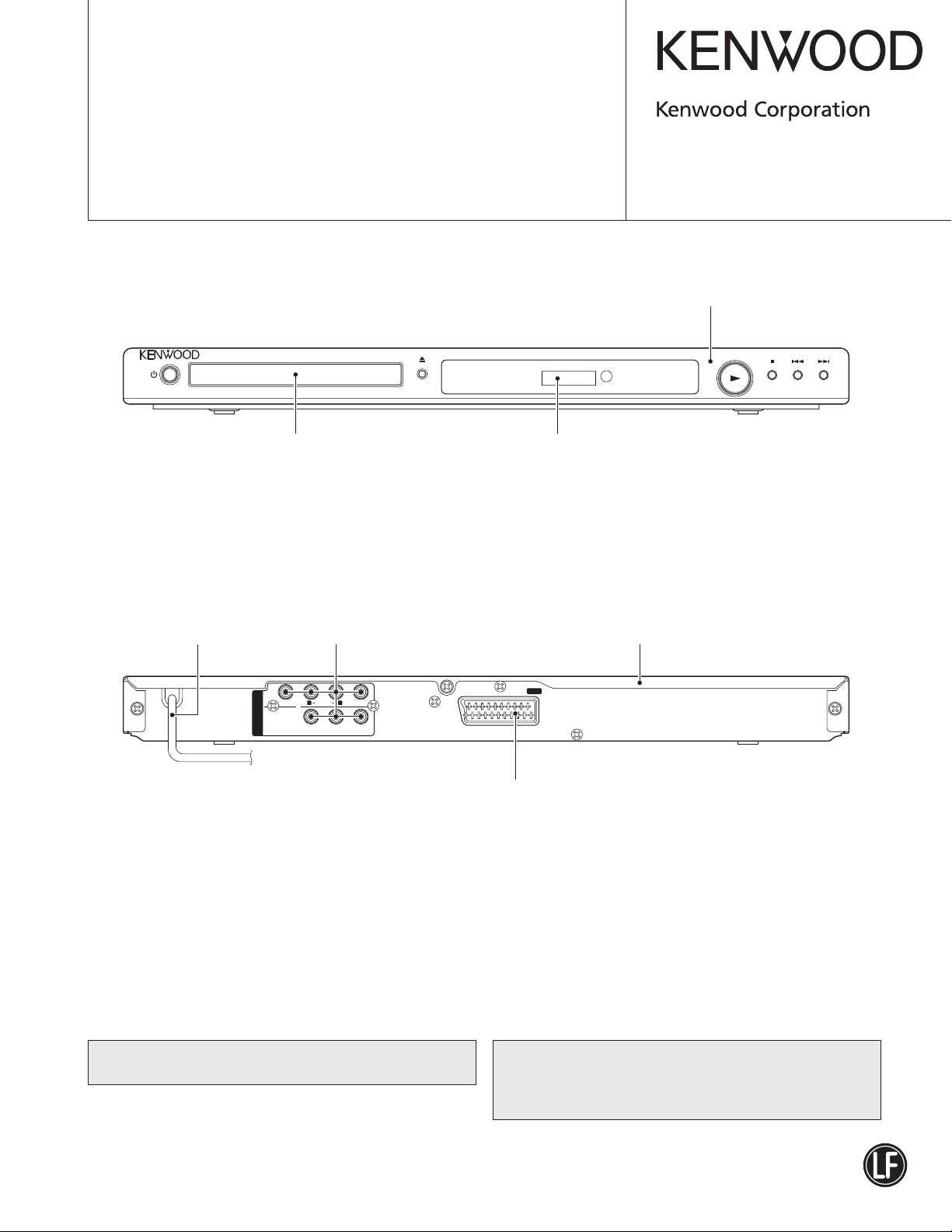

DVD/VCD/CD PLAYER

DVF-3400-B/3400-S

SERVICE MANUAL

© 2007-5 PRINTED IN JA PA N

B53-4009-00 (N/J) 102

Panel

(A60-2524-08): S

(A60-2522-08): B

Power Cord

(E30-7380-08): X

(E30-7388-08): E

Door

(A29-1276-08): S

(A29-1277-08): B

Jack

(E63-1355-08): X

(E63-1356-08): E

DIGITAL

AUDIO

R L

OUTPUT

COMPONENT/PROGRESSIVE SCAN

Window

(B11-1635-08)

Case

(A09-1330-08): S

(A09-1331-08): B

VIDEOAUDIOCOAXIAL

B PRY

P

TO TV

Jack

(E58-0073-08): E

S : Silver

B : Black

E : Europe

X : Australia

Figure is DVF-3400 (E)

In compliance with Federal Regulations, following are reproduction

of labels on, or inside the product relating to laser product safety.

This product complies with the

KENWOOD Corp. certifi es this equipment conforms to DHHS Regulations No.21 CFR 1040. 10, Chapter 1, subchapter J.

DANGER : Laser radiation when open and interlock defeated.

AVOID DIRECT EXPOSURE TO BEAM.

This product uses Lead Free solder.

RoHS directive for the European market.

DVF-3400

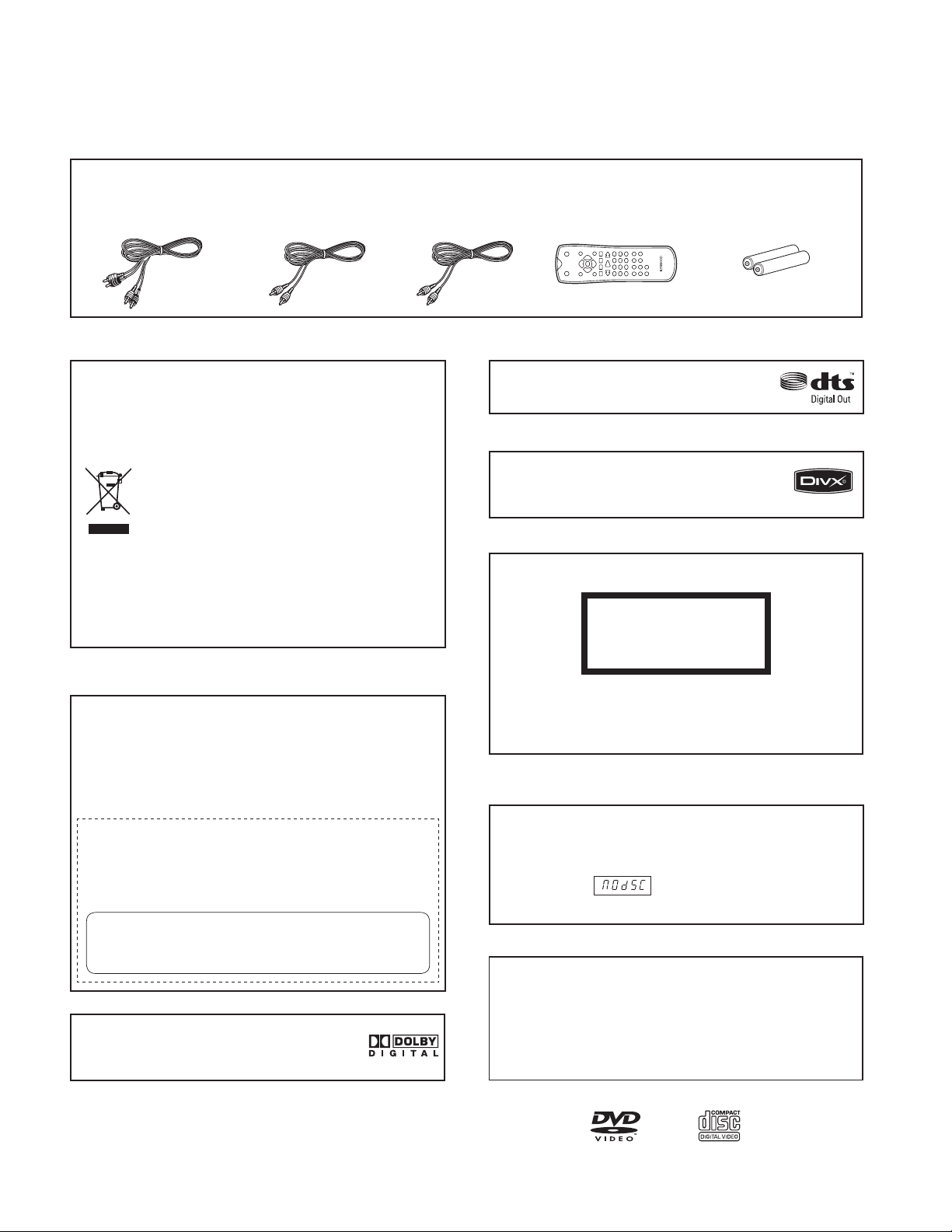

Accessories

ACCESSORIES / CAUTIONS

Audio cord (Red, White)

(x 1)

(E30-7381-08)

Video cord (Yellow)

(x 1)

(E30-7382-08)

Coaxial cable (Black)

Cautions

Information on Disposal of Old Electrical

and Electronic Equipment (applicable for EU

countries that have adopted separate waste

collection systems)

Products with the symbol (crossed-out wheeled

bin) cannot be disposed as household waste.

Old electrical and electronic equipment should

be recycled at a facility capable of handling

these items and their waste by products.

Contact your local authority for details in locating a

recycle facility nearest to you.

Proper recycling and waste disposal will help conserve

resources whilst preventing detrimental effects on our

health and the environment.

(x 1)

(E30-7383-08)

“DTS” and “DTS Digital Out” are registered

trademarks of DTS, Inc.

DivX, DivX Certified, and associated logos

are trademarks of DivX, Inc. and are used

under license.

Remote control unit

(RC-D0314 x 1)

(A70-1717-08)

Remote control batteries

(R03 x 2)

(-)

The marking of products using lasers

CLASS 1

LASER PRODUCT

For the U.S.A.

CAUTION:

Use of controls or adjustments or performance of

procedures other than those specifi ed herein may result in

hazardous radiation exposure. In compliance with Federal

Regulations, the following are reproductions of labels on,

or inside the product relating to laser product safety.

KENWOOD CORPORATION

2967-3, ISHIKAWA-CHO,

HACHIOJI-SHI,

TOKYO, JAPAN

KENWOOD CORP. CERTIFIES THIS EQUIPMENT

CONFORMS TO DHHS REGULATIONS NO. 21 CFR

1040.10, CHAPTER 1, SUBCHAPTER J.

Manufactured under license from Dolby

Laboratories. “Dolby” and the double-D

symbol are trademarks of Dolby Laboratories.

The marking this product has been classifi ed as Class 1.

It means that there is no danger of hazardous radiation

outside the product.

Location: Back panel

Caution for Transport or Movement

Before transporting or moving the system, prepare it as

described below.

Switch the system ON without placing a disc in it.

q

Ensure that

w

Wait a few seconds, and then switch the system OFF.

e

Operation to reset

The microprocessor may fall into malfunction (impossibility

to operate erroneous display, etc.) when the power cord is

unplugged while power is ON or due to an external factor.

In this case, switch off the power, wait for several seconds,

and then switch the power on again.

is displayed.

2

PARENTAL LOCK / DISASSEMBLY FOR REPAIR

hole A

(L3)

DVF-3400

FIG. 1-1

How to Reset Parental Lock

1. Connect the TV set to DVF-3400.

2. Push the power switch of DVF-3400 to be on.

3. Check the display of DVF-3400 shown “NO DISC”.

4. Push the “SETUP” key of remote control and TV has “set

up menu”.

5. Select the “16:9” on TV.

6. Push # key 1397139 and ENTER. Push # key again if

mistype.

7. Push the power switch of DVF-3400 to be off.

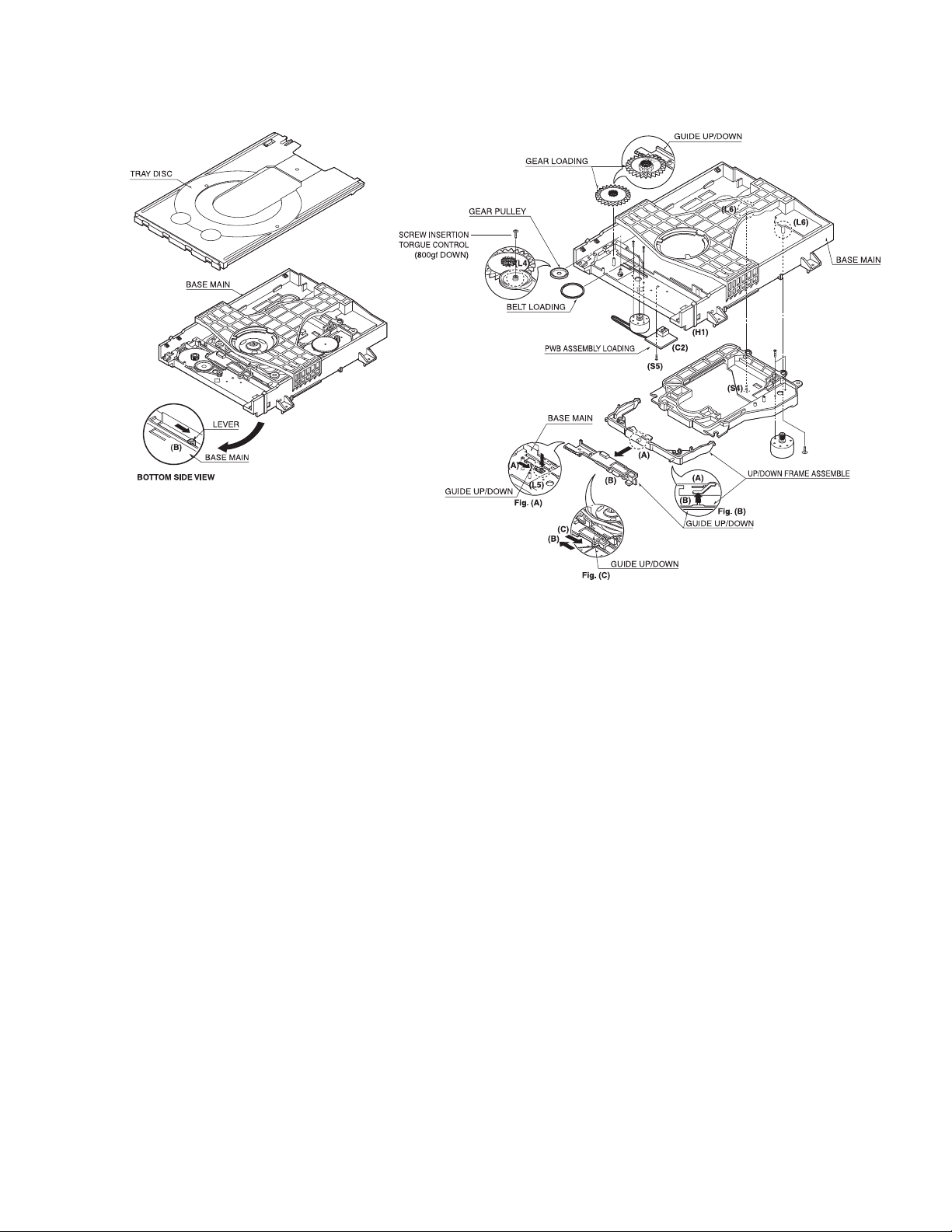

1. TRAY DISC (FIG. 1-1)

1) Insert and push a Driver in the emergency eject hole (A)

at the right side, or put the Driver on the Lever (B) of the

Gear Emergency and pull the Lever (B) in direction of

arrow so that the Tray Disc is ejected about 15~20mm.

2) Pull the Tray Disc until it is separated from the Base Main

completely.

2. FRAME ASSEMBLY UP/DOWN (FIG. 2-2)

Note

Put the Base Main face down (Bottom Side)

1) Release the screw (S4)

2) Unlock the Locking Tab (L3) in direction of arrow and

then lift up the Frame Assembly Up/Down to separate it

from the Base Main.

Note

• When reassembling move the Guide Up/Down in direction

of arrow (C) until it is positioned as Fig. (C).

• When reassembling insert (A) portion of the Frame

Assembly Up/Down in the (B) portion of the Guide Up/

Down as Fig. (B)

FIG. 2-2

3. BELT LOADING (FIG. 2-2)

Note

Put the Base Main on original position (Top Side)

4. GEAR PULLEY (FIG. 2-2)

1) Unlock the Locking Tab (L4) in direction of arrow (B) and

then separate the Gear Pulley from the Base Main

5. GEAR LOADING (FIG. 2-2)

6. GUIDE UP/DOWN (FIG. 2-2)

1) Move the Guide Up/Down in direction of arrow (A) as Fig.

(A)

2) Push the Locking Tab (L5) down and then lift up the Guide

Up/Down to separate it from the Base Main.

Note

When reassembling place the Guide Up/Down as Fig. (C)

and move it in direction arrow (B) until it is locked by the

Locking Tab (L5). And confi rm the Guide Up/Down as Fig. (A)

7. PWB ASSEMBLY LOADING (FIG. 2-2)

Note

Put the Base Main face down (Bottom Side)

1) Release 1 Screws (S5)

2) Unlock the Loading Motor (C2) from the Hook (H1) on

the Base Main.

3) Unlock 2 Locking Tabs (L6) and separate the PWB

Assembly Loading from the Base Main.

3

4

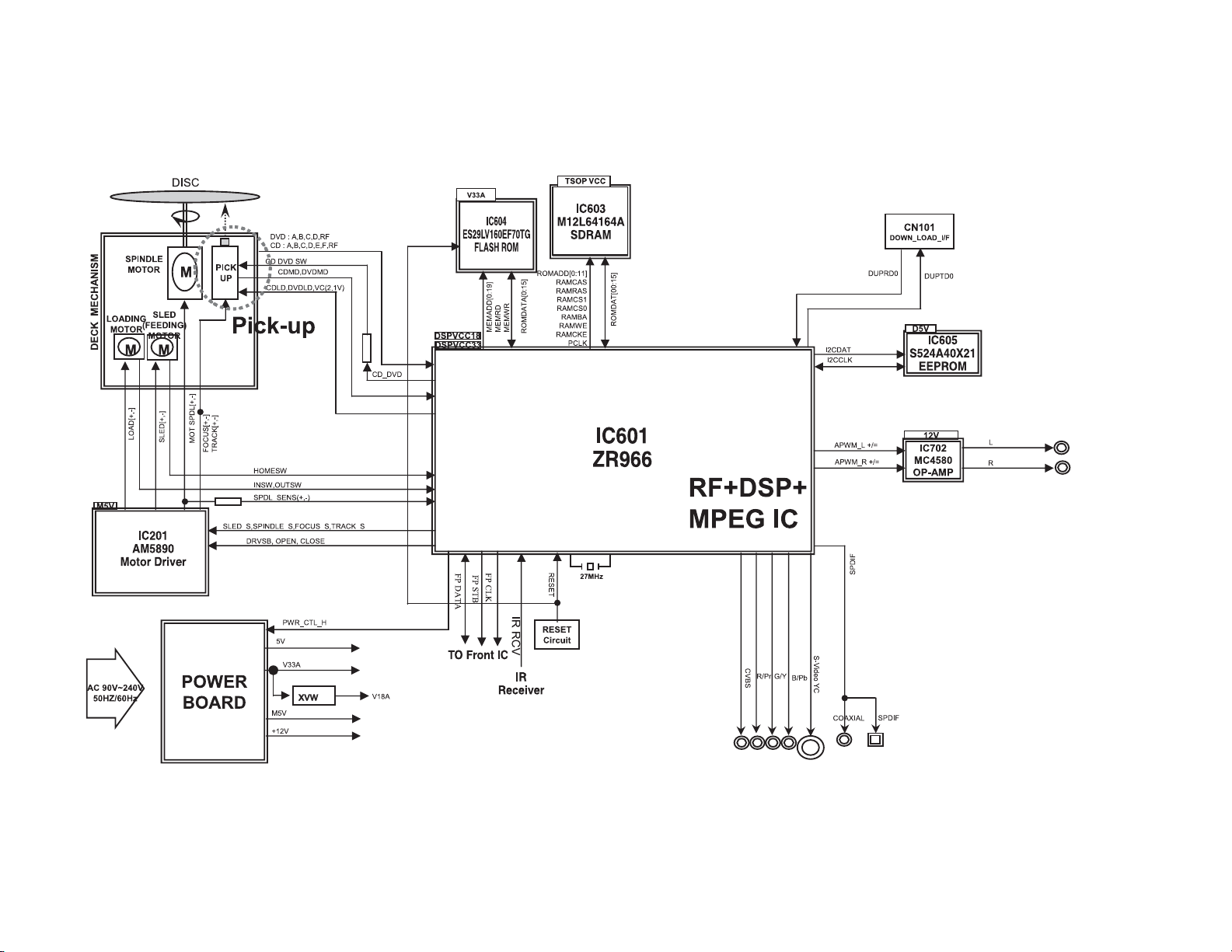

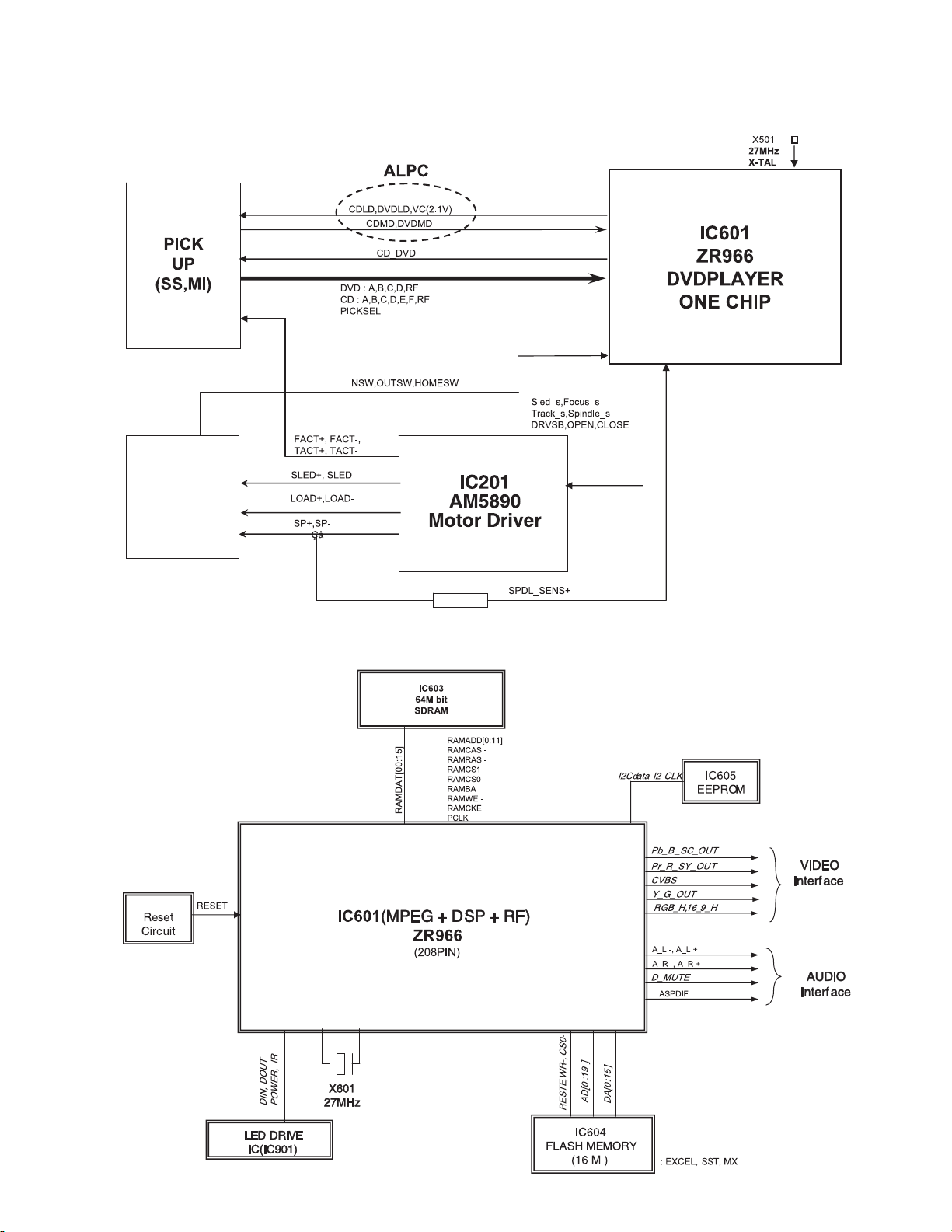

1. OVERALL BLOCK DIAGRAM

DVF-3400

BLOCK DIAGRAM

2. SERVO BLOCK DIAGRAM

MECHANISM

DECK

DVF-3400

BLOCK DIAGRAM

3. MPEG & MEMORY BLOCK DIAGRAM

5

DVF-3400

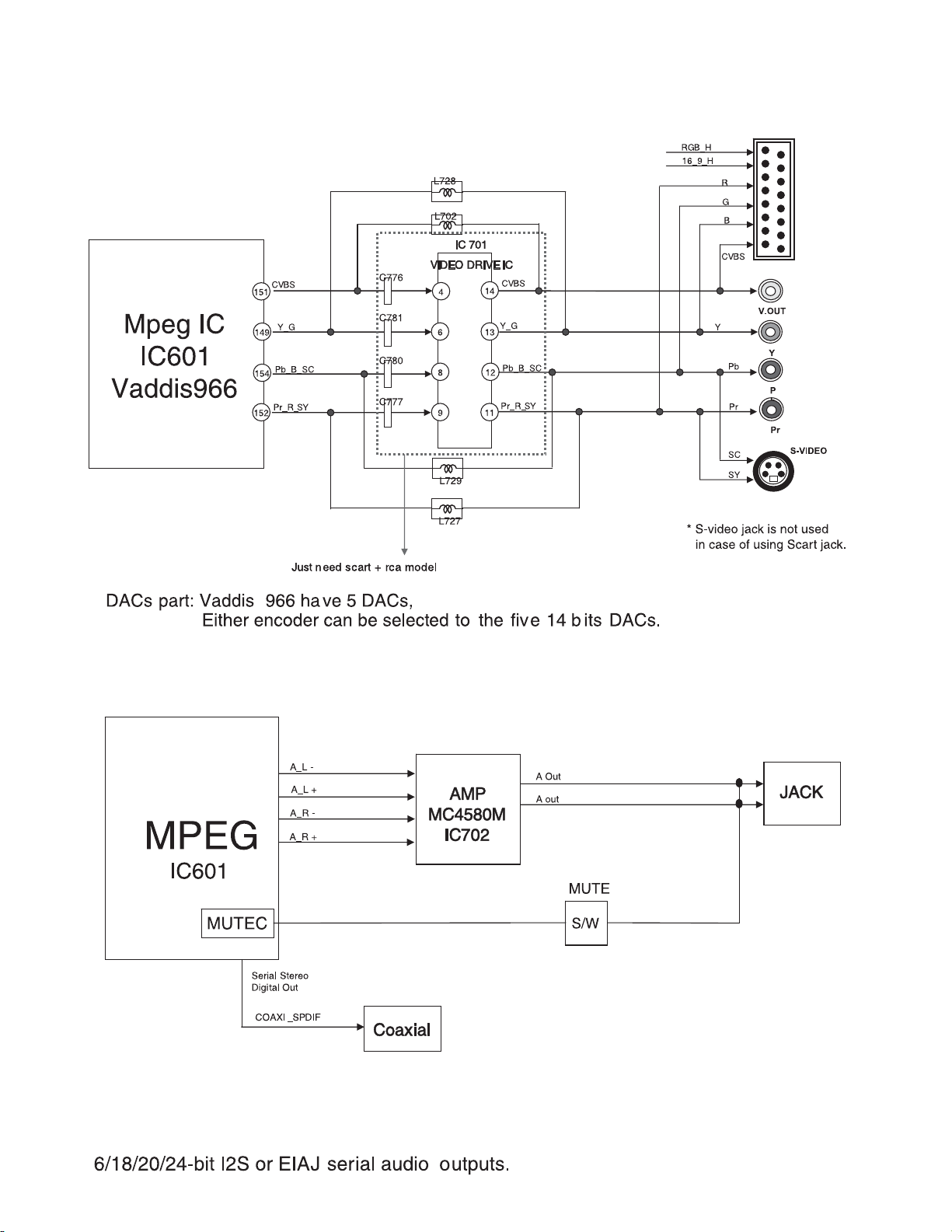

4. VIDEO BLOCK DIAGRAM

BLOCK DIAGRAM

5. AUDIO BLOCK DIAGRAM

Lch

Rch

6

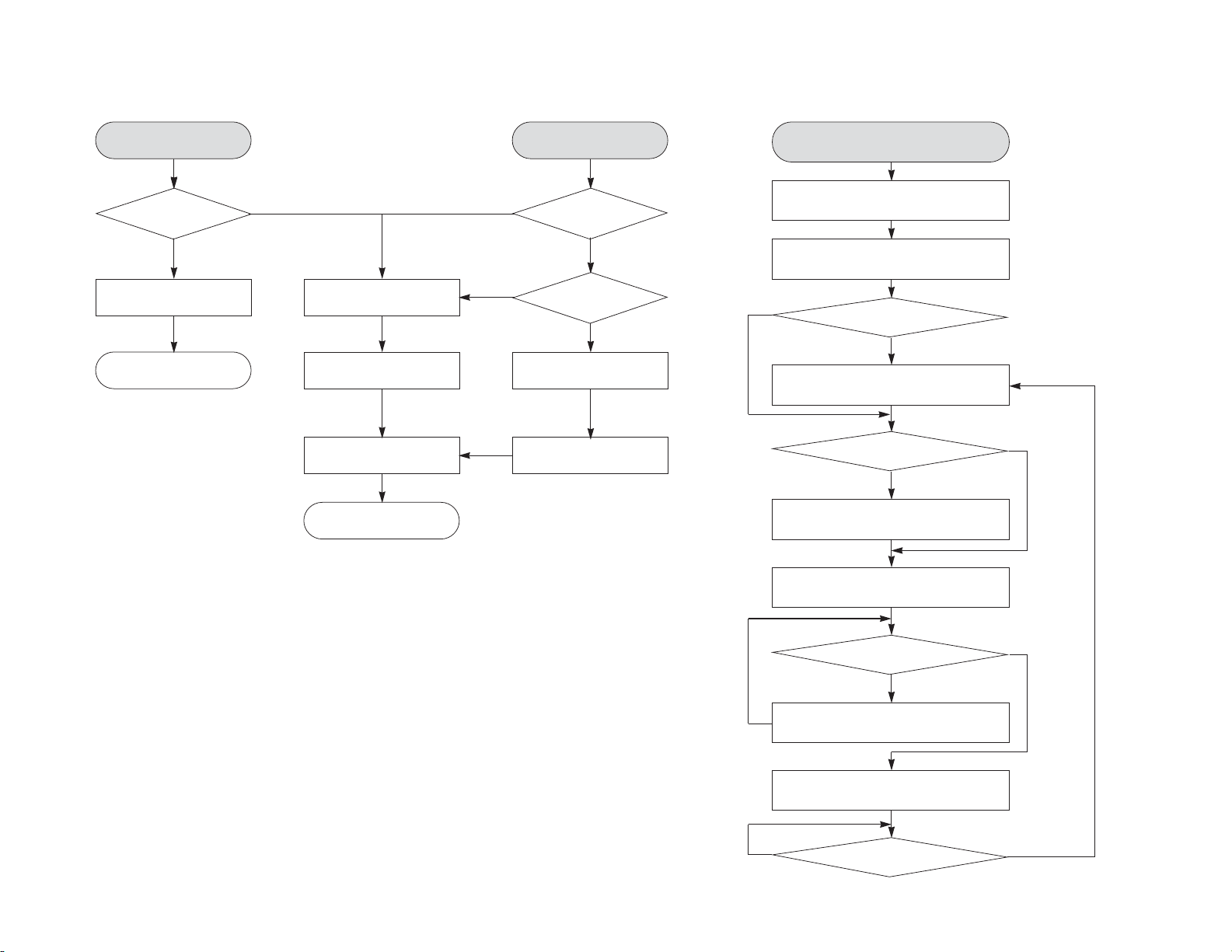

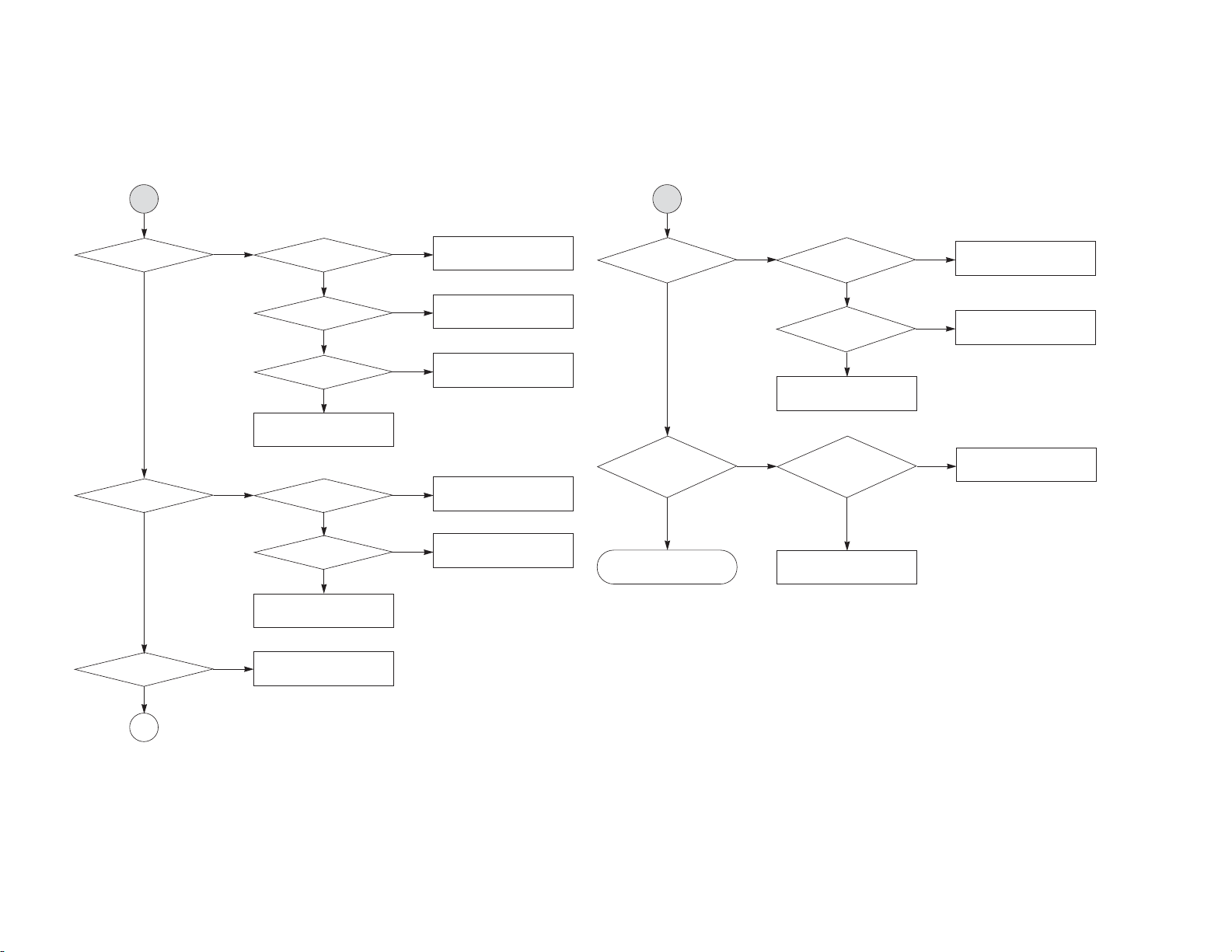

1. POWER CHECK FLOW 2. SYSTEM OPERATION FLOW

Is 5.6V present at

collector of Q126?

No 3.3VA

YES

YES

YES

YES

No 5V No 3.3VA.

Replace Q126. Check FR101 Replace Q121.

YES

Is there a DC voltage at

cathode of D105 or D107?

YES

NO

NO

NO

NO

Replace IC101.

A. B.

Check D105/D106/D107/

D108 and replace.

Is 3.3VA

section working?

Is 3.3VA

section working?

Is 3.3V

present at emitter

of Q121?

Power on

1. 8032 initializes SERVO,DSP & RISC registers

2. Write RISC code to SDRAM

3. Reset RISC

Show LOGO

YES

1. Judge whether have disc and disc type

2. Jump to related disc reading procedure

1. Execute pressed Key & IR key

2. System operation routine loop

Tray closed ?

NO

Tray close to closed position

SLED at inner side ?

NO

SLED moves to inner position

Recieve OPEN/CLOSE Key?

NO

TROUBLESHOOTING

YES

YES

DVF-3400

7

1. Stop playback & open Tray

2. Display tray open message & LOGO

NO

YES

Receive CLOSE Key?

8

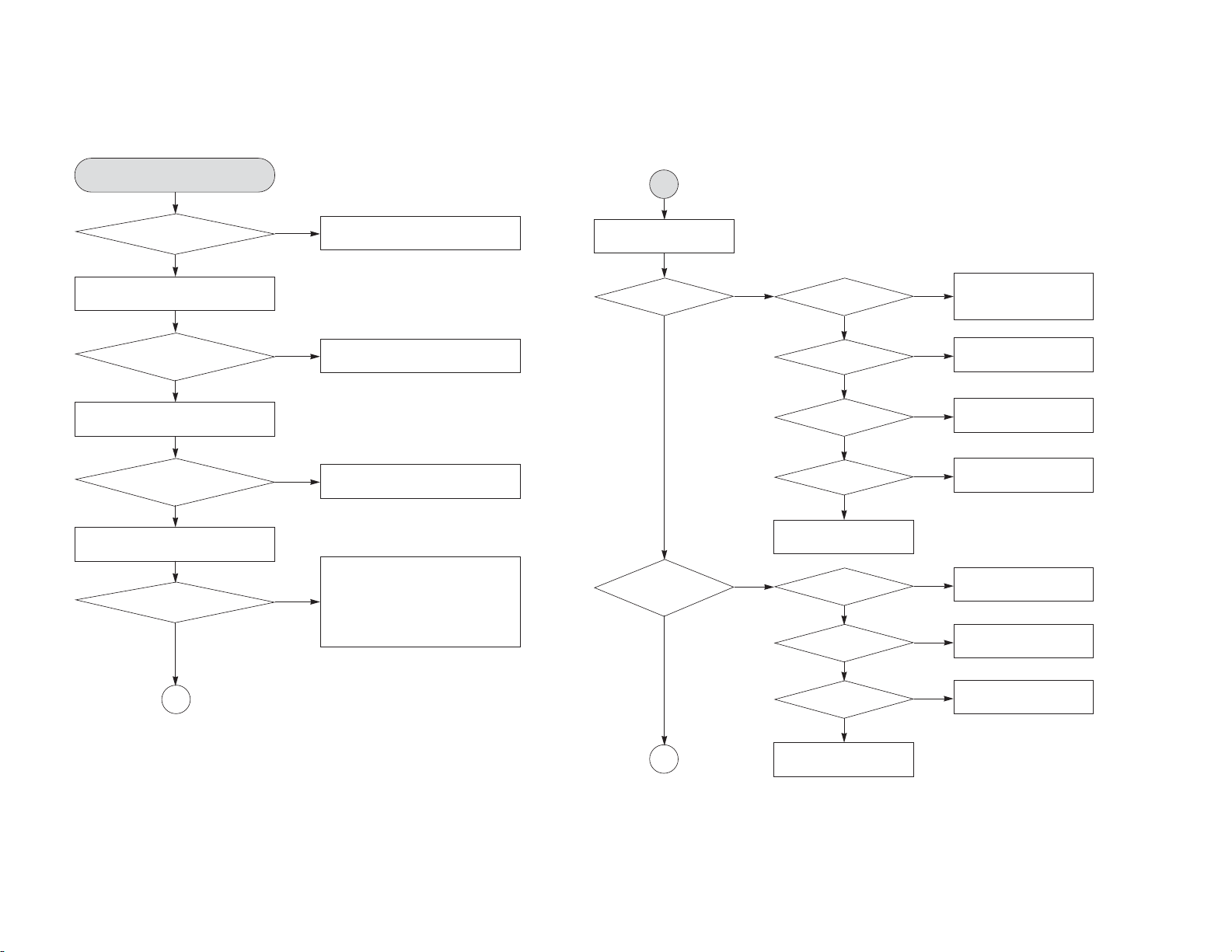

3. SYSTEM TEST FLOW

DVF-3400

TEST

Check the AC

Voltage Power PCBA (110V

or 220V)

YES

Switch on the power PCBA

Is the DC

voltage outputs OK?

(5V, 3.3V, 12V, 5.6V

MOTOR)

YES

Make sure the main PCBA don't

short on VCCs and switch it on.

YES

and 1.8V DC outputs normal

Connect to PC RS232 cable and

update the FLASH memory code.

Is 3.3V

on main PCBA?

YES

Update FLASH

successfully?

YES

A

NO

Replace power PCBA or AC transformer.

NO

NO

NO

Repair or Replace power PCBA

Check the regulators or related diodes.

1. Check 27MHz system clock.

2. Check system reset circuit.

3. Check FLASH R/W enable signal PRD,

RWR.

4. Check RS232 SIGNALS.

5. Check FLASH Memory related circuit.

A

RESET or power on.

Show LOGO?

YES

Does

Tray move inside

when it is not at closed

position?

YES

B

NO NO

NO

between main PCBA and loader.

Flash

memory operates

properly?

YES

SDRAM

works properly?

YES

ZR966

VIDEO outputs

properly?

YES

Have TV

signal output?

YES

Check AV cable

connection to TV set.

Normal

TROUT & TRIN

signals?

YES

Normal

TRCLOSE & TROPEN

signal?

YES

Normal LOAD+ &

LOAD signal?

YES

Check the cable connection

NO

NO

NO

NO

NO

NO

Check connection lines

between FLASH & ZR966

and the FLASH access time

whether is suitable or not.

Check connection lines

between SDRAM & ZR966

and the SDRAM is damaged.

Check the related

circuit of ZR966.

Check the filtering and amp

circuit of TV signal.

Check the load OPEN &

CLOSE switch

Check the Tray control IO

pins on ZR966 & AM5890S.

Check the Tray control

amplifying circuit on motor driver.

TROUBLESHOOTING

B

C

Does

the SLED move

to inner side when it is

at outter position?

YES

Do not put in disc and

tray close.

Optical Lens has

movements for searching

focus?

YES

C

Motor

Driver DRVSB Pin

is high?

YES

Is sled_s

DC Level higher than

1.4V?

YES

SL+ and

SL- output properly?

YES

Check the cable connection

with MECHA.

Proper

focus_s outputs to motor

driver?

YES

Proper F+ &

F- outputs?

YES

Check cable connect on

with pick-up head.

NONO

NO

NO

NONO

NO

Check the connection line

of DRVSB signal.

Check the related

Check the amp circuit on

Check focus_s connection

on ZR966 and motor dirver.

Check the amp circuit on

circuit of Sled_s.

motor driver.

motor dirver.

Laser

turns on when reading

disc?

YES

Put disc in?

YES

Disc ID is correct?

YES

Does spindle rotate?Does spindle rotate?

YES

NO NO

NO

NO

NO NO

DVD_LD,

CD_LD output properly?

YES

Collector

voltage of power transistor

is OK?

YES

Check cable connection

between transistor ouput

and pick-up head.

Laser off

Proper RF signal

on OPU

YES

Check DVD_LD &

CD_LD signal

Proper spindle_s

signal on ZR966

YES

SP+ & SP- output properly?

YES

NO

NO

NO

Check the laser power circuit

on ZR966 and connecting to

power transistor.

Check the related circuit on

laser power transistor

Check the related circuit

on RF signal.

Check spindle_s related

circuit on ZR966.

Check the spindle control

amp circuit of motor driver.

TROUBLESHOOTING

DVF-3400

D

Check the cable connection

between spindle and main

PCBA.

9

10

DVF-3400

D

Focus on OK?

YES

Track on OK?

YES

NO NO

NO NO

Proper signals on

A,B,C,D of ZR966

YES

Check focus_s

signal on ZR966

YES

F+ & F- output

properly?

YES

Check cable connection on

pick-up head.

Properly track_s

signal on ZR966?

YES

T+ & T- output

properly?

YES

Check cable connection on

pick-up head.

NO

NO

Check connections between

ZR966 and pick-up head.

Check the focus_s connection

on ZR966 and motor driver.

Check the focus control

amp circuit on motor driver.

Check the track_s connection

on ZR966 and motor dirver.

Check the tracking control

amp circuit on motor driver.

E

Normal

Audio output when disc

playback?

YES

Normal

IR.VFD & Front

pannel key

functions?

YES

TEST END

NO

NO NO

Check the cable connection

Audio

DAC received correct

data stream?

YES

Normal Audio

DAC out?

YES

Check Audio filter,

amplify, mute circuit.

Commu-

nications between

IR.VFD Front pannel

key & ZR966 is

normally?

YES

on Front pannel.

NO

NO

Check connection between

ZR966 & Audio DAC.

Check the related

circuit of Audio DAC.

Check communication

lines on ZR966.

TROUBLESHOOTING

Disc is play?

YES

E

NO

Check RF signal waveform.