Page 1

INSTRUCTION SHEET

KEPCO

An ISO 9001 Company.

CABLE

KIT

219-0445

CABLE KIT NO. 219-0445

BOP 1000W MODELS (2) IN PARALLEL

I.

DESCRIPTION.

This kit contains the three cables, Power Output, Bitbus and Master/Slave Control, required to operate

two 1000 Watt BOP High Power models in parallel, effectively doubling the output current capacity.

Only two identical models may be configured to operate in parallel. Table 1 lists the equipment supplies

in this Kit.

TABLE 1. EQUIPMENT SUPPLIED

Item Purpose Kepco Part Number

Connects the power output terminals of the slave unit (OUT

Power Output Cable

Master/Slave

Control Cable

and COMMON) to the corresponding power output terminals

of the master.

Connects the slave control ports of the master and slave for

parallel operation.

118-1112

118-1107

Bitbus Cable Allows communication between Master and Slave via Bitbus 118-1108

Instruction Manual

This manual is arranged as follows:

• Section I lists the equipment supplied.

• Section II explains how to install the cables and configure the two units to operate in parallel,

including initial calibration.

• Section III describes how to calibrate a previously installed parallel configuration.

• Section IV lists the specifications for the parallel combination.

• Section V provides special operating instructions for the parallel combination.

II.

INSTALLATION.

Provides installation and operation instructions for operating

two 1000W BOP models in Parallel

WARNING

BE SURE ALL POWER IS DISCONNECTED FROM

POWER SUPPLIES BEFORE INSTALLING CABLES

228-1472

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000 " FAX (718) 767-1102

©2003, KEPCO, INC

Data subject to change without notice

http://www.kepcopower.com "

228-1472 REV 3 091903

email: hq@kepcopower.com

Page 2

NOTE: The following procedure assumes that both individual units are properly calibrated. If not, refer

to the associated technical manuals to calibrate the individual units prior to connecting them

as a parallel pair. Perform all calibration steps for both master and slave unit.

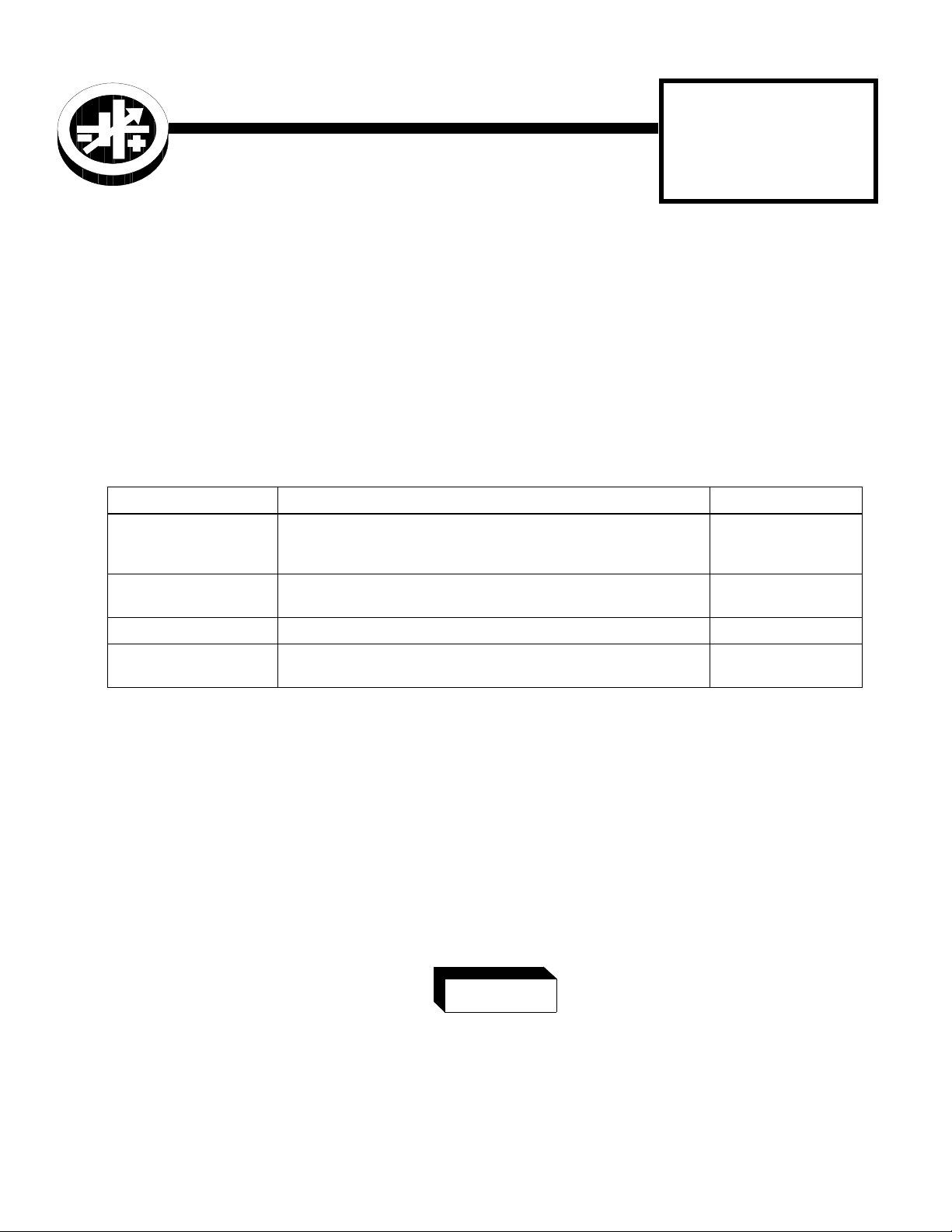

1. Before powering up the parallel combination, connect the Power Output, Bitbus, and Master/

Slave Control cables (supplied) to the master and slave units in parallel star type configuration

(load connected to the master output) as shown in Figure 1 for local sensing or Figure 2 for

remote sensing. Always remove link between COM and COM S terminals for the slave. For a

master configured for remote sensing, remove both links between OUT and OUT S and between

COM and COM S terminals.

CAUTION:The connectors of the Master/slave Control cable are marked Master and Slave.

Make sure these are installed properly. Installing the cable backwards (cable connector marked MASTER installed in a slave, cable connector marked SLAVE

installed in a master) can cause irreparable damage.

NOTE: To power down the combination, first press the STANDBY key on the master to disable the

output, then turn off the slave followed by the master.

2. To configure the unit to be designated as a slave proceed as follows:

a. Turn on power only to the unit to be designated as a slave.

b. From the main screen (power on default), press

to enter the Settings Menu.

%

c. From the Settings menu, gain access to the Protected Settings menu by first entering the

password. Scroll through the password characters using

to select the character position, then press ENTER. The status message changes to

tected settings enabled

ter and

d. Press

or ADJUST control to fix it, or press CLEAR to start over.)

U

to enter the Protected Settings Menu.

$

e. From the Protected Settings menu, highlight

keys) and press ! to modify. Highlight

U

f. From the Protected Settings menu, under

modify. Highlight

Parallel

. (If unsuccessful, use T or R to highlight the incorrect charac-

Unit Type

SLAVE #1

Unit Type

and press ! apply the change.

and press ! to apply the change.

g. Exit the Protected Settings menu and return to main screen by pressing

tings upon power-up. The unit goes to REMOTE mode, the status message reads

Module not found

, the Fault indicator is lit, and the unit continues to beep once a minute

until the master is found. The only function key displayed is

or ADJUST control and T or

U

(use ADJUST control or the Y or

highlight

Expansion

- LOCAL.

!

and press ! to

to save the set-

$

MASTER

R

Pro-

CAUTION: The unit has now been properly configured as a slave to be controlled only by the

master. Do not use the slave keypad, RS 232 port or GPIB port to try to control the

slave.

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000

FAX (718) 767-1102 " email: kepcopower@aol.com

2

228-1472 REV 3 091903

Page 3

FIGURE 1. INTERCONNECTIONS FOR PARALLEL OPERATION OF TWO (2) BOP HIGH

POWER MODELS USING LOCAL SENSING

FIGURE 2. INTERCONNECTIONS FOR PARALLEL OPERATION OF TWO (2) BOP HIGH

POWER MODELS USING REMOTE SENSING

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000

FAX (718) 767-1102 " email: kepcopower@aol.com

091903 228-1472 REV 3

3

Page 4

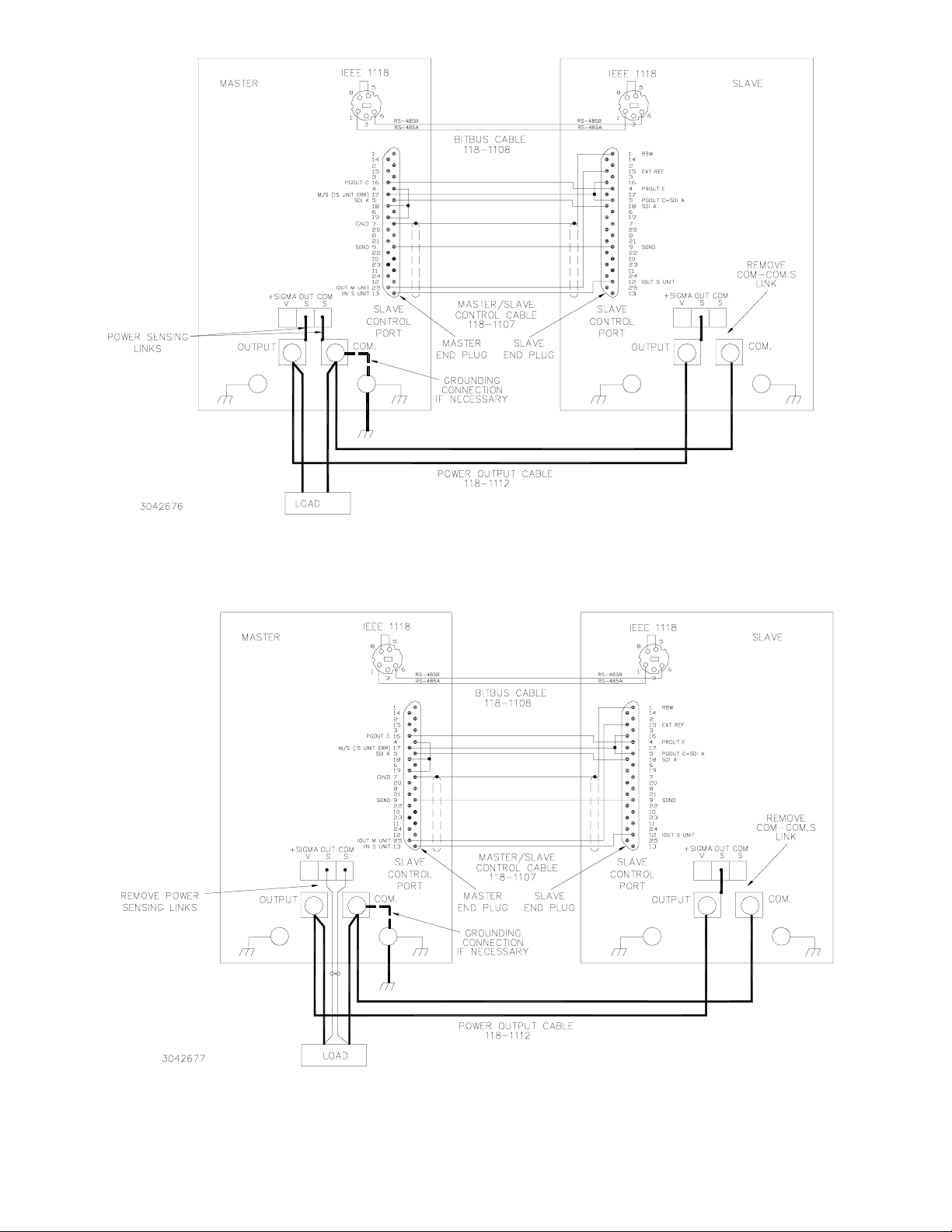

3. Turn on the unit to be configured as a master and note that upon power up the FAULT light will go

on (this is normal). Proceed as follows:

a. From the main screen, press

to enter the Settings Menu.

%

b. From the Settings menu, gain access to the Protected Settings menu by first entering the

password (see Step 2c above).

c. From the Protected Settings menu, highlight

keys) and press ! to modify. Highlight

d. From the Protected Settings menu, under

modify. Highlight

Parallel

and press ! to apply the change.

e. Exit the Protected Settings menu by pressing

Unit Type

Master +1

Unit Type

to test the system and to save the settings

$

(use ADJUST control or Y or

and press ! to apply the change.

highlight

Expansion

and press ! to

U

for subsequent power-up cycles. The display shows the master power-up screen (see Figure 3).

NOTE: Pressing

to exit will cause the unit to revert to a standalone unit.

%

f. The power-up master module screen (Figure 3) changes to show the status of Slave 1 (see

Table 2).

If the slave is recognized as ready, after about 10 seconds the master LCD reverts to the

Power On Default screen (see Figure 4). The slave also displays the Power On Default

screen (see Figure 5), except the unit will be in Current Mode, no function keys are active

and the Status message at the bottom is

KPAD Locked

, indicating the keypad is disabled.

The fault indicators on both units are off.

If the master power-up screen is still displayed after 10 seconds, the slave was not properly

recognized. Pressing

or turning power off, then on again, reconfigures the unit as a stan-

%

dalone unit. Verify that the BITBUS cable is installed correctly. Verify that the slave has

been properly configured as a slave per step 2 above. Repeat step 3. If the power up

screen still does not revert to the power on default screen, refer to troubleshooting.

VOLTAGE

CURRENT

VOLTAGE

SOURCE

CPROTECT

FIGURE 3. MASTER POWER UP SCREEN

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000

FAX (718) 767-1102 " email: kepcopower@aol.com

4

228-1472 REV 3 091903

Page 5

VOLTAGE

SOURCE

VO LTA G E

0.

0000

FIGURE 4. POWER ON DEFAULT SCREEN FOR MASTER UNIT

VOLTAGE

SOURCE

FIGURE 5. POWER ON DEFAULT SCREEN FOR SLAVE UNIT

TABLE 2. SLAVE STATUS MESSAGE DEFINITIONS (DISPLAYED ON MASTER POWER UP SCREEN)

DISPLAYED STATUS

(see Figure 3, SLAVE 1)

Ready Unit is ready for operation.

STANDBY Unit’s FAULT indicator is on.

Powered OFF Unit is not responding to polls via BITBUS.

Failed Unit’s FAULT indicator is on, and hardware error has been detected.

Not Used Unit is not part of parallel configuration

Unknown Waiting for interface communication

4. At the master unit calibrate the parallel combination as follows:

a. From the main screen, press

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000

FAX (718) 767-1102 " email: kepcopower@aol.com

091903 228-1472 REV 3

to enter the Settings Menu.

%

MEANING

5

Page 6

b. From the Settings menu, gain access to the Protected Settings menu by first entering the

password (see step 2c above).

c. Press

Calibration Multiple Units

Connect a short across Master Power Output.

Depress any Key to continue.

from the Protected Settings menu to begin Calibration. The LCD shows

@

After connecting a short across output terminals of master, depress any key on the keypad.

VOLTAGE

CURRENT

VOLTAGE

SOURCE

FIGURE 6. CALIBRATION SCREEN

d. Press # from the main calibration menu to select Multiple. The Calibration Screen (Figure

6) is displayed. The status of the process is updated as calibration proceeds (this may take

approximately three minutes). The Current State is updated from zero to maximum and

minimum as the current calibration proceeds (voltage calibration is not required for the parallel pair).

e. When the calibration is complete the LCD displays

PLEASE REMOVE SHORT FROM

OUTPUTS OF POWER SUPPLIES

Depress Any Key to continue.

After removing the short, depress any key on the keypad.

f. When prompted, enter the calibration date (8 characters maximum, any format) using

ADJUST control to scroll through the characters and

or R to select the character posi-

T

U

tion, then press ENTER.

g. Exit the Calibration menu by pressing

to save the settings upon power-up.

$

5. Adjust the limits to reflect the increased current capacity of the parallel combination as follows:

or

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000

FAX (718) 767-1102 " email: kepcopower@aol.com

6

228-1472 REV 3 091903

Page 7

a. From the main screen, press % to enter the Settings Menu.

b. From the Settings menu, press

@ to enter the Modify Limits menu. Press @ to restore defaults. The

values for +Current Max, –Current Min and ±Current Protect Max/Min should now be for the parallel

combination.

c. Exit the Modify Limits menu by pressing

$ to save the settings upon power-up.

6. Verify that the output is zero and remove the short across the output of the parallel configuration.

NOTE: Changing the password of the parallel pair (i. e., the master) does not change the password of the slave

unit. It is recommended that the slave unit password be recorded and be readily accessible when calibration of the slave unit is required.

III.

CALIBRATING AN EXISTING PARALLEL CONFIGURATION

If the individual units of a parallel comb7ination need to be calibrated proceed as follows:

1. Power down the combination: first press the STANDBY key on the master to disable the output, then turn off

the slave, followed by the master.

2. Disconnect the master/slave cable connections.

3. Turn on power to both units in any order.

4. The slave unit will power up in

REMOTE

and will display

LOCAL LOCKOUT

. To restore LOCAL control, press

to set the unit to LOCAL mode.

!

5. If calibration is to be done via the front panel keypad, refer to the front panel calibration procedure in the

associated technical manual and calibrate both units. If the calibration is to done via the GPIB (using either

SCPI commands or the soft panel) both master and slave units must be temporarily reconfigured as standalone units:

a. From the main screen (power on default), press

to enter the Settings Menu.

%

b. From the Settings menu, gain access to the Protected Settings menu by first entering the password

(see PAR. II, step 2c).

c. From the Protected Settings menu, highlight UNIT TYPE (use ADJUST control or arrow keys) and

press

d. From the Protected Settings menu, highlight MULTIPLE UNITS and press

NONE and press

e. Exit the Protected Settings menu and return to main screen by pressing

to modify. Highlight STANDALONE and press ! to apply the change.

!

to apply the change.

!

%

to modify. Highlight

!

.

f. Calibrate the master and slave units by referring to the applicable calibration procedure in the associ-

ated technical manual.

g. Turn off power to both units (since step e exited without saving the settings, this restores the previous

master/slave settings).

6. Refer to Figure 1 for local sensing or Figure 2 for remote sensing and connect the master and slave units in

parallel star type configuration (load connected to master) using the Master/slave Control, Power Output

and Bitbus cables.

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000

FAX (718) 767-1102 " email: kepcopower@aol.com

091903 228-1472 REV 3

7

Page 8

7. Verify the master unit is in STANDBY, then connect a short across the output of the parallel configuration (see Figure 1 or Figure 2).

8. At the master unit calibrate the parallel combination as follows:

a. From the main screen, press

to enter the Settings Menu.

%

b. From the Settings menu, gain access to the Protected Settings menu by first entering the

password (see step 2c above).

c. Press

d. Press

from the Protected Settings menu to begin Calibration.

@

from the main calibration menu to select Multiple. Monitor the LCD to see the sta-

#

tus while calibration of the parallel configuration proceeds automatically (this may take

approximately 3 minutes).

e. When the calibration is complete, the LCD will display

PUTS OF POWER SUPPLIES Depress Any Key to continue.

PLEASE REMOVE SHORT FROM OUT-

f. When prompted, enter the calibration date using U or ADJUST control to scroll through the

characters and

g. Exit the Calibration menu by pressing

or R to select the character position, then press ENTER.

T

to save the settings upon power-up.

$

9. Remove the short across the output of the parallel configuration.

IV.

SPECIFICATIONS

Table 3 lists the model parameters unique to a parallel combination of two 1000W BOP Power Supplies.

Table 4 lists the general specifications applicable all the parallel combinations listed in Table 3.

TABLE 3. MODEL PARAMETERS FOR TWO (2) HIGH POWER BOP 1000 WATT UNITS (PARALLEL)

d-c Output Range Closed Loop Gain

Model

TWO 1000 WATT MODELS

BOP 10-75MG ±10V d-c ±150A d-c 1.0 15.0

BOP 20-50MG ±20V d-c ±100A d-c 2.0 10.0

BOP 36-28MG ±36V d-c ±56A d-c 3.6 5.5

BOP 50-20MG ±50V d-c ±40A d-c 5.0 4.0

BOP 72-14MG ±72V d-c ±28A d-c 7.2 2.8

BOP 100-10MG ±100V d-c ±20A d-c 10.0 2.0

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000

FAX (718) 767-1102 " email: kepcopower@aol.com

E

O Max

8

I

O Max

228-1472 REV 3 091903

Vol ta ge

Channel

Current

Channel

Page 9

TABLE 4. GENERAL SPECIFICATIONS FOR TWO (2) HIGH POWER 1000W BOP UNITS

CONNECTED IN PARALLEL

SPECIFICATION RATING/DESCRIPTION

CONDITION

INPUT CHARACTERISTICS

a-c voltage nominal 230 Va-c

range 176 - 264 Va-c

Frequency nominal 50-60 Hz

range 47 - 65 Hz

Current 176 Va-c 19A maximum

264 Va-c 13A maximum

Power factor

Efficiency 65% minimum

Switching frequency 80 KHz PFC Stage

EMC Compliance EN61326-1 (1997) Class A equipment

EMC immunity to: ESD EN61000-4-2 Electrostatic discharge

EMC emissions Conducted EN61000-3-2 harmonics

Leakage current 3.5 mA 230V a-c 47-63 Hz

Insulation coordination Input Installation Category II

Pollution degree 2

Source 0.99 minimum

Sink 0.97 minimum

Radiated RF EN61000-4-3

EFT EN61000-4-4 Electrical fast transient/burst

Surges EN61000-4-5

Conducted RF EN61000-4-6

EN61000-3-3 fluctuation & flicker

Conducted EN55011/CISPR11 0.15 to 30 MHz

Radiated EN55011/CISPR11 30 to 1000 MHz

Overvoltage Category II

Output Installation Category II

Overvoltage Category II

Single phase

>65 Hz, leakage

exceeds spec

nominal output power

OUTPUT CHARACTERISTICS

Type of stabilizer Voltage-current, 4-quadrant Switch mode

Switching frequency 100KHz Output Stage

Source adjustment

range

Sink adjustment range voltage -100% to +100% of rating

Programming

resolution / accuracy

Readback

resolution / accuracy

Readback

rate/array

measurement rate 1 ms (default) range: 0.25-25ms

measurement array 64 samples

voltage -100% to +100% of rating

current -100% to +100% of rating

Recuperated energy is sent back into

current -100% to +100% of rating

Voltage 14 bits / 0.2%

Current 14 bits / 0.5%

Limits 12 bits / 0.5% voltage or current

Voltage 16 bits / 0.2% main or limit channel

Current 16 bits / 0.5% main or limit channel

0 to 50 deg C

line for reuse

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000

FAX (718) 767-1102 " email: kepcopower@aol.com

091903 228-1472 REV 3

9

Page 10

TABLE 4. GENERAL SPECIFICATIONS FOR TWO (2) HIGH POWER 1000W BOP (CONTIN-

UED)UNITS CONNECTED IN PARALLEL

SPECIFICATION RATING/DESCRIPTION

CONDITION

OUTPUT CHARACTERISTICS (Continued)

Voltage stabilization in

voltage mode

Current stabilization in

current mode

Error sensing 0.25V per wire Above rated output

Transient recovery in

voltage mode

Isolation voltage 300V Output to ground

Output limiting voltage and current limited in four quadrants

Output Stage Protection

Input Stage Protection (PFC)

source effect 0.05% of rating min-max input voltage

load effect 0.1% of rating 0-100% load current

time effect (drift) 0.05% of rating 0.5 through 24 hours

temperature 0.05%/deg C of rating 0 to 50 deg C

ripple and noise 2% E0max p-p Includes switching noise

source effect 0.05% of rating min-max input voltage

load effect 0.2% of rating 0-100% load voltage

temperature 0.05%/deg C of rating 0 to 50 deg C

ripple and noise 2% I0max p-p Includes switching noise

maximum excursion 5% of nominal output nominal voltage, 50% load step

Recovery time 200

Heatsink overtemperature,

switchers overcurrent for master

Overvoltage, undervoltage, overcurrent,

heat sink overtemperature, fan inopera-

tive for master and slave units

Circuit breaker overcurrent

µ

sec Return within 0.1% of set voltage

and slave units

Triggers latched shutdown protection of

entire master/slave combination

Triggers latched shutdown protection of

entire master/slave combination

Trips circuit breaker to shut off unit

(master or slave)

PROGRAMMING/DISPLAY CHARACTERISTICS

Small signal Bandwidth voltage channel 2 KHz minimum into nominal resistive load, 10% of rating

current channel 400 Hz minimum Into short circuit, 10% of rating

µ

Rise/Fall Time voltage channel 500/200

current channel 1.5/2.5 msec

Analog control voltage channel –10V to +10V

current channel –10V to +10V

Digital control local Panel-mounted keypad Direct Entry

remote IEEE 488-2 (GPIB)

remote RS 232

remote RS 485 (BITBUS) IEEE 1118

Display front panel 4" backlit LCD displays all functions

remote All parameters read back on GPIB or RS 232 buses

sec

into nominal resistive load, 10-90%,

0 to ±100% of rating

into short circuit, 10-90%,

0 to ±100% of rating

Full range output,

10K Ohm input impedance

SCPI

10

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000

FAX (718) 767-1102 " email: kepcopower@aol.com

228-1472 REV 3 091903

Page 11

TABLE 4. GENERAL SPECIFICATIONS FOR TWO (2) HIGH POWER 1000W BOP (CONTIN-

UED)UNITS CONNECTED IN PARALLEL

SPECIFICATION RATING/DESCRIPTION

CONDITION

BOP HIGH POWER INTERFACE CHARACTERISTICS

Waveform Support steps 1002

µ

step dwell time 250

Storage non-volatile FLASH-type EEPROM 24Kbytes

** User setups 99

interface steps 99

** waveform display 1024 steps

** waveform - interface 1800 steps

sec to 10 sec

GENERAL (ENVIRONMENTAL) CHARACTERISTICS

Temperature operating 0 to +50 deg C Full rated load

storage -20 to +85 deg C

Cooling Two internal fans per unit exhaust to the rear

Humidity 0 to 95% RH non-condensing

Shock 20g. 11msec ±50% half sine non-operating

Vibration 5-10HZ: 10mm double amplitude 3 axes, non-operating

10-55HZ: 2g 3 axes, non-operating

Altitude sea level to 10,000 feet

Safety Certification a-c power UL 3101-1 and EN 6101-1 Pending

** Optional Function. if you require an option that is not installed on your unit, please contact the factory for upgrade information.

V.

OTHER CONSIDERATIONS

When operating two units in parallel the following information supplements the Power Supply technical

manual.

1. Apply power to the combination by first turning on the master, then turn on the slave. If the master

is in STANDBY, depress the STANDBY key on the master to apply power to the output terminals.

(To power down the combination, first press the STANDBY key on the master to disable the output, then turn off the slave, followed by the master.

2. When the units of a parallel configuration are first turned on there is a brief delay until both units

are communicating over the BITBUS to form the parallel pair.

When the master is turned on, the unit initially displays the Power Up Status and Test screen (Figure 7), then displays the Master Power Up screen (Figure 3). As the master searches for slaves.

When the slave is turned on, the unit initially displays the Power Up Status and Test screen (Figure 7), then automatically goes to REMOTE mode. The status message reads

not found

is found. The only function key displayed is

, the Fault indicator is lit, and the unit continues to beep once a minute until the master

- LOCAL.

!

MASTER Module

When the master finally recognizes the slave, the master LCD reverts to the Power On Default

screen (see Figure 3). The slave displays the Power On Default screen (see Figure 3), except the

unit will be in Current Mode, no function keys are active and the Status message at the bottom is

KPAD Locked

, indicating the keypad is disabled. The fault indicators on both units are off.

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000

FAX (718) 767-1102 " email: kepcopower@aol.com

091903 228-1472 REV 3

11

Page 12

3. Operation of the parallel combination is done by operating the master as described for a single

unit in the High Power BOP Technical Manual. SCPI commands and front panel controls actions

applied to the master affect the parallel combination. The LCD display of the master refers to the

parallel combination, while the front panel LCD of the slave shows the actual voltage and current

provided by the slave.

FIGURE 7. POWER UP STATUS AND TEST SCREEN

12

KEPCO, INC. " 131-38 SANFORD AVENUE " FLUSHING, NY. 11352 U.S.A. " TEL (718) 461-7000

FAX (718) 767-1102 " email: kepcopower@aol.com

228-1472 REV 3 091903

Loading...

Loading...