Page 1

Page 2

THIS PAGE IS BLANK

Page 3

..............................

2

Theory of Operation

Wiring

...............................................................................

4

Typical Applications

..................................................................

.........................................................................

6

..........................................................................

Analog Output Calibration

Warranty

...........................................................................

Apendix A: Modbus RTU Protocol

....................................

Page 4

THIS PAGE IS BLANK

Page 5

* Slow input pulse rates, large delay setting and internal math

operations may delay the update rate of information.

4-20mA output proportional to the computed rate. The BATDT-M

Specifi cations

Supplied with 1 or 2 C size Lithium battery pack.

Voltage: 8.5 to 30 VDC

Current: Less than 5 mA

Supplied with 1 C size lithium battery

Protection: Reverse Polarity Protection on DC Power Input

Voltage: 8.5 to 30 VDC

Supplied with 1 or 2 C size lithium battery(ies)

Protection: Reverse Polarity Protection on Current Loop

Loop Burden: 8.5V maximum

tions at equipment duty cycles

Idle 2hrs/day 8hrs/day 24hrs/day

standby-operation

Battery shelf life is rated at 10 years by manufacturer

Life expectancy based on rated battery capacity at 20°C

The above table is shown with pulse output inactive. Use

of pulse output shortens battery life.

Example: A pulse output of 0.06 sec. duration, once per

second, would derate the battery life by 20%.

5 Digits (99999), 0.35" High, Display updates once per second

with battery power, 8X per second with DC or Loop power

8 Digits (99999999), 0.2" High

Totalizer Descriptors: GAL, LIT, FT3, M3, "blank"

GAL, BBL, MCF, M3, "blank" with "D"

option

Warning Displays: Low battery warning

The pulse output advances with the least signifi cant digit of the

totalizer or decimal multiples there of (see Pulse scale divider).

Type: Isolated photomos relay

Max. voltage (off state): 30 VDC

Current (on state): 100mA

Pulse Duration: Selectable 0.5, 0.25, 0.125, 0.0625 seconds

Pulse Scale divider (Pulscale): User selectable, ÷1, ÷10, ÷100

or OFF

NOTE: Select OFF for max. battery life.

ACCURACY

0.01% Reading, ±1 count

Temperature Drift: 50 ppm/°C Worst Case

-4°F (-20°C) to + 158°F (70°C)

Extended Temp: -22°F (-30°C) to + 158°F (70°C)

0 - 90% Noncondensing

0

- Circuit Board- OEM option (consult factory)

- Panel Mount - NEMA 4X Front

- Wall Mount - NEMA 4X Enclosure

(keypad mounted behind clear cover)

3

- Explosion Proof - Class I, Division I, Groups B, C & D

Class II, Division I, Groups E, F & G

5

- Wall Mount - NEMA 4X Enclosure

(keypad mounted on cover)

6

- Double Ended Explosion Proof -

Class I, Division I, Groups B, C & D

Class II, Division I, Groups E, F & G

(contact factory for details)

Meter mounting kits available for styles 2, 3 and 5

Consult factory for additional information.

Frequency Range: 0 to 3500 Hz

Trigger Sensitivity: 10 mV p-p

Over Voltage Protected: ± 30 VDC

High (logic 1): 4-30 VDC

Low (logic 0): Less Than 1 VDC

Minimum Current: .5 mA

Hysteresis: 0.4 VDC

Frequency Range: 0 to 5 kHz

Min. Pulse Width: 0.1 msec

Internal Pullup Resistor: 100 KΩ to +3.6 VDC

High (logic 1): Open or 4-30 VDC

Low (logic 0): Less Than .5 VDC

Internal Switch Debounce Filter: 0 to 40 Hz

battery life.

Internal Pullup Resistor: 100 KΩ to +3.6 VDC

High (logic 1): Open or 4-30 VDC

Low (logic 0): Less Than .5 VDC

Minimum On : 25 msec

battery life.

Range: 0.001 to 99999999

Decimal Point Locations: XXXX.XXXX to XXXXXXXX

20 Point Linearization Option

This feature allows the user to enter 20 different frequencies

with 20 different corresponding K-Factors to linearize non linear

signals.

ANALOG OUTPUT OPTION:

Type: 4-20 mA follows rate computation, Two wire hookup

Accuracy: 0.025% Full Scale at 20° C

Temperature Drift: 50 ppm/°C Typical

Reverse Polarity Protected

Update Rate: 8 times/second

The BATDT-M uses the 4-20 mA loop power as its primary

and

access a variety of process parameters. The Data Logger

stores the totalizer to fl ash memory once every 24 hours at

the time you set. The data logger can hold 24 days of totals,

on the 25th day the oldest total in the logger is dropped. Re-

quires external DC power: 6-28VDC (input is reverse polarity

Current Draw:

Receiving: 2 mA

Transmitting: 125 mA (instantaneous peak)

Setup Information: Stored in fl ash memory

Totalizer: Stored in battery backed RAM but can be saved to

fl ash memory by operator for recall after battery change out.

Idle 2hrs/day 8hrs/day 24hrs/day

standby-operation

Page 6

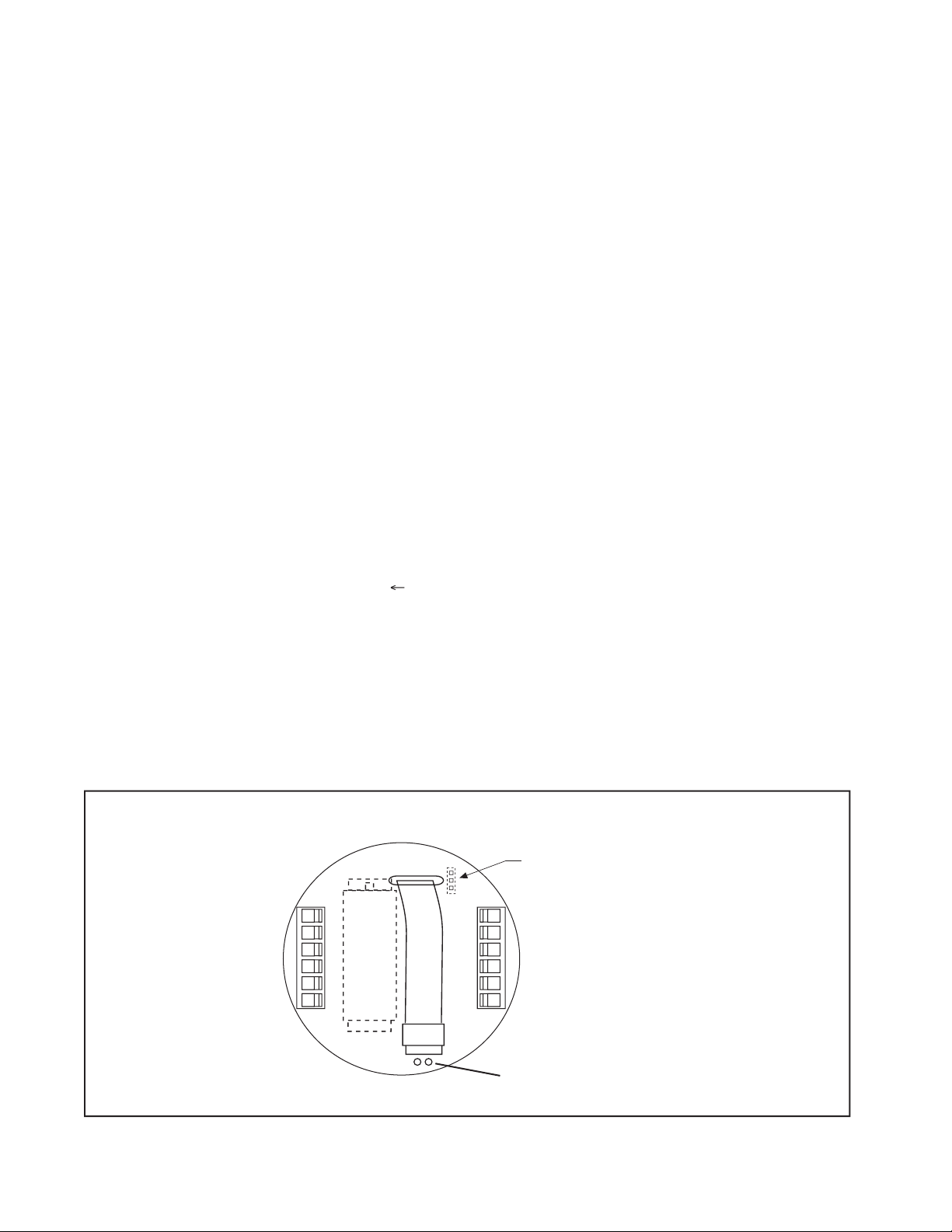

BATTERY INSTALLATION and REPLACEMENT

All BATDT-M models are shipped without the battery(ies) installed. This preserves battery life when the unit is not

To install the battery, begin by locating the battery holder. The BATDT-M-2, 3 and 5 require opening the enclosure

cover and removing the BATDT-M to expose the battery holder.

The plus terminal of the battery is marked with a (+) symbol stamped into the battery holder. Be sure to install the

The BATDT-M has a battery monitor feature which illuminates when the lithium battery voltage approaches its end

of life. A descriptor, “BAT”, illuminates when the battery voltage falls below this predetermined value. The low bat-

tery detector operates correctly with all power options.

The battery, or batteries, should be replaced within several weeks of the fi rst occurrence of low battery warning,

(left arrow) key to save the totalizer. The display will show "

If the display starts to fl ash after the "

to fl ash memory. At this point you must record the totalizer and setup information and re-enter the setup data after

the new battery(ies) is(are) installed.

6 5 4 3 2 1

Rear View

Battery

789101112

BATPACK

Connector

Jumper momentarily to reset unit to factory default values.

Page 7

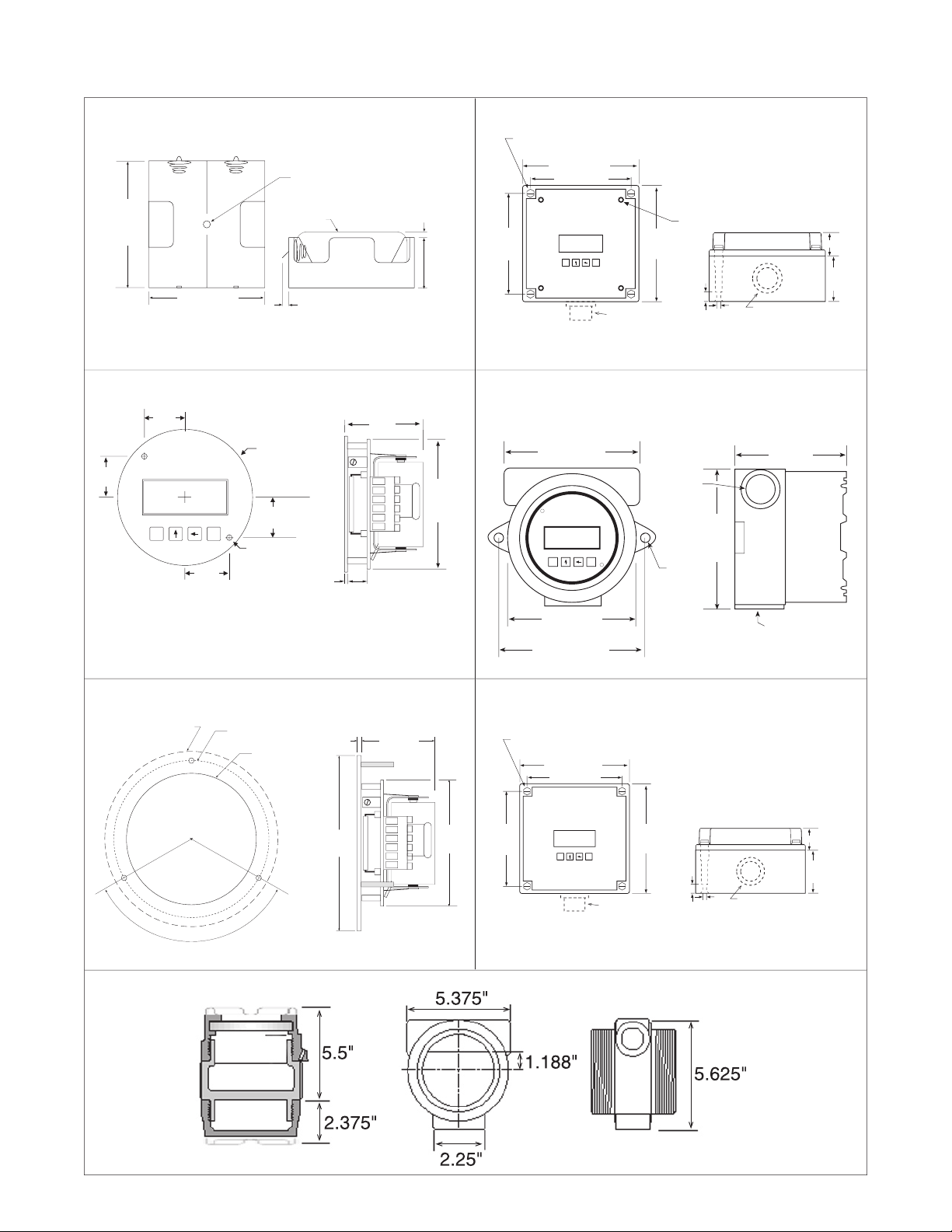

4.92

(125)

4.33

(110)

4.33 (110)

#8 Screw Mounting holes molded directly under cover

screws. Max. screw head .29" (Typ. 4 places)

E

M

.98

(25)

1.97

(50)

.18(5)

.43

(11)

BOTTOM VIEW

To access terminals, remove cover

and 4 panel screws. Terminals are

on bottom side of PC board.

Panel Screws

4.92(125)

TOP VIEW (PANEL INSTALLED)

Optional HF2, HF3

Hub Fitting

Optional H2, H3

Hub Holes

5.10

(130)

4.45

(113)

4.45 (113)

#8 Screw Mounting holes molded directly under cover

screws. Max. screw head .29" (Typ. 4 places)

E

M

1.1

(28)

1.97

(50)

.18(5)

BOTTOM VIEW

5.10(130)

TOP VIEW (PANEL INSTALLED)

Optional HF2, HF3

Hub Fitting

Optional H2, H3

Hub Holes

.36

(9.2)

To access terminals, remove cover.

Terminals are on bottom side of PC board.

4.63

(117)

3/4 NPT

(2) HLS

5.00

(127)

5/16

4.25

(108)

5.25

(133)

E

M

5.00

(127)

To access terminals, unscrew cover and loosen 2 panel screws.

Terminals are on bottom side of PC board.

Optional 3rd

Conduit Entry

3.062" (77.77)

Dia. Cutout

3.582" Dia. Bolt Circle

.125" Holes to be 120

° Apart

Outside Dotted Line Shows

Outside Panel Dimension

(4.00" Diameter)

120°

.10

(2.54)

4.00

(101.6)

1.7

(43)

2.875

(73)

Panel

Cutout

E

M

3.0120 DIAMETER

.900

(22.8)

.992

(25.2)

Mounting holes

.125 Drill (2 places)

.438 Nylon Spacer

Supplied

1.8

(46)

2.875

(73)

.10

(2.5)

.438

(11.1)

.900

(22.8)

.992

(25.2)

2.40

(61)

2.20 (56)

0.95 (24)

0.30 max. (7.6)

0.15 (3.8)

Battery

Mounting Hole

0.125 (3) dia.

BATPACK

5.5"

2.375"

5.375"

2.25"

5.625"

Additional conduit entries available upon request.

Additional conduit entries available upon request.

BATDT-M-2

BATDT-M-0

BATDT-M-1

BATDT-M-3

BATDT-M-5

BATDT-M-6

Page 8

THEORY OF OPERATION

TYPICAL APPLICATIONS

Remote

Reset Switch

12 VDC

Power

Supply

+

-

1 Mag Input 1

2 Mag Input 2

3 Shield/Common

4 Reset Input

5 Contact Input

6 Common/ DC In (-)

Turbine Meter with

Mag Pickup

6 5 4 3 2 1

MAG INPUT / DC POWERED

DC In (+) 12

Not Used (-) 11

Opto Input (+) 10

Opto Input (-) 9

Opto Out (+) 8

Opto Out (-) 7

789101112

KEP

115-12

or

Ext. Battery

(Power option

A

or B)

Flowmeter with

Switch Closure Output

DC In (+) 12

Not Used 11

Opto Input (+) 10

Opto Input (-) 9

Opto Out (+) 8

Opto Out (-) 7

1 Mag Input 1

2 Mag Input 2

3 Shield/Common

4 Reset Input

5 Contact Input

6 Common/ DC In (-)

6 5 4 3 2 1

CONTACT INPUT / PULSE OUTPUT / BATTERY POWERED

123456

789101112

(Power option

A

or B)

Remote

Reset Switch

1 Mag Input 1

2 Mag Input 2

3 Shield/Common

4 Reset Input

5 Contact Input

6 Common/ DC In (-)

Turbine Meter with

Mag Pickup

6 5 4 3 2 1

MAG INPUT / BATPACK POWERED

DC In (+) 12

Not Used(-) 11

Opto Input (+) 10

Opto Input (-) 9

Opto Out (+) 8

Opto Out (-) 7

789101112

BATPACK PLUGIN

CONNECTOR

BATPACK

(Power option

or B)

(Power option C or

AC)

Turbine Meter with

Mag Pickup

1 Mag Input 1

2 Mag Input 2

3 Shield/Common

4 Reset Input

5 Contact Input

6 Common

6 5 4 3 2 1

+

-

Strip Chart

Recorder

MAG INPUT / 4-20 mA LOOP POWERED

4-20mA (+)(+) 12

4-20mA (-) 11

Opto Input (+) 10

Opto Input (-) 9

Opto Out (+) 8

Opto Out (-) 7

789101112

24 VDC

Power

Supply

+

-

freely used so long as proper polarity is observed.

terminals (+) 12 and (-) 11. Accidental wiring to (+) 12 and (-)6 should be avoided since excessive current

fl ow may result with power option "C".

cidental connections to earth may result in erroneous operation of the analog output and/or excessive

current fl ow with power option "C".

eration of the analog output and/or excessive current fl ow with power option "C".

WIRING

A 10 point linearization table is used to construct a curve describing the relationship of K-Factor and input frequency.

The measured input frequency is used to access the table. A linear interpolation of adjacent point pairs is used to

arrive at the K-Factor at that input frequency. The fl ow rate and total are then computed based upon the K-Factor

for that measurement sample.

For best performance and resolution choose as many decimal places as possible in the K-Factor.

Example: Enter a K-Factor of 1 as 1.000.

otal

Sum of Input Pulses

C

C

x

Ti

Where

60 for rate per minute read out

3600 for rate per hour read out

86400 for rate per day read out

“D” option Only

The unit computes the rate for the analog output

Page 9

3

4

5

7

6

8

20

S

CTS

GND

G

T

5

4

3

1 ON

2 OFF

3 OFF

4 ON

5 OFF

Typical Hookup

18

17

16

15

14

13

18

17

16

15

14

13

BATDT-M

Unit

1

BA

TDT-M

Unit

2

Co

nnect 16 to 14

for optional

T

erminating Resistor

115 VAC

Model

115-24

24 VDC

Power Supply

(+)

(–)

G

+

T

T

+

Model

CA285

115 VAC

CA285

Po

wer Adaptor

PC with

RS-232 Port

Tx/Rx (-)

Tx/Rx (+)

Page 10

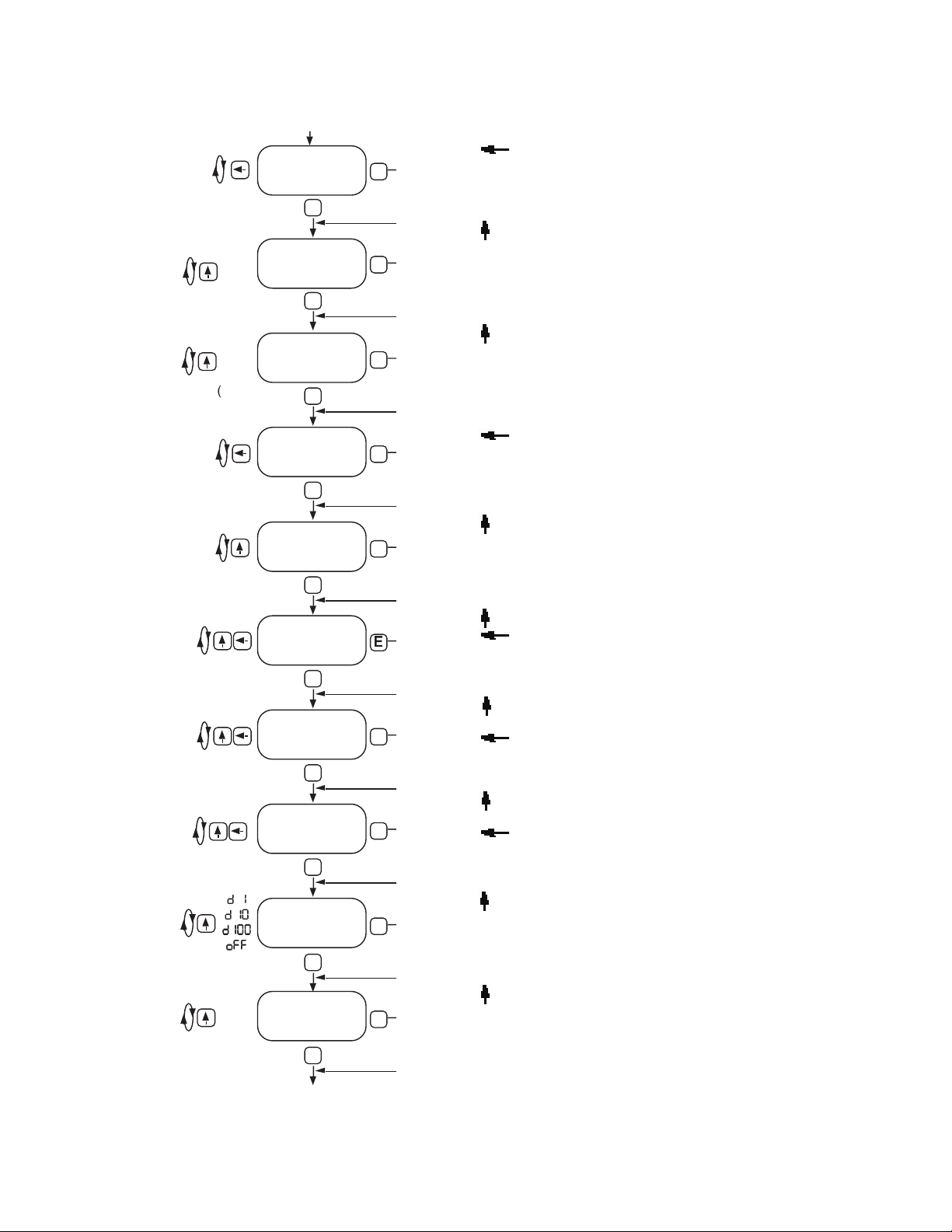

6

DEFINITIONS

key while the unit is running to save the total value. The display will show

the battery(ies)

key to step to the next digit to the left. Press the

key to enter the 5 digit code. If the entered

code is correct, the display will advance to the next menu prompt (

to the run mode.

key to clear the grand total and return to the

key to skip and advance to the next menu selection.

of this decimal automatically limits the number of decimal locations allowable in the rate and total to acceptable

key to move the decimal. Press the

key to select the displayed decimal location.

For best performance and resolution choose as many decimal places as possible in the K-Factor.

Example: Enter a K-Factor of 1 as 1.000.

/

tion. The

linearization selection is recommended for fl ow meters whose K-factors change with different

fl ow rates. This selection allows users to enter up to 10 different frequencies with 10 corresponding K-factors for

different fl ow rates. The

setting is used for fl ow meters whose output is linear over its' entire operating

fl ow range. Press the

key to enter the displayed factor type.

/

yes set Pnts

for

to skip and keep the existing values.

for the fl ow sensor. The pulses/unit volume is implied by the totalizer descriptor when a descriptor is used. The

GAL pulses/gallon GAL pulses/gallon

LIT pulses/liter BBL pulses/BBL

FT3 pulses/ft3 MCF pulses/MCF

M3 pulses/M3 M3 pulses/M3

Factors from 0.0001 to 99999999 may be used. A "0" value for the factor is not allowed and the unit will default

to "1" in LSD if a "0" entry is attempted . The factor is displayed on the subsidiary (lower) display. Press the

key to step to the next digit to the left. Press the

key to enter the

displayed factor.

the 20 points (#). Press the

key to step to the next digit to the left.

key to enter the desired frequency for point #.

key to step to the next digit to the left. Press

the

key to enter the desired factor for point #.

The display will advance to the next point (Fr#) after each entry of the Fr & Fac until all 20 points are com-

Page 11

DEFINITIONS

and will scale the totalizer display accordingly. (i.e. if the tdec is set in the tenths position (1234567.8), 100 will be

displayed as 100.0). The location of the decimal point allows for greater resolution of both the totalizer display

and the pulse output. The pulse output advances at a rate dependent on the least signifi cant digit of the total-

of totalizer decimal locations allowable is reduced with each decimal place added to the factor decimal. Press

the

key to move the decimal. Press the

key to enter the displayed decimal location.

Note:

The selection of the factor decimal point limits the available selections for the number of decimal

tor. Press the

key to enter the selected descriptor.

option.) The scale setting is shown on the main (upper) display. Press the

key to enter the displayed scale setting.

A rate descriptor corresponding to the above choice will be illuminated on the display.

The ratemeter decimal is not a dummy decimal and will scale the rate display accordingly. (i.e. if the r decloc is

set in the tenths position (123.4), 100 will be displayed as 100.0). The ratemeter decimal location is restricted

to a maximum of 4 places (.1234). However, the number of ratemeter decimal locations allowable is reduced

with each decimal place added to the factor decimal. Press the

key to move the decimal. Press the

key

to enter the displayed decimal location.

NORMALIZING FACTOR - Normalizes (averages or dampens) the fl ow rate data being received. Enter a

value from 0 to 9. Higher settings provide more normalizing (averaging) for a more stable display. Derived

from the equation:

("NOR" + 1)

are not detected within this "window", the rate will be computed as 0 and the analog output will read 4mA.

The output will update once every second as long as the unit receives valid data within a second. Some inter-

key to step to

the next digit to the left. Press the

key to enter the displayed delay value.

output 4mA. Press the

key to step to the next digit to the left. Press

the

key to enter the displayed out lo value.

will output 20 mA. Press the

key to step to the next digit to the left.

key to enter the displayed out hi value.

Page 12

DEFINITIONS

the selected divider. The pulse out can be divided by 1 (

the divider set at 1, the unit will give a pulse out for every increment of the LSD displayed.

does not exceed the maximum rate of the pulse output. If the pulse output

sage “E PULSE”. Press the “E” key to return to the run mode.

or 0.0625 (8Hz). This menu item is skipped if

is turned off.

to gain access to the menu when the unit is locked. Press the

key

to step to the next digit to the left. Press the

key to enter the displayed code.

Record this number for later use! LOCK CODE:

____________________

key to enter

the displayed selection.

Page 13

The

prompt will only appear if

key to choose YES or NO.

to the menu.

key to increment each individual digit of the code.

key to increment each individual digit of the code.

key to advance to the next digit.

to run mode

key to step the factor decimal to the desired location.

to skip and keep the existing location

For best performance and resolution choose as many decimal places as

key to choose factor type (

or

key to increment each individual digit of the factor for point

#.

key to advance to the next digit.

key to increment each individual digit of the frequency for

key to advance to the next digit.

Frequency/factor point pairs must be entered in ascending order of fre-

quency

The

prompt will only appear if

ordered without the 10 point linearization option.

key to increment each individual digit of the factor.

key to increment each individual digit of the factor.

key to advance to the next digit.

CLR ToT

CLEAR

TO

ACT

OR

ACT

OR

ent Code

correct

ACT

OR

TYPE

lInear

lInear

selected

selected

#####

for POINT

(Fr0-Fr9)

ACT

OR for

(F

AC0-F

AC9)

0

9

SET pnts

No

SET

selected

No

selected

TOTAL

TOTAL

Page 14

key to step the totalizer decimal to the desired location.

key to step to the desired totalizer descriptor.

When option "D" (rate per day) is ordered; selections are:

GAL, BBL, MCF, M3, "blank"

key to step to the desired scale setting.

When option "D" (rate per day) is ordered; selections are:

min, HRS, days

key to step the ratemeter decimal to the desired location.

key to increment each individual digit of the delay.

key to increment each individual digit of the delay.

key to advance to the next digit.

key to increment each individual digit of the out low setting

This will only display on units with Analog Output.

key to advance to the next digit.

key to increment each individual digit of the out high setting

This will only display on units with Analog Output.

key to advance to the next digit.

key to step to the desired pulse scale divider for the pulse output.

key to step to the desired pulse width for the pulse output.

This will not display if Pulse Out is turned OFF.

key to increment each individual digit of the "nor" factor.

)

GAL

(BBL, MCF)

to

99.9

.5

Continue On

TOTAL DECIMAL

TOTAL

SCALE

OUT LOW

OUT HIGH

SCALER

Page 15

address

baudrate

parity

ADDRESS

ARITY

odd

even

4800

2400

stopbits

STOP BITS

(only shows if

parity = none)

vieuulog

TE

VIEW LOG

no

CODE

loC UnIt

TURN LOCK

ON or OFF

no

TE

(date

of

last

log)

T

Continued From Previous Page

to

247

2

0.0

to

0101.2000

to

00.00

to

23.59

00.00

to

23.59

yes

YES

selected

No

selected

key to increment each individual digit of the address.

key to increment each individual digit of the address.

key to advance to the next digit.

key to select the desired baud rate.

key to select the desired parity.

key to select the desired number of stop bits.

key to increment each individual digit of the trans. delay.

key to increment each individual digit of the trans. delay.

key to advance to the next digit.

key to increment each individual digit of the date.

key to increment each individual digit of the date.

key to advance to the next digit.

key to increment each individual digit of the time.

key to increment each individual digit of the time.

key to advance to the next digit.

key to increment each individual digit of the log time.

key to increment each individual digit of the log time.

key to advance to the next digit.

key and select "yes" to view log. Select "no" to skip.

The date of last log will be shown in the format (MM.DD) if "yes" was se-

or

to view previous logs and exit when the end of datalog is

key to step to the desired lock setting.

key to increment each individual digit of the lock code.

key to increment each individual digit of the lock code.

key to advance to the next digit.

key and select "yes" to clear log. Select "no" to skip.

Page 16

A suitable pulse producing device or fl ow meter is wired to one of the three pulse inputs provided on the BATDT-M.

terminals 5 and 6. Any high level, DC pulse type may be connected to terminals 9(-) and 10(+).

The fl ow totalizer is updated once per second* with battery power, 8 times per second with DC or loop power. If no

The fl ow total may be cleared by the front panel switch sequence or by a contact closure on the remote reset ter-

To reset the unit from the front panel, the following key sequence is required:

Enter the proper code to advance to the

prompt)

To clear the total. Unit will return to operation

The unit will measure the fl ow rate once every second* with battery power, 8 times per second with DC or loop

The analog output will be scaled based on the user selected zero and full scale and the measured fl ow rate. The

analog output is updated at the same time as the rate computation.

The pulse output updates at the same rate as the total display in accordance with the instrument setup of pulse

scaling.

* Slow input pulse rates, large delay setting and internal math operations may delay the update rate of information.

A faster update rate occurs when the unit is loop powered or externally powered.

1. See also setup mode for description of its operation

2. See also Calibration Section for description of its Operation

This is the magnetic reset area when option "RN"

and slide across the top of housing. The 5 digit total will

is used to (after verifi cation of the password) clear the total

& enter the setup menus

is used to force a Save of the total to fl ash memory prior to

is used to enable the user to view the datalog of daily total

Press once to be offered "View log?"

Press

to change “NO” to “YES”

Press either

or

to view up to 27 total readings from

30 seconds automatically if no keys are pressed

Page 17

The BATDT-M is provided with extensive self checking which assists the user in the location of setup entry errors

and in reporting malfunctions or unusual operating conditions. When an error occurs, the display will fl ash. Press

any key to see the error message corresponding to the error that has occurred. Press any key again to acknowl-

edge the error. (If the error can be eliminated by a change of setup values, the unit will automatically advance to

the MENU so that the appropriate setup changes can be made).

Table - 2 illustrates the warning message, problem, and recommended corrective actions.

WARNING MESSAGE CAUSE CORRECTIVE ACTION

Total rollover None required

Rate value for analog Set rate value for analog high

low set higher than rate greater than rate value for

value for analog high. analog low.

Computed rate Use lower rate dec point

exceeds 99999

Factor = 0 Enter a factor other than 0

Pulse out Overfl ow Use different pulse scaler or

totalizer decimal point

Save to fl ash Write down displayed total and

memory failed setup values if you are changing

the battery. If total wasn't saved,

it will display an arbitrary total

when new battery is installed. In

this case, reset the total to 0 and

check the setup information.

ANALOG OUTPUT CALIBRATION

the 4-20 mA has been accurately set to 4.000 and

20.000 mA by the factory. No calibrationshould be required.

The 4-20 mA output may be verifi ed periodically by installing a digital milliamp meter(DMM) in series with the

analog output and simulating a full scale or over range fl ow rate.

with a power supply (8.5 to 30 volts DC) to TB12 (+) and TB11 (–). The output should read 4.000 ma (± 0.005).

down until the output reads 20.000 ma (± 0.005). Press "E" and the unit will return to the "RUN" mode.

Page 18

This product (excluding batteries) is warranted

against defects in materials and workmanship

for a period of two (2) years from the date of

shipment to Buyer.

The Warranty is limited to repair or replace-

otherwise abused.

ALL OTHER WARRANTIES, EXPRESSED

Ordering Information

Series:

* 0 = OEM

*

2 = NEMA 4X Box (BATDT-M behind clear cover)

3 = Explosion Proof Housing

5 = NEMA 4X Box (BATDT-M outside opaque cover)

6 = Double Ended Explosion Proof Housing (consult factory)

* A = Battery (2 supplied)

B = External Power Supply (8.5 to 30 VDC)

C = Loop Powered with 4-20 mA Output

AC = Loop Powered with 4-20 mA Output

and 2 Batteries

Options

(Multiple Options Available)

S1 = Serial Setup Software for use with BSAC1

S2 = RS485/Modbus/Data Logger - Isolated (power options B

and C only)

4 = 20 Point Linearization (10 point with S2 option)

D = Rate per Day , Hour or Minute

ET = Extended Temp.: -22°F to 158°F (-30°C to 70°C)

CE** = CE Compliant

CSA** = CSA Listed Explosion Proof

IS** = UL Listed IS (planned)

TRX = NEMA7 Explosion Proof Reset Switch

(mounting style 3 only)

RN = External Magnetic Reset

T = Third Conduit Entry in Ex-Proof Housing (mounting style 3 )

H2 = 0.875" Hole for mounting styles 2 and 5

HF2 = 0.5" Female NPT Hub fi tting for mounting styles 2 and 5

H3 = 1.125" Hole for mounting styles 2 and 5

HF3 = 0.75" Female NPT Hub fi tting for mounting styles 2 and 5

Accessories:

equal

* External battery pack supplied with models BATDT-M0A & BATDT-

** Contact factory for latest information

Page 19

Apendix A: Modbus RTU Protocol

When the BATDT-Millennium is equipped with the Modbus option, the protocol it uses is the Modbus RTU pro-

tocol. This protocol defi nes a message structure that hosts and clients will recognize and use on the Modbus

access to another device (BATDT-Millennium), how it will respond to requests from the other devices, and how

errors will be

detected and reported. It establishes a common format for the layout and contents of message fi elds. During

communications on a Modbus RTU network, the protocol determines how each BATDT-Millennium will know its

device address, recognize a message addressed to it, determine the kind of action to be taken, and extract any

data or other information contained in the message. If a reply is required, the BATDT-Millennium will construct the

The BATDT-Millennium with Modbus communications option supports the Modbus RTU (Remote Terminal Unit)

character density allows better data throughput than ASCII for the same baud rate. The Modbus RTU uses a Mas-

ter-Slave Query-Response Cycle in which the BATDT-Millennium is the slave device.

The BATDT-Millennium with Modbus communications option supports the following function codes:

01 Read Coil Status Reads the status of a coil (ON or OFF)

03 Read Holding Registers Reads the value in a holding register

05 Force Single Coil Forces a single coil (0x reference) to either ON or OFF

06 Preset Single Register Presets a value into a single holding register (4x reference)

15 Force Multiple Coil Forces each coil (0x reference) in a sequence of coils to either ON or

16 Preset Multiple Registers Presets values into a sequence of holding registers (4x reference)

The setup menu allows Modbus RTU Protocol communications parameters of: Device ID, Baud Rate, and Par-

Page 20

(each register is 2 bytes)

Access

Volume Flow Reg 40001 & 40002 Float Read

Total Reg 40003 & 40004 Float Read

Analog Out Low Reg 40049 & 40050 Float Read/Write

Analog Out High Reg 40051 & 40052 Float Read/Write

Page 21

Access

Total Decimal Point Reg 40135 Integer Read/Write

*Total Descriptors Reg 40136 Integer Read/Write

*Rate Time scale Reg 40137 Integer Read/Write

The Float data type follows the IEEE format for a 32 bit fl oat.

* Total Descriptor and Rate Time Scale Descriptor

Total Descrptor

Total Descrptor

Value

GAL 0

FT3 2

M3 3

Descrptor

Descrptor

Value

/SEC 0

/MIN 1

/HR 2

/DAY 3

The above values can be used to set the descriptors through the Modbus protocol.

(each coil is 1 bit)

Access

Total Reset Coil 00005 bit Write

(continued)

Loading...

Loading...