Page 1

INSTRUCTION MANUAL

KEPCO

An ISO 9001 Company.

KIT

BIT 4886

FIRMWARE UPGRADE

1. DESCRIPTION

The Kepco KIT Model 219-0452 contains the firmware upgrade PROM to be installed in BIT 4886 Interface

Cards that have been previously installed in Kepco’s BOP 100-2DM-4886-25968 power supply. The Firmware update provides for Output shutdown, automatically setting the output to off if any of the following error

conditions is detected:

• Output voltage exceeds +- 60 millivolts of the programmed output setting.

• Output current exceeds the programmed current protect level.

• Output current exceeds the fixed current limit of 1.1 amperes.

The shutting down of the output shall set the appropriate status bits in the Status questionable register, the

Event Status Register and add the appropriate error messages to the error queue.

219-0452

This instruction sheet provides procedures for installing the new PROM, initializing the BIT 4886 card, and

updating the BIT 4886 manual with a new procedure for calibrating the BOP power supply and modification

and additions to the SCPI commands and queries used to communicate with the power supply.

2. INSTALLATION OF UPGRADE PROM

A. MATERIAL REQUIRED (SEE TABLE 1.)

TABLE 1. MATERIAL REQUIRED

MATERIAL LOCATION

PROM Provided in this Kit

Extractor Provided in this Kit

ESD (Electrostatic Discharge) wrist strap. Not Supplied

Phillips Screw Driver Not Supplied

Sense Resistor Not Supplied (see Table 3-4 on page 8)

Heat Sink (cable of dissipating 10 times the power rating of the sense resistor) Not Supplied

Sealant, Kepco P/N 201-0002

(Glyptol P/N 7526P, 7625R or 7625G or equivalent)

Microsoft Windows-based computer with National Instruments VISA software installed Not Supplied

Digital Voltmeter (capable of measuring 100.0005V

(Keithly 2010 multimeter or equivalent

Not Supplied

Not Supplied

B. UPGRADE PROCEDURE

QUANTITY

4

1

N/A

N/A

1

N/A

N/A

N/A

N/A

1. Remove a-c power to BOP by disconnecting line cord.

CAUTION: Take care not to damage ground strap connected to cover when removing cover. Ground

strap may be removed for convenience by removing attaching nut.

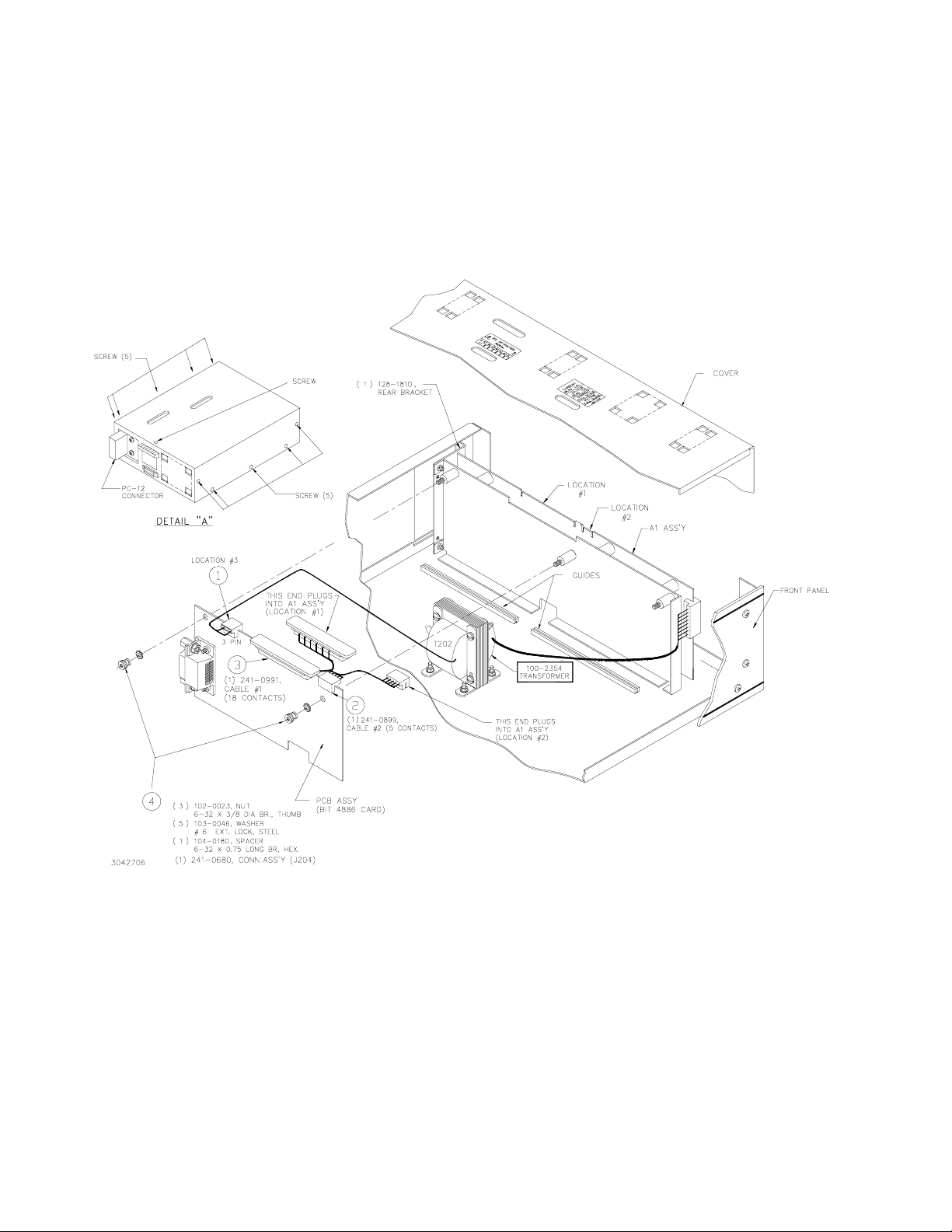

2. Remove BOP cover by removing 11 screws: (five from each side and one from the top (see Figure 1, Detail A).

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000 " FAX (718) 767-1102

http://www.kepcopower.com "

©2004, KEPCO, INC

Data subject to change without notice 228-1481 REV 3

email: hq@kepcopower.com

1

Page 2

3. Remove the BIT 4886 Interface card from the BOP as follows (See Figure 1):

NOTE:Numbers in circles of Figure 1 refer to numbered steps below:

Step 1. Unplug 3 pin Connector from Transformer at BIT 4886 Card, Location #3.

Step 2. Unplug Cable #2 (5-position connectors) from the BIT 4886 Interface Card.

Step 3. Unplug Cable #1 (18-position connectors) from the BIT 4886 Interface Card.

Step 4. Remove the knurled nuts and lockwashers securing the BIT 4886 Card to hex spacers and

remove BIT 4886 Card by sliding to front of BOP, then rotating away from A1.

FIGURE 1. BIT CARD REMOVAL

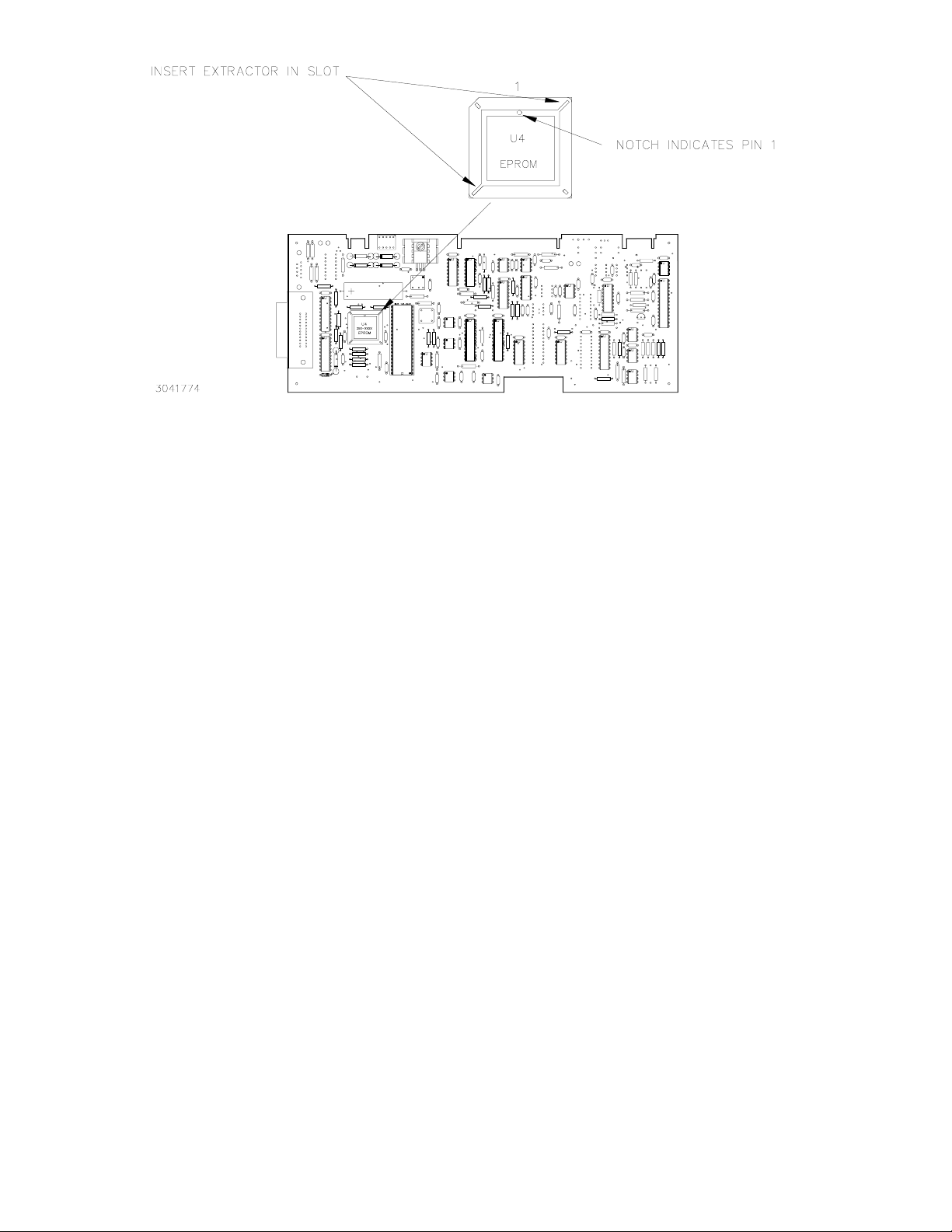

4. A brown IC socket located towards the rear of the unit contains the PROM. Locate the small depression

or notch in the PROM as shown in Figure 2. This is pin 1 of the PROM.

CAUTION: FAILURE TO USE AN ESD WRIST STRAP MAY DAMAGE THE PROM!

5. Connect the wrist strap to the chassis of the BOP. Place the strap on your wrist as indicated by the

instructions for the wrist strap.

6. Touch the IC tube to the chassis of the BOP. Open one end.

7. Use the extractor and insert the hook, first into one slot and then the other, and gently pry out the PROM.

Place the PROM in the tube and close the tube.

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000 "

2

http://www.kepcopower.com " email: hq@kepcopower.com

228-1481 REV 3 021704

FAX (718) 767-1102

Page 3

FIGURE 2. PROM LOCATION

8. Open the other end of the IC tube and remove the replacement PROM from the tube.

9. Insert the PROM into the socket, insuring pin one is as shown in Figure 2.

10. Reclose the IC tube. Remove wrist strap and disconnect it from the BOP.

11. Reinstall the BIT 4886 Card in the BOP by reversing removal (Section. 2.B.3, steps 4 through 1). If removed

earlier, secure ground strap using nut, then Install cover using 11 screws (five at each side, one at top).

12. On the label at the rear of the BOP, after the revision number (XX-Y) mark “A” (XX-YA).

13. Reconnect power cord and turn on the BOP. Verify the unit beeps and initializes normally.

14. Initialize the BIT 4886 card per Section 3.

15. Calibrate the BOP power supply using the revised procedure found in Section 4.

3. INITIALIZATION OF THE BIT 4886 CARD

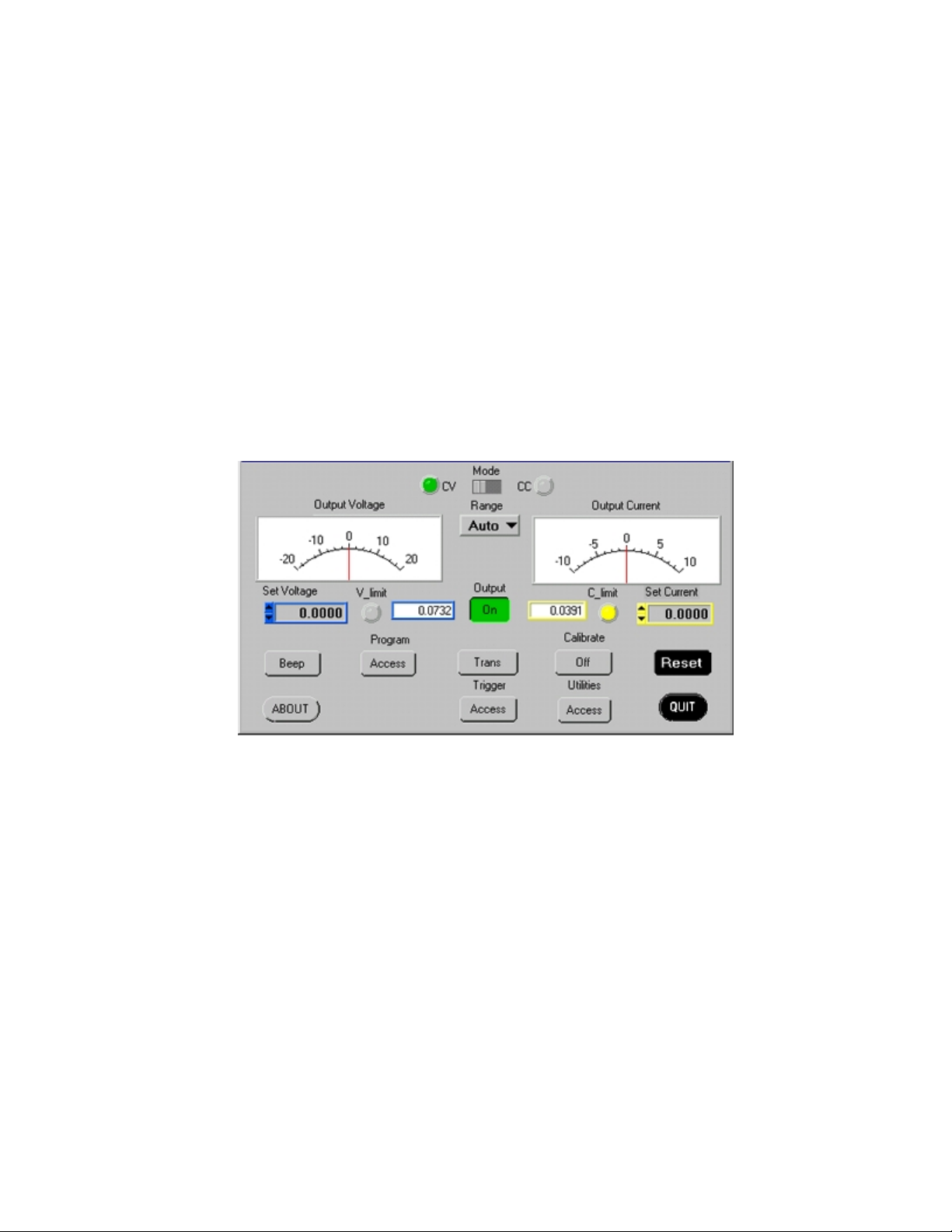

The initialization procedure uses the “soft” front panel which is part of the CVI driver for the BIT 4886 which can be

downloaded from the Kepco website at: www.kepcopower.com/all_bop.zip.

1. Unzip the files and doubleclick on setup.exe to install the driver. The bit_mdac folder will be added to the Start

- Programs folder. Doubleclick bit_mdac.exe to run the program, and refer to the visamdac.pdf in the bit_mdac

folder for details about using the soft front panel.

2. Connect GPIB cable from the rear of the BOP to a Microsoft Windows-based computer with National Instruments VISA software installed to BIT 4886 card and verify that BOP has standard PC-12 connector installed

(Figure 1).

3. Install the VISA driver per the text file included with the driver. At the Start-up screen (Figure 3) set the correct

GPIB Address and click CONNECT. Upon successful initialization the initialization window closes and the

Power Supply Type field of the Start-up window (Figure 3) shows BIT 4886. Click Continue.

4. Refer to Figure 4 and enter the following information:

• Select Model: BOP 100-2.

• Serial Number: Enter serial number found on the rear nameplate of BOP power supply.

• Option Number: Enter 25968

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000 "

http://www.kepcopower.com " email: hq@kepcopower.com

021704 228-1481 REV 3

FAX (718) 767-1102

3

Page 4

• Press the Initialize Card button

NOTE: If initialization fails and an error message is displayed, repeat step 3, making sure that the

proper information is entered, and the new PROM was installed

FIGURE 3. VISA DRIVER START-UP. FIGURE 4. BIT 4886 CARD INITIALIZATION

USING VISA DRIVER

5. After initialization, proceed to revised PAR. 3.3 to calibrate the upgraded unit.

4. BIT 4886 INSTRUCTION MANUAL CHANGES

A. REPLACE PAR. 3.3 CALIBRATION (INCLUDING TABLES 3-1 THROUGH 3-3 AND FIGURES 3-3

AND 3-4) WITH THE FOLLOWING (FIGURE 3-2 UNCHANGED, INCLUDED FOR CLARITY):

NOTE: ALL SENSE RESISTORS MUST BE MOUNTED

ON A HEATSINK WITH A MINIMUM SURFACE

AREA OF 36 SQUARE INCHES TO MAINTAIN

THERMAL STABILITY DURING CALIBRATION.

FIGURE 3-2. CURRENT SHUNT CONNECTIONS

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000 "

4

http://www.kepcopower.com " email: hq@kepcopower.com

228-1481 REV 3 021704

FAX (718) 767-1102

Page 5

3.3 CALIBRATION OF BIT 4886 INTERFACE CARD USING THE VISA DRIVER SOFT PANEL

Calibration of the BIT 4886 card installed in the BOP 100-2DM-4886-25698 is performed using SCPI commands implemented through the Instrument driver. The driver provides a graphical interface with informational displays and prompts which lead you through the calibration of the BIT 4886 card. This VISA

compliant driver works with many GPIB cards from suppliers like National Instruments and Hewlett-Packard.

NOTE: PC-12 connector (See Figure 1) must be installed for BOP to function.

3.3.1 CALIBRATION USING THE VISA DRIVER SOFT PANEL

The following calibration procedure uses the “soft” front panel which is part of the CVI driver for the BIT

4886, Model 25968 which can be downloaded from the Kepco website at:

www.kepcopower.com/all_bop.zip:

Unzip the files and doubleclick on setup.exe to install the driver. The bit_mdac folder will be added to the

Start - Programs folder. Doubleclick bit_mdac.exe to run the program, and refer to the visamdac.pdf in the

bit_mdac folder for details about using the soft front panel.

FIGURE 3-3. MAIN PANEL

3.3.1.1 CALIBRATION BASICS

CAUTION: Before performing calibration, set BOP OUTPUT to OFF and connect short across BOP out-

put, then set OUTPUT to ON and Voltage to 10V. It is necessary to wait 10 minutes before

calibrating the unit to allow for thermal stabilization. After 10 minutes, set OUTPUT to

OFF and remove short from BOP output, then proceed with calibration.

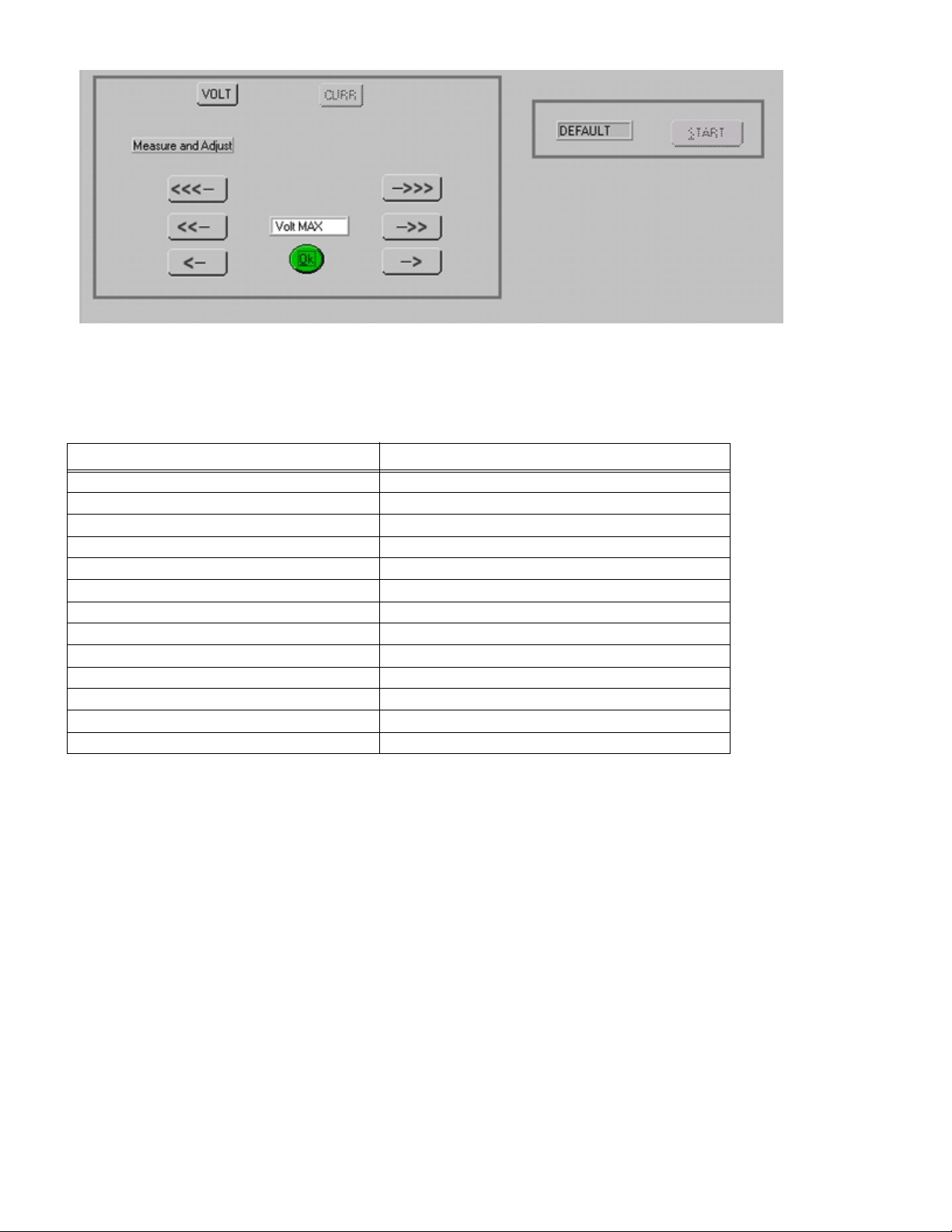

All adjustments are done using the six arrow buttons of the Calibration Panel (see Figure 3-4 and Table 3-

1). The double arrow buttons

time; the ! and " buttons either increase (") or decrease (!) the output one step at a time. The triple

arrow buttons <<<— and —>>> either increase (—>>>) or decrease (<<<—) the output 80 steps at a time

!, "

The

For MAX and MIN Calibrations fine adjustment is done using the

can not be set within the specified tolerance using the fine adjustment, use the coarse adjustment to

increase (—>>>) or decrease (<<<—) the output. as needed, then use the fine adjust buttons to set the

value within tolerance.Where large adjustment is necessary, <<<— and —>>> can be used first to bring the

output close before using the

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000 "

021704 228-1481 REV 3

, !, and " buttons only work within the 80-step window established by <<<— and —>>>.

http://www.kepcopower.com " email: hq@kepcopower.com

!

and " either increase (") or decrease (!) the output five steps at a

!, "

, !, and " buttons.

!, "

, !, and " buttons. If the value

FAX (718) 767-1102

5

Page 6

FIGURE 3-4. CALIBRATION PANEL

TABLE 3-1. CALIBRATION PANEL FUNCTIONS

BUTTON OR WINDOW Function

START button Initiates calibration

Text box (Adjacent to START button) Used to enter unit password

VOLT button Initiates Voltage calibration

CURR button Initiates Current calibration

Message box (below VOLT buttons) Provides instructions about the calibration process.

White text window (above OK button) Displays the parameter currently being calibrated.

Á button Fine Adjustment - Decreases the output value by one LSB.

Ë button Fine Adjustment - Increases the output value by one LSB.

button Adjustment - Decreases the output value by five LSBs.

!

button Adjustment - Decreases the output value by five LSBs.

8

<<<— button Coarse Adjustment - Decreases the output value by 80 LSBs.

—>>> button Coarse Adjustment - Increases the output value by 80 LSBs.

OK button Enters the value displayed in the white text window

3.3.1.2 CALIBRATION PROCEDURE

1. Click on the Calibration Off button on the main panel (see Figure 3-3).This will open a calibration panel

(see Figure 3-4 and Table 3-1) that allows calibration in either voltage or current mode.

2. The password (DEFAULT) has been set at the factory. If it has not been changed, it will be displayed in

the box adjacent to the Start button on the right side of the panel. If the password has been changed

from DEFAULT, substitute the proper password in the box adjacent to the Start button and click the

Start button. If the password has been forgotten, consult factory. If the password is correct, the Volt and

Curr buttons will become active. Otherwise the message ERROR! - Wrong Password is displayed

and you must enter the correct password and click Start again.

3. For Voltage Calibration, click Volt button. The text window reads Volt ZERO and the message Adjust

for ZERO R81 (Eo Zero) on BOP A1 card. is displayed.

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000 "

http://www.kepcopower.com " email: hq@kepcopower.com

6

FAX (718) 767-1102

228-1481 REV 3 021704

Page 7

4. Connect a DVM to the output of the unit and adjust the R81 Potentiometer on A1 board of BOP until the

DVM reads the voltage specified in Table 3-2 for Low Range Zero, then click OK button.

NOTE: Use external DVM for all measurements.

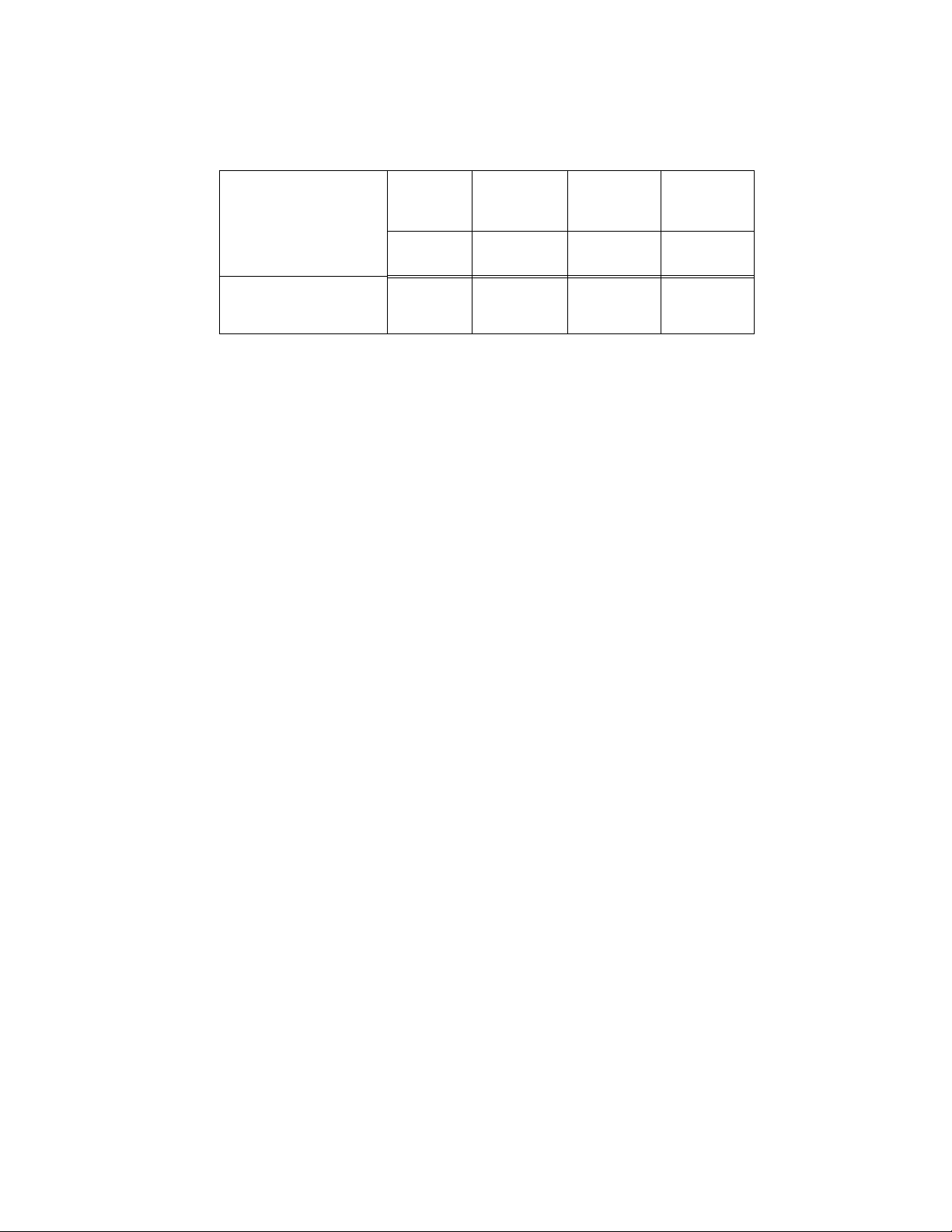

TABLE 3-2. CALIBRATION MEASUREMENTS AND TOLERANCES - VOLTAGE

MODEL

BOP 100-2M

LOW

RANGE

ZERO

PAR. 3.3.1

STEP 4

0V

±0.0001V

VOLT

ZERO

PAR. 3.3.1

STEP 5

0V

±0.001V

HIGH

RANGE

ACCURACY

PAR. 3.3.1

STEP 6 and 7

100V (MAX)

-100V (MIN)

±0.0075

LOW

RANGE

ACCURACY

PAR. 3.3.1

STEPS 8, 9

25V (MAX)

-25V (MIN)

±0.002

5. The text window reads Volt ZERO and the message Measure and Adjust. is displayed. Using the !

and " and

!

and " buttons (see PAR. 3.3.1.1), adjust the output until the DVM reads the voltage

specified in Table 3-2 for VOLT ZERO, then click OK button.

6. The text window reads Volt MAX and the message Measure and Adjust. is displayed. Using the !

and " and

!

and " buttons (see PAR. 3.3.1.1), adjust until DVM reading is as specified in Table 3-2

for High Range Accuracy. Click OK when done.

7. The text window reads Volt MIN and the message Measure and Adjust. is displayed. Using the !

and " and

!

and " buttons (see PAR. 3.3.1.1), adjust until DVM reading is as specified in Table 3-2

for High Range Accuracy, then click OK button. NOTE: If the <<<— or —>>> button is depressed, proceed to step 6 after clicking OK.

8. The text window reads LVolt MAX and the message Measure and Adjust. is displayed. Using the !

and " and

!

and " buttons (see PAR. 3.3.1.1), adjust output until DVM reads voltage specified in

Table 3-2 for Low Range Accuracy, then click OK button.

9. The text window reads LVolt MIN and the message Measure and Adjust. is displayed. Using the !

and " and

!

and " buttons (see PAR. 3.3.1.1), adjust until DVM reads voltage specified in Table 32 for Low Range Accuracy, then click OK button. NOTE: If the <<<— or —>>> button is depressed, proceed to step 8 after clicking OK.

10.Voltage calibration is complete. If desired, the voltage calibration can be repeated by clicking Volt at the

calibration panel (Figure 3-3). If current calibration is not necessary, proceed to step 19.

11.At the calibration panel (Figure 3-3) click CURR to begin current calibration of the unit. Connect CALI-

BRATION RESISTOR! window opens.

12.Connect load (see Table 3-4) across the output of the unit and connect DVM across the load as shown

in Figure 3-2. Voltage measurements must be converted to Amperes using Ohm’s law, E = IR. Click OK

button to close Connect CALIBRATION RESISTOR window.

13.The test window reads Curr ZERO and the message Adjust for ZERO R83 (Io Zero) on BOP A1 card.

will be displayed.

14.Adjust the R83 Potentiometer on A1 board of BOP, until the external DVM reads voltage specified in

Table 3-3, then click OK button.

15.The text window reads Curr MAX and the message Measure and Adjust. is displayed. Using the !

and " and

!

and " buttons (see PAR. 3.3.1.1), adjust output until DVM reads the voltage specified

in Table 3-3, then click OK button.

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000 "

http://www.kepcopower.com " email: hq@kepcopower.com

021704 228-1481 REV 3

FAX (718) 767-1102

7

Page 8

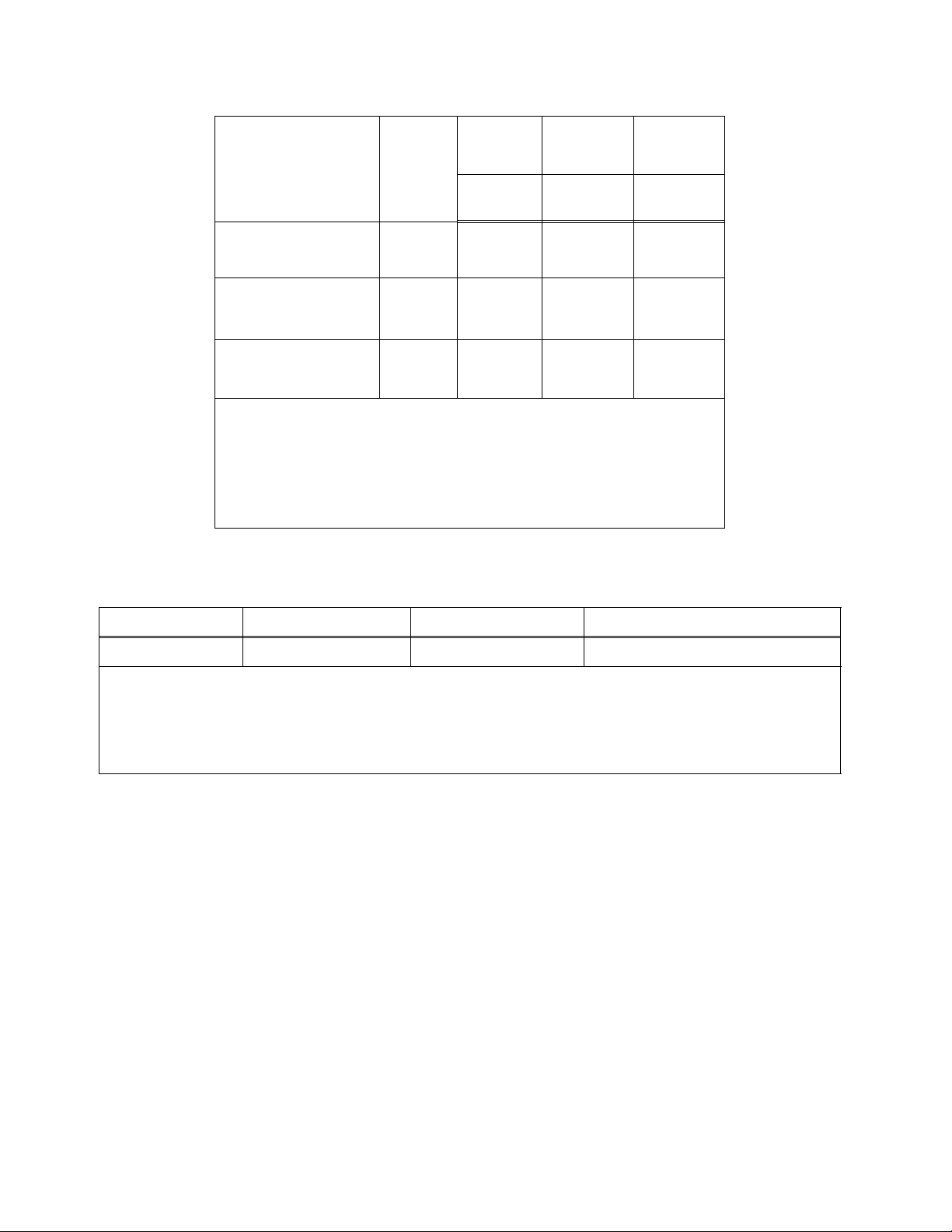

TABLE 3-3. CALIBRATION MEASUREMENTS AND TOLERANCES - CURRENT

SENSE

RESISTOR

MODEL

BOP 100-2M

REFER TO NOTES IF

EXACT SENSE RESISTOR

VALUE IS KNOWN.

USE SPACE PROVIDED

AT RIGHT FOR

CALCULATED VALUES.

NOTES: The following formulas are used to calculate proper calibration values if the

exact Sense Resistor value is known.

R

A. Adjust to 0V ±(

B. Adjust V to (

C. Adjust V to (

SENSE

=

the measured value of the sense resistor to 6 places (minimum).

(SEE NOTE

TABLE 3-4)

R

SENSE

R

SENSE

R

SENSE

VAL UE

AND

1 Ohm

R

SENSE

SEE

NOTES.

) (0.00005)

) (2) ± (

) (2) ± (

CURRENT

ZERO

PAR. 3.3.1

STEP 14

0V

±0.00005V

SEE

NOTE A.

R

SENSE

R

SENSE

) (0.00015)

) (0.0006)

HIGH

CURRENT

ACCURACY

PAR. 3.3.1

STEP 15, 16

2V (MAX)

-2V (MIN)

±0.00015V

SEE

NOTE B.

CURRENT

PROTECT

ACCURACY

PAR. 3.3.1

STEP 17

2V (MAX)

±0.0006V

SEE

NOTE C.

TABLE 3-4. SUGGESTED SENSE RESISTORS

VALUE KEPCO PART NO. MANUFACTURER MANUFACTURER PART NO.

1 OHM 115-2996 ISOTEK RUG-Z-1R00-0.1 TK10

NOTES:

1. For Sense resistor values not listed, calculate the nominal value and tolerance as follows:

Nominal Value (Volts) = Actual Sense resistor resistance (Ohms) (measured to 8 places) x rated current (Amps)

Tolerance (Volts) = Nominal value (Volts)/32000

2. Sense resistor must be used with heat sink capable of dissipating 10 times rated power with a minimum surface area of 36 square

inches to maintain thermal stability during calibration.

16.The text window reads Curr MIN and the message Measure and Adjust. is displayed. Using the !

and " and

!

and " buttons (see PAR. 3.3.1.1), adjust until DVM reading is as specified in Table 3-3.

NOTE: If the <<<— or —>>> button is depressed, proceed to step 15 after clicking OK.

17.The text window reads Curr PROTECT and the message Measure and Adjust. is displayed. Using the

! and " and

!

and " buttons (see PAR. 3.3.1.1), adjust until DVM reading is as specified in Table

3-3. Click OK when done.

18.Current calibration is complete. If desired, the current calibration can be repeated by clicking Curr at the

calibration panel (Figure 3-4).

19.To exit Calibration, click on the Calibration On button on the main panel (Figure 3-3). This will open a

panel that allows the calibration to be saved. Click SAVE to save the calibration constants (both voltage

and current), or CANCEL to return to the old calibration.

20.Upon completing calibration, seal adjustment potentiometers A1R81 and A1R83 on BOP using sealant

(see Table 1).

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000 "

8

http://www.kepcopower.com " email: hq@kepcopower.com

228-1481 REV 3 021704

FAX (718) 767-1102

Page 9

B. REPLACE PAR. 5.2, 5.2.1, AND 5.2.2 AS FOLLOWS:

5.2 ENHANCED OPERATION

The following paragraphs describe options that will permanently modify the behavior of the BIT 4886 and

associated BOP power supply. Although these options use SCPI commands, they are not intended to be

used during normal programming of the BOP output.

The commands described in the following paragraphs affect only RAM variables. The power up state of the

variables is retrieved from the FLASH EEPROM. The command MEMORY:UPDATE can be used to copy

this RAM information to the FLASH EEPROM. The WINDOW variable is stored using the command

MEM:UPDATE SHUTDOWN and the other variables, including the DIAG:SAV command, use the command

MEMORY:UPDATE INTERFACE

5.2.1 ERROR DETECTION

The BIT 4886 card has the ability to alter the way the unit responds to detection of load and settings errors.

The default behavior is for the BIT 4886 to measure the main channel and verify that it is within the specified channel tolerances of the BOP, setting the appropriate bits in the Status Questionable register. This

default behavior is established by the SYST:SEC:IMM command and the factory default window of 32

LSBs.

The default behavior can be modified using the DIAG:ERR, DIAG:ONL, DIAG:OFFL AND DIAG:WIN commands listed in Table 5-1 so that device errors are generated for conditions such as window exceeded, output current limit at setting and output current exceeding a hard limit. These errors can also be used to force

the unit to go to an output off state upon detecting the errors. The behavior is altered, the new setting is

stored in RAM and it remains in effect until a power off/power on cycle. The settings can be saved for power

up by sending the MEMORY:UPDATE SHUTDOWN command. Error responses are listed in Table 5-1.

5.2.2 LIMIT CHANNEL CONTROL

The unit supports three limit settings for the output off state. The standard configuration is for the limits to be

set to the minimum levels which causes the output not to vary beyond the BOX limits defined in the BOP

manual. The limits can also be set to maximum or 110% of rated voltage or current. This is useful for battery

operation. These limit settings are established by the DIAG:OUTPut command. With other types of devices,

it is possible to set the output off limit channels to be at any level by using the DIAG:OFFLimit commands to

establish the limit for the output off state. DIAG:OUTP n

when the output is set to OFF. n = 0 is the default. This sets both voltage and current limit channels to 0

when the output is off. n = 1 sets voltage limit to maximum when the output is off. n = 2 sets the current limit

to the maximum when the output is off. Bits 2 and 3 of the hex character allow the DIAG:OFFLimit commands to establish a specific voltage limit and current limit, respectively, when the output is off. Bits 0 and 2

or bits 1 and 3 should not be set at the same time since the maximum setting will override the value specified by DIAG:OFFLimit. The SYST:SEC:IMM command sets DIAG:OUTP n = 0. The variables are stored in

non-volatile EEPROM by the command MEMORY:UPDATE INTERFACE.

(see Table 5-1) controls the limit DAC values

H

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000 "

http://www.kepcopower.com " email: hq@kepcopower.com

021704 228-1481 REV 3

FAX (718) 767-1102

9

Page 10

C. REPLACE TABLE 5-1 TO UPDATE DIAG: COMMANDS AND QUERIES

TABLE 5-1. ENHANCED OPERATION - ERROR RESPONSE

COMMAND QUERY DESCRIPTION

DIAG:ERR:CURR xx

(xx =hex values from 00

to FF)

DIAG:ERR:VOLT xx

(xx =hex values from 00

to FF)

DIAG:OFFLimit:CURR xx

(xx = decimal value)

DIAG:ERR:CURR? Allows both current protect and current limit functionality.

Bit 7 - when set will establish a fixed Current Limit level when output is ON.

Bit 6 - when set enables the current protection error logic

Bit 5 - when set enables Current Protect error bit in ESR/ESE register

Bit 4 - when set causes the power up and reset state of the ESE register to

be as follows: ESE - 72 if bit 5 set, 8 if not set.

Bit 3 - when set allows a current protect error to create an error message of

“303 - Current above Protection limit.”

Bit 2 - when set causes a current protect error to set the output to off.

Bit 1 - when sets allows a current measurement in current mode to generate

a “Device Error” message.

Bit 0 - when set enables a current measurement error in current mode to

shut down unit.

The query provides one byte which indicates the current limit setting.

DIAG:ERR:VOLT? Allows voltage protect and voltage limit functionality.

Bit 7 - when set establishes a fixed Voltage Limit level when output is ON.

Bit 6 - when set enables the voltage protection error logic

Bit 3 - when set allows a voltage protect error to create an error message of

“304 - Voltage above Protection limit”

Bit 2 - when set causes a voltage protect error to set the output to off

Bit 1 - when set allows a voltage measurement error in voltage mode to

generate a “Device Error” message.

Bit 0 - when set allows voltage “device error” message (see bit 1) to set the

output to off.

The query provides one byte which indicates the voltage limit setting.

DIAG:OFFLimit:CURR? The decimal value allows the user to establish the actual current limit DAC (digital to ana-

log converter) setting when the output is off and the unit is in voltage mode. This variable is only used when bit 4 of the DIAG:OUTP register is set. The value is calculated

using the equation:

Current expected /(Current max * 1.1) * 256.

The DVS standard setting is 128 derived from (1.1 / 2.2 ) * 256.

The query provides one byte which indicates the actual DAC current limit setting.

DIAG:OFFLimit:VOLT xx

(xx = decimal value)

DIAG:ONLimit:CURR xx

(xx = decimal value)

DIAG:ONLimit:VOLT xx

(xx = decimal value)

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000 "

10

DIAG:OFFLimit:VOLT? The decimal value allows the user to establish the actual voltage limit DAC (digital to ana-

DIAG:ONLimit:CURR? The decimal value allows the user to establish the actual current limit DAC (digital to ana-

DIAG:ONLimit:VOLT? The decimal value allows the user to establish the actual voltage limit DAC (digital to ana-

http://www.kepcopower.com " email: hq@kepcopower.com

log converter) setting when the output is off and the unit is in current mode. This variable is only used when bit 3 of the DIAG:OUTP register is set. The value is calculated

using the equation:

Voltage expected / Voltage max * 1.1) * 256

The DVS standard setting is 0.

The query provides one byte which indicates the actual DAC current limit setting.

log converter) setting when the output is on and the unit is in voltage mode. This variable is only used when bit 7 of the DIAG:ERR:CURR register is set. The value is

calculated using the equation:

Current expected /(Current max * 1.1) * 256.

The DVS standard setting is 128 derived from (1.1 / 2.2 ) * 256.

The query provides one byte which indicates the actual DAC current limit setting.

log converter) setting when the output is on and the unit is in current mode. This variable is only used when bit 7 of the DIAG:ERR:VOLT register is set. The value is

calculated using the equation:

Voltage expected / Voltage max * 1.1) * 256

The DVS standard setting is 0.

The query provides one byte which indicates the actual DAC current limit setting.

FAX (718) 767-1102

228-1481 REV 3 021704

Page 11

TABLE 5-1. ENHANCED OPERATION - ERROR RESPONSE (CONTINUED)

COMMAND QUERY DESCRIPTION

DIAG:OUTP n

(n = hex character)

DIAG:SAV n/a DIAG:SAV stores variables established by SYST:SET. (See PAR. 5.2.3 and B.82)

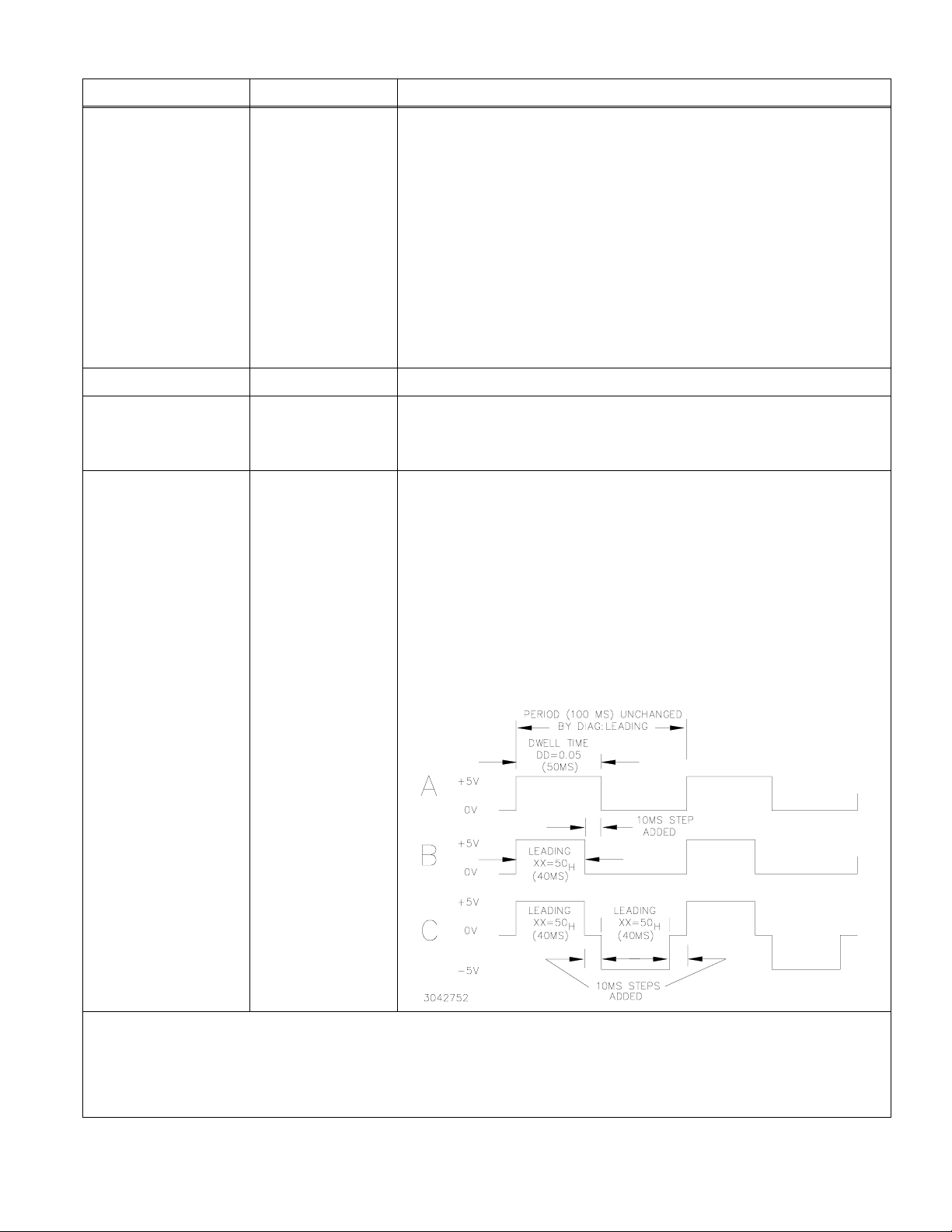

DIAG:WIN xx

(xx = hex value from 10

1

to 40)

DIAG:LEADING xx

(xx is the time in half milliseconds increments)

(hex)

DIAG:OUTP?

(Returns hex character)

DIAG:WIN?

(Returns window

value xx (hex)

DIAG:LEADING?

returns xx (hex), the

time in half milliseconds increments)

DIAG:OUTP n controls the limit DAC values when the output is set to OFF. The values

can either be set to maximum or to a user determined limit value (using the

DIAG:OFFLimit commands. The SYST:SEC:IMM command sets DIAG:OUTP n = 0.

DIAG:OUTP 0 = the default. This sets both voltage and current limit channels to 0 when

the output is off. The four bits of the hex character are defined as follows:

Bit 0 = 1 sets voltage limit to maximum when in Voltage mode and the output is off.

Bit 1 = 1 sets current limit to maximum when in Current mode and the output is off.

Bit 2 = 1 sets voltage limit to value determined by the DIAG:OFFLimit:VOLT command when the output is off.

Bit 3 = 1 sets current limit to value determined by the DIAG:OFFLimit:CURR command when the output is off.

For example, DIAG:OUTP 3 = sets both voltage and current limit to maximum. This

can be useful for battery applications where the limit channel can allow the battery to

discharge the battery voltage. Using both the maximum and DIAG:OFFLimit options

(e.g., bits 0 and 2) at the same time is not recommended - the maximum value overrides the DIAG:OFFLimit setting.

Allows user to specify value in LSB’s for error window used for detection of output voltage

or output current measurement errors (default = 32). Error window value can only be

set between 16 (10 Hex) and 64 (40 Hex) using one two-digit hex character (xx)

Query returns 2-digit hex character xx.

xx establishes max dwell time for a two-step list. If the dwell time DD for the two-step list

exceeds xx, a step is inserted with voltage = 0V for (DD - xx). MSTS default = 50.

Consider the following:

LIST:VOLT 0,5 Two step list, 0V then 5V.

LIST:DWEL .05 Dwell time of 50 ms

LIST:COUNT 0 Repeat continuously.

OUTP ON Output enabled.

VOLT:MODE LIST Run program

The above list would normally produce a continuous square wave, 50ms at 0V, 50ms

at 5V (Fig A). If DIAG:LEADING 50 (40 ms) is issued, the square wave changes to

60ms at 0V, 40ms at 5V as follows: the first 1/2 cycle = 50ms at 0V, the second 1/2

cycle = 40ms (the limit set by DIAG:LEADING) at 5V, then 10ms (50 - 40 = 10) at 0V

(Fig B). If LIST:VOLT 0,5 is changed to LIST:VOLT -5,5 both 1/2 cycles will show

10ms steps at 0V (Fig C).

1

.

1 The default window value of 32 indicates a 32 LSB margin for error during readback. The value for Readback is arrived at by taking 16 samples

of voltage or current and averaging them. A readback error is produced when the calculated readback value (with calibration constants applied)

exceeds the maximum readback (calculated readback + error window) or minimum readback (calculated readback – error window). Increasing

the error window can avoid undesired errors. For example, in cases where the LIST command is used to produce a square wave output, overshoot inherent in the characteristics of the power supply can sometimes cause the readback average to increase enough to cause a readback

error. Increasing the error window allows the square wave to be generated without producing an error.

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000 "

http://www.kepcopower.com " email: hq@kepcopower.com

021704 228-1481 REV 3

FAX (718) 767-1102

11

Page 12

D. MODIFY TABLE A-2 TO ADD BIT 6 = PROTECTION ERROR

TABLE A-2. STANDARD EVENT STATUS ENABLE REGISTER AND STANDARD

EVENT STATUS REGISTER BITS

NU (Not Used)

CONDITION NU PE CME EXE DDE QUE NU OPC

BIT 76543210

VALUE 128 64 32 16 8 4 2 1

PE Protection Error

CME Command Error

EXE Execution Error

DDE Device Dependent Error

QUE Query Error

OPC Operation Complete

E. ADD THE FOLLOWING TO APPENDIX B

B.4A CALibrate:CPRotect COMMAND

CAL:CPR

Syntax: Short Form: CAL:CPR {MIN | MAX}

Long Form: CALibrate:CPRotect {MIN | MAX}

Description: Selects Current Protection limit calibration, only effective with power supply in Calibrate status. CAL:CPR

MAX selects maximum positive current protection limit calibration. CAL:CPR MIN selects maximum negative current protection limit calibration. Related Commands: CAL:STAT, CAL:ZERO, CAL:DATA, CAL:SAVE.

F. MODIFY TABLE B-5 TO ADD BIT 14 = PROTECTION ERROR

TABLE B-5. QUESTIONABLE EVENT REGISTER, QUESTIONABLE CONDITION REGISTER

AND QUESTIONABLE CONDITION ENABLE REGISTER BITS

CONDITION NU PE CE VE NU CM VM

BIT 15 14131211 - 2 10

VALUE 32,768 16,359 8192 4096 2048 - 4 2 1

PE PROTECTION ERROR

CE CURRENT ERROR

VE VOLTAGE ERROR

CM CURRENT MODE

VM VOLTAGE MODE

NU NOT USED

12

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000 "

http://www.kepcopower.com " email: hq@kepcopower.com

228-1481 REV 3 021704

FAX (718) 767-1102

Loading...

Loading...