Page 1

P-500: Sierra Reader

Quick Start Guide

P-500

The P-500 Sierra Reader

The P-500 Sierra Reader is intended for mounting on a flat surface or a standard U.S. single

gang electrical box. It can be mounted on metal or non-metal surfaces. The P-500’s electronics

are housed in a black, weatherproof, shock resistant package. This package is mounted to the

installation surface. An attractive, snap-on, black or white front cover hides the electronics

package and installation mounting hardware providing an extra level of security.

The P-500 can be used with virtually any manufacturer’s access panel because it produces an

industry standard Wiegand output. The reader can be configured to work with access panels

using either single or dual LED control lines. It is able to read the following Keri Systems’

Wiegand cards.

• PSC-1 Standard Light Proximity Cards

• PSM-2 Multi Technology Cards

• PSK-3 Proximity Key Tags

When a card or tag is read, the P-500 immediately responds with a beep and an LED blink. The

access panel then handles subsequent LED and beeper responses. The P-500 also features

built-in diagnostics: a start-up self test to ensure reader functionality and a data line test to ensure

reader/access panel communication.

Specifications

Dimensions

• 4.5 inches High x 3.0 inches Wide x 0.38

inches Deep

• 114 mm High x 76 mm Wide x 10 mm

Deep

Operating Voltage

• 5v to 14v DC @ 80 ma nominal

Operating Temperature

• -40 °C to +65 °C (-40 °F to +150 °F)

Cable Specifications

• up to 500 feet using seven conductor,

shielded, stranded AWG 24 wire (such

as Belden 9537)

(1)

Per Wiegand specification, a minimum gauge of AWG 24 is required for data transfer in a 500-foot run length.

However the wire gauge to use should be determined by the current draw requirements of the reader, the length of

the cable run, and the voltage being applied to the reader. If the reader is to be operated at +5 VDC, +5 VDC must

be available at the reader (long cable runs have a voltage drop across the length of the run due to the resistance in

the cable). To ensure +5 VDC is available at the reader a larger gauge of wire (having less resistance) or a separate

power supply at the reader may be required.

(2)

Read Range is measured in a clean RF and electrical environment using a Keri Systems Standard Light Proximity

Card presented parallel to the reader surface. The Read Range will be less for a Key Tag and a Multi Technology

Card.

(1)

Frequency

• 125 KHz excitation

• 62.5 KHz data return (PSK)

Read Range

• up to 7 inches (17.8 cm) off metal

• up to 3 inches (7.6. cm) on metal

LED Indicator

• standard tri-color (Red, Green, Amber)

Audio Tone

• standard

Front Cover Colors

• Black, Off-White

(2)

1530 Old Oakland Road, Suite 100 01858-001 Rev. A

San Jose, CA 95112 USA

(800) 260-5265 (408) 451-2520 FAX (408) 441-0309 Page 1 of 4

Page 2

P-500: Sierra Reader

1.5" (38 mm)

0.38" (10 mm)

1.75" (44.5 mm)

0.6" (15.25 mm)

P-500

Quick Start Guide

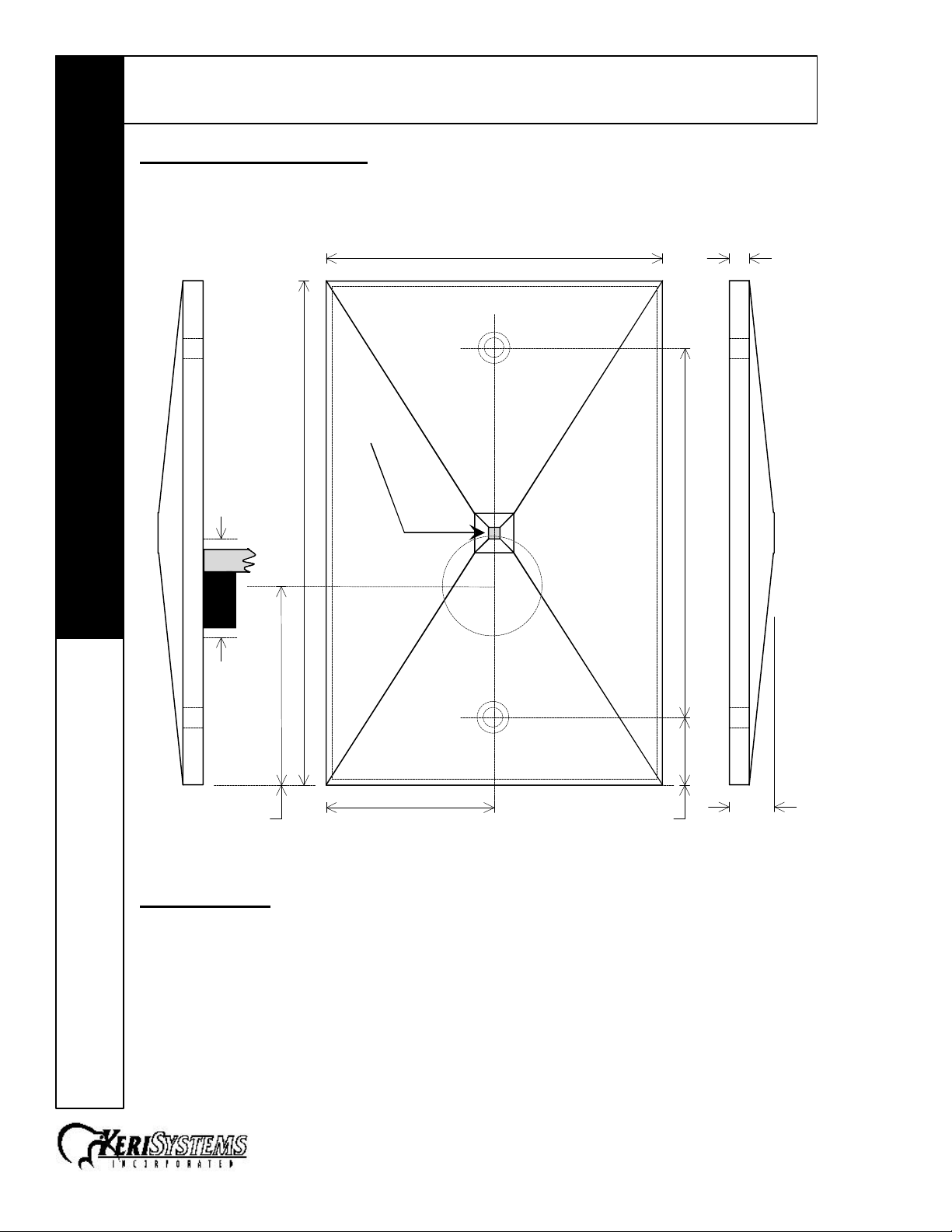

Mounting Instructions

Three holes need to be drilled to mount the P-500 Reader (see Figure 1). One large hole (7/8")

accommodates the beeper and the reader cable. Two small holes (for a #6 screw) are for

mounting the electronics package on the mullion or doorframe.

7/8" dia

Cable &

Beeper

LED

4.50" (114 mm)

3.00" (76 mm)

0.18" (4.6 mm)

3.30" (84 mm)

Connections

There are no switches or jumpers to set. The only configuration the P-500 requires is to set the

reader for single or dual LED control line operation (explained later in this document). The P-500

Reader can be connected to virtually any access panel that meets Wiegand interface standards.

All connections are made through the reader's cable. Please consult Table 1 and Figure 2 for

wiring instructions.

1530 Old Oakland Road, Suite 100 01858-001 Rev. A

San Jose, CA 95112 USA

(800) 260-5265 (408) 451-2520 FAX (408) 441-0309 Page 2 of 4

Figure 1 – P-500 Mounting Dimensions

Page 3

P-500: Sierra Reader

Quick Start Guide

P-500

Wire Color Function

Green Data 0

Blue Beeper

Red Reader Power

Black Reader Ground

Brown Second LED Control Line (Green LED)

Orange Single LED Control Line (Red LED)

White Data 1

Table 1 – Wiring Connections Figure 2 – Wiring Connections

Green - Data 0

Blue - Beeper

Red - Power

Black - Ground

Brown - Second LED

Orange - Single LED

White - Data 1

Installation Verification

The following information applies to an installation with an access panel. The access panel

controls the actions of the P-500’s LED and beeper.

Power

The P-500 is powered by the access panel, so the reader is powered on when the access panel

is powered on.

Read Range

To verify the P-500’s read range, hold a Keri Systems Wiegand card or tag parallel to the reader,

about 1 foot away and slowly bring the Card/Tag in toward the reader. Note the distance when

the reader recognizes the card (the reader beeps and the LED flashes). The reader's range will

be up to 7 inches (if mounted off a metal surface) or up to 3 inches (if mounted on a metal

surface) depending upon the installation conditions, the material on which the reader is mounted,

and whether it is a card or a tag being read. Due to the physical size difference between cards

and tags, cards provide approximately 50% greater read range than tags.

Refer to the Troubleshooting the Reader Installation section if the reader is not functioning

properly.

Switching Between Single or Dual LED Control Line Modes

The P-500 can work with control panels configured to drive either Wiegand single or dual LED

control line devices. The reader uses a “control” card to switch between single and dual line LED

control modes. The Control Line card must be ordered separately from the supplier. The default

setting for the P-500 reader is for dual LED control line operation.

To toggle between modes, simply present the LED Mode control card to the reader. The reader

will beep and the LED will flash indicating the control card was recognized and the mode has

been changed, but no data is sent to the access panel.

Troubleshooting the Reader Installation

Problem Probable Cause Corrective Action

The reader does

not recognize a

card/tag (no beep,

no LED flash).

1. One or more of the

reader's wiring

connections are

incorrect.

– continued next page –

• Power down the controller and verify

the wiring connections are correct for

the reader/access panel combination

per the instructions provided in the

Connections section on page 2.

1530 Old Oakland Road, Suite 100 01858-001 Rev. A

San Jose, CA 95112 USA

(800) 260-5265 (408) 451-2520 FAX (408) 441-0309 Page 3 of 4

Page 4

P-500: Sierra Reader

Quick Start Guide

P-500

Problem Probable Cause Corrective Action

The reader has a

short read range.

2. The reader is not

receiving proper

power from the access

panel.

3. The reader is mounted

too close to a device

that radiates

electromagnetic

interference.

1. The access panel is

not properly grounded.

2. The shield wire for the

reader's cable has

opened somewhere

between the reader

and the access panel.

3. The reader is mounted

too close to a device

that radiates

electromagnetic

interference.

4. The power supply is

generating

electromagnetic

interference.

• Verify the voltage supplied to the reader

is between 5 and 14 VDC.

• Devices such as computer monitors

radiate electromagnetic interference

that affects read range. When possible,

relocate either the reader or the device

to provide a greater distance between

the two.

• Ensure there is a quality earth ground

connection made to the access panel.

Refer to the access panel’s

documentation for specific information

regarding the earth ground connection.

• Verify the shield line from the access

panel to the reader is one continuous,

connected line. Refer to the access

panel’s installation documentation and

verify the shield line is correctly

connected to the access panel.

• Devices such as computer monitors

radiate electromagnetic interference

that affects read range. When possible,

relocate either the reader or the device

to provide a greater distance between

the two.

• The power supply on the alarm panel

should be a regulated linear supply – do

not use switching supplies as they are

often sources of electromagnetic

interference.

Data Line Level Test

The P-500 has an internal data line level test to verify the reader is able to communicate with the

access panel. A “control” card is used to trigger the data line level test. Present the card to the

reader. The reader beeps and the LED flashes to indicate the card has been read and the test

has begun. In this test the reader toggles the Wiegand data lines between high and low states –

+5 VDC to 0 VDC. This toggling occurs at a slow rate so that it can be viewed on a DVM.

1. Set the DVM to a range that can safely view +5 VDC.

2. Disconnect the Wiegand Data lines from the access panel.

3. At the access panel, connect the negative lead of the DVM to access panel ground.

4. Connect the positive lead of the DVM to the Wiegand Data 0 line.

5. Monitor the DVM. If the reader is operating correctly, the DVM will toggle between +5

VDC and 0 VDC.

6. Now connect the positive lead of the DVM to the Wiegand Data 1 line.

7. Again monitor the DVM. If the reader is operating correctly, the DVM will toggle between

+5 VDC and 0 VDC.

8. Reconnect the Wiegand Data lines to the access panel.

1530 Old Oakland Road, Suite 100 01858-001 Rev. A

San Jose, CA 95112 USA

(800) 260-5265 (408) 451-2520 FAX (408) 441-0309 Page 4 of 4

Loading...

Loading...