Page 1

MMI-TS

P

WR

CPU

COM

MMI-1500, MMI-850, MMI-750, MMI-730

Installation & Operations Manual, Software Reference,

Kessler Ellis Products

10 Industrial Way East

Eatontown, NJ 07724

Phone: 732-935-1320 Fax: 732-935-9344

www.kep.com

and Connection Guide

Version 2.7.0

99676REV20JAN06

$70.00

1

Page 2

ii

Page 3

About this Manual

This document is based on information available at the time of its publication. While efforts have been made

to be accurate, the information in this document may not cover all details or variations in hardware or

software, nor does it provide for every possibility concerning installation, operation, or maintenance. Features

may be described herein which are not present in all hardware. Kessler Ellis Products assumes no obligation

of notice to holders of this document with respect to subsequent changes.

Information in this document is subject to change without notice and does not represent a commitment on the

part of Kessler Ellis Products.

Text Construction

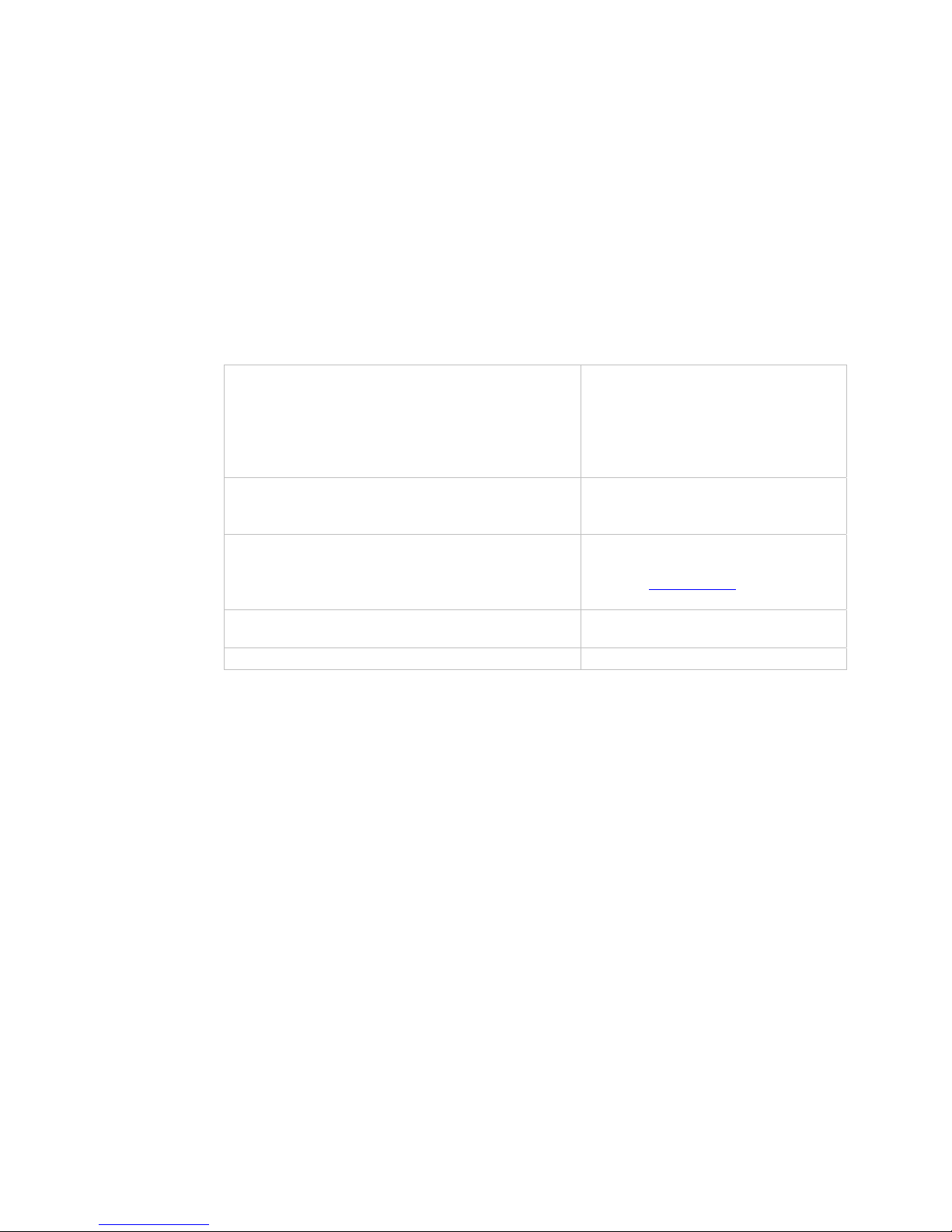

Construction Comment

Bold Characters Keywords that are menu or system items or text that is part of EasyBuilder. Example: BitLamp

Italic Characters Italics are used to draw emphasis to a portion of text. Example: “Note:”

[characters] Characters within the [ ] are to be typed in exactly as they are printed. Example: “[c:\eb500\drivers]”

< Characters> Indicates user information is required. A description of the information is between the < > characters.

Example: “<project name>”

Key1+Key2

Click Tap the primary mouse button once on the indicated object. Example: “Click the OK button.”

Double Click Tap the primary mouse button twice on the indicated object. Example: “Double Click to call up the

Right Click Tap the secondary mouse button once. Example: “Right Click on the highlighted object to open the

CAPITAL Characters All capitals are used for Directory names, file names, and acronyms. Example: “EB500”

Menu|Menu item

The abbreviations MMI and HMI are used interchangeably in this manual both refer to the touchscreen

interface units.

Press and hold Key1 then press Key2 (then release both keys). Example: “Ctrl + N” Hold Control

down while pressing the N. (starts a new project)

Part Attributes.”

shortcut menu.”

This construction is used to specify menu commands. The main menu is on the left with submenus

after it separated by the “|” character. Example: “Edit|Align|Left”

iii

Page 4

Safety Instructions

Overview

This section states the safety instructions which must be followed when installing, operating and servicing the

MMI. If neglected, physical injury and death may follow, or damage may occur to controller and related

equipment. The material in this chapter must be studied before attempting any work on, or with, the unit.

Warnings and Notes

This manual distinguishes safety instructions. Warnings are used to inform of conditions, which can, lead if

proper steps are not taken, to a serious fault condition, physical injury or death. Notes are used when the

reader is required to pay special attention or when there is additional information available on the subject.

Notes are less crucial than warnings, but should not be disregarded. Readers are notified of the need for

special attention or additional in formation available on the subject with the following symbols:

Warnings

Warnings

CAUTION!

Note:

Readers are informed of situations that can result in serious physical injury and/or serious damage to

equipment with the symbol shown to the left. A Warning symbol indicates that the reader should pay

special attention to the accompanying text. Take precautionary steps to insure that the installation

complies with warnings before continuing. Warnings include hazardous conditions that could cause

personal injury or equipment damage if care is not taken. The text next to this symbol describes ways to

avoid the danger.

Dangerous Voltage Warnings: Warns of situations in which high voltage can cause physical injury and

or damage equipment.

General warning: Warns of situations, which can cause physical injury and or damage equipment by

means other than electrical.

Electrostatic Discharge Warning: Warns of situations in which an electrostatic discharge can damage

equipment.

Caution: Aims to draw special attention to the text. Be sure to understand the implications of the text

before proceeding.

Note: gives additional information or points out more information available on the subject.

APPLICATIONS ASSISTANCE

This manual is designed to provide the necessary information for trouble-free installation and operation of

HMI Touchscreens. Additional help is available when accessing the help functions in the EasyBuilder

software. If further assistance is needed, please call KEP at 1-800-631-2165 or visit our web site at

www.kep.com.

IMPORTANT

NOTE!

Backup project files (*.epj) as needed to insure the ability to modify a project in

the future!

iv

Page 5

PROPRIETARY NOTICE

The information contained in this publication is derived in part from proprietary and patent data. This

information has been prepared for the expressed purpose of assisting operating and maintenance personnel

in the efficient use of the instrument described herein. Publication of this information does not convey any

rights to use or reproduce or to use it for any purpose other than in connection with the installation, operation

and maintenance of the equipment described herein.

Copyright 2005 by

Kessler Ellis Products

We hope you will be pleased with our product. If you have any questions concerning our warranty, repair,

modification or returned goods process, please contact your local distributor.

WARRANTY

This product is warrantied against defects in materials and workmanship for a period of twelve months from

the date of shipment to Buyer.

The Warranty is limited to repair or replacement of the defective unit at the option of the manufacturer. This

warranty is void if the product has been altered, misused, dismantled, or otherwise abused.

ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, ARE EXCLUDED, INCLUDING BUT NOT

LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE.

v

Page 6

About this Manual............................................................iii

Text Construction ............................................................iii

Safety Instructions.......................................................... iv

WARRANTY............................................................. v

Section 1: Installation and Startup Guide ........................1

1.0 Getting Started ..........................................................1

1.1 The MMI-Touchscreen Series................................ 1

2.0 Installation Instructions ..............................................2

2.1 Mounting Instructions............................................. 2

2.1.1 Location Considerations .................................. 2

2.1.2 Making a NEMA-4 Mounting............................ 2

2.1.3 Environmental Considerations......................... 3

2.2 Power Connections................................................ 4

2.2.1 Power Requirements....................................... 4

2.2.2 Grounding Requirements ................................5

2.2.3 CE Requirements ............................................5

2.2.4 Safety Guidelines ............................................6

2.3 CE Requirements................................................... 6

2.3.1 EU directives that apply to MMI Series............ 6

2.3.2 Guide Lines for EU Installations ......................7

2.3.3 Safety Guide Lines for EU Installations ........... 7

2.4 Communications Connections ...............................8

2.4.1 Connection to an External Device ...................8

2.4.2 Connection to a Personal Computer................9

2.4.3 Connection to a Printer..................................10

2.4.4 Ethernet Connections.................................... 10

2.5 Dip Switch Settings .............................................. 12

2.6 HMI Indicator Lights .............................................12

2.7 Other Hardware Considerations........................... 12

3.0 Specifications ..........................................................13

3.1 General Specifications ......................................... 13

3.2 Hardware Specification 1500, 850 Models........... 13

3.3 Hardware Specification 750, 720 Models............. 14

3.3 Functional Specification ....................................... 14

4.0 Trouble Shooting .....................................................15

4.1 Power Problems................................................... 15

4.2 Communications Problems .................................. 15

4.3 Commonly Asked Questions................................16

4.4 Hardware Problems .............................................16

4.4.1 Black Screen after download......................... 16

4.5 Repairs and Returns ............................................17

5.0 Quick Startup Guide ................................................17

5.1 Connections ......................................................... 17

5.2 Installing EasyBuilder........................................... 19

5.3 Initial Start Up ......................................................20

5.4 Creating a project................................................. 21

Section 2: Software Reference Guide ...........................24

6.0 EasyManager Operations........................................ 24

6.1 COM Port Drop-Down Box...................................24

6.2 Communications Speed Drop-Down Box.............24

6.3 Project or Recipe Download/Upload ....................24

6.4 Complete or Partial Download/Upload .................24

6.5 EasyBuilder.......................................................... 24

6.6 Online-Simulator ..................................................25

6.7 Direct Online-Simulator........................................ 25

6.8 Offline-Simulator...................................................25

6.9 Download .............................................................25

6.10 Upload................................................................25

6.11 Mode Change.....................................................26

7.0 Software Fundamentals...........................................27

7.1 Screen Editor Overview........................................27

7.1.1 Changing Screen Appearance.......................28

7.2 System Parameters..............................................29

7.2.1 The PLC Tab Parameters ..............................29

7.2.2 The General Tab............................................33

7.2.3 The Indicator Tab...........................................37

7.2.4 The Security Tab ...........................................38

7.2.5 The Editor Tab ...............................................39

7.2.6 The Hardware Tab.........................................40

7.2.7 The Auxiliary Tab...........................................42

7.3 Part Placement.....................................................44

7.3.1 Part Placement Summary..............................44

7.3.2 Part ID Numbers ............................................44

7.3.3 Part Dialog Features......................................45

7.4 Window Operations ..............................................50

7.4.1 Creating New Windows .................................51

7.4.2 Adding Objects to a Window..........................54

7.4.3 Copying and Importing Windows from Other

Projects...................................................................54

7.4.4 Changing and Popping Up Windows .............55

7.5 Task Bar Operations ............................................56

7.5.1 Task Button Overview....................................56

7.5.2 Procedure to Setup Task Buttons ..................57

7.5.3 Creating the Fast Selection Window..............60

7.5.4 Using the Task Bar ........................................61

7.6 Library Operations................................................62

7.6.1 Library Overview............................................62

7.6.2 Shape Library Operations..............................63

7.6.3 Bitmap Library Operations .............................66

7.6.4 Group Library Operations ..............................69

7.6.5 System Libraries............................................71

7.6.6 Library Toolbar Functions ..............................71

7.6.7 Shortcut for changing a Part’s assigned Shape

or Bitmap ................................................................71

7.7 Tag Definition and Use.........................................72

7.7.1 Adding a Tag to the Tag Library ....................72

7.7.2 Editing Tags...................................................73

7.7.3 Deleting Tags.................................................73

7.7.4 Using Tags.....................................................74

7.7.5 Exporting and Importing Tags........................74

7.8 Label Definition and Use ......................................75

7.8.1 Adding a Label to the Label Library ...............75

7.8.2 Editing Labels ................................................76

7.8.3 Deleting Labels ..............................................76

7.8.4 Using Labels ..................................................77

7.8.5 Exporting and Importing Labels .....................77

7.9 Security ................................................................78

7.9.1 Security Levels ..............................................78

7.9.2 Passwords .....................................................78

7.9.3 Assigning Security .........................................78

7.9.4 System Reserved Local Word Usage with

Security...................................................................80

vi

Page 7

7.9.5 System Reserved Retentive Word Usage with

Security.................................................................. 80

7.9.6 How to Implement User Security................... 81

7.9.7 Additional Security Through the PLC ............ 81

7.10 Print Operations................................................. 82

7.10.1 Compatible printers ..................................... 82

7.10.2 Screen Printing with Function Buttons ........ 82

7.10.3 PLC Controlled Printing............................... 83

7.10.4 Printing Events............................................ 83

8.0 Drawing................................................................... 84

8.1 Line/Rectangle/Ellipse/Arc/Polygon.................... 84

8.1.1 Note on Pattern Options................................ 84

8.1.2 Note on Color Options................................... 85

8.1.3 Drawing Lines, Rectangles, Ellipses, Arcs and

Polygons ................................................................ 85

8.2 Text ..................................................................... 86

8.3 Shape .................................................................. 87

8.4 Bitmap ................................................................. 87

8.5 Scale.................................................................... 88

9.0 Editing Placed Objects ............................................ 89

9.1 Moving and Resizing Objects .............................. 89

9.1.1 The Profile Tab ............................................. 89

9.1.2 Object Order ................................................. 90

9.1.3 Nudge ........................................................... 90

9.1.4 Aligning Objects ............................................ 91

9.1.5 Resizing Objects ........................................... 91

9.1.6 Transformation Tools .................................... 91

9.2 Grouping Objects................................................. 92

9.3 Editing Object Attributes ...................................... 92

9.3.1 Text Editing tools: ......................................... 92

9.3.2 Editing Stacked Objects ................................ 93

9.3.3 Editing Grouped Objects Attributes............... 93

9.4 Multi. Copy Command ......................................... 94

9.5 Finding and Replacing Device Addresses with the

Find/Replace Addr… Utility........................................ 95

9.6 Using the Window No. Treebar............................ 96

9.6.1 Treebar Operations ....................................... 96

10.0 System Bit and Register Reference ...................... 97

10.1 Local memory .................................................... 97

10.2 Remote memory ................................................ 98

10.3 Reserved Local Words/Bits ............................... 98

10.3.1 Reserved Local Bits .................................... 98

10.3.2 Reserved Local Words.............................. 102

10.4 Retentive memory ........................................... 104

10.4.1 Reserved Retentive Word ......................... 105

10.4.2 System Information ................................... 105

11.0 EasyBuilder Operations....................................... 106

11.1 Project Operations........................................... 106

11.1.1 Compiling a Project................................... 106

11.1.2 Simulating a Project .................................. 107

11.1.3 Downloading a Project .............................. 107

11.1.4 System Error Messages............................ 108

11.2 Debugging with EasyWindow .......................... 109

11.2.1 PLC Monitor .............................................. 110

11.2.2 Data Monitor ............................................. 111

11.2.3 System Resource...................................... 112

11.2.4 Search....................................................... 113

12.0 Project Management and Documenting a Project 114

12.1 Compressing/Uncompressing a project ...........114

12.2 Decompiling a project ...................................... 115

12.3 Documenting a project ..................................... 116

12.3.1 Print Object Summary ............................... 116

12.3.2 EasyWindow Documentation..................... 116

12.4 Using Compact Flash to transfer a project....... 117

12.4.1 Transferring a project to CompactFlash

memory ................................................................ 117

12.4.2 Transferring a project from CompactFlash

TM

TM

to HMI................................................................... 117

12.5 Using Compact Flash to transfer retentive memory

................................................................................. 118

12.5.1 Transferring data to CompactFlash

............................................................................. 118

12.5.2 Transferring data from CompactFlash

TM

memory

TM

to

retentive memory.................................................. 118

Section 3: Object Reference Guide ............................. 119

13.0 Objects Summary................................................ 119

13.1 Bit Lamp........................................................... 120

13.2 Word Lamp ......................................................122

13.3 Set Bit .............................................................. 124

13.4 Set Word.......................................................... 127

13.5 Toggle Switch ..................................................131

13.6 Multi-State Switch ............................................ 133

13.7 Function key..................................................... 134

13.7.1 Character Codes and Creating a Keypad.. 135

13.7.2 Hard Copy (Print Function)........................ 136

13.7.3 Change Window ........................................ 136

13.7.4 Return to Previous..................................... 137

13.7.5 Change Common Window......................... 137

13.7.6 Popup Window .......................................... 137

13.7.7 Close Window ...........................................137

13.7.8 JOG FS-Window ....................................... 138

13.7.9 Window Bar............................................... 138

13.7.10 Minimize Window .................................... 139

13.7.11 Message Board ....................................... 139

13.8 Numeric Input Extend ......................................141

13.8.1 Numeric Display Format............................ 142

13.8.2 Font Alignment .......................................... 143

13.9 Numeric Data................................................... 146

13.10 ASCII Input Extend ........................................147

13.11 ASCII Data..................................................... 149

13.12 Moving Shape................................................ 150

13.13 Animation....................................................... 152

13.14 Indirect Window .............................................154

13.15 Direct Window................................................ 156

13.16 Alarm Display................................................. 157

13.17 Trend Display................................................. 159

13.18 XY Plot........................................................... 162

13.19 Bar Graph ......................................................164

13.20 Meter Display................................................. 166

13.21 Alarm Bar....................................................... 168

13.22 Recipe Transfer ............................................. 169

13.23 Event Display................................................. 171

System Tools............................................................... 173

vii

Page 8

13.24 Alarm Scan ....................................................173

13.25 System Message............................................174

13.26 PLC Control ...................................................174

13.26.1 Change Window ...................................... 175

13.26.2 Back light control ..................................... 175

13.26.3 Screen hardcopy .....................................175

13.26.4 Report printout......................................... 175

13.26.5 Back light control (write back).................. 175

13.26.6 Write data to PLC (base window) ............175

13.26.6 General PLC Control ............................... 176

13.26.6 Execute macro program ..........................176

13.27 Event Log....................................................... 176

13.28 Data Transfer .................................................179

Section 4 Macro Reference ......................................... 180

14.1 Overview.............................................................. 180

14.1.1 Triggering a Macro ........................................ 180

14.2 Editing Macros..................................................... 180

14.2.1 Macro Dialog Features.................................. 181

14.2.2 Workspace Macro Editor............................... 181

14.3 Syntax..................................................................182

14.3.1 Constants and Variables ............................... 182

14.3.2 Operators ......................................................184

14.3.3 Reserved Keywords...................................... 185

14.4 Statement Construction .......................................185

14.4.1 Definition Statement...................................... 185

14.4.2 Assignment Statement .................................. 185

14.4.3 Logical Statements........................................185

14.4.4 Reiterative Statements.................................. 186

14.4.5 Optional Keywords........................................ 187

14.5 Macro Construction .............................................187

14.5.1 Local and Global Variables ...........................187

14.5.1 Function Blocks............................................. 188

14.5.2 Built in Function Blocks ................................. 188

14.6 Compile error messages...................................... 190

Error_Number descriptions ...................................... 190

14.7 Sample Macro Code............................................ 192

Index............................................................................ 195

16.13 IDEC OpenNET [PDS] ...................................231

16.14 IIS ESC (INDUSTRIAL INDEXING SYSTEMS)

.................................................................................232

16.15 Jetter Nano.....................................................234

16.16 Keyence KV/Visual KV [PDS].........................235

16.17 KOYO Direct...................................................237

16.18 Lenze .............................................................240

16.19 LG GLOFA Cnet and LG GLOFA Cnet [PDS] 241

16.20 LG Master K10S1...........................................243

16.21 LG Master K60S.............................................245

16.22 LG Master K C-Net.........................................247

16.23 LG Master K300S...........................................248

16.24 Matsushita FP (Aromat) .................................249

16.25 Memory Map Protocol ....................................252

16.26 MITSUBISHI A1S, A2A, A2US, A3N/A1SH....255

16.27 MITSUBISHI AJ71 - AnA/AnU CPU ...............256

16.28 MITSUBISHI FX0n/2/2n COM, FX0n/FX2, FX2n,

FX2n D(bit) [PDS].....................................................258

16.29 MITSUBISHI J2-S100 ....................................261

16.30 MODICON MODBUS RTU / MODBUS RTU(485

2W)...........................................................................263

16.31 MODBUS RTU Extend [PDS].........................273

16.32 MODBUS RTU TCP/IP...................................274

16.33 OMRON / OMRON (485 2W) Host Link .........275

16.34 OMRON CQM1H-CPU61 [PDS].....................278

16.35 OMRON CS/CJ [PDS]....................................280

16.36 SAIA PCD Series [PDS] .................................282

16.37 Samsung SPC-10...........................................284

16.38 Sharp JW Series [PDS] ..................................285

16.39 SIEMENS S7-200...........................................286

16.40 SIEMENS S7/300 MMI ADAPTOR.................287

16.41 Siemens S7/300 PC ADAPTOR.....................288

16.42 SIMATIC TI505...............................................289

16.43 Telemecanique Unitelway ..............................291

16.44 Toshiba T Serial .............................................292

16.46 Yokogawa PLC Series [PDS] .........................297

Section 5 Controller Reference.................................... 199

Contents ......................................................................199

15.0 Communications Overview .................................. 200

15.1 Communications settings ................................. 200

15.2 Master-Slave Configuration.............................. 201

16.0 Driver Specifications............................................ 203

16.1 AB DF1 ............................................................204

16.2 AB DH485 ........................................................ 207

16.3 AB PLC5 .......................................................... 209

16.4 A-B Logix DF1 [PDS] .......................................213

16.5 DELTA DVP .....................................................215

16.6 EMERSON PLC EC20 [PDS]........................... 216

16.7 ENTERTRON MODBUS RTU v1.00 ................ 218

16.8 FACON FB....................................................... 220

16.9 FUJI NB Series [PDS]...................................... 222

16.10 GE Fanuc SNP-X........................................... 223

16.11 HITACHI......................................................... 226

16.12 IDEC Micro

3

................................................... 229

viii

Page 9

Section 1: Installation and Startup Guide

1.0 Getting Started

1.1 The MMI-Touchscreen Series

Purpose of the MMI Series

These are small touch screen interfaces for controllers. They are used to display pictorial information, data

and messages. They are preloaded with a users custom designed project via a Personal Computer. Touch

screen areas may be programmed to modify internal or controller data.

Equipment

Checklist

An MMI system should include:

An MMI Series base unit MMI-730T MMI-850T

MMI-750T MMI-1500T

Older Models

MMI-720 MMI-750

MMI-850 MMI-1050

MMI-1500M MMI-1500S

An interface cable to the controller Refer Section 5 for available cables or

to make one using the cable diagrams

Designed Use

A personal computer with EasyBuilder programming

software installed.

A special PC to MMI programming cable is required MT5_PC cable ships with each unit.

A 24VDC power supply User Provided

Provides a convenient way for a machine operator to:

• View machine status and parameters.

• Change machine status or applicable operating parameters of the machine.

• Maintain the running of the machine.

It also gives enhanced capabilities to the machine through:

• Printer output

• Direct touch screen interface

• Visually displayed prompts

Installation CD provided with each unit.

Software is also available from the KEP

website. (www.kep.com)

1

Page 10

2.0 Installation Instructions

2.1 Mounting Instructions

2.1.1 Location Considerations

Care should be taken when locating equipment behind the unit to ensure that AC power wiring, PLC output modules,

contactors, starters and relays, and any other source of electrical interference are located away from the back of the unit.

Particular note should be taken to the position of variable speed drives and switching power supplies. Their input and load

cables should be screened to a central star earth point.

2.1.2 Making a NEMA-4 Mounting

Panel

Details

The unit can be mounted into panels with a depth of 4”(105mm). It is recommended that the unit

be mounted on the front panel of a steel enclosure, through an appropriate opening*. Allow a

clearance of 1”(25mm) around the sides of the unit for mounting hardware. Allow clearance for

cable connections to the back of the unit. Unit depth may vary according to cable type used.

Typically, plan a depth to accommodate at least 3”(105mm) behind the panel.

Note: Deburr and clean cutout before beginning installation.

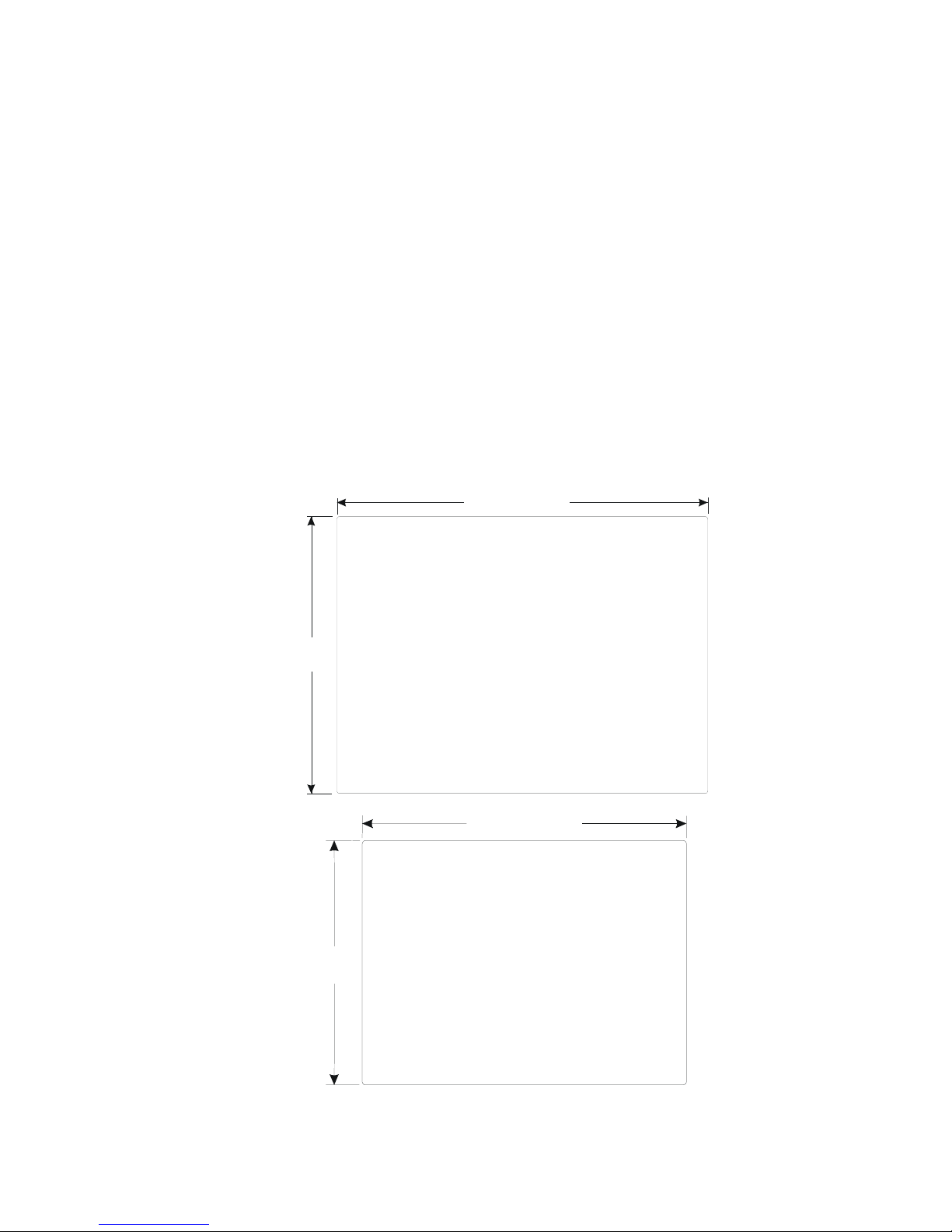

*Cutout dimensions:

11. 89 [ 302 ]

8.86

[225]

MMI-1500M / MMI-1500T

11.89"(302mm) W x 8.86"(225mm) H

6.58

[167]

8.74[222]

MMI-850T

8.75"(222mm) W x 6.57"(167mm) H

2

Page 11

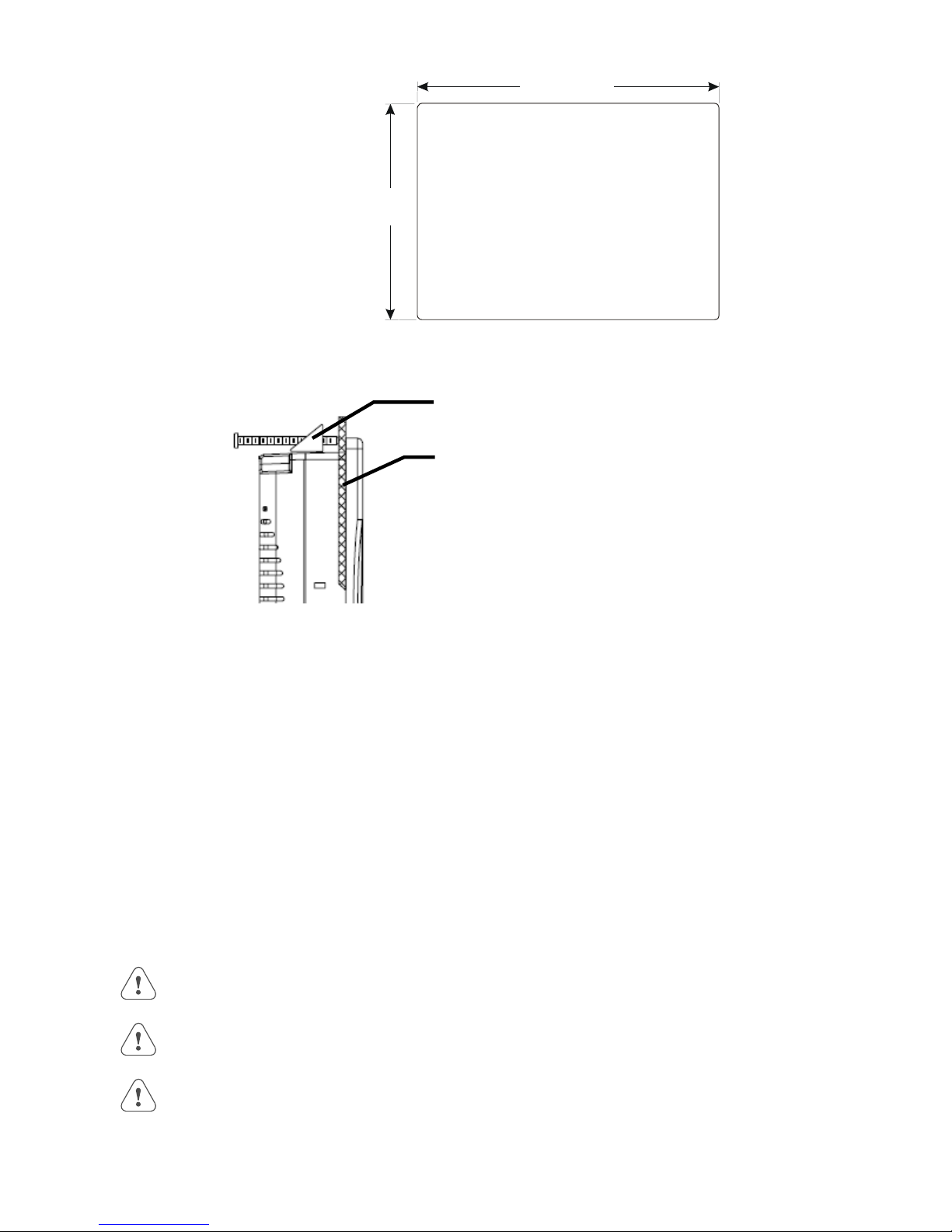

7.56 [192]

NEMA-4

Mounting

Caution!

5.43

[138]

MMI-720 / MMI-730 / MMI-750 Models

7.56"(192mm) W x 5.43"(138mm) H

Put the unit through the panel cut out. Slide the clamps into the 4 or 6 holes provided around the

case. Tighten the clamping screws in an even pattern until the unit is secured in the panel.

Panel Mounting clamp,

4or 6 places

Panel

Do not over tighten mounting clamps!

Note:

Specifications

To seal to NEMA-4 specifications, all supplied mounting clamps must be used and panel must

not flex more than 0.010”.

2.1.3 Environmental Considerations

See Specifications for environmental constraints.

Location

NEMA

Rating

The MMI Series is designed for use in a factory environment. It is designed to operate from 32 to 113 °F

(0 to 45 °C) temperatures, as found in most industrial environments. It may not be suitable for use in

certain outdoor applications. Please consult the factory for advised usage in outdoor applications.

The MMI Series front bezel is NEMA 4 rated. When installed properly in a NEMA 4 panel, the

NEMA 4 rating of the panel is not compromised. This means that fluids do not enter the panel

through the MMI series panel during wash downs.

Do not operate the unit in areas subject to explosion hazards due to flammable gases, vapors or dusts.

The unit should not be installed where fast temperature variations and/or high humidity are present.

This causes condensation of water in the device.

Avoid installing units in environments where severe mechanical vibration or shocks are present.

Vibration endurance: 10 to 25 Hz (X,Y,Z direction 2G 30 minutes)

3

Page 12

2.2 Power Connections

Make sure that all local and national electrical standards are met when the installing the unit. Contact your local authorities to

determine which codes apply.

2.2.1 Power Requirements

Power

Fusing

Requirements

Warning!

High Voltage

Supply Voltage

Condition

Wire Routing

The HMI can be powered by DC power only. The specified voltage range is +22 to 25

Volts DC. This insures compatibility with most controller DC systems.

The power conditioning circuitry inside the unit is accomplished by a switching power

supply. The peak starting current can be as high as 700mA.

It is recommended that all input power lines be protected from incorrect wiring or

product failure by a 2 Amp fuse or a breaker.

If the display does not come on within 2 seconds of power up, remove power. An

internal fuse prevents damage if the polarity of the DC power is incorrect. Check wiring

to insure proper connections and try to power up again.

Connecting high voltages or AC power mains to the DC input makes the unit unusable

and may create a hazard to personnel. Such a failure could result in serious personal

injury, loss of life and or equipment damage.

DC voltage sources should provide proper isolation from main AC power and similar

hazards.

Do not power the HMI and inductive DC loads, or input circuitry to the controller, with

the same power supply.

Note: The 24 VDC output from some controllers may not have enough current to power

the HMI.

Wire lengths should be minimized.

Electrical

Environment

Warning!

Emergency

Stop

Wires should be run in pairs with a neutral or common paired with a hot or signal line.

Always use shielded cable to prevent unwanted electrical interference.

If wiring is to be exposed to lightning or surges, use appropriate surge suppression

devices.

Keep AC, high energy, and rapidly switching DC wiring separate from signal wires by at

least 8 inches. If signal wires must cross AC power, cross at right angles.

Equip ungrounded DC supplies with a resistor and capacitor in parallel to earth ground.

This provides a path for static and high frequency dissipation. Typical values to use are

1MOhm and 4700pF.

The MMI Series has been tested to conform to European CE requirements. This means

that the circuitry is designed to resist the effects of electrical noise. This does not

guarantee noise immunity in severe cases. Proper wire routing and grounding insures

proper operation. The MMI Series is also UL certified.

A Hard-wired EMERGENCY STOP should be fitted in any system using an HMI to

comply with ICS Safety Recommendations.

4

Page 13

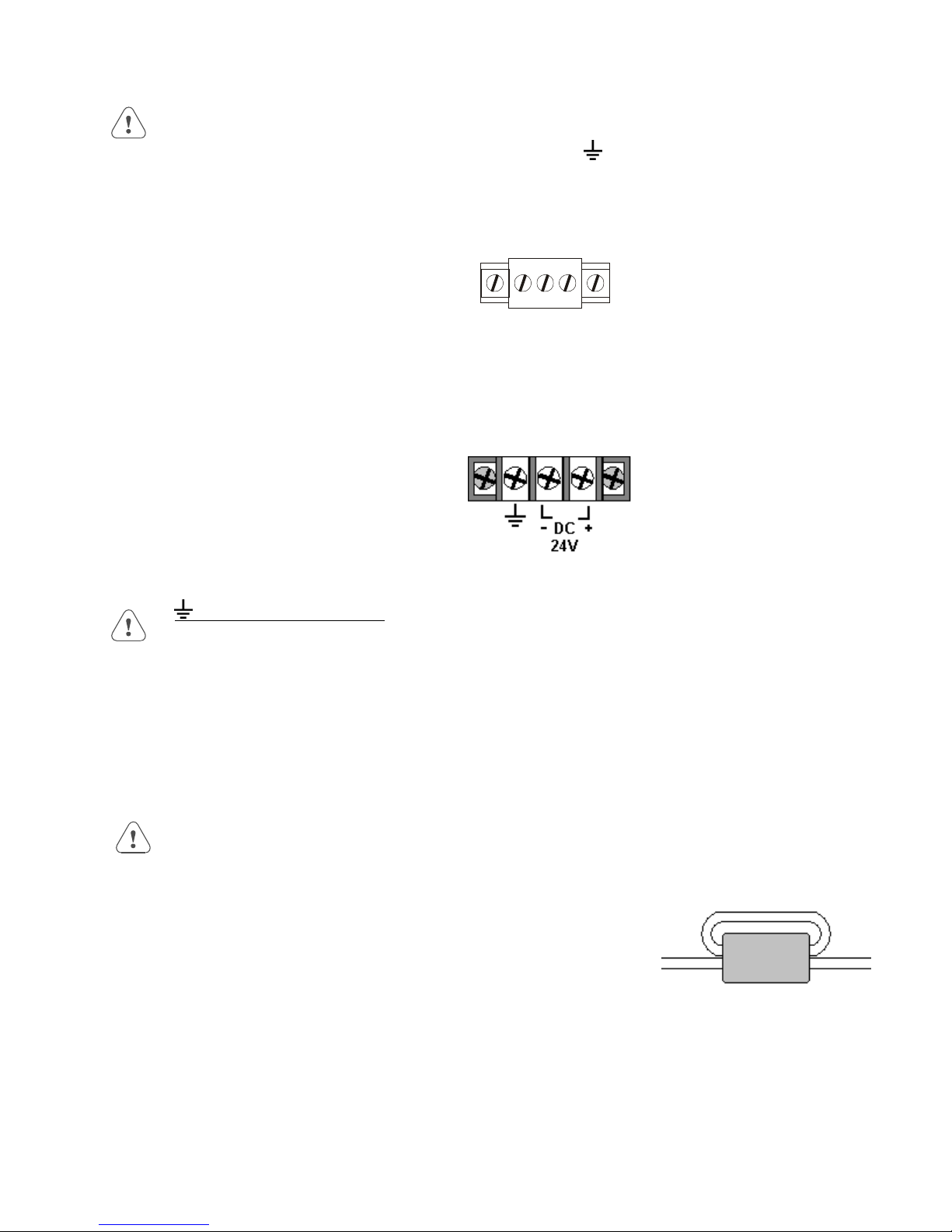

Connection

G

+24 VDC Wiring Diagrams

Use 18 AWG wire to connect positive DC line to the ‘+24V’ (DC+) terminal and the DC ground

to the ‘0V‘ (-DC) terminal. See text below about FG (

Terminal Plug: (MMI-720, 730, 750 Models) To make a connection, strip about 3/8” of

insulation off the end of the wire, and turn the connector screw counterclockwise until the gap

is wide open. Insert the wire all the way in, and turn the screw clockwise until it’s tight.

+24V 0V F

Terminal Block: (MMI-850, 1500 Models) To make a connection, strip about 3/8” of

insulation off the end of the wire, turn the connector screw counterclockwise until the hold

down plate is open wide enough to insert the wire. Insert the stripped portion of the wire

under the plate and turn the screw clockwise until it’s tight.

Chassis Ground).

2.2.2 Grounding Requirements

Chassis ground must be used. DC ground is not directly coupled to Earth ground internally. It

is preferable not to ground DC negative return to chassis ground. Poor site earths can introduce

noise into a system. If necessary, an earth connection should be made from the power supply

return point to the central star earth point.

Ground conductors should be as short and as large in diameter as possible. The conductors must

always be large enough to carry the maximum short circuit current of the path being considered.

Ground conductors should be connected to a tree from a central star earth ground point. This

ensures that no ground conductor carries current from any other branch.

2.2.3 CE Requirements

To make an HMI comply with EMC directives, and to reduce susceptibility to electrical interference, a separate

#14 AWG ground wire should be taken to the chassis ground terminal of the power connector. This ground

connection should be run directly to the central star earth connection point (as recommended in most Installation

Instructions).

Use a ferrite core on the power wiring to reduce radiated emissions from the

DC power lines. It is recommended to use a 140Ohm@100MHz ferrite core

with the DC power lines looped through the core once. Position the ferrite

core less than 1” away from the DC power connection points on the back of

the HMI.

140 Ohm @ 100MHz ferrite core

5

Page 14

2.2.4 Safety Guidelines

This section presents recommended installation practices, and procedures. Since no two applications are identical, these

recommendations should be considered as guidelines.

Hardware

Considerations

Programming

Considerations

ICS 3-304.81 Safety Recommendations:

Consideration should be given to the use of an emergency stop function, which is independent of the programmable

controller.

Where the operator is exposed to the machinery, such as in loading or unloading a machine tool, or where the

machine cycles automatically, consideration should be given to the use of an electromechanical override or other

redundant means, independent of the programmable controller, for starting and interrupting the cycle.

If provision is required for changing programs while the equipment is in operation, consideration should be giv en to the

use of locks or other means of assuring that such changes can be made only by authorized personnel.

These recommendations are intended as safeguards against the failure of critical components and the effects of such

failures or the inadvertent errors that might be introduced if programs are changed while the equipment is in operation. *

WARNING!

The system designer should be aware that devices in Controller systems could fail and thereby

create an unsafe condition. Furthermore, electrical interference in an operator interface, such as an

HMI, can lead to equipment start-up, which could result in property damage and/or physical injury to

the equipment operator.

If you, or your company, use any programmable control systems that require an operator or

attendant, you should be aware that this potential safety hazard exists and take appropriate

precautions. Although the specific design steps depend on your particular application, the following

precautions generally apply to installation of solid-state programmable control devices. In addition,

these precautions conform to the guidelines for installation of Controllers as recommended in the

NEMA ICS 3-304 Control Standards.

To conform with ICS Safety Recommendations, checks should be placed in the controller to ensure

that all writable registers that control critical parts of plant or machinery have limit checks built into the

program, with an out-of-limit safe shut down procedure to ensure safety of personnel.

* The ICS 3-304.81 Safety Recommendations are reproduced by permission of the National Electrical Manufacturers

Association from NEMA ICS 3-304

2.3 CE Requirements

2.3.1 EU directives that apply to MMI Series

• EMC Directive (89/336/EEC, 92/31/EEC, 93/68/EEC) electromagnetic emissions and immunity

• Machinery Directive (89/392/EEC, 91/368/EEC, 93/44/EEC, 93/ 68/EEC) machine safety

MMI products are CE-marked to indicate compliance with the EMC Directive. Declarations of Conformity that

specify the directive(s) and the catalog numbers of the products covered are available from Kessler Ellis Products.

6

Page 15

The MMI Series has been designed to operate satisfactorily in electromagnetic noise (immunity) and without emitting high

levels of electrical noise into the environment (emission). The units are designed to meet European Community standards

when installed per the wiring instructions in this manual.

Compatibility Standards

The MMI has been designed to meet electromagnetic compatibility for industrial environments.

Standard Description

CISPR (EN 55011) Group 1, Class A Radiated Emissions levels

EN50081-2 Generic emission standard, industrial environment (Also US FCC Class A)

EN50082-2 Generic immunity standard, industrial environment

2.3.2 Guide Lines for EU Installations

• Be aware that wiring leaving the cabinet where the unit is installed may be exposed to interference sources.

• The installation practices in the individual product installation manuals of other components in the system must also be

followed.

• Locally applicable grounding safety regulations and machinery directives should be followed for providing a protective

ground to earth. The EMC ground must be a low impedance, low inductance path to the machine chassis ground.

• Power supply to the unit must be through an IEC-rated isolation transformer.

• The Power supply to the controller must be controlled to ensure that it does not exceed over voltage category II per

EN60204-1 (IEC 240).

• Other requirements of the Machinery Directive involving displays, languages, instructions, Emergency Stop functions,

machine operation, protective guards and interlocks are the responsibility of the machine manufacturer.

• Use a ferrite core on the power wiring to reduce radiated emissions from the DC power lines. It is recommended to

use a 140Ohm@100MHz ferrite core with the DC power lines looped through the core once. Position the ferrite core

less than 1” away from the DC power connection points on the back of the UNIT.

2.3.3 Safety Guide Lines for EU Installations

• Only qualified personnel should be allowed to specify, apply, install, operate, maintain or perform any other function

related to HMI products. Qualified persons are defined as follows:

System application and design engineers who are familiar with the safety concepts of automation equipment.

Installation, start-up, and service personnel who are trained to install and maintain automation equipment.

Operating personnel trained to operate automation equipment and trained on the specific safety issues and

requirements of the particular equipment.

• Make sure that the voltage range for the equipment is correct before switching on the equipment.

• Emergency-tripping devices in accordance with EN60204/IEC204 must be effective in all operating modes of the

automation equipment. Resetting the emergency off device must not result in any uncontrolled or undefined restart of

the equipment.

• Automation equipment and its operating elements must be installed so that unintentional operation is prevented.

• Make sure that operating sequences, interrupted by a voltage dip or power supply failure, resume proper operation

when the power supply is restored. If necessary, the equipment must be forced into the “emergency off” state.

• Install the power supply and signal cables so that inductive and capacitive interference voltages do not affect

automation functions.

7

Page 16

2.4 Communications Connections

The ports as you look at the back of the case, are the ports for connecting to a printer, PLC or some external device

(Controller Connectors).

Printer Port

(25p D-Female)

(Not Available on MMI-720, 730

and 750 models)

PLC [RS-232] Port

(9 pin D-Female)

2.4.1 Connection to an External Device

Cable

Requirements

Warning

Different cables are required for various devices. See Controller Reference Section for cable details.

The KEP part numbers have the SMIC prefix. Refer to a KEP catalog or data sheet for a complete

listing of MMI compatible devices.

These cables can be obtained from the same distributor where you purchased the MMI.

Communications problems cause the display to show PLC no response... until communications

can be established. During this time, the controller cannot be affected by the HMI. The COM light

on the front of the HMI turns on with each communication and should appear as if always on or

slightly flickering when communications are good.

Restrict cable length to avoid communications problems due to weak signals.

Recommended distances:

RS232:............................................................................................ less than 50’ (15m)

RS485/422: ..................................................................................... less than 500’ (150m)

Ethernet: ......................................................................................... less than 328’ (100m)

Shielded cable must be used for long lengths or cables run in an electrically noisy environment.

Use twisted pair cables for all Ethernet connections.

PC [RS-232] &

PLC [RS-485] Port

(9 pin D-Male)

Ethernet Port

(RJ-45 Male)

(Not Available on all

models)

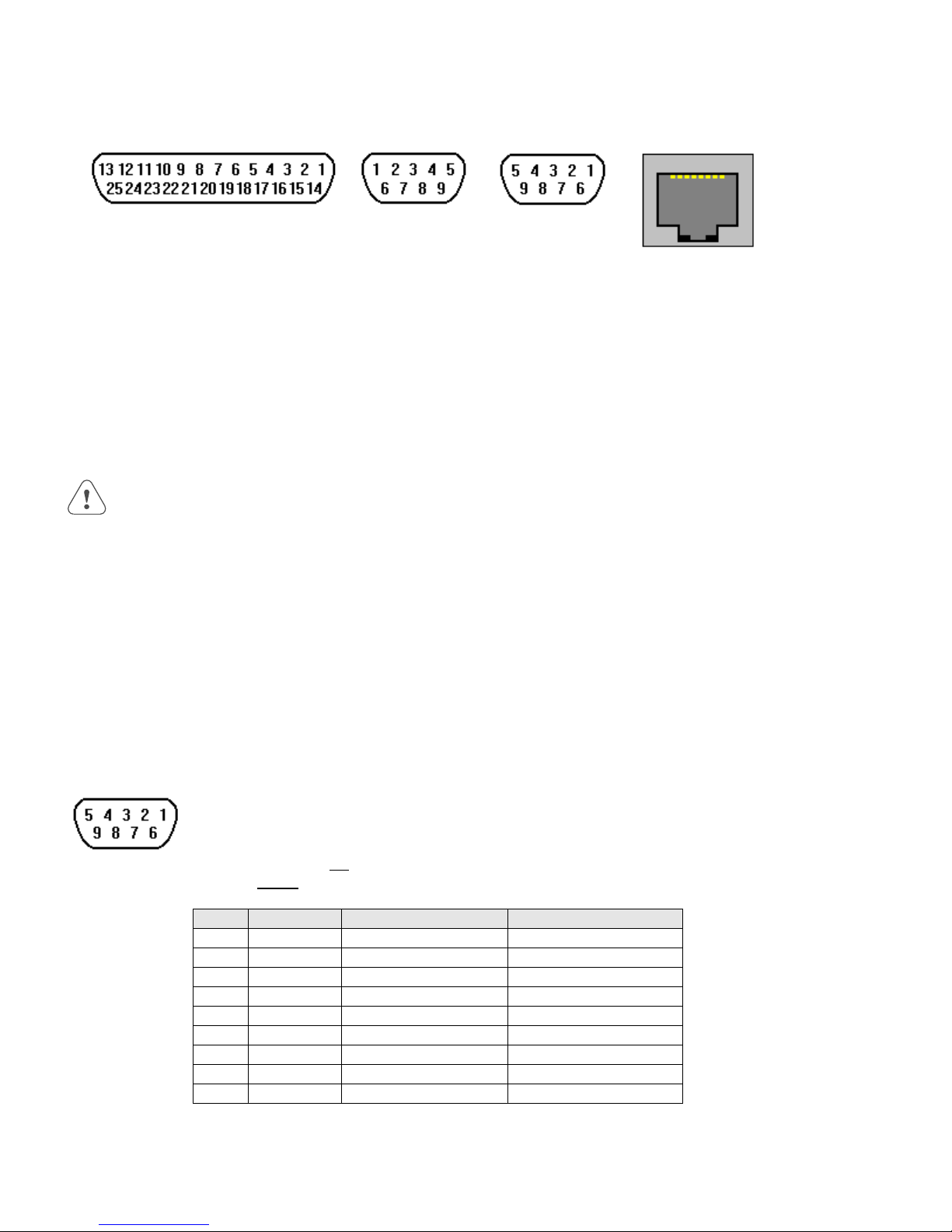

Pin Designations

PLC [RS-232]

Do not run cables next to AC power lines or near sources of electrical noise.

Be sure that the cable ends have been inserted all of the way into mating connectors and are secure.

Pin assignment of the 9 Pin, Female, D-SUB, PLC [RS-232] Port. This port is used for connecting the

HMI to a controller or Master HMI unit. The Auxiliary (AUX) RS232 port is also accessed through this

connector. Both PLC and AUX ports share the common ground.

Note: This port is not used for programming the HMI or for printing functions.

Do not plug the MT5_PC’s PLC cable end into this port.

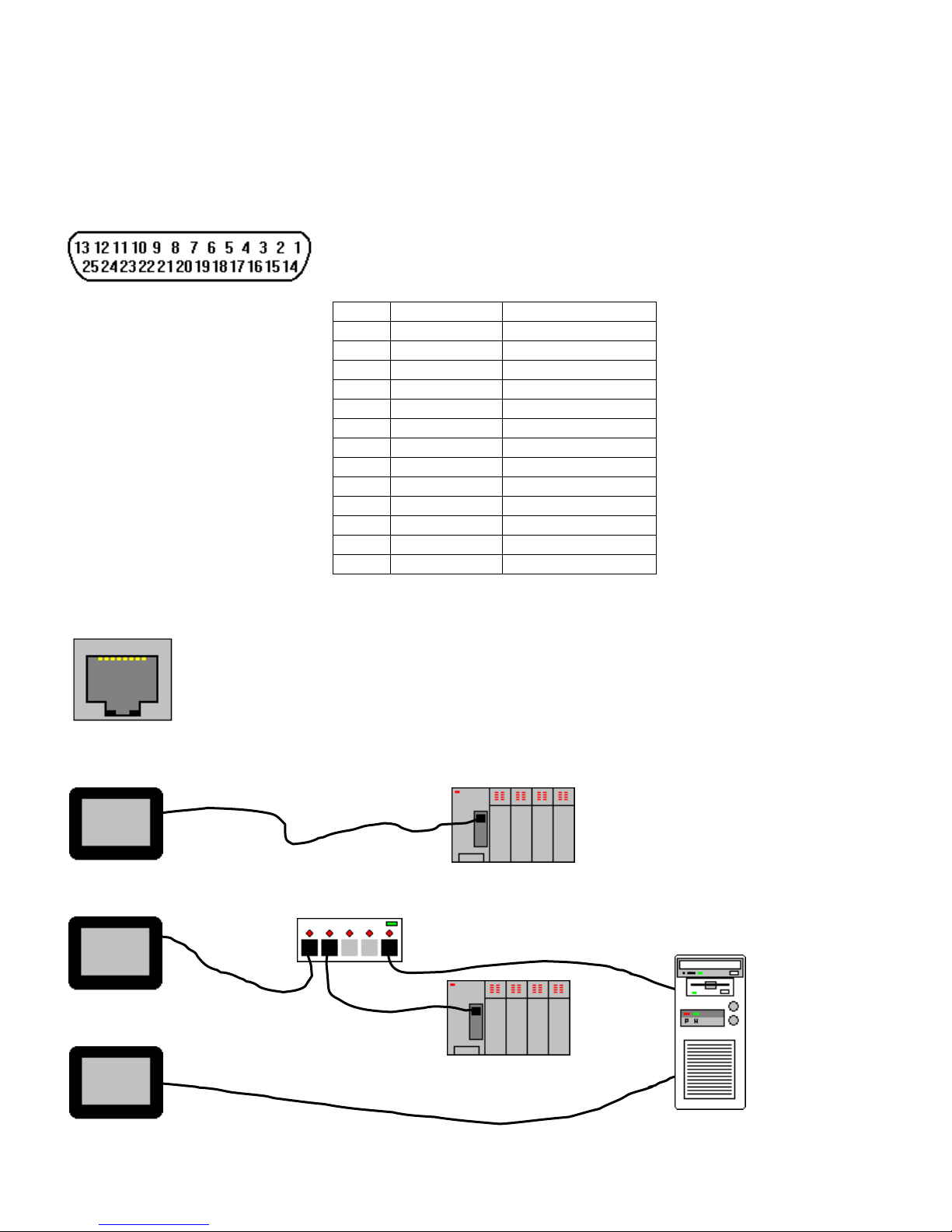

Pin # Symbol PLC[RS232] AUX[RS232]

1 AUX TxD Transmitted Data

2 PLC TxD Transmitted Data

3 PLC RxD Received Data

4 Not used Received Data

5 GND Signal Ground Signal Ground

6AUX RxD

7 PLC CTS Clear to send input

8 PLC RTS Ready to send output

9 Not used

8

Page 17

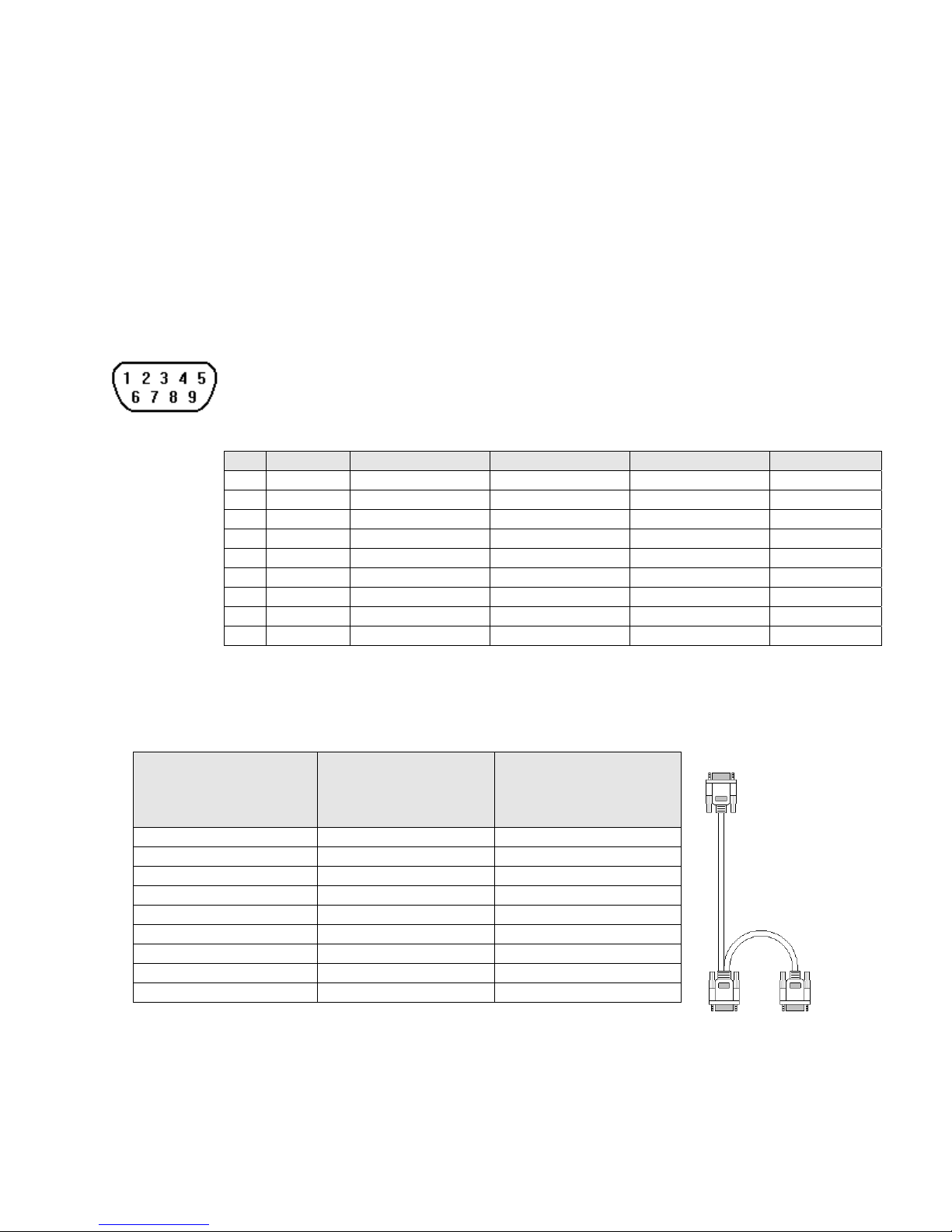

2.4.2 Connection to a Personal Computer

The 9 Pin, Female, D-SUB, PC [RS-232] & PLC [RS-485] Port on the back of the unit is the programming port (PC

Connector) and RS485/422 communications port for connecting to a controller. The Auxiliary (AUX) RS485 port is also

accessed through this connector.

Connection

Port Activation

Pin Designations

PC [RS-232] &

PLC [RS-485]

This port can be attached to a Computer via a special DB9 Female to DB9 Female cable provided

with the unit. (KEP P/N: MT5_PC)

This port is activated automatically by the PC during: On line simulation, Download and Upload

activities.

The Programmer Port cannot simulate, download or upload to the unit while it is on line with the

controller at the same time. The unit must be put into “RDS” mode with the EasyManager applet

first.

Pin assignment of the 9 Pin, Male, D-SUB PC [RS-232] & PLC [RS-485] Port

Pin # Symbol PLC[RS485] 2 Wire PLC[RS485] 4 Wire AUX[RS485] 2 Wire PC[RS232]

1 PLC RxD- Transmit/Receive - RS485 Receive

2 PLC RxD+ Transmit/Receive + RS485 Receive

3 PLC TxD- RS485 Transmit

4 PLC TxD+ RS485 Transmit

5 GND Signal Ground Signal Ground Signal Ground Signal Ground

6 AUX Data + Transmit/Receive +

7PC TxD RS232 Transmit

8 PC RxD RS232 Receive

9 AUX Data - Transmit/Receive -

HMI to PC, MT5_PC Cable Configuration

Connect to

Personal Computer (PC)

RS232 Serial Port

DB9 Female

1 Not used 1 RX- Æ 1 RX7 Not used 2 RX+ Æ 2 RX+

8 Not used 3 TX- Æ 3 TX4 Not used 4 TX+ Æ 4 TX+

5 GND Æ 5 GND Æ 5 GND

6 Not used 6 AUX Data + 6 AUX RS485+

2 TxD Æ 7 TxD 7 Not used

3 RxD Æ 8 RxD 8 Not used

9 Not used 9 AUX Data - 9 AUX RS485-

Connect to

HMI (HMI)

RS232/485 [PLC]

DB9 Female

Connect to

Controller

RS485 Port

DB9 Male

9

PC

HMI

PLC

RS485

Page 18

2.4.3 Connection to a Printer

The printer port on the back of the unit is a Parallel printer port and is compatible with most printers that accept parallel

connectors.

Print Out

Pin Designations

The MMI-1500 and 850 models have printout capabilities. The printer port

transmits data when a printable object is activated.

Pin assignment of the 25 Pin, D-SUB, Parallel Printer Port.

Pin # Symbol Function

1 STB Output

2 DATA0 Output

3 DATA1 Output

4 DATA2 Output

5 DATA3 Output

6 DATA4 Output

7 DATA5 Output

8 DATA6 Output

9 DATA7 Output

11 BUSY Input

15 ERROR Input

16 INIT Output

17-25 GND Signal Ground

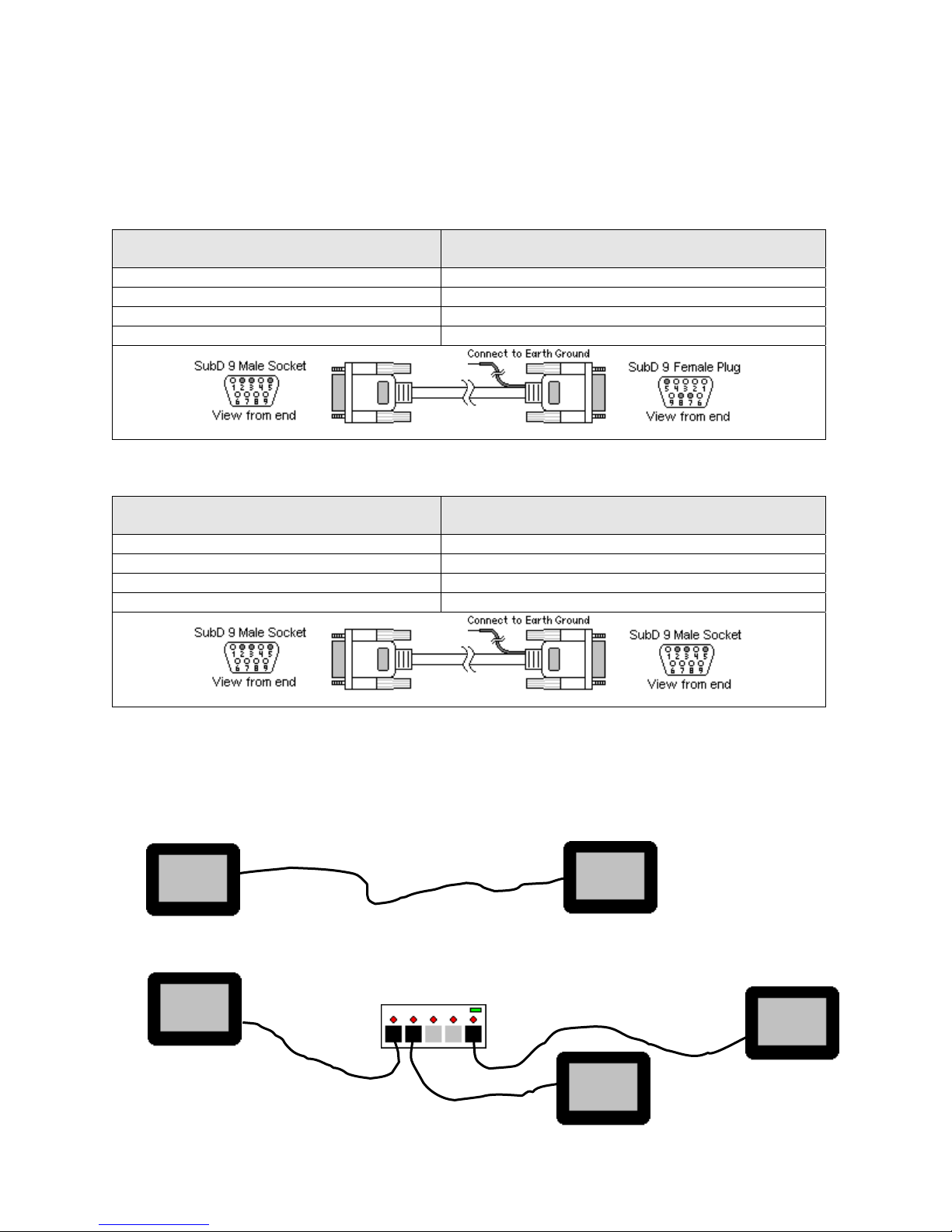

2.4.4 Ethernet Connections

Units equipped with the Ethernet port can be connected to Ethernet devices using standard 10T CAT5

Ethernet cables. Routing may pass through Hubs and Servers as needed to connect to the PLC.

The Ethernet port can also be used for HMI Master/Slave communications using the same type of

configurations.

Connect directly to PLC using 10T Crossover cable

Connect through Hub to PLC

Connecting through Server to PLC or Master

Hub

PLC

Server

PLC

10

Page 19

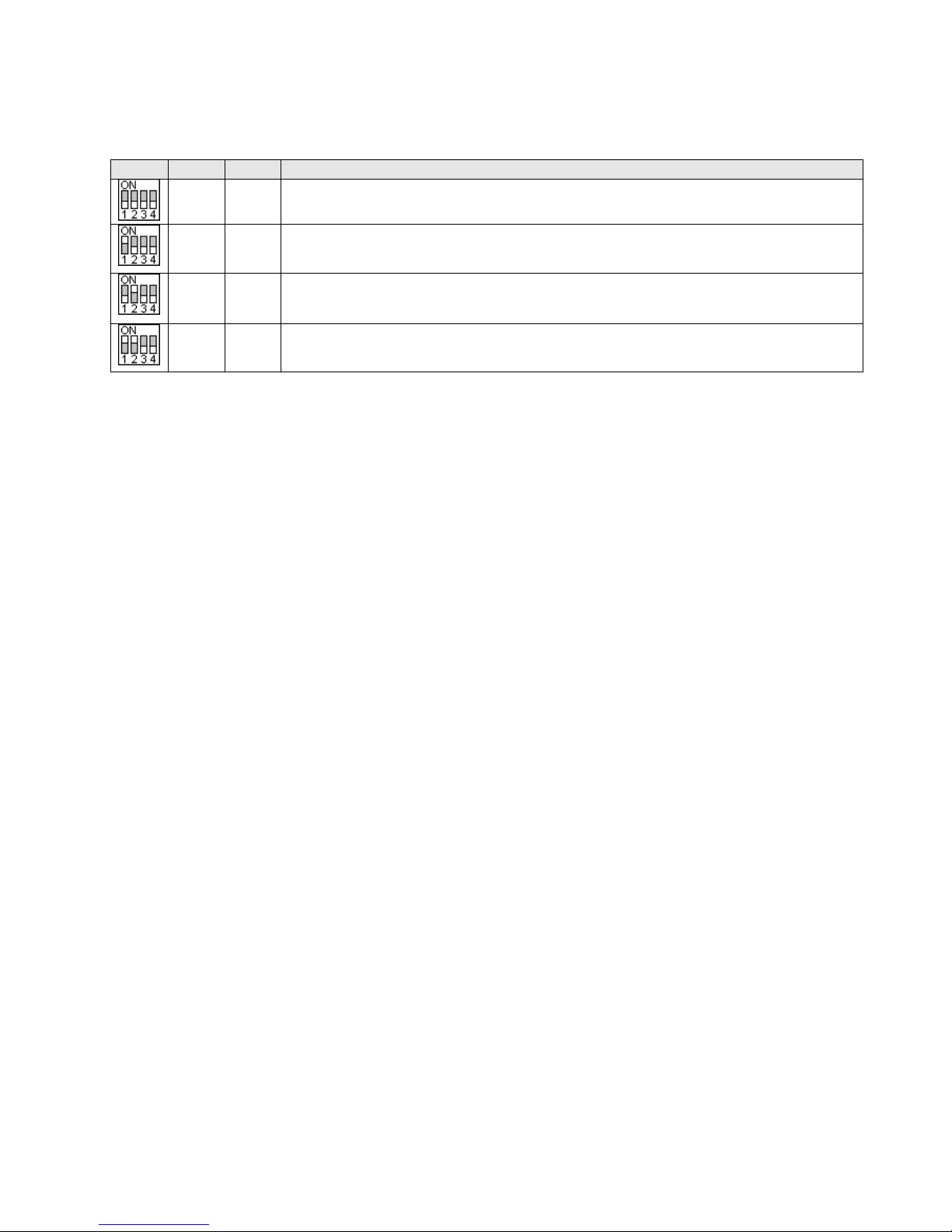

2.4.5 HMI to HMI Connections

The HMI supports a master - slave communications. One HMI is connected directly to the PLC and configured as the

Master. All the other HMIs are connected in series to it and are configured as Slaves. In theory there is no limitation to the

number of HMIs on a chain, however response time gradually decreases when more than three HMIs are linked together.

The HMI are configured with the EasyBuilder software to be the Master or a Slave.

Wiring between two HMIs

Case 1: Slave to Master, connecting PLC[RS232] directly to PC[RS-232]/PLC[RS485] combination port.

Connect to SLAVE HMI PLC[RS-232] port

Cable has D-SUB Male end

2 TxD Æ 8 RxD

3 RxD Æ 7 TxD

5 GND Æ 5 GND

Case 2: Slave to Master, connecting PLC[RS232] to PC side of split download cable (MT5_PC) with use of Male to Male Null

Modem cable.

Connect to SLAVE HMI PLC[RS-232] port

Cable has D-SUB Male end

2 TxD Æ 3 RxD

3 RxD Æ 2 TxD

5 GND Æ 5 GND

Connect to MASTER HMI PC[RS-232] port

Cable has D-SUB Female end

Shield Æ Earth Ground

Connect to MT5_PC to MASTER HMI PC[RS-232] port

Cable has D-SUB Male end

Shield Æ Earth Ground

Case 3: Ethernet Connections: Units equipped with the Ethernet port can be connected via Ethernet to a Master and Slaves

using standard 10T Ethernet cables. Slave to Master, connect the Ethernet ports with a standard (Category 5) Ethernet 10T

crossover cable (RJ-45 to RJ45). On the other hand, use standard cables with routing passing through Hubs and Servers as

needed.

Connecting a Master directly to a Slave using 10T Crossover cable

Master

Connecting a Master through a Hub to Slaves

Hub

Slave

11

Slave

Master

Slave

Page 20

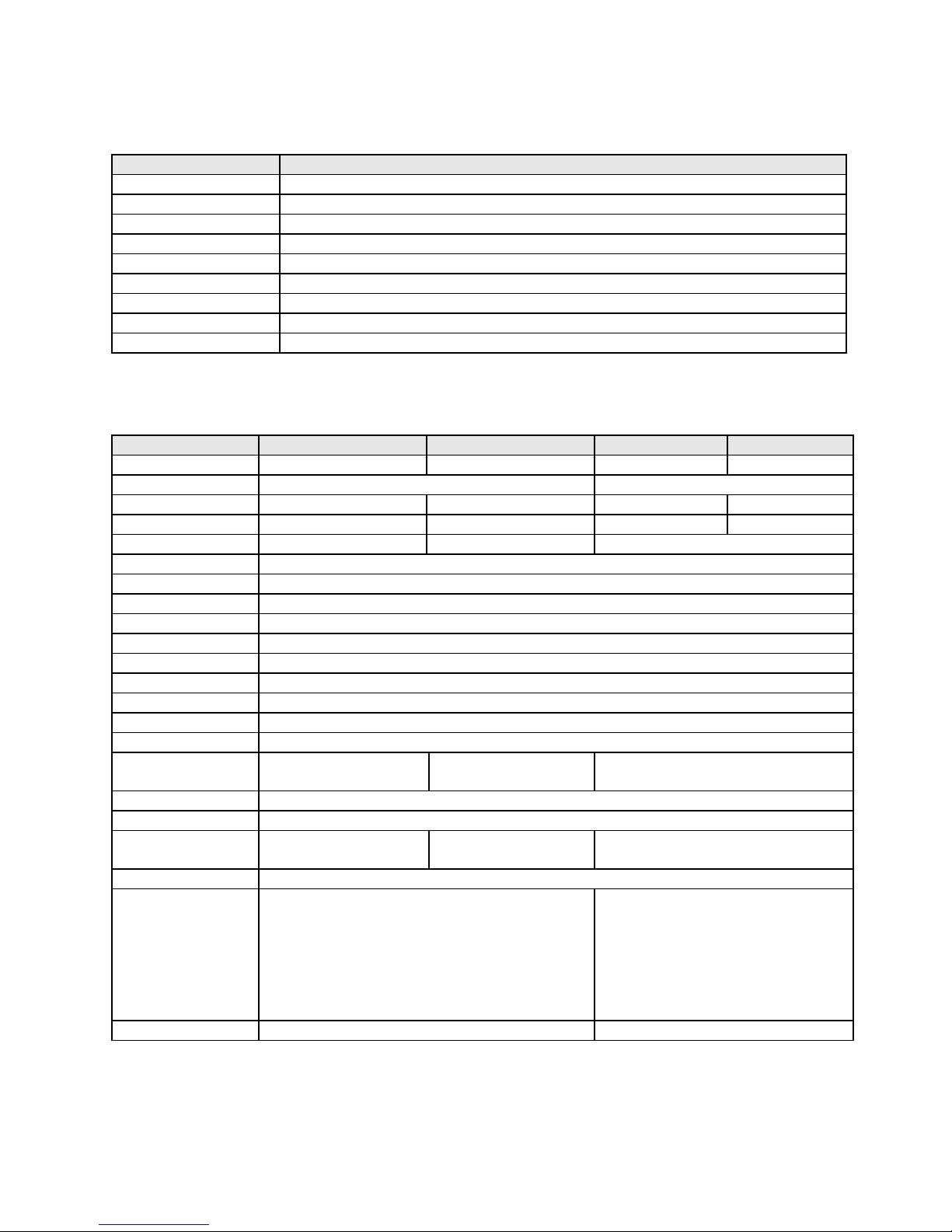

2.5 Dip Switch Settings

All dipswitches should normally be in the OFF (down) position. Dipswitches 1 and 2 are used to perform testing and

recovery functions. Dip Switch 3 and 4 are not used and should be left in the off position.

SW1 SW2 Mode

OFF OFF Application mode (On line operations, use EasyManager or EasyBuilder to change modes)

ON OFF Force to Touch Adjust mode (Used for touchscreen calibration)

OFF ON Force to RDS mode (Remote Debug and Simulation, used to recover from invalid states

due to corrupt downloads. Refer to section on troubleshooting.)

ON ON Force to Touch Screen Test mode (Used to check accuracy of Touch Screen)

Note: It is normally not necessary to change dipswitches to put the HMI into programming (RDS) mode.

2.6 HMI Indicator Lights

PWR – Indicates if power has been applied to the unit. If this indicator fails to light, check power, check polarity

of wiring and check fusing. If all conditions are correct, contact the factory for help.

CPU – Indicates that the CPU is operating properly. If this indicator fails to light, please contact factory.

COM – Lights when a serial transmission is sent or received. This indicator appears to flicker when trying to

establish communications.

2.7 Other Hardware Considerations

2.7.1 Touchscreen Calibration

Normally the touchscreen is calibrated at the factory for proper functionality. If the touchscreen cannot be

calibrated, please contact the factory for assistance.

Run the EasyManager Utility to get to the Touch screen calibration (Touch Adjust) mode.

Click Jump to Touch Adjust to put the unit in this mode. This is used to calibrate the touch screen.

On the screen of the HMI unit:

Touch the crosshairs as displayed in sequence on the screen.

Touch anywhere outside to the rectangles to move the crosshairs to that location.

Touch inside the left rectangle to repeat the calibration process.

Touch inside the right rectangle to accept and end the calibration procedure.

Touch the screen again to jump to application mode.

2.7.2 CCFL and Battery Replacement

It is recommended that the factory replacement of these components in case of their failure. Use our toll free

number to contact KEP.

Telephone: 1-800-631-2165.

If the product must be returned, be sure to call KEP and get a Return Goods Authorization

(RGA) number first.

Units should be returned in their original packaging container, otherwise, any suitable rigid

container can be used as a substitute. Use appropriate packing material. Damage due to

shipment is not covered by the warranty. Be sure to include a description of the problem and

contact details for our repair department.

All returns are evaluated for proper operation. During evaluation, customer projects are not

retained in the units. If you need your project retained, please indicate this in the documentation

included with the unit.

12

Page 21

3.0 Specifications

3.1 General Specifications

Item

Input power 21-25 VDC, 500 mA @ 24VDC

CE Complies with EN50081-2 and EN50082-2 standards

EMI Complies with FCC Class A (Ferrite core required if using unshielded power supply wires)

Isolation resistance Exceeds 50 MΩ at 500VDC

Vibration endurance 10 to 25 Hz (X,Y,Z direction 2G 30 minutes)

Protection structure NEMA 4 / IP65 front panel (when mounted with gasket seal)

Operating Temperature

Operation humidity 10 to 90% RH Non Condensing

Enclosure Plastic: Polybutylene Terephthalate (PBT) and Polycarbonate(PC)

Specification

32 to 113

°F (0 to 45 °C)

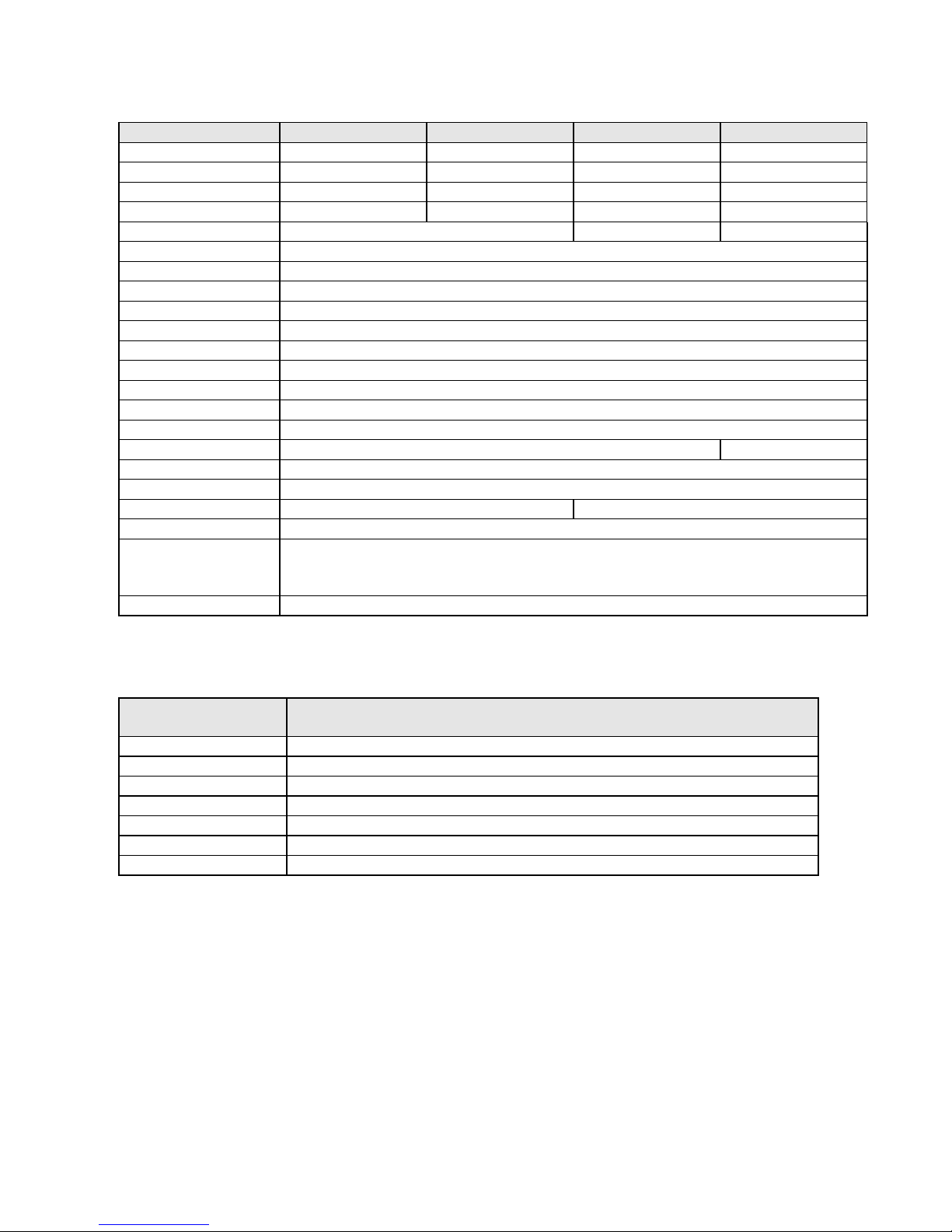

3.2 Hardware Specification 1500, 850 Models

Item 1500T 1500M 850T 850

LCD Display 10.4” TFT, 256 color 10.4” STN, 4 color gray 7.7” TFT, 256 color 7.7” STN, 256 color

Display area (mm) 215(W) x 162(H) 162(W) x 123(H)

Contrast Ratio 150:1 18:1 250:1 30:1

Brightness cd/m2 300 100 400 150

Back light CCFLx2(MTBF 25,000 hr) CCFLx1(MTBF15,000 hr) CCFLx1 (MTBF 50,000 hr)

Resolution pixels 640(W) x 480(H)

Pixel size 0.33(W) x 0.33 (H) mm

Touch panel 4 wire resistive type

Touch granularity 2mm grid

Touch Feedback Beeper and or Graphic Indicator

Surface hardness 4H

Processor 32 bit RISC CPU 200 MHz

Flash ROM Memory 2 MB Standard, 4MB with Ethernet option

System Memory 4MB DRAM

Battery Held Memory 128kB with Y2K compliant Real Time Clock/Calendar

Compact Flash Slot Used for Project

transfers only

Serial ports 1 RS-232 (controller port) and 1 RS-232 / RS-485 (PC & controller port)

Parallel port Standard parallel printer port

Ethernet Port RJ-45 8 wire

(10 BaseT) TCP/IP

System diagnostic Watch dog timer, power failure detection

Dimensions

Bezel

H x W x D inches

(H x W x D) mm

Cutout

H x W inches

(H x W) mm

Weight Approx. 2.0 kg Approx. 1.2 kg

Bezel:

9.37 x 12.40 x 2.44

(238 x 315 x 62 )

Cutout:

8.86 x 11.89

(225 x 302 )

Not Available Used for Project transfers only

Not Available RJ-45 8 wire (10 BaseT) TCP/IP

Bezel:

6.93 x 9.09 x 2.16

(176 x 231 x 55)

Cutout:

6.57 x 8.75

(167 x 222 )

13

Page 22

3.3 Hardware Specification 750, 720 Models

Item 750T / 750T-HB 750 730T 720

LCD Display 5.7” TFT 256 color 5.7” STN 256 color 5.7” TFT 256 color 5.7” STN blue mode

Contrast Ratio 60:1 30:1 150:1 15:1

Brightness cd/m2 500 150 500 60

Back light CCFLx1 MTBF 30,000 hr MTBF 30,000 hr MTBF 30,000 hr MTBF 50,000 hr

Resolution pixels 320(W) x 240(H) 320(W) x 234(H) 320(W) x 240(H)

Pixel size 0.33(W) x 0.33 (H) mm

Display area (mm) 120(W) x 90(H)

Touch panel 4 wire resistive type

Touch granularity 1.5mm grid

Touch Feedback Beeper and or Graphic Indicator

Surface hardness 4H

Processor 32 bit RISC CPU 200 MHz

Flash Memory 1 MB Standard, 2MB with Ethernet Option

System Memory 4MB DRAM

Battery Held Memory 128kB with Y2K compliant Real Time Clock/Calendar

Compact Flash Slot Used for Project transfers only Not Available

Serial ports 1 RS-232 (controller port) and 1 RS-232 / RS-485 (PC & controller port)

Parallel Printer port No printer port available

Ethernet Port RJ-45 8 wire (10 BaseT) TCP/IP Not Available

System diagnostic Watch dog timer, power failure detection

Dimensions

H x W x D inches

(H x W x D) mm

Weight Approx. 0.84 kg

Bezel: 5.90 x 8.00 x 2.95 (150 x 204 x 75 )

Cutout: 5.43 x 7.56 (138 x 192 )

3.3 Functional Specification

Screen editor EasyBuilder Version 2.6.2 or later

(to be run under Windows 98 / NT / 2000 / ME / XP*)

No. of window 1 ~ 1999, limited by memory

No. of object Up to 500 per window, limited by memory

Text strings limited only by memory

Bitmap graphics 256 KB per graphic, limited by memory

Support PLC Most popular PLC’s

Support Printer EPSON ESC/P2, HP PCL/(Simple page mode) or compatible

Macro scripts Up to 256 Macro scripts per project, limited by memory

Computer requirements include at least a Pentium 90Mhz PC, 16MB RAM, 10MB available hard disk space,

minimum 800x600 resolution VGA, and one available RS-232 serial port.

14

Page 23

4.0 Trouble Shooting

4.1 Power Problems

Problems on power up: Unit does not light or unit lights but does not display any windows.

1. Check wiring for proper polarity.

2. Check power Supply for proper Voltage and Current capacity.

3. Check fuse.

Problems during operation: Faulty unit operation may be due to problems with power quality. The HMI has been

designed to work in environments where electrical noise is present. However, extreme electrical noise still causes

problems. Make sure that the system is properly earth grounded.

4.2 Communications Problems

Sometimes communications fail. When communications fail, the unit automatically tries to establish the

communications link again. During the time the unit is establishing communications, the touchscreen of the unit does

not respond. Function key operations are interrupted. The implication is that the unit should not be used for

Emergency Stop applications. A loss of communications can happen at any time. Using the function keys on the unit

for critical operations can lead to a potential disaster. It is good programming practice to allow for safe operation in

case of interface failure.

There are various reasons why this happens;

Improper programming: If the MMI window is programmed to access data from an invalid register or bit address

for the PLC, the unit receives an error message from the PLC. The unit interprets this as a loss in communications.

Be sure that all data points being displayed are valid for the PLC that is connected.

Loose or incorrect cables: Make sure that all cables are secured and configured properly for the PLC.

Time outs: Make sure that the PLC is responding to requests from the HMI in a timely manner.

Power loss: Make sure the PLC has power and is running properly.

Electrical noise: Faulty unit operation may be due to problems with power quality. The HMI has been designed to

work in environments where electrical noise is present. However, extreme electrical noise still causes problems.

Make sure that the system is properly earth grounded.

The use of proper grounding techniques insures reliable communications. Make sure the controller and the HMI are

connected to good earth ground sites. This allows EMI (Electro-Magnetic Interference, commonly called electrical

noise) to be channeled to ground where it can no longer disrupt electrical operations. Be sure to route

communications cables in separate bundles and locations from AC power and control wiring. Do not run

communications cables near solenoid and relay coils or AC and DC drive controllers. Care should also be taken to

locate the HMI itself away from sources of EMI.

15

Page 24

4.3 Commonly Asked Questions

Q. Can I have multiple MMIs connected to one Controller?

A. The ability to connect more than one HMI to a controller is accomplished through an HMI to HMI link. This is not

done through any PLC protocol. It is done through the master-slave protocol of the MMI.

Q. How do I call up windows with my PLC?

A. Use the PLC Control part configured as “Change window” to call up windows by word value. Additionally, Direct

and Indirect Window parts can be used to bring up windows.

Q. Do I need to change any jumpers to go from one Controller type to another?

A. No, the driver that is downloaded into the unit at programming time determines the Controller type. The dip

switches on the back of the unit should all be in the OFF position.

Q. Is there any way to completely erase the HMI user memory?

A. No, the HMI memory is initialized automatically before every download cycle.

Q. How Do I change the Battery?

A. Battery replacement requires disassembly of the unit in an ESD controlled environment. Battery life expectancy

is greater than 5 years.

The MMI-7XX takes one coin type of CR2032 lithium battery to backup the recipe data and keep the RTC

running. Battery specification: CR2032 3V lithium battery.

Steps for battery replacement:

1. Use EasyManager to backup the retentive memory data.

2. Turn off the HMI and remove its rear cover.

3. Remove the battery from the socket.

4. Insert a new battery into the socket.

5. Put on the rear cover.

6. Reset the RTC time and download the retentive memory data.

The MMI-850 and 1500x products have the battery soldered to the main board. We recommend that these

units be sent back to the factory for battery replacement.

Q. Can I change the Backlighting bulbs in the field?

A. We recommend that the unit be sent back to the factory for bulb replacement. Backlight bulb life expectancy is

greater than 5 years even if running 24 hours a day. Use the Backlight auto shutdown to conserve backlight bulb life.

Q. Why am I getting slow updates on my windows?

A. PLC communication speed controls the update speed. Try using a higher baudrate and adjusting the Block pack

settings. If an overloaded window is causing a slow update, we suggest changing the window design.

NOTE: EasyWindow has a tool called “SystemResource”. It displays object queue item numbers. Use this to help

detect communication problems. This problem might not show up in Offline Simulation because the PC may have

more CPU speed, more caches, and more VGA speed.

4.4 Hardware Problems

4.4.1 Black Screen after download

Symptom: After project downloaded to a new touchscreen a blank black screen is displayed.

Cause: Using the older versions of EasyBuilder to download to newer model touchscreens.

Any version prior to version 2.0.2 downloading to Hardware version 3

Any version prior to version 2.5.1 downloading to Hardware version 4

Any version prior to version 2.6.0 downloading to Hardware version 4.5

Fix: Install new version of EasyBuilder on your computer.

Set DIP Switch 2 ON in the HMI and reset Unit.

Load your project using new EasyBuilder.

Set DIP Switch 2 OFF and reset Unit.

Project should now operate normally.

16

Page 25

4.5 Repairs and Returns

An MMI is designed to provide years of trouble free service. An MMI under goes a full functional test before

shipment.

The MMI warranty is for one year under normal use.

The MMI does not require any “Routine Maintenance” by the user. If a problem should occur, and all troubleshooting

procedures have been exhausted, contact your local representative or distributor.

Use our toll free number to contact KEP if persistent problems are encountered.

Telephone: 1-800-631-2165.

If the product must be returned for any reason, be sure to call KEP and get a Return Goods Authorization

(RGA) number first.

Units should be returned in their original packaging container, otherwise, any suitable rigid container can be

used as a substitute. Use appropriate packing material. Damage due to shipment is not covered by the

warranty. Be sure to include a description of the problem and contact details for our repair department.

All returns are evaluated for proper operation. During evaluation, customer projects are not retained in the

units. If you need your project retained, please indicate this in the documentation included with the unit.

Products passing normal QC tests are returned to the customer and an evaluation charge is incurred.

If the problem is verified and the unit is in warranty, KEP will repair or replace the unit.

5.0 Quick Startup Guide

5.1 Connections

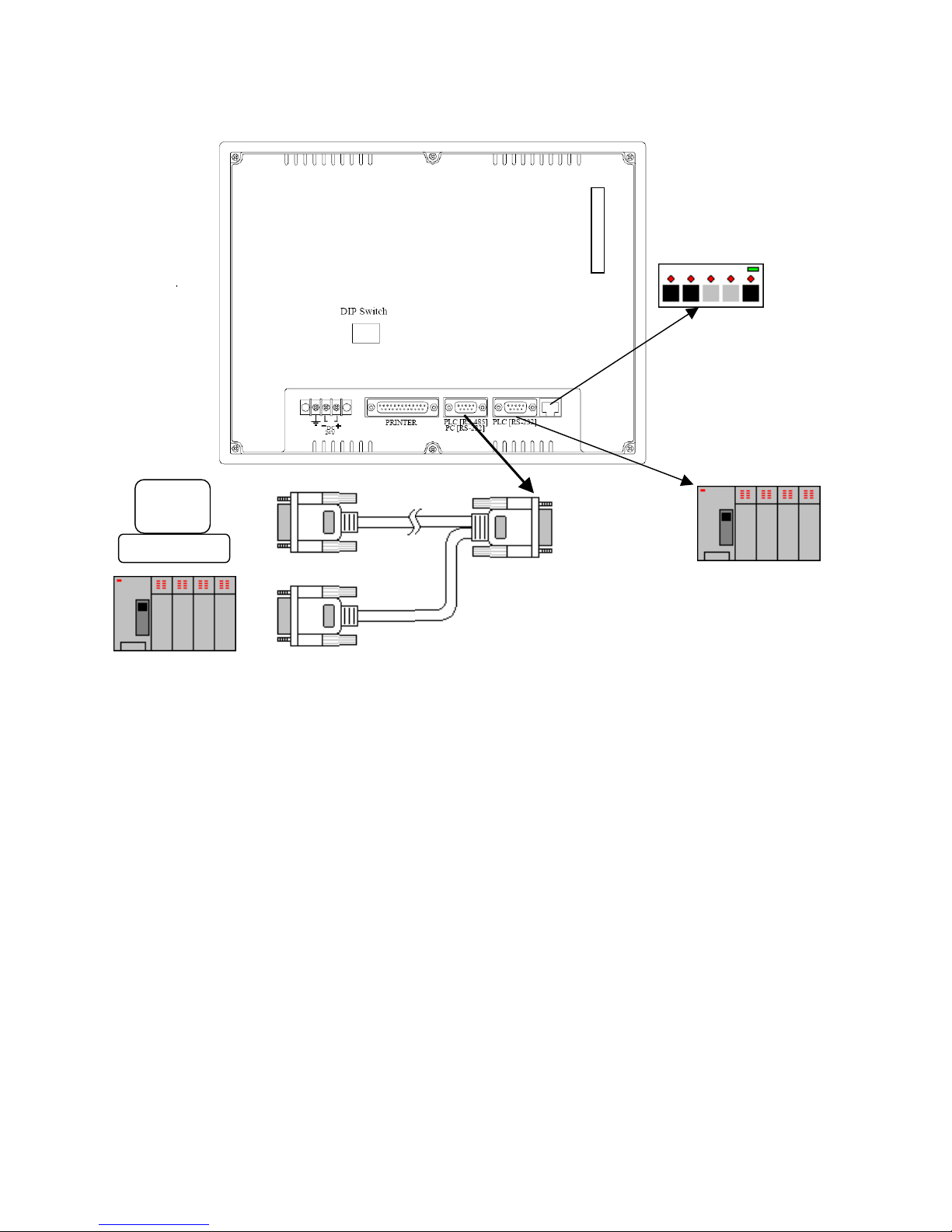

Set up the HMI with PC and PLC as described below.

a) Connect PC [RS-232] port of the HMI to the PC. Since the PC [RS-232] and PLC [RS-485] share the same D-SUB

connector, we recommend using the HMI to PC cable provided (MT5_PC). This splits the port into two separate connectors

to ease the program and test process.

b) Connect either the PLC [RS-485] or PLC [RS-232] port of the HMI to the PLC using the proper cable. (Check the PLC

signal type and cable listing in the back of this manual to assure proper port connections.)

c) Connect DC 24V power to the power connector. See Section 2.2.1 for power connection specifications.

Note: Check that all Dip switches are set to the “OFF” position.

d) Apply power and, if necessary, calibrate contrast adjust to the best viewing performance. (Not applicable for MMI-1500T)

Set new V4.5 hardware versions in RDS mode where contrast can be adjusted electronically.

17

Page 26

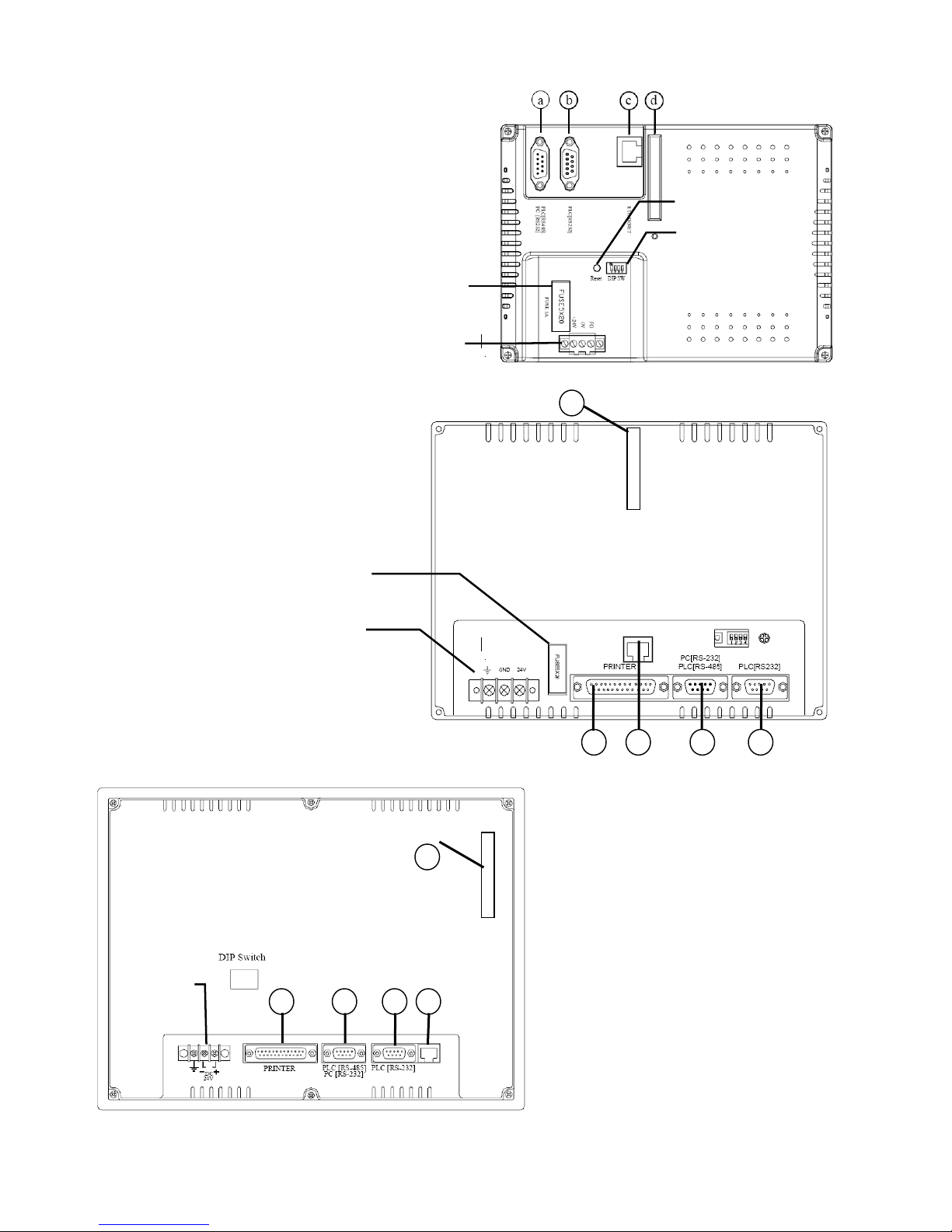

MMI-7XX Connection points

r

r

r

a. PLC[RS485]/PC[RS232]/AUX [RS485]

b. PLC[RS232]/AUX [RS232]

c. Ethernet port (RJ-45) (only on some models)

d. CF card slot (only on units with Ethernet ports)

Dip Switches

Fuse

Powe

Connections

MMI-850, MMI-1500 Connection Points

a. PLC[RS485]/PC[RS232]/AUX [RS485]

b. PLC[RS232]/AUX [RS232]

c. Ethernet port (RJ-45)

d. CF card slot

e. Printer port

Connections

Fuse

Powe

d

cb

e

a

Powe

Connections

d

c a be

18

Page 27

Typical connection

_

To Ethernet Port

To PLC RS-232

Interface

PC

PC

PLC

MT5

HMI

PC cable

To PLC RS-485

Interface

5.2 Installing EasyBuilder

Install EasyBuilder 500 on your PC. Software must be installed on a PC running Windows 98®, Windows 2000® or Windows

®

XP

software. PC screen resolution must be set to 800x600 or greater. Also, at least a Pentium 90Mhz CPU with 16MB

RAM, a CDROM drive, 15MB available hard disk space, VGA video controller, and one available RS-232 serial port is

required.

Put the EasyBuilder Installation CD into the CD drive. The autorun should bring up a screen showing an area to click to

begin the EasyBuilder Installation.

If the Autorun sequence does not start, browse the CD with Windows

the Installation process is done, the Start Menu has selections for starting EasyBuilder and EasyManager.

There is no need to restart your computer after installation, although this is recommended.

®

Explorer and start the installation from there. Once

19

Page 28

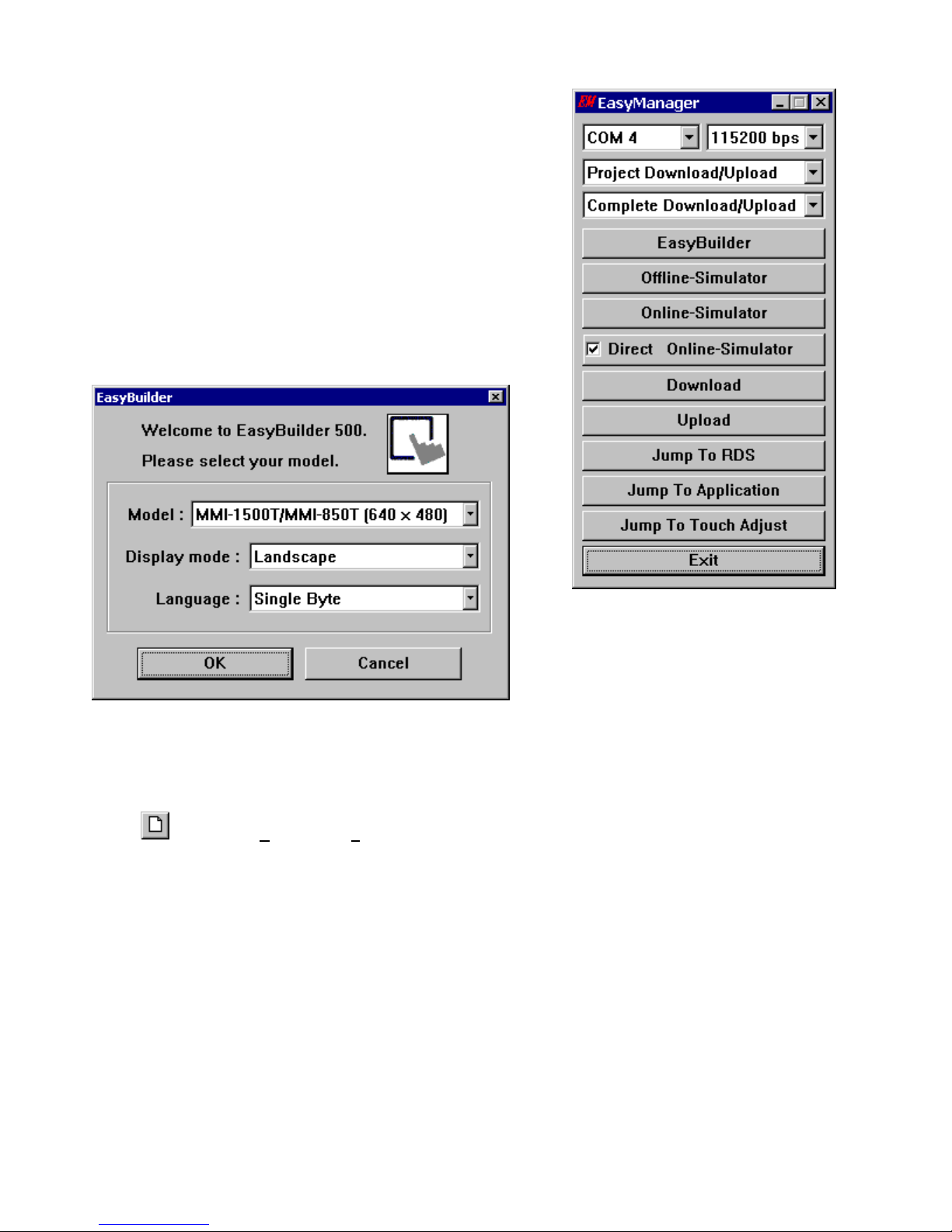

5.3 Initial Start Up

Use EasyManager to set the following:

1. COM Select Dropdown: Select the number of the RS232 Serial COM port

for communications to the MMI. Ports COM1 through COM10 are

available.

2. Click on EasyBuilder to start the screen editor for the MMI.

Note: See the Software Reference section for further details about the

EasyManager Application.

After clicking the EasyBuilder button, the following popup dialog appears if this is the first time running EasyBuilder.

Otherwise, the last open project is automatically opened for editing.

To start a new project, use the keyboard shortcut [Ctrl + N]

or click the

3. Select the appropriate Model number you are programming….

MMI1500T (640 x 480) 10.4” TFT 256 Color

MMI1500S (640 x 480) 10.4” STN 256 Color

MMI1500M (640 x480) 10.4” STN 4 Shade Grayscale

MMI850T (640 x 480) 7.7” TFT 256 Color

MMI850 (640 x 480) 7.7” STN 256 Color

MMI750T (320 x 240) 5.7” TFT 256 Color

MMI750 (320 x 240) 5.7” STN 256 Color

MMI730T (320 x 234) 5.7” TFT 256 Color

MMI720 (320 x 240) 5.7” STN 4 Shade Grayscale

tool or select [New] from the File menu and a new project is created from the project template.

20

Page 29

4. Select the Display Mode….

Landscape Portrait

5. Select the Language Mode….

This setting determines the character set that is used in project development.

Select Single Byte for European languages. These fonts are in the directory as Ascfont.8, Ascfont.16 and Ascfont.24.

These represent the 8, 16 and 24 point sizes. Larger sizes are generated from these base sizes (Example: Font size

32 is actually size 16 doubled).

Select Double Bytes for Asiatic languages. Use the Font setting in the System Parameters Editor Tab to select the

appropriate character set.

Then click, OK.

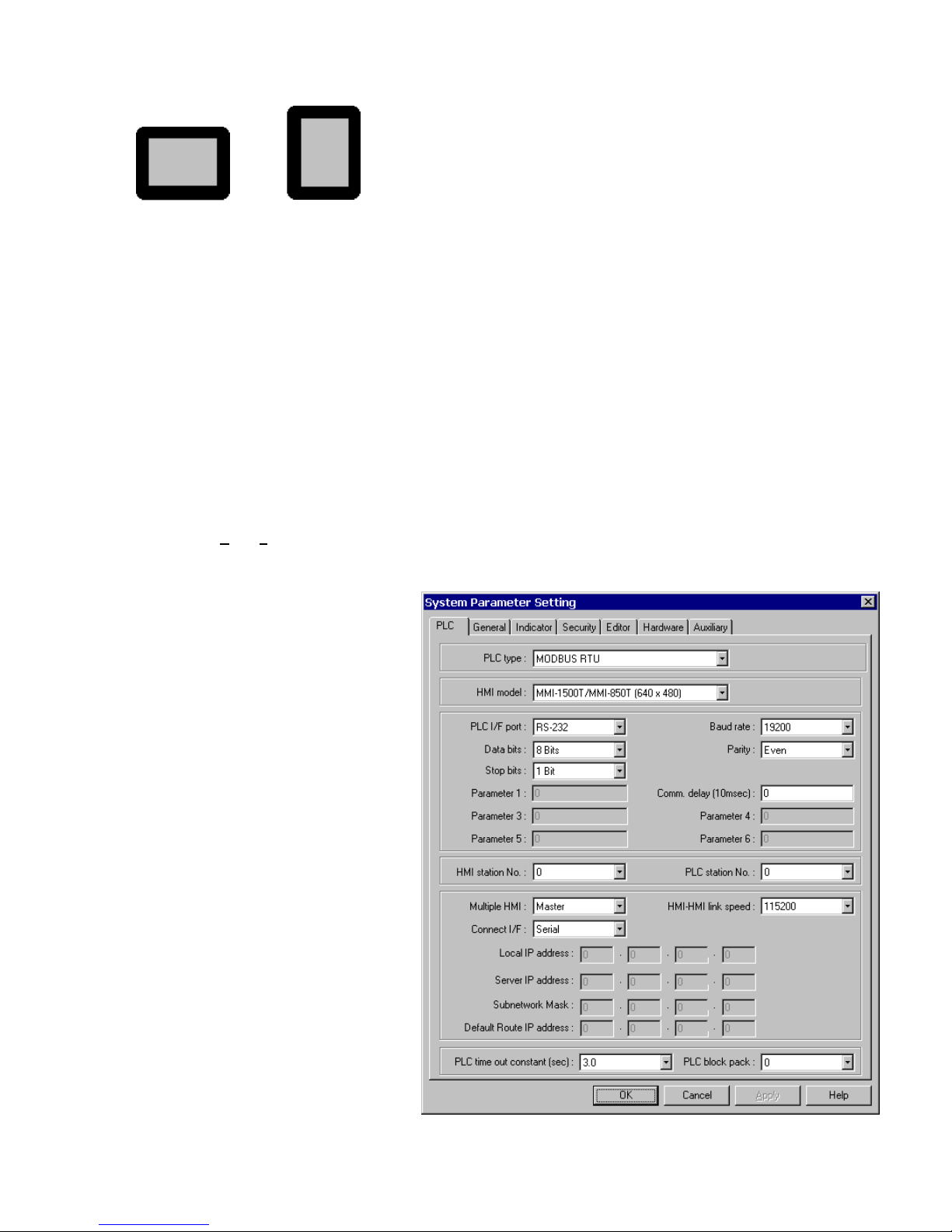

5.4 Creating a project

A project file (*.epj FILE) is simply a collection of all the windows and window data used by an application.

Step 1. Select Edit|System Parameters... and the following screen appears. Fill in the system parameters. Use the PLC

Tab to select the set up the parameters for communicating to the PLC.

a. Select the PLC type from the dropdown list.

b. Confirm that the HMI Model is the one you

are programming.

c. Check the communications settings:

Serial I/F port

Baud rate

Data bits

Parity

Stop bits

HMI station No.

PLC station No.

Set the communications parameters to match

the PLC. (See the Controller Reference Guide

for details.)

Note:

The General, Indicator, Security, Editor,

Hardware and Auxiliary Port tabs are used for

other settings. See Section 2.0 for full details.

For a quick start, these settings can be left at

their defaults.

21

Page 30

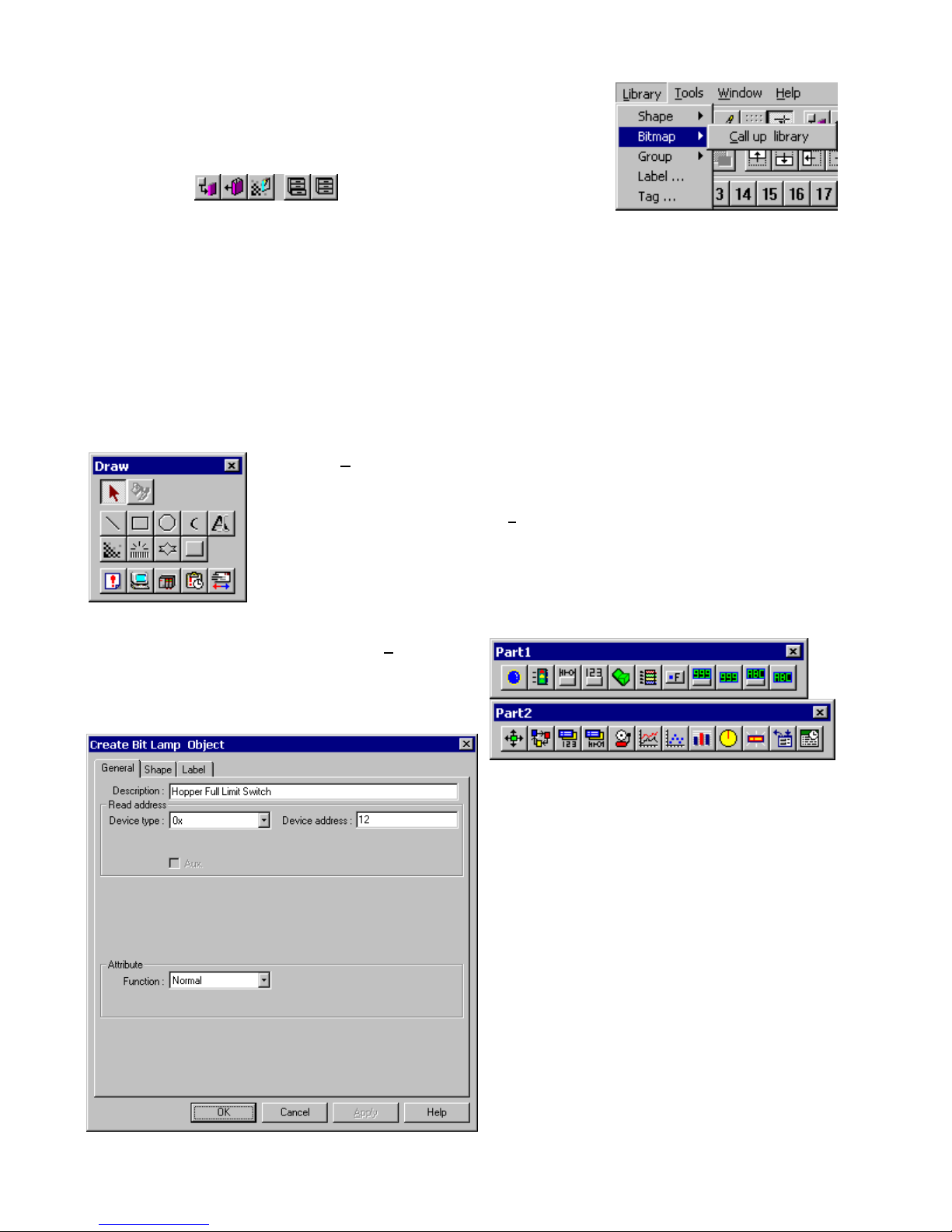

Step 2. Select any additional Group, BMP and/or Shape Libraries to attach to the

project. The default selection provides a good range of library objects. For a quick

start, no additional libraries are needed.

In the Library menu, select [Shape, Bitmap or Group] Æ [Call up Library] or use

the toolbar icons

EasyBuilder provides three types of libraries.

A Shape is a collection of drawing elements, those elements, when put together, defines a graphic symbol

representing a button, lamp, function key etc.

A Bitmap is a collection of pixel of data; each pixel can be 1, 4 or 8 bits.

A Group Library is a collection of shapes and bits that are frequently used and have been saved as a group.

.

Step 3. Design the windows

Using the parts and drawing elements, virtually any simple window display can be completed in 10 minutes. “Ease of

Use” is the greatest benefit of our EasyBuilder screen editor software.

a. Use the Draw menu/tools to put static text and shapes on the window. The drawing tools

are used in the similar fashion to most windows drawing packages.

For example: To draw a line: Select the Line tool. Change any attributes for the line. Click on

the screen where the line is to begin, move to where the line is to end and click again to set

the end point.

b. Put active parts on the screen by using the Parts

menu/tools. The parts automatically pop up a dialog for

entering information related to the part operation.

For example: Placing a Bit Lamp: Select Bit Lamp from

the Parts menu. Select the type of bit to access. Enter

the number of the bit. Go to the shape tab. Select Use

shape and click on the Shape Library button to select a

shape. Click OK to close the dialog. The Bit Lamp is

placed in the upper left corner of the display. Move it to

the desired position.

22

Page 31

Step 4. Save and Compile the project

In the menu, select File|S

In the menu select Tools|Compile… to compile the project.

ave to save the project.

Step 5. Simulate the project either On-line or Off-line.

Select Tool|O

the PLC through the unit and simulates operation. Before simulation, be sure to connect the unit and the PLC properly

and set the COM port in EasyManager.

Select Tool|Off-line S

emulates operations. The unit does not have to be connected to the PC for this type of simulation. Hint: Use this type

of simulation to demonstrate projects.

Using the Simulators before the

project is completely debugged,

saves time by avoiding repeated

downloads.

n-line Simulation operation in the menu. After the project is complied, the Simulator retrieves data from

imulation operation in the menu. After the project is complied, the PC simulates the PLC and

Step 6. Download the project

In the menu, select Tool|D

COM port in the Easy Manager menu. When the download is finished, click OK in response to the Mission complete

message. The HMI automatically switches to Application Mode.