Page 1

iNSTALLATiON AND SERVICE MUST BE PERFORMED BY A QUALiFiED iNSTALLER.

iMPORTANT: SAVE FOR LOCAL ELECTRICAL iNSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

if the information in this manual is not followed e×acfly,

a fire or e×plosion may result causing property damage, personal

injury or death.

FOR YOUR SAFETY:

DO NOT store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

WHAT TO DO iF YOU SMELL GAS:

• DO NOT try to light any appEance.

• DO NOT touch any electrical switch; DO NOT use any phone in

your building.

" Immediately call your gas suppffer from a neighbor's phone.

Follow the gas supplier's instructions.

O

if you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

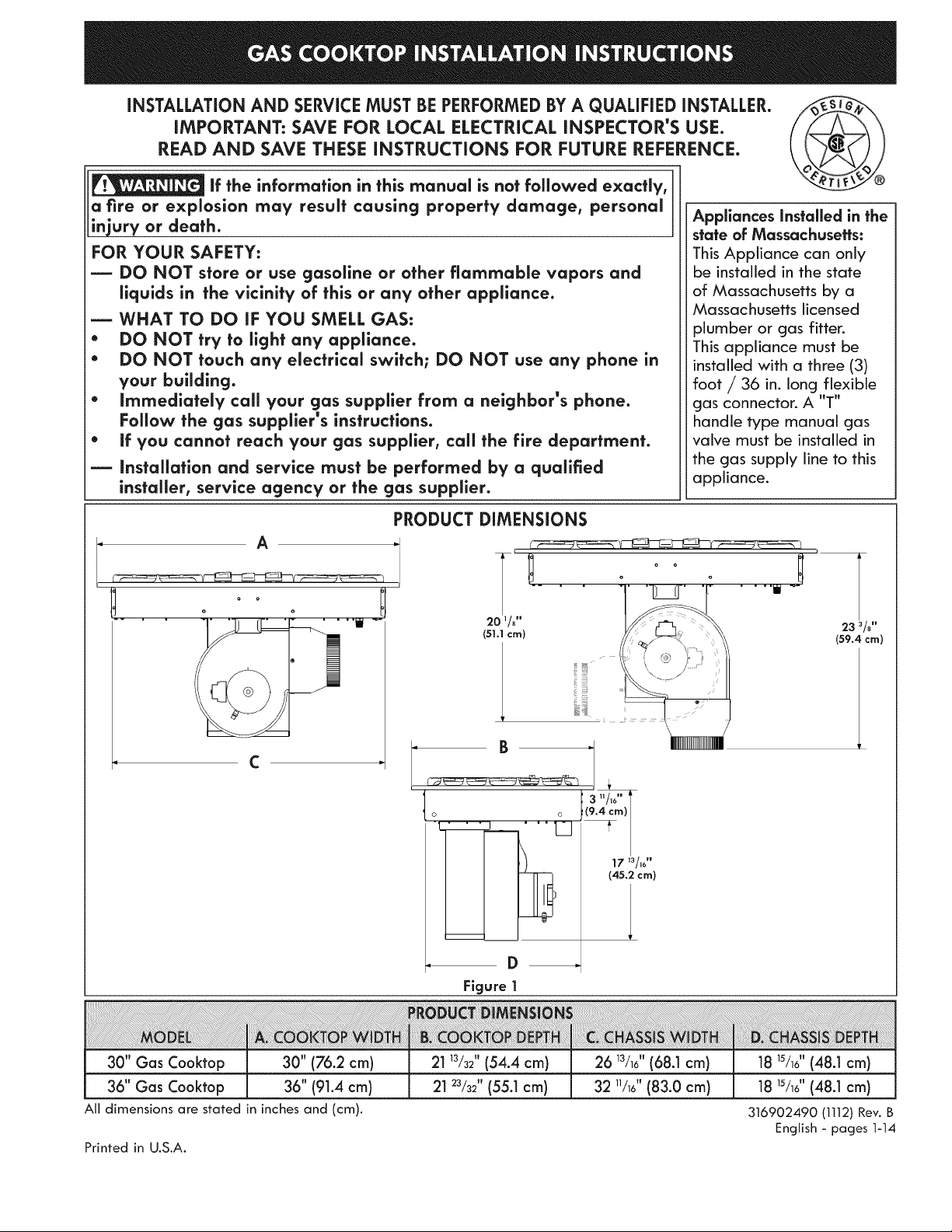

PRODUCT DiMENSiONS

Appliances Installed in the

state of Massachusetts:

This Appliance can only

be installed in the state

of Massachusetts by a

Massachusetts licensed

plumber or gas fitter.

This appliance must be

installed with a three (3)

foot / 36 in. long flexible

gas connector. A "T"

handle type manual gas

valve must be installed in

the gas supply line to this

appliance.

A

o o

o

o N

20 78" 23 /8"

(51.1 cm) (59.4 cm)

]

C

o o

B

D_

Figure 1

30" Gas Cooktop 30" (76.2 cm) 21 mhd' (54.4 cm) 26 m/l?' (68.1 cm)

36" Gas Cooktop 36" (91.4 cm) 21 23/32"(55.1 cm) 32 11/17'(83.0 cm)

All dimensionsare stated in inchesand (cm).

Printed in U.S.A.

18 1s/I?'(48.1 cm)

18 1s/I?'(48.1 cm)

316902490 (1112) Rev.

English - pages 1-14

Page 2

Important Notes to the Installer

1. Read all instructions contained in these

installation instructions before installing the

cooktop.

2. Remove all packing material before connecting

the electrical supply to the cooktop.

3. Observe all governing codes and ordinances.

4. Be sure to leave these instructions with the

consumer.

.

Note- For operation at 2000 ft. elevations

above see level, appliance rating shall be

reduced by 4 percent for each additional

1000 ft.

Important Note to the Consumer

Keep these instructions with your Use and Care

Guide for future reference.

IMPORTANT SAFETY

INSTRUCTIONS

Installation of this cooktop must conform

with local codes or, in the absence of local

codes, with the National Fuel Gas Code ANSI

Z223.1/NFPA 54 in the United States, or in

Canada, with the Canadian Fuel Gas Code,

CAN/CGA B149 and CAN/CGA B149.2.

• When installed in a manufactured (mobile)

home installation must conform with

the Manufactured Home Construction

and Safety Standard, title 24 CFR, part

3280 [Formerly the Federal Standard for

Mobile Home Construction and Safety,

title 24, HUD (part 280)] or, when such

standard is not applicable, the Standard

for Manufactured Home Installation, ANSI/

NCSBCS A225.1 or with local codes where

applicable.

This cooktop has been design certified by

Underwriters Laboratories (UL). As with any

appliance using gas and generating heat,

there are certain safety precautions you

should follow. You will find them in the Use

and Care Guide, read it carefully.

• Be sure your cooktop is installed and

grounded properly by a qualified installer

or service technician.

This cooktop must be electrically grounded

in accordance with local codes or, in their

absence, with the National Electrical Code

ANSi/NFPA No. 70--latest edition in

the United States, or in Canada, with the

Canadian Electrical Code, CSA C22.1 Part

1.

• The burners can be lit manually during an

electrical power outage. To light a burner,

hold a lit match to the burner head, then

slowly turn the Surface Control knob to

LITE. Use caution when lighting burners

manually.

DO NOT store items of interest

to children in cabinets above the cooktop.

Children could be seriously burned climbing

on the cooktop to reach items.

• To eliminate the need to reach over the

surface burners, cabinet storage space

above the burners should be avoided.

• Adjust surface burner flame size so it does

not extend beyond the edge of the cooking

utensil. Excessive flame is hazardous.

Never use your cooktop for

warming or heating the room. Prolonged use

of the cooktop without adequate ventilation

can be hazardous.

Storage on Appliance.

Flammable materials should not be stored

near surface units. This includes paper,

plastic and cloth items, such as cookbooks,

plasticware and towels, as well as flammable

liquids. DO NOT store explosives, such as

aerosol cans, on or near the appliance.

Flammable materials may explode and result

in fire or property damage.

The electrical power to the

cooktop must be shut off while gas line

connections are being made. Failure to do so

could result in serious injury or death.

Page 3

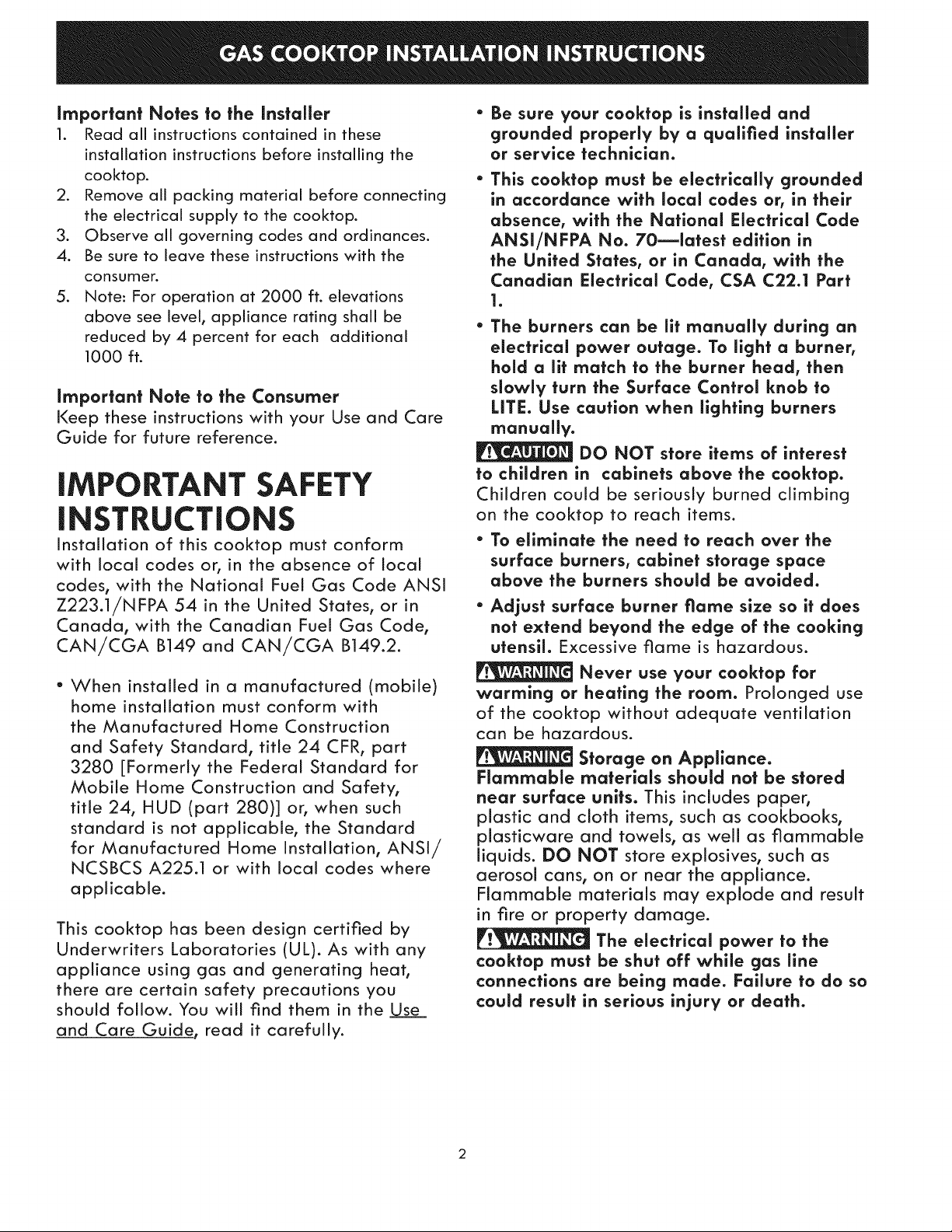

13" (33 cm)

Max. Depth

For Cabinet

Installed

Above

Cooktop.

30" (76.2 cm) Min.

Clearance Between

the Top of the

Cooking Platform

and Unprotected

Clearance

18" Min.

(45.7 cm)

\

24" Min.

(61cm)

1 3/8" (3.5 cm) Minimum Flat

Distance from Cutout Edge.

1 3/8" (3.5 cm) Minimum Flat

Distance from Cutout Edge.

Figure 2 - CABINET DESIGN

30" Cooktop 30" (76.2 cm) 9" (22.9 cm) 28" (71.1cm) 19 1/8"(48.6 cm)

36" Cooktop 36" (91.4 cm) 9" (22.9 cm) 34" (86.4 cm) 19 1/8"(48.6 crn)

storage space located above the cooktop should be avoided.

[ _[__ To eliminate the risk of burns or fire from reaching over heated surfaces, cabinet

Page 4

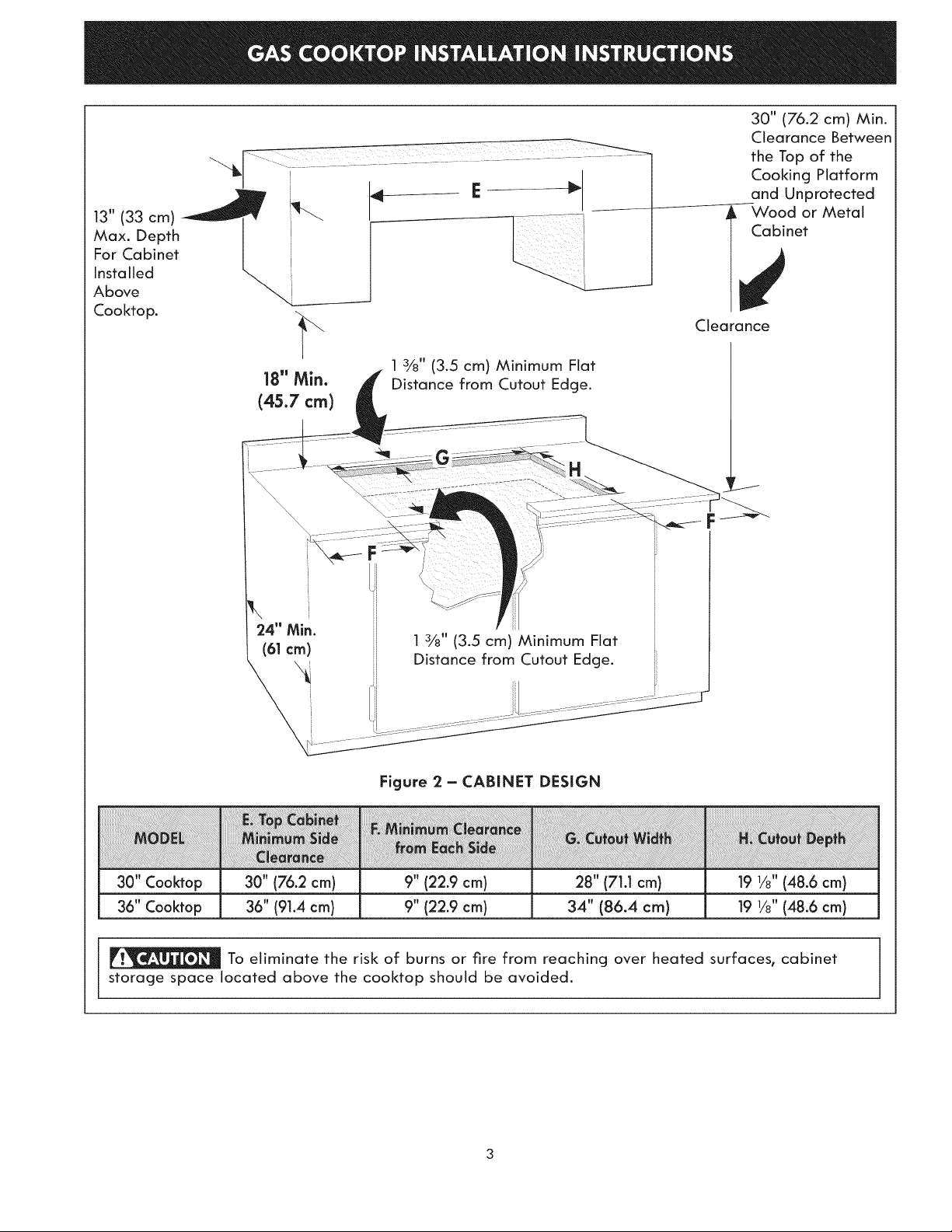

Required Tools for Installation

- Phillips Screwdriver

- 1/4" Nut driver / Ratchet

- 7/16 I' Nut driver / Ratchet

Supplied Hardware

Description

3

(8.3 cm)

q_

1 1II

(27.9cm)

(4)

(2)

(4)

(_ #8-18 Wide Head Transition Duct

(6)

(2) Hold Down Bracket (fig. 15 & 16)

1/4-20 Nylon Insert

7/16" Hex Nut

#10-24 3.5" Brackets

Long Phillips Screw (fig. 15 & 16)

Phillips Screw (fig. 18)

#8-18 Black Plenum and Wire

%" Hex Head Screw Box (fig. 17 & 21)

Blower (fig. 20)

Countertop

Wall Outlet Location

Install the electric wall outlet within the shaded area.

cL

I _1 11 1/2"

6" 8

(15.2cm) (22.2cm)

'_- 3/4,-, (29.2cm)

Figure 3B - 30" MODEL

ELECTRICALOUTLET INSTALL DIMENSIONS

Provide an Adequate Gas Supply

This cooktop is designed to operate on natural gas at 4"

of manifold pressure only.

A pressure regulator must be connected

in series with the manifold on the cooktop and must

remain in series with the supply line.

For proper operation, the maximum inlet pressure to the

regulator must be no more than 14" of water column

(W.C.) pressure.

For checking the regulator, the inlet pressure must be at

least 1" (or 2.5 kPa) greater than the regulator manifold

pressure setting. The regulator is set for 4" of manifold

pressure, the inlet pressure must be at least 5".

The gas supply line to the range should be 1/2" or 3/4"

pipe.

Figure 3A - 36" MODEL

ELECTRICALOUTLET INSTALL DIMENSIONS

Page 5

LP/Propane Gas Conversion

This appliance can be used with Natural gas or LP/

Propane gas. It is shipped from the factory for use with

natural gas.

A kit for converting to LP gas is supplied with your

cooktop. The kit is marked "FOR LP/PROPANE GAS

CONVERSION".

The conversion must be performed by a qualified

service technician in accordance with the kit instructions

and all local codes and requirements. Failure to follow

instructions could result in serious injury or property

damage. The qualified agency performing this work

assumes responsibility for the conversion.

Failure to make the appropriate

conversion can result in serious personal injury and

property damage.

NOTE: Purchase a new flexible line. DO NOT USE

AN OLD PREVIOUSLY USED LINE.

Important: Remove all packing material and literature

from cooktop before connecting gas and electrical

supply to cooktop.

The wall receptacle and circuit should be checked by

a qualified electrician to make sure the receptacle is

properly grounded.

Where a standard 2-prong wall receptacle is installed,

it is the personal responsibility and obligation of the

consumer to have it replaced by a properly grounded

3-prong wall receptacle.

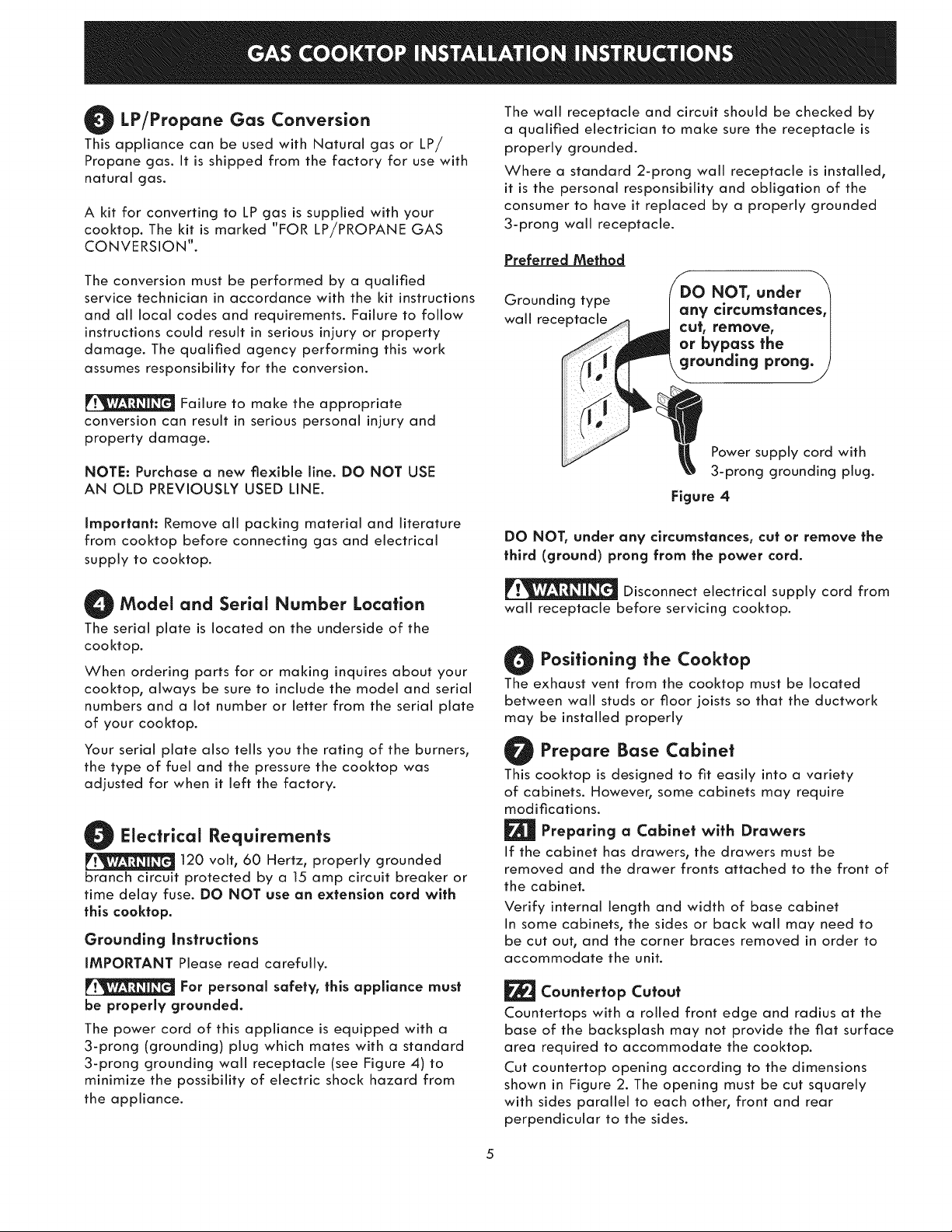

Preferred Method

Grounding type

wall receptacle

NOT, under -_

any circumstances, I

cut, remove, |

or bypass the |

grounding prong.J

Power supply cord with

3-prong grounding plug.

Figure 4

DO NOT, under any circumstances, cut or remove the

third (ground) prong from the power cord.

Model and Serial Number Location

The serial plate is located on the underside of the

cooktop.

When ordering parts for or making inquires about your

cooktop, always be sure to include the model and serial

numbers and a lot number or letter from the serial plate

of your cooktop.

Your serial plate also tells you the rating of the burners,

the type of fuel and the pressure the cooktop was

adjusted for when it left the factory.

Electrical Requirements

]20 volt, 60 Hertz, properly grounded

branch circuit protected by a 15 amp circuit breaker or

time delay fuse. DO NOT use an extension cord with

this cooktop.

Grounding instructions

IMPORTANT Please read carefully.

For personal safety, fhls appliance must

be properly grounded.

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

3-prong grounding wall receptacle (see Figure 4) to

minimize the possibility of electric shock hazard from

the appliance.

_ Disconnect electrical supply cord from

wall receptacle before servicing cooktop.

Positioning the Cooktop

The exhaust vent from the cooktop must be located

between wall studs or floor joists so that the ductwork

may be installed properly

Prepare Base Cabinet

This cooktop is designed to fit easily into a variety

of cabinets. However, some cabinets may require

modifications.

Preparing a Cabinet with Drawers

If the cabinet has drawers, the drawers must be

removed and the drawer fronts attached to the front of

the cabinet.

Verify internal length and width of base cabinet

In some cabinets, the sides or back wall may need to

be cut out, and the corner braces removed in order to

accommodate the unit.

Counterfop Cutout

Countertops with a rolled front edge and radius at the

base of the backsplash may not provide the fiat surface

area required to accommodate the cooktop.

Cut countertop opening according to the dimensions

shown in Figure 2. The opening must be cut squarely

with sides parallel to each other, front and rear

perpendicular to the sides.

5

Page 6

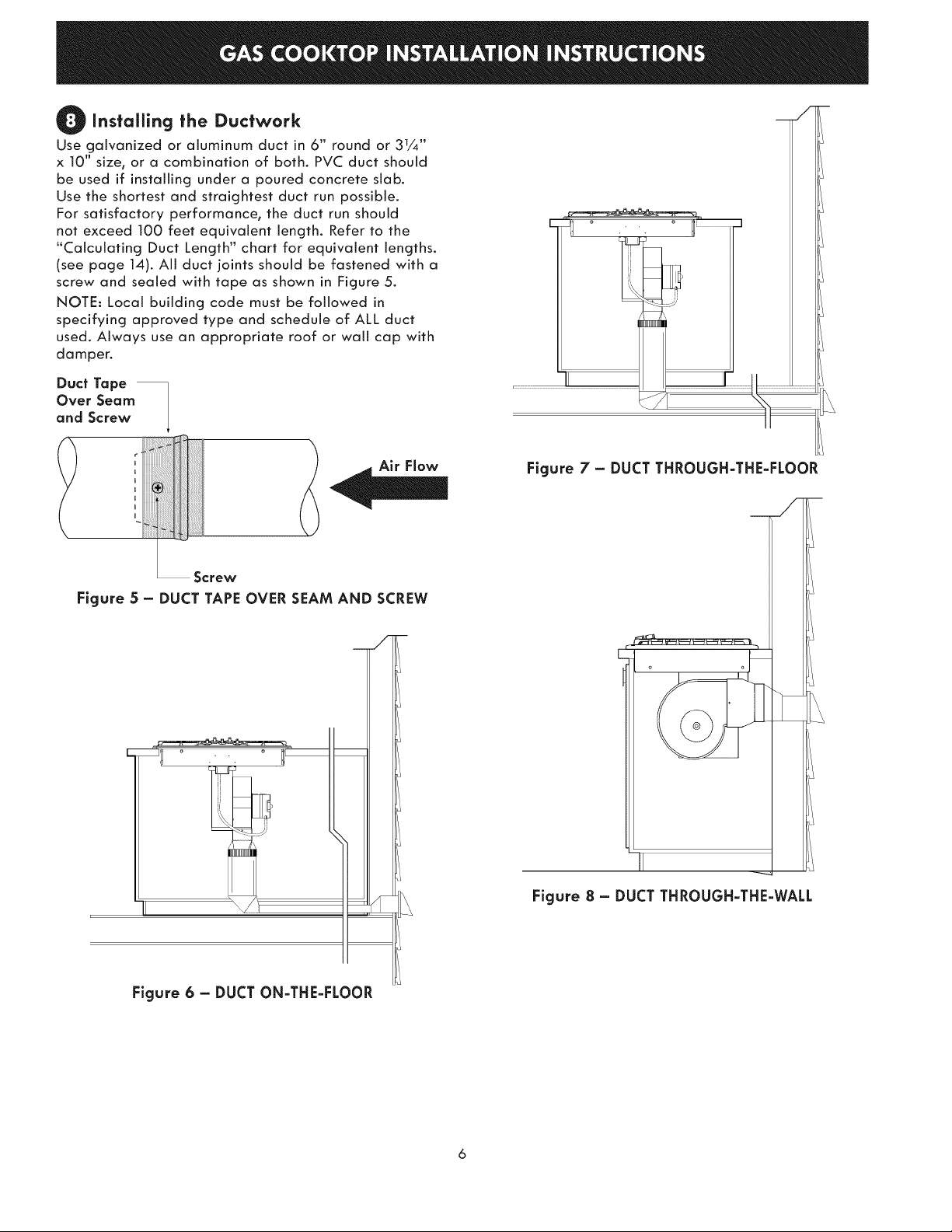

Installing the Ductwork

Use galvanized or aluminum duct in 6" round or 3½"

x 10" size, or a combination of both. PVC duct should

be used if installing under a poured concrete slab.

Use the shortest and straightest duct run possible.

For satisfactory performance, the duct run should

not exceed 100 feet equivalent length. Refer to the

"Calculating Duct Length" chart for equivalent lengths.

(see page 14). All duct joints should be fastened with a

screw and sealed with tape as shown in Figure 5.

NOTE: Local building code must be followed in

specifying approved type and schedule of ALL duct

used. Always use an appropriate roof or wall cap with

damper.

Duct Tape

Over Seam

and Screw

!

Figure 7 - DUCT THROUGH-THE-FLOOR

Screw

Figure 5 - DUCT TAPE OVER SEAM AND SCREW

° '. ° I["'

Figure 6 - DUCT ON-THE-FLOOR

Figure 8 - DUCT THROUGH-THE-WALL

Page 7

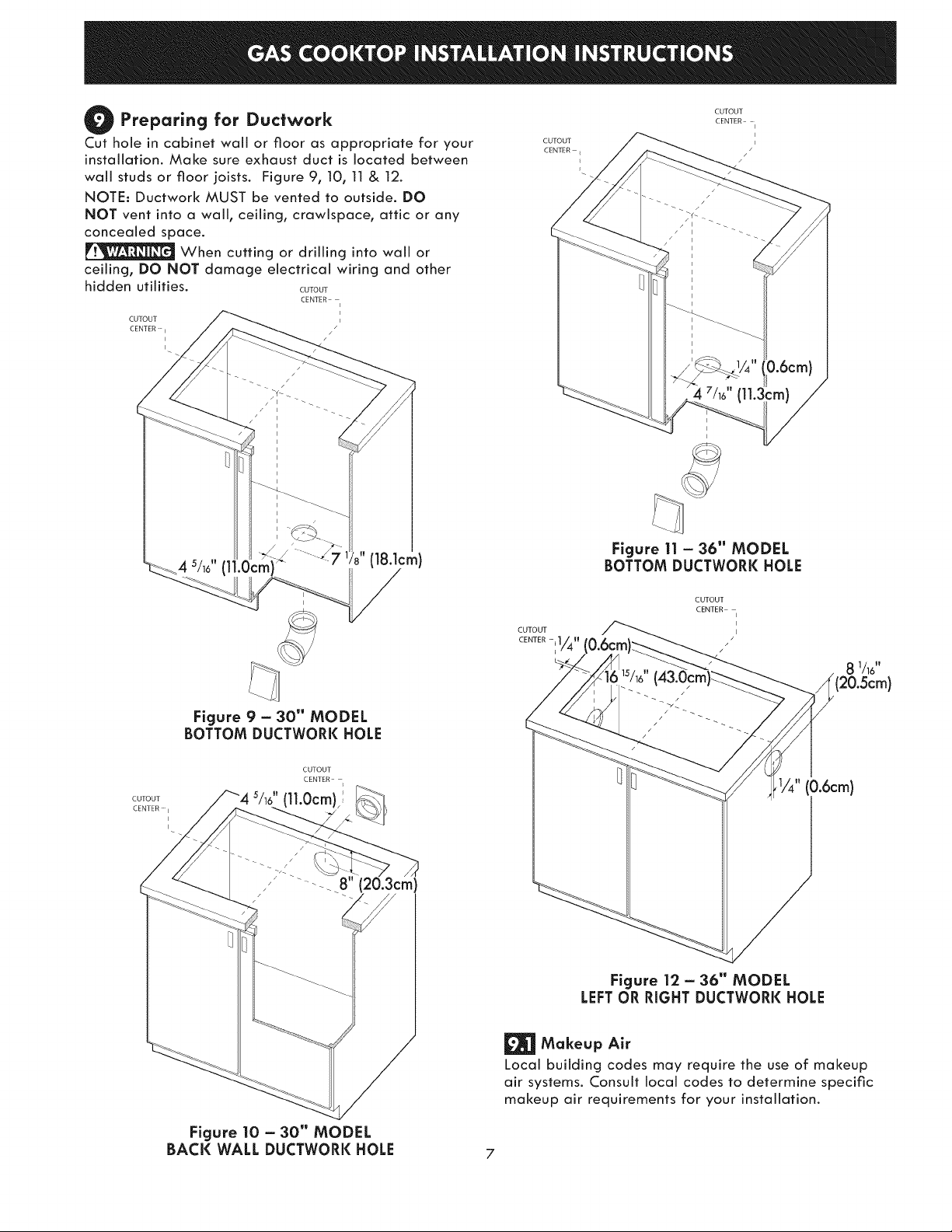

Preparing for Ductwork

Cut hole in cabinet wall or floor as appropriate for your

installation. Make sure exhaust duct is located between

wall studs or floor joists. Figure 9, 10, 11 & 12.

NOTE: Ductwork MUST be vented to outside. DO

NOT vent into a wall, ceiling, crawlspace, attic or any

concealed space.

When cutting or drilling into wall or

ceiling, DO NOT damage electrical wiring and other

hidden utilities. CUTOUT

CENTER

i

i

//

CUTOUT

CENTER ....

I

I

I

Figure 11 - 36" MODEL

BOTTOM DUCTWORK HOLE

CUTOUT

Figure 9 - 30" MODEL

BOTTOM DUCTWORK HOLE

CUTOUT

CENTER

(ll.0cm) :

/

/

(20.3crn)

CUTOUT

CENTER- -I

8 1/16"

.6cm)

Figure 12 - 36" MODEL

LEFTOR RIGHT DUCTWORK HOLE

_'_ Makeup Air

Local building codes may require the use of makeup

air systems. Consult local codes to determine specific

makeup air requirements for your installation.

Figure 10 - 30" MODEL

BACK WALL DUCTWORK HOLE

7

Page 8

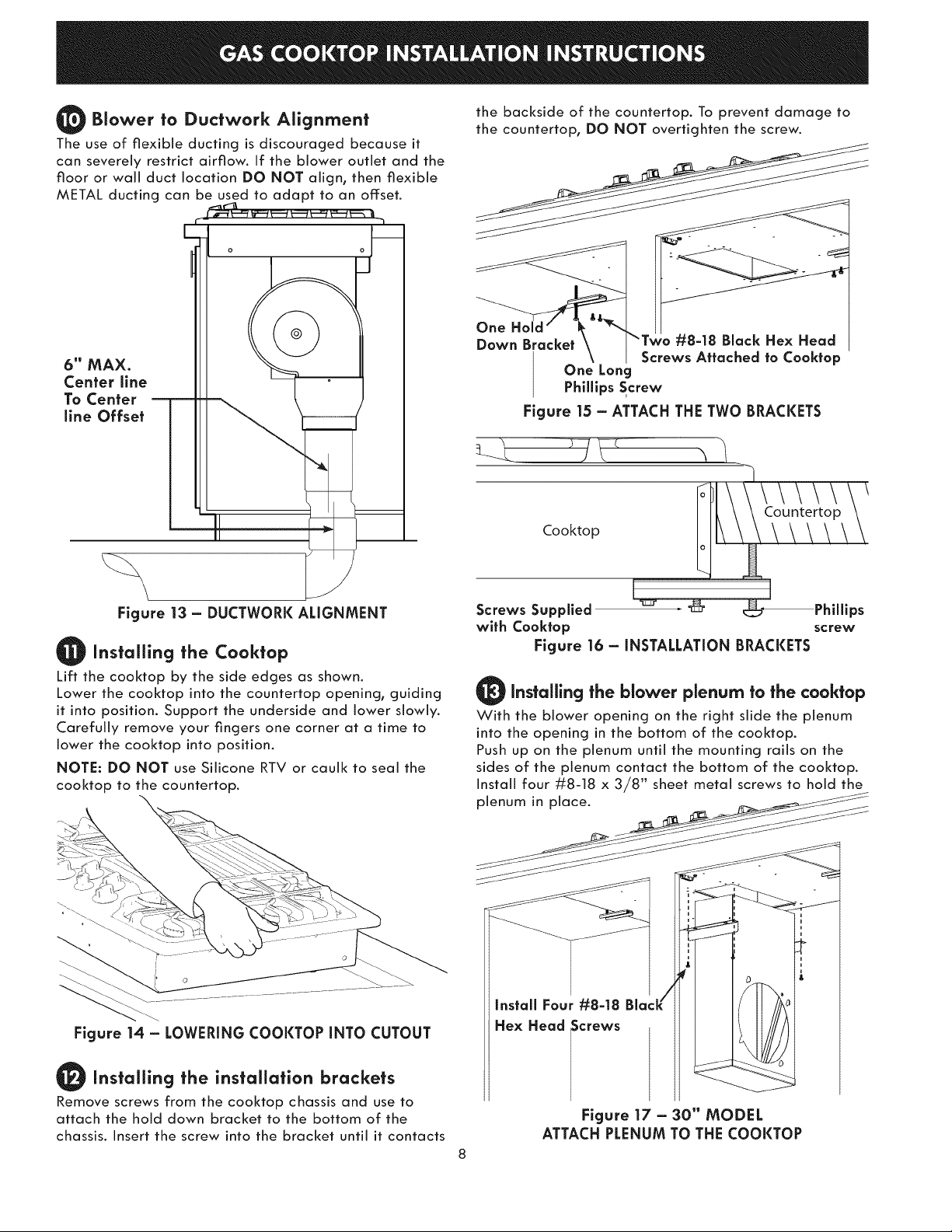

Blower to Ductwork Alignment

The use of flexible ducting is discouraged because it

can severely restrict airflow. If the blower outlet and the

floor or wall duct location DO NOT align, then Nexible

METAL ducting can be used to adapt to an offset.

I-- q

o o

6" MAX.

Center line

To Center

line Offset

the backside of the countertop. To prevent damage to

the countertop, DO NOT overtighten the screw.

_T_ #8-18 Black Hex Head

Screws Attached to Cooktop

One Long

Philllps Screw

Figure |5 - ATTACH THE TWO BRACKETS

Cooktop

Figure 13 - DUCTWORK ALIGNMENT

Insfallincj the Cooktop

Lift the cooktop by the side edges as shown.

Lower the cooktop into the countertop opening, guiding

it into position. Support the underside and lower slowly.

Carefully remove your Nngers one corner at a time to

lower the cooktop into position.

NOTE: DO NO]" use Silicone RTV or caulk to seal the

cooktop to the countertop.

Figure 14 - LOWERING COOKTOP INTO CUTOUT

Screws Supplled _ 6 ps

with Cooktop screw

Figure |6 - iNSTALLATiON BRACKETS

Installincj the blower plenum to the cooktop

V_/ith the blower opening on the right slide the plenum

into the opening in the bottom of the cooktop.

Push up on the plenum until the mounting rails on the

sides of the plenum contact the bottom of the cooktop.

Install four #8-18 x 3/8" sheet metal screws to hold the

Install Four #8-18 Blacl_

Hex Head icrews

Installing the installation brackets

Remove screws from the cooktop chassis and use to

attach the hold down bracket to the bottom of the

chassis. Insert the screw into the bracket until it contacts

Figure 17- 30" MODEL

ATTACH PLENUM TO THE COOl{TOP

Page 9

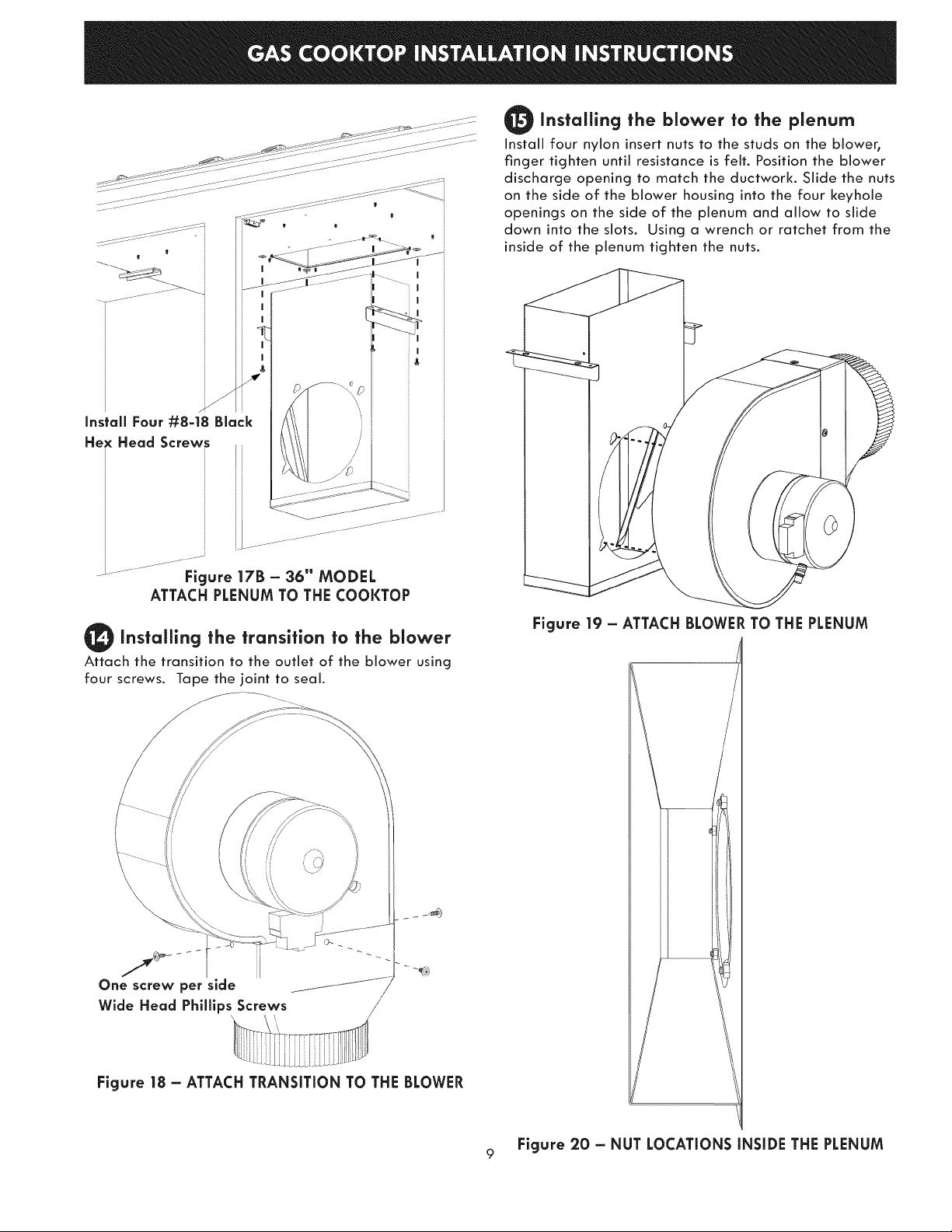

Installing the blower to the plenum

Install four nylon insert nuts to the studs on the blower,

finger tighten until resistance is felt. Position the blower

discharge opening to match the ductwork. Slide the nuts

on the side of the blower housing into the four keyhole

openings on the side of the plenum and allow to slide

down into the slots. Using a wrench or ratchet from the

inside of the plenum tighten the nuts.

Figure 17B - 36" MODEL

ATTACH PLENUM TO THE COOKTOP

Installing the transition to the blower

Attach the transition to the outlet of the blower using

four screws. Tape the joint to seal.

One screw per side

Wide Head Phillips Screws

Figure 19 - ATTACH BLOWERTO THE PLENUM

Figure 18 - ATTACH TRANSMON TO THE BLOWER

9 Figure 20 - NUT LOCATIONS iNSiDE THE PLENUM

Page 10

Blower electrical connection

Connect the 5-pin plug on the blower assembly to

the matching 5-pin receptacle on the bottom of the

cooktop.

Install Pressure Regulator

Install the pressure regulator with the arrow on the

regulator pointing up toward the unit in a position

where you can reach the access cap.

Fold all wires into the wire box on the end of the blower

conduit. Fasten the wire box to the cooktop with two #8

x 3/8" making sure that no wires are trapped.

Figure 21 - CONNECT BLOWERTO COOKTOP

Connecting the Ductwork

Connect the ductwork prepared in Steps 8, 9 and 10 to

the blower transition duct.

_DO NOT make the connection too

tight. The regulator is die cast. Overtightening may

crack the regulator resulting in a gas leak and possible

fire or explosion.

Manual GAS FLOW Pressure

Shutoff Flare I_ Flare Regulator

Valve Union Union

0n_!;_ t t Nip1'le_p

__. Nipple Flexible

Off Connector

Access

Cap

All connections must be wrench-tightened

Figure 22 - GAS SUPPLYLINE

Assemble the flexible connector from the gas supply

pipe to the pressure regulator in the following order:

1. manual shutoff valve

2. 1/2" (1.3 cm) nipple

3. 1/2" (1.3 cm) flare union adapter

4. flexible connector

5. 1/2" (1.3 cm) flare union adapter

6. 1/2" (1.3 cm) nipple

7. pressure regulator

Use pipe-joint compound made for use with Natural

and LP/Propane gas to seal all gas connections. If

flexible connectors are used, be certain connectors are

not kinked.

............ _j

Figure 22B - PHYSICAL ATTACHMENT OF THE GAS

LINE TO THE COOKTOP

10

Page 11

_The supply line must be equipped with

an approved manual shutoff valve. This valve should be

located in the same room as the cooktop and should be

in a location that allows ease of opening and closing.

DO NOT block access to the shutoff valve. The valve is

for turning on or shutting off gas to the appliance.

Shutoff Valve -

Open position

Figure 23 - SHUTOFF VALVE

Once regulator is in place, open the shutoff valve in the

gas supply line. Wait a few minutes for gas to move

through the gas line.

_ Check for leaks. After connecting the cooktop

to the gas supply, check the system for leaks with a

manometer. If a manometer is not available, turn on the

gas supply and use a liquid leak detector (or soap and

water) at all joints and connections to check for leaks.

Electrical Requirements

120 volt, 60 Hertz, properly grounded branch circuit

protected by a 15 amp circuit breaker or time delay

fuse. DO NOT use an extension cord with this cooktop.

| Grounding Instructions

iMPORTANT Please read carefully.

For personal safety, this appliance must be properly

grounded.

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

3-prong grounding wall receptacle (see Figure 25) to

minimize the possibility of electric shock hazard from

the appliance.

The wall receptacle and circuit should be checked by

a qualified electrician to make sure the receptacle is

properly grounded.

Where a standard 2-prong wail receptacle is installed,

it is the personal responsibility and obligation of the

consumer to have it replaced by a properly grounded

3-prong wall receptacle.

Preferred Method

Grounding type

wail receptacle

NOT, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

Flr_]__ DO NOT use a flame to check for

leaks from gas connections. Checking for leaks with a

flame may result in a fire or explosion.

Tighten a[[ connections if necessary to prevent

gas leakage in the cooktop or supply line.

Disconnect this cooktop and its individual

manual shutoff valve from the gas supply piping

system during any pressure testing of that system at test

pressures greater than 1/2 psig (3.5 kPa or 14"water

column).

| Isolate the cooktop from the gas suppJy

piping system by dosing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/2

psig (3.5 kPa or 14" water column).

Power supply cord with

3-prong grounding plug.

Figure 24 - POWER SUPPLYCORD

DO NOT, under any circumstances, cut or remove the

thlrd (ground) prong from the power cord.

_ Disconnect electrical supply cord from

wail receptacle before servicing cooktop.

11

Page 12

Install Burner Caps

A. Unpack the burner grates.

B. Burners: Unpack the Burner heads and burner caps.

Place the burner heads and caps on the matching

bases.

C. The caps should be level after installation

D. Be sure that all the burner caps burner head are

correctly placed BEFORE using your cooktop

Install Filter and Grates

DO NOT operate the vent without the filter in place.

* Place the filter diagonally through Vent Chamber

the vent chamber. ...._..... '

* Make sure it rests, at an angle, on ]

the supports in the vent opening. "'i

Chamber

...............................................I ............................................

f

* Carefully place vent grate seal over the vent chamber

on the cooktop, with the side marked FRONT to the

front. Make sure the collar on the bottom of the seal

is fully inserted the vent opening.

* Place the vent grate over the vent opening. Place the

burner grates over the burners.

Figure 25

VENT FILTER LOCATION - 30" MODEL

Vent

Chamber .......

Figure 27

VENT GRATE AND SEAL LOCATION - 30" MODEL

Grate

Vent Grate Seal

Figure 28

VENT GRATE AND SEAL LOCATION - 36" MODEL

Figure 26

VENT FILTER LOCATION - 36" MODEL

12

Page 13

Check Operation

Refer to the Use and Care Guide packaged with the

cooktop for operating instructions and for care and

cleaning of your cooktop.

Turn on Electrical Power and Open Main Shutoff

Gas Valve

_ Check the igniters

Operation of electric igniters should be checked after

cooktop and supply line connectors have been carefully

checked for leaks and the cooktop has been connected

to electric power.

To operate the surface burner:

A. Push in and turn a surface burner knob to the LITE

position. You will hear a small ticking noise; this

is the sound of the electric ignitor which lights the

burner.

B. After the burner lights, turn to the desired flame

size. The controls DO NOT have to be set at a

particular mark. Use the marks as a guide and

adjust the flame as needed.

When All Hookups are Complete

Make sure all controls are left in the OFF position.

Make sure the flow of combustion and ventilation air to

the cooktop is unobstructed.

Before You Call for Service

Read the Before You Call for Service Checklist and

operating instructions in your Use and Care Guide.

It may save you time and expense. The list includes

common occurrences that are not the result of defective

workmanship or materials in this appliance.

Refer to the warranty in your Use and Care Guide for

our service phone number and address. Please call or

write if you have inquiries about your product and/or

need to order parts.

13

Page 14

Calculating Duct Length Table

For maximum efficiency, use the shortest and straightest duct possible. Use as few fittings as

possible. For best performance, the duct run should not exceed 100 feet of equivalent length.

Calculations are approximate and based on HVAC industry standards.

DUCT PIECES EQUIVALENT NUMBER EQUIVALENT

6" (15.2cm) Round

Straight _ 1 Ft. (0.3m) Ft. or m

6" (15.2cm) Round Metal Flex

No Bends _ 1.5 Ft. (0.45m) Ft. or m

(_ 6" (15.2cm) 10 Ft. (3m) Ft.

Q_ 6" (15.2cm)

[__ 31/4" x 10" (8.2cm x 25.4cm)

90 ° Elbow

45 ° Elbow 5 Ft. (1.5m) Ft. or m

Straight _ 1 Ft. (0.3m) Ft. or m

31/4" x 10" (8.2cm x 25.4cm) 10 Ft. (3m) Ft. or m

90 ° Elbow

31/4'' x 10" (8.2cm x 25.4cm)

45 ° Elbow 5 Ft. (1.5m) Ft. or m

31/4" x 10"

90 ° Flat Elbow

(8.2cm X 25.4cm)

LENGTH X USED -- LENGTH

10 Ft. (3m) Ft. or m

or m

to (15.2cm) Round Transition 30 Ft. (9m) Ft. or m

31/46:,X 10" (8.2cm x 25.4cm)

90 ° Elbow

(8.2cm x 25.4cm) Transition 30 Ft. (9m) Ft. or m

6" (15.2cm) Round to 31/4" x 10"

90 ° Elbow

31/4" x 10" (8.2cm x 25.4cm) to 5 Ft. (1.5m) Ft. or m

6" (15.2cm) Round Transition

6" (15.2cm) Round to 31,/4 '' X 10"

(8.2cm x 25.4cm) Transition 5 Ft. (1.5m) Ft. or m

6" (15.2cm) Round Wall Cap

with Damper 30 Ft. (9m) Ft. or m

[_ 31/4" x 10" (8.2cm x 25.4cm)

_ For Straight Round / Rectangular Duct, measure actual linear

feet used and then multiply by Equivalent Length shown.

Wall Cap with Damper 30 Ft. (9m) Ft. or m

6"

(15.2cm) Round Roof Cap 30 Ft. (9m) Ft. or m

TOTAL DUCTWORK Ft. or m

14

Page 15

TODA TAREADEINSTALACiON O IV_NTENIMIENTO DEBERAREALIZARLAUN INSTALADORCUALIFICADO.

IMPORTANTE: GUARDE ESTASINSTRUCCIONES PARA EL iNSPECTOR LOCAL DE ELECTRICIDAD.

LEA Y GUARDE ESTAS INSTRUCCIONES PARA FUTURAS CONSULTAS.

Si no slgue las instrucciones recogldas en este manual al pie

de la leira se podrfa produclr un incendlo o una explosi6n que causarfa da_os

materiales, lesiones corporales o incluso la muerte.

POR RAZONES DE SEGURIDAD:

m NO guarde ni use gasollna u otros liquidos o gases inflamables

cerca de este o de cualquier otto electrodom_sflco.

QUE HACER SI HUELE A GAS:

• NO encienda ningOn electrodom_sfico.

• NO toque ningOninterruptor el_ctrlco, NO ufiEce ningOnfel_fono en el edificio.

• Llame a su compa_fa de gas de inmediafo desde el tel_fono de algOn veclno.

Siga las instrucciones que le d_ la compa_fa.

• Si no conslgue ponerse en conlacto con la compafiia de gas, llame a los

bomberos.

Toda tarea de instalaci6n o manfenimiento deber6 realizarla un

Para electrodom_sficos en el

estado de Massachusetts:

En el estado de

Massachusetts, este

electrodom_stico debe

instalarlo un instalador de gas

o un fontanero con licencia

de Massachusetts. Se debe

instalar un conector de gas

flexible que no supere los 3

pies/36 pulgadas. Se debe

instalar una v61vula manual

con mango en Ten la tuberfa

de gas utilizada para este

electrodom_stico.

instalador cualificado, el servicio t_cnico o la compafiia de gas.

DIMENSIONES DEL PRODUCTO

A l=

o o

o

o N

20 %"

(51.1 cm)

i

233/8"

(59.4 cm)

C

o o

D_

Figura 1

Modelo de 30" 30" (76,2 cm) 21 13132"(54,4 cm) 26 13/16"(68,1 cm)

Modelo de 36" 36" (91,4 crn) 21 23/32"(55,1 crn) 32 11/16"(83,0 crn)

Todas las dimensiones se expresan en pulgadas y (cm).

Impreso en EE. UU.

18 15116"(48,1 cm)

18 15116"(48,1 cm)

316902490 (1112) Rev.

Espa_ol - p6ginas 1-14

Page 16

Informaci6n importante para el instalador

1. Lea todas las instrucciones de instalaci6n

suministradas antes de preceder a instalar la

plancha.

2. Retire todo el embalaje antes de conectar el

suministro ei_ctrico aJ electrodom_stico.

3. Tenga en cuenta Ja normativa y los c6digos locales.

4. Aseg6rese de dejar estas instrucciones aJ propietario.

5. Nora: Para el use a m6s de 2000 pies de altura

sobre el niveJ del mar, la potencia del aparato

deber6 reducirse un 4 per ciento per cada 1000 pies

adicionales.

Informaci6n importante para el propietario

Conserve estas instrucciones con su Gufa de use y

cuidado para futuras consultas.

INSTRUCCIONES IMPORTANTES

PARA LA SEGURIDAD

La instalaci6n de esta plancha de cocinar debe

realizarse en conformidad con los c6digos locales

o, si estos no existen, con el National Fuel Gas

Code ANSi Z223.1/NFPA 54 en Estados Unidos, o

con el Canadian Fuel Gas Code, CAN/CGA B149 y

CAN/CGA B149.2 en Canad6.

• La instalaci6n de las unidades dise_ados para

casas (m6viles) deben respetar los "Manufactured

Home Construction and Safety Standards, titulo

24 CFR, arficulo 3280 (antes el The Federal

Standard for Mobile Home Construction and

Safety, tituto 24, HUD, artfculo 280)" o, cuando

la normativa no sea aplicable, con el Standard

for Manufactured Home Installation, ANSI/

NCSBCS A225.1 o con los c6digos locales.

Esta plancha ha side dise_ada y certificada

per Underwriters Laboratories (UL). Come con

cualquier electrodom6stico que funcione con gas

y genere calor, hay una serie de precauciones de

seguridad que debe seguir al utilizar esta plancha

de cocinar. Las encontrar6 en la Gufa de use y

cuidado_ lea estas instrucciones detenidamente.

• AsegOrese de que un instalador cualificado o el

personal del servlcJo t_cnico instalan V conectan

a fierra correctamente este electrodom_sfico.

La plancha de cocinar debe conectarse a

fierra de acuerdo con los c6dlgos locales o, de

no exisfir, con la 61tima edici6n del National

Electrical Code ANSI/NFPA No. 70 en Estados

Unidos o con el Canadian Electrical Code, CSA

C22.1 Part 1 en Canad6.

• En case de corte del suministro el_ctrlco puede

encender los quemadores manualmente. Para

encender un quemador, coloque una cerilla

encendida cerca de la cabeza del quemador V

gire el mando de control lentamente basra la

posJcJ6n LITE. Tenga cuidado al encender los

quemadores manualmente.

NO almacene objetos que puedan

captar la atenci6n de los ni_os en los muebles

situados sobre el electrodom_sfico. Los ni_os

podrfan intentar subirse al electrodom6stico y esto

podrfa provocar lesiones graves.

• Seria recomendable evitar almacenar utensilios

en los muebles situados sobre la plancha para

evltar el tenet que acceder a ellos.

• Ajuste la llama de forma que no sobresalga

fuera del borde del utensilio. Una llama de un

tamale excesivo es peligrosa.

Nunca ufillce este electrodom_sfice

para calentar la habitaci6n. El use prolongado de

la plancha sin la ventilaci6n adecuada podria ser

peligroso.

AImacenamiento cerca del

electrodom_sfico. No guarde materiales

inflamables cerca de este electrodom_sfico. Esto

incluye objetos de papel, pl6stico o tela, come libros

de cocina, utensilios de pl6stico o pa_os, asf come

Ifquidos inflamables. NO almacene materiales

explosives, per ejemplo, aerosoles, cerca del

electrodom@stico. Los materiales inflamables podrfan

explotar y provocar un incendio o da_os materiales.

Corte el suminlstro el_ctrlco de la

plancha mientras que se instalan las conexiones

de la tuberia de gas. Si no Io hace podrian

provocarse lesJones graves e incluso la muerte.

Page 17

13" (33 cm)

Profundidad m6x.

del mueble

situado sobre la

plancha.

13/8" (3,5 cm) Distancia minima

entre el hueco y el bordeo

30" (76,2 cm)

Espacio minimo

entre la plancha y

el mueble de metal

__1 o de madera no

Es_acio

egida

13/8" (3,5 cm) Distancia minima

entre el hueco y el borde.

Figura 2 - DISEI_IO DEL MUEBLE

iiii_!i_!i!_!_!_i!i_i_i_!ii_i!_!ii!_!_!!_:i_!ii_i_!ii!ii!_i!_!ii_!i_!i__i!iii!ii!!i!ii!!

ii!ii!ii!i_ii!ii!ii_ii_ii_ii_ii_ii_ii_ii!ililili_!_iiiiiiii!ii_!i_!_ii_!ii!i!ii!!i_!_!_i_iii:_!i_ii!ii_il¸ii'il¸ii!i!ii!ii!i!iiiiiiii_i:ii_i_i_i_!

Plancha de 30"

Plancha de 36"

evitar el riesgo de quemaduras por el contacto directo al acceder a ellos.

30" (76,2 cm)

36" (91,4 cm)

Seda recomendable evitar almacenar utensilios en los armarios situados sobre la plancha para

!!!!!i!ii!ii!ii!iiiiiii!ii!ii!!i!i!i!iii!iiiiiiiiiiii_iiiii!_!_!i_i_i_i!i_i_i_i_!_i_i_!_!_!i_i_i_!i_!_!i_i_iiiiii_i_!_iii_iiiiiiiiiiiiiiiiii!!ii:¸

ii_!_!i_!_!!_!i!_!i!_!_!!iii_i_ii!ii!i!i!ii!_i_ii_i_i_ii_i_i_ii_i_i_i_i_ii_ii_i_i_ii_i_i_i!_!_!_!i!_!_i_i!_!_!_!i_i_i!_!_!_i_!i_!_!_!i_!i_!i_!i_!_!_!_!i_!i_!_i!i!i_ii_iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_ii_ii

9" (22,9 cm)

9" (22,9 cm)

i¸i¸_!_!_!_!_!_!_!_i!i!i_!i_!i_i_!i!_!_i_!!i!!i!_!!!i_!_!_!_i_!_!!i_i_!iiiiiii_i!_i!_!_!_i!ii!ii!iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii!i!i!i!_

28" (71,1 cm)

34" (86,4 cm)

iiiiiiiiiiii,!i_!iiiiiiiiiiiiiiiiiiiiii_i_iii_ii_ii_ii_ii_i_i!i_ii_ii_ii_iiiiiiii_i!i!_!i!ii_!_!i!i!i_i_ii_ii_ii_iiiiiiii!!!_ii_ii_ii_ii_i_i_i_i_i_i_i_i_ii_ii_ii_ii_i_!_!i_!i_!i_!i_!i_i_iiiiiii_i_i_i!i!i!i_i_ii_i!i_i!i_i!i_ii_ii_ii_ii_ii_ii_ii_ii_ii_ii_iiiiiiii_ii_ii_iiiiiiii_iii_ii_i_i_!i_!i_!i_!i_iiiii_ii_ii_ii_iiiiiiii_iiiii!!!_iiiii_iiiiiiii_i_i_i_i_i_i_i_i_iiiiiiiiiiiiiiiiiiiiii_i_!_!

19 1/8" (48,6 cm)

19 1/8" (48,6 cm)

Page 18

Herramientas necesarias para la instalaci6n

- Destornillador Phillips

- ½" Liave para tuercas / trinquete

- z/16"Llave para tuercas / trinquete

Elementos suminlstrados

_antidad Descripci6n Uso

3

(8.3 cm)

cL

1 1II

(27.9 cm)

(4) hexagonal con insertos de

(2) #10-24 3.5" Torniilo con

(4) (_ #8-18 Torniios con Conducto de

(6)

(2) Soporte de sujecci6n (fig. 15 y 16)

1/4-20 tuercas de cabeza Ventilador (fig. 20)

nil6n 7/16"

cabeza Phillips largo (fig. 15 y 16)

cabeza Phillips transici6n (fig. 18)

#8-18 Negros 1/4" C_mara y caja de

Tornillos con cabeza cableado (fig. 17 y 21)

hexagonal

Soportes

Encimera

Ublcaci6n de la toma de corriente de pared

Instaie la toma de corriente de pared en e[ Orea sombreada.

q_

I _1 11 1/2"

6" 8

(15.2 cm) (22.2 cm)

I= 3/4-, (29.2 cm)

Ubicaci6n reco-

mendada para eli

tubo de[ suminis- [

tro de gas ]

Figura 3B - MODELO DE30" DIMENSIONES DEL HUECO

PARA LA INSTALACION DE LA TOMA DE CORRIENTE

Conexi6n a un suminlstro de gas adecuado

Esta plancha se ha diseffado para funcionar Onicamente con

un colector de gas natural de 4".

_EI colector debe estar conectado en serie

a un regulador de presi6n y debe conectarse en serie con la

Ifnea de suministro de gas.

Para un funcionamien|a adecuado, [a presi6n de entrada

mOxima al regulador no debe ser superior a una coiumna de

agua de 14".

Para comprobar e[ regu[ador, [a presi6n de entrada a[ mismo

deberO ser de a[ menos 1" (o 2,5 kPa) mayor que [a presi6n

de[ co[ector de[ regu[ador. E[ regu[ador se configura para

una presi6n de co[ector de 4", [a presi6n de entrada deberO

ser a[ menos de 5".

La [inea de suministro de gas debe ser una tuberia de 1/2" o 3/4".

Figura 3A - MODELO DE 36" DIMENSIONES DEL HUECO

PARA LA INSTALACION DE LA TOMA DE CORRIENTE

Page 19

Conversi6n a gas propano/LP

Este eJectrodom_stico ha sido dise_ado para utiNzar gas

natural o gas propano. Los valores predeterminados de

f6brica se han establecido para su uso con gas natural.

Con este producto se suministra un kit para Ja conversi6n a

gas propano. El kit se titula "PARA CONVERSION A GAS

PROPANO/LP".

La conversi6n a gas propano debe realizarla el personal

cualificado deJ servicio t6cnico de acuerdo con Jas

instrucciones suministradas y con todos los c6digos y

normativas locales. De Jo contrario, podrian producirse graves

lesiones o daBos materiales. La agencia cualiflcada que

ejecute esta conversi6n se responsabilizar6 de este trabajo.

_Si la conversi6n no se realizara

correctamente podrian provocarse lesiones corporales y

daBos materiales.

NOTA: Adquiera una Irnea nueva y flexible. NO UTILICE

UNA L{NEA USADA ANTERIORMENTE.

P6ngase en contacto con un electricista cualificado para

comprobar el circuito y que Ja toma de corriente de pared

est6 correctamente conectada a tierra.

Si la 6nica toma de corriente de pared al alcance es para

dos clavijas, es su responsabilidad y obligaci6n reemplazarla

por otra toma de corriente de pared para tres clavijas que

est_ correctamente conectada a tierra.

M_todo recomendado

Toma de corriente

de pared

con conexi6n

a tierra

NO corte, extralga_

o desv_e la clavija|

de toma de tJerra |

bajo nincj6n |

concepto. /

Cable eJ6ctrico con enchufe

con toma de tierra de tres

clavijas

Figura 4

Jmportante: Retire todo el embalaje y Jas instrucciones de Ja

plancha antes de conectar el suministro de gas y el el6ctrico

al electrodom_stico.

Ubicaci6n del n6mero de serie ¥ modelo

La placa de serie est6 ubicada en la parte inferior de

la plancha.

Si tiene alguna pregunta sobre el electrodom@stico o

si desea encargar alguna pieza, aseg6rese de incluir el

modelo, el n0mero de serie y el n0mero o la letra dei

Iote que encontrar6 en la pJaca de serie de Ja plancha.

La placa de serie tambi@n induye informaci6n

sobre la potencia de los quemadores, el tipo de

combustible y el ajuste de presi6n fijado en la f6brica.

Requisltos para el sumlnlstro el_ctrico

_Un circuito derivado conectado

correctamente a tierra de 120 voJtios, 60 hercios protegido

por un disyuntor de 15 amperios o un fusible de retardo.

NO utilice un alargador el_ctrico para conectar este

electrodom_stico.

Instrucciones para la conexi6n a fierra

JMPORTANTE Lea estas instrucciones detenidamente.

_Por razones de seguridad, este

eJectrodom_.stico deber6 estar correctamente conectado a tierra.

El cable el6ctrico de este eJectrodom_stico est6 equipado

con un enchufe con tres clavijas (con toma de tierra) que

encaja con una toma de corriente para tres clavijas (consulte

Figura 4) para reducir el riesgo de descargas el6ctricas.

NO corte o extraiga la cJavija de toma de tierra del enchufe

bajo nJngOn concepto.

_ Antes de Ilevar a cabo cualquier tarea de

mantenimiento, desconecte el cable de suministro el6ctrico de

Ja toma de corriente de pared.

Fijaci6n de la plancha

El extractor de Ja plancha debe estar situado entre un

soporte en Ja pared o en una viga de soporte de manera que

permita instalar eJ conducto de ventiJaci6n correctamente.

Preparaci6n del mueble inferior

Este eJectrodom6stico ha sido dise_ado para encajar en

diferentes muebles. Puede que algunos muebles necesiten

modificaciones.

Instalaci6n en un mueble con cajones

Si el mueble tiene cajones, deber6 retirarlos y acoplar la

zona deJantera de los cajones al mueble.

Compruebe la Jongitud y Ja anchura deJ mueble.

En algunos muebles puede que sea necesario cortar los

laterales o la pared de Ja zona trasera y retirar las escuadras

para poder instalar la unidad.

Corte de la encJmera

Las encimeras con el borde curvo y una curva en la base

de los azulejos no proporcionarian una superficie plana

necesaria para instalar Ja plancha.

Realice un corte en la encimera de acuerdo con Jas

dimensiones que se muestran en la Figura 2. El hueco debe

formar un cuadrado cuyos lados sean paraJelos y Ja parte

delantera y la trasera sean perpendicuJares a los lados.

5

Page 20

Instalaci6n del conducto de ventilaci6n

Utilice un conducto galvanizado o de alumino redondo

de o 6" o 3'q/4x 10", o una combinaci6n de ambos. Utilice

un conducto de PVC siva a instalarlo ba]o una Iosa de

hormig6n. Intente que el conducto recorra el tramo mrs corto

y mrs recto posible. Para un rendimiento 6primo, el conducto

no deberia exceder los cien pies de Iongitud. Consulte la

tabla para calcular la Iongitud del conducto para ver la

equivalencia de medidas. (consulte la p_gina 14). Las juntas

del conducto deben a]ustarse con un tornillo y sellarse con

cinta adhesiva tal y como se muestra en la Figura 5.

NOTA: Debe tener en cuenta la normativa local de construcci6n

respecto al tipo y la planificaci6n de TODOS los conductos

utilizados. Utilice siempre una tapa de techo o de pared con

regulador de ventilaci6n.

Colocar clnta

adhesiva sobre

la uni6n y el

tornillo

Figura 7 - CONDUCTO A TRAVES DEL SUELO

Tornillo

Figura 5 - COLOCAR CINTA ADHESIVA SOBRE LA

UNION Y ELTORNILLO

° '. ° II"'

II 2

Figura 6- CONDUCTO EN EL SUELO

Figura 8 - CONDUCTO A TRAVES DE LA PARED

Page 21

Instalaci6n del conducto de ventilaci6n

Haga un orificio en la pared del mueble o en el suelo,

dependiendo de Io que sea mrs adecuado para su

instalaci6n en particular. Aseg0rese de que el conducto del

extractor est_ situado entre un soporte en la pared o una

viga de soporte. Figura 9, 10, 11 y 12.

NOTA: Ei conducto de ventilaci6n DEBE desembocar en el exterior.

NO instale el conducto de forma que desemboque en un muro,

techos, 6ticos, s6tanos de servicio o cualquier otro espacio oculto.

AI cortar o taladrar en una pared o en el

techo, NO dafie el cableado el6ctrico ni otras instalaciones.

CENTRO DEL

HU ECO / _ I

CENTRO DEL

HUECO

cm)

CENTRO DEL

HUECO

CENTRO DEL

HUECO

Figura 11 - MODELO DE 36" ORIFICIO INFERIOR

PARA EL CONDUCTO DEVENTILACION

CENTRO DEL

HUECO

CENTRO DEL

HUECO

Figura 9 - MODELO DE 30" ORIFICIO INFERIOR

PARA EL CONDUCTO DEVENTILACION

CENTRO DEL

HUECO

CENTROHuECODEL 5/16!1 (11,0cm)

Figura 10 - MODELO DE 30" ORIFICIO EN LA PARED

TRASERA PARA ELCONDUCTO DEVENTILACION

8 1/16"

cm)

Figura 12- MODELO DE 36" ORIFICIO EN

ELLATERALDERECHO O IZQUIERDO PARA EL

CONDUCTO DE VENTILACION

_ Tratarnlento de alre

De acuerdo con la normativa local de construcci6n, podria

ser necesario instalar un sistema de tratamiento de aire.

Consulte la normativa local para obtener mrs informaci6n

sobre los requisitos de tratamiento de aire para su

instralaci6n.

7

Page 22

Alineaci6n del condudo de ventilaci6n ¥ el ventilador

No se recomienda el uso de conductos flexibles pues podrian

impedir el fujo de aire. Si la salida del ventilador y la

ubicaci6n del conducto en la pared o en el suelo NO est6n

aNneadas, podria utilizar conductos flexibles de METAL para

favorecer la nivelaci6n.

6" MAX. de

dlferencia

entre el

centro de

arnbos

inferior de la encimera. Para evitar da_ar la encimera, NO

apriete demasiado el tornillo.

de suiecci6n \ _Das tarnillas con cabeza

ae sujecclon \ hexagonal #8-18 negros,

Un tarnilla con atornilladas a la plancha

cabeza Phillips LI

largo

Figura 15 - ATORNILLE LOS DOS SOPORTES

Parrilla de cocinar

Figura 13 - ALINEACI6N DELCONDUCTO DE

VENTILACI6N

Instalaci6n de la plancha

Levante la plancha por los bordes laterales tal y como se

muestra en la imagen.

Introduzca la plancha en el hueco de la encimera, col6quela

en la posici6n adecuada. Apoye la parte inferior y b6jela

cuidadosamente. Retire las manos de las esquinas, primero

una y luego la otra, hasta dejar la plancha en su ubicaci6n.

Figura 14 - INTRODUZCA LA PLANCHA EN EL HUECO

NOTA: NO utilice silicona RTV ni masilla para adherir la

plancha a la encimera.

TarniHas sumlnistradas :on cabeza

6 Tornillo

con la plancha PhiHips

Figura 16 - SOPORTES DE MONTAJE

Instalaci6n de la c6mara del ventHador en la plancha

Deslice la c6mara hacia el orificio del ventilador en la zona

inferior de la plancha.

Empuje la c6mara hasta que los railes de montaje de los

laterales de la misma toquen el fondo de la plancha. Instale

cuatro tornillos para chapa de metal (#8 x 3/8") para sujetar

Instale cuatro torniHos

con cabeza hexagonal

#8-18 negros.

/

Instalaci6n de los soportes de montaje

Retire los tornillos de la caja de la plancha y col6quelos para

sujetar el soporte de sujecci6n a la parte inferior de la caja.

Introduzca el tornillo en el soporte hasta que toque la parte

Figura 17-MODELO DE 30"

SUJETELA CAMARA A LA PLANCHA

Page 23

Instale cuatro tornillos con

cabeza he×agonal

#8-18 negros,

Uni6n del venfilador a la c_mara

Instaie cuatro tuercas con insertos de nii6n en los soportes dei

ventiiador, aiOsteJos Jo m_ximo posible. CoJoque eJ orificio de

descarga deJ ventiiador de forma que coincida con ei conducto

de ventiJaci6n. Deslice las tuercas en el laterai dei ventiiador de

manera que encaien en Jos orificios en eJ lateral de ia c_mara y

desJiceias en Jas ranuras. UtiJice una Have ingJesa o un trinquete

desde el interior de ia c_mara para aiustar ias tuercas.

I

I

I

Ficjura 17B- MODELO DE 36"

SUJETELA CAMARA A LA PLANCHA

Instalaci6n del conducto de transici6n del

venfilador

Sujete el conducto de transici6n a la salida del ventilador con

cuatro tornillos. Utilice cinta adhesiva para quede sellado.

Un tomillo en cada lado

Ficjura 19 - UNA EL VENTILADOR A LA CAMARA

Tomillos con cabeza Phillips

Ficjura 18 - UNA ELCONDUCTO DE TRANSICION AL

VENTILADOR

9 Ficjura 20 - UBICACION DE LASTUERCAS DENTRO DE

LA CAMARA

Page 24

Conexi6nel_ctricadelvenfilador

Conecte los cinco polos del conjunto del ventilador en el

recept6culo con cinco entradas en la parte inferior de la plancha.

Doble los cables y gu6rdelos dentro de la caja al final del tubo

del ventilador. Asegure la caja de cableado a la plancha con dos

tornillos #8 x 3/8", aseg6rese de no aprisionar ning6n cable.

Instalaci6n del regulador de presi6n

Instale el regulador de presi6n de forma que la flecha del

regulador se_ale hacia la unidad en una ubicaci6n que

permita acceder a la tapa de entrada.

_NO ajuste demasiado conexi6n.

regulador est6 fundido a presi6n. AI ajustarla demasiado se

_uede romper el regulador causando una fuga de gas y un

)osible incendio o explosi6n.

V61vula FLU, JO DE GAS Regulador

de cierre _ de presi6n

la El

Figura 21 - CONEXI6N DEL VENTILADOR A LA

PLANCHA

Conexi6n del conducto de venfilaci6n

Conecte el conducto de ventilaci6n, cuya instalaci6n se explico

en los pasos 8, 9 y 10, al conducto de transici6n del ventilador.

Cerrada

Conector

flexible Tapa de

entrada

Ajuste todas las uniones con una Ilave inglesa

Figure 22 - TUBERiADELSUMINISTRODEGAS

Monte el conector flexible del tubo del suministro de gas al

regulador de presi6n en el orden siguiente:

1. V61vula de cierre manual

2. Boquilla de 1/2" (1,3 cm)

3. Adaptator de 1/2" (1,3 cm)

4. Conector flexible

5. Adaptator de 1/2" (1,3 cm)

6. Boquilla de 1/2" (1,3 cm)

7. Regulador de presi6n

Utilice una junta de tubo dise_ada para el uso con gas natural

y propano para sellar todas las conexiones de gas. Si se utiNzan

conectores flexibles, aseg6rese que estos no est_n torcidos.

............ _j

Figura 22B- UNION DE LA TUBERJA DE GAS A LA

PLANCHA

10

Page 25

_EI tubo de suministro de gas debe induir

una v_lvula de cierre manual certificada. Esta v61vula debe

estar ubicada en la misma habitaci6n que la plancha de

coninar en un lugar que faciNte la apertura y el cierre. NO

bloque6 el acceso a la v61vula de cierre. La v_lvula sirve

para abrir o cerrar el paso de gas al electrodom_stico.

V_ivula de

cierre - Abierta

Figura 23 - VALVULA DE CIERRE

Con el regulador instalado, abra la v_lvula de la tuberia de

suministro de gas° Espere unos minutos para que el gas fluya

a trav6s de la tuberia.

_Cornpruebe si hay alguna fuga. Tras conectar la

plancha al suministro de gas, compruebe el sistema con un

man6metro. Si no cuenta con un man6metro, d6 la vuelta al

suministro de gas de la cocina y utilice un detector de fugas

I[quidas (o agua y ]ab6n) en todas las uniones y conexiones

para verificar si existen fugas.

Requisltos para el surninistro ei_ctrico

Un circuito derivado conectado correctamente a tierra de

120 voltios, 60 hercios protegido por un disyuntor de 15

amperios o un fusible de retardo. NO utiHce un alargador

el_.ctrlco para conectar este electrodom_sticoo

_ Instrucclanes para la conexi6n a tlerra

IMPORTANTE Lea estas instrucciones detenidamente.

Par razones de seguridad, este electrodom_.stico deber6

estar correctarnente conectado a tierra.

El cable el6ctrico de este electrodom_stico est6 equipado

con un enchufe con tres davijas (con toma de tierra) que

encaia con una toma de corriente para tres daviias (consulte

Figura 25) para reducir el riesgo de descargas el6ctricas.

P6ngase en contacto con un electricista cualificado para

comprobar el circuito y que la toma de corriente de pared

est_ correctamente conectada a tierra.

Si la Onica toma de corriente de pared al alcance es para

dos claviias, es su responsabilidad y obNgaci6n reemplazarla

por otra toma de corriente de pared para tres claviias que

est_ correctamente conectada a tierrao

M_todo recornendado

Toma de corriente NO cotter extralga

de pared o desvie la clavija

con conexi6n a de torna de tlerra

tierra ba]o ningOn

conceF

_NO use ningOn tipo de llama para

comprobar si hay fugas de gas. Esto podria causar un

incendio o una explosi6n.

_ Ajuste todas las conexlones si fuera necesario

para evitar fugas de gas en la pJancha o en la tuberia del

suministro.

Desconecte la plancha y su v61vula de clerre

manual individual del suministro de gas durante durante

cualquier ensayo de presi6n del sistema en ensayos de presi6n

superiores a 1/2 psig (3,5 kPa o columna de agua de 14").

m

Aisle la cocina del slsterna de tuberia del

surnlnlstro de gas, para ello, cierre la v_lvula de cierre

manual individual durante cualquier ensayo de presi6n del

sistema de suministro de gas en ensayos iguales o inferiores a

1/2 psig (3,5 kPa o de coiumna de agua de 14").

Cable el6ctrico con enchufe

con toma de tierra de tres

claviias

Figura 24 - CABLE DE SUMINISTRO ELECTRICO

NO carte o extraiga la clavlja de torna de tlerra del enchufe

bajo nlngOn conceptoo

_ Antes de Ilevar a cabo cualquier tarea de

mantenimiento, desconecte el cable de suministro el6ctrico de

la toma de corriente.

11

Page 26

Instalaci6n de las tapas de los quemadores,

A. Desembale las parrillas de los quemadores.

B. Quemadores: Desembale las cabezas y las tapas de los

quemadores. Coloque las cabezas de los quemadores y

las tapas en las bases correspondientes.

C. Verifique que las tapas est6n niveladas tras instalarlas.

D. Aseggrese de que todas las tapas y las cabezas de los

quemadores est6n correctamente situadas ANTES de

poner la plancha en funcionamiento.

Instalaci6n del filtro y de las rejillas

NO utilice el sistema de ventilaci6n sin haber colocado el filtro.

Coloque el filtro en posici6n diagonal

en la c6mara de ventilaci6n.

Aseggrese de que se queda apoyado,

en posici6n diagonal, en los soportes en

la apertura de ventilaci6n.

\ Fiffro de grasa\

C6mara de

ventilaci6n

C6mara de

ventilaci6n

I

/

/

f

/

• Coloque la bandeja de la rejilla de ventilaci6n sobre la

c6mara de ventilaci6n en la plancha, asegOrese de que el

lado con la marca FRONT est_ colocado hacia el frente.

Aseggrese de que el collarin de la parte inferior de la

bande]a se ha insertado en la apertura de ventilaci6n.

• Coloque la rejilla de ventilaci6n sobre la apertura de

ventilaci6n. Coloque las parrillas de los quemadores sobre

los quemadores.

Rejilla de

ventitaci6n

Bandeja de

la rejilla de

ventllaci6n

C6mara de

ventffaci6n

Figura 27

UBICACI6N DE LA REJILLA DE VENTJLACI6N Y LA

BANDEJA - MODELO DE 30"

_Ffftro de grasa

......'\\\\\

Figura 28

UBICACI6N DE LA REJILLA DE VENTILACI6N Y LA

BANDEJA - MODELO DE 36"

Figura 26

UBICACI6N DEL FILTRO - MODELO DE 36"

12

Page 27

Compruebe el funcionamiento

Consulte la Guia de uso y cuidado suministrada con este

electrodom_stico si desea obtener m6s informaci6n sobre

las instrucciones generales de funcionamiento, asi como

sugerencias de cuidado y limpieza.

Cuando se havan reallzado todas las conexiones

Aseg6rese de que todos los mandos de control est6n en la

posici6n OFF.

Aseggrese de que el flujo de combusti6n y de ventilaci6n de

aire de la plancha no est6n obstruidos.

_ Conecte el suminlstro el_.ctrlco y abra la v61vula de

clerre principal del gas

_ Compruebe los encendedores

Compruebe el funcionamiento de los encendedores tras

haber revisado detenidamente la plancha de cocinar y

los conectores del tubo del suministro para comprobar si

hay fugas y tras haber conectado el electrodom_stico al

suministro el6ctrico.

Para poner en funcionamiento los quemadores:

A. Presione y gire el mando de control hasta la posici6n

LITE. Escuchar6 un clic. El encendedor el6ctrico emite

este sonido al encender el quemador.

B. Cuando se haya encendido el quemador, gire el mando

de control hasta conseguir el tamaSo de llama deseado.

Los mandos NO tienen que estar en una posici6n en

particular. Utilice Jas marcas como guia y ajuste el

tamaSo de la llama seg6n Io necesite.

Antes de solicitar serviclo t_cnico

Lea la tabla de la secci6n antes de solicitar servicio t_cnico

y Jas instrucciones generales de funcionamiento en la Guia

de uso y culdado. Puede ahorrarle tiempo y dinero. Esta Jista

incluye situaciones comunes que no son el resultado de mano

de obra o materiales defectuosos en este electrodom6stico.

Consulte Ja garantia incluida en la Guia de uso y cuidado,

en ella encontrar6 el nOmero de tel6fono y direcci6n de

nuestro servicio t_cnico. No dude en Ilamar por tel6fono o en

escribirnos si tiene alguna duda sobre el electrodom_stico o

si necesita encargar alguna pieza.

13

Page 28

Tabla para calcular ia Iongitud del conducto

Para me]orar la eficiencia, intente que el conducto sea Io m6s corto y el recorrido Io m6s recto posible. Use el menor

nOmero de uniones posible. Para un rendimiento 6ptimo, el conducto no deberia exceder los cien pies de Iongitud.

Estos c61culos son aproximados y est6n basados en los est6ndares de la industria de la calefacci6n,

ventilaci6n y aire acondicionado.

PARTES DEL CONDUCTO EquivalenciaDE UNIDADES EQUIVALENCIA

6" (15,2 cm) Redondos rectos 1 pie (0,3 m) pies o m

6"

(15.2 crn)

flexible _

(_ 6" (15,2 cm) 10 (3 m)

(_ 6" (15,2 cm)

[__ x (8,2 cm x 25,4 cm) Recto 1 pie (0,3 m) pies o m

90 ° Codo

45 ° Codo 5 pies (1,5 m) pies o m

3V4" 10"

3V4" x 10" (8,2 cm x 25,4 cm)

Codo de 90 °

3V4" x 10" (8,2 cmx 25,4 cm)Codo de 45 ° 5 pies (1,5 m) pies o m

3V4" x 10" (8,2 cmx 25,4 cm)

Codo piano de 90 °

Redondo recto de metal

ALTURA X UTILIZADAS : DE ALTURA

1,5 pies (0,45 m) pies o m

pies pies

10

pies (3 m) pies

10

pies (3 m) pies

o m

o rn

o rn

6" (15,2 cm) Codos redondos de 30 pies (9 m) pies o m

3V4" x 10" (8,2 cmx 25,4 cm) a

transici6n de 90 °

transici6n 3V4" x 10" (8,2 cm x 25,4 cm) 30 pies (9 m) pies o m

6" (15,2 crn) Codo redondo de

de 90 °

31/4" x 10" (8,2 cm x 25,4 cm) a 6"

(15,2 cm) Redondos de transici6n 5 pies (1,5 m) pies o m

de transici6n 3V4" x 10" 5 pies (1,5 m) pies o m

6" (15,2 cm) Redondo

(8,2 cm x 25,4 cm)

(_ 6" (15,2 cm) Tapa redonda de pared

[_ 3V4" x 10" (8,2 cm x 25,4 cm)

_ Para el conducto redondo o rectangular, mida los pies utilizados y

multiplfquelos por Io Iogitud equivolente mostrodo.

con regulador 30 pies (9 m) pies o m

Tapa de pared con regulador 30 pies (9 m) pies o m

6" (15,2 cm) Tapa redonda de techo 30 pies (9 m) pies o m

MEDIDA TOTAL DEL CONDUCTO DE VENTILACKDN pies o m

14

Loading...

Loading...