Kenwood KDC-7024, KDC-7024Y, KDC-8023 Service Manual

CD RECEIVER

KDC-7 024/Y

KDC-7 22

KDC-8023

SERVICE MANUAL

© 2003-2 PRINTED IN JAPAN

B53-0036-00 (N) 3379

CD mechanism operation description is

not in this service manual.

Please, refer to service manual X924030-0x (B51-7867-00).

KDC-722 only

CD mechanism extension cord : W05-0935-00

Panel assy

(A64-2981-01): KDC-722, (A64-2983-01): KDC-8023

50 4W

COMPACT

DIGITAL AUDIO

Panel assy

(A64-2987-01): KDC-7024/Y

50 4W

COMPACT

DIGITAL AUDIO

Escutcheon

(B07-3078-01)

Panel assy

(A64-2995-02):

KDC-722/8023

Escutcheon

(B07-3078-01)

Escutcheon

(B07-3078-01)

Remote controller assy

(RC-505)

(A70-2040-05)

: KDC-722

Mounting hardware assy

(J21-9823-03)

Remote controller assy

(RC-420)

(A70-2026-05)

: KDC-8023

Plastic cabinet assy

(A02-2731-03)

Lever

(D10-4674-04) x 2

Size AA battery

(Not supplied)

DC cord (ISO)

(E30-4942-05)

: KDC-7024/Y

Screw set

(N99-1723-05)

: KDC-722/8023

Panel assy

(A64-3003-02):

KDC-7024/Y

DC cord

(E30-6062-05) : KDC-8023

(E30-6106-05) : KDC-722

Antenna adaptor

(T90-0552-05)

: KDC-7024/Y

Screw set

(N99-1734-05)

KDC-7024/Y,7 22,8023

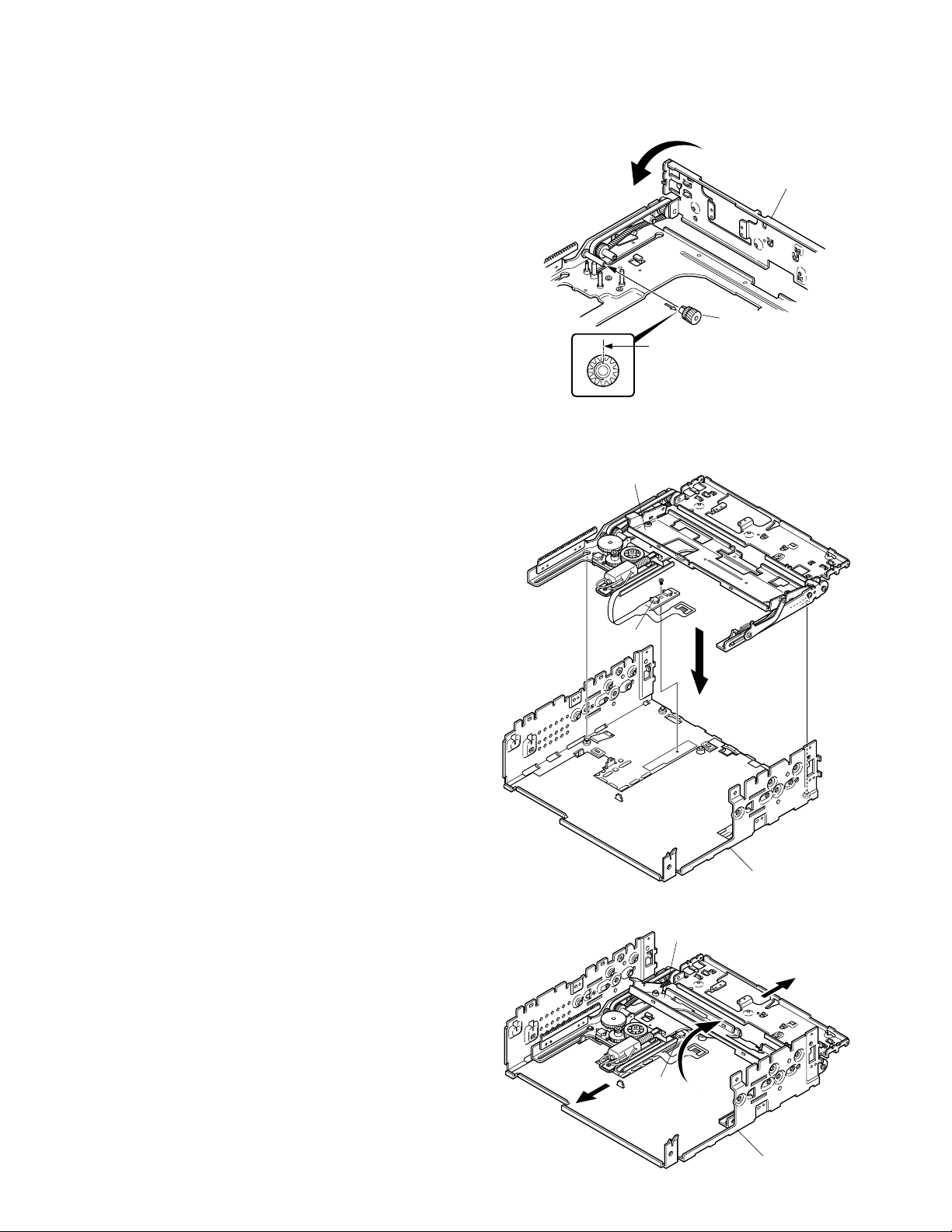

HOW TO THE PANEL MECHANISM ASSEMBLY

1. Fixed the position of operation side

(Fixed the horizontal position when the panel opened)

q The mounting hardware (281) of operation side is rota-

tion (A) into the stop position with close side.

w As figure (B) line is just above and the gear (230) at-

tached to pin.

2. The slider assembly insert to bottom chassis

q The bracket for display panel (284) is leave down, in-

sert to the chassis (702). (C)

A

Rotary to the

stop position

B

This line attached just above

Fig. B

(This figure from look at B arrow)

284

281

230

w The slider assembly insert to the chassis (702) after

that shift (D) direction.

e The bracket for display panel (284) is raised (E) direc-

tion.

r Keep the raising conditions, the slider assembly is shift

(F) direction.

(Note) Do not bend the knob of chassis detection switch

when the slider assembly insert.

SW

C

702

284

F

E

SW

D

702

3

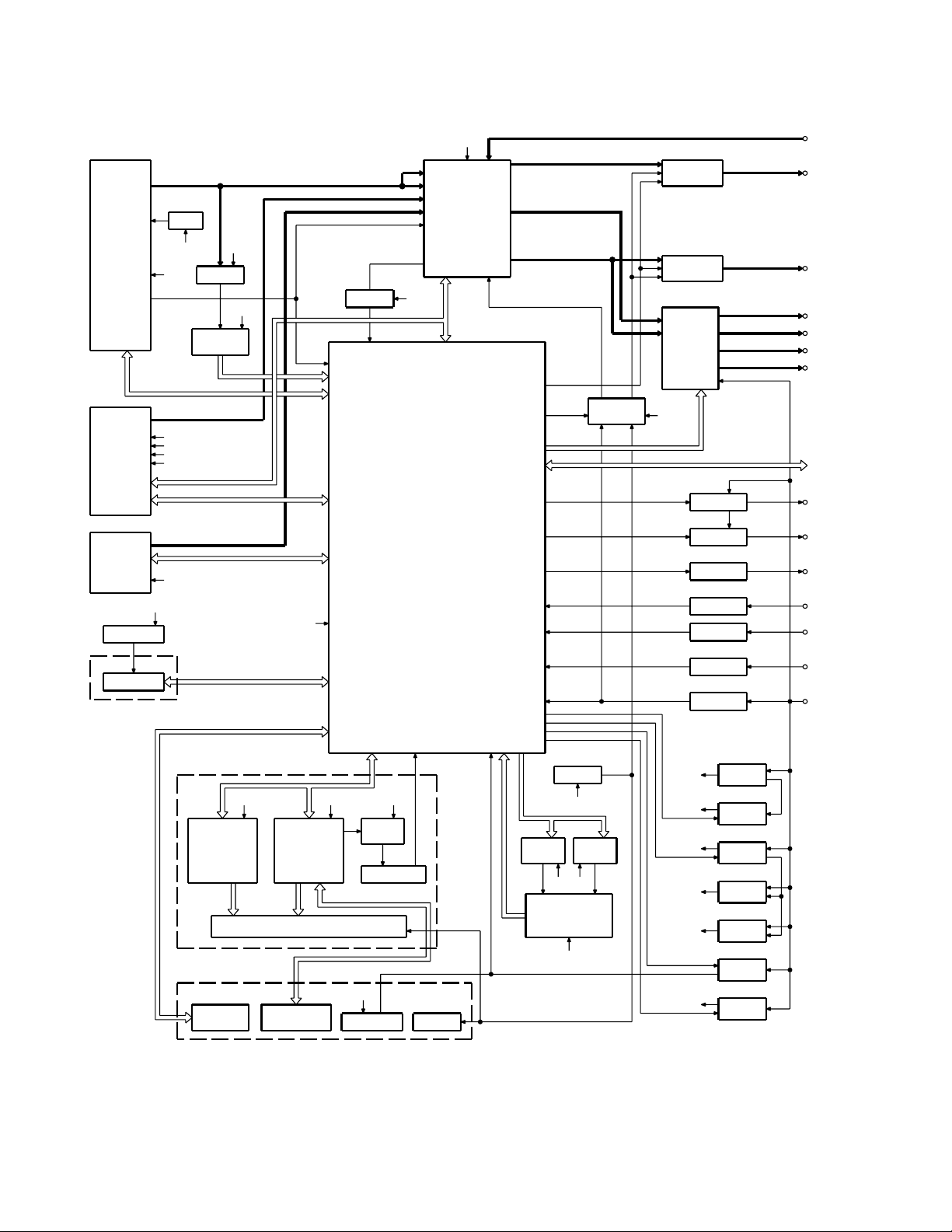

BLOCK DIAGRAM

KDC-7024/Y,722,8023

(X25-966)

TUNER

AUDIO OUT

Q102,103

AM+B

8V 8V

8V

S-METER

CD

BU5V

8V

SERVO

CD4.7V

CH

BACK UP

BU5V

Q501

EEP5V

IC1

EEPROM

TDF UNIT (X16-208)

Q104

BUFFER

IC12

RDS

DECODER

SW5V

BU5V

IC1

Q53

BUFFER

SW5V

u-COM

IC2

FM

AM

CD

CH

QUAL

8V

E-VOL

&

MPX

IC8

MUTE

DRIVER

Q59,60

PRE MUTE

PRE MUTE

IC4

POWER

IC

BU5V

Q25,26

P-CON P CON

Q23,24

ANT-CON ANT CON

Q29

EXT AMP

Q30

DIMMER DIMMER

TEL MUTE

Q33

ACC DET

Q32

B.U DET

AUX IN

PRE OUT

(REAR/NF)

PRE OUT

(FRONT)

SP OUT (FL)

SP OUT (FR)

SP OUT (RL)

SP OUT (RR)

WIRED REMO/

OPEL DISP I/F

EXT.AMP.CON

TEL MUTE

ACC

BACK UP

DISPLAY UNIT

(X16-214)

BU5V BU5V BU5V

IC2

LCD DRIVER

SWITCH UNIT

(X16-219)

ROT AR Y

ENCODER

IC1

LCD DRIVER

WITH

KEY MATRIX

LCD

KEY

KEY MATRIX

Q6

PANEL

SW5V

IC3

REMOCON

BU5V

RESET SW

KEY ILL

IC13

MOTOR

IC7

RESET

BU5V

IC14

MOTOR

DRDR

SERVO

PANEL

MECHA

SW5V

BU5V

SW5V

SW14V

A8V

SERVO

CD5.0V

Q1,2

BU5V

Q3

SW 5V

Q4,5

SW 14V

Q6-8

A8V

Q9,34

SERVO

Q11-14

ILL+B

IC5

SW REG

3

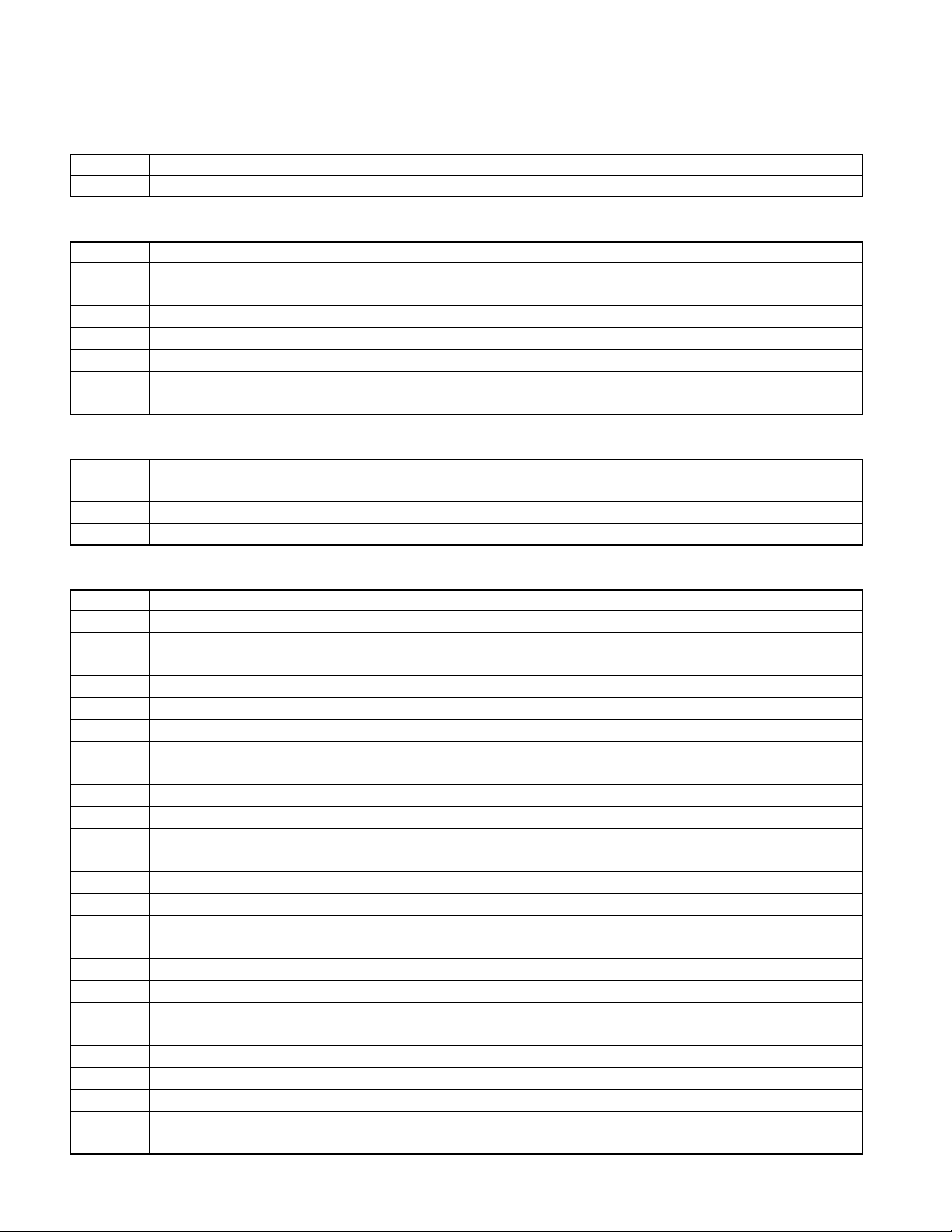

KDC-7 024 /Y,7 22,8023

COMPONENTS DESCRIPTION

● SUB-CIRCUIT UNIT (X16-2080-10)

Ref. No. Application/Function Operation/Condition/Compatibility

IC1 E2PROM For security

● SUB-CIRCUIT UNIT (X16-2140-10)

Ref. No. Application/Function Operation/Condition/Compatibility

IC1 LCD driver KEY Input

IC2 LCD driver

IC3 Remote control sensor

Q1 KEY scan start SW ON when the base goes “L”.

Q5, D26 VLCD AVR

Q6

Q11 Dimmer control LCD back light control. OFF when the base goes “L”, ON when the base goes “H”.

● SWITCH UNIT (X16-2190-10)

Ref. No. Application/Function Operation/Condition/Compatibility

Q1 DSI (Disabled System Indicator) DSI blinks when the base goes “H/L”

Q2 KEY illumination SW (GREEN) ON (KEY illumination green) when the base goes “H”

Q3 KEY illumination SW (RED) ON (KEY illumination red) when the base goes “H”

Remote control sensor power supply SW

ON when the base goes “L”.

● ELECTRIC UNIT (X25-966x-xx)

Ref. No. Application/Function Operation/Condition/Compatibility

IC1 System µ-com

IC2 E-vol & N.C. & MPX

IC3 Regulator IC for A8V

IC4 Power IC

IC7 Reset IC

IC8 Logic IC for muting

IC12 RDS decoder IC

IC13, 14

IC15 ROM IC For ROM correction.

Q1, 2 B.U.5V AVR While BU is applied, BU5V AVR outputs +5V.

Q3 SW5V When Q3’base goes Lo, SW5V outputs +5V.

Q4, 5 SW14V When Q5’base goes Hi, SW14V outputs 14V.

Q6~8 AUDIO 8V AVR When Q6’base goes Hi, A8V AVR outputs 8.4V.

Q9, 34 SERVO+B AVR When Q34’base goes Hi, S+B AVR outputs 7.4V.

Q11~14 ILL+B AVR When Q11’base goes Hi, AVR outputs 10.5V.

Q23, 24 P-ANT SW When Q23’base goes Hi, P-ANT SW outputs 14V.

Q25, 26 P-CON SW When Q26’base goes Hi, P-CON SW outputs 14V.

Q27, 28 P-CON protection Protect Q27 by turning on when P-CON output is grounded.

Q29 Ex Amp control buffer

Q30 Small lamp det SW When Q30’base goes Hi, Q30 is turned on.

Q32 BU det When Q32’base gose Hi, Q32 is turned on.

Q33 ACC det When Q33’base gose Hi, Q33 is turned on.

Q51, 52 Mute driver When a base gose Lo, mute driver is turned on.

Q53 Noise buffer

Q54 E-vol mute SW When a base gose Hi, mute SW is turned on.

Motor driver IC for panel mechanism

4

KDC-7024/Y,722,8023

COMPONENTS DESCRIPTION

Ref. No. Application/Function Operation/Condition/Compatibility

Q55, 56 Pre-out mute SW When a base gose Hi, Pre-out is muted.

Q59, 60 Pre-out mute SW When a base gose Hi, Pre-out is muted.

Q63 E2P 5V SW When Q63’base gose Lo, E2P 5V is out.

Q102, 103 AM+B SW When Q102’base gose Hi, AM+B is out.

Q104 Composite signal buffer for RDS

MICROCOMPUTER’S TERMINAL DESCRIPTION

● SYSTEM MICROCOMPUTER : UPD703030GC015 (X25-966 : IC1)

Pin No.

1 PLL_DATA I/O Tuner Data output/input with F/E.

2 AM+B I/O

3 (FM+B) O

4

5

6 EVDD 7 EVSS 8 AFS O Tuner Noise detection time constant switching.

9 BEEP O Audio Beep output.

10 REMO I Extra Remote control input (Panel, External display).

11 P_MUTE O Audio Power IC MUTE output. Power OFF : L, All OFF : L, TEL mute : L

12 (SVR) O Audio Power IC SVR discharge circuit control.

13 IC2_SDA I/O Audio IC2 data line.

14 IC2_CLK I/O Audio IC2 clock line.

15 P_STBY O Audio Power IC STBY output.

16 P_CON I/O Extr a Power control.

17

18 TEST - Connect to GND.

19

20 MUTE O Audio Mute output. ON : OPEN, OFF : L

21 PRE_MUTEL O Audio PREOUT (L ch) mute.

22 PRE_MUTER O Audio PREOUT (R ch) mute.

Pin Name I/O Module Purpose / Description

Power supply

Power supply

V_ILL PAN_E2P DATA

V_ILL PAN_E2P CLK

DIMMER_CONT

TYPE2 I Extra Destination select. w

NC O Extra NC (MP3 mechanism model). w Output : L

I/O To panel

I/O To panel

CD CD mechanism data line.

Extra ROM correction data line.

CD CD mechanism clock line.

Extra ROM correction clock line.

O To panel Dimmer control (W-LED only).

AM+B. AM operation : H

FM+B (S01 F/E only).

V-ILL D/A converter (V-ILL, LCD), E2PROM data.

V-ILL D/A converter (V-ILL, LCD), E2PROM clock.

Truth table

FM operation : H,

Last FM : H (With RDS, RBDS model)

FM seek, AF search : L, Receiving : H, Auto 0 : L

Power OFF momentary power dropped

: H (5 second) and then L

Power IC ON : H, Power IC OFF : L, All OFF : H

Power ON : H, Power OFF : Hi-Z, All OFF : Hi-Z

Dimmer : Pulse control,

Frequency : 1kHz, Normally : H

M MUTE L is L : L (CD), Momentary power

dropped : L, 2 zone, NAVI interrupt : Fixed H

M MUTE R is L : L (CD), Momentary power

dropped : L, 2 zone, NAVI interrupt : Fixed H

Processing Operation

5

KDC-7 024 /Y,7 22,8023

MICROCOMPUTER’S TERMINAL DESCRIPTION

Pin No.

23 BU_DET I Extra Momentary power dropped detection.

24 ACC_DET I Extra ACC detection. With ACC : L, Without ACC : H

25 SW5V I/O

26

27 DIMMER I Extra Small lamp detection. ON : L, OFF : H

28 ANT_CON O Extra Antenna control. w

29 P_ON I/O

30 ILL_ON I/O

31 RESET 32 XT1 - Sub clock. 32.768kHz

33 XT2 - Sub clock. 32.768kHz

34 REGC - Connect to 1µF capacitor.

35 X2 - Main clock. 20MHz

36 X1 - Main clock. 20MHz

37 VSS 38 VDD 39 CLKOUT 40 LX_REQ_M O LX Communication request to external slave. Request : L

41 LX_MUTE I LX Mute request from external slave. Mute ON : H

42 LX_CON O LX External slave select. ON : H, OFF : L

43 LX_RST O LX Reset output to external slave µ-com.

44 NC O NC (Without WMA, MP3 model) Output : L

45 TYPE0 I Extra Destination select. w

46 TYPE1 I Extra Destination select. w

47 IC2_TYPE0 I Extra IC2 destination. w

48 IC2_TYPE1 I Extra IC2 destination. w

49 NC O NC Output : L

50 E2P5V I/O

51 DSI I/O To panel DSI control. ON : L, OFF : Hi-Z

52 L_CE O To panel Chip enable output to LCD driver.

53 L_INH O To panel Inhibit signal output to LCD driver.

54 VOL A I To panel VOL input.

55 BVDD 56 BVSS 57 VOL B I To panel VOL input.

58 M_RST O CD Reset output to CD mechanism.

59 M_STOP O CD Stop request to CD mechanism. Stop : L, CD : H

60 CD_SW3 I CD DC down switch detection. Chucking : H

61 LO/EJ I/O CD CD mechanism loading/eject switch. Stop, brake : Hi-Z, Loading : L, Eject : H

62 MOSW O CD CD mechanism motor driver switch. Loading, eject, brake : H

63 FPM MOTOR B O P-mecha FPM mechanism (Slider) control. e

Pin Name I/O Module Purpose / Description

Power supply

EXT_AMP_CONT

NC O NC (Without EXT_AMP_CONT model) Output : L

O Extra External amplifier control. Refer to external amplifier control.

Power supply

Power supply

Power supply

5V power supply. ON : L, OFF : Hi-Z

SW 14V, SW 5V control, AD reference

voltage control output.

FL, illumination output. ON : H, OFF : Hi-Z

E2PROM, DA converter power supply control. ON : L, OFF : Hi-Z

Truth table

Backup : L,

No backup, momentary power dropped : H

Tuner ON : H, Other source With RDS last FM

: H, Other source with RDBS TI ON last FM : H

Power ON : H, Power OFF : Hi-Z

Normally : L, After system reset : H (400ms

or more) and then L

Normally : H, Reset, momentary power dropped : L

Normally : H, Reset : L (Per mechanism control)

Processing Operation

6

KDC-7024/Y,722,8023

MICROCOMPUTER’S TERMINAL DESCRIPTION

Pin No.

64 FPM MOTOR F O P-mecha FPM mechanism (Slider) control. e

65 FPM MOTOR O O P-mecha FPM mechanism (Angle) control. e

66 FPM MOTOR C O P-mecha FPM mechanism (Angle) control. e

67

68

69

70 M_MUTER I CD Mute request form CD mechanism. (R ch). ON : L (CD)

71 AVDD 72 AVSS 73 AVREF - Connect to P_ON (29 pin).

74 M_MUTEL I CD Mute request form CD mechanism. (L ch). ON : L (CD)

75 PAN_DET I To panel Panel E2PROM detection. With : L, Without : H

76 J type 1V or less, 2.5V or more : NAVI mute

77 FPM SW4 I P-mecha

78 FPM SW1 I P-mecha FPM mechanism position detection. e

79 FPM SW2 I P-mecha FPM mechanism position detection. e

80 FPM SW3 I P-mecha FPM mechanism position detection. e

81 FPM PHOUT I P-mecha FPM mechanism position detection. e H : 2.2V or more

82 S_METER I Tuner S-meter detection. Refer to S03 F/E control.

83 NOISE I Tuner FM noise detection. Refer to S03 F/E control.

84 IFC_OUT I Tuner F/E IFC OUT input.

85

86 NC O NC (Except J type) Output : L

87

88 LX_REQ_S I LX Receive request from external slave. Request : L

89 KEY_REQ I To panel Communication request from LCD driver

90 CD_SW1 I CD Loading switch detection. Loading start power off : L

91 CD_SW2 I CD 12cm disc detection switch. 12cm disc power off : L

92

93

94 LX_DATA_S I LX Data input from external slave.

95 LX_DATA_M O LX Data output to external slave.

96 LX_CLK I/O LX Clock input/output with external slave.

97 L_DATAL I To panel Data input from LCD driver.

98 L_DATAS O To panel Data output to LCD driver.

99 L_CLK O To panel Clock output to LCD driver.

100 PLL_CLK I/O Tuner Clock input/output with F/E.

Pin Name I/O Module Purpose / Description

O_DATA I/O Extra External display data input/output. External display

NC O NC (Without external display model) Output : L

O_CLK I/O Extra External display clock input/output. External display

NC O NC (Without external display model) Output : L

O_CE I/O Extra External display chip enable input/output. External display

NC O NC (Without external display model) Output : L

PHONE I Extra PHONE detection.

NC I NC (Without TEL-MUTE model) Connect to GND.

FPM mechanism position detection,

mechanism detection. 1.25V or more : H, Less than 1.25V : L

NC (POWER_DET)

R_CLK I Tuner RDS decoder clock input.

NC I NC (Without RDS, RBDS model) Connecto to GND.

R_QUAL I Tuner RDS decoder QUAL input.

NC I NC (Without RDS, RBDS model) Connecto to GND.

R_DATA I Tuner RDS decoder data input.

NC I NC (Without RDS, RBDS model) Connecto to GND.

I Extra Power IC DC offset detection. 03 model not used. Connect to GND.

Truth table

e

Processing Operation

TEL mute : 1V or less, NAVI mute : 2.5V or more,

3.75V or more : No mechanism,

With station : 2.5V or more, refer to S03 F/E control.

7

KDC-7 024 /Y,7 22,8023

MICROCOMPUTER’S TERMINAL DESCRIPTION

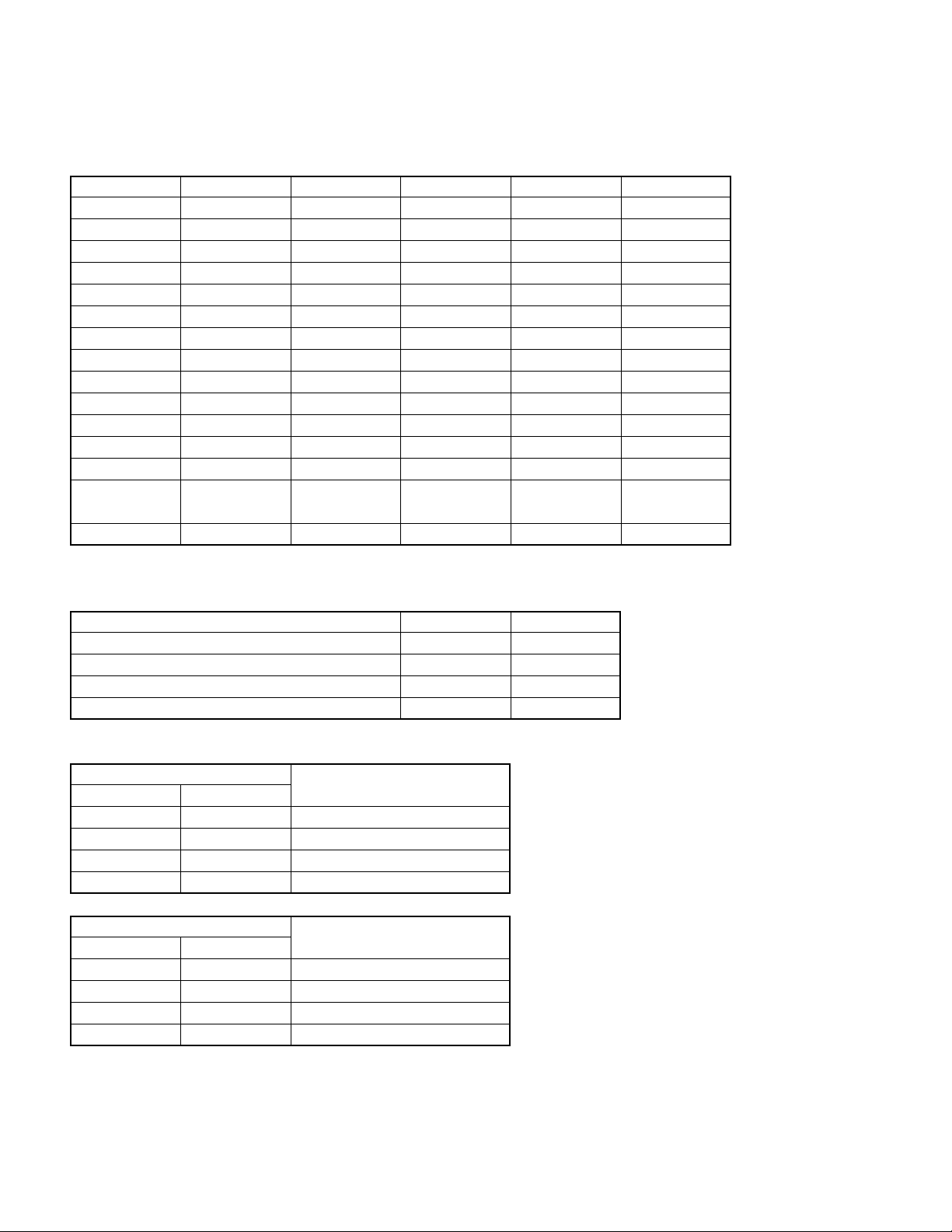

Truth table

w Destination port

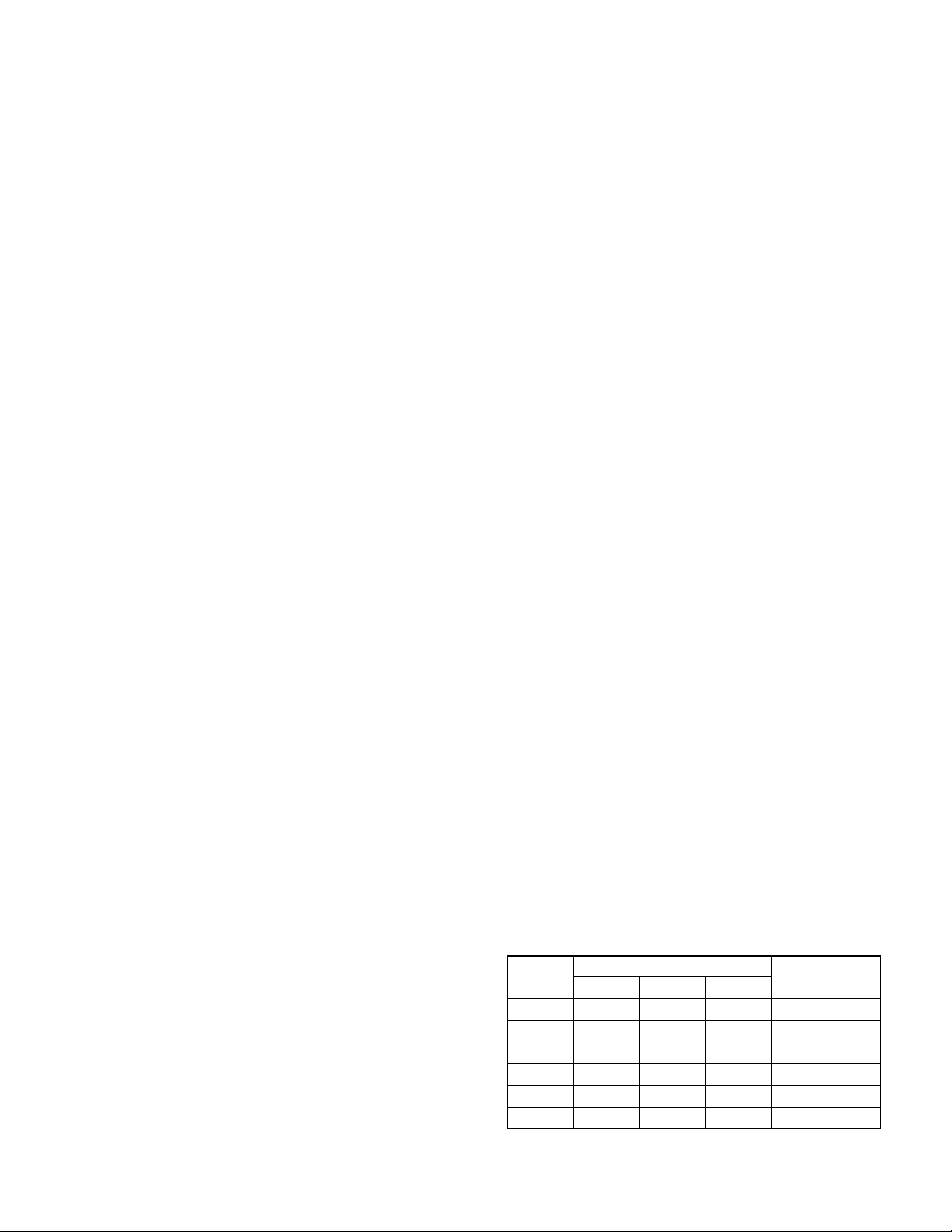

MODEL Destination DISPLAY TYPE2 TYPE1 TYPE0

KDC-X969 K FL 0 0 0

KDC-MP922 K FL 0 0 1

FX-9000 J FL 0 1 0

KDC-PSW9524 E FL 1 0 0

KDC-9023R M (E) FL 1 0 1

KDC-X869 K FL 0 1 1

KDC-8024 E FL - - KDC-MP822 K LCD - 0 0

KDC-M7024 E LCD - 0 1

FX-5000 J LCD - 1 0

KDC-V7022 K LCD 0 0 0

KDC-X769 K LCD 0 0 1

KDC-722 K LCD 0 1 0

KDC-7024

KDC-7024Y

KDC-8023 M (K) LCD 1 0 0

Note : When FL model using TYPE2, K & J type (with ANT_CON model) : L, E type (without ANT_CON model) : H

E LCD 0 1 1

Destination(IC2)

TYPE0 TYPE1

Market model L L

Market model CRSC modiification L H

OEM model CRSC modification H L

OEM model CRSC and de-emphasis modification H H

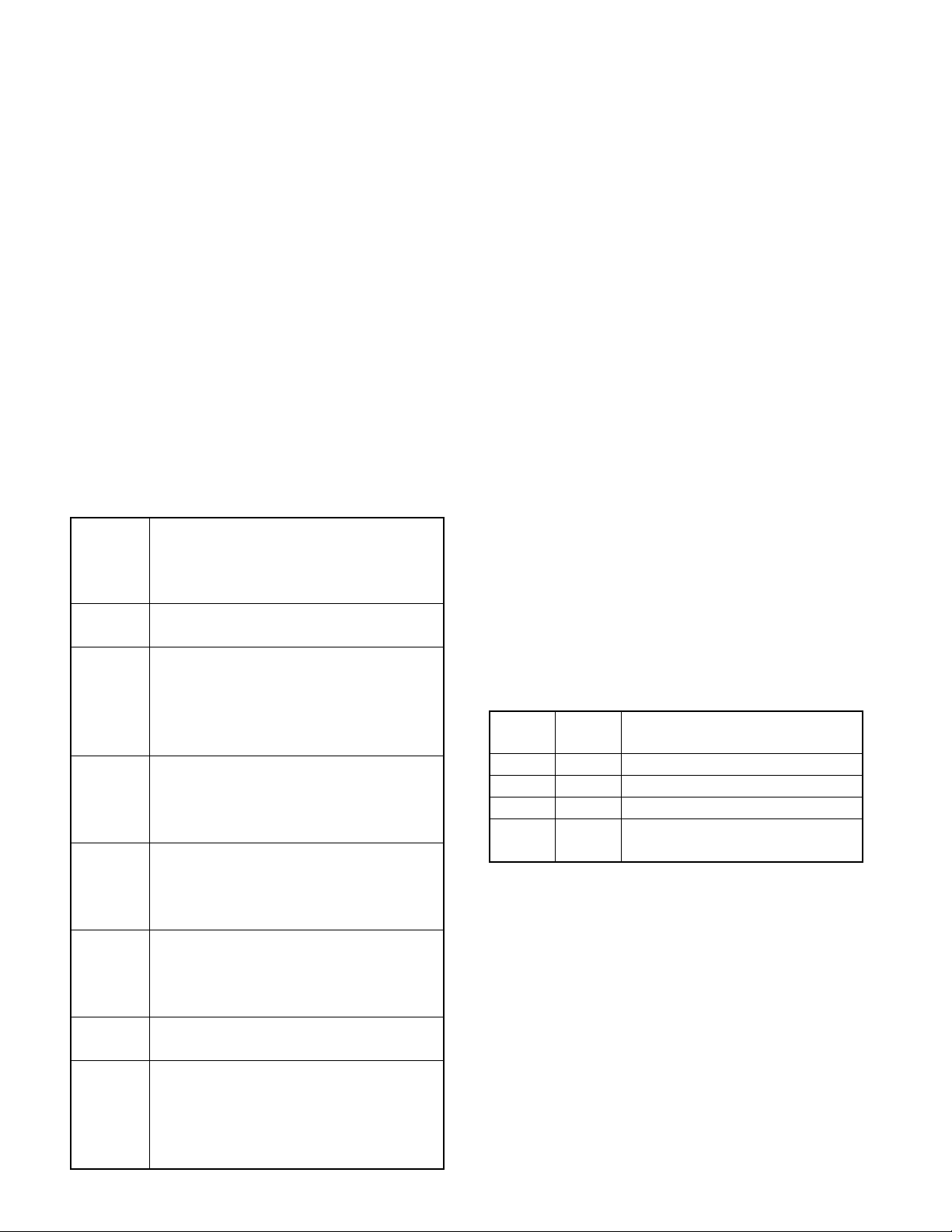

e FPM MOTOR

Slide

FPM MOTOR B FPM MOTOR F

0 0 Standby

1 0 Backward operation

0 1 Forward operation

1 1 Brake

Angle

FPM MOTOR O FPM MOTOR C

0 0 Standby

1 0 Angle open direction

0 1 Angle close direction

1 1 Brake

FPM mechanism operation

FPM mechanism operation

8

TEST MODE

KDC-7024/Y,722,8023

● How to enter the test mode

While pressing and holding the Preset 1 and Preset 3 keys,

reset the unit.

● How to exit from the test mode

While holding the Preset 6 key, reset the unit.

(Note) The test mode cannot be terminated by reset the

unit, ACC OFF, power OFF and Panel detached, momentary power down.

● Initial status in the test mode

• Sources : ALL OFF

• Display : All segments are lit.

• Volume : -10 dB (displayed as “30” )

• Loudness : OFF

• CRSC : OFF regardless of the presence of switching function.

• SYSTEM Q : Flat

• WOW : All OFF

• BEEP : When pressing any keys, the buzzer generates a

beep at any time.

• AUX : ON

• MENU SYSTEM Q : OFF

• Variable model : Default is white

• Multifunction : Source dependency (Preset, SCAN, etc.)

● Special display in Tuner mode

When any of the following messages is displayed in Tuner

mode, the F/E may be abnormal.

• “TNE2P NG” : The EEPROM is set to the default (unstable

values) because the F/E was shipped without passing

through the adjustment process, etc.

• “TNCON NG” : Communication with the F/E is not possib le .

● Forced switching of K3I

Each press of the Preset 6 key in Tuner mode should switch

K3I from AUT O → F orced Wide → F orced Middle → Forced

Narrow → AUTO.

The initial status is AUTO and the display shows these

modes as follows.

• AUTO : FMA

• Forced Wide : FMW

• Forced Middle : FMM

• Forced Narrow : FMN

● Test mode specifications of the CD receiver

• Forced ejection is inhibited in the reset start operation. When

the unit is reset while a CD is loaded in it, the CD is not

recognized by resetting.

• Each press of the Track Up key jumps to the following track

numbers:

No. 9 → No. 15 → No. 10 → No. 11 → No. 12 → No. 13 →

No. 22 → No. 14 → No. 9 (The cycle restarts from here.)

• Each press of the Track Down key jumps to the previous

track number to the track being played.

• When the number of total trucks of the MP3 disc or the

WMA disc is less than 9, 1st truck is played.

• When the disc media is CD, A short press of the Preset 1

key jumps to the track number 28.

• When the model is equipped the CD mechanism assembly

adapted for MP3 or MP3/WMA disc , the mechanism name

and version number are displayed during the FL model is

lower stand and Display mode of LCD model is DNPS.

● Audio-related specifications

• Pressing the ✽ k ey on the remote initiates the audio adjustment mode.

• BL/F key on the Fader initials.

• Continuous holding of a remote control key is inhibited, and

workings are short press of any keys.

• Bass, Middle and Treble are adjusted in 3 steps of -8 / 0 /

+8 with the Track Up/Down keys (Default value at 0).

• Balance is adjusted in 3 steps of L15 / 0 / R15 with the

Track Up/Down keys (Default value at 0).

• Fader is adjusted in 3 steps of R15 / 0 / F15 with the Track

Up/Down keys (Default value at 0).

• HPF is adjusted in 2 steps of OFF / 170Hz (or 220Hz) with

the Track Up/Down keys (Default value at OFF).

• LPF is adjusted in 2 steps of OFF / 120Hz with the Track

Up/Down keys (Default value at OFF).

• Bass f, Bass Q, Bass EXT, Middle f, Middle Q and Treble f

are not dealt with by the audio adjust.

• The WOW key pass during the audio adjustment as following steps.

Order

q OFF OFF OFF SRS WOW OFF

w ON OFF OFF SRS T ruBass ON

e OFF LOW OFF FOCUS LOW

r OFF HIGH OFF FOCUS HIGH

t OFF OFF ON SRS ON

y ON HIGH ON SRS WOW HIGH

TruBass FOCUS SRS

Mod.

Display

9

KDC-7 024 /Y,7 22,8023

TEST MODE

● Menu-related specifications

• A short press of the Q key initiates the menu mode.

• Pressing the DNPP key on the remote initiates the Menu

mode.

• Continuous holding of a remote control key is inhibited, and

workings are short press of any keys.

• Contrast is adjusted in 3 steps of 0 / 5 / 10 with the Track

Up/Down keys (Default value at 5).

● Backup current measurement

When the unit is reset while ACC is OFF (i.e. by turning

Backup ON), the MUTE terminal goes OFF in 2 seconds in

place of 15 second. (The CD mechanism is not activ ated at

this time.)

● Special display when the display is all on

Pressing the Preset keys while the power is ALL OFF displays the following information.

[PRESET 1] Version display (8 digits, Month/Day/Hour/Minute)

(Display) SYS xxxxxxxx : System microcomputer

PAN xxxxxxxx : FL model only

MEM xxxxxxxx : 4 contrasts FL model only

[PRESET 2] Serial number display (8 digits)

(Display) SNo xxxxxxxx

[PRESET 3] Short press : View power ON time. (The All OFF

period is not counted.)

2 seconds long press/hold : Clear power ON time

at the power ON time displaying.

(Display) PonTim xxxxx Max. 60000 (hours)

[PRESET 4] Short press : Display CD operation time.

2 seconds long press/hold : Clear CD operation

time at the CD operation time displaying.

(Display) CDTim xxxxx Max. 60000 (hours)

[PRESET 5] Short press : Display CD ejection count.

2 seconds long press/hold : Clear CD ejection

count at the CD ejection count displaying.

(Display) EjeCnt xxxxx Max. 60000 (times)

[PRESET 6] Short press : Display Panel open/close count.

2 seconds long press/hold : Clear Panel open/close

count at the Panel open/close count.

(Display) PnCnt xxxxxx Max. 600000 (times)

FM key Display ROM collection version.

(Display) ROM R xxx Invalid : “R – – –”

AM key Display panel E2PROM condition.

(Display) P–ROM OK (Registered code)

P–ROM NG (Code is write in error)

P–ROM WAIT (Unregistered code)

P-ROM NON

(Panel security nonfunctional)

10

● Panel mechanism

• Auto-panel close inhibition when set-in the CD.

• The panel operation inhibition at power ON/OFF and ACC

ON/OFF.

• The panel position changing Eject ←→ Last with a short press

of the PLAY/PAUSE keys.

● Other specifications

• No displays such as “CODE OFF/ON” during Power-ON.

• The LINE MUTE inhibition time is one second from 10 seconds when start-up the test mode.

• Do not write the security code with the security jig on the

test mode.

• Do not write the serial with the serial writing jig on the test

mode.

• OEM display output is not stop if OEM display not connection on the test mode.

● Switching the frequency span (K/M type)

While holding the Preset 1 key and Preset 5 key, reset the

unit.

● Response to OEM setting

(Destination of electronic volume setting)

S03F/E models are response to OEM models option at put

in µ-com 2 pin.

Its setting are following steps.

IC2 TYPE0 IC2 TYPE1

(47 pin) (48 pin)

Low Low q Trade model (Initial quantify)

Low High w Trade model (CRSC change)

High Low e OEM model-ready CRSC change

High High

r OEM model-ready CRSC &

de-emphasis change

Description

● Security-related information

1. Forced Power ON mode (All models)

Even when the security (Cord) is approved, resetting the

unit while holding the Q and Preset 4 keys makes it possible to turn the power ON for 30 minutes.

After 30 minutes have elapsed, it is not possible to return to

the previous condition unless the unit is reset again. (Security code is do not clear at this mode. Put the power on fillin.)

TEST MODE

KDC-7024/Y,722,8023

2. Method of registration of the security code after EEPROM (F/E) replacement (Code security model)

1) Enter the test mode. (See How to enter the test mode)

2) Press the MENU key to enter the Menu mode.

3) When the message “Security” is displayed, press and hold

the Track Up/Down key for 1 second to enter the security

registration mode.

4) Enter the code using the FM/AM/T rack Up/Trac k Down ke ys.

FM key : Number up

AM key : Number down

Track Up key : Cursor right shift

Track Down key : Cursor left shift

5) Hold down the Track Up key for at least 3 seconds and the

message, “RE-ENTER” appears, so once again enter the

code according to Step 4 above.

6) Press and hold the Track Up key for 3 seconds until “APPROVED” is displayed.

7) Exit from the test mode. (See 2. How to exit from the test

mode)

(Note 1) All Clear is not applicable to the security code of

this model.

(Note 2) When the F/E changed, need re-inscription because the panel security is clear.

3. Simple way to c lear the security code (K type only)

1) During code request mode, press the Track UP key for at

least 3 seconds while holding down the AUTO key . (– – – –

will disappear)

2) Enter, “KCAR” with the remote controller as described below.

• Press the remote controller 5 key twice, and press the

Track Up key. (Enters a “K” )

• Press the remote controller 2 key three times, and press

the Track Up key. (Enters a “C” )

• Press the remote controller 2 key once, and press the

Track Up key. (Enters an “A” )

• Press the remote controller 7 key twice, and press the

Track Up key. (Enters an “R” )

3) Security function is canceled and unit sets to All-Off mode.

4) Code request mode appears if a mistake was made in entering the numbers.

4. How to inscription the panel security code

1) Enter the test mode.

2) Pressing the AM key on all lighting, check the “P-ROM W AIT”

display.

3) The NEXT key is long press 2 seconds, writing the code.

4) Display is “P-ROM OK”.

5) Exit from the test mode.

(Note) E2PROM connection is NG when display is “P-R OM

NG”, so detach the panel and rewrite after the display is “PROM WAIT”. This code can not clear.

● Check the SRAM

Output (Hi) to the SRAM_CHECK terminal on 101 pin when

SRAM is function properly on the panel of 4 gradation FL

models.

● Check the Flash ROM

1) Display to the following effect at ALL OFF by assortment

system computer and panel for cover the customization

model attach the panel with no Flash ROM.

• Customization system computer + Flash ROM panel : All

lighting

• Non customization system computer + Non Flash ROM

panel : All lighting

• Customization system computer + Non Flash ROM panel

: Panel NG

• Non customization system computer + Flash ROM panel

: Panel NG

2) Output (Hi) to the FLASHROM_CHECK terminal on 102

pin when Flash ROM is function properly.

3) Flash ROM data is initialized when pressing the AM key

long hold at all lighting.

Display is “Data Erase ....” in data erasing mode. Do not

touch anything this mode. When the data erase completed,

display is “Erase OK!!”.

If display is “Erase NG!!!!!!”, Flash ROM data unable erase

for some kind or another factors.

When same effect as pressing the AM key long hold and

data erase once again, Flash ROM is defective.

11