Page 1

iNSTALLATiON AND SERVICE MUST BE PERFORMED BY A QUALiFiED iNSTALLER.

iMPORTANT: SAVE FOR LOCAL ELECTRICAL iNSPECTOR'S USE.

READ AND SAVE THESE iNSTRUCTiONS FOR FUTURE REFERENCE.

If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.

FOR YOUR SAFETY:

-- Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the

gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

-- Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

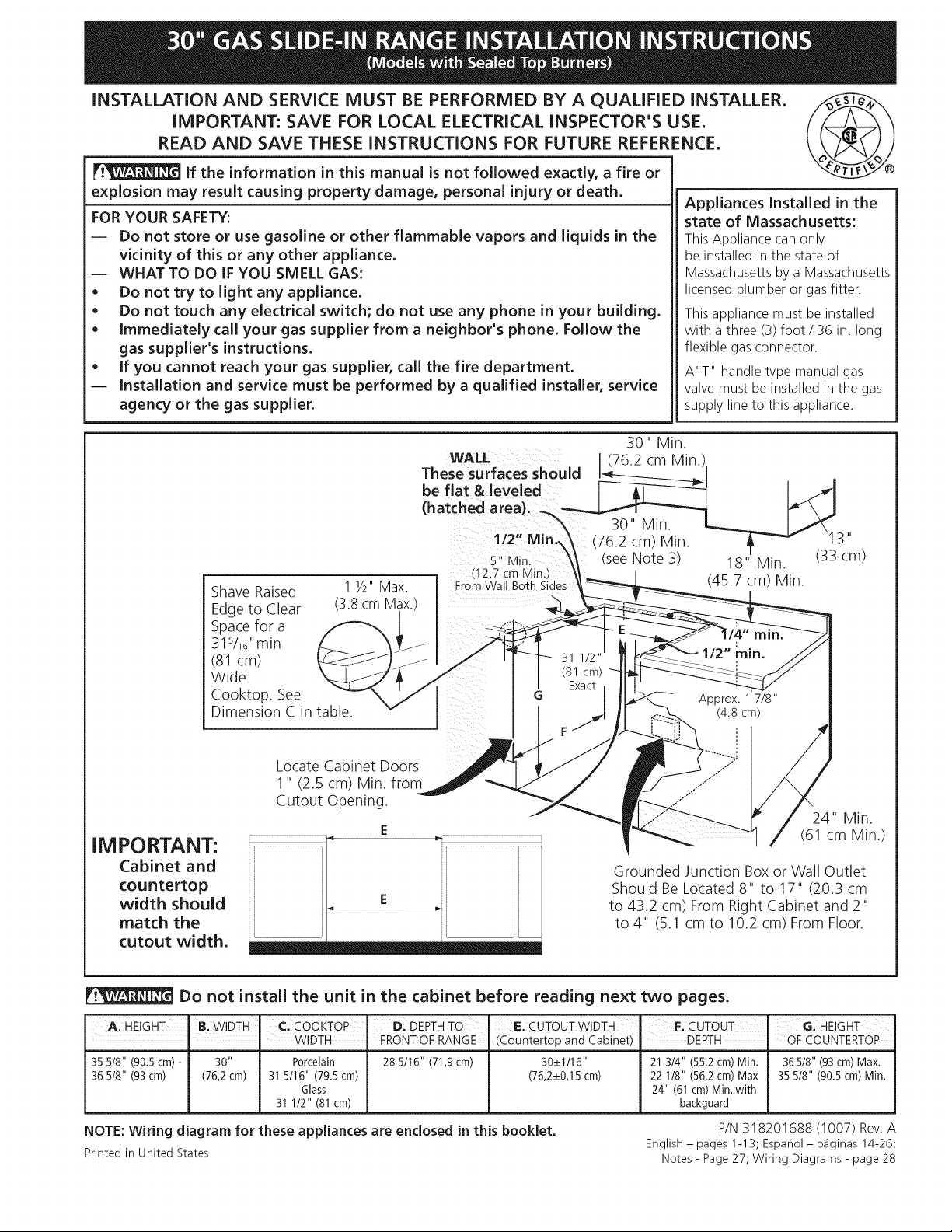

30" Min.

WA

(76.2 cm Min.

These surfaces should

be flat &leveled

(hatched area).

1

(seeNote 3) 18" Min. (33 cm)

Shave Raised

Edge to Clear

11/2"Max.

(3.8 cm Max.

Spacefor a

31s/16"min

(81 cm)

Wide

Cooktop. See

Dimension C in table.

Appliances Installed in the

state of Massachusetts:

This Appliance can only

be installed in the state of

Massachusetts by a Massachusetts

licensed plumber or gas fitter.

This appliance must be installed

with athree (3) foot / 36 in. long

flexible gas connector.

A"T" handle type manual gas

valve must be installed in the gas

supply line to this appliance.

(45.7 cm) Min.

11

Locate Cabinet Doors

1" (2.5 cm) Min. from

Cutout Opening.

IM PORTANT:

Cabinet and

countertop

width should

match the

cutout width.

Do not install the unit in the cabinet before reading next two pages.

A. HBGHT

35 518" (90.5 cm) -

36 518" (93 cm)

NOTE: Wiring diagram for these appliances are enclosed in this booklet.

Printed in United States

B. WIDTH" _.cooKToP

WIDTH

30" Porcelain

(76,2cm) 315/16" (79.5cm)

Glass

31 1/2" (81cm)

Di DEPTHTO E. CUTOUT WIDTH

FRONTOF RANGE (Countertop and Cabinet)

28 5116" (71,9cm) 30_+1116"

(76,2_+0,15cm)

24" Min.

(61 cm Min.)

Grounded Junction Box or Wall Outlet

Should Be Located 8" to 17" (20.3 cm

to 43.2 cm) From Right Cabinet and 2"

to 4" (5.1 cm to 10.2 cm) From Floor.

F: CUTOUT G. HEIGHT

DEPTH " OF COUNTERTOP

21 3/4" (55,2 cm)Min.

22 1/8" (56,2 cm)Max

24" (61 cm) Min.with

backguard

P/N 318201688 (1007) Rev. A

English- pages 1-13; Espahol- p_iginas 14-26;

Notes- Page 27; Wiring Diagrams- page 28

36 5/8" (93 cm) Max.

35 5/8" (90.5 cm) Min.

Page 2

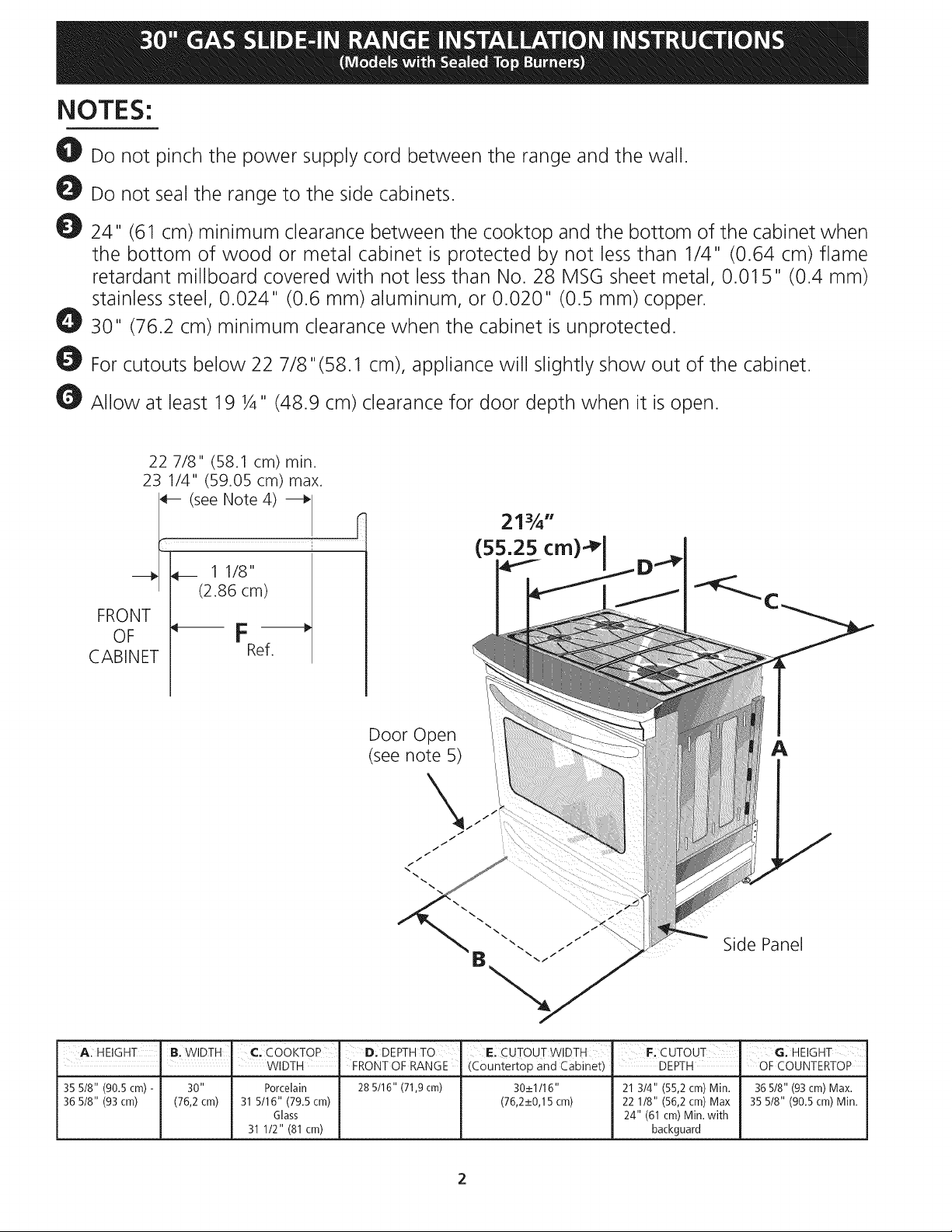

NOTES:

O! Do not pinch the power supply cord between the range and the wall.

Do not seal the range to the side cabinets.

24" (6! cm) minimum clearance between the cooktop and the bottom of the cabinet when

the bottom of wood or metal cabinet is protected by not less than 1/4" (0.64 cm) flame

retardant millboard covered with not less than No. 28 MSG sheet metal, 0.01 5" (0.4 mm)

stainless steel, 0.024" (0.6 mm) aluminum, or 0.020" (0.5 mm) copper.

30" (76.2 cm) minimum clearance when the cabinet is unprotected.

For cutouts below 22 7/8"(58.1 cm), appliance will slightly show out of the cabinet.

Allow at least 19 ¼" (48.9 cm) clearance for door depth when it is open.

22 7/8" (58.1 cm) min.

23 1/4" (59.05 cm) max.

(see Note 4)

______ 1 1/8"

(2.86 cm)

FRONT

OF _F -_

CABINET Ref.

S

Door Open

(see note 5)

A

Side Panel

A: HEIGHT B. WIDTH" C, Co©KToP" D; DEPTHT0 E. CUTOUT WIDTH F; cUTOUT' GIHEIGHT

I I WIDTH FRONTOF RANGE (Countertop and Cabinet) DEPTH OFCOUNTERTOP

35 5/8" (90.5 cm) - 30" Porcelain 28 5/16" (71,9 cm) 30_+1/16" 21 3/4" (55,2 cm) Min. 36 5/8" (93 crn) Max.

36 5/8" (93 cm) (76,2 cm) 31 5/16" (79.5 cm) (76,2_+0,15 cm) 22 1/8" (56,2 cm) Max 35 5/8" (90.5 cm) Min.

Glass 24" (61 cm) Min. with

31 1/2" (81 cm) backguard

Page 3

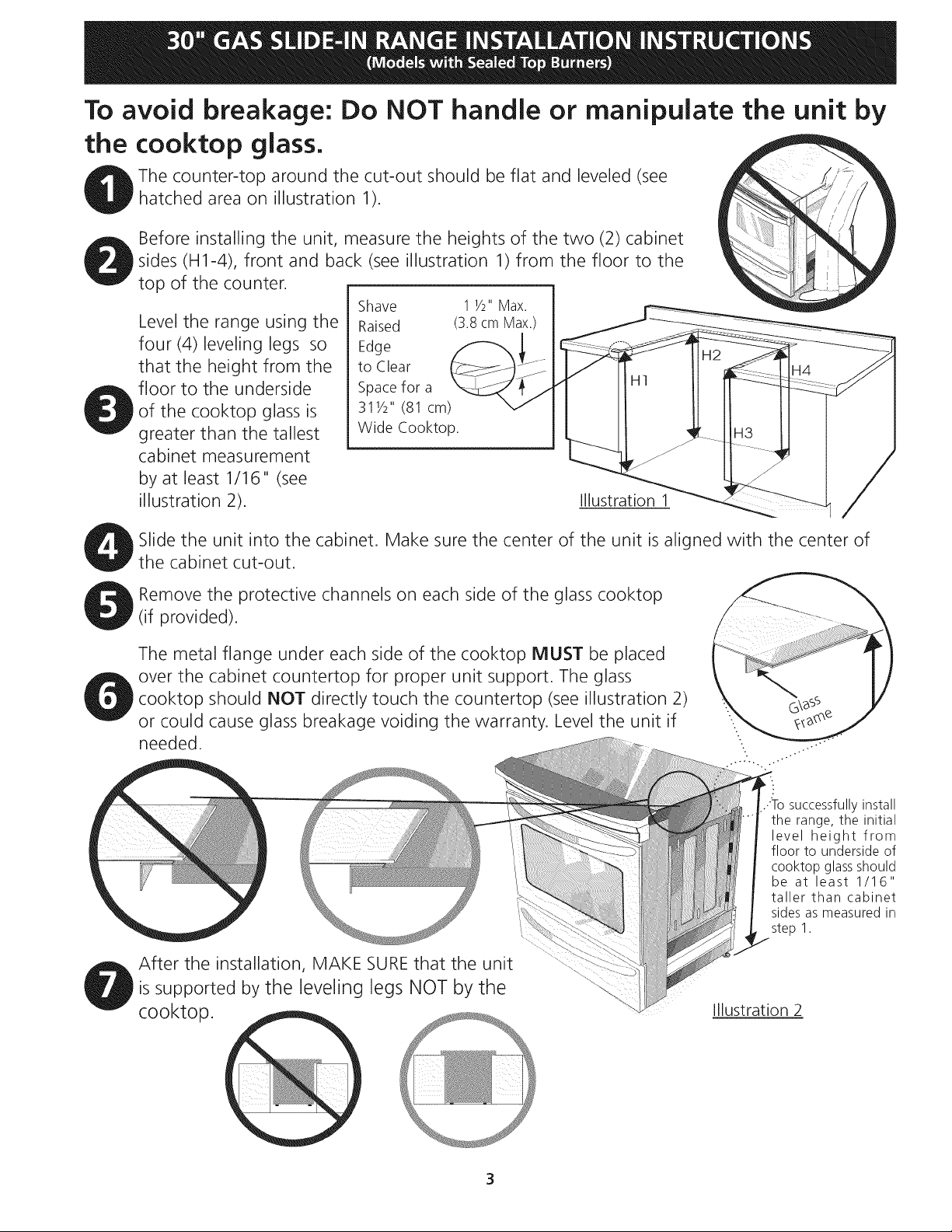

To avoid breakage: Do NOT handle or manipulate the unit by

the cooktop glass.

The counter-top around the cut-out should be flat and leveled (see

hatched area on illustration 1).

Before installing the unit, measure the heights of the two (2) cabinet

sides (H1-4), front and back (see illustration 1) from the floor to the

top of the counter•

Shave

Level the range using the

four (4)leveling legs so

that the height from the

floor to the underside

of the cooktop glass is

greater than the tallest

Raised

Edge

to Clear

Space for a

311/2" (81 cm)

Wide Cooktop.

cabinet measurement

by at least 1/16" (see

illustration 2).

Slide the unit into the cabinet. Make sure the center of the unit is aligned with the center of

the cabinet cut-out.

1 1/2"Max.

(3.8cm Max.)

Illustration 1

Remove the protective channels on each side of the glass cooktop

(if provided)•

The metal flange under each side of the cooktop MUST be placed

over the cabinet countertop for proper unit support• The glass

cooktop should NOT directly touch the countertop (see illustration 2)

or could cause glass breakage voiding the warranty• Level the unit if

needed•

After the installation, MAKE SUREthat the unit

is supported by the leveling legs NOT by the

cooktop.

successfully install

the range, the initial

level height from

floor to underside of

cooktop glass should

be at least 1/16"

taller than cabinet

sides as measured in

step 1.

Illustration 2

3

Page 4

important Notes to the Installer

1. Read all instructions contained in these installation

instructions before installing range.

2. Remove all packing material from the oven

compartments before connecting the gas and

electrical supply to the range.

3. Observe all governing codes and ordinances.

4. Besure to leave these instructions with the consumer.

5. Note: For operation at 2000 ft. elevations above see

level, appliance rating shall be reduced by 4 percent

for each additional 1000 ft.

unless you place an insulating pad or sheet of 1/4"

(10,16 cm) thick plywood between the range and

carpeting.

Make sure the wall coverings around the range

can withstand the heat generated by the range.

Do not obstruct the flow of combustion air at the

oven vent nor around the base or beneath the

lower front panel of the range. Avoid touching the

vent openings or nearby surfaces as they may become

hot while the oven is in operation. This range requires

fresh air for proper burner combustion.

important Note to the Consumer

Keep these instructions with your Use & Care Guide for

future reference.

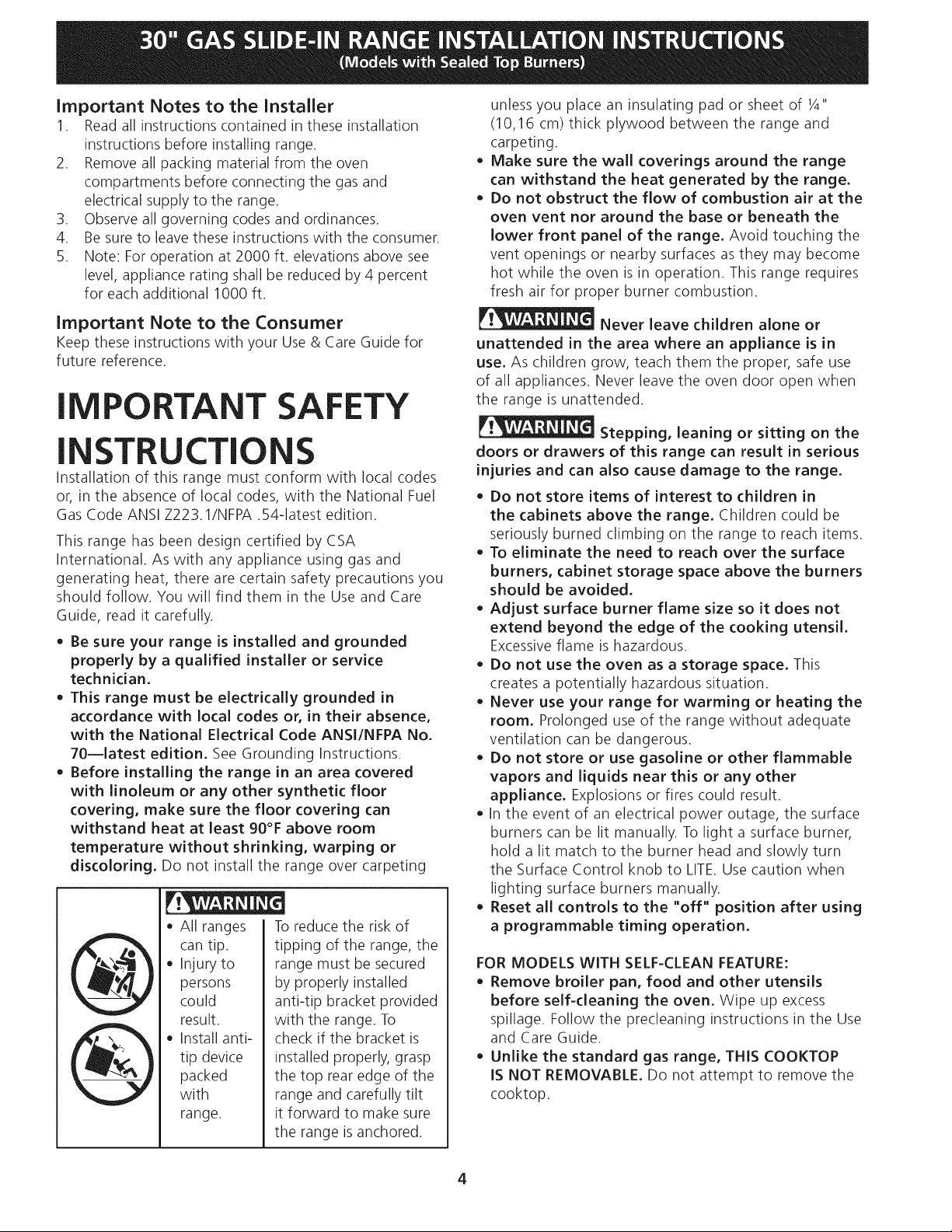

IMPORTANT SAFETY

INSTRUCTION

Installation of this range must conform with local codes

or, in the absence of local codes, with the National Fuel

Gas Code ANSI Z223.1/NFPA .54-latest edition.

This range has been design certified by CSA

International. As with any appliance using gas and

generating heat, there are certain safety precautions you

should follow. You will find them in the Useand Care

Guide, read it carefully.

• Be sure your range is installed and grounded

properly by a qualified installer or service

technician.

This range must be electrically grounded in

accordance with local codes or, in their absence,

with the National Electrical Code ANSI/NFPA No.

70--latest edition. See Grounding Instructions.

Before installing the range in an area covered

with linoleum or any other synthetic floor

covering, make sure the floor covering can

withstand heat at least 90°F above room

temperature without shrinking, warping or

discoloring. Do not install the range over carpeting

All ranges

can tip.

Injury to

persons

could

result.

Install anti-

tip device

packed

with

range.

To reduce the risk of

tipping of the range, the

range must be secured

by properly installed

anti-tip bracket provided

with the range. To

check if the bracket is

installed properly, grasp

the top rear edge of the

range and carefully tilt

it forward to make sure

the range is anchored.

Never leave children alone or

unattended in the area where an appliance is in

use. As children grow, teach them the proper, safe use

of all appliances. Never leave the oven door open when

the range is unattended.

Stepping, leaning or sitting on the

doors or drawers of this range can result in serious

injuries and can also cause damage to the range.

Do not store items of interest to children in

the cabinets above the range. Children could be

seriously burned climbing on the range to reach items.

To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessiveflame is hazardous.

Do not use the oven as a storage space. This

creates a potentially hazardous situation.

Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

Do not store or use gasoline or other flammable

vapors and liquids near this or any other

appliance. Explosions or fires could result.

In the event of an electrical power outage, the surface

burners can be lit manually. To light a surface burner,

hold a lit match to the burner head and slowly turn

the Surface Control knob to LITE.Use caution when

lighting surface burners manually.

Reset all controls to the "off" position after using

a programmable timing operation.

FOR MODELS WITH SELF=CLEAN FEATURE:

Remove broiler pan, food and other utensils

before self=cleaning the oven. Wipe up excess

spillage. Follow the predeaning instructions in the Use

and Care Guide.

Unlike the standard gas range, THIS COOKTOP

IS NOT REMOVABLE, Do not attempt to remove the

cooktop.

4

Page 5

Cabinet Construction

Toeliminate the risk of cabinet burns

and fire, do not have cabinet storage space above the

range. If there is cabinet storage space above range,

reduce risk by installing a range hood that projects

horizontally a minimum of 5" (12.7 cm) beyond the

bottom of the cabinet.

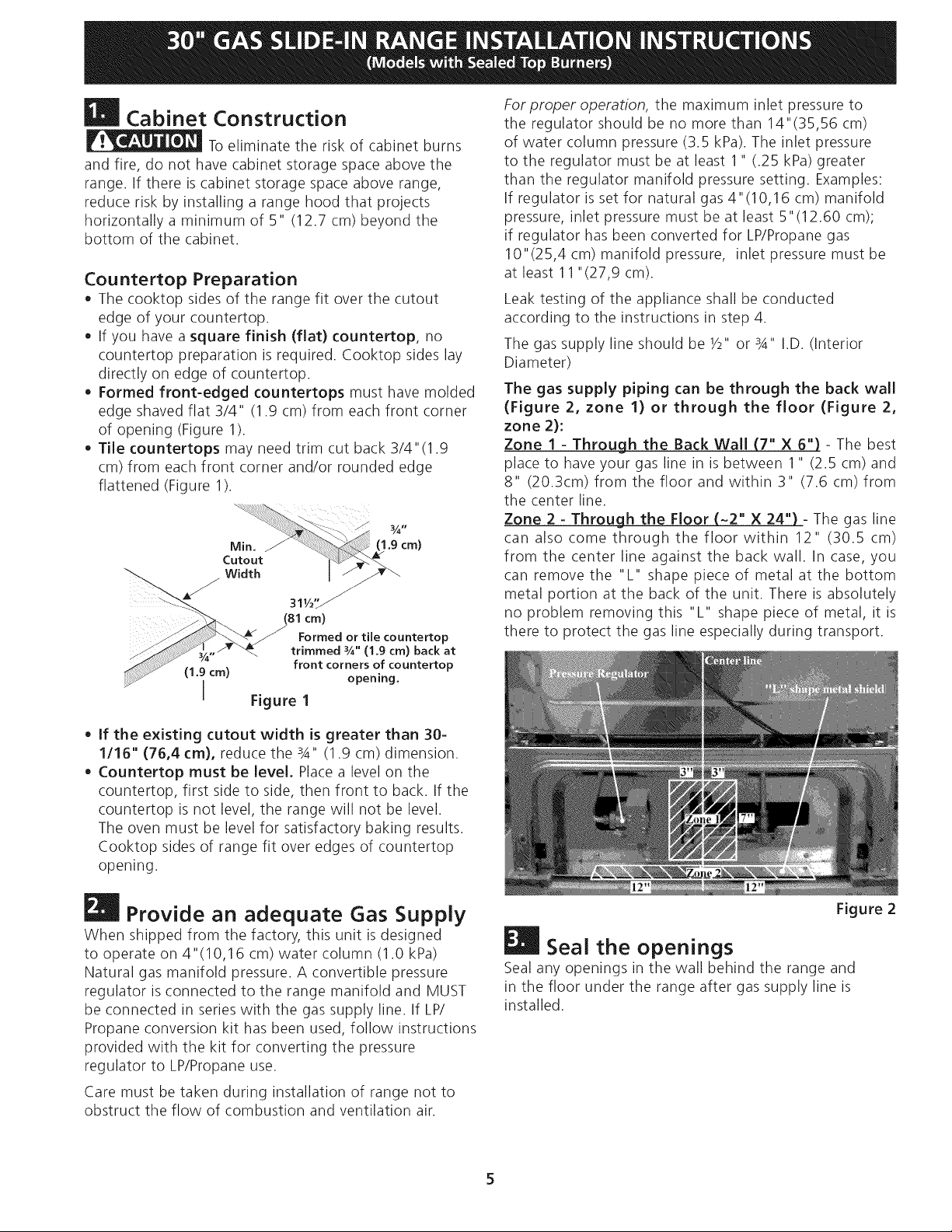

Countertop Preparation

• The cooktop sides of the range fit over the cutout

edge of your countertop.

• If you have a square finish (flat) countertop, no

countertop preparation is required. Cooktop sides lay

directly on edge of countertop.

• Formed front-edged countertops must have molded

edge shaved flat 3/4" (1.9 cm) from each front corner

of opening (Figure 1).

• Tile countertops may need trim cut back 3/4"(1.9

cm) from each front corner and/or rounded edge

flattened (Figure 1).

311/2,,_ _

(81cm)

Formed or tile countertop

trimmed _A" (1_9 cm) back at

front corners of countertop

(1.9 cm) opening,

I Figure I

Forproper operation, the maximum inlet pressure to

the regulator should be no more than 14"(35,56 cm)

of water column pressure (3.5 kPa). The inlet pressure

to the regulator must be at least 1" (.25 kPa) greater

than the regulator manifold pressure setting. Examples:

If regulator is set for natural gas 4" (10,16 cm) manifold

pressure, inlet pressure must be at least 5"(12.60 cm);

if regulator has been converted for LP/Propane gas

10"(25,4 cm) manifold pressure, inlet pressure must be

at least 11 "(27,9 cm).

Leak testing of the appliance shall be conducted

according to the instructions in step 4.

The gas supply line should be 1/2"or 3A" I.D. (Interior

Diameter)

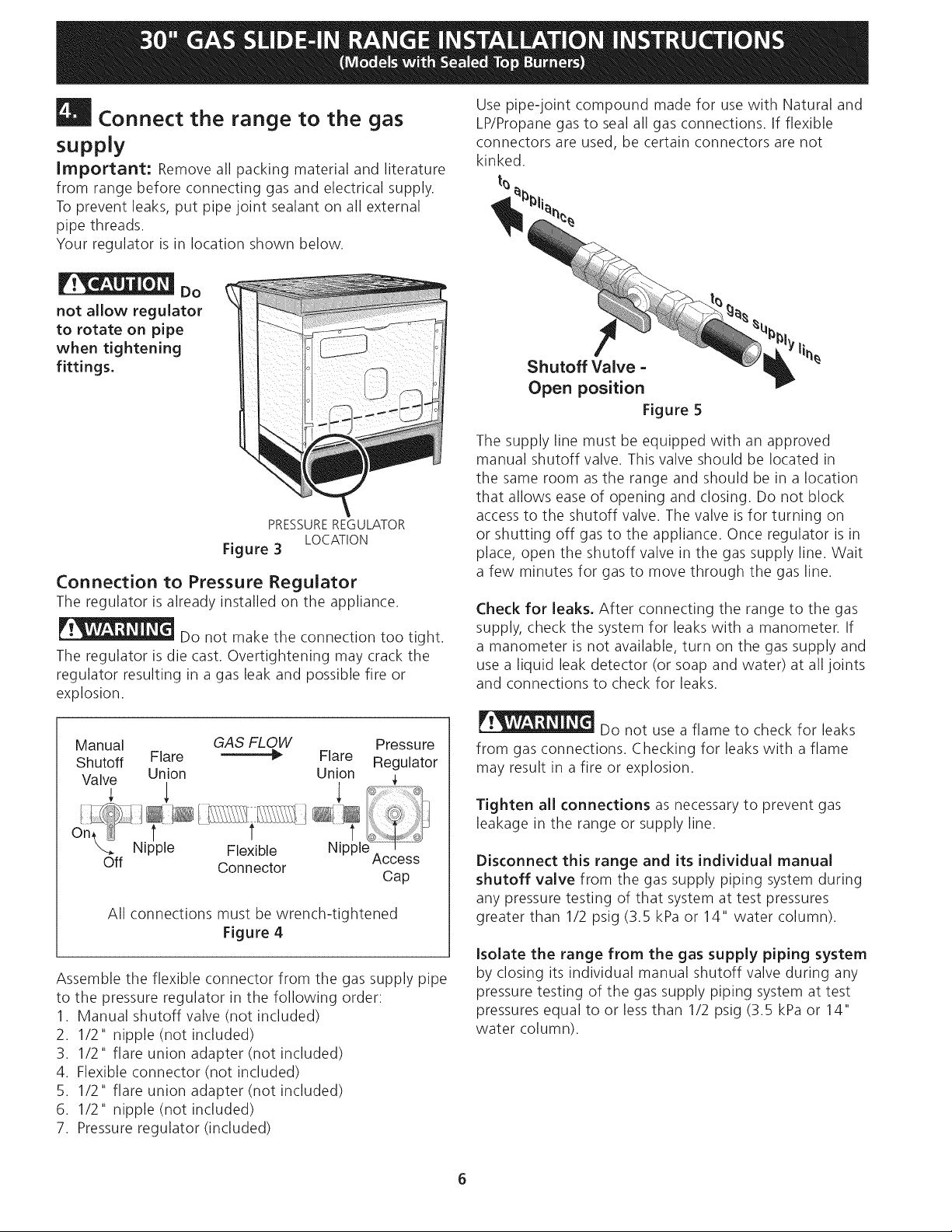

The gas supply piping can be through the back wall

(Figure 2, zone 1) or through the floor (Figure 2,

zone 2):

Zone I - Through the Back Wall (7" X 6") - The best

place to have your gas line in is between 1" (2.5 cm) and

8" (20.3cm) from the floor and within 3" (7.6 cm) from

the center line.

Zone 2 = Through the Floor (~2" X 24") - The gas line

can also come through the floor within 12" (30.5 cm)

from the center line against the back wall. In case, you

can remove the "L" shape piece of metal at the bottom

metal portion at the back of the unit. There is absolutely

no problem removing this "L" shape piece of metal, it is

there to protect the gas line especially during transport.

• If the existing cutout width is greater than 30-

1/16" (76,4 cm), reduce the 3A" (1.9 cm) dimension.

• Countertop must be level, Place a level on the

countertop, first side to side, then front to back. If the

countertop is not level, the range will not be level.

The oven must be level for satisfactory baking results.

Cooktop sides of range fit over edges of countertop

opening.

m

Provide an adequate Gas Supply

When shipped from the factory, this unit is designed

to operate on 4"(10,16 cm) water column (1.0 kPa)

Natural gas manifold pressure. A convertible pressure

regulator is connected to the range manifold and MUST

be connected in series with the gas supply line. If LP/

Propane conversion kit has been used, follow instructions

provided with the kit for converting the pressure

regulator to LP/Propane use.

Care must be taken during installation of range not to

obstruct the flow of combustion and ventilation air.

Figure 2

Seal the openings

Seal any openings in the wall behind the range and

in the floor under the range after gas supply line is

installed.

Page 6

m

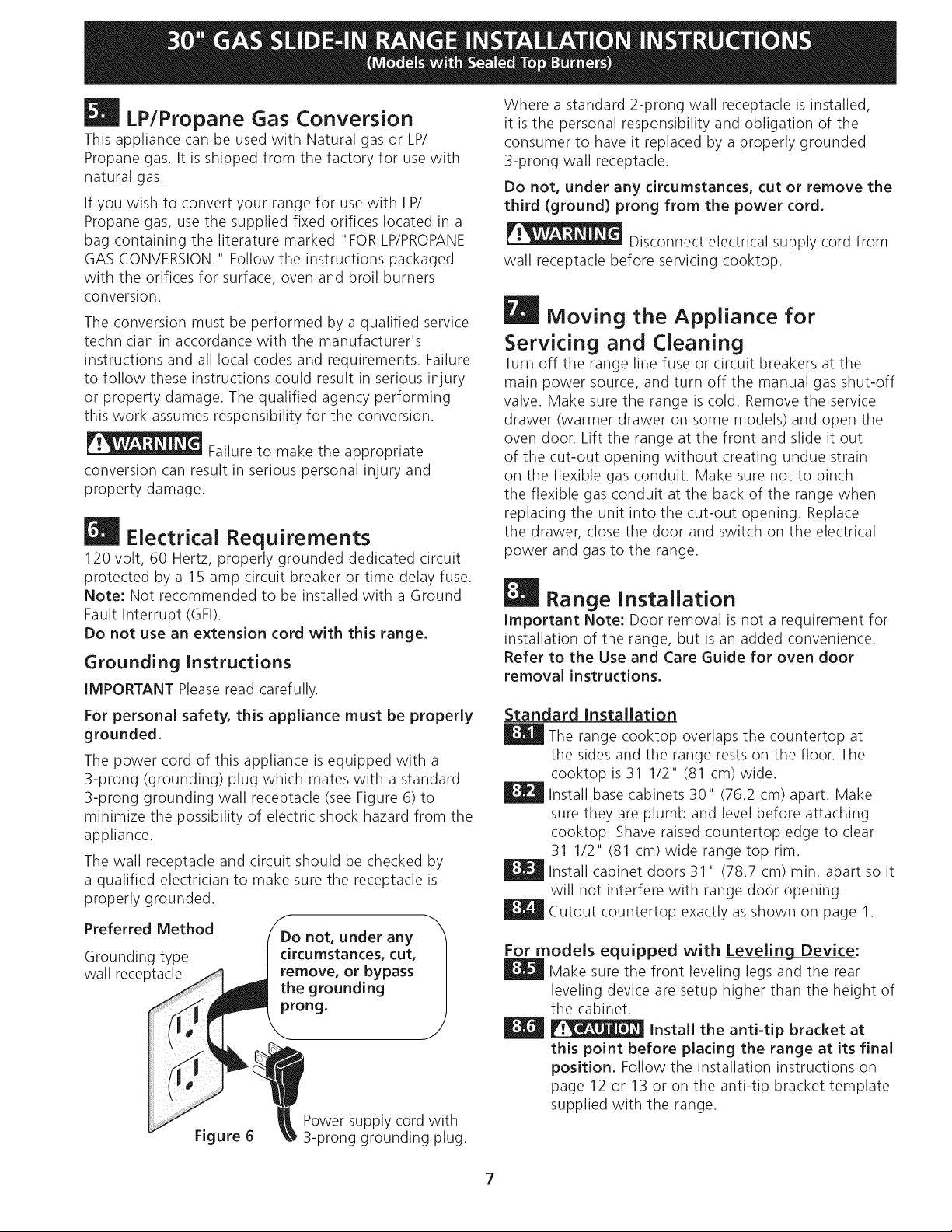

| Connect the range to the gas

supply

Important: Remove all packing material and literature

from range before connecting gas and electrical supply.

To prevent leaks, put pipe joint sealant on all external

pipe threads.

Your regulator is in location shown below.

Do

not allow regulator

to rotate on pipe

when tightening

fittings.

PRESSUREREGULATOR

LOCATION

Figure 3

Connection to Pressure Regulator

The regulator is already installed on the appliance.

_Do not make the connection too tight.

The regulator is die cast. Overtightening may crack the

regulator resulting in a gas leak and possible fire or

explosion.

Use pipe-joint compound made for use with Natural and

LP/Propane gas to seal all gas connections. If flexible

connectors are used, be certain connectors are not

kinked.

t_

Shutoff Valve -

Open position

Figure 5

The supply line must be equipped with an approved

manual shutoff valve. This valve should be located in

the same room as the range and should be in a location

that allows ease of opening and closing. Do not block

access to the shutoff valve. The valve is for turning on

or shutting off gas to the appliance. Once regulator is in

place, open the shutoff valve in the gas supply line. Wait

a few minutes for gas to move through the gas line.

Check for leaks, After connecting the range to the gas

supply, check the system for leaks with a manometer. If

a manometer is not available, turn on the gas supply and

use a liquid leak detector (or soap and water) at all joints

and connections to check for leaks.

Manual GAS FLOW Pressure

Shutoff Flare _I_ Flare Regulator

Valve Union Union _,

Off Connector

All connections must be wrench-tightened

Figure 4

Assemble the flexible connector from the gas supply pipe

to the pressure regulator in the following order:

1. Manual shutoff valve (not included)

2. 1/2" nipple (not included)

3. 1/2" flare union adapter (not included

4. Flexible connector (not included)

5. 1/2" flare union adapter (not included

6. 1/2" nipple (not included)

7. Pressure regulator (included)

Access

Cap

Do not use a flame to check for leaks

from gas connections. Checking for leaks with a flame

may result in a fire or explosion.

Tighten all connections as necessary to prevent gas

leakage in the range or supply line.

Disconnect this range and its individual manual

shutoff valve from the gas supply piping system during

any pressure testing of that system at test pressures

greater than 1/2 psig (3.5 kPa or 14" water column).

Isolate the range from the gas supply piping system

by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.5 kPa or 14"

water column).

Page 7

m

LP/Propane Gas Conversion

This appliance can be used with Natural gas or LID/

Propane gas. It is shipped from the factory for use with

natural gas.

If you wish to convert your range for use with LP/

Propane gas, use the supplied fixed orifices located in a

bag containing the literature marked "FOR LP/PROPANE

GAS CONVERSION." Follow the instructions packaged

with the orifices for surface, oven and broil burners

conversion.

The conversion must be performed by a qualified service

technician in accordance with the manufacturer's

instructions and all local codes and requirements. Failure

to follow these instructions could result in serious injury

or property damage. The qualified agency performing

this work assumes responsibility for the conversion.

Failure to make the appropriate

conversion can result in serious personal injury and

property damage.

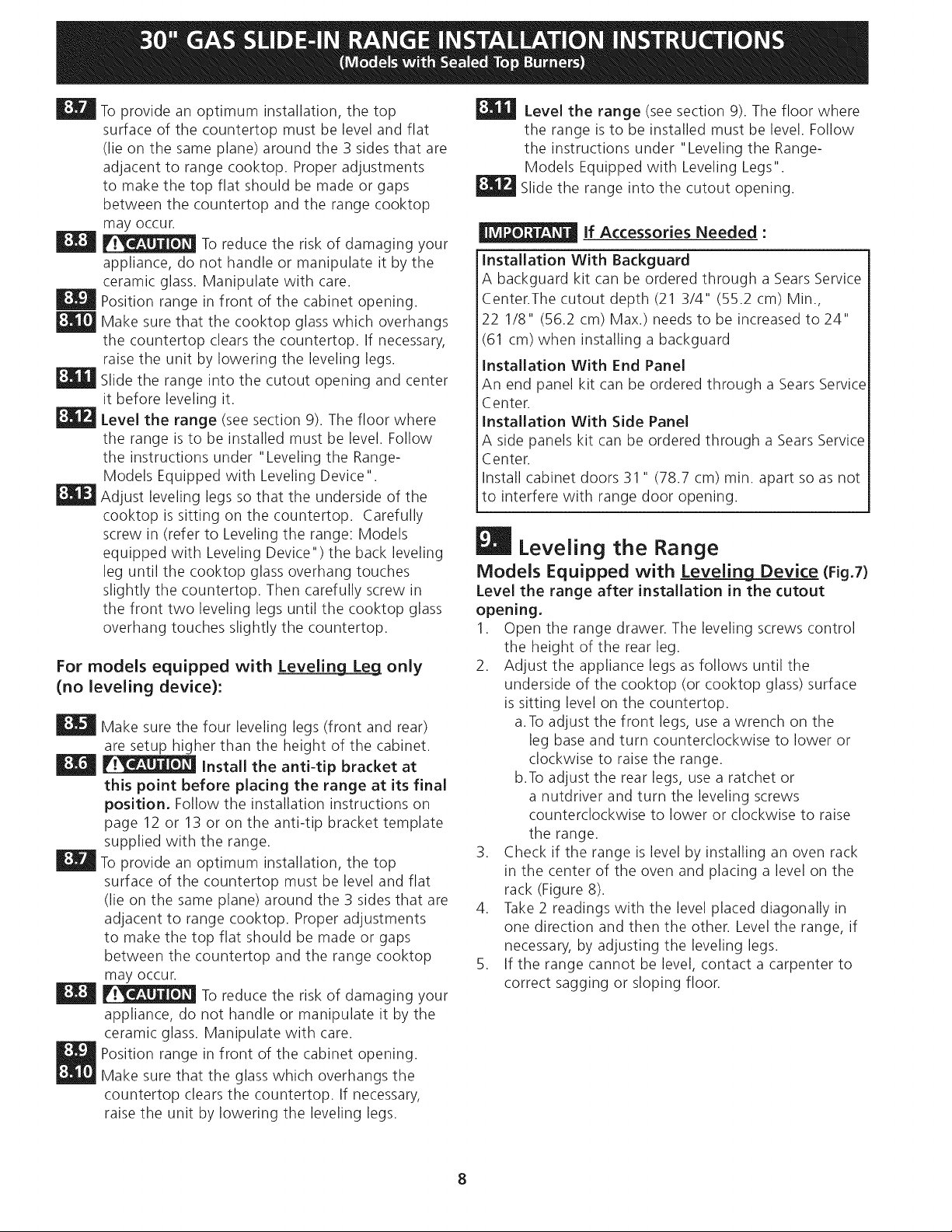

| Electrical Requirements

120 volt, 60 Hertz, properly grounded dedicated circuit

protected by a 15 amp circuit breaker or time delay fuse.

Note: Not recommended to be installed with a Ground

Fault Interrupt (GFI).

Do not use an extension cord with this range.

Grounding Instructions

IMPORTANT Pleaseread carefully.

For personal safety, this appliance must be properly

grounded.

The power cord of this appliance isequipped with a

3-prong (grounding) plug which mates with a standard

3-prong grounding wall receptacle (see Figure 6) to

minimize the possibility of electric shock hazard from the

appliance.

The wall receptacle and circuit should be checked by

a qualified electrician to make sure the receptacle is

properly grounded.

Preferred Method Do not, under any -_

Grounding type circumstances, cut,

wall receptacle remove, or bypass

the grounding

prong.

Power supply cord with

Figure 6

3-prong grounding plug.

Where a standard 2-prong wall receptacle is installed,

it is the personal responsibility and obligation of the

consumer to have it replaced by a properly grounded

3-prong wall receptacle.

Do not, under any circumstances, cut or remove the

third (ground) prong from the power cord.

Disconnect electrical supply cord from

wall receptacle before servicing cooktop.

Moving the Appliance for

Servicing and Cleaning

Turn off the range line fuse or circuit breakers at the

main power source, and turn off the manual gas shut-off

valve. Make sure the range is cold. Remove the service

drawer (warmer drawer on some models) and open the

oven door. Lift the range at the front and slide it out

of the cut-out opening without creating undue strain

on the flexible gas conduit. Make sure not to pinch

the flexible gas conduit at the back of the range when

replacing the unit into the cut-out opening. Replace

the drawer, close the door and switch on the electrical

power and gas to the range.

Range Installation

Important Note: Door removal is not a requirement for

installation of the range, but is an added convenience.

Refer to the Use and Care Guide for oven door

removal instructions.

Standard Installation

The range cooktop overlaps the countertop at

the sides and the range rests on the floor. The

cooktop is 31 1/2" (81 cm) wide.

| Install base cabinets 30" (76.2 cm) apart. Make

sure they are plumb and level before attaching

cooktop. Shave raised countertop edge to clear

31 1/2" (81 cm) wide range top rim.

Install cabinet doors 31 " (78.7 cm) min. apart so it

will not interfere with range door opening.

Cutout countertop exactly as shown on page 1.

For models equipped with Leveling Device:

Make sure the front leveling legs and the rear

leveling device are setup higher than the height of

the cabinet.

_:_ _ Install the anti-tip bracket at

this point before placing the range at its final

position. Follow the installation instructions on

page 12 or 13 or on the anti-tip bracket template

supplied with the range.

7

Page 8

Toprovideanoptimuminstallation,thetop

surfaceofthecountertopmustbelevelandflat

(lieonthesameplane)aroundthe3 sidesthatare

adjacentto rangecooktop.Properadjustments

tomakethetopflatshouldbemadeorgaps

betweenthecountertopandtherangecooktop

mayoccur.

_ To reduce the risk of damaging your

appliance, do not handle or manipulate it by the

ceramic glass. Manipulate with care.

| Position range in front of the cabinet opening.

| Make sure that the cooktop glass which overhangs

the countertop clears the countertop. If necessary,

raise the unit by lowering the leveling legs.

| Slide the range into the cutout opening and center

it before leveling it.

Level the range (see section 9). The floor where

the range isto be installed must be level. Follow

the instructions under "Leveling the Range-

Models Equipped with Leveling Device".

Adjust leveling legs so that the underside of the

cooktop is sitting on the countertop. Carefully

screw in (refer to Leveling the range: Models

equipped with Leveling Device") the back leveling

leg until the cooktop glass overhang touches

slightly the countertop. Then carefully screw in

the front two leveling legs until the cooktop glass

overhang touches slightly the countertop.

For models equipped with Leveling Leg only

(no leveling device):

Make sure the four leveling legs (front and rear)

are setup higher than the height of the cabinet.

_:_ _ Install the anti-tip bracket at

this point before placing the range at its final

position. Follow the installation instructions on

page 12 or 13 or on the anti-tip bracket template

supplied with the range.

To provide an optimum installation, the top

surface of the countertop must be level and flat

(lie on the same plane) around the 3 sides that are

adjacent to range cooktop. Proper adjustments

to make the top flat should be made or gaps

between the countertop and the range cooktop

may occur.

_ To reduce the risk of damaging your

appliance, do not handle or manipulate it by the

ceramic glass. Manipulate with care.

Position range in front of the cabinet opening.

Make sure that the glass which overhangs the

countertop clears the countertop. If necessary,

raise the unit by lowering the leveling legs.

Level the range (see section 9). The floor where

the range isto be installed must be level. Follow

the instructions under "Leveling the Range-

Models Equipped with Leveling Legs".

Slide the range into the cutout opening.

If Accessories Needed :

Installation With Backguard

A backguard kit can be ordered through a Sears Service

Center.The cutout depth (21 3/4" (55.2 cm) Min.,

22 1/8" (56.2 cm) Max.) needs to be increased to 24"

(61 cm) when installing a backguard

Installation With End Panel

An end panel kit can be ordered through a Sears Service

Center.

Installation With Side Panel

A side panels kit can be ordered through a Sears Service

Center.

Install cabinet doors 31 " (78.7 cm) min. apart so as not

to interfere with range door opening.

Leveling the Range

Models Equipped with Leveling Device (Fig.7)

Level the range after installation in the cutout

opening.

1. Open the range drawer. The leveling screws control

the height of the rear leg.

2. Adjust the appliance legs as follows until the

underside of the cooktop (or cooktop glass) surface

is sitting level on the countertop.

a.To adjust the front legs, use a wrench on the

leg base and turn counterclockwise to lower or

clockwise to raise the range.

b.To adjust the rear legs, use a ratchet or

a nutdriver and turn the leveling screws

counterclockwise to lower or clockwise to raise

the range.

3. Check if the range is level by installing an oven rack

in the center of the oven and placing a level on the

rack (Figure 8).

4. Take2 readings with the level placed diagonally in

one direction and then the other. Level the range, if

necessary, by adjusting the leveling legs.

5. If the range cannot be level, contact a carpenter to

correct sagging or sloping floor.

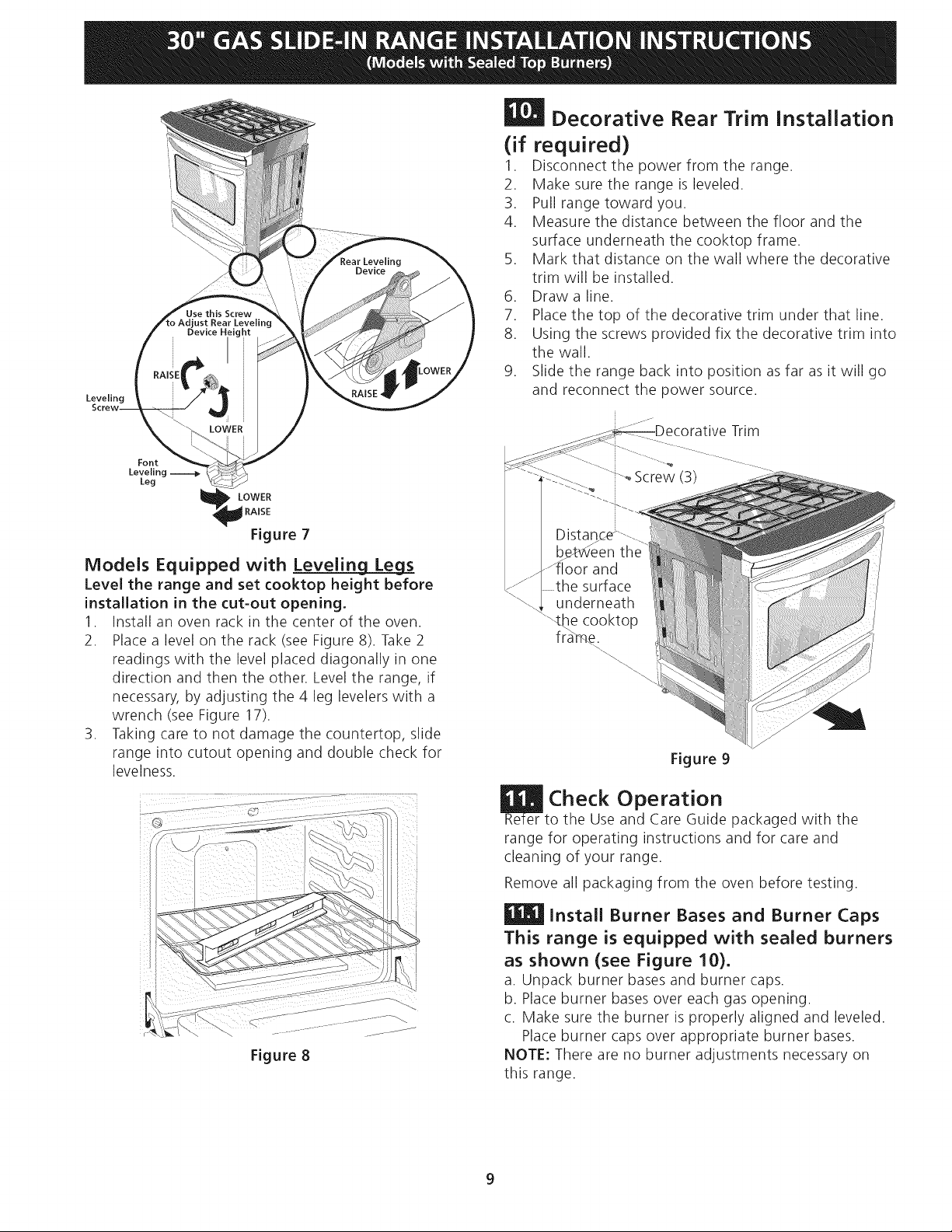

Page 9

Leveling

Font

Leveling

Leg

Decorative Rear Trim Installation

(if required)

1. Disconnect the power from the range.

2. Make sure the range is leveled.

3. Pull range toward you.

4. Measure the distance between the floor and the

surface underneath the cooktop frame.

5. Mark that distance on the wall where the decorative

trim will be installed.

6. Draw a line.

7. Place the top of the decorative trim under that line.

8. Using the screws provided fix the decorative trim into

the wall.

9. Slide the range back into position as far as it will go

and reconnect the power source.

Trim

oScrew (3)

LOWER

RAISE

Figure 7

Models Equipped with Levelin_

Level the range and set cooktop height before

installation in the cut-out opening.

1. Install an oven rack in the center of the oven.

2. Place a level on the rack (see Figure 8). Take 2

readings with the level placed diagonally in one

direction and then the other. Level the range, if

necessary, by adjusting the 4 leg levelers with a

wrench (see Figure 17).

3. Taking care to not damage the countertop, slide

range into cutout opening and double check for

levelness.

Figure 8

:loor and

surface

underneath

"\the cooktop

fra_

Figure 9

Check Operation

Re-

to the Use and Care Guide packaged with the

range for operating instructions and for care and

cleaning of your range.

Remove all packaging from the oven before testing.

| Install Burner Bases and Burner Caps

This range is equipped with sealed burners

as shown (see Figure 10).

a. Unpack burner bases and burner caps.

b. Place burner bases over each gas opening.

c. Make sure the burner is properly aligned and leveled.

Place burner caps over appropriate burner bases.

NOTE: There are no burner adjustments necessary on

this range.

9

Page 10

Electrode ................ J

Figure 10

Turn on Electrical Power and Open

Main Shutoff Gas Valve

Check the Igniters

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks, and range has been connected to

electric power. Tocheck for proper lighting:

a. Push in and turn a surface burner knob to the LITE

position. You will hear the igniter sparking.

b. The surface burner should light when gas is available

to the top burner. Each burner should light within

four (4) seconds after air has been purged from supply

lines. Visually check that burner has lit.

c. Once the burner lights, the control knob should be

rotated out of the LITEposition.

There are separate ignition devices for each burner. Try

each knob separately until all burner valves have been

checked.

Adjust the "LOW" Setting of Surface

Burner Valves (see Figure 11)

a. Push in and turn each control to LITEuntil burner

ignites.

b. Quickly turn knob to LOWEST POSITION.

c. If burner goes out, readjust valve asfollows:

Reset control to OFF.Remove the surface burner

control knob, insert a thin-bladed screw driver into the

hollow valve stem and engage the slotted screw inside.

Flame size can be increased or decreased with the

turn of the screw. Adjust flame until you can quickly

turn knob from LITEto LOWESTPOSITIONwithout

extinguishing the flame. Flame should be as small as

possible without going out.

Figure 11

Operation of Oven Burners and Oven

Adjustments

11.5.1 Electric Ignition Burners

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks, and range has been connected to

electric power.

The oven burner is equipped with an electric control

system as well as an electric oven burner igniter. If your

model isequipped with a waist-high broil burner igniter,

it will also have an electric burner igniter. These control

systems require no adjustment. When the oven isset to

operate, current will flow to the igniter. It will "glow"

similar to a light bulb. When the igniter has reached

a temperature sufficient to ignite gas, the electrically

controlled oven valve will open and flame will appear

at the oven burner. There is atime lapse from 30 to 60

seconds after thermostat is turned ON before the flame

appears at the oven burner. When the oven reaches the

display setting, the glowing igniter will go off. The burner

flame will go "out" in 20 to 30 seconds after igniter goes

"OFF". Tomaintain any given oven temperature, this cycle

will continue as long as the display is set to operate.

After removing all packing materials and literature from

the oven:

a) Set the oven to BAKEat 300% See Use & Care Guide

for operating instructions.

b) Within 60 seconds the oven burner should ignite.

Check for proper flame, and allow the burner to cycle

once. Reset controls to off.

c) If your model is equipped with a high-waist broiler,

set oven to broil. See Use & Care Guide for operating

instructions.

d) Within 60 seconds the broil burner should ignite. Check

for proper flame. Resetcontrols to off.

10

Page 11

L wer

OvenBaffle

Waist-HighBurner

Shutter

(removable),

!1

LowerOvenBottom

_l--Air Shutter (removable)

Figure12

11.5.2Air Shutter-OvenBurner

Theapproximateovenburnerflamelengthis1inch

(distinctinnerconeofblueflame).

Todetermineiftheovenburnerflameisproper,removethe

ovenbottomandburnerbaffleandsettheoventobakeat

300%

Toremovetheovenbottom,removeovenholddown

screwsatrearofovenbottom.Pullupatrear,disengage

frontofovenbottomfromovenfrontframe,andpullthe

ovenbottomoutof theoven.Removeburnerbafflesothat

burnerflamecanbeobserved.

Iftheflameisyellow,increaseairshutteropeningsize(see

"2" inFigure13).Iftheentireflameisblue,reducetheair

shutteropeningsize.

Toadjustframeloosenlockscrew(see"3" inFigure13),

repositionairshutter,andtightenlockscrew.Replaceoven

bottom.

When All Hookups are Complete

MakesureallcontrolsareleftintheOFFposition.

Makesuretheflowofcombustionandventilationairto

therangeisunobstructed.

Model and Serial Number Location

The serial plate is located on the oven front frame behind

the oven door (some models) or on the drawer side

frame (some models).

When ordering parts for or making inquiries about your

range, always be sure to include the model and serial

numbers and a lot number or letter from the serial plate

on your range.

Your serial plate also tells you the rating of the burners,

the type of fuel and the pressure the range was adjusted

for when it left the factory.

Before You Call for Service

Read the Before You Call Checklist and operating

instructions in your Use and Care Guide. It may save you

time and expense. The list includes common occurrences

that are not the result of defective workmanship or

materials in this appliance.

Refer to your Use & Care Guide for Sears service phone

numbers or call 1-800-4-MY-HOME®.

Burner Tube

(_ Lock Screw_

Air Shutter--II_!

Orifice Hood

Figure 13

11.5.3 Air Shutter-Broil Burner

The approximate flame length of the burner is 1 inch

(distinct inner cone of blue flame). Todetermine if the broil

burner flame is proper, set the oven to broil. If flame is

yellow, increase air shutter opening size (see "2" in Figure

13 ). If the entire flame is blue, reduce the air shutter

opening size. Toadjust, loosen lock screw (see "3" in

Figure 13), reposition air shutter, and tighten lock screw.

11

Page 12

Anti-Tip Brackets Installation

instructions

ModeJs Equipped with Leveling Device

To reduce the risk of tipping of the

range, the range must be secured to the floor by properly

installed anti-tip bracket and screws packed with the

range. These parts are located in the oven. Failureto

install the anti-tip bracket will allow the range to tip over

if excessive weight is placed on an open door or if a child

climbs upon it. Serious injury might result from spilled hot

liquids or from the range itself.

Follow the instructions below to install the anti-tip

brackets.

If range is ever moved to a different location, the anti-

tip brackets must also be moved and installed with the

range.

Tools Required:

Adjustable Wrench

Ratchet

Drill & 1/8"(0,32 cm) bit

5/16" (0,8 cm) Nutdriver

Level

The anti-tip bracket attaches to the floor at the back of

the range to prevent range from tipping. When fastening

bracket to the floor, be sure that screws do not penetrate

electrical wiring or plumbing. The screws provided will

work in either wood or concrete.

1. Draw a center line (CL) on the floor where the range

should be installed. Also draw a line on the floor at

the range back position if there is no wall.

2. Unfold paper template and place it flat on the floor

with the right rear corner positioned exactly on the

intersection of the center and back lines you just drew

before. (Use the diagram below to locate brackets if

template is not available (Figure 14)).

3. Mark on the floor the location of the 4 mounting

holes shown on the template. For easier installation,

3/16"(0,48 cm) diameter pilot holes 1/2"(1,27 cm)

deep can be drilled into the floor.

4. Remove template and place bracket on floor. Line up

holes in bracket with marks on floor and attach with

4 screws provided. Bracket must be secured to solid

floor (Figure 16). If attaching to concrete floor, first

drill 3/16" (0,48 cm) dia. pilot holes using masonry drill

bit.

5. Besure the 4 leveling legs are at the highest position

they can be.

6. Slide range into place making sure structure of the

range is trapped by the anti-tip bracket (Figure 15).

Lower the range by adjusting the 4 leveling legs until

the underside of the cooktop is sitting level on the

countertop. Refer to "Leveling the Range" section.

7. After installation, verify that the anti-tip bracket is

engaged by grasping the top rear edge of the range

and carefully attempt to tilt it forward to make sure

range is properly anchored.

i}

i}

i}

i}

i}

Figure 14

Floor Mount_

Screws

Figure 15

BACK

12

Page 13

ped with Leveli_

To reduce the risk of tipping of

the range, the range must be secured to the floor by

properly installed anti-tip brackets and screws packed

with the range. These parts are located in a plastic bag in

the oven. Failure to install the anti-tip brackets will allow

the range to tip over if excessive weight is placed on

an open door or if a child climbs upon it. Serious injury

might result from spilled hot liquids or from the range

itself.

Follow the instructions below to install the anti-tip

brackets.

If range is ever moved to a different location, the anti-

tip brackets must also be moved and installed with the

range. To check for proper installation, see step 5.

Tools Required:

5/16" (0,79 cm) Nutdriver or Flat Head Screwdriver

Adjustable Wrench

Electric Drill

3/16"(0, cm) Diameter Drill Bit

3/16"(0, cm) Diameter Masonry Drill Bit (if installing in

concrete

Brackets attach to the floor at the back of the range to

hold both rear leg levelers. When fastening to the floor,

be sure that screws do not penetrate electrical wiring or

plumbing. The screws provided will work in either wood

or concrete.

Anti-tip Bracket

1. Unfold paper template and place it flat on the floor

with the back and side edges positioned exactly

where the back and sides of range will be located

when installed. (Use the diagram below to locate

brackets if template is not available. (Figure 16))

2. Mark on the floor the location of the 4 mounting

holes shown on the template. For easier installation,

3/16" (0.5 cm) diameter pilot holes 1/2" (1.3 cm)

deep can be drilled into the floor.

3. Remove template and place brackets on floor

with turned up flange to the front. Line up holes

in brackets with marks on floor and attach with 4

screws provided. Brackets must be secured to solid

floor. If attaching to concrete floor, first drill 3/16"

(0.5 cm) dia. pilot holes using a masonry drill bit.

4. Level range if necessary, by adjusting 4 leg levelers

with wrench (Figure 17). A minimum clearance of

1/8" (0.8 cm) is required between the bottom of the

range and the rear leg levelers to allow room for the

anti-tip brackets.

5. Slide range into place making sure rear legs are

trapped by ends of brackets. Range may need to

be shifted slightly to one side as it is being pushed

back to allow rear legs to slide under brackets. You

may also grasp the top rear edge of the range and

carefully attempt to tilt it forward to make sure

range is properly anchored.

BackEdgeof Range /

or RearWall _41€/

C /- "--.. "...........-.

: .-9 1/8" _. 18'_ ">" _ .....

<--_,_.>_ (23.2 cm) " _(46.4 cm)

Anti-tip Bracket "--. _(71.4cm)

(CL = Center line)

Figure 16

(Rearwidth of range

with bodysides)

Figure 17

SlideBack

13

Page 14

LA INSTALACION Y EL SEP,VICIO DEBEN SEP, EFECTUADOS POP, UN INSTALADOP, CAUFICADO.

IMPOP,TANTE: GUAP,DE ESTAS INSTP,UCCIONES PAP,A USO DEL INSPECTOR LOCAL DE /__s jo__..

ELECTP,ICIDAD. LEA Y GUAP,DE ESTAS INSTP,UCCIONES PAP,A P,EFEP,ENCIA FUTUP,A.

Sila informaci6n contenida en este manual no es seguida

exactamente, puede ocurrir un incendioo explosion causandodaffos materiales, l.._/_

lesion personalo la muerte.

PARASU SEGURIDAD:

-- No almacene ni utilice gasolina u otros vapores y liquidos inflamables en la

proximidad de _ste o de cualquier otro artefacto.

-- QUEDEBEHACERSIPERClBEOLORA GAS:

• No trate de encender ningun artefacto.

• No toque ningun interruptor el6ctrico; no use ningun tel6fono en su

edificio.

• Llame a su proveedor de gas desde el tel6fono de un vecino. Siga las

instrucdones del proveedor de gas.

• Si no logra comunkarse con su proveedor de gas, flame al departamento

de bomberos.

-- La instalad6n y el servMo de mantenimiento deben ser efectuados por un

instalador calificado, la agenda de servkio o el proveedor de gas.

PARED

La superfide debe

estar plana y nive!ada

(area sornb

1/2" Min.i

Min. 5"

(!2.TCm) delaPaied;

Acepille el borde

ambos lados...

subido a que

deje espacio

para un borde

31Y2" (81 cm)de

anchura de estufa

31 1/2"

(81 cm)

Exacto

Aparatos Instalados en el estado

de Massachusetts;

EsteAparato s61o puede ser instalado

en el estado de Massachusetts por un

plomero o ajustador de gas licenciado

de Massachusett.

Esteaparato se debe instalar con un

largo conector flexible de gas de tres (3)

pies/36 pulgadas.

Una wilvula manual de gas de tipo

manija de forma de "T" se debe instalar

en la Ifnea del suministro de gas de este

aparato.

30" Min.

76.2 cm Min.)

30" Min.

(76.2 cm Min.) 13"

(v6a la nota 3) (33 cm)

18" Min.

(45.7 cm) Min.

Approx. 1 7/8"

(4.8 cm)

Localice las puertas del

armario 1"(2.5 cm) min

del hueco de la abertura.

IMPORTANTE: El

ancho de la cubierta

y el armario debe

de ser igual al ancho

E

del corte.

ll_J___No instale la unidad en el gabinete si no ha lado esta p_qgina.

A ALTURA ' B:ANcNo " C. ANCH0 DE D. PROFUNDIDAD A

I LA PLANCHA DE LA FRENTEDE LA

- COC NAR - ESTUFA

355/8" (90.5cm) - 30" Porcelana 28 5/16" (71,9 cm)

365/8" (93cm) (76,2 cm) 315/16" (79.5cm)

Vidrio

31 1/2" (81cm)

NOTA: Se adjunta el diagrama de cables de esta codna al final de este libreta.

Impreso en los Estados Unidos

E. ANc HO F. PROFUNDIDAD DE G[ ALTURA DEL

DE RECORTADO RECORTADO .... MOSTRADOR

(cubierta y armario) i

30_+1/16" 21 3/4" (55,2 cm)Min. 36 5/8" (93cm)Max.

(76,2_+0,15cm) 22 1/8" (56,2 cm) Max 35 5/8" (90.5cm) Min.

Notas - p_igina 27; Diagrama de la instalaci6n akimbrica - p_igina 28

La caj de empalmesoel enchufe con

puesta a tierra deberia situarse de 8" a 17"

(20.3 cm a 43.2 cm) del armario derecho y

de 2" a 4" (5.1 cm a 10.2 cm) del suelo.

24" (61cm) Min. conun

protectortrasero.

English- pages 1-13; Espahol- p_iginas 14-26;

°°°÷,°"

24" Min.

(61 cm Min.)

/

P/N 318201688 (1007) Rev. A

Page 15

NOTAS:

No pellizque el cord6n electrico entre la estufa y la pared.

No selle la estufa a los armarios de lado.

Un espacio minimo de 24" (61 cm) entre la superficie de la estufa y el fondo del

armario esto cuando el fondo del armario de madera o metal est,1protegido pot

no menos de 1/4" (0.64 cm) de madera resistente al fuego cubierta pot una I_imina

met_ilica de MSG, n0mero 28, 0.01 5" (0.4 mm) de acero inoxidable, 0.024" (0.6

mm) aluminio, 6 0.020" (0.5 mm) de cobre.

Un espacio minimo de 30" (76.2 cm) cuando el armario no este protegido.

Para los recortados menos que 22 7/8", el electrodomestico apareceria ligeramente

en el exterior del armario.

Deje pot los 19 ¼" (48.9 cm) de espacio libre para la profundidad de la puerta

cuando este abierta.

22 7/8" (58.1 cm) min.

23 1/4" (59.05 cm) max.

÷ (yea la nota 4) ÷ r"

PARTE

DELANTERA

DEL

ARMARIO

r I

1 1/8"

_(2.86 cm)

Ref.

Panel lateral

A ALTURA B. ANcH0 c. ANCHO DE D: PROFUNDIDAD A

LA PLANCHA DE LA FRENTEDE LA

- - COCINAR " ESTUFA

355/8" (90.5cm) - 30" Porcelana 28 5/16" (71,9cm)

365/8" (93cm) (76,2 cm) 315/16" (79.5cm)

Vidrio

31 1/2" (81cm)

E. ANCHO F: PROFUNDIDAD DE G. ALTURA DEL

DE RECORTADO RECORTADO MOSTRADOR

(cubierta y armario) • -

30_+1/16" 21 3/4" (55,2 cm)Min. 36 5/8" (93cm)Max.

(76,2_+0,15cm) 22 1/8" (56,2 cm) Max 35 5/8" (90.5cm) Min.

24" (61cm) Min. conun

protectortrasero.

15

Page 16

Para evitar fractura de la unidad: NO manipule la unidad sosteniendo

la cubierta de vidrio.

Lacubierta alrededor del espacio donde usted instalara su unidad debe de

estar plana y nivelada (Vea el _qreasombreada en la ilustracion n0mero 1).

Antes de instalar la unidad, mida la altura de los dos (2)lados de los

gabinetes (H1-4), frente y parte trasera (yea ilustracion 1)del piso a Io

alto de la cubierta.

/

Nivele la estufa usando

las 4 patas niveladoras de

manera que la altura del

piso a la superficie interior

de la cubierta de vidrio es

mayor que la altura del

gabinete mas alto de su

Lime el borde

levantado

paradejar

espacio para

una unidad

con un

dimensi6n d_

31 Y2"(81

cm).

1 1/2"Max.

(3.8cm Max.)

mobiliario de cocina por

Io menos por 1/16" (yea

ilustracion 2).

IlustraciOn 1

Deslice la unidad hacia el gabinete. Aseg0rese que la unidad este centrada con el centro de la

abertura del gabinete.

Remueva la parte en pl_qsticoextruido en cada lado de la cubierta de

vidrio. (Algunos modelos)

Es imprescindible que el reborde de metal que se encuentra debajo de

la cubierta este sobre la cubierta del gabinete. La cubierta de vidrio no

deber_qtocar directamente la cubierta del gabinete (yea ilustracion 2)

de no ser asi la fractura del vidrio anular_q la garantia. Nivele la unidad

si es necesario.

Despues de la instalacion, ASEGORESE que la unidad

este sostenida pot las patas niveladoras y NO por la

cubierta.

16

Para instalar

.: exitosamente su

estufa, la medida

inicial del piso a la

superficie interior de

la cubierta de vidrio

debe ser mayor que

la altura del gabinete

por Io menos 1/16"

como se midi6 en el

paso nOmero 1.

IlustraciOn 2

Page 17

Notas importantes para el Instalador

1. Lea todas las instrucciones contenidas en este manual

antes de instalar la estufa.

2. Saque todo el material usado en el embalaje del

compartimiento del homo antes de conectar el suministro

electrico o de gas a la estufa.

3. Observe todos los codigos y reglamentos pertinentes.

4. Deje estas instrucciones con el comprador.

5. Nota: Para la utilizacion a m_is de 2 000 pies de altura, la

potencia del aparato deber_i set reducida de 4 pot ciento

a cada 1 000 pies adicionales.

Nota Importante para el Consurnidor

Conserve estas instrucciones y el Manual del Usuario para

referencia futura.

IMPORTANTES INSTRUCCIONES

DE SEGURIDAD

Instalacion de esta estufa debe cumplir con todos los

codigos locales, o en ausencia de codigos locales con el

Codigo Nacional de Gas Combustible ANSI Z223.1/NFPA

.54--01tima edicion.

El diseho de esta estufa ha sido certificado pot la CSA

Internacional. En este como en cualquier otto artefacto

que use gas y genere calor, hay ciertas precauciones de

seguridad que usted debe seguir. Estas set,in encontradas

en el Manual del Usuario, lealo cuidadosamente.

* Asegurese de que la estufa sea instalada y

conectada a tierra en forrna apropiada por un

instalador calificado o por un tecnico.

* Esta estufa debe ser electricarnente puesta a tierra de

acuerdo con los c6digos locales, o en su ausencia, con

el Codigo Electrico Nacional ANSI/NFPA No. 70, ultirna

edicion, Vea las instrucciones para la puesta a tierra.

* Antes de instalar la estufa en un _rea cuyo piso

este recubierto con IinOleo u otro tipo de piso

sintetico, asegurese de que estos puedan resistir

una ternperatura de por Io rnenos 90°F sobre la

ternperatura arnbiental sin provocar encogirniento,

deformaciOn o decoloraciOn. No instale la estufa sobre

una alfombra al menos que coloque una plancha de

material aislante de pot Io menos 1_ pulgada, entre la

estufa y la alfombra.

[]

@

* Todas las

estufas pueden

volcarse.

* Esto podr[a

resultar en

lesiones

personales.

* Instale el

dispositivo

antivuelcos

que se ha

empacado

junto con esta

estufa.

Para reducir el riesgo de

que se vuelque la estufa,

hay que asegurarla

adecuadamente colo

candole los soportes

antivuelco que se

proporcionan. Para

comprobar si estos est_in

instalados y apretados en

su lugar como se debe,

ase el borde trasero

superior de la estufa y

cuidado samente incline

la hacia adelante para

asegurar que la estufa se

ancle.

* Asegurese de que el material que recubre las

paredes alrededor de la estufa, pueda resistir el

calor generado por la estufa.

* No obstruya el flujo del aire de cornbustion en la

ventilacion del homo ni tarnpoco alrededor de la

base o debajo del panel inferior delantero de la

estufa. Evite tocar las aberturas o _ireas cercanas de la

ventilacion, ya que pueden estar muy calientes durante el

funcionamiento del homo. La estufa requiere aire fresco

para la combustion apropiada de los quemadores.

Nunca deje ni_os solos o

desatendidos en un _rea donde un artefacto est_

siendo usado. A medida que los nihos crecen, enseheles

el uso apropiado y de seguridad para todos los artefactos.

Nunca deje la puerta del homo abierta cuando la estufa

est,1 desatendida.

No se pare, apoye o siente en las

puertas o cajones de esta estufa pues puede resultar en

serias lesiones y puede tarnbien causar da_o a la estufa.

* No alrnacene articulos que puedan interesar a los

ni_os en los gabinetes sobre la estufa. Los nihos

pueden quemarse seriamente tratando de trepar a la

estufa para alcanzar estos art[culos.

* Los gabinetes de alrnacenarniento sobre la estufa

deben ser evitados, para elirninar la necesidad de

tenet que pasar sobre los quernadores superiores de

la estufa para Ilegar a ellos.

* Ajuste el tarna_o de la llama de los quernadores

superiores de tal rnanera que esta no sobrepase el

borde de los utensilios de cocinar. La llama excesiva es

peligrosa.

* No use el homo corno espacio de almacenaje. Esto

create1una situacion potencialmente peligrosa.

* Nunca use la estufa para calentar el cuarto. El uso

prolongado de la estufa sin la adecuada ventilacion puede

resultar peligroso.

* No almacene ni utilice gasolina u otros vapores y

liquidos inflarnables en la proxirnidad de este o de

cualquier otro artefacto electrico. Puede provocar

incendio o explosion.

* En caso de una interrupcion del servicio electrico, es posible

de encender los quemadores de superficie a mano. Para

encender un quemador de superficie, acerque un fosforo

encendido del cabezal del quemador, y gire delicadamente

el boton de control de superficie a LITE(encendido). Tenet

cuidado al encender los quemadores a mano.

* Ajuste todos los controles a la posicion "OFF"

(apagada) despues de haber hecho una operaci6n

con tiernpo prograrnado.

PARA MODELOS AUTOUMPIANTES:

* Saque la asadera, alirnentos o cualquier otto

utensilio antes de usar el ciclo de autolirnpieza del

horno. Limpie todo exceso de derrame de alimentos. Siga

las instrucciones de prelimpiado en el Manual del Usuario.

o A diferencia de la gama est_ndar cocinas de gas,

ESTA PLANCHA DE COCINA NO ES MOVlBLE No

intente quitar la plancha de cocina.

17

Page 18

m

Construccion del armario

Para eliminar el riesgo de quemaduras

o de fuego tratando de alcanzar algo pot encima de las

zonas calientes, evite de colocar articulos sobre la cocina.

Si cree necesitar este espacio, el riesgo puede disminuir

si instala un sombrerete que proteja horizontalmente un

minimo de S" (12.7cm) sobre la base del armario.

Preparacion del mostrador

• Las extremidades de la cocina sobrepasan el horde de

su mostrador.

• Si tiene un mostrador con las extremidades

cuadradas (planas), no se necesita ninguna

preparaci6n del mostrador.

El reborde de frente de mostradores moldeados

deben tenet hordes moldeados a 3/4" (1.9cm) a partir

de cada extremidad de la apertura (Figura 1).

• Los mostradores enazulejos deber_in necesitar un

recorte de 3/4" (1.9 cm) a partir de cada extremidad

y/o un horde redondeado aplanado (Figura 1).

311/2,,//_

(81 cm)

ostrador moldeado o

azulejo recortado 3/4

cm) hacia atr_s en las

........ _l,_, cmj esquinas de frente de la

abertura del mostrador,

Figura I

Si el ancho de la abertura del mostrador es

mas grande que 30 1/16" (76,4 cm), ajuste alas

dimensiones como para el 3/4" (1.9).

El mostrador deber ser nivelado. Coloque un

nivelador sobre el mostrador, primero de lado a lado

y luego del frente hacia atr_is. Si el mostrador no est,1

nivelado, la cocina no estate1nivelada. El homo debe

set nivelado para tenet resultados satisfactorios al

hornear. Las extremidades de la plancha de la cocinar

sobrepasan los hordes de la abertura del mostrador.

proporcionadas el juego para convertir el regulador de

presi6n al uso de LP/Propano.

se debe de tener cuidado durante la instalaci6n de la

estufa para no obstruir el flujo de aire de combusti6n y

ventilaci6n

Para la operaci6n apropiada, la m_ixima presi6n de

entrada al regulador no debe exceder la presi6n de una

columna de agua de 14"(35,56 cm) (3.5 kPa). La presi6n

de entrada al regulador debe set pot Io menos 1" (.25

kPa) m_isgrande que la wilvula distribuidora. Ejemplos:

Si regulador se pone para el gas natural con una presi6n

de 4"(10,16 cm), la presi6n de entrada al regulador debe

set pot Io menos 5"(12.60 cm); si el regulador se ha

convertido para gas LP/Propano 10"(25,4 cm)la presi6n

de entrada al regulador debe set pot Io menos 11"(27,9

cm).

Un examen de detecci6n de fugas del aparato debe set

realizado segOn las instrucciones en el paso 4.

La linea de fuente de gas debe set de 1/2" o de 3A".

La tuberia de suministro de gas puede salir tanto de

la pared (Figura 2, zona 1) o como del piso (Figura 2,

zona 2):

Zona I -Por medio de pared (7" X 6") - El mejor

espacio para la linea de gas esta dentro de 1" (2.5 cm) y

8" (20.3cm) distancia con respecto al piso y 3" (7.6 cm)

del centro de la linea.

Zona 2 - Por medio del piso (~2" X 24") - La linea de

gas puede salir del suelo con 12" (30.5 cm) del centro de

la linea con respecto al la pared de atr_is. Puede remover

la pieza de metal en "L" Iocalizada atr_is del aparato.

No existe problema alguno al remover esta pieza "L" de

metal, la cual existe solamente para proteger la linea de

gas durante transporte.

Proporcione un suministro de gas

adecuado

Cu_indo se envia de la f_ibrica, esta unidad ha sido

ajustada para operar con un mOltiple de admisi6n para

gas natural de 4" (10.16 cm)(1.0 kPa). Un regulador

de presi6n convertible esta conectado a la wilvula

distribuidora y DEBEset conectado con la tuberia del

suministro de gas. Si el juego de conversi6n del propano

LP/Propano se ha utilizado, sigue las instrucciones

Figure 2

18

Page 19

m

Selle las aperturas

sella todas las aperturas en la pared detr_is de la estufa y

en el suelo debajo de la estufa despu_s que la linea del

suministro de gas sea instalada.

m

| Conecte la estufa al surninistro

de gas

Irnportante: Quite todo el material de embalaje y

literatura de la estufa antes de conectar el gas y la fuente

el_ctrica.

Para evitar fugas, aplique sellador de tuberias en todas

las partes roscadas machos (exterior) de la tuberia. El

regulador se encuentra en el lugar que se muestra en la

ilustraci6n.

No permita que el

regulador gire sobre la

tuber{a al apretar las

uniones.

Re0na el conector flexible del tubo del suministro de gas

al regulador de la presi6n en la orden siguiente:

1. V_ilvula de cierre manual (no incluido)

2. Boquilla de 1/2" (no incluido)

3. 1/2" Adaptador de uni6n (no incluido)

4. Conector flexible (no incluido)

5. 1/2" Adaptador de uni6n (no incluido)

6. Boquilla de 1/2" (no incluido)

7. Regulador de presi6n (incluido)

Use sellador para uniones de tuberias hecho para el

uso de gas natural y LP/Propano para sellar todas las

conexiones de gas. Si se utilizan los conectadores

flexibles, asegOresede que los conectadores no est_in

enroscados.

La linea del suministro se debe de set equipada de una

wilvula de cierre manual aprobada. Esta wilvula se debe

Iocalizar en el mismo cuarto que la estufa y debe estar en

una Iocalizaci6n que permita la facilidad de la abertura y

del cierre. No bloquee el acceso a la wilvula. La wilvula es

para encender o apagar el gas del aparato.

UBICACION DEL

REGULADOR DE PRESION

Figura 3

Conecte el Regulador de Presi6n

El regulador de presiOn esta ya instalada para la estufa.

No haga la conexi6n demasiado

apretada. El regulador es de die cast. Elapretar

demasiado puede agrietar el regulador dando pot

resultado una fuga de gas y un fuego o una explosi6n.

Valvula de FLUJO DEL GAS Regulador

cierre Uni6n Uni6n

manual 4.

(On) \_ Boquilla Conector II

Apagado flexible Tapa de

(Off) entrada

Todas las conexiones deben set apretadas con

una Ilave inglesa- Figura 4

_ de presi6n

V ivula de cierre -

Abierta

Figura 5

Una vez que regulador est,1en su lugar, abra la wilvula

en la linea del suministro de gas. Espere algunos minutos

para que el gas pueda moverse a trav_s de la linea de

gas.

Compruebe para saber si hay fugas de gas. Despu_s

de conectar la estufa con la fuente de gas, compruebe

el electrodom_stico para saber si hay fugas con un

manOmetro. Si un manOmetro no est,1disponible, gire

la fuente de gas y utilice un detector liquido de fugas (o

jab0n y agua) en todos los empalmes y conexiones has la

comprobaci0n para fugas.

No utilice una llama para verificar

fugas en las conexiones de gas. Verificar para fugas con

una llama puede tenet como resultado un fuego o la

explosi6n.

Apriete todas las conexiones como necesario para

prevenir fugas de gas en la superficie de la estufa o en la

linea de suministro.

19

Page 20

Desconectela estufa y su valvula de cierre manual

del sistema de tuberia del suministro de gas durante

cualquier prueba de presiOn de ese sistema a presiones

mayores de 1/2 psig (3,5 kPa o 14" columna de agua).

Aisle la estufa del sistema de tuberia del suministro

de gas cerrando su wilvula de cierre manual durante

cualquier prueba de presiOn del sistema de tuberia del

suministro de gas prueba de presiOn iguala a o a menos

de 1/2 psig (3,5 kPa o 14" columna de agua).

Metodo preferido

Enchufe de pared

con toma de

tierra

corte, retire o

deribe, bajo ninguna

drcunstancia, la

patilla de la toma de

tierra del enchufe

Cable de suministro

el_ctrico con enchufe con

toma de tierra

Conversion para uso de Propano

Liquido

Este aparato puede set usado con gas natural o propano

liquido. Ha sido ajustado en la f_ibrica para operar con

gas natural solamente.

Si desea convertir su estufa para uso con propano

liquido, use los orificios provistos ubicados en el bolso

que contiene la literatura titulada "FOR LP/PROPANEGAS

CONVERSION." Siga las instrucciones que vienen con los

orificios.

La conversion debe set efectuado pot un t_cnico de

servicio capacitado, de acuerdo con las instrucciones

del fabricante y con todos los cOdigos y requisitos

de las autoridades correspondiente. El no seguir las

instrucciones podria dar como resultado lesiones graves

o daSos a la propiedad. El organismo autorizado para

Ilevar a cabo este trabajo asume la responsabilidad de la

conversion.

_!_J___ La falta de una conversion

apropiada puede resultar en lesiones graves y dahos a la

propiedad.

Requisitos electricos

120 voltio, 60 Hertzio, circuito dedicado apropiadamente

puestos a tierra protegido pot un circuito de amperio

o fusible de demora de tiempo de 15 amp. Nota: no

es recomendado instalarlo con un Interruptor (GFI) de

puesta a tierra.

No utilice una extension con esta estufa.

Instrucdones de puesta a tierra

IMPORTANTE Por favor lea con cuidado.

Para la seguridad personal, este aparato debe set

puesto a tierra apropiadamente.

El cable del suministro el_ctrico de esta estufa est,1

equipado con un enchufe de tres patillas (para puesta a

tierra) que coincida con un enchufe de pared est_indar

con puesta a tierra de tres patillas para minimizar la

posibilidad que se produzcan descargas el_ctricas.

El cliente deber_i encargar a un t_cnico para asegurarse

de que el enchufe se encuentra debidamente conectado

a tierra y polarizado.

Figura 6

En lugares en los que aya un enchufe de pared est_indar

de dos patillas, el cliente tendr_i responsabilidad directa

y la obligaciOn de reemplazarlo pot un enchufe de pared

de tres patillas debidamente cableado a tierra.

Bajo ninguna circunstanda, corte, retire o derribe

la tercera patilla (de toma de tierra) del cable del

suministro de energia electrica.

Desenchufa el cable del

suministro de energia el_ctrica del enchufe de pared

antes de mantener la plancha de cocina.

m

| La mudanza del aparato para

reparaciones o limpieza

Apague la corriente electrica a la estufa a la fuente de

poder principal, y apague lawilvula de cierre manual de gas.

Aseg0resede que laestufa este fresca. Quite el cajon de

servicio(el cajon calentador en algunos modelos) y abre la

puerta del homo. Levante la frente de la estufa y desl[cela

fuera de la abertura sincrear tension desmedida sobre

el conducto flexible de gas. Aseg0resede no pellizque el

conducto flexible de gas detr_isde la estufa al reemplazar la

unidad en la abertura. Reemplaceel cajon, cierre la puerta

y enciende elgas y la corriente electrica a la estufa que est,1

colgado toque levemente la mesada.

Instalacion de la estufa

Nota importante: No es necesario, pero si es

conveniente, quitar la puerta para instalar el horno.

Consulte las instrucciones para retirar la puerta en la Guia

de Uso y Cuidado.

InstaladOn sin panel(es) lateral(es).

La plancha de cocinar se sobrepone pot encima

del mostrador con sus extremidades y la cocina

reposa sobre el suelo. La plancha de cocinar es 31

1/2" (81 cm) de ancho.

| Instale la base de los armarios a 30" (76.2 cm)

de espacio entre elias. Aseg0rese que estos est_qn

verticales y alineados antes de instalar la plancha

de cocinar. Lije el borde del mostrador para

obtener las 31 1/2 (81 cm)" en la parte superior

del mostrador.

2O

Page 21

Instalelaspuertasdelarmarioa31" (78,7cm)de

espacioentreeliasparaquenointerfieranconla

aberturadelapuertadelacocina.

| Corteelmostradorexactamentecomoenla

p_igina14.

Paralosmodelosequipadoconunsistema de

dispositivo de nivelad6n:

Aseg0rese que el frente de las patas niveladoras y el

dispositivo de nivelaciOn posterior est_n ajustados

mas altos que la altura del gabinete.

_:_ _ Instale el soporte anti-

inclinacion de acuerdo a las instrucciones del

patron anti-indinaci0n ( si no Io tiene vea la p_igina

25 o 26).

| Parauna instalaci0n Optima, la superficie superior

de la cubierta debe estar nivelada y ser plana (sobre

el mismo piano) en los 3 lados adyacentes a la

cocina. Se deben hacer los ajustes correspondientes

para hacer que la parte superior quede plana, de Io

contrario podr_in quedar espacios entre la cubierta y

la cocina.

_ Parareducir el riesgo de

daflar su artefacto, no Io manipule cerca del vidrio

cer_imico. Manip01elo con cuidado.

Coloque la cocina enfrente de la abertura del

armario.

Aseg0rese de que el vidrio que est,1colgado

sobre la cubierta deje despejada la cubierta. Sies

necesario, levante la unidad bajando las patas de

nivelaci0n.

Deslice la unidad hacia el gabinete y central antes

de nivelarla.

Nivele la cocina (vea NivelaciOn de la estufa). El

piso donde se instala la cocina debe estar nivelado.

Siga las instrucciones "nivelaciOn de la estufa-

modelos equipado con un sistema de dispositivo de

nivelaci0n".

Ajuste a las patas de nivelaciOn de manera que

la parte de abajo de la plancha de cocinar est,1

apoyada contra el mostrador. Atornille con cuidado

en la pata de nivelaciOn trasera hasta que el vidrio

que est,1colgado toque levemente la cubierta. El

vidrio debe soportar el peso de la unidad. Luego,

atomille con cuidado en las dos patas de nivelaciOn

anteriores (igual a 15) hasta que el vidrio que est,1

colgado toque levemente la cubierta.

Para los modelos equipado con las patas

niveladoras:

Aseg0rese que el frente de las patas niveladoras

y el dispositivo de nivelaciOn posterior est_n

ajustados mas altos que la altura del gabinete.

_:_ _ Instale el soporte anti-

inclination de acuerdo alas instrucdones

del patron anti-indinaci0n ( si no Io tiene vea la

p_igina 25 o 26).

Para una instalaci0n Optima, la superficie

superior de la cubierta debe estar nivelada y

ser plana (sobre el mismo piano) en los 3 lados

adyacentes a la c. Se deben hacer los ajustes

correspondientes para hacer que la parte superior

quede plana, de Io contrario podr_in quedar

espacios entre la cubierta y la cocina.

_ Para reducir el riesgo de

daflar su artefacto, no Io manipule cerca del vidrio

cer_imico. Manip01elo con cuidado.

Coloque la cocina enfrente de la abertura del

armario.

Aseg0rese de que el vidrio que est,1colgado

sobre la cubierta deje despejada la cubierta. Si es

necesario, levante la unidad bajando las patas de

nivelaciOn.

Nivele la cocina (vea NivelaciOn de la estufa).

El piso donde se instala la cocina debe estar

nivelado. Siga las instrucciones "nivelaciOn

de la estufa- modelos equipado con las patas

niveladoras".

Deslice la estufa en la abertura.

Instalad6n con el repuesto.

La profundidad del corte de (21 3/4" (55.2 cm) Min., 22

1/8" (56.2cm) Max.) necesita ser aumentada a 24" (61

cm) cuando instala el repuesto.

Instaladon con el juego de termino de panel.

Un juego de termino de panel puede ser pedido con

su representante.

InstaladOn con Paneles Laterales Menos

Paneles Laterales puede ser pedido con su

representante. Instale las puertas de los armarios a

31 " (78.7 cm) de espacio entre elias para que no

interfieran con la abertura de la puerta de la cocina.

21

Page 22

Nivelad6n de la estufa

Para los rnodelos equipado con un sisterna

de dispositivo de nivelad6n.

Nivele la codna despues de haberla instalado en la

abertura del mostrador.

1. Abra la gaveta.

2. Baje el aparato, las4 patas de nivelaci0n

alternadamente, hasta que la parte baja de la

superficie de cocci6n repose sobre el mostrador.

3. Verifique si la cocina est,1 nivelada colocando una

parrilla en el centro del homo y poniendo un nivel

sobre esta (Figura 8).

4. Mida dos veces con el nivel en posici6n diagonal en

una direcci6n y luego en otra. Nivele la cocina si es

necesario ajustando las patas de nivelaci0n.

5. Sial cocina no se nivela, aseg0rese que el piso este

nivelado.

Para los modelos equipado con ias patas

niveladoras.

Nivele la estufa y ajuste la altura de la estufa antes

de instalarla en la abertura.

1. Coloque una parrilla del homo en el centro del homo.

2. Ponga un nivel sobre la parrilla (Figura 8). Tome dos

lecturas con el nivel puesto diagonalmente en una

direcci6n y despu_s en la otra. Nivele la estufa, sies

necesario, ajustando las 4 patas niveladoras con una

Ilave de tuercas (Figura 17).

3. Aseg0rese de no dahar al mostrador, deslice la estufa

dentro de la abertura del hueco y vuelva a verificar a la

nivelaciOn.

Figura 8

Instalacion de Accesorio

Decorativo Trasero (si se requiere)

1. Desconecte la alimentaciOn del aparato.

2. Aseg0rese de que el aparato est_ nivelado.

3. Tire la cocina hacia usted.

4. Tome la distancia entre el piso y la superficie debajo

del marco de la parte superior de la cocina.

5. Marque la distancia sobre la pared donde instalar_i el

accesorio decorativo.

6. Dibuje una linea.

7. Coloque la parte superior del accesorio decorativo

debajo de esa linea.

8. Utilizando los tornillos provistos con este juego, fije el

accesorio decorativo a la pared.

9. Deslice el aparato hacia atr_ishasta que quede en la

posici6n deseada y encienda la alimentaci6n (la parte

inferior de la parte superior de la cocina debe estar

ubicada sobre el accesorio decorativo).

trasero

Tornillos de

niveladOn

Pata

de frente

Figura 9

BAJAR

LEVANTAR

Figura 7

22

Page 23

Comprobacion del

funcionamiento

Consulte el Manual del Usuario incluido con la estufa para

instrucciones de operaciOn y instrucciones para el cuidado y

limpieza de su estufa.

No toque los elementos o quemadores. Pueden estar

bastante calientes para causar quemaduras.

Quite todo el embalaje de la unidad antes de comprobarla.

b. El quemador se deber_i encender en cuatro (4)

segundos para un funcionamiento normal, despu_s

de que el aire haya sido purgado de la tuberia de

suministro de gas. Controle visualmente que el

quemador se haya encendido.

c. Despu_s de que el quemador se haya encendido, la

plancha de cocina debe ser girada fuera de la posici6n

LITE.Cada quemador tiene su encendedor individual.

Controle las perillas separadamente hasta que todas

laswilvulas hayan sido controladas.

Instala las Bases y las tapas de los

Quemadores

Esta estufa esta equipada con quemadores

sellados como mostrado (vea la Figura 10).

a. Desembale las basas y las tapas de los quemadores.

b. Coloque una basa de quemador sobre cada abertura

de gas.

c. AsegOrese que el quemador est,1correctamente

alineado y nivelado. Coloque las tapas de los

quemadores sobre las correctas basas de....... quemadores.

Tapa de quemador r -z:i --_f'-

Ajuste de la Posicion LOW (BAJA) Para

la Valvula del Quemador Superior (Fig. 11)

a. Gire el bot6n de control a la posici6n LITE(encender)

hasta que el quemador encienda.

b. R_pidamente gire el bot6n de control a la POSICION

MAS BAJA.

c. Si el quemador se apaga, reajuste la wilvula de la

siguiente forma: Mueva el control a la posici6n OFF

(apagada). Saque la perilla de control del quemador

superior, inserte un destornillador piano pequeflo en

el hueco del wistago del a wilvula hasta enganchar

el tornillo interior. El tamaflo de la llama puede

ser aumentado o disminuido girando el tornillo.

Ajuste el tamaflo de la llama hasta que pueda pasar

r_ipidamente de la posici6n LITEhasta la posici6n MAS

BAJA sin que se apague la llama. La llama debe ser Io

m_ispequefla posible sin que se apague.

electrodo .............. J

Figura 10

NOTA: No hace falta ning0n ajuste de quemador en esta

estufa.

| Enciende la corriente electrica y abre

la valvula principal de cierre.

| Comprobaci6n de los Encendedores

Elfuncionamiento de los encendedores el_ctricos

debe ser comprobado despu_s de que la estufa y los

conectores a la tuberia de suministro de gas hayan

sido comprobados para las fugas y la estufa haya sido

conectada el_ctricamente. Para comprobar que el

encendido sea correcto:

a. Empuje y gire un bot6n control del quemador superior

hasta la posici6n LITE(encender). Se podria oir el

encendedor haciendo chispas.

Figura 11

11.50perad6n de Quemadores del Homo y

Ajustes de Homo

11.5.1 Quemador de igniciOn electrica

La operaciOn de los encenderse el_ctricos debe de ser

revisada despu@sde que la cocina y los conectores de la

linea de suministro haya sido cuidadosamente revisada

para descartar fugas y que la cocina haya sido conectada a

la corriente el@ctrica.

El quemador del homo est,1equipado con un sistema de

control el@ctricoasi como un encendedor de quemador

de homo el@ctrico.Si su modelo esta equipado con un

quemador de asado central superior, tambi@n contar_i

con un encendedor de quemador el@ctrico.Estossistemas

de control no requieren ajustes. Cuando el homo esta

configurado para operar, la corriente fluir_i hacia el

encendedor y tendr_i un resplandor de manera similar a

23

Page 24

unabombilladeluz.Cuandoelencendedoraalcanzado

unatemperaturasuficienteparaencenderelgas,la

wilvuladelhomocontroladael_ctricamenteseabrirciy

elfuegoaparecercienelquemadordelhomo.Hayun

lapsodetiempode30a60segundosdespu_sdequeel

termostatoseenciendeyantesdequelallamaaparezca

enelquemadordelhomo.Cuandoelhomoalcanzala

configuraci0ndeldial,elencendedorresplandecientese

apagarci,lallamadelquemadordesaparecercipor20a

30segundosdespu_sdequeelencendedorseapaga.

Paramantenercualquiertemperaturadehomodada,este

cicIocontinuarcitantocomoeldial(ovisualizador)est_

configuradoparaoperar.

Despu_sderetirartodoslosmaterialesdelempaqueyla

literaturadelhomo:

a)FijeelhomoenHORNEAR(BAKE)a300%Vealaguia

deUsoyCuidadoparaconocerlasinstruccionesde

funcionamiento.

b)En60segundoselquemadordelhomoseencenderci.

Revisequeexistaunfuegoadecuado,ypermita

queelquemadorcumplasucicIounavez.Girelos

controladoreshaciaoff(APAGADO).

c)Sisumodeloestaequipadoconunasadorcentral

superior,fijeelhomoenASAR.VealaGuiade

UsoyCuidadoparaconocerlasinstruccionesde

funcionamiento.

d)En60segundoselquemadordeasardebede

encenderse.Revisesiexistaunallamaadecuada.Gire

loscontroleshaciaoff(APAGADO).

Deflectorinferior

delhomo

,turador

deaire

Quemadora

laalturadela

(extraible),

ntura

_4.-Obturador

deaire

Parte i!ferior del

homo (extraible)

Figura12

11,5.20bturador del Aire - Quemador del horno

La Iongitud aproximada de la llama del quemador del

homo es 1 pulgada (interior claro, llama azul). Para

determinar si la llama del quemador de homo es la

adecuada, retire el fondo del homo y el deflector del

quemador i fije el homo en la opciOn hornear a 300%

Para retirar el fondo del homo, retire los tornillos de ajuste

del homo en la parte posterior del fondo del homo. Jale