Page 1

SERVICE MANUAL

MAT 1/3 RACK (EXCEPT 6-32)

POWER SUPPLY

KEPCO INC.

An ISO 9001 Company.

MAT 1/3 RACK

(EXCEPT 6-32)

MODEL

POWER SUPPLY

ORDER NO. REV. NO.

This on-line version of the Technical Manual

includes only Installation and Operating

Instructions. For the complete manual,

please contact Kepco.

©2004, KEPCO, INC

P/N 243-

KEPCO, INC. ! 131-38 SANFORD AVENUE ! FLUSHING, NY. 11352 U.S.A. ! TEL (718) 461-7000 ! FAX (718) 767-1102

KEPCO®

THE POWER SUPPLIER™

email: hq@kepcopower.com ! World Wide Web: http://www.kepcopower.com

Page 2

Declaration of Conformity

Application of Council directives:

Standard to which Conformity is declared:

EN61010-1:2001 (Safety requirements for electrical equipment for measurement,

control and laboratory use - Part 1)

Manufacturer's Name and Address:

Importer's Name and Address:

Type of Equipment:

Model No.:

73/23/EEC (LVD)

93/68/EEC (CE mark)

KEPCO INC.

131-38 SANFORD AVENUE

FLUSHING, N.Y. 11352 USA

P

O

C

E

V

I

T

A

T

N

E

S

E

R

P

E

R

Component Power Supply

[PRODUCT MODEL NUMBER]

Y

Year of Manufacture:

I, the undersigned, declare that the product specified above, when used in conjunction with the conditions of conformance set forth in the product instruction manual, complies with the requirements of the

Low Voltage Directive 73/23/EEC, which forms the basis for application of the CE Mark to this product.

Place: KEPCO Inc.

131-38 Sanford Ave.

Flushing, N.Y.11352 USA

Saul Kupferberg

(Full Name)

Date:

228-1348 DC-COMP/INST 112404

VP OF SALES

(position)

A

Page 3

Conditions of Conformance

When this product is used in applications governed by the requirements of the EEC, the following restrictions and conditions apply:

1. For European applications, requiring compliance to the Low Voltage Directive, 73/23/EEC, this power

supply is considered a component product, designed for "built in“ applications. Because it is incomplete in construction, the end product enclosure must provide for compliance to any remaining electrical safety requirements and act as a fire enclosure. (EN61010-1:2001, Cl. 6, Cl. 7, Cl.8, and Cl. 9)

2. This power supply is designed for stationary installation within an RA 50 or RA 51 rack adapter. Mains

power is supplied via a detachable power supply cord or via direct wiring to the source power terminal

block.

3. This power supply is considered a Class 1 (earthed) product. It is intended for use as part of equipment meant for test, measurement and laboratory use, and is designed to operate from single phase,

three wire power systems. This equipment must be installed within a suitably wired equipment rack,

utilizing a three wire (grounded) mains connection. See wiring section of this manual for complete

electrical wiring instructions. (EN61010-1:2001, Cl.6.10.1)

4. This power supply has secondary output circuits that are considered hazardous, and which exceed

240 VA at a potential of 2V or more.

5. The output wiring terminals of this power supply have not been evaluated for field wiring and, therefore, must be properly configured by the end product manufacturer prior to use.

6. This power supply employs a supplementary circuit protector in the form of a circuit breaker mounted

on the front panel. This circuit breaker protects the power supply itself from damage in the event of a

fault condition. For complete circuit protection of the end product, as well as the building wiring, it is

required that a primary circuit protection device be fitted to the branch circuit wiring. (EN610101:2001, Cl. 9.5)

7. Hazardous voltages are present within this power supply during normal operation. All operator adjustments to the product are made via externally accessible switches, controls and signal lines as specified within the product operating instructions. There are no user or operator serviceable parts within

the product enclosure. Refer all servicing to qualified and trained Kepco service technicians.

B

228-1373 COND/CONFORM 112404

Page 4

SAFETY INSTRUCTIONS

1. Installation, Operation and Service Precautions

This product is designed for use in accordance with EN 61010-1 and UL 3101 for Installation Category 2,

Pollution Degree 2. Hazardous voltages are present within this product during normal operation. The

product should never be operated with the cover removed unless equivalent protection of the operator

from accidental contact with hazardous internal voltages is provided:

!

!

!

There are no operator serviceable parts or adjustments within the product enclosure.

Refer all servicing to trained service technician.

Source power must be removed from the product prior to performing any servicing.

This product is factory-wired for the nominal a-c mains voltage indicated on the rating nameplate located adjacent to the source power connection on the product's rear

panel. To reconfigure the product input for other nominal mains voltages as listed

herein, the product must be modified by a trained service technician.

2. Grounding

This product is a Class 1 device which utilizes protective earthing to ensure operator safety.

The PROTECTIVE EARTHING CONDUCTOR TERMINAL must be properly con-

!

nected prior to application of source power to the product (see instructions on installation herein) in order to ensure safety from electric shock.

PROTECTIVE EARTHING CONDUCTOR TERMINAL - This symbol indicates the

point on the product to which the protective earthing conductor must be attached.

EARTH (GROUND) TERMINAL - This symbol is used to indicate a point which is

connected to the PROTECTIVE EARTHING TERMINAL. The component installer/

assembler must ensure that this point is connected to the PROTECTIVE EARTHING TERMINAL.

CHASSIS TERMINAL -This symbol indicates frame (chassis) connection, which is

supplied as a point of convenience for performance purposes (see instructions on

grounding herein). This is not to be confused with the protective earthing point, and

may not be used in place of it.

3. Electric Shock Hazards

This product outputs hazardous voltage and energy levels as a function of normal operation. Operators

must be trained in its use and exercise caution as well as common sense during use to prevent accidental

shock.

This symbol appears adjacent to any external terminals at which hazardous voltage

!

228-1352 SAFETY - (COVER REMOVAL) 112404 C/(D BLANK)

levels as high as 500V d-c may exist in the course of normal or single fault conditions.

This symbol appears adjacent to any external terminals at which hazardous voltage

levels in excess of 500V d-c may exist in the course of normal or single fault conditions.

Page 5

Page 6

TABLE OF CONTENTS

SECTION PAGE

SECTION 1 - INTRODUCTION

1.1 Scope Of Manual..................................................................................................................................... 1-1

1.2 General Description................................................................................................................................. 1-1

1.3 Specifications, Electrical.......................................................................................................................... 1-3

1.4 DC Output Ratings For 1/3, 2/3 And Full Rack Modules....................................................................... 1-4

1.5 Miscellaneous Features ......................................................................................................................... 1-7

1.6 Accessories ............................................................................................................................................. 1-7

1.7 Safety ...................................................................................................................................................... 1-8

SECTION 2 - INSTALLATION

2.1 Unpacking And Inspection....................................................................................................................... 2-1

2.2 Transport instructions.............................................................................................................................. 2-1

2.3 Terminations............................................................................................................................................ 2-2

2.4 AC Input Requirement............................................................................................................................. 2-5

2.5 Cooling .................................................................................................................................................... 2-6

2.6 Installation ............................................................................................................................................... 2-6

2.7 Grounding................................................................................................................................................ 2-7

2.7.1 Safety Grounding............................................................................................................................... 2-7

2.7.2 DC (Output) Grounding...................................................................................................................... 2-8

2.7.3 Power Module To Load Interface..................................................................................................... 2-8

2.7.4 Load Connection, Local Error Sensing.............................................................................................. 2-9

2.7.5 Load Connection With Remote Error Sensing................................................................................... 2-10

2.8 Operating Configuration .......................................................................................................................... 2-10

2.9 Preliminary Check-out............................................................................................................................. 2-11

2.9.1 Example 1: Full Scale Voltage Check................................................................................................ 2-12

2.9.2 Example 2: Full Scale Current Check............................................................................................... 2-13

2.9.3 Example 3: To Reset the Power Module ........................................................................................... 2-14

SECTION 3 - OPERATION

3.1 General.................................................................................................................................................... 3-1

3.2 Series Connection Of MAT Power Modules............................................................................................ 3-1

3.3 Power Module Controller/MAT Time Delays (To Obtain A Valid Status):................................................ 3-1

3.4 Power Loss Circuit .................................................................................................................................. 3-2

3.5 Introduction To Controlling The MAT Power Module Output................................................................... 3-2

3.5.1 MAT/Power Module Controller System.............................................................................................. 3-4

3.5.2 MAT/TMA Pc-27 System................................................................................................................... 3-5

3.6 Remote Programming ............................................................................................................................. 3-6

3.6.1 General.............................................................................................................................................. 3-6

3.6.2 SCPI Programming............................................................................................................................ 3-6

3.6.2.1 SCPI Program Example............................................................................................................... 3-7

3.6.3 CIIL Programming.............................................................................................................................. 3-8

3.6.3.1 Examples Using CIIl To Program The MAT Power Module......................................................... 3-8

3.6.3.1.1 Example 1: Program Positive Voltage With Current Limit......................................................3-8

3.6.3.1.2 Example 2 : Program Negative Voltage With Current Limit ...................................................3-10

3.6.3.1.3 Example 3: Program Current And Voltage Limit .....................................................................3-11

APPENDIX A - CIIL COMMAND DEFINITIONS

MAT 25-14 112404

i

Page 7

LIST OF FIGURES

FIGURE TITLE PAGE

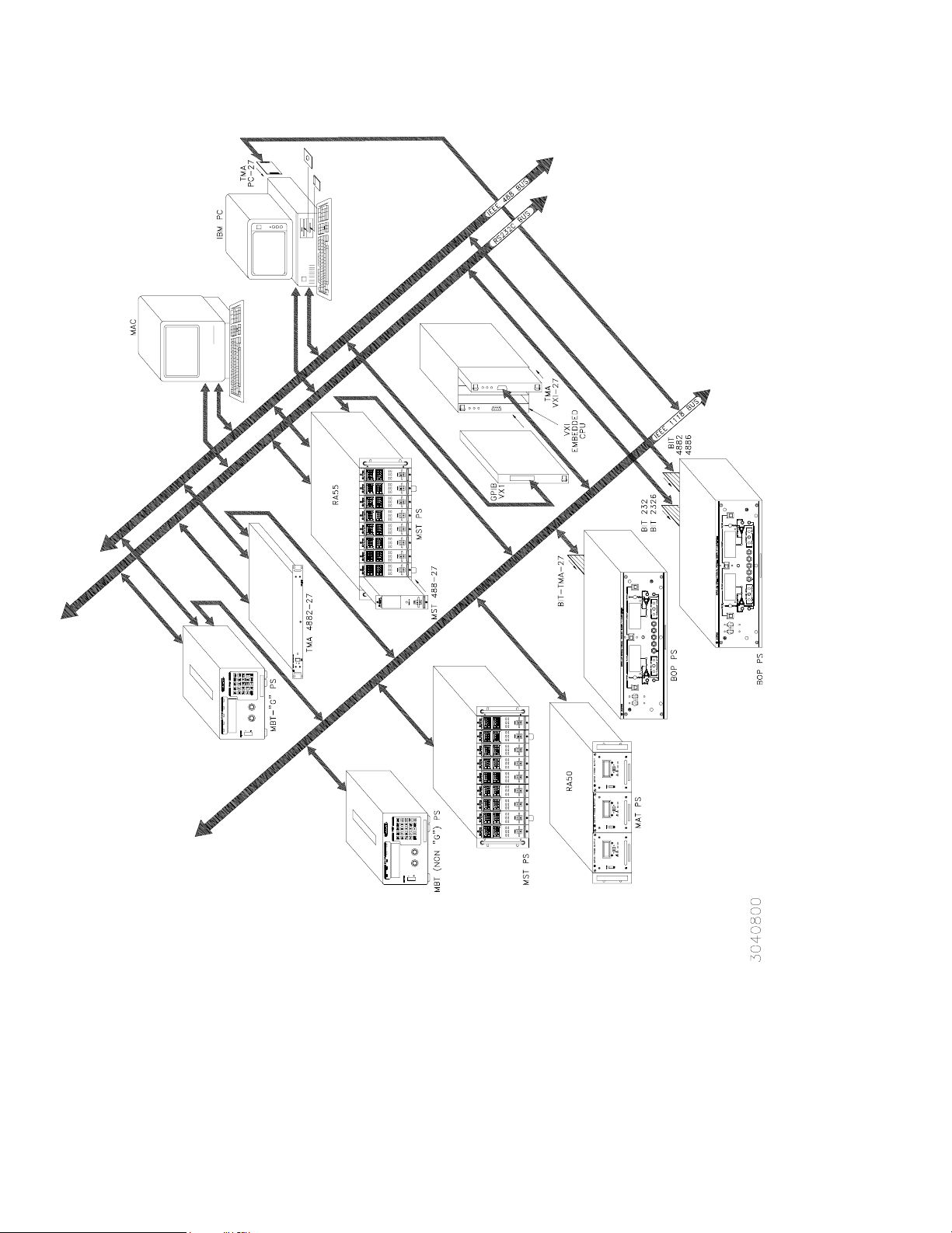

1-1 Remotely Controlled Power Supply Configurations Using Kepco Products............................................... 1-2

1-2 MAT Power Module Mechanical Outline Drawing...................................................................................... 1-6

1-3 The TMA 4882-27 Controller And MAT Power Modules............................................................................ 1-8

2-1 Front View Of The 1/3 Rack MAT Power Supply ...................................................................................... 2-3

2-2 Rear View Of The 1/3 Rack Power Module............................................................................................... 2-4

2-3 MAT Module Barrier Strip With Jumpers For 115 Or 230 Va-c ............................................................... 2-6

2-4 Variation Of Output Impedance With Frequency For A Voltage Source And A Current Source................ 2-8

2-5 Load Connections, Local Sensing.............................................................................................................. 2-9

2-6 Load Connections, Remote Sensing.......................................................................................................... 2-10

3-1 Two MAT 1/3 RACK Power Modules Connected In Series Via Their Output Connector......................... 3-2

3-2 MATPower Module Control Section, Top Cover Removed ........................................................................ 3-3

3-3 Tree Diagram of SCPI Commands Used with MAT Power Supplies ......................................................... 3-6

3-4 Typical Example Of MAT Power Supply Program Using SCPI Commands............................................... 3-7

3-5 Schematic Diagram MAT Front Panel Display Board A8.......................................................................... 3-13

A-1 FNC — Function Command....................................................................................................................... A-1

A-2 INX — Initiate Op Code Command ............................................................................................................ A-2

A-3 FTH — Fetch Command ............................................................................................................................ A-2

A-4 SET Command........................................................................................................................................... A-3

A-5 OPN, CLS — Open, Close Relay Commands ........................................................................................... A-4

A-6 RST — Reset Command............................................................................................................................ A-4

A-7 CNF, IST — Confidence Test, Internal Self Test Commands .................................................................... A-4

A-8 STA — Status Command........................................................................................................................... A-5

ii

MAT 25-14 112404

Page 8

LIST OF TABLES

TABLE TITLE PAGE

1-1 MAT Power Module Features And Specifications .......................................................................................1-3

1-2 MAT Power Modules Power Output Ratings ...............................................................................................1-4

1-3 Safety Symbols ...........................................................................................................................................1-8

2-1 Hardware Required for Reshipment in Transport Cover .............................................................................2-1

2-2 Internal Controls Accessible Through Top Cover .......................................................................................2-2

2-3 Front Control MAT Power Module ..............................................................................................................2-3

2-4 Rear Terminations MAT Power Module ......................................................................................................2-4

2-5 Ac Input/Control Bus Connector Pin Designations .....................................................................................2-4

2-6 DC Output Connector Pin Designations .....................................................................................................2-5

2-7 Internal Jumper Configuration .....................................................................................................................2-11

3-1 Device Address Selection For The MAT power Module .............................................................................3-4

A-1 CIIL Subsystem Command/query Index .................................................................................................... A-1

A-2 CIIL Error Messages ..................................................................................................................................A-5

MAT 25-14 112404

iii/(vi Blank)

Page 9

Page 10

1.1 SCOPE OF MANUAL

This manual contains instructions for the installation, operation, and maintenance of the 1/3

Rack size 360W MAT series of voltage and current stabilized DC Power Modules manufactured

by Kepco, Inc. Flushing, New York, U.S.A.

1.2 GENERAL DESCRIPTION

The Kepco MAT Power Module with overvoltage, overcurrent, overtemperature, polarity reversal, and power loss protection is a digitally controlled precision stabilized Power Module that

delivers either stabilized voltage or current. A single front panel meter with a selector switch

constantly monitors the output voltage or the output current. The prevailing operating mode is

indicated by LED mode indicators on the front panel. Operating mode crossover is dependent on

commands from a Host Computer. The Power Module has a linear and fully dissipative NPN

pass transistor driven by high gain integrated circuit amplifiers. The output of the Power Module

is fully programmable.

The Power Module features full range output control by means of a compatible Kepco Power

Module Controller. Control of the MAT Power Module is via the IEEE 1118 2-wire serial bus

operating at 375KHz; as many as 27 separate modules of either the MAT, MST, MBT or BOP

Series design can be addressed via the bus (see Figure 1-1). Decoders for RS232, IEEE-488

and VXI are available in modular form and stand-alone types. As shown in Figure 1-1, the following controllers are available to control of MAT Power Modules directly from a computer.

SECTION 1 - INTRODUCTION

a. Controller Model TMA PC-27 plugs into a half-card slot of a DOS-based PC and allows key-

board control of the MAT via the IEEE 1118 bus.

b. Controller Model TMA 4882-27 is free-standing and allows host computers designed for

RS232 or IEEE 488 bus communication to control the MAT via the IEEE 1118 bus.

c. Controller Model TMA-VXI-27 plugs into a slot in a VXI chassis and allows VXI-based com-

puters to control the MAT via the IEEE 1118 bus.

d. Controller Model MST 488-27 plugs into a slot in a Model RA 55 Rack Adapter and allows

host computers designed for RS232 or IEEE 488 bus communication to control the MAT via

the IEEE 1118 bus.

e. The MAT Power Module can also be directly controlled via the keypad of the MBT Series

(“G” Option) Power Supply via the IEEE 1118 bus.

An important feature of the MAT Series Power Module is the overvoltage and overcurrent protection circuits. This protection is provided by two autotracking amplifiers that have an overvoltage and overcurrent tracking range of 10% ± 3% above the programmed Power Module output

voltage or current.

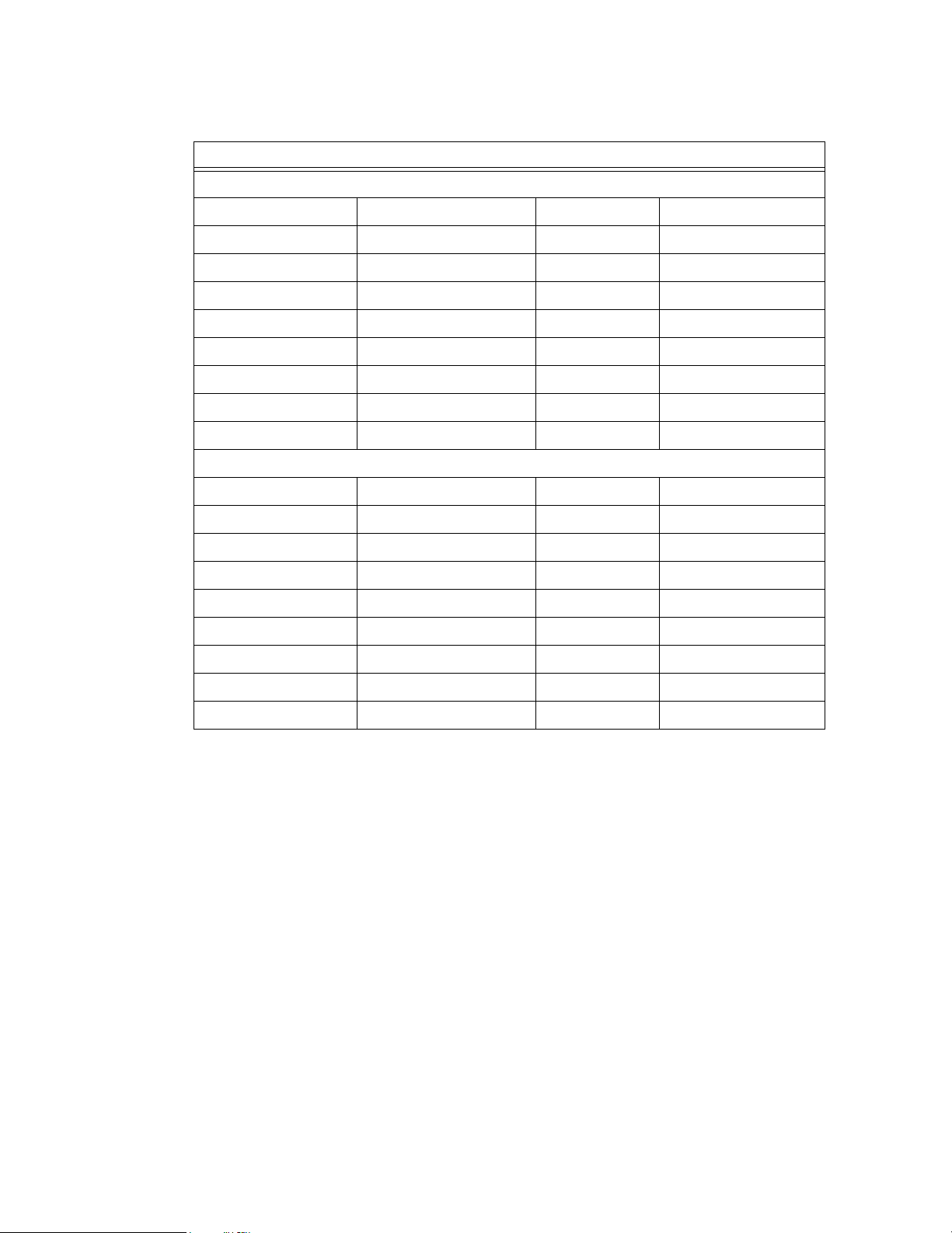

The MAT series Power Modules are built in 1/3 Rack, 2/3 Rack and Full Rack mechanical sizes

according to their approximate output power rating (see Mechanical Outline Drawing of the

Power Module Chassis, Figure 1-2).

Power transistors and drivers on all Power Module designs are mounted on highly efficient patented heat sink assemblies that are cooled by fans.

MAT 1/3 and 2/3 Rack size modules are designed to operate in either one of two housings

called RA 50 and RA 51. RA 50 is 5-1/4" x 19" x 25" and accepts up to three 1/3 Rack Power

Modules. RA 51 is similarly sized, but configured for one 1/3 Rack Module and one 2/3 Rack

Module. Full Rack MAT Power Modules mount directly into a standard 19 inch Equipment Rack.

MAT 1/3 RACK/ 112404

1-1

Page 11

FIGURE 1-1. REMOTELY CONTROLLED POWER SUPPLY CONFIGURATIONS USING KEPCO PRODUCTS

1-2

MAT 1/3 RACK/ 112404

Page 12

1.3 SPECIFICATIONS, ELECTRICAL

a) MAT Power Module Features And Specification

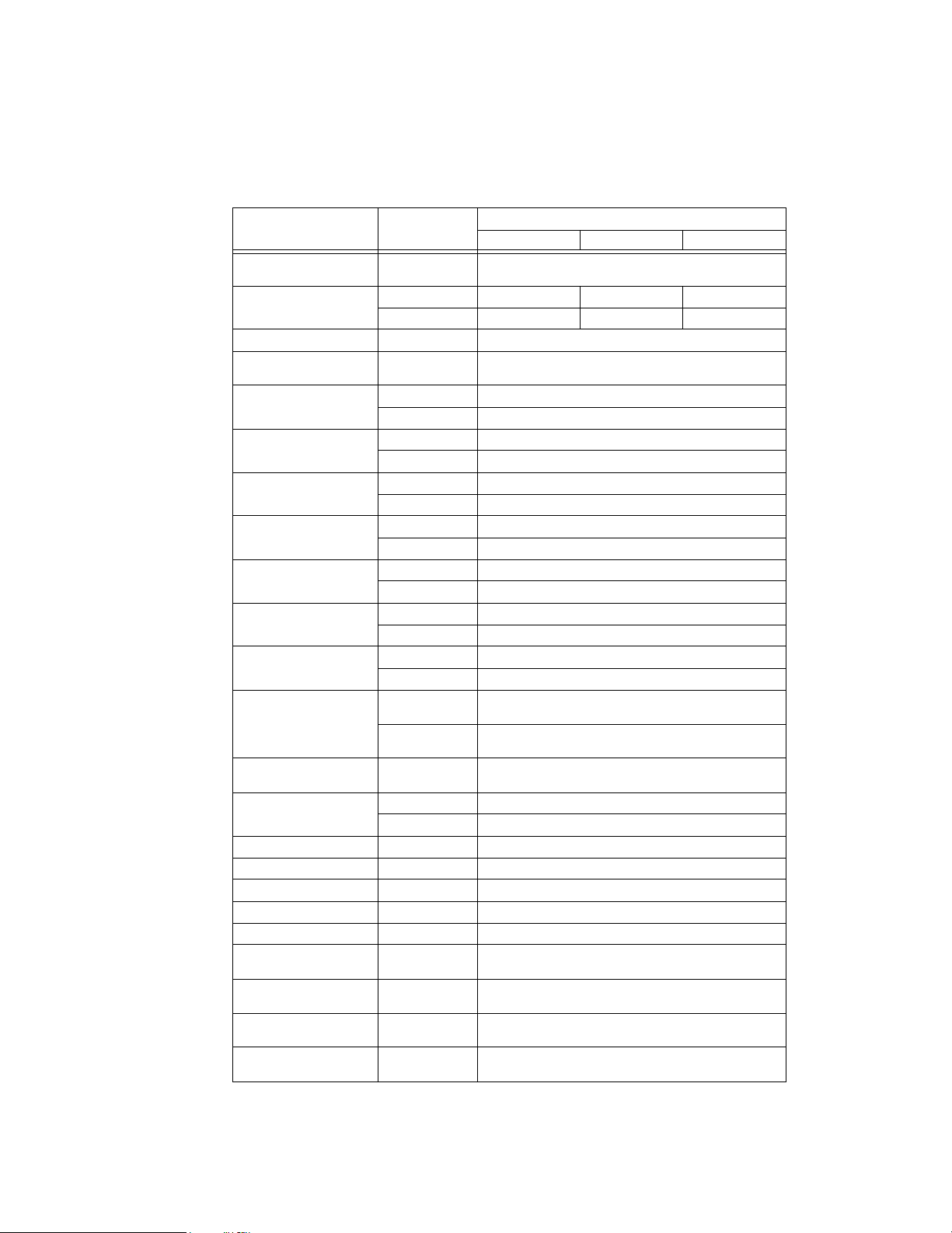

TABLE 1-1. MAT POWER MODULE FEATURES AND SPECIFICATIONS

PARAMETER CONDITION

Input Voltage Range

Input Current Max

Input Frequency RANGE 47-63 Hz

Voltage/Current Adjust-

ment Range

Programming

Resolution

Programming Accuracy

Data Read Back

Accuracy via Digital Bus

Source Effect

Load Effect

Time 8 Hour Drift

Temperature

Coefficient/°C

Ripple & Noise

Transient Recovery Voltage

Temperature

Cooling Built-in fan, air exhaust to rear

Remote Sensing Range 0.5 volts per lead (Provision for 4-terminal connection to load)

DC Output Isolation Voltage 500 Vdc

Leakage Current Output to chassis 5

Series/Parallel Operation Consult Kepco application engineering

Output Display

IndIcators 4 LEDs

Output Enable/Disable

Polarity Reversal

USER

SELECTABLE

115 VAC 7.0A 14.0A 21.0A

230 VAC 3.5A 7.0A 10.5A

RANGES

Voltage 0.024% Eo max (12 bits)

Current 0.024% Io max (12 bits)

Voltage 0.024% Eo max

Current 0.1% Io max

Volt ag e 0.1% Eo m ax

Current 0.12% Io max

Voltage 0.001% Eo max

Current 0.005% Io max

Voltage 0.002% Eo max

Current 0.024% Io max or 4 mA (whichever is greater)

Voltage 0.01% Eo max

Current 0.02% Io max

Voltage 0.01% Eo max

Current 0.02% Io max

Volt ag e

Current

Operating 0 to 50 °C

Storage -20 to +70 °C

3-1/2 digit LCD

Panel Meter

1/3 RACK 2/3 RACK FULL RACK

0 to 100% of rating, by preprogrammed setting,

rms: 0.001% Eo max or 0.3 mV (whichever is greater)

p-p: 0.01% Eo max or 3 mV (whichever is greater)

150

sec to recover within 0.1% Eo max for 10% to 100%

µ

Voltage and Current Mode,Output Enabled, Polarity

Reversed

Built in power and sensing relays controlled through IEEE

1118 b us

Built in power and sensing relays controlled through IEEE

1118 b us

MAT POWER MODULE

105-125 VAC

210-250 VAC

within inherent resolution limits

rms: 0.03% Io max

p-p: 0.3% Io max

step in rated load current

A rms or 50µA p-p @ 115V a-c

µ

Switch selectable voltage/current

MAT 1/3 RACK/ 112404

1-3

Page 13

TABLE 1-1. MAT POWER MODULE FEATURES AND SPECIFICATIONS (CONTINUED)

PARAMETER CONDITION

Overvoltage Tracks program voltage, Crowbars output and turns off input

Overcurrent Tracks program current, Crowbars output and turns off input

Protection

Source Connections

Load Connections

Remote Control

Signal Connections

Dimensions See Figure 1-2.

Weight LBS336075

Mounting Front

Filler Panels

Overtemperature

Polarity Reversal Built in diodes protect unipolar supply output

Power Loss Detects loss of ac input power, disables output

For either RA 50

or RA 51

1/3 RACK 2/3 RACK FULL RACK

Monitors heat sink temperature, Crowbars output and turns

off input

3-wire power entry, via user-configurable mating connector

(supplied) and proper gage wires (not supplied)

5-wire connection, via user-configurable mating connector

(supplied) and proper gage wires (not supplied)

DC Power Output: 2 wires

Output Sense Terminals: 2 wires

Ground: 1 wire

Two 2-wire connections via user-configurable mating

connector supplied and 22 AWG wire (not supplied).

Connectors in parallel for daisy chaining multiple power

supplies (full rack only).

Three 1/3 rack

modules plug into

RA 50. One 1/3

and one 2/3 rack

modules plug into

RA 51

MAT POWER MODULE

One 1/3 and one

2/3 rack modules

plug into RA 51

RFP 50-1: 1/3 Panel

RFP 50-2: 2/3 Panel.

Full Rack mounts

directly into 19

inch Rack

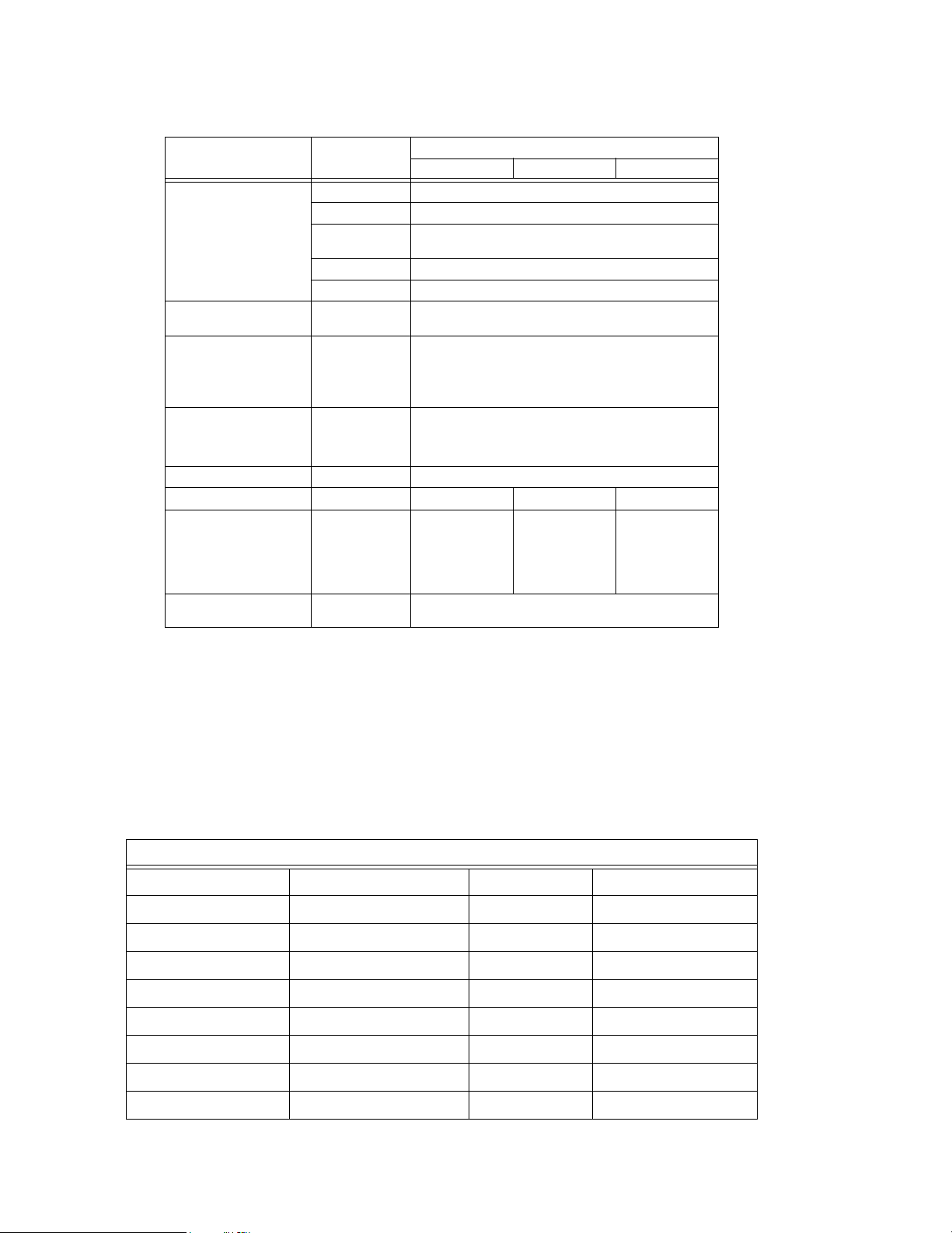

1.4 DC OUTPUT RATINGS FOR 1/3, 2/3 AND FULL RACK MODULES

a. MAT Power Module DC Output Ratings 1/3, 2/3, and Full Rack Size - see Table 1-2

b. Output range:

1) Voltage mode: 0-100% of rated voltage

2) Current mode: 0-100% of rated current

TABLE 1-2. MAT POWER MODULES POWER OUTPUT RATINGS

360W MODULES-1/3 RACK SIZE-DC OUTPUT RATINGS

MODEL VOLTS AMPS POWER

MAT 6-32 0-6 0-32 192

MAT 15-20 0-15 0-20 300

MAT25-14 0-25 0-14 350

MAT 36-10 0-36 0-10 360

MAT 55-7 0-55 0-7 385

MAT 75-5 0-75 0-5 375

MAT 100-3.6 0-100 0-3.6 360

MAT 150-2.4 0-150 0-2.4 360

1-4

MAT 1/3 RACK 112404

Page 14

TABLE 1-2. MAT POWER MODULES POWER OUTPUT RATINGS

360W MODULES-1/3 RACK SIZE-DC OUTPUT RATINGS

720W MODULES-2/3 RACK-DC OUTPUT RATINGS

MODEL VOLTS AMPS POWER

MAT 6-64 0-6 0-64 384

MAT 15-40 0-15 0-40 600

MAT25-28 0-25 0-28 700

MAT 36-20 0-36 0-20 720

MAT 55-14 0-55 0-14 770

MAT 75-10 0-75 0-10 750

MAT 100-7.2 0-100 0-7.2 720

MAT 150-4.8 0-150 0-150 720

1080W MODULES-FULL RACK-DC OUTPUT RATINGS

MODEL VOLTS AMPS POWER

MAT 6-100 0-6 0-100 600

MAT 15-60 0-15 0-60 900

MAT 25-42 0-25 0-42 1050

MAT 36-30 0-36 0-30 1080

MAT 55-20 0-55 0-20 1100

MAT 75-15 0-75 0-15 1125

MAT 100-10 0-100 0-10 1000

MAT 150-7 0-150 0-7 1050

MAT 1/3 RACK/ 112404

1-5

Page 15

FIGURE 1-2. MAT POWER MODULE MECHANICAL OUTLINE DRAWING

1-6

MAT 1/3 RACK 112404

Page 16

1.5 MISCELLANEOUS FEATURES

a. Mode flag: A pair of panel LED indicators indicate whether the Power Module is in voltage

mode or in current mode.

b. Remote error sensing: Separate voltage-sensing terminals permit 4-wire connections to a

load to compensate for static load effects (up to 0.5V per lead). An additional 1 volt output

voltage, beyond the nominal voltage rating of each MAT Power Module, is provided for this

purpose.

c. Storage temperature range: -20 to +85° C.

d. Cooling: The fans are high efficiency, single bearing fans with special low-noise non-metallic

blades

1.6 ACCESSORIES

NOTE: All Kepco rack adapters fit standard EIA rack dimensions. They are drilled for chassis

slides (see the RA 50 or RA 51 manual).

a. Kepco Rack Adapter Model RA-50 is for three 1/3 Rack Size Power Modules. Filler panels

are available to cover empty slots, if the adapter is not used to its full capacity.

b. Kepco Rack Adapter Model RA-51 is for one 1/3 Rack Size, and one 2/3 Rack Size Power

Modules. Filler panels to cover empty slots are available if the adapter is not used to its full

capacity. The Full Rack MAT Power Modules fit directly into a standard 19 inch Rack.

c. One 2 meter long shielded twisted pair cable with two mating connectors, one at each end

(Kepco P/N 118-0699) is supplied with each Rack Adapter (RA 50 or RA 51) and with each

Full Rack MAT Power Module. The Power Module Controller (see PAR. 1.2) and up to 27

MAT Power Modules can be connected in a daisy chain configuration as shown in FIG. 1-3.

The last (in the daisy chain) Power Module Control Bus Outlet must be terminated with a Terminating Connector Assembly (Kepco P/N 195-0075) that is supplied with the Power Module Controller.

MAT 1/3 RACK/ 112404

1-7

Page 17

FIGURE 1-3. THE TMA 4882-27 CONTROLLER AND MAT POWER MODULES

1.7 SAFETY

There are no operator serviceable parts inside the case. Service must be referred to authorized

personnel. Using the power supply in a manner not specified by Kepco. Inc. may impair the protection provided by the power supply. Observe all safety precautions noted throughout this manual. Table 1-3 lists symbols used on the power supply or in this manual where applicable.

TABLE 1-3. SAFETY SYMBOLS

SYMBOL Meaning

CAUTION: RISK OF ELECTRIC SHOCK.

CAUTION: REFER TO REFERENCED PROCEDURE.

!

1-8

WARN ING

CAUTION

INDICATES THE POSSIBILITY OF BODILY INJURY

OR DEATH.

INDICATES THE POSSIBILITY OF EQUIPMENT

DAMAGE.

MAT 1/3 RACK 112404

Page 18

SECTION 2 - INSTALLATION

2.1 UNPACKING AND INSPECTION

This instrument has been thoroughly inspected and tested prior to packing and is ready for

operation. After careful unpacking, inspect for shipping damage before attempting to operate.

Perform the preliminary operational check as outlined in PAR 2.9 If any indication of damage is

found, file an immediate claim with the responsible transport service.

The MAT 1/3 rack module may be received in either of two ways; with a special transport cover

or in a RA 50 or RA 51 housing. Below are the procedures necessary to remove the MAT power

module from its housing or transport cover

a. For the MAT 1/3 rack power module in a transport cover, there are ten screws (self tap-

ping countersunk Flat Head Phillips size no. 6-32 x 3/8, Kepco P/N 101-0344) located

at each side of the transport cover. These screws must be removed and saved with the

cover for later transport use.

NOTE: If the Power Modules are shipped in the RA 50 or RA 51 Rack Adapter, the power

modules must be removed before installing the rack adapter in a rack.

b. To remove the 1/3 rack power module from the RA 50/RA 51 housing, loosen the two

slotted captive thumb screws on the front panel, then remove and save the six Flat

Head Phillips screws from the base of the housing. Slide the power module out of the

housing and set the Control Bus Address (see PAR. 3.5). Slide the power module back

into the housing and fasten the two slotted captive thumb screws It is not advisable to

replace the six Flat Head Phillips screws in the base of the housing unless the unit is

going to be transported.

2.2 TRANSPORT INSTRUCTIONS

THE MAT POWER MODULE SHOULD BE SHIPPED ONLY IN THE RACK

ADAPTER OR IN A TRANSPORT COVER. FAILURE TO PROPERLY

SECURE THE MAT POWER MODULE BEFORE SHIPPING WILL RESULT

IN SEVERE DAMAGE TO THE EQUIPMENT AND VOID THE WARRANTY.

The MAT Power Module is a relatively heavy piece of equipment, particularly due to the main

Power Transformer, chassis frame and electrolytic capacitors. This means that the unit when

shipped, must be properly fastened in a transport cover, rack adapter or by other means; otherwise the Power Module may buckle at the center of gravity of the chassis due of its weight.

To transport the MAT Power Module in the transport cover (supplied with the unit) secure the

power module with 6-32 steel round head phillips screws (see Table 2-1).

TABLE 2-1. HARDWARE REQUIRED FOR RESHIPMENT IN TRANSPORT COVER

FOR THESE MAT

POWER MODULES

1/3 RACK 129-0231 QTY 10 N/A

2/3 RACK 129-0232 QTY 14 QTY 2

USE THIS TRANSPORT COVER

KEPCO P/N

To transport the MAT Power Module in the Rack Adapter RA 50/ RA 51, secure each Power

Module with Flat Head Phillips screws (self tapping countersunk Flat Head Phillips size no.

8-5/8, Kepco P/N 101-0421), six for 1/3 rack models and eight for 2/3 rack models.

MAT 1/3 RACK/ 112404

CAUTION

6-32 x 3/8

(KEPCO P/N 101-0344)

USE THESE SCREWS

6-32 x 3/4

(KEPCO P/N 101-0349

2-1

Page 19

If a transport cover is not available, the MAT power module may be mounted on a 3/4 inch thick

(or greater) piece of wood by using 8-18 thread-forming screws with a type B style point. A

screw should be used to secure the wood to each of the mounting grommets in the bottom of

the chassis.

2.3 TERMINATIONS

1. Internal Calibration Controls: Refer to Table 2-2 and Figure 3-2.

2. Front Panel: Refer to Table 2-3 and Figure 2-1.

3. Rear Panel: Refer to Table 2-4 and Figure 2-2.

TABLE 2-2. INTERNAL CONTROLS ACCESSIBLE THROUGH TOP COVER

REFERENCE

DESIGNATION

A1R28 I

A1R20 E

A1R15 I

A1R16 I

A1R11 V

A1R12 I

A3S1 Node Address Used to select Node address (node number or channel number) of the

A1TP1 Test Points Provides four test points used for testing/calibration

NOTES:

1. These adjustments must be done in accordance with the calibration procedure (see PAR. 5.5).

O ZERO

O ZERO

CURRENT SENSING ZERO

FULL SCALE CURRENT ADJUST

(NOTE 1)

REF

REF

CONTROL PURPOSE

(NOTE 1) Used to adjust output current of power supply to initial value.

CONDITIONS: current mode, shunt at the output.

(NOTE 1) Used to adjust output voltage of power supply to zero.

CONDITIONS: voltage mode, no load.

(NOTE 1) Used to adjust current monitor amplifier to zero.

CONDITIONS: voltage mode, no load.

Used to calibrate the full scale value of the output current.

CONDITIONS: current mode, shunt at the output.

(NOTE 1) Used to calibrate full scale voltage.

CONDITIONS: voltage mode, no load.

(NOTE 1) Used to adjust internal full scale current.

CONDITIONS: current mode, shunt at the output.

MAT Power Supply from 1 - 31

1 -CURRENT REFERENCE

2 -CURRENT MONITOR

3 - VOLTAGE REFERENCE

4 - COMMON

2-2

MAT 1/3 RACK/ 112404

Page 20

FIGURE 2-1. FRONT VIEW OF THE 1/3 RACK MAT POWER SUPPLY

TABLE 2-3. FRONT CONTROL MAT POWER MODULE

ITEM NO.

(See Fig. 2-1)

1 AC POWER SWITCH/CIRCUIT BREAKER

2 VOLTAGE MODE INDICATOR, GREEN LED ENERGIZED IN VOLTAGE MODE

3 CURRENT MODE INDICATOR, YELLOW LED ENERGIZED IN CURRENT MODE

4

5 OUTPUT ENABLED INDICATOR, GREEN LED

6 POLARITY REVERSED INDICATOR, GREEN LED

VOLTAGE/CURRENT METER WITH SELECTION

SWITCH, GREEN LED/ YELLOW LED

CONTROL FUNCTION

SERVES AS AN AC POWER SWITCH AND

TURNS THE AC POWER LINE OFF ON OVERVOLTAGE, OVERCURRENT, OVERTEMPERATURE OR POWER LOSS.

ENERGIZES TO READ OUTPUT VOLTAGE

ENERGIZES TO READ OUTPUT CURRENT

ENERGIZED WHEN RELAY CLOSES AND

VOLTAGE IS PRESENT AT THE POWER MODULE OUTPUT TERMINALS

ENERGIZED WHEN RELAY CLOSES AND

POLARITY AT POWER MODULE OUTPUT

TERMINALS IS REVERSED

MAT 1/3 RACK/ 112404

2-3

Page 21

FIGURE 2-2. REAR VIEW OF THE 1/3 RACK POWER MODULE

TABLE 2-4. REAR TERMINATIONS MAT POWER MODULE

ITEM NO.

(See Fig. 2-2)

1 DC OUTPUT CONNECTOR

2

REAR TERMINATION FUNCTION

AC INPUT POWER/CONTROL

BUS CONNECTOR

TABLE 2-5. AC INPUT/CONTROL BUS CONNECTOR PIN DESIGNATIONS

CONNECTOR PIN

(See Figure 2-2)

1 SAFETY GROUND

2 AC “H” (HOT)

3 AC “N” (NEUTRAL)

4 NOT USED

Connects the MAT power module output lines, sensing lines and

ground line to the load (See Table 2-6 for pin designations.) Type

MS3102A16-10P, (mating connector MS3108A16--10S, KEPCO

P/N 143-0331, supplied).

Connects MAT power module to a-c input power source and Bitbus

controller via RA 50 or RA 51 rack adapter. Five pins are used for

ac input, two for control bus connections (see Table 2-5). The

power module controller and up to 27 MAT power modules can be

connected (daisy chained) to the control bus (see PAR. 1.2).

FUNCTION

2-4

5 CONTROL BUS (IEEE 1118 BUS) LINE

6 CONTROL BUS (IEEE 1118 BUS) LINE

MAT 1/3 RACK/ 112404

Page 22

TABLE 2-6. DC OUTPUT CONNECTOR PIN DESIGNATIONS

CONNECTOR PIN

(See Figure 2-2)

H CONNECTED TO OUTPUT TERMINAL 1

I CONNECTED TO OUTPUT TERMINAL 2

A CONNECTED TO SENSE TERMINAL 1

E CONNECTED TO SENSE TERMINAL 2

D CONNECTED TO SAFETY GROUND

2.4 AC INPUT REQUIREMENT

These Power Modules operate on a single phase, 115 Va-c nominal line. The Power Module

can also be connected to 230 Va-c by the following procedure:

1. Disconnect the AC Input power from the RA 50 or RA 51 rack adapter

Turn OFF the circuit breaker on the module (if operating).

2. Remove the MAT Power Module from the RA 50 or RA 51 Rack Adapter by loosening two

slotted captive screws at the top of the MAT front panel, then locate the barrier terminal

block mounted on the chassis.

FUNCTION

NOTE: Do not move the wires connected to the barrier strip, they are properly placed for both

115 Va-c and 230 Va-c operation.

3. Figure 2-3A shows the barrier terminal block set to 115 Va-c

operation. Remove the jump-

ers on the barrier strip connecting terminals 2 to 3, and terminals 4 to 5.

4. Place a jumper between terminals 3 and 4. For 230 Va-c the barrier strip appears as in Figure 2-3B.

5. Verify that the source voltage on the Rack Adapter matches that of the Power Module.

6. Return the Module to the Rack Adapter

NOTE: To return to 115 Va-c operation reverse the procedure. Remove the jumper in step 4 and

replace the jumpers in step 3.

MAT 1/3 RACK/ 112404

2-5

Page 23

FIGURE 2-3. MAT MODULE BARRIER STRIP WITH JUMPERS FOR 115 OR 230 VA-C

2.5 COOLING

The power transistors and rectifiers in the MAT Power Module are maintained within their operating temperature range by means of special heat sink assemblies, cooled by an internal fan.

SIDE PANEL OPENINGS AND THE TOP OF THE CASE MUST BE KEPT CLEAR FROM

OBSTRUCTIONS TO ENSURE PROPER AIR CIRCULATION. If the MAT Power Module is

rack mounted, or installed in confined spaces, care must be taken that the ambient temperature

(the temperature immediately surrounding the Power Module) does not rise above the limit

specified in Table 1-1.

2.6 INSTALLATION

If the unit is to be rack mounted install the RA 50 or RA 51 Rack Adapter in the rack per Rack

Adapter instruction manual. Install the MAT 1/3 Rack Power Module in the Rack Adapter housing and secure with two front panel slotted screws. Refer to Rack Adapter manual for electrical

connections of the rack adapter.

The following steps are recommended for inserting the Power Module into the Rack Adapter.

• Tilt the front of the Power Module slightly lower then the rear, set the two rearmost grommets of the Module on the front lip of the Rack Adapter opening.

• Lift the front of the Module until the bottom is approximately parallel to the bottom of the

Rack Adapter and gently begin slidding in the Module, maintaining support with both

hands as needed to prevent the bottom of the Module from scrapping the lip of the Rack

Adapter.

2-6

• Once the Module has been inserted approximately 1 inch, lift the handle upward, raising

the front of the Power Module some 20° up relative to the back bottom edge of the unit

(about an inch over the bottom front lip of the Rack Adapter). Allow the Module to slide

against the bottom inside guides of the Rack Adapter. As this step is being done MAKE

SURE that the top of the Power Module, in particular the white connector on top of the

power module, clears the top edge of the Rack Adapter.

• Continue to lift the unit by the front handle while inserting the Module, until the frontmost

pair of grommets clear the front lip of the Rack Adapter, then allow the Module weight to

be fully supported by the grommets on the bottom of the Module.

MAT 1/3 RACK/ 112404

Page 24

• Proceed further to slide the Module in by lifting the handle upward. When the Module is

half way inserted (at the begining of the transformer) remove the hand from the bottom

of the unit

• At this point of the insertion process ensure that the Bit Bus twisted pair of white wires

on the right side of the Power Transformer (as viewed when looking down over the front

panel towards the back of the unit) does not get caught by the right edge of the Rack

Adapter

• As the Power Module is inserted inside the Rack Adapter completely, a slight resistance

will be felt when the Module connectors engage the mating connectors of the Rack

Adapter. Continue to apply steady but firmer pressure to overcome the insertion force of

the various connectors.

• If the module cannot be inserted fully using this type of force, remove the Power Module

and inspect the rear panel and Rack Adapter for obstruction or damage. If the damage

cannot be isolated return both the Power Module and Rack Adapter to Kepco along with

a complete description of the problems encountered.

• when installed in a Rack Adapter that is in a Rack, the Rack Adapter must be securely

fastened to the Rack before the Power Module is installed to avoid structural damage to

the Rack Adapter.

• when being installed into the Rack Adapter, must be supported not only at the front of

the assembly at the handle (by one hand), but also at or near the center of gravity of the

chassis, underneath the assembly near the Power Transformer (by the other hand).

• if already in a Rack Adapter which is to be installed in an Equipment Rack, must be handled in exactly the same way as when installing the Power Module itself into a Rack

Adapter. Failure to observe this caution could result in misalignment of the Power Modules with the Rack Adapter.

MAT Power Modules may also be operated as a bench type instrument. Leave the RA 50 or RA

51 feet installed, then install the MAT 1/3 Rack Power Module in the RA 50 or RA 51 Rack

Adapter housing and secure with two front panel slotted screws. The RA 50 Rack Adapter

houses up three 1/3 Rack Power Modules. The Rack Adapter may be equipped with Front Filler

panels. The RFP 50-1 may be used to close one channel in the RA 50 or RA 51 Rack Adapter.

Filler Panel RFP 50-2 can be used to close two channels in the RA 50 or RA 51 Rack Adapter.

For installation into confined spaces care must be taken that the surrounding environment does

not exceed the maximum specified ambient temperature of 50°C (see PAR. 2.5).

2.7 GROUNDING

2.7.1 SAFETY GROUNDING

a. AC Safety Ground: The Power Module is connected to the AC safety ground via the

AC INPUT/CONTROL BUS connector and the corresponding rack adapter connector.

b. Isolation From Ground: The DC output is isolated from the ac source and from the

chassis or ground. The maximum output voltage that can be supported between either

output terminals and ground or chassis is 500 Vdc plus the maximum output voltage of

the Power Module. Either terminal of the output may be grounded.

MAT 1/3 RACK/ 112404

2-7

Page 25

2.7.2 DC (OUTPUT) GROUNDING

DC output connections are those between the Power Module and the load, including remote

sensing connections if necessary. Despite precautions to eliminate noise such as shielding and

twisted wire-pairs, output connections may pick up radiated noise of a wide frequency. To minimize such undesired effects, one side of the Power Module output/load should be grounded.

Successful D.C. grounding depends on careful analysis of the system operation. However here,

only general guide lines are provided. One of the major points, is to avoid ground loops. Ground

loops are created when two or more points of different ground potentials in the output circuit are

grounded. A noise voltage is developed that is superimposed on the load (output potential). A

way to avoid ground loops is to investigate for points of resistance to ground. Differences in

ground potential can be avoided if the output circuit is completely isolated. A single point is then

selected along the Power Module output circuit and returned to ground with a single wire. This

method is dependent on the specific application.

The MAT Power Modules are designed with Power Isolation relays that comply with MATE

(Modular Automated Test Equipment) Test Module Adapter requirements. Each output is fully

isolated from other outputs and from ground.

2.7.3 POWER MODULE TO LOAD INTERFACE

The general function of a voltage or current stabilized Power Module is to deliver rated output to

the load. The load may be fixed or variable; resistive, capacitive, or inductive; and may be

located close to or far away from the Power Module. The Power Module is designed for varied

applications. The aim of the following paragraphs is to instruct the user in the interface of the

Power Module to the load.

The perfect interface between a Power Module and load insures optimum performance. To

approach this state of operation, one must be familiar with certain requirements, such as interconnection guidelines, Ohm's Law and ac theory.

Load Wire Selection - A stabilized dc Power Module is not an ideal voltage or current source

with zero output impedance (voltage mode) or infinite output impedance (current mode): All voltage sources have some amount of impedance which increases with frequency and all current

sources have impedance which decreases with frequency. (See FIG. 2-4).

FIGURE 2-4. VARIATION OF OUTPUT IMPEDANCE WITH FREQUENCY FOR A VOLTAGE SOURCE AND A

CURRENT SOURCE

2-8

MAT 1/3 RACK/ 112404

Page 26

A practical model for a voltage stabilized Power Module includes a series inductance representing dc and low frequency source impedance. Load leads should have minimum voltage drops

(error sensing is discussed below) and minimum inductance (error sensing does not compensate for this). Similarly a model for a current stabilized Power Module includes a parallel capacitor representing the dc and low frequency source impedance.

These considerations are important if:

1) The load is constantly changing value

2) The load is switched "on" and "off"

3) The output of the Power Module is step programmed

4) The load is reactive

5) Dynamic output response of the Power Module is of concern

2.7.4 LOAD CONNECTION, LOCAL ERROR SENSING

The DC OUTPUT connector is located on the back of chassis, and is designated A6-J2 in the

schematic. Table 2-6 and Figure 2-2 provide the function and location of DC OUTPUT connector

pins.

NOTE: The sense terminals MUST be configured for either local sensing (as follows) or

remote sensing (see PAR. 2.7.5) for the MAT Power Module to operate. If left

unconnected the unit will automatically isolate the load and shut down.

For Local sensing connect Output Terminal 1 to Sense Terminal 1, and Output Terminal 2 to

Sense Terminal 2 at the DC Output connector (see Figure 2-5).

FIGURE 2-5. LOAD CONNECTIONS, LOCAL SENSING

MAT 1/3 RACK/ 112404

2-9

Page 27

2.7.5 LOAD CONNECTION WITH REMOTE ERROR SENSING

The MAT series of Power Modules can operate with sensing external to the Module. Sensing

should be with a twisted wire pair to reduce noise. The sensing wires must be connected as follows: Output terminal 1 to Sense Terminal 1 and Output Terminal 2 to Sense Terminal 2, each at

the load (see Figure 2-6). Refer to Table 2-6 and Figure 2-2 for DC Output connector pin functions and locations.

When the MAT Power Module is connected for remote error sensing (in the voltage mode), a situation might occur where the output capacitor C14 must be supplemented to achieve optimum

performance. If oscillations are observed at the output terminals or at the load, the load should

be decoupled with another high quality capacitor of a value equal to or greater than C14.

FIGURE 2-6. LOAD CONNECTIONS, REMOTE SENSING

2.8 OPERATING CONFIGURATION

The complete operating configuration is defined by

• The Model Number (e.g. MAT 36-10)

• Jumper configuration of internal boards.

Table 2-4 lists the location of the internal jumpers and their function. This information is provided

for reference purposes only, to indicate the configuration options available. Do not attempt to

2-10

MAT 1/3 RACK/ 112404

Page 28

alter the jumper configuration. For assistance in changing any jumper-selected parameter contact Kepco Applications Engineering.

LOCATION FUNCTION

Establish the

Model

A1

Path Fault

Protection

A2

Input Power

Loss Protec-

tion

TABLE 2-7. INTERNAL JUMPER CONFIGURATION

JUMPER

INSTALLED

J1-J5 MAT 6-32

J1,J2,J3,J4 J5 MAT 15-20

J1,J2,J3, J5 J4 MAT 25-14

J1,J2-J3 J4 J5 MAT 36-10

J1-J3 J4,J5 MAT 55-7

J1,J2, J4 J3,J5 MAT 75-5

J1, J2, J5 J3, J4 MAT 100-3.6

J1,J2 J3-J5 MAT 150-2.4

J7

J5

(Default)

JUMPER

NOT

INSTALLED

J7

(Default)

J5

DESCRIPTION

Enables crowbar protection circuit to trip circuit

breaker and shut off unit if path fault detected.

Allows software complete control of path fault protection. Outputs (voltage and current) are programmed to zero and relays opened to isolate load

in case of path fault.

Enables crowbar protection circuit to trip circuit

breaker and shut off unit when power loss

detected.

Disables crowbar protection circuit which trips circuit breaker and shuts off unit when power loss

detected.

2.9 PRELIMINARY CHECK-OUT

For a preliminary electrical check-out of the MAT Power Module a Host Computer, a Power

Module Controller (see PAR. 1.2) and all the necessary interconnection cables are required.

Connect the MAT Power Module DC Output connector for local sensing: Output 1 to Sense 1,

Output 2 to Sense 2 (see Table 2-4). Connect a resistive load across Output 1 and Output 2 that

is capable of dissipating the maximum current and voltage capabilities of the Power Module.

In this procedure the MAT Power Module Control Bus address is 3, (it is set at the factory to 3).

Connect the Kepco Power Module Controller and the MAT Power Module (following check-out

uses a Power Module Model MAT 36-10 as an example) to the Control Bus. Connect the Host

Computer and the Power Module Controller to the IEEE 488 GPIB. Apply the ac power to the

units in the following sequence: MAT Power Modules first and Power Module Controller last. In

the event that this sequence is reversed (the Power Module Controller is connected first, and

then the MAT Power Module is connected second) the operator must send a IEEE 488 GPIB

Device Clear Interface Function via the Host Computer. For proper time delays between commands refer to PAR. 3.3. For details on the CIIL commands refer to PAR. 3.6.3 and Appendix C

as well as the Power Module Controller Manual. The following does not include the IEEE 488

Bus Commands.

1. To verify the Power Module is operational the Host Computer sends:

CNF(cr)(lf)

a. The Power Module Controller does self test

MAT 1/3 RACK/ 112404

2-11

Page 29

b. All MAT Power Modules output enable relays open, all Power Modules go to maximum

rating, and the Power Module Controller checks for error flags. After the test, the relays

remain open and the Power Modules are set to zero.

2. To verify the CNF command was implemented, the Host Computer sends:

STA(cr)(lf)

The Power Module Controller sends back (if no errors occur)

(sp)(cr)(lf)

3. Proceed per PAR. 2.9.1 through 2.9.3 substituting full scale voltage/current values appropiate to the model being checked

2.9.1 EXAMPLE 1: FULL SCALE VOLTAGE CHECK

Program the Power Module MAT 36-10 to full scale voltage and check that the front panel meter

reading and internal measured values are the same.

1. To program the Power Module to 36 volts, with a current limit of 10 amps the Host Computer sends:

FNC DCS :CH3 SET VOLT 36 SET CURL 10(cr)(lf)

The MAT at address 3, is now set to 36 volts, with a current limit of 10 amps.

2. To verify the FNC command was implemented, the Host Computer sends:

STA(cr)(lf)

The Power Module Controller sends back (if no errors occur):

(sp)(cr)(lf)

3. To measure the voltage at the output the Host Computer sends:

FNC DCS VOLT :CH3(cr)(lf)

The MAT at address 3 is now set to take a reading;

4. To take a reading the Host Computer sends:

INX VOLT(cr)(lf)

a. The MAT previously set up now starts to measure and send the proper time delay

needed for the measurement.

b. The Power Module Controller will send the time delay value back to the Host Com-

puter when it has been properly Talk Addressed (see specific IEEE 488 interface

requirements):

00(cr)(lf)

2-12

5. The Host Computer then sends:

MAT 1/3 RACK/ 112404

Page 30

FTH VOLT(cr)(lf)

a. The MAT then sends the measured voltage in scientific notation to the Power Module

Controller (for example 36.005 volts) which

b. The Power Module Controller in turn sends:

3.6005E1(cr)(lf)

6. Check that the front panel meter reading and the computer value are identical within the

measurement tolerance. The meter selection switch must be set to “voltage” for a reading.

2.9.2 EXAMPLE 2: FULL SCALE CURRENT CHECK

Program the Power Module MAT 36-10 to full scale current and check that the front panel meter

and internal measured values are the same.

1. To program the Power Module to 10 amps, with a voltage limit of 36 volts, the Host Computer sends:

FNC DCS :CH3 SET CURR 10 SET VLTL 36(cr)(lf)

The MAT at address 3, is now set to 10 amps, with a voltage limit of 36 volts.

2. To verify the FNC command was implemented, the Host Computer sends:

STA(cr)(lf)

The Power Module Controller sends back (if no errors occur):

(sp)(cr)(lf)

3. To measure the current at the output ,the Host Computer sends:

FNC DCS CURR :CH3(cr)(lf)

The MAT at address 3 is now set to take a reading,

4. To take a reading the Host Computer sends:

INX CURR(cr)(lf)

a. The MAT previously set up now starts to measure and send the proper time delay

needed for the measurement.

b. The Power Module Controller will send the time delay value back to the Host Com-

puter when it has been properly Talk Addressed (see specific IEEE 488 interface

requirements):

00(cr)(lf)

5. The Host Computer then sends:

MAT 1/3 RACK/ 112404

FTH CURR(cr)(lf)

2-13

Page 31

a. The MAT then sends the measured current in scientific notation to the Power Module

Controller (for example 9.9998 amps) which

b. The Power Module Controller in turn sends

9.9998E0(cr)(lf)

6. Check that the front panel meter reading and the computer are identical within their measurement tolerance. The meter selection switch must be set to "Current" for a reading.

2.9.3 EXAMPLE 3: TO RESET THE POWER MODULE

1. To reset the Power Module at address 3 the Host Computer sends:

RST DCS :CH3(cr)(lf)

2. To verify the RST command was implemented, the Host Computer sends:

STA(cr)(lf)

The Power Module Controller sends back (if no errors occur):

(sp)(cr)(lf

3. This concludes the preliminary check-out of the MAT Power Module.

2-14

MAT 1/3 RACK/ 112404

Page 32

SECTION 3 - OPERATION

3.1 GENERAL

Interconnections linking a stabilized Power Module to an AC power source and a load

are critical. For optimum performance certain rules must be observed. These rules are

described in detail in the following paragraphs.

3.2 SERIES CONNECTION OF MAT POWER MODULES

When connecting MAT Power Modules in series, it is recommended that they be

enabled and disabled in sequentially. That is to say the output enable relays will be

closed or opened one immediately preceding the other. The Power Modules can be

enabled or disabled in any order. The system Status must be checked after a Relay

Enable or Disable Command is sent. The two MAT Power Module addresses in this

example are 17 and 21.

To enable the Modules connected in series, the Host Computer sends:

CLS :CH17(cr)(lf

STA(cr)(lf)

CLS :CH21(cr)(lf)

STA(cr)(lf)

To disable the Modules connected in series, the Host computer sends:

OPN :CH21(cr)(lf)

STA(cr)(lf)

OPN :CH17(cr)(lf)

STA(cr)(lf)

For parallel operation it is recommended that the user seek the manufacturer's assistance for specific applications.

3.3 POWER MODULE CONTROLLER/MAT TIME DELAYS (TO OBTAIN A VALID STATUS):

After sending a command that might affect the output of the Power Modules or their

relays, it is recommended that the Status command be sent. For information on this

command see the Power Module Controller Operator's Manuals. The required time

delay before a valid status of the TMA/MAT system is as follows:

After an Open, Close, Change of Polarity, or Change of Mode wait approximately 300

milliseconds.

After a Confidence Test command or an Internal Self Test wait approximately 400 milliseconds.

After a Reset command wait approximately 300 milliseconds

After an INX Command the maximum delay time is 2 seconds

MAT 1/3 RACK/112404

3-1

Page 33

FIGURE 3-1. TWO MAT 1/3 RACK POWER MODULES CONNECTED IN SERIES

VIA THEIR OUTPUT CONNECTOR

3.4 POWER LOSS CIRCUIT

An Automatic Shutdown option is available when a Power Loss is detected. Dependent on the

setting of jumper J5 on the A2 Sense and Polarity Relay Board, the Power Module will shutdown

automatically or remain in operation (see Figure 3-2). If the jumper is in place the AC Input

Power circuit breaker will trip; if the jumper is removed the circuit breaker will not trip. The MAT

Power Module is supplied with the jumper installed. To remove the jumper see Section 6 for

PCB access, and Figure 3-2.

3.5 INTRODUCTION TO CONTROLLING THE MAT POWER MODULE OUTPUT

The MAT family of Power Modules communicates remotely with a controller via the Control Bus.

Each MAT Power Module has a specific address on the bus. The address (from 1 to 30) is

selected by the switches on the side of the unit (see FIG. 3-2 and Table 3-1). This address is set

at Kepco to 3.

3-2

MAT1/3 RACK/ 112404

Page 34

The MAT family of Power Modules is controlled by the Power Module Controller (see PAR. 1.2).

For an explanation of remote programming refer to PAR 3.6 and Appendix A, as well as the

applicable Power Module Controller Manuals.

FIGURE 3-2. MATPOWER MODULE CONTROL SECTION, TOP COVER REMOVED

MAT 1/3 RACK/112404

3-3

Page 35

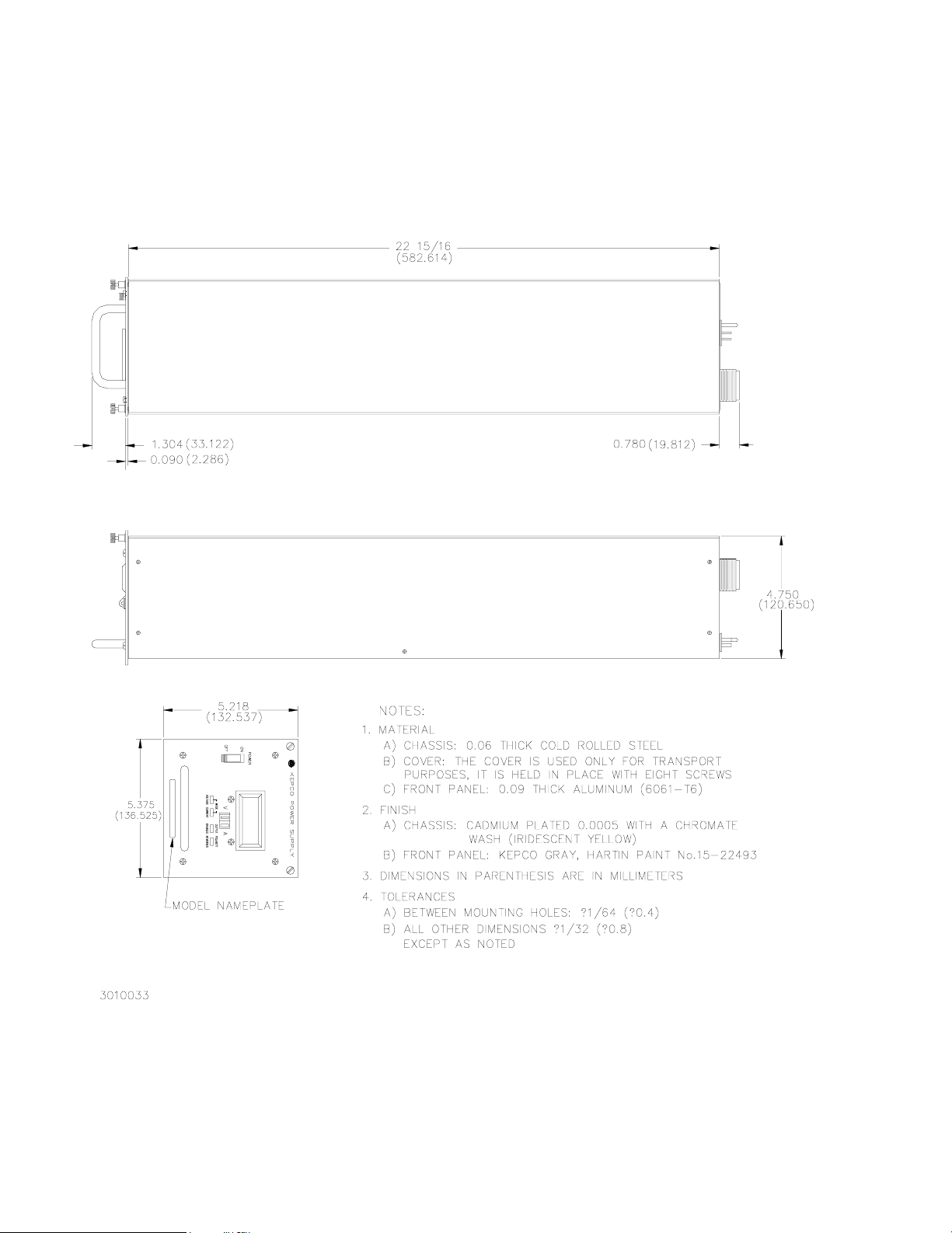

TABLE 3-1. DEVICE ADDRESS SELECTION FOR THE MAT POWER MODULE

DECIMAL

ADDRESS

10000 1

20001 0

30001 1

40010 0

50010 1

60011 0

70011 1

80100 0

90100 1

100101 0

110101 1

120110 0

130110 1

140111 0

150111 1

161000 0

171000 1

A3S1-4

(A4)

A3S1-3

(A3)

A3S1-2

(A2)

A3S1-1

(A1)

A3S1-0

(A0)

181001 0

191001 1

201010 0

211010 1

221011 0

231011 1

241000 0

251110 0 1

261101 0

271101 1

281110 0

291110 1

301111 0

311111 1

3.5.1 MAT/POWER MODULE CONTROLLER SYSTEM

MAT Power Modules are digitally controlled power supplies. Up to twenty seven Power Modules

at a maximum distance of 1000 feet (300 meters) can be controlled by the Power Module Controller (see PAR. 1.2). The Power Module Controller communicates as a Talker/Listener with a

Host Computer over the IEEE-488 GPIB using either the Standard Commands For Program-

3-4

MAT1/3 RACK/ 112404

Page 36

mable Instruments (SCPI) or the Control Interface Intermediate Language (CIIL). Refer to the

Power Module Controller Operator’s Manual for details regarding SCPI and CIIL commands.

Communications with the MAT Power Modules are accomplished via a two-wire high speed

(375 KHz) bidirectional serial communications bus, called the Control Bus.

The Power Module Controller is designed with a microcomputer board containing a relatively

powerful CPU, 256K of RAM, programmable timers, priority interrupt circuits, an RS-232 input/

output interface port and ROM firmware (embedded software). A discrete fault line is designed

into the Power Module Controller to report catastrophic failures. Communications with an external terminal are achieved via an RS-232 communications bus and related interface card.

Power for the microcomputer board of the TMA 4882-27 Power Module Controller is provided by

a wide range input Power Supply, Kepco Model MRW 150KV. The AC input voltage can range

from 95 Volts AC to 264 Volts AC, thereby eliminating the need for an input voltage selector.

The IEEE-488 GPIB implements a number of Interface Functions from the IEEE-488 protocol

(see the Power Module Controller Operator's Manual for details on these functions). The Power

Module Controller microcomputer continuously polls all the Power Modules (via the Power Module microcontroller on Digital Card A3, see PAR. 4.25.3) on the high speed Control Bus for any

change in their Status conditions. A Status Monitor Interface Board is provided in the Power

Module Controller as an interface to the Host Computer for reporting catastrophic failures within

the Power Modules. If such an error is reported back to the Power Module Controller, the Host

Computer then sends a Device Clear Command to open the isolation relays and reset all the

Power Modules to zero. Following that, a Status command is sent to determine the nature of the

failure. In Data Mode the Power Module Controller sends or receives messages per the IEEE

488 GPIB protocol. The messages are Enabled when the Attention line goes high. A Handshake

cycle is performed for every ASCII character sent or received over the IEEE-488 GPIB.

3.5.2 MAT/TMA PC-27 SYSTEM

A Power Module Controller is available from Kepco that plugs directly into any DOS based computer to control the Power Modules (up to twenty seven Modules daisy-chained to a single Control Bus) without the need for an IEEE 488 GPIB. The use of the TMA PC-27 allows the Power

Module Controller microcomputer board, the IEEE-488 GPIB interface input/output port and the

RS 232 interface input/output port to be bypassed.

The TMA PC-27 Software can be loaded into a DOS based computer either as a Terminate and

Stay (TSR) resident program, or as a stand-alone program. As a TSR it may be called from any

of the following languages TURBO C, QUICK C, POWER C, TURBO PASCAL, QUICK PASCAL, QUICK BASIC and INTERPRETED BASIC.

With the TMA Software loaded, the MAT Power Modules may be programmed over the Control

Bus using CIIL or KPL (Kepco Programming Language). KPL is a simplified command set

based on CIIL. Catastrophic error messages will remain in memory until the cause of the failure

is determined and the error condition is corrected. Additional functions not supported by CIIL

have been included. A non-CIIL command, T0, calls for a noncatastrophic error message to be

erased when a command other than Status is sent. A T1 command causes noncatastrophic

error messages to be stacked in memory until interrogated by a Status command.

A programming language, referred to as KPL (Kepco Programming Language), is used to facilitate input/output operations for the TMA PC-27. It has embedded in it the software that supports the TMA PC-27 and is also compatible with National Instruments NI 488 DOS Handler for

the IEEE-488 GPIB.

MAT 1/3 RACK/112404

3-5

Page 37

3.6 REMOTE PROGRAMMING

3.6.1 GENERAL

Kepco MAT Power Supplies are programmed over a control bus using either SCPI (Standard

Commands for Programmable Instruments) or CIIL (Control Interface Intermediate Language)

commands. SCPI and CIIL provide a common language conforming to IEEE488.2 for instruments used in an automatic test system. The control bus can be either the IEEE 488 standard

communication bus (General Purpose Interface Bus, GPIB), or the RS232C communication

bus. Remote programming of the MAT requires connection to one of the controllers specified in

PAR. 1-2 .

3.6.2 SCPI PROGRAMMING

SCPI (Standard Commands for Programmable Instruments) is a programming language conforming to the protocols and standards established by IEEE 488.2 (reference document ANSI/

IEEE Std 488.2, IEEE Standard Codes, ForMATs, Protocols, and Common Commands). SCPI commands are sent to the MAT Power Supply as output strings within the selected programming

language (PASCAL, BASIC, etc.) in accordance with the manufacturer’s requirements for the

particular GPIB interface card used and the Kepco controller selected (see PAR 1-2.)

Figure 3-3 illustrates typical SCPI commands used for remote programming of the MAT power

supply. For the complete command set, and detailed SCPI programming information, consult

the Technical Manual for the applicable controller (the SCPI command sets among Kepco controllers are slightly different). See PAR.3.5 to establish the MAT power supply Control Bus (BITBUS) address.

ROOT : (colon)

FIGURE 3-3. TREE DIAGRAM OF SCPI COMMANDS USED WITH MAT POWER SUPPLIES

INITiate

[:IMMediate]

:CONTinuous

MEASure

:CURRent?

:VOLTage?

OUTPut

[:STATe]

[SOURce:]

VOLTage

[:LEVel]

[:IMMediate]

:TRIGgered

CURRent

[:LEVel]

[:IMMediate]

:TRIGgered

FUNCtion

:MODE

STATus

:OPERation

:CONDition?

:ENABle

[:EVENt]?

:PRESet

:QUEStionable

:CONDition?

:ENABle

[:EVENt]?

SYSTem

:ERRor?

:LANGuage

3-6

MAT1/3 RACK/ 112404

Page 38

3.6.2.1 SCPI PROGRAM EXAMPLE

Figure 3-4 is an example of a program using SCPI commands to program the MAT Power Supply. The program illustrated is for a configuration using an IBM PC or compatible with a National

Instruments GPIB interface card. (It will be necessary to consult the manufacturer’s data to

achieve comparable functions with an interface card from a different manufacturer.) This program sets output voltage (Voltage mode) or voltage limit (Current mode) to 5V, and current limit

(Voltage mode) or output current (Current mode) to 1A, then reads the measured (actual) voltage and current, then prints the measurements.

/**************************************************************************/

/* Sample Program For KEPCO power supply, using National Instruments */

/* GPIB interface card and IBM PC or compatible computer */

/**************************************************************************/

#include <stdio.h>

#include "decl.h"

char rd_str[80]; // Input buffer

char dat_str[80]; // Output buffer

int bd,adr;

main() {

adr = ibfind("DEV6"); // Open DEV6 (defined by IBCONF)

bd = ibfind ("GPIB0"); // Open GPIB card

ibsic (bd); // Send Interface Clear

ibsre(bd,1); // Set remote line true

strcpy(dat_str,"VOLT 5;CURR 1"); // Define a set command

strcat(dat_str,"\r\n"); // Append delimiter

ibwrt(adr,dat_str,strlen(dat_str)); // Send string to power supply

strcpy(dat_str,"MEAS:VOLT?;CURR?"); // Define a measure command

strcat(dat_str,"\r\n"); // Append delimiter

ibwrt(adr,dat_str,strlen(dat_str)); // Send string to power supply

strset(rd_str,'\0'); // Clear input buffer

ibrd(adr,rd_str,64); // Read result of measure

printf("received : %s\n",rd_str); // Print voltage and current

}

FIGURE 3-4. TYPICAL EXAMPLE OF MAT POWER SUPPLY PROGRAM USING SCPI COMMANDS

MAT 1/3 RACK/112404

3-7

Page 39

3.6.3 CIIL PROGRAMMING

The CIIL command language is used on early models of Kepco power supplies and controllers.

The command functions are included here for compatibility with other equipment programmed

with CIIL commands. The CIIL command set for the MAT Power Supply is defined and

explained in Appendix C.

CIIL is the test instrumentation module programming language standard for all new Air Force

MATE test equipment programs. CIIL is a subset of a higher level language used in automatic

test equipment systems, ATLAS (Abbreviated Test Language for All Systems).

The CIIL statements sent to monitor and program Power Modules consist of CIIL operation

codes, nouns and noun modifiers, with data values expressed as ASCII integer, decimal or in

scientific notation.

3.6.3.1 EXAMPLES USING CIIL TO PROGRAM THE MAT POWER MODULE.

The following examples show the use of CIIL (Control Interface Intermediate Language). They

do not show the IEEE 488 bus commands from the Host Computer to the Power Module Controller nor do they show the proper time delays (refer to PAR. 3.3). The examples are for a MAT

55-7 model with Control Bus address 9. The ASCII characters for space, carriage return and

line feed are represented as (sp), (cr) and (lf) respectively. The MAT Power Module, the Power

Module Controller, a Host Computer, and the IEEE 488 must be interconnected for this routine

Note: Make sure the sense leads are connected to their respective load leads. When output

current is programmed, a load must be connected at the output terminals.

1. To verify the Power Module, is operational, the Host Computer sends:

CNF(cr)(lf)

The Power Module Controller does self test All MAT Power Module output relays are disabled, all Power Modules go to maximum ratings and the Power Module Controller checks

for error flags. After the test, the relays remain disabled and the Power Modules are then

set to zero.

2. To verify the CNF command was implemented the Host Computer sends:

STA(cr)(lf)

The Power Module Controller sends back (if no errors occur):

(sp)(cr)(lf)

3.6.3.1.1 EXAMPLE 1: PROGRAM POSITIVE VOLTAGE WITH CURRENT LIMIT

1. To program the Power Module MAT 55-7 to 50 volts with a current limit of 3 amps, the Host

Computer sends:

FNC DCS :CH9 SET VOLT 50 SET CURL 3(cr)(lf)

The MAT at address 9, is then set to 50 volts, with a current limit of 3 amps

3-8

MAT1/3 RACK/ 112404

Page 40

2. To verify the previous command was implemented the Host Computer sends:

STA(cr)(lf)

The Power Module Controller sends back (if no errors occur)

(sp)(cr)(lf)

3. To close the Output Enable relay (connects the Power Module to the load) the Host Computer sends

CLS :CH9(sp)(lf)

The Power Module at address 9, closes the relay

4. To verify the previous command was implemented the Host Computer sends:

STA(cr)(lf)

The Power Module Controller sends back (if no errors occur):

(sp)(cr)(lf)

5. To measure the current at the output the Host Computer sends:

FNC DCS CURR :CH9(cr)(lf)

The MAT at address 9 is now set to take a reading

6. To take a reading the the Host Computer sends:

INX CURR(cr)(lf)

a. The MAT previously set up now starts to measure and sends the proper time delay

needed for the measurement

b. The Power Module Controller will send the time delay back to the Host Computer when

it has been Talk Addressed (see specific IEEE 488 interface requirements):

00(cr)(lf)

7. The Host Computer then sends:

FTH CURR(cr)(lf)

a. The MAT then sends the measured current in scientific notation to the Power Module

Controller (for example 1.9598 amps)

b. The Power Module Controller in turn sends:

1.9598E0(cr)(lf)

MAT 1/3 RACK/112404

3-9

Page 41

8. To open the Output Enable relay (disconnect the load from the Power Module), the Host

Computer sends:

OPN :CH9(cr)(lf)

The Power Module relay at address 9 is open

9. To verify the previous command was implemented, the Host Computer sends:

STA(cr)(lf)

The Power Module Controller sends back (if no errors occur)

(sp)(cr)(lf)

3.6.3.1.2 EXAMPLE 2 : PROGRAM NEGATIVE VOLTAGE WITH CURRENT LIMIT

1. To program the Power Module MAT 55-7 to -45 volts with a current limit of 2 amps, the Host

Computer sends:

FNC DCS :CH9 SET VOLT -45 SET CURL 2(cr)(lf)

The MAT at address 9, is then programmed to -45 volts, with a current limit of 2 amps

2. To verify the previous command was implemented the Host Computer sends:

STA(cr)(lf)

The Power Module Controller sends back (if no errors occur):

(sp)(cr)(lf)

3. To enable output (connect the load to the Power Module), the Host Computer sends:

CLS :CH9 (sp)(lf)

The Power Module relay at address 9, closes

4. To verify the previous command was implemented the Host Computer sends:

STA(cr)(lf)

The Power Module Controller sends back (if no errors occur):

(sp)(cr)(lf)

5. To measure the voltage at the output, the Host Computer sends:

FNC DCS VOLT :CH9(cr)(lf)

The MAT at address 9 is now set to take a reading

3-10

MAT1/3 RACK/ 112404

Page 42

6. To take reading the Host Computer sends:

INX VOLT(cr)(lf)

a. The MAT previously set up now starts to measure and sends the proper time delay

needed for the measurement

b. The Power Module Controller will send the time delay back to the Host Computer when

it has been Talk Addressed (see specific IEEE 488 interface requirements):

00(cr)(lf)

7. The Host Computer then sends:

FTH VOLT(cr)(lf)

a. The MAT then sends the measured (in the example it is -45.01 volts) voltage in scien-

tific notation to the Power Module Controller

b. The Power Module Controller in turn sends

-4.5010E1(cr)(lf)

8. To reset the Power Module at address 9 the Host Computer sends:

RST DCS :CH9(cr)(lf)

The MAT then programs the output to zero and opens the Output Enable relay.

9. To verify the previous command was implemented the Host Computer sends:

STA(cr)(lf)

The Power Module Controller sends back (if no errors occur)

(sp)(cr)(lf)

3.6.3.1.3 EXAMPLE 3: PROGRAM CURRENT AND VOLTAGE LIMIT

1. To program the MAT Power Module MAT 55-7 in current mode with a current of 4 amps and

a voltage limit of 30 volts, the Host Computer sends:

FNC DCS :CH9 SET CURR 4 SET VLTL 30(cr)(lf)

The MAT at address 9, is then set up as a current source giving 4 amps with a voltage limit

of 30 volts

2. To verify the previous command was implemented the Host Computer sends:

STA(cr)(lf)

The Power Module Controller sends back (if no errors occur):

MAT 1/3 RACK/112404

(sp)(cr)(lf)

3-11

Page 43

3. To enable the output, the Host Computer sends:

CLS :CH9(cr)(lf)

4. To verify the previous command was implemented the Host Computer sends:

STA(cr)(lf)

The Power Module Controller sends back (if no errors occur):

(sp)(cr)(lf)

5. To measure the current at the output the Host Computer sends:

FNC DCS CURR :CH9(cr)(lf)

The MAT at address 9 is now set to take a reading

6. To take a reading the Host Computer sends

INX CURR(cr)(lf)

a. The MAT previously set up now starts to measure and sends the proper time delay