Page 1

KERN & Sohn GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@kern-sohn.com

Service manual

Precision balance

KERN PEJ/PES

Version 1.1

4/2009

GB

Tel: +49-[0]7433- 9933-0

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

PEJ/PES-SH-e-0911

Page 2

GB

KERN PEJ/PES

Version 1.1 4/2009

Service manual

Contents

1. Basic information................................................................................................. 3

2. Total View............................................................................................................ 4

3. Electronic Construction........................................................................................ 5

3.1 Block Diagram.............................................................................................. 5

3.2 Whole Wiring................................................................................................ 6

4. Troubleshooting................................................................................................... 7

4.1 Troubleshooting Procedure .......................................................................... 7

4.2 Troubleshooting Table.................................................................................. 8

4.3 Troubleshooting Table 2............................................................................... 9

4.4 Primary Checks.......................................................................................... 10

4.5 Checks for Electric/Electronic Parts ........................................................... 11

4.5.1 Check of VIBA-2A board ..................................................................... 13

5. Adjustment and Setting ..................................................................................... 14

5.1 Span Calibration (Adjustment with internal weight – PEJ).......................... 14

5.2 Span Calibration (Adjustment with external weight – PES) ........................ 15

5.3 Corner Error Adjustment ............................................................................ 16

5.4 Linearity Adjustment................................................................................... 17

5.4.1 Table Increasing Calibration Weight for Linearity Adjustment............. 18

5.5 Calibration of Built-In Weight (Ref Cal) – only PEJ..................................... 19

6. Parts Replacement............................................................................................ 20

6.1 How to Remove the Case .......................................................................... 20

6.2 How to Cover the Case .............................................................................. 20

6.3 How to Replace Mechanical Unit ............................................................... 21

6.4 How to Remove Mechanical Unit ............................................................... 21

6.5 How to Install Mechanical Unit ................................................................... 22

6.6 Sequence of Tuning-Fork Sensor Replacement ........................................ 23

6.7 How to Remove Tuning-Fork Assy............................................................. 23

6.8 How to Install Tuning-Fork Assy................................................................. 24

6.9 Adjustment of Overload Stopper ................................................................ 25

6.10 Sequence of Circuit Board Replacement ................................................... 26

7. Installation of Options........................................................................................ 27

7.1 Installation of Battery Option ...................................................................... 27

7.2 Installation of Relay Contact Option ........................................................... 28

8. Parts List ........................................................................................................... 30

8.1 Explosion Diagram ..................................................................................... 30

8.2 Bill of Material............................................................................................. 31

8.3 View of Components PES 31000-1M ......................................................... 32

Precision balance

2 PEJ/PES-SH-e-0911

Page 3

1. Basic information

Grundlegende Hinweise

The device must be repaired only by trained specialist staff or personnel with

professional formation (such as a repair-specialist accredited by law

concerning verification).

The service manual is obligatory for repair work.

After repair, original conditions of the device have to be restored.

Only original spare parts should be used.

Instructions about conformity-evaluated scales:

Repair must be carried only at 100% compliance with the type approval.

A violation of this specification will result in a loss of the type approval!

After successful repair the balance will have to be reverified before it can be

used again in a statutorily regulated field.

Das Gerät darf nur von geschultem oder beruflich ausgebildetem

Fachpersonal (z. B. eichrechtlich anerkannter Instandsetzer) repariert werden.

Die Serviceanleitung ist bindend für Reparaturen.

Das Gerät muss nach erfolgter Reparatur wieder in den Originalzustand

zurückversetzt werden.

Es dürfen nur Originalersatzteile verwendet werden.

Hinweis zu konformitätsbewerteten Waagen:

Reparatur darf nur in 100% -iger Übereinstimmung mit der

Bauartzulassung erfolgen. Ein Verstoß gegen diese Vorgabe führt zum Erlöschen

der Bauartzulassung!

Nach erfolgreicher Reparatur muss eine Nacheichung erfolgen, um die Waage

wieder im gesetzlich geregelten Bereich verwenden zu können.

PEJ/PES-SH-e-0911 3

Page 4

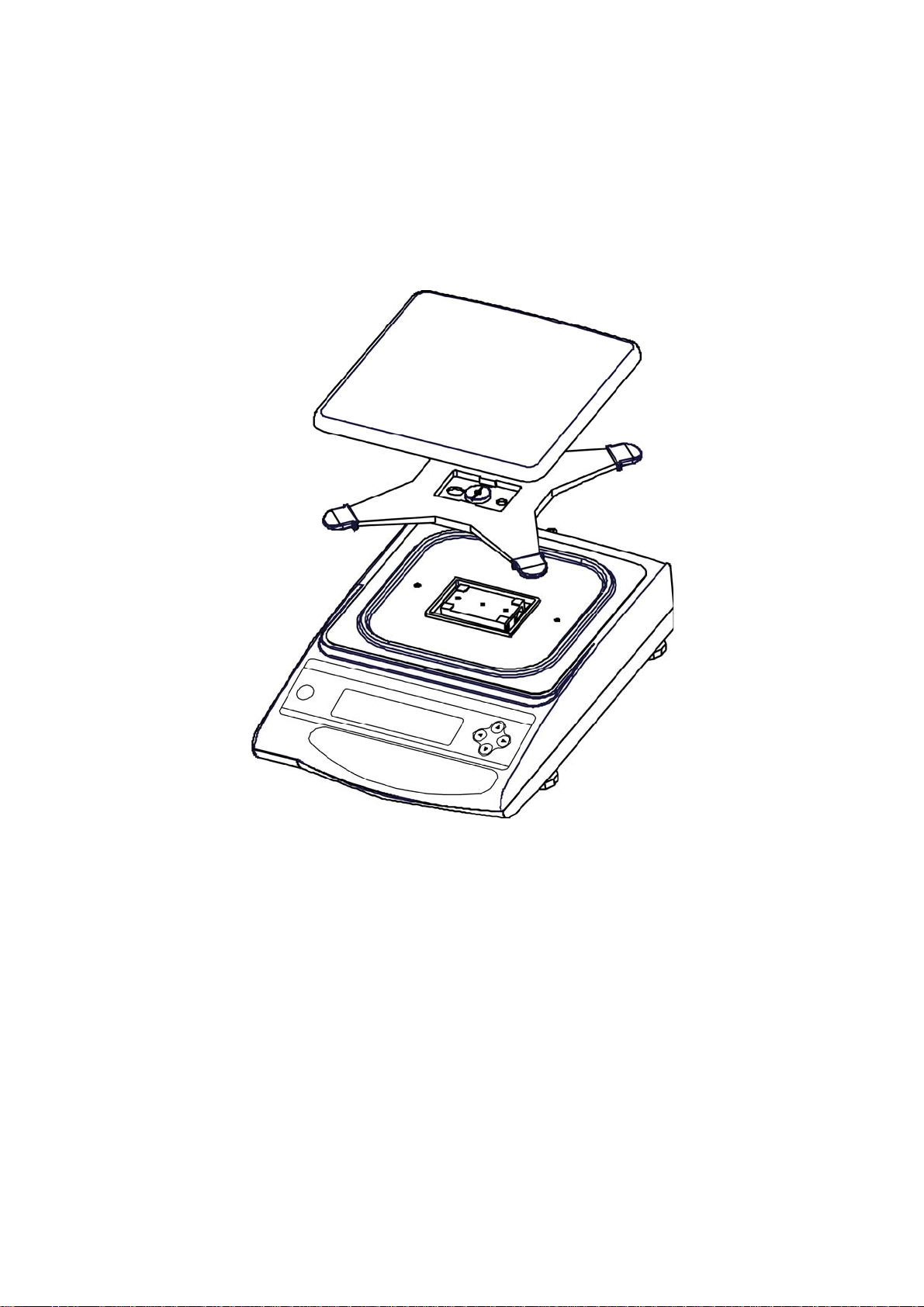

2. Total View

4 PEJ/PES-SH-e-0911

Page 5

3. Electronic Construction

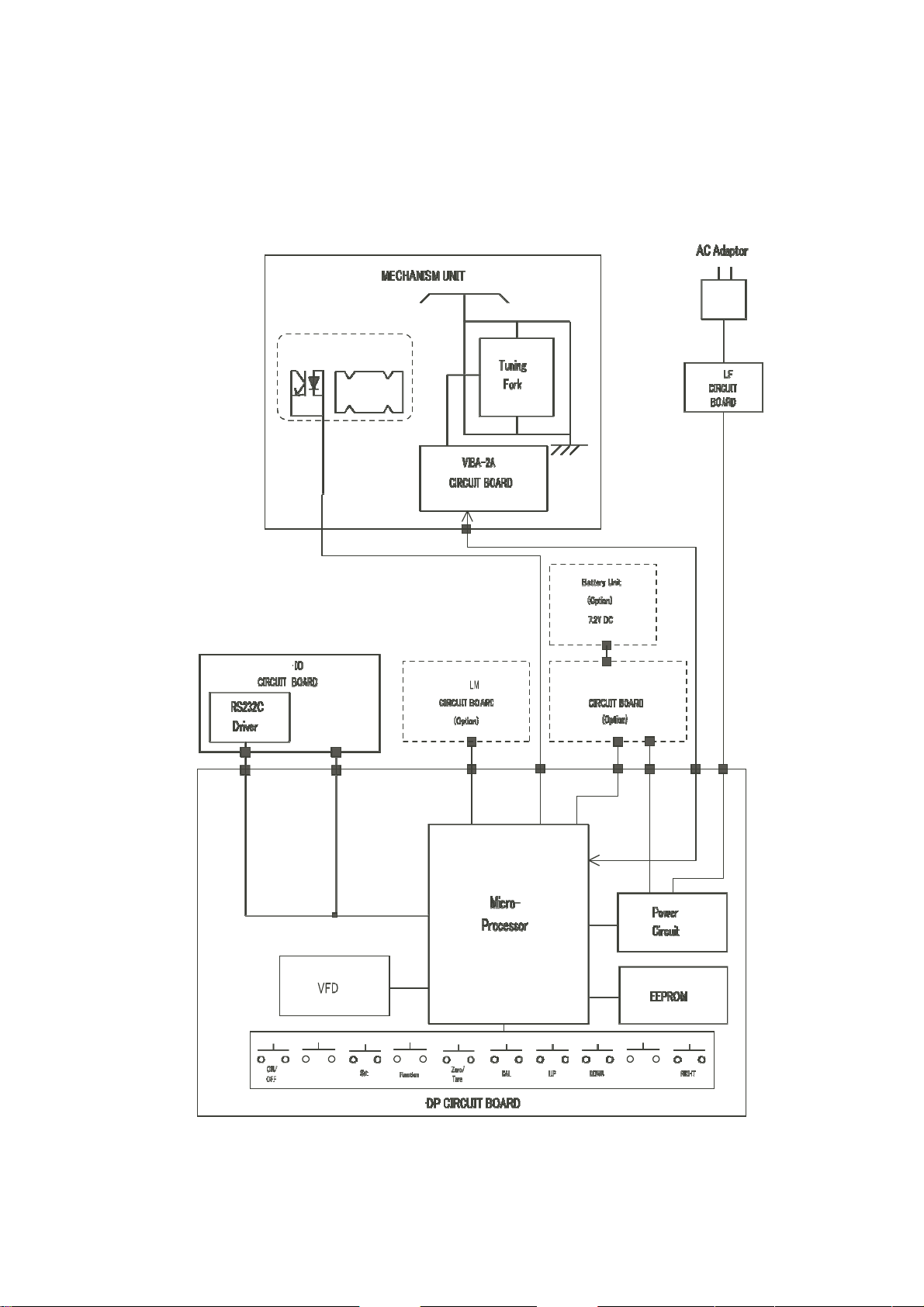

3.1 Block Diagram .1 Block Diagram

Calibration Weight Unit

(PEJ only)

PRINT

BT

LEFT

PEJ/PES-SH-e-0911 5

Page 6

3.2 Whole Wiring

Calibration Weight Unit

(PEJ only)

PRINT LEFT

6 PEJ/PES-SH-e-0911

Page 7

4. Troubleshooting

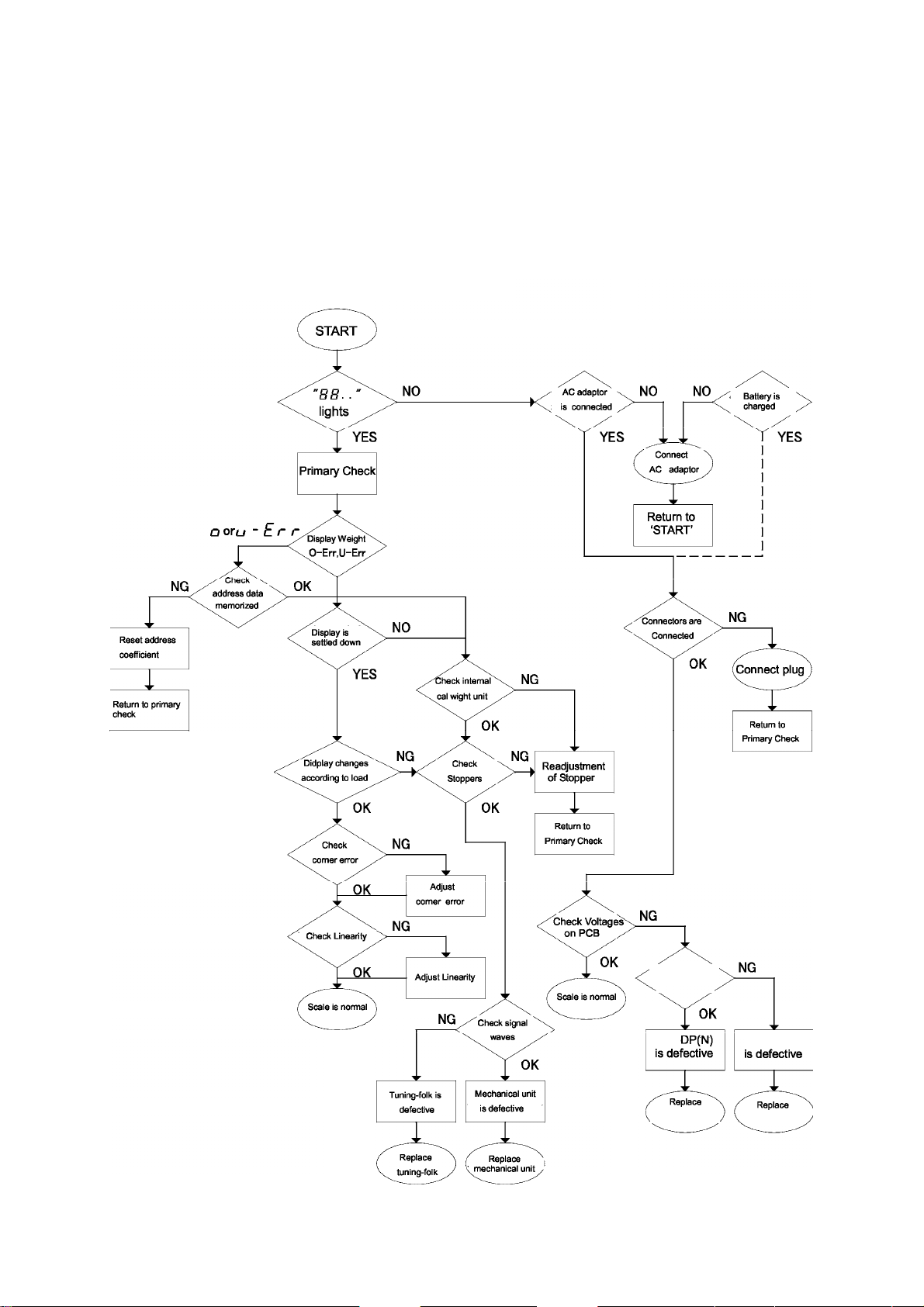

4.1 Troubleshooting Procedure

LF Board

is normal

Board

DP (N) Board

LF Board

LF Board

PEJ/PES-SH-e-0911 7

Page 8

4.2 Troubleshooting Table

SYMPTOMS CAUSES & REMEDY

No display lights on 1. DP board is defective.

2. AC adaptor is defective.

3. Wrong connection of connection cords inside.

4. Built-in battery is discharged.

‘u-Err’ or ‘o-Err’ appears self

test of segment.

Display does not get settled

down.

Display does not repeat

correctly.

Zero points drifts.

‘o-Err’ appears with a net

load less than specified

capacity.

Span is out of specified

range.

Linearity is out of specified

range.

1. Wrong weighing pan is applied.

2. Tuning-fork sensor or mechanism unit is

defective.

3. DP board is defective.

4. Setting of address date has mistake.

5. Coefficient memories (address data) have

changed by noise or static electricity. Adjust

linearity.

1. Some parts such as stopper touch others.

2. Internal calibration weight touches other parts.

3. Weighing pan touches other parts.

4. Foreign substances are in the scale.

5. Tuning-fork sensor or mechanism unit is

defective.

6. Affected by wind or disturbing oscillation.

Check environment or working base. Check

also setting of stabilization time.

1. Gross weight applied to the scale pan (net

weight + tare value) exceeds the scale

capacity.

2. Setting of address data has mistake.

3. Coefficient memories (address data have

changed by noises or static electricity. Adjust

linearity.

4. Wrong external calibration weight is used in

span calibration.

5. Internal calibration weight touches other parts.

1. Tuning-fork sensor or mechanism unit is

defective.

2. DP board is defective.

3. Setting of address data has mistake.

4. Coefficient memories (address data) have

changed by noises or static electricity. Adjust

linearity.

1. Tuning-fork or mechanism unit is defective.

2. Setting of address data has mistake.

3. Coefficient memories (address data) have

changed by noises or static electricity. Adjust

linearity.

4. Wrong external calibration weight is used in

span calibration.

8 PEJ/PES-SH-e-0911

Page 9

4.3 Troubleshooting Table 2

SYMPTOMS CAUSES & REMEDY

- Corner error is too much. 1. Mechanical unit is defective, such as roberval

plate (spring) has been bent or twisted.

2. Pan base touches other parts.

- Display suddenly

disappeared

- appears.

- appears.

- appears.

- appears.

- appears.

- appears.

- appears.

- appears.

- appears.

- appears.

- appears.

1. DP board is defective.

2. AC adaptor is defective.

1. Wrong external calibration weight is used in

span calibration. (External weight is less than

50% of capacity).

1. Span error exceeds 1% of capacity in span

calibration (check the external weight).

2. Tuning-fork sensor or mechanical unit is

defective.

Something is loaded on the pan in automatic span

calibration (remove the things from the pan).

1. Span error exceeds 1% of capacity in

automatic span calibration.

2. Tuning-fork sensor or mechanical unit is

defective.

Interval time is not properly set.

Automatic span calibration stops due to battery

consumption.

The weight error exceeds +/- 100.00mg. Re-set the

weight error within +/- 100.00mg.

Coefficient memories (address data) have changed.

Reset the data.

Internal clock function is defective. Check internal

clock and replace DP board, if necessary.

Coefficient memories (address data) have changed.

Check the address data and reset it, if necessary.

The weight of sample is too light (counting mode and

% mode).

Counting function is not properly operated.

PEJ/PES-SH-e-0911 9

Page 10

4.4 Primary Checks

1. Is any wind around the site?

Is any oscillation? Is the working table stable?

2. Is anything under the pan base or the weighing pan?

3. Is the weighing pan the right one?

4. Is AC adaptor connected both with the scale and with the scale and with the

outlet properly?

5. Is battery option charged sufficiently?

10 PEJ/PES-SH-e-0911

Page 11

4.5 Checks for Electric/Electronic Parts

PEJ/PES-SH-e-0911 11

Page 12

1. Check of input voltage

TP0 – CN1- +12V~+14V

2. Power voltage in the circuit

TP0 – TP1 +4.75V~+5.25V

TP0 – IC13-O +9.5V~+10.5V

TP0 – D13 anode +3.7V~+4.3V

TP0 – D10 cathode +23.5V~+24.5V

3. Check of signal wave

TP0 – TP3 (tuning-fork waveform)

TP0 – TP4 (temperature waveform)

D13 anode – IC11-6pin (VFD filament frequency)

VFD1-1 pin – 56 pin

12 PEJ/PES-SH-e-0911

Page 13

4.5.1 Check of VIBA-2A board

1. Preparation for checks

Prepare the oscilloscope. Turn off the scale and connect probe to CN2.

CH – 1 → (1)

GND → (2)

CH – 2 → (3)

Voltage and Frequency range of

oscilloscope.

• Voltage Range

CH – 1 → 0.1~0.5V/DIV.

CH – 2 → 1V/DIV.

• Frequency Range

0.2m sec/DIV.

CN 1

1. Power Source +4V - +6V

2. GND

3. Power Source -4V - -6V

4. Rectangular Wave Output (tuning-fork)

5. GND

6. Rectangular Wave Output (temperature)

2. How to Check

(1) Vibration starts in 3 seconds after turning on the switch of scale.

(2) Check the amplitude and phase difference of CH-1 and CH-2 as ½ of full

capacity is loaded.

E -amplitude (P-P)

CH-2 → more than 700mV (average: 3.5V)

…

CH-1 → more than 150mV (average: 750mV)

- (phase difference) … 15~120° /T:0.3~0.8 division (0.2msec/DIV.)

PEJ/PES-SH-e-0911 13

Page 14

5. Adjustment and Setting

5.1 Span Calibration (Adjustment with internal weight – PEJ)

The installed adjusting weight allows checking and resetting the weighing accuracy at

any time.

Procedure for adjustment (according to the operating instructions):

Observe stable environment conditions. A warming-up time of approx. 2 hours for

stabilisation is necessary.

Setting: 7. CA. "1"

Operation Display

Switch on the balance using the -key

Press -key, [Auto CAL] is displayed.

Automatic adjustment is started.

Calibration will be carried out automatically.

Calibration process has been concluded.

Auto CAL

CH. 0

CAL

CAL

CH. F5

End

14 PEJ/PES-SH-e-0911

Page 15

5.2 Span Calibration (Adjustment with external weight – PES)

Procedure for adjustment (according to the operating instructions):

Observe stable environment conditions. A warming-up time of approx. 2 hours for

stabilisation is necessary.

Setting: 7. CA. "3"

Operation Display

Switch on the balance using the -key

Press -key.

Zero point will be saved.

Carefully place adjusting weight in the centre

of the weighing plate

Adjustment process is started.

The process of adjustment is completed.

Remove adjusting weight, balance will return

into weighing mode automatically. In case of

an adjustment error or incorrect adjusting

weight the display will show [- Err]; repeat

adjustment process.

PEJ/PES-SH-e-0911 15

Page 16

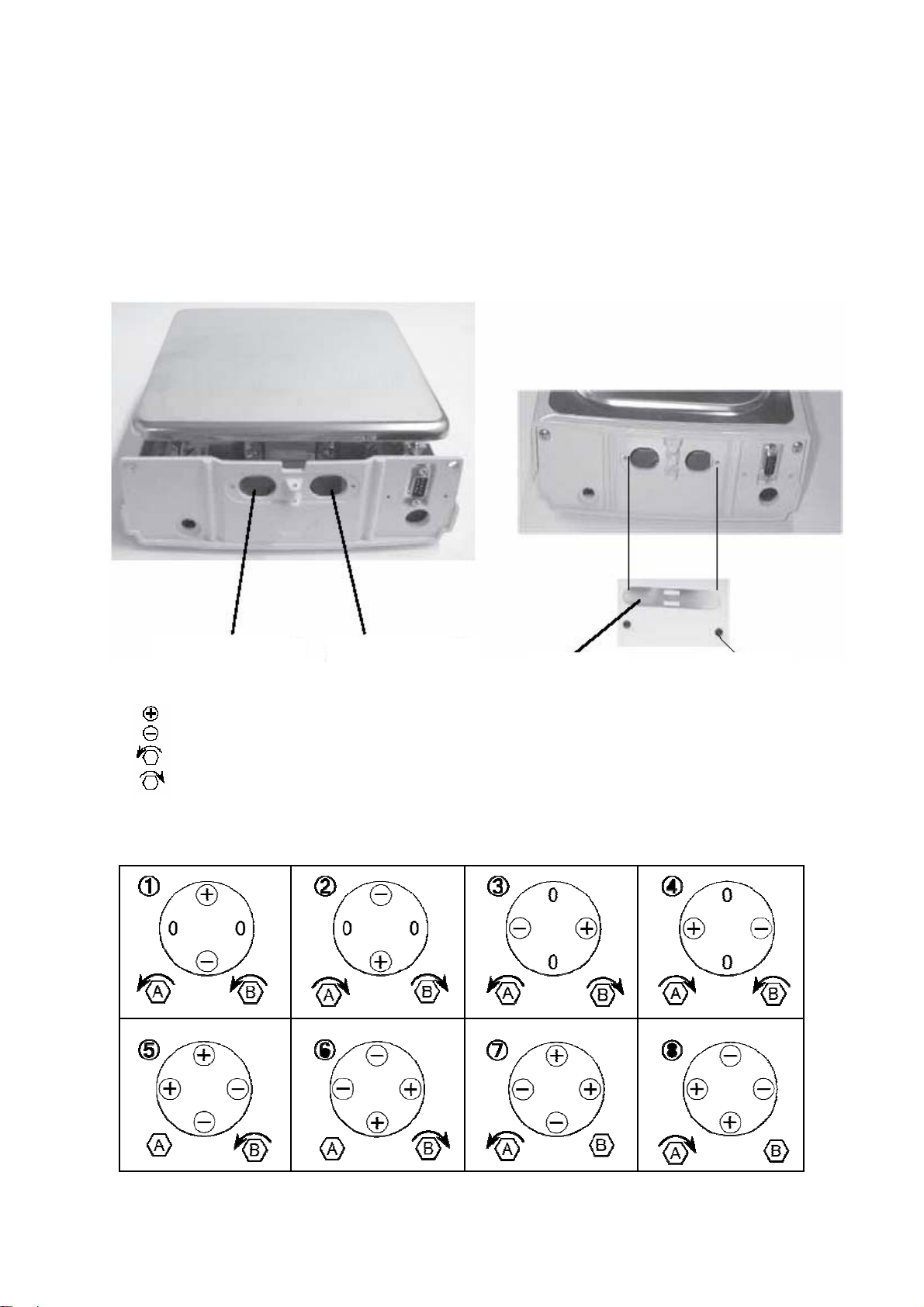

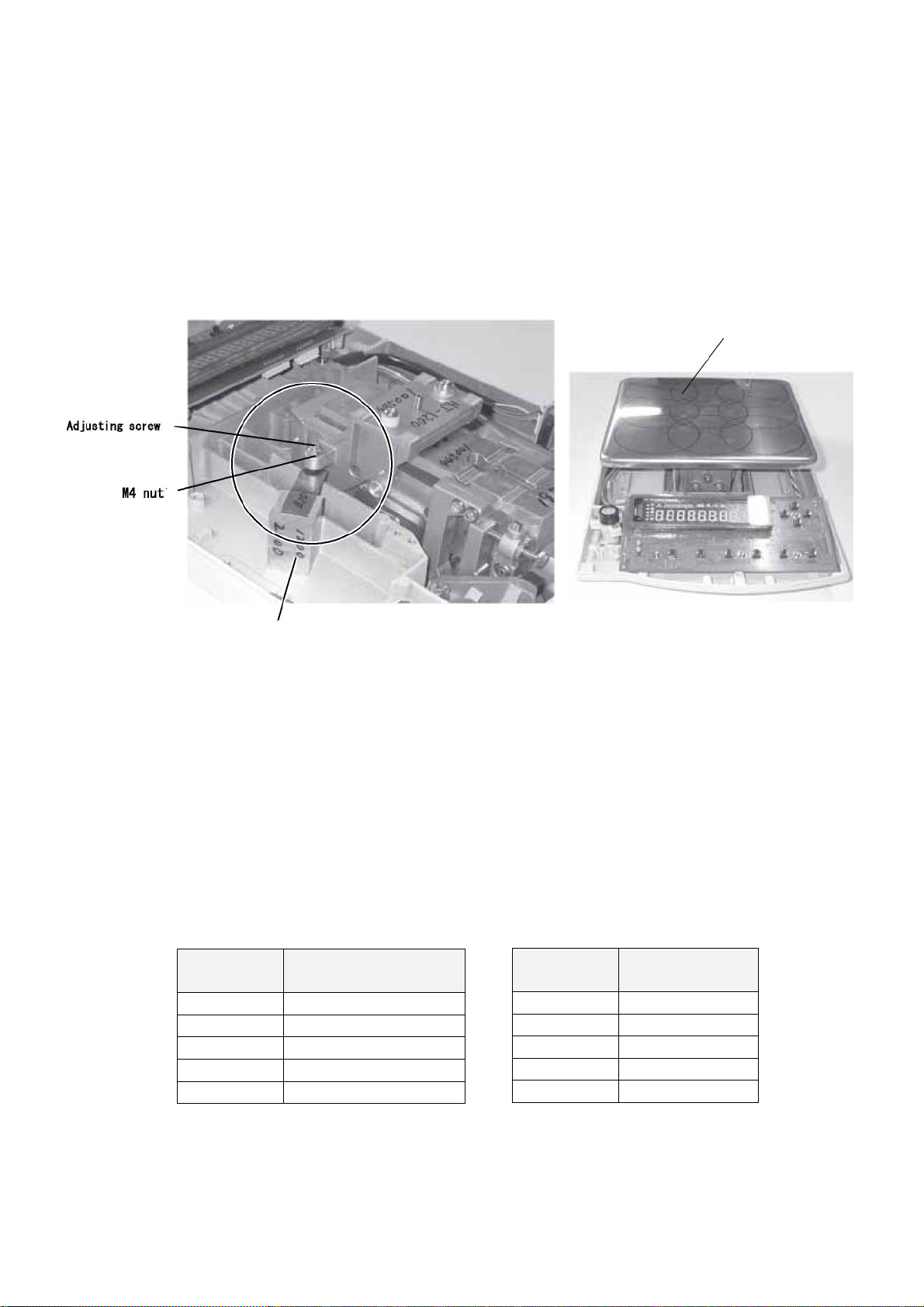

5.3 Corner Error Adjustment

1. Remove the case, then after setting the pan base and the pan, turn the

adjuster legs to bring the bubble of the level to the center of the circle.

2. Push nylon rivet from the inside and remove the rear shutter.

3. Load full scale weight and push T key. Check the corner error referring to

the diagram below.

Adjusting Bolt (A)

Adjusting Bolt (B)

: The error is positive to the center.

: The error is negative to the center.

: Drive the bolt counter-clockwise.

: Drive the bolt clockwise.

Corner Error Adjusting Diagram:

Rear shutter

Nylon rivet

16 PEJ/PES-SH-e-0911

Page 17

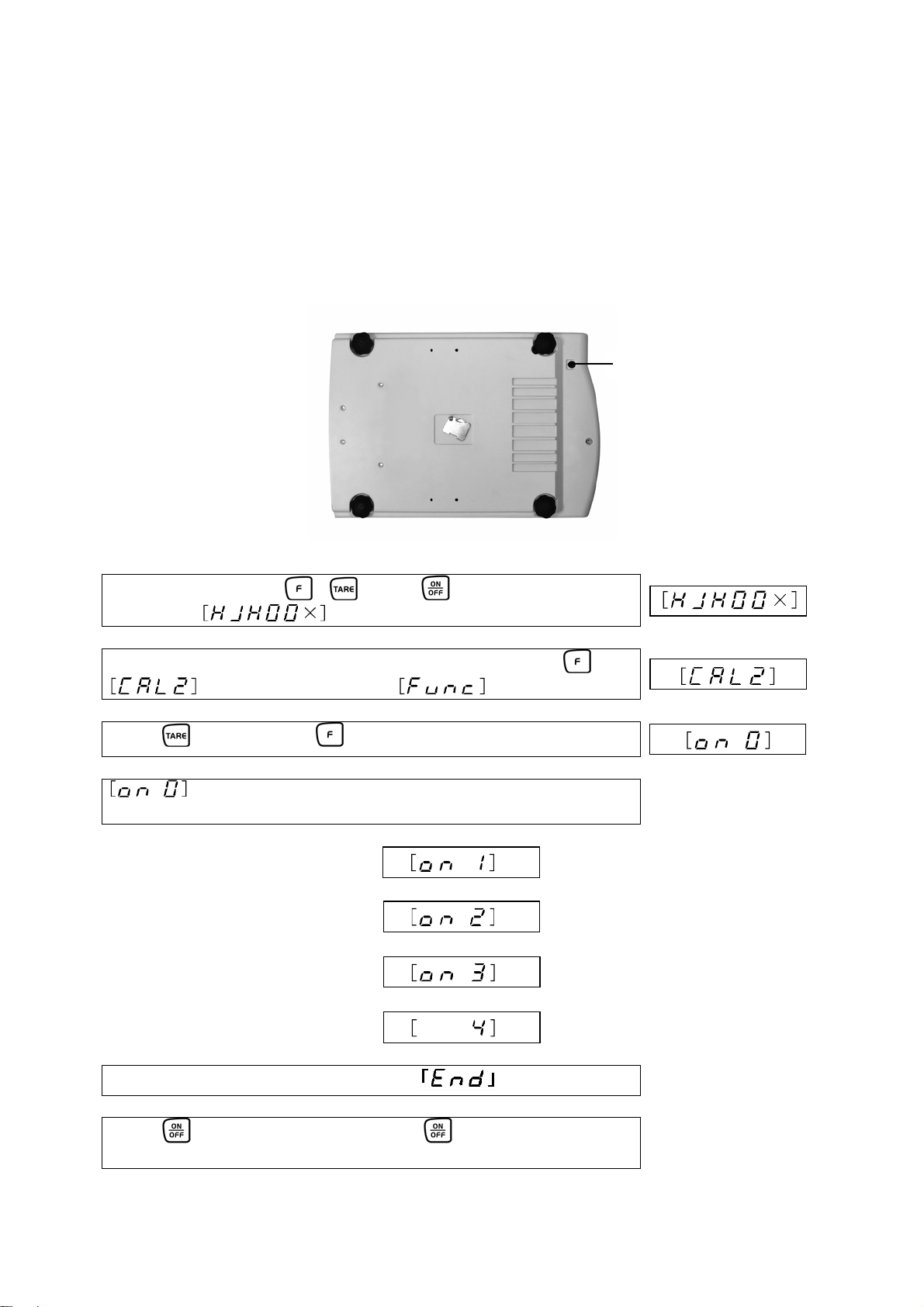

5.4 Linearity Adjustment

Set the verification switch to unlocked before doing the linearity adjustment (see

drawing).

Prior to verification, the verification switch must be moved into the verification

position.

• Position forwards: enabled (unlocked)

• Position backwards: verification position

Position verification switch

While pressing both + , press to ON. Release both

keys when appears (maintenance mode).

After a while, display changes to weight value. Press until

appears after displaying .

Press first and press together and release both.

display starts blinking to indicate zero adjusting is

performed automatically.

Put the weight referring

to the table at the next

page

Returns to weight value after reading .

Press to turn off Power and press again. Then return to

normal weighing mode.

PEJ/PES-SH-e-0911 17

Page 18

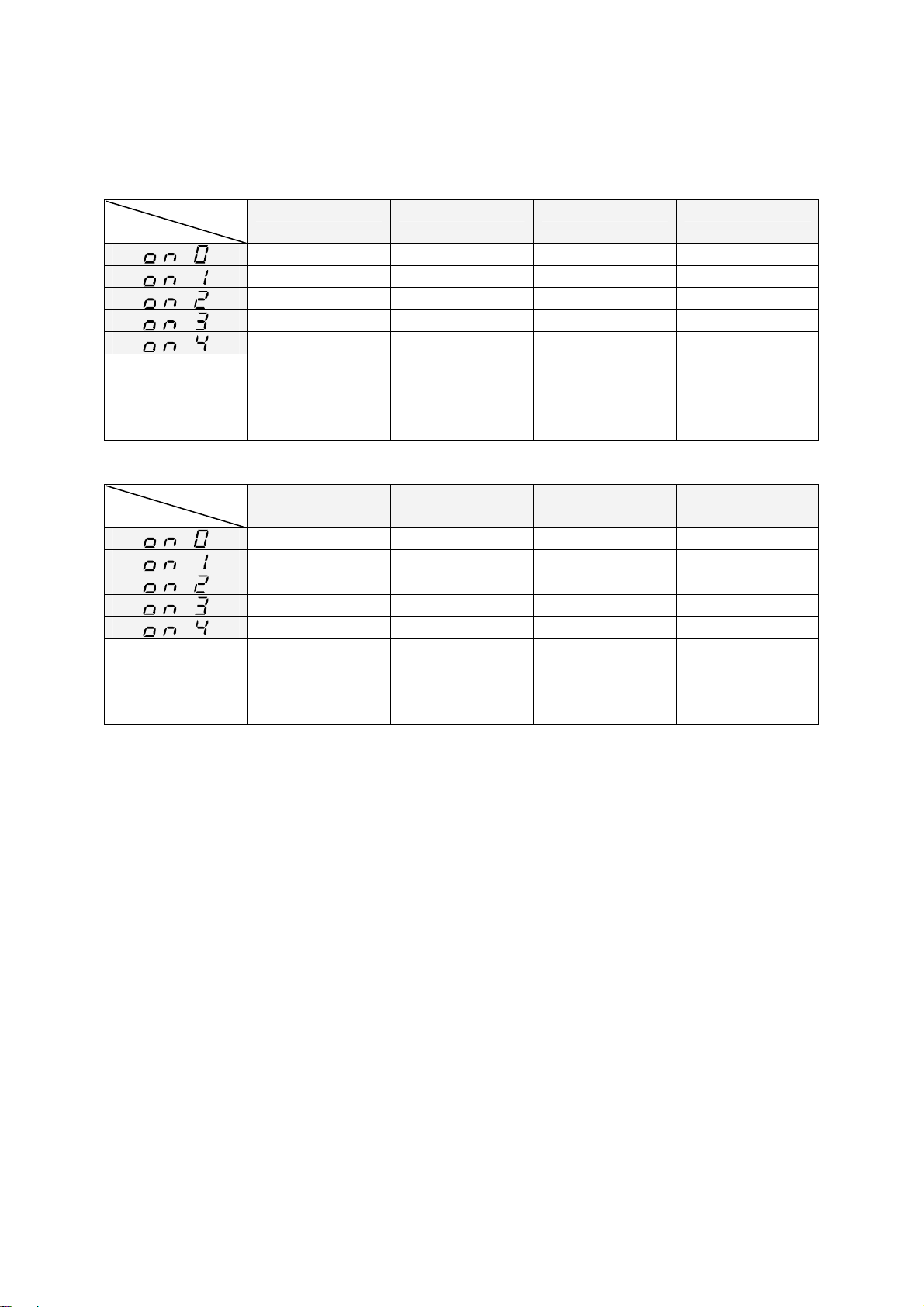

5.4.1 Table Increasing Calibration Weight for Linearity Adjustment

Model

Display

Calibration

Weight

Required

Model

Display

Calibration

Weight

Required

*Please use the weight for F1 or higher class to maintain the accuracy.

220 g 420 g 620 g 2200 g

0 g 0 g 0 g 0 g

50 g 100 g 150 g 500 g

100 g 200 g 300 g 1000 g

150 g 300 g 450 g 1500 g

220 g 420 g 620 g 2200 g

50 g x 4

20 g x 1

4200 g 6200 g 8200 g 15000 g

0 g 0 g 0 g 0 g

100 g 0 1500 g 2000 g 3000 g

2000 g 3000 g 4000 g 7000 g

3000 g 4500 g 6000 g 11000 g

4200 g 6200 g 8200 g 15000 g

1000 g x 4

200 g x 1

100 g x 4

20 g x 1

1000 g x 4

500 g x 4

200 g x 1

100 g x 4

50 g x 4

g x 1

20

2000 g x 4

200 g x1

500

200 g x 1

2000 g x 7

1000 g x 1

g x 4

18 PEJ/PES-SH-e-0911

Page 19

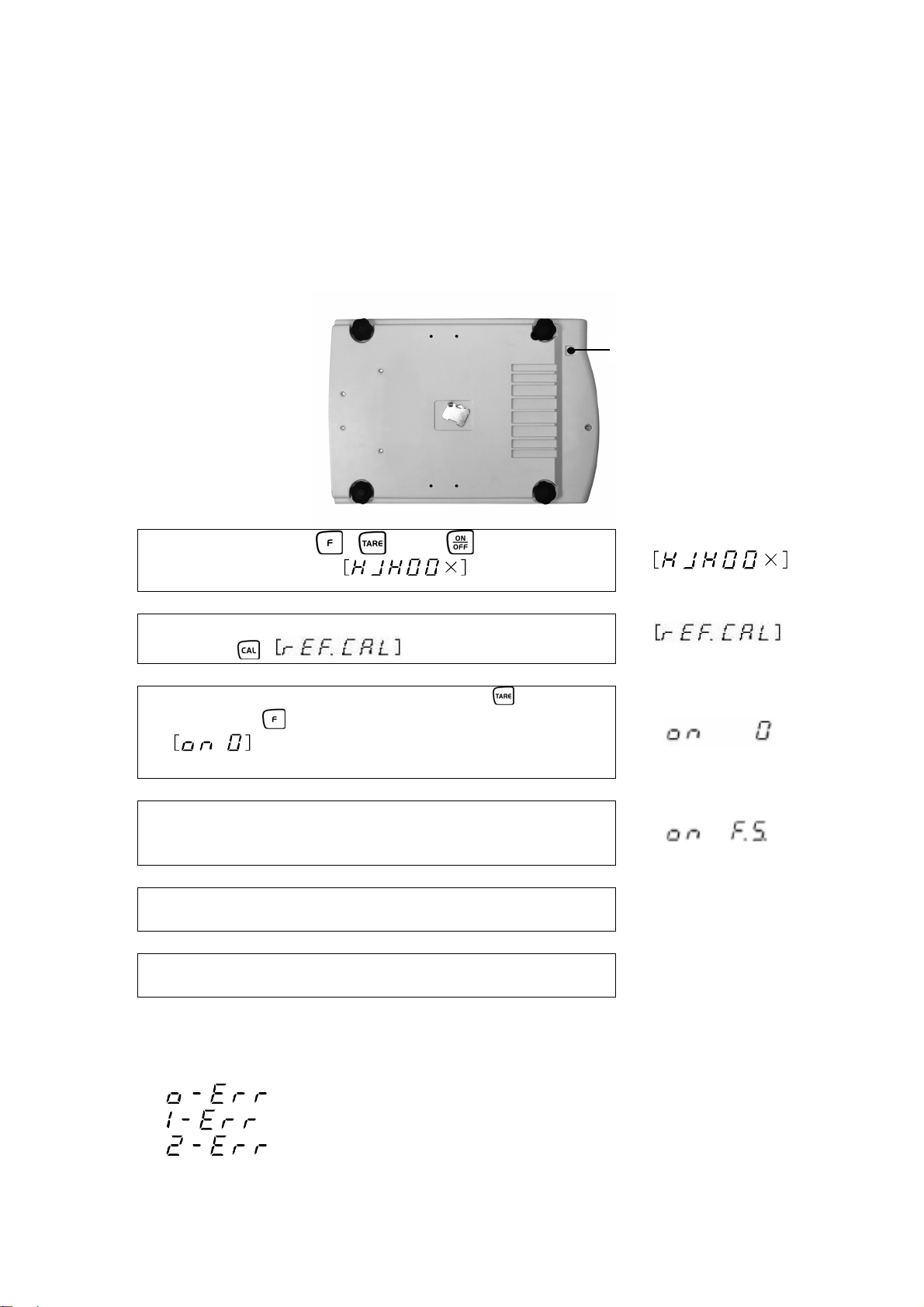

5.5 Calibration of Built-In Weight (Ref Cal) – only PEJ

Set the verification switch to unlocked before doing the calibration of built-in weight

(see drawing).

Prior to verification, the verification switch must be moved into the verification

position.

• Position forwards: enabled (unlocked)

• Position backwards: verification position

While pressing both + , press to ON. Release

1

both keys when appears.

Position verification switch

After a while, display changes to weight value. Press

2

, is displayed.

Verify that no load is on the pan. Press first and

3

press key together and release both.

display starts to blinking to indicate zero

adjustment is performed automatically.

When Zero adjustment is completed, display advances

4

to [on F5], indicating the span adjustment is ready to

start.

5

Load the reference weight. Display starts blinking to

adjust the span automatically.

The calibration is finished and display stops blinking,

6

then automatically returns to weighing mode.

1. It is recommended to use a weight of full scale capacity for accurate

calibration (max. load).

2. Error messages:

: The reference weight is over than the full capacity.

: The reference weight is less than ½ of the capacity.

: The data error exceeds 1% of the capacity.

3. It is recommended to use reference calibration weight of better accuracy than

the scale.

PEJ/PES-SH-e-0911 19

Page 20

6. Parts Replacement

6.1 How to Remove the Case

1. Remove pan and pan base.

2. Remove three screws fixing the case.

M4 x 8 Screws

6.2 How to Cover the Case

1. Cover the case

2. Fixing the case with screws

3. Put the pan base and the pan.

M3 x 15 Screw

20 PEJ/PES-SH-e-0911

Page 21

6.3 How to Replace Mechanical Unit

Mechanical Unit is defective

Replace Mechanical Unit

Reset address data

(data of replacing mechanical unit)

Span Calibration

Adjust the overload stopper

Performance Check

6.4 How to Remove Mechanical Unit

↓

↓

↓

↓

↓

1. Remove the case.

2. Remove the cords (black and white) of tuning-fork assy from VIBA board assy

(remove the solder).

3. Remove nylon cramp fixing cords of tuning-fork assy.

Cord of tuning-fork assy

(black) (white)

Nylon cramp

4. Remove four bolts fixing mechanical unit.

5. Remove the mechanical unit from the chassis.

PEJ/PES-SH-e-0911 21

Page 22

M5 x 20 bolt

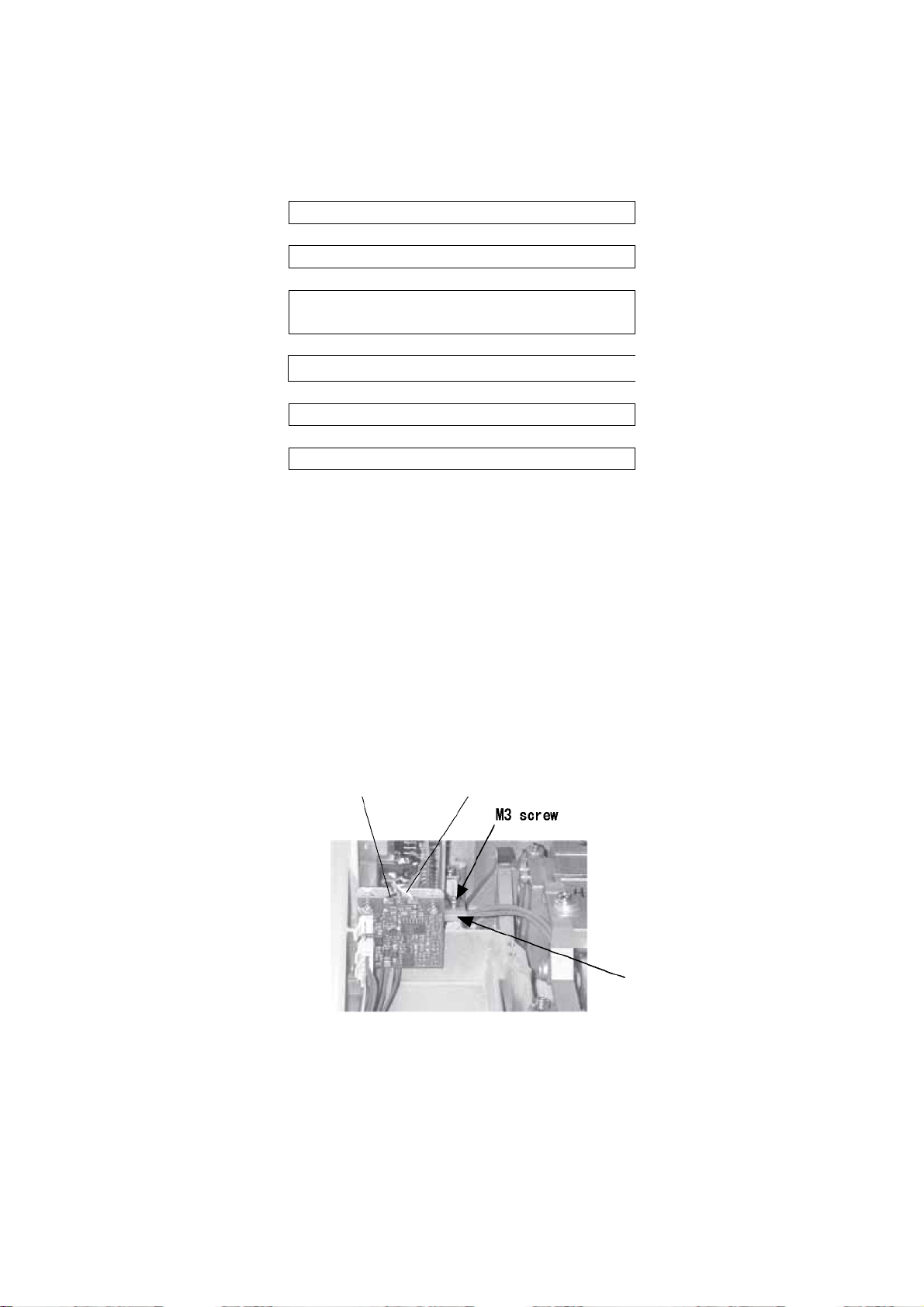

6.5 How to Install Mechanical Unit

1. Put the mechanical unit on the chassis (take care to put radiation shield

between the chassis and the mechanical unit.

2. Solder the cords of tuning-fork sensor to VIBA board assy (black cord to “1”

and white cord to “3”, referring to the picture below.

3. Fix the cords of tuning-fork sensor with nylon cramp (be sure these cords are

not touch with other parts).

4. Cover the case.

black cord white cord

nylon cramp

22 PEJ/PES-SH-e-0911

Page 23

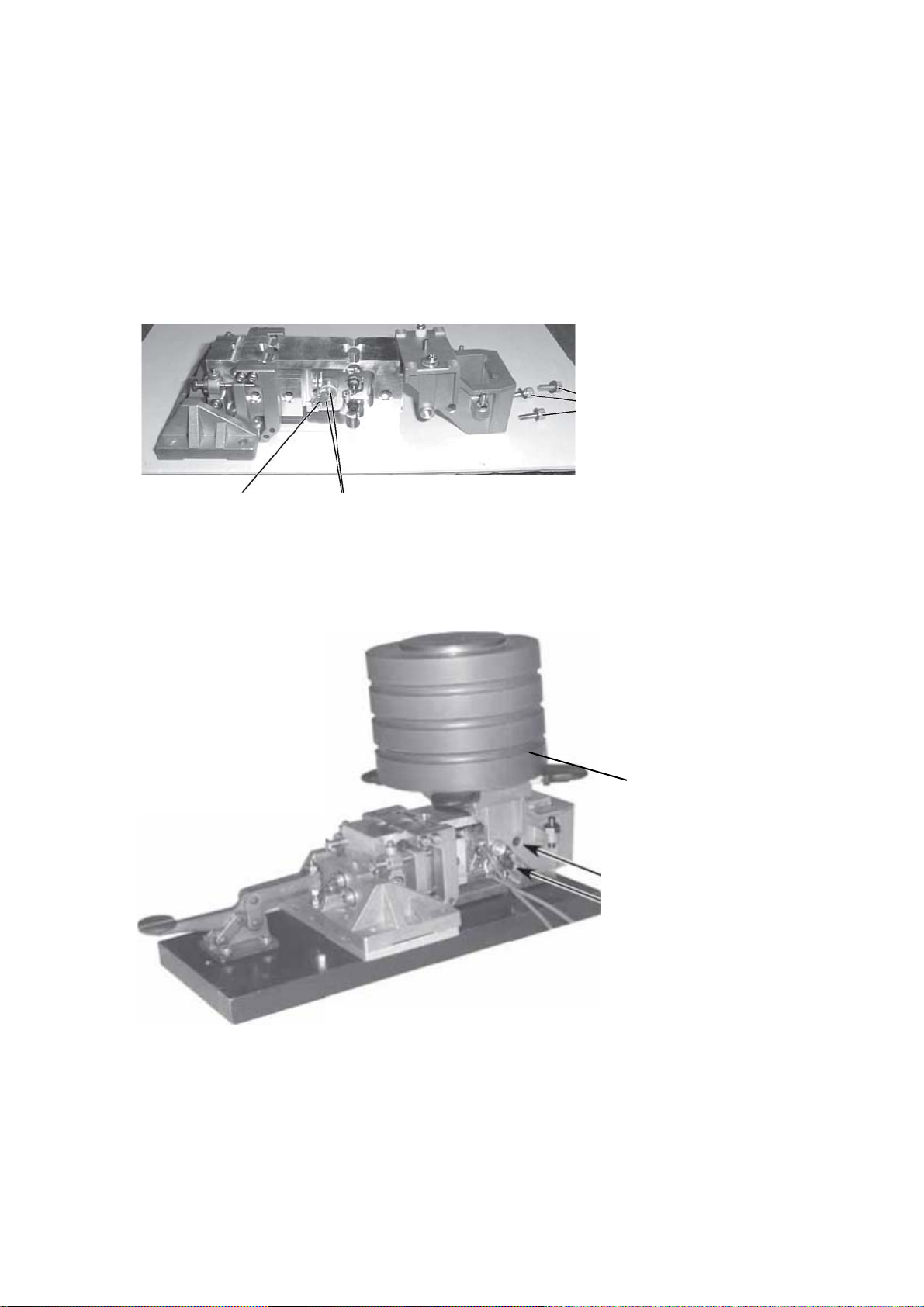

6.6 Sequence of Tuning-Fork Sensor Replacement

Tuning-Fork sensor is defective.

↓

Replace Tuning-Fork sensor.

↓

Linearity adjustment

↓

Adjust the overload stopper

↓

Performance check

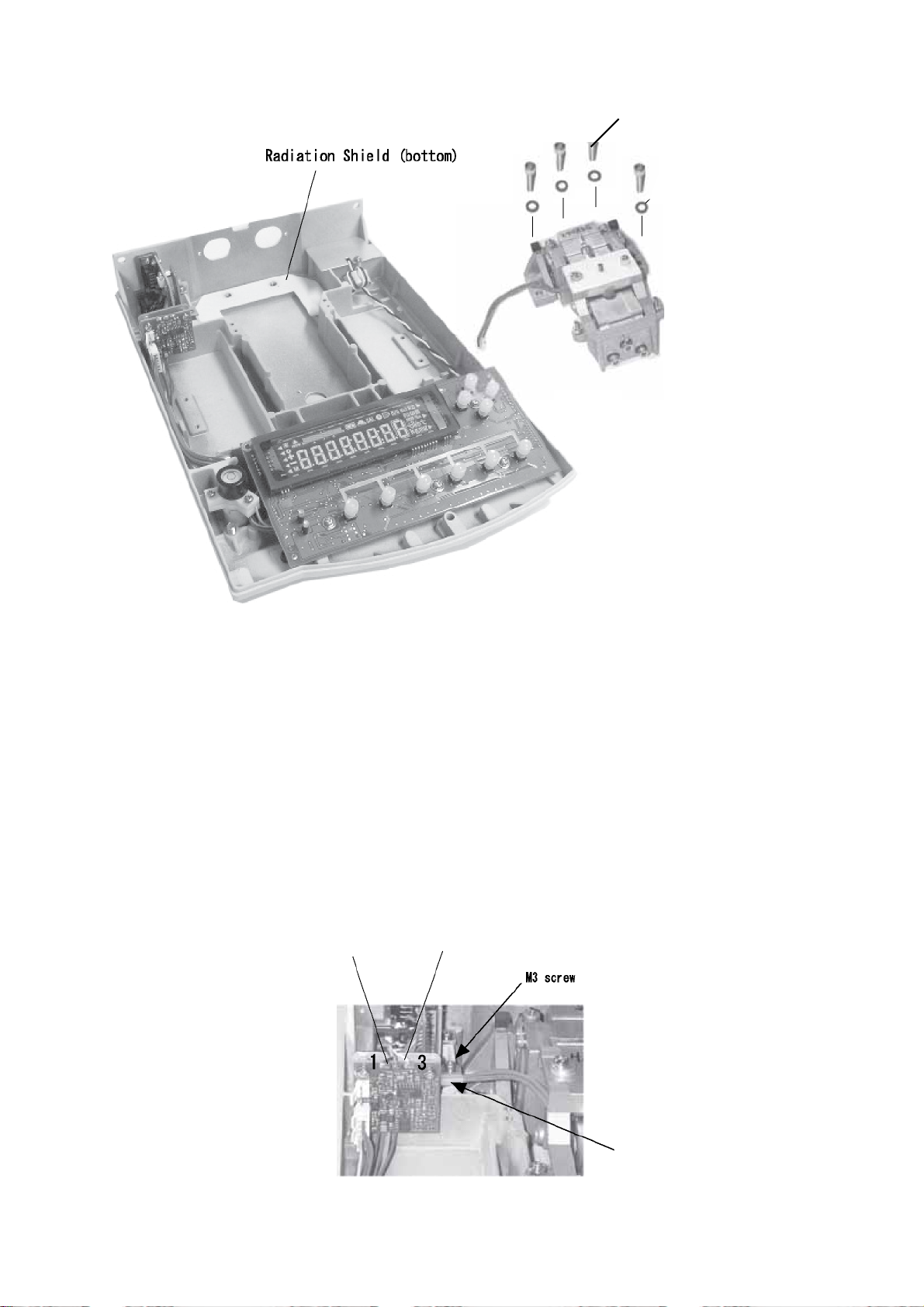

6.7 How to Remove Tuning-Fork Assy

1. Remove the mechanical unit from the chassis.

2. Remove the sub-pan base assy by loosing three screws on the mechanical

unit.

3. Loose two screws to remove tuning-fork assy.

4. Replace tuning-fork assy.

Three screws

fixing sub-pan

base assy

tuning-fork assy two screws fixing tuning-fork assy

PEJ/PES-SH-e-0911 23

Page 24

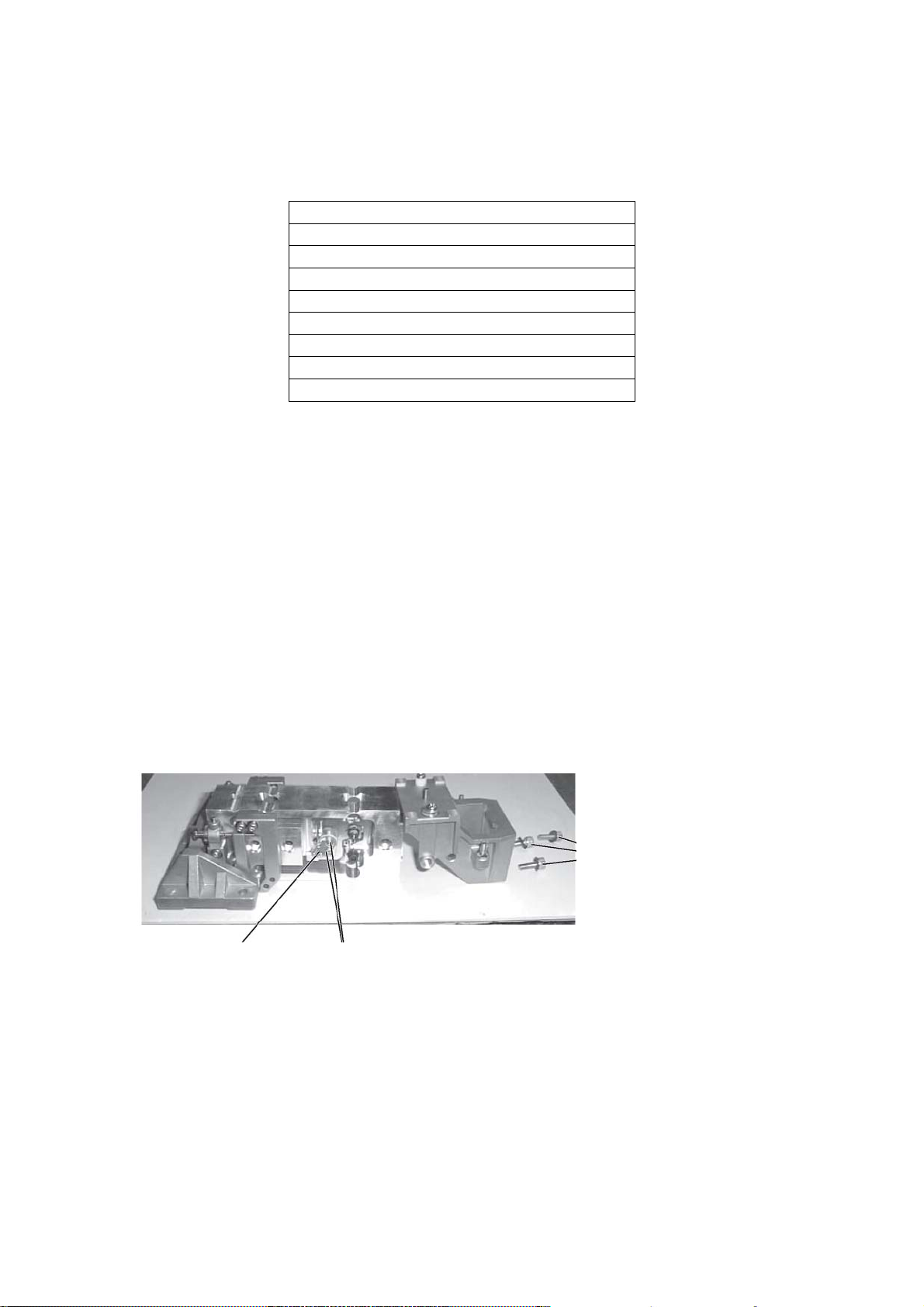

6.8 How to Install Tuning-Fork Assy

1. Temporarily fix tuning-fork assy to mono-metal block.

2. Fix sub-pan base assy to mono-metal block with screws (torque: 52.5kgfcm).

3. Tightly fix tuning-fork assy with screws while putting the weight (10kg) on the

sub-pan base assy (torque: 30kgfcm).

sub-pan base

fixing screws

(three)

tuning-fork assy tuning-fork fixing screws (two)

Weight 10kg

Torque: 30kgfcm

24 PEJ/PES-SH-e-0911

Page 25

6.9 Adjustment of Overload Stopper

q

1. Fix the pan base assy to the mechanical unit and put the square pan on it.

2. Connect AC adaptor and turn on the switch.

3. Change to maintenance mode.

4. Adjust the overload stopper.

S

uare pan

[Adjusting procedure]

1. Remove the pan and the pan base.

2. Push TARE key to display [0.0.0.].

3. Put the clearance gauge between the adjusting screw and the chassis, then

4. After adjusting the stopper, check the overload-error value in referring to the

Jig to adjust the stopper

adjust the stopper.

table below.

Capacity Overload stopper

adjustment

2200 g 6000 ~ 7000 g

4200 g 6000 ~ 7000 g

6200 g 9500 ~ 11500 g

8200 g 18500 ~ 20000 g

15000 g 24000 ~ 26000 g

Capacity Clearance

2200 g 0.2

4200 g 0.2

6200 g 0.2

8200 g 0.35

15000 g 0.4

PEJ/PES-SH-e-0911 25

Page 26

6.10 Sequence of Circuit Board Replacement

[How to Remove DP (N) Board]

1. Open the case. Remove SW spacer and key spacer from DP (N) board.

2. Loose four screws from DP (N) board.

3. Take off the connectors of CN1, CN3 and CN4 on DP (N) board.

SW spacer Key spacer

[How to Install DP (N) Board]

1. Connect the connectors to DP (N) board.

CN1: LFM board assy cord

CN3: Tuning-fork assy cord

CN4: RS Board assy cord

2. Fix DP (N) board with screws.

3. Fix SW spacer and key spacer.

CN1

DP (N) board fixing screws (four)

CN4

Key Spacer

CN3

This projection should

be on right lower side.

26 PEJ/PES-SH-e-0911

Page 27

7. Installation of Options

7.1 Installation of Battery Option

1. Remove the case.

2. Fix battery assy to the chassis with two screws.

3. Fix cords of BT board assy with nylon cramp and two screws.

4. Connect the cord of BT board assy to CN2 of DP (N) board.

5. Put “BATTERY” label on the AC adaptor.

Battery Assy

M4 screws

CN2 connector

PEJ/PES-SH-e-0911 27

Page 28

7.2 Installation of Relay Contact Option

1. Remove the case.

2. Fix LM board assy to the chassis with two screws.

M3 x 10 screws

28 PEJ/PES-SH-e-0911

Page 29

3. Fix cords of LM board assy with LCD packing and connect the cords to CN7 of

display board.

4. Put RELAY label.

CN 7

LCD packing

RELAY label

PEJ/PES-SH-e-0911 29

Page 30

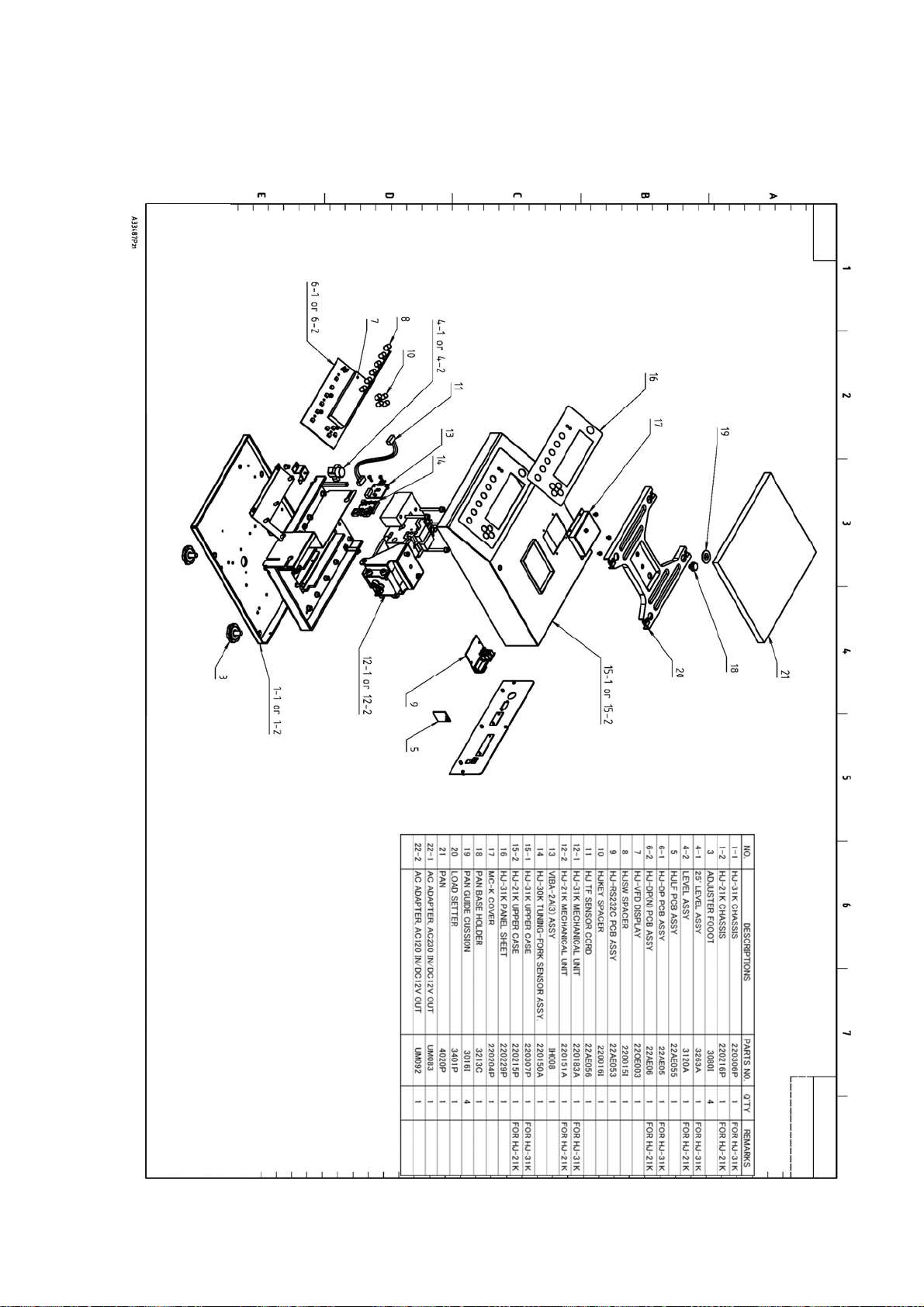

8. Parts List

8.1 Explosion Diagram

30 PEJ/PES-SH-e-0911

Page 31

8.2 Bill of Material

A

A

)

A

A

A

A

A

POS. NO. DESCRIPTIONS

1 CHASSIS 220012I 1

2

3 HOLE PLUGDP-312 110002J 1

4 SHUTTER 3190P 1

5 DP PCB SUPPORT PLATE 220072P 1

6 LCD SPACER 3650P 1

7 LCD PACKING 7398P 1

8 LEVEL ASSY 3120

9 RS232C PCB ASSY 22AE053 1

10 RS BLIND 220062P 1

11 RS BRACKET 220069P 1

12 PCB SPACER FOR RS232 3166C 2 for RS232 PCB

13 RS SUTTER 220073P 1

14 RS PACKING 220090P 1

15 REAR SHUTTER 220066P 1

16 NYLON RIVET NRP-355 22CN0L3 2 with rear shutter (220066P

17 LF PCB ASSY 22AE055 1

18 LF PCB SUPPORT PLATE 220071P 1

19 LF COVER 220032P 1

20 DP(N) PCB ASSY 22AE06 1

20-1 VFD DISPLAY 22OE003 1

20-2 TACT SWITCH 22SW001 1

20-3 SLIDE SWITCH 11SW002 10

21 SW SPACER 220015I 1

22 KEY SPACER 220016I 1

23 TF SENSOR CODE 22AE056 1

24 VIBA-2A (3) Assy IH008 1

25 VIBA STAY 22AE70P 1

26 PCB SPACER FOR VIBA-2

27 NYLON CLAMP NK-2N OM007 2

28 HEAT SHUTTER PLATE 220068P 1

29 MECHANICAL UNIT 1

29-1 TUNING FORK SENSOR ASSY 1

30 SUB PAN BASE ASSY 22006

31 UPPER CASE 220011I 1

32 DISPLAY PANEL SHEET 220063P 1

33 SWITCH PANEL SHEET 220064P 1

34 DUST COVER 220014I 1

35 PROTECTOR 220065P 1

36 PAN BASE ASSY 220063

36-1 PAN GUIDE 3071I 4

36-2 M-1064 22OM014 1

37 SQUARE PAN 220067P 1

38(A)

38(B)

DJUSTER 200034I 4

C ADAPTER, AC230 IN/DC12V OUT UM083 1

C ADAPTER, AC120 IN/DC12V OUT UM092 1

PARTS NO. Q'TY REMARKS

1

3166C11 1 for VIBA-2A(3) PCB

1

1

PEJ/PES-SH-e-0911 31

Page 32

8.3 View of Components PES 31000-1M

32 PEJ/PES-SH-e-0911

Loading...

Loading...