Page 1

COMPACT DISC PLAYER

70%

POWER

- ON – OFF

PHONES

P.MODE

EDIT

CHECK

CLEAR

PEAK SEARCH

TIME DISPLAY

OPEN/CLOSE

REPEAT RANDOM

0

76

4¢

1¡

OUTPUT

OPTICAL

DIGITAL

OUTPUT

SYSTEM CONTROL

L

R

TEXT

DPF-1030/1030E/1030-S

DPF-2030/2030E/2030-S

SERVICE MANUAL

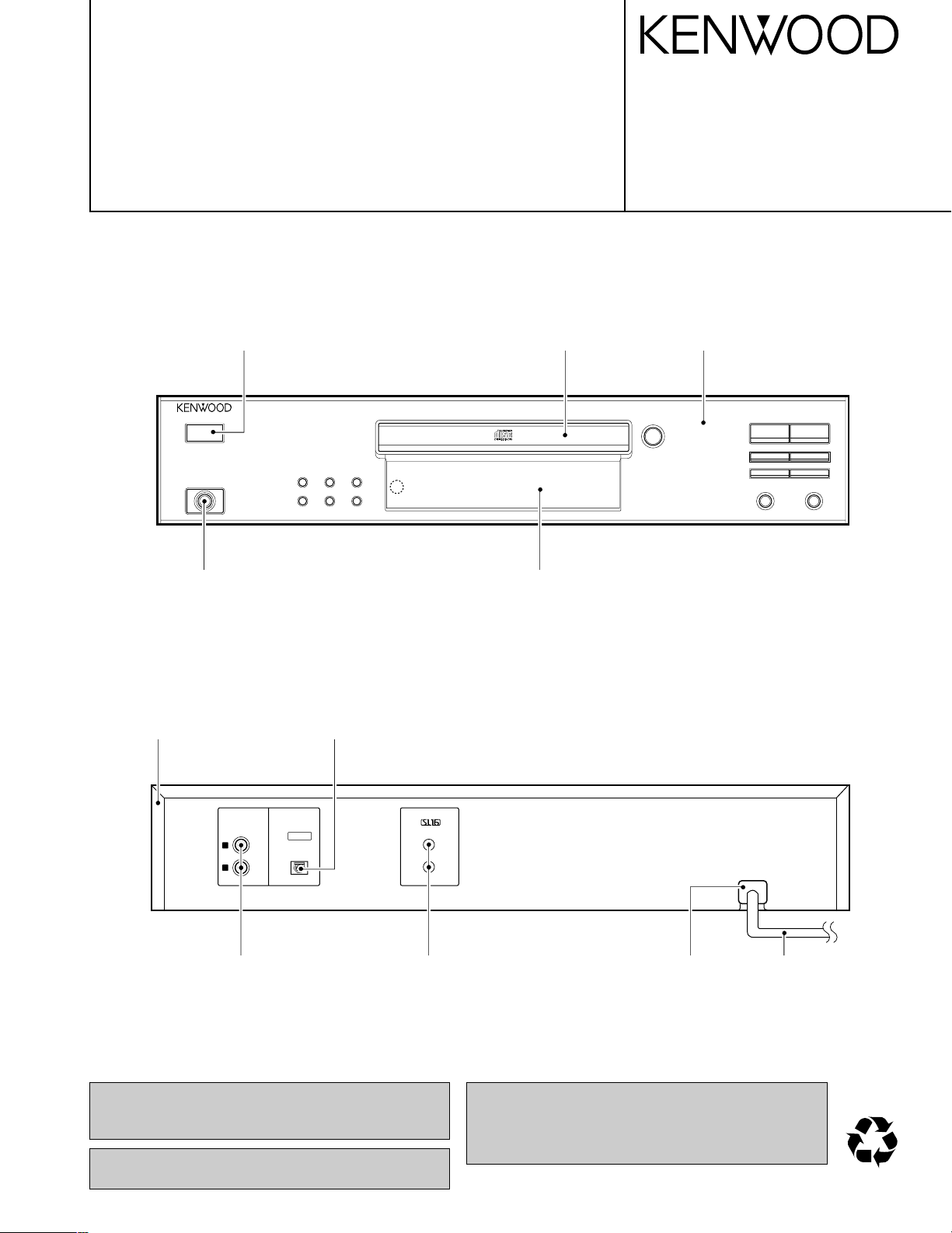

Power Knob *

(K29-)

H/P jack

(E11-0345-08)

Tray cover *

(A21-)

FL window

(B10-3611-08)

© 2000-3/B51-5603-00 (K/K) 2100

Front cab ass'y *

(A60-)

Top cabinet *

(A01-)

Digital output jack

(W02-2752-08)

Pin jack

(E63-1081-08)

In compliance with Federal Regulations, following are reproductions of labels on, or inside the product relating to laser

product safety.

Refer to DP-3080MKΙΙ/3090 Service manual (B51-5349-00),

if you require disassembly for repair.

System jack

(E11-0188-05)

AC power cord bushing

(J42-0083-05)

KENWOOD-Corp. certifies this equipment conforms to DHHS

Regulations No. 21 CFR 1040. 10, Chapter 1, Subchapter J.

DANGER : Laser radiation when open and interlock defeated.

AVOID DIRECT EXPOSURE TO BEAM.

* Refer to parts list on page 14.

AC power cord *

(E30-)

Page 2

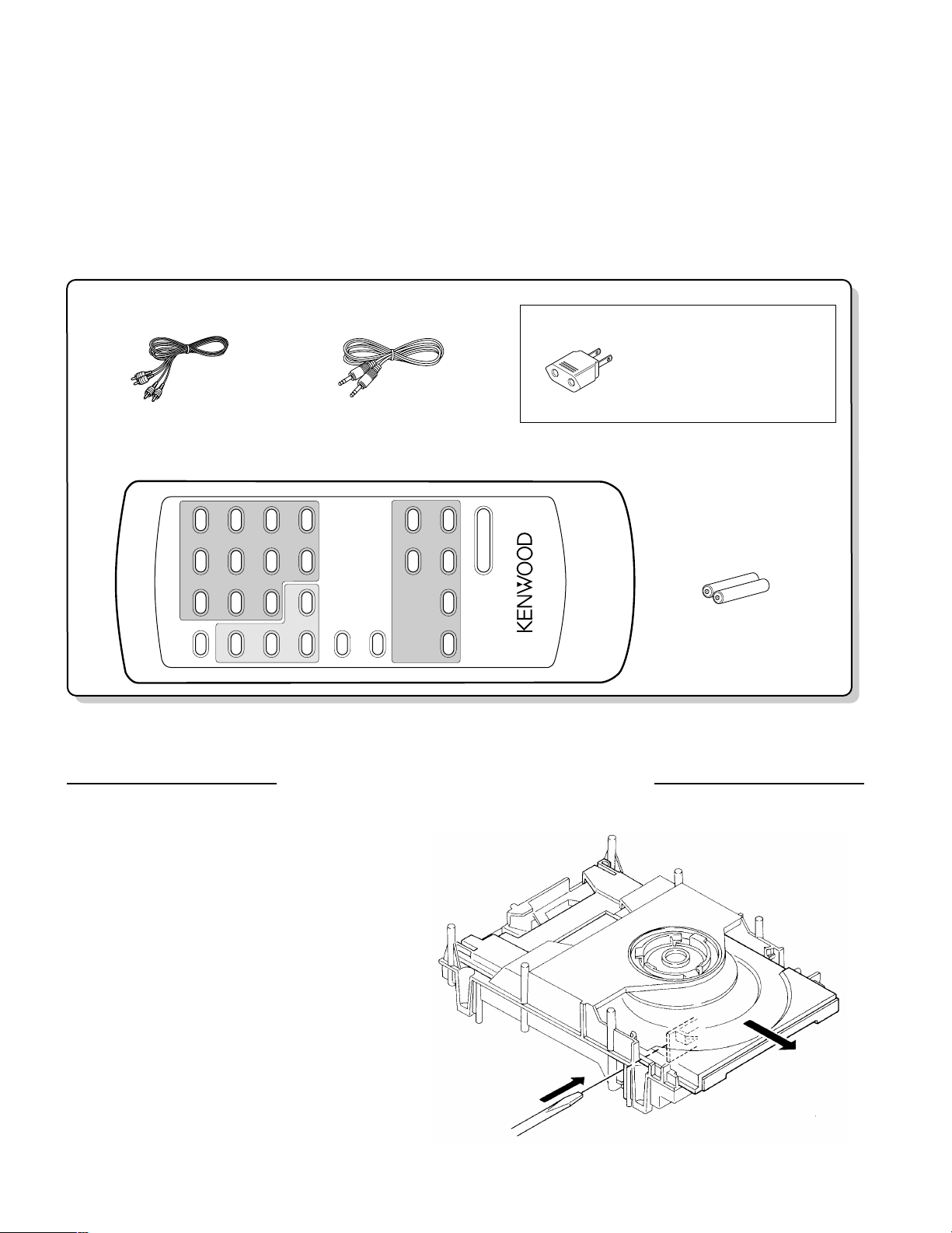

DPF-1030/2030

Audio

(E30-2913-08)

(A70-1414-08) : RC-P0715

(DPF-2030 only)

Battery cover : (A09-1190-08)

(E30-2912-08)

cord .................. (1) System control cord ...... (1)

Remote control unit ......... (1)

Batteries

(DPF-2030 only)

(R6/AA)........ (2)

AC

(E03-0115-05)

plug adaptor .............. (1)

Use to adapt the plug on the

power cord to the shape of the

wall outlet.

(Accessory only for regions where

use is necessary.)

TIME DISP

123

P.MODE

456

EDIT

789

CLEAR

RANDOM

REPEAT

OUTPUT LEVEL

DOWN UP

CHECK

0 +10

76

4¡1¢

REMOTE CONTROL UNIT RC-P0715

CONTENTS / ACCESSORIES

Contents

CONTENTS / ACCESSORIES .................................. 2

DISASSEMBLY FOR REPAIR....................................2

CIRCUIT DESCRIPTION............................................3

ADJUSTMENT............................................................4

PC BOARD ................................................................ 5

Accessories

SCHEMATIC DIAGRAM............................................ 7

EXPLODED VIEW ....................................................12

PARTS LIST..............................................................14

SPECIFICATIONS ......................................Back cover

DISASSEMBLY FOR REPAIR

1. How to open tray when tray not come out.

1. Insert the screw driver to left side hole of mechanism ass'y.

2. While pushing the rack gear fully right wards, then the tray pull.

2

Page 3

Pin No. Pin Name I/O Description

1-6 6G-1G O FL grid control port.

7 NC - Unused.

8 VDD - Power supply(+5V).

9-11 - - Connected to ground.

12 C-RESET O DSP signal output.

13 S-MUTE O Muting signal output for system.

14 NC - Unused.

15 TEXT I Text copy detection.

16 - - Connected to ground.

17 RESET I Hardware reset signal input.

18 LD CLOSE O Tray motor control.

19 LD OPEN O Tray motor control.

20 AVSS - Connected to ground.

21 - - Connected to ground.

22 PU IN SW I Pickup location.

23 OPEN SW I Tray open switch input.

24 CLOSE SW I Tray close switch input.

25-28 KEYO-3 I Key input port.

29 AVDD - Power supply(+5V).

30 AVREF - Reference voltage(+5V).

31,32 XT1,2 - Connected to ground.

33 VSS - Connected to ground.

34,35 XO,1 - X'tal 4.19MHz.

36 WRQ I Sub code Q output.

37 COIN O Command data to DSP.

38 16BIT - Unused.

39 HF - Connected to ground.

40 NC - Unused.

41 CQCK O Clock output to DSP.

42 SQOUT I SQ data to dsp.

43 RWC O Reading/writing control port.

44 GND - Connected to ground.

45 S BUSY I/O System control data.

46 S DATA I/O System control status.

47 RMC I Remote control signal input.

48 GND - Connected to ground.

49 TRY L/H O Tray motor speed control.

50 SL- O Sled motor control port(reverse).

51 SL+ O Sled motor control port(forward).

52 VDD - Power supply(+5V).

53-59 NC - Unused.

60 DRF I CD focus OK signal input.

61 NC - Unused.

62-70 a-j O FL segment(a-j) control port.

71 VLOAD - Power supply(-30V).

72,73 k,l O FL segment(k,l) control port.

74-77 NC - Unused.

78-80 9G-7G O FL grid(9G-7G) control port.

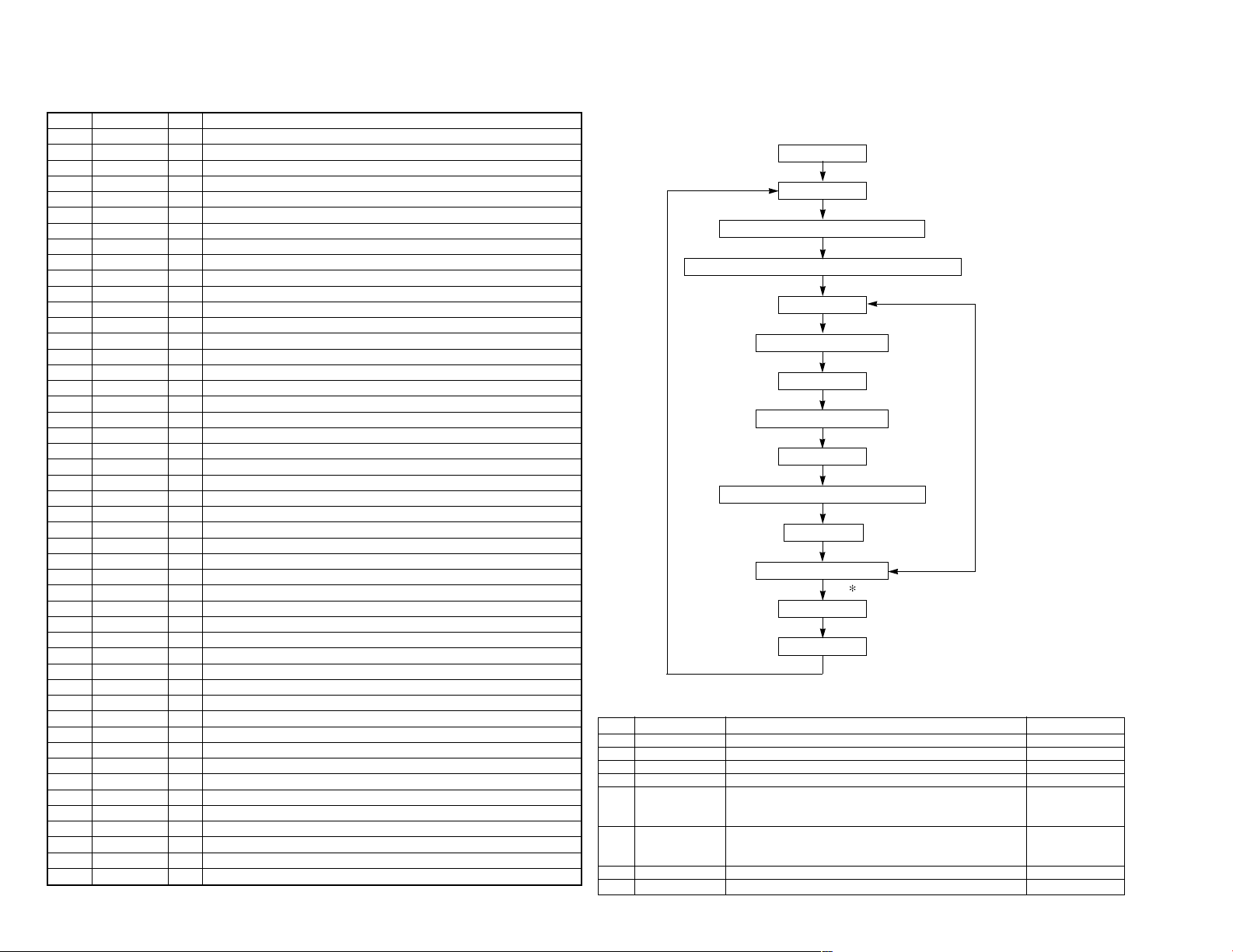

STOP key enable

If key in STOP,

return to start

stage.

START

FL LIGHT UP ALL

Tray open/close enable (display no change)

For move Pick-up, UP and DOWN key enable only stop mode

Key in PLAY

Laser ON , Display [LD ON]

Key in Play

Focus ON, Display [FS ON]

Key in PLAY

PLAY (Track servo OFF) Display [Sb OFF]

Key in PLAY

Play (Track servo ON)

Key in STOP

STOP

WITH TIME DISPLAY

Setting the test mode

: While pressing the STOP key, press the POWER switch.

Test mode will be cancelled by pressing the

POWER switch key in the stop mode.

When play mode, UP key enable

but only track jump.

1. Pin description of microprocessor

3

2. Test mode

CIRCUIT DESCRIPTION

DPF-1030/2030

3. Key function in test mode

No. INPUT KEY FUNCTION DISPLAY

1 PLAY(1ST) LASER ON LD ON

2 PLAY(2ND) FOCUSING SERVO ON FS ON

3 PLAY(3RD) PLAY(TRACKING SERVO OFF) Sb off

4 PLAY(4TH) PLAY(TRACKING SERVO ON) TN0. And Time

5 UP In the stop mode. Moves the pickup slightly

toward the outer position disc. –

When tracking servo is ON, set the track number up.

6 DOWN In the stop mode. Moves the pickup slightly

toward the inner position disc. –

When tracking servo is ON, set the track number up.

7 STOP Laser off, focusing servo off, tracking servo off. All segments

8 OPEN/CLOSE In the stop mode, Tray is opened or closed. All segments

Page 4

DPF-1030/2030

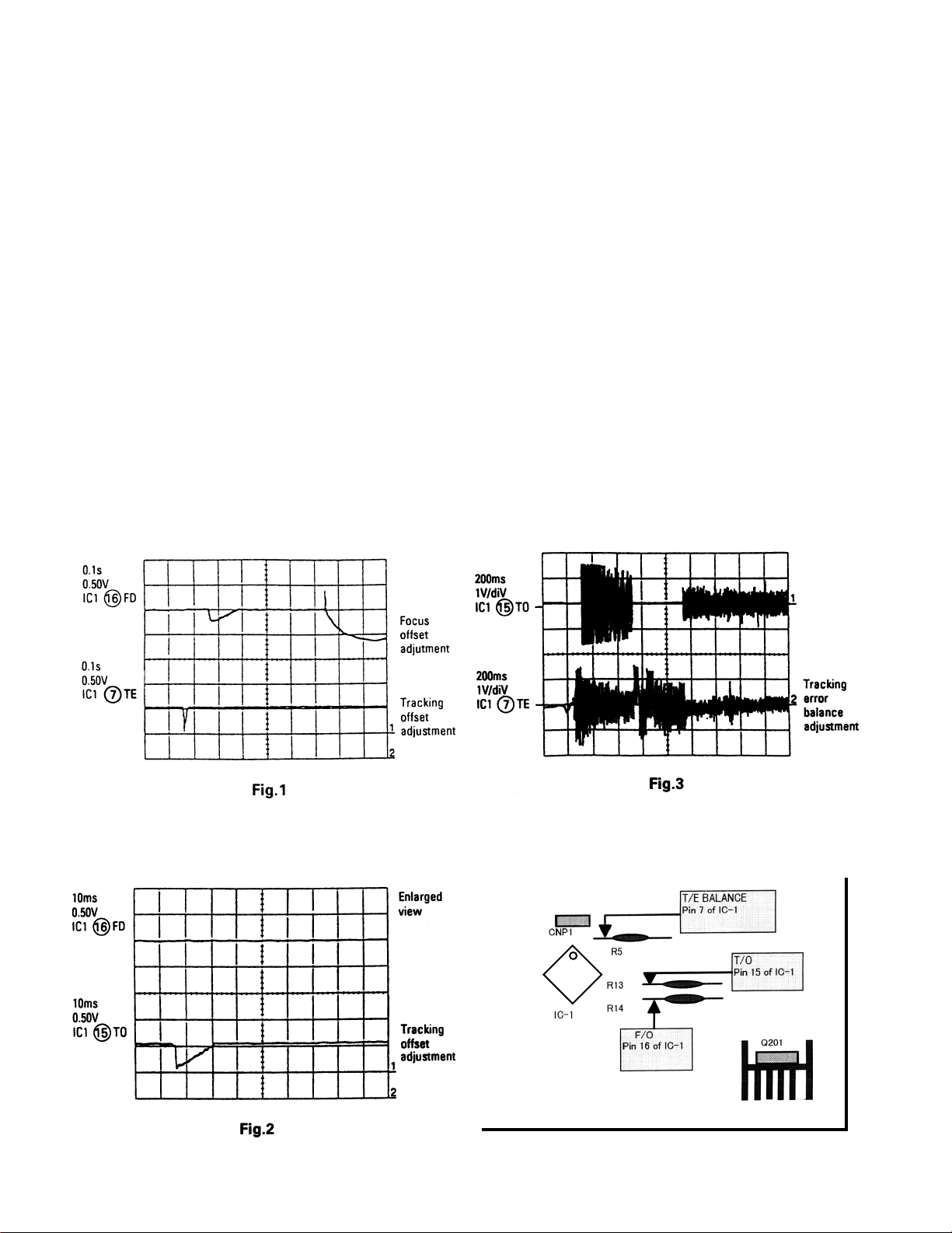

Fig.4 Checking points

ADJUSTMENT

CD section

Since this CD system incorporates the following automatic

adjustment function, when the pickup is replaced, it is not necessary to readjust it

Since this CD unit does not need adjustment, the combination

of PWB and laser pickup unit is not restricted.

•Automatic adjustment item

1. Focus offset(Fig.1)

2. Tracking offset(Fig.2)

3. E/F balance (Tracking error balance) (Fig.3)

4. RF level AGC function (HF level : constant)

5. RF level automatic follow-up of the tracking gain

This automatic adjustment is performed each time a disc is

changed. Therefore, each disc is played back using the optimal

settings

4

Page 5

ACEGIBDFHJ

R406

J401

SW407

RANDOM

SW408

REPEAT

SW405

REWIND

SW403

LAST

SW420

CNP401

2

1

29

1

1

19

5

2

O

G

I

28

1

28

65

64

41

1

4

3

1

E

B

E

E

B

B

E

B

E

E

B

E

B

II

I

GG

G

OO

O

E

E

B

B

1

7

B

8

5

1

1

1

1

18

36

19

1

1

18

7

6

16

17

32

33

48

49

64

80

65

64

41

40

25

24

4

85

40

25

24

34 2

1

1

3

2

1

7

1

2

DISPLAY-2 PWB

POWER PWB

DISPLAY-1 PWB

MAIN PWB

PHONES

SYSTEM

CONTROL

DIGITAL

OUT

OUTPUT

OPTICAL

POWER

28

29

OPEN/CLOSE

SW401

STOP

SW406

FORWARD

SW404

NEXT

SW402

PLAY

1

2

3

PC BOARD(Component side view

)

4

5

6

7

Refer to the schematic diagram for the value of resistors and capacitors.

5 6

Page 6

A BDFHJCEGI

5

4

3

2

1

5

4

2

3

1

5

4

6

7

8

3

C

F

E

B

PD

LD

TR+

FO+

FO-

TR-

K

E

A

B

F

F

AB

C

E

F

A

B

E

K

LD

VR

PD

GND

FO-

FO+

LTOH30P1

K

GND

ACTUATOR

TR-1

TR+2

CH1CH2

CH4CH3

1

2

4

5

6

7

8

9

10

11

3

12

13

14

15

16

17

18

20

31

30

32

33

21

22

24

23

25

34

35

36

BY

STAND

TSD

29

28

27

26

19

9

8

7

6

543

2

1

L-OPEN

VREF

LM-

VCC

GND

LM+

VCC

L-CLOSE

62K

REF

REF

REF

REF

1

2

3

4

5

BAL

VCR

VCR

REF

FE1

VCR

VCR

5K

5K

63

62LDO

LDS

RF

BHI 61

PHI 60

DRF

HFL

DEF

LF2 59

REF

VR 58

6

REF

REF

7

HIST. COMP

8

SHOCK:WCOMP

9 SCI

TESI

TE

TE-

TB

F

E

FIN1

FIN2

10 TH

REF

TA11

TD-12

TD13

TGL1

GL

THDL

THD

WCOMP

REF

GEN

JP14

JP

TO15

REF

TO

REF

REF

FD16

GEN

GEN

FSC

REF

FOF

REF

FD-17

18 FA

19 FA-

20 FE

21 FE-

22 AGND

VCC

S.Q.R.

PSTR

REF

SP23

454

5

1

2

3

1

2

3

878

7

66

8

7

6

5

4

3

2

1

TRTR+

FO+

FO-

GND

PD

VR

LD

SP+

SP-

SL+

SL-

PU-IN

3

2

1

6

5

4

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

4

5

3

2

1

4

5

3

2

1

64

VCC1

0.33u50

C33

+

C34

1000P

560

R40

R41 12

100u10

C35

+

0.01

C30

100u10

C29

+

1u50

C32

+

15K

R3

100K

R2

0.1

C3

2.2KR40.033

C5

6.8KR50.033

C6

0.068

C8

1000P

C4

0.047

C9

1K

R7

27KR912K

R8

180P

C10

R10

3.3K

C14

0.01

R20

1.5K

330P

C13

47K

R19R17

10K

C12

0.1

R12

15K

R11

33K

1K

R14

1K

R13

82K

R18

150K

R21

47u10

C2

+

R43

10K

24

25

30

31

R65

3.3

680P

C64

100P

C65

10K

R45 R46

22K

R44

12K

6

7

13

12

470u10

C37

+

R49

2.2

7

100u10

C38

+

R47

10K

414243

44454647484950

51525354555657585960616263

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

24

23

2221201918

17

16

151413

121110

9

876

543

2

1

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

CQCK

SQOUT

RWC

GND

SBUSY

SDATA

RMC

GND

TRY L/H

SL-

SL+

VDD

NCNCNCNCNCNCNC

DRF

NC

a

b

c

d

e

f

g

i

J

VLOAD

K

L

NC

NC

NC

NC

9G

8G

7G

CLOSE SW

OPEN SW

PUIN SW

AVSS

LD OPEN

LD CLOSE

RESET

TEXT

S-MUTE

C-RES

VDDNC1G2G3G4G5G

6G

NC

HF

16BIT

COIN

WRQ

XO

XI

VSS

XT2

AVREF

AVDD

KEY3

KEY2

KEY1

KEY0

1G

2G3G4G

5G

6G

9G

8G

7G

A

B

C

L

K

J

I

G

F

E

D

29V

R333

100K

VDD

R324

41

220

R325

3.3K

42

R326

1K

43

45

46

3.3K

R329

15K

R345

3.3K

R344

R343

3.3K

51

50

10K

R331

R332

10K

R319

3.3K

1K

R320

37

36

R321

3.3K

4.19MHz

1M

R342

C308

1000P

3.3K

R317

R318

10K

K3

10K

3.3K

K2

R316

R315

10K

3.3K

K1

R314

R313

10K

3.3K

K0

R312

R311

R308

10K

24

R307

3.3KR306

10K

23

R305

3.3KR304

10K

22

R303

3.3K

R310

R309

10K

10K

19

18

3.3K

R347

3.3K

R348

GND

IN OUT

3.3K

R349

R301

47K

R302

10K

R350

3.3K

3.3K

R346

47

13

16

15

29

27

16

3

7

18

19

22

23

24

7

6

13

12

31

30

24

25

6

8

8

6

3

4

82K

R42

1u50

C40

+

12

+7.2V+7.2V+7.2V

+7.2V

+7.2V+7.2V

+7.2V +7.2V VCC

VCC

VDDVCC

VCC

VDDVDDVDD

VDD

VDD

VDDVDD

+5V+5V+5V+5V

+5V

+5V+5V

+5V

+5V

+5V+5V

+5V+5V

+5V

29V29V29V

29V 29V 29V

B

+B

15

CLOSE

OPEN

22K

R78

330u10

C304

+

13

2

1CH

Q1

100R60.1u50

C7

+

R16

22K

R15

22K

VREF

FOCUS

TRACKING

3

+7.2V

+7.2V+7.2V

XL301

680P

C303

100P

C309

767

6

R79 82K

R80 82K

R82 82K

R81 82K

R84 82K

4

R83 82K

VCC

VCC VCC VCC VCC

VCC

VCC

VCC

3

VREF

7

5

6

4

3

2

1

6

7

1

4

5

2

3

C

C

A

VREF

R60 1

R85 47

C66

0.1u50

C301

+

100P

Q3

CNP2A

CNP1A

CNP1CNS1

BTL DRIVER

RF SERVO

PICKUP

CNS2 CNP2

CNS3 CNP3

M

M

DISC

SLIDE

PU-IN

CLOSE SW

LOADING

CNS4MCNP4

SW2

M3

Q1

D3D2

Q3

LOADING DRIVER

(BOTTOM VIEW)

u-COM

D4

D1

DIGITAL LINE

GND LINE

SIGNAL LINE

B LINE

B LINE

IC1 : LA9241M

IC2 : LC78620E

IC3 : M56748FP

IC4 : TA7291S

IC101,102 : NJM4565DD

IC201 : KIA78S08P

IC202 : NJM79L08A

IC301 : IX0346(DPF-1030)

IC302 : KIA7036AP

Q1,202 : KTA1266GR

Q3 : KTA1271Y

Q101-104 : 2SC2878B

Q201 : KTC2026

Q203 : KRC102M

D1-4,201-204,211,301-304,

: 1SS133

D210,212-218 : 1N4004S

ZD202 : MTZJ30B

ZD203 : MTZJ5.6B

ZD205 : MTZJ8.2B

RESET IC

IC203 KIA78S05P:

CONTROL

L D

IC103 : TOTX178A-1

701,702

IX0299(DPF-2030)

+4.9V

AVR

-

-

-

-

-

-

CD PICKUP UNIT

IC3

IC4

IC1

IC301

IC302

MAIN PWB

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.4V

2.5V

2.4V 2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.3V

2.3V

2.2V

4.4V

2.5V

OFF: 1.5V

ON: 1.8V

ON: 2.7V

OFF: 4.3V

OFF: 4.9V

ON: 3.5V

2.5V

2.5V

2.5V

2.5V

2.5V

2.5V

7.2V

2.5V

4.9V

3.1V

1.0V

7.2V

1.0V

7.2V

-27.2V

-27.2V

-27.2V

-27.2V

-27.2V

-27.2V

-27.2V

-27.2V

-27.2V

-7.7V

-4.8V

-4.8V

-19.7V

-16.7V

-22.5V

-22.5V

-28.5V

-16.7V

-16.7V

-7.7V

-29.0V

4.1V

4.1V

4.0V 4.1V

OFF: 3.5V

MUTING ON: 0V

0V

4.5V

0V

7.2V

5.9V

6.5V

4.9V

4.4V

4.1V

4.1V

4.1V

4.1V

1

2

3

4

5

6

7

Page 7

REFI 57

VCC

VCC2

56NC55

DRF

54CE53

DAT

52CL51

CLK

50

DEF

49

THLD

LATCH

8/12CM

SLOF

FEBAL

FOSTA

TOSTA

2FREQ

LASER

FSTA

DAT

CL

CLK

CE

P-ON RES

REF

SPOF

REF

24 SP1

25 SPG

26 SP-

REF

REF

27 SP0

28 SLEO

29 SLD

30 SL-

31 SL+

32 JP-

JP-

JP+

JP

CV+

CV-REF

REF

OR

SLOF

SLOF

SLOF

REF

REF

SLI 44

SLC 43

RFS- 42

RFSM

41

DGND 45

FSC

46

NC

47

NC

48

SLOF

CV-

CV+

39

38

40

HFL

TOFF

TES

35

36

37

TGL

JP+

33

34

INTERFACE

ANT!SHOCK

ATTENUATOR

OUT

DIGITAL

Q CRC

SEPARATE

SUBCODE

38 USDAK

SYNCHRO DETECTION

FST

17

24

23 TOFF

TGL

21

22

PCK

FSEQ

18

19

20

FZD

HFL

TES

V/P

16 FOCS

13

14

15

CLV+

CLV-

10

11

12

EFMO

EFMIN

TEST2

7

8

9

FR

VSS

EFMO

PEAK METER

DIGITAL

INTERFACE

SERVO

COMMANDER

29 JP-

JP+

VDD

TEST3

THLD

26

252827

EMPH

TEST4

DEMO

31

30

32

u-COM

DIGITAL FILTER

8X OVERSAMPLING

DFOLO

DFORO

LRCKO

34

33

35

TSTIO

DACKO36

37

LEVEL METER

INTERPOLATION

RAM

2kX8bit

GENERATOR

ADDRESS

DIGITAL SERVO

CLV

MUTE

CONTROL

SLICE LEVEL

EFM MULTIPLEX

RAM

TEST1

ISET5

6

VVDD

34PDO

VVSS

2

TA1

1

80

DEFI

PROCESSING

FLAG

&CORRECTION

DETECTION

C1C2 ERROR

72

CLOCK CONTROL

OSCILLATION

VCO CLOCK

TIMING GENERATOR

XTAL SYSTEM

79

XVDD

77

XIN

78

XOUT

CS

75

76

XVSS

73

CONT

74

TEST5

70

71

16M

4M

69

TST11

LASER

68

RES

67

CQCK

41USLRCK

USDFIR

USDFIN39

40

C2F

ROMXA

CK2

LRSY

43

42

45

44

LCHN

LCHP

LVDD

MUTEL4746

49

48

RVDD

RCHP

RCHN

RVSS

LVSS

1bit DAC

51

50

54

53

52

SFSY

EFLG

SBSY

DOUT

MUTER

57

56

55

60

59

PW

58

RWC

WRQ

FSX

SBCK

65

SQOUT

66

COIN

63

62

61

64

R63

2.2

10u35

C28

+

C41

100u10

+

1K

R73

1K

R74

220

R75

4.7u50

C26

+

4.7K

R38

0.47u50

C18

+

1.2K

R26

56K

R23

220K

R22

39K

R25

100P

C17

4700P

C15

1.2K

R28

1u50

C19

+

R27

47u50

C20

+

10K

3300P

C21

R30

220K

220K

R29

R36

47K

C25

0.033

1000P

C24

47K

R35

2700P

C22

1K

R34

56K

R32

4.7K

R33

470

R31

27P

C23

3.3K

R76

3.3K

R77

C58

1000P

1M

R55

C56

15P

18P

C55

XL1

1K

R54

33

R56

1K

R39

0.047

C51

680

R51

R37

33K

R52

27KR53

5.1K

R64

18

0.047

C52

100u10

C63

+

3.3K

R67

R68

3.3K

R70

R72

3.3K

3.3K

R71

R58

3.3

R69

3.3K

R66

3.3K

3.3K

33

32

18

R59

SBUSY

SDATA

SL16

XS8

C305

220P C306

220P

C307

0.047

R336 100K

330

R334

R337 100K

R335

330

1K

R61

R62

3.3

238

1

4.7K

R105

6.8K

R111

470P

C107

6.8K

R109

150P

C115

47

R133

100P

22u25

C121

+

C111

33P

4.7K

R107

C113

180P

120P

C109

10K

R113

12K

R115

0.022

C117

C105

100P

R103

6.8K

R101

6.8K

C103

5P

C101

5P

R129

10K

R131

12K

120P

C125

330

R119

1K

R125

100K

R117

330

R127

1K

R121

100

R123

C135

1000P

C102

5P

5P

C104

6.8K

R102

R104

6.8K

100P

C106

C110

120P

R116

12K

4.7K

R106

6.8K

R110

R108

4.7K

R112

6.8K

R114

10K 470P

C108 R132

12K

R130

10K

C126

120P

C112

33P

C114

180P

C116

150P

R134

47

5

6

7

4

100K

R118

1000P

100P

C118

22u25

+

C122

330

R120

330

R122

100

R124

R1261KR128

1K

C137

1000P

GND

OUT IN

100u10

C210

+

2.2

R223

10u35

C206

+

10K

R204

100P

C231

1/4W

2.2

R221

GND

INOUT

100u10

C215

+

R207

470

R206

47

R203

2.2

GND

INOUT

C216

100u10

+

R205

2.2

4700u25

C202

+

C203

2200u25

+

+7.2V

+5V

B

+B

B

+8V

+B

+B

100u50

C219

+

100u50

C221

+

1

R214

100

R215

2.2K

R213

47u50

C220

+

8V

29V

+B

1

2

3

4

5

6

7

100u50

C222

+

R217

10K

220

R219

R218

220

0.01

C218

2.7K

R208

10

R224

10u50

C223

+

3.3K

R220

10K

R211

C227

Q203

KEY1

KEY3K3

29K127K228

KEY2

1G1G

25K026

KEY0

3G

232G24

2G

3G

a

J

14

8G

18

4G225G

21

4G

5G

6G

207G19

7G

6G

L

169G17

9G

8G

K

15

k

l

e

gG

12I13

i

j

F

11E10

f

c

D

9C8

d

A

6B7

b

F145F2

+5V

23

GND

+5V1RMC

46

45

47

10

R341

13

R339 100K

R338 100K

43

37

41

42

12

36

0.01

C201

3332

50

51

29

27

53

52

51

50

50

51

52

53

F1

F2

F1

F2

+8V +8V +8V

+8V

+8V

+7.2V+7.2V

+7.2V+7.2V+7.2V

VDD

VDD

VDDVDD

VDD

VDD VDD

VDD

VDDVDDVDD

VDDVDD VDD VDD

VDD

VDD VDD

VDD

VDD

VDD

VCC

VDD

+5V +5V +5V +5V

+5V+5V+5V

8V8V

8V

8V8V

29V29V

RF

TO

3

2

21

3

1

2

3

3

2

1

IC201

100P

1000P

C57

0.01

C71

1000P

C62

1000P

C60

150P C119

C140

100P

100P

330P

C226

C224C225

1000P

C59

7

4

6

5

3

218

+8V

+8V

8V 8V

8V

10u16

C128

+

10K

R142

1K

R144

10u16

C127

10K

R141

+

1K

R143

R145

12K

+8V

56

R147

C131

100P100P

C132

R148

56

100

R149

100

R150

12K

R146

0.01

C136

330P

C129

330P

C130

220P

R154

C138

220P

R153

C139

47K 47K

3

2

1

3

2

1

Lch

GND

Rch

R701 10

R702 10

2.2uH

L701

0.047

C701

IC102

C61

C123C124

C142

C143

100P

150P

C120

470u10

C53

+

C310

1

C208 1000P

C211

1000P

1000P

C212

0.01

0.01

0.010.01

R86

100

1000P

C302

100P

C141

JK2

SYSTEM

CONTROL

D304

D303

D301

D302

IC103

OPTICAL

DIGITAL

OUT

IC101

(1/2)

Q101 Q103

MUTING

OPE AMP

Lch

OUTPUT

Lch

Rch

JK1

(2/2)

IC101

Rch

Q104Q102

+5V AVR

D210

Q201

+7.2V AVR

+8V AVR

D203D204

D213

ZD202

Q202

29V AVR

-8V AVR

CNP201

ZD203

D212

D211

ZD205

Q203

D217

MUTING

CONTROLLER

CNP5

D201

D202

DSP

D218

D216

D214D215

Lch

IC102

Rch

IC102

(1/2)

(2/2)

CNP702 CNP701

JK3

D702

D701

HEADPHONES

HEADPHONES

AMP

CNS401

IC203

IC201

IC202

IC2

DPF-2030 ONLY

4.8V

2.2V

4.0V

3.8V

3.9V

0V

2.6V

2.2V

4.8V

1.3V

2.4V

2.6V

0V

0V

4.8V

0V

0V

4.9V

4.9V

2.5V 2.5V

2.5V

2.5V

2.5V

2.4V2.4V

0V

4.8V

0V

0V

0V

0V

0.3V

2.2V

2.6V

2.4V

2.4V

2.5V

2.5V

0V

2.5V

3.8V

3.9V

0V

4.7V

4.9V

1.5V

1.5V

0V

1.5V

0V

1.5V

OFF: -7.8V

ON: 1.7V

11.7V

5.0V

11.7V

7.8V

8.0V

-14.6V

-7.9V

-36.5V

-29.0V

12.8V

12.0V

OFF: -5.8V

OFF: -7.8V

ON: 1.7V

ON: -7.8V

-7.9V

9.6V

0V

4.9V

4.9V

-36.8V

-29.5V

12.8V

TKMOQSLNPR

Page 8

F501

T1AL

T1AL

F502

R501

2.2

2.2

R502

PT501

2

7

6

5

4

3

1

(M)

(X)

(T,E)

: AC110-120V/

50/60Hz

: AC240V~ 50Hz

: AC230V~ 50Hz

2G

5

F1

1

NC

9G

3

NP

F12NC49G

9G 7G

a

A

9

7

6

NCNCNC8NC8GNC10NC

11

12

8G

8G

B

7G

C

b

14

137G15

16

c

6G

D

E

5G

18

17

6G

d

20

19

e

5G

6G

kK

24

4G

F

G

22

4G

f

21

23

NC

g

I

3G

J

26i25

3G

j

27

5G 4G

L

2G

l

28

29

2G

30

31

NC

1G

F2

321G33

34

NC35F2

3G

36

1G

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

RMC

+5V

GND

F1

F2

a

b

c

d

e

f

g

i

j

k

l

9G

8G

7G

6G

5G

4G

3G

2G

1G

KEY0

KEY1

KEY2

KEY3

100u10

C402

+

10

R431

1000P

C401

R407

12K

R406

6.8K

R405

3.9K

R404

2.7K

R403

1.8K

R402

1.5K

K3

K2

K1

R419 R420

1.8K 27K

6.8K

R426

R425

3.9K

R423

1.8K

R424

2.7K

R422

1.5K

K3

K2

K1

K0

F1

1G

F2

A

B

C

D

E

F

G

2G

3G

4G

5G

6G

7G

8G

9G

L

K

J

I

+5V

K0

21

21

220-240V~

FH502 FH501

FH504 FH503

0

J501

4700P

C501

SW502

VOLTAGE

SELECTOR

CNP501

K502

K501

FL401

CNP401

RMC401

REMOTE

SENSOR

SW407

RANDOM

SW406

FF

REVERSE

SW405

NEXT

SW404

LAST

SW403

PLAY

SW402

SW401

STOP

REPEAT

SW408 SW420

CNS503

EDIT

SW425

PROGRAM

SW426

CLEAR

CHECK

SW423 SW424

P. SEARCHTIME

SW421 SW422

CNP502

CNS501

CNS502

CLOSE

OPEN/

SW501

POWER

SW

DISPLAY-2 PWB

POWER PWB

DISPLAY-1 PWB

DPF-2030/2030E/2030-S

DPF-2030 ONLY

ONLY

(M) TYPE

DPF-1030/1030E/1030-S

c

j

k

l

i

f

g

a

e

d

i

b

l

l

i

j

g

f

a

b

d

e

c

j

a

k

k

l

i

a

l

i

aa

j

k

l

b

d

c

b

d

c

a

i

d

c

b

k

j

l

e

c

d

f

g

a

b

e

f

c

d

g

a

b

TRACK

REPEAT

PGM

TRACK

SINGLE

TOTAL

P.C.

NO.

TIME

BA

TIME

123

7

12

1716

6

11

18

8

13

45

10

15

2019

14

9

U VXWY

CAUTION: For continued safety, replace

safety critical components only with manufacturer's recommended parts (refer to

parts list). indicates safety critical components. For continued protection against

risk of fire, replace only with same type

and rating fuse(s). To reduce the risk of

electric shock, leakage-current or resistance measurements shall be carried out

(exposed parts are acceptably insulated

from the supply circuit) before the appliance is returned to the customer.

The DC voltage is an actual reading measured with a high impedance type voltmeter. The measurement value may vary

depending on the measuring instruments

used or on the product. Refer to the voltage dur ing PLAY unless otherwise specified; The value shown in ( ) is the voltage

measured at the moment of STOP.

2SC2878B LC78620E

LA9241M

Y22-8290-50

DPF-1030/2030

Page 9

DPF-1030/2030

EXPLODED VIEW (MECHANISM)

A B

1

2

3

12

Parts with the exploded numbers larger than 700 are not supplied.

Page 10

DPF-1030/2030

P.MODE

EDIT CLEAR TIME DISPLAY

CHECK PERK SEARCH

PL401

STOP PLAY/PAUSE

REPEAT

PHONES

RANDOM

AC110-120V

AC220-240V

SYSTEM

CONTROL

DIGITAL

OUTPUT

OUTPUT

SW502

JK2 JK1IC103

SW501

PT501

SW403

SW405

JK3

SW408

SW401 SW402

SW404

SW406

SW407

SW420

SW426 SW423 SW422

SW425 SW424 SW421

E/K

E/K

E/K

E/K

E/Kx2

E/Kx2

A

B

A

C

x7

E/Kx4

Dx2

Dx2

Fx2

Gx2

Gx2

Cx4

H

C

C

F

J

E

E

E

E

E

x2

A

B

C

D

E

F

G

H

J

K

:

:

:

:

:

:

:

:

:

:

4x8

3x8

2.6x10

3x6

3x8

3x10

3x20 (BLK)

2.6x10

3x6 (BLK)

3x8 (SIL)

N09-5224-08

N89-3008-46

N89-2610-46

N89-3006-46

N89-3008-45

N09-5222-08

N89-3020-45

N09-5223-08

N89-3006-45

N89-3008-41

OPTICAL

621

626

628

611

602

610

609

603

635

615

631

631

627

630

630

633

627

620

632

706

750

705

634x2

745

755

755

601

604

DPF-2030/only

DPF-2030/only

E : BLACK COLOR

K : SILVER COLOR

600

Parts with exploded numbers larger than 700 are not supplied.

C

1

D

E

EXPLODED VIEW (UNIT)

DPF-1030/2030

13

2

Page 11

14

DPF-1030/2030

✽ New Parts

Parts without Parts No. are not supplied.

Les articles non mentionnes dans le Parts No. ne sont pas fournis.

Teile ohne Parts No. werden nicht geliefert.

New

Ref. No

Add-

ress

Parts

Parts No.

Description

Desti-

nation

1

Re-

marks

DPF-1030/1030E/1030-S/2030/2030E/2030-S

600 1D ✽ A01-3760-08 TOP CABINET GCAB-3089AWSA ETE2

600 1D ✽ A01-3761-08 TOP CABINET GCAB-3089AWSB MXE3

601 1C ✽ A09-1190-08 BATTERY COVER GFTAB1022AWFA

602 2C ✽ A21-3873-08 CD TRAY COVER GCOVA1250AWSA TEE2

602 2C ✽ A21-3874-08 CD TRAY COVER GCOVA1250AWSB MXE3

603 2C ✽ A60-1855-08 FRONT CAB ASSY CAB3279AS1 EE2 1

603 2C ✽ A60-1856-08 FRONT CAB ASSY CAB3281AS1 ME3 1

603 2C ✽ A60-1857-08 FRONT CAB ASSY CAB3274AS1 TEE2 2

603 2C ✽ A60-1858-08 FRONT CAB ASSY CAB3276AS1 MX 2

604 1C ✽ A70-1414-08 REMOCON RRMCG0213AWSA 2

609 ✽ B11-1515-08 FL FILTER PSHEP0034AWSA

610 2C ✽ B10-3611-08 FL WINDOW HDECQ0518AWSA

611 2C B43-0302-04 KENWOOD BADGE

- B46-0096-53 WARRANTY CARD X

- B46-0310-03 WARRANTY CARD TGANZ0005AWZZ TEE2E3

- ✽ B60-4634-08 INST BOOK(EN) TINSE0271AWZZ MXTE2

- ✽ B60-4635-08 INST BOOK(I/F) TINSZ0487AWZZ EE3

- ✽ B60-4636-08 INST BOOK(G/N) TINSZ0488AWZZ EE3

- ✽ B60-4637-08 INST BOOK(ES) TINSZ0489AWZZ MEE3

- ✽ B60-4638-08 INST BOOK(TC) TINSZ0494AWZZ M

- ✽ B60-4639-08 INST BOOK(PL) TINSZ0490AWZZ E2

- ✽ B60-4640-08 INST BOOK(HU) TINSZ0491AWZZ E2

- ✽ B60-4641-08 INST BOOK(CZ) TINSZ0492AWZZ E2

- ✽ B60-4642-08 INST BOOK(RU) TINSZ0493AWZZ E2

- ✽ B60-4688-08 INST BOOK(AR) TINSZ0543AWZZ M

615 2D D21-1934-08 POWER SW LVR MLEVP0086AWZZ

620 1E E30-2750-08 AC CORD CORDA1387C X

620 1E E30-2911-08 AC CORD QACCE0003AW00 EE2E3

620 1E E30-2914-08 AC CORD QACCE0008AW00 M

620 1E E30-2915-08 AC CORD QACCB0009AW00 T

621 1C E30-2912-08 SYSTEM CORD QCNWG0002AWZZ

626 E30-2913-08 RCA CORD QCNWG0003AWZZ

627 E35-2315-08 FFC CABLE QCNWN1338AWZZ

628 E03-0115-05 AC PLUG ADAPTER QPLGA0250AFZZ M

- ✽ H10-7701-08 P-PAD SPAKA0234AWZZ

- H25-1650-08 SETPOLY BAG SPAKP0038AWZZ

- ✽ H50-3694-08 P-CASE SPAKC0866AWZZ TE 2

- ✽ H50-3695-08 P-CASE SPAKC0867AWZZ E2 2

- ✽ H50-3696-08 P-CASE SPAKC0873AWZZ MX 2

- ✽ H50-3697-08 P-CASE SPAKC0868AWZZ E 1

- ✽ H50-3698-08 P-CASE SPAKC0869AWZZ E2 1

- ✽ H50-3699-08 P-CASE SPAKC0871AWZZ E3 1

- ✽ H50-3700-08 P-CASE SPAKC0872AWZZ M 1

630 ✽ J02-1488-08 DECORATION LEG GLEGP0006AWSD

632 J42-0083-05 AC CORD BUSH

633 J19-5972-08 PWB SUPPORT LX-LZ0009AWZZ

634 J19-5974-08 SNAP 19MM LX-LZ0008AWZZ

635 ✽ K29-7809-08 POWER KNOB JKNBZ0652AWSA TEE2

635 ✽ K29-7810-08 POWER KNOB JKNBZ0652AWSB MXE3

A ✽ N09-5224-08 SCREW(4X8)+WASHER

F ✽ N09-5222-08 SCREW(3X10)+WASHER

L : Scandinavia K : USA P : Canada R : Mexico C : China I :Malaysia

Y : PX(Far East,Hawaii) T : England E : Europe G : Germany V : China(Shanghai)

Y : AAFES(Europe) X : Australia Q : Russia H : Korea M : Other Areas indicates safety critical components .

2

✽ New Parts

Parts without Parts No. are not supplied.

Les articles non mentionnes dans le Parts No. ne sont pas fournis.

Teile ohne Parts No. werden nicht geliefert.

New

Ref. No

H ✽ N09-5223-08 SCREW(2.6X10)+WASHER

Address

Parts

Parts No.

Description

Desti-

nation

2

Re-

marks

ELECTRICAL PARTS

FL401 CM1703C FL DISPLAY

C2 CE04KW1A470M ELECTRO 47UF 10WV

C3 CQ92FM1H104K MYLAR 0.10UF K

C4 CQ92FM1H102K MYLAR 1000PF K

C5 ,6 CQ92FM1H333K MYLAR 0.033UF K

C7 CE04KW1HR10M ELECTRO 0.10UF 50WV

C8 CQ92FM1H683K MYLAR 0.068UF K

C9 CQ92FM1H473K MYLAR 0.047UF K

C10 CC45FSL1H181J CERAMIC 180PF J

C12 CQ92FM1H104K MYLAR 0.10UF K

C13 CC45FSL1H331J CERAMIC 330PF J

C14 CQ92FM1H103K MYLAR 0.010UF K

C15 CQ92FM1H472K MYLAR 4700PF K

C17 CC45FSL1H101J CERAMIC 100PF J

C18 CE04KW1HR47M ELECTRO 0.47UF 50WV

C19 CE04KW1H010M ELECTRO 1.0UF 50WV

C20 CE04KW1H470M ELECTRO 47UF 50WV

C21 CQ93FM1H332K MYLAR 3300PF K

C22 CQ93FMG1H272J MYLAR 2700PF J

C23 CC45FSL1H270J CERAMIC 27PF J

C24 CQ92FM1H102K MYLAR 1000PF K

C25 CQ92FM1H333K MYLAR 0.033UF K

C26 CE04KW1H4R7M ELECTRO 4.7UF 50WV

C28 CE04KW1V100M ELECTRO 10UF 35WV

C29 CE04KW1A101M ELECTRO 100UF 10WV

C30 CQ92FM1H103K MYLAR 0.010UF K

C32 CE04KW1H010M ELECTRO 1.0UF 50WV

C33 CE04KW1HR33M ELECTRO 0.33UF 50WV

C35 CE04KW1A101M ELECTRO 100UF 10WV

C37 CE04KW1A471M ELECTRO 470UF 10WV

C38 CE04KW1A101M ELECTRO 100UF 10WV

C40 CE04KW1H010M ELECTRO 1.0UF 50WV

C41 CE04KW1A101M ELECTRO 100UF 10WV

C51 ,52 CQ92FM1H473K MYLAR 0.047UF K

C53 CE04KW1A471M ELECTRO 470UF 10WV

C55 CC45FSL1H180J CERAMIC 18PF J

C56 CC45FSL1H150J CERAMIC 15PF J

C57 CC45FSL1H102J CERAMIC 1000PF J

C58 CQ92FM1H102K MYLAR 1000PF K

C59 ,60 CC45FSL1H102J CERAMIC 1000PF J

C61 CC45FSL1H101J CERAMIC 100PF J

C62 CC45FSL1H102J CERAMIC 1000PF J

C63 CE04KW1A101M ELECTRO 100UF 10WV

C64 CC45FSL1H681J CERAMIC 680PF J

C65 CC45FSL1H101J CERAMIC 100PF J

C66 CC45FSL1H681J CERAMIC 680PF J

C71 CK45FB1H103Z CERAMIC 0.010UF Z

C101-104 CC45FSL1H050C CERAMIC 5.0PF C

C105,106 CC45FSL1H101J CERAMIC 100PF J

C107,108 CC45FSL1H471J CERAMIC 470PF J

C109,110 CC45FSL1H121J CERAMIC 120PF J

L : Scandinavia K : USA P : Canada R :Mexico C : China I :Malaysia

Y : PX(Far East,Hawaii) T : England E : Europe G : Germany V : China(Shanghai)

Y : AAFES(Europe) X : Australia Q : Russia H : Korea M : Other Areas indicates safety critical components .

PARTS LIST

Page 12

✽ New Parts

Parts without Parts No. are not supplied.

Les articles non mentionnes dans le Parts No. ne sont pas fournis.

Teile ohne Parts No. werden nicht geliefert.

New

Ref. No

C111,112 CC45FSL1H330J CERAMIC 33PF J

C113,114 CC45FSL1H181J CERAMIC 180PF J

C115,116 CC45FSL1H151J CERAMIC 150PF J

C117 CK45FB1H223Z CERAMIC 0.022UF Z

C118 CC45FSL1H102J CERAMIC 1000PF J

C119,120 CC45FSL1H151J CERAMIC 150PF J

C121,122 CE04KW1E220M ELECTRO 22UF 25WV

C123,124 CC45FSL1H101J CERAMIC 100PF J

C125,126 CC45FSL1H121J CERAMIC 120PF J

C127,128 CE04KW1C100M ELECTRO 10UF 16WV 2

C129,130 CC45FSL1H331J CERAMIC 330PF J 2

C131,132 CC45FSL1H101J CERAMIC 100PF J 2

C135 CC45FSL1H102J CERAMIC 1000PF J

C136 CQ92FM1H103K MYLAR 0.010UF K 2

C137 CC45FSL1H102J CERAMIC 1000PF J

C138,139 CC45FSL1H221J CERAMIC 220PF J 2

C140-143 CC45FSL1H101J CERAMIC 100PF J

C201 CK45FB1H103Z CERAMIC 0.010UF Z

C202 CE04KW1E472M ELECTRO 4700UF 25WV

C203 CE04KW1E222M ELECTRO 2200UF 25WV

C206 CE04KW1V100M ELECTRO 10UF 35WV

C208 CQ92FM1H102K MYLAR 1000PF K

C210 CE04KW1A101M ELECTRO 100UF 10WV

C211,212 CC45FSL1H102J CERAMIC 1000PF J

C215,216 CE04KW1A101M ELECTRO 100UF 10WV

C218 CQ92FM1H103K MYLAR 0.010UF K

C219 CE04KW1H101M ELECTRO 100UF 50WV

C220 CE04KW1H470M ELECTRO 47UF 50WV

C221,222 CE04KW1H101M ELECTRO 100UF 50WV

C223 CE04KW1H100M ELECTRO 10UF 50WV

C224-227 CK45FB1H103Z CERAMIC 0.010UF Z

C231 CC45FSL1H101J CERAMIC 100PF J

C301 CE04KW1H0R1M ELECTRO 0.1UF 50WV

C302 CC45FSL1H102J CERAMIC 1000PF J

C303 CC45FSL1H101J CERAMIC 100PF J

C304 CE04KW1A331M ELECTRO 330UF 10WV

C305,306 CC45FSL1H221J CERAMIC 220PF J

C307 CK45FB1H473Z CERAMIC 0.047UF Z

C308 CQ92FM1H102K MYLAR 1000PF K

C309 CC45FSL1H101J CERAMIC 100PF J

C401 CQ92FM1H102K MYLAR 1000PF K 2

C402 CE04KW1A101M ELECTRO 100UF 10WV 2

C501 ✽ C90-3936-08 CERAMIC 0.0047UF J

C701 CK45FB1H473Z CERAMIC 0.047UF Z 2

CNP1 ✽ E35-2628-08 CONNECTOR CONE7P53253

CNP2 E35-2316-08 CONNECTOR QCNCM705HAFZZ

CNP3 E40-8381-08 CONNECTOR CONE6P53253

CNP4 E40-8382-08 CONNECTOR CONE5P53253

CNP5 E40-8378-08 FFC CONE TOP QCNCWZG29AWZZ

CNP201 E40-8379-08 CONNECTOR WIRE,CONE-7P5267X

CNP401 E40-8377-08 FFC CONE SIDE QCNCWZF29AWZZ

CNP501 E35-2314-08 CONNECTOR QCNWN0757AWZZ

CNP502,503

FH501-504 J19-5865-08 FUSE HOLDER QFSHD0001AWZZ

L : Scandinavia K : USA P : Canada R : Mexico C : China I :Malaysia

Y : PX(Far East,Hawaii) T : England E : Europe G : Germany V : China(Shanghai)

Y : AAFES(Europe) X : Australia Q : Russia H : Korea M : Other Areas indicates safety critical components .

15

Add-

ress

Parts No.

Parts

J19-5973-08 2P CABLE HLDR QCNCW015BAWZZ

Description

Desti-

nation

3

Re-

marks

✽ New Parts

Parts without Parts No. are not supplied.

Les articles non mentionnes dans le Parts No. ne sont pas fournis.

Teile ohne Parts No. werden nicht geliefert.

New

Ref. No

JK1 E63-1081-08 PIN JACK QJAKZ0012AWZZ

JK2 E11-0188-05 SYSTEM JACK QJAKZ0013AWZZ

JK3 E11-0345-08 H/P JACK QJAKH0002AWZZ 2

K501,502 E35-1953-08 LUG1746A POWER SUPPLY

F501,502 ✽ F50-0168-08 FUSE FUSET801E

- ✽ J19-6090-08 FL HOLDER LHLDZ1207AWFW

L701 L90-0312-08 COIL VP-DH2R2K0000 2

PT501 ✽ L07-2879-08 POWER TRANS RTRNP0292AWZZ EE2E3

PT501 ✽ L07-2879-08 POWER TRANS RTRNP0292AWZZ TX

PT501 ✽ L07-2880-08 POWER TRANS RTRNP0293AWZZ M

XL1 L77-2231-08 CRYSTAL RCRSP0005AWZZ

XL301 L78-0677-08 CRYSTAL 4.19MHZ,CRSTL1595AT

R203 RD14BB2C2R2J RD 2.2 J 1/6W

R205 RD14BB2C2R2J RD 2.2 J 1/6W

R208 ✽ R92-1965-08 RC 2.7K 1/2W

R220 RD14BB2H332J RD 3.3K J 1/2W

R223 RD14BB2E2R2J RD 2.2 J 1/4W

R501,502 RD14BB2E2R2J RD 2.2 J 1/4W

SW401-408

SW420-426

SW501 ✽ S68-0128-08 SWITCH QSW-P0014AWZZ

SW502 S62-0087-08 SLIDE SWITCH QSOCE0004AWZZ M

SW701 S70-0071-08 SWITCH QSW-K0005AWZZ

D1 -4 1SS133 DIODE

D201-204 1SS133 DIODE

D210 ✽ 1N4004S DIODE

D211 1SS133 DIODE

D212-218 ✽ 1N4004S DIODE

D301-304 1SS133 DIODE

D701,702 1SS133 DIODE 2

IC1 LA9241M IC(AFAMP,SERVO)

IC2 LC78620E IC(CD SERVO DSP)

IC3 M56748FP IC

IC4 TA7291S IC(BRIDGE DRIVER)

IC101 NJM4565DD IC OP AMP

IC102 NJM4565DD IC OP AMP 2

IC201 KIA78S08P IC

IC202 NJM79L08A IC(VOLTAGE REGULATOR/ -8V)

IC203 KIA78S05P IC

IC301 IX0299 IC SYSTEM U-CON 2

IC301 ✽ IX0346 IC SYSTEM U-CON 1

IC302 KIA7036AP IC

Q1 KTA1266GR TRANSISTOR

Q3 KTA1271Y TRANSISTOR

Q101-104 2SC2878B TRANSISTOR

Q201 ✽ KTC2026 TRANSISTOR

Q202 KTA1266GR TRANSISTOR 2

Q203 KRC102M TRANSISTOR

ZD202 MTZJ30B ZENER DIODE

ZD203 MTZJ5.6B ZENER DIODE

ZD205 MTZJ8.2B ZENER DIODE

L : Scandinavia K : USA P : Canada R : Mexico C : China I :Malaysia

Y : PX(Far East,Hawaii) T : England E : Europe G : Germany V : China(Shanghai)

Y : AAFES(Europe) X : Australia Q : Russia H : Korea M : Other Areas indicates safety critical components .

Address

Parts No.

Parts

S70-0071-08 SWITCH QSW-K0005AWZZ

S70-0071-08 SWITCH QSW-K0005AWZZ

Description

Desti-

nation

4

Re-

marks

PARTS LIST

DPF-1030/2030

Page 13

[ Format ]

System ............................. Compact disc digital audio system

Laser ...................................................... Semiconductor laser

[ D/A Convertors ]

D/A Conversion ............................................................... 1 Bit

Oversampling ................................................ 8 fs (352.8 kHz)

[ Audio ]

Frequency response ..........................6 Hz ~ 20 kHz, ±0.5 dB

Signal to noise ratio ..................................... More than 94 dB

Dynamic range ............................................. More than 92 dB

Total harmonic distortion + noise

.................................................. Less than 0.007% (at 1 kHz)

Channel separation ..................... More than 90 dB (at 1 kHz)

Wow & flutter...........................................Unmeasurable Limit

Output level/impedance

Variable ........................ (only DPF-2030) (Max.) 2.0 V/0.8 kΩ

Fixed ....................................... (only DPF-1030) 2.0 V/0.8 kΩ

Digital output

Optical........................................... –15 dBm ~ –21 dBm

(Wave length 660 nm)

Headphone output (Max.) ................................ 20 mW (32 Ω)

[ General ]

Power consumption ....................................................... 12 W

Dimensions ........................................ W : 440 mm (17-5/16")

H : 95 mm (3-3/4")

D : 370 mm (14-9/16")

Weight (Net) ......................................................4.3 kg (9.5 lb)

1. KENWOOD follows a policy of continuous advancements in development. For this reason specifications may be changed without notice.

2. The full performance may not be exhibited in an extremely cold location (under a water-freezing temperature).

NotesNotes

Notes

Note:

HOW TO READ THE PARTS LIST

ABBREVIATION OF MODEL AND MASS PRODUCTION'S DESTINATIONS

MODEL ABB. Australia Canada China England Europe Germany Korea Malaysia

DPF-1030 1 - - - - E - - DPF-1030E 1 - - - - E2 - - DPF-1030-S 1 - - - - E3 - - DPF-2030 2 - - - T E - - DPF-2030E 2 - - - - E2 - - DPF-2030-S 2 X - - - - - - -

MODEL ABB. Mexico PX/AAFES Russia Scandinavia Shanghai USA Other area

DPF-1030 1 - - - - - - - DPF-1030E 1 - - - - - - - DPF-1030-S 1 - - - - - - M DPF-2030 2 - - - - - - - DPF-2030E 2 - - - - - - - DPF-2030-S 2 - - - - - - M -

Component and circuit are subject to modification to insure best operation

under differing local conditions. This manual is based on Europe (E) standard,

and provides information on regional circuit modification through use of alter-

nate schematic diagrams, and information on regional component variations

through use of parts list.

SPECIFICATIONS

14-6,Dogenzaka 1-chome, Shibuya-ku, Tokyo, 150-8501 Japan

KENWOOD SERVICE CORPORATION

P.O BOX 22745, 2201 East Dominguez St., Long Beach, CA 90801-5745, U.S.A.

✽ New Parts

Parts without Parts No. are not supplied.

Les articles non mentionnes dans le Parts No. ne sont pas fournis.

Teile ohne Parts No. werden nicht geliefert.

New

Ref. No

RMC401 W02-2689-08 REM CNTRL MDL VHLN63H380A-1 2

IC103 W02-2752-08 OPTICAL OUT

Add-

ress

Parts

Parts No.

Description

Desti-

nation

MECHANISM PARTS

1 1B A10-3468-08 LOADING CHS LCHSM0072AWZZ

5 2B J90-0862-08 GUIDE SFT NSFTM0002AWFW

6 1A D13-1726-08 RACK GEAR NGERR0001AWZZ

7 1A D13-1727-08 TRAY GEAR GEAR1728B

8 2B D13-1869-08 MIDDLE GEAR NGERH0011AWZZ

9 2B D13-1870-08 DRIVING GEAR NGERH0012AWZZ

10 1B D15-0388-08 DRIVE PULLEY PULLY1728A

11 1B D16-0396-08 DRIVE BELT BELT1728A

15 2B,3B J02-1146-08 CUSHION MCUSN1524A

16 2B J11-0811-08 STABILIZER LHLDM1001AWZZ

17 1B J11-0812-08 CD MAGNET RING LANGZ0002AWFW

18 3A J19-5661-08 MEC HOLDER LHLDZ1001AWZZ

19 2B J19-5662-08 GUIDE RAIL MLEVP0080AWZZ

20 2A J99-0809-08 DISC HOLDER GCOVA1201AWSA

25 2B S74-0080-08 LEAF SWITCH SWICHL1749A

26 3B S74-0054-08 LEAF SWITCH

30 1B T99-0609-08 MAGNET PMAGF0001AWZZ

CNS1 E35-2615-08 CD PICKUP A WIRE,QCNWN1535AWZZ

CNS2 E35-2320-08 CD PICKUP B WIRE,QCNWN1182AWZZ

CNS3 E35-2321-08 MOTOR WIRE(6P) QCNWN1339AWZZ

CNS4 E35-2322-08 TRAY WIRE QCNWN1379AWZZ

DM 3B T42-0825-08 MOTOR ASSY DISC

FM 3B T42-0824-08 MOTOR ASSY FEED

LM 2B T42-0823-08 MOTOR ASSY TRAY

PU 2A ✽ T25-0101-08 PICKUP ASSY HPC1LXASY

5

Re-

marks

DPF-1030/2030

PARTS LIST

L : Scandinavia K : USA P : Canada R : Mexico C : China I :Malaysia

Y : PX(Far East,Hawaii) T : England E : Europe G : Germany V : China(Shanghai)

Y : AAFES(Europe) X : Australia Q : Russia H : Korea M : Other Areas indicates safety critical components .

Loading...

Loading...