Page 1

KERN & Sohn GmbH

Ziegelei 1

E-mail: info@kern-sohn.com

Phone: +49-[0]7433-9933-0

www.kern-sohn.com

Operating manual

Analytical and precision balances

KERN ALJ/ALS/PLJ/PLS

Type TALJG-A / TALSG-A / TPLJG-A / TPLSG-A

Version 1.2

2021-06

GB

D-72336 Balingen

Fax: +49-[0]7433-9933-149

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 2

GB

KERN ALJ/ALS/PLJ/PLS

Analytical and precision balances

Version 1.2 2021-06

Operating manual

Contents

1 Technical specification ................................................................................. 5

2 Declaration of Conformity ........................................................................... 15

3 Device overview ........................................................................................... 16

3.1 Parts .........................................................................................................................16

3.2 Operating controls ....................................................................................................20

3.2.1 Keyboard overview ................................................................................................................... 20

3.2.2 Navigation buttons / Introducing the numerical value .............................................................. 21

3.3 Display overview .......................................................................................................22

3.4 User interface ...........................................................................................................23

4 Basic instructions ........................................................................................ 24

4.1 Intended use .............................................................................................................24

4.2 Non-intended use .....................................................................................................24

4.3 Warranty ...................................................................................................................24

4.4 Testing equipment supervision .................................................................................24

5 Basic safety instruct io n s ............................................................................ 25

5.1 Compliance with the instructions included in the user manual ...................................25

5.2 Personnel training .....................................................................................................25

6 Transport and storage ................................................................................. 25

6.1 Checking during reception ........................................................................................25

6.2 Packaging / return transport ......................................................................................25

7 Unpacking, positioning and start-up .......................................................... 28

7.1 Installation place, operation place .............................................................................28

7.2 Unpacking and check................................................................................................29

7.2.1 Setting....................................................................................................................................... 29

7.3 Power supply ............................................................................................................33

7.4 Operation with battery supply (solely the model PLS 420-3F) ...................................33

7.5 Operator language selection .....................................................................................34

7.6 Connecting peripherals .............................................................................................34

8 Adjustment ................................................................................................... 34

8.1 Adjustment mode selection .......................................................................................35

8.2 Automatic adjustment using the internal weight ........................................................36

8.3 Adjustment using the internal weight after the Model CAL button is pressed (models

ALJ/PLJ) ..............................................................................................................................37

8.4 Adjustment using the external weight ........................................................................38

8.5 Changing the weight of the internal calibration weight...............................................39

8.6 Adjustment report display/print ..................................................................................40

8.7 Verification ................................................................................................................41

9 Basic mode ................................................................................................... 42

2 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 3

9.1 Switching the scale on and off ..................................................................................42

9.2 Resetting ..................................................................................................................42

9.3 Ordinary weighing .....................................................................................................43

9.4 Weighing range indicator ..........................................................................................43

9.5 Taring .......................................................................................................................44

9.6 Weighing using the under-scales weighing hanger ...................................................45

11 Setup menu .................................................................................................. 46

11.1 Weight units (unit1/unit2) ..........................................................................................49

11.2 RS-232 .....................................................................................................................50

11.3 Transmission speed ..................................................................................................51

11.4 Aut o zero ..................................................................................................................52

11.5 Filter .........................................................................................................................53

11.6 Stability .....................................................................................................................53

11.7 Set ting the display contrast .......................................................................................54

11.8 Dis p lay backlight .......................................................................................................55

11.9 Autom atic switch-off function ....................................................................................55

11.10 Setting time and date ............................................................................................56

11.11 User interface language ........................................................................................57

12 Main menu “Applications” .......................................................................... 58

12.1

12.1.1 Determining the reference value by weighin g ...................................................................... 59

12.1.2 Introducing the reference weight in the numerical value ..................................................... 62

12.1.3 Automatic optimization of the reference value ..................................................................... 63

12.2 Det er mining density using the equipment for the under-scales weighing hanger ......64

12.2.1 Determining solid body density using the equipment for the under-scales weighing hanger

64

12.2.2 Liquid density determination ................................................................................................ 68

12.3 Formulation ...............................................................................................................70

12.3.1 Free formulation ................................................................................................................... 70

12.3.1 Formulation defining and implementat ion ............................................................................ 72

12.4 Test weighing ...........................................................................................................81

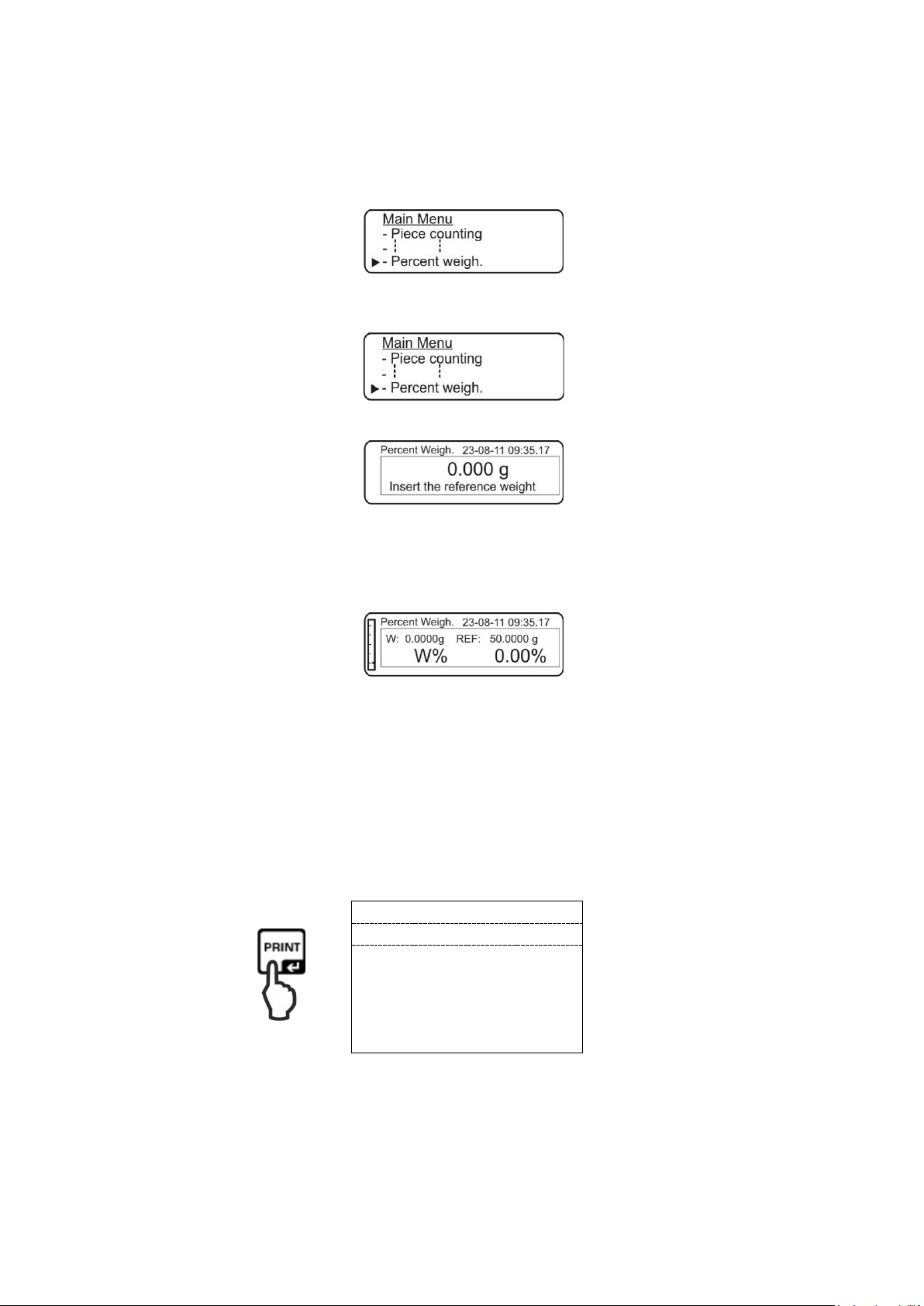

12.5 Det er mining the percentage value ............................................................................84

12.5.1 Entering the reference weight by weighing .......................................................................... 84

12.5.2 Introducing the reference weight in the numerical value ..................................................... 85

12.6 Weighing animals .....................................................................................................86

12.7 Peak value function ..................................................................................................87

12.8 GLP function (Good Laboratory Practice) .................................................................88

Counting the number of pieces .................................................................................59

13 RS-232C interface ........................................................................................ 90

13.1 Technical specification ..............................................................................................90

13.2 Use of t he scale plug pins .........................................................................................90

13.3 Interface....................................................................................................................

13.3.1 Printer connection ................................................................................................................ 92

91

13.4 Dat a transmission .....................................................................................................92

13.5 Data transmission formats ........................................................................................92

13.6 Rem ot e control command .........................................................................................94

14 Error messages ............................................................................................ 95

15 Maintenance, service and disposal ............................................................ 95

15.1 Cleaning ...................................................................................................................95

15.2 Maintenanc e and service ..........................................................................................95

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 3

Page 4

15.3 Disposal ....................................................................................................................96

16 Help for any minor failures ......................................................................... 96

17 Ionizing unit (factory option for KERN ALJ-A03) ...................................... 97

17.1 General information ..................................................................................................97

17.2 Basic s af ety instructions ...........................................................................................97

17.3 Technical specification ..............................................................................................99

17.4 Device overview ........................................................................................................99

17.5 Start ........................................................................................................................ 100

17.6 Intended use ........................................................................................................... 101

17.7 Cleaning ................................................................................................................. 101

4 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 5

1 Technical specification

counting the number of pieces in

counting the number of pieces in

KERN ALJ 160-4A ALJ 210-5A ALJ 200-5DA

Product number / type TALJG 160-4-A

Weighing range (Max) 160 g

Interval (d) 0.1 mg

Reproducibility 0.1 mg

Linearity ±0.3 mg

Settling time (standard) 4 s

Minimum part weight when

1 mg

laboratory conditions*

Minimum part weight when

10 mg

standard conditions**

Heating time 8 h

Adjustment weight internal

Number of reference pieces

when counting the number of

pieces

10, 25, 50, 100, selected freely

TALJG 210-5-A

210 g

0.01 mg

0.05 mg

± 0.1 mg

6 sec.

1 mg

10 mg

TALJG 220-5-A

82 g/220 g

0.01 mg/0.1 mg

0.04 mg/0.1 mg

±0.1 mg/0.2 mg

10 s

1 mg

10 mg

Weight units

Power supply

Operating temperature +15°C ... +30°C

Air humidity max. 80% (non-condensing)

Housing (W × D × H) mm 210 × 340 × 330

Wind breaker dimensions

(W × D × H) mm

Scale plate (stainless steel) Ø 80 mm

(Net) weight kg 6.5 kg 7 kg

Interface RS-232C

Contamination degree 2

Overvoltage category Category II

Installation height

above sea level

tl (Hong Kong), tl (Singapore, Malaysia), tl (Taiwan), pen

160 × 140 × 205

(inner)

190 × 195 × 225

(outer)

ct, g, gn, lb, mo, oz, ozt,

24 V DC, 1A

160 x 170 x 225

(inner)

172 x 185 x 245

(outer)

up to 4000 m

160 × 170 × 225

190 × 195 × 225

(inner)

(outer)

Location site Solely indoors

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 5

Page 6

KERN ALJ 250-4A ALJ 310-4A ALJ 500-4A

counting the number of pieces in

counting the number of pieces in

Product number / type TALJG 250-4-A TALJG 310-4-A TALJG 510-4-A

Weighing range (Max) 250 g 310 g 510 g

Interval (d) 0.1 mg 0.1 mg 0.1 mg

Reproducibility 0.1 mg 0.1 mg 0.2 mg

Linearity ±0.3 mg ±0,3 mg ±0,4 mg

Settling time (standard) 4 s 4 s 4 s

Minimum part weight when

1 mg 1 mg 1 mg

laboratory conditions*

Minimum part weight when

10 mg 10 mg 10 mg

standard conditions**

Heating time 8 h

Adjustment weight internal

Number of reference pieces

when counting the number of

pieces

10, 25, 50, 100, selected freely

Weight units

Power supply

Operating temperature +5°C ... +30°C

Air humidity max. 80% (non-condensing)

Housing (W × D × H) mm 210 × 340 × 330

Wind breaker dimensions

(W × D × H) mm

Scale plate (stainless steel) Ø 80 mm

(Net) weight kg 6.5 kg

Interface RS-232C

Contamination degree 2

Overvoltage category Category II

Installation height

above sea level

tl (Hong Kong), tl (Singapore, Malaysia), tl (Taiwan), pen

ct, g, gn, lb, mo, oz, ozt,

24 V DC, 1A

160 × 140 × 205 (inner)

190 × 195 × 225 (outer)

up to 4000 m

Location site Solely indoors

6 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 7

KERN ALJ 160-4AM ALJ 250-4AM

Product number / type TALJG 160-4M-A TALJG 250-4M-A

Weighing range (Max) 160 g 250 g

Interval (d) 0.1 mg 0.1 mg

Reproducibility 0.1 mg 0.1 mg

Linearity ±0.3 mg ±0,3 mg

Verification scale interval (e) 1 mg 1 mg

Verification class I I

Minimum weight (Min) 10 mg 10 mg

Settling time (standard) 4 s 4 s

Minimum part weight when counting

the number of pieces in laboratory

conditions*

Minimum part weight when counting

the number of pieces in standard

conditions**

1 mg 1 mg

10 mg 10 mg

Heating time 8 h

Adjustment weight internal

Number of reference pieces

when counting the number of pieces

Weight units ct, g

Power supply

Operating temperature +15°C ... +30°C

Air humidity max. 80% (non-condensing)

Housing (W × D × H) mm 210 × 340 × 330

Wind breaker dimensions

(W × D × H) mm

Scale plate (stainless steel) Ø 80 mm

(Net) weight kg 6,5

Interface RS-232C

Contamination degree 2

10, 25, 50, 100, selected freely

24 V DC, 1A

160 × 140 × 205 (inner)

190 × 195 × 225 (outer)

Overvoltage category Category II

Installation height

above sea level

Location site Solely indoors

up to 4000 m

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 7

Page 8

KERN ALS 160-4A ALS 250-4A

Product number / type TALSG 160-4-A TALSG 250-4-A

Weighing range (Max) 160 g 250 g

Interval (d) 0.1 mg 0.1 mg

Reproducibility 0.1 mg 0.1 mg

Linearity ±0.3 mg ±0,3 mg

Settling time (standard) 4 s 4 s

Minimum part weight when counting

the number of pieces in laboratory

conditions**

Minimum part weight when counting

the number of pieces in standard

conditions**

Heating time 8 h

Recommended adjustment weight

(class),

not delivered

1 mg 1 mg

10 mg 10 mg

150 g (E2) 250 g (E2)

Number of reference pieces

when counting the number of pieces

Weight units

Power supply

Operating temperature +15°C ... +30°C

Air humidity max. 80% (non-condensing)

Housing (W × D × H) mm 210 × 340 × 330

Wind breaker dimensions

(W × D × H) mm

Scale plate (stainless steel) Ø 80 mm

(Net) weight kg 6,2 kg

Interface RS-232C

Contamination degree 2

Overvoltage category Category II

10, 25, 50, 100, selected freely

ct, g, gn, lb, mo, oz, ozt,

tl (Hong Kong), tl (Singapore, Malaysia), tl

(Taiwan), pen

24 V DC, 1A

160 × 140 × 205 (inner)

190 × 195 × 225 (outer)

Installation height

above sea level

Location site Solely indoors

up to 4000 m

8 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 9

KERN PLJ 420-3F PLJ 720-3A PLJ 1200-3A

counting the number of pieces in

counting the number of pieces in

Product number / type TPLJG 420-3-A TPLJG 720-3-A TPLJG 1200-3-A

Weighing range (Max) 420 g 720 g 1200 g

Interval (d) 0.001 g 0.001 g 0.001 g

Reproducibility 0.001 g 0.001 g 0.001 g

Linearity ±0.003 g ±0,002 g ±0,003 g

Settling time (standard) 2 s 2 s 2 s

Minimum part weight when

5 mg 1 mg 5 mg

laboratory conditions**

Minimum part weight when

50 mg 10 mg 50 mg

standard conditions**

Heating time 4 h 4 h 8 h

Adjustment weight internal

Number of reference pieces

when counting the number of

pieces

10, 25, 50, 100, selected freely

Weight units

Power supply

Operating temperature +15°C/+30°C

Air humidity max. 80% (non-condensing)

Equipment for the under-scales

weighing hanger

Housing (W × D × H) mm 210 × 340 × 160

Wind breaker [mm]

Scale plate (stainless steel) Ø 11 cm

(Net) weight kg

Interface RS-232C

Contamination degree 2

Overvoltage category Category II

tl (Hong Kong), tl (Singapore, Malaysia), tl (Taiwan), pen

230 V/50 Hz

(Euro) 9 VDC

– attachment lug, serial equipment

3.5 kg 4.9 kg 4.9 kg

ct, g, gn, lb, mo, oz, ozt,

230 V/50 Hz (Euro) 24 V DC

internal: Ø 150, height 60

external: Ø 160, height 70

Installation height

above sea level

Location site Solely indoors

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 9

up to 4000 m

Page 10

KERN PLJ 2000-3A PLJ 4200-2F PLJ 6200-2A

number of pieces in

counting the number of pieces in

Product number / type TPLJG 2100-3-A TPLJG 4200-2-A TPLJG 6200-2-A

Weighing range (Max) 2100 g 4200 g 6200 g

Interval (d) 0.001 g 0.01 g 0.01 g

Reproducibility 0.002 g 0.02 g 0.01 g

Linearity ±0.004 g ±0,04 g ±0,03 g

Settling time (standard) 2 s 2 s 2 s

Minimum part weight when

counting the

laboratory conditions**

Minimum part weight when

standard conditions**

Heating time 8 h 4 h 4 h

Adjustment weight internal

Number of reference pieces

when counting the number of

pieces

50 mg 50 mg 10 mg

500 mg 500 mg 100 mg

10, 25, 50, 100, selected freely

Weight units

Power supply

Operating temperature +15°C ... +30°C

Air humidity max. 80% (non-condensing)

Equipment for the under-scales

weighing hanger

Housing (W × D × H) mm

Wind breaker mm

internal: Ø 150, height 60

external: Ø 160, height 70

Scale plate (stainless steel) Ø 11 cm Ø 16 cm Ø 16 cm

(Net) weight kg

Interface RS-232C

Contamination degree 2

Overvoltage category Category II

tl (Hong Kong), tl (Singapore, Malaysia), tl (Taiwan), pen

230 V/50 Hz

(Euro) 24 V DC

attachment lug,

serial

equipment

210 x 340 x 330 210 x 340 x 95 210 x 340 x 160

yes no no

6.8 kg 3.8 kg 5.4 kg

ct, g, gn, lb, mo, oz, ozt,

230 V/50 Hz

(Euro) 9 VDC

–

230 V/50 Hz

(Euro) 24 V DC

attachment lug,

serial

equipment

Installation height

above sea level

Location site Solely indoors

10 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

up to 4000 m

Page 11

KERN PLJ 720-3AM PLJ 6200-2AM

counting the number of pieces in

Product number / type TPLJG 720-3M-A TPLJG 6200-2M-A

Weighing range (Max) 720 g 6200 g

Interval (d) 0.001 g 0.01 g

Reproducibility 0.001 g 0.01 g

Linearity ±0.002 g ±0,02 g

Verification scale interval (e) 10 mg 100 mg

Verification class II II

Minimum weight (Min) 20 mg 50 mg

Settling time (standard) 2 s 2 s

Minimum part weight when

counting the number of pieces in

laboratory conditions**

Minimum part weight when

standard conditions**

Heating time 4 h 4 h

1 mg 10 mg

10 mg 100 mg

Adjustment weight internal

Number of reference pieces

when counting the number of

pieces

Weight units ct, g

Power supply

Operating temperature +15°C ... +30°C

Air humidity max. 80% (non-condensing)

Housing (W × D × H) mm

Wind breaker [mm]

Scale plate (stainless steel) Ø 11 cm Ø 16 cm

(Net) weight kg

Interface RS-232C

Contamination degree 2

Overvoltage category Category II

210 x 345 x 155 210 x 345 x 160

10, 25, 50, 100, selected freely

230V/50Hz AC (Euro), 24V/1A DC

internal: Ø 150, height 60

external: Ø 160, height 70

4.9 kg 5.4 kg

Installation height

above sea level

Location site Solely indoors

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 11

up to 4000 m

Page 12

KERN

PLS 420-3F

PLS 720-3A

PLS 1200-3A

Product number / type TPLSG 420-3-A TPLSG 720-3-A TPLSG 1200-3-A

Linearity

±0.004 g

±0,002 g

±0,003 g

Settling time (standard)

3 s

2 s

2 s

Operating temperature

+15°C ... +30°C

Air humidity

max. 80% (non-condensing)

Housing (W × D × H) mm

210 × 340 × 160

Interface

RS-232C

Contamination degree

2

above sea level

Weighing range (Max) 420 g 720 g 1200 g

Interval (d) 0.001 g 0.001 g 0.001 g

Reproducibility 0.001 g 0.001 g 0.001 g

Minimum part weight when

counting the number of

pieces in laboratory

conditions**

Minimum part weight when

counting the number of

pieces in standard

conditions**

Heating time 4 h 4 h 8 h

Recommended adjustment

weight (class),

not delivered

Number of reference pieces

when counting the number of

pieces

5 mg 5 mg 5 mg

50 mg 50 mg 50 mg

400 g (E2) 600 g (E2) 1 kg (E2)

10, 25, 50, 100, selected freely

Weight units

Power supply

Battery

Equipment for the underscales weighing hanger

Wind breaker mm

Scale plate (stainless steel) Ø 11 cm

(Net) weight kg 2,7 kg 4.5 kg 4.5 kg

Overvoltage category Category II

tl (Hong Kong), tl (Singapore, Malaysia), tl (Taiwan), pen

230 V/50 Hz (

Euro) 9 VDC

operating time 30 h

charging time 10 h

ct, g, gn, lb, mo, oz, ozt,

230 V/50 Hz (Euro) 24 V DC

– –

attachment lug, serial equipment

internal: Ø 150, height 60

external: Ø 160, height 70

Installation height

Location site Solely indoors

12 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

up to 4000 m

Page 13

KERN PLS 4200-2F PLS 6200-2A

the number of pieces in

counting the number of pieces in

Product number / type TPLSG 4200-2-A TPLSG 6200-2-A

Weighing range (Max) 4200 g 6200 g

Interval (d) 0.01 g 0.01 g

Reproducibility 0.01 g 0.01 g

Linearity ±0.04 g ±0,03 g

Settling time (standard) 3 s 2 s

Minimum part weight when

counting

laboratory conditions**

Minimum part weight when

standard conditions**

Heating time 4 h 4 h

Recommended adjustment

weight (class),

not delivered

Number of reference pieces

when counting the number of

pieces

50 mg 50 mg

500 mg 500 mg

4 kg (E2) 5 kg (E2)

10, 25, 50, 100, selected freely

Weight units

Power supply

Battery

Operating temperature +15°C ... +30°C

Air humidity max. 80% (non-condensing)

Equipment for the under-scales

weighing hanger

Housing (W × D × H) mm

Wind breaker no

Scale plate (stainless steel) Ø 16 cm

(Net) weight kg 3 kg 4.5 kg

Interface RS-232C

Contamination degree 2

Overvoltage category Category II

tl (Hong Kong), tl (Singapore, Malaysia), tl (Taiwan), pen

230 V/50 Hz (Euro)

operating time 30 h

charging time 10 h

ct, g, gn, lb, mo, oz, ozt,

230 V/50 Hz (Euro)

9 V DC

attachment lug, serial equipment

24 V DC

210 x 345 x 105

–

Installation height

above sea level

Location site Solely indoors

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 13

up to 4000 m

Page 14

KERN PLS 8000-2A

counting the number of pieces in

counting the number of pieces in

PLS 20000-1F

Product number / type TPLSG 8200-2-A TPLSG 20000-1-A

Weighing range (Max) 8200 g 20 kg

Interval (d) 0.01 g 0.1 g

Reproducibility 0.01 g 0.1 g

Linearity ±0.04 g ±0,4 g

Settling time (standard) 4 s 3 s

Minimum part weight when

10 mg 500 mg

laboratory conditions*

Minimum part weight when

100 mg 5 g

standard conditions**

Heating time 4 h 4 h

Recommended adjustment

weight (class), not delivered

5 kg (E2) 20 kg (E2)

Number of reference pieces

when counting the number of

10, 25, 50, 100, selected freely

pieces

Weight units

tl (Hong Kong), tl (Singapore, Malaysia), tl (Taiwan), pen

Power supply 230 V/50 Hz (Euro)

24 V DC

ct, g, gn, lb, mo, oz, ozt,

230 V/50 Hz (Euro)

9 V DC

Operating temperature +15°C ... +30°C

Air humidity max. 80% (non-condensing)

Equipment for the under-scales

weighing hanger

attachment lug, serial

equipment

-

Housing (W × D × H) mm 210 × 345 × 100 210 × 340 × 100

Wind breaker no no

Scale plate (stainless steel) Ø 16 cm 200 x 175 mm

(Net) weight kg

4.8 kg 3.5 kg

Interface RS-232C

Contamination degree 2

Overvoltage category Category II

Installation height

above sea level

Location site Solely indoors

14 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

up to 4000 m

Page 15

* Minimum part weight when counting the number of pieces in laboratory

For verified scales (= the ones subject to the conformity

assessment procedure), the Declaration of Conformity is included

conditions:

There are optimum ambient conditions to count pieces with high resolution

No diversification of the counted pieces’ weight

**Minimum part weight when counting the number of pieces in standard

conditions:

There are unsteady ambient conditions (wind gusts, vibrations)

There is diversification of the counted pieces’ w eig ht

2 Declaration of Conformity

The valid Declaration of Conformity EC/UE is available at:

www.kern-sohn.com/ce

in the delivery scope.

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 15

Page 16

3 Device overview

3.1 Parts

Front:

Model ALJ 200-5DA Models ALJ/ALS

Modell TALJG 210-5-A

Item Name

1 Glass wind breaker

2 Wind breaker ring

3 Scale plate

4 Leveler

5 Display

6 Keyboard

7 Leveling screw foot

8 Ionisator

16 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 17

Model PLJ 2000-3A

Models PLJ/PLS:

Scale plate dimensions Ø 110 mm

Item Name Item Name

1 Glass wind breaker 1 Leveler

2 Scale plate 2 Cover of the glass wind breaker

3 Display 3 Glass wind breaker

4 Keyboard 4 Scale plate

5 Leveling screw foot 5 Display

6 Leveler 6 Leveling screw foot

7 Keyboard

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 17

Page 18

Models PLS

scale plate dimensions Ø 160 mm

Item Name

1 Leveler

Models PLS 20000-1F

scale plate dimensions 200 x 175 mm

2 Scale plate

3 Display

4 Keyboard

5 Leveling screw foot

Sample drawing with a ionizing unit installed (KERN ALJ-A03):

18 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 19

Scale back and bottom

2

3

4

5

6

5

7

1. Scale plate

2. RS-232C interface

3. Leveling screw foot

4. Power supply socket

5. Housing screws

(in models with 4

leveling screw feet,

first screw out both rear

ones)

6. Equipment for the

under-scales weighing

hanger

7. Transport protecti on

(solely models with an

internal adjustment

weight)

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 19

Page 20

3.2 Operating controls

Button

Name

Button pressing

Pressing and holding

sound is heard

3.2.1 Keyboard overview

the button until the

MENU

button

CAL button

ON/OFF

button

PRINT

button

TARE

button

• Displaying the main /

• Menu item selection —

• Switching on/off

• Leaving the main / application menu,

• Adjustment

• Menu item selection — scrolling backward

• Weight data transfer via the interface

• Setting confirmatio n/saving

• Taring

• Resetting

application menu

scrolling forward

return to the weighing mode

• Displaying the setup

menu

• Leaving the setup

menu

20 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 21

3.2.2 Navigation buttons / Introducing the numerical value

Button Name Button pressing Pressing and holding

the button

Navigation

button

Navigation

button

Navigation

button

Navigation

button

ESC

• Increasing the digit value

• In the menu: scrolling

forward

• Decreasing the digit value

• In the menu: scrolling

backward

• Digit positioning

• Entry deleting

Saving

Canceling

Setting a decimal point

Changing to

upper/lowercase

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 21

Page 22

3.3 Display overview

Item

Name

2

4

Weighing value

7

1

Weighing range indicator

Stabilization indicator

3

5

6

Zero indicator

Unit

Current time

Current date

Symbol Description see chapter

Stabilization indicator

PC

H

Zero indicator

The scale is in the percentage value determination mode

The scale is in the piece count mode

Upper limit value

+ chapter 9.3

+ chapter 9.3

+ chapter 12.5

+ chapter 12.1

+ chapter 12.4

L

Lower limit value

ct, g, gn, lb, mo,

tl (Hong Kong),

22 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

DS

oz, ozt,

tl (Singapore,

Malaysia), tl

(Taiwan), pen

The scale is in the density determination mode

The scale is in the data entry mode

Weight units

In the verified scales, the non-verified value is displayed in brackets

+ chapter 12.2

+ chapter 11.1

Page 23

3.4 User interface

Item

Name

8

Operation carried out

Once the application is downloaded, the operator is guided step by step. It is possible

to select a language (D, GB, F, IT, ESP, P; see chapter 11.11).

Display example “Piece count”

9

10

11

Active application

Current date

Current time

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 23

Page 24

4 Basic instructions

4.1 Intended use

The scale you bought is intended for weighing the weighed material. It should be

considered a “non-automatic scale”, e.g. the weighed material should be carefully

placed manually on the scale plate center. The weight can be read after it has

stabilized.

4.2 Non-intended use

Do not use the scale for dynamic weighing. If the amount of the weighed material is

reduced or increased significantly, the scale’s “stabilizing and compensating”

mechanism can result in displaying erroneous weighing results! (Example: slow

outflow of the liquid from the container placed on the scale.)

Do not subject the plate to long-term load. This may damage the weighing

mechanism.

Avoid any scale impact and overload higher than the stipulated maximum load (Max),

deducting the tare from the existing load. This could damage the scale.

Never operate the scale in explosive atmospheres. The standard version is not

explosion-proof.

Never introduce any structural modifications to the scale. This may result in

displaying erroneous weighing results, violating the technical safety conditions, and

also in scale damage.

The scale should always be operated in line with the provided guidelines. Other

operation ranges / areas require a written consent of KERN .

4.3 Warranty

The warranty expires:

• if you fail to follow our guidelines included in the user manual;

• if you fail to use the device in line with the intended use;

• if you introduce any modifications or open the device;

• if the device gets damaged mechanically or damaged by the utilities, liquids and

ordinary wear and tear;

• if the device is not set correctly or the electrical system is not as required;

• if the weighing mechanism gets overloaded.

4.4 Testing equipment super vi s ion

Within the quality assurance system, you must check the technical measurement

properties of the scale and possibly of the available reference weight regularly. To

that aim, the responsible user should define a relevant cycle, as well as the type and

scope of such an inspection. The information on the supervision of the testing

equipment, i.e. scales, and the required reference weights, can be found on the

home page of KERN (www.kern-sohn.com). The reference weights and scales can

be calibrated fast and for a low cost in the KERN calibration laboratory (against the

national reference) approved by DKD (Deutsche Kalibrierdienst).

24 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 25

5 Basic safety instructions

the device, read this user manual

Please keep all the parts of the original packaging in case you had

5.1 Compliance with the instruc t ions included in the user manual

Before you set and start

thoroughly even if you are familiar with KERN scales.

All language versions contain non-binding translation.

Only the original document in German is binding.

5.2 Personnel training

The device can be operated and maintained solely by trained workers.

6 Transport and storage

6.1 Checking during reception

Immediately after you have received the shipment, please check if it is free from any

visible outer damage. The same applies for the unpacked device.

6.2 Packaging / return transport

to send it back to us.

Always use the original packaging for the return transport.

Before you dispatch the device, disconnect any connected cables

as well as loose/moving parts.

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 25

Page 26

Protect all the parts, e.g. glass wind breaker, scale plates, power

Reinstall any transport locks, if present.

supply etc. from slipping and damage.

26 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 27

Sample drawing for analytical scales:

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 27

Page 28

7 Unpacking, positioning and start-up

7.1 Installation plac e, operat ion place

The scales are designed to ensure reliable weighing results in standard operating

conditions.

The choice of a correct scale location ensures its accurate and fast operation.

This is why you should follow the following rules in the location site:

• Place the scale on stable, flat surface.

• Avoid extreme temperatures and temperature fluctuations, occurring e.g. when

you place it at the radiator or in a place exposed to direct sun rays.

• Protect the scale from the direct draft present at open windows and doors.

• Avoid impact when weighing.

• Protect the scale from high humidity of air, vapors and dust.

• Do not expose it to long-term heavy moisture. Any forbidden condensation of

the air moisture on the device may occur when a cold device is placed in a

much hotter environment. In such circumstances, leave the device not

connected to the mains for 2 hours to adapt to the ambient temperature.

• Avoid static discharge from the weighed material and scale container.

If there are any electromagnetic fields, static discharge and unstable power supply,

high readout deviations (erroneous weighing results) may occur. In such

circumstances, change the location.

28 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 29

7.2 Unpacking and check

Remove the device and accessories from the packaging, remove the packaging

material and place the device in the target location. Check if all components included

in the delivery are present and not damaged.

Scope of delivery / standard accessories

• Scale, see chapter 3.1

• Power supply

• Dust cover

• User manual

• Transport protecti on (solely models with an internal adjustment weight)

7.2.1 Setting

The correct location is decisive for the accurate weighing results of highresolution analytical and precision scales (see chapter 7.1).

Removing transport protection

Models with an internal adjustment weight:

Follow the description in the information leaflet, either

Replace the brass screw [A] with the steel one [B], to the left of the scale bottom

(follow the description in the yellow information leaflet).

or

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 29

Page 30

Scale installation

Place the scale plate with the grate.

Model ALJ 200-5DA

Install the wind breaker ring.

Models ALS/ALJ, d = 0.1 mg

30 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 31

Models PLS/PLJ, d = 1 mg

Models PLS/PLJ, d = 100 mg

Models PLS/PLJ, d = 10 mg

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 31

Page 32

Leveling

Level the scale using the leveling feet. The air bubble in

Accurate setting and stable installation are the conditions enabling to obtain

repeatable results. Small unevenness or inclination of the base surface can be

compensated by leveling the scale.

•

the leveler must be present in the marked area.

• Check leveling at regular intervals.

Connecting power supply

Connect the scale power supply.

The scale autotest will be carried out. Next, the scale will switch to the

stand-by mode.

The scale connected to the power supply is always on. When you press

the ON/OFF button, the display will be switched on or off.

32 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 33

7.3 Power supply

Choose the plug appropriate for the operation country and plug it into

scale voltage is set correctly. The scale can be connected

to the mains only when the voltage specified on the scale (sticker) and

Always use the original power supply by KERN. Using any other

products requires KERN consent.

To get accurate weighing results using electronic scales, ensure the scales

achieves the appropriate operating temperature (see “Heating time”,

1). During the heating time, the scale must be connected to the power

Always follow the guidelines in the “Adjustment” chapter.

The battery capacity will soon run down. Connect the power

The voltage is below the recommended minimum. Connect the

chapter

source (the socket, rechargeable battery or batteries).

The scale accuracy depends on the local standard gravity.

the power supply.

Check if the

the local voltage are identical.

Important information:

Before you start the device, check the power cord for damage.

The power cord must not have any contact with liquids.

The plug must be always readily available.

7.4 Operation with battery supply (solely the model PLS 420-3F)

The rechargeable battery is charged using the delivered power supply.

The battery operating time is ca. 30 h, the charging time until fully charged is ca. 10

h.

The AUTO-OFF function can be enabled in the menu, see chapter 11.9. Depending

on the menu setting, the scale will be switched to the battery saving mode

automatically.

When the scale is battery-operated, the following symbols are displayed:

The battery is sufficiently charged.

supply as soon as possible to charge the battery.

power supply to charge the battery.

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 33

Page 34

7.5 Operator language selection

When the device is shipped, German is the preset display language.

To set other languages, see chapter 11.11.

7.6 Connecting peripherals

Before you connect or disconnect any extra devices (printer, computer) to/from the

data interface, the scale should always be disconnected from the mains.

Use solely accessories and peripherals supplied by KERN with the scale, being

perfectly compatible with it.

8 Adjustment

As the standard gravity value is not the same in every spot on Earth, every scale

should be adjusted, in line with the weighing rules resulting from the laws of physics,

to the standard gravity in the scale location (provided the scale has not already been

subject to factory adjustment in its location). Such an adjustment process should be

carried out during the first start, following every location change and also in the case

of any ambient temperature fluctuations. To ensure achieving accurate measurement

date, it is also recommended to carry out regular scale adjustment in the weighing

mode.

Ensure stable environmental conditions. The heating time is required for the

stabilization (see chapter 1).

Ensure there are no objects on th e scale pl at e.

Adjustment report printout, see chapter 8.6.

34 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 35

8.1 Adjustment mode selection

button until the

button, the current setting will be

To leave the menu/return to the weighing mode, press and hold the

In the weighing mode press and hold the MENU

sound signal stops. The configuration menu is displayed.

Using the navigation buttons , select the menu item <Calibration

mode>.

Confirm by pressing the PRINT

displayed.

Using the navigation buttons , select the required setting.

Auto. calibration

Internal calib.

External calib.

Technical calib.

Automatic adjustment using the internal weight.

Factory setting in the models in the verifiable setting.

Adjustment using the internal weight after the CAL button

is pressed.

Not available in the models in the verifiable setting.

Adjustment using the external weight, not available in the

models in the verifiable setting.

In models with the internal adjustment weight we do not

recommend adjustment using the external weight.

Changing the weight of the internal calibration weight.

Not available in the models in the verifiable setting.

After the “Internal, external or automatic adjustment” option is

selected confirm by pressing the PRINT button.

After the “Technical adjustment” option is selected, to confirm press

and hold the PRINT button until the sound signal stops.

The scale will be switched to the menu again.

MENU button until the sound signal stops.

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 35

Page 36

8.2 Automatic adjustment using the internal weight

Factory setting in the models in the verifiable setting (ALJ/PLJ)

The automatic adjustment using the internal weight is started automatically:

• when the scale was disconnected from the mains,

• after the ON/OFF button is pressed in the stand-by mode,

• after the temperature is changed by 1.5 degrees Celsjus for the non-

loaded scale plate / zero indication (this prevents adjustment when a

series of measurements is performed)

• after 20 minutes, for the non-loaded scale plate / zero indication (this

prevents adjustment when a series o f measurements is performed).

The automatic adjustment function is always on. However, it is always possible to

carry out manual adjustment (by pressing the CAL button) using the internal weight,

see chapter 8.3.

Automatic adjustment course:

The <Cal 25> symbol informs about the approaching adjustment.

In that time, the user should finish weighing.

The countdown starting from 25 s starts [CAL 25] → [CAL 0].

During that period of 25 s, the adjustment can be stopped and delayed for 5 minutes,

pressing the ON/OFF button. As a result, the scale will be switched back to the

weighing mode, e.g. to complete the ongoing measurement.

36 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 37

8.3 Adjustment using the internal weight after the Model CAL button is pressed (models ALJ/PLJ)

Preliminary condition: Menu setting “Internal adjustment”, see chapter 8.1.

In the weighing mode, press the CAL button, the adjustment will be carried out

automatically.

,

After the successful adjustment, the scale will switch to the weighing mode

again automatically.

If an adjustment error occurs (e.g. following an impact), the error message

“CAL bUt” will appear on the display. Start the adjustment process again, by

pressing the CAL button.

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 37

Page 38

8.4 Adjustment using the ext er na l w eight

• Factory setting in ALS/PLS models

Preliminary condition: Menu setting “External adjustment”, see

http://www.kern-sohn.com.

Ensure there are no objects on the scale plate. In the weighing mode, press the

Wait until the blinking weight value of the required adjustment weight is

blinking, place the required adjustment weight carefully in the middle of

• In ALJ/PLJ models it is available only in the verifiable setting.

•

chapter 8.1.

• The weight of the recommended adjustment weight, see chapter 1

“Technical Specification”.

• Information on reference weights can be found on the Internet at

CAL button.

displayed.

During

the scale plate. The blinking symbol will disappear.

After the successful adjustment, the scale will switch to the weighing mode again

automatically.

Remove the adjustment weight.

,

38 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 39

8.5 Changing the weight of the internal calibration weight

Information on reference weights can be found on the Internet at

button until the sound signal stops. The scale will switch to

Ensure there are no objects on the scale plate. Press the CAL button.

blinking, place the required adjustment weight carefully in the middle of the

After the successful change, the scale will switch to the weighing mode again

! This change can be carried out solely by a specialist holding thorough knowledge of

handling scales.

!

http://www.kern-sohn.com.

Display the menu item “Technical adjustment”, see chapter 8.1.

To confirm, press and hold the PRINT button until the sound signal stops.

Press and hold the MENU

the weighing mode again automatically.

Wait until the blinking weight value of the adjustment weight is displayed.

During

scale plate. The blinking symbol will disappear.

Wait until the stabilization indicator is displayed, remove the adjustment weight.

Press and hold the PRINT button until the sound signal stops.

The weight of the internal adjustment weight will be changed.

automatically.

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 39

Page 40

8.6 Adjustment report display/print

The scale and printer communication parameters must be compatible.

Printout conforming to GLP see chapter 12.8.

ntil the sound signal

button. The following will be displayed: date, time,

After the optional printer is connected, the data can be printed by pressing the

button. The scale will be switched to the menu again.

This function enables to print the report on the most recent adjustment.

Communication parameters, see chapter 11.2 and 11.3.

In the weighing mode press and hold the MENU button u

stops. The configuration menu is displayed.

Using the navigation buttons , select the menu item <Calibration info>.

Confirm, pressing the PRINT

adjustment type and deviation when compared to the most recent adjustment.

PRINT button.

Sample printout (KER N YKB-01N):

27-08-20 10:41:17 Current date/time

Balance ID:

WI2000077

User ID

Miller

Project ID

KERN

Calibration mode

27-08-20 10:11:17 AM Adjustment date/time

Internal calib. Adjustment type

Corr.: 0.21 g Deviation when compared

to the most recent adjustment

Signature:

Press the ON/OFF

Whenever required, carry out other settings in the menu or press the ON/OFF

button. The scale will switch to the weighing mode again.

40 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 41

8.7 Verification

The verifiable scales should be removed from operation if:

is why the scale should be loaded with the reference weight of a known

load) regularly and the displayed value should

The re-verification deadline is exceeded.

Seal location (PLJ models)

General information:

According to the Directive 2014/31/EU, the scales must be verified if they are used in

the following way (legally determined scope):

a) for commercial purposes when the goods’ price is determined by weighing

them,

b) to produce medications in pharmacies and also for analyses in medical and

pharmaceutical laboratories,

c) for official purposes,

d) for manufacturing finished packagings.

In the case of any doubts, contact the local Office of Measures.

Guidelines concerning verification

The scale which is marked verifiable in the technical specification holds a type

approval certificate in force in the European Union. If the scale is to be used in the

above-mentioned area requiring verification, it must be verified and its verification

must be renewed on a regular basis.

Re-verification of the scale is carried out in line with the regulations in force in a given

country. E.g. in Germany the scale verification validity period is usually 2 years.

Always follow the regulations in force in the country of use!

Once the verification process is completed, the scale is sealed in the determined

position.

Scale verification with no “seal” is invalid.

The scale weighing result is outside the permissible error limit. This

weight (ca. 1/3 of the Max

be confirmed with the reference weight.

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 41

Page 42

9 Basic mode

Switching off:

9.1 Switching the scale on and off

Switching on:

In the stand-by mode, press the ON/OFF button.

The scale is ready to weigh immediately after the

weight symbol is displayed.

Press the ON/OFF button. The scale will be switched

to the stand-by mode (energy saving function). The

scale is in the stand-by node.

To switch the scale off entirely, disconnect the power

supply.

9.2 Resetting

Remove the load from the scale.

Press the TARE button. The zero indicator and [-0-]. symbol will be displayed.

42 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 43

9.3 Ordinary weighing

] from the bottom upwards reflects

Consequently, the current use of the weighing range is presented in an

To get accurate weighing results, ensure the scale achieves the appropriate

operating temperature (see “Heating time”, chapter 1).

Wait until the zero symbol is displayed, reset the scale whenever required, by

pressing the TARE button.

Place the weighed material.

Wait until the stabilization indicator is displayed [ ].

Read out the weighing result.

Once the optional printer is connected, the weighing value can be printed.

Sample printouts (KERN YKB-01N):

27-08-20 10:41:17 AM Current date/time

Gewic.: 50.5773 g Weighing value

9.4 Weighing range indicator

The weighing range indicator shift [

the scale load. Its full height is reached for the maximum load.

analogue way.

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 43

Page 44

9.5 Taring

After the load is removed from the scale, the tare weight is displayed as

To delete the saved tare value, remove the load from the scale plate and

button. The “Tare” symbol will be displayed. Wait until the

The taring process can be repeated any number of times. The limit is

The empty weight of any container used for weighing can be tared, pressing the

button which results in displaying the net weight of the weighed material during

consecutive weighing processes.

Place the scale container on the scales plate.

Wait until the stabilization indicator is displayed [], and press the TARE

button. The “Tare” symbol will be displayed.

Once the stabilization check is successfully completed, the zero symbol will be

displayed.

The container weight will be saved in the scale memory.

Place the weighed material.

Wait until the stabilization indicator is displayed [].

Read out the net weight.

Tip:

•

a negative value.

•

press TARE

zero symbol is displayed.

•

reached when the complete weighing scope is used.

44 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 45

9.6 Weighing using the under-scales weighing hanger

All hung objects must be stable enough and the weighed material

No people or animals or items who/which could be injured or

After you have finished weighing, always close the opening on the

Weighing using the under-scales weighing hanger enables to weigh any objects

which cannot be placed on the scale plate because of their size or shape.

Carry out the following steps:

• Switch the scale off.

• Remove the plug (1) at the scale bottom.

• Suspend the under-scales weighing hanger carefully and accurately.

• Place the scale over an opening.

• Hang the weighed material on the hook and carry out weighing.

1

Figure 1: Prepare the scale to use the under-scales weighing hanger

▬

must be fixed securely (the risk of separating).

CAUTION

▬ Never hang any loads exceeding the specified maximum load

(Max) (risk of separa ting).

▬

damaged can stay under the load.

scale bottom (dust protection).

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 45

Page 46

11 Setup menu

enable to select subsequent, individual

menu items. The active menu item is indicated by the cursor

The current setting is displayed. The subsequent setting is

In the configuration menu, all the basic settings and parameters affecting the total

scale operation are entered.

Menu navigation

Entering the menu In the weighing mode press and hold the MENU button until

the sound signal stops.

The configuration menu is displayed.

Selecting the

menu items

Changing settings Confirm the menu item selection by pressing the PRINT button.

Saving settings

Navigation buttons

(►) to the left of the text.

displayed after pressing the navigation buttons .

Confirm the selection, pressing the PRINT button.

The scale will be switched to the menu again. Whenev er

required, select the subsequent menu setting or return to the

weighing mode as described below.

Closing the menu /

return to the

weighing mode

46 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Press the ON/OFF button.

Confirm the selection of the menu item <Back> by pressing the

PRINT button.

or

Page 47

Menu overview:

Menu item

Selection

Description

Unit 1

g

gram

ct

karat

Oz

ounce

Lb

pound

Dwt

Pennyweight

Ozt

Ounce Troy

GN

Grain

tl 1

Tael (Hong Kong)

tl 2

Tael (Singapore)

tl 3

Tael (Taiwan)

mo

Momme

RS-232

Transmission speed

1,200 bauds

2,400 bauds

4800 bauds

9600 bauds

Auto zero

Filter

Stability

Unit 2

(see chapter 11.1)

(see chapter 11.2)

Continuous Continuous data transfer

PRINT button

Not documented

Not documented –

PRINT + DPL

Not documented

Not documented

Sending the stable weighing value after the

PRINT button is pressed

–

Printout conforming to GLP after the PRINT

button is pressed

–

–

(see chapter) 11.3)

Automatic zero point

correction (see

chapter 11.4)

(see chapter 11.5)

(see chapter 11.6)

Transmission speed

Auto zero OFF “Auto zero” function is off

Auto zero 1

Auto zero 2

Auto zero 3 Range of the “Auto zero” function ±7 digits

Auto zero 3E

Filter 1

Filter 2 Sensitive and fast — very calm setting item

Filter 3

Stability 1

Stability 2

Stability 3

Range of the “Auto zero” function ±½ digits

Range of the “Auto zero” function ±3 digits

Range of the “Auto zero” function ±7 digits

in the entire weighing range

Dosing setting

Not sensitive but slow — not calm setting

item

Fast stabilization check / very calm setting

item

Fast and accurate stabilization and check /

calm setting item

Accurate stabilization check / very uncalm

setting item

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 47

Page 48

Display contrast

(see chapter 11.7)

Display backlight

(see chapter 11.8)

AUTO OFF

Time and date

(see chapter 11.10)

Language

Deutsch

Français

Español

Português

English

Italiano

Adjustment mode

Adjustment report

(see chapter 8.6)

Back

(The automatic switch -off

function in the stand-by

mode)

(see chapter 11.9)

(see chapter 11.11)

1-15

on Back light on

off

Auto

Disabled

2 min

5 min

15 min

Setting time and date

Contrast selection

Backlight off

Automatic switch-off of the backlight 3 s after

the stable weighing value is achieved. The

backlight will be switched on again

automatically after the weight is changed or

the button is pressed.

AUTO-OFF function off

Automatic switch off after 2 minutes with no

weight change

Automatic switch off after 5 minutes with no

weight change

Automatic switch off after 15 minutes with no

weight change

User interface language

(see chapter 8.1)

External adjustment Adjustment using the exter nal wei ght

Automatic

adjustment

Internal adjustment

Technical

adjustment

Automatic adjustment using the internal

weight

Adjustment using the internal weight after the

CAL button is pressed

Changing the weight of the internal

calibration weight

Printout of the most recent adjustment report

Return to the weighing mode

48 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 49

11.1 Weight uni t s (unit1/unit2)

• For verified scales, not all units are available, see chapter 1 “Technical

• When delivered, the factory setting is the “unit1”.

g

gram

1.0000

ct

karat

5.0000

Oz

ounce

0.035273962

Lb

pound

0.0022046226

Dwt

Pennyweight

0.643014931

Ozt

Ounce Troy

0.032150747

GN

Grain

15.43235835

tl 1

Tael (Hong Kong)

0.02671725

tl 2

Tael (Singapore)

0.02646063

tl 3

Tael (Taiwan)

0.02666666

mo

Momme

0.2667

Weight units which are to be available during operation can be specified in the menu.

After different units (unit1 and unit2) are selected, the weighing result can be

displayed in two weight units (unit1 and unit2) simultaneously.

To switch between the values in weight “unit1” and “unit2”, use the PRINT button.

Specification”.

Activating the switchable weight units:

Using the navigation buttons , select the menu item <Weight unit 1>.

Confirm by pressing the PRINT button, the current setting will be displayed.

Using the navigation buttons , select the required setting.

Symbol Weight unit Conversion coefficients

for 1 g =

Confirm the selection, pressing the PRINT button.

The scale will be switched to the menu again.

Using the navigation buttons , select the menu item <Weight unit 2> and select

the required weight unit as described above.

Return to the weighing mode, pressing the ON/OFF button.

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 49

Page 50

Unit switching:

button until the sound signal

• When switchin g on from the stand-by mode using the ON/OFF button, the

After the device is disconnected from the mains, the scale will be started

with “Unit 1”.

In the weighing mode press and hold the PRINT

stops, then release the button.

Unit 1 Unit 2

scale will be started with the unit used most recently.

•

11.2 RS-232

Using the navigation buttons , select the menu item <Serial output>.

Confirm by pressing the PRINT button, the current setting will be displayed.

Using the navigation buttons , select the required setting.

50 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 51

Sending the stable weighing value after the

Sending data to the standard printer

Sending data to the printer supporting the

The setting used to obtain printouts

The printout conforming to GLP on a

GLP on the

button. The scale will be switched to

button. The scale will be switched to

Symbol Description

<Continuous>

<On demand>

<Generic printer>

<Printer TLP>

<On demand – GLP>

<Generic print.-GLP>

<Printer Tlp – GLP>

Continuous data transfer

PRINT button is pressed

following the remote control request.

LP-50 protocol.

conforming to GLP, after the PRINT button is

pressed

standard printer following the remote setting

request

The printout conforming to

printer supporting the LP-50 protocol

Confirm the selection, pressing the PRINT

the menu again.

Return to the weighing mode, pressing the ON/OFF button.

11.3 Transmission speed

Using the navigation buttons , select the menu item <Baud rate>.

Confirm by pressing the PRINT button, the current setting will be displayed.

Using the navigation buttons , select the required setting.

It is possible to select 1,200, 2,4 00, 4, 8 00 or 9,60 0 bauds.

Confirm the selection, pressing the PRINT

the menu again.

Return to the weighing mode, pressing the ON/OFF button.

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 51

Page 52

11.4 Auto zer o

button. The scale will be switched to

This menu item enables to switch on or off the automatic zero point correction. In the

switched on state, the deviation or zero point disturbance is corrected automatically.

Tip:

If the amount of the weighed material is reduced or increased significantly, the

scale’s “stabilizing and compensating” mechanism can result in displaying erroneous

weighing results! (e.g.: slow outflow of the liquid from the container placed on the

scale, evaporating processes).

When dosing with small weight fluctuations, it is recommended to switch this function

off.

Using the navigation buttons , select the menu item <Auto zero>.

Confirm by pressing the PRINT button, the current setting will be displayed.

,

Using the navigation buttons , select the required setting.

Symbol Description

Auto zero off

Auto zero 1

Auto zero 2

Auto zero 3

Auto zero 3E

“Auto zero” function is off

Range of the “Auto zero” function ±½ digits

Range of the “Auto zero” function ±3 digits

Range of the “Auto zero” function ±7 digits

Range of the “Auto zero” function ±7 digits in the entire

weighing range

Confirm the selection, pressing the PRINT

the menu again.

Return to the weighing mode, pressing the ON/OFF button.

52 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 53

11.5 Filter

button. The scale will be switched to

This menu item enables to adapt the scale to the specific environment conditions and

measurement objectives.

Using the navigation buttons , select the menu item <Filter>.

Confirm by pressing the PRINT button, the current setting will be displayed.

,

Using the navigation buttons , select the required setting.

Symbol Description

Filter 1

Filter 2

Filter 3

Dosing setting

The scale response is sensitive and fast — very calm

setting item

The scale response is not sensitive but slow — not

calm setting item

Confirm the selection, pressing the PRINT

the menu again.

Return to the weighing mode, pressing the ON/OFF button.

11.6 Stability

Using the navigation buttons , select the menu item <Stability>.

Confirm by pressing the PRINT button, the current setting will be displayed.

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 53

Page 54

Using the navigation buttons , select the required setting.

button. The scale will be switched to

button. The scale will be switched to

Symbol Description

Stability 1 Fast stabilization check — very calm setting item

Stability 2

Stability 3 Accur at e stabilization check — uncalm setting item

Confirm the selection, pressing the PRINT

the menu again.

Return to the weighing mode, pressing the ON/OFF button.

Fast and accurate stabilization and check — calm setting

item

11.7 Setting the display contrast

When setting the display contrast, you can choose from 15 values.

Using the navigation buttons , select the menu item <Contrast adjustment>.

Confirm by pressing the PRINT button, the current setting will be displayed.

Using the navigation buttons , select the required setting.

Symbol Description

0 Low contrast

15 High contrast

Confirm the selection, pressing the PRINT

the menu again.

Return to the weighing mode, pressing the ON/OFF button.

54 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 55

11.8 Displa y backlight

button. The scale will be switched to

Using the navigation buttons , select the menu item <Backlight>.

Confirm by pressing the PRINT button, the current setting will be displayed.

Using the navigation buttons , select the required setting.

Symbol Description

Automatic switch-off of the backlight 3 s after the stable

Auto

weighing value is achieved. The illumination will be

switched on again automatically after the weight is

changed or the button is pressed.

On Backlight on

Confirm the selection, pressing the PRINT

the menu again.

Return to the weighing mode, pressing the ON/OFF button.

off Backlight on

11.9 Automati c switch-off function

Using the navigation buttons , select the menu item <Timer off>.

Confirm by pressing the PRINT button, the current setting will be displayed.

Using the navigation buttons , select the required setting.

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 55

Page 56

button. The scale will be switched to

button until the sound signal stops.

button, set the date and time in

Symbol Description

Disabled AUTO-OFF function off

2 minutes

5 minutes

15 minutes

Confirm the selection, pressing the PRINT

the menu again.

Return to the weighing mode, pressing the ON/OFF button.

Automatic switch off after 2 minutes with no weight

change

Automatic switch off after 5 minutes with no weight

change

Automatic switch off after 15 minutes with no weight

change

11.10 Setting time and date

In the weighing mode press and hold the MENU

The configuration menu is displayed.

Using the navigation buttons , select the menu item <Time and date>.

Confirm by pressing the PRINT button, the current setting will be displayed.

Using the navigation buttons , select the required format.

dd-mm: Day/month

mm-dd: Month/day

Confirm the format selection by pressing the PRINT

the following way.

The active item is displayed by underlining, e.g. 25.

Using the navigation buttons , set the day and confirm by pressing the PRINT

button.

The month will become the active item (it will be underlined). Using the navigation

buttons , set the month and confirm by pressing the PRINT button.

In the same way set the year, hours, minutes and seconds.

After you finish setting, press and hold the PRINT button until the sound signal

stops. The scale will be switched to the menu again.

56 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 57

11.11 User interface language

button. The scale will be switched to

Using the navigation buttons , select the menu item <Language>.

Confirm by pressing the PRINT button, the current setting will be displayed.

Using the navigation buttons , select the required setting.

Language

Deutsch

Français

Español

Português

English

Italiano

Confirm the selection, pressing the PRINT

the menu again.

Return to the weighing mode, pressing the ON/OFF button.

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 57

Page 58

12 Main menu “Applications”

enable to select subsequent, individual

menu items. The active menu item is indicated by the cursor

The current setting is displayed. The subsequent setting is

, by pressing

Menu navigation:

Entering the menu

Selecting the

menu items

Changing settings

In the weighing mode, press the MENU button.

The main menu is displayed.

Navigation buttons

(►) to the left of the text.

Confirm the menu item selection by pressing the PRINT button.

displayed after pressing the navigation buttons .

Saving settings

Closing the menu /

return to the

weighing mode

Confirm the selection, pressing the PRINT button.

The scale will be switched to the menu again. Whenev er

required, select the subsequent menu setting or return to the

weighing mode as described below.

Press the ON/OFF button.

or

Confirm the selection of the menu item <Back>

the PRINT button.

58 TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112

Page 59

12.1 Counting the num be r of pieces

application and

button, the current setting of reference pieces will

Whenever required, place the scale container, confirm the preset number of

Place the number of the counted parts corresponding to the preset number of

The <Piece counting> application enables to count many pieces placed on the scale

plate.

Before it is possible to count pieces using the scale, you should determine the

average weight of an individual part (unit weight), the so-called reference value. For

that purpose, place a specific number of counted parts on it. The scale will determine

the total weight which will be divided by the number of pieces, the so-called reference

piece number. Next, based on the calculated mean weight of an individual part, the

number of pieces will be counted.

The following rule applies:

The higher number of the reference pieces, the higher the accuracy of counting.

12.1.1 Determining the reference value by weighing

Using the navigation buttons , select the <Piece counting>

confirm by pressing the PRINT

be displayed.

Using the navigation buttons , select the required setting.

Symbol Description

10 pieces

25 pieces

50 pieces

100 pieces

Manual

Number of reference items 10

Number of reference items 25

Number of reference items 50

Number of reference items 100

Entering the reference weight value in the numerical

form, see chapter 12.1.2

reference items by pressing the PRINT button.

reference items.

TALJG_A/TALSG_A/TPLJG_A/TPLSG_A-BA-e-2112 59

Page 60

Confirm, pressing PRINT.

The determined average weight of an individual part will be assumed as the

The following will be displayed: the currently placed “G” weight, reference weight

If it is impossible to create the reference value due to the weighed

material instability or insufficient reference load, the following will be

Increase the weight of the counted pieces or choose a scale with

or

Press the PRINT button, the reference value is calculated again.

reference weight immediately after the weighing result is stabilized.

“AUW” and the number of pieces “St.”.

Remove the reference load. The scale is in the counting mode and counts all

parts present on the scales plate.

displayed in the course of determining the reference value:

Exceeding the minimum weight of the counted pieces

greater interval.

The scale request “Consecutive part...” will be displayed to optimize the

reference weight as the placed number of pieces is not sufficient to

ensure correct determination of the reference value.

Place consecutive parts in at least double amount.

If the placed number of pieces is

still too low, add other parts (double

amount) and confirm by pressing

the PRINT button. Repeat the