Page 1

KERN & Sohn GmbH

Ziegelei 1

E-Mail: info@kern-sohn.com

Phone: +49-[0]7433- 9933-0

Internet: www.kern-sohn.com

Operating and Installati on Instructions

Display devices

KERN KFB/KFN-TM

Version 2.0

02/2012

GB

D-72336 Balingen

Fax: +49-[0]7433-9933-149

KFB/KFN-TM-BA_IA-e-1220

Page 2

KERN KFB/KFN -TM

Display units

GB

Version 2.0 02/2012

Operating and installa t ion instructions

Contents

1 Technical data ................................................................................................ 4

2 Appliance overview ....................................................................................... 5

2.1 Keyboard overview ..................................................................................................................... 7

2.1.1 Numerical input via the navigation buttons................................................................................. 8

2.2 Overview of display .................................................................................................................... 8

3 Basic Information (Gen eral) .......................................................................... 9

3.1 Proper use .................................................................................................................................. 9

3.2 Improper Use .............................................................................................................................. 9

3.3 Warranty ..................................................................................................................................... 9

3.4 Monitoring of Test Resources .................................................................................................. 10

4 Basic Safety Precauti o ns ............................................................................ 10

4.1 Pay attention to the instructions in the Operation Manual........................................................ 10

4.2 Personnel training ..................................................................................................................... 10

5 Transport and storage ................................................................................. 10

5.1 Testing upon acceptance ......................................................................................................... 10

5.2 Packaging / return transport ..................................................................................................... 10

6 Unpacking and placing ................................................................................ 11

6.1 Installation Site, Location of Use .............................................................................................. 11

6.2 Unpacking ................................................................................................................................. 11

6.3 Scope of delivery / serial accessories: ..................................................................................... 11

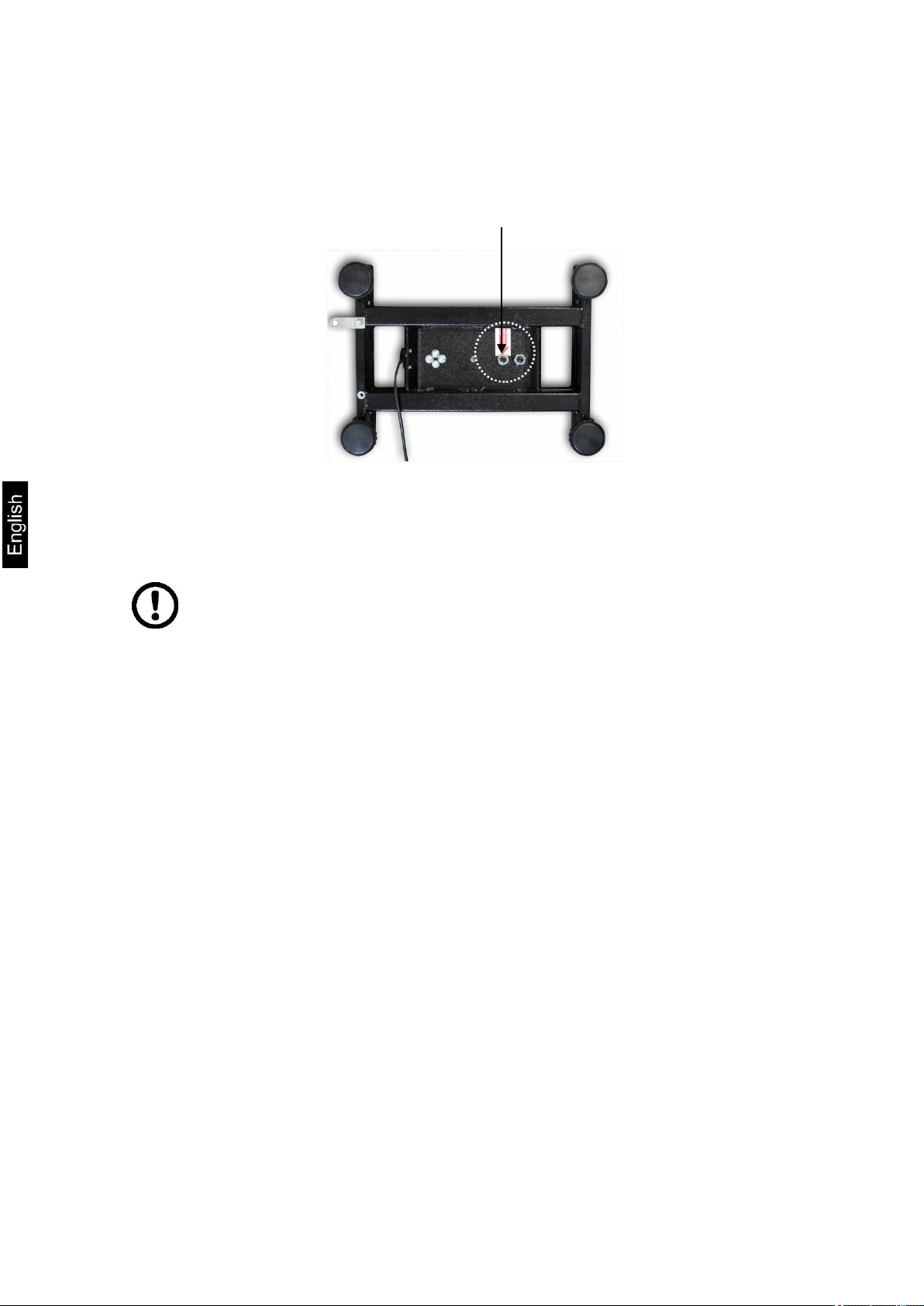

6.4 Transportation lock (illustration example) ................................................................................. 12

6.5 Error message .......................................................................................................................... 12

6.6 Placing ...................................................................................................................................... 13

6.7 Mains connection ...................................................................................................................... 14

6.8 Storage battery operation (optional) ......................................................................................... 14

6.9 Adjustment ................................................................................................................................ 15

6.9.1 Verified weighing systems ........................................................................................................ 15

6.9.2 Not verifiable weighing systems ............................................................................................... 18

6.10 Linearization ............................................................................................................................. 19

6.10.1 Verified weighing systems:................................................................................................... 19

6.10.2 Non-verified weighing systems ............................................................................................ 20

6.11 Verification 21

2 KFB/KFN-TM-BA_IA-e-1220

Page 3

7 Operation ...................................................................................................... 24

7.1 Start-up ..................................................................................................................................... 24

7.2 Switching Off ............................................................................................................................ 24

7.3 Zeroing ..................................................................................................................................... 24

7.4 Simple weighing ....................................................................................................................... 24

7.5 Switch-over weighing unit (only not verifiable weighing systems) ........................................... 25

7.6 Weighing with tare .................................................................................................................... 26

7.7 Weighing with tolerance range ................................................................................................. 26

7.8 Manual totalizing ....................................................................................................................... 29

7.9 Automatic adding-up ................................................................................................................. 31

7.10 Parts counting ........................................................................................................................... 32

7.11 Animal weighing ....................................................................................................................... 33

7.12 Lock keyboard .......................................................................................................................... 34

7.13 Display background illumination ............................................................................................... 34

7.14 Automatic switch-off function „AUTO OFF“ .............................................................................. 35

8 Menu ............................................................................................................. 36

8.1 Overview non verifiable weighing systems (contacts of circuit board [K1] not short-circuited) 37

8.2 Overview verified weighing systems (contacts of circuit board [K1] short-circuited by means of

jumper) 39

9 Service, maintenance, disposal .................................................................. 43

9.1 Clean ........................................................................................................................................ 43

9.2 Service, maintenance ............................................................................................................... 43

9.3 Disposal .................................................................................................................................... 43

9.4 Error messages ........................................................................................................................ 43

10 Data output RS 232C ................................................................................... 45

10.1 Technical data .......................................................................................................................... 45

10.2 Printer mode ............................................................................................................................. 46

10.3 Output log ................................................................................................................................. 46

10.4 Remote control instructions ...................................................................................................... 46

11 Instant help ................................................................................................... 47

12 Installing display unit / weighing bridge .................................................... 48

12.1 Technical data .......................................................................................................................... 48

12.2 Weighing system design........................................................................................................... 48

12.3 How to connect the platform ..................................................................................................... 49

12.4 Configure display unit ............................................................................................................... 50

12.4.1 Verified weighing systems (contacts of circuit board [K1] short-circuited by means of

jumper) 50

12.4.2 Non verifiable weighing systems (contacts of circuit board [K1] not short-circuited ) .......... 56

13 Declaration of Conformity / Type Approval Certificate / Test Certificate 60

KFB/KFN-TM-BA_IA-e-1220 3

Page 4

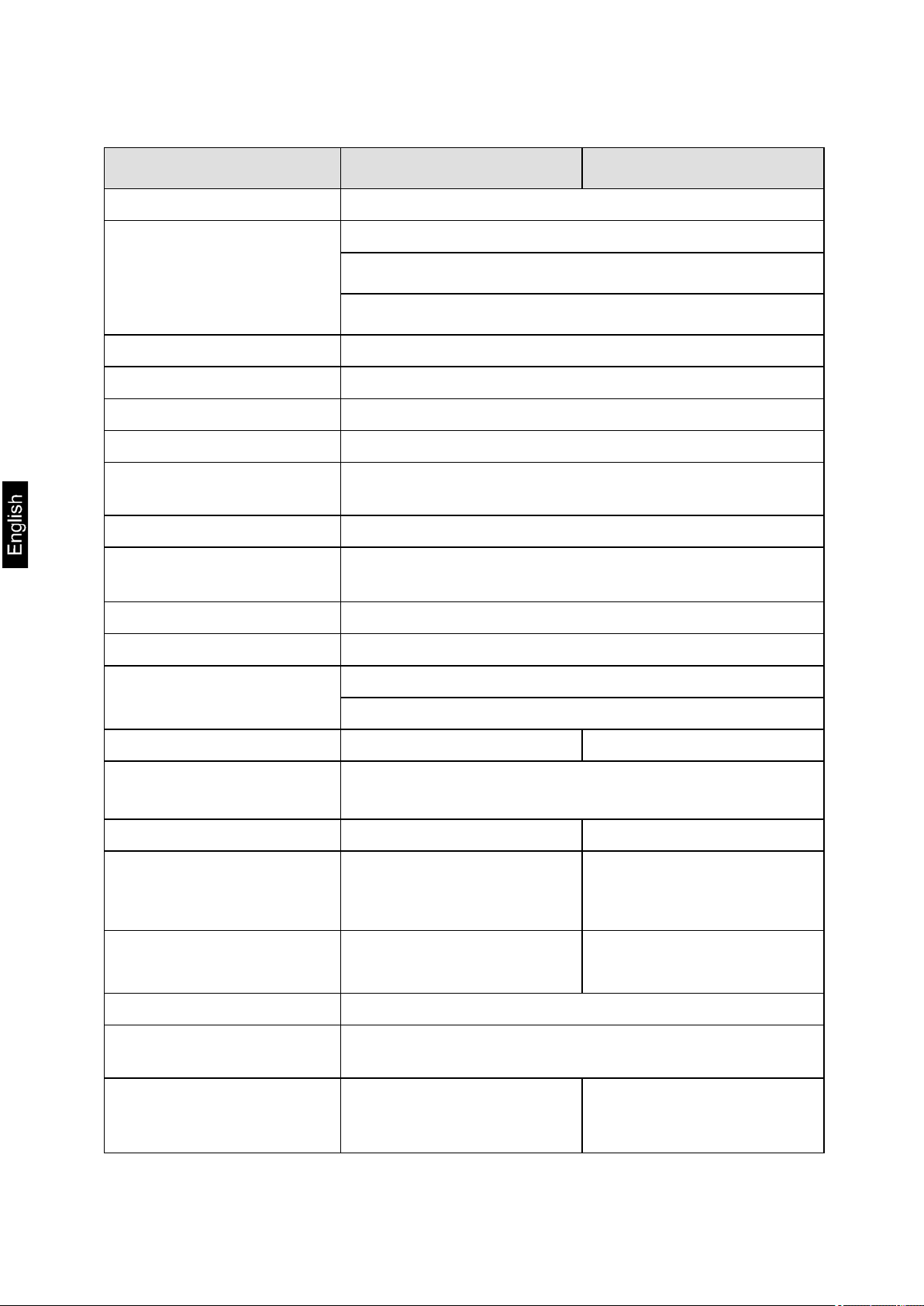

1 Technical data

KERN KFB-TM KFN-TM

Display 5 ½ - digit

Resolution (verified) 6000

Single (Max.) 6.000 e

Dual (Max.) 3.000 e

Resolution (non-verified) 30.000

Weighing ranges 2

Divisions 1,2,5,…10n

Weighing Units kg

Functions

Display LCD 52 mm digits with back lighting

DMS weighing cells

Range calibration We recommend ≥ 50 % max.

Data output RS232

Electric Supply

Housing 250 x 160 x 58 266 x 165 x 96

Admissible

ambient temperature

Net weight 1.5 kg 2 kg

Rechargeable battery

(optional)

Operating / charge time

Weighing with tolerance range, Totalizing, Animal

weighing

80-100 Ω. Max. 4 item per 350 Ω;

Sensitivity 2-3 mV/V

Input voltage 220 V – 240 V, 50 Hz

Power pack secondary voltage 9V, 800mA

0°C – 40°C (non-verified)

-10°C – 40°C (verified)

35 h / 12 h 90 h / 12 h

RS 232 interface Standard Option

Tripod KERN BFS-07, option

Support base

incl. wall bracket

IP protection -

4 KFB/KFN-TM-BA_IA-e-1220

Standard

IP 67 as per DIN 60529

(rechargeable battery

operation only)

Page 5

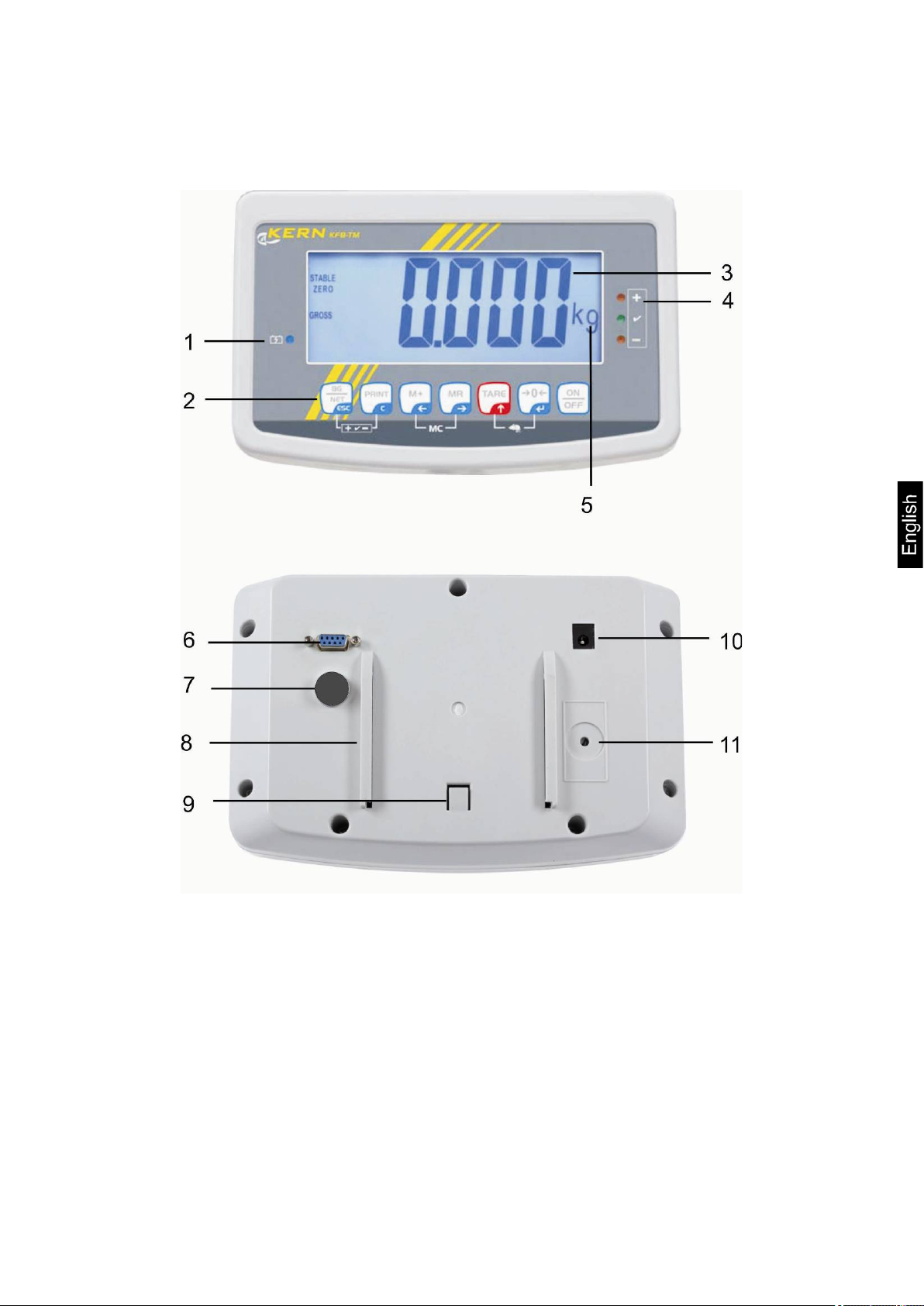

2 Appliance overview

KFB-TM: Synthetic finis h

1. Status of rechargeable battery

2. Keyboard

3. Weight display

4. Tolerance margin, see chap. 7.7

5. Weighing unit

6. RS-232

7. Input connection load cell cable

8. Guide rail support base / stand

9. End stop support base / stand

10. Mains adapter connection

11. Adjustment switch

KFB/KFN-TM-BA_IA-e-1220 5

Page 6

KFN-TM: Stainless steel finish

1. Status of rechargeable battery

2. Keyboard

3. Weight display

4. For tolerance mark see chap. 7.7

5. Weighing unit

6. Input connection load cell cable

7. Mains adapter connection

6 KFB/KFN-TM-BA_IA-e-1220

Page 7

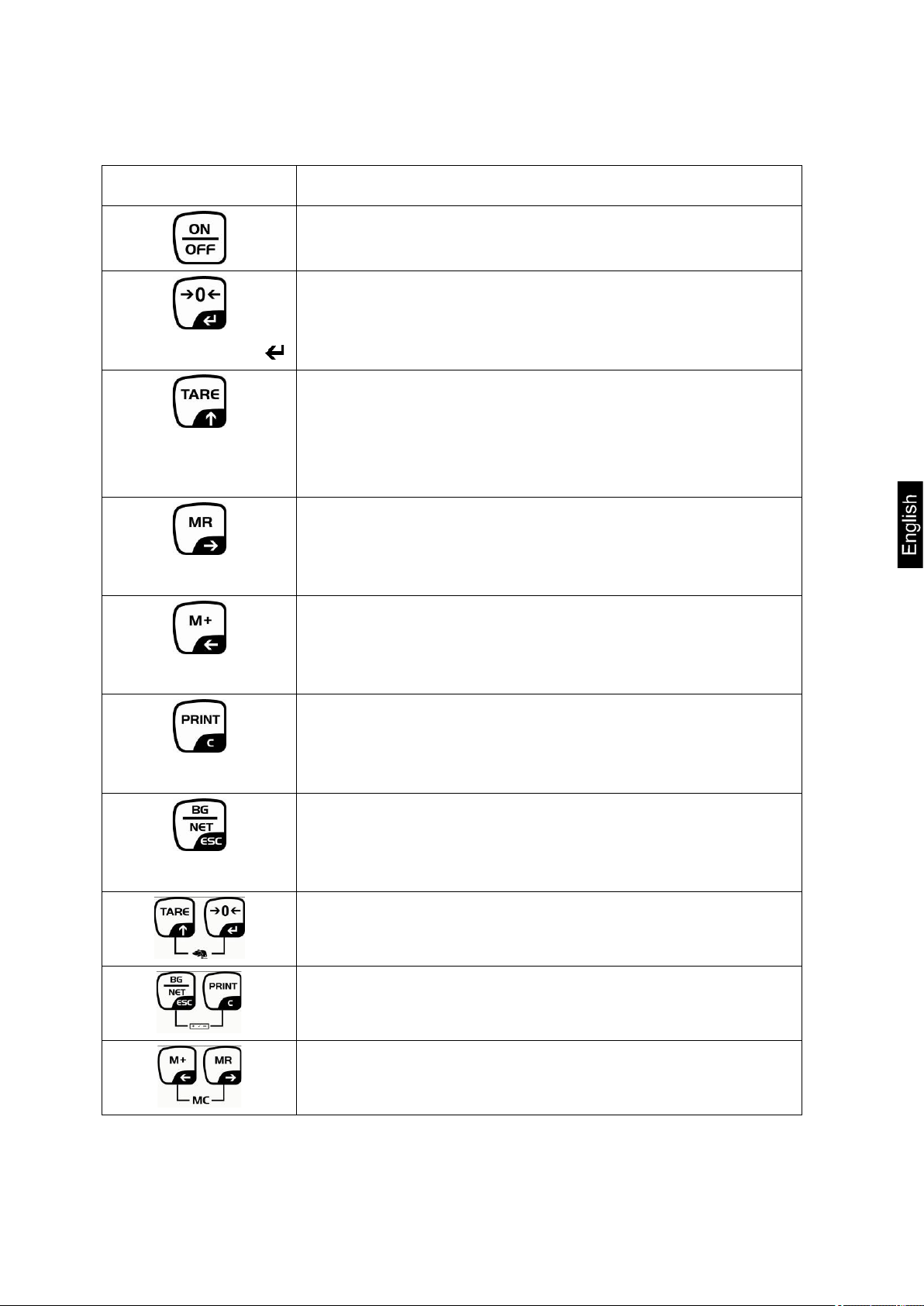

2.1 Keyboard overview

Key Function

• Turn on/off

• Zeroing

Navigation button

Navigation key

Navigation key

Navigation key

C

• Confirm entry

• Taring

• At numeric input increase flashing digit

• Scroll forward in menu

• Display sum total

• Digit selection to the right

• Add weighing value to summation memory

• Digit selection to the left

• Calculate weighing data via interface

• Delete

• Change between gross and net weight

ESC

KFB/KFN-TM-BA_IA-e-1220 7

• Back to menu/weighing mode

• Call up animal weighing function

• Call up weighing with tolerance range

• Delete total added memory

Page 8

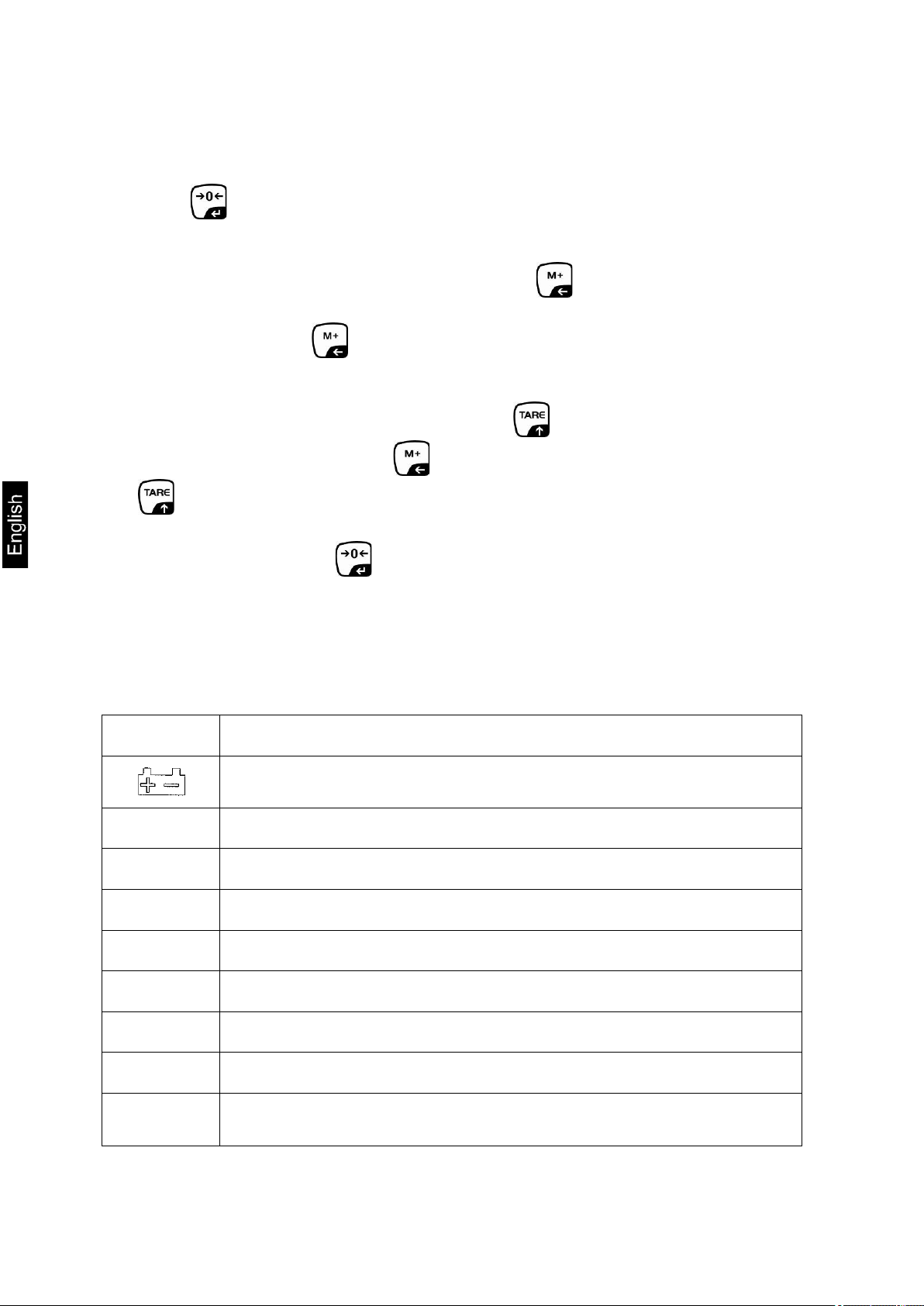

2.1.1 Numerical input via the navigation buttons

Press and current setting will be displayed. The first digit will be flashing

and is ready for changing.

If you do not wish to change the first digit, press and the second digit will

start flashing.

Each time you press , the display will move to the subsequent digit, after the

last digit the display will return to the first digit.

To change the selected (flashing) digit, press repeatedly until the desired

value is displayed. Then press to access further digits and change them by

.

Complete your entry by .

2.2 Overview of display

Display Significance

Battery very low

STABLE Stability display

ZERO Zero indicator

GROSS Gross weight

NET Net weight

AUTO Automatic add-up enabled

Kg Weighing unit

M+ Totalisation

LED

+ / / -

8 KFB/KFN-TM-BA_IA-e-1220

Indicators for weighing with tolerance range

Page 9

3 Basic Information (General)

3.1 Proper use

The display unit acquired by you is used in combination with a weighing plate and

serves to determine the weighing value of material to be weighed. It is intended to be

used as a “non-automatic weighing system”, i.e. the material to be weighed is

manually and carefully placed in the centre of the weighing plate. As soon as a stable

weighing value is reached the weighing value can be read.

3.2 Improper Use

Do not use display unit for dynamic weighings. In the event that small quantities are

removed or added to the material to be weighed, incorrect weighing results can be

displayed due to the “stability compensation“ in the display unit. (Example: Slowly

draining fluids from a container on the balance.)

Do not leave permanent load on the weighing pan. This may damage the measuring

system.

Impacts and overloading exceeding the stated maximum load (max) of the weighing

plate, minus a possibly existing tare load, must be strictly avoided. Both, the weighing

plate and the display unit may be damaged during this process.

Never operate display unit in explosive environment. The serial version is not

explosion protected.

Changes to the display unit's design are not permitted. This may lead to incorrect

weighing results, safety-related faults and destruction of the display unit.

The display unit may only be operated in accordance with the described default

settings. Other areas of use must be released by KERN in writing.

3.3 Warranty

Warranty claims shall be voided in case

• Our conditions in the operation manual are ignored

• The appliance is used outside the described uses

• The appliance is modified or opened

• Mechanical damage or damage by media, liquids, natural wear and tear

• The appliance is improperly set up or incorrectly electrically connected

• The measuring system is overloaded

KFB/KFN-TM-BA_IA-e-1220 9

Page 10

3.4 Monitoring of Test Resources

In the framework of quality assurance the measuring-related properties of the display

unit and, if applicable, the testing weight, must be checked regularly. The responsible

user must define a suitable interval as well as type and scope of this test. Information

is available on KERN’s home page (www.kern-sohn.com with regard to the

monitoring of display units’ test substances and the test weights required for this. In

KERN’s accredited DKD calibration laboratory test weights and display units may be

calibrated (return to the national standard) fast and at moderate cost.

4 Basic Safety Precautions

4.1 Pay attention to the instructions in the Operation Manua l

Carefully read this operation manual before setup and commissioning, even if you

are already familiar with KERN balances.

4.2 Personnel training

The appliance may only be operated and maintained by trained personnel.

5 Transport and storage

5.1 Testing upon acceptance

When receiving the appliance, please check packaging immediately, and the

appliance itself when unpacking for possible visible damage.

5.2 Packaging / return transport

Keep all parts of the original packaging for a possibly

required return.

Only use original packaging for returning.

Prior to dispatch disconnect all cables and remove

loose/mobile parts.

Reattach possibly supplied transport securing devices.

Secure all parts such as the glass wind screen, the

weighing platform, power unit etc. against shifting and

damage.

10 KFB/KFN-TM-BA_IA-e-1220

Page 11

• Display Unit

6 Unpack ing and placing

6.1 Installation Site, Location of Use

The display units are designed in a way that reliable weighing results are achieved in

common conditions of use.

Precise and fast work is achieved by selecting the right place for your display unit

and your weighing plate.

On the installation site observe the following:

• Place the display unit and the weighing plate on a stable, even surface.

• Avoid extreme heat as well as temperature fluctuation caused by installing

next to a radiator or in the direct sunlight;

• Protect the display unit and the weighing plate against direct draft from open

windows or doors.

• Avoid jarring during weighing;

• Protect the display unit and the weighing plate against high humidity, vapours

and dust.

• Do not expose the display unit to extreme dampness for longer periods of

time. Non-permitted condensation (condensation of air humidity on the

appliance) may occur if a cold appliance is taken to a considerably warmer

environment. In this case, acclimatize the disconnected appliance for ca. 2

hours at room temperature.

• Avoid static charge of goods to be weighed or weighing container.

Major display deviations (incorrect weighing results) may be experienced should

electromagnetic fields (e.g. due to mobile phones or radio equipment), static

electricity accumulations or instable power supply occur. Change location or remove

source of interference.

6.2 Unpacking

Take the display unit carefully out of its packaging, remove the plastic jacket and

install it at the designated work space.

6.3 Scope of delivery / serial accessories:

• Mains adapter

• Support base incl. wall bracket

• Operating instructions

KFB/KFN-TM-BA_IA-e-1220 11

Page 12

Transport Securing

6.4 Transportation lock (illustration example)

Please note: if the display unit is used together with platform with transportation lock,

this transportation lock must be released prior to use:

6.5 Error message

As soon as an error message appears in the balance display, the

balance must not more be used, e.g. Err 4

12 KFB/KFN-TM-BA_IA-e-1220

Page 13

6.6 Placing

Mount the display unit in a way that facilitates operation and where it is easy to see.

Usage with support base (KFB-TM only)

Push support base holder in guide rail [8] up to end stop [9], see chpt 2.

Usage with wall mount (KFB-TM only)

Use the wall mount to affix the display unit to the wall.

Using with tripod (optional)

An optional tripod (KERN BFS-07) is available if the display unit is to be mounted

in a raised position.

KFB/KFN-TM-BA_IA-e-1220 13

Page 14

6.7 Mains connection

Power is supplied via the external mains adapter. The stated voltage value must be

the same as the local voltage.

Only use original KERN mains adapters. Using other makes requires consent by

KERN.

6.8 Storage battery operation (optional)

Before the first use, the battery should be charged by connecting it to the mains

power supply for at least 12 hours.

If the weight display shows , this is an indication that the capacity of the

rechargeable battery is almost exhausted. The unit will be ready for operation for

approx. another 10 hours before switching off automatically. Charge the battery with

the help of the supplied power pack.

The LED display informs you during loading about the loading status of the

rechargeable battery.

red: Voltage has dropped below prescribed minimum.

green: Battery is completely discharged

yellow: Charging storage battery

To conserve energy, enable the automatic switch-off function „AUTO OFF“, see

chap. 7.14.

14 KFB/KFN-TM-BA_IA-e-1220

Page 15

•

6.9 Adjustment

As the acceleration value due to gravity is not the same at every location on earth,

each display unit with connected weighing plate must be coordinated - in compliance

with the underlying physical weighing principle - to the existing acceleration due to

gravity at its place of location (only if the weighing system has not already been

adjusted to the location in the factory). This adjustment process must be carried out

for the first commissioning, after each change of location as well as in case of

fluctuating environment temperature. To receive accurate measuring values it is also

recommended to adjust the display unit periodically in weighing operation.

• In weighing systems with a resolution of < 15 000 dividing steps an

adjustment is recommended.

In weighing systems with a resolution of > 15 000 dividing steps a

linearisation is recommended (see chap. 6.10).

• Prepare the required adjustment weight. The weight to be used depends

on the capacity of the scale. Carry out adjustment as near as possible to

the scale’s maximum weight. Info about test weights can be found on

the Internet at: http://www.kern-sohn.com.

• Observe stable environmental conditions. Stabilisation requires a certain

warm-up time.

6.9.1 Verified weighing systems

In verified weighing systems the menu item for adjustment „P2 mode“ is

blocked.

KERN KFB-TM

To disable the access lock, destroy the seal and actuate the adjustment

switch. Position of the adjustment switch see chap. 6.11

KERN KFN-TM

To override the blocked access you will have to destroy the seal before calling

up the menu and to short-circuit the two contacts on the circuit board [K2],

using a jumper (See chap. 6.11).

Attention:

After destruction of the seal the weighing system must be re-verified by an

authorised agency and a new verification wire/seal mark fitted before it can be

reused for applications subject to verification.

KFB/KFN-TM-BA_IA-e-1220 15

Page 16

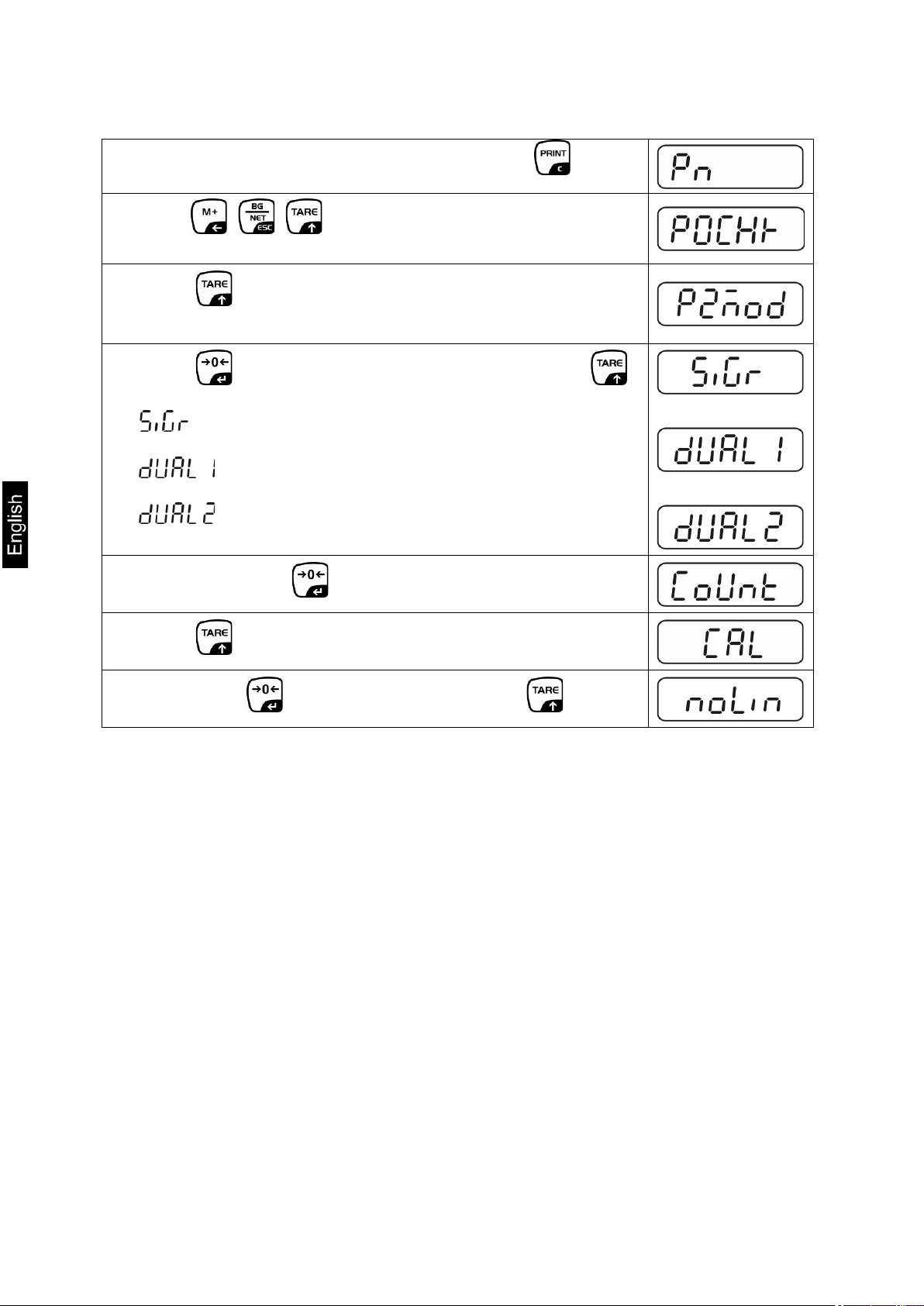

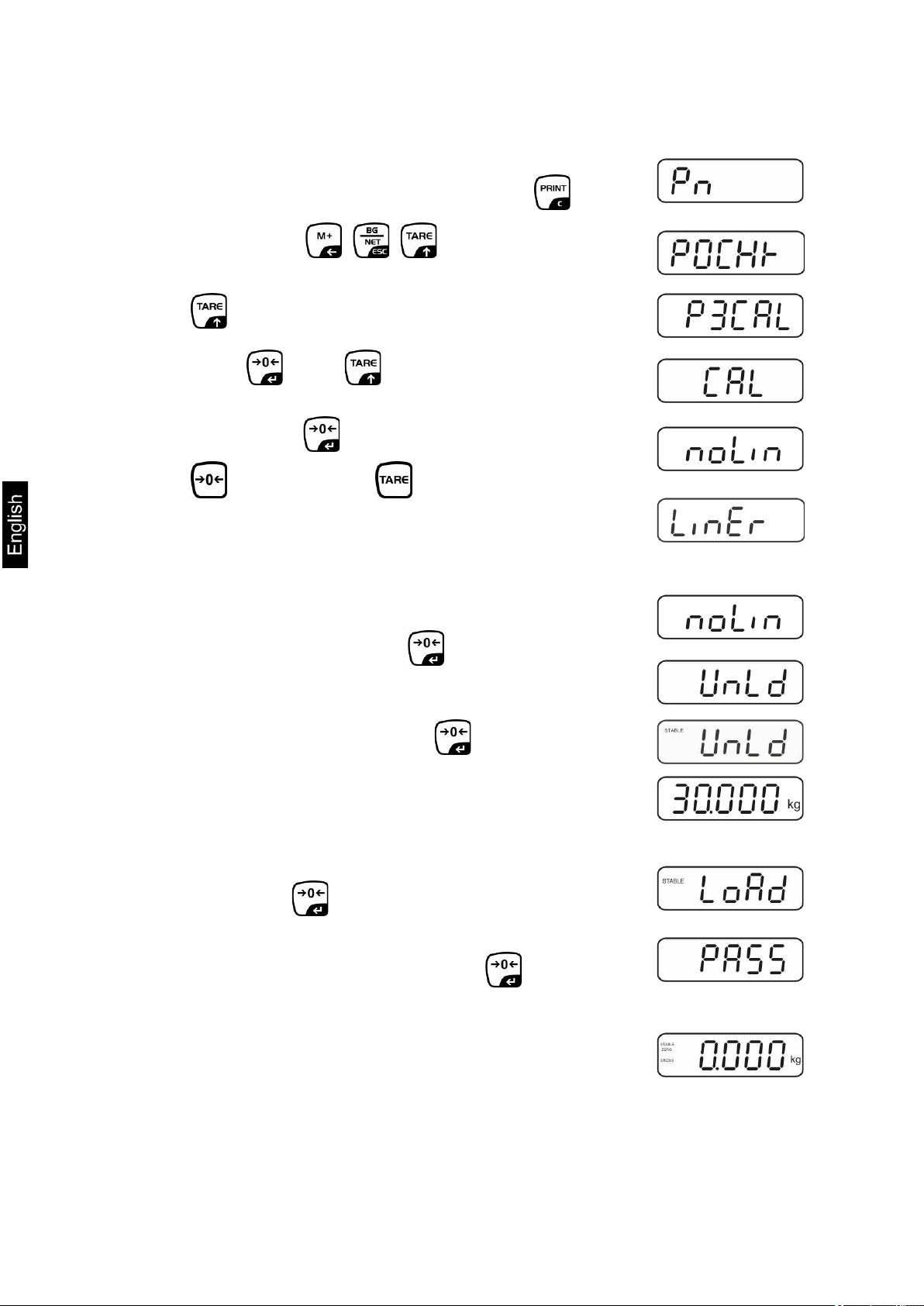

Call up menu:

1. Switch-on balance and during the selftest press .

2. Press , , subsequently, the first menu block

„PO CHK“ will be displayed.

3. Press repeatedly until „P2 mode“ will be displayed.

For the KFB-TM model operate the adjustment switch.

4. Press and select the set weighing scales type by .

= Single-range balance

= Dual range balance

= Multi-interval balance

5. Acknowledge with .

6. Press repeatedly until „CAL“ will be displayed.

7. Confirm with and select setting „noLin“ by .

16 KFB/KFN-TM-BA_IA-e-1220

Page 17

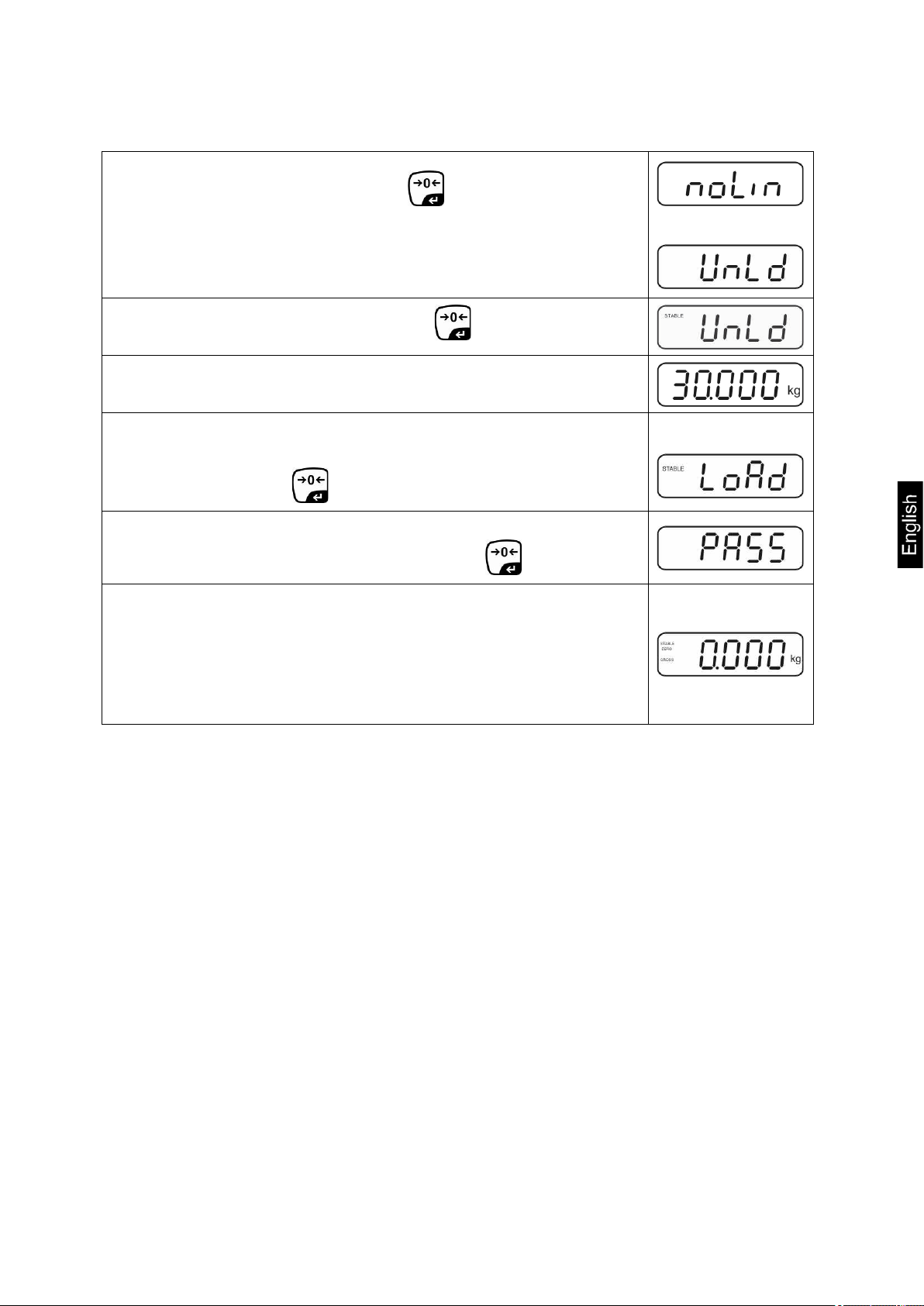

How to carry out an adjustment:

Confirm menu setting „noLin“ by .

Ensure that there are no objects on the weighing plate.

Wait for stability display, then press .

The currently set adjustment weight will be displayed.

To change by using the navigation buttons (see chap. 2.1.1)

select the desired setting, the active digit is flashing.

Acknowledge with .

Carefully place adjusting weight in the centre of the weighing

plate. Wait for stability display, then press .

After the adjustment the balance will carry out a self-test.

Remove adjusting weight during selftest, balance will return

into weighing mode automatically.

An adjusting error or incorrect adjusting weight will be

indicated by the error message; repeat adjustment

procedure.

KFB/KFN-TM-BA_IA-e-1220 17

Page 18

Call up menu:

6.9.2 Non verifiable weighing systems

1. Switch-on balance and during the selftest press .

2. Press subsequently , , the first menu block

„PO CHK“ will be displayed.

3. Press repeatedly until „P3 CAL“ will be displayed.

4. Confirm with ; press repeatedly until „CAL“

appears.

5. Acknowledge using , the current setting is displayed.

Press to confirm; press to select setting.

noLin = adjustment

LineAr = linearization, see chap. 6.10

How to carry out adjustment:

Confirm menu setting „noLin“ by .

Ensure that there are no objects on the weighing plate.

Wait for stability display, then press .

The currently set adjustment weight will be displayed.

To change by using the navigation buttons (see chap. 2.1.1)

select the desired setting, the active digit is flashing.

Acknowledge with .

Carefully place adjusting weight in the centre of the weighing

plate. Wait for stability display, then press .

After the adjustment the balance will carry out a self-test.

Remove adjusting weight during selftest, balance will return

into weighing mode automatically. An adjusting error or

incorrect adjusting weight will be indicated by the error

message; repeat adjustment procedure.

18 KFB/KFN-TM-BA_IA-e-1220

Page 19

• In balances with a resolution of > 15 000 dividing steps carrying out a

the adjustment switch see chap. 6.11

6.10 Linearization

Linearity shows the greatest deviation of a weight display on the scale to the value of

the respective test weight according to plus and minus over the entire weighing

range. If linearity deviation is discovered during a testing instrument control, you can

improve this by means of linearization.

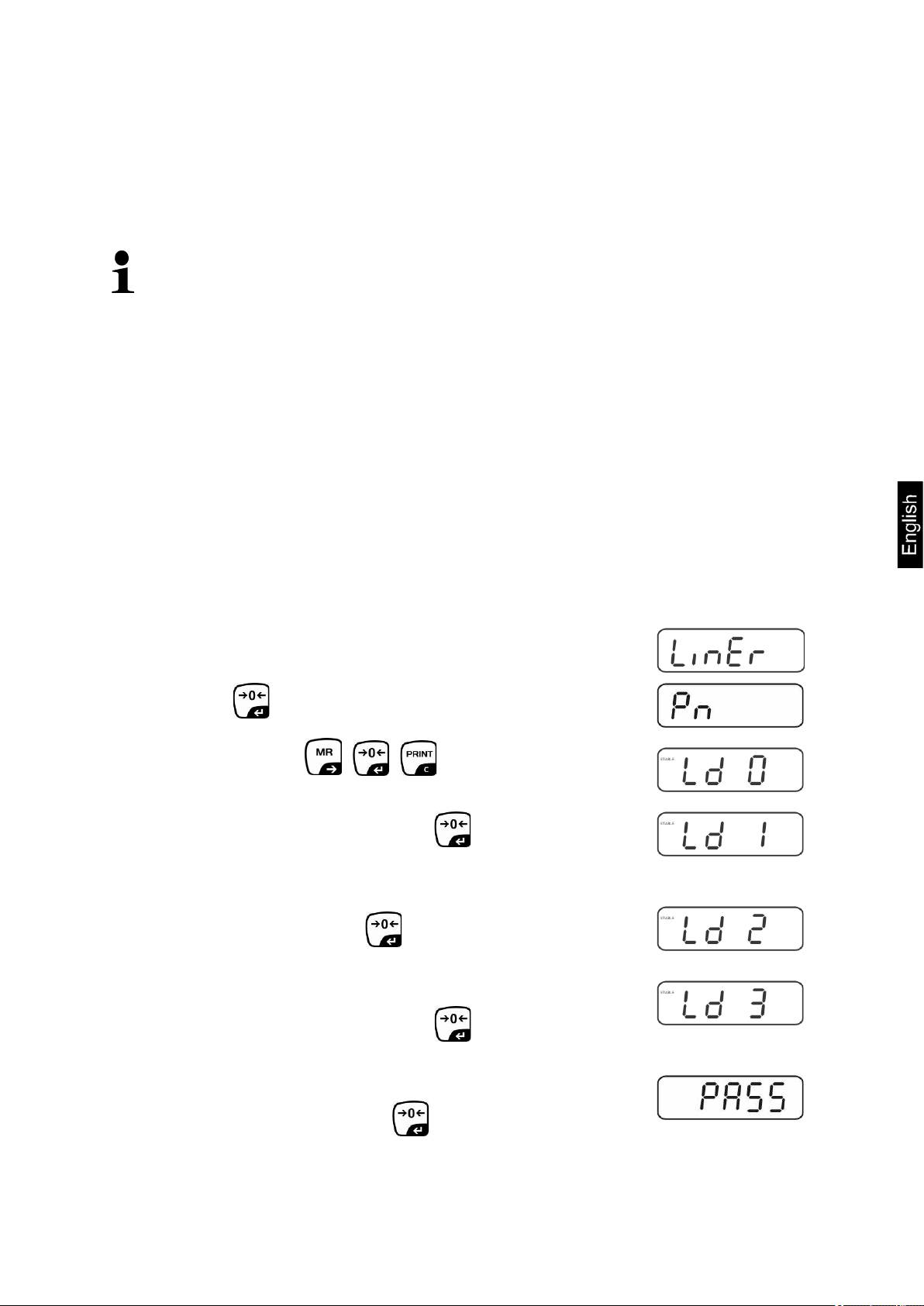

6.10.1 Verified weighing systems:

linearisation is recommended.

• Carrying out linearization is restricted to specialist staff possessing

well acquainted with the workings of weighing scales.

• The test weights to be used must be adapted to the weighing scale’s

specifications; see chapter “testing instruments control”.

• Observe stable environmental conditions. Stabilisation requires a

certain warm-up time.

• After successful linearisation you will have to carry out calibration;

see chapter “testing instruments control”.

• The adjustment is locked for verified balances. To disable the access

lock, destroy the seal and actuate the adjustment switch. Position of

Menu item P2 modeCalCall up liner, see chap. 6.9.1

Confirm by , the password query „Pn“ will be displayed.

Press subsequently , , .

Ensure that there are no objects on the weighing pan.

Wait for stability display, then press .

When “Ld 1“ is displayed, put the first adjustment weight (1/3

max) carefully in the centre of the weighing platform. Wait for

stability display, then press .

When “Ld 2“ is displayed, put the second adjustment weight

(2/3 max) carefully in the centre of the weighing platform.

Wait for stability display, then press .

When “Ld 3“ is displayed, put the third adjustment weight

(max) carefully in the centre of the weighing platform. Wait

for stability display, then press .

KFB/KFN-TM-BA_IA-e-1220 19

Page 20

After linearisation the balance will carry out a self-test.

Remove adjusting weight during selftest, balance will return

into weighing mode automatically.

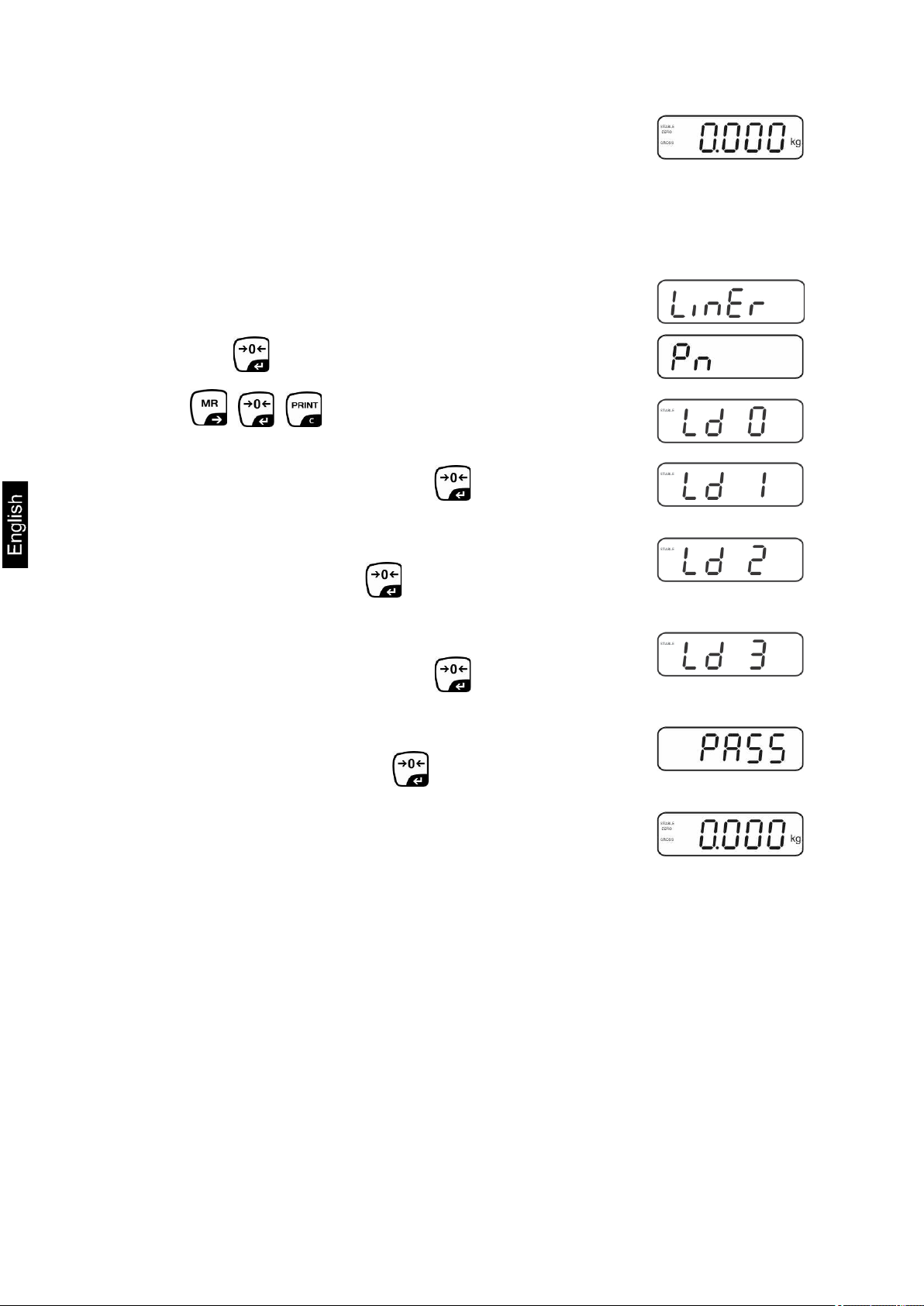

6.10.2 Non-verified weighing systems

Call-up menu item P3 CALCalLiner, see chap. 6.9.1

Confirm by , the password query „Pn“ will be displayed.

Press , , subsequently.

Ensure that there are no objects on the weighing pan.

Wait for stability display, then press .

When “Ld 1“ is displayed, put the first adjustment weight (1/3

max) carefully in the centre of the weighing platform. Wait for

stability display, then press .

When “Ld 2“ is displayed, put the second adjustment weight

(2/3 max) carefully in the centre of the weighing platform.

Wait for stability display, then press .

When “Ld 3“ is displayed, put the third adjustment weight

(max) carefully in the centre of the weighing platform. Wait

for stability display, then press .

After a successful linearisation the balance will carry out a

self-test. Remove adjusting weight during selftest, balance

will return into weighing mode automatically.

20 KFB/KFN-TM-BA_IA-e-1220

Page 21

6.11 Verification

General introduction:

According to EU directive 90/384/EEC balances must be officially verified if they are

used as follows (legally controlled area):

a) For commercial transactions if the price of goods is determined by weighing.

b) For the production of medicines in pharmacies as well as for analyses in the

medical and pharmaceutical laboratory.

c) For official purpose.

d) For manufacturing final packages.

In cases of doubt, please contact your local trade in standard.

Verification notes:

An EU Qualification Approval is in existence for verified weighing systems. If a

balance is used where obligation to verify exists as described above, it must be

verified and re-verified at regular intervals.

Reverification is carried out according to the relevant national statutory regulations.

The validity for verification of balances in Germany is e.g. 2 years.

The legal regulation of the country where the balance is used must be observed!

• Verification of the weighing system is invalid without the "seal".

KFB/KFN-TM-BA_IA-e-1220 21

Page 22

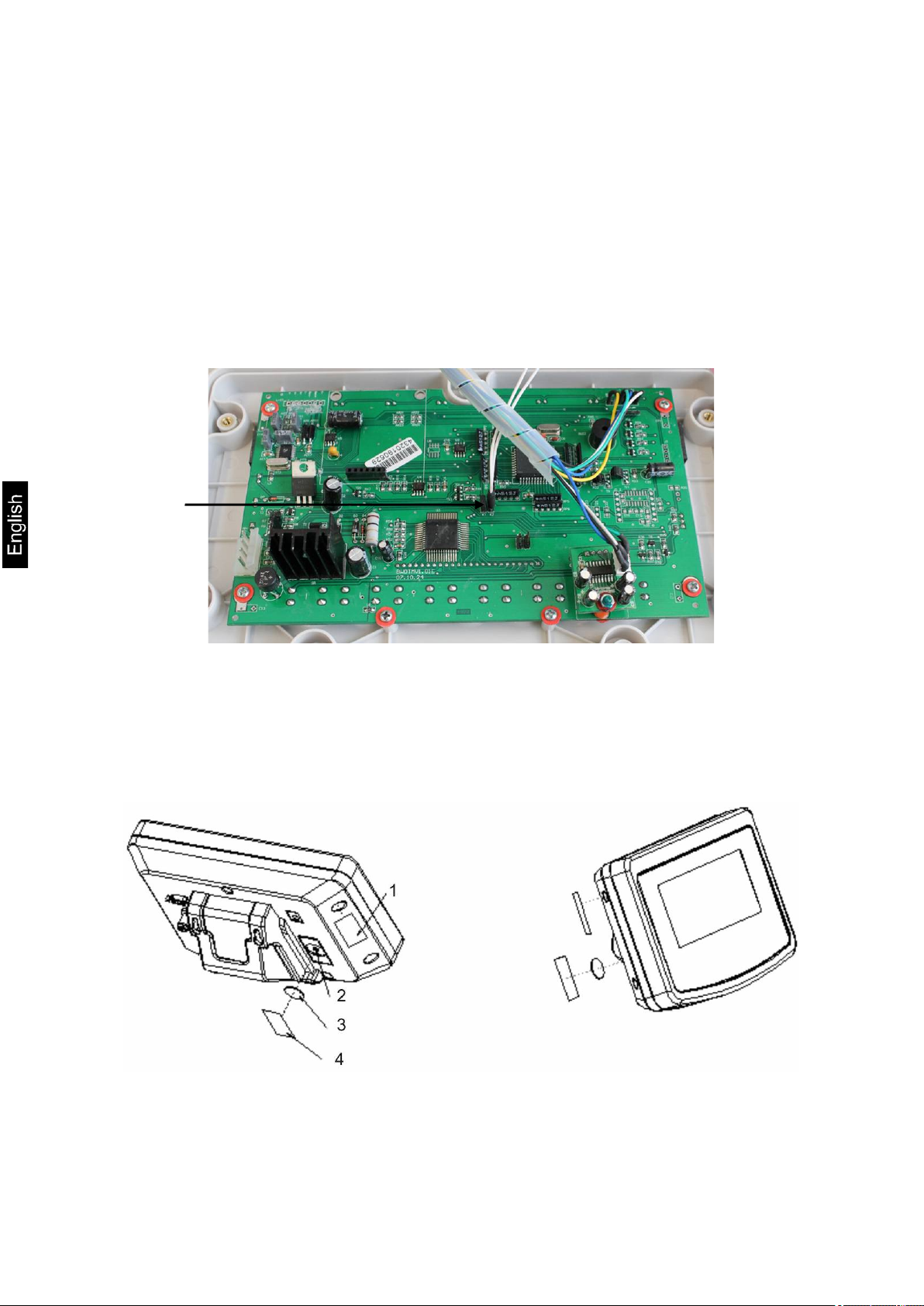

[K1]

Notes on verified weighing systems

KFB-TM:

Access to conductor plate:

• Remove seal

• Open display unit

• The application of the display unit as a weighing system able to be verified

requires that the contacts of the circuit board are short-circuited with the help

of a jumper [K1].

For non verifiable weighing systems remove the jumper.

In verified weighing systems the menu item for adjustment, „P2 mode“ will be

blocked.

To disable the access lock, destroy the seal and actuate the adjustment switch.

Position of seals and adjusting switch

1. Self-destroying seal mark

2. Adjustment switch

3. Cover of adjustment switch

4. Self-destroying seal mark

22 KFB/KFN-TM-BA_IA-e-1220

Page 23

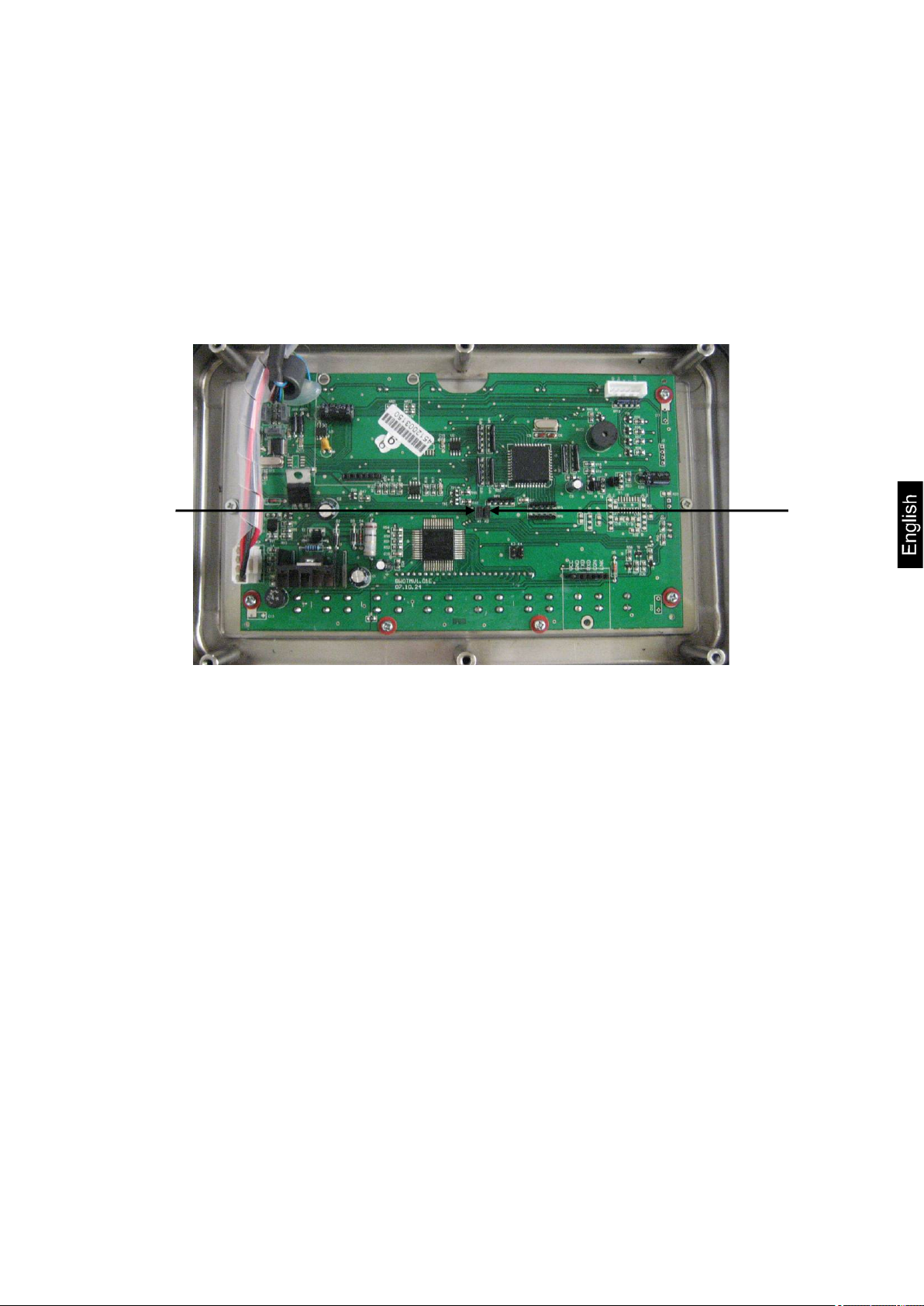

[K1]

[K2]

KFN-TM:

Access to conductor plate:

• Remove seal

• Open display unit

• The application of the display unit as a weighing system able to be verified

requires that the contacts of the circuit board are short-circuited with the help

of a jumper [K1]. For non verifiable weighing systems remove the jumper.

• To adjust, short-circuit the contacts of the circuit board, using a jumper [K2].

KFB/KFN-TM-BA_IA-e-1220 23

Page 24

exceeding the stated maximum load (max) of the device, minus a

7 Operation

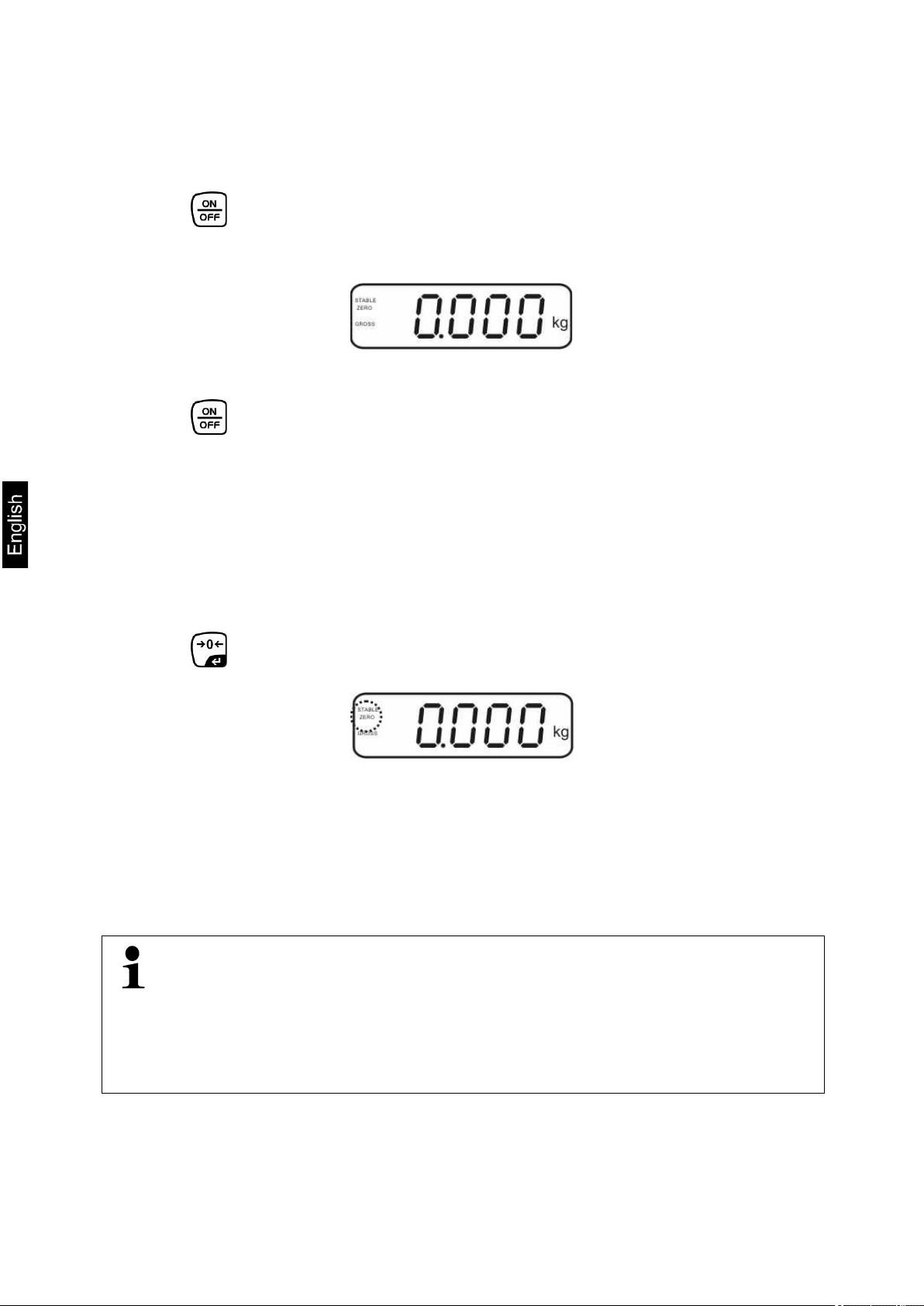

7.1 Start-up

Press and the instrument will carry out a self-test. As soon as the weight

display appears, the instrument will be ready to weigh.

7.2 Switching Off

Press and the display will disappear.

7.3 Zeroing

Resetting to zero corrects the influence of light soiling on the weighing plate. The unit

is equipped with an automatic zero setting function. Therefore the unit can be reset to

zero at any time as follows:

To unload the weighing system

Press and zero display as well as indicator ZERO will appear.

7.4 Simple weighing

Place goods to be weighed on balance.

Wait until stability display STABLE appears.

Read weighing result.

Overload warning

Overloading

possibly existing tare load, must be strictly avoided. This could damage the

instrument.

Exceeding maximum load is indicated by the display of „----“ and an audio

sound. Unload weighing system or reduce preload.

24 KFB/KFN-TM-BA_IA-e-1220

Page 25

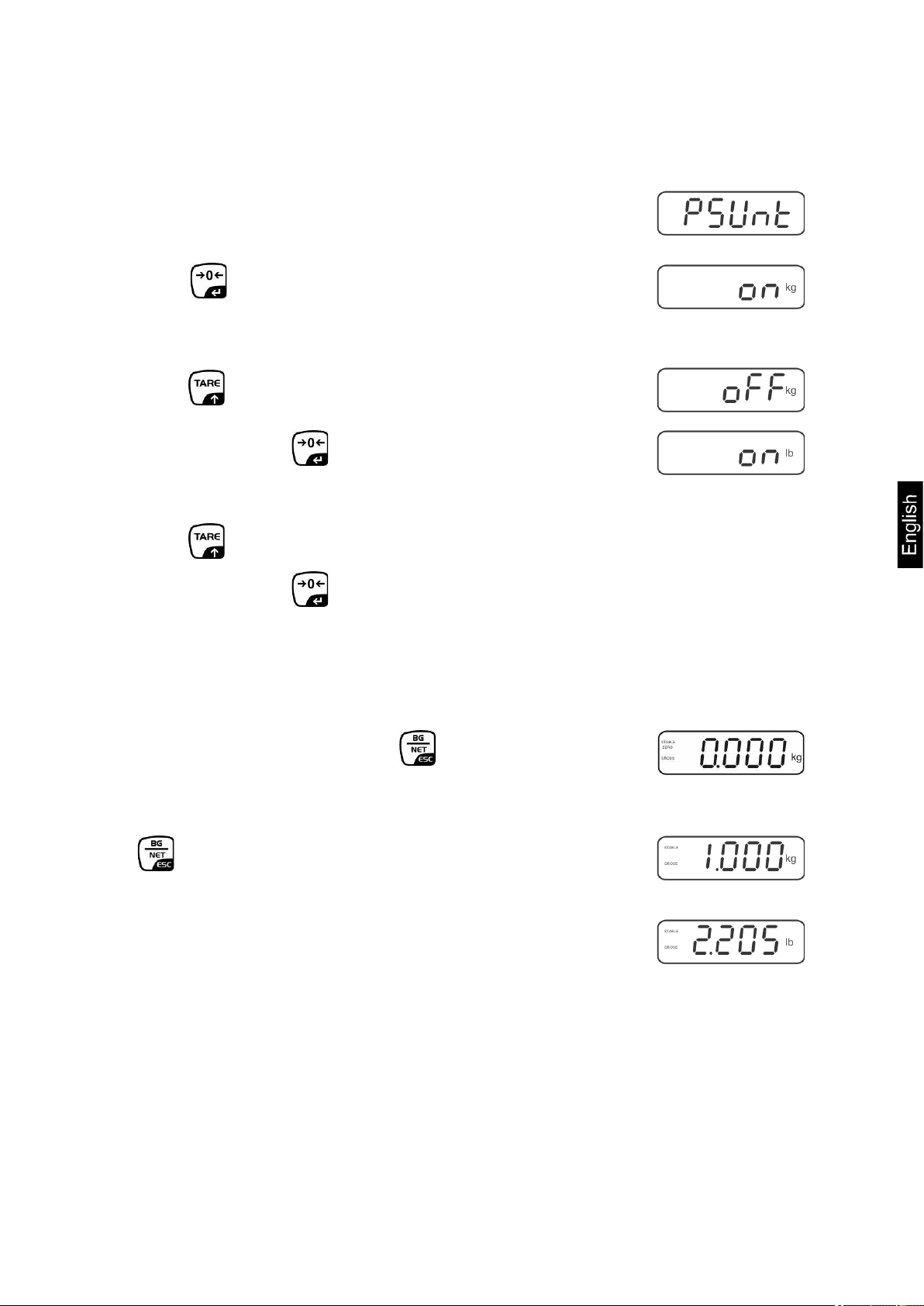

7.5 Switch-over weighing unit (only not verifiable weighing systems)

How to enable weighing units:

Call-up menu item P5 Unt, see chap. 8.1

Press and the first weighing unit with the current setting

will be displayed.

To enable [on] / disable [off] the displayed weighing unit,

press

Acknowledge with . The next unit with the current setting

will be displayed.

To enable [off] / disable [on] the displayed weighing unit,

press .

Acknowledge with .

Repeat sequence for each weighing unit.

Note:

„tj“ and „Hj“ cannot be activated at the same time, only either

... or ... .

Return to weighing mode using

Switch-over weighing unit:

Keep pressed, the display changes over to the

weighing units activated before (e.g. kg lb)

KFB/KFN-TM-BA_IA-e-1220 25

Page 26

7.6 Weighing with tare

Deposit weighing vessel. After successful standstill control press the button.

Zero display and indicator NET appear.

The weight of the container is now internally saved.

Weigh the material, the net weight will be indicated.

The weight of the weighing container will be displayed as a minus number after

removing the weighing container.

The tare procedure can be repeated as many times as necessary, for example

with initial weighing of several components for a mix (add-on weighing). The limit

is reached when the taring range capacity (see type plate)is full.

To change between gross weight and net weight, press .

To delete the tare value, remove load from weighing plate and press .

7.7 Weighing with tolerance range

You can set an upper or lower limit when weighing with tolerance range and thus

ensure that the weighed load remains exactly within the set limits.

During tolerance tests such as dosing, portioning and sorting the unit will indicate

exceeded or undershot limits by emitting an optical or acoustic signal.

Audio signal:

The acoustic signal depends on the settings in menu block „BEEP“.

Options:

• no

• ok

• ng

Acoustic signal turned off

An acoustic signal sounds when load is within tolerance

limits

An acoustic signal sounds when load is beyond tolerance

limits

26 KFB/KFN-TM-BA_IA-e-1220

Page 27

Optical signal:

Three colour signal lights indicate whether the load is within the two tolerance limits.

The signal lights provide the following information:

+

The settings for tolerance weighing may be called up either via menu block „P0 CHK“

(see chap. 8) or faster via the key combination

Settings

Goods to be weighed above tolerance limit

Goods to be weighed within tolerance range

Goods to be weighed below tolerance limit

-

Red signal light

glowing

Green signal light

glowing

Red signal light

glowing

Press and at the same time in weighing mode.

Press until the display for entering the lower limit value

appears.

Press , current setting will be displayed.

To enter the lower limit, e. g. 1000 Kg, press the navigation

keys (See chap. 2.1.1); the currently enabled digit will be

flashing.

Confirm input by .

Use to select

KFB/KFN-TM-BA_IA-e-1220 27

Page 28

Press and the current setting for the upper limit will be

displayed.

Press the navigation keys (See chap. 2.1.1) to enter the

upper limit, e.g. 1,100 kg; the currently enabled digit will be

flashing.

Confirm input by .

Use to select

Press and the current setting for the acoustic signal will

be shown.

Select desired setting (no, ok, ng) by .

Confirm input by .

Press repeatedly; weighing system is in tolerance

weighing mode. From here evaluation takes place whether

the goods to be weighed are within the two tolerance limits.

Weighing with tolerance range

Tare when using a weighing container

Put on goods to be weighed, tolerance control is started The signal lights

indicate whether the load is within the two set limits.

Load below specified

tolerance

Red signal light

next to „-“ ON illuminated

• The tolerance control is not active when the weight is under 20d.

• To delete limits, enter “00.000 kg“.

Load within specified

tolerance

Green signal light

next to „„ illuminated

Load exceeds specified

tolerance

Red signal light

next to „+“ ON illuminated

28 KFB/KFN-TM-BA_IA-e-1220

Page 29

• Menu setting:

• The totalizing function is not active when the weight is under 20d.

7.8 Manual totalizing

With this function the individual weighing values are added into the summation

memory by pressing and edited, when an optional printer is connected.

„P1 COM“ or „P2 COM“ „MODE“ „PR2““, see chap. 8

Add up:

Place weighing goods A.

Wait until the stability display STABLE appears, then press . The weight value

will be saved and printed if an optional printer is connected.

Remove the weighed good. More weighed goods can only be added when the

display ≤ zero.

Place goods to be weighed B.

Wait until the stability display appears, then press . Weighing value will be

added to summation memory and possibly printed.

The number of weighing actions, followed by the total weight will be displayed for

2 sec.

Add more weighed goods as described before.

Please note that the weighing system must be unloaded between the individual

weighing procedures.

This process may be repeated 99 times or till such time as the capacity of the

weighing system has been exhausted.

Display of the saved weighing data:

Press , number of weighing, followed by the total weight will be displayed for

2 sec. Press to print out this display.

KFB/KFN-TM-BA_IA-e-1220 29

Page 30

Menu setting

Menu setting

Delete weighing data:

Press and at the same time The data in the summation memory are

deleted.

Printout example KERN YKB-01N, verified weighing system:

„P1 COM“ or „P2 COM“ „Lab 2“ / Prt 7“

„P1 COM“ or „P2 COM“ „Lab 0“ / Prt 0“

1 First weighing

2 Second weighing

3 Third weighing

4 Number of weighings / total

+

30 KFB/KFN-TM-BA_IA-e-1220

Page 31

• Menu settings:

7.8.

7.9 Automatic adding-up

With this function the individual weighing values are automatically added into the

summation memory when the balance is unloaded without pressing and edited,

when an optional printer is connected.

„P1 COM“ or „P2 COM „MODE“ „AUTO““, see chap. 8

Der Indikator AUTO wird angezeigt.

Add up:

Place weighing goods A.

After the standstill control sounds a signal tone. The weighing value will be added

to the summation memory and printed.

Remove the weighed good. More weighed goods can only be added when the

display ≤ zero.

Place goods to be weighed B.

After the standstill control sounds a signal tone. The weighing value will be added

to the summation memory and printed. Number of weighing, followed by the total

weight will be displayed for 2 sec.

Add more weighed goods as described before.

Please note that the weighing system must be unloaded between the individual

weighing procedures.

This process may be repeated 99 times or till such time as the capacity of the

weighing system has been exhausted.

Display and delete the weighing data, as well as printout examples see chap.

KFB/KFN-TM-BA_IA-e-1220 31

Page 32

7.10 Parts c ounti ng

Before the balance can count parts, it must know the average part weight (i.e.

reference). Proceed by putting on a certain number of the parts to be counted. The

balance determines the total weight and divides it by the number of parts, the socalled reference quantity. Counting is then carried out on the basis of the calculated

average piece weight.

As a rule:

The higher the reference quantity the higher the counting exactness.

In weighing mode , press and hold until the message „P

10“ appears that is used to set the reference quantity.

Use to set the desired reference quantity (such as 100),

options include P 10, P 20, P 50, P100, P 200.

Place as many items to be counted (such as 100 items) as

demanded by the set reference quantity and confirm by

The weighing scales calculate the reference weight. The

current quantity (such as 100 items) will be displayed.

Remove reference weight. The balance is from now in parts

counting mode counting all units on the weighing plate.

Back to Weighing mode by .

32 KFB/KFN-TM-BA_IA-e-1220

Page 33

7.11 Animal weighing

The animal weighing function is suitable for weighing restless loads.

The weighing system will display a mean value derived from several weighing results.

The animal weighing program can be enabled by either calling up menu block

„P3 OTH“ or „P4 OTH“ „ANM“ „ON“ (See chap. 8) or faster via key combination.

The indicator shows HOLD as long as the animal weighing function remains enabled.

Place the load on the weighing system and wait until the scale is steady.

Press and at the same time; you will hear an acoustic signal, indicating

that the animal weighing function is enabled.

Whilst averaging is taking place you can add or remove loads as the measuring

value will be constantly updated.

To deactivate the animal weighing function press and at the same time.

KFB/KFN-TM-BA_IA-e-1220 33

Page 34

7.12 Lock keyboard

To enable/disable the keyboard lock go to menu item „P3 OTH“ or „P4 OTH“

„LOCK“, see chap.8.

Whilst the function is enabled the keyboard will self-lock after no key has been

pressed for 10 minutes. „K-LCK“ will be displayed as soon as a key is pressed.

To disable the lock, press , and hold plus (2 s) until „U LCK“ appears.

7.13 Display background illumination

Keep pressed (3s) until „setbl“ appears.

Press again, the current setting will be displayed.

Use to select the desired setting.

bl on Continuous background lighting

bl off Background illumination off

bl Auto Automatic background illumination on when weighing pate is

loaded or key pressed.

Either save by or cancel by pressing .

Back to weighing mode by .

34 KFB/KFN-TM-BA_IA-e-1220

Page 35

7.14 Automatic switch-off function „AUTO OFF“

The unit is automatically switched off within the preset time when the display unit or

the weighing bridge are not operated.

Keep pressed (3s) until „setbl“ appears.

Press to call up AUTO OFF-function

Press , the current setting will be displayed.

Use to select the desired setting.

of 0 AUTO OFF - function disabled

of 3 Weighing system will be turned off after 3 min.

of 5 Weighing system will be turned off after 5 min.

of 15 Weighing system will be turned off after 15 min.

of 30 Weighing system will be turned off after 30 min.

Either save by or cancel by pressing .

Back to weighing mode by .

KFB/KFN-TM-BA_IA-e-1220 35

Page 36

current setting will be displayed.

8 Menu

The application of the display unit as a verified weighing system requires that you

short-circuit the two contacts [K1] of the circuit board, using a jumper. To that effect,

a menu for verified weighing systems is available. For menu layout see chap. 8.2.

There is no jumper for weighing systems that cannot be verified. To that effect, a

menu is available for weighing systems that cannot be verified, Menu layout

see chap. 8.1

Navigation in the menu:

Call up menu

Switch-on balance and during the selftest press .

Press , , subsequently, the first menu

block „PO CHK“ will be displayed.

Select menu block

Select setting

Change settings

Acknowledge setting /

exit the menu

Return to weighing

mode

With help of , the individual menu items can be

selected one after the other.

Confirm selected menu item by pressing . The

To change to the available settings, press the

navigations keys as described in chap. 2.1.

Either save by pressing or cancel by pressing .

Press repeatedly to exit menu.

36 KFB/KFN-TM-BA_IA-e-1220

Page 37

Menu block

Main menu

Menu item

Submenu

Acoustic signal for weighing with tolerance range

switched off

P1 REF

P2 COM

MODE

CONT

Continuous data output

ST1

One output for stable weighing value

STC

Continuous data output of stable weighing

values

PR1

Output after pressing

PR2

Manual totalizing, see chap. 7.8.

added to the summation memory and issued.

AUTO*

For automatic add-up see chap. 7.9.

memory on unloading of weighing scale.

wirel

kit 1

BAUD

Available Baudrate: 600, 1200, 2400, 4800, 9600*

8.1 Overview non verifiable weighing systems

(contacts of circuit board [K1] not short-circuited)

Available settings / explanation

PO CHK

Weighing with

tolerance range,

see chap. 7.7

Zero point

settings

SET H Upper limit value, input see chap. 7.7

SET LO Lower limit value, input see chap. 7.7

PCS H Not documented

PCS L Not documented

BEEP no

ok Audio sound when load is within tolerance limits

nG Audio sound when load is beyond tolerance limits

A2n0 Automatic zero point correction (Autozero) by changing the

display, digits selectable (0.5d, 1d, 2d, 4d)

0AUto Zero setting range

Load range where the display after switching-on the

balance is set to zero. Selectable 0, 2, 5, 10, 20, 50, 100

%

0rAGE Zero setting range

Load range where the display is set to zero by pressing

. Selectable 0, 2, 4, 10 , 20* , 50, 100%.

0tArE Automatic taring „on / off“, taring range adjustable in menu

item „0Auto“.

SPEEd Not documented

Zero Zero point setting

Interface

parameter

ASK

Press and the weighing value will be

This function is used to issue and add individual

weighing values automatically to the summation

For remote control commands, see chap. 10.4

Not documented

KFB/KFN-TM-BA_IA-e-1220 37

Page 38

Pr

7E1

7 bits, even parity

7o1

7 bits, odd parity

8n1*

8 bits, no parity

PTYPE

tPUP*

Standard printer setting

LP50

Not documented

Lab

Lab x

(Lab 0*)

Prt

Prt x

(Prt 0*)

LAnG

eng*

Standard settings English

chn

P3 CAL

COUNT

Display internal resolution

DECI

Position of the decimal dot

DUAL

Setting balance type, capacity (Max) and readability (d)

off

Single-range balance

R1 inc

Readability

R1 cap

Capacity

on

Dual range balance

R1 inc

Readability 1st weighing range

R1 cap

Capacity 1st weighing range

R2 inc

Readability 2nd weighing range

R2 cap

Capacity 2nd weighing range

CAL

noLin

For adjustment, see chap. 6.9.2

Liner

For linearization, see chap. 6.10.2

GrA

Not documented

on

Keyboard lock enabled, see chap. 7.11

off*

Keyboard lock disabled

on

Animal weighing enabled, see chap. 7.10

off*

Animal weighing disabled

kg

on* off

g on off*

lb

on off*

oz

on off*

tJ

on off

HJ

on off

Configuration

data

see chap. 12.4

For data output format, see chap.8.2, tab. 1

P4 OTH

LOCK

ANM

P5 Unt

Switch-over

weighing unit,

see chap. 7.5

P6 xcl Not documented

P7 rst

Use to reset balance settings to factory default.

P8 uwb Not documented

Factory settings are marked by *.

38 KFB/KFN-TM-BA_IA-e-1220

Page 39

Menu block

Main menu

Menu item

Submenu

Acoustic signal for weighing with tolerance

range switched off

Audio sound when load is within tolerance

limits

Audio sound when load is beyond tolerance

limits

8.2 Overview verified weighing systems

(contacts of circuit board [K1] short-circuited by means of jumper)

In verified weighing systems the access to „P2 mode and „P4 tAr“ is locked.

KERN KFB-TM:

To disable the access lock, destroy the seal and actuate the adjustment switch.

Position of the adjustment switch see chap. 6.11.

KERN KFN-TM:

In order to unlock the access, the seal must be destroyed and both contacts of the

printed circuit board [K2] must be short-circuited by a jumper, see chap. 6.11.

Attention:

After destruction of the seal the weighing system must be re-verified by an

authorised agency and a new verification wire/seal mark fitted before it can be

reused for applications subject to verification.

PO CHK

Weighing with

tolerance range,

see chap. 7.7

SET H

SET LO

PCS H Not documented

PCS L Not documented

BEEP

Available settings / explanation

Upper limit value, input see chap. 7.7

Lower limit value, input see chap. 7.7

no

ok

ng

KFB/KFN-TM-BA_IA-e-1220 39

Page 40

P1 COM

MODE

CONT

Continuous data output

ST1

One output for stable weighing value

STC

Continuous data output of stable weighing

values

PR1

Output after pressing

PR2

Manual totalizing, see chap. 7.8

added to the summation memory and issued.

AUTO

ASK

For remote control commands, see chap. 10.4

baud

Available Baudrate: 600, 1200, 2400, 4800, 9600

Pr

7E1

7 bits, even parity

7 bits, odd parity

8 bits, no parity

PtYPE

Standard printer setting

Not documented

Lab

Prt

Interface

parameter

Press and the weighing value will be

For automatic totalizing see chap. 7.9

This function is used to issue and add

individual weighing values automatically to the

summation memory on unloading of weighing

scale.

7o1

8n1

tPUP

LP50

Lab x

Details see following table 1

Prt x

40 KFB/KFN-TM-BA_IA-e-1220

Page 41

P2 mode

SiGr

Single-range balance

COUNT

Display internal resolution

DECI

Position of the decimal dot

Div.

Readability [d] / verification value[s]

CAP

Balance capacity [Max]

noLin

Adjustment, see chap. 6.9

LinEr

Linearisation, see chap. 6.10

GrA

Not documented

dUAL 1

Dual range balance

scales will remain in 2nd range.

COUNT

Display internal resolution

DECI

Position of the decimal dot

Readability [d] / verification value [e]

1. weighing range

Readability [d] / verification value [e]

2. weighing range

Weighing scale capacity [max]

1. Weighing range

Weighing scale capacity [max]

2. Weighing range

noLin

Adjustment, see chap. 6.9

LinEr

For linearization, see chap. 6.10

GrA

Not documented

dUAL 2

Multi-interval balance

changed during loading and unloading.

COUNT

Display internal resolution

DECI

Position of the decimal dot

Readability [d] / verification value [e]

1. weighing range

Readability [d] / verification value [e]

2. weighing range

Weighing scale capacity [max]

1. Weighing range

Weighing scale capacity [max]

2. Weighing range

noLin

Adjustment, see chap. 0

LinEr

Linearisation, see chap. 6.10

GrA

Not documented

P3 OTH

on

Keyboard lock enabled

off

Keyboard lock disabled

on

Animal weighing enabled

off

Animal weighing disabled

P4 tAr

Confirm input by .

Konfigurationsdaten

CAL

Balance with two weighing ranges and different maximum load

and weighing ranges and interval sizes but only one loadsupporting pan, whereby each range extends from zero to the

respective maximum capacity. When load is removed, weighing

div 1

div.

div 2

CAP 1

CAP

CAP 2

CAL

Weighing scales with one weighing range subdivided into partial

weighing ranges, each providing a different scale interval. The

scale interval depends on the applied load and is automatically

div 1

div.

div 2

CAP 1

CAP

CAP 2

CAL

LOCK

s. Kap. 7.10 / 7.11

ANM

Restricted taring

range

KFB/KFN-TM-BA_IA-e-1220 41

Press , the current setting will be displayed. Using the

navigation buttons (see chap. 2.1.1) select the desired setting, the

active digit is flashing.

Page 42

NT:

0.666 kg

GS:

0.222 kg

NT:

TOTAL:

0.222 kg

0.222 kg

NT:

0.666 kg

GS:

0.222 kg

NT:

TOTAL:

0.222 kg

0.444 kg

NT:

0.666 kg

GS:

0.222 kg

NT:

TOTAL:

0.222 kg

0.666 kg

GS:

0.888 kg

NT:

0.666 kg

GS:

0.222 kg

NT:

TOTAL:

0.222 kg

0.888 kg

NO:

4

NO:

4

NO:

TOTAL:

4

1.000 kg

NO:

5

NO:

5

NO:

5

NO:

TOTAL:

5

1.222 kg

NO:

6

NO:

6

NO:

6

NO:

TOTAL:

6

1.444 kg

NO:

7

NO:

7

NO:

7

NO:

TOTAL:

7

1.666 kg

GS / GW

Gross weight

NT

Net weight

TW

Tare weight

NO

Number weighing processes

TOTAL

Total of all individual weighings

Tab. 1. Printout examples

Lab

0 1 2 3

pr

0

1

2

3

4

5

GS: 0.888 kg

GS: 0.888 kg

GS:

NO:

GS:

GS:

11/11/11

0.888 kg

4

0.888 kg

0.888 kg

TW:

GW:

TW:

GW::

TW:

GW::

TW:

GW::

NT:

TW:

GW::

NT:

TW:

GW::

0.222 kg

0.888 kg

0.222 kg

0.888 kg

0.222 kg

0.888 kg

0.222 kg

0.888 kg

0.666 kg

0.222 kg

0.888 kg

0.666 kg

0.222 kg

0.888 kg

TOTAL:

TOTAL:

TOTAL:

TOTAL:

GS:

TOTAL:

GS:

TOTAL:

0.222 kg

0.444 kg

0.666 kg

0.888 kg

0.222 kg

1.000 kg

0.222 kg

1.222 kg

TW:

GW:

TW:

GW:

TW:

GW:

TW:

GW:

NT:

TW:

GW:

NT:

TW:

GW:

0.666 kg

0.888 kg

0.666 kg

0.888 kg

0.666 kg

0.888 kg

0.666 kg

0.888 kg

0.222 kg

0.666 kg

0.888 kg

0.222 kg

0.666 kg

0.888 kg

6

7

GS:

GS:

0.888 kg

0.888 kg

NT:

TW:

GW::

NT:

TW:

GW::

0.666 kg

0.222 kg

0.888 kg

0.666 kg

0.222 kg

0.888 kg

GS:

TOTAL:

GS:

TOTAL:

0.222 kg

1.444 kg

0.222 kg

1.666 kg

NT:

TW:

GW:

NT:

TW:

GW:

0.222 kg

0.666 kg

0.888 kg

0.222 kg

0.666 kg

0.888 kg

42 KFB/KFN-TM-BA_IA-e-1220

Page 43

Value outside the A/D changer

9 Service, maintenance, disposal

9.1 Clean

• Before cleaning, disconnect the appliance from the operating voltage.

• Do not use aggressive detergents (solvents or similar).

9.2 Service, maintenance

The appliance may only be opened by trained service technicians who are authorized

by KERN.

Before opening, disconnect from power supply.

9.3 Disposal

Disposal of packaging and appliance must be carried out by operator according to

valid national or regional law of the location where the appliance is used.

9.4 Error messages

Error

message

Description Possible causes

- - - - -

Maximum load exceeded

- - ol - -

Err 1

Err 2

Err 4 Zeroing range exceeded due

Err 5 Keyboard error

Err 6

Incorrect data input

Incorrect time entry

to switching-on balance or

pressing (normally 4%

max)

range

• Unload weighing system or reduce

preload.

• Follow format “yy:mm:dd“

• Follow format “hh:mm:ss“

• Object on the weighing plate

• Overload when zeroing

• Weighing plate not installed

• Damaged weighing cell

Err 9 Stability display does not

appear

KFB/KFN-TM-BA_IA-e-1220 43

• Damaged electronics

• Check the environmental

conditions.

Page 44

Err 10 Communication error

Err 15 Gravitation error

Err 17 Taring range exceeded

Fai l h /

Fai l l

Err P

Ba lo /

Lo ba

Should other error messages occur, switch balance off and then on again. If the error

message remains inform manufacturer.

Adjustment error

Printer error

Battery very low

• No data

• Range 0.9 ~ 1.0

• Reduce load

• Repeat adjustment.

• Check communication parameters

• Recharge battery

44 KFB/KFN-TM-BA_IA-e-1220

Page 45

Pin 5 signal earth

10 Da t a out put RS 2 32C

You can print weighing data automatically via the RS 232C interface or manually by

pressing via the interface according to the setting in the menu.

This data exchange is asynchronous using ASCII - Code.

The following conditions must be met to provide successful communication between

the weighing system and the printer.

• Use a suitable cable to connect the display unit to the interface of the printer.

Faultless operation requires an adequate KERN interface cable.

• Communication parameters (baud rate, bits and parity) of display unit and

printer must match. For a detailed description of interface parameters see

chap. 8, menu block „P1 COM“ or ‚“P2 COM“

10.1 Technic al da ta

Connection 9 pin d-subminiature bushing

Pin 2 input

Pin 3 output

Baud rate 600/1200/2400/4800/9600 may be selected

Parity 8 bits, no parity / 7 bits, even parity / 7 bits, odd parity

KFB/KFN-TM-BA_IA-e-1220 45

Page 46

ST

Stable value

US

Instable value

GS

Gross weight

NT

Net weight

<lf>

Space line

<lf>

Space line

ST, GS 1.000kg

****************************

10.2 Printer mode

Printout examples (KERN YKB-01N):

• Weighing

• Counting

10.3 Output log

Weighing mode

10.4 Remote control instructions

PCS 100

****************************

HEADER1: ST=STABLE, US=UNSTABLE

HEADER2: NT=NET, GS=GROSS

Command Significance

T <CR><LF> Taring

Z <CR><LF> Zeroing

W <CR><LF> Send all weighing details

S <CR><LF> Send stable weight value

P <CR><LF> Piece counting

46 KFB/KFN-TM-BA_IA-e-1220

Page 47

The displayed weight does

not glow.

• Mains power supply interrupted (mains cable

defective).

• Power supply interrupted.

• (Rechargeable) batteries are inserted incorrectly or

empty

• No (rechargeable) batteries inserted.

The displayed weight is

• Table/floor vibrations

• Weighing pan has contact with other objects.

possible)

The weighing result is

obviously incorrect

• Adjustment is no longer correct.

• Great fluctuations in temperature.

possible)

11 Instant help

In case of an error in the program process, briefly turn off the display unit and

disconnect from power supply. The weighing process must then be restarted from the

beginning.

Help:

Fault Possible cause

• The display unit is not switched on.

permanently changing

Should other error messages occur, switch display unit off and then on again. If the

error message remains inform manufacturer.

• Draught/air movement

• Electromagnetic fields / static charging (choose

different location/switch off interfering device if

• The display of the balance is not at zero

• Warm-up time was ignored.

• Electromagnetic fields / static charging (choose

different location/switch off interfering device if

KFB/KFN-TM-BA_IA-e-1220 47

Page 48

12 Installing displa y unit / weighi ng bridge

• Installation / configuration of a weighing system must be carried out

12.1 Technic al da ta

Supply voltage: 5 V/150mA

Max. signal voltage 0-10 mV

Zeroing range 0-2 mV

Sensitivity 2-3 mV/V

Resistance parameter 80 - 100 Ω, max 4 items per 350 Ω load cell

by a well acquainted specialist with the workings of weighing

balances.

12.2 Weighing system design

The display unit is suitable for connection to any analogue platform in compliance

with the required specifications.

The following data must be established before selecting a weighing cell:

• Weighing balance capacity

This usually corresponds to the heaviest load to be weighed.

• Preload

This corresponds to the total weight of all parts that are to be placed on the

weighing cell such as upper part of platform, weighing pan etc.

• Total zero setting range

This is composed of the start-up zero setting range (± 2%) and the zero

setting range available to the user via the ZERO-key (2%). The total zero

setting range equals therefore 4 % of the scale’s capacity.

The addition of weighing scales capacity, preload and the total zero setting

range give the required capacity for the weighing cell.

To avoid overloading of the weighing cell, include an additional safety

margin.

• Smallest desired display division

• Verifiability, if required

The application of the display unit as a verified weighing system requires

that you short-circuit the two contacts [K1] of the circuit board, using a

jumper; for position see chap. 6.11.

Remove the jumper for weighing systems not able to be verified.

48 KFB/KFN-TM-BA_IA-e-1220

Page 49

12.3 How to connect the platform

Disconnect the display unit from the power supply.

Solder the individual leads of the load cell cable onto the circuit board. See

diagram below.

Please see diagram below for plug allocation.

Use the connecting cable to connect the platform to the display unit, see chap. 2,

item [7]. Tighten the coupling ring.

KFB/KFN-TM-BA_IA-e-1220 49

Page 50

12.4 Configure displ ay unit

12.4.1 Verified weighing systems

(contacts of circuit board [K1] short-circuited by means of jumper)

For menu overview see chap. 8.2.

In verified weighing systems the menu item for calibration „P2 mode“ is blocked.

KERN KFB-TM:

To disable the access lock, destroy the seal and actuate the adjustment switch.

Position of the adjustment switch see chap. 6.11

KERN KFN-TM:

To override the blocked access you will have to destroy the seal before calling up the

menu and to short-circuit the two contacts on the circuit board [K2], using a jumper

(See chap. 6.11).

Attention:

After destruction of the seal the weighing system must be re-verified by an

authorised agency and a new verification wire/seal mark fitted before it can be

reused for applications subject to verification.

Call up menu:

Switch-on balance and during the selftest press .

Press , , subsequently, the first menu block

„PO CHK“ will be displayed.

Press repeatedly until „P2 mode“ will be displayed.

Operate the adjustment switch (models KFB-TM).

Press and use to select the weighing scales type.

Single-range balance

Dual range balance

Multi-interval balance

50 KFB/KFN-TM-BA_IA-e-1220

Page 51

Example single range scales (d = 10 g, max. 30 kg)

Confirm selected weighing scales type by pressing ; the

first menu item „COUNT“ will be shown.

1. Display internal resolution

Press , the internal resolution will be shown.

Return to menu by .

Press to select the next menu item.

2. Position decimal point

Press , the currently set position of the decimal dot is

displayed.

Press to select the desired setting.

Options 0, 0.0, 0.00, 0.000, 0.0000.

Confirm input by .

Press to select the next menu item.

3. Readability

Press and current setting will be displayed.

Select desired setting by .

Options 1, 2, 5, 10, 20, 50.

Confirm entry by .

Press to select the next menu item.

KFB/KFN-TM-BA_IA-e-1220 51

Page 52

6.10.1 for linearisation

4. Capacity

Press , the current setting will be displayed.

Using the navigation buttons (see chap. 2.1.1) select the

desired setting, the active digit is flashing.

Confirm input by .

Press to select the next menu item.

5. Adjustment / linearization

Adjustment or linearization is required after entering

configuration data.

For carrying out adjustment see chap. 6.9.1/step 6 or chap.

52 KFB/KFN-TM-BA_IA-e-1220

Page 53

Example dual range scales (d = 2 / 5 g, max. 6 / 15 kg)

Confirm selected weighing scales type by ; the first

menu item „COUNT“ will be shown.

1. Display internal resolution

Press , the internal resolution will be shown.

Return to menu by .

Press to select the next menu item.

2. Position decimal point

Press , the currently set position of the decimal dot is

displayed.

Use to select the desired setting.

Options 0, 0.0, 0.00, 0.000, 0.0000.

Confirm input by .

Press to select the next menu item.

KFB/KFN-TM-BA_IA-e-1220 53

Page 54

3. Readability

Press , the display used to enter readability/verification

value for first weighing range will appear.

Press , the current setting will be displayed.

Select desired setting with and acknowledge by .

Press to enter the next menu item for

readability/verification value for second weighing range.

Press and current setting will be displayed.

Select desired setting with and acknowledge by .

Press , the unit will return to the menu

Press to select the next menu item.

54 KFB/KFN-TM-BA_IA-e-1220

Page 55

6.10.1 for linearisation

4. Capacity

Press and the display for entering the capacity for the

first weighing range will appear.

Press and current setting will be displayed.

Select desired setting with and acknowledge by .

Press to select the next menu item used to enter the

capacity for the second weighing range.

Press and current setting will be displayed.

Select desired setting with and acknowledge by .

Press , the unit will return to the menu

Use toselect next menu item.

5. Adjustment / linearization

Adjustment or linearization is required after entering

configuration data.

For carrying out adjustment see chap. 6.9.1/step 6 or chap.

Acknowledge using , the current setting is displayed.

Acknowledge by , select desired setting with

= Adjustment

= Linearisation

KFB/KFN-TM-BA_IA-e-1220 55

Page 56

Press repeatedly to exit menu.

12.4.2 Non verifiable weighing systems

(contacts of circuit board [K1] not short-circuited )

+ For menu overview see chap. 8.1.

Call up menu

Switch-on balance and during the selftest press .

Press , , subsequently , the first menu block

„PO CHK“ will be displayed.

Press repeatedly until „CAL“ will be displayed.

Press , the first menu item „COUNT“ will be displayed.

Navigation in the menu

With help of , the individual menu items can be

selected one after the other.

Confirm selected menu item by pressing . The current

setting will be displayed.

To change to the available settings, press the navigations

keys as described in chap. 2.1.1.

Either save by pressing or cancel by pressing .

56 KFB/KFN-TM-BA_IA-e-1220

Page 57

Parameter selection

1. Display internal resolution

Press , the internal resolution will be shown.

Return to menu by .

Use to select another menu item.

2. Position decimal point

Press , the currently set position of the decimal dot is

displayed.

To make changes using the navigation keys (See chap.

2.1.1), select the desired setting. Options 0, 0.0, 0.00,

0.000, 0.0000.

Confirm input by .

Use to select another menu item.

3. Weighing scales type, capacity and readability

Press and current setting will be displayed.

Select desired setting by .

„off“ Single-range balance

„on“ Dual range balance

Press to confirm, the display for entering readability (for

dual range scales for the first weighing range) appears.

Press , the current setting will be displayed.

KFB/KFN-TM-BA_IA-e-1220 57

Page 58

the current setting will be shown (such as max. =

Select desired setting with and acknowledge by .

Press , the display for entering capacity will appear (at

dual range balance for the first range).

Press ,

2000kg).

Using the navigation buttons (see chap. 2.1.1) select the

desired setting, the active digit is flashing.

Acknowledge with .

In a single-range balance the entry of capacity / readability

is finished.

either in single-range balance

Press , the unit will return to the menu Press to call

up next menu item „CAL“.

or

In a dual range balance enter readability/verification value

and capacity of the second weighing range.

Press , the display for entering the capacity of the

second weighing range will appear.

Press , the current setting will be displayed.

Using the navigation buttons (see chap. 2.1.1) select the

desired setting, the active digit is flashing.

Confirm input by .

58 KFB/KFN-TM-BA_IA-e-1220

Page 59

6.10.2 for linearisation

Press , the display for entering the readability of the

second weighing range will appear.

Press , the current setting will be displayed.

Select desired setting with and acknowledge by .

Press , the unit will return to the menu

Press to call next menu item.

4. Adjustment or linearisation

Adjustment or linearisation is required after entering

configuration data.

For carrying out adjustment see chap. 6.9.2/step 4 or chap.

Acknowledge using , the current setting is displayed.

Press to confirm, press to select the desired

setting

noLin = Adjustment

LineAr = Linearisation

KFB/KFN-TM-BA_IA-e-1220 59

Page 60

KERN & Sohn GmbH

D-72322 Balingen-Frommern

Phone: 0049-[0]7433- 9933-0

D

Konformitätserklärung

Wir erklären hiermit, dass das Produkt, auf das sich diese Erklärung bezieht,

mit den nachstehenden Normen übereinstimmt.

EN

Declaration of

conformity

We hereby declare that the product to which this declaration refers conforms

to the following standards.

CZ

Prohlášení o

shode

Tímto prohlašujeme, že výrobek, kterého se toto prohlášení týká, je v souladu

s níže uvedenými normami.

E

Declaración de

conformidad

Manifestamos en la presente que el producto al que se refiere esta

declaración está de acuerdo con las normas siguientes

F

Déclaration de

conformité

Nous déclarons avec cela responsabilité que le produit, auquel se rapporte la

présente déclaration, est conforme aux normes citées ci-après.

I

Dichiarazione di

conformità

Dichiariamo con ciò che il prodotto al quale la presente dichiarazione si

riferisce è conforme alle norme di seguito citate.

NL

Conformiteitverklaring

Wij verklaren hiermede dat het product, waarop deze verklaring betrekking

heeft, met de hierna vermelde normen overeenstemt.

P

Declaração de

conformidade

Declaramos por meio da presente que o produto no qual se refere esta

declaração, corresponde às normas seguintes.

PL

Deklaracja

zgodności

Niniejszym oświadczamy, że produkt, którego niniejsze oświadczenie dotyczy,

jest zgodny z poniższymi normami.

RUS

Заявление о

соответствии

Мы заявляем, что продукт, к которому относится данная декларация,

соответствует перечисленным ниже нормам.

EU Directive

Standards

2004/108/EC

EN55022: 2006 A1:2007

EN55024: 1998+A1:2001+A2:2003

2006/95/EC

EN 60950-1:2006

EN 60065:2002+A1:2006

2005/32/EC

Date: 13.10.2011

Signature:

KERN & Sohn GmbH

Management

KERN & Sohn GmbH, Ziegelei 1, D-72336 Balingen, Tel. +49-[0]7433/9933-0

Fax +49-[0]7433/9933-149, E-Mail: info@kern-sohn.com, Internet: www.kern-sohn.com

13 De c laration of Conformity / Type Approval Certificate /

Test Certificate

Postbox 4052

E-Mail: info@kern-sohn.de

Fax: 0049-[0]7433-9933-149

Internet: www.kern-sohn.de

Declaration of confor m ity

EC Declaration of Conformity EC-Declaration of -Conformity

EC- Déclaration de conformité EC-Declaración de Conformidad

EC-Dichiarazione di conformità EC-Conformiteitverklaring

EC- Declaração de conformidade EC- Prohlášení o shode

EC-Deklaracja zgodności EC-Заявление о соответствии

Electronic Balance:

KERN KFB-TM, KFN-TM, BFB, BFN, IFB, NFB, SFB, UFA, UFB, UFN

EN61000-3-3:1995+A1:2001+A2:2005

60 KFB/KFN-TM-BA_IA-e-1220

Page 61

VAT No. DK 12275110

EC Type-Approval Certificate

No. DK 0199.202 Revision 1

KFN-TM / KFB-TM / BFB / IFB / SFB / UFB / UFN / NFB /

BFN / NFN

NON-AUTOMATIC WEIGHING INSTRUMENT

Issued by DELTA Danish Electronics, Light & Acoustics

EU - Notified Body No. 0199

In accordance with the requirements for the non-automatic weighing instrument of

EC Council Directive 2009/23/EC.

Issued to Kern & Sohn GmbH

Ziegelei 1

D 72336 Balingen-Frommern

GERMANY

In respect of Non-automatic weighing instrument designated KFN-TM / KFB-TM / BFB /

IFB / SFB / UFB / UFN / NFB / BFN / NFN with variants of modules of load

receptors, load cells and peripheral equipment.

Accuracy class III and IIII

Maximum capacity, Max: From 1 kg up to 199 950 kg

Verification scale interval: e = Max / n

Maximum number of verification scale intervals: n = 6000 for single-interval

and n = 2×3000 for multi-range and multi-interval (however, dependent on

environment and the composition of the modules).

Variants of modules and conditions for the composition of the modules are set

out in the annex.

The conformity with the essential requirements in annex 1 of the Directive is met by the ap-

plication of the European Standard EN 45501:1992/AC:1993 and WELMEC 2.1:2001.

Note: This certificate is a revised edition which replaces previous revisions.

The principal characteristics and approval conditions are set out in the descriptive

annex to this certificate.

The annex comprises 14 pages.

DELTA

Danish Electronics,

Light & Acoustics

Venlighedsvej 4

2970 Hørsholm

Denmark

Tel. (+45) 72 19 40 00

Fax (+45) 72 19 40 01

www.delta.dk

Issued on 2011-12-19