Page 1

KERN & Sohn GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: info@kern-sohn.com

Phone: +49-[0]7433- 9933-0

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

Operating manual

Electronic Crane Scales

Logbook

Regular maintenance and care

KERN HFT

Version 1.2

2018-04

GB

HFT-BA-e-1812

Importør:

Impex Produkter AS

Gamle Drammensvei 107

1363 Høvik

www.impex.no

info@impex.no

Tel.: 22 32 77 20

Page 2

2 HFT-BA-e-1812

GB

KERN HFT

Version 1.2 2018-04

Operating instructions / logbook

Electronic Crane Scales

Contents

1 Technical data _________________________________________________ 4

1.1 Dimensions balance (mm) ______________________________________________________ 5

1.2 Dimensions display unit (mm) ___________________________________________________ 6

1.3 Nameplate __________________________________________________________________ 7

1.4 EC-Declaration of -Conformity ___________________________________________________ 8

2 General Safety Instructions ______________________________________ 9

2.1 Duties of the owner-operator ____________________________________________________ 9

2.2 Organizational measures _______________________________________________________ 9

2.3 Pay attention to the instructions in the Operation Manual ______________________________ 9

2.4 Environmental conditions ______________________________________________________ 10

2.5 Proper use _________________________________________________________________ 10

2.6 Improper Use _______________________________________________________________ 10

2.7 Warranty ___________________________________________________________________ 11

2.8 Safe working _______________________________________________________________ 11

2.9 Monitoring of Test Resources __________________________________________________ 11

2.10 Testing upon acceptance ______________________________________________________ 11

2.11 Initial Commissioning _________________________________________________________ 11

2.12 Shutdown and storage ________________________________________________________ 11

3 The crane scales at a glance ____________________________________ 12

3.1 Appliance overview crane scale _________________________________________________ 12

3.2 Appliance overview display unit _________________________________________________ 13

3.3 Overview of display __________________________________________________________ 14

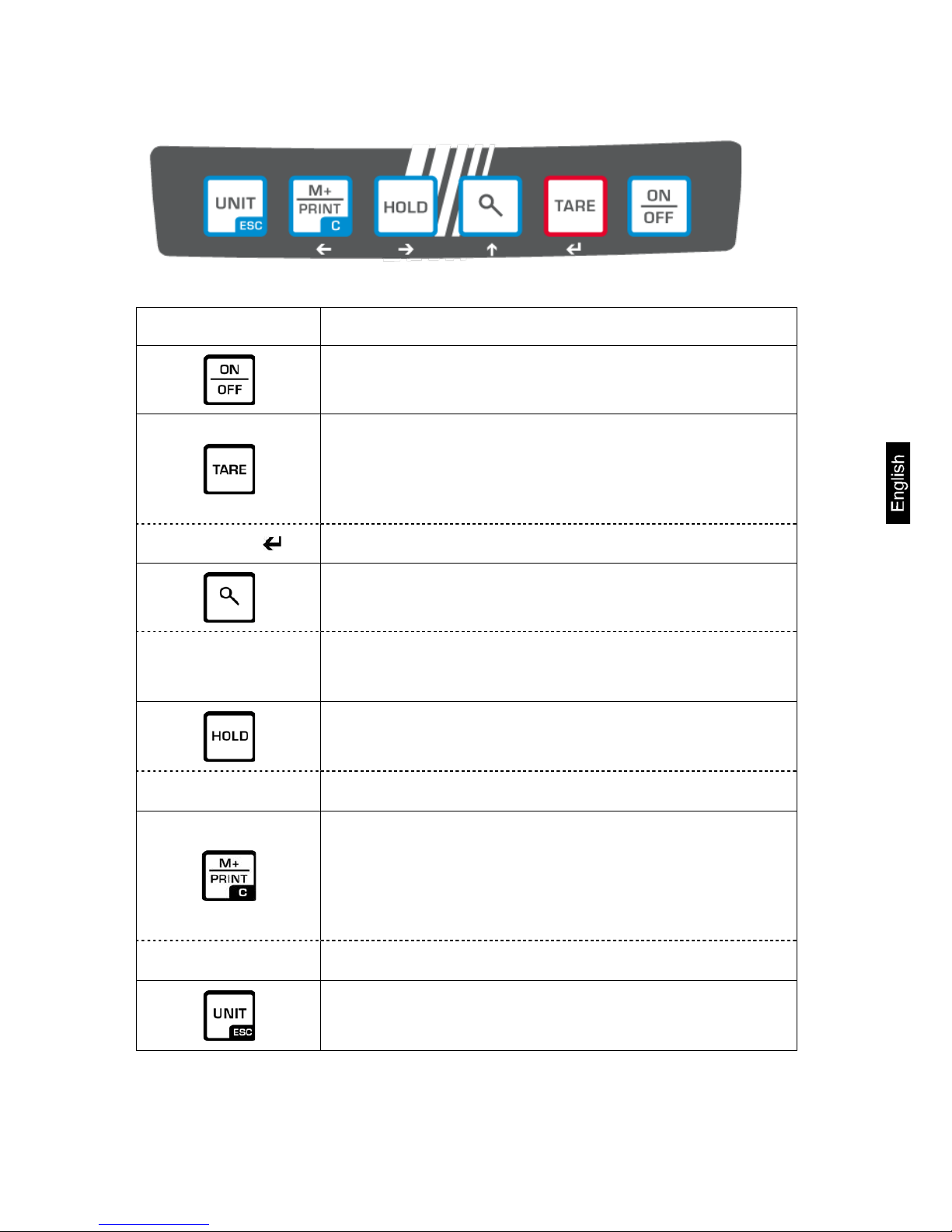

3.4 Keyboard overview ___________________________________________________________ 15

3.5 Numerical input via the navigation buttons ________________________________________ 16

3.6 Label______________________________________________________________________ 16

4 Commissioning _______________________________________________ 17

4.1 Unpacking _________________________________________________________________ 17

4.2 Checking the original dimensions _______________________________________________ 17

4.3 Rechargeable battery operation _________________________________________________ 18

4.4 Suspending the balance_______________________________________________________ 19

5 Operation ____________________________________________________ 20

5.1 Safety instructions ___________________________________________________________ 20

5.2 Loading the crane scales ______________________________________________________ 21

5.3 Turn on/off _________________________________________________________________ 24

5.4 Set balance to zero __________________________________________________________ 24

5.5 Taring _____________________________________________________________________ 25

5.6 Weighing __________________________________________________________________ 25

5.7 Fix the weight value (Data-HOLD function) ________________________________________ 26

Page 3

HFT-BA-e-1812 3

5.8 Weighing Units ______________________________________________________________ 26

5.9 Totalization _________________________________________________________________ 28

5.10 Automatische Nullpunktkorrektur ________________________________________________ 31

6 Menu ________________________________________________________ 32

6.1 Navigation in the menu: _______________________________________________________ 32

6.2 Menu overview ______________________________________________________________ 33

7 Adjustment ___________________________________________________ 35

8 Data output RS 232 ____________________________________________ 37

8.1 Technical data ______________________________________________________________ 37

8.2 Technical data ______________________________________________________________ 37

8.3 Continuous data output _______________________________________________________ 37

8.4 Printer mode ________________________________________________________________ 38

9 Error messages _______________________________________________ 39

10 Cleaning, Repair, Maintenance and Disposal _______________________ 40

10.1 Cleaning and Disposal ________________________________________________________ 40

10.2 Regular maintenance and care _________________________________________________ 41

10.3 Regular maintenance _________________________________________________________ 41

10.4 Checklist „Regular maintenance“, (see chapter 10.3) ________________________________ 42

11 Enclosure ____________________________________________________ 45

11.1 Checklist „Enhanced maintenance“ (General revision) _______________________________ 45

11.2 List „spare parts and repair of safety-relevant parts“ _________________________________ 46

Page 4

4 HFT-BA-e-1812

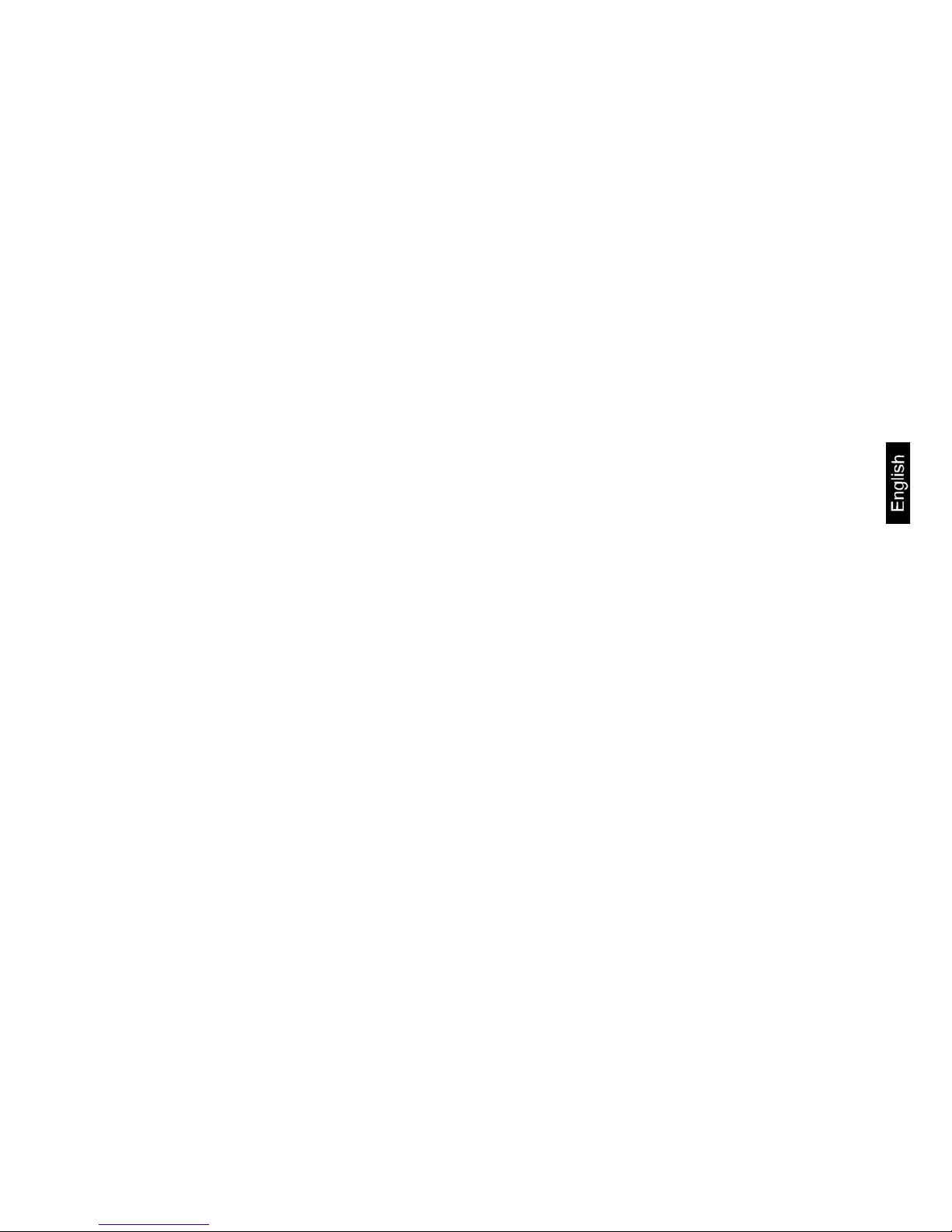

1 Technical data

KERN HFT 3T0.5 HFT 5T1 HFT 10T2 HFT 15T5

Readability (d) 0.5 kg 1 kg 2 kg 5 kg

Weighing range (max) 3 000 kg 5 000 kg 10 000 kg 15 000 kg

Taring range (subtractive) 3 000 kg 5 000 kg 10 000 kg 15 000 kg

Reproducibility 500 g 1 kg 2 kg 5 kg

Linearity ± 1 kg ± 2 kg ± 4 kg ± 10 kg

Recommended adjustment

weight, not added (class)

3 t (M3) 5 t (M3) 10 t (M3) 15 t (M3)

Stabilization time 2 s

Precision 0.2 % of max.

Warm-up time 30 min 10 min 10 min 10 min

Unit kg, lb

Allowable ambient

temperature

0…+40 °C

Relative humidity 0 to 80 %, non-condensing

Input Voltage 220V - 240V AC 50 Hz

Secondary voltage powerpack 12V, 500 mA

Rechargeable battery

(standard equipment)

6 V, 4 Ah

Service life (background illumination OFF) 35 h

Loading time 12 h

Display Digit height 22 mm

Dimensions display unit

W x D x H, ( mm)

175 x 84 x 39

Dimensions, completely

assembled

W x D x H, ( mm)

130x650x130 160x760x160 180x870x180 180x870x180

Housing material Chromatized steel

Material of display unit Plastic

Net weight (kg) 87

Page 5

HFT-BA-e-1812 5

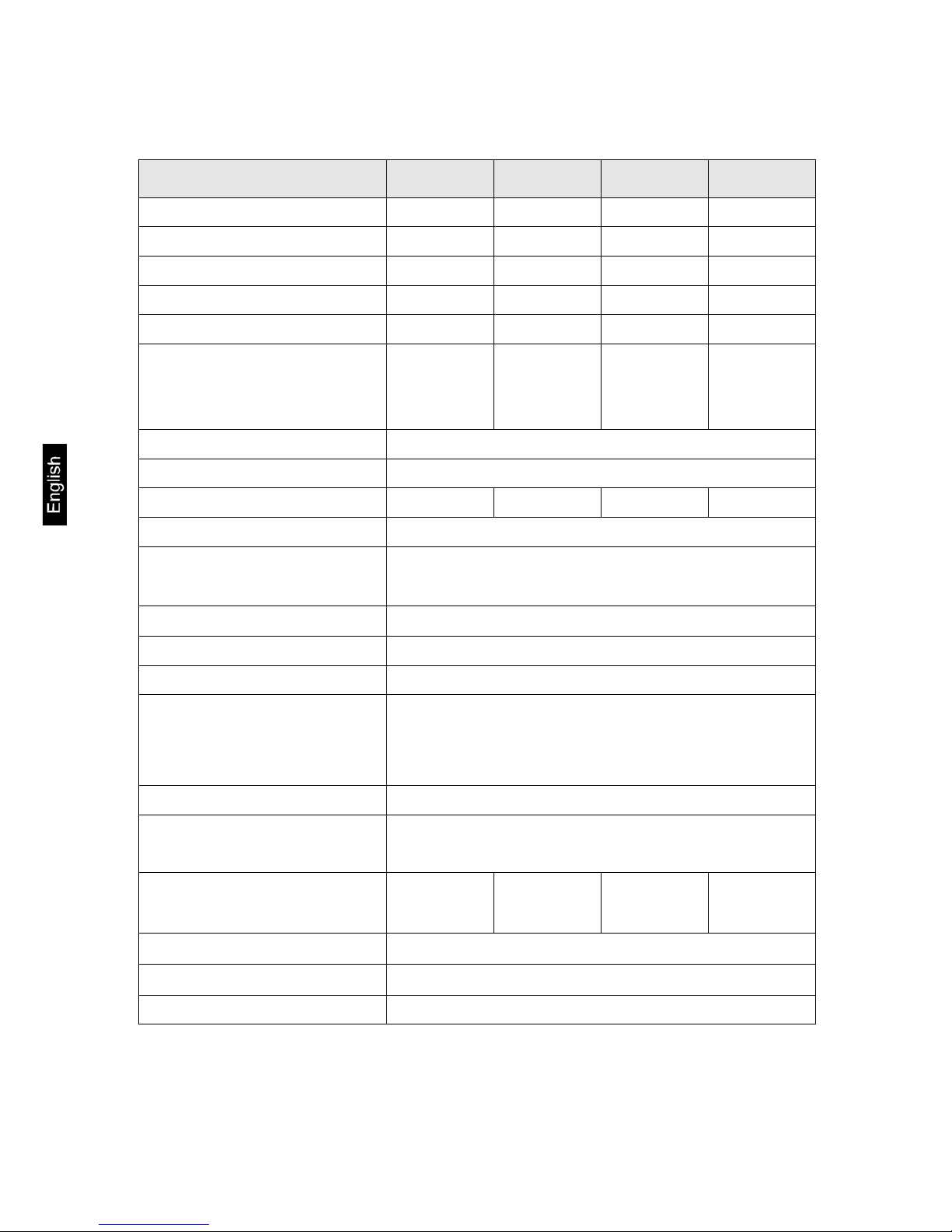

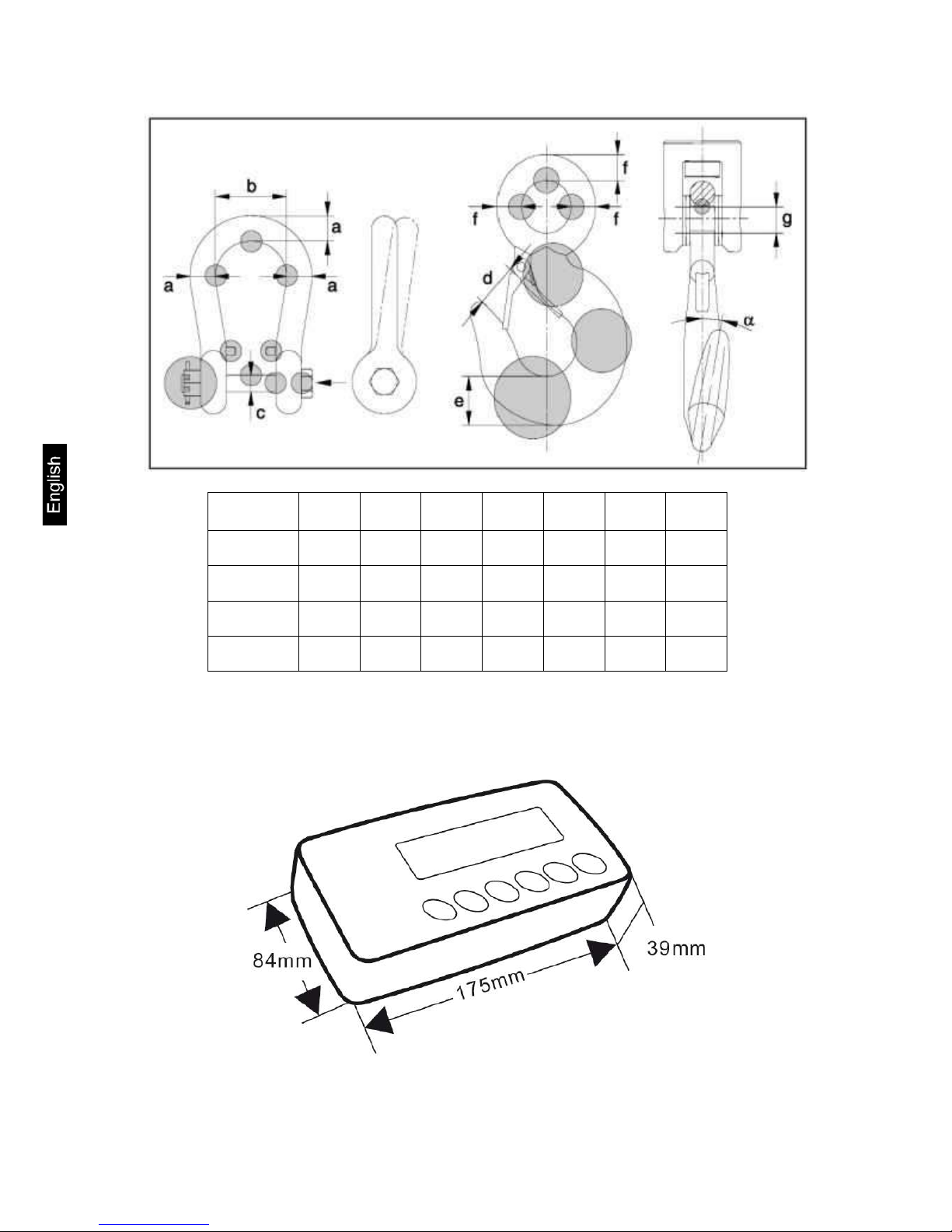

1.1 Dimensions balance ( mm)

Model A B C D E

HFT 3T0.5 43 28 606 650 130

HFT 5T1 58 40 693 760 160

HFT 10T2 83 51 781 870 180

HFT 15T5 99 57 842 950 180

Page 6

6 HFT-BA-e-1812

Model a b c d e f g

HFT 3T0.5 16 42.9 19.1 27.5 28 16 31

HFT 5T1 22.4 57.9 25.4 40 45 31 51

HFT 10T2 31.8 82.6 35.1 51 57 30 62

HFT 15T5 38.1 98.6 41.4 57 70 30 73

1.2 Dimensions display unit (mm)

Page 7

HFT-BA-e-1812 7

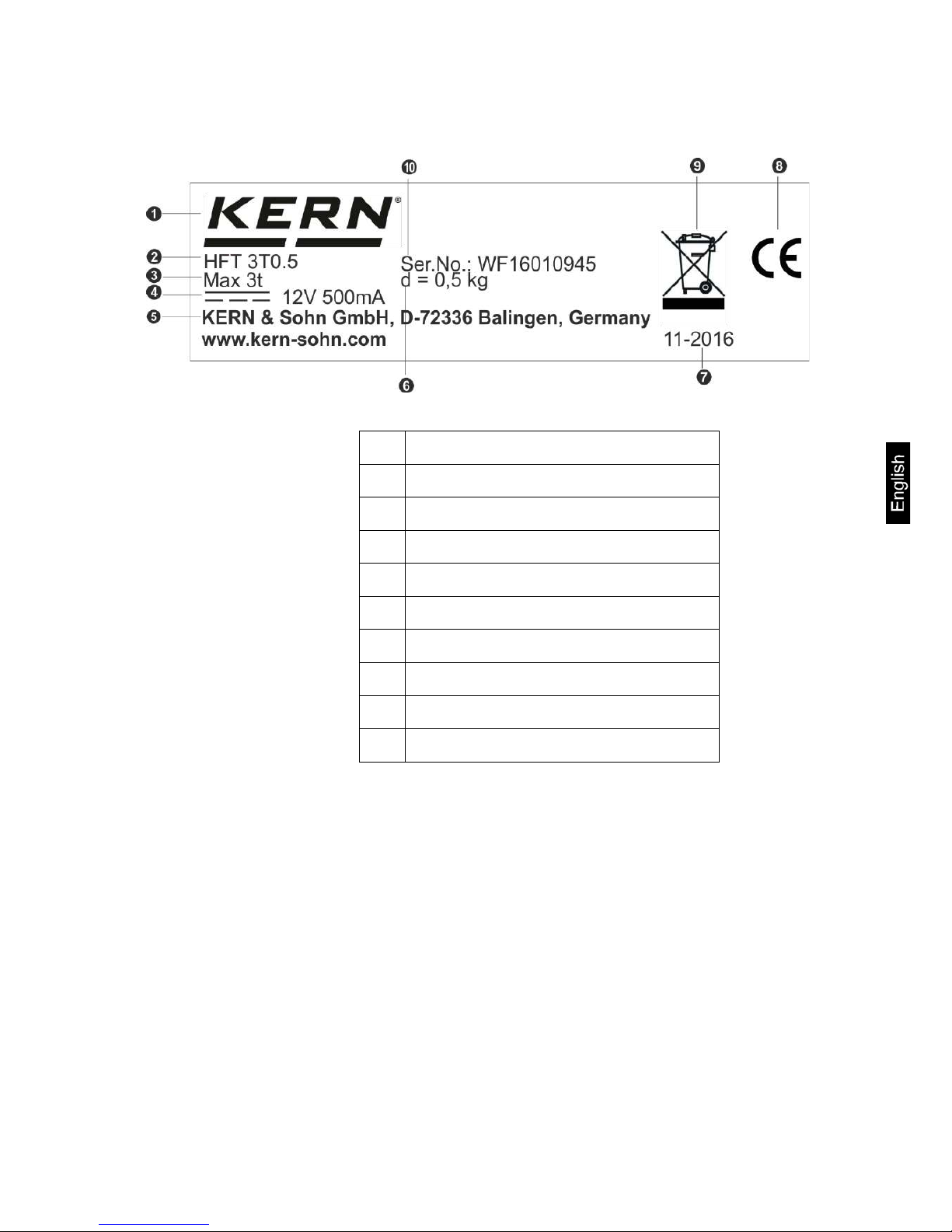

1.3 Nameplate

1

KERN Logo

2

Model designation

3

Weighing range [Max]

4

Data for power supply

5

Company address

6

Readability [d]

7

Date of manufacture

8

CE mark

9

Disposal symbol

0

Serial number

Page 8

8 HFT-BA-e-1812

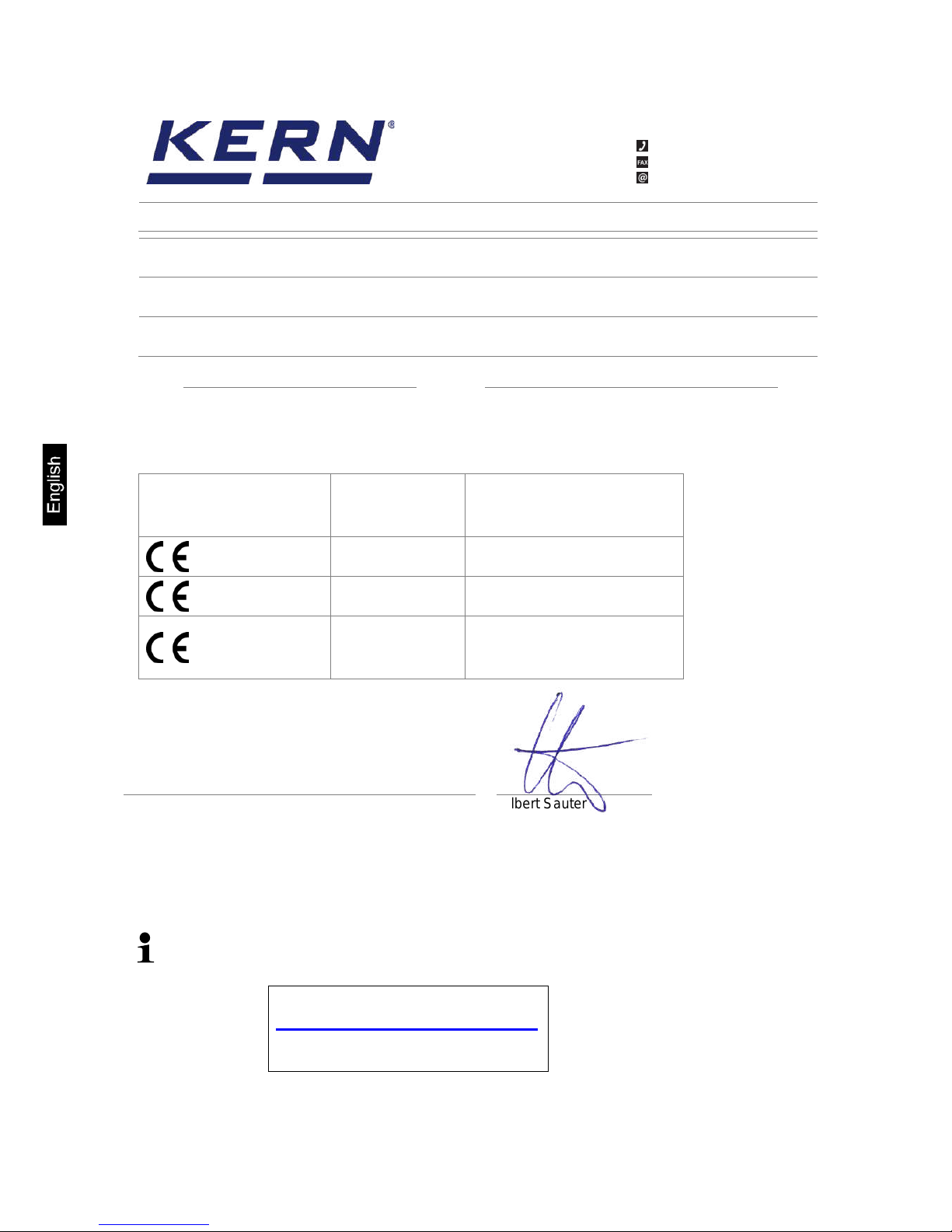

1.4 EC-Declaration of -Conformity

KERN & Sohn GmbH

www.kern-sohn.com

Ziegelei 1

72336 Balingen-Frommern

Germany

+0049-[0]7433-9933-0

+0049-[0]7433-9933-149

info@kern-sohn.com

Déclaration de conformité UE | EU Declaration of Conformity | EU-Konformitätserklärung

FR Nous déclarons par la présente sous notre entière responsabilité que le produit concerné par cette

déclaration respecte les exigences des directives mentionnées ci-après.

EN We hereby declare and assume sole responsibility for the declaration that the product complies with the

directives hereinafter.

DE Wir erklären hiermit unter alleiniger Verantwortung, dass das Produkt, auf das sich diese Erklärung bezieht,

mit den nachstehenden Richtlinien übereinstimmt.

Type | Type | Typ

Nº de série | Serial no. | Seriennr.

HFT 3T0.5

HFT 5T1

HFT 10T2

HFT 15T5

xxxxxxxxxx

Marquage CE

Mark applied

CE Kennzeichnung

Directive UE

EU directive

EU-Richtlinie

Normes

Standards

Normen

2006/42/EC

(MD)

EN 13155:2003/A2:2009

2014/30/EU

(EMC)

EN 50581:2012

2014/35/EU

(LVD)

EN 55022:2010

EN 55024:2010

EN 61000-3-3:2013

Date | Date | Datum:

29.08.2016

Lieu de délivrance:

Place of issue:

Ort der Ausstellung:

72336 Balingen,

Germany

Albert Sauter

KERN & Sohn GmbH

Signature:

Signature:

Signatur:

Directeur Exécutif

Managing director

Geschäftsführer

Further language versions you will find online under:

www.kern-sohn.com/ce

Page 9

HFT-BA-e-1812 9

2 General Safety Instructions

2.1 Duties of the owner-operator

Follow national accident prevention regulations and all operator health and safety at

work and operating regulations.

• Observe all safety regulations of the crane manufacturer.

• The balance may only be used for the proposed purpose. Any type of use which

is not specified in these operating instructions, will be considered as improper

use. The customer is solely responsible for material damage and injury of persons

resulting from an improper use, Messrs. KERN & Sohn will not be liable under

any circumstance.

Messrs . KERN & Sohn cannot be held liable, if the crane scales are modified or

used improperly and if damage is resulting from such use.

• Inspect and service crane balance, crane and load suspension devices regularly

(see chap. 10.3).

• Log the test result and keep it in the logbook.

2.2 Organizational measures

• Only trained and instructed staff may operate the balance.

• Make sure that the operating instructions are kept nearby the operation site of the

crane scales.

• Assembly, commissioning and maintenance should only be carried out by trained

specialists.

• Repair of safety-relevant pieces may only be carried out by KERN or by service

partners authorized by Messrs. KERN. (competence certificate or training).

• Use original spare parts only.

• All repairs and spare parts must be documented by the service partner (see list,

chap. 11.2).

• All maintenance must be documented (see checklist chap. 11.1).

• Load suspending components may only be exchanged as a complete spare parts

set. The dimensions of the new compon ents must be noted (see checklist chapter

11.1).

2.3 Pay attention to the instructions in the Operation Manual

Carefully read this operation manual before setup and

commissioning, even if you are already familiar with KERN balances.

All language versions contain a non-binding translation.

The original German is binding.

Page 10

10 HFT-BA-e-1812

2.4 Environmental conditions

• Never operate the crane scales in explosive environment. The serial version is

not explosion protecte d.

• Operate the crane scales only under environmental conditions as specified in

these operating instructions (especially in chapter 1 „Technical data“).

• Do not expose the crane scales to strong humidity. Non-permitted condensation

(condensation of air humidity on the appliance) may occur if a cold appliance is

taken to a considerably warmer environment. In this case, acclimatize the

disconnected appliance for ca. 2 hours at room temperature.

• Do not operate the crane scales in corrosive environment.

• Protect the crane scales against high humidity, vapours and dust.

• Major display deviations (incorrect weighing results) may be experienced should

electromagnetic fields (e.g. due to mobile phones or radio equipment), static

electricity accumulations or instable power supply occur. Change locati on or

remove source of interference.

2.5 Proper use

The balance you purchased is intended to determine the weighing value of material

to be weighed. It is intended to be used as a “non-automatic“ balance, i.e. the

material to be weighed is suspended on the crane hook only vertically, manually,

carefully and without jerks. As soon as a stable weighing value is reached the

weighing value can be read.

• Use the crane scales only for lifting and weighing of freely movable loads.

• Danger of injury due to improper use. Not allowed are e.g.:

Exceeding the allowed nominal load of crane, crane scales or any type of

load attachment devices

Conveying persons,

Pulling loads over an inclined surface,

Tearing-off, pulling or towing loads.

• Modifications or reconstructions of the crane scales or of the crane are not

allowed.

2.6 Improper Use

Do not use balance for dynamic weighing. In the event that small quantities are

removed or added to the material to be weighed, incorrect weighing results can be

displayed due to the “stability compensation“. (Example: Slowly draining fluids from a

container suspended on the balance.) Do not leave permanent load suspended on

the balance. This may damage the measuring system as well as safety-relevant

parts.

The balance may only be used according to the described conditions. Other areas of

use must be released by KERN in writing.

Page 11

HFT-BA-e-1812 11

2.7 Warranty

Warranty claims shall be voided in case

• Our conditions in the operation manual are ignored

• The appliance is used outside the described uses

• The appliance is modified or opened

• Mechanical damage and damage caused by media, liquids,

• Natural wear and tear

• The appliance is improperly set up or incorrectly electrically connected

• The measuring system is overloaded

2.8 Safe working

• Do not stand underneath suspended loads!

• Position the crane in a way that the load is lifted vertically.

• When working with the crane and crane scales wear personal safety equipment

(helmet, safety shoes etc.).

2.9 Monitoring of Test Resources

In the framework of quality assurance the measuring-related properties of the

balance and, if applicable, the testing weight, must be checked regularly. The

responsible user must define a suitable interval as well as type and scope of this test.

Information is available on KERN’s home page (www.kern-sohn.com) with regard to

the monitoring of balance test substances and the test weights required for this. In

KERN’s accredited DKD calibration laboratory test weights and balances may be

calibrated (return to the national standard) fast and at moderate cost.

2.10 Testing upon acceptance

When receiving the appliance, please check packaging immediately, and the

appliance itself when unpacking for possible visible damage.

2.11 Initial Commissioning

In order to obtain exact results with the electronic balances, your balance must have

reached the operating temperature (see war mi ng up time cha p. 1) .

During this warming up time the balance must be connected to the power supply

(mains, accumulator or battery).

The accuracy of the balance depends on the local acceleration of gravity.

Strictly observe hints in chapter Adjustment.

For checking original dimensions, s. chap. 4.2

2.12 Shutdown and storage

• Take off the crane scales from the crane and dismantle all load attachment

devices from the crane scales.

• Do not store the crane scales at open air

Page 12

12 HFT-BA-e-1812

3 The crane scales at a glance

The crane scales are a multi-purpose and cost-saving solution for overhead weighing

applications such as e.g. recycling, metal processing, machine engineering, transport

and logistics.

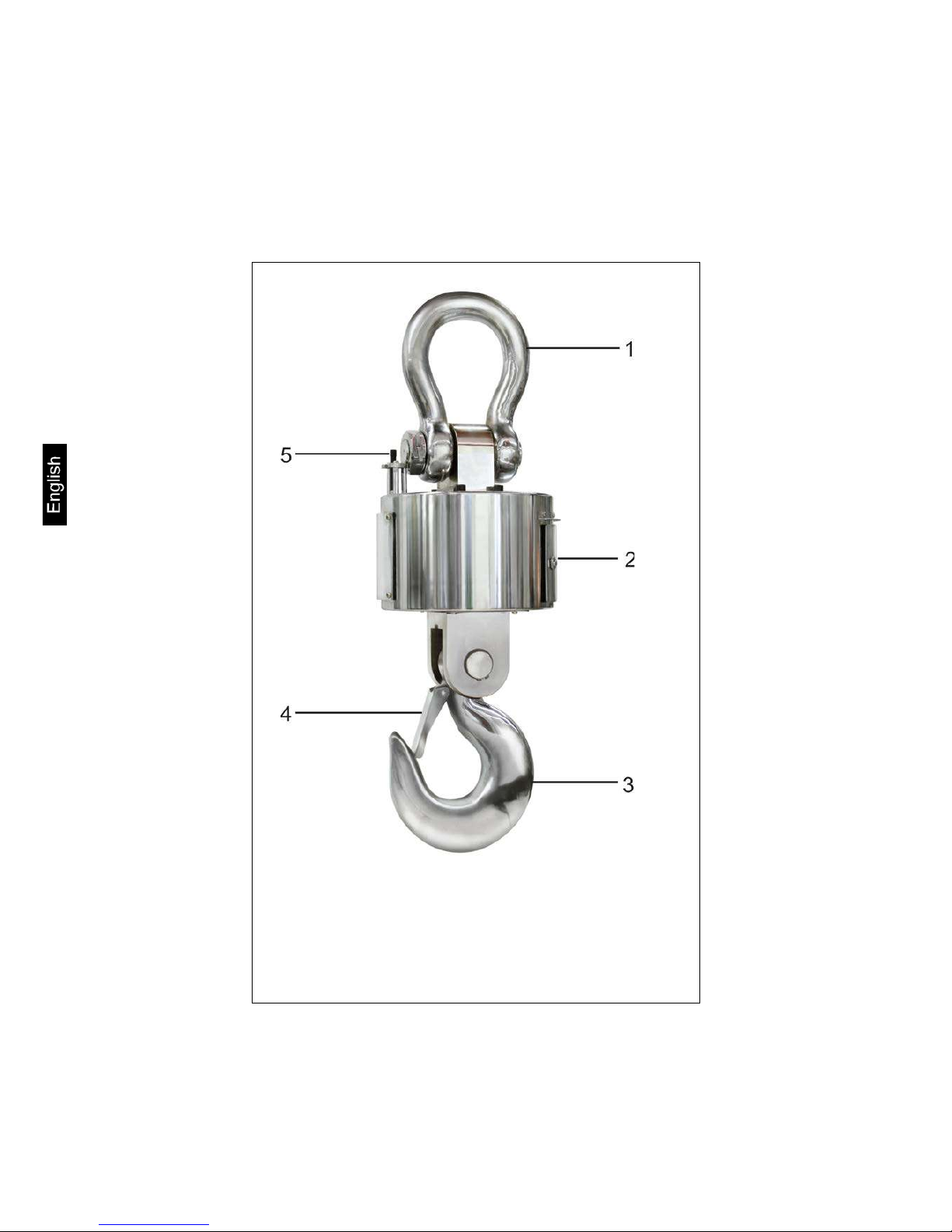

3.1 Appliance overview crane scale

1 Shackle

2 Housing cover

3

Hooks

4 Safety bracket

5 Antenna

Page 13

HFT-BA-e-1812 13

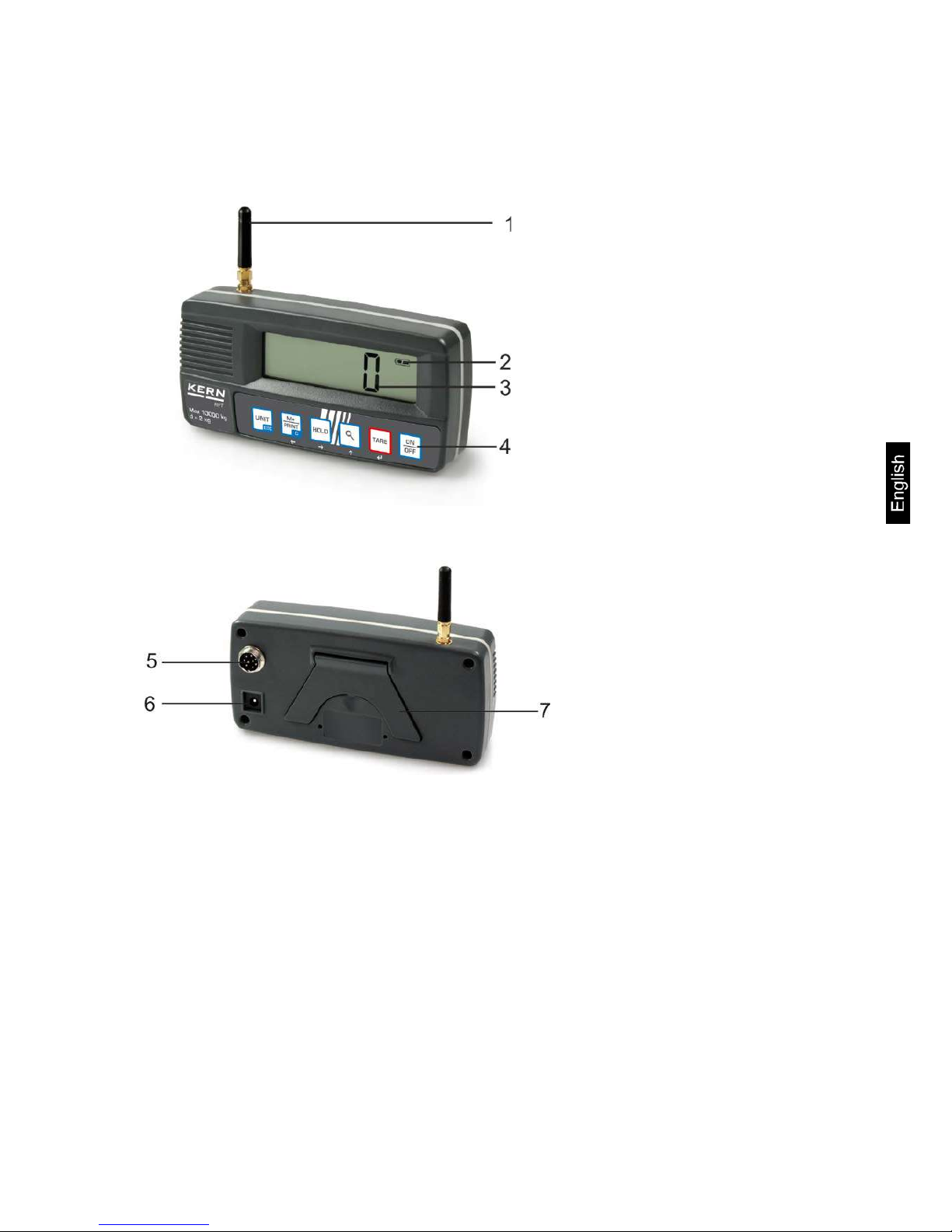

3.2 Appliance overview display unit

Front view display unit (receiver):

1. Antenna

2. Battery charge status

3. Weight display

4. Keyboard

Back view display unit (receiver):

5. RS-232

6. Mains adapter

connection

7. Table leg

Page 14

14 HFT-BA-e-1812

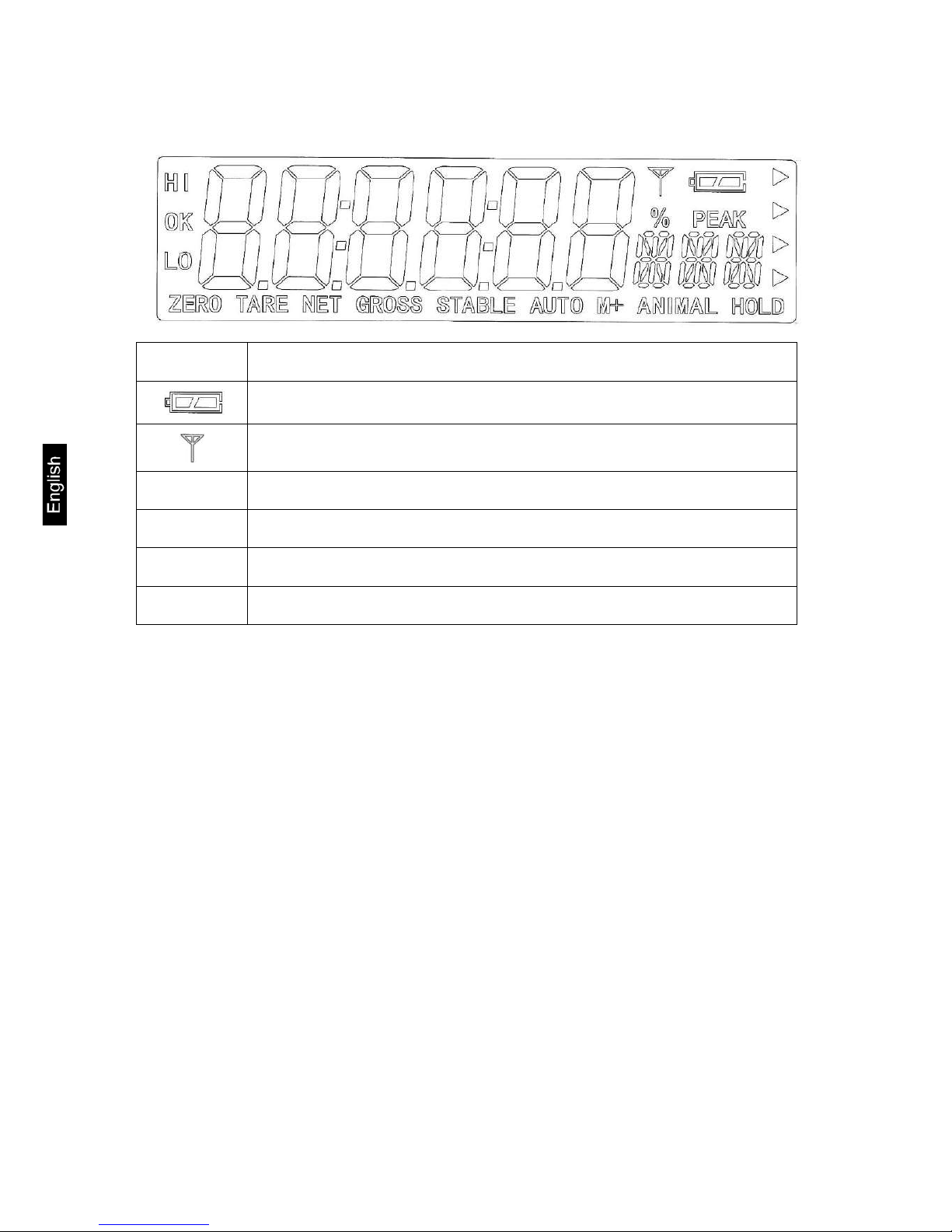

3.3 Over view of d isplay

Display Significance

Charging status of rechargeable battery

Radio communication between display unit and crane scale

STABLE Stability display

ZERO Zero indicator

M+ Totalization

HOLD HOLD function

Page 15

HFT-BA-e-1812 15

3.4 Keyboard overview

Button Function

• Tur n on/off

• With a weight value >10% Max. the button function is

Taring

• With a weight value <10% Max. the button function is

Zero setting

Navigation

• Confirm entry

• Short-time increase of the resolutio n

Navigation

• At numeric input increa se flashing digit

• Scroll forward in menu

• Hold function / determination of a mean value

• In adjustment process: Change decimal digit

Navigation

• Digit selection to the right

• Add weighing value to summation memory

• Display sum total

• Calculate weighing data via interface

• Delete

Navigation button

• Digit selection to the left

• Switch-over weighing unit

• Back to menu/weighing mode

Page 16

16 HFT-BA-e-1812

3.5 Numerical input via the navigation buttons

Button

Navigation

Function

Increase flashing dig it

Digit selection to the left

Delete

Digit selection to the right

Confirm

3.6 Label

Do not stand or go under suspended loads.

Do not use on building site.

Keep an eye on suspended loads.

(example)

Do not exceed nominal load of crane scales.

The product conforms to the requirements of the

German Equipment and Product Safety Act.

Page 17

HFT-BA-e-1812 17

4 Commissioning

Attention: Always observe chapter 2 „General Safety Instructions“!

4.1 Unpacking

SAFETY

INSTRUCTIONS

for protection against

break

Once delivered and unpacked, crane scales will not be

taken back.

The crane scales have been sealed by Messrs. KERN.

Shackles and hooks are sealed by Sella tape.

The packaging is also sealed by adhesive tape.

+ Broken seal obliges to purchase.

Thanks for your comprehension.

Your KERN Quality assurance team

Danger for the back!

The crane scales are compact and quite heavy.

Remove the scales from packaging only with the help of

a second person.

Use a lifting device such as a crane or a forklift truck.

Secure the scales that they cannot fall down when they

are lifted.

Only use original packaging for returning.

Make sure that all parts are completely present:

• Crane scales

• Display Unit

• Cable screwing „Interface cable“

• 2 x mains adapter

• Operating instructions (l og book )

4.2 Checking the original dimensions

Enter the original dimensions shown on the production data sheet in the grey

boxes of checklist chap. 10.4.

Check original dimension of crane scales; for implementation see chap. 10.3

„Regular Maintenance“

Enter all data (date, tester, results) in the first line under „Inspection before first

use“ in the checklist (see chapter 10.4)

CAUTION

If the dimensions of your first safety inspection do not match

those of KERN, the balance must not be put into operation.

In this case please contact a service partner authorised by

Messrs. KERN.

Page 18

18 HFT-BA-e-1812

4.3 Rechargeable battery operation

Crane scales:

CAUTION

Material damage on crane scales

Only use the delivered mains adapter.

Make sure that the mains adapter, the cable and the

mains plug are in a perfect condition.

Do not use the crane scales during the loading process.

1

ON/OFF switch

2

LED „Battery charging status“

3

LED „rechargeable battery is

charged“

4

Mains connection

Before the first use, the rechargeable battery should be charged by connecting it to

the mains power cable for at least 12 hours. For loading the rechargeable battery

please only use the delivered mains adapter. The operating time of the rechargeable

battery is approx. 35 hours.

• If the LED display (2) next to the mains connection (4) is illuminated, the

battery should be recharged.

• LED (3) is illuminated during the battery loading.

Display Unit

Before the first use , the battery shoul d be char ged by connecti ng it t o the mains p ower su pply

for at least 12 hours. The appearanc e of th e recha rgeabl e battery symbol in th e weight display

indicates that th e battery is almost exha usted. The unit wi ll be rea dy for o peratio n for a pprox.

another 10 hours before sw itching off auto maticall y. Charge the batt ery w ith the help of the

supplied power pac k.

The recharge able ba ttery s ymbol s hows the charg e status of the recharg eable battery :

Voltage has dropped below prescribed minimum.

Rechargeable battery very low.

Rechargeable battery completely reloaded

Page 19

HFT-BA-e-1812 19

4.4 Suspending the balance

Condition

The crane needs a safety bracket (1) that the unloaded crane scales cannot fall

down.

If the safety bracket is missing or damaged, please contact the crane manufacturer in

order to receive a hook with this safety equipment.

Suspend the crane scales on the lower hook of a crane and close the safety

bracket.

The crane scale’s upper eyelet should rest in the saddle (2).

Page 20

20 HFT-BA-e-1812

5 Operation

5.1 Safety instructions

Danger

Risk of injury due to falling loads!

Take great care when operating the crane and follow the

general rules for crane operation.

Check all parts (hook, eyelet, rings, rope slings, cables,

chains etc.) for excessi v e wear or damage

If faults can be seen on the safety bracket of the hook

or if it is missing

completely, the scales must not be

used

Work only with appropriate speed

Always avoid vibrations and horizontal forces. Avoid

any kind of shock, torsion and oscillating (e.g. caused

by inclined suspending)

Do not use the crane scales for transporting loads.

Do not stand or go under suspended loads.

Do not use on building site.

Keep an eye on suspended loads.

(example)

Do not exceed the nominal load of crane, crane scales

or any kind of load attachment devices at the crane

scales.

For weighing dangerous goods (e.g molten masses,

radioactive materials) the “Dangerous Goods

Regulations” are to be regar ded!

Page 21

HFT-BA-e-1812 21

5.2 Loading the crane scales

For good weighing results observe the following, illustrations see next page:

Only use load attachment devices which guarantee a one-spot suspension and

where the scales can be suspended freely.

Do not use too large load attachment devices which do not guarantee any one-

spot suspension.

Do not use multiple suspensions.

Do not pull or push the load or the loaded balance.

Do not pull the hook horizontally.

Loading the balance

1. Position the hook of the crane scales over the load.

2. Move downwards the crane scales until the load can be suspended on the hook

of the balance. Reduce the speed when the respective height is going to be

reached.

3. Suspend the load on the hook. Ensure that the safety bracket is closed. If the load

is fixed by slings, ensure that the slings rest completely on the saddle of the

balance hook.

4. Lift-off the load slowly.

When the load is fixed by slings, ensure that the load is well balanced on both

sides and that the slings are correctly positioned

Page 22

22 HFT-BA-e-1812

Only use load attachment devices

which guarantee a one-point

suspension and where the scales

can be suspended freely.

Do not use too large load

attachment devices which cannot

guarantee a one-point

suspension.

Page 23

HFT-BA-e-1812 23

Do not push or pull

Do not pull the hook horizontally

Do not use multiple suspensions

Page 24

24 HFT-BA-e-1812

5.3 Turn on/off

Start-up

Press on the display unit; the unit will carry out a self-test. As soon as the

weight display appears, the instrument will be ready to weigh.

At the crane scales put the ON/OFF switch to „ON“

If „Err 10“ appears in the weight display no radio

communication with the balance could be established.

Either the crane scale is not yet switched on or the

rechargeable battery has not been sufficiently loaded.

Switch on the crane scale with the ON/OFF switch or reload

the battery.

„Err 10“ disappears and the zero display will appear. The

balance is now in weighing mode and ready for operation.

Switching Off

Press at the display unit, the display disappears.

At the crane scales put the ON/OFF switch to „OFF“

5.4 Set balance to zero

In order to obtain optimal weighing results, reset to zero the balance before weighing.

Manual

Unload the balance

Press , zero display as well as indicator ZERO will appear.

Automatic

In the menu the amount of the automatic zero point correction can be changed,

see chapter 6 / Function „F1 A20“.

Page 25

HFT-BA-e-1812 25

5.5 Taring

Suspend preload.

Press the -button and wait until the zero display appears. The weight of the

container is now internally saved.

Weigh the material, the net weight will be indicated.

After removing the preload weight appears as negative display.

To delete the tare value, remove load from crane scales and press the

button.

5.6 Weighing

Loading the crane scales.

Wait for stability display STABLE.

Read weighing result.

Overload warning

Overloading exceeding the stated maximum load (max) of the balance, minus

a possibly existing tare load, must be strictly avoided. This could cause

damage to the balance.

Exceeding the maximum load is indicated by the display „--ol-“. Unload

balance or reduce preload.

Page 26

26 HFT-BA-e-1812

5.7 Fix the weight value (Data-HOLD function)

Suspend the material to be weighed

Press the button, the fixed weighing value will be displayed.

The indicator HOLD appears.

The weighing value will be held in the display until it is deleted by .

5.8 Weighing Units

1. How to enable weighing units

Switch on the balance and during selftest press , „Pn“ will be displayed.

Press , , subsequently.

Acknowledge with . The first function „F0 di“ is displayed.

Press repeatedly until „F5 Unt“ will be displayed

Page 27

HFT-BA-e-1812 27

Press , the current setting will be displayed.

To enable [on] / disable [off] the displayed weighing unit, press

Acknowledge with , the active setting of the next weighing unit will be

displayed.

To enable [off] / disable [on] the displayed weighing unit, press .

Press , balance returns to menu

Return to weighing mode using

2. How to change weighing units

To return to the previously enabled weighing units go to weighing mode by

.

Page 28

28 HFT-BA-e-1812

5.9 Totalization

With this function the individual weighing values are added into the summation

memory by pressing and edited, when an optional printer is connected.

Prerequisite: Totalizing function „F11 ACC“ on setting „on“, see chap. 6.2.

• With active totalizing function the indicator „M+“ is displayed

• The totalizing function is not active when the weight is under 20d.

• Totalizing is only possible in weighing mode.

• The data output depends on the menu setting „F7 Prt“.

• When s witching-over to another weighing unit the summation memory will

be deleted.

Hook-on the item to be weighed A.

Wait until the stability display “STABLE” appears, then press .

„n001“ followed by the weight value will be displayed. The weight is added to the

summation memory and printed if an optional printer is connected, depending on

the menu setting „F7 Prt“.

Printout example YKB-01N (menu setting „F7 PrtPrt 5“):

No.

1

N :

100.0KG

C

100.0KG

Page 29

HFT-BA-e-1812 29

Remove the weighed good. More weighed goods can only be added when the

display ≤ zero.

Suspend the item to be weighed B.

Wait until the stability display appears, then press . Weighing value will be

added to summation memory and possibly printed.

The number of weighing actions „n002“, followed by the total weight will be

displayed for 2 sec. After that the current weighing value is displayed.

Printout example YKB-01N (menu setting „F7 PrtPrt 5“):

Add more weighed goods as described before.

Please note that the crane scales must be unloaded between the individual weighing

procedures.

You can repeat this process until the capacity of the crane scales is exhausted.

No.

2

N :

100.0KG

C

200.0KG

Page 30

30 HFT-BA-e-1812

Display the summation memory:

If you see a display of zero , press and the number of weighings, followed by the

total weight will be shown for 2 sec and printed if an optional printer is connected.

Printout example YKB-01N (menu setting „F7 PrtPrt 5“):

NO.

2 C 200.0KG

Page 31

HFT-BA-e-1812 31

Delete total added memory:

When zero is displayed press , the number of weighings followed by the total

weight will be displayed for 2 sec. During this display press again.

The data in the summation memory are deleted, the indicator „M+“ extinguishes.

5.10 Automatische Nullpunktkorrektur

Under this menu item the automatic zero point correction can be switched on or off.

In enabled status the zero point will be corrected automatically, selectable 0.5d – 4 d

(see chap.6.2, Menu item “F1 A20“)

Invoke menu item „F1 A20“, see chap. 6.1

Press , the current setting will be displayed.

Select the desired setting by pressing

Acknowledge with .

Return to weighing mode using

Page 32

32 HFT-BA-e-1812

6 Menu

6.1 Navigation in the menu:

Call function

Switch on the balance and during selftest press ,

„Pn“ will be displayed.

Press , , subsequently.

Acknowledge with .

The first function „F0 di“ is displ ay ed.

Select function

With help of , the individual functions can be

selected one after the other.

Select setting

Confirm selected function by . The current setting

will be displayed.

Change settings

Switch into the available settings using .

Confirm setting

Acknowledge with or reject with

Exit menu / Return to

weighing mode

Press button

Page 33

HFT-BA-e-1812 33

6.2 Menu overview

Function

Available

settings

Description

How to change readability

High *

Modifications may only be carried out by a

specialist with competent knowledge.

Low

cap

d (low)

d (high)

3 t 10kg 5kg 2kg 2kg 1kg 500g

5 t 10kg 5kg 2kg 2kg 1kg 500g

10 t 20kg 10kg 5kg 5kg 2kg 1kg

15 t 50kg 20kg 10kg 10kg 5kg 2kg

Automatic zero point

correction

(zero tracking)

AZ 0.5d 0.5 d

AZ 1d* 1 d

AZ 2d 2 d

AZ 4d 4 d

Capacity

3 000 kg

5

15 000 kg

20 000 kg 3

Background lighting

bK on* Background lighting of display is switched

on permanently

bK oFF Display background illumination off

bK AU

Automatic background illumination on when

weighing pate is loaded or key pressed.

Internal A/D converter value

Select weighing unit

kg on/off

lb on/off

Automatic shutdown

function

oFF 5 min* Autom. shutdown after 5 minutes

oFF 10 min Autom. shutdown after 10 minutes

oFF 15 min Autom. shutdown after 15 minutes

oFF 30 min Autom. shutdown after 30 minutes

oFF 0 min Autom. shutdown disabled

Page 34

34 HFT-BA-e-1812

Interface parameters

Cont* Continuous data output

printout examples see chap. 8.4

Prt 1 Not documented

Prt 2 Not documented

Prt 3 Not documented

Prt 4 Data output format 4,

Printout example see chap. 8.4

Prt 5 Data output format 5,

Printout example see chap. 8.4

Adjustment see chap. 7

Baud rate

Selectable 1200, 2400, 4800, 960 0*

Not documented

Adding function

on Totalizing function switched on

off Totalizing function switched off

* default setting

Page 35

HFT-BA-e-1812 35

7 Adjustment

As the acceleration value due to gravity is not the same at every location on earth,

each balance must be coordina ted - in compliance with the underlying physical

weighing principle - to the existing acceleration due to gravity at its place of location

(only if the balance has not already been adjusted to the location in the factory). This

adjustment process must be carried out for the first commissioning, after eac h

change of location as well as in case of fluctuating environment temperature. To

receive accurate measuring values it is also recommended to adjust the balance

periodically in weighing operation.

• The weight to be used depends on the capacity of the scale. Carry

out adjustment as near as possible to the scale’s maximum weight.

Info about test weights can be found on t he In ter net at :

http://www.kern-sohn.com.

• Observe stable environmental conditions. A warming up time (see

chapter 1) is required for stabilization.

Procedure:

Switch-on balance and during the selftest press .

„Pn„ will be displayed.

Use the numeric keys to enter password:

Press , , subsequently.

Acknowledge with button .

„F0 di“ will be displayed

Press the button repeatedly until „F8 C AL” will be displayed.

Press button, „ULoAd“ will be displayed.

Unload the balance and wait until the symbol „STABLE“ lights up.

Press the button, the currently set adjustment weight is displayed after some

seconds.

In order to change, select the numbers to be changed using the button and

set the desired value using the button, the respective active digit flashes.

Page 36

36 HFT-BA-e-1812

Confirm by , „LoAd“ will be shown.

Attach the adjustment weight and wait until the symbol „STABLE“ lights up.

Press button

After successful adjustment the balance carries out a selftest, then it

automatically returns to weighing mode.

An adjusting error or incorrect adjusting weight will be indicated by the error

message; repeat adjus tme nt pr oc ed ur e.

Page 37

HFT-BA-e-1812 37

8 Data output RS 232

You can print weighing data via the RS 232C interface by pressing via the

interface according to the setting in the menu.

This data exchange is asynchronous using ASCII - Code.

The following conditions must be met to provide successful communication between

the weighing balance and the printer.

Use a suitable cable to connect the display unit to the interface of the printer.

Faultless operation requires an adequate KERN interface cable.

Communication parameters of display unit and printer must match (baud rate see

chap. 6.2, Menu item ,)

8.1 Technical data

8.2 Technical data

Connection: Pin allocation plug

Pin 2 input

Pin 3 output

Pin 5 signal earth

Baud-Rate: 600, 1200, 2400, 4800, 9600 selectable

Parity 8 bits, no parity

8.3 Continuous data output

Con1: Weighing mode

HEADER1: ST=STABLE, US=UNSTABLE

HEADER2: N=NET, GS=GROSS

Page 38

38 HFT-BA-e-1812

8.4 Printer mode

Printout examples printer KERN YKB-01N:

Menu setting „F7 PrtCont“:

St, GS, + 100 kg

Menu setting „F7 PrtPrt 4“:

1.weighing

2.weighing

Total

N :

100

N :

100

No.

2 C

200KG

Menu setting „F7 PrtPrt 5“:

1.weighing

2.weighing

Total

No.

1

No.

2 G

100KG

G

100KG

No.

2 C 100KG

C

200KG

C 200KG

GS

Gross weight

N

Net weight

No.

Number weighing processes

C

Total of all individual weighings

ST

Stable weighing values

Page 39

HFT-BA-e-1812 39

9 Error messages

Error

message

Description

Possible causes

--ol- Maximum load exceeded

Reduce load

Check whether the balance has

been damaged

Err 4

Zeroing range exceeded due

to switching-on balance or

pressing (normally 4%

max)

Load attached

Overload during setting to zero

Err 5

Keyboard error

Improper operation of the balance

Err 6

Value outside the A/D changer

range

Damaged weighing cell

Damaged electronics

Err 10 No signal

Distance emitter / receiver too

long

Emitter (connecting box) not

switched on

Lo bA

Capacity of rechargeable

battery exhausted

Recharge battery

Should other error messages occur, switch balance off and then on again. If the error

message remains inform manufacturer.

Page 40

40 HFT-BA-e-1812

10 Cleaning, Repair, Maintenance and Disposal

Danger

Risk of injury and risk of material damage!

The crane scales are part of a hoisting device!

For a safe operation please observe the following:

Have carried out a regular maintenance by trained specialized

staff

Carry out regular maintenance and care, see chapter 10.2 and

10.3

Have the parts exchanged only by trained specialized staff.

If there arose discrepancies with the safety checklist, the balance

must not more be put into operation.

Do not repair the crane scales by yourself. Repair may only be

carried out by service partners authorized by Messrs. KERN.

10.1 Cleaning and Disposal

CAUTION

Damage on the crane scales!

Do not use any industrial solutions or chemicals

Clean the keyboard and the display with a soft cloth soaked in mild window

cleaning agent.

Disposal of packaging and appliance must be carried out by operator according to

valid national or regional law of the location where the appliance is us ed.

Page 41

HFT-BA-e-1812 41

10.2 Regular maintenance and care

• The regular 3-month maintenance may only be carried out by an expert with

competent knowledge of working with crane scales. Thereby the national

regulations for prevention of accidents as well as the working, operation and

safety regulations of the owner-operator.

• To check the dimensions only use suitable test devices.

• The regular 12-month maintenance must only be carried out by trained

specialized staff (KERN customer service).

• The results of the maintenance must be written down in the checklist (chap.

10.4).

• The additional results of the extended maintenance have to be entered in the

checklist (chapter 11.1).

• The replaced spare parts also must be entered, (chapter 11.2)

10.3 Regular maintenanc e

Initial start-up,

every 3 months or

definitely after

12 500 weighing

processes

• Check all dimensions, see checklist chap. 10.4

• Check the shackle or the eyelet for wear and tear, such as e.g.

plastic deformation, mechanical damage (unevenness), notches,

striation, cracks, corrosion, thread damage and torsions.

• Check the application of the safety bracket on the hook, moreover

check for fault and correct function

• For balances of big construction size: Check that the split pin and

the nut on the shackle are not loose

If a dimension exceeds the admitted deviation from the original

dimension (see checklist, chap. 10.4) or if other discrepancies have

been found, the balance must be repaired at once by trained

specialized staff (KERN customer service). Never do repair it by

yourself!

Take balance out of operation immediately!

All repairs and spare parts must be documented by the service partner

(see list, chap. 11.2).

Every 12 months or

in any case after

50 000 weighings

• If the enhanced maintenance has to be carried out by trained staff

(KERN customer service). At this general revision all load carrying

parts must be checked for gaps with magnetic powder

Every 5 years or

anyway after 250

000 weighings

• All load carrying parts have to be exchanged by trained specialized

staff (KERN customer service).

Every 10 years or

anyway after

500 000 weighings

• Replace the crane balance entirely

Note

During the revision for wear and tear please refer to the following drawings.

Page 42

HFT-BA-e-1812 42

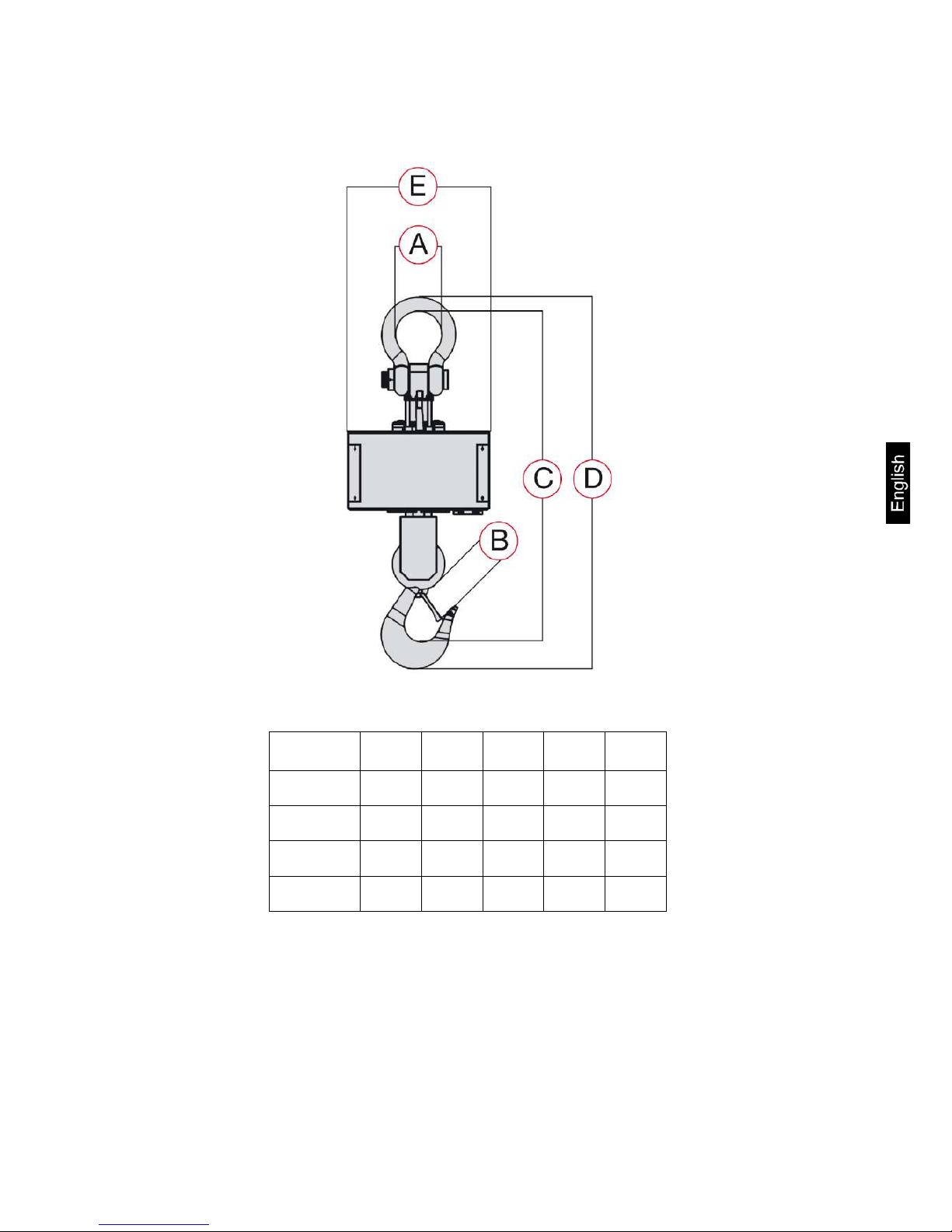

10.4 Checklist „Regular maintenance“, (see chapter 10.3)

Original dimensions crane scales, serial no.: ………………………………… Capacity ………………………………

Shackle Hooks

a (mm) b (mm) c (mm) Wear and

tear

Split pin&Nut d (mm) e (mm) f (mm) g (mm)

Angle α (°)

Wear and tear Safety bracket

Date ………………………………… Tester ………………………………………

*These data can be found in the document attached to the balance. Please keep this document always available.

Shackle Hooks

a b c

Wear and tear

(see grey

fields)

Split

pin&

Nut

d e f g

Angle

α

Wear and tear

(see grey fields)

Safety

bracket

Datum Tester

Max. admitted variation

5 % 0 % 5 %

No deformation

or cracks

tight

10 % 5 % 5 % 5 %

10 °

No deformation or

cracks

Perfect

working

order

Revision prior to first use

3 months/12,500 x

6 months/25,000 x

9 months/37,500 x

12 months/50,000 x

15 months/62,500 x

18 months/75,000 x

21 months/87,500 x

Page 43

HFT-BA-e-1812 43

Shackle Hooks

a b c

Wear and tear (see

grey fields)

Split pin&

Nut

d e f g

Angle

α

Wear and tear

(see grey fields)

Safety

bracket

Datum Tester

Max. admitted variation

5 % 0 % 5 %

No deformation or

cracks

tight

10 % 5 % 5 % 5 %

10 °

No deformation or

cracks

Perfect

working

order

24 months/100,000 x

27 months/112,500 x

30 months/125,000 x

33 months/137,500 x

36 months/150,000 x

39 months/162,500 x

42 months/175,000 x

45 months/187,500 x

48 months/200 000

51 months/212,500 x

54 months/225,000 x

57 months/237,500 x

60 months/250 000x

All load carrying parts have to be exchanged by a service partner authorised by KERN.

bold letters = this maintenance work has to be carried out by a service partner authorized by KERN.

Page 44

HFT-BA-e-1812 44

Page 45

HFT-BA-e-1812 45

11 Enclosure

11.1 Checklist „Enhanced maintenance“ (General revision)

The enhanced maintenance has to be carried out by a service partner authorized by KERN.

Crane scales Model ………………………………….. Serial no. ……………………………………………..

Interval

Magnetic powder

test for cracks

Hooks Shackle

Screwed

connections

Datum Name Signature

12 months/50,000 x

24 months/100,000 x

36 months/150,000 x

48 months/200,000 x

60 months/250,000 x

72 months/300,000 x

84 months/350,000 x

96 months/400,000 x

108 months/450 000 x

120 months/500 000x

Replace crane scales entirely

Page 46

HFT-BA-e-1812 46

11.2 List „spare parts and repair of safety-relevant parts“

Repair has to be carried out by a service partner authorized by KERN.

Crane scales Model ………………………………….. Serial no. ……………………………………………..

Part Action Datum Name Signature

Page 47

HFT-BA-e-1812 47

Crane scales Model ………………………………….. Serial no. ……………………………………………..

Part Action Datum Name Signature

Loading...

Loading...