 KEN-TM / KET_TM-BA-e-1420

Page 61

No

Output disabled

Stable

Stable weighing value above LO weight

MIN stable

Stable weighing value below threshold MIN

MIN unstable

Unstable weighing value below threshold MIN

OK stable

Stable weighing value between thresholds MIN and MAX

OK unstable

Unstable weighing value between thresholds MIN and MAX

MAX stable

Stable weighing value above threshold MAX

MAX unstable

Unstable weighing value above threshold MAX

Zero

Stable weighing value zero net

Cycle end confirmation

Confirmation signal for cycle completion of dispensing

Zero

Zero weighing result (character “zero“)

! OK unstable

Unstable weighing value outside OK threshold

! OK stable

Stable weighing value outside OK threshold

7.5.2 Outputs

For pin allocation OUT1 – OUT4, see chap. 1.2

Tap < Outputs >.

Select output to configure

(OUT1 – OUT4).

Tab. 6:

The default setting for all parameters is

<none>.

Select event that is to trigger enabling of

output, see table below. 6.

KEN-TM / KET_TM-BA-e-1420 61

Page 62

Function <Access Level> is only available when you are logged on as

<Administrator>.

7.6 Authorisations

This function is used by the administrator (See chap.2.4 / Table. 1) to set protection for

certain functions individually and to grant rights to a user of the weighing scale who is

not logged on (“anonymous user“ ).

1. Anonymous user

This function is used to grant rights to a user of the weighing scale who

is not logged on.

Tap < Access level >.

Tap <Anonymous operator>

The menu will appear.

For available rights and functions of the

respective option, see chap.2.4 / table. 1

62 KEN-TM / KET_TM-BA-e-1420

Page 63

2. Date and time

This function is used to grant the user access to <Date and Time>.

Tap < Date and time >

The menu will appear.

Select users who are to be granted rights

of access.

For available rights and functions of the

respective option, see chap.2.4 / table 1

3. Print document

This function is used to grant the user right of access to define logs.

Tap <Printouts>

Select users who are to be granted rights

of access.

For available rights and functions of the

respective option, see chap.2.4 / table 1

Selecting <none> results in free access to the function.

KEN-TM / KET_TM-BA-e-1420 63

Page 64

4. Editing database

This function is used to grant rights that are supposed to be available to

the user for editing the respective database.

Tap < Database edition >

Select database for which right of access

is to be granted.

Selecting <none> results in free access to the function.

Select access level.

For available rights and functions of the

respective option, see chap.2.4 / table 1

64 KEN-TM / KET_TM-BA-e-1420

Page 65

5. Select database

This function is used to grant rights that are to be available to the user

for viewing the respective database.

Tap < Set element from the database >

Select database for which right of access

is to be granted.

Selecting <none> results in free access to the function.

6. FPVO

Not documented

Select access level.

For available rights and functions of the

respective option, see chap.2.4 / table. 1

KEN-TM / KET_TM-BA-e-1420 65

Page 66

7.7 Weighing Units

This function is used to determine which weighing units are to be used

for the operation of the weighing scale.

Tap < Units >.

1. Unit switch over

This function is used to set the units into which the weighing result can be

switched to, see chap.2.2. [6].

To call up and change settings tap the

icons.

Tap < Accessibility >.

Weighing unit activated

Weighing unit deactivated

66 KEN-TM / KET_TM-BA-e-1420

Page 67

The selected unit will be displayed after a

2. Starting unit

This function is used to set the unit to be displayed when the weighing scale is

started.

3. Gravitational acceleration

Tap < Start unit >.

Select desired starting unit.

restart.

Not all units are available for

weighing scales with type approval.

Tap < Acceleration of gravity >.

Enter local gravitations constant in input

window.

KEN-TM / KET_TM-BA-e-1420 67

Page 68

This is used to set parameters influencing the operation of the weighing

y, key level, brightness of

7.8 General parameters

scale, such as user language, date / time displa