Page 1

MINItrol-S SERIES

MODELS:

MRT-S

INSTALLATION & OPERATING INSTRUCTIONS

http://www.kep.com

99549 09/21/04

KESSLER-ELLIS PRODUCTS

10 Industrial Way East

Eatontown, NJ 07724

800-631-2165 • 732-935-1320

Fax: 732-935-9344

Page 2

WARNING

This instrument contains electronic components that are susceptible to damage by static electricity. Proper handling*

procedures must be observed during the removal, installation or handling of internal circuit boards or devices.

*Handling Procedure

1. Power to unit must be removed.

2. Personnel must be grounded, via wrist strap or other safe, suitable means, before any printed circuit board or other

internal device is installed, removed or adjusted.

3. Printed circuit boards must be transported in a conductive bag or other conductive container. Boards must not be

removed from the protective enclosure until the immediate time of installation. Removed boards must be placed immediately in a protective container for transport, storage or return to factory.

Comments:

This instrument is not unique in its content of EDS (electrostatic discharge) sensitive components. Most modern electronic

designs contain components that utilize metal oxide technology (NMOS, CMOS, etc.). Experience has proven that even

small amounts of static electricity can damage or destroy these devices. Damaged components, even though they appear

to function properly, exhibit early failure.

Page 3

TABLE OF CONTENTS

DESCRIPTION & SPECIFICATIONS ..................................................................... 1

DECODING PART NUMBER..................................................................................2

HOW TO MOUNT THE UNIT..................................................................................3

WIRING GUIDELINES ............................................................................................4

TOTALIZER INHIBIT INPUT ................................................................................... 4

WHAT CAN YOU VIEW ..........................................................................................6

OUTPUT JUMPER SELECTIONS .......................................................................... 6

MILLIVOLT INPUT OPTION JUMPER SELECTIONS............................................6

OPERATING FRONT PANEL ................................................................................. 7

PROGRAMMING FLOW CHART ........................................................................... 7

PROGRAM CODES & DESCRIPTIONS ................................................................ 8

WIRING TERMINATIONS.......................................................................................9

CALCULATING SCALE FACTORS ........................................................................10

PROGRAMMING .................................................................................................... 11

SETTING SCALING FACTORS..............................................................................11

SETTING THE COUNTER......................................................................................12

SETTING THE RATE .............................................................................................. 13

SETTING THE LOCK CODE & LOCKING THE UNIT ............................................14

SETTING THE RELAYS & PRESETS ....................................................................15

OUTPUT WIRING ...................................................................................................16

ANALOG OUTPUT OPTION...................................................................................17

RS232/RS422 SERIAL COMMUNICATIONS ......................................................... 18

TROUBLESHOOTING GUIDE................................................................................21

WARRANTY

Page 4

THIS PAGE IS BLANK

Page 5

DESCRIPTION & SPECIFICATIONS

DESCRIPTION:

The Minitrol-S is a single input totalizer/ratemeter. The totalizer

and ratemeter each have their own 5 digit dividing scale factor.

The two 5 AMP preset relay outputs can be programmed by the

user to apply to the “A” total counter or the “A” ratemeter. The user

can view the rate, total and grand total. The B relay can be used to

create a scaled pulse output. Magnetic pickup input, analog output

and RS232 communication options are available.

SPECIFICATIONS:

DISPLAY

6 digit, 0.55" High LED

INPUT POWER:

110 VAC ± 15% or 12 to 15 VDC

220 VAC ± 15% or 12 to 15 VDC

24 VAC ± 15% or 12 to 15 VDC

CURRENT:

250 mA DC max. or 6.5 VA AC

OUTPUT POWER (AC powered units only)

+12 VDC @ 50 mA, unregulated -10 + 50%

TEMPERATURE:

Operating:

+32°F (0°C) to +130 F (+54°C)

Storage:

-40 F (-40°C) to +200°F (93°C)

MEMORY

EEPROM stores data for 10 years if power is lost.

INPUTS:

3: High Impedance DC pulse input 4-30 VDC (high), Open or 0-

1 VDC (low),10 KΩ imp. 10 kHz max. speed.

3M: Mag. Input, Rate/total input only, accepts 30mV input (50 V

max. P/P) signals 10 KΩ imp. 5 kHz max. (Inhibit input, 430V)

NOTE: The Mag. input has filtering as follows: 30mV trigger level up

to 300Hz , 0.25 V trigger level at 5KHz

RESET:

Front Panel: Resets displayed total value and control output.

Remote: 4-30 VDC negative edge resets total and

relay control output.

NOTE: The remote reset does not reset the grand total.

K FACTOR/SCALING

The K-Factors are used to convert the input pulses to engineering

units. The 5 digit K-Factor dividers, with decimal keyed into any

position, allow easy direct entry of any K-Factor from 0.0001 to

99999. Separate factors may be entered for rate and total.

CONTROL OUTPUTS:

Relays:

2 each N.O. Relay; 5 Amps120/240 VAC or 28 VDC.

(N.C. relay contacts and NPN transistor output

available with solder jumpers. Transistor output is

internally pulled up to 10 VDC through relay coil, sinks

from 10 VDC to .5 V @ 100 mA)

Analog Output:

An optional 4-20mA (0-20mA) output is available for

the Minitrol series. The output can be programmed

to track rate or total. This feature is available by

adding suffix A to the part number. Connections are

via a 2 terminal pluggable screw connector.

Programming is accomplished by using the front panel

in conjunction with rear dip switches.

Accuracy: ± 0.25% FS

Compliance Voltage: 3 to 30 VDC non inductive.

RS232/RS422 SERIAL INTERFACE

If the serial interface option is supplied, up to 99 units can be linked

together. (The terminal addressing the unit must be capable of

driving all loads in the loop.) Unit status and new set points can be

communicated by serial communication. Mode changes, however,

must always be made on the front panel. Data is transmitted at

selected baud rates using standard seven bit ASCII characters and

parity with two additional bits of “Start” and “Stop” to make up the

standard ten bit character.

Data is received and transmitted over standard EIA RS232 or

RS422 levels. Each 10 bit character is made up of a start bit, 7 bit

ASCII code, parity bit and stop bit. Unit number, baud rate and

parity are entered in the “Program Setting” set up mode and remain

in memory even if power is off.

Note that the input impedance of RS232 is 3K or 7K Ohm worst

case. The terminal addressing the unit must be capable of driving

all loads in the loop. RS422 input impedance is much higher and

there is usually no problem driving 25 units. Unit serial transmit line

remains in a high impedance “OFF” state until addressed.

1

Page 6

SPECIFICATIONS

(continued)

DECODING PART NUMBER

PRESETS

Two control outputs are provided. To set relay A or B's functionality, press “menu” button until “Relay” appears on the display, the A

and B outputs can be assigned to the rate alarm (high/low), or for

total/grand total. A 5 digit value can be entered for both presets A

and B. The decimal point location is the same as the counter. The

outputs can be set to energize from 0.1 to 99.9 seconds or latch

(0.0). If a value other than 0.0 is entered, the corresponding

totalizer will auto reset at the preset. This may be used to create a

relay scaled pulse output.

LOCKOUT

Unauthorized front panel changes can be prevented by entering a

user selected 5 digit code, in the “LOC" mode. The front panel can

be completely locked out or the presets can remain accessible.

RATEMETER

Accurate to 4 1/2 digits (±1 display digit). The rate meter can be

programmed to:

• accept almost any number of pulses per unit of measurement

• sample from 2 to 24 seconds maximum

• auto-range up to 5 digits of significant information.

The display can be programmed to read in units per Second (

Minute (

TOTALIZER

The two 6-digit totalizers can count at 10kHz speed. They share a

5-digit dividing scale factor. The totalizer advances on the positive

edge of each pulse.

min

), Hour (

hour

), or Day (

day

).

sec

MINItrol-S

Example: MRTS A 3 1 A

Series:

MRTS=6 digits, counter / ratemeter

with presets and scaling.

Operating Voltage:

A= 110 VAC ± 15% or 12 to 15 VDC

B= 220 VAC ± 15% or 12 to 15 VDC

C= 24 VAC ± 15% or 12 to 15 VDC

Count Inputs:

3 = Standard, 4-30 VDC simultaneous inputs.

3M = Mag. Input, Irate/total input only, 30mV input

(Inhibit input, 4-30V)

Options (Multiple Options Available)

1= RS232 Communications

2= RS422 Communications

A= Analog Output (4-20/0-20 mA)

),

2

Page 7

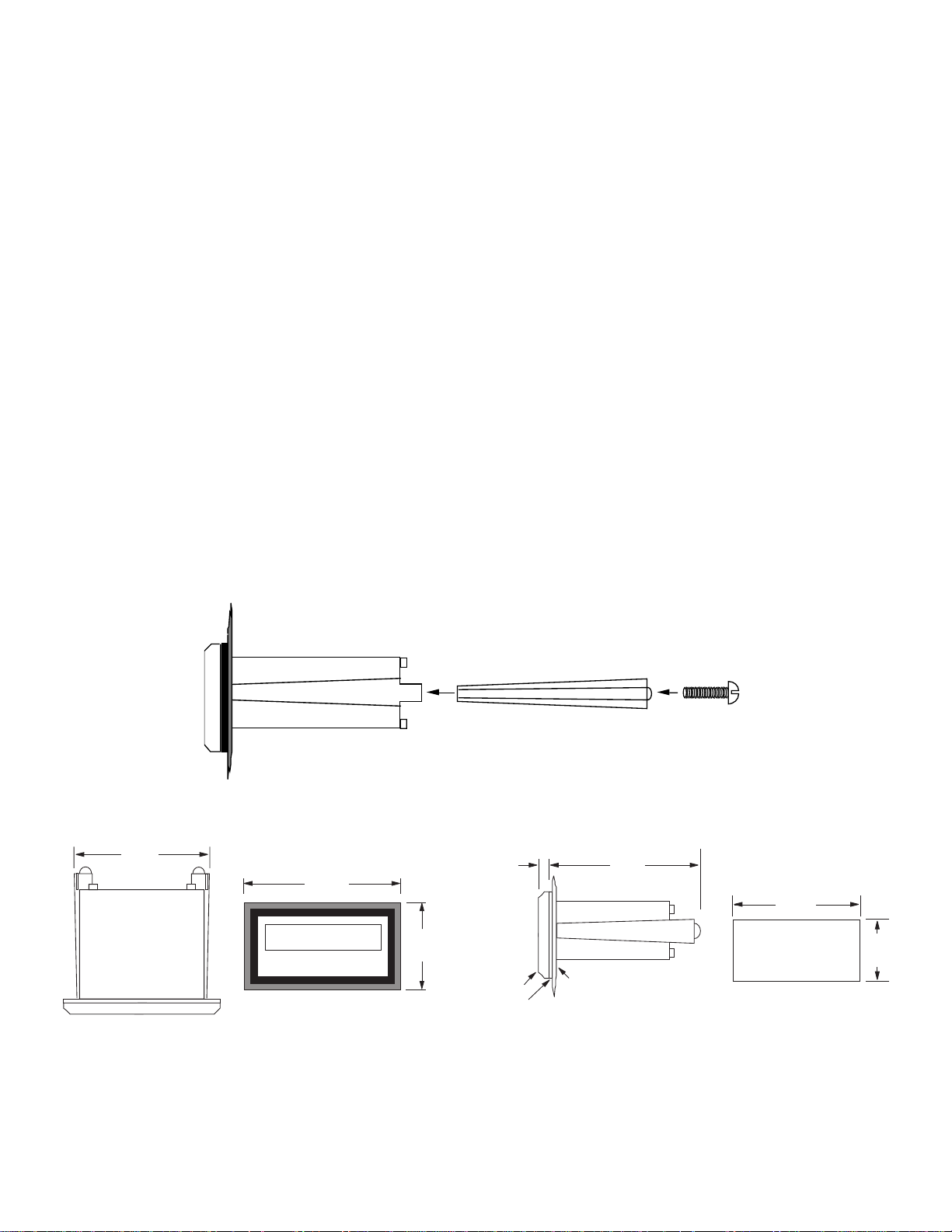

HOW TO MOUNT THE UNIT

The unit is designed to be mounted with a gasket providing a water tight seal. Two mounting brackets are provided to

secure the unit to the panel. A panel less than .1" may distort if the clamps are screwed too tightly.

Slide the body of the unit through the rubber gasket. Insert the unit into the panel. As shown in "FIG. A", slide the brackets

up the groove to press against the back of the panel. Insert screws into rear of brackets and tighten them evenly and

alternately. Do not over tighten! A normal level of torque is required. Maximum torque should be 3" pounds.

This product is designed to be panel mounted and is NEMA 4 rated if proper mounting procedures are followed and the

required and supplied hardware is correctly used.

If the panel in which the unit is mounted is less than .125 of an inch thick, the possibility exists that there will be some

flexing. Should this flexing occur, the resulting deformation of the panel could cause a loss of the water tight seal. In case

this should occur, the use of silicone or other sealant would be recommended.

This product is designed to the NEMA 4 rated. However, the fact that we are unable to control either the location in which

the device is installed or the actual installation itself requires that the company's liability shall extend only to the repair or

replacement of a defective product.

We are prepared to offer additional assistance in those special situations where normal mounting methods do not seem to

satisfy the customers needs. This assistance may be obtained by calling the factory and asking for Application Engineering.

DIMENSIONS

3.925

(99.7)

FIG. A

4.437

(112.7)

2.625

(66.68)

0.587

(14.91)

BEZEL

GASKET

4.245

(107.8)

CUSTOMER PANEL

Panel Thickness 0.062" (1.5)

to 0.187" (4.7) max.

3.622

(92)

1.772

(45)

3

Page 8

WIRING GUIDLINES

The rear terminal contains 12 screw terminals for connecting #14 to #28 gauge wire.

The unit is controlled by a microprocessor and, therefore, an electrically "noisy" environment could cause operating

problems. The input power line should not be common to power lines for motors, pumps, contactors, etc.

The unit is designed to be immune from line or transient voltage interference. In some environments voltage spikes of over

1000 volts can occur. When common to a power line driving motors voltage fluctuations can be extreme and rapid. Lines

driving DC or AC solenoids, relays, or actuators can also cause problems.

Four sources of noise can occur:

1) AC power line noise - If the unit cannot be connected to a clean power source, an inductive load suppressing device

(MOV as GE # V130LA1 or Resistor Capacitor as Paktron # .2 uf/220 ohm @ 400V) can be installed. Although locating

the suppressor across the AC supply at the unit should help, best results are obtained by connecting the suppressor

across the leads of the "load" at the device causing the spike.

2) Input line noise -The noise is carried on the input and D.C. ground lines. Make sure the input wires are never run into

the unit in a bundle with power input lines. Also, keep these input lines isolated from inductive lines from devices

drawing heavy loads. If there is a possibility of electrical noise, we recommend using shielded cable, with the shield

being hooked to the D.C. ground terminal on the instrument, and to "earth" at one point in the circuit, preferably at the

D.C. ground terminal of the unit.

3) Output lines - The unit has two relay outputs. When these outputs are used to run external relays or solenoids, spikes

can be generated upon activation. This noise can spread through the instrument causing operating problems. If the

source is a D.C. operated device, a general purpose diode (IN4004) placed across the solenoid prevents electrical

noise spikes. Connect the cathode (banded side) to the more positive side of the coil. If the source is an A.C. operated

device, use a MOV or Resistor Capacitor across the coil.

4) 12 VDC output supply - Noise can be generated on the 12 VDC output supply if it is used to drive inductive loads or if

the current draw exceeds 50 mA. Insure that all inductive loads have a diode (such as IN4004) across the coil and that

the current does not exceed 50 mA.

TOTALIZER INHIBIT INPUT

In many applications it is sometimes necessary to inhibit totalization while certain operations are present. A high logic level

on this input inhibits totalization while the rate indication is still active. This feature is useful during meter proving and may

be used with liquid phase detectors.

4

Page 9

CONNECTING AC / DC POWER

NOTE: Connect power only after other connections are finished. Do not touch the live AC power terminals! The unit has

been designed with an isolated AC input. Thus, polarity is not a concern for the AC input. The chassis is plastic, therefore

earth ground is not used. For D.C. operation, connect + 12V to pin 7 and - D.C. to pin 8.

CONNECTING SENSOR INPUTS

These diagrams show how to hook a typical input sensor to the unit. The unit supplies an unregulated 12 Volt (50mA)

output to power these sensors (Pin 7).

A valid pulse is one which makes a transition from the off-state (0 to 1V) to the on-state (4 to 30V): a positive going edge.

The input impedance is 10K Ohms to ground. The unit can be programmed from the front panel for slow switch closure

inputs up to 40Hz (select "Lo CPS"), or solid state switches (select "hi CPS") up to 9.99KHz. No rear terminal jumpers are

required. Use PNP (sourcing) type pulsers.

TYPICAL SENSOR HOOKUP

High Level Pulse Low Level Pulse (Mag Pickup)

Flowmeter

RELAYS

A

B

1 COMMON

2 N.O. (N.C./NPN)

3 COMMON

OUTPUT

POWER

GROUND

4 N.O. (N.C./NPN)

5 A INPUT

6INHIBIT TOTAL INPUT

7 12 V OUTPUT/ + DC INPUT

8 - DC (GROUND)

9 RESET INPUT

10 NOT USED

11 AC INPUT

12 AC INPUT

*

* PULLUP RESISTOR REQUIRED FOR

OPEN COLLECTOR OUTPUTS

4.7KΩ TYPICAL

Flowmeter

with Mag. Pickup

RELAYS

A

B

1 COMMON

2 N.O. (N.C./NPN)

3 COMMON

SIGNAL

GROUND

4 N.O. (N.C./NPN)

5 A INPUT

6INHIBIT TOTAL INPUT

7 12 V OUTPUT/ + DC INPUT

8 - DC (GROUND)

9 RESET INPUT

10 NOT USED

11 AC INPUT

12 AC INPUT

5

Page 10

WHAT CAN YOU VIEW?

J4

J5

J6

J3

J1

J2

CR1

R3

C8R7R5

R4

U1

CR2

REV

20229

CR6

CR3

U3

P1

R10R6C6

C7

CR4

CR5

C4

R2

R1

C3

C5

U2

U4

U6

U5

R8

R9

C1

C2

C9

B

Pressing VIEW shows:

A) The total of input A. If “reset to 0” is selected A counts up, if “set to preset” is selected A will count down.

B) The rate of input A.

C)* The grand total of input A which always count up.

NOTE:

* All decimal points are inverted when “Grand Total” is being displayed to distinguish from the A total.

OUTPUT JUMPER SELECTIONS

FUNCTION

"A" RELAY

N.C. OUTPUT

"B" RELAY

N.C. OUTPUT

"A" PRESET

*

TRANSISTOR (NPN)

*

"B" PRESET

TRANSISTOR (NPN)

BOTTOM VIEW AT TERMINAL

* The unit must be removed from the case to access jumpers C & F, all

other jumpers can be accessed by removing the plastic extender.

NOTE: All three pads at jumpers 2 and 4 are connected.

12 11 10 9 8 7 6 5 4 3 2 1

L

20192

MODIFICATION

CUT JUMPER

AT "A" "B" TO "2"

CUT JUMPER

AT "D" "E" TO "4"

CUT JUMPER

AT "A" "C" TO "2"

CUT JUMPER

AT "D" "F" TO "4"

FC

H

G

4

DE

AB

2

MILLIVOLT INPUT OPTION

JUMPER SELECTIONS

If the unit has the millivolt input bd.# 20229, The A inputs can be

solder jumper programmed to accept either a low millivolt or 4-30 V

input. The B input should always be set for 4-30 V. Each unit

shipped is programmed according to part number. If solder jumpers are made, the part number should be modified to reflect the

changes made

C=CLOSE, O=OPEN

4-30V INPUT Millivolt INPUT

Input A J1-O, J2-C, J3-O J1-C, J2-O, J3-C

Inhibit Input J4-O, J5-C, J6-O

6

Page 11

OPERATING THE FRONT PANEL

Press to "reset"

in operating

mode.Press to

"enter" in

programming

mode.

Start Here

PRGM

4

Press to

view or

change

preset B.

3

21

Press to alternately

view A rate, A total

or A grand total.

Press to

enter

lock code for

panel lock.

65

RST

ENTER

LOCK PRE A PRE B VIEW PRGM

Press to

view or

change

preset A.

PROGRAMMING FLOWCHART

Press this key to step through menu choices.

PRGM

RST

ENTER

Press this key to enter displayed value

Press to cycle

through PROGRAM

choices. Press to

toggle between

choices in program

mode.

FACToR

ENTER

DP F A

ENTER

#####

ENTER

DP F B

ENTER

#####

ENTER

RUN MODE

PRGM

CouNT

RST

0

DPLoC

Hi

CPS

RUN MODE

ENTER

PRGM

ENTER

ENTER

PRGM

ENTER

PRGM

RATE

ENTER

sec

min

hour

PRGM PRGM

SET

PR

day

ENTER

NoR ##

Lo

CPS

ENTER

FiguR#

ENTER

dly ##

ENTER

RUN MODE

LoC

ENTER

LC

PRGM

PRg

ENTER

CoDE

#####

ENTER

RUN MODE

A

ToT

RELAY

ENTER

PRGM

PRGM

LC

ENTER ENTER

ALL

A ##.#

ENTER

B

PRGM

ToT

ENTER ENTER

B ##.#

RUN MODE

A

RATE

B

RATE

ENTER

7

Page 12

The following is a list of abbreviations as they appear on the display and front panel of the unit.

ABBREVIATION DESCRIPTION

FACTOR

DP F A

DP F B

COUNT

RST 0

SET PR

DP LOC

HI CPS

LO CPS

RATE

SCALING FACTOR - Enter the 5 digit dividing scale factor (K-Factor) for the total input (Input A).

DECIMAL POINT FOR FACTOR A (rate) - Enter location of decimal point for the rate scaling factor by

pressing the button under the digit where the decimal is desired.

DECIMAL POINT FOR FACTOR B (total) - Enter location of decimal point for the total scaling factor by

pressing the button under the digit where the decimal is desired.

PORTION OF MENU FOR SETTING TOTALIZER VARIABLES

RESET TO 0 - Totalizer will reset to 0. The totalizer will count up from 0.

SET TO PRESET - Totalizer will reset to preset A. The totalizer will count down from preset A. The grand

totalizer will count up .

DECIMAL POINT LOCATION - Enter desired location of decimal by pushing the button under the digit where

the decimal is desired. Changing the decimal will change the decimal location in the totalizer and grand

totalizer, but not the rate display.

HIGH COUNTS PER SECOND - This sets the unit for high count speeds (0-9.99KHz)

LOW COUNTS PER SECOND – This sets the unit for contact debounce filtering (0-40Hz)

PORTION OF MENU FOR SETTING RATE VARIABLES

sec

min

hour

day

NOR##

FIGUR ##

DLY##

RATE PER SECOND - The display will read in rate per second.

RATE PER MINUTE - The display will read in rate per minute.

RATE PER HOUR - The display will read in rate per hour.

RATE PER DAY- The display will read in rate per day.

NORMALIZING FACTOR - Normalizes (averages) the data being received. Higher settings provide more

normalizing (averaging) for a more stable display. Derived from the equation:

(Old Data x “NOR” + New Data)

(“NOR” + 1)

SIGNIFICANT FIGURE - This sets the amount (1-5) of meaningful figures the unit will display. (RATE DIS

PLAY ONLY). FOR EXAMPLE: If “2” is set as the figure, a rate of 273.45 will be displayed as 270.

DELAY FACTOR - The amount of time (02 to 24 sec.) the unit will “look” for valid data, before the display

defaults to zero. (RATE DISPLAY ONLY)

8

Page 13

LOC

LOCK - This portion of the menu allows you to:

1) lock the program (presets are still accessible)

2) lock all (presets and program are locked).

LC PRG

LC ALL

CODE

RELAY

A TOT

A RATE

A##.#

B TOT

B RATE

LOCK PROGRAM - This will lock the program and allow the presets to be changed when the unit is in the

lock mode.

LOCK ALL - This will lock the program and the presets when the unit is in the locked mode. The presets can

be viewed, but not changed.

LOCK CODE - This message (code) will flash on display for approximately 3 seconds. It will be followed by a

5 digit number (xxxxx). The number you enter here will be the code to lock and unlock the unit.

RELAY - This portion of the menu allows you to set your relay operation variables.

RELAY A FOR TOTALIZER - When this is selected relay A will activate when the total has reached

Preset A.

RELAY A FOR RATE - When this is selected relay A will activate when the Rate of input A equals or exceeds

preset A.

RELAY A DURATION - This message will appear when “A TOT” is selected. It is the duration which the

relay will remain energized (00.1 to 99.9 sec). If 00.0 is selected, the relay will latch until reset. When the

duration is not at 00.0, the unit will autorecycle.

RELAY B FOR TOTALIZER - When this is selected relay B will activate when the total has reached preset B.

RELAY B FOR RATE - When this is selected relay B will activate when the rate equals or exceeds preset B.

The relay will drop out when the rate falls below preset B.

B##.#

RELAY B DURATION - Follow same procedure as A ##.#.

WIRING TERMINATIONS

ANALOG

1- COMMON

2- N.O.(N.C./NPN)

3- COMMON

4- N.O.(N.C./NPN)

5- RATE / TOTAL INPUT

6- INHIBIT TOTAL INPUT

7- 12VDC OUT/+DC IN

8- -DC (GROUND)

9- RESET INPUT

10- NOT USED

11- A.C. INPUT

12- A.C. INPUT

A

B

SWITCH

RELAYS

ON

13- V+

14- I SINK

OFF

RUN

4-20mA

RATE

RUN

1 2 3 4

OUTPUT

ON

CAL.

0-20mA

TOTAL

SET

Analog Out Setup SwitchesSerial Port

13 14

REAR VIEW

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4

ON

9

Page 14

CALCULATING SCALE FACTORS

There are two separate dividing scale factors, one for rate and one for total. The factors are entered as

the number of pulses per the desired unit of measurement. The factor ranges from 0.0001 to 99999.

Because the “units per second”, “minute”, “hour” or “day” are field programmable from the keypad,

scale factor calculations for the ratemeter are easy.

RATE (Factor A)

The Rate K-Factor value should be entered in pulses per unit of measure. Be sure to choose the

desired Time Base (sec, min, hour, day) in the Rate menu section.

Rate =

Where Time Base:

SEC = 1

MIN = 60

HOUR = 3600

DAY = 86400

TOTAL (Factor B)

The Total K-Factor (Factor B) value should be entered as pulses per least significant digit for display.

The DPLOC (decimal location) under the count section is a "dummy" decimal. Therefore the Total KFactor must be scaled properly for totalizer decimal adjustments.

EXAMPLE:

Flowmeter Output: K = 56.27 pulses per gallon

FACTOR B TO READ

56.27 0 GAL

5.627 0.0 GAL

.5627 0.00 GAL

Input Frequency x Time Base

Factor A

Total = Input Frequency

Factor B

10

Page 15

PROGRAMMING

STEP

1

SETTING

SCALING

FACTORS

PRESS

PRGM

ENTER

ENTER

ENTER

DISPLAY

factor

dp f a

#####

dp f b

REMARKS

This section of the menu is used to set up

the scaling factors for rate and total.

This sets the decimal for rate factor.

Press the arrow key under the digit where

the decimal is desired. To clear the

decimal, press the arrow key furthest to

the right (PRGM) .

This is the scaling factor for the rate. To

change, press the arrow key under the

digit(s) to change. Press ENTER to enter

the displayed value.

This sets the decimal for total factor.

Press the arrow key under the digit where

the decimal is desired. To clear the

decimal, press the arrow key furthest to

the right (PRGM) .

ENTER

#####

This is the scaling factor for the totalizer.

To change, press the arrow key under

the digit(s) to change. Press ENTER to

enter the displayed value.

11

Page 16

PRESS DISPLAY REMARKS

STEP

2

SETTING

THE

COUNTER

PRGM

PRGM

ENTER

ENTER

ENTER

factor

count

rst 0

or

set pr

dp loc

hi cps

or

lo cps

This section of the menu sets up the

totalizer information.

Press the PRGM key to choose RST 0

(reset to 0, count up) or SET PR (set to

preset, count down), press the ENTER

key to enter the displayed choice.

This sets the decimal location for the

totalizer and grand totalizer Press the

arrow key under the desired digit location. To clear the decimal, press the

arrow key furthest to the right. Press

the ENTER key to enter the displayed

location.

Press the PRGM key to choose HIGH

CPS (0-9.99KHz) or LOW CPS (040Hz). Press the ENTER key to enter

the displayed choice.

12

Page 17

STEP

3

SETTING

THE RATE

PRGM

PRGM

REMARKSPRESS DISPLAY

factor

count

PRGM

ENTER

ENTER

ENTER

rate

Sec

min

hour

day

nor #.#

figur #

This section of the menu is used to set up

the rate information.

Press the PRGM key to choose rate time

base.

SEC (rate per second)

MIN(RPM)

HOUR (RPH)

DAY (rate per day)

Press ENTER to enter displayed choice.

This sets the normalizing (averaging) factor. Press the arrow keys under the desired digits to change. Press ENTER to

enter displayed value.

This sets the minimum number of significant figures to be displayed. Press the arrow key under the digit to change. Press

ENTER to enter displayed value.

ENTER

dly ##

This sets the delay time (2 to 24 sec.) that

the unit will “look” for valid input data before the display falls to 0. Press the arrow

key under the digits to change. Press ENTER to enter displayed value.

13

Page 18

PRESS

DISPLAY REMARKS

STEP

4

SETTING

LOCK

PRGM

PRGM

PRGM

PRGM

ENTER

ENTER

factor

count

rate

loc

LC PrG

or

LC ALL

CoDE

Flashes

followed by:

#####

This section of the menu is used to set up

the lockout type and code.

LC PRG = Locks program but presets and

reset are accessible.

LC ALL= Locks entire keypad.

Press the PRGM button to toggle between

choices; Press ENTER to enter displayed

choice.

After CODE flashes the display will show the

existing lock code. To change the code press

the key under each digit to be changed. Press

ENTER to enter displayed value.

SETTING

THE

LOCK

STATUS

LOCK

ENTER

CoDE

Flashes

followed by:

0

LoC

or

uN LoC

Key in the lock code (see programming step

4) by pressing the keys under the digits to be

changed. Press the ENTER key to enter the

displayed code.

After the code is entered the unit will display

LOC (unit is locked) or UN LOC (unit is unlocked). This message will be displayed for

approximately 3 seconds before the unit returns to the run mode.

14

Page 19

DISPLAYPRESS

REMARKS

STEP

5

SETTING

THE

RELAYS

THIS SELECTION

WILL ONLY APPEAR

IF "A TOT" IS

CHOSEN

PRGM

PRGM

PRGM

PRGM

PRGM

ENTER

ENTER

ENTER

factor

count

rate

loc

relay

a tot

or

a rate

A ##.#

b tot

or

b rate

This section sets up the relay information.

Press the PRGM key to choose A TOT (A

assigned to total) or A RATE (A assigned to

rate). Press enter when the desired choice is

displayed.

This is the duration (.1 to 99.9 sec) that relay

A will remain energized. If 00.0 is selected,

the relay will latch until reset

Press the PRGM key to choose B TOT (B

assigned to total) or B RATE (B assigned to

rate). Press enter when the desired choice is

displayed.

THIS SELECTION

WILL ONLY APPEAR

IF "B TOT" IS

CHOSEN

SETTING

THE

PRESETS

ENTER

PRE A

PRE B

b ##.#

PRE A

Followed by

last PRE A

entered

PRE B

Followed by

last PRE B

entered

This is the duration (.1 to 99.9 sec) that relay

B will remain energized. If 00.0 is selected,

the relay will latch until reset

PRE A = Preset A; The set point at which

output A will trigger. If the displayed value is

not the desired preset, press the key(s) under

the digit to be changed.

PRE B = Preset B; The set point at which

output B will trigger. If the displayed value is

not the desired preset, press the key(s) under

the digit to be changed.

15

Page 20

OUTPUT WIRING

The following diagrams detail the connection of the relay and analog output options. Each relay consist of a form A contact

(Normally Open). NPN transistor or Normally Closed contacts are available with solder jumpers (see Jumper Options).

ANALOG OUTPUT

The analog output can be selected to output 4-20 mA or 0-20 mA and can be selected to track the rate or total.

Pin 13 supplies 12 to 18V to power the current loop. Pin 14 supplies the current sinking driver. When connecting

a strip chart recorder, make connections as follows:

ALARMS

STRIP CHART

ANALOG

OFF

RUN

RATE

RUN

OUTPUT

ON

CAL.

0-20mA

TOTAL

SET

RECORDER

TURBINE FLOWMETER

+

–

-

PULSE OUTPUT

+12V

GND

1- COMMON

2- N.O.(N.C./NPN)

3- COMMON

4- N.O.(N.C./NPN)

5- RATE / TOTAL INPUT

6- INHIBIT TOTAL INPUT

7- 12VDC OUT/+DC IN

8- -DC (GROUND)

9- RESET INPUT

10- NOT USED

11- A.C. INPUT

12- A.C. INPUT

A

B

SWITCH

RELAYS

ON

13- V+

14- I SINK

4-20mA

1 2 3 4

The relays can be used to trigger alarms which warn the operator that the total or the rate has

exceeded a setpoint. The outputs are programmable to be assigned for rate or total. When assigned to the

total, the relays can have a user selectable on time (duration) or can be latched until reset. The total autorecycles

when set for a selectable on time. This can be use to create a relay pulse output.

ANALOG

OFF

RUN

RUN

OUTPUT

ON

CAL.

0-20mA

TOTAL

SET

LIGHT

BELL

RELAYS

1- COMMON

A

2- N.O.(N.C./NPN)

3- COMMON

B

4- N.O.(N.C./NPN)

5- RATE / TOTAL INPUT

6- INHIBIT TOTAL INPUT

7- 12VDC OUT/+DC IN

8- -DC (GROUND)

SWITCH

9- RESET INPUT

10- NOT USED

11- A.C. INPUT

12- A.C. INPUT

13- V+

14- I SINK

4-20mA

1 2 3 4

ON

RATE

16

Page 21

ANALOG OUTPUT OPTION

Description:

An optional 4-20mA (0-20mA) output has been added to the Minitrol

series. The output can be programmed to track rate or total. This

feature is available by adding suffix A to the part number. Connections are via a 2 terminal pluggable screw connector.

Connections: (see FIG. 1)

PIN13 supplies the 12 to 18 VDC to power the current loop.

PIN14 is the control sink driver

Accuracy:

± 0.25% FS

Compliance Voltage:

3 to 30 VDC non conductive

Setup:

The optional analog output feature uses 4 dip switches on the back

for setup. These switches are used as follows:

SW1 - View or change "set low" and/or "set high" values

SW2 - Select output for rate or total

SW3 - Select 4-20mA or 0-20mA

SW4 - Calibrate the unit.

After the regular parameters shown in the programming flowchart

have been set, locate the 4 switches on the back of the unit. (see

FIG. 1)

Switch Settings:

SWITCH 1: Enter Analog Low & High (normally off)

Switch 1 is used to load in the low (4mA or 0mA) and/or the high

(20mA) output settings. With power on, set switch 1 ON (up).

SWITCH 4: Calibrate (normally off)

Switch 4 is used for calibration. Calibration is done at the factory

and should not be needed (see SWITCH 1 to enter high and low

values). If recalibration is desired, a calibrated 20mA ammeter

with 1uA resolution is needed. Attach the "+" lead of the meter to

pin 13 and the "-" lead to pin 14. Set switch 4 ON (up). The unit

will output approximately 20.000mA and a decimal will light in the

third position. Read the output using the ammeter. Press PRE A.

If the display is the same as the ammeter reading, press ENTER.

If not, press buttons A through E to step to ammeter reading and

ENTER. (Disregard display which now shows the last count reading with decimal point in third position) Return switch 4 to OFF

(down) position.

RS232 & RS422 Operation:

When the unit is suppled with RS232 or RS422, the analog output

"low" and "high" settings can be accessed and changed through

the serial port. The codes are as follows:

AL Unit will display (transmit) analog out "low" value.

AL(S)XXXXX Unit will load analog out "low" with entered

number. (S) = space

AH Unit will display (transmit) analog out "high" value.

AH(S)XXXXX Unit will load analog out "high" with entered

number. (S) = space

FIG. 1

Analog Out Setup SwitchesSerial Port

13 14

1 2 3 4

ON

LOW SETTING is viewed or changed by pressing PRE A. If the

displayed value is correct, press ENTER. If not, press buttons A

through E to step to the desired value and press ENTER. (after

the "low set" is entered, the disply will show the last total reading).

HIGH SETTING is viewed or changed by pressing PRE B. If the

displayed value is correct, press ENTER. If not, press buttons A

through E to step to desired value and press ENTER.

Return switch 1 to OFF (down) position, PRE A and PRE B buttons

now function to view or change relay trip values.

SWITCH 2: Select Count or Rate

SW2 OFF (down): Analog output follows rate

SW2 ON (up): Analog output follows total

SWITCH 3: Select 4-20mA or 0-20mA

SW3 OFF (down): Selects 4-20mA output range

SW3 ON (up): Selects 0-20mA output range

1 2 3 4 5 6 7 8 9 10 11 12

Typical Wiring:

STRIP CHART

RECORDER

TURBINE FLOWMETER

REAR VIEW

+

-

PULSE OUTPUT

+12V

GND

1- COMMON

2- N.O.(N.C./NPN)

3- COMMON

4- N.O.(N.C./NPN)

5- A INPUT

6- INHIBIT TOTAL INPUT

7- 12VDC OUT/+DC IN

8- -DC (GROUND)

9- RESET INPUT

10- NOT USED

11- A.C. INPUT

12- A.C. INPUT

A

B

SWITCH

RELAYS

ON

13- V+

14- I SINK

OFF

RUN

4-20mA

RATE

RUN

1234

ON

CAL.

0-20mA

TOTAL

SET

ANALOG

OUTPUT

17

Page 22

INTERFACE CARD RS 232/422 OPERATION

RS 232/422 SET-UP:

All serial communication mode changes must be done

through serial communications. Mode changes cannot be

done through the front panel. To initialize the unit, place a

jumper between pin 7(+12V )[bottom board] and pin 1(init) [DB

-9 connector] on initial power up. The unit defaults to: 300

baud rate,”MARK” parity and device number 01. To enter the

program mode you must set your terminal for 300 baud rate

and “MARK” parity. Next, type D1(s), (s)= space bar. The unit

will echo back “DEVICE #1:”. Now type EP (enter program)

and a carriage return (enter). The unit will echo back “PROGRAM SETTING”. You are now in the programming mode.

SETUP PROCEDURE:

The following sections consist of the communications setup

options as they appear in the menu. (If you wish to exit the

program mode, at any time you can hit the “escape key” (Hex

Code: 1B) and the unit will save the changes made but not

effect the remaining data values.) When each section of the

setup menu is displayed, the current data will appear in the <

> signs. If you wish to change the data, type in the number

of the desired choice and press return (enter). If you wish to

keep the current data, simply press return.

DEVICE NUMBER:

Each unit in the hook-up must be assigned it’s own device

number (1 to 99). Zero is reserved for a dedicated hook-up to

only one terminal, and it’s transmit output line remains in an

“on” active state. The device number is entered in the program

mode. The unit will prompt you:

DEVICE# <XX>?

If XX is the desired device number press return (enter), if not

enter the desired number after the question mark and press

return (enter).

BAUD RATE:

The baud rate is the speed at which data is transmitted,

expressed in bits per second. Baud rates of 300, 600, 1200,

2400, 4800 or 9600 are available. When in the baud rate

section of the menu, the unit will list :

BAUD RATES:

1:300 2:600 3:1200

4:2400 5:4800 6:9600

then prompt you:

BAUD RATE <300>?

Press return (enter) if this is the desired baud rate or enter the

assigned number of one of the six possible baud rates. If an

invalid baud rate is entered the unit will prompt you to choose

another baud rate. This will occur until a valid baud rate is

entered or escape is pressed.

“EVEN” (parity bit is logic 0 if total number of logic 1’s in the first

seven data bits is even), “MARK” (parity bit is always logic 1

- High / Mark) or “SPACE” (parity bit is always logic 0 - Low /

Space). If a “MARK” parity is chosen, it will appear that two

stop bits are used. Use the “MARK” parity with terminals using

parity “OFF” or “NONE”. These terminals ignore the parity.

The unit does not check the parity but does transmit the parity

chosen. When setting the parity, the unit will print:

PARITIES:

MARK-0 SPACE-1 EVEN-2 ODD-3

Then the unit will prompt you:

PARITY<MARK>?

If this is the desired parity press return (enter), if it isn’t enter

the number of the desired parity then press return (enter).

STROBE LIST:

The serial interface card is also equipped with a strobe line.

When the strobe line is triggered, a chosen set of data will be

transmitted to be displayed or printed. The selections for the

display list are entered in the program mode. Enter “1” to add

selections to the list and enter “0” to delete selections from the

list. The seven available items for the strobe display list are:

(1) Preset A, (2) Preset B, (3) K-Factor A, (4) K-Factor B, (5)

Rate of A, (6) Count A, (7) Count B. When setting the strobe

list the unit will print :

ENTER STROBE LIST:

DO NOT DISPLAY-0 DISPLAY-1

The unit will prompt you:

PRESET A<DISPLAY>?

PRESET B<DISPLAY>?

K-FACTOR A<DISPLAY>?

K-FACTOR B<DISPLAY>?

RATE<DISPLAY>?

COUNT A<DISPLAY>?

COUNT B<DISPLAY>?

If the above choices are entered, when the strobe line is

triggered (3-30V positive pulse) the unit will transmit:

DEVICE# 1:

PA XXXXX

PB XXXXX

KA XXXXX

KB XXXXX

DR XXXXXX

DA XXXXXX

DB XXXXXX

(SEE COMMANDS BELOW FOR DESCRIPTION OF COMMAND CODES).

Each time the strobe line gets triggered the unit will transmit

this data unless the program mode is entered and the strobe

list altered.

PARITY:

Parity is a bit of information that is inserted before the stop bit

and is used to help check if the transmission is correct. When

setting the parity you may select “ODD” (parity bit is logic 0 if

total number of logic 1’s in the first seven data bits is odd),

After these four items have been entered they will remain

unaltered unless the program mode is entered again and the

values changed. The unit is now set and must be addressed

by it’s device number to come on line again.

18

Page 23

SERIAL INPUT COMMANDS:

To get a unit on line you must address it by it’s device number.

This is done by typing DXX(S), XX= device number. The unit

comes on line and echoes back DEVICE# XX. Insure that

“DEVICE# XX:” is received before requests are sent. The unit

is now ready to receive a command or string of commands

separated by a space. A carriage return (enter) will enter the

commands and processing of requests begins. The carriage

return (Hex Code “D”) puts the unit “off line” after data is

processed.

COMMANDS:

EP...........Unit will enter program mode.

DA..........Unit will display (transmit) TOTAL A.

DB..........Unit will display (transmit) TOTAL B (grand total).

DR..........Unit will display (transmit) rate A.

KA..........Unit will display K-factor A.

†*KA(S)XXXXX....Unit will load K-factor A

with entered number.

KB..........Unit will display K-factor B

†*KB(S)XXXXX....Unit will load K-factor B

with entered number.

PA...........Unit will display Preset A.

†PA(S)XXXXX....Unit will load Preset A with

entered number.

PB...........Unit will display Preset B

†PB(S)XXXXX....Unit will load Preset B with

entered number.

RA..........Total A will reset

†*RA(S)XXXXXX...Unit will set Total A to

entered number.

RB..........Total B (grand total) will reset.

†*RB(S)XXXXXX...Unit will reset Total B (grand total) to

entered number.

*THE UNIT WILL RECOGNIZE A DECIMAL IF ONE IS

PLACED IN ANY OF THESE DATA VALUES.

†THE UNIT WILL ONLY RECOGNIZE THE LAST FIVE

DIGITS ENTERED (SIX DIGITS FOR RA & RB).

The following is an example of requests and responses:

Transmit from terminal Receive from unit

(s)=Space

D5(s) [Unit #5 Activated] DEVICE# 5:

PA(s)12345(s)PA PA 12345 PA

KA(s)1576(s)KA KA 1576 KA

KB(s)6751(s)KB KB 6751 KB

RA(s)RB[RETURN] RA RB

(UNIT PRESETS AND A & B K-FACTORS ARE SET AND

BOTH COUNTERS ARE RESET)

12345

1576

6751

SERIAL INTERFACE OPERATION:

Data is received and transmitted over standard EIA RS232 or

RS422 levels. Each ten bit character is made up of a start bit,

seven bit ASCII code, a parity bit and a stop bit. Device

number, baud rate, parity and strobe list are entered in the

program setup mode and will remain in memory even if power

is lost.

The input impedance of RS232 is 3KΩ to 7KΩ worst case. The

terminal addressing the unit must be capable of driving all

loads in the loop. The input impedance of RS422 is much

higher and there should be no problem driving as many as 99

units. The transmit line remains in a high impedance “off” state

until addressed. Only one unit is to be on line at a time!!! More

than one unit on line could damage the unit or corrupt the

transmitted data.

When the unit is active (on line) it will operate in a full duplex,

echo back mode, so that data sent from the terminal will be

transmitted back for verification. When the unit is “on line”, use

the proper serial transmit commands to request data or set a

new value. Up to 80 characters of data can be linked together

and transmitted to the unit in a string as long as there is a

space between the commands. If an error is made, a

correction can be made by back spacing and retyping correct

data before the return (enter) is sent. Once a return (enter) is

sent, the unit begins processing the data and will transmit the

requested data on a non-priority basis over the data transmit

line. A keypad entry or incoming data will halt the data

communication cycle. Therefore, there should be a pause

after data is requested to insure that all data has been

transmitted before making another request or addressing

another unit. If the unit is not busy, it should not take longer

than 300 msec to process each request. To find the cycle time

to process and transmit a request, calculate the bit transmit

time by using this formula: [(1÷ baud rate) x (80) + .005] x

number of requests made. This time will be extended if the

unit must service the front keypad. If transmission has not

started within two seconds after data is requested, it can be

assumed that there is a problem. The unit transmits a carriage

return and line feed after each data value. Any new communication must be started with DXX(S) (device number and

space).

RS232/RS422 - IBM-PC INTERFACE:

The following program is for IBM basic to set up RS232/RS422

on serial port (#1) at 300 baud. Run this program after

connecting the serial interface connections.

10 SCREEN 0,0:WIDTH 80

20 CLS:CLOSE

30 OPEN “COM1:300,n,7,1,CS,DS,CD” AS #1

40 ON ERROR GOTO 110

50 B$=INKEY$

60 IF B$< >”” THEN PRINT #1,B$;

70 IF EOF (1) THEN 50

80 A$=INPUT$ (LOC(1),#1)

90 PRINT A$;

100 GOTO 50

110 RESUME

19

Page 24

RS232 / RS422 WIRING

234

5

678

9

RS 232

COMPUTER HOOKUP:

RS 232: When connecting the unit to a computer with RS 232

communication, only three connections are needed. These

connections are: Receive data, Transmit data and Ground.

The connections should be made as follows:

DP -9 CONNECTOR COMPUTER

Transmit data (pin 2) Receive data

Receive data (pin 3) Transmit data

Ground (pin 5) Ground

RS 422: When connecting the unit to a computer with RS 422,

five connections are needed. These connections are: Receive data A (+), Receive data B (-), Transmit data A (+),

Transmit data B (-) and Ground. The connections should be

made as follows:

DP -9 CONNECTOR COMPUTER

Transmit data A(+) (pin 2 Receive data A(+)

Transmit data B(-) (pin 7) Receive data B(-)

Receive data A(+) (pin 3) Transmit data A(+)

Receive data B(-) (pin 8) Transmit data B(-)

Ground (pin 5) Ground

RST

B C

D E

A

ENTER LOCK PRE A PRE B VIEW PRGM

RST

B C

D E

A

ENTER LOCK PRE A PRE B VIEW PRGM

RS 232

1. INITIALIZE

2. TRANSMIT

3. RECEIVE

4. N/C

5. GROUND

6. STROBE

7. N/C

8. N/C

9. N/C

RECEIVE PIN (3)

TRANSMIT PIN (2)

GROUND PIN (5)

RS 422

RECEIVE A (+) PIN (3)

RECEIVE B (-) PIN (8)

TRANSMIT A (+) PIN (2)

TRANSMIT B (-) PIN (7)

GROUND PIN (5)

1

RS 422

1. INITIALIZE

2. TRANSMIT A (+)

3. RECEIVE A (+)

4. N/C

5. GROUND

6. STROBE

7. TRANSMIT B (-)

8. RECEIVE B (-)

9. N/C

RS 232

STROBE PIN (6)

PRINTER HOOKUP:

When connecting the unit to a printer, you must first program

the desired baud rate, parity and strobe list with a computer.

RST

B C

A

ENTER LOCK PRE A PRE B VIEW PRGM

After the unit is programmed it can be connected to the printer.

Connect the transmit line(s) of the unit to the receive line(s) of

the printer and be sure that both devices have common

grounds. When the strobe line is triggered the unit will transmit

the selected strobe list which you had previously programmed.

RST

B C

A

ENTER LOCK PRE A PRE B VIEW PRGM

20

+12V PIN (7)

(BOTTOM BOARD)

TRANSMIT PIN (2)

D E

GROUND PIN (5)

STROBE PIN (6)

+12V PIN (7)

(BOTTOM BOARD)

TRANSMIT A (+) PIN (2)

D E

TRANSMIT B (-) PIN (7)

GROUND PIN (5)

RS 422

Page 25

TROUBLESHOOTING GUIDE

PROBLEM SOLUTIONSPOSSIBLE CAUSES

Power is applied to unit but the display

does not light.

Unit works, but occasionally the display

freezes or skips counts.

Input signal is connected but the unit

does not count or display rate.

Rate is displaying: r FFFFF.

1. AC or DC power wiring is incorrect.

1. Line noise is affecting the processor

due to a current spike or surge.

1. Input wiring is incorrect.

2. Scale factors are incorrect.

3. Transmitting device is defective.

4. Wrong debounce filtering selected.

5. Minitrol is defective.

1. The unit is trying to display a

number which it can’t (too large).

2. Line noise affected unit on power

up.

1. Recheck power wiring

1. Use a different power supply or

install a surge suppressor.

1. Recheck input wiring.

2. Recheck scale factors and factor

calculations.

3. Replace transmitting device.

4. Recheck debounce filtering selection

“hi cps” or “lo cps”.

5. To confirm set scale factors at one

and connect a wire to pin #7 and

touch it to pin # 5 (input A). Each

time pin #5 is touched counter A

should count once. If not, call

factory for RMA.

1. Check scaling factor, if it is correct,

lower the number of significant

figures.

2. Reprogram the unit and be sure to

enter a decimal (enter one and re

move it if a decimal is not desired).

Relays are not activating properly.

Counter resets before reaching 999999.

1. Wrong relay duration.

2. Relay set for wrong activation

i.e. count instead of rate.

1. Relay duration is set at a value other

than 00.0. This causes the counter

to auto-reset at the preset.

1. Recheck programmed relay duration.

2. Recheck programmed relay

activation mode.

1. If relay outputs are not being used,

set the relays for rate.

2. Set the relay durations to 00.0.

21

Page 26

NOTE TO OUR CUSTOMER

KEP is dedicated to providing complete customer service and customer satisfaction. If you

have any comments or criticisms about how to improve this manual, please make a note

of the problem/improvement and notify us. We are always open to new ideas and

improvements. So please let us know your ideas and comments.

Call us toll free: 800-631-2165

WARRANTY

This product is warranted against defects in materials and workmanship for a period of two

(2) years from the date of shipment to Buyer.

The Warranty is limited to repair or replacement of the defective unit at the option of the

manufacturer. This warranty is void if the product has been altered, misused, dismantled, or

otherwise abused.

ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, ARE EXCLUDED, INCLUDING

BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE.

Loading...

Loading...