Kenmore Elite 11078062801, 11078072801, 11078082701, 11078087701, 11078092700 Owner’s Manual

...

I T

qasis

am

Gas Dryer

Secadora a gas

Models/Modelos 110.7708_, 7709_

= color number/nOmero de color

®

W10180628A Sears Roebuck and Co., Hoffman Estates, IL 60179 U.S.A. www.sears.com

TABLEOF CONTENTS

KENMORE ELITE®

WARRANTY ..................................................................................... 2

DRYER SAFETY .............................................................................. 3

INSTALLATION INSTRUCTIONS .................................................. 4

Tools and Parts ............................................................................ 4

Location Requirements ............................................................... 5

Electrical Requirements ................................................................ 6

Gas Supply Requirements ........................................................... 6

Venting Requirements .................................................................. 7

Plan Vent System ......................................................................... 8

Install Vent System ....................................................................... 9

Install Leveling Legs .................................................................. 10

Make Gas Connection ............................................................... 10

Connect Vent ............................................................................. 10

Connect Inlet Hose .................................................................... 11

Level Dryer ................................................................................. 11

Reverse Door Swing .................................................................. 11

Complete Installation ................................................................. 13

DRYER USE ................................................................................. 14

Starting Your Dryer .................................................................... 14

Stopping, Pausing or Restarting ............................................... 15

Drying and Cycle Tips ............................................................... 15

Status Lights .............................................................................. 16

Cycles ........................................................................................ 16

Modifiers .................................................................................... 17

Options ...................................................................................... 18

Cycle Signal ............................................................................... 18

Changing Cycles, Modifiers and Options ................................. 19

Dryer Rack ................................................................................. 19

DRYER CARE .............................................................................. 20

Cleaning the Dryer Location ...................................................... 20

Cleaning the Lint Screen ........................................................... 20

Cleaning the Dryer Interior ........................................................ 20

Removing Accumulated Lint ..................................................... 21

Water Inlet Hoses ...................................................................... 21

Vacation, Storage and Moving Care ......................................... 21

Changing the Drum Light .......................................................... 21

TROUBLESHOOTING .................................................................. 22

PROTECTION AGREEMENTS .................................................... 23

SERVICE NUMBERS ............................................... BACK COVER

APPLIANCE WARRANTY

ONE YEAR LIMITED WARRANTY

When installed, operated and maintained according to all

instructions supplied with the product, if this appliance fails due

to a defect in material or workmanship within one year from the

date of purchase, call 1-800-4-MY-HOME ®to arrange for free

repair.

If this appliance is used for other than private family purposes,

this warranty applies for only 90 days from the date of purchase.

THIS WARRANTY COVERS ONLY DEFECTS IN MATERIAL

AND WORKMANSHIP. SEARS WILL NOT PAY FOR:

1. Expendable items that can wear out from normal use,

including but not limited to filters, belts, light bulbs, and bags.

2. A service technician to instruct the user in correct product

installation, operation or maintenance.

3. A service technician to clean or maintain this product.

4. Damage to or failure of this product if it is not installed,

operated or maintained according to all instructions supplied

with the product.

5. Damage to or failure of this product resulting from accident,

abuse, misuse or use for other than its intended purpose.

6. Damage to or failure of this product caused by the use of

detergents, cleaners, chemicals or utensils other than those

recommended in all instructions supplied with the product.

7. Damage to or failure of parts or systems resulting from

unauthorized modifications made to this product.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATION OF

REMEDIES

Customer's sole and exclusive remedy under this limited

warranty shall be product repair as provided herein. Implied

warranties, including warranties of merchantability or fitness for a

particular purpose, are limited to one year or the shortest period

allowed by law. Sears shall not be liable for incidental or

consequential damages. Some states and provinces do not allow

the exclusion or limitation of incidental or consequential

damages, or limitations on the duration of implied warranties of

merchantability or fitness, so these exclusions or limitations may

not apply to you.

This warranty applies only while this appliance is used in the

United States and Canada.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Sears, Roebuck and Co.

Dept. 817WA, Hoffman Estates, IL 60179

Sears Canada Inc.

Toronto, Ontario, Canada M5B 2B8

2

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others,

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately/

follow instructions,

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

WARNING: For your safety, the information in this manual must be followed to minimize

the risk of fire or explosion, or to prevent property damage, personal injury, or death.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Clear the room, building, or area of all occupants.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency, or

the gas supplier.

in the State of Massachusetts, the following installation instructions apply:

• installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

• if using a ball valve, it shall be a T-handle type.

• A flexible gas connector, when used, must not exceed 3 feet.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: Toreducetheriskoffire,electrioshock,or injury topersonswhenusing the dryer, followbasicprecautions,

including the following:

• Read all instructions before using the dryer.

• Do not place items exposed to cooking oils in your dryer.

Items contaminated with cooking oils may contribute to

a chemical reaction that could cause a load to catch fire.

• Do not dry articles that have been previously cleaned in,

washed in, soaked in, or spotted with gasoline, dry-

cleaning solvents, or other flammable or explosive

substances as they give off vapors that could ignite or

explode.

• Do not allow children to play on or in the dryer. Close

supervision of children is necessary when the dryer is

used near children.

• Before the dryer is removed from service or discarded,

remove the door to the drying compartment.

• Do not reach into the dryer if the drum is moving.

• Do not install or store the dryer where it will be exposed

to the weather.

• Do not tamper with controls.

SAVE THESE INSTRUCTIONS

• Do not repair or replace any part of the dryer or attempt

any servicing unless specifically recommended in this

Use and Care Guide or in published user-repair

instructions that you understand and have the skills to

carry out.

• Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product.

• Do not use heat to dry articles containing foam rubber or

similarly textured rubber-like materials.

• Clean lint screen before or after each load.

• Keep area around the exhaust opening and adjacent

surrounding areas free from the accumulation of lint, dust,

and dirt.

• The interior of the dryer and exhaust vent should be

cleaned periodically by qualified service personnel.

• See installation instructions for grounding requirements.

IMPORTANT: The gas installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas I

Code, ANSI Z223.1/NFPA 54.

The dryer must be electrically grounded in accordance with local codes or in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70.

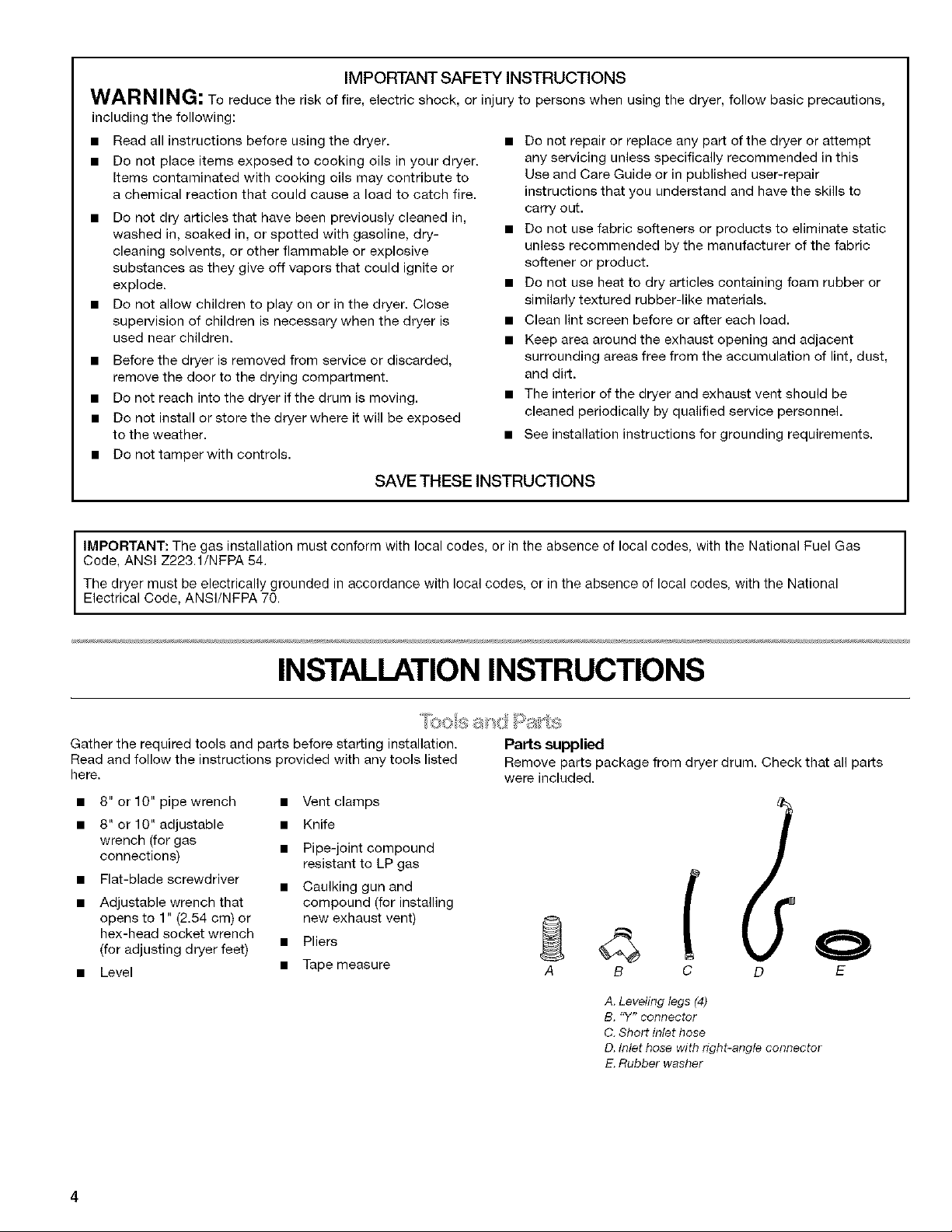

INSTALLATIONINSTRUCTIONS

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

8" or 10" pipe wrench

8" or 10" adjustable

wrench (for gas

connections)

Flat-blade screwdriver

Adjustable wrench that compound (for installing

hex-head socket wrench

opens to 1" (2.54 cm) or new exhaust vent) _ _

(for adjusting dryer feet) • Pliers

Level • Tape measure A B C D E

• Vent clamps

• Knife

• Pipe-joint compound

resistant to LP gas

• Caulking gun and

Parts supplied

Remove parts package from dryer drum. Check that allparts

were included.

I

A. Leveling legs (4)

B. "Y" connector

C. Short inlet hose

D. Inlet hose with right-angle connector

E.Rubber washer

4

Parts needed

Check local codes and with gas supplier. Check existing gas

supply, electrical supply and venting. Read "Electrical

Requirements," "Gas Supply Requirements" and "Venting

Requirements" before purchasing parts.

Mobile home installations require special parts (listed following)

available for purchase from your local Sears store or Sears

Service Center. For further information, please call

1-800-4-MY-HOME _ (1-800-469-4663).

• Mobile Home Installation Kit. Ask for Part Number 346764.

• Metal exhaust system hardware.

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 18 inches (46 cm) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

You will need

• A location that allows for proper exhaust installation. A gas

dryer must be exhausted to the outdoors. See "Venting

Requirements."

• A grounded electrical outlet located within 2 ft (61 cm) of

either side of the dryer. See "Electrical Requirements."

• A sturdy floor to support the total weight (dryer and load) of

200 Ibs (90.7 kg). The combined weight of a companion

appliance should also be considered.

• Cold water faucets located within 4 ft (1.2 m) of the water fill

valves, and water pressure of 20-100 psi (138-690 kPa). You

may use the water supply for your washer using the "Y"

connector and short hose (if needed) which are provided.

• 20-100 psi (138-690 kPa) for best performance.

• A level floor with a maximum slope of 1" (2.5 cm) under entire

dryer.

Do not operate your dryer at temperatures below 45°F (7°C). At

lower temperatures, the dryer might not shut off at the end of an

automatic cycle. Drying times can be extended.

The dryer must not be installed or stored in an area where it will

be exposed to water and/or weather.

Check code requirements. Some codes limit, or do not permit,

installation of the dryer in garages, closets, mobile homes or

sleeping quarters. Contact your local building inspector.

NOTE: No other fuel-burning appliance can be installed in the

same closet as a dryer.

Installation Clearances

The location must be large enough to allow the dryer door to

open fully.

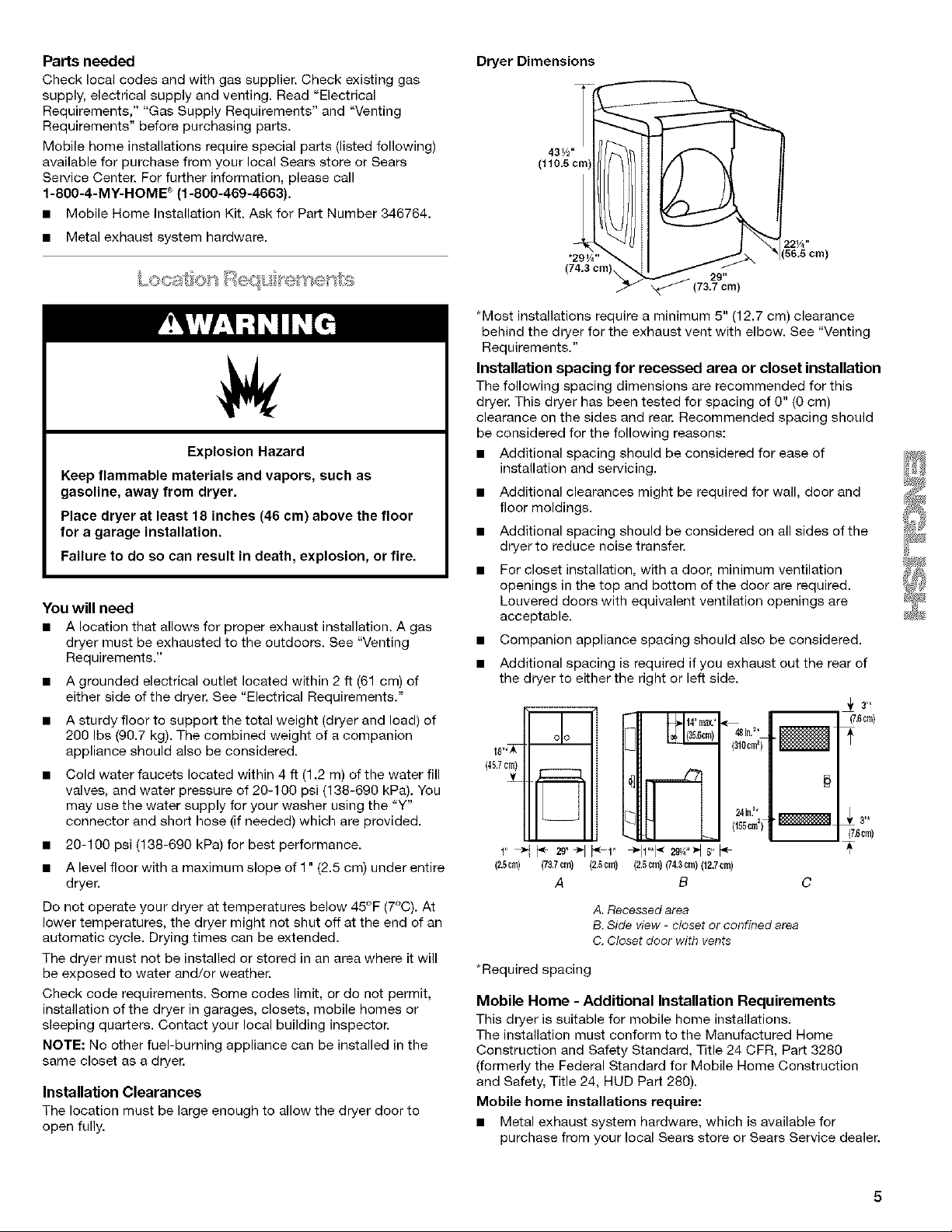

56.5 cm)

*Most installations require a minimum 5" (12.7 cm) clearance

behind the dryer for the exhaust vent with elbow. See "Venting

Requirements."

Installation spacing for recessed area or closet installation

The following spacing dimensions are recommended for this

dryer. This dryer has been tested for spacing of O" (0 cm)

clearance on the sides and rear. Recommended spacing should

be considered for the following reasons:

• Additional spacing should be considered for ease of

installation and servicing.

• Additional clearances might be required for wall, door and

floor moldings.

• Additional spacing should be considered on all sides of the

dryer to reduce noise transfer.

For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings are

acceptable.

• Companion appliance spacing should also be considered.

• Additional spacing is required if you exhaust out the rear of

the dryer to either the right or left side.

m

18,,.3C

(45.7cm)

Z

14,,ma_, 4_in2_j

¢6cm)

_ 3,,,

lT.6cm)

1"_ _ 2m'__fl _1 _ ÷11"_1_2_'__ s_'

(25cm) (73.7cm) (2.5crn) (2.5cm) (7&3cm)(12.7crn)

A B C

A. Recessed area

B. Side view - closet or confined area

C. Closet door with vents

*Required spacing

Mobile Home - Additional Installation Requirements

This dryer is suitable for mobile home installations.

The installation must conform to the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part 3280

(formerly the Federal Standard for Mobile Home Construction

and Safety, Title 24, HUD Part 280).

Mobile home installations require:

• Metal exhaust system hardware, which is available for

purchase from your local Sears store or Sears Service dealer.

3.*

MobilehomeInstallationKitPartNumber346764.See"Tools

andParts"sectionforinformationonordering.

Specialprovisionsmustbemadeinmobilehomesto

introduceoutsideairintothedryer.Theopening(suchasa

nearbywindow)shouldbeatleasttwiceaslargeasthedryer

exhaustopening.

ElectricalShock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure

gas pressure does not exceed 13" (33 cm) water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

120 Volt, 60 Hz., AC only, 15- or 20-amp fused electrical

supply is required. A time-delay fuse or circuit breaker is

recommended. It is also recommended that a separate circuit

serving only this dryer be provided.

GROUNDING INSTRUCTIONS

• For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with the

dryer: if it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

SAVE THESE INSTRUCTIONS

Gas Type

Natural Gas:

This dryer is equipped for use with Natural gas. It isdesign-

certified by CSA International for LP (propane or butane) gases

with appropriate conversion.

• Your dryer must have the correct burner for the type of gas in

your home. Burner information is located on the rating plate

in the door well of your dryer. If this information does not

agree with the type of gas available, contact your dealer or

call the phone numbers referenced on the front page of this

manual.

LP gas conversion:

Conversion must be made by a qualified technician.

No attempt shall be made to convert the appliance from the gas

specified on the model/serial rating plate for use with a different

gas without consulting your gas company. For information on

ordering an LP conversion kit, please refer to the "Assistance or

Service" section. Ask for Part Number 49572.

Gas Supply Line:

• Must include 1/8"NPT minimum plugged tapping accessible

for test gauge connection, immediately upstream of the gas

connection to the dryer (see illustration).

• 1/2"IPS pipeis recommended.

• 3/8"approved aluminum or copper tubing is acceptable for

lengths under 20 ft (6.1 m) if local codes and gas supplier

permit.

6

• If you are using Natural gas, do not use copper tubing.

• 3/8"flare x %" NPT adapter fitting between dryer pipe and %"

approved tubing.

• Lengths over 20 ff (6.1 m) should use larger tubing and a

different size adapter fitting.

• If your dryer has been converted to use LP gas, 3/8"LP

compatible copper tubing can be used. If the total length of

the supply line is more than 20 ft (6.1 m), use larger pipe.

NOTE: Pipe-joint compounds that resist the action of LP gas

must be used. Do not useTEFLON "_ttape.

• Must include a shutoff valve:

An individual manual shutoff valve must be installed within

six (6) feet (1.8 m) of the dryer in accordance with the

National Fuel Gas Code, ANSI Z223.1. The location should be

easy to reach for opening and closing.

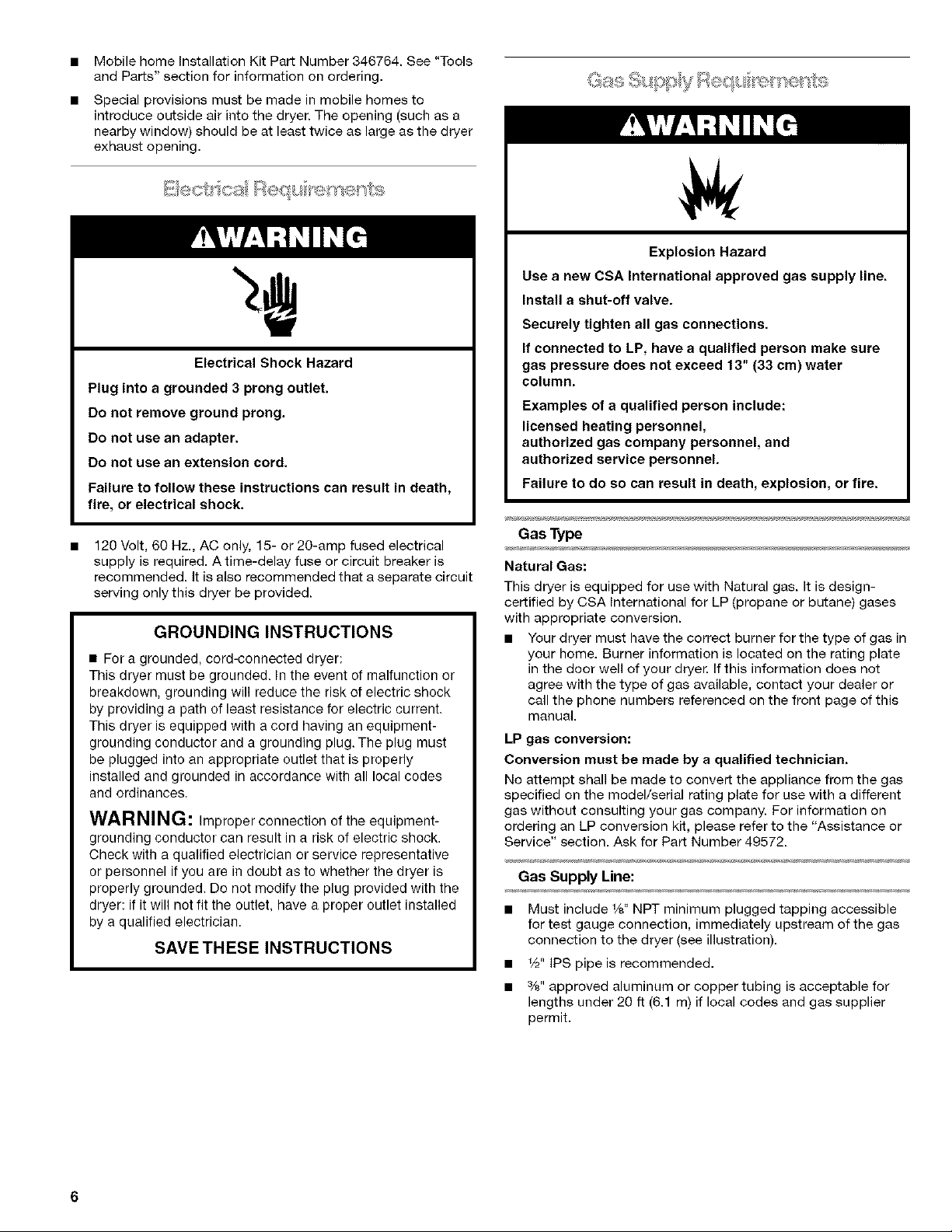

A C E

B D

A. _" flexible gas connector

B. _" pipe to flareadapter fitting

C. W NPTminimum plugged tapping

D._/_" NPT gas supply line

E.Gasshutoff valve

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

WARNING: To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

The dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling or a concealed space of a building. _

If using an existing vent system Yf_

Gas supply connection requirements

• Use an elbow and a %" flare x 3/8"NPT adapter fitting

between the flexible gas connector and the dryer gas pipe, as

needed to avoid kinking.

• Use only pipe-joint compound. Do not use TEFLON ®ttape.

• This dryer must be connected to the gas supply line with a

listed flexible gas connector that complies with the standard

for connectors for gas appliances, ANSI Z21.24.

Burner Input Requirements:

Elevations above 10,000 ft (3,048 m):

• When installed above 10,000 ff (3,048 m) a 4% reduction of

the burner Btu rating shown on the model/serial number plate

is required for each 1,0OOft (305 m) increase in elevation.

Gas Supply Pressure Testing

• The dryer must be disconnected from the gas supply piping

system during pressure testing at pressures greater than

1/2psi.

Dryer Gas Pipe

• The gas pipe that comes out through the rear of your dryer

has a 3/8"male pipe thread.

__ II (5.12crn)

(1.9era)

A.3/8"NPTdryer pipe

• Clean lint from the entire length of the system and make sure

exhaust hood is not plugged with lint.

• Replace any plastic or metal foil vent with rigid or flexible

heavy metal vent.

• Review Vent system chart. Modify existing vent system if

necessary to achieve the best drying performance.

If this is a new vent system

Vent material

• Use a heavy metal vent. Do not use plastic or metal foil vent.

• 4" (10.2 cm) hea W metal exhaust vent and clamps must be

used. DURASAFE TM venting products are recommended.

4" (10.2 cm) heavymetal exhaust vent

DURASAFE TM vent products can be purchased from your

dealer. For further information, please call

1-800-4-MY-HOME ®(1-800-469-4663) or visit our website at

www.sears.eom or www.sears.ca.

Rigid metal vent

• For best drying performance, rigid metal vents are

recommended.

• Rigid metal vent is recommended to avoid crushing and

kinking.

Flexible metal vent

• Flexible metal vents are acceptable only if accessible for

cleaning.

1-®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

Flexiblemetalventmustbefullyextendedandsupported

whenthedryerisinitsfinallocation.

Removeexcessflexiblemetalventtoavoidsaggingand

kinkingthatmayresultinreducedairflowandpoor

performance.

Donotinstallflexiblemetalventinenclosedwalls,ceilingsor

floors.

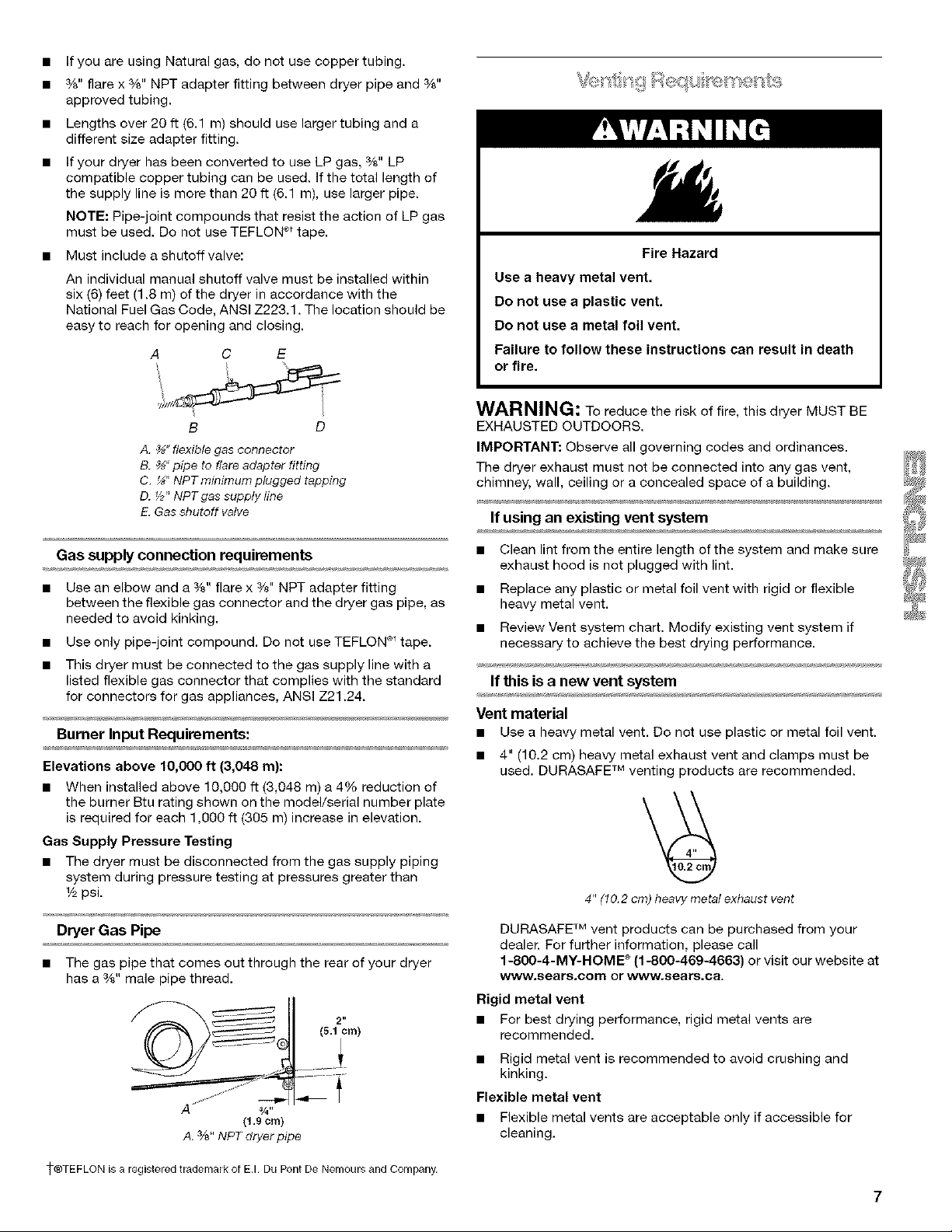

Elbows

45°elbowsprovidebetterairflowthan90°elbows.

Good Better

Clamps

Use clamps to seal all joints.

Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into the interior of the

duct. Do not use duct tape.

Improper venting can cause moisture and lint to collect

indoors, which may result in:

• Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

• Housecleaning problems and health problems.

_2_ __, _, _ _:_,o_

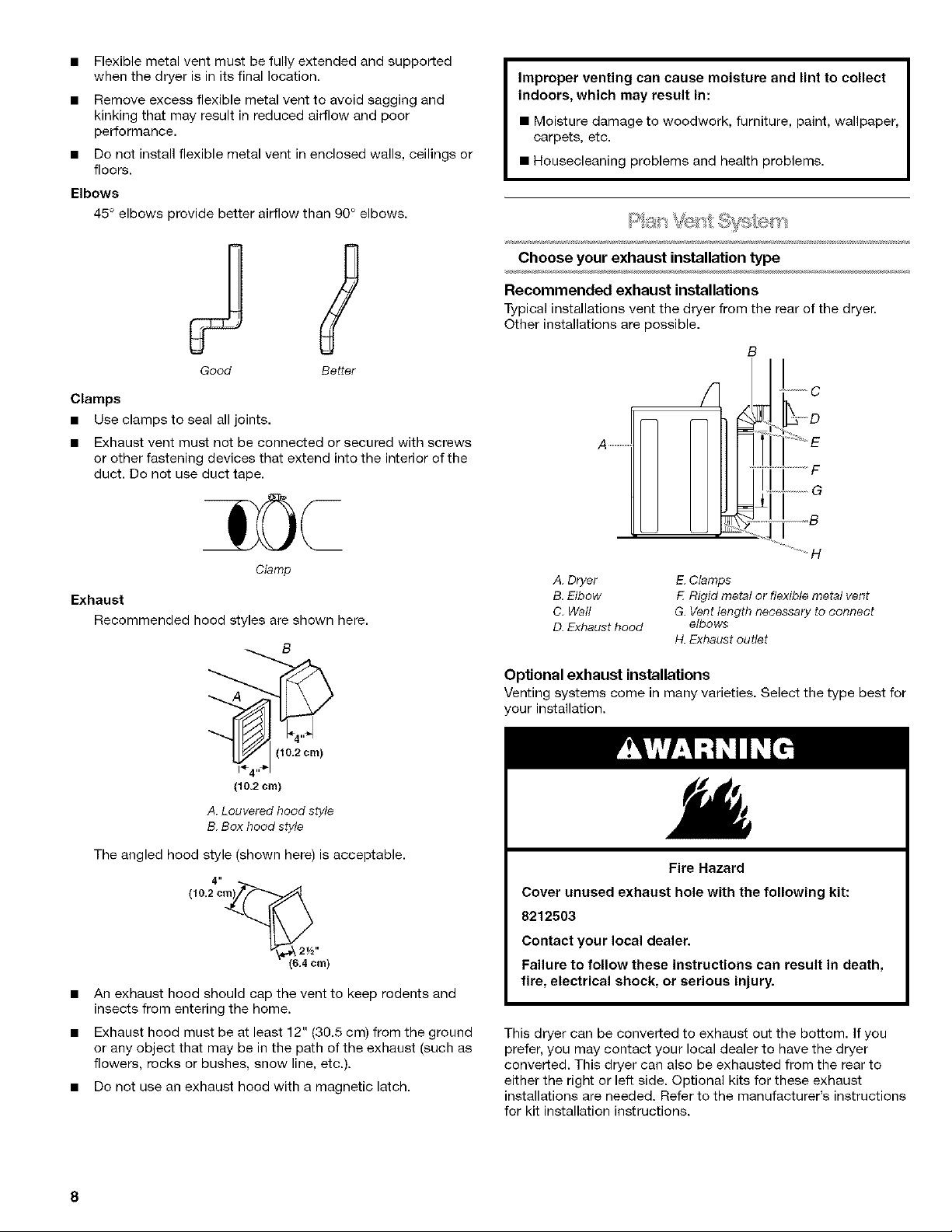

Choose your exhaust installation type

Recommended exhaust installations

Typical installations vent the dryer from the rear of the dryer.

Other installations are possible.

B

A .................

Clamp

Exhaust

Recommended hood styles are shown here.

B

1_4,,_" I

(10.2 crn)

A. Louveredhood style

B.Box hood style

The angled hood style (shown here) is acceptable.

• An exhaust hood should cap the vent to keep rodents and

insects from entering the home.

• Exhaust hood must be at least 12" (30.5 cm) from the ground

or any object that may be in the path of the exhaust (such as

flowers, rocks or bushes, snow line, etc.).

• Do not use an exhaust hood with a magnetic latch.

...........

A. Dryer

B. Elbow

C. Waft

D. Exhaust hood

Optional exhaust installations

Venting systems come in many varieties. Select the type best for

your installation.

Cover unused exhaust hole with the following kit:

8212503

Contact your local dealer.

Failure to follow these instructions can result in death,

fire, electrical shock, or serious injury.

This dryer can be converted to exhaust out the bottom. If you

prefer, you may contact your local dealer to have the dryer

converted. This dryer can also be exhausted from the rear to

either the right or left side. Optional kits for these exhaust

installations are needed. Refer to the manufacturer's instructions

for kit installation instructions.

E. Clamps

F. Rigid metal or flexible metal vent

G. Vent length necessary to connect

elbows

H. Exhaust outlet

Fire Hazard

8

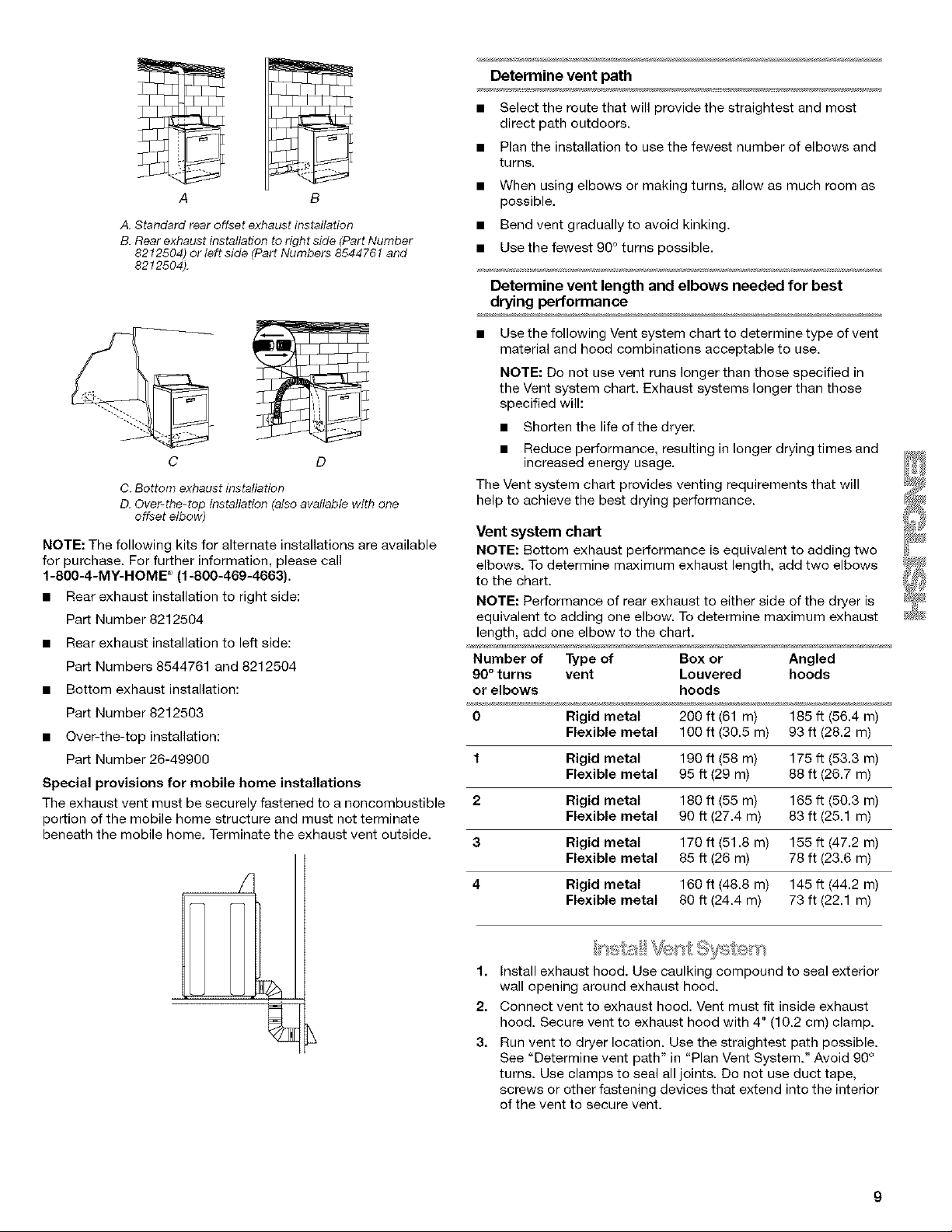

A B

A. Standard rear offset exhaust installation

B. Rear exhaust installation to right side (Part Number

8212504) or left side (Part Numbers 8544761 and

8212504).

C D

C.Bottom exhaust installation

D.Over-the-top installation (alsoavailable with one

offset elbow)

NOTE: The following kits for alternate installations are available

for purchase. For further information, please call

1-800-4-MY-HOME _ (1-800-469-4663).

• Rear exhaust installation to right side:

Part Number 8212504

• Rear exhaust installation to left side:

Part Numbers 8544761 and 8212504

• Bottom exhaust installation:

Part Number 8212503

• Over-the-top installation:

Part Number 26-49900

Special provisions for mobile home installations

The exhaust vent must be securely fastened to a noncombustible

portion of the mobile home structure and must not terminate

beneath the mobile home. Terminate the exhaust vent outside.

Determine vent path

• Select the route that will provide the straightest and most

direct path outdoors.

• Plan the installation to use the fewest number of elbows and

turns.

• When using elbows or making turns, allow as much room as

possible.

• Bend vent gradually to avoid kinking.

• Usethe fewest 900 turns possible.

Determine vent length and elbows needed for best

drying performance

• Use the following Vent system chart to determine type of vent

material and hood combinations acceptable to use.

NOTE: Do not use vent runs longer than those specified in

the Vent system chart. Exhaust systems longer than those

specified will:

• Shorten the life of the dryer.

• Reduce performance, resulting in longer drying times and

increased energy usage.

The Vent system chart provides venting requirements that will

help to achieve the best drying performance.

Vent system chart

NOTE: Bottom exhaust performance is equivalent to adding two

elbows. To determine maximum exhaust length, add two elbows

to the chart.

NOTE: Performance of rear exhaust to either side of the dryer is

equivalent to adding one elbow. To determine maximum exhaust

length, add one elbow to the chart.

Number of Type of Box or Angled

90° turns vent Louvered hoods

or elbows hoods

0 Rigid metal 200 ft (61 m) 185 ft (56.4 m)

Flexible metal 100 ft (30.5 m) 93 ft (28.2 m)

1 Rigid metal 190 ft (58 m) 175 ft (53.3 m)

Flexible metal 95 ft (29 m) 88 ft (26.7 m)

2 Rigid metal 180 ft (55 m) 165 ft (50.3 m)

Flexible metal 90 ft (27.4 m) 83 ft (25.1 m)

3 Rigid metal 170 ft (51.8 m) 155 ft (47.2 m)

Flexible metal 85 ft (26 m) 78 ft (23.6 m)

4 Rigid metal 160 ft (48.8 m) 145 ft (44.2 m)

Flexible metal 80 ft (24.4 m) 73 ft (22.1 m)

1. Install exhaust hood. Use caulking compound to seal exterior

wall opening around exhaust hood.

2. Connect vent to exhaust hood. Vent must fit inside exhaust

hood. Secure vent to exhaust hood with 4" (10.2 cm) clamp.

3. Run vent to dryer location. Use the straightest path possible.

See "Determine vent path" in "Plan Vent System." Avoid 90°

turns. Use clamps to seal all joints. Do not use duct tape,

screws or other fastening devices that extend into the interior

of the vent to secure vent.

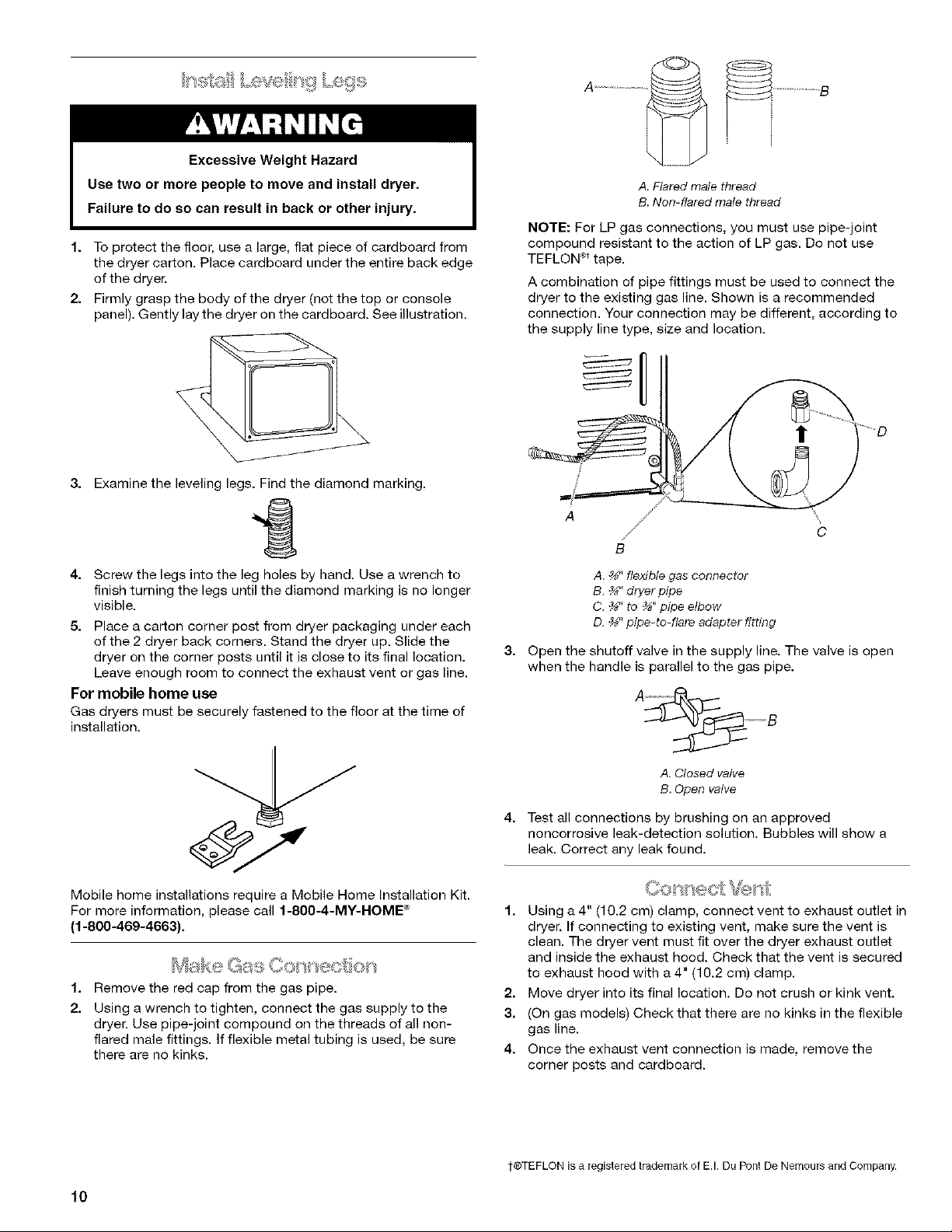

1. Toprotectthefloor,usealarge,flatpieceofcardboardfrom

thedryercarton.Placecardboardundertheentirebackedge

ofthedryer.

2. Firmlygraspthebodyofthedryer(notthetoporconsole

panel).Gentlylaythedryeronthecardboard.Seeillustration.

3=

Examine the leveling legs. Find the diamond marking.

4=

Screw the legs into the leg holes by hand. Use a wrench to

finish turning the legs until the diamond marking is no longer

visible.

5.

Place a carton corner post from dryer packaging under each

of the 2 dryer back corners. Stand the dryer up. Slide the

dryer on the corner posts until it is close to its final location.

Leave enough room to connect the exhaust vent or gas line.

For mobile home use

Gas dryers must be securely fastened to the floor at the time of

installation.

A. Flared male thread

B. Non=flared male thread

NOTE: For LP gas connections, you must use pipe-joint

compound resistant to the action of LP gas. Do not use

TEFLON"<tape.

A combination of pipe fittings must be used to connect the

dryer to the existing gas line. Shown is a recommended

connection. Your connection may be different, according to

the supply line type, size and location.

I

\

c

B

A, _" flexible gas connector

B, _" dryer pipe

C. _" to _" pipe elbow

D. _" pipe-to-flare adapter fitting

3. Open the shutoff valve in the supply line. The valve is open

when the handle is parallel to the gas pipe.

Mobile home installations require a Mobile Home Installation Kit.

For more information, please call 1-800-4-M¥-I-IOME ®

(1-800-469-4663).

£J'iskeGas Con se<; t

1=

Remove the red cap from the gas pipe.

2.

Using a wrench to tighten, connect the gas supply to the

dryer. Use pipe-joint compound on the threads of all non-

flared male fittings. If flexible metal tubing is used, be sure

there are no kinks.

10

A. Closed valve

B. Open valve

4. Test all connections by brushing on an approved

noncorrosive leak-detection solution. Bubbles will show a

leak. Correct any leak found.

1. Using a 4" (10.2 cm) clamp, connect vent to exhaust outlet in

dryer. If connecting to existing vent, make sure the vent is

clean. The dryer vent must fit over the dryer exhaust outlet

and inside the exhaust hood. Check that the vent is secured

to exhaust hood with a4" (10.2 cm) clamp.

2. Move dryer into its final location. Do not crush or kink vent.

3. (On gas models) Check that there are no kinks in the flexible

gas line.

4. Once the exhaust vent connection is made, remove the

corner posts and cardboard.

t@TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

S' -- > .

_:_ _ _Tj:* _:_-:S thirds turn.

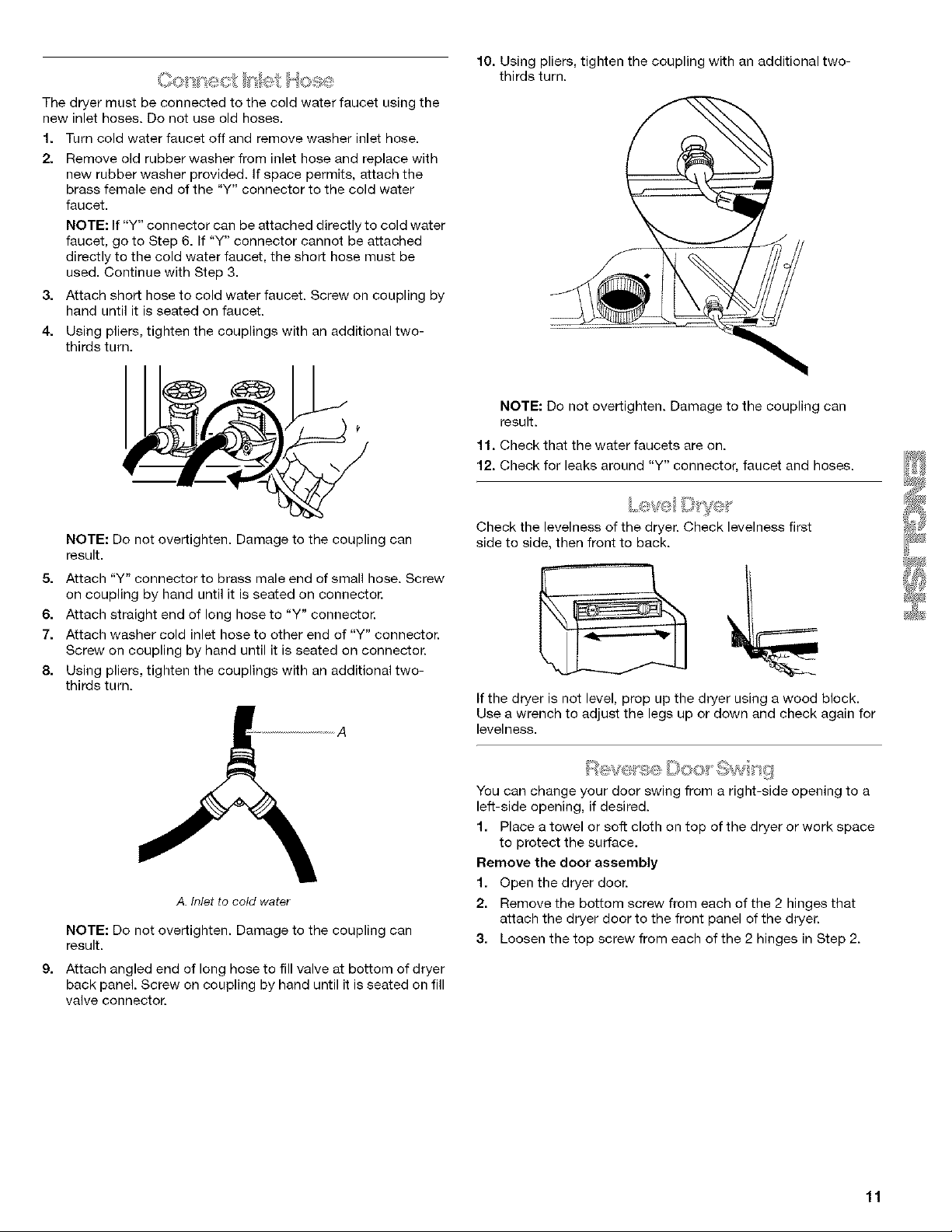

The dryer must be connected to the cold water faucet using the

new inlet hoses. Do not use old hoses.

1. Turn cold water faucet off and remove washer inlet hose.

2. Remove old rubber washer from inlet hose and replace with

new rubber washer provided. If space permits, attach the

brass female end of the "Y" connector to the cold water

faucet.

NOTE: If "Y" connector can be attached directly to cold water

faucet, go to Step 6. If "Y" connector cannot be attached

directly to the cold water faucet, the short hose must be

used. Continue with Step 3.

3. Attach short hose to cold water faucet. Screw on coupling by

hand until it is seated on faucet.

4. Using pliers, tighten the couplings with an additional two-

thirds turn.

10. Using pliers, tighten the coupling with an additional two-

NOTE: Do not overtighten. Damage to the coupling can

result.

11. Check that the water faucets are on.

12. Check for leaks around "Y" connector, faucet and hoses.

NOTE: Do not overtighten. Damage to the coupling can

result.

5. Attach "Y" connector to brass male end of small hose. Screw

on coupling by hand until it is seated on connector.

6. Attach straight end of long hose to "Y" connector.

7. Attach washer cold inlet hose to other end of "Y" connector.

Screw on coupling by hand until it is seated on connector.

8. Using pliers, tighten the couplings with an additional two-

thirds turn.

A

A. Inlet to cold water

NOTE: Do not overtighten. Damage to the coupling can

result.

9. Attach angled end of long hose to fill valve at bottom of dryer

back panel. Screw on coupling by hand until it is seated on fill

valve connector.

Check the levelness of the dryer. Check levelness first

side to side, then front to back.

If the dryer is not level, prop up the dryer using a wood block.

Use a wrench to adjust the legs up or down and check again for

levelness.

You can change your door swing from a right-side opening to a

left-side opening, if desired.

1. Place a towel or soft cloth on top of the dryer or work space

to protect the surface.

Remove the door assembly

1. Open the dryer door.

2. Remove the bottom screw from each of the 2 hinges that

attach the dryer door to the front panel of the dryer.

3. Loosen the top screw from each of the 2 hinges in Step 2.

11

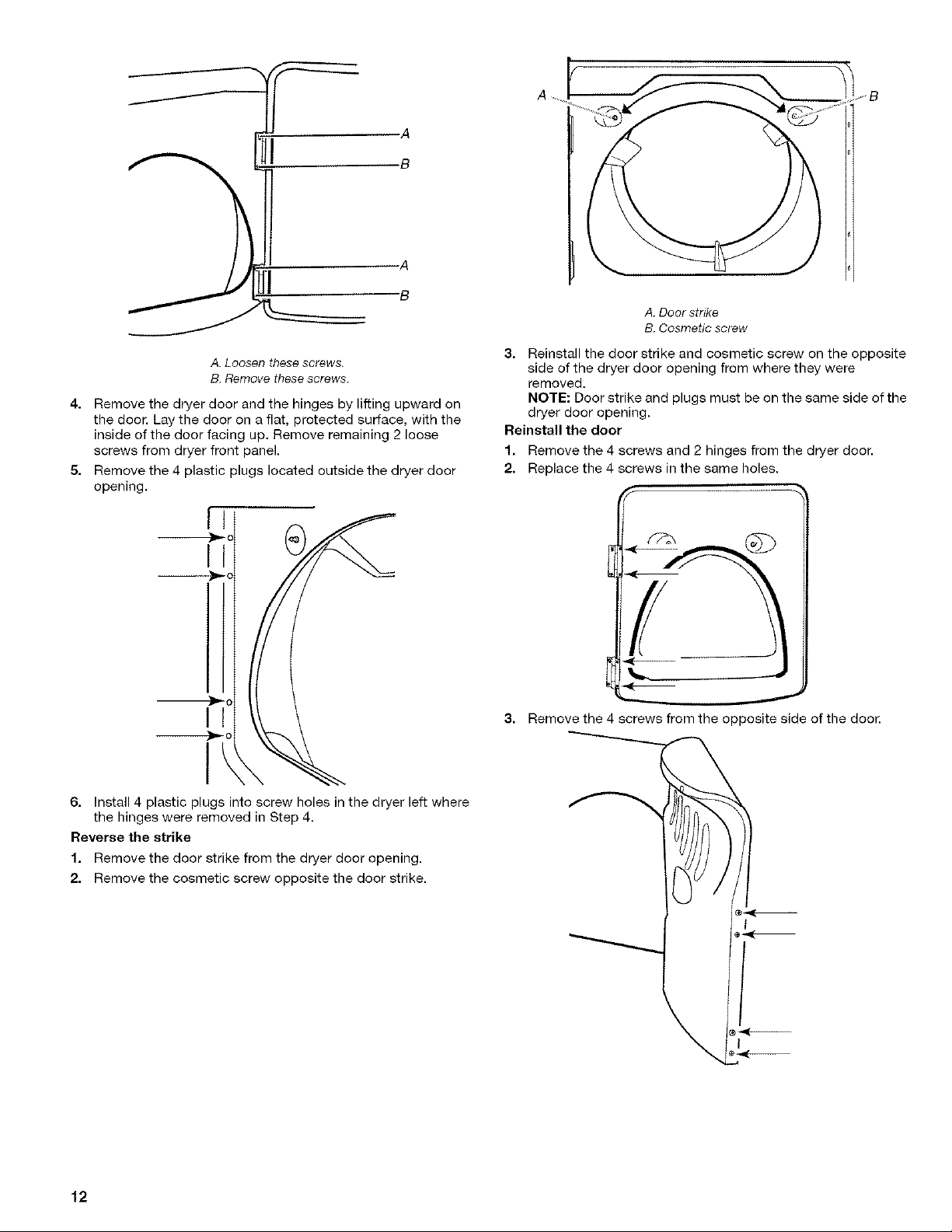

A

.A

B

A

B

A. Door strike

B. Cosmetic screw

A. Loosen these screws.

B. Remove these screws.

4. Remove the dryer door and the hinges by lifting upward on

the door. Lay the door on a flat, protected surface, with the

inside of the door facing up. Remove remaining 2 loose

screws from dryer front panel.

5. Remove the 4 plastic plugs located outside the dryer door

opening.

6. Install 4 plastic plugs into screw holes in the dryer left where

the hinges were removed in Step 4.

Reverse the strike

1. Remove the door strike from the dryer door opening.

2. Remove the cosmetic screw opposite the door strike.

3. Reinstall the door strike and cosmetic screw on the opposite

side of the dryer door opening from where they were

removed.

NOTE: Door strike and plugs must be on the same side of the

dryer door opening.

Reinstall the door

1. Remove the 4 screws and 2 hinges from the dryer door.

2. Replace the 4 screws in the same holes.

J

3. Remove the 4 screws from the opposite side of the door.

__

12

I

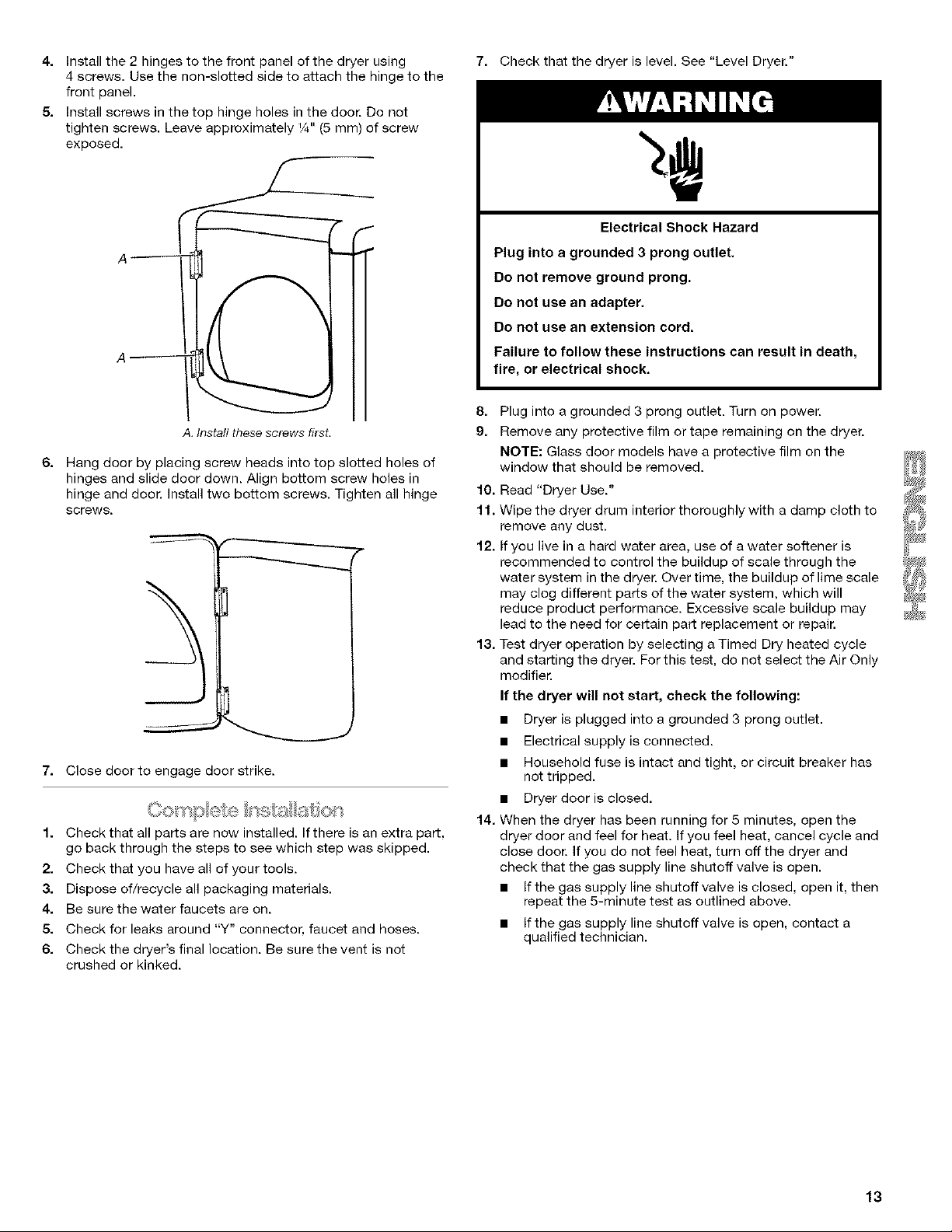

4. Install the 2 hinges to the front panel of the dryer using

4 screws. Use the non-slotted side to attach the hinge to the

front panel.

5. Install screws in the top hinge holes in the door. Do not

tighten screws. Leave approximately 1/4"(5 ram) of screw

exposed.

7. Check that the dryer is level. See "Level Dryer."

7 f

A _

A _

A. Instafl these screws firsL

6. Hang door by placing screw heads into top slotted holes of

hinges and slide door down. Align bottom screw holes in

hinge and door. Install two bottom screws. Tighten all hinge

screws.

7. Close door to engage door strike.

1. Check that all parts are now installed. If there is an extra part,

go back through the steps to see which step was skipped.

2. Check that you have all of your tools.

3. Dispose of/recycle all packaging materials.

4. Be sure the water faucets are on.

5. Check for leaks around "Y" connector, faucet and hoses.

6. Check the dryer's final location. Be sure the vent is not

crushed or kinked.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

8.

Plug into a grounded 3 prong outlet. Turn on power.

9.

Remove any protective film or tape remaining on the dryer.

NOTE: Glass door models have a protective film on the

window that should be removed.

10. Read "Dryer Use."

11. Wipe the dryer drum interior thoroughly with a damp cloth to

remove any dust.

12. If you live in a hard water area, use of a water softener is

recommended to control the buildup of scale through the

water system in the dryer. Over time, the buildup of lime scale

may clog different parts of the water system, which will

reduce product performance. Excessive scale buildup may

lead to the need for certain part replacement or repair.

13. Test dryer operation by selecting a Timed Dry heated cycle

and starting the dryer. For this test, do not select the Air Only

modifier.

If the dryer will not start, check the following:

Dryer is plugged into a grounded 3 prong outlet.

Electrical supply is connected.

Household fuse is intact and tight, or circuit breaker has

not tripped.

• Dryer door is closed.

14. When the dryer has been running for 5 minutes, open the

dryer door and feel for heat. If you feel heat, cancel cycle and

close door. If you do not feel heat, turn off the dryer and

check that the gas supply line shutoff valve is open.

• If the gas supply line shutoff valve is closed, open it, then

repeat the 5-minute test as outlined above.

• If the gas supply line shutoff valve is open, contact a

qualified technician.

13

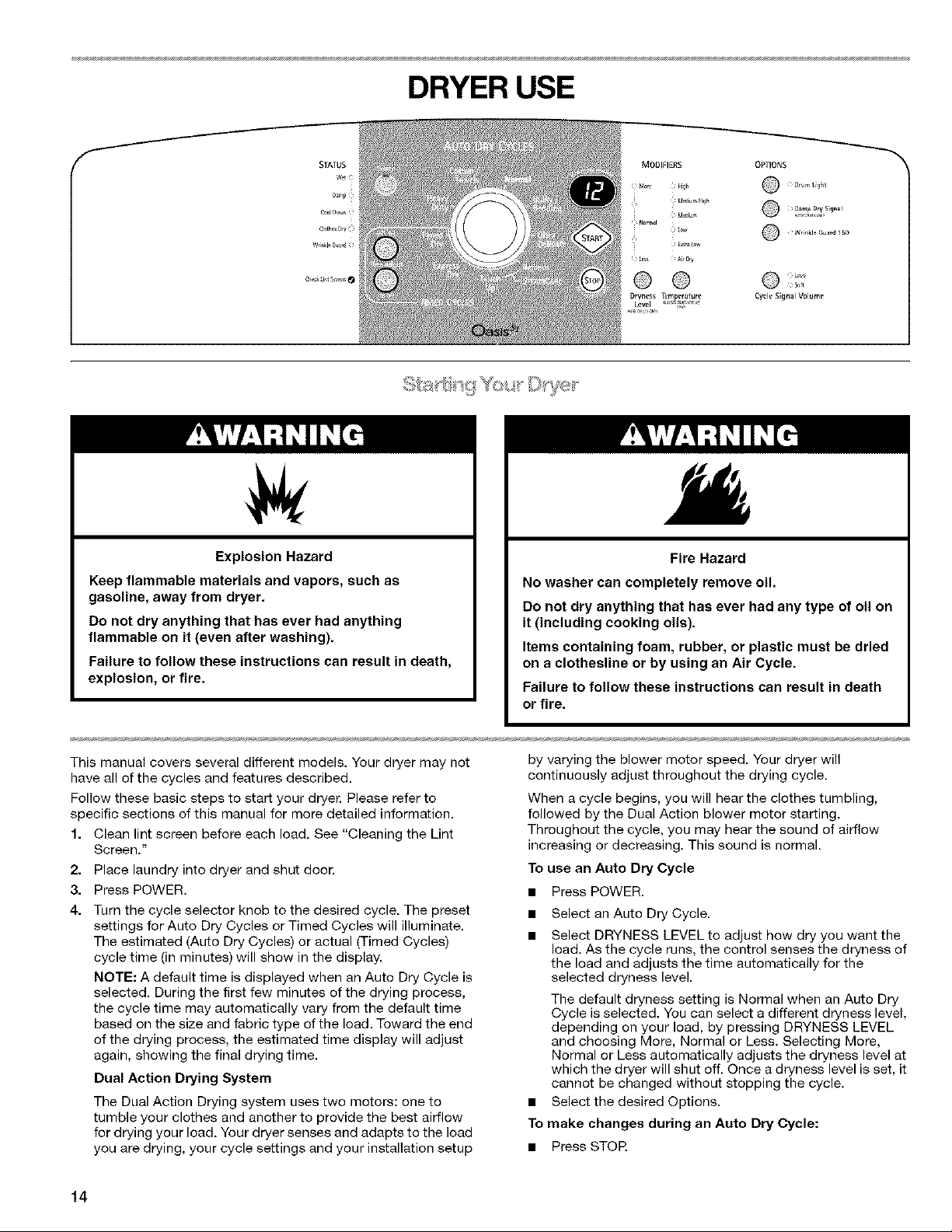

DRYER USE

STATUS

w_t

b_r.p

¢oulD,Jwr

Ch_X_i_t_,_

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Do not dry anything that has ever had anything

flammable on it (even after washing).

Failure to follow these instructions can result in death,

explosion, or fire.

MODIFIERS OPTIONS

_ Wrinkle 6_d I SO

L_ _r Dr,¸

Dryness Temperature

Level _*_r_,,_

5o_t

_yI!le Signal Volumi_

Fire Hazard

No washer can completely remove oil.

Do not dry anything that has ever had any type of oil on

it (including cooking oils).

Items containing foam, rubber, or plastic must be dried

on a clothesline or by using an Air Cycle.

Failure to follow these instructions can result in death

or fire.

This manual covers several different models. Your dryer may not

have all of the cycles and features described.

Follow these basic steps to start your dryer. Please refer to

specific sections of this manual for more detailed information.

1. Clean lint screen before each load. See "Cleaning the Lint

Screen."

2. Place laundry into dryer and shut door.

3. Press POWER.

4. Turn the cycle selector knob to the desired cycle. The preset

settings for Auto Dry Cycles or Timed Cycles will illuminate.

The estimated (Auto Dry Cycles) or actual (Timed Cycles)

cycle time (in minutes) will show in the display.

NOTE: A default time is displayed when an Auto Dry Cycle is

selected. During the first few minutes of the drying process,

the cycle time may automatically vary from the default time

based on the size and fabric type of the load. Toward the end

of the drying process, the estimated time display will adjust

again, showing the final drying time.

Dual Action Drying System

The Dual Action Drying system uses two motors: one to

tumble your clothes and another to provide the best airflow

for drying your load. Your dryer senses and adapts to the load

you are drying, your cycle settings and your installation setup

14

by varying the blower motor speed. Your dryer will

continuously adjust throughout the drying cycle.

When a cycle begins, you will hear the clothes tumbling,

followed by the Dual Action blower motor starting.

Throughout the cycle, you may hear the sound of airflow

increasing or decreasing. This sound is normal.

To use an Auto Dry Cycle

• Press POWER.

• Select an Auto Dry Cycle.

Select DRYNESS LEVEL to adjust how dry you want the

load. As the cycle runs, the control senses the dryness of

the load and adjusts the time automatically for the

selected dryness level.

The default dryness setting is Normal when an Auto Dry

Cycle is selected. You can select a different dryness level,

depending on your load, by pressing DRYNESS LEVEL

and choosing More, Normal or Less. Selecting More,

Normal or Less automatically adjusts the dryness level at

which the dryer will shut off. Once a dryness level is set, it

cannot be changed without stopping the cycle.

Select the desired Options.

To make changes during an Auto Dry Cycle:

• Press STOR

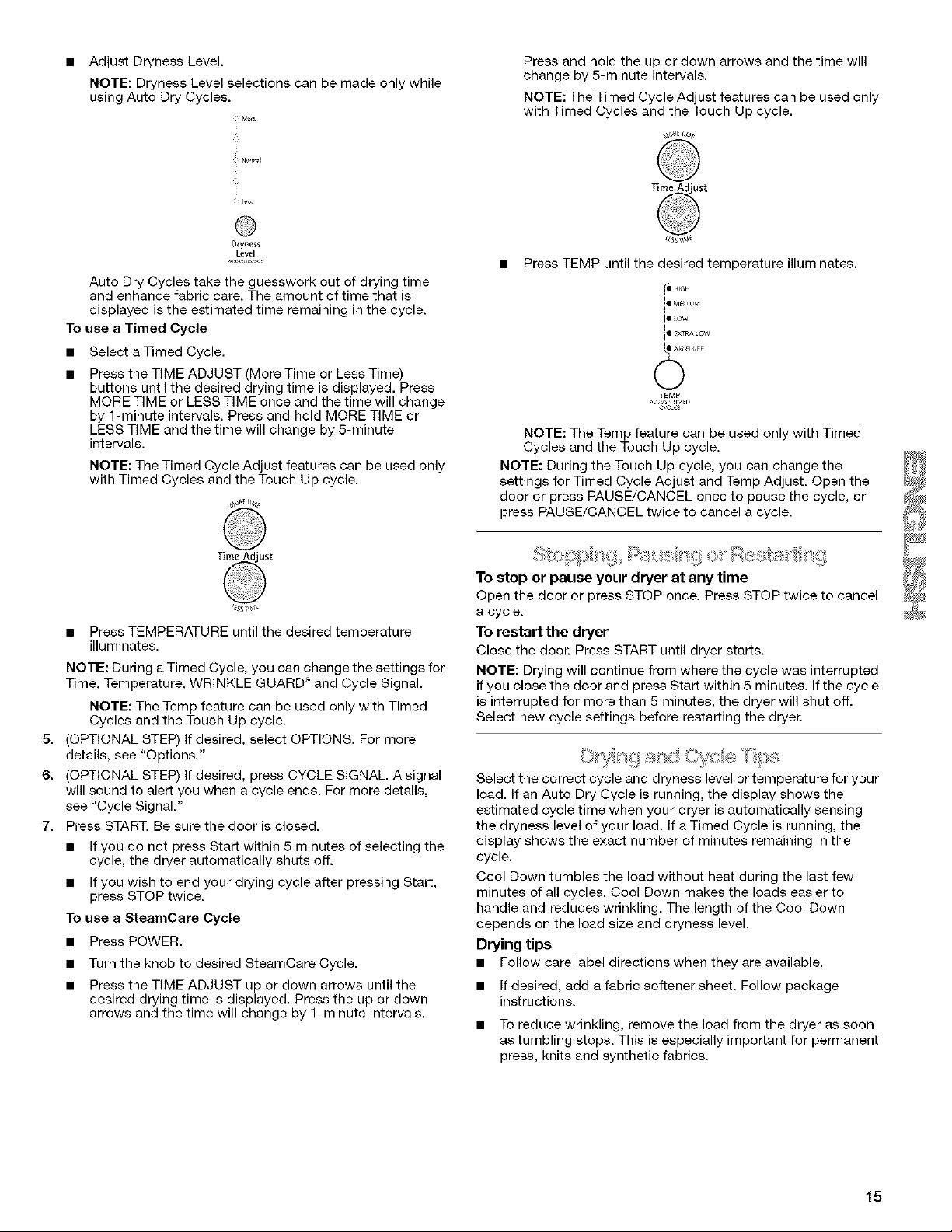

• Adjust Dryness Level.

NOTE: Dryness Level selections can be made only while

using Auto Dry Cycles.

Not_l

0tyness

Level

Auto Dry Cycles take the guesswork out of drying time

and enhance fabric care. The amount of time that is

displayed is the estimated time remaining in the cycle.

To use a Timed Cycle

• Select aTimed Cycle.

Press the TiME ADJUST (More Time or Less Time)

buttons until the desired drying time is displayed. Press

MORE TiME or LESS TiME once and the time will change

by 1-minute intervals. Press and hold MORE TiME or

LESS TiME and the time will change by 5-minute

intervals.

NOTE: The Timed Cycle Adjust features can be used only

with Timed Cycles and the Touch Up cycle.

Press and hold the up or down arrows and the time will

change by 5-minute intervals.

NOTE: The Timed Cycle Adjust features can be used only

with Timed Cycles and the Touch Up cycle•

• Press TEMP until the desired temperature illuminates.

Io_ow

TEMP

C¥CL_

NOTE: The Temp feature can be used only with Timed

Cycles and the Touch Up cycle.

NOTE: During the Touch Up cycle, you can change the

settings for Timed Cycle Adjust and Temp Adjust. Open the

door or press PAUSE/CANCEL once to pause the cycle, or

press PAUSE/CANCEL twice to cancel a cycle•

• Press TEMPERATURE until the desired temperature

illuminates.

NOTE: During aTimed Cycle, you can change the settings for

Time, Temperature, WRINKLE GUARD ®and Cycle Signal•

NOTE: The Temp feature can be used only with Timed

Cycles and the Touch Up cycle.

5. (OPTIONAL STEP) If desired, select OPTIONS. For more

details, see "Options."

6. (OPTIONAL STEP) If desired, press CYCLE SIGNAL• A signal

will sound to alert you when a cycle ends. For more details,

see "Cycle Signal."

7. Press START. Be sure the door is closed.

• If you do not press Start within 5 minutes of selecting the

cycle, the dryer automatically shuts off.

• If you wish to end your drying cycle after pressing Start,

press STOP twice.

To use a SteamCare Cycle

• Press POWER•

• Turn the knob to desired SteamCare Cycle•

• Press the TIME ADJUST up or down arrows until the

desired drying time is displayed• Press the up or down

arrows and the time will change by 1-minute intervals.

_;Lr !, .... ....

To stop or pause your dryer at any time

Open the door or press STOP once. Press STOP twice to cancel

a cycle.

To restart the dryer

Close the door. Press START until dryer starts.

NOTE: Drying will continue from where the cycle was interrupted

if you close the door and press Start within 5 minutes• If the cycle

is interrupted for more than 5 minutes, the dryer will shut off.

Select new cycle settings before restarting the dryer.

Select the correct cycle and dryness level or temperature for your

load. If an Auto Dry Cycle is running, the display shows the

estimated cycle time when your dryer is automatically sensing

the dryness level of your load. If a Timed Cycle is running, the

display shows the exact number of minutes remaining in the

cycle.

Cool Down tumbles the load without heat during the last few

minutes of all cycles. Cool Down makes the loads easier to

handle and reduces wrinkling. The length of the Cool Down

depends on the load size and dryness level.

Drying tips

• Follow care label directions when they are available•

• If desired, add a fabric softener sheet. Follow package

instructions.

• To reduce wrinkling, remove the load from the dryer as soon

as tumbling stops. This is especially important for permanent

press, knits and synthetic fabrics.

15

• Avoid drying heavy work clothes together with lighter fabrics.

This could cause overdrying of lighter fabrics and lead to

increased shrinkage or wrinkling.

Cycle tips

• Dry most loads using the presetcycle settings.

• Refer to the Auto or Timed Preset Cycle Settings charts (in

the "Cycles" section) for a guide to drying various loads.

Drying temperature and dryness level are preset when

you choose an Auto Dry Cycle. You can select a different

dryness level, depending on your load, by pressing

Dryness Level and choosing More, Normal or Less.

NOTE: You cannot use the Time Adjust and you cannot

choose a Temperature with the Auto Dry Cycles.

If you wish to adjust the cycle length of a Timed Cycle,

press the Time Adjust (More Time or Less Time) arrows.

Adjust the temperature of a Timed Cycle by pressing

Temperature until the desired temperature is selected.

NOTE: You cannot choose a dryness level with Timed

Cycles.

Follow the progress of your dryer with the drying Status indicator

lights.

STATUS

We

_mp

Check Lint Screen

The Check Lint Screen light reminds you to check the lint screen.

The light illuminates when the user selects a cycle, it goes out

when the door is opened, Start is pressed, or after 5 minutes

elapses.

Indicator lights

Other indicator lights show Cycle, Options, Modifiers and Cycle

Signal settings selected. The display shows the estimated or

actual time remaining.

Select the drying cycle that matches the type of load you are

drying. See Auto or Timed Preset Cycle Settings charts.

AUTO DRY CYCLES

Cotton ]

Towels Normal

Heavy _ Bulky /

Timed Ultra

ii_ Delicate

Duty _ 8edding

Express Refresh

Dry Touch SIPJ_MCARE

TIMED CYCLES

Up

Auto Dry Cycles

Clot_'IsQH

Wet

The Wet light illuminates at the beginning of an Auto Cycle if a

wet item is detected.

In an Auto Cycle, if a wet item is not detected after

approximately 5 minutes, the dryer goes directly into Cool

Down and the Cool Down and WRINKLE GUARD®indicators

illuminate, if selected.

• In a Timed Cycle, wet items are not detected. The dryer will

continue to run for the length of time selected, and the Wet

light will illuminate. The damp light will not illuminate.

Damp

The Damp light illuminates in an Auto Dry Cycle when the laundry

is approximately 80% dry. Damp Dry Signal beeps, if selected.

See "Options."

Cool Down

The Cool Down light illuminates during the cool down part of the

cycle. Laundry cools for ease in handling.

Clothes Dry

The Clothes Dry light illuminates when the drying cycle is

finished. This indicator stays on during WRINKLE GUARD ®.

WRINKLE GUARD ®

The WRINKLE GUARD ®light illuminates when this option is

selected. This indicator stays on during WRINKLE GUARD ®.

Auto Dry Cycles allow you to match the cycle to the load you are

drying. See the following Auto Preset Cycle Settings chart. Each

cycle dries certain fabrics at the recommended temperature. A

sensor detects the moisture in the load and automatically adjusts

the drying time for optimal drying.

Heavy Duty

Use this cycle to get high heat for heavyweight mixed loads,

cottons and jeans.

Cotton/Towels

Use this cycle to get high heat for drying heavy fabrics such as

towels, sheets or cottons.

Normal

Use this cycle to get medium heat for drying casual business

clothes, permanent press blends or work clothes.

Bulky/Bedding

Use this cycle to get medium heat for drying large items that

require very long drying times such as jackets, comforters and

cotton or polyester fiber filled pillows. Rearrange the load when

the Damp Dry signal sounds. This step will aid in the drying

process.

Ulka Delicate

Use this cycle to get extra-low heat to gently dry items such as

washable knit fabrics, blouses or lingerie.

Auto Preset Cycle Settings

Follow care label directions.

Auto Dry Cycles Temperature Time*

Load Type (Minutes)

HEAVY DUTY High 50

Heavyweight mixed loads

cottons, jeans

16

Auto Preset Cycle Settings

Follow care label directions.

Auto Dry Cycles Temperature Time*

Load Type (Minutes)

COTTON/TOWELS High 45

Towels, sheets, cottons

NORMAL Medium 40

Casual clothes,

permanent press

BULKY/BEDDING Medium 60

Jackets, comforters,

cotton or polyester fiber

filled pillows

ULTRA DELICATE Extra-Low 25

Washable knits, blouses,

lingerie

*Estimated Time with Auto Dry Level (Normal) setting. Time will

vary depending on load type and load size.

SteamOare Cycles

Use SteamCare Cycles to help smooth out wrinkles from dry

items, such as clothes that have been worn or clothes that have

been left in the dryer too long. When a SteamCare Cycle is

selected, the estimated time remaining display shows the actual

time remaining in the cycle.

NOTE: Results may vary depending on fabric. 100% cotton

garments with wrinkle-free finish may yield better results than

those without.

Use of a fabric softener sheet is not recommended with

steam cycles as it may cause temporary staining on the

clothes.

Refresh

This cycle is best for smoothing out wrinkles and reducing odors

from loads consisting of one to four dry items of wrinkle-free

cotton, cotton-polyester blend, common knits and synthetic

garments. In this cycle a small amount of water is sprayed into

the dryer drum after several minutes of tumbling with heat. The

dryer will continue to tumble with heat followed by a brief cool

down. The heat level and cycle time are not adjustable.

Touch Up

This cycle is best for touching up clothes that have been left in

the dryer too long. In this cycle, a small amount of water is

sprayed into the dryer drum after several minutes of tumbling

with heat. The dryer will continue to tumble with heat followed by

a brief cool down. The dry time and temperature can be adjusted

for this cycle.

NOTE: Overloading the dryer may not yield the same results.

SteamCare Preset Cycle Settings

Timed Cycles Default Default Time

Load Type Temperature (Minutes)

REFRESH Medium High 15

Helps to smooth out

wrinkles and reduce odors

from loads consisting of

one to four dry items.

Touch Up

Helps to smooth out

wrinkles in loads left in the

dryer for an extended

period.

Timed Cycles

Use Timed Cycles to select a specific amount of drying time and

a drying temperature. When a Timed Cycle is selected, the

Estimated Time Remaining display shows the actual time

remaining in your cycle. You can change the actual time in the

cycle by pressing the TIME ADJUST (More Time or Less Time)

buttons. See "Changing Cycles, Modifiers and Options."

NOTE: Timed Cycles may also be used with the dryer rack. See

"Dryer Rack."

Timed Dry

Use this cycle to complete drying if items are still damp after an

Auto Dry Cycle. Timed Dry is also useful for drying heavyweight

and bulky items, such as blankets and work clothes. Lightweight

garments, such as exercise wear, can be dried using Timed Dry

on a low temperature setting.

EXPRESS DRY TM

Use this cycle for drying small loads or loads that need a short

drying time.

Timed Preset Cycle Settings

Timed Cycles Default Default Time*

Load Type Temperature (Minutes)

TIMED DRY Heawweight, High 40

bulky items, work clothes

EXPRESS DRY TM High 23

Small loads

*Default times are remembered from the previous cycle.

Auto Dry Cycle Modifiers

Use the Dryness Level Modifier to select dryness levels for the

Auto Dry Cycles. Press Dryness Level until the desired Dryness

Level setting illuminates.

Medium High 20

17

The preset dryness setting is Normal when an Auto Dry Cycle is

selected. You can select a different dryness level, depending on

your load, by pressing Dryness Level and choosing More, Normal

or Less. Selecting More, Normal or Less automatically adjusts

the dryness level at which the dryer will shut off. Once a dryness

level is set, it cannot be changed without stopping the cycle.

NOTE: Dryness Level selections cannot be used with the Timed

Cycles.

[_Wnes_

Level

Timed Cycle Modifiers

Use the Temperature Modifier to select temperatures for the

Timed Cycles. Press Temperature until the desired temperature

setting illuminates.

NOTE: Temperature modifiers cannot be used with the Auto Dry

Cycles.

Hi#_

MerJum Hgh

Medum

Low

ExtraJ0w

ADr_

Temperature

Air Dry

Use the Air Dry Modifier for items that require drying without heat

such as rubber, plastic and heat-sensitive fabrics. This table

shows examples of items that can be dried using Air Dry.

Type of Load Time*

(Minutes)

Foam rubber - pillows, padded bras, stuffed toys 20 - 30

Plastic - Shower curtains, tablecloths 20 - 30

Rubber-backed rugs 40 - 50

Olefin, polypropylene, sheer nylon 10 - 20

*Reset cycle to complete drying, if needed.

When using Air Dry

• Check that coverings are securely stitched.

• Shake and fluff pillows by hand periodically during the cycle.

• Dry item completely. Foam rubber pillows are slow to dry.

NOTE: Air Dry is not available with Auto Dry Cycles.

You can customize your cycles by selecting options.

OPTIONS

Light

Drum

O Damp Dry Signal

Wrinkle Guard 150

Drum Light

Select Drum Light to turn on the light inside the dryer drum.

During a cycle, if Drum Light is selected, the drum light turns on

and will remain on until DRUM LIGHT is pressed again, the door

is open and closed, or the door is left open for 5 minutes.

When the dryer is not running, the drum light will turn on when

DRUM LIGHT is pressed or the dryer door is opened, and it will

remain on until the dryer door has been open for 5 minutes, the

dryer door is closed or DRUM LIGHT is pressed again.

Press DRUM LIGHT at any time to turn the drum light ON or OFE

Damp Dry Signal

Select the Damp Dry Signal to alert you that your clothes are

approximately 80% dry. This is useful when you want to remove

lightweight items in a mixed load to avoid overdrying or remove

partially dry items that may need ironing.

The DAMP DRY SIGNAL is useful when drying bedsheets/linens

in a mixed load. When the signal goes off, open the door to stop

the dryer, rearrange the load inside the dryer, close the door and

restart the dryer to finish the drying cycle. Rearranging the load

will aid in the drying process.

NOTE: The Damp Dry Signal is available only with the Auto Dry

Cycles.

WRINKLE GUARD ®(30, 60, 90, 150 minutes)

WRINKLE GUARD ®helps keep wrinkles from forming when you

cannot unload the dryer promptly at the end of a cycle. During

this option, the dryer stops tumbling and then tumbles again for a

brief period.

• Press WRINKLE GUARD '_to get heat-free, periodic tumbling

at the end of a cycle. WRINKLE GUARD ® periodically starts

and stops the dryer, tumbling the load without heat for 30, 60,

90 or 150 minutes (depending on your model) unless you

open the dryer door.

• Stop WRINKLE GUARD ®at any time by pressing WRINKLE

GUARD ®,opening the dryer door or pressing STOR

The Auto Dry and Timed Dry Cycles will retain the WRINKLE

GUARD ®setting. For example, if you select WRINKLE

GUARD ® in the Normal cycle, WRINKLE GUARD ®will be on

the next time you select the Normal cycle.

NOTE: If you do not select WRINKLE GUARD ®,the dryer stops

after cool down.

Cycle Signal

The Cycle Signal produces an audible sound when the drying

cycle is finished. Promptly removing clothes at the end of the

cycle reduces wrinkling.

18

Press CYCLE SIGNAL VOLUME until the desired volume (Loud or

Soft) is selected. On some models, press CYCLE SIGNAL to turn

the Cycle Signal On or Off.

Or, Loud

Sds

£_/cle Signal Cycle Signal Volume

NOTE: When WRINKLE GUARD ®is selected, a tone sounds

every 5 minutes until the clothes are removed, or WRINKLE

GUARD ®ends.

You can change Auto and Timed Cycles, Modifiers and Options

anytime before pressing Start.

• Three short tones sound if an unavailable combination is

selected. The last selection will not be accepted.

Changing Cycles after pressing Start

1. Press STOP twice.

2. Select the desired cycle and options.

3. Press START. The dryer starts at the beginning of the new

cycle.

NOTE: If you do not press Start within 5 minutes of selecting the

cycle, the dryer automatically shuts off.

The dryer rack was shipped in the dryer drum.

Use the dryer rack for items that you do not want to tumble dry,

such as sweaters.

Use Timed Dry to select the desired time.

NOTE: Do not use Auto Dry Cycles with the dryer rack.

To use the dryer rack:

Do not remove the lint screen.

1. Open dryer door.

2. Slide dryer rack over the bottom of the dryer door opening.

Rest the back wire on the dryer back ledge. Push down on

the frame front to secure over lint screen.

Changing Modifiers and Options after pressing Start

You can change a Modifier or Option anytime before the selected

Modifier or Option begins.

1. Press STOP once.

2. Select the new Modifier and/or Options.

3. Press START to continue the cycle.

NOTE: If you happen to press STOP twice, the program clears

and your dryer shuts down. Restart the selection process.

Changing the Preset Dryness Level Settings

If all of your loads on all Auto Dry cycles are consistently not as

dry as you would like, you may change the preset Dryness Level

settings to increase the dryness. This change will affect all of your

Auto Dry cycles.

Your Dryness Level settings can be adjusted to adapt to different

installations, environmental conditions or personal preference.

There are 3 drying settings: 1 (factory preset dryness level),

2 (slightly dryer clothes, approximately 15% more drying time)

and 3 (much dryer clothes, approximately 30% more drying

time).

1. The Dryness Level settings cannot be changed while the

dryer is running.

2. Press and hold the DRYNESS LEVEL button for 5 seconds.

The dryer will beep, and "CF" will be displayed for 1 second

followed by the current drying setting.

3. To select a new drying setting, press the DRYNESS LEVEL

button again until the desired drying setting is shown.

NOTE: While cycling through the settings, the current setting

will not flash, but the other settings will flash.

4. Press START to save the drying setting.

5. The drying setting you selected will become your new preset

drying setting for all Auto Dry cycles.

3. Place wet items on top of the dryer rack. Allow space around

items for air to circulate. The dryer rack does not move, but

the drum will rotate. Make sure items do not hang over the

edges or between dryer rack grille.

4. Close the door.

5. Select TIMED DRY and TIME ADJUST MORE TIME or LESS

TIME. Refer to the following table.

6. Select the desired temperature setting to match the fabrics in

your load by pressing TEMPERATURE. Items containing

foam, rubber or plastic must be dried on a clothesline or by

using an air cycle. Refer to the following table.

7. Start the dryer.

NOTE: Check the lint screen and remove any lint accumulated

from items dried on the dryer rack.

19

Suggested Items for Rack Cycle Suggested

Drying Setting Time*

(Minutes)

Washable wool items Low 20

(block to shape and lay flat

on dryer rack)

Stuffed toys or pillows Low 30

(cotton or polyester

fiber filling)

Stuffed toys Air Dry 50

(foam rubber filled)

Galoshes (rubber) Air Dry 20

Foam rubber pillows Air Dry 50

Tennis shoes Air Dry 20

*Reset time as needed to complete drying.

NOTE: You must remove dryer rack for normal tumbling• To

remove the dryer rack, lift it straight up and out of the dryer.

DRYER CARE

Keep dryer area clear and free from items that would obstruct the

flow of combustion and ventilation air.

2. Push the lint screen firmly back into place.

IMPORTANT:

• Do not run the dryer with the lint screen loose, damaged,

blocked, or missing• Doing so can cause overheating and

damage to both the dryer and fabrics•

• If lint falls off the screen into the dryer during removal, check

the exhaust hood and remove the lint. See "Venting

Requirements."

As needed cleaning

Laundry detergent and fabric softener residue can build up on the

lint screen. This buildup can cause longer drying times for your

clothes, or cause the dryer to stop before your load is completely

dry. The screen is probably clogged if lint falls off while the screen

is in the dryer.

Clean the lint screen with a nylon brush every 6 months, or more

frequently, if it becomes clogged due to a residue buildup•

To wash

1. Roll lint off the screen with your fingers•

2. Wet both sides of lint screen with hot water.

3. Wet a nylon brush with hot water and liquid detergent. Scrub

lint screen with the brush to remove residue buildup•

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 18 inches (46 cm) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

"...... _ " L '_c ee_

Every load cleaning

The lint screen is located in the door opening of the dryer. The

control panel has an indicator light to remind you to clean the lint

screen before each load. A screen blocked by lint can increase

drying time.

To clean

1. Pull the lint screen straight up. Roll lint off the screen with

your fingers. Do not rinse or wash screen to remove lint. Wet

lint is hard to remove•

4. Rinse screen with hot water.

5. Thoroughly dry lint screen with a clean towel. Replace screen

in dryer.

To clean dryer drum

1. Make a paste with powdered laundry detergent and very

warm water.

2. Apply paste to a soft cloth•

OR

Apply a liquid, nonflammable household cleaner to the

stained area and rub with a soft cloth until all excess dye and

stains are removed.

3. Wipe drum thoroughly with a damp cloth•

20

4. Tumble a load of clean cloths or towels to dry drum.

NOTE: Garments that contain unstable dyes, such as denim blue

jeans or brightly colored cotton items, may discolor the dryer

interior. These stains are not harmful to your dryer and will not

stain future loads of clothes. Dry unstable dye items inside out to

avoid transfer of dye.

From Inside the Dryer Cabinet

Lint should be removed every 2 years, or more often, depending

on dryer usage. Cleaning should be done by a qualified person.

From the Exhaust Vent

Lint should be removed every 2 years, or more often, depending

on dryer usage.

Replace inlet hoses and hose screen after 5 years of useto

reduce the risk of hose failure. Periodically inspect and replace

inlet hoses if bulges, kinks, cuts, wear or leaks are found.

When replacing your inlet hoses, record the date of replacement.

Install and store your dryer where it will not freeze. Because some

water may stay in the hoses, freezing can damage your dryer. If

storing or moving your dryer during freezing weather, winterize it.

Non-Use or Vacation Care

Operate your dryer only when you are at home. If you will be on

vacation or not using your dryer for an extended period of time,

you should:

1. Unplug dryer or disconnect power.

2. Closeshutoffvalve in gas supply line.

3. Clean lint screen. See "Cleaning the Lint Screen."

4. Turn off the water supply to the dryer. This helps to avoid

unintended flooding (dueto a water pressure surge) while you

are away.

To use dryer again

1. Flush water pipes. Reconnect water inlet hose to faucet. Turn

on water faucet.

2. Plug in dryer or reconnect power.

3. Open shutoff valve in gas supply line.

Moving care

1. Unplug the power supply cord.

2. Close shutoffvalve in gas supply line.

3. Disconnect gas supply line pipe and remove fittings attached

to dryer pipe.

4. Cap the open fuel supply line

5. Shut off water faucet.

6. Disconnect the water inlet hose from faucet, then drain the

hose. Transport hose separately.

7. Make sure leveling legs are secure in dryer base.

8. Use masking tape to secure dryer door.

Reinstalling the dryer

Follow the "Installation Instructions" to locate, level and connect

the dryer.

The dryer light automatically turns on inside the dryer drum when

you open the door.

To change the drum light

1. Unplug dryer or disconnect power.

2. Open the dryer door. Locate the light bulb cover on the back

wall of the dryer. Remove the screw located in the lower right

corner of the cover Remove the cover.

To winterize dryer

1. Unplug dryer or disconnect power.

2. Shut off water faucet.

3. Disconnect water inlet hose from faucet and drain.

4. Closeshutoffvalve in gas supply line.

3. Turn bulb counterclockwise. Replace the bulb with a lO-watt

appliance bulb only. Replace the cover and secure with the

screw.

4. Plug in dryer or reconnect power.

21

TROUBLESHOOTING

Firsttry the solutions suggested here and possibly avoid the cost of a service call...

ye_ Ope at o s

Dryer will not run

Has a household fuse blown, or has a circuit breaker

tripped?

Replace the fuse or reset the circuit breaker. If the problem

continues, call an electrician.

• Was a regular fuse used?

Use a time-delay fuse.

• Is the dryer door firmly closed?

• Was the Start button firmly pressed?

Large loads may require pressing and holding the Start

button for 2-5 seconds.

No heat

Has a household fuse blown, or has a circuit breaker

tripped?

The drum may be turning, but you may net have heat.

Replace the fuse or reset the circuit breaker. If the problem

continues, call an electrician.

• Is the valve open on the gas supply line?

Unusualsounds

• Has the dryer had a period of non-use?

If the dryer hasn't been used for a while, there may be a

thumping sound during the first few minutes of operation.

Is a coin, button or paper clip caught between the drum

and front or rear of the dryer?

Check the front and rear edges of the drum for small objects.

Clean out pockets before laundering.

Is it a gas dryer?

The gas valve clicking is a normal operating sound.

• Are the four legs installed, and is the dryer level front to

back and side to side?

The dryer may vibrate if not properly installed. See

"Installation Instructions."

• Is the clothing knotted or balled up?

When balled up, the load will bounce, causing the dryer to

vibrate. Separate the load items and restart the dryer.

• Are there unusual sounds at any time during a cycle?

You may hear the Dual Action Drying system blower motor

starting, changing speeds, or increasing or decreasing

airflow. These sounds are normal. See "Dual Action Drying

System" in "Dryer Use."

Is the dryer vibrating?

The Dual Action Drying system may be operating the blower

at its maximum speed. This may be required for your

conditions. Verify that your vent meets the requirements listed

in "Installation Instructions."

Dryer displaying code message

• "PF" (power failure), check the following:

Was the drying cycle interrupted by a power failure?

Press and hold START to restart the dryer.

• "F" Variable (F1, F2, F20, etc.) service codes:

Call for service.

Clothes are not drying satisfactorily, drying times are too

long, or load is too hot

• Is the lint screen clogged with lint?

Lint screen should be cleaned before each load.

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

Is the exhaust vent or outside exhaust hood clogged with

lint, restricting air movement?

Run the dryer for 5-10 minutes. Hold your hand under the

outside exhaust hood to check air movement. If you do not

feel air movement, clean exhaust system of lint or replace

exhaust vent with heavy metal or flexible metal vent. See

"Installation Instructions."

Are fabric softener sheets blocking the grille?

Use only one fabric softener sheet, and use it only once.

Is the exhaust vent the correct length?

Check that the exhaust vent is not too long or has too many

turns. Long venting will increase drying times. See

"Installation Instructions."

Is the exhaust vent diameter the correct size?

Use 4" (10.2 cm) diameter vent material.

22

Lint on load

• Is the lint screen clogged?

Clean lint screen. Check for air movement.

Stains on load or drum

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 18 inches (46 cm) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

• Is the dryer located in a room with temperature below

45°F (7°C)?

Proper operation of dryer cycles requires temperatures above

45°F (7°C).

• Is the dryer located in a closet?

Closet doors must have ventilation openings at the top and

bottom of the door. The rear of the dryer requires 5" (12.7 cm)

of airspace. See "installation Instructions."

• Has the Air Dry modifier been selected?

Select the right temperature for the types of garments being

dried. See "Modifiers."

• Is the load too large and heavy to dry quickly?

Separate the load to tumble freely.

• Are all your Auto Dry cycle loads consistently not as dry

as you would like?

You may change the preset Dryness Level settings to

increase dryness for all Auto Dry cycles. See "Changing

Cycles, Modifiers and Options."

• Are clothes coming out of the Refresh cycle with damp or

wet spots?

Under certain environmental or installation conditions you

may experience underdrying. Select the Touch Up cycle

(20 min. default time), which can be customized by choosing

temperature by pressing TEMP and/or cycle time by pressing

the Timed Cycle Adjust up or down buttons.

Cycle time too short

Was dryer fabric softener properly used?

Add dryer fabric softener sheets at the beginning of the cycle.

Fabric softener sheets added to a partially dried load can

stain your garments.

Drum stains are caused by dyes in clothing (usually blue

jeans). This will not transfer to other clothing.

Loads are wrinkled

• Was the load removed from dryer at the end of the cycle?

Select Touch Up Cycle to tumble the load with water and heat

to help smooth out wrinkles from a load left in the dryer.

Was the dryer overloaded?

Dry smaller loads that can tumble freely. Smaller loads yield

best results with the Refresh Cycle. Results may also vary

depending on fabric type. This cycle is best for reducing

wrinkles and odors from loads consisting of wrinkle-free

cotton, cotton polyester blends, common knits and

synthetics.

Loads are still wrinkled following SteamCare cycles?

Make sure water is connected to the dryer. Check that water

inlet hose is connected to both the faucet and dryer's water

inlet valve. Check that the water supply is turned on. These

cycles are best for smoothing out wrinkles and reducing

odors from loads consisting of wrinkle-free cotton, cotton

polyester blends, common knits and synthetic garments.

NOTE: Refer to garment care label instructions. Dry clean

only garments are not recommended.

Odors

Have you recently been painting, staining or varnishing in

the area where your dryer is located?

If so, ventilate the area. When the odors or fumes are gone

from the area, rewash and dry the clothing.

Is water connected to the dryer?

Check that water inlet hose is connected to both the faucet

and dryer's water inlet valve. Check that the water supply is

turned on.

To remove odors left in garments after wearing, select the

Refresh cycle for small loads of two to four garments. This

cycle is best for reducing wrinkles and odors from loads

consisting of wrinkle-free cotton, cotton polyester blends,

common knits and synthetics.

• Is the Auto Dry Cycle ending early?

The load may not be contacting the sensor strips. Level the

dryer.

Change the dryness level setting on Auto Dry Cycles.

Increasing or decreasing the dryness level will change the

amount of drying time in a cycle.

Do not use a dryer rack with an Auto Dry Cycle.

PROTECTION AGREEMENTS

Master Protection Agreements

Congratulations on making a smart purchase. Your new

Kenmore '_product is designed and manufactured for years of

dependable operation. But like all products, it may require

preventive maintenance or repair from time to time. That's when

having a Master Protection Agreement can save you money and

aggravation.

23

The Master Protection Agreement also helps extend the life of

your new product. Here's what the Agreement* includes:

Parts and labor needed to help keep products operating

properly under normal use, not just defects. Our coverage

goes well beyond the product warranty. No deductibles, no

functional failure excluded from coverage-- real protection.

v' Expert service by a force of more than 10,000 authorized

Sears service technicians, which means someone you can

trust will be working on your product.