Page 1

INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED iNSTALLER.

iMPORTANT: SAVE FOR LOCAL ELECTRICAL iNSPECTOR'S USE.

READ AND SAVE THESE iNSTRUCTiONS FOR FUTURE REFERENCE.

if the information in this manual is not followed e×acfly,

a fire or e×plosion may result causing property damage, personal

injury or death.

FOR YOUR SAFETY:

DO NOT store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

WHAT TO DO iF YOU SMELL GAS:

* DO NOT tw to light any appliance.

* DO NOT touch any electrical switch; DO NOT use any phone in

your building.

* Immediately call your gas supplier from a neighbor's phone.

Foffow the gas suppiier's instructions.

* if you cannot reach your gas supplier, cail the fire department.

installation and service must be performed by a qualified

installer, service agency or the gas supplier.

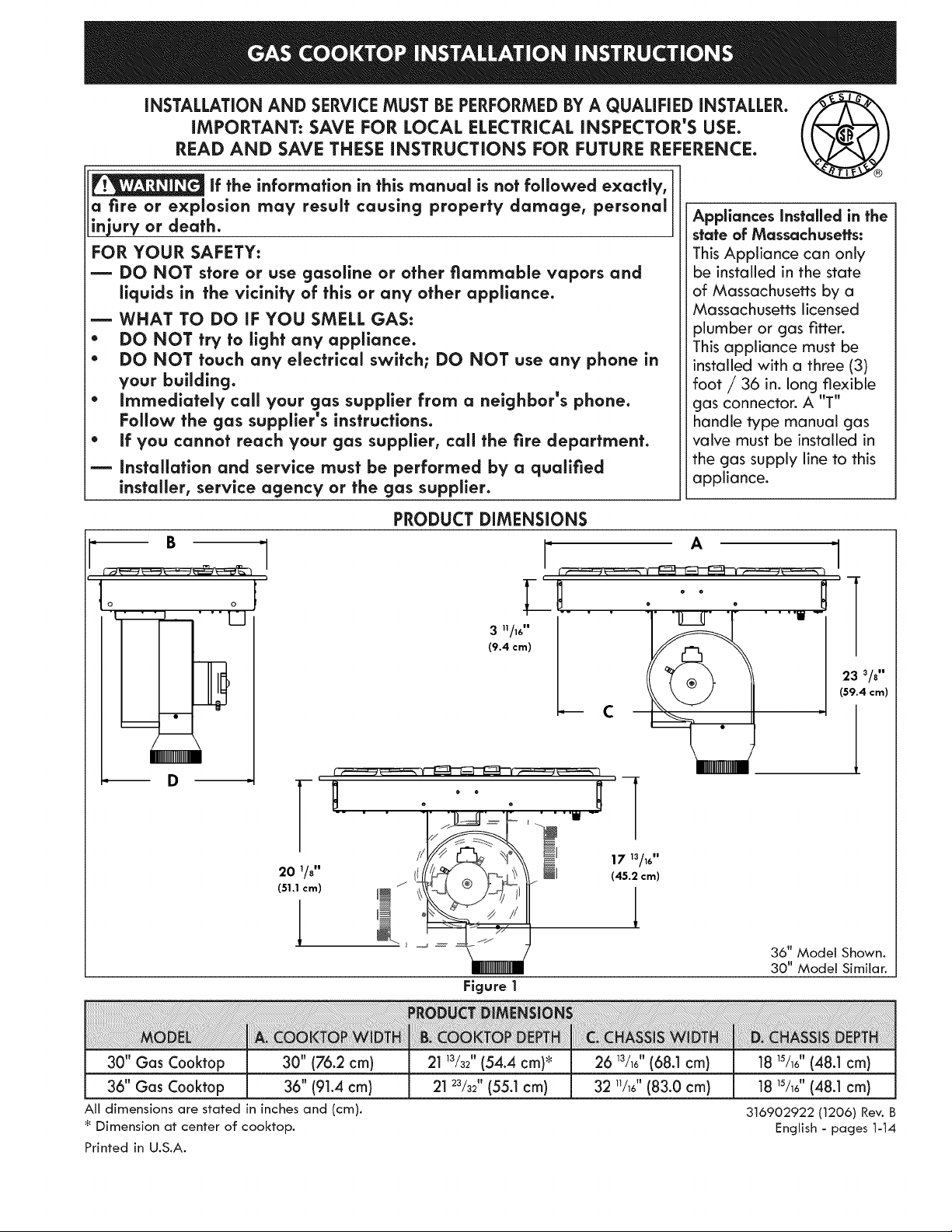

PRODUCT DIMENSIONS

B D

i

o o

Appliances Installed in the

state of Massachusetts:

This Appliance can only

be installed in the state

of Massachusetts by a

Massachusetts licensed

plumber or gas fitter.

This appliance must be

installed with a three (3)

foot / 36 in. long flexible

gas connector. A "T"

handle type manual gas

valve must be installed in

the gas supply line to this

appliance.

A

D

V

20 1/8"

(51.1 cm)

1

30" Gas Cooktop 30" (76.2 cm)

36" Gas Cooktop 36" (91.4 cm)

All dimensions are stated in inches and (cm).

Dimension at center of cooktop.

Printed in U.S.A.

3 11/16 n

(9.4 cm)

C

17 13/16"

(45.2 cm)

l

Figure |

21 _3/3_"(54.4 ¢rn)_ 26 _3/_6"(68.1 ¢m)

21 23/3_"(55.1 ¢m) 32 _/_6"(83.0 ¢m)

23 3/8"

(59.4 cm)

36" Model Shown.

30" Model Similar.

18 15/16"(48.1 cm)

18 15/16"(48.1 cm)

316902922 (1206) Rev. B

English - pages 1-14

Page 2

important Notes to the installer

1. Read all instructions contained in these

installation instructions before installing the

cooktop.

2. Remove all packing material before connecting

the electrical supply to the cooktop.

3. Observe all governing codes and ordinances.

4. Be sure to leave these instructions with the

consumer.

.

Note: For operation at 2000 ft. elevations

above see level, appliance rating shall be

reduced by 4 percent for each additional

1000 ft.

important Note to the Consumer

Keep these instructions with your Use and Care

Guide for future reference.

iMPORTANT SAFETY

iNSTRUCTiONS

Installation of this cooktop must conform

with local codes or, in the absence of local

codes, with the National Fuel Gas Code ANSI

Z223.1/NFPA 54 in the United States, or in

Canada, with the Canadian Fuel Gas Code,

CAN/CGA B149 and CAN/CGA B149.2.

• When installed in a manufactured (mobile)

home installation must conform with

the Manufactured Home Construction

and Safety Standard, title 24 CFR, part

3280 [Formerly the Federal Standard for

Mobile Home Construction and Safety,

title 24, HUD (part 280)] or, when such

standard is not applicable, the Standard

for Manufactured Home Installation, ANSI/

NCSBCS A225.1 or with local codes where

applicable.

This cooktop has been design certified by

Underwriters Laboratories (UL). As with any

appliance using gas and generating heat,

there are certain safety precautions you

should follow. You will find them in the Use

and Care Guide., read it carefully.

• Be sure your cooktop is installed and

grounded properly by a qualified installer

or service technician.

This cooktop must be electrically grounded

in accordance with local codes or, in their

absence, with the National Electrical Code

ANSI/NFPA No. 70--latest edition in

the United States, or in Canada, with the

Canadian Electrical Code, CSA C22.1 Part

1.

• The burners can be lit manually during an

electrical power outage. To light a burner,

hold a lit match to the burner head, then

slowly turn the Surface Control knob to

LITE. Use caution when lighting burners

manually.

DO NOT store items of interest

to children in cabinets above the cooktop.

Children could be seriously burned climbing

on the cooktop to reach items.

• To eliminate the need to reach over the

surface burners, cabinet storage space

above the burners should be avoided.

* Adjust surface burner flame size so it does

not extend beyond the edge of the cooking

utensil. Excessive flame is hazardous.

Never use your cooktop for

warming or heating the room. Prolonged use

of the cooktop without adequate ventilation

can be hazardous.

Storage on Appliance.

Flammable materials should not be stored

near surface units. This includes paper,

plastic and cloth items, such as cookbooks,

plasficware and towels, as well as flammable

liquids. DO NOT store explosives, such as

aerosol cans, on or near the appliance.

Flammable materials may explode and result

in flre or property damage.

The electrical power to the

cooktop must be shut off while gas line

connections are being made. Failure to do so

could result in serious injury or death.

Page 3

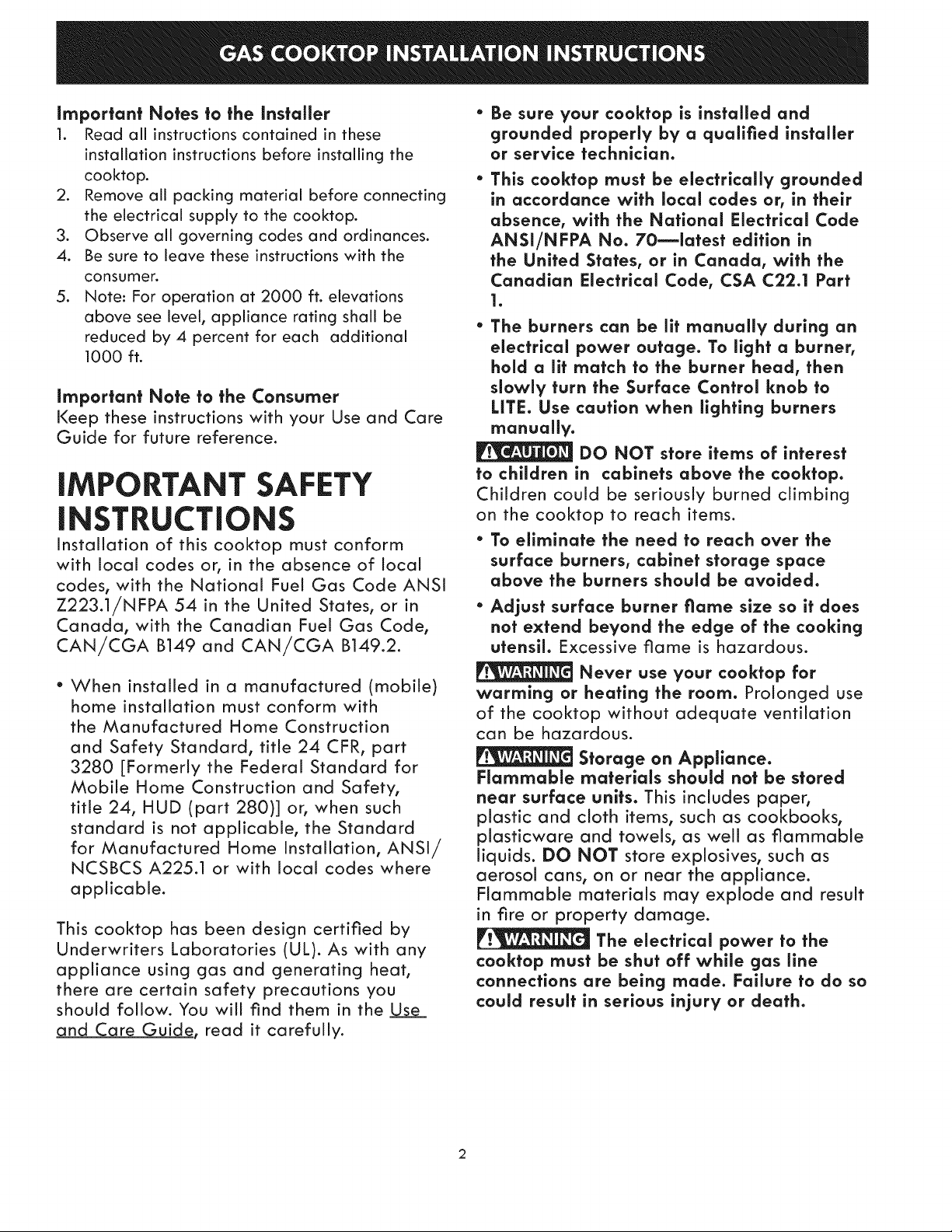

13" (33 cm)

Max. Depth

For Cabinet

installed

Above

Cooktop.

30" (76.2 cm) Min.

Clearance Between

the Top of the

Cooking Platform

and Unprotected

__detr Metal

Clearance

1 3/8" (3.5 cm) Minimum Flat

Distance from Cutout Edge.

i

24" Min.

(61cm)

1 3/8" (3.5 cm) Minimum Fiat

Distance from Cutout Edge.

Figure :2 - CABINET DESIGN

30" Cooktop _ 30" (76.2 cm) 9" (22.9 cm)

36" Cooktop 36" (91.4 cm) 9" (22.9 cm)

storage space located above the cooktop should be avoided.

[ _[__ To eliminate the risk of burns or fire from reaching over heated surfaces, cabinet

19 3/16" (49.2 cm)

19 3/16" (49.2 cm)

3

Page 4

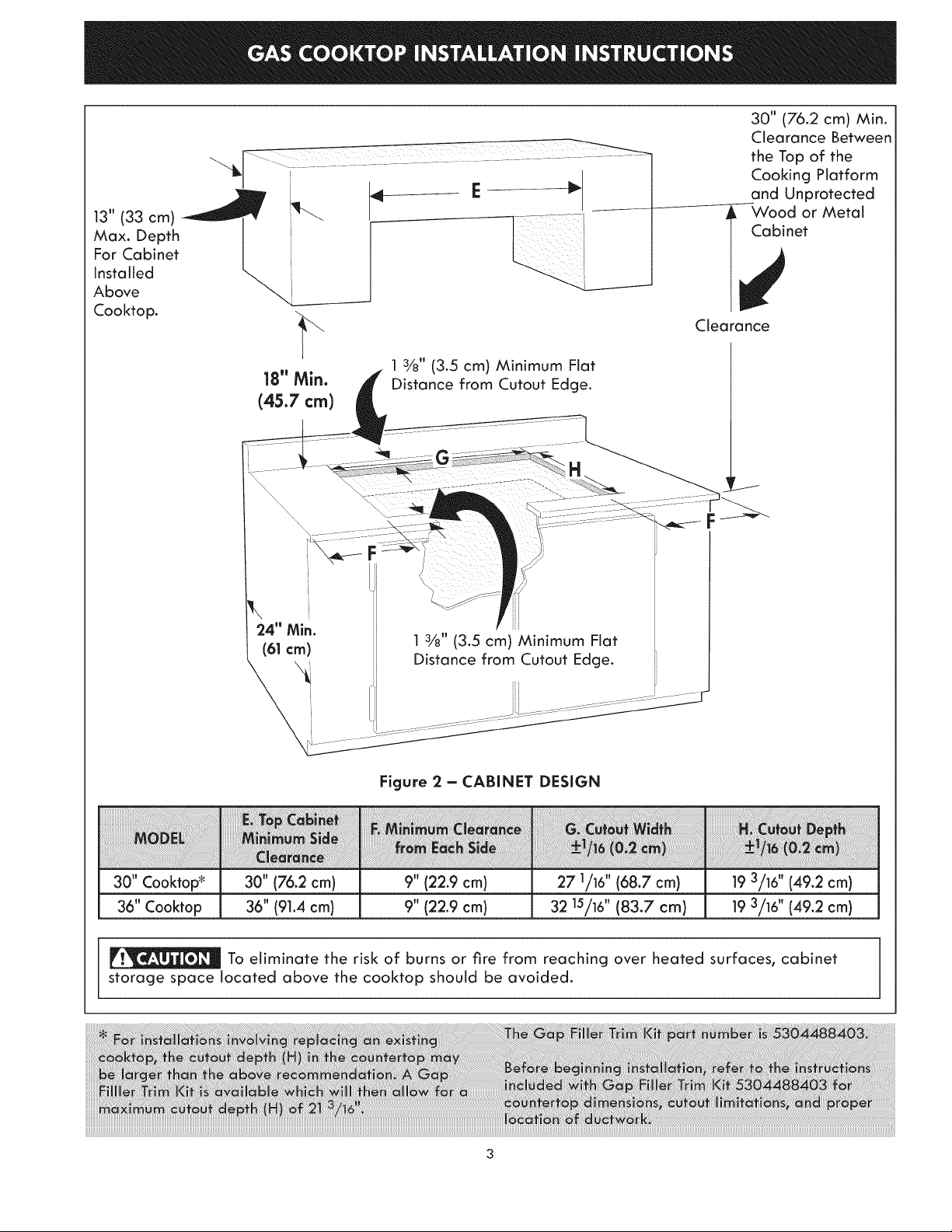

Required Tools for Installation

- Phillips Screwdriver

- 1/4" Nut driver / Ratchet

- 7/16" Nut driver / Ratchet

Supplied Hardware

Qty. Description

Used for

3

(8.3 cm)

cL

1 1II

(27.9 cm)

(4)

_) 1/4-20 Nylon Insert

(2)

(4)

(6)

7/16" Hex Nut

#8-18 Wide Head Transition Duct

Phillips Screw (fig. 18)

#8-18 Black Plenum and Wire

1/4" Hex Head Screw Box (fig. 17 & 21)

#10-24 3.5" Brackets

Long Phillips Screw (fig. 15 & 16)

Blower (fig. 20)

Countertop

(2) Hold Down Bracket (fig. 15 & 16)

Wall Outlet Location

Install the electric wall outlet within the shaded area.

cL

I _I 11 1/2"

6" 8

(15.2 cm) (22.2 cm)

I_ 3/4-, (29.2 cm)

Recommended I

Gas Supply [

Stub Area ]

r_

Figure 3B - 30" MODEL

ELECTRICALOUTLET INSTALL DIMENSIONS

Provide an Adequate Gas Supply

This cooktop is designed to operate on natural gas at 4"

of manifold pressure only.

A pressure regulator must be connected

in series with the manifold on the cooktop and must

remain in series with the supply line.

For proper operation, the maximum inlet pressure to the

regulator must be no more than 14" of water column

(W.C.) pressure.

For checking the regulatob the inlet pressure must be at

least 1" (or 2.5 kPa) greater than the regulator manifold

pressure setting. The regulator is set for 4" of manifold

pressure, the inlet pressure must be at least 5".

The gas supply line to the range should be 1/2" or 3/4"

pipe.

Figure 3A - 36" MODEL

ELECTRICALOUTLET INSTALL DIMENSIONS

Page 5

LP/Propane Gas Conversion

This appliance can be used with Natural gas or LP/

Propane gas. It is shipped from the factory for use with

natural gas.

A kit for converting to LP gas is supplied with your

cooktop. The kit is marked "FOR LP/PROPANE GAS

CONVERSION".

The conversion must be performed by a qualified

service technician in accordance with the kit instructions

and all local codes and requirements. Failure to follow

instructions could result in serious injury or property

damage. The qualified agency performing this work

assumes responsibility for the conversion.

Failure to make the appropriate

conversion can result in serious personal injury and

property damage.

NOTE: Purchase a new flexible line. DO NOT USE

AN OLD PREVIOUSLY USED LINE.

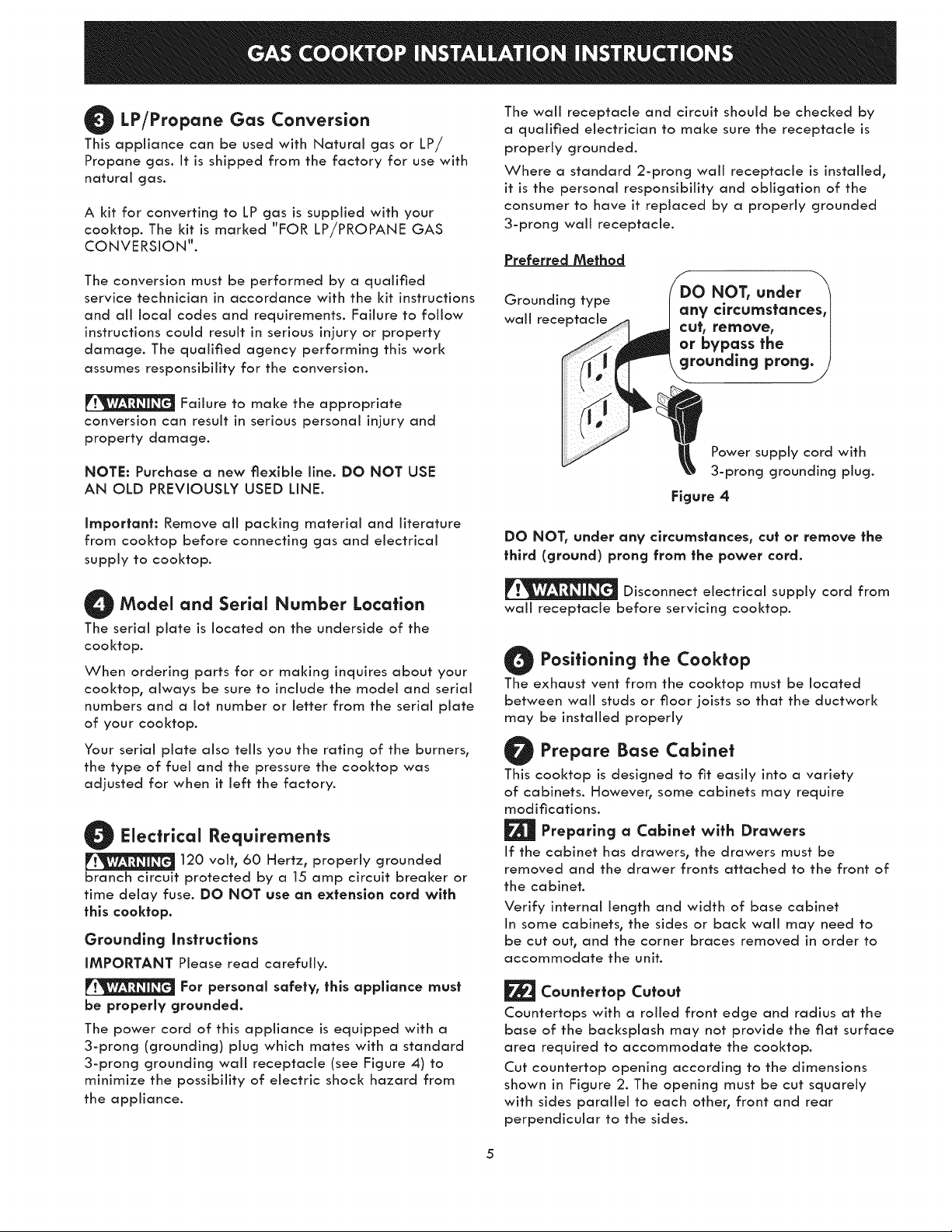

The wall receptacle and circuit should be checked by

a qualified electrician to make sure the receptacle is

properly grounded.

Where a standard 2-prong wall receptacle is installed,

it is the personal responsibility and obligation of the

consumer to have it replaced by a properly grounded

3-prong wall receptacle.

Preferred Method

Grounding type

wall receptacle

NOT, under -_

any circumstances, I

cut, remove, |

or bypass the |

grounding prong.J

Power supply cord with

3-prong grounding plug.

Figure 4

Important: Remove all packing material and literature

from cooktop before connecting gas and electrical

supply to cooktop.

Model and Serial Number Location

The serial plate is located on the underside of the

cooktop.

When ordering parts for or making inquires about your

cooktop, always be sure to include the model and serial

numbers and a lot number or letter from the serial plate

of your cooktop.

Your serial plate also tells you the rating of the burners,

the type of fuel and the pressure the cooktop was

adjusted for when it left the factory.

Electrical Requirements

120 volt, 60 Hertz, properly grounded

branch circuit protected by a 15 amp circuit breaker or

time delay fuse. DO NOT use an extension cord wlfh

fhls cooklop.

Grounding Instructions

IMPORTANT Please read carefully.

For personal safety, thls appliance must

be properly grounded.

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

3-prong grounding wall receptacle (see Figure 4) to

minimize the possibility of electric shock hazard from

the appliance.

DO NOT, under any circumstances, cut or remove the

third (ground) prong from the power cord.

_ Disconnect electrical supply cord from

wall receptacle before servicing cooktop.

Positioning the Cooktop

The exhaust vent from the cooktop must be located

between wall studs or floor joists so that the ductwork

may be installed properly

Prepare Base Cabinet

This cooktop is designed to fit easily into a variety

of cabinets. However, some cabinets may require

modifications.

Preparing a Cabinet with Drawers

If the cabinet has drawers, the drawers must be

removed and the drawer fronts attached to the front of

the cabinet.

Verify internal length and width of base cabinet

In some cabinets, the sides or back wail may need to

be cut out, and the corner braces removed in order to

accommodate the unit.

F_ Counfertop Cutout

Countertops with a rolled front edge and radius at the

base of the backsplash may not provide the fiat surface

area required to accommodate the cooktop.

Cut countertop opening according to the dimensions

shown in Figure 2. The opening must be cut squarely

with sides parallel to each other, front and rear

perpendicular to the sides.

5

Page 6

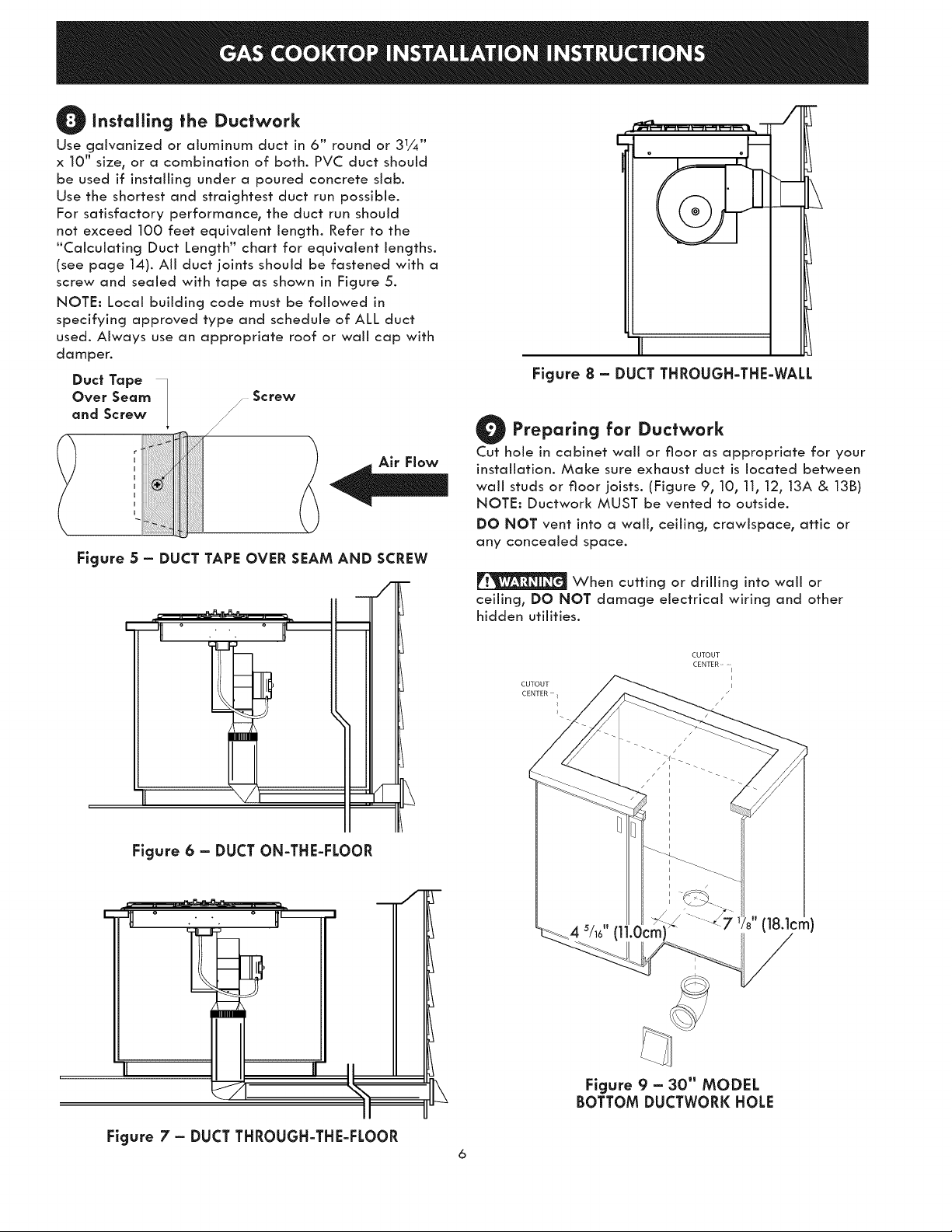

Installing the Ductwork

Use galvanized or aluminum duct in 6" round or 31/4"

x 10" size, or a combination of both. PVC duct should

be used if installing under a poured concrete slab.

Use the shortest and straightest duct run possible.

For satisfactory performance, the duct run should

not exceed 100 feet equivalent length. Refer to the

"Calculating Duct Length" chart for equivalent lengths.

(see page 14). All duct joints should be fastened with a

screw and sealed with tape as shown in Figure 5.

NOTE: Local building code must be followed in

specifying approved type and schedule of ALL duct

used. Always use an appropriate roof or wail cap with

damper.

Duct Tape

Over Seam

and Screw

r

I

I

I

I

I

Figure 5 - DUCT TAPE OVER SEAM AND SCREW

Jll o . . o

j Screw

J

'l_J'

Figure 8 - DUCT THROUGH-THE-WALL

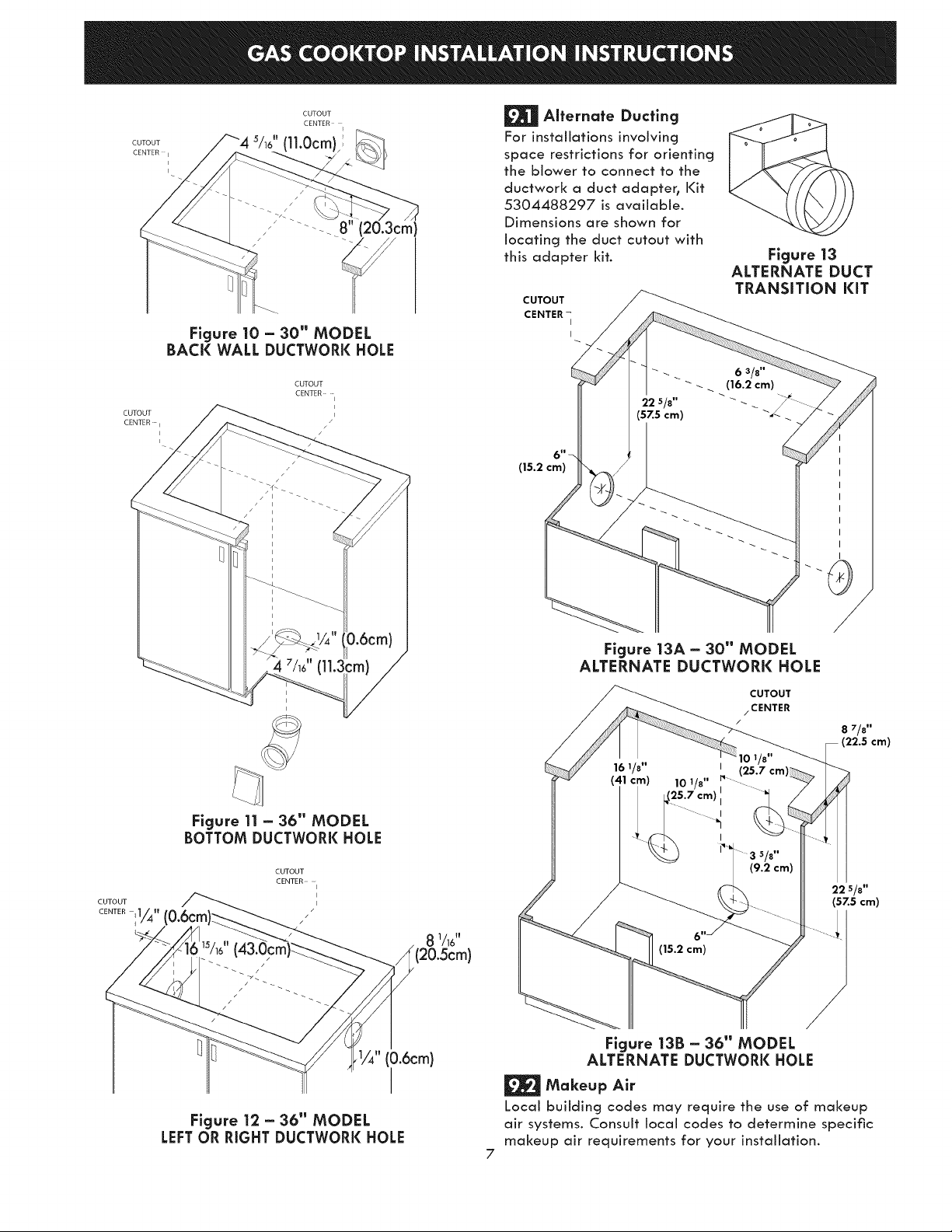

Preparing for Ductwork

Cut hole in cabinet wall or floor as appropriate for your

installation. Make sure exhaust duct is located between

wall studs or floor joists. (Figure 9, 10, 11, 12, 13A & 13B)

NOTE: Ductwork MUST be vented to outside.

DO NOT vent into a wail, ceiling, crawispace, attic or

any concealed space.

When cutting or drilling into wail or

ceiling, DO NOT damage electrical wiring and other

hidden utilities.

CUTOUT

CENTER I

%

\/i

Figure 6 - DUCT ON-THE-FLOOR

Figure 7 - DUCT THROUGH-THE-FLOOR

Figure 9 - 30" MODEL

BOTTOM DUCTWORK HOLE

Page 7

CUTOUT

CENTER

(ll.Ocm);

/.

Figure 10 - 30" MODEL

BACK WALL DUCTWORI{ HOLE

CUTOUT

CENTER I

Alternate Ductlng

For installations involving

space restrictions for orienting

the blower to connect to the

ductwork a duct adapter, Kit

5304488297 is available.

Dimensions are shown for

locating the duct cutout with

this adapter kit.

CUTOUT

CENTER

I

I

(15.2 cm)

Figure 13

ALTERNATE DUCT

TRANSITION KiT

i

i

Figure 11 - 36" MODEL

BOTTOM DUCTWORK HOLE

CUTOUT

CENTER- -

I

Figure 12 - 36" MODEL

LEFT OR RIGHT DUCTWORK HOLE

Figure 13A - 30" MODEL

ALTERNATE DUCTWORK HOLE

CUTOUT

/CENTER

....3 s/s"

(9.2 cm)

6 I

(15.2 cm)

Figure 13B - 36" MODEL

ALTERNATE DUCTWORI{ HOLE

Makeup Air

Local building codes may require the use of makeup

air systems. Consult local codes to determine specific

makeup air requirements for your installation.

7

8 7/8"

22 5/8'1

(57.5 cm)

Page 8

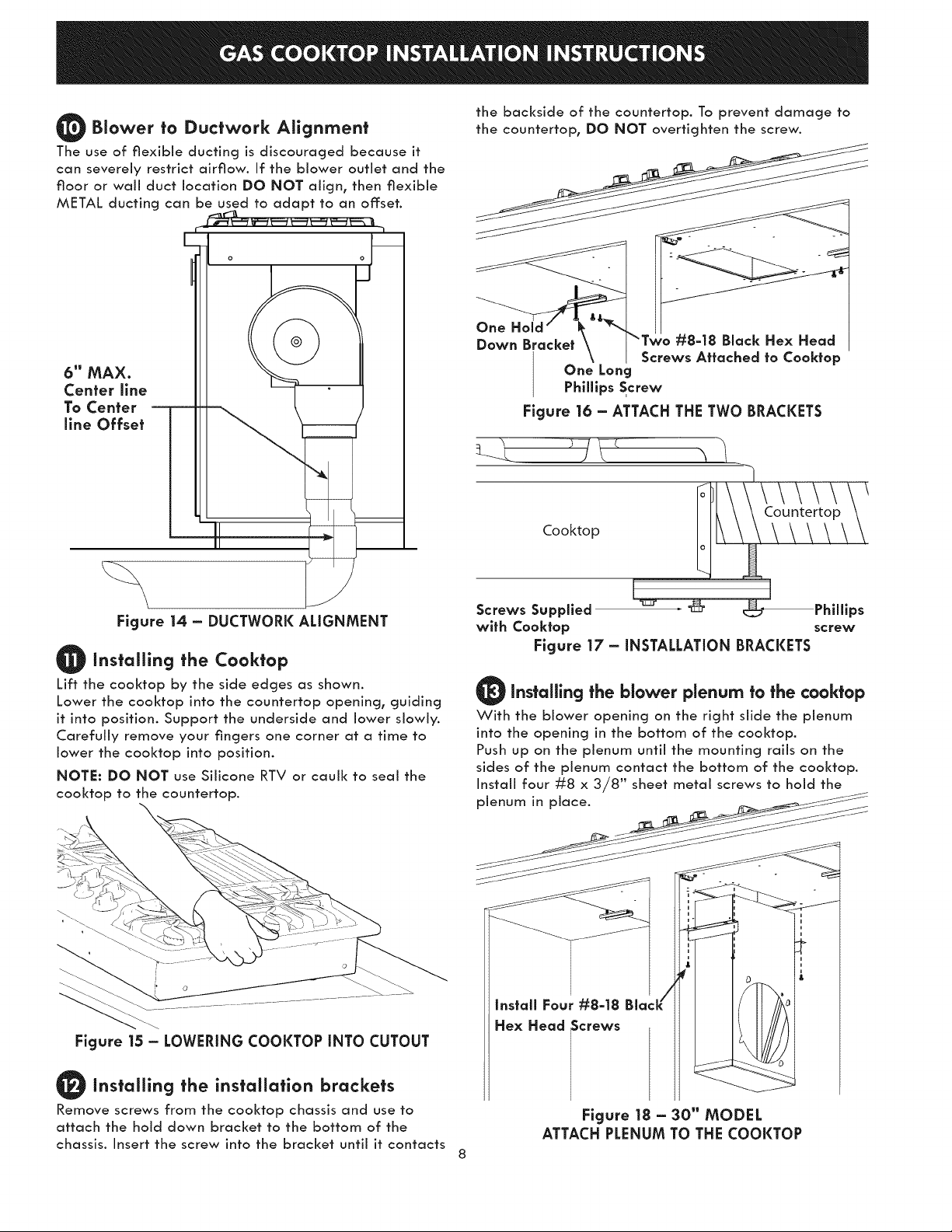

Blower to Dudwork Alignment

The use of flexible ducting is discouraged because it

can severely restrict airflow. If the blower outlet and the

floor or wall duct location DO NOT align, then fexible

METAL ducting can be used to adapt to an offset.

the backside of the countertop. To prevent damage to

the countertop_ DO NOT overfighten the screw.

""T_ #8-18 Black Hex Head

Screws Attached to Cooktop

One Long

Philllps Screw

Figure 16 - ATTACH THE TWO BRACKETS

Cooktop

Figure 14 - DUCTWORK ALIGNMENT

Installing fhe Cookfop

Lift the cooktop by the side edges as shown.

Lower the cooktop into the countertop opening_ guiding

it into position. Support the underside and lower slowly.

Carefully remove your fingers one corner at a time to

lower the cooktop into position.

NOTE: DO NOT use Silicone RTV or caulk to seal the

cool<top to the countertop.

Figure 15 - LOWERING COOKTOP INTO CUTOUT

L_

Screws Supplied -_r 6 ps

with Cooktop screw

Figure 17- INSTALLATION BRACKETS

Installing fhe blower plenum fo fhe cooktop

With the blower opening on the right slide the plenum

into the opening in the bottom of the cooktop.

Push up on the plenum until the mounting rails on the

sides of the plenum contact the bottom of the cooktop.

Install four _8 x 3/8" sheet metal screws to hold the

installing fhe installation brackefs

Remove screws from the cooktop chassis and use to

attach the hold down bracket to the bottom of the

chassis. Insert the screw into the bracket until it contacts

Figure 18- 30" MODEL

ATTACH PLENUM TO THE COOKTOP

Page 9

.... _s_ -__ ............

I

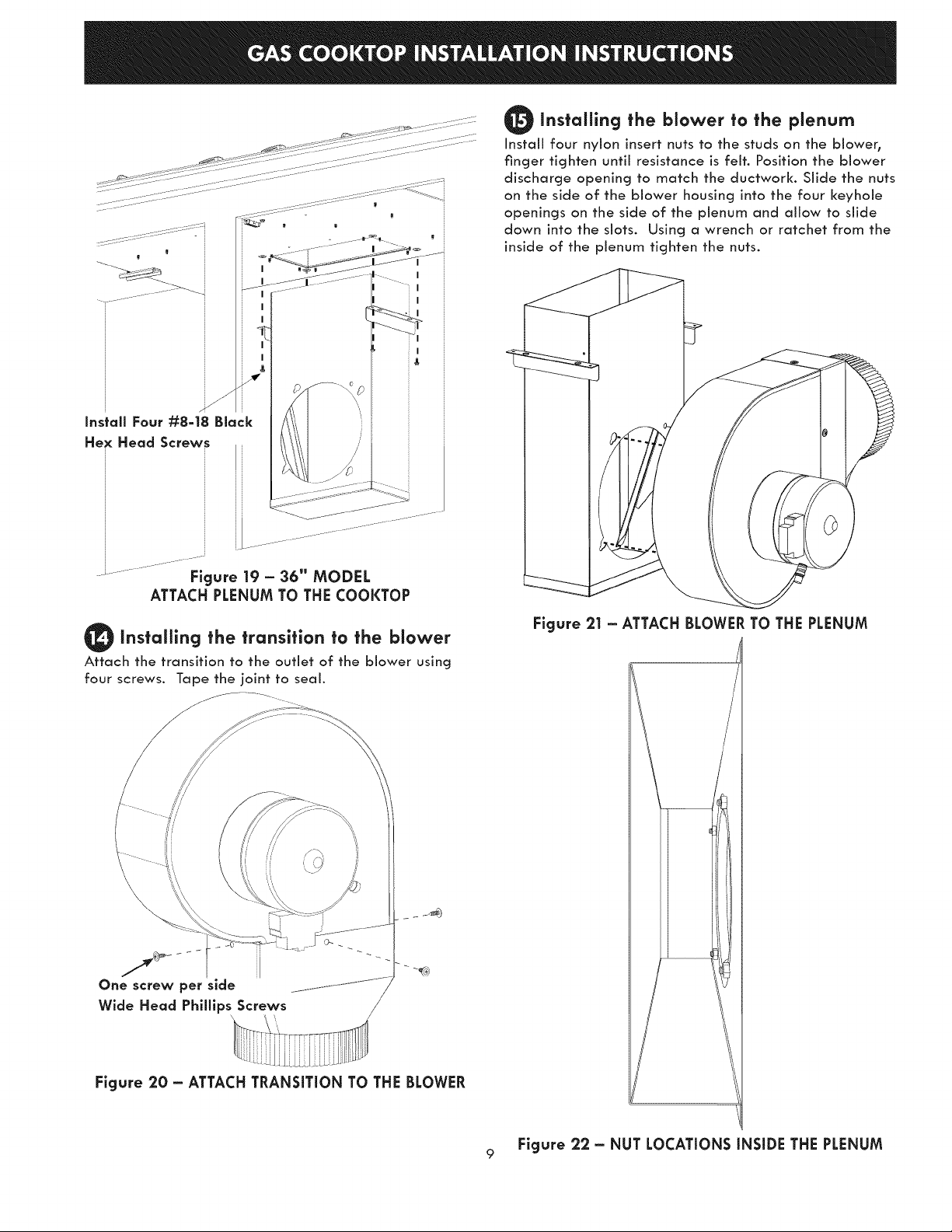

Installing fhe blower fo fhe plenum

Install four nylon insert nuts to the studs on the blower,

finger tighten until resistance is felt. Position the blower

discharge opening to match the ductwork. Slide the nuts

on the side of the blower housing into the four keyhole

openings on the side of the plenum and allow to slide

down into the slots. Using awrench or ratchet from the

inside of the plenum tighten the nuts.

Figure 19 - 36" MODEL

ATTACH PLENUM TO THE COOKTOP

installing the fransifion to the blower

Attach the transition to the outlet of the blower using

four screws. Tape the joint to seal.

One screw per side

Wide Head Phillips Screws

Figure 21 - ATTACH BLOWER TO THE PLENUM

Figure 20 - ATTACH TRANSITION TO THE BLOWER

9 Figure 22 - NUT LOCATIONS INSIDE THE PLENUM

Page 10

Blower electrical connection

Connect the 5-pin plug on the blower assembly to

the matching 5-pin receptacle on the bottom of the

cooktop.

Install Pressure Regulator

Install the pressure regulator with the arrow on the

regulator pointing up toward the unit in a position

where you can reach the access cap.

Fold all wires into the wire box on the end of the blower

conduit. Fasten the wire box to the cooktop with two #8

x 3/8" making sure that no wires are trapped.

Figure 23 - CONNECT BLOWERTO COOKTOP

Connecting the Ductwork

Connect the ductwork prepared in Steps 8, 9 and 10 to

the blower transition duct.

_DO NOT make the connection too

tight. The regulator is die cast. Overtightening may

crack the regulator resulting in a gas leak and possible

fire or explosion.

Manual GAS FLOW Pressure

Shutoff Flare _ Flare Regulator

Valve Union Union

Off Connector

All connections must be wrench-tightened

Figure 24 - GAS SUPPLY LiNE

Assemble the flexible connector from the gas supply

pipe to the pressure regulator in the following order:

1. manual shutoff: valve

2. 1/2" (1.3 cm) nipple

3. 1/2" (1.3 cm) flare union adapter

4. flexible connector

5. 1/2" (1.3 cm) flare union adapter

6. 1/2" (1.3 cm) nipple

7. pressure regulator

Use pipe-joint compound made for use with Natural

and LP/Propane gas to seal all gas connections. If

flexible connectors are used, be certain connectors are

not kinked.

Access

Cap

Figure 25 - PHYSICAL ATTACHMENT OF THE GAS

LINE TO THE COOKTOP

lO

Page 11

_The supply line must be equipped with

an approved manual shutoff valve. This valve should be

located in the same room as the cooktop and should be

in a location that allows ease of opening and closing.

DO NOT block access to the shutoff valve. The valve is

for turning on or shutting off gas to the appliance.

Shutoff Valve =

Open position

Figure 26 - SHUTOFF VALVE

Once regulator is in place, open the shutoff valve in the

gas supply line. Wait a few minutes for gas to move

through the gas line.

_ Check for leaks. After connecting the cool<top

to the gas supply, check the system for leaks with a

manometer. If a manometer is not available, turn on the

gas supply and use a liquid leak detector (or soap and

water) at all joints and connections to check for leaks.

Electrical Requirements

120 volt, 60 Hertz, properly grounded branch circuit

protected by a 15 amp circuit breaker or time delay

fuse. DO NOT use an extension cord with this cooktop.

| Grounding instructions

iMPORTANT Please read carefully.

For personal safety, this appilance must be properly

grounded.

The power cord of this appliance is equipped with a

3=prong (grounding) plug which mates with a standard

3=prong grounding wall receptacle (see Figure 27) to

minimize the possibility of electric shock hazard from

the appliance.

The wail receptacle and circuit should be checked by

a qualified electrician to make sure the receptacle is

properly grounded.

Where a standard 2=prong wail receptacle is installed,

it is the personal responsibility and obligation of the

consumer to have it replaced by a properly grounded

3=prong wall receptacle.

Preferred Method

Grounding type

wall receptacle

NOT, under _

any circumstances, I

cut, remove, |

or bypass the |

grounding prong.J

_J__ DO NOT use a flame to check for

leaks from gas connections. Checking for leaks with a

flame may result in a fire or explosion.

| Tighten all connections if necessary to prevent

gas leakage in the cooktop or supply line.

Disconnect this cooktop and its indivldual

manual shutoff valve from the gas supply piping

system during any pressure testing of that system at test

pressures greater than 1/2 psig (3.5 kPa or 14"water

column).

isolate the cooktop from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or Jess than 1/2

psig (3.5 kPa or 14" water column).

Power supply cord with

3=prong grounding plug.

Figure 27 - POWER SUPPLYCORD

DO NOT, under any circumstances, cut or remove the

third (ground) prong from the power cord.

_ Disconnect electrical supply cord from

wall receptacle before servicing cooktop.

11

Page 12

install Burner Caps

A. Unpack the burner grates.

B. Burners: Unpack the Burner heads and burner caps.

Place the burner heads and caps on the matching

bases.

C. The caps should be level after installation

D. Be sure that all the burner caps burner head are

correctly placed BEFORE using your cooktop

install Filter, Vent Grate Seal and Grates

Carefully place vent grate seal over the vent chamber

on the cooktop as shown in Figures 30 - 31. Maize sure

the collar on the bottom of the seal is fully inserted

into the vent opening. Remove the 1/4" hex head

screw located in the vent chamber underneath the tab

on the vent grate seal. Bend the tab on the vent grate

seal down into the vent chamber and secure it with the

hex head screw.

• Place the filter diagonally through

the vent chamben

• Maize sure it rests, at an angle, on

the supports in the vent opening.

Grease Filler

\ \

nf

Chamber

Figure 28

VENT FILTER LOCATION - 30" M(

Venf Chamber

Vent

Grate

Seal

Figure 30

VENT GRATE SEAL ATTACHMENT - 30" MODEL

Ven,'

Grate _

Seal

)DEL

Vent

Chamber .......

Grease Filler

Figure 29

VENT FILTER LOCATION - 36" MODEL

Hex Screw

Figure 31

VENT GRATE SEAL ATTACHMENT - 36" MODEL

12

Page 13

PIocetheventgroteontopoftheventgroteseol_over

theventopening.Piocetheburnergratesoverthe

burners.

Vent

Grate

Check Operation

Refer to the Use and Care Guide packaged with the

cooktop for operating instructions and for care and

cleaning of your cooktop.

_Turn on EJectrlca_ Power and Open Main Shutoff

Gas Valve

Vent Grate

Seal

Figure 32

VENT GRATE AND SEALLOCATION - 30" MODEL

Vent Grate

Vent

Grate

Seal

Figure 33

VENT GRATE AND SEAL LOCATION - 36" MODEL

r_'_'_ Check [he I{::jni|ers

Operation of electric igniters should be checked after

cooktop and supply line connectors have been carefully

checked for leaks ond the cooktop hos been connected

to electric power.

To opera|e the surface burner:

A. Push in and turn o surface burner knob to the LITE

position. You will hear o small ticking noise; this

is the sound of the electric ignitor which lights the

burner.

B. After the burner lights, turn to the desired flame

size. The controls DO NOT have to be set at o

particular mark. Use the marks as o guide and

adjust the flame as needed.

When All Hookups are Complete

Make sure oil controls ore left in the OFF position.

Make sure the flow of combustion and ventilation air to

the cooktop is unobstructed.

Before You Call for Service

Read the Before You Coil for Service Checklist and

operating instructions in your Use and Care Guide.

It may save you time and expense. The list includes

common occurrences that ore not the result of defective

workmanship or materials in this appliance.

Refer to the warranty in your Use and Care Guide for

our service phone number ond address. Please coil or

write if you have inquiries about your product and/or

need to order parts.

13

Page 14

Calculating Duct Length Table

For maximum ef_ciency, use the shortest and straightest duct possible. Use as few fittings as

possible. For best performance_ the duct run should not exceed 100 feet of equivalent length.

Calculations are approximate and based on HVAC industry standards.

DUCT PIECES EQUIVALENT NUMBER EQUIVALENT

(_ 6" (15.2cm) RoundStraight _ 1 Ft. (0.3m) Ft. or m

_) 6" (15.2cm) Round Metal Flex

(_ 6" (15.2cm)

(_ 6" (15.2cm)

No Bends _ 1.5 Ft. (0.45m) Ft. or m

90 ° Elbow 10 Ft. (3m) Ft. or m

45 ° Elbow 5 Ft. (1.5m) Ft. or m

31/4" x 10" (8.2cm x 25.4cm)

Straight _ 1 Ft. (0.3m) Ft. or m

31/4" x 10" (8.2cm x 25.4cm)

90 ° Elbow 10 Ft. (3m) Ft. or m

31/4" x 10" (8.2cm x 25.4cm)

45 ° Elbow 5 Ft. (1.5m) Ft. or m

31/4" x 10" (8.2cm x 25.4cm)

90 ° Flat Elbow 10 Ft. (3m) Ft. or m

LENGTH X USED : LENGTH

to 6" (15.2cm) Round Transition 30 Ft. (9m) Ft. or m

31/4" x 10" (8.2cm x 25.4cm)

90 ° Elbow

(8.2cm x 25.4cm) Transition 30 Ft. (9m) Ft. or m

6" (15.2cm) Round to 31/4" X 101'

90 ° Elbow

31/4'' x 10" (8.2cm x 25.4cm) to 5 Ft. (].5m) Ft. or m

6" (15.2cm) Round Transition

¢:_ 6" (15.2cm) Round to 31/4" x 10"

[_ 30 Ft. (9m) Ft. or m

_ For Straight Round / Rectangular Duct° measure actual linear

feet used and then multiply by Equivalent Length shown.

(8.2cm x 25.4cm) Transition 5 Ft. (].5m) Ft. or m

6"

(15.2cm)

with Damper

31/4" 10"

WaN Cap with Damper

6"

(15.2cm) Round Roof Cap 30 Ft. (9m) Ft. or m

Round Wall

(8.2cm

Cap

30 Ft. (9m) Ft. or m

25.4cm)X X

TOTAL DUCTWORK Ft. or m

14

Page 15

LAINSTALACIONYELSERVICIODEBENSERREALIZADOSPORUN INSTALADORCALIFICADO.

IMPORTANTE: CONSERVE ESTASINSTRUCCIONES PARAEL USO POR PARTEDEL iNSPECTOR DE

INSTALACIONES ELF:CTRICASLEAY GUARDE ESTAS INSTRUCCIONES PARAREFERENCIA EN ELFUTURO.

_Si no se cumplen estrlctamente las instrucclones y los avlsos informafivos

contenldos en este manual, podrian produclrse incendlos y e×ploslones que causen da_os

a blenes, leslones personales y hasta la muerte°

PARA SU SEGURIDAD:

NO almacene nl ufillce gasollna nl otros liquldos inflamabies (y los vapores de

dlchos materlales) en las cercanias de este nl de nlngOn otto electrodom_stl¢o,

QUE DEBE HACER Si HAY OLOR A GAS:

® NO utlllce nlngOn electrodom_stl¢o,

® NO toque nlng6n interruptor el_ctrlco; NO utlllce nlng6n tel_fono en nlng6n lugar

de la edfficaci6n.

® Comuniquese de inmedlato con su proveedor de gas desde la casa de un veclno°

Siga las instrucclones que le d_ el proveedor de gas°

® Si no puede comunlcarse con su proveedor de gas, flame al departamento de

bomberos,

La insfalaci6n Y el servlclo de este electrodom_stl¢o deben set reallzados pot

un instalador/representante, una agencla de servlclo o un representante de la

¢ompa_a proveedora de gas, que ¢uenten con las ¢erffficaclones ¢orrespondlentes°

DiMENSiONES DELPRODUCTO

- B -

i

o o

Electrodom_sticos instalados en

el estado de Massachuseffs:

este electrodom_sfico solo puede

ser instalado en el estado de

Massachusetts por un plomero

o un t6cnico especiaiista en

instalaciones de gas certiflcado

por el estado de Massachuseffs.

Este eiectrodom6sfico se debe

instaiar con el uso de un conector

flexible de gas de 3 ff (36 in)

de Iongitud. Se debe instalar

una v6ivuia manual del fipo

de asa en "T" en la tuberia de

alimentaci6n conectada a este

electrodom6stico.

A

D

20 1/8" I/

(51.1cm) J

Estufade gas de 30 in 30 in(76,2 cm)

Estufade gas de 36 in 36 in (91,4cm)

Todas las dimensiones se indican en pulgadas (cm).

Dimensi6n en el centro de la estufa.

Impreso en los EE. UU.

3 11/16 wl

(9.4 cm)

C

17 lz/16wl

(45.2 cm)

1

Se muestra el modelo de 36 pulgadas

El modelo de 30 pulgadas es similar

Figura |

2113/32in(54,4 cm)_ 2613/16in(68,1cm)

2123/32in(55,1cm) 32 11/16in (83,0 cm)

23 3/8"

(59.4 cm)

1815/16in (48,1cm)

1815/16in (48,1cm)

316902922 (1206) Rev.B

Espa_ol - p6ginas 1-14

Page 16

Notas importaintes para el iinstaiador

1. Lea toda la informaci6n contenida en estas

instrucciones de instalaci6n antes de instalar la

estufao

2. Retire de la estufa todo el material de

embalaje antes de conectar las alimentaciones

de gas y de electricidad a la estufa.

3. Cumpla con todos los c6digos y ordenanzas

que rigen en su Iocalidad.

4. AsegOrese de dejar estas instrucciones en

manos del propietario de la estufa.

5. Nora: si la estufa se opera a elevaciones

mayores de 2000 ft (600 m) par encima del

nivel del mar, se reduce la capacidad nominal

de la estufa en un 4 par ciento par cada 1000

ft (300 m) adicionales

Notas impartaintes para el prapietarlo de la estufa

Conserve estas instrucciones junto con la gu_a de usa

y cuidado para referencia en el futuro.

INSTRUCCIONES

IMPORTANTES PARA LA

SEGURIDAD

La instalaci6n de esta estufa debe hacerse en

conformidad con los c6digos vigentes en ta

localidad, yen caso de que no existan dichos

c6digos, en conformidad con el C6digo National

de Gas Combustible ANSI Z223.1/NFPA 54 si se

encuentra en los Estados Unidos, o en conformidad

con el C6digo Canadiense de Gas Combustible,

CAN/CGA B149 y CAN/CGA B149.2 si se

encuentra en Canad6.

* Cuando la instataci6n se haga en una casa

prefabricada (rodante), la instalaci6n se debe

hater en conformidad con ta norma fituto 24

CFR, parte 3280 de ta Manufactured Home

Construction and Safety, [anteriormente la

norma fituto 24, HUD (parte 280) det Federal

Standard for Mobile Home Construction

and Safety] o, cuando dicha norma no sea

pertinente, en conformidad con la norma ANSI/

NCSBCS A225.1 del Standard for Manufactured

Home Installation, o cuando corresponda, en

conformidad con los c6digos locales.

El diseho de esta estufa cuenta con ta certificaci6n

de los taboratorios Underwriters Laboratories (UL).

At igual que en todo electrodom6stico que utilice

gas y genere calor, existen varias precauciones de

seguridad que se deben cumptir. Las encontrar6

en la Guia de usa y cuidado, y debe leerlas

atentamente.

• Aseg_rese de que su estufa haya sldo iinstalada

y coinectada correctameinte a tlerra par uin

iinstalador o uin t_cinlco cali_cada de servlcla.

Esta estufa se debe conectar el_ctrlcameinte a

tlerra ein cainfarmidad coin los c6digas locales,

y en caso de que no existain dichas c6dlgas, ein

cainfarmidad coin la edlci6in m_s recleinte de la

norma ANSI/NFPA No. 70 del C6dlgo El_ctrlca

Nacianal estadauinldeinse sl se encueintra ein

los Estadas Uinldas, a ein cainfarmldad coin la

inorma CSA C22.1 Porte 1 del C6diga El_ctrlca

Cainadleinse sl se eincueintra ein Cainad_.

* Se puede enceinder manualmeinte los

quemadares ein case de clue se produzca ulna

iinterrupci6in del sumlinistra de electrlcldad.

Para einceinder mainualmeinte uincluemador de

superficie, acerque uin f6sfara einceindido al

cabezal del quemadar y luego lleve leintameinte

la perilla de control a la paslci6in LITE. Sea

culdadoso al einceinder mainualmeinte los

quemadares de superficie.

NO almaceine articulos que Ilamein

la ateinci6in de los hi,as ein gablinetes que se

eincueintrein einclma de la estufa. Los nihos podr_an

sufrir quemaduras graves si se trepan sabre

la estufa para alcanzar alga que les ltame la

atenci6n.

* A fin de elimiinar el riesga de quemaduras y

de incendias al calacar el cuerpa sabre los

cluemadores de superficie, se debe evitar la

iinstalaci6in de gablinetes de almaceinamleinta par

eincima de los quemadares.

" Ajuste el ramada de la llama del quemador de

superficle basra clue no se extleinda m_s all_

del horde del uteinsllla de caclna. Los llamas de

tamaho excesivo son petigrosas.

Nuinca utlilce la estufa para caleintar

el reclinta ein el que se eincueintra la estufa. El usa

protongado del estufa sin ventitaci6n adecuada

puede ser peligroso.

Almaceinamieinta ein el

electradam_stlco. No se debe almaceinar materlales

iinflamables cerca de las uinldades de superficle.

Dichos materiales incluyen arficutos de papel,

pl6stico y tela, coma libros de cocina, recipientes de

pl6stico y pahos, at igual que liquidos inflamables.

NO almacene en la estufa ni cerca de ella

materiales potencialmente explosivos, coma latas de

aerosol. Los materiales inflamables podr_an explotar

y causar incendios y dahos a bienes.

Se debe iinterrumplr el sumiinistra

de electricidad a la estufa cuaindo se est_in

hacienda las cainexiaines de la tuberia de gas.

Si no se cumple la iindlcaci6in anterior, pudlerain

acurrlr leslaines persainales groves y hasta la

muerte.

Page 17

m6ximade

13in(33cm)

delgabinete

instalado

enla parte

superior

de la estufa.

18 in

(45,7 cm) (rain)

Separaci6n minima de 30 in

(76,2 cm) entre la parte superior

de la plataforma de la estufa y

todo gabinete de madera o de

metal no protegido

Separacidn

1 3/8in (3,5 cm) distancia minima

piana desde el borde del boquete.

24 in

...... 1 3/8in (3,5 cm) distancia minima

ol cm) _mm; plana desde el borde del boquete.

Figura :2 - DISENO DEL GABINETE

I__ Para eiiminar ei riesgo de quemaduras y de incendios al coiocar ei cuerpo sobre superficies

caiienfes, se debe evitar ia instalaci6n de cjabinetes de aimacenamienfo situados encima de ia estufa.

Page 18

Herramientas necesarias para la instalaci6n

- Destornillador de cruz

- Destornillador / Ilave de trinquete de 1/4"

- DestorniJJador / JJave de trinquete de 7/16"

Accesorios de sujeci6n suministrados

Cant. DescriF_ci6n Se utiliza en

3

(8.3 cm)

q_

1 1II

(27.9 cm)

(4)

(2)

(6) 1/4" de cabeza hexagonal cables (figs. 17 y 21)

(2) Soportes de sujeci6n (figs. 15 y 16)

7/16" con inserto de nailon

Tuercas hexagonates de

1/4-20

Tornitlo #10-24 de 3,5

in de longitud, de cruz

Torniltos #8-18 de Ducto de transici6n(4) cabeza ancha, de cruz (fig. 18)

Tornillos #8-18 negros C6mara y cajetfn de

Soplador (fig. 20)

Soportes

(figs. 15 y 16)

Encimera

Ubicaci6n del tomacorriente de pared

Instale el tomacorriente de pared en la zona sombreada.

cL

I _1 11 1/2"

6" 8

(15.2 cm) (22.2 cm)

I_ 3/4-, (29.2 cm)

Figura 3B - DIMENSIONES DE INSTALACION DE LA

SALIDA ELECTRICADEL MODELO DE 30 PULGADAS

Suministre una alimentaci6n adecuada

de gas

Esta estufa est6 diseffada para funcionar exclusivamente con

gas natural a una presi6n en el mOltiple de 4 pulgadas de

columna de agua.

Se debe Jnstalar un reguJador de presi6n en

serie con el mOitJpie de [a estufa, y debe permanecer en serie

con la tuberfa de alimentaci6n.

Para un funcionamJento correcto, [a presi6n mc_xima en [a

admisi6n del regulador no debe ser superior a 14 pulcjadas

de columna de acjua.

Para inspeccionar el regulador, la presi6n en la admisi6n

debe ser de a[ menos 1 pulgada de agua (2,5 kPa) superior

al ajuste de la presi6n en el mOItiple del recjulador. Si el

recjulador est6 ajustado para una presi6n de 4 pulgadas en

el mOltiple, la presJ6n en la admisi6n del recjulador debe ser

de al menos 5 pulcjadas.

El di6metro de la tuberfa de alimentacJ6n de gas que va al

electrodom_stico debe ser de 1/2" o de 3/4".

Figura 3A - DIMENSIONES DE INSTALACION DE LA

SALIDA ELECTRICA DFL MODFLO DE 36 PULGADAS

Page 19

Conversi6n a gas licuado de petr61eo/

propano

Este electrodom6stico se puede utilizar con gas natural y

tambi_n con gas licuado de petr61eo/propano (GLP). Se

despacha de f6brica ajustado para el uso con gas natural.

Junto con la estufa se suministra un kit de conversi6n a GLP.

El kit est6 marcado "FOR LP/PROPANE GAS CONVERSION"

(para conversi6n a GLP/propano).

La conversi6n debe ser realizada por un t_cnico calificado de

servicio, yen conformidad con las instrucciones suministradas

con el kit, yen conformidad con todos los c6digos y

requerimientos locales. Si no se cumplen las instrucciones

anteriores, podrian producirse lesiones personales graves

y/o da_os a bienes. La agencia certificada que realice este

trabajo asume toda la responsabilidad de la conversi6n.

Si la conversi6n no se realiza correctamente,

podrfan ocurrir lesiones personales graves y da_os a bienes.

NOTA: compre una tuber{a flexible nueva. NO UTiLiCE

LA TUBERiA FLEXIBLE ViEJA USADA.

Importante: Retire de la estufa todo el material de embalaje

y el material impreso antes de conectar las alimentaciones

de gas y de electricidad a la estufa.

Un electricista calificado debe inspeccionar el tomacorriente

de pared y su cJrcuito, a fin de asegurarse de que el

tomacorriente cuente con una correcta conexi6n a tierra.

Si el Onico tomacorriente disponible es de 2 patas, el

propietario de la estufa estc] obligado yes personalmente

responsable de que un electricista calificado reemplace dicho

tomacorriente por uno de 3 patas, que tenga la polarizaci6n

correcta y que est_ conectado correctamente a tierra.

M_todo preferido

Tomacorriente

de pared con

conexi6n a

CIRCUNSTANCIA I

es permislble |

NINGUNA_

tartar, elimlnar o|

anular la pata de)

cone×i6n a tlerra. /

Cable de suministro de

electricidad con enchufe

de 3 patas con conexi6n

a tierra

Figura 4

BAJO NINGUNA CIRCUNSTANCIA, es permisible tartar,

eliminar o anular la pata de conexi6n a fierra del enchufe

del cable de alimentaci6n de electricidad.

Ubicaci6n del nOmero del modelo y del

nOmero de serie

La placa del nOmero de serie se encuentra en la parte inferior

de la estufa.

AI hacer pedidos de piezas y al hacer consuitas acerca de su

estufa, no de]e de incluir los nOmeros del modelo y de serie y

tambi_n el nOmero o la letra del Iote de fabricaci6n, que se

indican en la placa del nOmero de serie de la estufa.

La placa del nOmero de serie tambi6n indica la capacidad

t6rmica nominal de los quemadores, el tipo de combustible y

la presi6n a la que se ajust6 la estufa en f6brica.

Requerimientos de la alimentaci6n de

electricidad

Circuito ramal de 120 Voltios, 60 Hertz con

correcta conexi6n a tierra, protegido por un disyuntor o

fusible de 15 A, con retardo. NO ufilice cables de extensi6n

en la alimentaci6n de electricidad de la estufa.

Instrucciones para la conexi6n a tlerra

IMPORTANTE Lea cuidadosamente esta informaci6n.

A efectas de la seguridad de las personas, la

estufa se debe canectar correctamente a tierra.

El cable de aNmentaci6n de electricidad de esta estufa est6

equipado con un enchufe de 3 patas (con conexi6n a tierra)

que se debe conectar a un toma¢orriente est6ndar de 3

patas con conexi6n a tierra (yea la figura 4), a fin de reducir

al mfnimo la posibilidad de peligros de descargas el_ctricas

en la estufa.

_ Desconecte del tomacorriente de pared el

cable de alimentaci6n de electricidad antes de realizar toda

tarea de servicio en la estufa.

Posicionamiento de la estufa

El ativio de escape de la estufa se debe colocar entre dos vigas de

pared o entre dos travesa_os de piso, a efectos de la instataci6n

correcta de la ducterfa.

Preparaci6n del gabinete base

Esta estufa est6 dise_ada para encajar f6cilmente en gabinetes de

distintos tipos. No obstante, atgunos gabinetes podrfan requerir de

modificaciones.

Preparaci6n de un gabinete que tenga

gavetas

Si el gabinete tiene gavetas, se debe desmontar y desarmar las

cjavetas, y fijar las caras de las cjavetas a la parte detantera det

cjabinete.

Mida la Iongitud y el ancho internos del gabinete base.

En atgunos tipos de gabinetes, podr_a ser necesario hacer cortes en

las paredes taterates y/o en ta pared trasera, y/o eliminar tambi_n

los esquineros a fin de poder instatar la estufa.

Boquete en la enclrnera

La superficies de las encimeras provistas de un borde delantero

redondeado y de una curva en ta base det satpicadero trasero

podrfan no tenet et tamafio necesario para la instataci6n de la

estufa.

Carte el boquete en la encimera en conformidad con tas

dimensiones que se indican en la figura 2. El boquete se debe cortar

perpendicutarmente y con los lados en paraleto entre etlos, con los

lados delantero y trasero perpendiculares a los lados izquierdo y

derecho.

Page 20

lnstalaci6n de la ducteria

Utilice ductos redondos de atuminio o de metal cjatvanizado, de

6 o de 31/4pulcjadas de di6metro y de 10 pulcjadas de loncjitud, o

una combinaci6n de ambos. Se debe utitizar ductos de PVC si se

instalan debajo de ptacas de concreto vaciado. Coloque ta ducteHa

de modo que sea Io m6s corta y recta posibte. Para un desempe_o

satisfactorio, la loncjitud equivatente de ta ducterfa no debe set

mayor de 100 ft (30 m). Consutte el cjr6fico de '"C6tculo de ta

Ioncjitud de la ducterfa" para conocer tas loncjitudes equivalentes.

(vea la p6cjina 14). Todas uniones entre ductos deben estar sujetas

con un tornitlo y settadas con cinta para ductos, como se muestra en

la flcjura 5.

NOTA: se debe cumptir con los c6dicjos de construcci6n locales al

especiflcar el tipo aprobado y las especiflcaciones de TODOS los

ductos que se utilicen. Siempre utilice un casquete adecuado para

pared o techo, provisto de amorticjuador.

Cinta de ductos •

sobre la uni6n -- /Tornilloy el tornillo _/

/

Flujo de

.

Figura 5 - CINTA DE DUCTOS SOBRE LA UNION Y EL

TORNILLO

Figura 8 - DUCTO QUE ATRAVIESA LA PARED

Preparaci6n para la ducteria

Corte un orificio en la pared o en el piso del cjabinete, secj0n

corresponda, en funci6n de las caracteHsticas det tucjar de

instataci6n. Asecj0rese de que et ducto de escape se encuentre

entre dos vicjas de pared o entre dos travesa_os de piso, secjOn

corresponda. (Ficjuras 9, 10, 11, 12, 13A y 13B) NOTA: la descarcja de

la ducterfa DEBE SER at exterior.

BAJO NINGUNA CIRCUNSTANCIA, es permisible que ta ducterfa

descarcjue at interior de una pared, a un techo, a un espacio libre

entre pisos o paredes, a un 6tico o a un recinto oculto.

ql o , . o

'l_J'

%

\/i

Figura 6 - DUCTO EN EL PISO

...I/_

_AI hacer cortes o perforaciones en una pared

o en un techo, EVlTE causar da5os a cables et_ctricos y a otras

instataciones en et interior de la pared o det techo.

CENTRO

CENTRO

DE BOQUETE

DE BOQUETE

/

//

Figura 9 - MODELO DE 30 PULGADAS

Figura 7 - DUCTO QUE ATRAVIESA EL PISO ORIFICIO DE LA DUCTERiA EN EL FONDO

6

Page 21

CENTRO

CENTRO

DE BOQUETE

DE BOQUETE

Figura 10 - MODELO DE 30 PULGADAS ORIFiCiO

DE LA DUCTERIA EN LA PARED TRASERA

CENTRO

CENTRO

DE BOQUETE

DE BOQUETE

Ducteria aJterna

En el caso de JnstaJaciones en

ias que haya restri¢cJones de

espacio que no perrnJtan orientar

el sopJador para ¢onectarJo a

ia ducterfa, estc_ disponible eJ

kit 5304488297. Se muestran

ias dimensiones para ubicar Ja

abertura para eJ ducto cuando se

utiliza este kit de adaptaci6n.

CENTRO

DE BOQUETE _

(15.2 cm)

I

I

_ _ 6 3/8"

_ _ (16.2 cm)

22 5/8" _

(57.5 cm)

Figura 13

KiT DE DUCTO ALTERNO

DE TRANCISION

i

i

Figura 11- MODELO DE 36 PULGADAS

ORIFICIO DE LA DUCTERiA EN EL FONDO

CENTRO

DE BOQUETE

I

[_ I/4" (0,6 cm)

Figura 12- MODELC) DE 36 PULGADAS

ORIFICIO DE LA DUCTERIA DEL LADO IZQUIERDO O

DERECHO

Figura 13A - ORJFICIO ALTERNO DE LA

DUCTERJA, MODELO DE 30 PULGADAS

CENTRO

DE BOQUETE

8 7/8 H

22 s/8"

(57.5 cm)

(15.2 cm)

Figura 13B- ORiFiCIO ALTERNO DE LA

DUCTERiA, MODELO DE 36 PULGADAS

Aire de reposlci6n

Los c6digos locales de construcci6n podrfan exigir el uso de

sistemas de aire de reposici6n. Consulte los c6digos IocaJes a fin

de determinar los requerimientos especfficos de aire de reposici6n

correspondientes a su instalaci6n.

Page 22

Alineaci6n del soplador y la ducteria

No se sugiere et uso de ductos flexibles dado que pueden restrincjir

en gran medida el flujo de aire. Si la satida del soplador y el ducto

en el suelo o en ta pared NO est6n atineados, se puede utilizar

ductos flexibtes de METAL para compensar por la desviaci6n.

con la parte trasera de ta encimera. A fin de prevenir da_os a la

encimera, EVITE apretar en exceso et tornillo.

Desviaci6n

MAXIMA de

6 in entre

las Iineas

centrales

Figura 14 - ALINEACI6N DE LA DUCTERiA

Instalaci6n de la estufa

Eleve ta estufa pot sus bordes laterales como se muestra.

Haga descender la estufa en el boquete de ta encimera, y cot6quela

cuidadosamente en su posici6n correcta. Apoye la estufa en su parte

inferior y h6gata descender lentamente. Retire cuidadosamente los

dedos de debajo de la estufa una esquina a la vez, para terminar

de cotocar la estufa.

NOTA: NO utilice compuestos RTV de siticona ni compuestos de

catafateo para sellar la uni6n entre la estufa y la encimera.

Un so F

sujeci6n

] cabeza hexagonal sujetos a la

Un tornillo estufa

argo, de cruz EI

tornillos #8-18 negros de

Figura 16 - FIJE LOS DOS SOPORTES

ESTUFA DE GAS

Tornillos

scsumlnistrados

con la estufa de cruz

Figura 17 - SOPORTES DE INSTALACI6N

Instalaci6n de la cbmara del soplador en

Ja estufa

Con la abertura del soplador en el lado derecho, deslice la c6mara

en ta abertura que se encuentra en la parte inferior de la estufa.

Haga presi6n hacia arriba sobre la c6mara hasta que los rieles

de instalaci6n que se encuentran a los lados de la c6mara hagan

contacto con la parte inferior de la estufa. Instate cuatro tornittos de

#8 x 3/8" de fljaci6n de 16minas de metal para sujetar la c6mara

en su sitio.

Figura 15- DESCENSO DE LA ESTUFA EN EL

BOQUETE DE LA ENCIMERA

lnstalaci6n de los soportes de sujeci6n

Quite los tornitlos que se encuentran en el bastidor de la estufa y

utilfcetos para fljar el soporte de suieci6n a la parte inferior del

bastidor. Inserte et tornillo en et soporte hasta que hacja contacto

Instale cuatro tornillos negros

#8-18 de cabeza hexagonal

Figura 18- MODELO DE 30 PULGADAS

FUE LA CAMARA A LA ESTUFA

Page 23

I

Instale cuatro tornillos

necjros #8-18

de cabeza he×acjonal

i_ _ _

I

I

.... _s_ -__ ............

I

Fijaci6n del soplador a la c_mara

Instale cuatro tuercas de inserto de nailon en los esp6rragos del

soptador, y apri_telas con ta mano hasta que se sienta resistencia.

Atinee la abertura de descarga det soptador con el ducto. Cotoque

las tuercas que se encuentran a un lado del atojamiento det

soptador en los cuatro orificios de montaje que se encuentran a un

lado de la c6mara, y deje que et soptador deslice hacia abajo para

encajar en los orificios. Utitice una llave de tuercas o una Itave de

trinquete desde et interior de la c_mara para apretar las tuercas.

.L.......F_gura 19 - MODELO DE 36 PULGADAS

FIJE LA CAMARA A LA ESTUFA

Instalaci6n del ducto de transici6n en

el soplador

Fije el ducto de transici6n a la satida det soplador con el uso de

cuatro tornillos. Rodee la uni6n con cinta para settarta.

Figura 21 - FiJF FLSOPLADOR A LA CAMARA

Figura 22 - UBiCACIONES D_ LAS TU_:RCASFN FL

iNT_:RiOR DF LA CAMARA

Page 24

Conexiones el_ctricas del soplador

Conecte el enchufe de 5 ctavijas del conjunto del soptador at

recept6cuto correspondiente de 5 orificios que se encuentra en la

parte inferior de la estufa.

Pliegue todos los cables en el interior det cajefin de cableado que

se encuentra en el extremo del tubo conduit del soptador. Fije el

cajetfn de cableado a la estufa con et uso de dos tornitlos #8 x

3/8"t y compruebe que no haya quedado atrapado ningOn cable,

Figura 23 - CONECTE ELSOPLADOR A LA ESTUFA

Instalaci6n del regulador de presi6n

Instale el regulador de presi6n con la flecha marcada en el

regulador apuntando hacia la estufa, en una posici6n en la

que se alcance f_cilmente la tapa de acceso.

_NO apriete en exceso la conexi6n. El

cuerpo deJ reguiador es de fundici6n. El apriete excesivo

podr[a agrietar el regulador, Io que causar[a una fuga de gas

y el peNgro de un incendio o de una explosi6n.

V&lvula FLUJO DE GAS Regulador

de corte de presi6n

manual Adaptador Adaptador

T r,

Cerrada flexible .a_,a

Ajuste todas las uniones con una llave inglesa

Figure 24 -TUBERJA DEALJMENTACJONDE GAS

Conecte el conector flexible de la tuber[a de alimentaci6n de

gas al regulador en la secuencia a continuaci6n..

1. v_lvula manual de torte

2. empalme de 1/2" (1,3 cm)

3. adaptador de uni6n abocardada de 1/2" (1,3 cm)

4. conector flexible

5. adaptador de uni6n abocardada de 1/2" (1,3 cm)

6. empalme de 1/2" (1,3 cm)

7. regulador de presi6n

de

acceso

Conexi6n de la ducteria

Conecte ta ducterfa que fue preparada en los pasos 8, 9 y 10 at

ducto de transici6n det soplador.

Para sellar las conexiones de los componentes, utilice un

¢ompuesto de uni6n de tuber[as adecuado para el uso

con gas natural y GLP/propano. Si se utilizan ¢onectores

flexibles r aseg0rese de evitar que se tuerzan.

Figura 25 - CONEXI6N FtSICA DE LA TUBER{A DE

GAS A LA ESTUFA

10

Page 25

_J_]]__ La tuberfa de aJimentaci6n debe estar

provista de una v61vula manual de corte que cuente con las

aprobaciones pertinentes. Dicha v61vula se debe instalar

en el mismo recinto en el que se encuentra la estufa, en un

lugar que permita su apertura y cierre con facilidad. FVIT_:

bloquear el acceso a la v61vula de corte. La funci6n de dicha

v61vula es permitir o cortar el flujo de gas a la estufa.

Valvula de corte -

Abierta _

Figura 26 - VALVULA DE CORTE

Una vez que est8 instalado el regulador, abra la v61vula de

corte que se encuentra en la tuberfa de aJimentaci6n de gas.

Espere algunos minutos a que el gas se desplace a travSs de

la tuberfa.

Jnspecclone en busca de fucjas. Despu6s de

conectar la estufa a la alimentaci6n de gas, inspeccione el

sistema en busca de fugas, con el uso de un man6metro. Si no

est6 disponible un man6metro, abra la alimentaci6n de gas y

utilice un ffquido detector de fugas (o agua y jab6n) en todas

las uniones y conexiones a fin de inspeccionarlas en busca de

fugas.

_NO utilice llamas abiertas para

inspeccionar las conexiones y las uniones en busca de fugas.

Si se utiliza una llama abierta para inspeccionar la tuberfa

podHa producirse un incendio o una explosi6n.

| Aprlete todas las conexlones de ser necesario

a fin de prevenir fugas de gas en la estufa y/o en la tuber[a

de alimentaci6n.

Requerimienfos de la alimenfaci6n de

elecfricidad

Circuito ramal de 120 Voltios, 60 Hertz con correcta conexi6n

a tierra, protegido por un disyuntor o fusible de 15 A, con

retardo. NO utilice cables de extensi6n en la alimentaci6n

de elec/ricidad de la estufa.

Instrucciones para la conexi6n a tlerra

IMPORTANTE Lea cuidadosamente esta informaci6n.

A efec/os de la seguridad de las personas, la estufa se debe

conectar correctamente a fierra.

El cable de alimentaci6n de electricidad de esta estufa

est6 equipado con un enchufe de 3 patas (con conexi6n a

tierra) que se debe conectar a un tomacorriente est6ndar

de 3 patas con conexi6n a tierra (vea la flgura 27), a fin de

reducir al mfnimo la posibilidad de peligros de descargas

el_ctricas en la estufa.

Un electricista calificado debe inspeccionar el tomacorriente

de pared y su cJrcuito, a fin de asegurarse de que el

tomacorriente cuente con una correcta conexi6n a tierra.

Si el 6nico tomacorriente disponible es de 2 patas, el

propJetario de la estufa est_ obligado y es personalmente

responsable de que un electricista calificado reemplace dicho

tomacorriente por uno de 3 patas, que tenga la polarizaci6n

correcta y que est6 conectado correctamente a tierra.

M_todo preferldo

Tomacorriente de NINGUNA

pared con conexi6n CIRCUNSTANCiAes

a tierra permisible cortar,

eliminar o anular la

pata de conexi6n a

erra.

Cable de suministro de

eiectricidad con enchufe

de 3 patas con conexi6n

a tierra

Figura 27 - CABLE DE ALIMENTACI6N DE

ELECTRICIDAD

alpine Desconecte del slstema de tuberias de

ntaci6n de gas la estufa y la v_ivula manual

de torte especifica de Ja estufa al realizar toda

prueba de presi6n de dicho sistema a presiones de prueba

superiores a 1/2 psig (3,5 kPa o 14 pulgadas de columna de

agua).

Aisle la estufa deJ sistema de tuberias de

allrr_erltaci6n de gas; para ello cierre la v6Jvula manual

de corte especffica de la estufa aJ reaHzar toda prueba de

presi6n dei sistema de tuberfas de aNmentaci6n de gas a

presJones de prueba iguales o menores de I/2 psig (3,5 kPa o

14 puigadas de coiumna de agua).

BAJO NINGUNA CIRCUNSTANCIAes permisible cortar,

eliminar o anular la pata de conexi6n a fierra del enchufe

del cable de alimentaci6n de electricidad.

_ Desconecte del tomacorriente de pared el

cable de alimentaci6n de electricidad antes de realizar toda

tarea de servicio en la estufa.

11

Page 26

Instalaci6n de las tapas de los

quernadores

A.

Desembale las rejillas de los quemadores.

B.

Quemadores: Desembate los cabezales y las tapas de los

quemadores. Coloque los cabezates y las tapas de los

quemadores sobre sus bases correspondientes.

C.

Las tapas deben quedar a nivel despu_s de su instataci6n

D.

AsegOrese de que todas las tapas y los cabezales de los

quemadores est_n correctamente en su sitio ANTES de porter en

uso la estufa

Instalaci6n del Nitro, de la rejilla de

ventilaci6n y del seilo de la rejilla

Coloque el fittro diagonatmente en la

c6mara de ventitaci6n.

Aseg0rese de que quede apoyado_ en

6ngulo, sobre los soportes de la abertura de

ventilaci6n.

Filtro de

f grasa

\

Coloque cuidadosamente el selto de la rejitla sobre la c6mara de

ventilaci6n de la estufa, como se muestra en las tlguras 30 - 31.

AsegOrese de que el cottarfn que se encuentra en el fondo del

selto quede totatmente insertado en ta abertura de ventilaci6n.

Quite el tornilto de 1/4" de cabeza hexagonal que se encuentra

en la c6mara de ventilaci6n, debajo de la pesta_a det setlo de ta

rejilta de ventitaci6n. Doble la pesta_a del sello de la rejitla de

ventitaci6n hacia la c6mara de ventitaci6n_ y fijela con et tornilto

de cabeza hexagonal.

Figura 28 ...................

UBICACI6N DEL FtLTRO DE LA VENTILACI6N -

MODELO DE 30 PULGADAS

Figura 30

FIJACI6N DEL SELLODE LA REJILLA DE

VENTILACI6N - MODELO DE 30 PULGADAS

Sello de la

rejilla

Tornillo #8=18 de

cabeza hexagonal

Figura 31

FIJACI6N DEL SELLODE LA REJILLA DE VENTtLACI6N

- MODELO DE 36 PULGADAS

Figura 29

UBICACI6N DEL FILTRO DE LA VENTILACI6N -

MODELO DE 36 PULGADAS

12

Page 27

* Cotoque la rejilla de ventilaci6n sobre el sello de ta rejitla, sobre

la abertura de ventilaci6n. Coloque las rejitlas de los quemadores

sobre los quemadores.

ilia de

ventilaci6n

Figura 32

UBICACI6N DE LA REJILLADE VENTILACI6N Y DE SU

SELLO- MODELO DE 30 PULGADAS

Comprobaci6n del buen

funcionamiento

Consulte la Guia de uso y cuidado suministrada junto con la

estufa a fin de conocer las instrucciones de operaci6n y la

informaci6n de ¢uidado y limpieza de la estufa.

Active el sumlnistro de electricidad y abra la v61vula

principal de torte de gas

_'_ Cornprobaci6n del correcto funclonamiento del sistema de

chlspas el6ctrlcas de los quemadores

Se debe inspeccionar el funcionamiento del sistema de

chispas el@ctricas de los quemadores despu@s de inspeccionar

cuidadosamente tos conectores en la estufa yen ta tuber{a

de atimentaci6n en busca de fugas, y despu@s de que se haya

conectado la estufa a la alimentaci6n de electricidad.

Operaci6n de los quemadores de superflcle:

A. Haga presi6n sobre la peritta del quemador de superflcie y

II@veta a la posici6n LITE (encender). Se escuchar6 un ruidito de

tic tic. Es el sonido del sistema de generaci6n de chispas que

enciende los quemadores.

B. Una vez que el quemador haya encendido, ajuste la perilla

hasta obtener et tama_o deseado de la llama. La posici6n

de la peritla de control NO tiene que estar en un punto en

particular. Utilice la posici6n det indicador de la perilla para

ajustar la llama seg0n sea necesario.

de la

rejilla

Figura 33

UBICACI6N DE LA REJILLA DE VENTILACI6N Y DE SU

SELLO- MODELO DE 36 PULGADAS

Una vez finalizadas todas las conexiones

AsegOrese de que todos los controtes se encuentren en la posici6n OFF.

AsecjOrese de que et flujo de gas combustible y de aire en la estufa no

tencja obstrucciones.

Antes de liamar al servicio t6cnico

Lea la lista de comprobaci6n "Antes de Ilamar al servicio

t@cnico" y las instrucciones de operaci6n que se encuentran

en la Guia de usa y cuidada. Podr[a ahorrarle tiempo

y dinero. La Iista incluye situaciones comunes en este

electrodom6stico que no son el resultado de mano de obra ni

de materiales defectuosos.

Consulte la informaci6n de garant[a que se encuentra en la

Guia de uso y cuidado a fin de conocer el nOmero telef6nico

y la direcci6n de nuestro departamento de servicio. LI6menos

o escribanos si tiene alguna consulta acerca de su producto

y/o si necesita hacer un pedido de piezas.

13

Page 28

C61culo de ia tabla de iongitud de la ducteria

Para una m6xima eflciencia0 coloque ta ducteHa de modo que sea 1o m6s corta y recta posible. Utitice la menor cantidad

de acoptes que sea posible. Para un 6primo desempeffo, la loncjitud equivatente de la ducterfa no debe set mayor de

100 ft (30 m).

Los c6tculos son aproximados y se basan en los est6ndares de la industria del aire acondicionado y la catefacci6n.

SEGMENTOS DE DUCTO

6 in (15,2 cm) de di6metro, recto 1 ft (0,3 m) fto m

LONGITUD CANTIDAD LONGITUD

EQUIVALENTE X UTILIZADA -- EQUIVALENTE

ft

1,5

5 ft

(O,45m)

m)

(1,5m)

de metal flexible de 6 in (15,2 cm) de

di6metro, sin dobteces **

(_ Codo de 6 in (15,2 cm), de 90 ° 10 ft (3 ft

(_ Codo de 6 in (15,2 cm), de 45 °

[__ 31/4" x 10 in (8,2 cm x 25,4 cm)recto ** 1 ft (0,3 m) ft o m

Codo de 31/4 '' x 10 in

(8,2 cm x 25,4 cm), de 90 ° 10 ft (3 m) fto m

(8,2 cm x 25,4 cm), de 45 ° 5 ft (1,5 m) fto m

Codo de 31/4 in x 10 in

Codo piano de 31/4 in x 10 in

(8,2 cm x 25,4 cm), (3 m) o m

Codo redondo de transici6n de 31/4 in

x 10 in (8,2 cm x 25,4 cm) a 6 in (15,2

cm), de 90 ° 30 ft (9 m) fto m

[_ Codo de 6 in (15,2 cm) redondo a 31/4

in x 10 in (8,2 cm x 25,4 cm), de 90 ° 30 ft (9 m) ft o m

de 9O ° 10 ft ft

ft o m

o m

ft o m

x 10 in (8,2 cm x 25,4 cm) a 6 in (15,2 5 ft (1,5 m) ft o m

Codo redondo de transici6n de 31/4 in

cm)

redondo a 31/4'' x 10 in 5 ft (1,5 m) fto m

Codo de transici6n de 6 in (15,2 cm)

(8,2 cm x 25,4 cm)

3O ft

Tapa redonda de pared de 6 in (15,2

cm), con amortiguador

[_ Tapa de pared con amortiguador, de

** En el caso de ductos rectos de secci6n rectangutar/redonda, mida ta

Iongitud lineal real de la ducterfa y luego multiptiquela pot la tongitud

equivalente que se indica.

31/4 in x 10 in (8,2 cm x 25,4 cm) 30 ft (9 m) fto m

Tapa redonda para techo de 6 in (15,2

cm) 30 ft (9 m) ft o m

(9 m)

14

ft o m

DUCTERiA TOTAL fto m

Loading...

Loading...