Page 1

Steam Metering Concepts

PRINT

5

0

–

TIME

CLEAR•MENU

ENTER

HELP

TEMP

4

ALARM 1

3

RATE

2

TOTAL

1

GRAND6SCROLL7ALARM 2

8

PRES

9

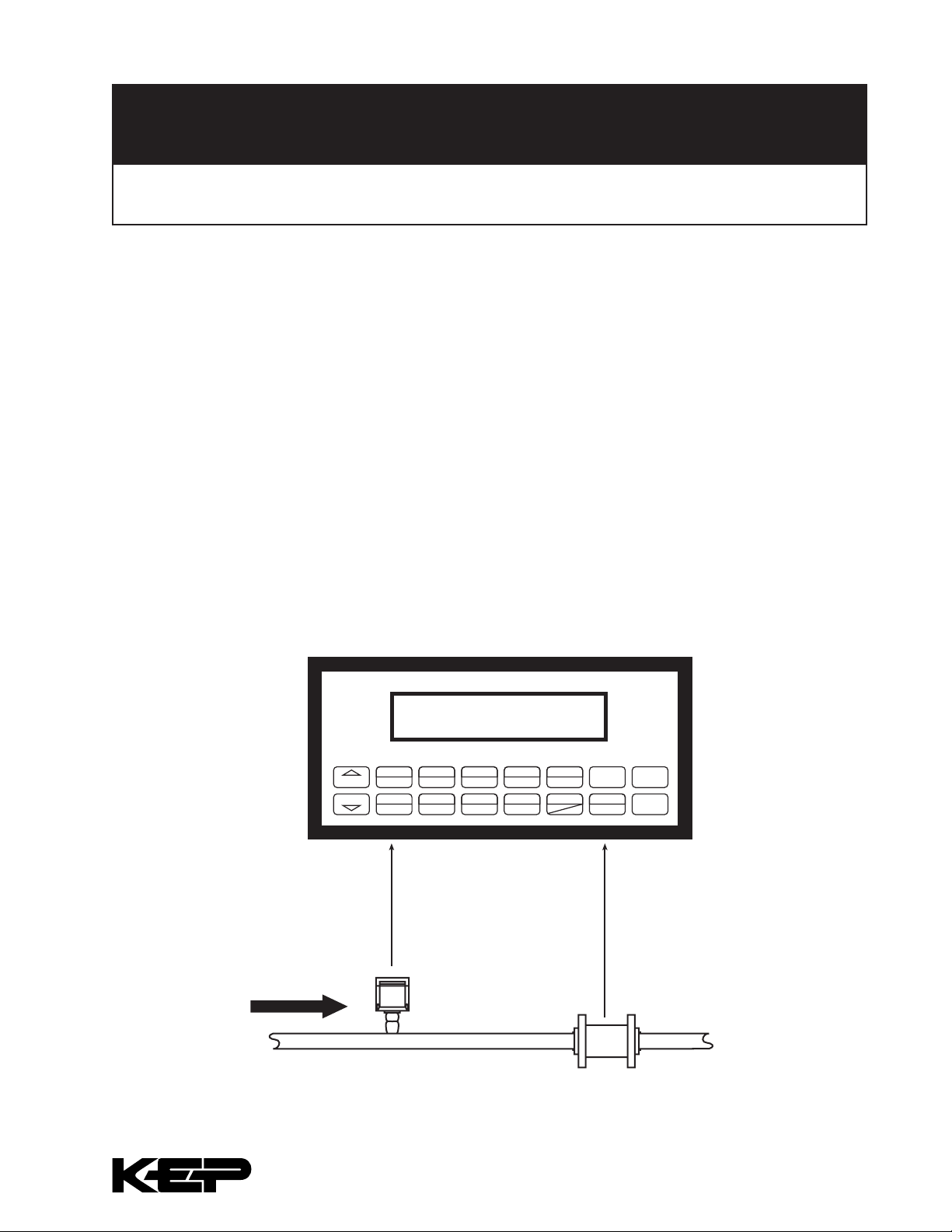

Pressure

Transmitter

Vortex

Flowmeter

Typical Steam Metering System

Using Vortex Flowmeter and Electronic Flow Computer

This document was created to aid in the explanation of the measurement of steam by a vortex steam

owmeter system and the related service operations.

General

A typical steam-metering system typically consists of several components:

• Vortex Flow Meter installed in the saturated steam line

• A static pressure transmitter to measure steam pressure

• A Flow Computer to compute the steam ow

• A Data Logger/Modem to monitor the customer site and provide trend information

NOTE: If remote metering is supported, a remote PC, modem, and remote metering software may be used

in conjunction with this system.

HELP TIP: The piping surrounding the location where the owmeter and related transmitters are installed is

called the “meter run”.

Tech Note#F049 06/10/10

KESSLER-ELLIS PRODUCTS 10 Industrial Way East, Eatontown, NJ 07724

800-631-2165 • 732-935-1320 • Fax 732-935-9344 • http://www.kep.com

Page 2

Equipment Selection

The owmeter is sized by the manufacturer, based on the expected line conditions and ow rate anticipated

in the application. This normally requires that the line size, steam pressure range and expected steam ow

rate range be known. The vortex owmeter is selected for steam service with a measurement range that

will meet or exceed the maximim owrate. The static pressure transmitter is selected for steam service with

a measurement range that will meet or exceed the range of static line pressure to be encountered in the

application. The ow computer performs the necessary calculations needed to compute the steam ow from

the electrical signals being fed into it. The datalogger and modem permit remote monitoring of the information

fed into the data logger. The information is sent to the datalogger by either the input measurement or the

computed outputs from the ow computer. A remote PC with modem can access the information either in the

data logger or in the current readings of the ow computer.

Factory Calibration

The ow meter, transmitters, ow computer, and data logger are calibrated by their respective manufacturer’s

prior to being supplied to a utility company, in accordance with the instructions provided when the units are

purchased.

Installation

During installation the owmeter and static pressure transmitters are installed in accordance with industry

guidelines and manufacturers’ instructions.

The individual calibration and setup documents provided by the manufacturers are reviewed.

Startup

During startup the individual components of the systems are setup so that they operate correctly.

For the transmitters this normally involves double-checking of each transmitter range and optional features

using a hand held terminal.

The ow computer is setup by entering the information on the owmeter and static pressure transmitter. In

addition, the items to be included in the data logger are also setup. This is usually done from the front keypad,

although connecting the device to a laptop and using a special program supplied by the manufacturer can

also be used. Setup may also be accomplished remotely via the modem connection.

The setup of each individual item is veried. For each measurement, there is a transmitter to scale and send

an electrical signal to the receivers that need this information. The scaling of each transmitter must also be set

into the corresponding ow computer input channel. If a change is made to one, it must be made to all.

The basic operation of the system can be veried by checking that the respective sensors are producing

the correct signals, based on the observed signal, the ow range setup in the sender and receiver of the

information, and the observed process conditions in the steam line. Signal simulators and multi-meters may

also be used.

There is a “low ow cutoff” that should be set to prevent the system from metering when no ow is present.

This also limits the low ow measurement range, so it is usually set to the lowest practical value.

Meter Readings

Meters may be read either locally by taking a reading from the ow computer, or remotely by taking a reading

from the ow computer via modem, or by reading the data logger. The operational status of the metering

system is also checked periodically.

KESSLER-ELLIS PRODUCTS 10 Industrial Way East, Eatontown, NJ 07724

800-631-2165 • 732-935-1320 • Fax 732-935-9344 • http://www.kep.com

Page 3

Servicing the Metering System

Often a utility will perform various inspections each year on each steam meter. Manufacturers of the

components used in a steam system provide a number of service and test aids for Service personnel that

permit them to interrogate a component to determine if it is operating properly. From time to time problems

may occur in any system. The transmitters ow computer, and data logger usually have some diagnostic

capability and can assist in problem detection and notication.

If it becomes necessary, for any reason, the owmeter may be changed out. This sometimes occurs when

the heating load changes or the actual steam range is different than the expected range as a result of

inaccurate sizing information. When a change out occurs the information on the new owmeter must also be

set into corresponding transmitter and the ow computer ow input channel. If a change is made to one, the

change must be made to all.

If a transmitter is changed by either replacement, re-scaling, or re-spanning then the new scaling of that

transmitter must also be set into corresponding ow computer input channel. If a change is made to one, the

change must be made to all.

Most utilities remove portions of the meter system from service after several years for recalibration. The ow

computer and data logger can usually be checked in place using simulators. They can be removed from

service if needed and replaced with another device that then must be setup for use as described earlier.

Inputting known pressure using a special hydrostatic pressure pump may check many pressure transmitters.

In other cases, the transmitters are replaced with a calibrated replacement unit

KEP Flow Computer

Kessler-Ellis Products (KEP) offers the Supertrol 2 Flow Computer for Steam Metering applications. It is

available in a variety of housings to suit a wide range of application environments.

SUPERtrol II

• “EZ Setup”- Guided Setup for First Time Users

• Liquid, Gas, Steam and Heat Flow Equations

• Utility Metering

• Menu Selectable Hardware & Software

Features

• Internal Data Logging Option

• Isolated Pulse and Analog Outputs Standard

• RS-232 Port Standard, RS-485 Optional

Windows™ Setup Software

• NX19 Gas Equations, Stacked DP Transmitters

KESSLER-ELLIS PRODUCTS 10 Industrial Way East, Eatontown, NJ 07724

800-631-2165 • 732-935-1320 • Fax 732-935-9344 • http://www.kep.com

• DDE Server & HMI Software Available

• Remote Metering by Wireless or Modem

• NEW! - Attractive Wall Mount Enclosure

Loading...

Loading...