KEP INTELLECT-69 Series, INT-69RT, INT-69T, INT-69R Installation & Operating Instructions Manual

Page 1

INTELLECT-69

INSTALLATION & OPERATING INSTRUCTIONS

MODELS

INT-69RT

INT-69R

INT-69T

(with RS232 &

RS422 Option)

V ersion V_41

KESSLER-ELLIS PRODUCTS CO.

10 Industrial Way East

Eatontown, NJ 07724

http://www.kep.com

99318 10/2/98

Telephone: (732) 935-1320

T oll Free: (800) 631-2165

Fax: (732) 935-9344

Page 2

Proprietary Notice

The information contained in this publication is derived in part from proprietary and patent data.

This information has been prepared for the expressed purpose of assisting operating and

maintenance personnel in the efficient use of the instrument described herein. Publication of

this information does not convey any rights to use or reproduce it or to use for any purpose other

than in connection with the installation, operation and maintenance of the equipment described

herein.

Copyright 1990

Printed in USA. All Rights Reserved.

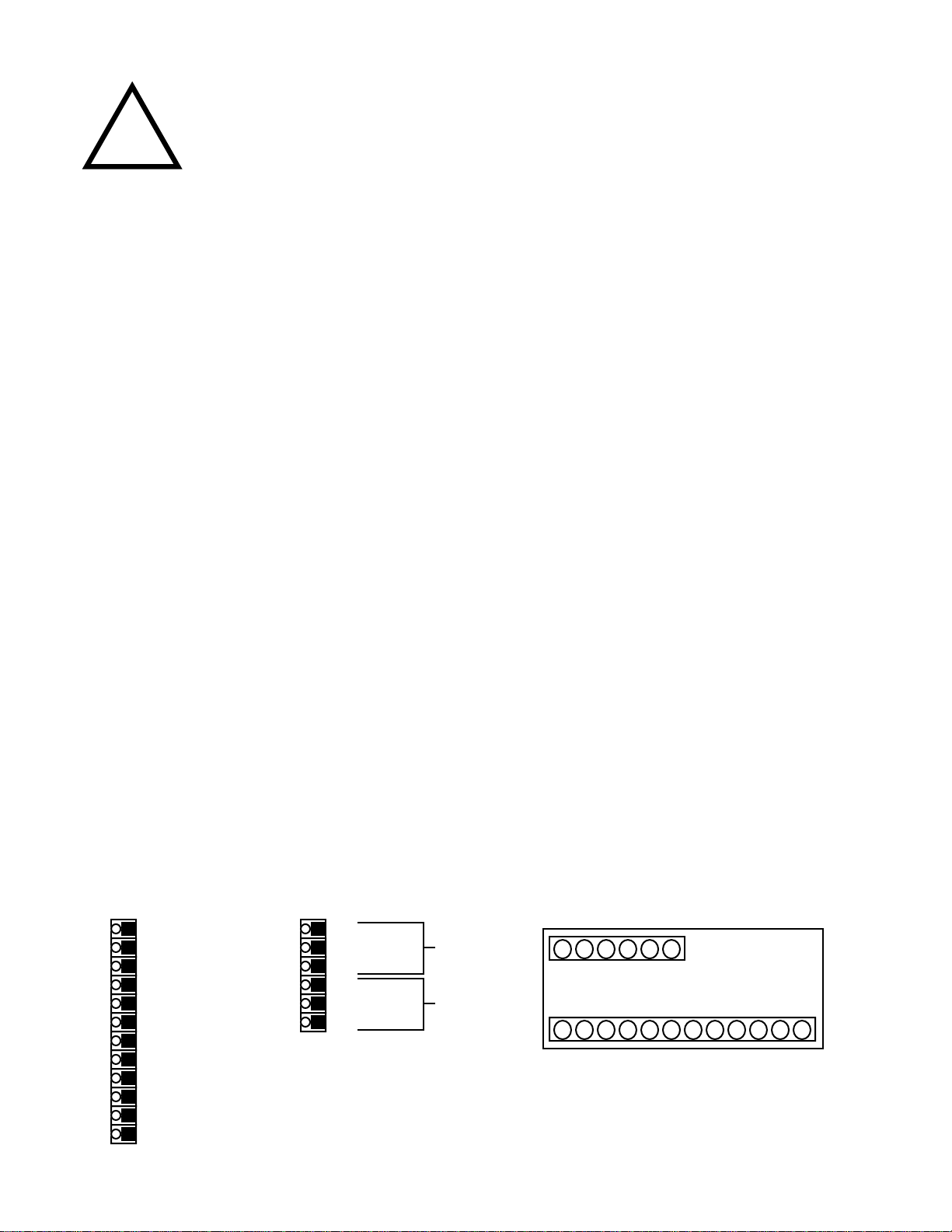

!

WARNING!

This instrument contains electronic components that are susceptible to damage by static

electricity. Proper handling* procedures must be observed during the removal, installation, or

handling of internal circuit boards or devices.

*Handling Procedure

1. Power to unit must be removed.

2. Personnel must be grounded, via wrist strap or other safe, suitable means, before any

printed circuit board or other internal device is installed, removed or adjusted.

3. Printed circuit boards must be transported in a conductive bag or other conductive container.

Boards must not be removed from protective enclosure until the immediate time of installation.

Removed boards must be placed immediately in protective container for transport, storage, or

return to factory.

Comments

This instrument is not unique in its content of ESD (electrostatic discharge) sensitive

components. Most modern electronic designs contain components that utilize metal oxide

technology (NMOS, CMOS, etc.). Experience has proven that even small amounts of static

electricity can damage or destroy these devices. Damaged components, even though they

appear to function properly, may exhibit early failure.

Page 3

TABLE OF CONTENTS

SAFETY INSTRUCTIONS ...........................................................1

DESCRIPTION & SPECIFICATIONS ..........................................2

MOUNTING .................................................................................3

WIRING........................................................................................4

TYPICAL WIRING HOOKUPS.....................................................5

OPEN COLLECTOR & RELAY OPERATION .............................5

PROGRAMMING FLOWCHART .................................................6

DEFINITIONS .............................................................................. 7

FRONT PANEL OPERATIONS ...................................................10

PROGRAMMING .........................................................................10

SETTING PRESETS & PANEL LOCK.........................................15

RS 232/422 OPERATIONS .........................................................16

RS 232/422 WIRING....................................................................20

TROUBLESHOOTING GUIDE ....................................................21

WARRANTY ................................................................................22

DECODING PART NUMBER ......................................................22

Page 4

THIS PAGE IS BLANK

Page 5

SAFETY INSTRUCTIONS

!

The following instructions must be observed.

• This instrument was designed and is checked in accordance with regulations in force

EN 60950 (“Safety of information technology equipment, including electrical business

equipment”).

A hazardous situation may occur if this instrument is not used for its intended purpose

or is used incorrectly. Please note operating instructions provided in this manual.

• The instrument must be installed, operated and maintained by personnel who have

been properly trained. Personnel must read and understand this manual prior to

installation and operation of the instrument.

• The us of an external line fuse is recommended. Add or replace the external fuse with

the following specified type and rating only:

Input Power Recommended Fuse

115 VAC 100 mA slow blow fuse

230 V AC 50 mA slow blow fuse

12-24 VDC 250 mA slow blow fuse

Disconnect power supply before adding or replacing fuse!

• The manufacturer assumes no liability for damage caused by incorrect use of the

instrument or for modifications or changes made to the instrument.

Symbols Used On Unit

Number Symbol Publication Description

1 IEC 417, No. 5031 Direct current

2 IEC 417, No. 5172 Equipment protected throughout by

DOUBLE INSULATION or REINFORCED

INSULATION (equivalent to Class II of IEC

536–see annex H)

3

!

ISO 3864, No. B.3.1 Caution (refer to accompanying documents)

Technical Improvements

• The manufacturer reserves the right to modify technical data without prior notice.

1

Page 6

DESCRIPTION & SPECIFICATIONS

Description:

Featuring 6 digits of bright, 7-segment LED displays,

this unit is an integrating totalizer/ratemeter which accepts analog signal inputs. The unit can be field

programmed to accept 0-20mA, 4-20mA, 0-5V, 010V or 1-5V signals. An optional Square Law input is

available for inputs that require square root extraction. A 4-20mA output option is available to control

strip recorders or other peripherals. Two assignable

set points are standard for two stage shut off. The

high and low scaling settings are programmable from

the front panel. By pressing the "view" button, the

unit will display: integrated total, rate, peak or valley.

RS-422 or RS-232 serial communications are available options for data communication with a host computer.

Specifications:

Display: 6 digit, .55" high, LED.

Input Power: 110, 220 VAC ± 15% or 12 to 24VDC.

Current: maximum 300 mA DC or 10.0 VA at rated

AC voltage.

Output Power: (AC powered units only) + 24VDC.

@ 50 mA regulated ±5%

Temperature:

Operating: +41°F (5°C) to +130°F (+54°C).

Storage: -40°F (-40°C) to +200°F (93°C).

Memory: EEPROM stores data for ten years if power

is lost.

Reset:

Front Panel: resets displayed values and control outputs.

Remote: 4-30 VDC positive edge, resets totalizer and

control outputs.

Control Outputs:

Standard: Open collector sinks 250 mA from 30VDC

when active.

Optional: 2 each Form C SPDT 10Amp @ 120/240

VAC or 28 VDC. (Open collector outputs are also

supplied with 10VDC provided at transistor outputs

through relay coil. If greater than 2mA is used, relay

will remain energized. Applying greater than 10 VDC

may destroy unit. Transistor will sink 100mA in "ON"

state.)

Input:

Standard: Linear 0-20mA, 4-20mA, 0-5V, 0-10V or 15V selectable from the front panel.

Optional: Square Law 0-20mA, 4-20mA, 0-5V, 0-10V,

or 1-5V, is available for inputs that require square root

extraction.

Input Impedance: Current: 100Ω; Voltage: 115KΩ

Calibration: The unit does all of the calibrations inter-

nally. There are no potentiometers to adjust and the unit

never needs to be removed from the case.

Set Points: The two control set points can be set at any

number from 0 to 59999. The set point outputs can be

assigned to rate or total. The unit comes standard with

two open collector control outputs. Two 5 Amp, Form C

relays are optional. The outputs are programmable

from .01 to 599.99 sec or latched until reset when

assigned to the total and a hysteresis (alarm range)

when assigned to the rate.

Rate Display: Updates 5 times per second, Accurate to

4.5 digits. Set "low" greater than "high" for inverted

display (LINEAR ONLY).

Totalizer: Integrates from the rate reading and accumulates up to 6 digits of total count. The time base

(hours, minutes or seconds) is field programmable from

the front panel.

Analog Out: The unit can be ordered with an optional

4-20mA output which is proportional to the rate display.

The high and low settings are programmable from the

front panel. Set "low" greater than "high" for inverted

output. A sinking driver generates a corresponding

linear current through the external devices. The output

updates with each update of the rate. Accuracy is 50uA

worst case. For rated accuracy, load must be connected to the analog output before unit is powered.

Compliance voltage must be 3 to 30 VDC non inductive.

(The unit can provide the DC source as long as the drop

across the devices being driven does not exceed 21V).

Programming: Decimal points, Scaling from 0 to

59999 units per selected time base, set points, input

type, security lock code, and assigning outputs are all

programmable from the front panel.

Housing: Standard 1/8 DIN, high impact 94VO plastic

case.

Shipping Weight: 2 lbs.

Overvoltage Protection:

50 V

Overcurrent Protection:

50 mA

Resolution: 14.5 Bits

Accuracy:

RANGE % FS ERROR % FS ERROR

(worst case) (typical)

4-20 mA 0.1% .05%

0-10 VDC 0.2% 0.1%

0-5 VDC .25% .15%

1-5 VDC .25% .15%

Square Law: (above 5% of bottom range) 0.1%

(5V inputs .4%) Worst case over complete range: 2%

Temperature Stability: Will not drift more than 20

parts per million per °C from 5°C to 54°C

2

Page 7

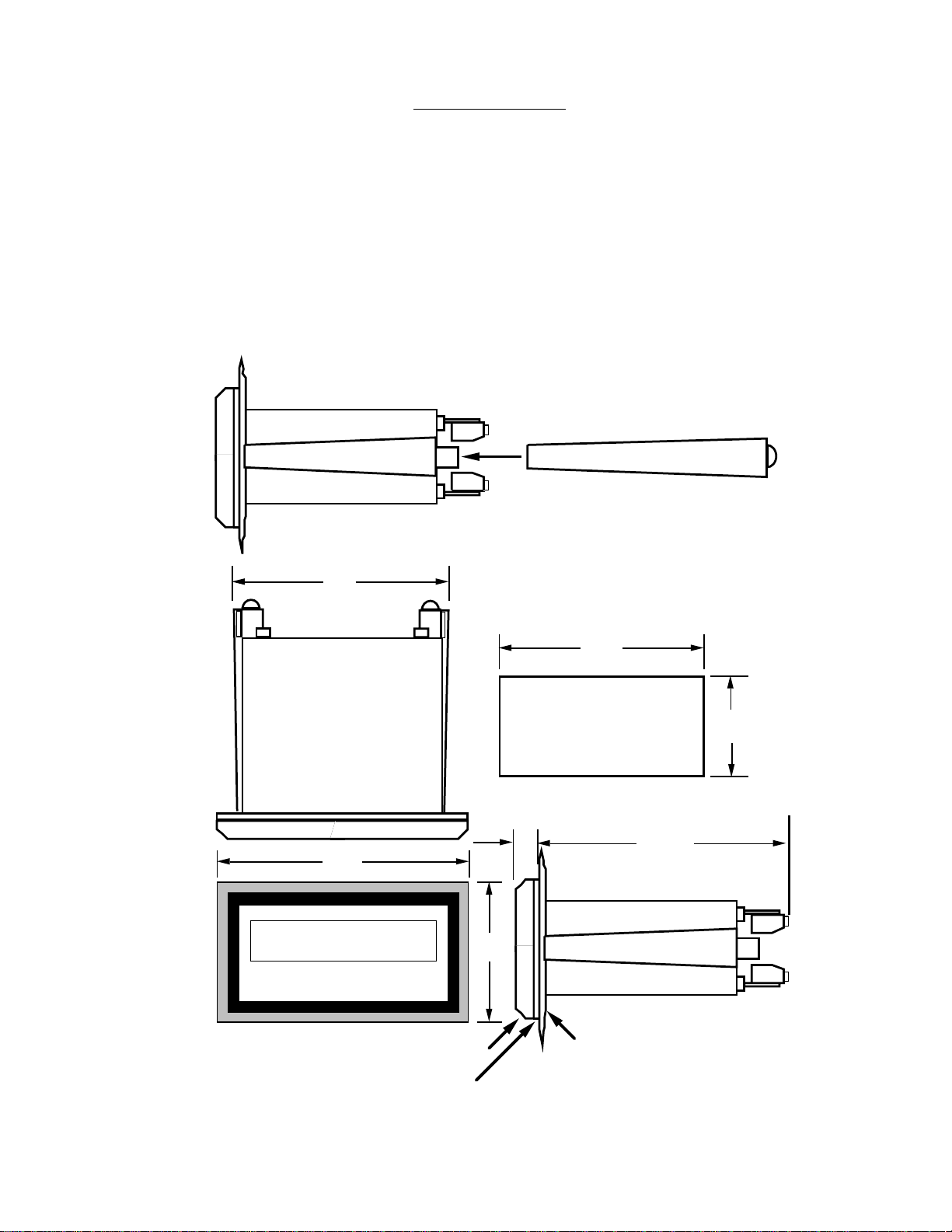

HOW TO MOUNT:

MOUNTING

Slide the body of the unit through the rubber

gasket. Insert the unit into the panel. Slide the

brackets up the groove to press against the

back of the panel, as shown in "FIG. A". Insert

the screws into the rear of the brackets.

FIG. A

3.925

(99.7)

Tighten the screws evenly and alternately. A

panel less than .1" may distort if the clamps are

screwed too tightly. Do not over tighten! A

normal level of torque is required. Maximum

torque should be 3" pounds.

The panel must be parallel to the bezel to

assure proper seal. Unit seals to NEMA 4/

IP65 if properly mounted.

4.437

(112.7)

BEZEL

GASKET

.587

2.625

(66.68)

3.622

(92)

1.772

(45)

4.245

(107.8)

CUSTOMER PANEL

Panel Thickness 0.062" (1.5)

to 0.187" (4.7) max.

3

Page 8

!

WIRING

AC / DC CONNECTIONS:

NOTE: Connect power only after other connections are finished. Do not touch the live AC power

terminals. The unit has been designed with an

isolated AC input, therefore polarity is not a concern for the AC power. The chassis is plastic,

therefore earth ground is not used. For DC operation, connect +DC to terminal 10 and -DC to

terminal 3.

This Product complies with requirements of the

European Community Directive 89/336/EEC [Electromagnetic Compatibility]. However, electrical

noise or intense electromagnetic fields in the vicinity of the unit may disturb the microprocessor.

Users should exercise care and should take proper

precautions to avoid microprocessor disturbance.

Four common sources of noise are:

1) AC power line noise- The input power lines

should not be common to power lines for motors,

pumps, contactors, etc. If the unit cannot be connected to an electrically clean power source, an

inductive load suppressing device (MOV as

GE#V130LA1 or Resistor Capacitor as Paktron#

.2uf/220 ohm @ 400V) can be installed. Although

locating the suppressor across the AC supply at

the unit should help, best results are obtained by

connecting the suppressor across the leads of the

"load" at the device causing the spikes.

2) Input line noise- The noise is carried on the input

and DC ground lines. Make sure the input wires

are not run into the unit in a bundle with power input

lines. We recommend using shielded cable. Connect the shield to DC ground of the unit and "earth"

at one point in the circuit preferably at the DC

ground terminal of the unit.

3) Output lines- The unit has two open collector

outputs and two optional relay outputs. When

these outputs are used to run external relays or

solenoids, spikes can be generated upon activation. This noise can spread through the instrument

causing operating problems. If the source is a D.C.

operated device, a general purpose diode (IN4004)

placed across the solenoid prevents electrical

noise spikes. Connect the cathode (banded side)

to the more positive side of the coil. If the source

is an A.C. operated device, use a Resistor Capacitor or MOV across the coil.

4) 24 VDC output supply- Noise can be generated

on the 24 VDC output supply if it is used to drive

inductive loads or if the current draw exceeds

50mA. Insure that all inductive loads have a diode

(such as IN4004) across the coil and that the

current does not exceed 50mA.

RESET IN

1

ANALOG OUT (SINK)

2

SIGNAL GND (-DC)

3

(CURRENT) +I IN

4

(VOLTAGE) +V IN

5

NOT USED

6

+24V OUT

7

PRESET B COLLECTOR

8

PRESET A COLLECTOR

9

+D.C. IN

10

110 / 220 VAC

11

110 / 220 VAC

12

WIRING CONNECTIONS

13

COMMON

14

N.C.

15

N.O.

16

COMMON

17

N.C.

18

N.O.

RELAY A

RELAY B

4

13 14 15 15 17 18

1 2 3 4 5 6 7 8 9 10 11 12

REAR VIEW

Page 9

TYPICAL WIRING HOOKUPS

3-Wire 0-10V Transmitter2-Wire 4-20mA Transmitter

Flowmeter

(4-20mA T ransmitter)

4-Wire 4-20mA Transmitter

Power

Supply

Flowmeter

(4-20mA T ransmitter)

2-Wire 4-20mA Transmitter

with Multiple Devices

-

+

Flowmeter

(4-20mA T ransmitter)

-

Strip Chart

Recorder

•7 - +24V Out.•11 - AC In

•12 - AC In

..•11 - AC In

•12 - AC In

•7 - +24V Out.•11 - AC In

•12 - AC In

110 VAC

60/50 Hz

110 VAC

60/50 Hz

110 VAC

60/50 Hz

•3 - Signal GND (-DC)

•4 - I In + (Current)

.

-

+

•3 - Signal GND (-DC)

•4 - I In + (Current)

-

+

•3 - Signal GND (-DC)

•4 - I In + (Current)

.

+

Flowmeter

(0-10 V Transmitter)

2-Wire 4-20mA Transmitter

Flowmeter

(4-20mA Transmitter)

AC Supply

LOAD

LOAD

+

-

recommende

for inductive

recommende

signal

with Analog Output

Strip Chart

Recorder

+

-

+

Relay Output

Neutral

MOV

loads

Diode

for inductive

loads

-

DC

Supply

•13 Common

•14 N.C.

•15 N.O.

•16 Common

•17 N.C.

•18 N.O.

+

•3 - Signal GND (-DC)

.

•5 - V In + (Voltage).•7 - +24V Out.•11 - AC In

-

+

•2 - Analog Out

•3 - Signal GND (-DC)

•4 - I In + (Current)

.

•7 - +24V Out.•11 - AC In

110 VAC

•12 - AC In

60/50 Hz

110 VAC

•12 - AC In

60/50 Hz

Relay A

Relay B

OPEN COLLECTOR & RELAY OPERATION

The open collector and relay outputs trigger when the

total or rate (assignable; see programming step 2)

equals the corresponding Preset (A or B).

When the outputs are assigned to the "total", the operator can assign a duration of time (.01 to 599.99 sec.) that

the output will remain energized. If 0.00 is assigned, the

output will latch until reset. If output A is set at a duration

(other than 0.00), the totalizer will autorecycle when

Preset A is reached. At this time, output B will deenergize (if it was energized). Preset A is the final

preset and should be set higher than Preset B, when

both outputs are assigned to the total. If output A is set

at a duration other than 0.00 and Preset A is set less

than Preset B, Preset B will be ignored (provided that

they are both assigned to total). The totalizer will never

autorecycle at Preset B.

When the outputs are assigned to the "rate", the outputs

can be assigned a hysteresis (alarm range). The

hysteresis is the number of units below the preset that

the output will remain energized. EXAMPLE: Preset set

@ 100; Hysteresis set @ 10. The output will energize

when the rate equals 100 and de-energize when the

rate falls below 90 (10 below Preset).

NOTE: If the input scaling is inverted, the control output

functions are inverted (LINEAR ONLY).

5

Page 10

V41 & V_41 PROGRAMMING FLOWCHART

4-20

EE

EE

LLAAAAYYYYSSSS

AA

AA

AA

AA

TTEEEE

AA

AA

tt

YYYYSS

SS

AA

AA

AA

AA

YYYYSS

SS

BB

BB

CC

CC

LLCCCC

AA

AA

LL

CC

CC

ddeeee

ssssee

ee

pp

pp

DDEEEECCCC

SSSSEE

EE

SSSSEE

EE

CC

CC

tt

SSSSEEEECCCCSS

SS

pp

pp

tt

AA

AA

TTEEEE

tt

bbaaaa

dd

tt

PP

PP

SS

SS

TT

ttaaaallll

D

300

E

DDEEEECCCCttttffffaaaaCCCCtttt

NOTE:

SSTTAARRT

PRGM

input

ENTER

i

i 0-20

e 0-5

PRGM

e 1-5

e 0-10

ENTER

LiNEAR

PRGM

S9RT

ENTER

RUN MODE

SEVERAL PROGRAMMING SELECTIONS

WILL NOT APPEAR WITH "RATE ONLY"

& "TOTAL ONLY" UNITS

OPTIONS NOT ORDERED WILL NOT APPEAR

IN PROGRAM SELECTIONS

T

RR

RR

PRGM

RR

RR

ENTER

HH

HH

XXXXX

ENTER

RR

BBBB RR

TT

HH

HH

XXXXX

BB

LL

ENTER

TT

PRGM

PRGM

ttttoooott

ENTER

dddduuuurrrr

PRGM

XXX.XX

ENTER

BBBB ttttoooott

PRGM

ENTERENTER

dddduuuurrrr BB

XXX.XX

oo

lllloo

ENTER

LL

LLLLLL

gg

LLLLCCCC ppppgg

ENTER

oooodd

XXXXX

ENTER

RUN MODE

PRGM

This symbol indicates any key.

Press this key to step through Menu choices

PRGM

Press this key to enter displayed value.

ENTER

uu

ttttuu

PRGM

ENTER

*

lllloooo

PRGM

TTTT lllloo

TTTT HHHHii

uuuutt

nnnnoooorr

oo

ii

rr

NNNNNNNNiiiiNNNNSS

hhhhoooouuuurrrrss

rrrrDD

ENTER

XXXXX

ENTER

XXXXX

ENTER

XXXXX

ENTER

XX.X

ENTER

SS

ss

oooouuuutttt lllloo

oooouuuutttt HHHHii

uuuunnnniiiitt

oo

ii

PRGM

bb

oo

oo

ENTER

uuuudd

ENTER

tt

1200

2400

9600

PRGM

XXXXX

XXXXX

XX

ENTER

ENTER

RUN MODE

* For Version V41,

(with space between V & 41) ,

RDEC

appears after

Lo Cut

rdeC

appears as shown

. In Version V_41

For best results, choose the highest resolution possible when

entering the "set lo", "set hi" and "lo cut" values.

Enter the proper decimal location at the "rdec" prompt.

For V41

EXAMPLE: To scale the unit from 0.00 to 100.00, enter 0 for "set

lo" and 10000 for "set hi", enter the decimal at "rdec".

The Version number is displayed at power up.

NOTE: Model INT69T & units with RS232/RS422 option can only

be used with V_41.

ii

LLLLii

ENTER

TT

PRESS

"PRGM"

TO

ADVANCE

TO NEXT

SELECTION

ttttoooott

RRRRAAAATTTTEE

PPPPEEEEAAAACC

uuuuaaaallllllllyy

PPPPRRRREEEE AA

PPPPRRRREEEE BB

SSSSEEEETTTT lllloo

SSSSEEEETTTT HHHHii

EEEENNNNDD

PRGM

RUN MO

EE

CC

yy

AA

BB

oo

ii

DD

PRGM

ttttDD

ENTER

ENTER

1111000000

11110000000000

111100

11

11

00

00

00

RUN MODE

6

Page 11

DEFINITIONS

input

- INPUT; This section of the program menu assigns the type of input the unit will be using (0-20 mA, 4-

20 mA, 0-5 V, 0-10 V, 1-5 V, Linear or square root extraction).

i 4-20

- I 4-20; This sets the unit for a current input of 4 to 20 mA.

i 0-20

- I 0-20; This sets the unit for a current input of 0 to 20 mA.

E 1-5

- E 1-5; This sets the unit for a voltage input of 1 to 5 volts.

E 0-5

- E 0-5; This sets the unit for a voltage input of 0 to 5 volts.

E 0-10

- E 0-10; This sets the unit for a voltage input of 0 to 10 volts.

LiNEAR

S9RT

RELAYS

A RATE

HYS A

A tot

DuR A

B RATE

HYS B

b tot

- LINEAR; This sets the unit for linear input.

- SQUARE ROOT; This sets the unit for square root extraction.

- RELAYS; This section of the program menu sets the control output variables (relays & open collec-

tor).

- OUTPUT A FOR RATE; This assigns the A output to the rate.

- HYSTERESIS FOR OUTPUT A; This value is the number of units below Preset A that the output will

remain "ON". EXAMPLE: Preset A set at 100, Hys set at 10. Output A will activate (turn on) when the

rate equals 100; Output A will deactivate (turn off) when the rate falls below 90 (10 below Preset A)

- OUTPUT A FOR TOTAL; This assigns the A output to the totalizer.

- OUTPUT A DURATION; This is the duration of time (.01 to 599.99 sec) that Output A will remain

energized. If 0.00 is entered the output will latch until reset. If a value other than 0.00 is entered the unit

will autorecycle at Preset A.

- OUTPUT B FOR RATE; This assigns the B output to the rate.

- HYSTERESIS FOR OUTPUT B; Same as HYS A.

- OUTPUT B FOR TOTAL; This assigns the B output to the totalizer.

DuR B

- OUTPUT B DURATION; This is the duration of time (.01 to 599.99 sec) that Output B will remain

energized. If 0.00 is entered the output will latch until reset.

loc

- LOCK; This section of the program menu sets up the lockout type and code.

LC ALL

- LOCK ALL; When this is selected the lockout will lock the program as well as the Presets and reset

button. The presets can be viewed but not changed.

7

Page 12

lc pg

- LOCK PROGRAM; When this is selected the lockout will lock only the program. The Reset can be

activated and the presets can be viewed and changed.

code

- CODE; This is a 5-digit code which will be used to lock and unlock the front panel.

setup

- SETUP; This section of the program menu sets up the operating variables.

rdec

- RATE DECIMAL LOCATION; This allows the user to program a decimal point for the rate display.

set lo

SET Hi

lo cut

nor

SECS

NNiNs

hours

tdec

tfact

- SET LOW; This is the rate value for the lowest input (0 or 1 Volts; 4 mA). (i.e. 4 mA = 10 lbs/hr.)

- SET HIGH; This is the rate value for the highest input (5 or 10 Volts; 20 mA). (i.e. 20 mA = 500 lbs/

hr.)

- LOW CUT-OFF; This is the lowest rate value to be recognized. All rate readings below this value will

assume the "set lo" value.

- NORMALIZING FACTOR; This is an averaging factor (00.0 to 99.9). Higher settings provide more

normalizing (averaging) for a more stable display. Derived from the equation:

(OLD DATA x "NOR" + NEW DATA)

("NOR" + 1)

- SECONDS; This tells the unit that the High and Low input values are entered in units per second.

- MINUTES; This tells the unit that the High and Low input values are entered in units per minute.

- HOURS; This tells the unit that the High and Low input values are entered in units per hours.

- TOTALIZER DECIMAL LOCATION; This allows the user to enter a decimal for the totalizer display.

This decimal is not a dummy decimal and will scale the totalizer display accordingly. (i.e. if the tdec is set

in the tenths position (#####.#), 100 will be displayed as 100.0)

- TOTALIZER FACTOR; This factor divides the totalizer display by 1, 10, 100 or 1000.

opt

- OPTIONS; This section of the program menu is for setting up optional features (analog out, RS232/422

serial communications).

out lo

out hi

BAuD

9600

2400

1200

300

- OUT LOW; The displayed rate value at which the unit will output 4 mA (2 lbs./hr = 4 mA out).

- OUT HIGH; The displayed rate value at which the unit will output 20 mA (2000 lbs./hr = 20 mA out).

- BAUD RATE; The baud rate at which the RS232 or RS422 communications will operate.

- 9600 BAUD; This sets the communications at 9600 Baud.

- 2400 BAUD; This sets the communications at 2400 Baud.

- 1200 BAUD; This sets the communications at 1200 Baud.

- 300 BAUD; This sets the communications at 300 Baud.

8

Page 13

unit

- UNIT NUMBER; This assigns the unit an ID number from 1 to 99. This number is to be addressed

when the unit is to be on line. A unit with 0 assigned will never come on line.

P LiST

- PRINT LIST; This sets a list of data that will be transmitted whenever the strobe is activated.

total

- TOTAL COUNT; When this is added to the print list, the unit will transmit the total when the strobe is

activated.

RATE

- RATE; When this is added to the print list, the unit will transmit the present rate value when the strobe

is activated.

PEAK

- PEAK; When this is added to the print list, the unit will transmit the present peak value when the strobe

is activated.

uALLEY

PRE A

PRE B

set lo

set hi

END

PXXXXX

uXXXXX

- VALLEY; When this is added to the print list, the unit will transmit the present valley value when the

strobe is activated.

- PRESET A; When this is added to the print list, the unit will transmit the Preset A value when the

strobe is activated.

- PRESET B; When this is added to the print list, the unit will transmit the Preset B value when the

strobe is activated.

- SET LOW; When this is added to the print list, the unit will transmit the Set Low value when the

strobe is activated.

- SET HIGH; When this is added to the print list, the unit will transmit the Set High value when the

strobe is activated.

- END; This is the only exit from the P List. If END is not entered the unit will start at the beginning of the

P List again.

- P; This will appear in the 6th (furthest to the left) digit when viewing the Peak. The peak value is the

highest rate reading that the unit had displayed since the peak had been reset. The peak is not retained

in memory when power is lost.

- U; This will appear in the 6th (furthest to the left) digit when viewing the Valley. The valley value is

the lowest rate reading that the unit had displayed since the valley had been reset. The valley is not

retained in memory when power is lost.

RXXXXX

- R; This will appear in the 6th (furthest to the left) digit when viewing the Rate.

9

Page 14

FRONT PANEL OPERATIONS

Press to RESET

in operating

mode; Press to

"ENTER" in

programming

mode.

Press once to freeze

display. Press any

key to update display

normally.

Press rapidly

(3 times within 5

seconds) to "enter"

LOCK code for panel

lock.

RST

ENTER LOCK PRE A PRE B VIEW PRGM

Press to view or

change Preset A

A B C D

Press to view or

change Preset B

E

PROGRAMMING

Press to alternately view Rate,

Total, Peak &

Valley.

Press to cycle

through PROGRAM choices;

Press to step

through set up

choices in

program mode.

STEP

1

SETTING

INPUT

PRESS

PRGM

ENTER

ENTER

DISPLAY

iNPuT

i 4-20, i 0-20

E 1-5, E 0-5

E 0-10

LiNEAR

or

S9RT

or

REMARKS

This section of the menu is used to set

up the type of signal the unit will be

receiving.

Press the PRGM key to step through

choices. Press the RST/ENTER key

to enter the displayed choice.

This section will only appear on units

with the square root extraction option.

Press the PRGM key to toggle between the choices and press the RST/

ENTER key to enter the desired choice.

10

Page 15

PRESS DISPLAY REMARKS

STEP

2

SETTING

RELAYS

NOTE: If relay outputs

are not used,

set dur A &

dur B at "0.0"

to prevent the

counters from

resetting at the

presets.

PRGM

PRGM

ENTER

ENTER

ENTER

ENTER

input

RELAYS

A RATE

or

A ToT

(IF TOT SELECTED)

DuR A

(hit any key to view or

change existing dur A

value XX.X)

(IF RATE SELECTED)

HYS A

(hit any key to view or

change existing HyS A

value XXXXX)

B RATE

or

B ToT

This section of the menu sets up the

open collector outputs and/or relays.

Output A assigned to the rate or total.

Press the PRGM key to toggle between choices, press the RST/ENTER

key to enter the displayed choice.

dur A = the duration of time (.01 to

599.99 sec) that output A will remain

on or energized. When dur A is displayed, hit any key to view or change

dur A. Press the RST/ENTER key to

enter displayed value. When dur A is

set at 0.00,output A will latch until reset; when dur A is set other than 0.00

the counter will autorecycle at Preset

A.

Hys (hysteresis)= The number of units

below the preset that the output will

remain "ON". EXAMPLE: Preset set

@ 100; HyS set @ 10. Output will

activate (turn on) when rate = 100 and

turn off when rate falls below 90 (10

below preset).

Follow instructions for A RATE & A

TOT.

ENTER

ENTER

(IF TOT SELECTED)

DuR B

(IF RATE SELECTED)

HYS B

11

Follow instructions for dur A

Follow instructions for hys A

Page 16

PRESS

DISPLAY REMARKS

STEP

3

SETTING

LOCK

STEP

4

SETTING

SETUP

PRGM

PRGM

PRGM

ENTER

ENTER

PRGM

PRGM

PRGM

PRGM

input

RELAYS

LoC

LC PG or LC ALL

CoDE

Press any key to view

or change the lock

code

input

RELAYS

LoC

SETuP

This section of the menu is used to set

up the lockout type and code.

LC PG = Locks program but presets

are accessible.

LC ALL= Locks program & presets.

Press the PRGM button to toggle between choices; Press RST/ENTER to

enter displayed choice.

When CODE is displayed, press any

key to view existing lock code. To

change the code press the key under

each digit to be changed. Press RST/

ENTER to enter displayed value.

This section of the menu is used to set

up important operating variables.

ENTER

ENTER

ENTER

rDEC

RDEC= rate decimal location; Press

the key under the digit with the desired

location. Press the "E" key if a decimal

is not desired. Press RST/ENTER to

enter the displayed location.

SET Lo

Press any key to view

or change existing

value

SET LO= Rate value for the lowest

input (0 or 1V; 4mA).(i.e. 4mA = 10 lbs/

hr.) Key in the desired low value and

press RST/ENTER to enter displayed

value.

SET Hi

Press any key to view

or change existing

value

SET HI= Rate value for the highest

input (5 or 10V; 20mA).(i.e. 20mA =

500 lbs/hr.). Key in the desired high

value and press RST/ENTER to enter

displayed value.

CONTINUED ON NEXT PAGE

12

Page 17

STEP

4

CONT...

SETTING

SETUP

ENTER

DISPLAYPRESS

Lo CuT

Press any key to view

or change existing

value

REMARKS

LO CUT= Low cut-off; Lowest rate

value to be recognized. All rate readings below the "cutoff" will assume the

"set lo" value. Key in the desired value

and press RST/ENTER to enter displayed value.

PRGM

ENTER

ENTER

ENTER

NoR

Press any key to view

or change existing

value

NNiNS, HouRS

or

SECS

tdec

NOR= Normalizing (averaging) factor

(00.0 to 99.9); Key in the desired value

and press RST/ENTER to enter displayed value. Higher settings provide

more normalizing (averaging) for a

more stable display.

This section tells the unit that the high

& low setting are entered in units per

Minutes, Hours or Seconds. Press the

PRGM key to step through choices.

Press RST/ENTER to enter displayed

choice.

TDEC= Totalizer Decimal; Press the

arrow keys to enter in the desired

totalizer decimal. Press RST/ENTER

to enter displayed choice. Entering a

decimal will add resolution to the total.

(i.e. tdec=#####.#; 100 will be displayed as 100.0)

PRGM

ENTER

ENTER

tfact

Press any key to view

or change existing

value

1, 10, 100

or

1000

13

TFACT= Totalizer Factor; This factor

allows you to divide the totalizer by 1,

10, 100, 1000

Press the PRGM key to step to the

desired factor. Press RST/ENTER to

enter displayed choice.

Page 18

DISPLAYPRESS

REMARKS

STEP

5

SETTING

OPTIONS

PRGM

PRGM

PRGM

PRGM

PRGM

ENTER

ENTER

input

RELAYS

LoC

SETuP

oPT

ouT Lo

Press any key to view

or change existing

value

ouT Hi

Press any key to view

or change existing

value

This section of the menu is for setting

up the variables for any options which

were ordered (Analog out or Serial

communications).

OUT LO= The rate value represented

by the 4 mA end of the 4-20 mA output

Key in the desired value and press

RST/ENTER to enter displayed value.

OUT HI= The rate value represented

by the 20 mA end of the 4-20 mA

output. Key in the desired value and

press RST/ENTER to enter displayed

value.

BAuD

Press any key to view

or change existing

BAUD = Baud rate for RS 232 or RS

422 communications option. Press

any key to view existing value.

value

ENTER

9600, 1200,

2400 or 300

Press the PRGM key to view available

baud rates; Press RST/ENTER to enter displayed value.

unit

Press any key to view

or change existing

ENTER

value

P LiST

Press any key to enter

print list

ToTAL

RATE

PEAK

ENTER

OR

PRGM

uALLY

PRE A

PRE B

set lo

set hi

END

THE PROGRAM SETUP IS COMPLETE! YOU ARE NOW READY TO SET THE PRESETS.

14

UNIT = Unit ID number. Key in the

desired unit number (1-99) and press

RST/ENTER to enter displayed value.

P LIST = Print list.

Press RST/ENTER to add items to list;

Press PRGM to remove items from

list.

TOTAL = Total

RATE = Rate

PEAC = Peak

UALLY = Valley

PRE A = Preset A

PRE B = Preset B

SET LO = Low Input Value

SET HI = High Input Value

END = Press RST/ENTER to exit (end) print list;

Press PRGM to recycle through list choices.

Page 19

SETTING THE PRESETS & PANEL LOCK

SETTING

THE

PRESETS

NOTE:

Presets can

be set at any

value form 0

to 59999.

SETTING

THE

LOCK

STATUS

Press LOCK 3 times within 5 seconds

(If LOCK is pressed once, unit freezes display)

PRE A

PRE B

LOCK

LOCK

LOCK

DISPLAYPRESS

PRE A

Press any key to view

or change existing

value

PRE B

Press any key to view

or change existing

value

CoDE

Press any key to enter

the 5-digit lock code.

REMARKS

PRE A = Preset A (Final Preset); The

set point at which output A will trigger.

If the displayed value is not the desired preset, press the key(s) under

the digit to be changed.

PRE B = Preset B (Prewarn); The set

point at which output B will trigger. If

the displayed value is not the desired

preset, press the key(s) under the digit

to be changed.

Key in the lock code (see programming step 3) by pressing the keys

under the digits to be changed. Each

time a key is pressed the digit will

increment one. Press the RST/ENTER key to enter the displayed code.

ENTER

LoC

or

UN LoC

After the code is entered the unit will

display LOC (unit is locked) or UN LOC

(unit is un-locked). This message will

be displayed for approximately 3 seconds before the unit returns to the run

mode. If an invalid code is entered, no

message is displayed; try again.

15

Page 20

RS 232/422 OPERATIONS

This section applies to units which have the

serial communications interface option. Up to

99 units can be linked together. Unit status

can be accessed and many menu items can

be entered through the serial port. Data is

transmitted at selected baud rates using standard eight bit ASCII characters and one “stop”

bit. The unit does not check or transmit a parity

bit.

UNIT I.D. (DEVICE #)

Each unit in the hookup must be assigned a

unit number from 1 to 99. This can be entered

through the front panel (see step 5 of the

programming section). If “00” is assigned, the

unit can not be brought on line through the

serial port. The units will remain in an “off” high

impedance state until addressed by the assigned unit number. Once a unit is addressed,

do not address another unit until the data has

been sent and any data requested has been

transmitted back.

BAUD RATE

The baud rate is the speed at which data is

transmitted, expressed in bits per second.

Baud rates of 300, 1200, 2400 or 9600 are

available. Select the desired baud rate from

the menu. (see step 5 of the programming

section).

PRINT LIST

The serial interface card is equipped with a

strobe line. When the strobe line is activated

a user selectable set of data (print list) is

transmitted. This transmission can be sent to

a computer or printer. The print list consists of

eight selectable items: COUNT, RATE, PEAK,

VALLEY, PRE A, PRE B, LOW SET, HIGH

SET. The list can be entered through the front

panel (see step 5 of the programming section)

or through the serial port (read on).

HELP

A help command has been installed for easy

access of the command and data variables.

When help is needed, type a “?” and press

return (enter) whenever a unit is on line. The

following list will be transmitted:

D#XX:

S Set

E Exam

R Reset

G Lock

L*List

C*Count

R*Rate

P*Peak

V*Valley

A*PreA

B*PreB

L*Lo Set

H*Hi Set

J Lo Out

K Hi Out

N Norm

D Unit

E Input

G Hy/DrA

I Hy/DrB

M Time

T Baud

W Lock

X Meter

Y A Typ

Z B Typ

O Code

F RDec

Q TDec

U TFact

The unit transmits the unit ID (D#XX) as well as

the variables for the corresponding commands

and data. A “*” indicates that the data is

available for the print list.

16

Page 21

COMMANDS:

Each command consists of an instruction and

an address. Each instruction and address is

represented by a letter. The prefix of each

command must be an instruction followed by

an address (and address variable if applicable).

INSTRUCTIONS (1st letter of command):

[S] Set - Used to set the value or operating

parameter of an address. (i.e. “SC 5000” will

set the count at 5000)

[E] Examine - Used to examine the value or

status of an address. (i.e. “ER” will examine

the present rate reading)

[R] Reset - Used to reset the count & control

output, peak or valley. (i.e. “RP” will reset the

peak value)

[G] Lock - used to lock and unlock the unit.

Type “G” followed by the “lock code” to lock

and unlock the unit.

ADDRESSES (2nd letter of command):

[C]*Count

[R]*Rate

[P]*Peak

[V]*Valley

[A]*PreA

[B]*PreB

[L]*Lo Set

[H]*Hi Set

[J] Lo Out

[K] Hi Out

[N] Norm

[D] Unit

[E] Input

[G] Dur A

[I] Dur B

[M] Time

[T] Baud

[W] Lock

[X] Meter

[Y] A Type

[Z] B Type

[O] Code

[F] RDec

[Q] TDec

[U] TFact

[L]*List - Used to set the print list. (i.e. “LCRVA”

will set the list for count, rate, valley and preset

A. These values will be transmitted whenever

the strobe is activated.)

17

Page 22

POSSIBLE COMMANDS:

Each command must be followed by a carriage

return for execution.

DXX: (device “unit ID” #)- Unit XX will come “on

line” and stay “on line” until another device

is addressed.

SD XX: (set device “unit ID”#)- sets unit ID # at

requested value

ED: (examine device)- Unit will transmit the present

device (unit ID) number (i.e. d = 000000XX).

SC XXXXXX: (set count)- Sets count at requested

value.

EC: (examine count)- Unit will transmit the present

count value ( i.e. c=00XXXXXX).

RC: (reset count)- Resets the counter and control

output .

ER: (examine rate)- Unit will transmit the present

rate value (i.e. r= 000XXXXX).

RR: (reset rate)- Resets the normalization

EP: (examine peak)- Unit will transmit the present

peak value (i.e. p= 000XXXXX).

RP: (reset peak)- Unit will reset the peak.

EV: (examine valley)- Unit will transmit the present

valley value (i.e. v=000XXXXX).

RV: (reset valley)- Resets the valley.

SA XXXXX: (set preset A)- Sets preset A at re-

quested value.

EA: (examine preset A)- Unit will transmit present

preset A value (i.e. a=000XXXXX).

SB XXXXX: (set preset B)- Sets preset B at re-

quested value.

EB: (examine B)- Unit will transmit present preset

B value (i.e. b = 000XXXXX).

SL XXXXX: (set “Low”)- Sets “set low” at re-

quested value.

EL: (examine “Low”)- Unit will transmit present “set

low” value (i.e. l = 000XXXXX).

SH XXXXX: (set “High”)- Sets “set high” at re-

quested value.

EH: (examine “High”)- Unit will transmit present

“set high” value. (i.e. h = 000XXXXX)

SJ XXXXX: (set “low out”)- Sets “out low” at

requested value. Only available with ANALOG OUT option.

EJ: (examine “low out”)- Unit will transmit present

“out low” value. (i.e. j = 000XXXXX)

SK XXXXX: (set “high out”)- Sets “out high” at

requested value. Only available with ANALOG OUT option

EK: (examine “high out”)- Unit will transmit present

“out high” value. (i.e. k = 000XXXXX)

SN XX.X: (set norm)- Sets “norm” at requested

value. Must be a 3-digit number with

decimal.

EN: (examine norm)- Unit will transmit present

“norm” value (i.e. n = 000XX.X).

SE i 4-20, i 0-20, e 0-5, e 1-5 or e 0-10: (set input)-

sets input to one of the 4 available types.

Enter type exactly as it appears on the

display.

EE: (examine input)- Unit will transmit input type

(i.e. e 0-10).

SG XXXXX: (set dur A or hys A)- Sets dur A or hys

A at requested value. (dur A when A is

assigned to total; hys A when A assigned to

rate).

EG: (examine dur A or hys A)- Unit will transmit

present dur A or hys A value (i.e.g =

000XXXXX)

SI XXXXX: (set dur B or hys B)- Sets dur B or hys

B at requested value. (dur B when B is

assigned to total; hys B when B assigned to

rate).

EI: (examine dur B or hys B)- Unit will transmit

present dur B or hys B value (i.e.I =

000XXXXX)

SM secs, mins or hours: (set time base)- Sets

time base to desired setting.

EM: (examine time base)- Unit will transmit present

time base (i.e. secs).

ST XXXX: (set baud)- Sets baud at desired rate

(9600, 2400, 1200 or 300).

ET: (examine baud)- Unit will transmit present

baud rate (i.e. 9600).

EW: (examine lock type)- unit will transmit present

lock type (i.e. lc pg).

SX linear or sqrt: (set meter type)- Sets meter

input for linear or square root extraction.

Only available with square law option.

EX: (examine meter type)- Unit will transmit present

meter type (i.e. linear).

SY A tot or A rate: ( set A type)- Assigns control

output A to rate or total.

EY: (examine A type)- Unit will transmit present A

type (i.e. a tot).

SZ B tot or B rate: ( set B type)- Assigns control

output B to rate or total.

EZ: (examine B type)- Unit will transmit present B

type (i.e. b tot).

18

Page 23

SO XXXXX: (set lock code)- Sets lock code at

requested value.

EO: (examine code)- Unit will transmit present

code (i.e. o=000XXXXX).

SF X: (set rate decimal location)- Sets rate decimal

at requested location (0 to 4).

EF: (examine rate decimal location)- Unit will trans-

mit the present rate decimal location

(i.e. f = 0000000X).

G XXXXXX: (lock unit)- Locks and unlocks unit.

(XXXXX = code)

SQ X: (set totalizer decimal location)- Sets total-

izer decimal at requested location (0 to 4)

EQ: (examine totalizer decimal location)- Unit will

transmit present total decimal location (i.e.

Q = 0000000X).

SU XXXX: (set totalizer scale factor)- Sets totalizer

scale factor at requested value. This factor

divides the totalizer by 1, 10, 100 or 1000.

(i.e. SUXXX100 sets the divider at 100

where "X" represents the required space

characters.

EU: (examine totalizer scale factor )- Unit will

transmit present total scale factor (i.e. U =

XXX100 where "X" represents the space

characters).

L CRPVABLH: (list)- The list can consist of any

combination of the eight available options.

Any address with a "*" next to it can be

listed.

When the unit is active (on line) it will operate

in an echo back mode so that data sent from

the terminal will be transmitted back for verification. When the unit is "on line", use the

proper serial transmit commands to request

data or set a new value. Be sure to send only

one command at a time followed by a carriage

return to insure proper operation. If an error

is made, a correction can be made by back

spacing and retyping correct data before the

return (enter) is sent. Once a return (enter) is

sent, the unit begins processing the data and

will transmit the requested data on a nonpriority basis over the data transmit line. The

unit will not transmit data if the Printer Busy line

is activated (high). When the Printer Busy line

is activated all transmissions are halted until

the line goes low or open. There should be a

pause after data is requested to insure that all

data has been transmitted before making another request or addressing another unit. If

transmission has not started within two seconds after data is requested, it can be assumed that there is a problem. The unit

transmits a carriage return and line feed after

each data value. The unit will stay "on line"

until another unit is addressed.

SERIAL INTERFACE OPERATION:

Data is received and transmitted over standard EIA RS232 or RS422 levels. Each ten bit

character is made up of a start bit, eight bit

ASCII code and a stop bit.

The input impedance of RS232 is 3KΩ to 7KΩ

worst case. The terminal addressing the unit

must be capable of driving all loads in the loop.

The input impedance of RS422 is much higher

and there should be no problem driving as

many as 99 units. The transmit line remains in

a high impedance "off" state until addressed.

Only one unit is to be on line at a time!!! More

than one unit on line could damage the unit or

destroy the transmitted data.

RS232/RS422 - PC INTERFACE:

The following BASIC program is for setting up

RS232/RS422 on serial port (#1) at 300 baud.

Run this program after connecting the serial

interface connections.

10 SCREEN 0,0:WIDTH 80

20 CLS:CLOSE

30 OPEN "COM1:300,n,8,1,CS,DS,CD" AS #1

40 ON ERROR GOTO 110

50 B$=INKEY$

60 IF B$< >"" THEN PRINT #1,B$;

70 IF EOF (1) THEN 50

80 A$=INPUT$ (LOC(1),#1)

90 PRINT A$;

100 GOTO 50

110 RESUME

19

Page 24

RS232 / RS422 WIRING

COMPUTER HOOKUP:

RS 232: When connecting the unit to a

computer with RS 232 communication, only

three connections are needed. These connections are: Receive data, Transmit data

and Ground. The connections should be

made as follows:

DB-9 CONNECTOR COMPUTER

Transmit data (pin 2) Receive data

Receive data (pin 3) Transmit data

Ground (pin 5) Ground

RS 232

RECEIVE PIN (3)

TRANSMIT PIN (2)

GROUND PIN (5)

RS 422: When connecting the unit to a computer with RS 422, five connections are

needed. These connections are: Receive

data A (+), Receive data B (-), Transmit data A

(+), Transmit data B (-) and Ground. The

connections should be made as follows:

DB-9 CONNECTOR COMPUTER

Trans. data A(+) (pin 2) Rec. data A(+)

Trans. data B(-) (pin 7) Rec. data B(-)

Rec. data A(+) (pin 3) Trans. data A(+)

Rec. data B(-) (pin 8) Trans. data B(-)

Ground (pin 5) Ground

RS 422

RECEIVE A(+)PIN (3)

RECEIVE B(-)PIN (8)

TRANSMIT A(+)PIN (2)

TRANSMIT B(-) PIN (7)

GROUND PIN (5)

PRINTER HOOKUP:

When connecting the unit to a printer, you

must first program the desired baud rate,

parity and strobe list with a computer. After

the unit is programmed it can be connected to

the printer. Connect the transmit line(s) of the

unit to the receive line(s) of the printer and be

sure that both devices have common

grounds. When the strobe line is triggered the

unit will transmit the selected strobe list which

you had previously programmed.

DB - 9 CONNECTOR

1- Printer busy: 3 to 30 VDC, Level activated.

2- Transmit A(+) (RS422); Transmit (RS232)

3- Receive A(+) (RS422); Receive (RS232)

4- Not Used

6789

5- Ground

6- Strobe: 3 to 30 VDC Positive Edge

12345

7- Transmit B(-) (RS422 Only)

8- Receive B(-) (RS422 Only)

9- Not Used

RS 422

STROBE PIN (6)

PRINTER BUSY PIN (1)

TRANSMIT B (-)PIN (7)

TRANSMIT A (+) PIN (2)

GROUND PIN (5)

RS 232

STROBE PIN (6)

PRINTER BUSY PIN (1)

TRANSMIT PIN (2)

GROUND PIN (5)

20

Page 25

TROUBLESHOOTING GUIDE

PROBLEM POSSIBLE CAUSES SOLUTIONS

Power is applied to unit but

the display does not light.

Unit works but occasionally

the display freezes or skips

counts.

Input signal is connected but

the unit does not totalize or

rate.

1. AC or DC power wiring is

incorrect.

1. Line noise is effecting the

processor due to a current

spike or surge.

1. Input wiring is incorrect

2. High and low scaling settings are incorrect.

3. Transmitting device is defective.

4. Unit is defective.

1. Recheck power wiring.

1. Use a different power supply or install a surge suppressor.

1. Recheck input wiring.

2. Recheck high and low scaling settings.

3. Replace transmitting device.

4. To confirm set meter for 010V input, low @ 0; high @

10. Apply a 0-10V signal to

the voltage input (pin 5).

When viewing the rate the

meter should display the

voltage value that is applied.

If not call factory for an

RMA#.

Display reading is inaccurate.

Ratemeter works properly but

totalizer is incorrect.

1. Input wiring is incorrect.

1. Time base is incorrect.

1. Be sure that voltage signals are connected to voltage input (pin 5) and current signals are connected

to current input (pin 4).

1. Recheck time base setting

in setup section of the program menu.

IF YOU HAVE ANY OTHER PROBLEMS, PLEASE CALL THE FACTOR Y.

21

Page 26

We hope you will be pleased with our product. If you have any questions concerning our

warranty, repair, modification or returned goods process, please contact your local distributor.

WARRANTY

This product is warranted against defects in materials and workmanship for a period of

two (2) years from the date of shipment to Buyer.

The Warranty is limited to repair or replacment of the defective unit at the option of the

manufacturer. This warranty is void if the product has been altered, misused, dismantled, or

otherwise abused.

ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, ARE EXCLUDED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE.

Kessler - Ellis Products Co.

10 Industrial Way East

Eatontown, NJ 07724

(732) 935- 1320

Toll Free 800 - 631 - 2165

Fax (732) - 935- 9344

DECODING PART NUMBER

SAMPLE: INT69RT A L 1 C1

Series

INT69RT= Ratemeter / Totalizer

INT69R= Ratemeter Only

INT69T= Totalizer Only

Operating Voltage

A= 110 VAC ± 15% or 12 to 24 VDC

B= 220 VAC ± 15% or 12 to 24 VDC

Inputs

L= Linear (standard)

S= Square Law (optional)

Control outputs

1= 2 - Open Collector Outputs (standard)

2= 2 - 10 Amp Form C Relays (optional)

Options

A= Analog Output (4-20 mA)

C1= RS 232 communications

C2= RS 422 communications

Accessories

Separate non keyboard panel order # 34235

Separate keyboard panel order # 34237

Loading...

Loading...