Kenwood DPFJ-6030, CD-4700-M, CD-425-M, CD-4260-M Service manual

70%

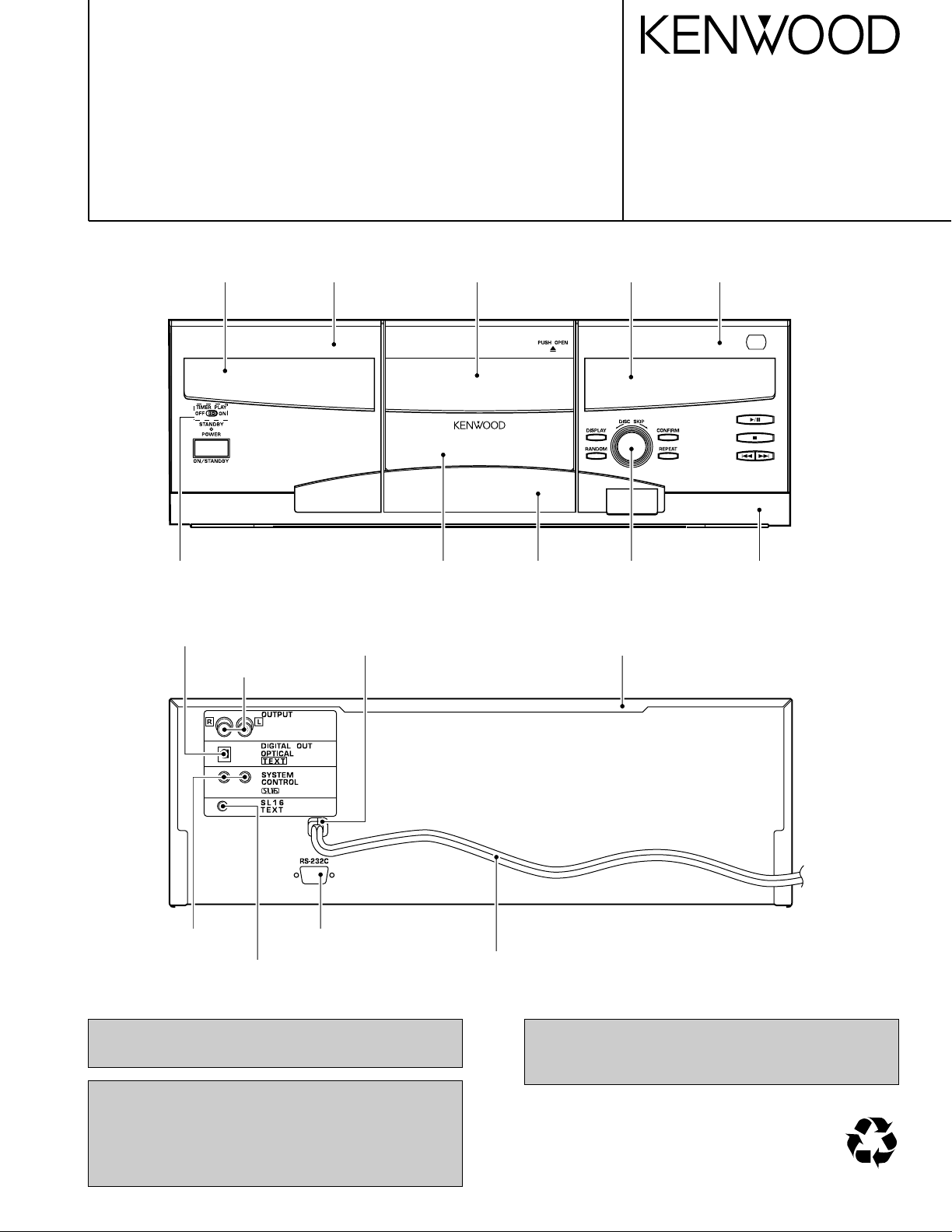

MULTIPLE COMPACT DISC PLAYER

CD-425M/4260M/4700M

DPF-J6030

SERVICE MANUAL

Front glass

(B10-3557-08)

Knob

(K29-7717-18)

Oscillating module

(W02-1114-15)

Pin jack

(E63-1078-05)

Dressing panel

(A21-3813-08)

Power cord bushing

(J42-0083-05)

Front glass

(B10-3558-18)

Dressing panel

(A21-3815-08)

Panel

(A29-1081-18)

© 2000-3/B51-5610-00 (K/K) 3037

Front glass

(B10-3559-08)

Knob

(K29-7716-18)

Metallic cabinet *

(A01-)

Dressing panel *

(A21-)

Panel

(A60-1753-38)

Miniature phone jack

(E11-0293-05)

Miniature phone jack

(E11-0360-05)

In compliance with Federal Regulations, following are

reproduction of labels on, or inside the porduct relating to

laser product safety.

KENWOOD-Crop. certifies this equipment conforms to

DHHS Regulations No.21 CFR 1040. 10, Chapter 1, Subchapter J.

DANGER : Laser radiation when open and interlock

defeated.

AVOID DIRECT EXPOSURE TO BEAM.

Rectangular receptacle

(E58-0024-05)

AC power cord

(E30-2883-05)

* Illustration is CD-4260M/4700M.

* Refer to parts list on page 18.

Refer to CD-223M/DPF-J3010 service manual (B51-5409-

00) if require the following items in detail.

1) Mechanism operation description.

2) Disassembly for repair.

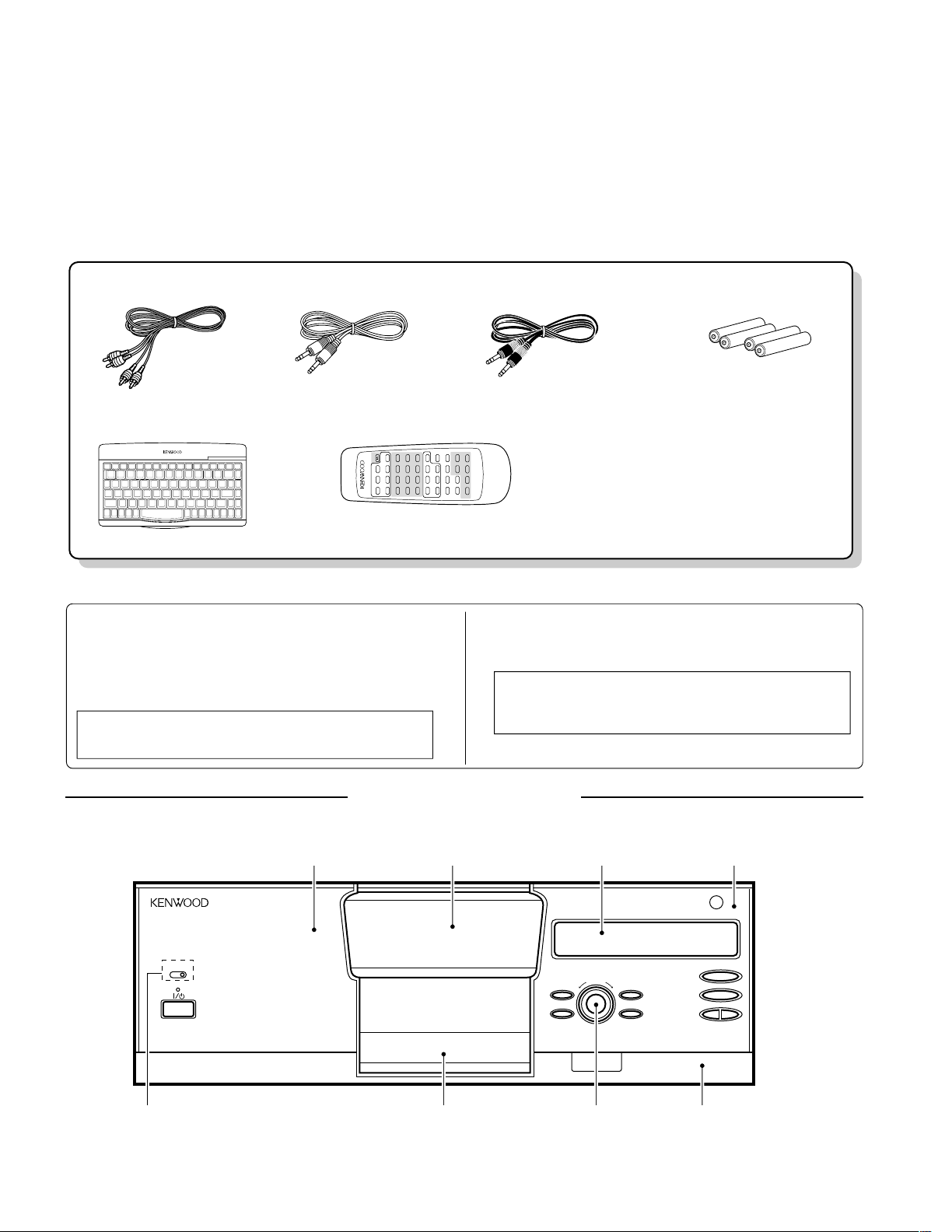

Audio

(E30-0505-05) (E30-2816-05) (E30-2861-05)

cord ....................... (2)

System control cord ........ (1)

Batteries (R6/AA) ............ (4)

Communication cord ....... (1)

REMOTE CONTROL UNIT RC-KB2

REMOTE CONTROL UNIT

RC-P0714

T

U

V

X

Y

Z

W

/

.

–

(

'

)

MODE

SET

SELECTOR

DISC

DELETE

/CLEAR

SPACE CHARAC.

/CHECK /P.MODE

RANDOM

SELECTON

DISPLAY

CONFIRM

A

B

C

D

E

F

G

REPEAT

BEST

POWER

32

4

H

J

K

L

M

N

O

P

Q

R

S

1

76

8

5

+100 +100

9

7

ENTER

6

4¢

1¡

DISC SKIP

DOWN UP

CURSOR

CHARACTER

DOWN

UP

LEFT RIGHT

I

Remote control units

...... (2)

(A70-1326-05): RC-KB2

Battery cover (A09-1176-08)

(A70-1336-18): RC-P0714

Battery cover (A09-0374-08)

To reset the registered contents

The registered contents for title, music type, user file, best selection and DTS disc can be reset by the following procedure.

Operation to reset

The microcomputer may malfunction (impossibility to operate,

erroneous display, etc.) when the connection cords are unplugged while power is ON or due to an external factor. In this

case, execute the following method to reset the microcomputer

and return it to normal condition.

Unplug the power cord from the power socket and plug the

power cord into the socket again.

Unplug the power cord from the power socket, and while

holding the 7 key depressed, plug the power cord into the

socket again.

CD-425M/4260M/4700M/DPF-J6030

TIMER PLAY

OFF ON

MULTIPLE COMPACT DISC PLAYER

ON/STANDBY

DISPLAY

DISC SKIP

0

PUSH OPEN

RANDOM

CONFIRM

REPEAT

6

7

4 ¢

200 DISC LOADING WITH TWIN PICK UP MECHANISM

STANDBY

CONTENTS / ACCESSORIES / CAUTIONS

Contents

CONTENTS / ACCESSORIES / CAUTIONS............. 2

EXTERNAL VIEW.......................................................2

CIRCUIT DESCRIPTION............................................3

ADJUSTMENT............................................................8

PC BOARD ................................................................ 9

Accessories

SCHEMATIC DIAGRAM.......................................... 11

EXPLODED VIEW ....................................................15

PARTS LIST..............................................................17

SPECIFICATIONS ......................................Back cover

Cautions

EXTERNAL VIEW

Dressing panel *

(A21-)

Front glass

(B10-2395-08)

Front glass

(B10-2396-18)

Dressing panel

(A21-3786-08)

2

Knob

(K29-6885-38)

Panel

(A29-1087-08)

Knob

(K29-6824-18)

* Illustration is CD-425M/DPF-J6030.

Panel

(A60-1755-18)

* Refer to parts list on page 17.

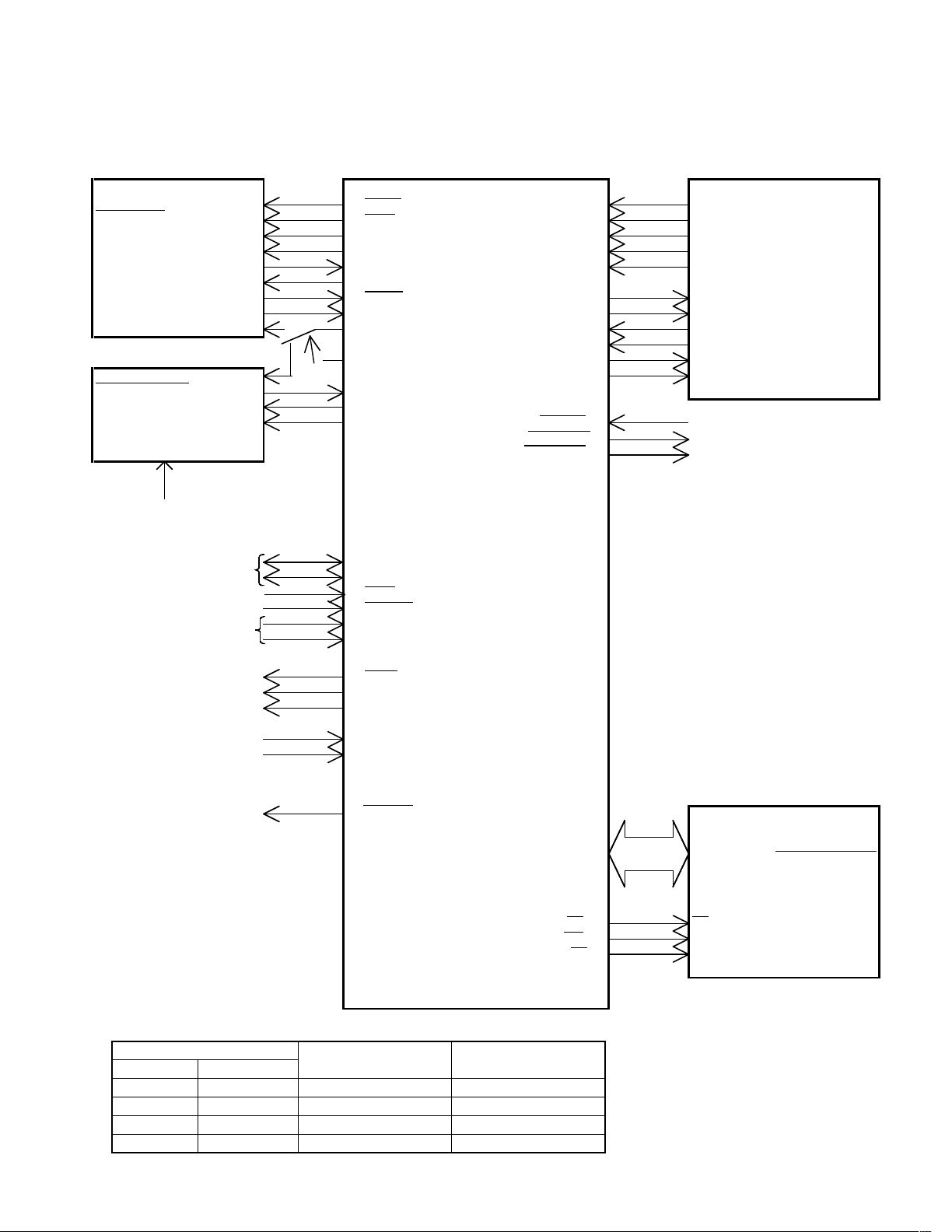

CD-425M/4260M/4700M/DPF-J6030

IC2 IC6 CD MECHA

CXD2587Q

CLOCK 35 CLOK S1_SW 56 S1_SW

(DSP) XLAT 36 XLAT S2_SW 28 S2_SW

DATA 44 DATA S3_SW 27 S3_SW

SCLK 33 SCLK D1_SW 58 DISC_SW1

SENS 34 SENS D2_SW 57 DISC_SW2

SYSM 45 MUTG

SCOR 46 SCOR R_CW 24 ROTARY+

SQCO 73 SQSI R_CCW 25 ROTARYSQCK 75 SCK/SQCK LOAD_SW 55 LOAD_SW

UNLOAD_SW 54 UNLOAD_SW

IC13 67 SCK_SW LOAD_P 31 LOADM+

uPD780232GC

CLK LOAD_M 30 LOADM-

(DOT DRIVER)

SO 72 SI

SI 74 SO

STB 71 STB RESET 43 RESET INPUT

REG_ON 29 PERIPHERY IC ON

T

IC RESET 63 PERIPHERY IC RESET

uPD784217GF501

TIMER PLAY

ON/OFF

SERIAL COMMUNICATION

49 SBUSY

50 SDATA

REMOCOM INPUT 48 REM

POWER KEY 47 POWER

JOG

60 JOG_2

59 JOG_1

DISC SENSOR ON/OFF 23 PWM

LASER ON/OFF 32 LDC

SPINDLE MOTOR ON/OFF 26 MON

DOOR OPEN/CLOSE 70 DOOR_SW

PROTECTION 53 PROTECT

IC10

ANALOG MUTE 10 RMUTE

84~91

(AD0~AD7)

CY62128L-70SC

(SRAM)

76~83,92~98

(A0~A14)

RD 5 OE

WR 6 WE

CS 7 CS

CIRCUIT DESCRIPTION

1. Main Microprocessor : uPD784217GF501

Microprocessor periphery block diagram

IMER_SW

2. Key matrix

PORT

VOLTAGE RESISTER

2.9V 5.1K RANDOM REPEAT

2.0V 3K DISPLAY CONFIRM

1.2V 2K STOP DOWN

0.4V SHORT PLAY UP

A/D 0(IC13,22pin) A/D 1(IC13,21pin)

3

CD-425M/4260M/4700M/DPF-J6030

CIRCUIT DESCRIPTION

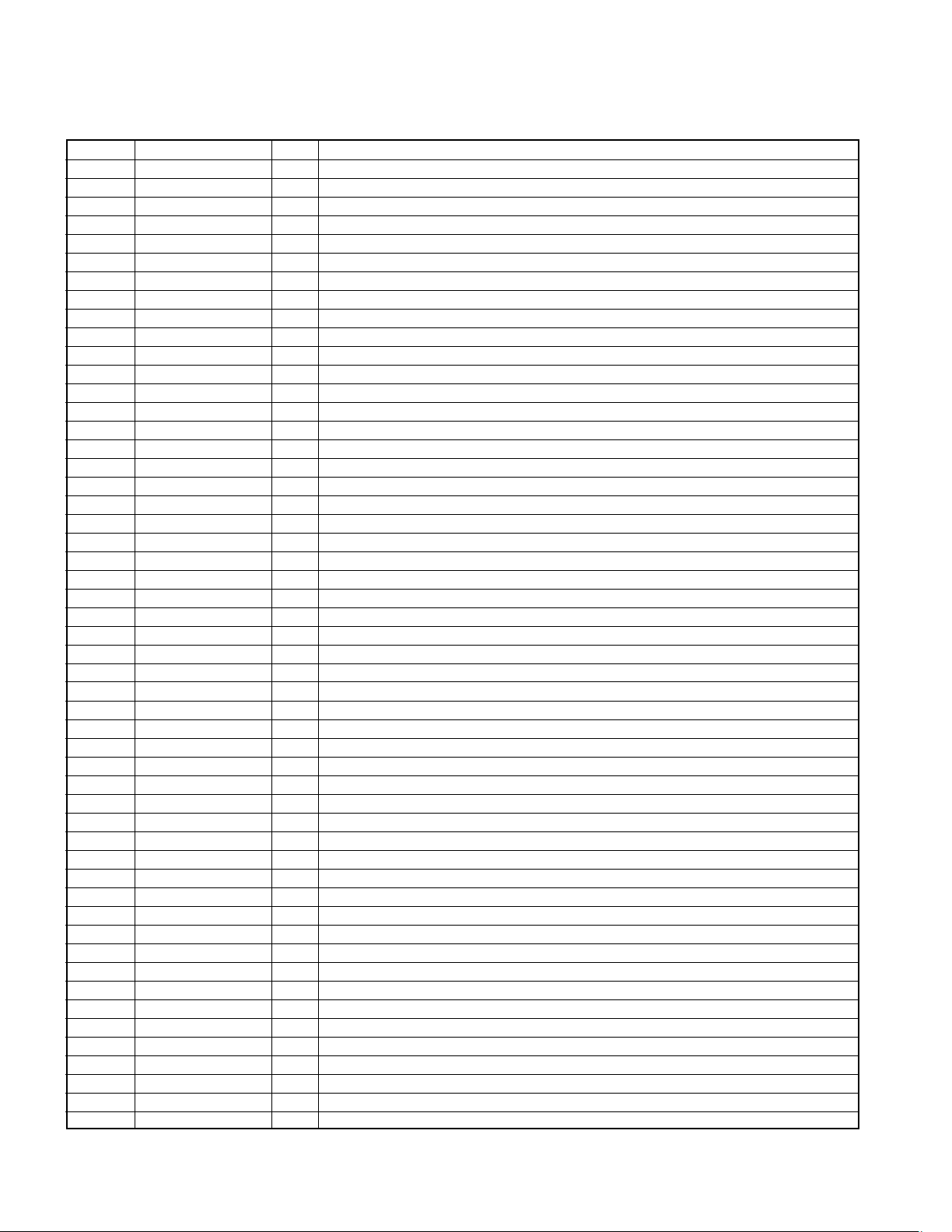

3. Microprocessor pin description (X32, IC6) :UPD784217GF501

Pin No. Pin Name I/O Description

1 A16(1M) O No used.

2 A17 O No connection.

3 SCL O No connection.

4 SDA I/O No connection.

5 RD O SRAM read strobe.

6 WR O SRAM write strobe

7 CE O Chip selector

8 ASTB(CE) O No connection.

9 VDD - Power supply(+5V).

10 RMUTE O Analog muting signal output.

11 RWRR O No connection.

12 RWR I No connection.

13 RTRN I No connection.

14-21 L-D7-D0 O No connection.

22 VPP - GND.

23 +5VPWM O Disc sensor ON/OFF. L:on

24 R-M-CW O Mechanism rotary motor(+). H:CCW

25 R-M-CCW O Mechanism rotary motor(-). H:CW

26 MON O Control port of poor focus works.

27 S3-SW I Mechanism address detector switch.

28 S2-SW I Mechanism address detector switch.

29 REG-ON O Power ON/OFF control.

30 LOADM- (IN2) O Loading motor(-) for main pickup.

31 LOADM+ (IN1) O Loading motor(+) for main pickup.

32 LDC O Laser on/off. L: Laser diode on.

33 SCLK O Sens serial data read clock.

34 SENS I SENS signal input.

35 CLK O Serial data clock.

36 XLAT O CXD2587Q latch. H î L:latch

37 VDD - Power supply(+5V).

38,39 X1,2 - Main system clock(12.5MHz).

40 VSS - GND.

41 XT2 - No connection.

42 XT1 I GND.

43 RESET I System reset signal input.

44 DATA O Serial data output.

45 MUTEG(SYSTEM) O System muting control output.

46 SCOR I Sub code synchro detection.

47 POWER I Power key input terminal.

48 REM I Remote control signal input.

49 SBUSY I/O Serial busy signal I/O.

50 SDATA I/O Serial data signal I/O.

51 AVDD - Power supply(+5V).

52 AVREF - A/D reference power supply.

53 PROTECT I Detection signal input of protection.

54 UNLOAD-SW1 I Unloading switch for main pickup.

55 LOAD-SW1 I Loading switch for main pickup.

56 S1-SW I Mechanism address detector switch.

57 DISC-SW2 I Disc2 sensor input..

58 DISC-SW I Disc sensor.

59 JOG2 I Encoder signal input.

60 JOG1 I Encoder signal input.

4

CD-425M/4260M/4700M/DPF-J6030

CIRCUIT DESCRIPTION

Pin No. Pin Name I/O Description

61 AVSS - GND.

62 LED O STANDBY LED control terminal.

63 ICRESET O IC reset.

64 AVREF1 - D/A reference power supply.

65 RXD-232C I No connection.

66 TXD-232C O No connection.

67 SQCK/SCK-SW O SQCK,SCK(DOT/DSP clock) selector. L:DSP.

68 RXD-R I No connection.

69 TXD-R O No connection.

70 DOOR-SW I Door open/close detector switch.

71 STB1 O Strobe signal output to dot driver.

72 S1 O Data output to dot driver.

73 SQS1 I Sub code read data input.

74 S0 I Data input from dot driver.

75 SCK/SQCK O Dot driver/sub code read clock.

76-83 A0~A7 O Address output to SRAM.

84-91 D0-7 I/O SRAM data bus.

92-98 A8~A14 O Address output to SRAM.

99 A15(1M) O No used.

100 VSS - GND.

4. FL Microprocessor : UPD 780232GC-012 (X32-IC13)

Pin description

Pin No. Pin Name I/O Description

1 VDD - Power supply(+5V)

2 VSS - GND.

3,4 X1,2 - Main system clock.(5MHz).

5 VPP - GND.

6 RESET I System reset input.

7 SCK I Serial clock.

8 SI I Data input.

9 SO O Data output.

10 POW-P I/O Timer sw on input. .

11 LED-A O No used.

12 LED-B O No used.

13 STANDBY O No used.

14 NC - No used.

15 STB I Strobe signal input.

16 REM I No used.

17 NC - No used.

18 AVSS - GND.

19,20 A/D3,A/D2 - GND.

21,22 A/D1,A/D0 I Key return signal input(1,0).

23 VSS - GND.

24,25 AVDD/VDD - Power supply(+5V)

26 NC - No connection.

27-43 P1-P17 O FL control output. 1G(38),2G-16G(P1to P17).

44-58 P21-35 O FL control output. 2G-16G(P21to P35).

59 VDD - Power supply(+5V)

60 VLOAD - Negative power supply(-37.5V)

61-63 P18-P20 O FL control output. 2G-16G(P18 to P20).

64 NC - No connection.

65-72 1G-8G O FL control output.1G-8G.

73-80 9G-16G O FL control output.9G-16G.

5

CD-425M/4260M/4700M/DPF-J6030

CIRCUIT DESCRIPTION

5. Test mode

INPUT KEY PROCEDURE DISPLAY

Insert the AC plug to INITIAL CONDITION MECHA. INITIAL

the wall outlet with • Disc No.1 moves to the center. INITIAL OK!!

pressing the SKIP- • Clear the memory of the SRAM.

DOWN key. • Door opens. INITIAL NG

• Set the switch of TIMER ON PLAY to ON. TIMER, NG

• Set the switch of SYSTEM CONTROL to XS8. SER, NG

Insert the AC plug to CIRCUIT ADJUSTMENT TEST ON

the wall outlet with • Open the door and load the disc to the Disc No.1.

pressing the REPEAT • Close the door. The unit changes to test mode 05 .

key after clamping the disc

PLAY/PAUSE Change the mode 05(tracking-on) and 03(tracking-off) alternately . 05 XX:XX 03 XX:XX

by the PLAY key

STOP Stop the function. 00

UP The pickup travels outwards. MOTOR FORWARD

DOWN The pickup travels inwards. MOTOR REVERSE

RANDOM Shows the result of self-adjustment.

07 EF/FB 07 XXX:XXX

08 TG/FG 08 XXX:XXX

09 FE/RF 09 XXX:XXX

10 TE/VC 10 XXX:XXX

Mode changes alternately by the RANDOM key. NG: blinking

REPEAT Playback PGM signal of the Track No.7,13,23,30,34

and 41 in the order. And release the test mode.

CONFIRM Release the test mode.

(TIMER PLAY SW) Check the switch position. TIMER ON , TIMER OFF

Insert the AC plug CHECK THE MECHANISM JAMMING.

to the wall outlet with Clamp the Disc No1,2,100,50,200 and 199 in the order.

pressing the UP key.

Insert the AC plug THE MECHANISM TEST MODE.

to the wall outlet with Display shows Niagara until pressing any keys.

pressing the

RANDOM key.

PLAY/PAUSE Change the mode 05(tracking-on) and 03(tracking-off) alternately 05 XX:XX 03X:XX

by the PLAY key.

STOP Stop the function.

Shows the result of self-adjustment.

07 EF/FB 07 XXX:XXX

08 TG/FG 08 XXX:XXX

09 FE/RF 09 XXX:XXX

10 TE/VC 10 XXX:XXX

Mode changes alternately by the STOP key. NG: blinking

UP Arm Motor Load operation. MOTOR LOAD

DOWN Arm Motor Unload operation. MOTOR UNLOAD

RANDOM Rotary Motor Clockwise turning. MOTOR CW

DISPLAY Rotary Motor Counterclockwise turning. MOTOR CCW

REPEAT Playback PGM signal of the Track No.1,23 and 41

in the order.And release the test mode.

CONFIRM Release the test mode.

(TIMER PLAY SW) Check the switch position. TIMER ON , TIMER OFF

6

Loading...

Loading...