Page 1

INSTRUCTION MANUAL

KEPCO

An ISO 9001 Company.

KRR

12-20

12 VOLT, 300W RAILROAD BATTERY CHARGER

I — INTRODUCTION

SCOPE OF MANUAL.

This instruction manual covers the installation and operation of the Kepco Model KRR 12-20 12-Volt, 300W Railroad Battery

Charger.

DESCRIPTION.

The Kepco Model KRR 12-20 12-V ol t, 300W Railro ad Batte ry Charger is a wall-mounted unit designed to charge 12-Volt leadacid or nickel cadmium batteries used in railroad applications. The output vo ltage is set to 13.50V d-c, and is adjus table from

10.5 to 18V d-c from the front panel. An optional temperature compensation probe (supplied) provides automatic adju stment of

the float voltage to accommodate temperatures from 0° to 50°C. Units may be operated with a nominal 100V a-c to 240V a-c

(input voltage range 85 to 265 Va-c), 50-60 Hz (input frequency range 47-66Hz.). Both line and neutral lines are protected by

10A fuses. A front panel ammeter shows charging current.

The heart of the Model KRR 12-20 is a 300W solid-state switching power supply, Kepco’s RKW 15-22K-26534, which has an

integral cooling fan. A front panel CHARGER ON indicator lights while input power is applied to the a-c input terminals. The

front panel TEMP PROBE ERROR indicator ligh ts to show that the temperat ure compensation pr obe is not connected to the

unit. An internal diode network across the output provides protection in the event that the battery connections are reversed,

causing the front panel circuit breaker to open.

FEATURES

• Wide Range Input - Operates from input voltage range of 85 to 265V a-c, input frequency range 47-66Hz

with no adjustment or modification required.

• Adjustable Float Voltage - The float voltage is factory set to 13.50V d-c, and is adjustable from 10.5 to 18V

d-c at the front panel by connecting a precision voltmeter to the + and – VOLTAGE MONITOR test points

and adjusting the output using the V. FLOAT ADJUST potentiometer.

• Temperature Compensation - An optional temperature compensation probe (supplied) provides automatic

adjustment of the float voltage to accommodate temperatures from 0° to 50°C

• CHARGER ON indicator - on while a-c input power applied to unit.

• Charging Current ammeter - indicates charging current

• Input protection - Two line fuses (10A/250V) are provided.

• Battery connection protection - If battery connections are reversed, an internal diode network across the

output is forward biased; the resulting current flow causes the front panel circuit breaker to pop open. The

connections must be switched and the circuit breaker pushed in to reset.

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000 " FAX (718) 767-1102

http://www.kepcopower.com " email: hq@kepcopower.com

©2006, KEPCO, INC 1

Data subject to change without notice 228-1561

Page 2

II — SPECIFICATIONS

The following specifications are at nominal input voltages at 25°C unless otherwise specified.

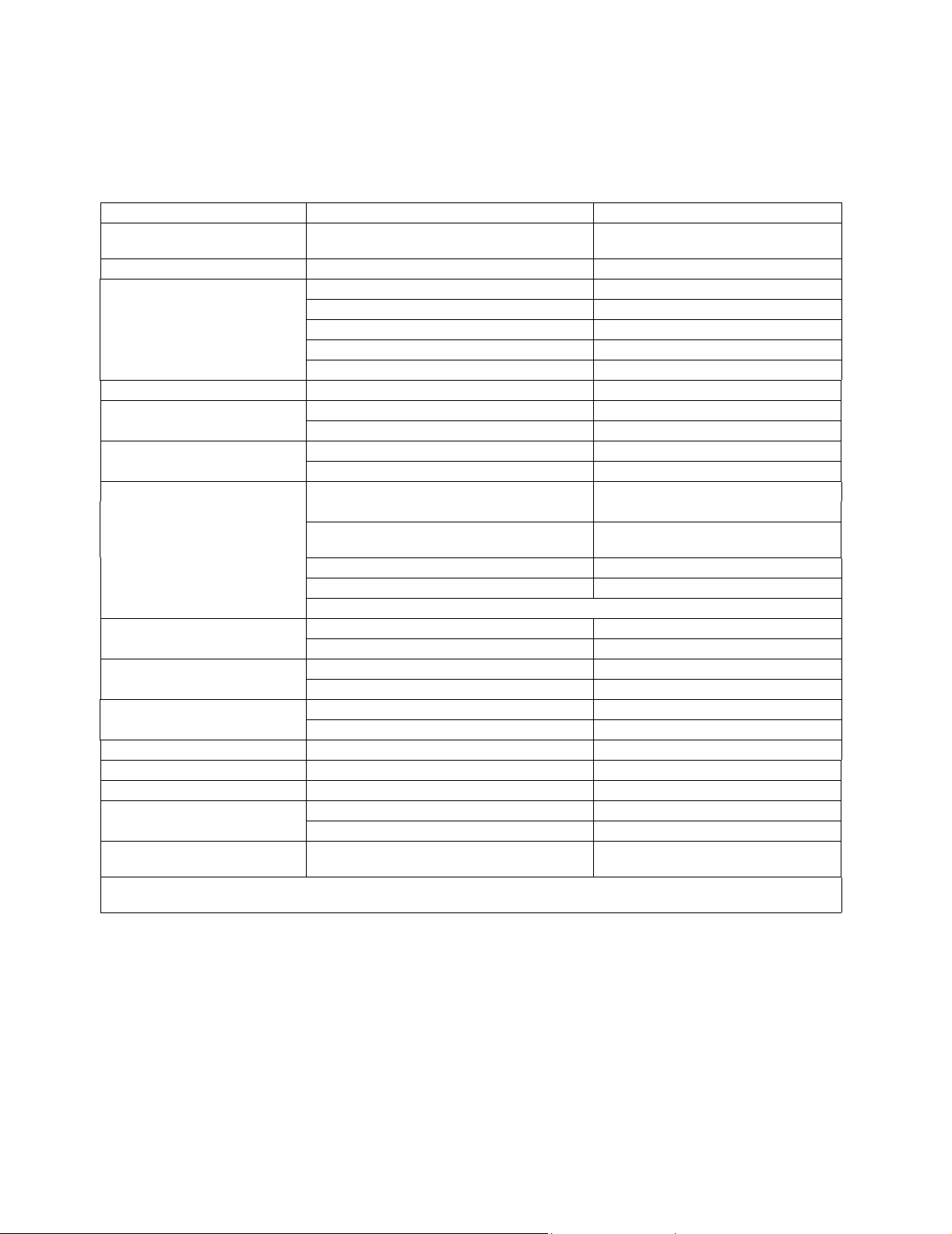

TABLE 1. MODEL KRR 12-20 SPECIFICATIONS

SPECIFICATION

Output Volts d-c

Temperature Compensation 3mV/°F/cell (5.4mV/°C/cell) Pb

Stabilization

Load Effect, measured at sensing

Input Current: (Maximum Load At

25°C with Nominal Output Voltage)

Input Surge cold start,

(1) Ripple and noise specification is 1.5 times the indicated values for a temperature range of -10 to 0°C. Ripple and noise levels

above are satisfied when conditions are 0 to 100% load, 0 to 65°C, and bandwidth </= 100MHz.

Adjustment Range

Maximum Output

Ratings

(A,W)

Current Short Circuit 29 A

Efficiency

(1)

Ripple & Noise

(mV, p-p)

Source Effect (min - max) (85 to 132 V a-c, 170 to 265V a-c) 0.1% typical, 0.2% maximum

Temperature Effect –10° to 65°C 0.5% typical, 1.0% maximum

interval > 30 sec

Leakage Current: 120V a-c, 60Hz (per IEC 950 and UL1950) 024mA typ., 0.3mA max.

Power Factor 0.99 typical at rated output, rated input

Cooling Forced air flow - one fan

Weight 9.0 lbs. (4.1 Kg.)

Dimensions

Input Protection Fuses (2) 10A, 150V

terminals

Combined Effect Envelope, Source, Load and Temperature ±0.9% typical, ±1.8% maximum

Time Effect 8 hours at 25°C 0.2% typical, 0.5% maximum

(1)

240V a-c, 60Hz (per IEC 950 and UL1950) 0.31mA typ., 0.38mA max. at

CONDITION

Factory set to 13.50V d-c,

adjustable from 10.5-18.0V d-c

–10°C to 40°C 22A (330W)

50°C amb 22A (330W)

56°C amb 19.4A (290.4W)

60°C amb 17.6A (264W)

65°C amb 15.4A (231W)

AC Input 100V 77% typical

AC Input 200V 81% typical

ripple 120

ripple noise 150

(0%-100% load change) 0.2% typical, 0.4% maximum

100 - 120V a-c 4.4A rms max.

200 - 240V a-c 2.2A rms max.

100 - 120V ac 15A typ., 20A max. first surge

200- 240 V ac 30A typ., 40 max. first surge

Inches 7.25H x 11.14W X 9D

mm 184.2H x 283W x 228.6D

Kepco P/N 141-0057

(Bussman P/N MDA-10)

DESCRIPTION

III — INSTALLATION

If desired, the battery charger output can be preset prior to mounting at a separate location.

PRESETTING THE OUTPUT

1. Remove the front panel window protecting input and output connections by loosening two captive screws.

2. Route the AC Input line wires through the appropriate opening s in the to p of the cha ssis and secure to L1 and L2 studs.

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000 " FAX (718) 767-1102

http://www.kepcopower.com " email: hq@kepcopower.com

2 228-1561 033006

Page 3

3. Connect the ground connection to the ground stud (see Figure 1) using the 10-32 x 3/8 ACF Brass Hex nut provided

(Kepco P/N 102-0007)

4. Turn a-c power on and connect a precision digital voltmeter (DVM) to the + and – VOLTAGE MONITOR test points at the

front panel.

5. Monitor the DVM and set the float voltage as desired using the V. FLOAT ADJUST potentiometer at the front panel. It is

recommended that the unit be tagged with the float voltage.

6. Turn a-c power off and disconnect DVM. If unit is to be mounted at a different location, disconnect ground and a-c input

connections, then reinstall window on front panel.

MOUNTING THE BATTERY CHARGER

1. Two slotted holes, 7 inches apart, are provided on the upper r ear chassi s (See Fig ure 1) to wa ll mount t he unit. Th e unit

has forced air cooling from a single fan located within the integral RKW 15-22K-26534 power supply as well as ventilation

holes in the chassis which must be kept clear from obstructions to ensure proper air circulation. Enough space must be

provided around the chassis to allow the hot air to exhaust from the components inside the chassis.

2. Remove the front panel window protecting input and output connections by loosening two captive screws.

3. Route the AC source power line and neutral wires through the appropriate openings at the top of the chassis and install

on the studs labeled AC INPUT LINE, L1 and L2.

4. Connect ground wire to the ground stud (see Figure 1) using the 10-32 x 3/8 ACF Brass Hex nut provided (Kepco P/N

102-0007)

5. Proceed to CONNECTIING THE BATTERY or, if the battery will be connected later, reinstall the front panel window using

the two captive screws.

CONNECTING THE BATTERY

1. If not done previously, remove the front panel window protecting input and output connections by loosening two captive

screws.

2. Disconnect load from the battery. Route the + and – battery connections through the appropriate openings at the top of

the chassis and install on the studs labeled DC OUTPUT, + and – respectively. NOTE: Verify the polarity! If the polarity is

reversed, the front panel circuit breaker will pop.

3. Reinstall the front panel window using the two captive screws.

IV — OPERATION

USING TEMPERATURE COMPENSATION (OPTIONAL)

Temperature compensation allows the output voltage of the Model KRR 12-20 battery charger to be automatically decreased

or increased for temperatures above or below 77°F (25°C), respectively. Compensation is 3mV/°F/cell (5.4mV/°C/cell), so for a

standard 12 Volt battery using six 2-volt cells, compensation is 18mV/°F. As an example, if temperature measured by the sensor was 80°F, (3°F above 77°F) the output voltage would be decreased by 3 x 18mV or 54mV. Since the temperature is

expected to rise while charging, and then fall as the battery becomes fully charged, temperature compensation can prolong

battery life by adjusting the float voltage automatically.

1. Connect the temperature probe cable to the TEMP PR OBE connector at the fron t panel. Verify that the TEMP PROBE

ERROR indicator is not lit.

2. Attach the temperature probe to the negative (–) terminal of the battery being charged. If the threaded stud is long

enough, mount the probe on the threade d stud and attach with another nut. Otherwise, remove the existing nut and use it

to attach the temperature probe. In either case observe torque requirements when tightening the nut.

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000 " FAX (718) 767-1102

http://www.kepcopower.com " email: hq@kepcopower.com

033006 228-1561 3

Page 4

CHARGING THE BATTERY

1. If the float voltage has been preset, proceed to step 2. Otherwise, refer to PRESETTING THE OUTPUT under INSTALLATION and set the float voltage for the battery to be charged.

2. Connect the battery (see INSTALLATION) and install temperature compensation if desired (see above). Verify all battery and a-c line connections are tight.

3. Apply a-c source power to the unit. If the circuit breaker pops, the battery connections are reversed; disconnect a-c

power, reverse the battery connections, reapply a-c power and reset (push in) the circuit breaker. The front panel

ammeter indicates the charging current. NOTE: If the CHARGER ON indicator fails to light, verify that a-c source power

is present and that the AC INPUT fuses have not blown.

4. When the charging current as indicated on the front panel ammeter falls to near zero, the battery is fully charged.

FIGURE 1. MODEL KRR 12-20, FRONT VIEW

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000 " FAX (718) 767-1102

http://www.kepcopower.com " email: hq@kepcopower.com

4 228-1561 033006

Loading...

Loading...