Kenmore Elite 41794132000, 41794131000, 41794130000, 41794130002, 41791102000 Installation Guide

...Page 1

Installation instructions

Instrucciones de Instalaci6n

instructions d'lnstaliation

English / Espa_ol / Frangais

re Elite

®

P/N 137412900 A (1012)

Sears Brands Management Corporation

Hoffman Estates, IL 60179 U.S.A.

www.kenmore.com

www.sea rs.com

Sears Canada Inc.

Toronto, Ontario, Canada M5B 2C3

WWW.Sea rs.ca

Page 2

important Safety instructions

For your safety the information in this manual must be followed to minimize the risk of fire or explosion or to prevent

property damage, personal injury or loss of life. Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance.

A WARNING- RiSK OF FiRE

Read all of the following instructions before installing and using this appliance:

° Destroy the carton and plastic bags after the dryer is unpacked. Children might use them for play. Cartons covered

with rugs, bedspreads, or plastic sheets can become airtight chambers causing suffocation. Place all materials in a

garbage container or make materials inaccessible to children.

° Clothes dryer installation and service must be performed by a qualified installer, service agency or the gas supplier.

° Install the clothes dryer according to the manufacturer's instructions and local codes.

° The electrical service to the dryer must conform with local codes and ordinances and the latest edition of the Nation-

ai Electrical Code, ANSI/NFPA 70, or in Canada, the Canadian electrical code C22.1 part 1.

° The gas service to the dryer must conform with local codes and ordinances and the latest edition of the National Fuel

Gas Code ANSI Z223.1, or in Canada, CAN/ACG B149.1-2000.

° The dryer is designed under ANSI Z 21.5.1 or ANSI/UL 2158 - CAN/CSA C22.2 No. 112 (latest editions) for HOME

USE only. This dryer is not recommended for commercial applications such as restaurants, beauty salons, etc.

° Do not install a clothes dryer with flexible plastic or flexible foil venting material. Flexible venting materials are

known to collapse, be easily crushed and trap lint. These conditions wiii obstruct clothes dryer airflow and increase

the risk of fire.

° Do not stack a dryer on top of washer already installed on pedestal. Do not stack dryer on top of another dryer. Do

not stack washer on top of dryer. Do not stack washer on top of another washer.

° The instructions in this manual and aii other literature included with this dryer are not meant to cover every possible

condition and situation that may occur. Good safe practice and caution MUST be applied when installing, operating

and maintaining any appliance.

WHAT TO DO IF YOU SMELL GAS:

° Do not try to light any appliance.

° Do not touch any electrical switch; do not use any phone in your building.

° Clear the room, building or area of aii occupants.

° Immediately caii your gas supplier from a neighbor's phone. Follow the gas suppiier's instructions.

° If you cannot reach your gas supplier, caii the fire department.

Save these instructions for future reference.

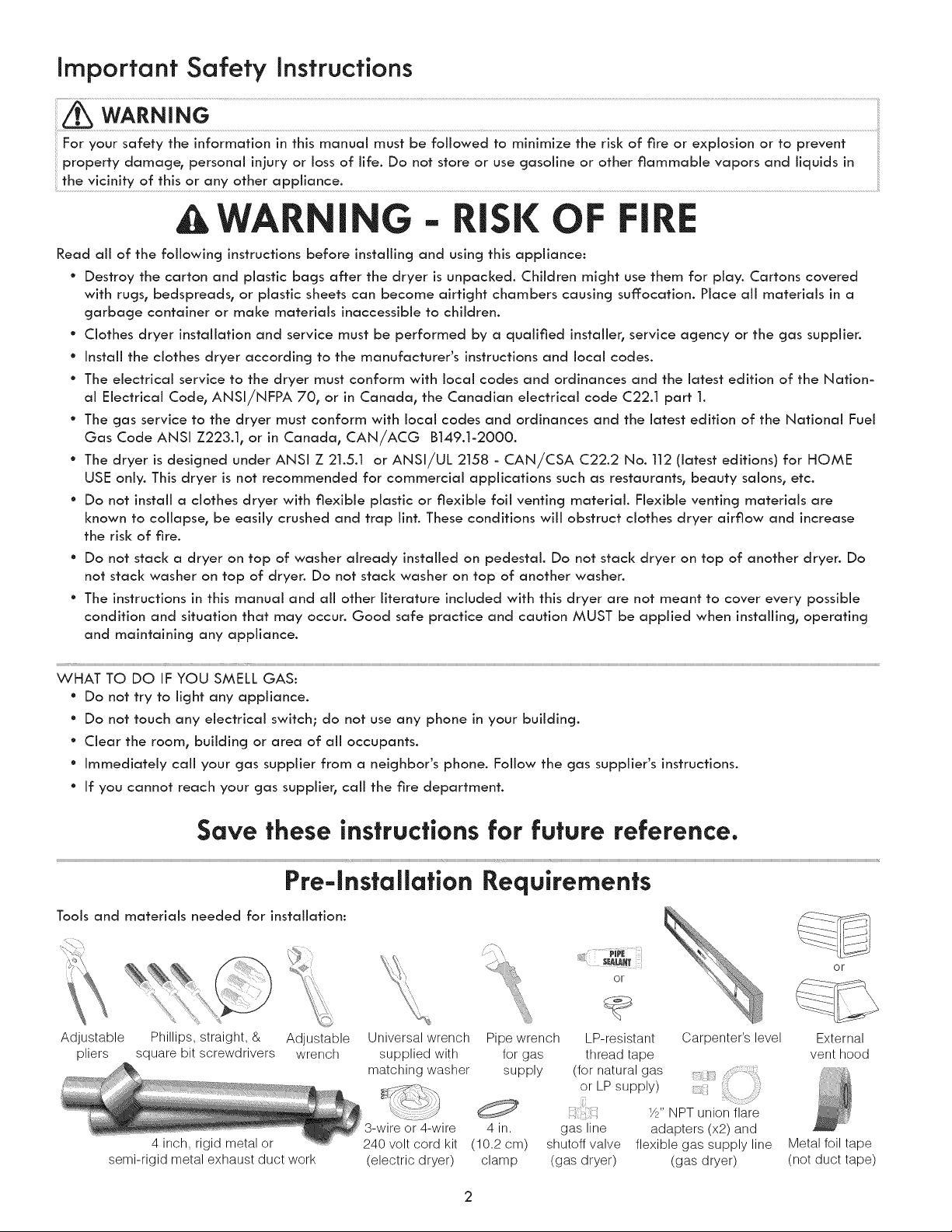

Pre--Insfallation Requirements

Tools and materials needed for installation:

or

Adjustable Phillips, straight, & Adjustable

pliers square bit screwdrivers wrench

4 inch, rigid metal or

semi-rigid metal exhaust duct work

Universal wrench Pipe wrench

supplied with for gas

matching washer supply

or 4-wire 4 in.

240 volt cord kit (10.2 cm)

(electric dryer) clamp

LP-resJstant Carpenter's level External

thread tape vent hood

(for natural gas

or LP supply) _-

1/2"NPT union flare

gas line adapters (x2) and

shutoff valve flexible gas supply line Metal foil tape

(gas dryer) (gas dryer) (not duct tape)

or

Page 3

Please read all instructions before using this dryer.

Recognize safety symbols, words and

labels

Safety items throughout this manual are labeled with

a WARNING or CAUTION based on the risk type as

described below:

Important Safety Instructions

Installation Checklist

Exhaust Venting

[] Free-flowing, clear of lint buildup

[] 4 inch (102 mm) rigid or semi-rigid ducting of

minimal length and turns

[] NO foil or plastic venting material

[] Approved vent hood exhausted to outdoors

Definitions

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury

or death.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

ii • *

injury.

IMPORTANT indicates installation, operation or

maintenance information which is important but not

hazard-related.

Leveling

[] Dryer is level, side-to-side and front-to-back

[] Cabinet is setting solid on all corners

Water Supply (Add Steam)

[] Rubber washer (shipped in drum) is installed in

NEW inlet hose (shipped in drum)

[] Inlet hose connected to "Y" connector on COLD

supply

[] Water supply turned on

[] No leaks present at water supply connections

or appliance inlet connection -

recheck in 24 hours

GaS

Supply (Gas Dryer)

[]

Manual shutoff: valve present in supply

[]

All connections sealed with approved sealer

and wrench tight

[]

Conversion kit for LP system

[]

Gas supply turned on

[]

No leaks present at all connections -

check with soapy water, NEVER check with flame

240v Electric Supply (Electric Dryer)

[] Approved NEMA 10-30R or 14-30R service cord

with aii screws tight on terminal block

[] Approved strain relief installed

[] Terminal access cover installed before initial

operation

Table of Contents

Important Safety Instructions ............................................ 2-3

Installation Requirements ................................................. 4-10

Dryer Dimensions ................................................................... 11

Installation Instructions ................................................... 12-20

Reversing Door ................................................................ 21-23

Accessories ........................................................................... 24

EspaSoi ................................................................................... 25

Francois ................................................................................. 49

Door Reversal

[] Follow detailed instructions in this guide

[] Test hinge and latch for function

Electrical Power

[] House power turned on

[] Dryer plugged in

Final Checks

[] Installation Instructions and Use and Care

Guide have been read thoroughly

[] Door latches and drum tumbles when cycle

starts

Page 4

Installation Requirements

Because of potentially inconsistent voltage capabilities, the use of this dryer with power created by gas powered

generators, solar powered generators, wind powered generators or any other generator other than the local utility

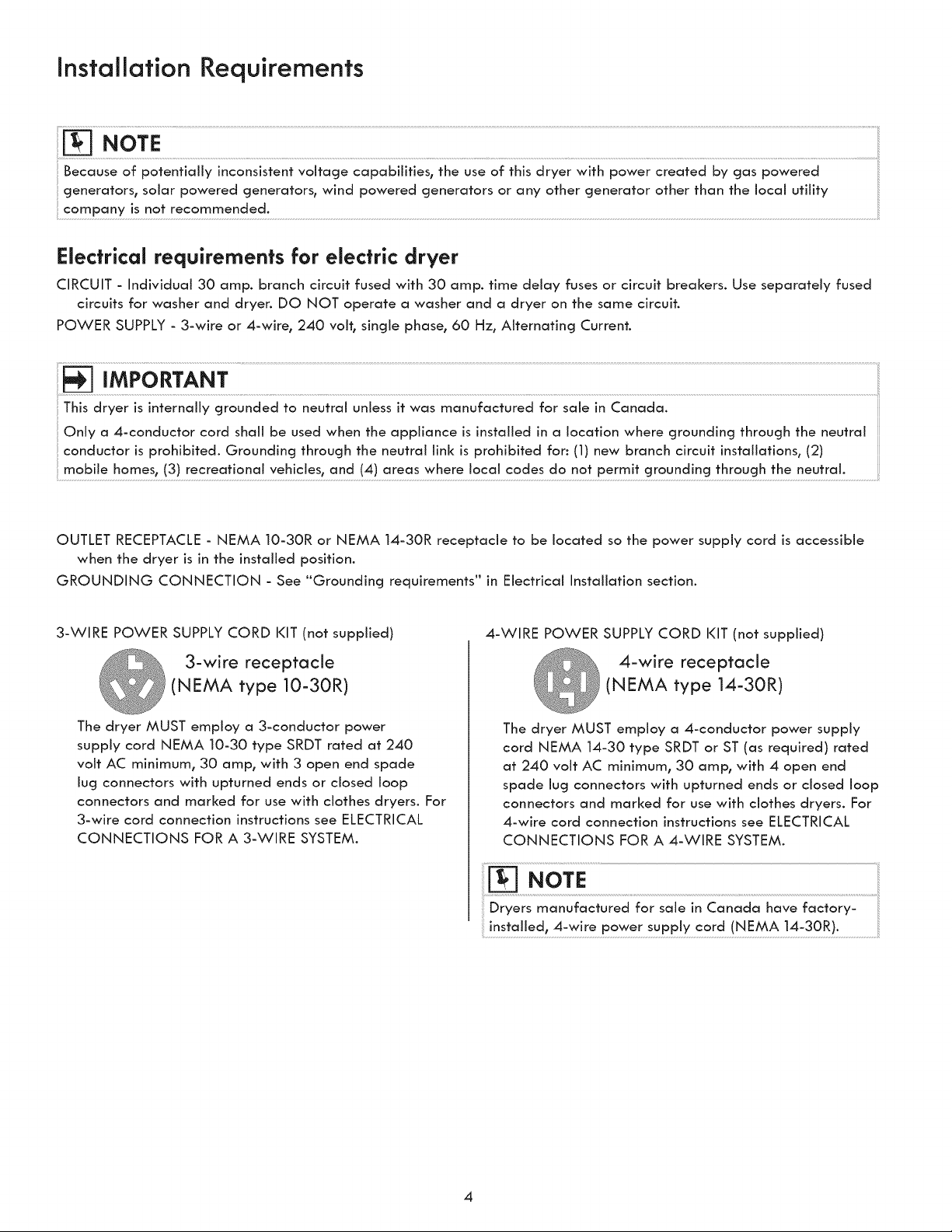

Electrical requirements for electric dryer

CIRCUIT = Individual 30 amp. branch circuit fused with 30 amp. time delay fuses or circuit breakers. Use separately fused

circuits for washer and dryer. DO NOT operate a washer and a dryer on the same circuit.

POWER SUPPLY - 3-wire or 4-wire, 240 volt, single phase, 60 Hz, Alternating Current.

This dryer is internally grounded to neutral unless it was manufactured for sale in Canada.

Only a 4-conductor cord shall be used when the appliance is installed in a location where grounding through the neutral

conductor is prohibited. Grounding through the neutral link is prohibited for: (1) new branch circuit installations, (2)

mobile homes, (3) recreational vehicles, and (4) areas where local codes do not permit grounding through the neutral.

OUTLET RECEPTACLE - NEMA 10-30R or NEMA 14-30R receptacle to be located so the power supply cord is accessible

when the dryer is in the installed position.

GROUNDING CONNECTION - See "Grounding requirements" in Electrical Installation section.

3=WIRE POWER SUPPLY CORD KIT (not supplied)

3-wire receptacle

(NEMA type 10-30R)

The dryer MUST employ a 3=conductor power

supply cord NEMA 10=30 type SRDT rated at 240

volt AC minimum, 30 amp, with 3 open end spade

lug connectors with upturned ends or closed loop

connectors and marked for use with clothes dryers. For

3-wire cord connection instructions see ELECTRICAL

CONNECTIONS FOR A 3-WIRE SYSTEM.

4=WIRE POWER SUPPLY CORD KIT (not supplied)

4=wire receptacle

(NEMA type 14=30R)

The dryer MUST employ a 4-conductor power supply

cord NEMA 14-30 type SRDT or ST (as required) rated

at 240 volt AC minimum, 30 amp, with 4 open end

spade Jug connectors with upturned ends or closed loop

connectors and marked for use with clothes dryers. For

4=wire cord connection instructions see ELECTRICAL

CONNECTIONS FOR A 4-WIRE SYSTEM.

installed, 4-wire power supply cord (NEMA 14-30R).

4

Page 5

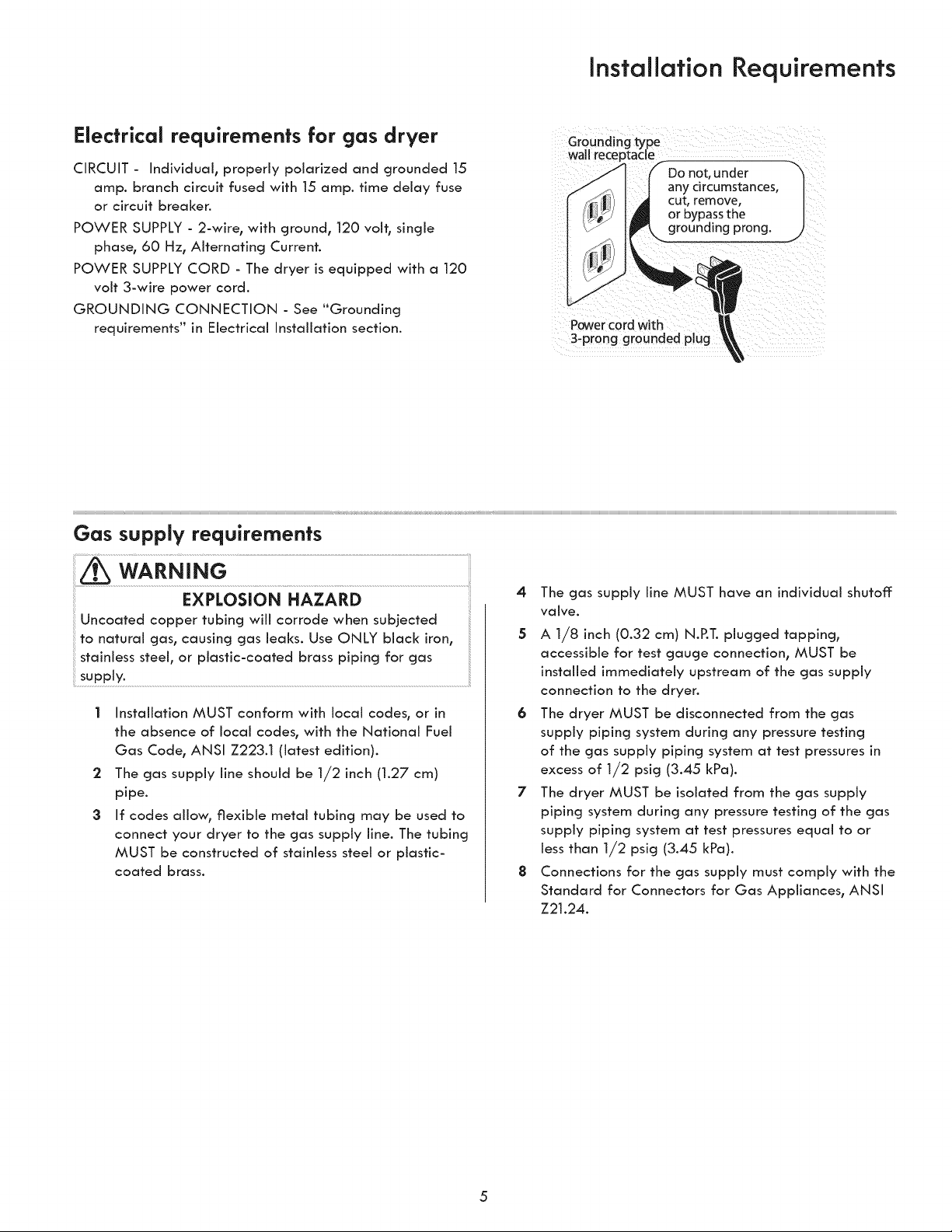

Electrical requirements for gas dryer

Installation Requirements

CIRCUIT - Individual, properly polarized and grounded 15

amp. branch circuit fused with 15 amp. time delay fuse

or circuit breaker.

POWER SUPPLY - 2-wire, with ground, 120 volt, single

phase, 60 Hz, Alternating Current.

POWER SUPPLY CORD - The dryer is equipped with a 120

volt 3-wire power cord.

GROUNDING CONNECTION - See "Grounding

requirements" in Electrical Installation section.

Powercord with

3-prong grounded plug

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

Gas supply requirements

wA,N,No...............................................................................................................................................................

EXPLOSION HAZARD

Uncoated copper tubing will corrode when subiected

:i

to natural gas, causing gas leaks. Use ONLY black iron,

stainless steel, or plastic-coated brass piping for gas

supply.

| Installation MUST conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.1 (latest edition}.

2 The gas supply line should be 1/2 inch (1.27 cm)

pipe.

3 If codes allow, flexible metal tubing may be used to

connect your dryer to the gas supply line. The tubing

MUST be constructed of stainless steel or plastic-

coated brass.

4 The gas supply line MUST have an individual shutoff:

Valve.

5 A 1/8 inch (0.32 cm) N.P.T. plugged tapping,

accessible for test gauge connection, MUST be

installed immediately upstream of the gas supply

connection to the dryer.

6 The dryer MUST be disconnected from the gas

supply piping system during any pressure testing

of the gas supply piping system at test pressures in

excess of 1/2 psig (3.45 kPa).

7 The dryer MUST be isolated from the gas supply

piping system during any pressure testing of the gas

supply piping system at test pressures equal to or

less than 1/2 psig (3.45 kPa).

8 Connections for the gas supply must comply with the

Standard for Connectors for Gas Appliances, ANSI

Z21.24.

5

Page 6

Installation Requirements

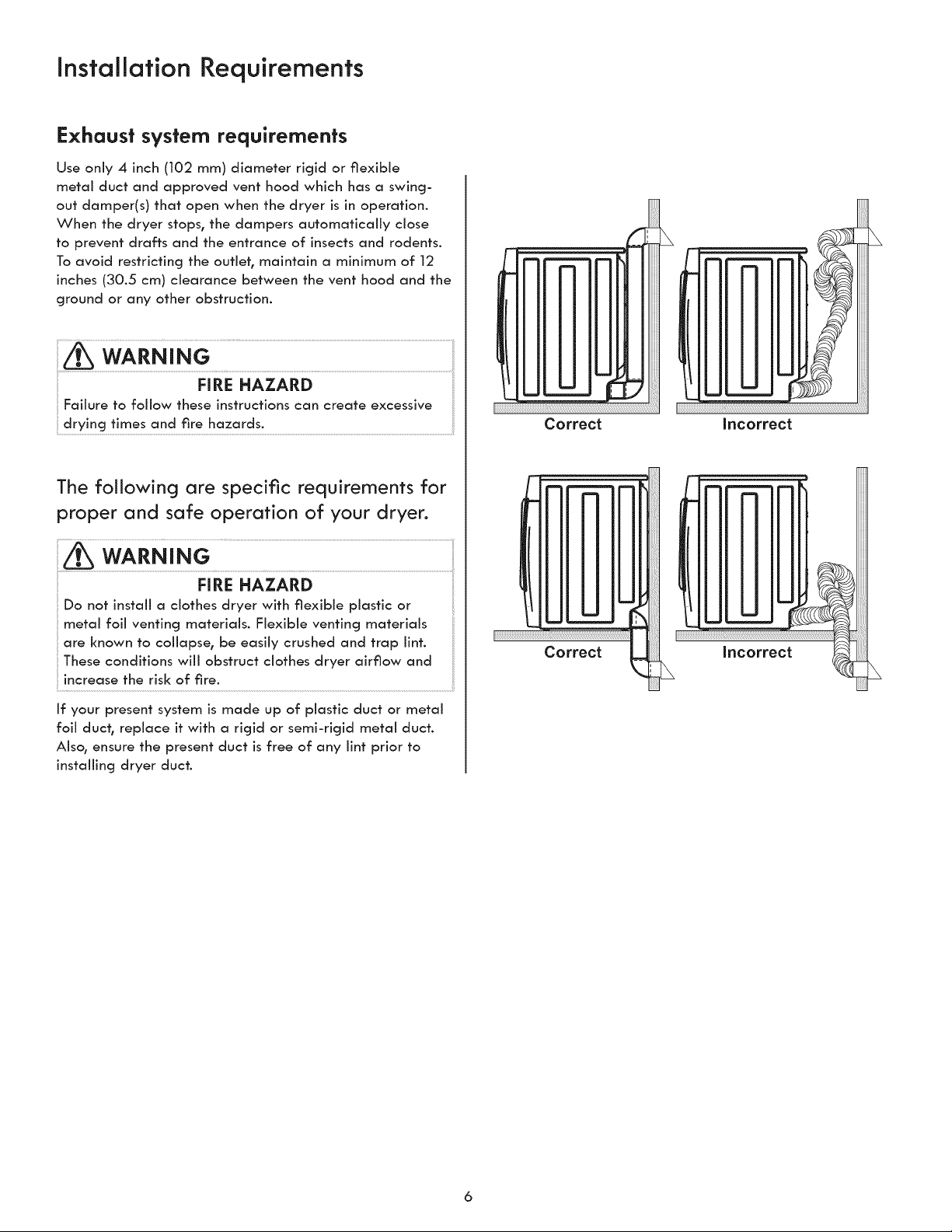

Exhaust system requirements

Use only 4 inch (102 mm) diameter rigid or flexible

metal duct and approved vent hood which has a swing-

out damper(s) that open when the dryer is in operation.

When the dryer stops, the dampers automatically close

to prevent drafts and the entrance of insects and rodents.

To avoid restricting the outlet, maintain a minimum of 12

inches (30.5 cm) clearance between the vent hood and the

ground or any other obstruction.

FiREHA D....

] Failure to follow these instructions can create excessive

The following are specific requirements for

proper and safe operation of your dryer.

WARNING ...............

FiRE HAZARD

Do not install a clothes dryer with flexible plastic or

metal foil venting materials. Flexible venting materials

ii

are known to collapse, be easily crushed and trap lint.

These conditions will obstruct clothes dryer airflow and

increase the risk of fire.

If your present system is made up of plastic duct or metal

foil duct, replace it with a rigid or semi-rigid metal duct.

Also, ensure the present duct is free of any lint prior to

installing dryer duct.

m

m

Correct

m

m m

Incorrect

m

m m

Incorrect

Page 7

Installation Requirements

Exhaust system requirements, continued

wA.N .............................................................................................................................................................

A clothes dryer must be exhausted outdoors. Do not

exhaust dryer into a chimney, a wail, a ceiling, an attic,

a crawl space or any concealed space of a building. A

clothesdryerproducescombustiblelint.ifthedryeris

notexhaustedoutdoors,somefinelintwUlbeexpelled

into the laundry area. An accumulation of lint in any

area of the home can create a health and fire hazard.

ii

The dryer must be connected to an exhaust outdoors.

Regularly inspect the outdoor exhaust opening and remove

any accumulation of lint around the outdoor exhaust

opening and in the surrounding area.

FIRE HAZARD

* Do not allow combustible materials (for example:

clothing, draperies/curtains, paper) to come in

contact with exhaust system. The dryer MUST NOT

be exhausted into a chimney, a wall, a ceiling, or any

concealed space of a building which can accumulate

lint, resulting in a fire hazard.

* Do not screen the exhaust ends of the vent system, or

J

use any screws, rivets or other fasteners that extend

J

into the duct to assemble the exhaust system. Lint can

become caught in the screen, on the screws or rivets,

clogging the duct work and creating a fire hazard

as well as increasing drying times. Use an approved

vent hood to terminate the duct outdoors, and seal

J

all joints with metal foil duct tape. All male duct pipe

J

fittings MUST be installed downstream with the flow

of air.

ii

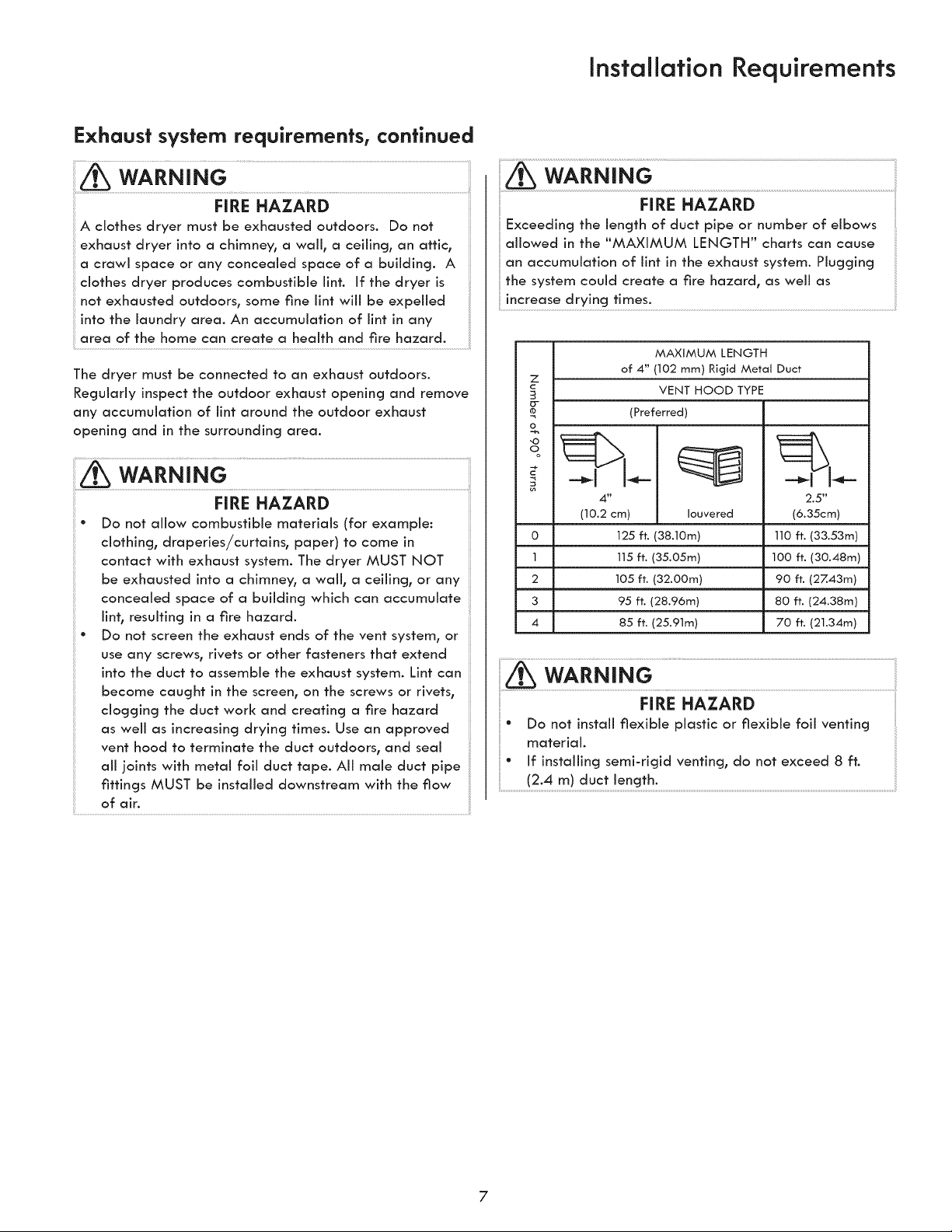

Exceeding the length of duct pipe or number of elbows

allowed in the "MAXIMUM LENGTH" charts can cause

an accumulation of lint in the exhaust system. Plugging

the system could create a fire hazard, as well as

MAXIMUM LENGTH

Z

of 4" (102 ram) Rigid Metal Duct

VENT HOOD TYPE

(Preferred)

o

_-..11.==

4"

(10.2 crn) Iouvered

0 125 ft. (38.10m)

1 115ft. (35.05m)

2 105 ft. (32.00m)

3 95 ft. (28.96m) 80 ft. (24.38m)

4 85 ft. (25.91m) 70 ft. (21.34m)

2.5"

(6.35cm)

110 ft. (33.53m)

100 ft. (30.48m)

90 ft. (27.43m)

WARNING

................ FIRE HAZARD .....

Do not install flexible plastic or flexible foil venting

material.

* If installing semi-rigid venting, do not exceed 8 ft.

7

Page 8

Installation Requirements

Exhaust system requirements, continued

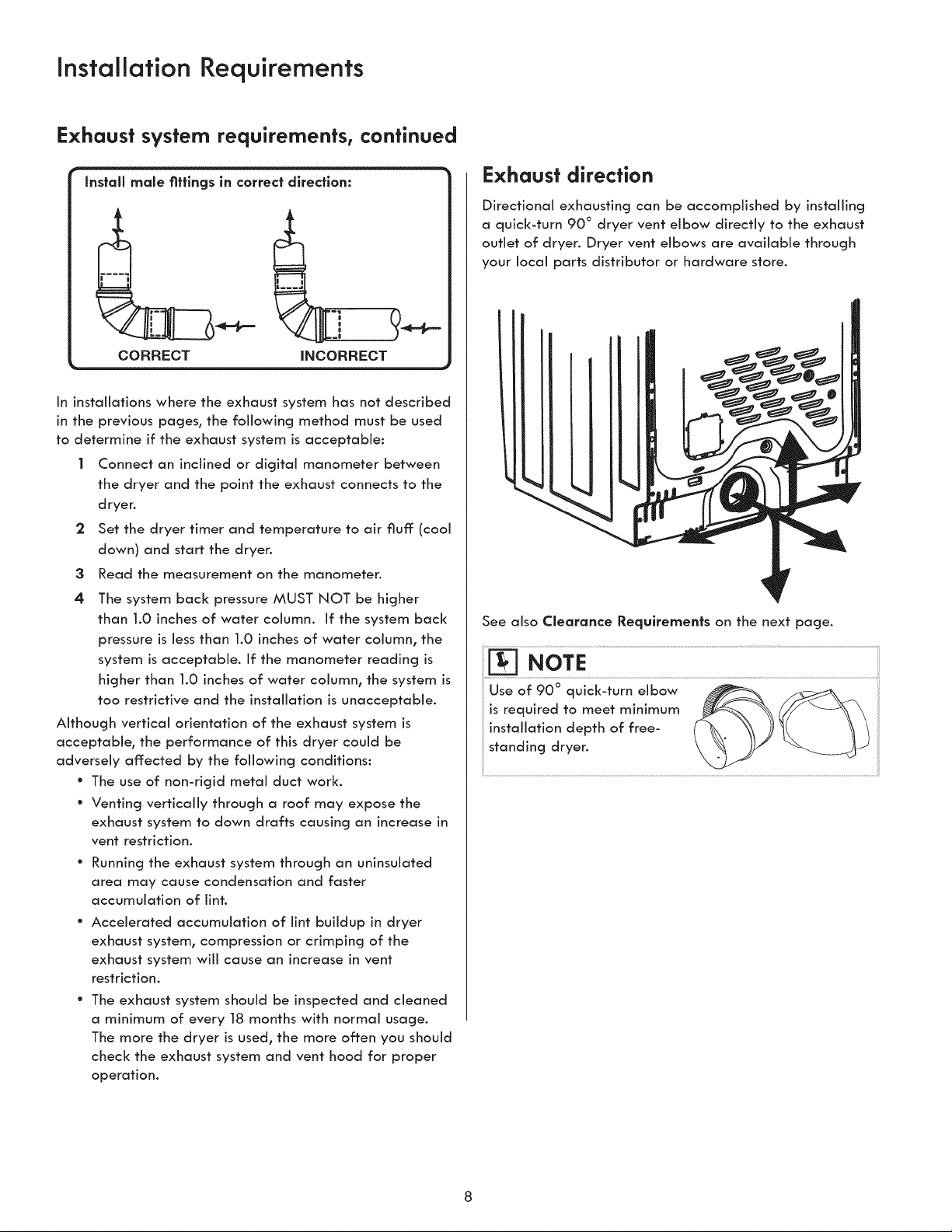

Install male fittings in correct direction:

CORRECT INCORRECT

In installations where the exhaust system has not described

in the previous pages, the following method must be used

to determine if the exhaust system is acceptable:

| Connect an inclined or digital manometer between

the dryer and the point the exhaust connects to the

dryer.

2 Set the dryer timer and temperature to air fluff (cool

down) and start the dryer.

3 Read the measurement on the manometer.

4 The system back pressure MUST NOT be higher

than 1.0 inches of water column. If the system back

pressure is less than 1.0 inches of water column, the

system is acceptable. If the manometer reading is

higher than 1.0 inches of water column, the system is

too restrictive and the installation is unacceptable.

Although vertical orientation of the exhaust system is

acceptable, the performance of this dryer could be

adversely affected by the following conditions:

° The use of non-rigid metal duct work.

° Venting vertically through a roof may expose the

exhaust system to down drafts causing an increase in

vent restriction.

° Running the exhaust system through an uninsulated

area may cause condensation and faster

accumulation of lint.

° Accelerated accumulation of lint buildup in dryer

exhaust system, compression or crimping of the

exhaust system will cause an increase in vent

restriction.

° The exhaust system should be inspected and cleaned

a minimum of every 18 months with normal usage.

The more the dryer is used, the more often you should

check the exhaust system and vent hood for proper

operation.

Exhaust direction

Directional exhausting can be accomplished by installing

a quick-turn 90 ° dryer vent elbow directly to the exhaust

outlet of dryer. Dryer vent elbows are available through

your local parts distributor or hardware store.

See also Clearance Requirements on the next page.

Use of 90 ° quick-turn elbow

is required to meet minimum

installation depth of free-

standing dryer.

Page 9

Manufactured or mobile home installation

Installation Requirements

1 Installation MUST conform to current Manufactured

Home Construction & Safety Standard, Title 24

CFR, Part 32-80 (formerly the Federal Standard for

Mobile Home Construction and Safety, Title 24, HUD

Part 280) or Standard CAN/CSAZ240 MH.

2 Dryer MUST be exhausted outside (outdoors, not

beneath the mobile home) using metal ducting that

will not support combustion. Metal ducting must be

4 inches (10.16 cm) in diameter with no obstructions.

Rigid metal duct is preferred.

3 If dryer is exhausted through the floor and area

beneath the mobile home is enclosed, the exhaust

system MUST terminate outside the enclosure with

the termination securely fastened to the mobile

home structure.

4 Refer to previous sections in this guide for other

important exhaust venting system requirements.

5 When installing a gas dryer into a mobile home, a

provision must be made for outside make up air. This

provision is to be not less than twice the area of the

dryer exhaust outlet.

6 Installer MUST anchor this (1) dryer or (2) dryer

mounted on pedestal to the floor with approved

Mobile Home Installation Kit - P/N 137067200.

Clearance requirements

WA"NING......................................................

EXPLOSION HAZARD

Do not install the dryer where gasoline or other

flammables are kept or stored. If the dryer is installed

in a garage, it must be a minimum of 18 inches {45.7

cm) above the floor. Failure to do so can result in death,

explosion_ fire or burns.

NOT INSTALL YOUR DRYER:

1 In an area exposed to dripping water or outside

weather conditions.

2 In an area where it will come in contact with

curtains, drapes, or anything that will obstruct the

flow of combustion and ventilation air.

3 On carpet. Floor MUST be solid with a maximum

slope of 1inch (2.54 cm).

9

Page 10

Installation Requirements

Clearance requirements, continued

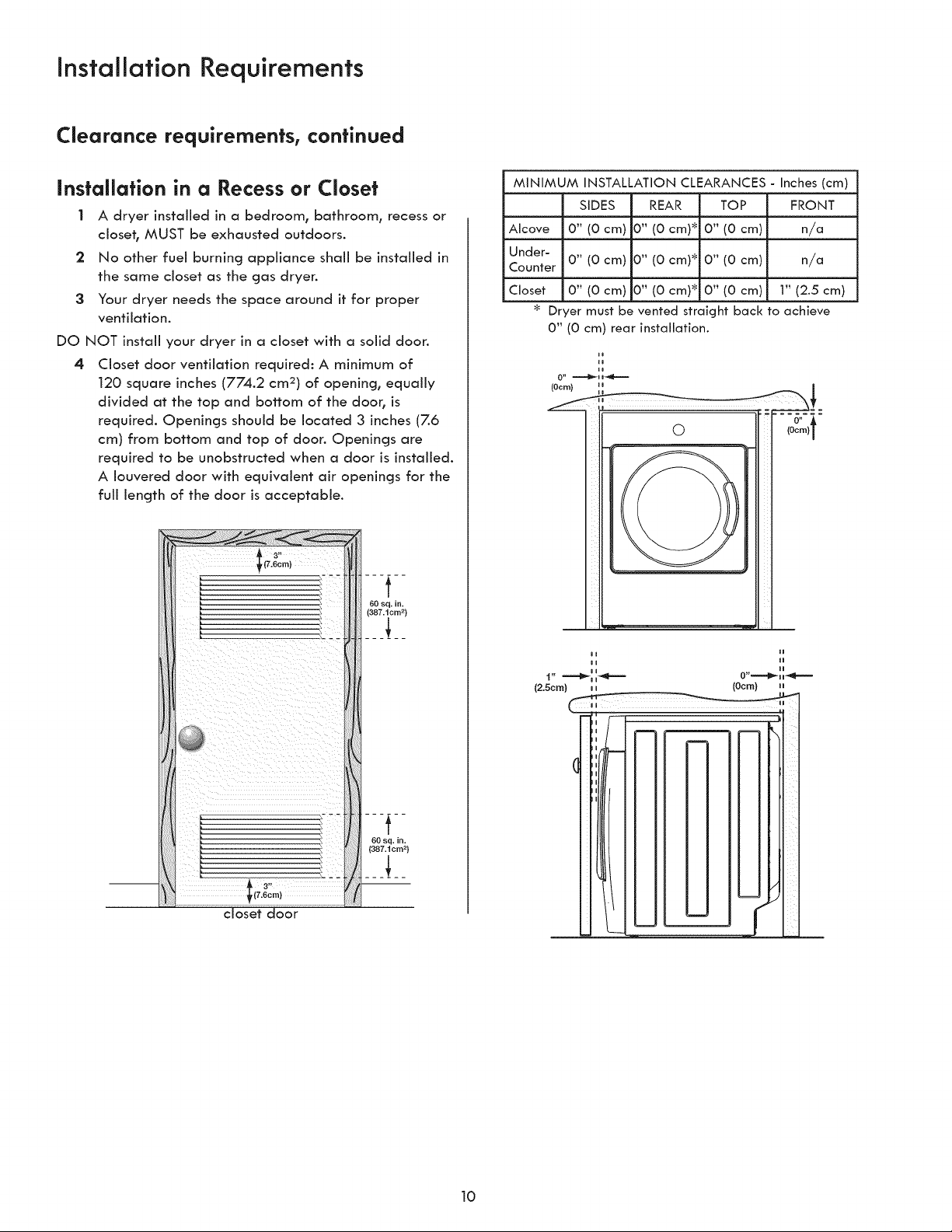

Installation in a Recessor Closet

| A dryer installed in a bedroom, bathroom, recess or

closet, MUST be exhausted outdoors.

2 No other fuel burning appliance shall be installed in

the same closet as the gas dryer.

3 Your dryer needs the space around it for proper

ventilation.

DO NOT install your dryer in a closet with a solid door.

4 Closet door ventilation required: A minimum of

120 square inches (774.2 cm 2) of opening, equally

divided at the top and bottom of the door, is

required. Openings should be located 3 inches (7.6

cm) from bottom and top of door. Openings are

required to be unobstructed when a door is installed.

A Iouvered door with equivalent air openings for the

full length of the door is acceptable.

_, (7.6cm)

MINIMUM INSTALLATION CLEARANCES - Inches (cm)

SIDES REAR TOP FRONT

Alcove 0" (0 cm) 0" (0 cm) € 0" (0 cm) n/a

Under-

Counter

Closet 0" (0 cm) 0" (0 cm) € 0" (0 cm) 1" (2.5 cm)

0" (0 cm) 0" (0 cm) € 0" (0 cm) n/a

* Dryer must be vented straight back to achieve

0" (0 cm) rear installation.

ao

l0

io

(Ocm} 101° _! _

0 "- 0,,it(Ocm

closet door

10

Page 11

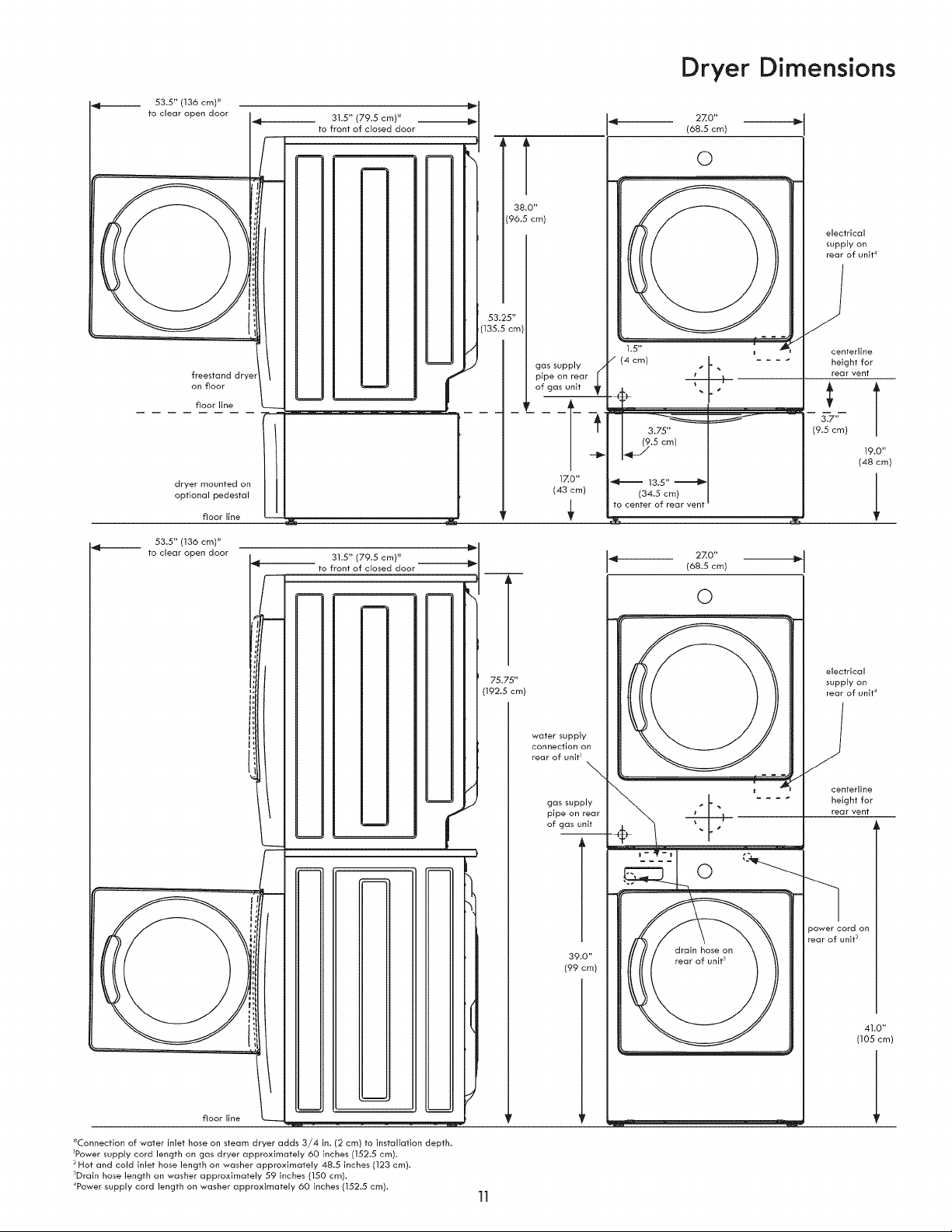

53.5" (136 cm)*

to clear open door

freestand drye

on floor

floorline

dryer mounted on

optional pedestal

floorline

53.5" (136 cm) _

to clear open door

31.5" (79.5 cm) _'

to front of closed door

31.5" (79.5 cm) _

to front of closed door

38.0"

(96.5 cm)

!5"

cm)

gas supply

p_pe on

of gas unit

.... l

1ZO"

(43 cm)

13.5 _'

(34.5 cm)

to center of rear

Dryer Dimensions

27.0 ''

(68.5 cm)

0

electrical

supply on

rear of unit _

centerline

height for

rear vent

3.7"

(9.5 cm)

19.0"

(48 cm}

75.75"

(192.5 cm)

water supply

connection on

rear of unit I

gas supply

pipe on rear

of gas unit

39.0"

(99 cm)

0

0

drain hose on

rear of unit3

electrical

supply on

rear of unit _

centerline

height for

rear vent

power cord on

rear of unit 2

41.0"

(105 cm)

floorline

_Connection of water inlet hose on steam dryer adds 3/4 in. (2 cm) to installation depth.

1Power supply cord length on gas dryer approximately 60 inches (152.5 cm).

2Hot and cold inlet hose length on washer approxlnqately 48.5 inches (123 cnq).

3Drain hose length on washer approximately 59 inches (150 cm).

4Power supply cord length on washer approximately 60 inches (152.5 cm).

11

Page 12

Installation instructions

Electrical installation

The following are specific requirements for proper and

safe electrical installation of your dryer. Failure to follow

these instructions can create electrical shock and/or a fire

hazard.

* A U.L.-approved strain relief must be installed onto

z% RNI ..............................................................................................................................................................

ELEC?RICALSH6aZHAZARD

* This appliance MUST be properly grounded.

Electrical shock can result if the dryer is not properly

grounded. Follow the instructions in this manual for

proper grounding.

* Do not use an extension cord with this dryer. Some

extension cords are not designed to withstand the

amounts of electrical current this dryer utilizes

and can melt, creating electrical shock and/

or fire hazard. Locate the dryer within reach of

the receptacle for the length power cord to be

purchased, allowing some slack in the cord. Refer to

the pre-instailation requirements in this manual for

the proper power cord to be purchased.

* Do not use an aluminum wired receptacle with a

A chemical reaction occurs between copper and

wiring and receptacle is a copper wired power cord

with a copper wired receptacle.

Dryers operating on 208 volt power supply will have

longer drying times than dryers operating on 240 volt

power supply.

ELECTRICAL SHOCK HAZARD

power cord. If the strain relief is not attached, the

cord can be pulled out of the dryer and can be cut

by any movement of the cord, resulting in electrical

shock.

copper wired power cord and plug (or vice versa).

aluminum and can cause electrical shorts. The proper

.oTE..........................................................................................................................................................................

Grounding requirements - Electric dryer (USA)

ELECTRICAL SHOCK HAZARD

Improper connection of the equipment grounding

conductor can result in a risk of electrical shock. Check

with a licensed electrician if you are in doubt as to

whether the appliance is properly grounded.

For a grounded, cord-connected dryer:

I The dryer MUST be grounded. In the event of a

malfunction or breakdown, grounding will reduce

the risk of electrical shock by a path of least

resistance for electrical current.

2 After you purchase and install a 3 wire or 4 wire

power supply cord having an equipment-grounding

conductor and a grounding plug that matches your

3

For a

1

wiring system, the plug MUST be plugged into

an appropriate, copper wired receptacle that is

properly installed and grounded in accordance with

aii local codes and ordinances. If in doubh caiia

licensed electrician.

DO NOT modify the plug you've installed on this

appliance. If it wiii not fit the outlet, have a proper

outlet installed by a qualified electrician.

permanently connected dryer:

The dryer MUST be connected to a grounded

metal, permanent wiring system; or an equipment

grounding conductor must be run with the circuit

conductors and connected to the equipment-

grounding terminal or lead on the appliance.

12

Page 13

Installation instructions

Grounding requirements - Electric dryer (Canada)

the risk of electrical shock by providing a path of

ELECTRICALSH6a HAZARD

Improper connection of the equipment grounding

conductor can result in a risk of electrical shock. Check

with a licensed electrician if you are in doubt as to

whether the appliance is proper!y grounded. ................................................................................

For a grounded_ cord-connected dryer:

I The dryer MUST be grounded. In the event of a

malfunction or breakdown° grounding will reduce

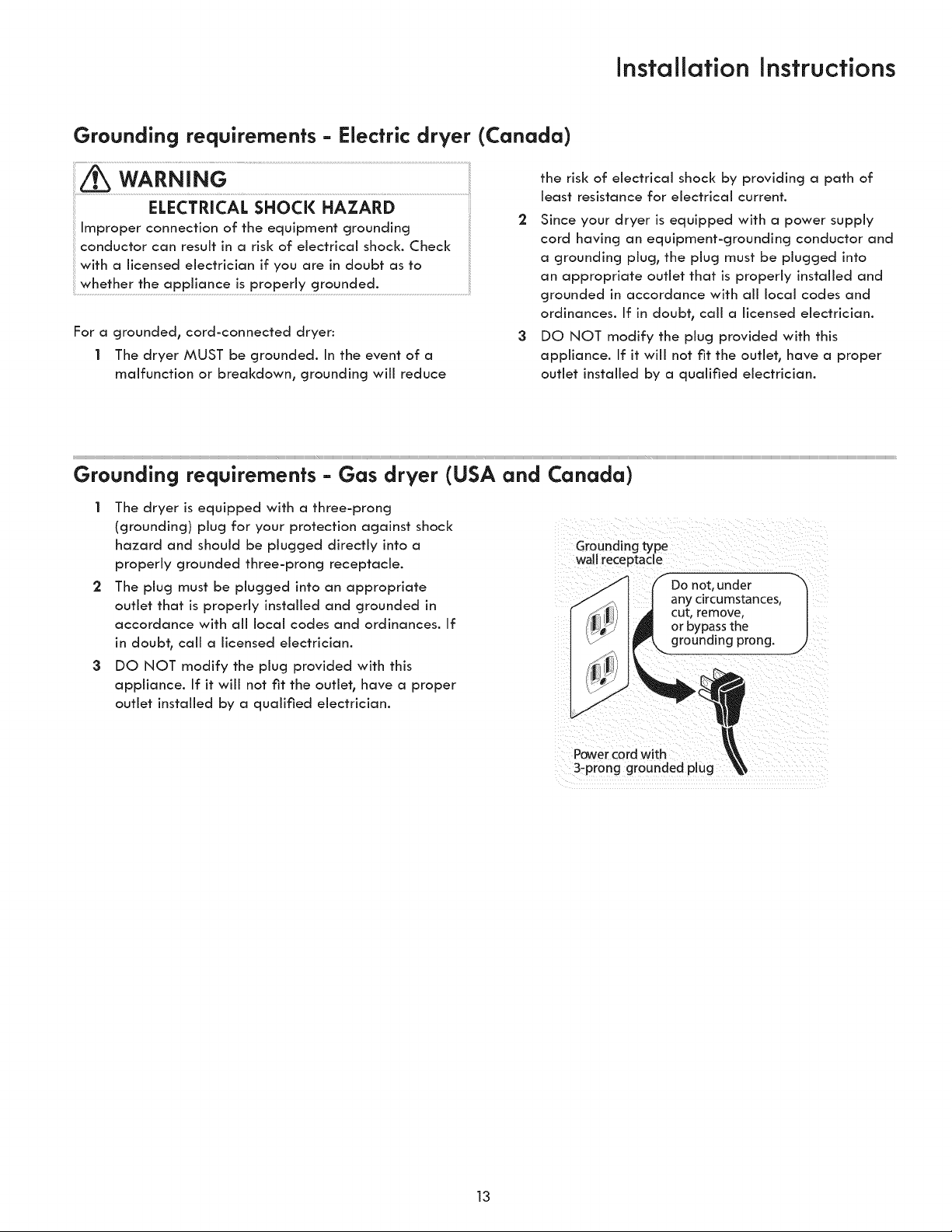

Grounding requirements - Gas dryer (USA and Canada)

1 The dryer is equipped with a three-prong

(grounding) plug for your protection against shock

hazard and should be plugged directly into a

properly grounded three-prong receptacle.

2 The plug must be plugged into an appropriate

outlet that is properly installed and grounded in

accordance with aii local codes and ordinances. If

in doubh caiia licensed electrician.

3 DO NOT modify the plug provided with this

appliance. If it wiii not fit the outlet, have a proper

outlet installed by a qualified electrician.

least resistance for electrical current.

2 Since your dryer is equipped with a power supply

cord having an equipment-grounding conductor and

a grounding plug, the plug must be plugged into

an appropriate outlet that is properly installed and

grounded in accordance with all local codes and

ordinances. If in doubh carl a licensed electrician.

3 DO NOT modify the plug provided with this

appliance. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

Grounding type

wall receptacle

i- any circumstances,

f

Do not, under

cut, remove,

or bypass the

grounding prong.

13

Page 14

Installation instructions

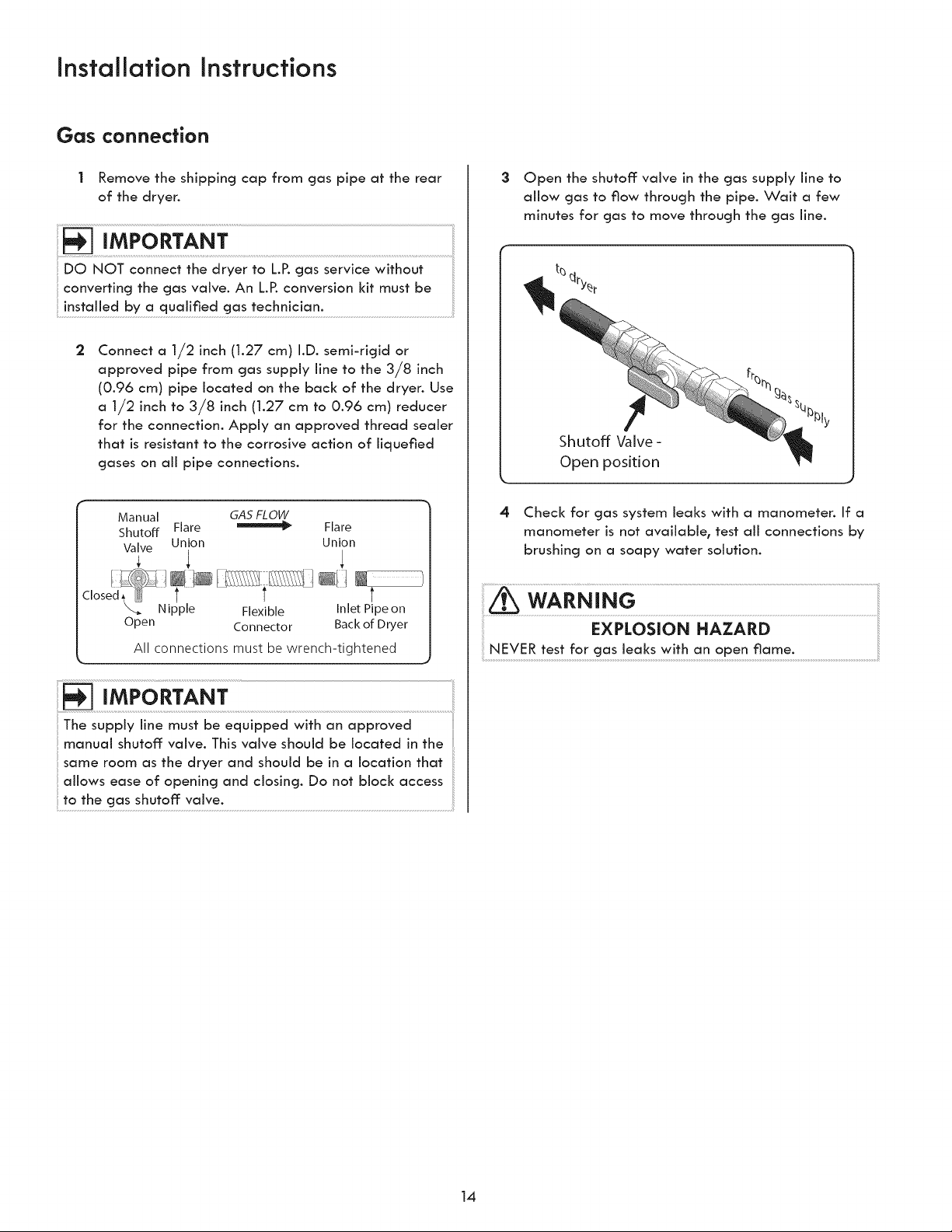

Gas connection

1 Remove the shipping cap from gas pipe at the rear

of the dryer.

IMPORTANT ..................................................................

DO NOT connect the dryer to L.P. gas service without

converting the gas valve. An L.P. conversion kit must be

installed by a qualified gas technician.

Connect a 1/2 inch (1.27 cm) I.D. semi-rigid or

approved pipe from gas supply line to the 3/8 inch

(0.96 cm) pipe located on the back of the dryer. Use

a 1/2 inch to 3/8 inch (1.27 cm to 0.96 cm) reducer

for the connection. Apply an approved thread sealer

that is resistant to the corrosive action of liquefied

gases on allpipe connections.

F

Manual GASFLOW

Shutoff Flare _ Flare

Valve Union Union

closea__ t ...... t t

Nipple Flexible Inlet Pipeon

Open Connector Backof Dryer

All connections must be wrench-tightened

.......wA,,,,G

N E t orga aksw!t op .............................................................................

3 Open the shutoff valve in the gas supply line to

allow gas to flow through the pipe. Wait a few

minutes for gas to move through the gas line.

Shutoff Valve-

Open position

4 Check for gas system leaks with a manometer. If a

manometer is not available, test all connections by

brushing on a soapy water solution.

ExPLBS 6N,AZARD

_ IMPORTANT ..............................................................................................

The supply line must be equipped with an approved

manual shutoff valve. This valve should be located in the

same room as the dryer and should be in a location that

allows ease of opening and closing. Do not block access

14

Page 15

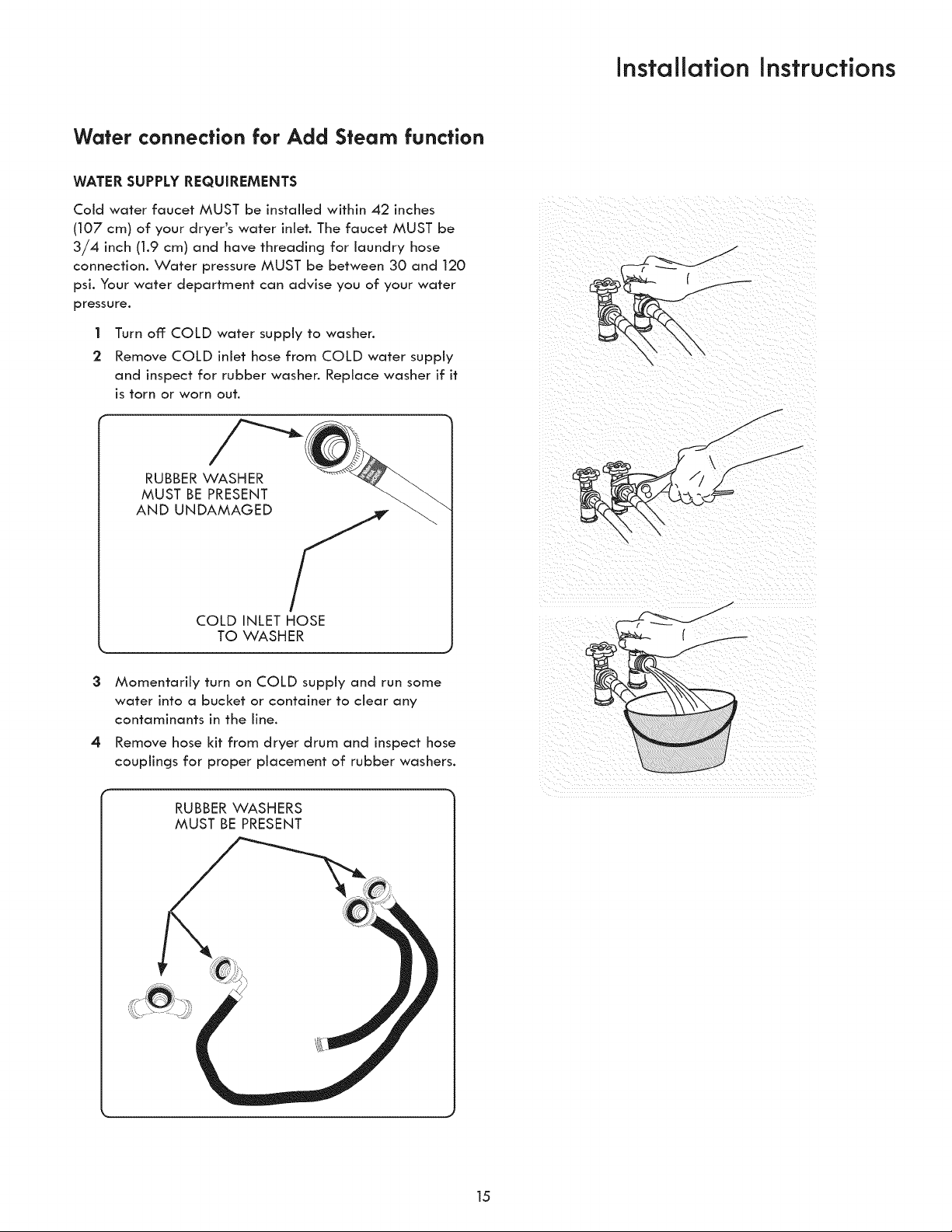

Water connection for Add Steam function

WATERSUPPLYREQUIREMENTS

Cold water faucet MUST be installed within 42 inches

(107 cm) of your dryer's water inlet. The faucet MUST be

3/4 inch (1.9 cm) and have threading for laundry hose

connection. Water pressure MUST be between 30 and 120

psi. Your water department can advise you of your water

pressure.

1

Turn off: COLD water supply to washer.

2

Remove COLD inlet hose from COLD water supply

and inspect for rubber washer. Replace washer if it

is torn or worn out.

RUBBER WASHER

MUST BE PRESENT

AND UNDAMAGED

Installation instructions

J

COLD INLET HOSE

TO WASHER

Momentarily turn on COLD supply and run some

water into a bucket or container to clear any

contaminants in the line.

4

Remove hose kit from dryer drum and inspect hose

couplings for proper placement of rubber washers.

RUBBER WASHERS

MUST BE PRESENT

jJ

15

Page 16

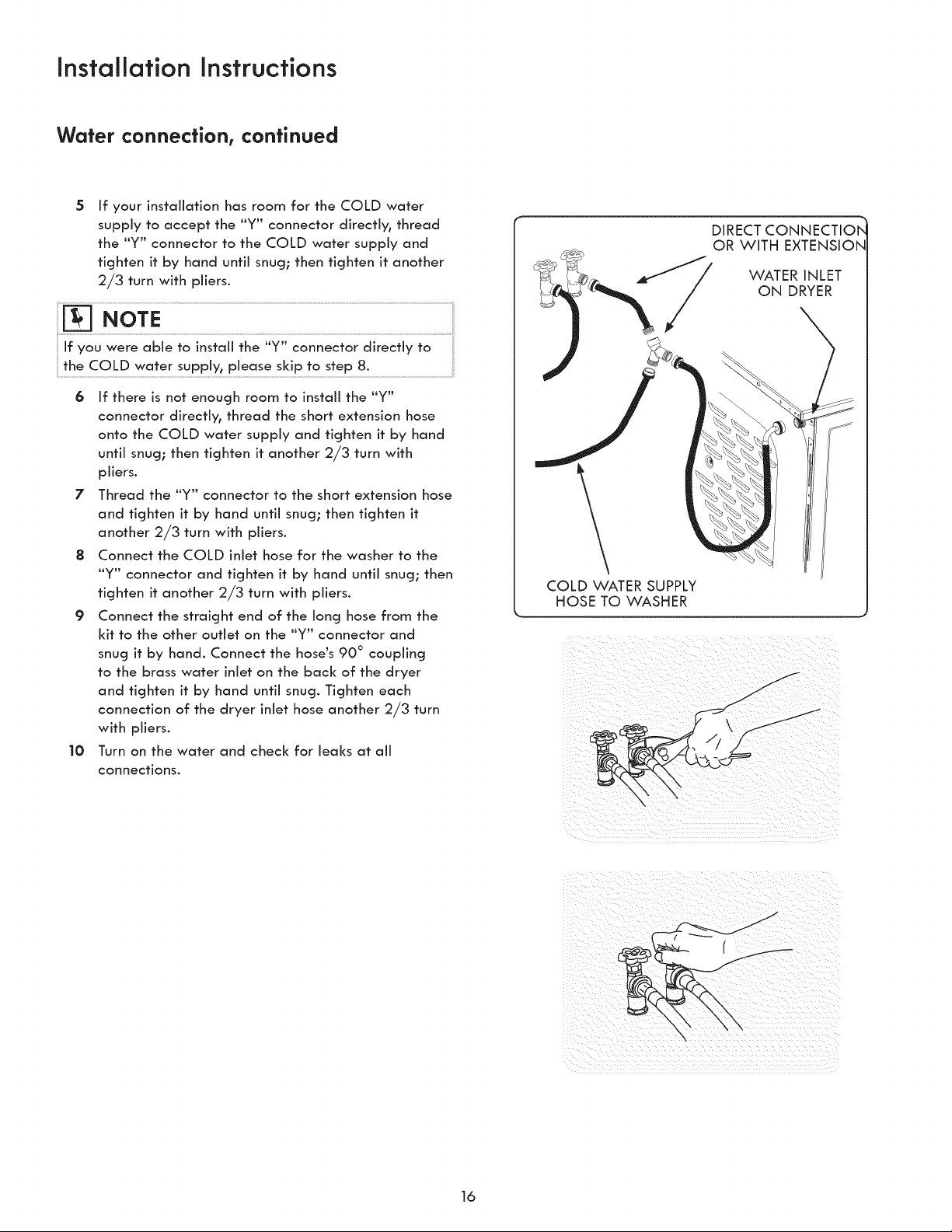

Installation instructions

Water connection, continued

If your installation has room for the COLD water

supply to accept the "Y" connector directly, thread

the "Y" connector to the COLD water supply and

tighten it by hand until snug; then tighten it another

2/3 turn with pliers.

DIRECT CONNECTION

OR WITH EXTENSION

ON DRYER

If you were able to install the "Y" connector directly to

the COLD water supply, please skip to step 8.

6 If there is not enough room to instafl the "Y"

connector directly_ thread the short extension hose

onto the COLD water supply and tighten it by hand

until snug; then tighten it another 2/3 turn with

pliers.

7 Thread the "Y" connector to the short extension hose

and tighten it by hand until snug; then tighten it

another 2/3 turn with pliers.

8 Connect the COLD inlet hose for the washer to the

"Y" connector and tighten it by hand until snug; then

tighten it another 2/3 turn with pliers.

9 Connect the straight end of the long hose from the

kit to the other outlet on the "Y" connector and

snug it by hand. Connect the hose's 90 ° coupling

to the brass water inlet on the back of the dryer

and tighten it by hand until snug. Tighten each

connection of the dryer inlet hose another 2/3 turn

with pliers.

10 Turn on the water and check for leaks at all

connections.

____ WATER INLET

COLD WATER SUPPLY

HOSE TO WASHER

16

J

Page 17

Installation instructions

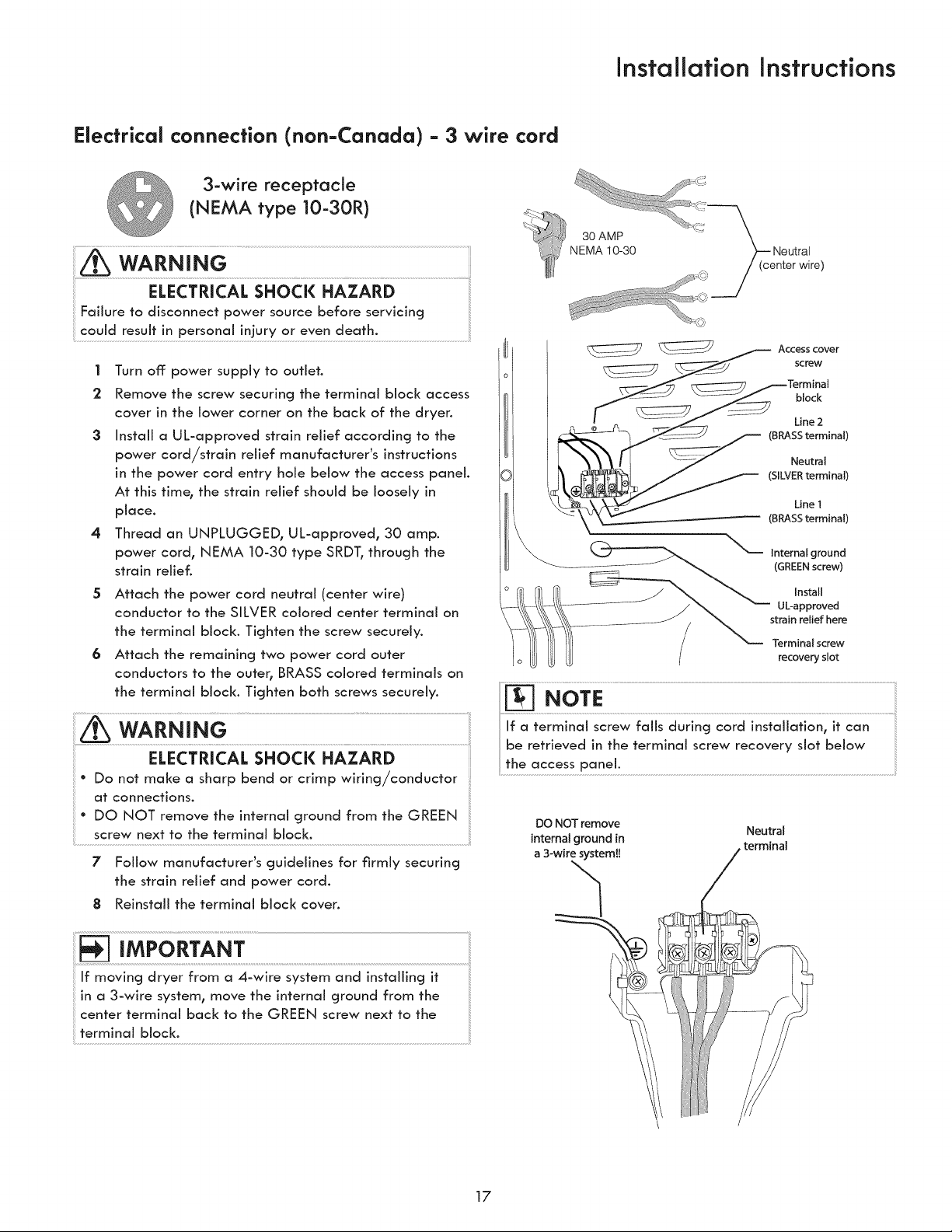

Electrical connection (non-Canada) - 3 wire cord

3-wire receptacle

(NEMA type 10-30R)

wA,,, ...........................................................................................................................................................

ELECTe CALSHOa HAZARD ....

Failureto disconnectpowersourcebeforeservicing

could result in personal injury or even death.

_ _ Access cover

1 Turn off power supply to outlet.

2 Remove the screw securing the terminal block access

cover in the lower corner on the back of the dryer.

3 Install a UL-approved strain relief according to the

power cord/strain relief manufacturer's instructions

in the power cord entry hole below the access panel.

At this time, the strain relief should be loosely in

place.

4 Thread an UNPLUGGED, UL-approved, 30 amp.

power cord, NEMA 10-30 type SRDT, through the

strain relief.

,5 Attach the power cord neutral (center wire)

conductor to the SILVER colored center terminal on

the terminal block. Tighten the screw securely.

6 Attach the remaining two power cord outer

conductors to the outer, BRASS colored terminals on

the terminal block. Tighten both screws securely.

,, ELECT" CALSH6ci HAZARD

* Do not make a sharp bend or crimp wiring/conductor

at connections.

* DO NOT remove the internal ground from the GREEN

screw next to the terminal block.

7 Follow manufacturer's guidelines for firmly securing

the strain relief and power cord.

8 Reinstall the terminal block cover.

___S Tblm icrk1

__---_- _ (BRASSterminal)

_ Line1

....NOTE.......

If a terminal screw falls during cord installation, it can

be retrieved in the terminal screw recovery slot below

the access panel.

DO NOTremove

internal ground in

a 3-wire system!!

_zj/ screw

Line 2

..... (BRASSterminal)

_ Internalground

(GREEN screw)

Terminal screw

recovery slot

Neutral

terminal

iMPORTANT

If moving dryer from a 4-wire system and installing it

in a 3-wire system, move the internal ground from the

center terminal back to the GREEN screw next to the

terminalblock.

17

Page 18

Installation instructions

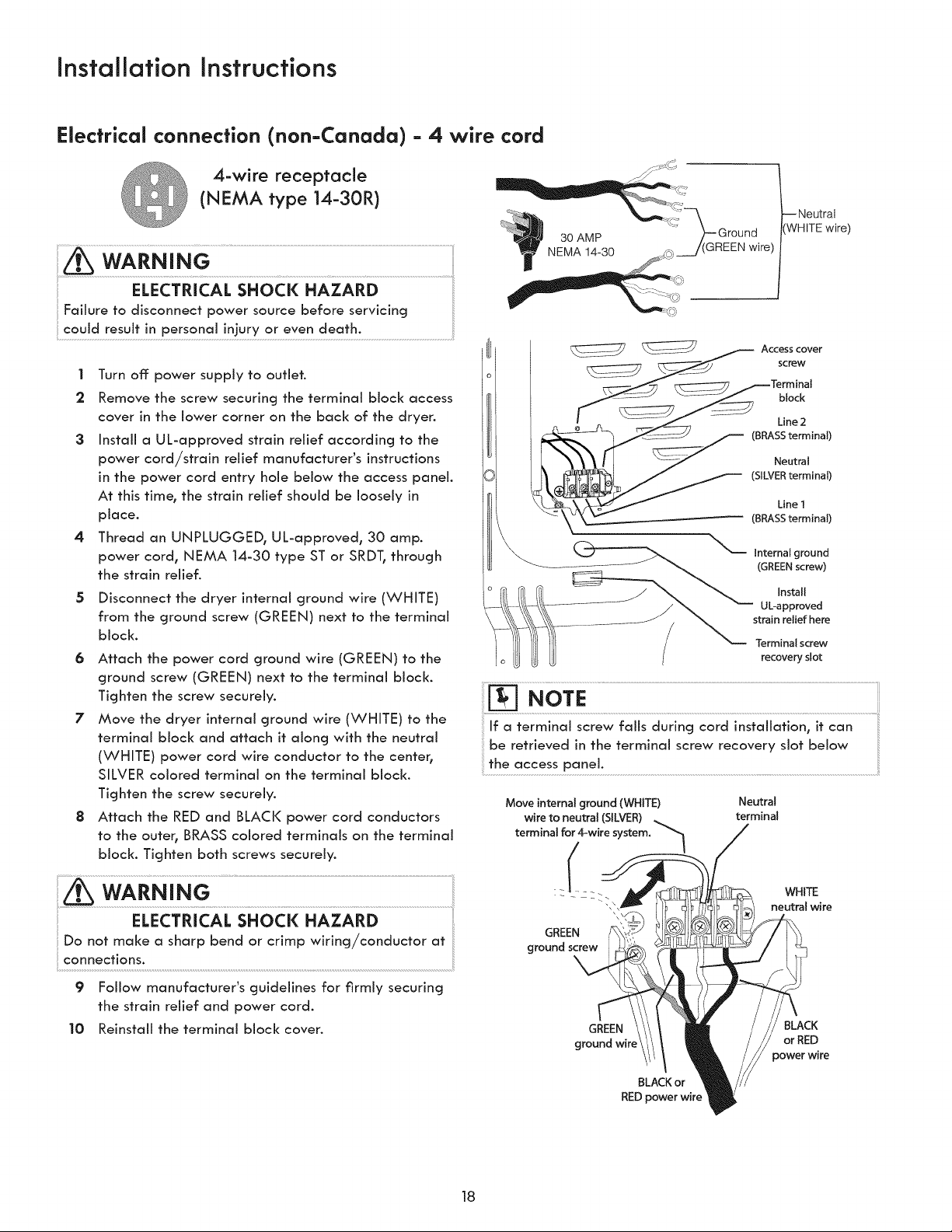

Electrical connection (non-Canada) - 4 wire cord

4-wire receptacle

(NEMA type 14-30R)

| Turn off power supply to outlet.

2 Remove the screw securing the terminal block access

cover in the lower corner on the back of the dryer.

3 Install a UL-approved strain relief according to the

power cord/strain relief manufacturer's instructions

in the power cord entry hole below the access panel.

At this time, the strain relief should be loosely in

place.

4 Thread an UNPLUGGED, UL-approved, 30 amp.

power cord, NEMA 14-30 type ST or SRDT, through

the strain relief.

5 Disconnect the dryer internal ground wire (WHITE)

from the ground screw (GREEN) next to the terminal

block.

6 Attach the power cord ground wire (GREEN) to the

ground screw (GREEN) next to the terminal block.

Tighten the screw securely.

7 Move the dryer internal ground wire (WHITE) to the

terminal block and attach it along with the neutral

(WHITE) power cord wire conductor to the center,

SILVER colored terminal on the terminal block.

Tighten the screw securely.

8 Attach the RED and BLACK power cord conductors

to the outer, BRASS colored terminals on the terminal

block. Tighten both screws securely.

If a terminal screw falls during cord installation, it can

be retrieved in the terminal screw recovery slot below

the access panel.

Moveinternalground(WHITE)

wireto neutral(SILVER)

terminalfor 4-wiresystem."_

Neutral

WHITE wire)

I _ _ _ Access cover

_j/ screw

_:___A___ _--__ _ (BRASS term na )

[_b___ (SILVERterminal)

\b ___ (BRASSterminal)

........... _ Install

Line 2

Internal ground

(GREEN screw)

UL-approved

strain relief here

Terminal screw

recovery slot

Neutral

terminal

GREEN

ground screw

9 Follow manufacturer's guidelines for firmly securing

the strain relief and power cord.

|0 Reinstall the terminal block cover. GREEN

ground win

18

WHITE

neutral wire

BLACK

or RED

power wire

BLACKor

REDpower wire

Page 19

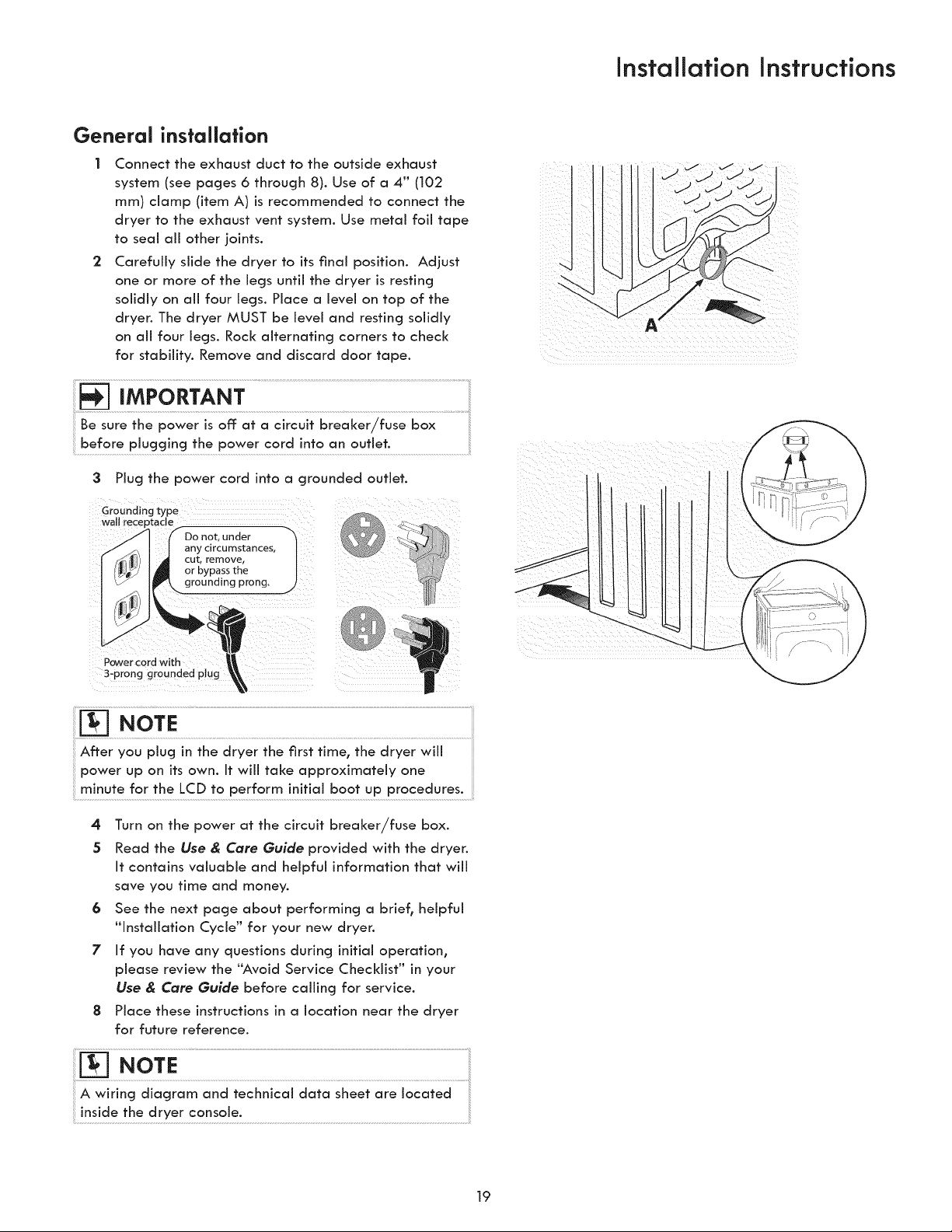

General installation

1 Connect the exhaust duct to the outside exhaust

system (see pages 6 through 8). Use of a 4" (102

mm) clamp (item A) is recommended to connect the

dryer to the exhaust vent system. Use metal foil tape

to seal all other joints.

2 Carefully slide the dryer to its final position. Adjust

one or more of the legs until the dryer is resting

solidly on all four legs. Place a level on top of the

dryer. The dryer MUST be level and resting solidly

on all four legs. Rock alternating corners to check

for stability. Remove and discard door tape.

Be sure the power is off: at a circuit breaker/fuse box

before pluggMg the power cord into an outlet.

3 Plug the power cord into a grounded outlet.

Installation Instructions

Pawer cord with

3-prong grounded plug

After you plug in the dryer the first time, the dryer will

power up on its own. It will take approximately one

minute for the LCD to perform initial boot up procedures.

4 Turn on the power at the circuit breaker/fuse box.

5 Read the Use & Care Guide provided with the dryer.

It contains valuable and helpful information that will

save you time and money.

6 See the next page about performing a brief, helpful

"Installation Cycle" for your new dryer.

7 If you have any questions during initial operation,

please review the "Avoid Service Checklist" in your

Use & Care Guide before calling for service.

8 Place these instructions in a location near the dryer

for future reference.

A wiring diagram and technical data sheet are located

19

Page 20

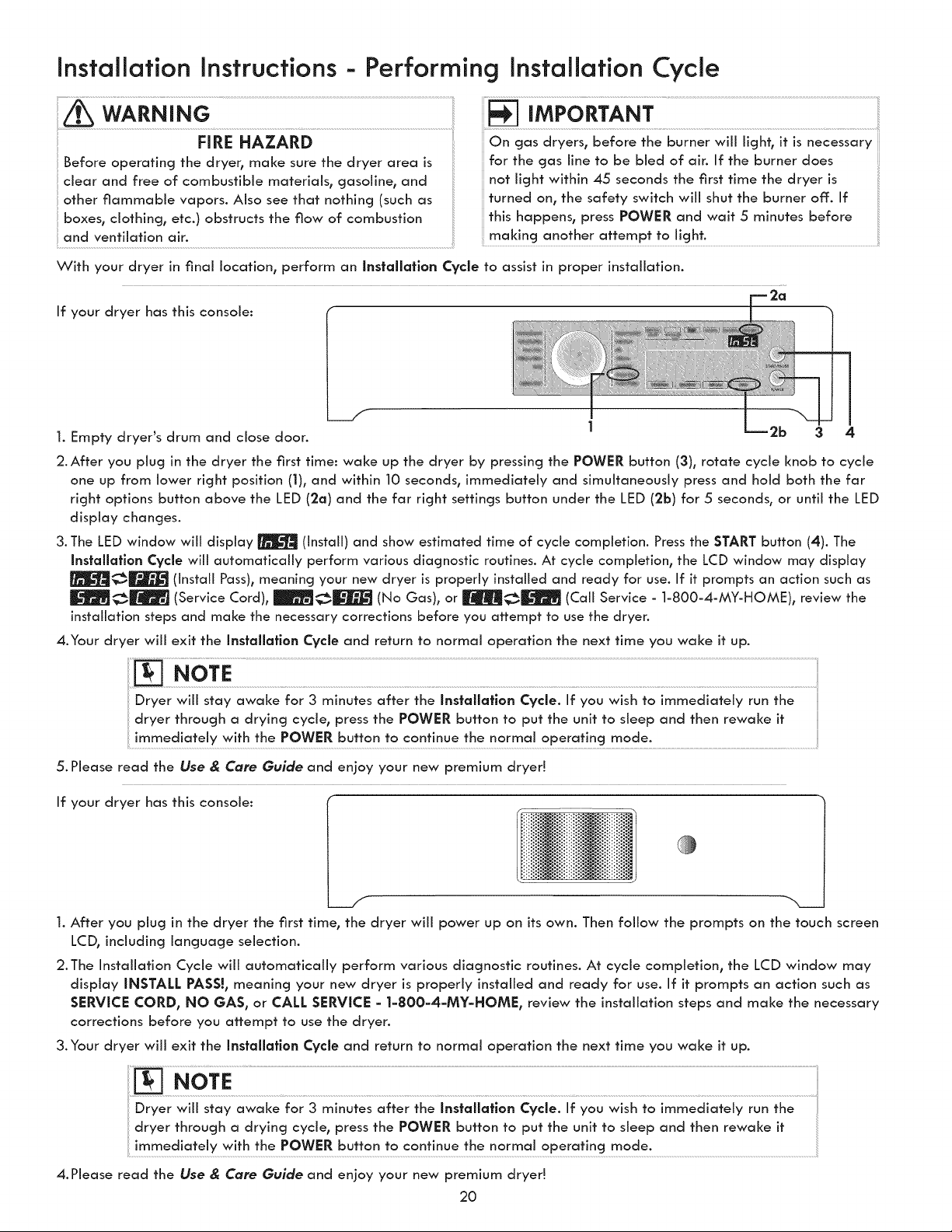

Installation instructions - Performing installation Cycle

,MPo .........................................................................................................................

On gas dryers, before the burner wiii light, it is necessary

Before operating the dryer, make sure the dryer area is

clear and free of combustible materials, gasoline, and

other flammable vapors. Also see that nothing (such as

] boxes, clothing, etc.) obstructs the flow of combustion

and ventilation air.

With your dryer in final location, perform an lnstallatlon Cycle to assist in proper installation.

If your dryer has this console:

J

1. Empty dryer's drum and close door. | 2b 3 4

2.After you plug in the dryer the first time: wake up the dryer by pressing the POWER button (3), rotate cycle knob to cycle

one up from lower right position (1), and within 10 seconds, immediately and simultaneously press and hold both the far

right options button above the LED (2a) and the far right settings button under the LED (2b) for 5 seconds, or until the LED

display changes.

3. The LED window will display | (Install) and show estimated time of cycle completion. Press the START button (4). The

Insfallatlon Cycle will automatically perform various diagnostic routines. At cycle completion, the LCD window may display

_-_ (Install Pass), meaning your new dryer is properly installed and ready for use. If it prompts an action such as

__lml_J (Service Cord), |_l_J_J (No Gas), or __JD! (Call Service- 1-800-4-MY-HOME), review the

installation steps and make the necessary corrections before you attempt to use the dryer.

4.Your dryer will exit the Instaffatlon Cycle and return to normal operation the next time you wake it up.

for the gas line to be bled of air. If the burner does

not light within 45 seconds the first time the dryer is

turned on, the safety switch wiii shut the burner off:. If

this happens, press POWER and wait 5 minutes before

making another attempt to light.

Dryer will stay awake for 3 minutes after the Insfaffafion Cycle. If you wish to immediately run the

dryer through a drying cycle, press the POWER button to put the unit to sleep and then rewake it

immediately with the POWER button to continue the normal ...........................................................................

5. Please read the Use & Care Guide and enjoy your new premium dryer!

If your dryer has this console:

J "_

1. After you plug in the dryer the first time, the dryer will power up on its own. Then follow the prompts on the touch screen

LCD, including language selection.

2.The Installation Cycle wiii automatically perform various diagnostic routines. At cycle completion, the LCD window may

display INSTALL PASS!, meaning your new dryer is properly installed and ready for use. If it prompts an action such as

SERVICE CORD, NO GAS, or CALL SERVICE - |-800-4-MY_HOME, review the installation steps and make the necessary

corrections before you attempt to use the dryer.

3.Your dryer will exit the Instailatlon Cycle and return to normal operation the next time you wake it up.

NOTE .............................

Dryer will stay awake for 3 minutes after the Installa|ion Cycle. If you wish to immediately run the

dryer through a drying cycle, press the POWER button to put the unit to sleep and then rewake it

immediately with the POWER button to continue the normal operating mode.

4.Please read the Use & Care Guide and enjoy your new premium dryer!

20

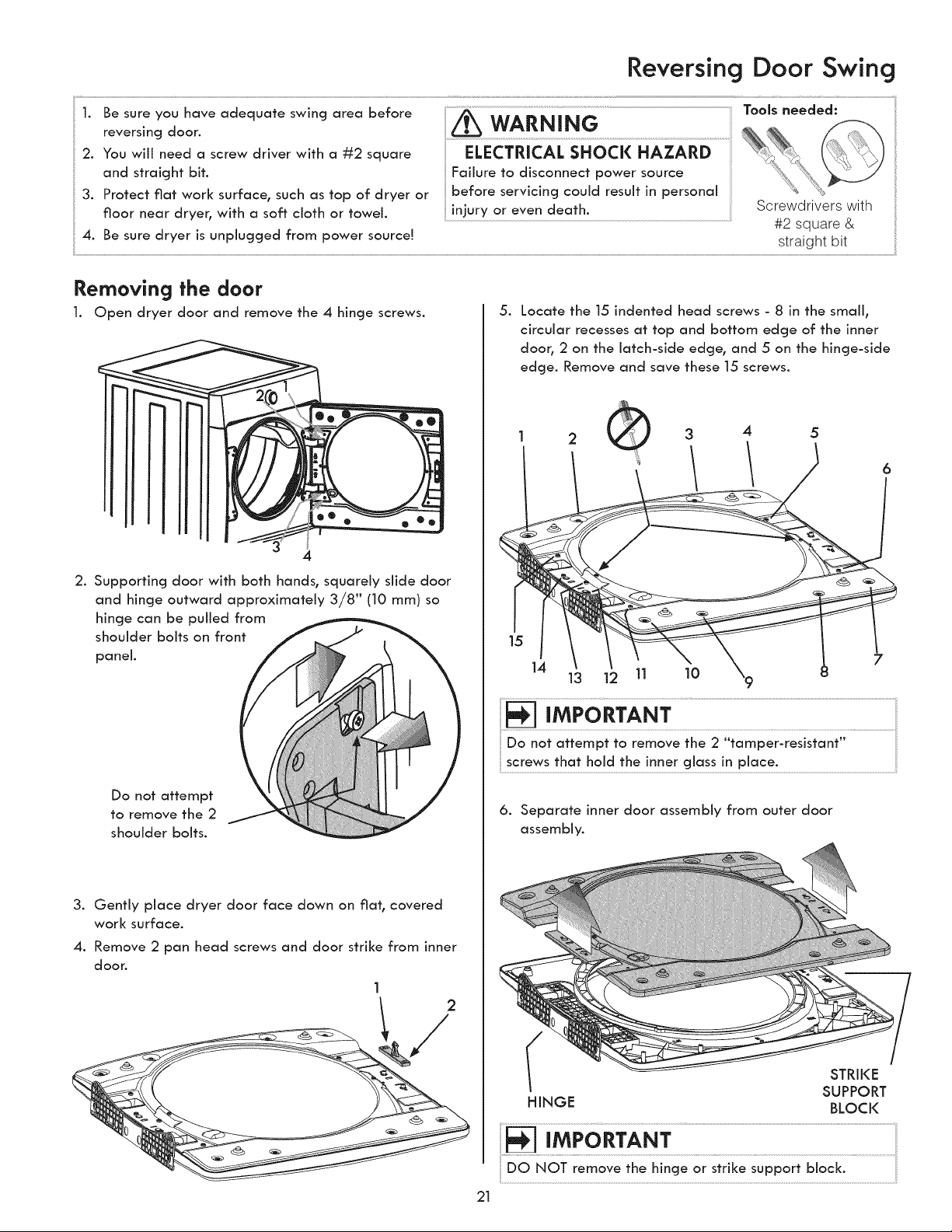

Page 21

Reversing

Door Swing

1. Be sure you have adequate swing area before

reversing door.

2. You wiii need a screw driver with a #2 square

and straight bit.

3. Protect fiat work surface, such as top of dryer or

floor near dryer, with a soft cloth or towel.

4. Be sure dryer is unplugged from power source!

Removing fhe door

1. Open dryer door and remove the 4 hinge screws.

4

WARNING .........................................

ELECTRICAL SHOCK HAZARD

Failure to disconnect power source

before servicing could result in personal

injury or even death.

.

Locate the 15 indented head screws - 8 in the small,

circular recesses at top and bottom edge of the inner

door, 2 on the latch-side edge, and 5 on the hinge-side

edge. Remove and save these 15 screws.

Tools needed:

Screwdrivers with

#2 square &

straight bit

2. Supporting door with both hands, squarely slide door

and hinge outward approximately 3/8" (10 mm) so

hinge can be pulled from

shoulder bolts on front

panel.

Do not attempt

to remove the 2

shoulder bolts.

3. Gently place dryer door face down on fiat, covered

work surface.

4. Remove 2 pan head screws and door strike from inner

door,

14

.....................................................................................

Do not attempt to remove the 2 tamper-resistant

screwsthatholdtheinnerglassinplace.

6. Separate inner door assembly from outer door

assembly.

2

f STRIKE

HINGE BLOCK

DO NOT remove the hinge or strike support block.

21

SUPPORT

Page 22

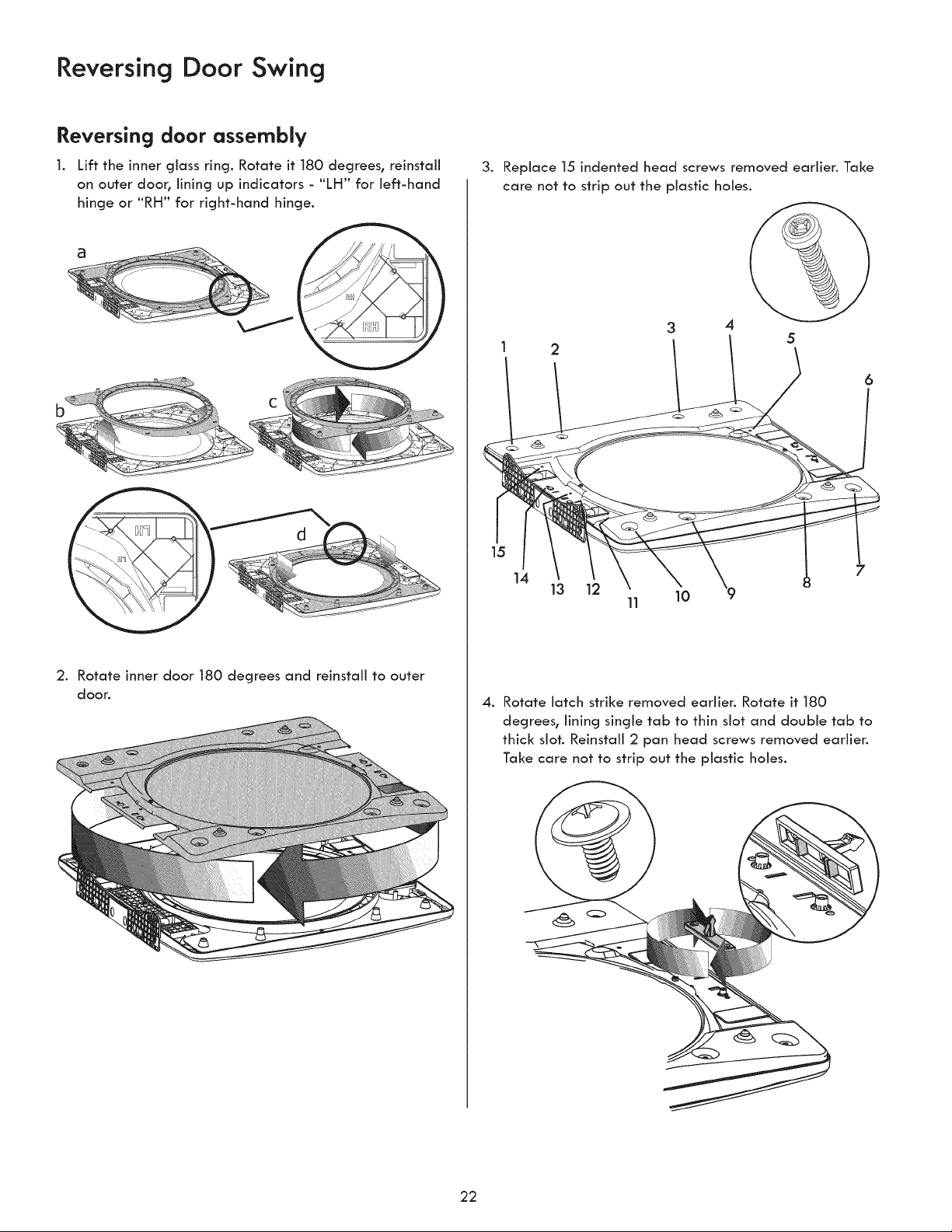

Reversing Door Swing

Reversing door assembly

1. Lift the inner glass ring. Rotate it 180 degrees, reinstall

on outer door, lining up indicators - "LH" for left-hand

hinge or "RH" for right-hand hinge.

.

Replace 15 indented head screws removed eariien Take

care not to strip out the plastic holes.

2. Rotate inner door 180 degrees and reinstall to outer

dooL

3 4

5

6

7

4. Rotate latch strike removed earlier. Rotate it 180

degrees, lining single tab to thin slot and double tab to

thick slot. Reinstall 2 pan head screws removed earlier.

Take care not to strip out the plastic holes.

22

Page 23

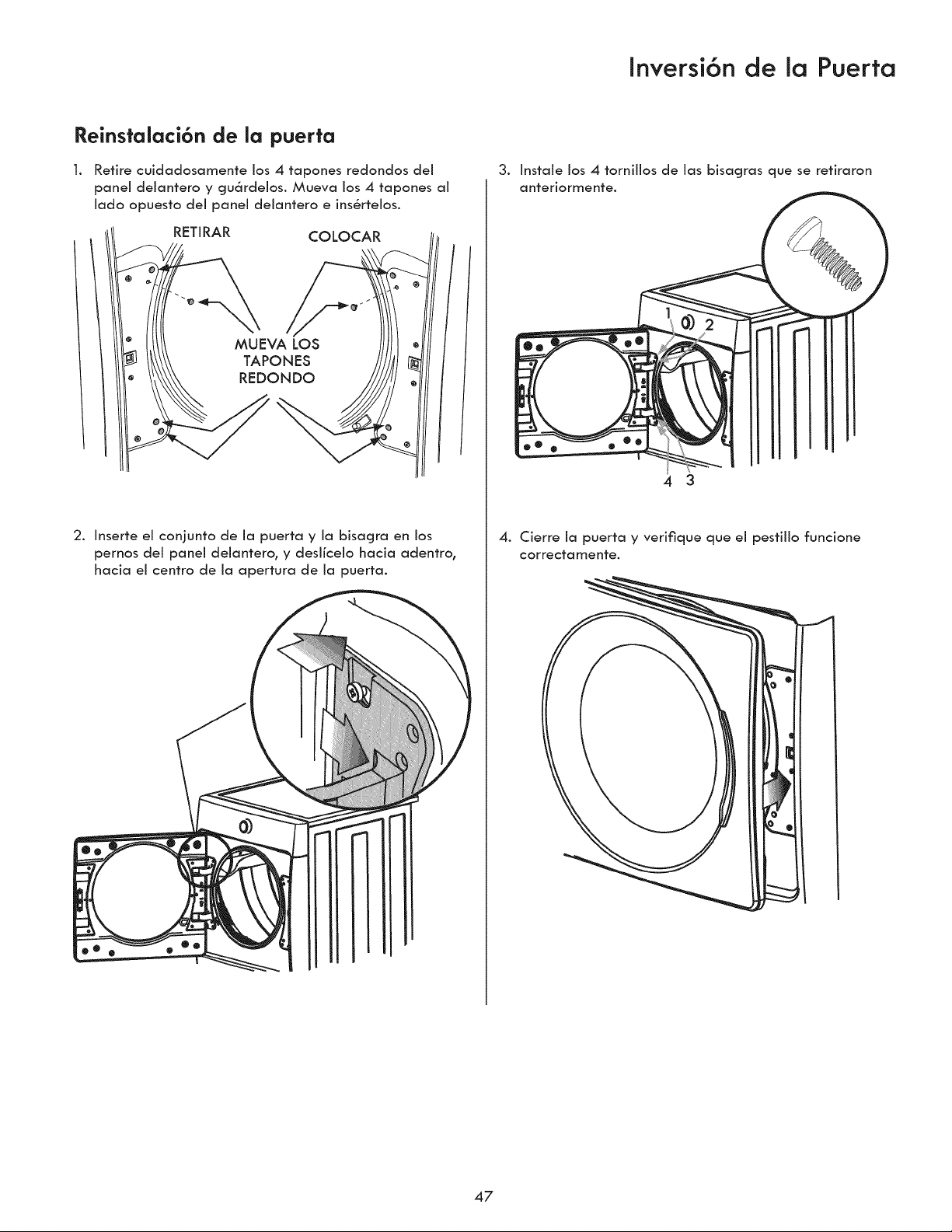

Reaffaching fhe door

Reversing Door Swing

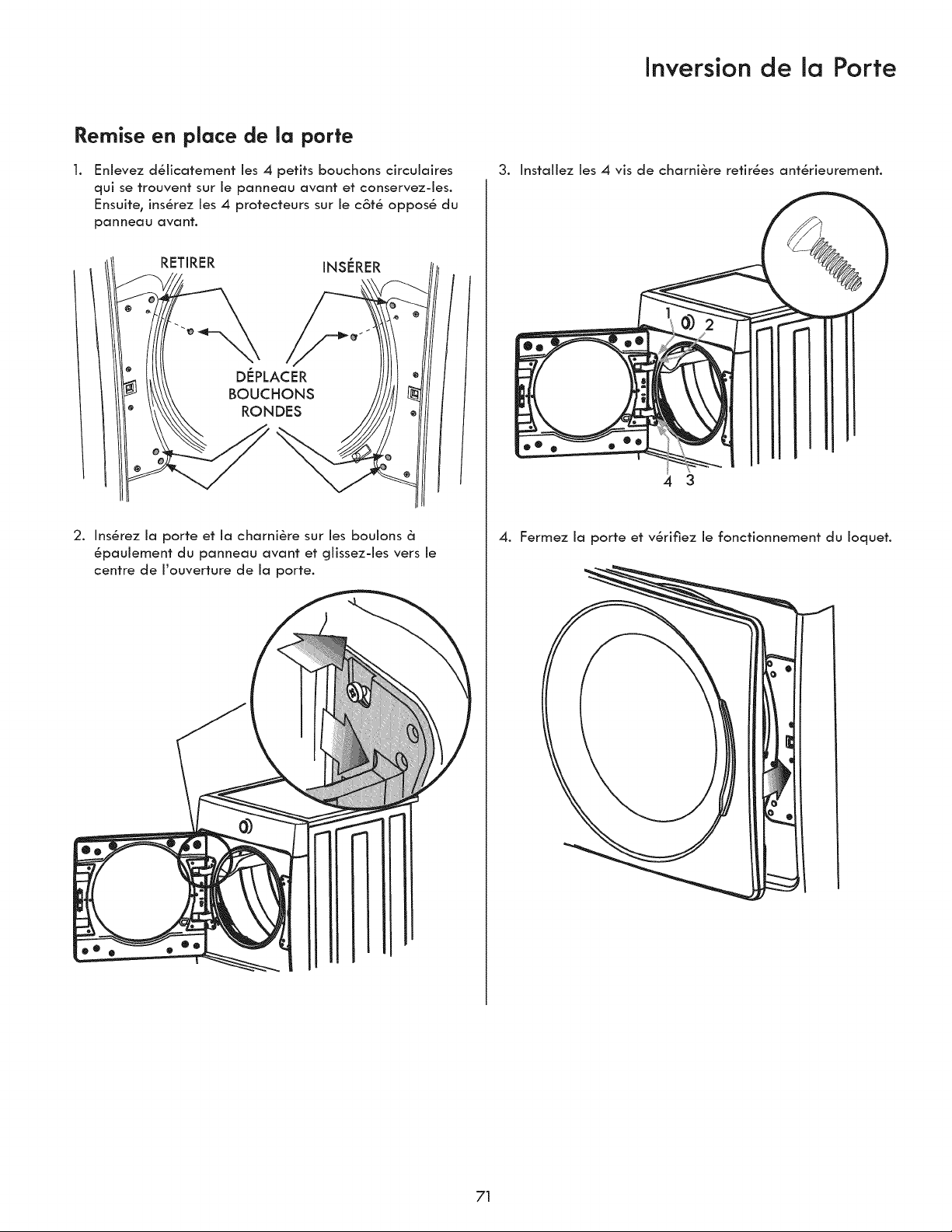

1. Carefully pull out the 4 small round hole plugs from the

front panel and save. Move all 4 plugs to the opposite

side of the front panel and insert.

OUT IN

2. Insert door and hinge assembly onto front panel

shoulder bolts and slide inward to center of door

opening.

3. Install the 4 hinge screws removed earlier.

4.

Close the door and test operation of hinge, strike and

latch.

J

23

Page 24

Accessories

MATCHING STORAGE PEDESTAL _

White Pedestal - P/N 4175889200

Lemon Grass Pedestal - P/N 4175889100

Blackberry Pedestal - P/N 4175889000

A storage pedestal accessory, specifically designed for this dryer

may be used to elevate the washer for ease of use. This pedestal

wiii add about 15.25" (39 cm) to the height of your unit for a total

height of 53.25" (135.5 cm).

_Other colors may be available. Contact the source where you

purchased your dryer.

DRYER STACKING KiT

P/N 137385300

Depending on the model you purchased, a kit for stacking this

dryer on top of matching washer may have been included in the

initial purchase of your dryer. If your model did not include a

stackincj kit or you desire another stackincj kit, you may order one.

LP CONVERSION KIT

P/NPCK4200

Gas dryers intended for use in a location supplied with LP must use

a conversion kit prior to installation.

MOBILE HOME iNSTALLATION KiT

P/N 137067200

Installation in a mobile home requires the use of a MOBILE HOME

INSTALLATION KIT.

DRYING RACK

P/N 134912700

Depending on the model you purchased, an expandable drying

rack may have been included in the initial purchase of your dryer.

If your model did not include a drying rack or you desire another

drying rack, you may order one.

UNIVERSAL APPLIANCE WRENCH

P/N 137019200

A UNIVERSAL APPLIANCE WRENCH is available to aid in dryer/

washer/pedestal feet adjustment.

TOUCH UP PAINT PENS _

White Touch Up Pen - P/N 5304468812

Lemon Grass Touch Up Pen - P/N 5304481253

Blackberry Touch Up Pen - P/N 5304481254

_Other colors may be available. Contact the source where you

purchased your dryer.

Replacement parts:

If replacements parts are needed for your dryer,

contact the source where you purchased your washer or

refer to your Use and Care Guide for more information.

RNING ................................................................................................................................................................................

ELECTRICALSH6a HAZARD.....

Label all wires prior todisconnection when servicing controls.

Wiring errors can cause improper and dangerous operation.

Ver! p pe operat!o a!te serv!€!ng:...........................................................................................................................................

24

Page 25

Installation instructions

Instrucciones de Instalaci6n

instructions d_lnstaliation

English / Espa_ol / Franc;ais

re Elite

®

Sears Brands Management Corporation

Hofl:man Estates, IL 60179 U.S.A.

www.kenmore.com

www.sea rs.com

Sears Canada Inc.

Toronto, Ontario, Canada M5B 2C3

WWW.sea rs.ca

Page 26

Instrucciones Importantes de Secjuridad

ADVERTENCIA ....................

Para su seguridad, debe seguir la informaci6n de esta guia para minimizar el riesgo de incendio o exp!osi6n o para

evitar da_os a ia propiedad, iesiones personales o inciuso ia muerte. No almacene ni utilice gasolina ni otros liquidos o

vapores inflamabies cerca de este o de cuaiquier otro eiectrodom_stico. .............

ADVERTENCIA- PELIGRO DE INCENDIO

Lea las siguientes instrucciones antes de instalar y utilizar este electrodom6stico:

° DespuSs de desembaiar la secadora, destruya los cartones y ias boisas de pi6stico. Los ni_os podrian utilizarios para

jugar. Los cartones cubiertos con alfombras, cubrecamas, o i6minas de pi6stico pueden convertirse en c6maras de

aire herm(_ticamente cerradas y provocar asfixia. Coloque todos los materiaies en un basurero o mantSngalos fuera

del alcance de los ni_os.

° La instaiaci6n y el servicio de ia secadora de ropa deben ser ilevados a cabo por un instalador calificado, agencia

de servicios o proveedor de gas.

° Instale ia secadora de ropa de acuerdo con ias instrucciones dei fabricante y los c6digos locales.

° La reparaci6n ei_ctrica de ia secadora debe cumpiir con los c6dicjos y las ordenanzas locales y ia 6itima edici6n dei

C6digo EiSctrico Nacionai (Nationa! Electrical Code), ei ANSI/NFPA 70, o bien en Canad6, ei CSA C22.1 dei C6digo

EiSctrico de Canad6 (Canadian Electrical Code) Parte 1.

• Ei servicio de gas de la secadora debe cumpiir con los c6digos y las ordenanzas locales, y la 6itima edici6n del C6di-

go de Gas Nacional (National Fuel Gas Code), ei ANSI Z223.1, o bien en Canad6, ei CAN/CGA B149,1-2000.

• La secadora se dise_6 conforme a los c6digos ANSI Z 21.5.1 o ANSIiUL 2158 - CAN/CSA C22.2 N.° 112 (6itimas

ediciones) solo para USO DOMF:STICO. No se recomienda esta secadora para uso comerciai, como por ejempio, en

restaurantes, salones de beiieza, etc.

° No utiiice materiaies de ventiiaci6n de pi6stico ni de papei de aiuminio flexibies para instaiar ia secadora de ropa.

Por io general, dichos materiales se desarman, se deterioran con faciiidad y acumuian peiusa. Estas condiciones obs-

truyen ei flujo de aire de ia secadora y aumentan ei riescjo de incendio.

° No apiie ia secadora sobre ia iavadora si ya est6 instaiada sobre un pedestal. No apiie ia iavadora sobre ia secado-

ra. No apiie ia iavadora sobre otra iavadora.

° Las instrucciones de esta guia y todo el material que se inciuye con esta secadora no tienen como prop6sito cubrir

todas ias condiciones y situaciones que puedan presentarse. Cuando instale, opere o repare cuaiquier artefacto DEBE

tener cuidado y hacer uso de buenas pr6cticas de seguridad.

QUE HACER SI SIENTE OLOR A GAS:

° No intente encender ning6n eiectrodom6stico.

° No toque ning6n interruptor eiSctrico; no utiiice nincj6n teiSfono en ia vivienda.

° Despeje ia habitaci6n, ei edificio o ei 6rea de todos los ocupantes.

* Llame inmediatamente a su proveedor de gas desde el telSfono de un vecino. Siga las instrucciones del proveedor de gas.

° Si no puede ponerse en contacto con ei proveedor de gas, iiame a los bomberos.

Conserve estas instrucciones para referencia futura.

Requisitos de preinstalaci6n

Herramientas y materiaies necesarios para ia instaiaci6n:

• Pinzas ajustabies

° Destornilladores Philips con punta

derecha y cuadrada

° Liave ajustabie

° Liave para tubos de suministro de

gas

• Cinta aislante resistente al gas LP

(para suministro de gas natural o LP)

° Nivei de carpintero

° Capucha de ventiiaci6n externa

* Conducto de escape de metal rigido

o semirigido de 4 pulgadas (102 ram)

" Kit de cables de alimentaci6n trifilar

o tetrafllar de 240 voltios (secadora

el_ctrica)

° Abrazadera de 4" (10,2 cm)

• V61vula de cierre de linea de gas

(secadora a gas)

• Adaptadores NPI de uni6n acampa-

nada (x2) y ffnea flexible de suminis-

tro de gas (secadora a gas) de 1/2'

(15,2 cm)

° Cinta de papei aluminio (no cinta

adhesiva aisiante)

26

Page 27

instrucciones Importantes de Secjuridad

Lista de Verificaci6n

Lea todas las instrucciones antes de usar este secadora.

Identificaci6n de los sirnbolos, palabras

y avisos de seguridad

Las indicaciones de secjuridad induidas en este manual

aparecen precedidas de un aviso titulado "ADVERTENCIA"

o "PRECAUCION"0 de acuerdo con ei nivei de riescjo.

Definiciones

Este es el sfmbolo de alerta de secjuridad. Se usa para

alertar sobre pelicjros potenciaLes de lesiones personales.

Obedezca todos los mensajes de secjuridad que tencjan este

sfmbolo para evitar posibles lesiones personales o la muerte.

PELIGRO indica una situaci6n de pelicjro inminente que,

causar_esioneS _amuerte.........

ADVERTENClA

ADVERTENCIA indica una situaci6n potencialmente

pelicjrosa que0 si no se evita0 podria causar lesiones

personales cjraves o la muerte.

PRECAUCION indica una situaci6n potencialmente

pelicjrosa que0 si no se evita0 podria causar lesiones

........

IMPORTANTE indica informaci6n de instalaci6n,

funcionamiento o mantenimiento que es importante,

pero que no est6 relacionada con la secjuridad.

{NDICE

Instrucciones importantes de secjuridad ..................... 26-27

Requisitos de instaiaci6n .............................................. 28-34

Dimensiones de la secadora ............................................... 35

Instrucciones de instalaci6n ......................................... 36-44

Inversi6n de la puerta ................................................... 45-47

Accesorios ............................................................................. 48

de Instalaci6n

Venfilaci6n de escape

[] De flujo libre y sin acumulaci6n de pelusa

[] Conductos ricjidos o semiricjidos de 4" (102 ram)

de distancias y cjiros minimos

[] SIN materiaies de ventiiaci6n de aluminio o de

pi6stico

[] Ei sistema de evacuaci6n debe ventiiar al

exterior y contar con una capucha de ventiiaci6n

aprobada

Nivelaci6n

[] La secadora est6 nivelada de lado a lado y de

adelante hacia atr6s

[] El secadora descansa firmemente sobre sus cuatro

esquinas

Suministro de agua (agregar vapor)

[] Se instalaron la arandela de cjoma {empacada

en el tambor) en mancjuera de admisi6n NUEVA

(empacada en el tambor)

[] La mancjuera de admisi6n debe estar conectada

al conector en "Y" del suministro de acjua FR{A.

[] Se abri6 el suministro de acjua

[] No hay escapes en las conexiones del suministro

de acjua o en las conexiones de admisi6n del

electrodom_stico -

vuelva a verificar alas 24 horas

Suministro de gas (secadora a gas)

[] V61vula de cierre manual instalada en la tuberia

de suministro

[] Todas las conexiones selladas con un sellante

aprobado y bien apretadas con una llave

[] Kit de conversi6n para el sistema de cjas LP

[] Suministro de cjas abierto

[] No hay escapes en nincjuna conexi6n:

verifique con acjua jabonosa, NUNCA con una

llama

Suministro el_ctrico de 240V (secadora

el_ctrica)

[] Cord6n de servicio el_ctrico 10-30R o 10-40R

aprobado por la NEMA con todos los tornilios

bien apretados en el tablero de terminaies

[] Dispositivo de liberaci6n de tensi6n aprobado

[] Tapa de acceso a los terminales instalada antes

del primer uso

Inversi6n de la puerta

[] Sicja las instrucciones detailadas en esta cjuia

[] Pruebe la bisacjra y el cjancho para asecjurarse de

que funcionen

Suministro ei_ctrico

[] El suministro el_ctrico del hocjar est6 activado

[] La secadora est6 enchufada

Inspecci6n final

[] Lea bien las instrucciones de instalaci6n y la cjuia

de uso y cuidado

[] La puerta se cierra y el tambor cjira cuando se

inicia el cicio

27

Page 28

Requisitos de instalaci6n

Debido a posibies variaciones en ei voitaie , no se recomienda utiiizar esta secadora con eiectricidad generada a

partir de cjeneradores a gas, soiares, e61icos ni de nincjuna otra ciase que no sean los empleados por su empresa de

electricidad local.

Requisitos el ctricos de la secadora el ctrica

CIRCUITO: circuito independiente individual de 30 amp. con fusibies de acci6n retardada o disyuntores. Use circuitos con

fusibies separados para ia iavadora y ia secadora. NO haga funcionar una iavadora y una secadora en ei mismo

circuito.

SUMINISTRO ELI_CTRICO: trifilar o tetrafilar, 240 V, 1 fase, 60 Hz, corriente alterna.

IMPORTANTE

A menos que haya sido fabricada para la venta en Canad6, esta secadora est6 conectada a tierra internamente a

trav_s de un enlace a un conductor neutro. La conexi6n a tierra a trav_s dei neutro est6 prohibida para: (1) instalaciones

de circuitos de bifurcaci6n nuevos; (2) casas rodantes; (3) vehiculos recreafivos; y (4) 6reas cuyas leyes locales no

RECEPTJ_CULO DEL TOMACORRIENTE - recept6culo NEMA 10-30 R o NEMA 14-30 R que debe estar ubicado en un

iugar ai que pueda acceder el cable de aiimentaci6n eiSctrica cuando ia secadora est8 instaiada.

CONEXION A TIERRA: consuite "Requisitos de conexi6n a tierra" en ia secci6n Instalaci6n eiSctrica.

CABLE DEALIMENTACION ELF:CTRICATRIFILAR(no

inciuido)

Recept6culo trifliar

(tipo NEMA 10-30R)

La secadora DEBE empiear un cable de aiimentaci6n

eiSctrica de 3 conductores tipo NEMA 10-30, SRDT

calificado para CA minima de 240 voitios, 30

amp., con 3 conectores de terminal horquilla con

extremos dobiados hacia arriba o de bucie cerrado

y calificados para uso en secadoras de ropa. Para

obtener instrucciones sobre ia conexi6n trifiiar, consuite

CONEXIONES ELF:CTRICAS PARA UN SISTEMA

TRIFILAR.

CABLE DE ALIMENTACION ELF:CTP,ICA TETRAFILAR (no

incluido)

Recept6culo tetrafilar

(fipo NEMA 14-30R)

La secadora DEBE emplear un cabJe de alimentaci6n

el_ctrica de 4 conductores tipo NEMA 14-30, SRDT o

ST (secjOn se especifique) calificado para CA minima

de 240 voltios, 30 amp., con 4 conectores de terminal

horquilla con extremos doblados hacia arriba o de

bucle cerrado y calificados para uso en secadoras

de ropa. Para obtener instrucciones sobre la conexi6n

tetrafiJar, consulte CONEXIONES ELI_CTRICAS PARA

UN SISTEMA TETRAFILAR.

Las secadoras fabricadas para la venta en Canad6

vienen con un cable de aiimentaci6n el_ctrica tetrafilar

(NEMA 14-30R) de f6brica.

28

Page 29

Requisitos de Instalaci6n

Requisitos el ctricos de la secadora a gas

CIRCUITO - Circuito individual de bifurcaci6n de 15 amp.,

correctamente polarizado y con conexi6n a tierra con

fusible de retardo de 15 amp. o con interruptor autom6tico.

SUMINISTRO ELECTRICO: corriente alterna de 2 cables, con

conexi6n a tierra, 120 voltios, monof6sica, 60 Hz.

CABLE DE ALIMENTACION ELECTRICA: la secadora est6

equipada con un cable de alimentaci6n trifllar de 120

voltios.

CONEXION A TIERRA: consulte "Requisitos de conexi6n a

tierra" en la secci6n Instalaci6n el_ctrica.

Requerimientos del surninistro de gas

Tomacorriente con

No corte, retire nl _'_

deshabilite la clavija de I

conexi6n a tierra bajo /

ninguna circunstanciaJ

Cord6nel_cl_icode3clavijas

conpuestaatierra

PELIGRO DE EXPLOSION

Las tuberias de cobre sin recubrimiento se corroen al

exponerse al gas natural, Io que provoca p_rdidas de

gas. Utilice SOLAMENTE tuberias de hierro negro, acero

inoxidable o iat6n plastiflcado para el suministro de gas.

| La instalaci6n DEBE realizarse de acuerdo con

los c6digos locales o, en ausencia de ellos, con el

C6dicjo de Gas Nacional (National Fuel Gas Code),

ANSI Z223.1 (6itima edici6n).

2 La Iinea de suministro de gas debe ser un tubo de

1,27 cm (1/2 puigada).

3 Si los c6digos Io permiten, se puede utilizar un tubo

de metal flexible para conectar la secadora a la

linea de suministro de gas. La tuberia DEBE ser de

acero inoxidable o de lat6n plastiflcado.

4 La iinea de suministro de gas DEBE tener una v61vula

de cierre individual.

5 Se DEBE instalar una derivaci6n N.P.T de 0,32 cm

(1/8 puigadas) con tap6n roscado, que permita

conectar un medidor de prueba, inmediatamente

despu_s de la conexi6n de suministro de gas a la

secadora, en contracorriente al flujo de gas.

6 La secadora DEBE estar desconectada de la tuberia

de gas durante cualquier prueba en la que la

presi6n exceda los 3,45 kPa (1/2 psig).

7 La secadora DEBE estar aislada de la tuberia de

gas durante cualquier prueba en la que la presi6n

sea igual o inferior a 3,45 kPa (1/2 psig).

8 Las conexiones del suministro de gas deben cumplir

con la norma de conexiones de electrodom(_sticos a

gas, ANSI Z21.24.

29

Page 30

Requisitos de Instalaci6n

Requisitos del sisterna de escape

Utilice solo un conducto de metal flexible o r[gido

de 102 mm (4 pulgadas) de di6metro (mfnimo) y una

capucha de ventilaci6n aprobada que tenga uno o m6s

reguladores de tiro que se abran cuando la secadora est_

en funcionamiento. Cuando la secadora se detiene, el

regulador de tiro se cierra autom6ticamente para evitar

la corriente de aire y el ingreso de insectos y roedores.

Para evitar restringir la salida del conducto, mantenga un

espacio m[nimo de 30,5 cm (12 pulgadas) entre la capucha

de ventilaci6n y el suelo, o cualquier otra obstrucci6n.

El no seguir estas instrucciones puede producir tiempos

de secado excesivos y peligro de incendio.

Los siguientes son requisitos necesarios

para el funcionamiento seguro y correcto

de su secadora.

..... ADVERTENCIA .............

PELIGRO DE INCENDIO

No utilice materiales de ventilaci6n de pl6stico ni de

papel de aJuminio flexibies para instalar la secadora

de ropa. Por io general, dichos materiaies se desarman,

se deterioran con faciiidad y acumuian peiusa. Estas

condiciones obstruyen ei flujo de aire de la secadora y

Si su sistema actual est6 compuesto de un conducto

de pl6stico o papel de aluminio, reempl6celo por un

conducto de metal rigido o semiricjido. AsegOrese de que

el conducto existente no tenga pelusas antes de instalar el

conducto de la secadora.

m

m

Correcto

m

m m

Incorrecto

m

m m

Incorrecto

30

Page 31

Requisitos del sistema de escape (continuaci6n)

Una secadora de ropa debe tener ventilaci6n al exterior.

No ventile la secadora a una chimenea, pared, techo,

6tico, pasajes entre pisos ni nincj0n espacio oculto de

la vivienda. Las secadoras de ropa producen pebsa

combustible. Si la secadora no tiene ventilaci6n al

exterior, alcjunas pelusas finas se expulsar6n en el 6rea

de lavanderia. La acumulaci6n de pelusa en cualquier

_rea de Ja vivienda puede constituir un peligro sanitario

y un riesgo de incendio.

La secadora debe estar conectada a un sistema de escape

que termine en el exterior de la vivienda. Inspeccione la

abertura de escape al exterior con frecuencia y elimine

cuaiquier acumulaci6n de pelusa en la abertura yen el

6rea que ia rodea.

PELIGRO DE INCENDIO

* No permita que materiales combusfibJes (por ejempio:

ropa, tapicer[a/cortinas, papeJ) entrenen contacto

con el sistema de escape. La secadora NO DEBE

tener escape a una chimenea, una pared, un techo

ni ning0n espacio cerrado de un edificio que pueda

acumuiar peJusa y constituir un peJigro de incendio.

* No bloquee los extremos de escape del sistema

ii

de ventilaci6n, ni utilice tornillos, remaches ni otros

sujetadores que se extiendan hacia la parte interna

del conducto para ensamblarlo. Es posible que la

pelusa quede atrapada en el filtro, los tornillos o los

ii

remaches, Io que puede obstruir la red de conductos

ii

y constituir un peligro de incendio, asi coma tambi_n

aumentar los tiempos de secado. En ia saiida

del conducto ai exterior, utilice una capucha de

ventiiaci6n aprobada y seiie todas ias uniones con

ii

cinta de papei aluminio. Todos los accesorios macho

para tubas DEBEN instalarse teniendo en cuenta el

Si se excede la Iongitud del tuba del conducto o

el nOmero de codas permitidos en las tabias de

"LONGITUD M_,XIMA", se pueden acumular pelusas en

el sistema de escape. La obstrucci6n del sistema podria

constituir un peligro de incendio, asi coma aumentar los

* Siva a instalar conductos de ventilaci6n semirrigidos,

Requisitos de Instalaci6n

ADVERTENCIA

PELIGRO DE INCENDiO

LONGITUD M,_,XiMA

Conducto de metal rfgido de 102 mm (4 pulgadas)

O_

Q

O_

O_

_D

3

O-

_D

'4D

O

c

0 125 ft. (38.10m)

1 115 ft. (35.05m)

2 105 ft. (32.00m)

3 95 ft. (28.96m) 80 ft. (24.38m)

4 85 ft. (25.91m) 70 ft. (21.34m)

TIPO DE CAPUCHA DE VENTILACION

(recomendada)

4"

(10,2 cm)

aberturas de

ventitaci6n

2.5"

(6,35 cm)

110 ft. (33.53m)

100 ft. (30.48m)

90 ft. (27.43m)

ADVERTENCIA

PEuGRODE NcEND 6

Noutilicematerialdeventilaci6nnexibledepl stico

o aluminio.

no exceda una Iongitud de 8 pies (2,4 m).

31

Page 32

Requisitos de Instalaci6n

Requisitos del sisfema de escape (confinuaci6n)

Direcci6n del escape

El escape direccional se puede Iograr mediante la

instalaci6n de un codo de ventilaci6n de cjiro r6pido de

90 ° directamente en la saJida de la secadora. Los codos

de ventilaci6n de la secadora se encuentran disponibies a

trav_s de su distribuidor de repuestos o ferreteria local.

INCORRECTO

En instalaciones en ias que el sistema de escape no se

describa en ias tabias, se debe utiiizar el siguiente mStodo

para determinar si dicho sistema es aceptabie:

| Conecte un man6metro inclinado o digital entre ia

secadora y ei punto donde el tubo de escape se

conecta con ia secadora.

2 Coloque ei temporizador y ia temperatura de

ia secadora en ia opci6n Air fluff - cool down

(Esponjado con aire, enfriamiento) y ponga en

marcha ia secadora.

3 Lea ia medici6n dei man6metro.

4 La contrapresi6n dei sistema NO DEBE ser mayor

que 2_5 cm (1 pulgada) de columna de agua. Si

ia contrapresi6n dei sistema es menor que 2,5 cm

(1 pulcjada) de coiumna de agua, ei sistema es

aceptabie. Si ia iectura dei man6metro es mayor

que 2,5 cm (1 puigada) de columna de agua, el

sistema es demasiado restrictivo y ia instaiaci6n es

inaceptabie.

Si bien ia orientaci6n vertical dei sistema de escape es

aceptabie, ciertas circunstancias atenuantes podrian

afectar ei funcionamiento de ia secadora:

° S6io se debe utiiizar una red de conductos de metal

ricjido.

° Si ia ventiiaci6n se efect0a en forma vertical a travSs

del techo, es posibie que el sistema de escape se vea

expuesto a r6fagas descendentes que restringir6n ia

ventiiaci6n.

° Si ei sistema de escape se extiende a travSs de

un 6rea que no est6 aislada, puede producirse

condensaci6n y una acumuiaci6n m6s r6pida de

peiusa.

° La r6pida acumuiaci6n de peiusa en ia secadora

sistema de escape_ compresi6n o los pliegues del

sistema de escape aumentar6n ia restricci6n de ia

ventilaci6n.

° Se debe inspeccionar y iimpiar ei sistema de escape

cada 18 meses como minimo cuando se ie da un

uso normal. Cuanto m6s utiiice ia secadora, m6s a

menudo deber6 comprobar que ei sistema de escape

y ia capucha de ventilaci6n funcionan correctamente.

Consuite tambi&n los Requisitos de Despeje en la sicjuiente

p6gina.

Utilice un codo de cjiro

r6pido de 90 ° para cumpiir

con la profundidad minima

de instalaci6n de la

secadora independiente.

32

Page 33

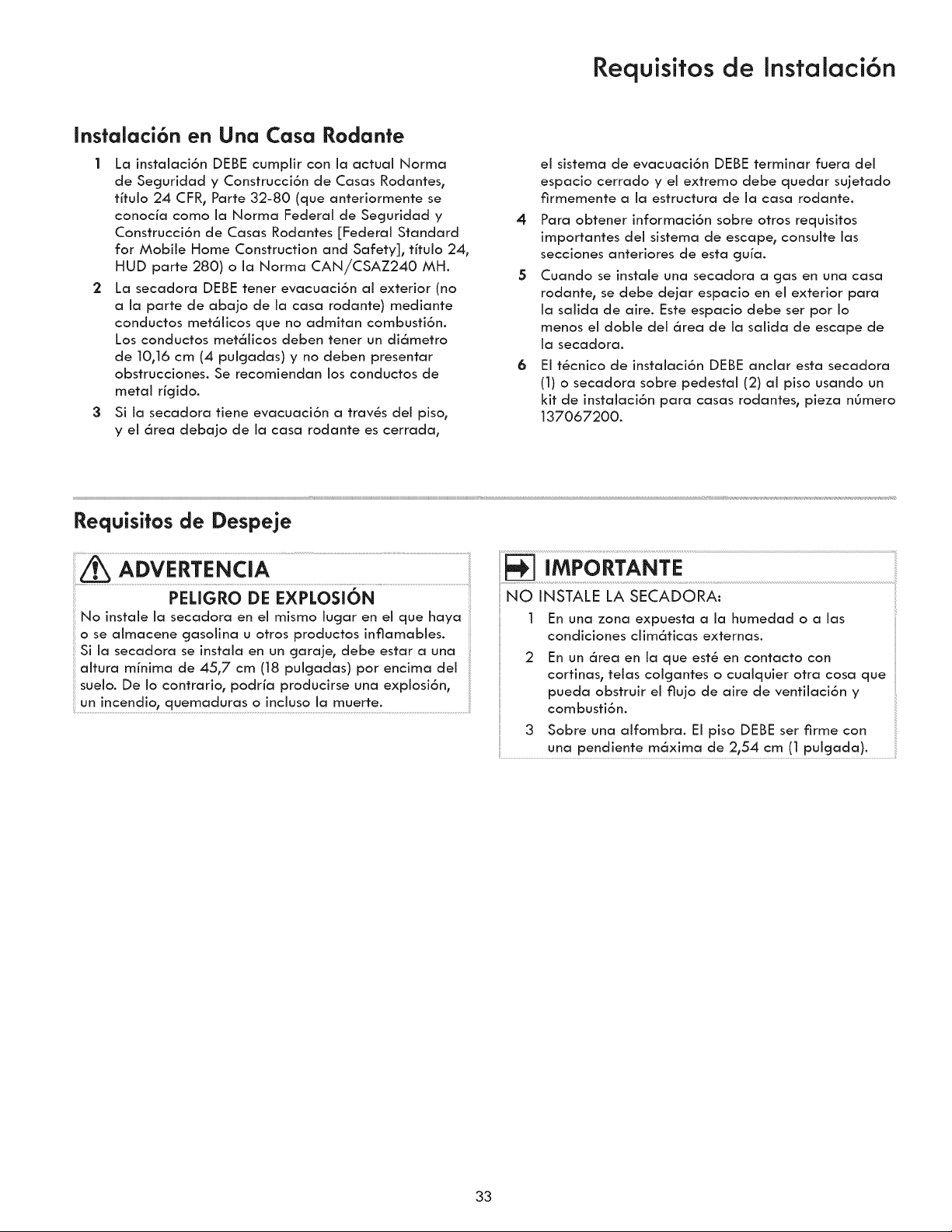

Instalaci6n en Una Casa Rodante

1 La instaJaci6n DEBE cumplir con la actual Norma

de Seguridad y Construcci6n de Casas Rodantes,

titulo 24 CFR, Parte 32-80 (que anteriormente se

conocia como la Norma Federal de Secjuridad y

Construcci6n de Casas Rodantes [Federal Standard

for Mobile Home Construction and Safety], titulo 24,

HUD parte 280) o la Norma CAN/CSAZ240 MH.

2 La secadora DEBE tener evacuaci6n aJ exterior (no

a la parte de aba]o de la casa rodante) mediante

conductos met6Jicos que no admitan combusti6n.

Los conductos met6ficos deben tener un di6metro

de 10,16 cm (4 pulcjadas) y no deben presentar

obstrucciones. Se recomiendan los conductos de

metal rigido.

3 Si la secadora tiene evacuaci6n a trav_s del piso,

y el 6rea debajo de la casa rodante es cerrada,

Requisitos de Instalaci6n

ei sistema de evacuaci6n DEBE terminar fuera del

espacio cerrado y ei extremo debe quedar sujetado

firmemente a ia estructura de ia casa rodante.

4 Para obtener informaci6n sobre otros requisitos

importantes del sistema de escape, consuite ias

secciones anteriores de esta guia.

5 Cuando se instaie una secadora a gas en una casa

rodante, se debe dejar espacio en el exterior para

ia saiida de aire. Este espacio debe ser por io

menos el dobie del 6rea de la salida de escape de

ia secadora.

6 Ei tScnico de instaiaci6n DEBE anciar esta secadora

(1) o secadora sobre pedestal (2) ai piso usando un

kit de instalaci6n para casas rodantes, pieza nOmero

137067200.

Requisitos de Despeje

ERTENC,A..........................

PELIGRO DE EXPLOSION

No instale la secadora en el mismo lugar en el que haya

o se aimacene gasolina u otros productos inflamabies.

Si ia secadora se instaia en un garaje, debe estar a una

aitura minima de 45,7 cm (18 puicjadas) por encima del

suelo. De Io contrario, podria producirse una explosi6n,

un incendio, quemaduras o inciuso !a muerte- ............................................................................

IMPORTANTE

NO INSTALE LA SECADORA:

1 En una zona expuesta a la humedad o alas

condiciones ciim6ticas externas.

2 En un 6tea en la que est_ en contacto con

cortinas, telas coigantes o cualquier otra cosa que

:i

:i

pueda obstruir el flujo de aire de ventilaci6n y

combusti6n.

3 Sobre una aifombra. El piso DEBE ser firme con

una pendiente m6xima de 2,54 cm (1 pulgada).

33

Page 34

Requisifos de Instalaci6n

Requisifos de Despeje (confinuaci6n)

Instalaci6n en un Nicho o Armario

1 Una secadora insfalada en un dormiforio, baKo,

nicho o armario0 DEBE fener venfilaci6n al exterior.

2 No se debe insfalar ning(Jn ofro artefacto de

combusfi6n en el mismo armario que la secadora a

gas.

3 La secadora necesita espacio a su alrededor para

que la ventilaci6n sea adecuada.

NO insfaJe la secadora en un armario con puerta maciza.

4 Ventilaci6n requerida en la puerfa del armario: Se

necesifa un minimo de 774,2 cm2 (120 puicjadas 2)

de aberfura, dividido en partes icjuaJes en la parte

superior e inferior de la puerfa. Las aberturas

de ventilaci6n deben estar ubicadas a 7,6 cm (3

pulcjadas) de la parte superior e inferior de la

puerfa. Es necesario que las aberturas de aire no

est_n obstruidas al insfalar una puerfa. Se acepfa

una puerfa que tenga aberturas de ventilaci6n

distribuidas uniformemente en toda la superficie.

60 sq. in.

(387.1 cm 2)

MINIMUM INSTALLATION CLEARANCES - Inches (cm)

SIDES REAR TOP FRONT

Hueco 0" (0 cm) 0" (0 cm) _ 0" (0 cm) n/d

Debajo

de la 0" (0 cm) O" (0 cm) _ O" (0 cm) n/d

encimera

Armario 0" (0 cm) 0" (0 cm) _ 0" (0 cm) 1" (2.5 cm)

La ventilaci6n derecho hacia atr6s permite la

instalaci6n de la secadora a 0" (0 cm) de la pared.

ii

lo

0" _l 0_====

(Ocm)

0

(Ocm

puerfa deJ armario

f....

60 sq. in.

(387.1 cm 2)

II II

II II

II II

12.5cm1 i i (Ocm) i i

34

Page 35

-- 53.5" (136 cm)*

para destapar abra la puerta

secadora Jndependlente

secadora colocada sobrel J

-- 53.5" (136 cm)*

para destapar abra la puerta ._ 31.5" (79.5 cm) _

sobre el plso

llnea del plso

pedestal opcionall I

hnea del plso .... _

31.5" (79.5 cm)*

al frente de la puerta cerrada

E

E

al frente de la puerta cerrada

Dimensiones de la Secadora

27.0"

(68.5 cm)

E

0

T

38.0"

(96.5 cm)

!5"

cm)

tubeda de

suministro

de gas en la

m

de la unldad

de gas

.... l

(43 cm)

1ZO"

_,-- 13.5 t' --

(34.5 cm)

hacla el centro de la

ventilaci6n trasera

suministro el@ctrlco

en la parte trasera

de la unldad 1

altura de la IJnea

central para

venfilaci6n trasera

3.7"

(9.5 cm)

19.0"

(48 cm)

75.75"

(192.5 cm)

conexi6n del

suministro de

agua en la

parte trasera de

la lavadora 2

tuberla de

suministro de gas en

la parte trasera de

la unldad de gas

39.0"

(99 cm)

0

÷

0

manguera de drenaje

en la parte trasera de

la lavadora 3

suministro el@ctrlco

en la parte trasera

de la unldad 1

altura de la IJnea

central para

venfilaci6n trasera

sumlnlstro

el@ctrlco en la

parte trasera

de la unidad 4

(105 cm)

41.0"

linea de] plsc

1La Iongltud del cable de alimentaci6n de la secadora a gas es de aproxlmadamente t52,5 cm (60 in).

2La Iongitud de la manguera de admlsi6n de agua caliente y fria de la lavadora es de aproxlmadamente 123 cm (48_5 in).

SLa Iongitud de la manguera de drenaje de la lavadora es de aproximadamente 150 cm (59 in).

4La Iongitud del cable de alimentaci6n de la lavadora es de aproxlmadamente 152,5 cm (60 in).

35

Page 36

Instrucciones de Instalaci6n

Instalaci6n el_ctrica

Los sicjuientes son requisitos necesarios para ia instalaci6n

el_ctrica segura y correcta de su secadora. Ei no secjuir

estas instrucciones puede producir una descarga el_ctrica

y/o incendio.

* Este electrodom6stico DEBE estar debidamente

conectado a tierra. Si la secadora no est6 conectada

a tierra correctamente, se pueden producir descarcjas

el_ctricas. Sicja las instrucciones de esta cjuia para

ver c6mo se reaiiza una correcta conexi6n a tierra.

* No utilice un cable de extensi6n con esta secadora.

AIcjunos cables de extensi6n no est6n diseSados

para soportar la cantidad de corriente el6ctrica

que utiliza esta secadora y pueden derretirse, Io

que constituye un peligro de descarcja el_ctrica y/o

incendio. Ubique la secadora en un lugar donde el

cabledealimentaci6nquecompreest_alalcance

del recept6culo, permitiendo que el cable quede

holgado. Consuite los requisitos de preinstalaci6n de

esta cjuia para ver cu61 es ei cable de alimentaci6n

correcto que se debe comprar.

ADVERTENCIA ...............

PELIGRO DE DESCARGA ELI_CTRICA

* Debe instalarse, en el cable de alimentaci6n, un

dispositivo de iiberaci6n de tensi6n aprobado por

U.L. Si no se coioca un dispositivo de iiberaci6n

de tensi6n, el cable podria desenchufarse de la

secadora y cortarse por cuaiquier movimiento, y

provocar asi una descarcja el_ctrica.