Page 1

INSTRUCTIONS

MODEL 1232oZIGo ZAG SEWING MACHINE

/

q

!

Page 2

Sears, Roebuck and Co.

Dear Homemaker:

You have just invested in a very fine stretch stitch sewing machine Be-

fore using your new Kenmore machine, please pause for a moment and

carefully read this booklet wllich contains instructions on how to oper-

ate and care for your machine

Specific instructions are given on threading, tension adjustments, clean-

ing, oiling, etc This will help you obtain tile best sewing results and

avoid unnecessary sen'ice expense for conditions beyond our control

Advice on the operation and care of your machine is always available at

your nearest Sears Retail Store

Please remembeI, any correspondence or reference to your- machine

must mention tile model number and serial number of your machine

Kenmore Sewing Machine

Recmd in space provided below tile model number

and serial number of this appliance Ihe model num-

ber and serial number are located on the nomenclature

plate, as identified on Page 3 of this booklet

Mode! No Serjai No

Retain these numbers for future reference.

Page 3

TABLE OF

CORITEr_TS

Section i Knowing Your Sewing Machine

Identifying Parts

Installing Machine

Converting to Free-arm Sewing

Winding the Bobbin

Threading the Bobbin Case

Threading of Top Thread

Using the Controls

Adjusting Top Tension

Adjusting Bobbin Tension

Checking Tensions

Stitch Width Control

Stitch Length Controf

Reverse Stitch Control

Stretch Stitch Control

Pressure Regulator

Sewing Light

Seam Guides

Presser Foot Lever

Accessories

Needles

Needle, Thread and Fabric Chart

Presser Feet

2,3

4

5

6

7

8

9

t0

tt

12_13

12.13

14

14

15

16

17

17

18

19

20

Section

[[ Starting to Sew

Garment Construction Stitches

S_raight Stitching

Zigzag Stitching

Stretch Stitching

Special Finishing Stitches

Satin Stitching. Appliqueing

Buttonhole Making

Zipper-Application

Button Sewing, Bar Tacking

Darning

Free-arm Sewing

2

3

4

5

6

7

8

9

10

Section ill Checking Performance Problems

Section

IV Caring for the Machine

Cleaning Feed Dogs and Shuttle

Oiling Under Arm Cover Plate

Oiling Underside

Oihng in Face Cover Plate

Parts List

1

2

3

4

5,6

Page 4

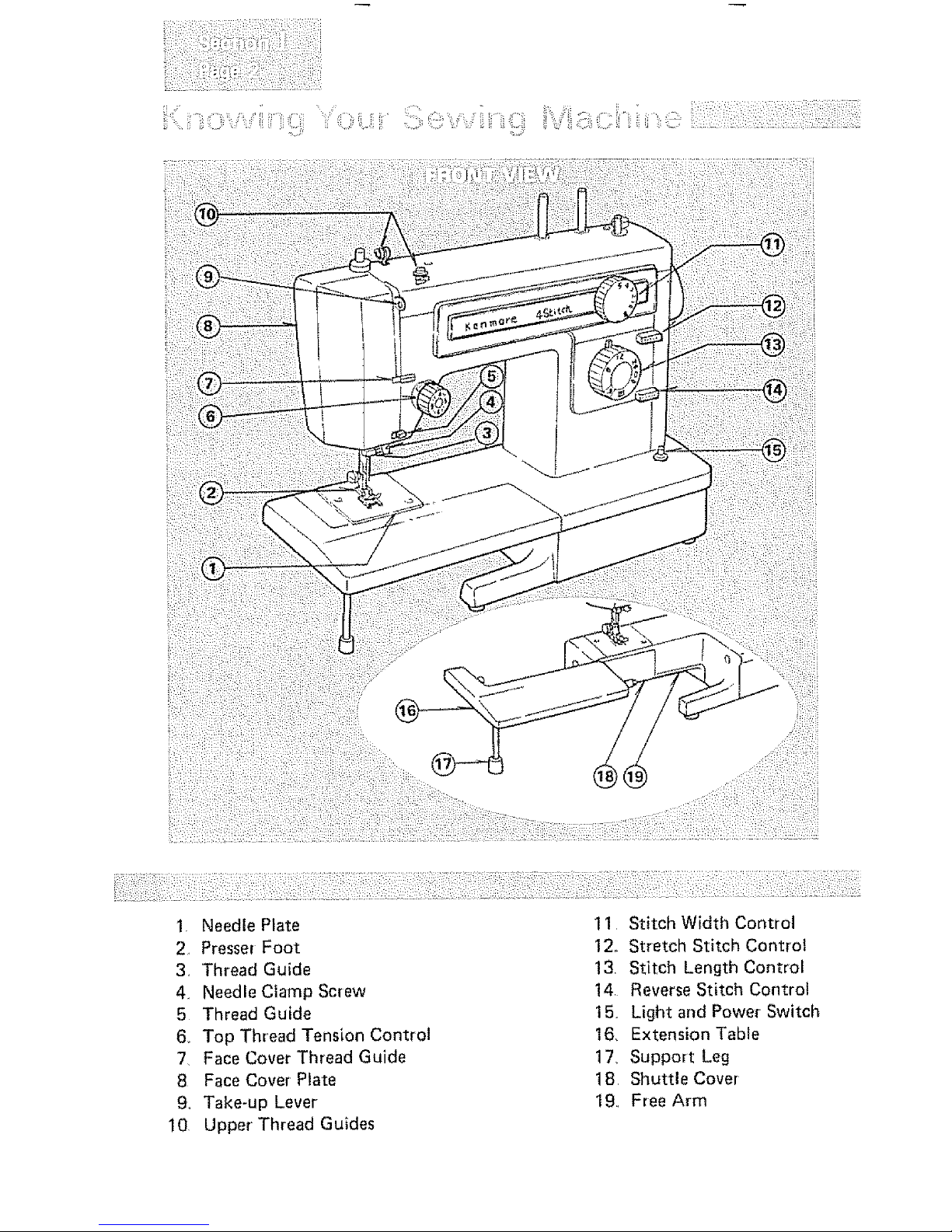

1. Needle Plate

2, Presser Foot

3, Thread Guide

4, Needle Clamp Sinew

5 Thread Guide

64 Top Thread Tension Control

7 Face Cover Thread Guide

8 Face Cover Plate

9o Take-up Lever

t0 Upper Thread Guides

11, Stitch Width Control

12,, Stretch Stitch Control

13. Stitch Length Control

14 Reverse Stitch Control

15. Light and Power Switch

16, Extension Table

17, Support Leg

18. Shuttle Cover

19, Free Arm

Page 5

20,ElectricCordReceptacle

21 NomenclaturePlate

22,,ClutchKnob

23,HandWheel

24 BobbinWinder

25 ThreadSpoolPins

26.BobbinWinderTensionDisc

27,,PressureRegulator

28 PresserFootLever

29,ThreadCutter

30,PresserFootThumbScrew

31,FeedDogs

Page 6

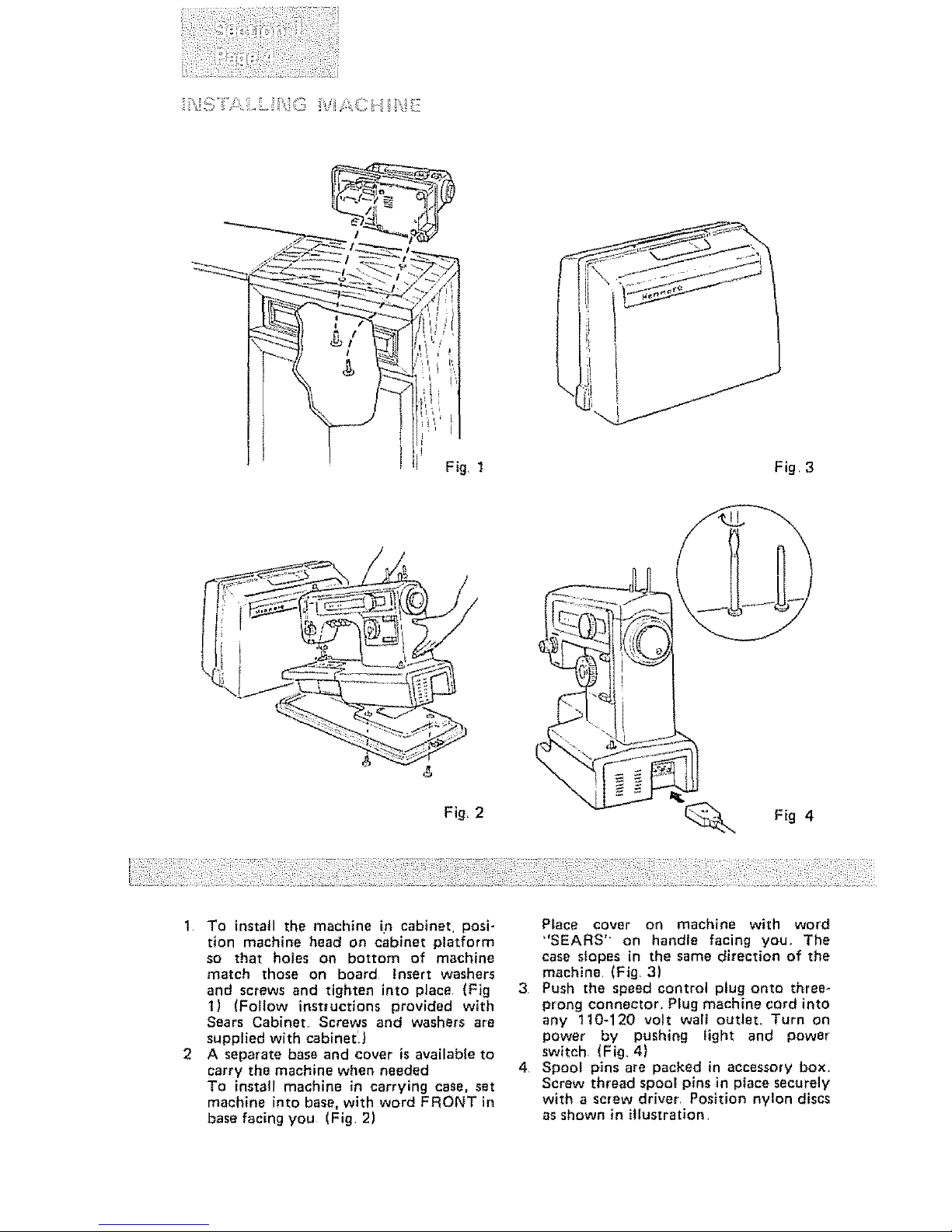

Fig, 1

Fig, 3

Fig, 2

Fig 4

1 To install the machine in cabinet, posi-

tion machine head on cabinet platform

so that holes on bottom of machine

match those on board Insert washers

and screws and tighten into place. (Fig

1) (Follow instructions provided with

Sears Cabinet Screws and washers are

supplied with cabinetl)

2 A separate base and cover is available to

carry the machine when needed

To install machine in carrying case, set

machine into base, with word FRONT in

base facing you (Fig. 2)

Piece cover on machine with word

"SEARS" on handle facing you° The

case slopes in the same direction of the

machine, (Fig 3)

Push the speed control plug onto three-

prong connector. Plug machine cord into

any 1t0-120 volt walt outlet. Turn on

power by pushing light and power

switch. (Fig. 4)

Spool pins are packed in accessory box.

Screw thread spool pins in place securely

with a screw driver Position nylon discs

as shown in illustration

Page 7

(/i_(}?.i_:./:_Zii!ct!7_?.!'::!iiii'ii ,11}:=!i¸::_.7.1;ii!!i!}}i¸,i& _:i::iii'_ii :!!i_.!i:ii_'V:_:__11i'_!_111i:_

Fig., 1

Fig 2

t. Remove the extension table from the

machine by folding the support leg up

and pulting table to the left (Fig 1. :2)

2 To replace the table, simply slide it along

the free arm to its originaf position and

pIace supporting teg in down position

(Fig.. t)

Page 8

_i'.:iii,;] ii::.![,i ":-i-ii:;iE{] [,: {:,:!,i{_i iG

®

®

o

®

®

®

3

t

1, Release clutch by turning clutch

knob toward you,

2, Draw thread from spool through

bobbin winder tension disc as

shown,,

3, Pull end of thread th[ough hole in

bobbin asshown,.

4. Place bobbin onto bobbin winder

shaft with end of thread coming

from the top of the bobbin,, Push

bobbin ,winder shaft to the right

until it clicks, Holding onto end of

thread, start machine, When bobbin

is slightly filled, snip off end of

thread.

5, Start machine. Wind thread until

bobbin winder' shaft releases,

6. Tighten clutch knob and remove

bobbin,

Page 9

T':?::::i;:::::(:!i::£:ID:(i'::,i(:_:::" ::-i::i:::!9::::£:::J?i:_i:::::!'::::'_:C :'::_::!:it:::£

Q ®

k:'_l

®

®

® ® ®

t, Remove the extension table from

the machine by pulling it to the

left. Open the shuttle cover.

2,, Raise needle to its highest position

by rotating hand wheel toward you,,

3, To remove bobbin case from shut-

tle, putt open latch of bobbin case,

4, Pul! bobbin case straight out of

shuttle,

5. Insert bobbin into bobbin case

making sure thread is coming from

bobbin as shown.

6., Pull thread through slot of case as

shown.

7,, Pull thread under tension spring,

8. Holding latch open, position case

into shuttle, and release latch, Case

should lock into place when latch is

released.

Page 10

-T_i_:__.-!__il_:'_i"_ _i_-_:::T _ i:_ 'T ii _:__ _ 19

Fig_

Fig,3

Fig 1

:ig 5

Place thread on spoot pin as shown

with thread coming from the back of

the spool Draw thread through the

top thread guides. Holding the spool

stationary with right hand, putl the

end of the thread between the tension

discs as shown. Pull the spring wire

loop up and past the top hook until

the thread can be slipped into the

hook (See Fig. 2), When the thread is

released, the spring wire loop wilt re-

turn to position (See Fig.. 3) with

thread in proper place. Release spool

of thread and continue to thread

machine exactly as shown. Needle

must always be threaded in direction

as shown in Fig. 4.

Hotd needle thread loosety in left hand

and rotate hand wheel toward you one

complete turn. Bring bobbin thread up

by pulling upper thread. (Fig.. 5}

Page 11

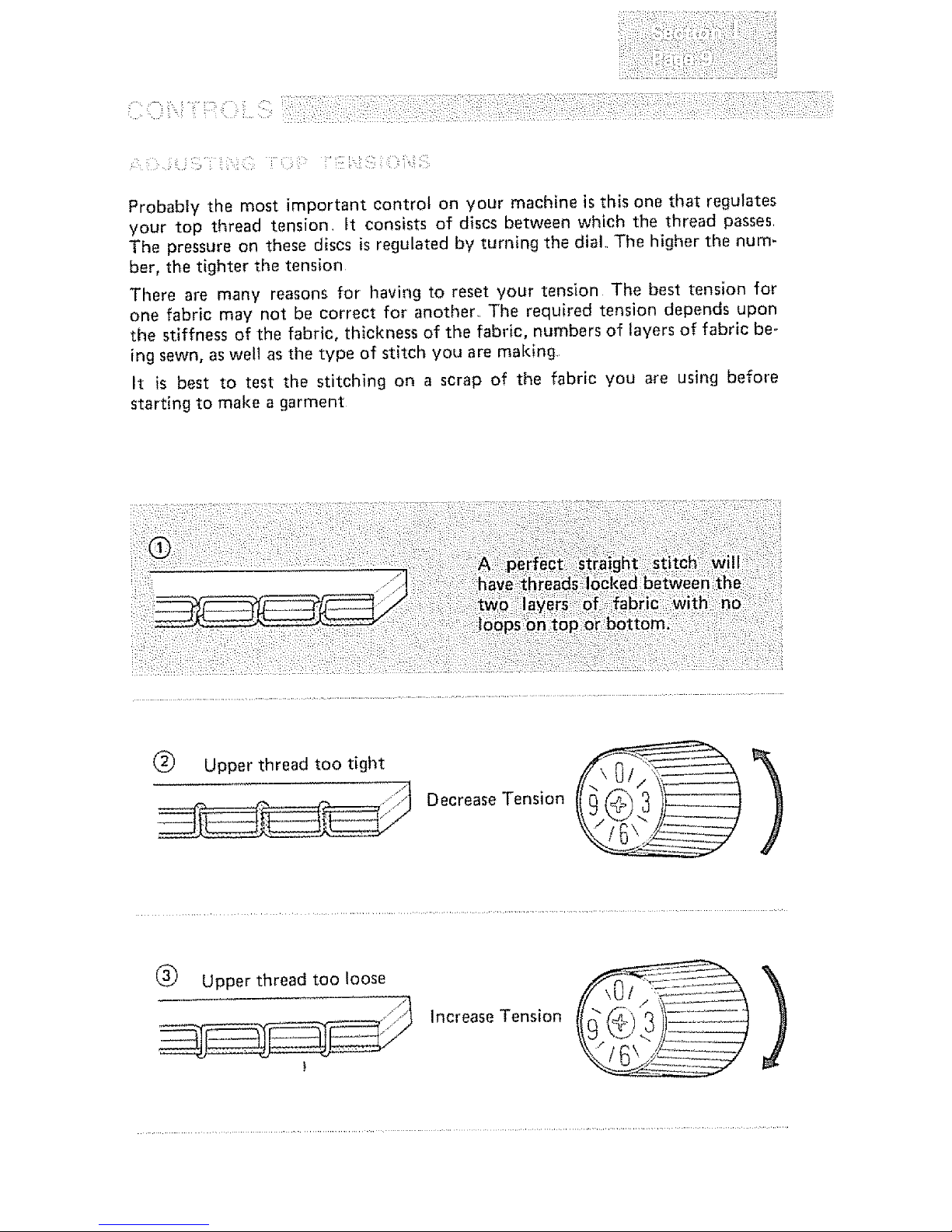

Probably the most important control on your machine is this one that regulates

your top thread tension. It consists of discs between which the thread passes.

The pressure on these discs is regulated by turning the dial.. The higher the num-

ber, the tighter the tension

There are many reasons for having to reset your tension The best tension for

one fabric may not be correct for another.. The required tension depends upon

the stiffness of the fabric, thickness of the fabric, numbers of layers of fabric be-

ing sewn, as wel! as the type of stitch you are making..

It is best to test the stitching on a scrap of the fabric you are using before

starting to make a garment

(_) Upper thread too tight

......._ Decrease Tension

(_ Upper thread too loose

,J

Increase Tension

Page 12

Bobbintensionrequiresadjustinglessfrequentlythantheupperthreadtension.

If thestitchissatisfactorybuttheseamis puckered,it maybenecessaryto

loosenthetensiononboththetopandbottomthreads..Besuretobalancethem

asindicatedonPage9.

When adjusting the tension on the bobbin case, make slight adjustments with a

screwdriver.

Turn Counter- Clockwise

Ii',!C REASE TENSION

Turn Clockwise

Page 13

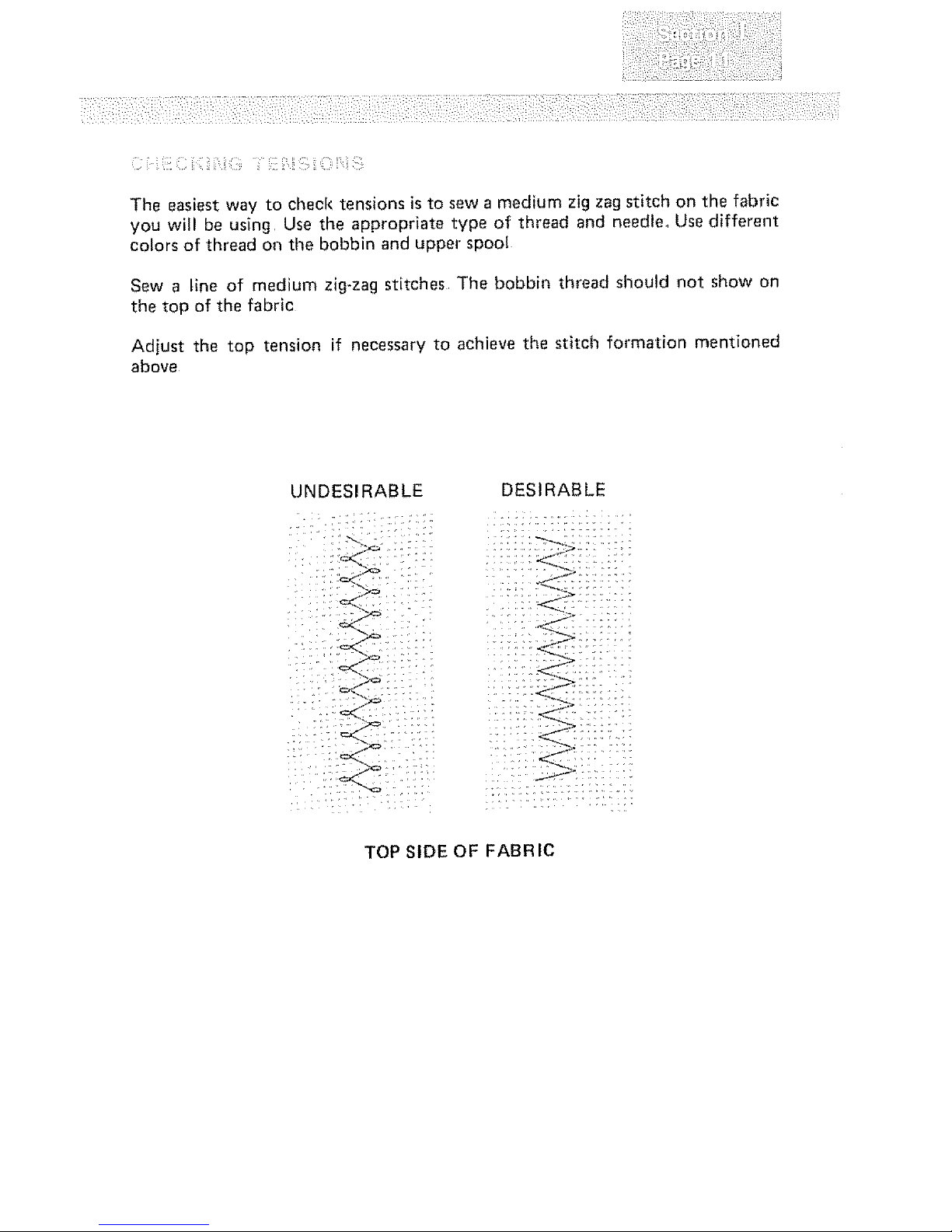

Theeasiestwaytochecktensionsistosewamediumzig zag stitch on the fabric

you wilt be using, Use the appropriate type of thread and needle., Use different

colors of thread on the bobbin and upper spool

Sew a line of medium zig-zag stitches The bobbin thread should not show on

the top of the fabric

Adjust the top tension if necessary to achieve the stitcll formation mentioned

above

UNDESIRABLE

__,i_ _I_!II!

DESIRABLE

!i! iiiili,i,

TOP SIDE OF FABRIC

Page 14

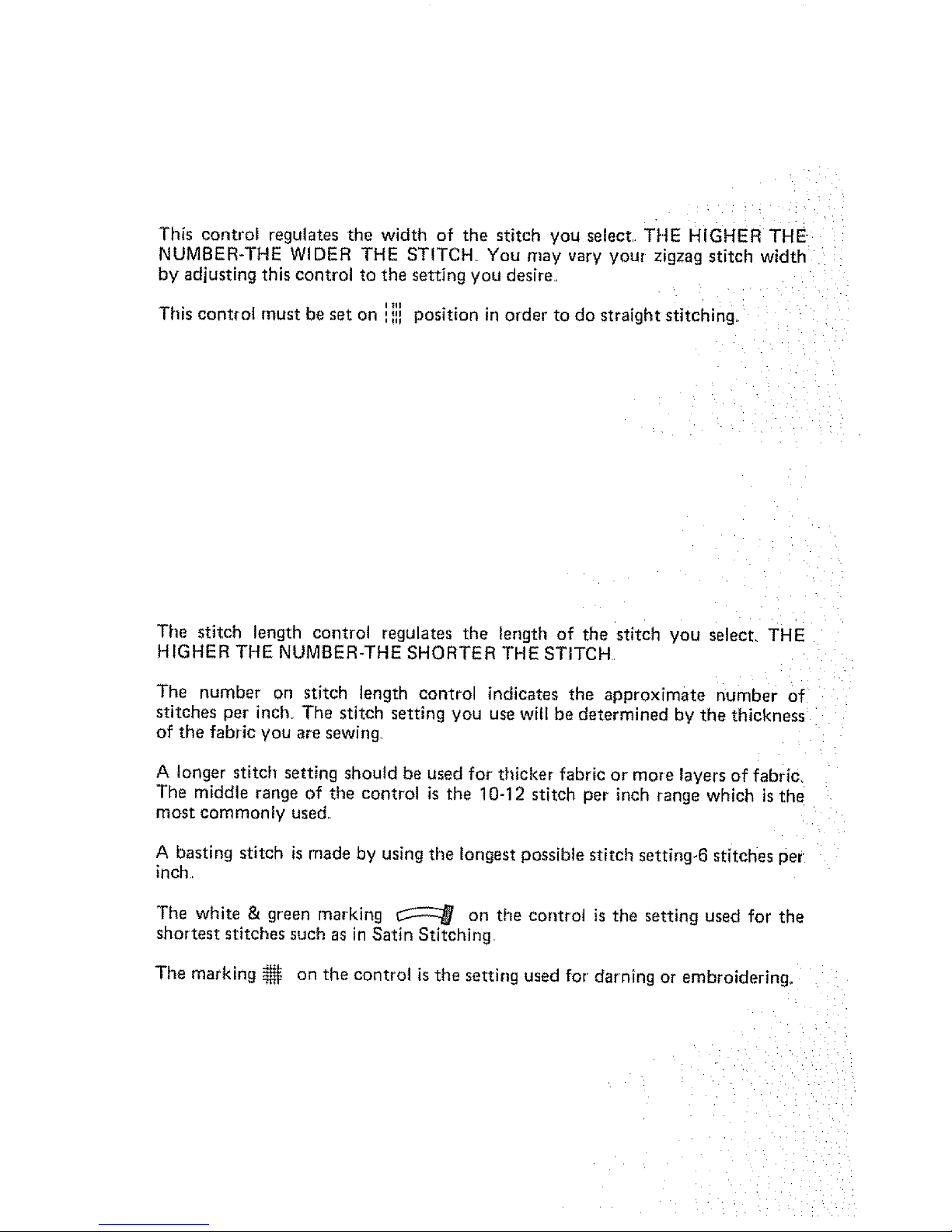

Thiscontrolregulatesthewidthof thestitchyouselect..THEHIGHERTHE

NUMBER-THEWIDERTHESTITCH.Youmayvaryyourzigzagstitchwidth

byadjustingthiscontroltothesettingyoudesire.

Thiscontrolmustbeseton,,,,,,,,positioninordertodostraightstitching°

Thestitchlengthcontrolregulates the length of the stitch you select. THE

HIGHER THE NUMBER-THE SHORTER THE STITCH.

The number on stitch length control indicates the approximate number of

stitches per' inch. The stitch setting you use will be determined by the thickness

of the fabric you are sewing.

A longer stitch setting should be used for thicker fabric or more layers of fabric_

The middle range of the control is the 10-12 stitch per inch range which is the

most commonly used..

A basting stitch is made by using the longest possible stitch setting-6 stitches per

inch.

The white & green marking _ on the control is the setting used for the

shortest stitches such as in Satin Stitching.

The marking _ on the control is the setting used for" darning or embroidering,

Page 15

: ::L::::::T:: i

WIDTH

!:¢::::V

LENGTH

: :::L:¸

Page 16

REVERSE_II_-

Page 17

__,_i _:!_i!_:_i' ii ¸__'/i:i ¸¸/ _ i i: :/,!i ¸ ii _/_:: i ii :_:iiii_i¸I_i_,ii¸i,:!i ii_i i:iiiiiii_i_'_,_ili:ii_

In addition to the obvious controls of your machine, there are other small

regulators and controls to aid you in using your sewing machine

:/i i:¸:::_!: i !!_/:i!/:: :::i:::/i:i ',i¸_;//:_ :ii:_:¸I¸_

Push down the outer ring of the pressure regulator., This will release the pressure

on the presser foot, (See above)

To increase the pressure, push down inner pin until a suitable pressure is

obtained,.

Insufficient pressure may cause poor feeding of the fabric, skipped stitches, or

difficulty in guiding the fabric, If feed dogs or presser foot marks appear on the

fabric, reduce the pressure.

When sewing multiple thickness or heavy fabric, reduce the pressure. Increase

pressure when sewing lighter weight fabrics

Page 18

:!ii!_ii!!

Fig. I

The light and power switch shown in

Fig. 1 provides the electric current for'

the motor as wetl as the light In order

to operate the machine, this switch

must be on,

To turn on the light, depress the

switch,, If you are interrupted while

sewing and must leave the machine un-

attended, just turn off the switch and

the machine cannot be started ac-

cidentally,

The sewing light is located in the face

cover as shown,, To replace the bulb,

turn the light off and open the face

cover,. Push the bulb up and turn the

bulb counter-clockwise and remove it

from the socket

Push a new butb in and turn it

clockwise,

NOTE:

First, unplug the machine prior to re-

moving and replacing the bulb Be

aware that the light bulb may be

warm

Fig 2

Page 19

CorneringGuide

Seam guides are printed on either side

of the needle plate to aid you in guid-

ing your fabric, THE GUIDE LINE

EXTENDING ALONG THE RIGHT

SIDE OF THE NEEDLE PLATE IS

THE "ALL IMPORTANT" 5/8"

SEAM LINE

The cornering guides are convenient

when turning a square corner 5/8"

from the fabric edge,. See next section

of this book for directions.,

:;:::=_:::i::i:!.!!i:!!i!;=i!i!i!_::ili::::

To aid you in the placement of heavy

fabrics under the presser foot, the

lever can raise foot beyond the normal

"up" position.. This is also an aid in

changing your presser feet

Page 20

Fig° 1

Use KENMORE needles_ The size of

the needle should conform with tbe

size of the thread and both should be

suitable to the fabric (See next page),

Never use a bent needle or one with a

blunt point..

Fig, 1_ shows you the exact length of

your needle. Be sure you never use one

in your machine that is not this exact

length,

"Q Needle" with blue shank is avail.

able at any store or service center of

Sears Roebuck and Co, or Simpson

Sears Limite& This special needle is

to be used when sewing certain knits

and difficult synthetic fabrics, If you

experience skipped stitches in any of

your sewing, use "'Q Needle",

F iat

side

away

from

you

::_L,/:_;_i:ii i_i i!i_iqi: :[::' i•_i

Raise needle bar to its highest position

by turning the hand wheel toward

you, Loosen the needle clamp screw,

Holding the needle with the flat side

away from you, slip the needle into

the needle bar, When it is in as far as it

will go, tighten the needle clamp screw

with a screwdriver,,

Page 21

D:i_£i:::iE;=:::):i;::£,_::!'!::-:i;i::!iL:::!ii£iL;_iLi;q_);3::;::L:_::!L!I::i::T:;;IIiCI:I::_iil]i:_ii:L!i:!_-ii-

:!:::!://:

:14-R ED : :

::::: :::::or: :

::16-PU RPLE

: I8_GREE

THREAD SIZE

Polyester Core/Cotton

Wrap

Fine Mercerized Cotton

Silk A

50 Mercerized Cotton

Polyester CoretCotton

Wrap

Silk A

50 Mercerized Cotton

Mercerized Heavy-Duty

Polyester Core/Cotton

Wrap

Silk A

Heavy Duty Mercerized

Cotton

Polyester Core/Cotton

Wrap

Silk A

Buttonhole Twist

(Use as top thread only)

Polyester Core Cotton

Wrap

50 Mercerized Cotton

RECOMMENDED

STITCH LENGTH

SETTING

t 2 stitches

per inch

10 to 12 stitches

per inch

8 to t0 stitches

per inch

8 stitches

per inch

6 stitches

per inch

I0 for Regular

or

6 for Stretch

S_itches

Page 22

!

i_ _"__iii_ _i i_5:::_i!_¸_i__:.__T

To change the various presser feet,

raise the presser bar to its highest posi-

tion by lifting the presser foot lever.

Loosen the presser foot thumb screw,

choose the proper foot, insert from

the bottom Tighten the screw using

the large screw driver to make certain

the foot is secure.

A

8 C

You have been gwen a variety of presser' feet:

A. Zigzag Foot

B.. Satin Stitch Foot

C. Zipper Foot

NOTE:

Additionat feet and attachments are available at most large retail stores or

through the catalog. Please select attachments for' left needle position with

low bar.

Page 23

Nowthatyouarefamiliarwiththecontroisoilyourmachineandwiththeac-

cessoriesprovidedfor[tiemachine,youarereadytostarttosewwithyournew

l<enmoresewingmachineBelowaresomegoodhabitstofolloweachtimeyou

sitdowntosew:

1,, Test the needte it should be straight, propedy set and sharp on the point° It

should be the correct size for the fabric and thread being used.. Do not be

afraid to change your needle frequently, Many of the new fabrics made of

synthetic blends tend to dull the needles more easily than fabrics made of

natural fibers,,

2.. Before placing the material on the machine, see that the ends of the threads

have been drawn about 4 inches to the rear of the machine. Hold on to

threads during the sewing of the first 3 or 4 stitches of the seam_

3, Test the machine stitch on a scrap of fabric you plan to use. The fabric

should be double thickness,, Adjust the machine for the length of stitch and

tension suitable to your fabric,

4, Fabric should be placed under the presser foot with the bul!< of the material

to the left of the needle and the right edge of the material placed on the 5/8"

seam marking on the needle plate when making a simple seam,

5, Run the machine at a slow even speed,, The more pressure you put on the

speed control, the faster the machine will sew.,

6, Fasten each seam by back tacking at the beginning and end of the seam.,

7 Atways finish sewing each seam with the needle at its highest point.

8 Guide the fabric gently with your hand in front of the needle, Never pull or

hold the fabric in such a way that the normal feeding is altered,

9.. When turning the hand wheel manually, always turn it toward you,

Page 24

GARMENT CONSTRUCTOON STITCHES

STRARGHT STOTCHONG

Set your machine just as shown in the

illustration in order to straight stitch,

tt is important each dial has the fol-

lowing settings:

SETTINGS

Stretch Stitch Control ....... Horizontal

Stitch Width Control .............. !iii

Stitch Length Control ......... 12 to 6

Zigzag Presser Foot

You will find in garment construction that you are doing two types of sewing °

temporary and permanent,.

1, Temporary stitching-Usually the longest stitch possible and often done on a

single layer' of fabric,, The various types of temporary stitching are:

Basting

Stay stitching

Guide line marking

2 Permanent stitching-This is the actual stitching that holds the garment to-

gether, Much of this stitching is visible on the outside of the garment and

therefore must be good looking..

The best length stitch to use for medium weight fabrics is 10-12 stitches per

inch. This is in the middle range of the Stitch Length Control

You must remember to lengthen the stitch for heavier fabrics, multiple layers of

fabric and thicker seams, Some of these seams are:

Common two layer seams

Curved two layer seams

Top stitched three layer seams

Top stitched four layer seams

When you have two seams crossing each other with considerable thickness, sew

slowly and carefully sothe seam will be asstrong as possible in this area,

FASTENING A SEAM

Be sure both threads are drawn back under the presser foot, Lower needle into

fabric about 1/2 inch from beginning of seam, Turn the reverse stitch control

clockTvise and stitch in reverse until needle reaches beginning of seam,, Release

control and complete seam.. When you reach the end, turn the control clockwise

and sew back over' 1/2 inch of completed seam,

Page 25

TURNING A SQUARE CORNER

To turn a square corner 5/8" from the

fabric edge, stop stitching with the

needle tip piercing the fabric, when

reaching the cornering guide as shown..

Raise the presser foot, turn fabric.

New stitching line will align with 5/8"

seam guide on side of needle plate.

Lower the presser foot and begin

stitching in new direction.

ZgGZAG STiTCHiNG

SETTINGS

Stretch Stitch Control ...... Horizontal

Stitch Width Control ....... ! to 5

Stitch Length Contro! ......... Any Number

Zigzag Presser Foot

This type of stitching greatly expands

the use of your machine, This is the

feature that enables you to overcast

seams, applique and buttonhole.,

Simply use the settings indicated in

the illustration for the simple zigzag.

Follow directions given in the follow-

ing pages for more specific uses.

Fig !

Fig 2

OVERCASTING

This is one of the more frequently

used zigzag stitches in garment const-

ruction You may want to overcast

along the raw edge of each seam allow-

ance or fold the raw edge toward the

garment and stitch.

Fig 1 shows the raw edge finished.

Fig. 2 illustrates the folded edge

stitched

Stitch so the needle pierces the fabric

just short of the outside edge. Raw or

worn edges of older garments can be

overcast to prevent further raveling.

Page 26

ii

i • %

•:!:-: ::i¸ _, !::: L:, ••

STRAgGHT STRETCH

STgTCHING

SETTINGS

Stretch Stitch Control ......... Vertical

Stitch Width Control ........ IIII

, I I!_

Stitch Length Control ......... 6

Zigzag Presser Foot

Use this stretch stitch with knitted

fabric and other fabrics that stretch,.

Sew as you do with regular straight

stitch seaming,. The seam may be pres-

sed open aswith any regular seam, but

wil! stretch if necessary,

This is also a good stitch to use on

curved seams regardless of the type of

fabric, Any seam that will receive a

great deal of strain when worn should

be sewn with the stretch stitch, Use in

children's shorts and slacks as well as

adult sports clothes_

ZDGZAG STRETCH

STITC HillllG

SETTINGS

Stretch Stitch Control ..........Vertical

Stitch Width Control ............. 2 to 5

Stitch Length Contro! ......... 6

Zigzag Presser Foot

Sew on stretch fabrics in any area that

you might use a zigzag stitch, This

stitch can be used as a decorative top

stitch as welt,

Page 27

Aftertl_ebasicconstr[_ctionof yourgarmentisfinished,tiserearestillmany

finishingtouchestobecloneToaidyourcompletionofyourgarment,theKen-

moret_asbeendesignedtodothefollowingtasksthatformerlyhadtobedone

byhand

SA'_N S'TFCH_NG

SETTINGS

Stretch Stitch Control .... Horizontal

Stitch Width Control ........ 2 to 5

Stitch Length Control ..... Green Zone

Satin Stitch Foot

Closely spaced zigzag stitches are called satin stitches This is an attractive stitch

used for appliqueing, buttonhole making.

Whenever you are using this stitch, it is well to remember to loosen the tension

of the top thread slightly. The wider the stitch you make, the looser the tension

should be.

If you are stitching on a very soft fabric, it is well to use a backing of tissue

paper or interfacing for a well formed stitch.. Puckering of the materia! wilt be

eliminated and the bobbin thread will not be visible on the top side of the fabric..

As with all special stitches, it is best to make a sampie design on your fabric

before starting the design on the garment

APPLIIQLIE_RIG

SETTINGS

Same as with Satin Stitching

Select an applique design to be applied

to your garment and baste it in place

Satin stitch around the raw edge of the

applique completely covering the edge

You may want to do this with a con-

trasting color of thread or self color,

Page 28

BUTTONHOLEMAlt{.QNG

SETTINGS

Stretch Stitch Controi ....... Horizontal

Stitch Width Control ............ Green Zone

Stitch Length Control ........... Green Zone

Satin Stitch Foot

Fig. 1

A/ Fig. 2

}

Always make a practice buttonhole on

a scrap of fabric you plan to use, Try

the buttonhole with the button you

wil! use,,

Always use an interfacing in area of

garment where buttonholes are placed,

Tissue paper or regular interfacing can

be used, Tear paper away after

stitching, if it is used.

Mark the buttonhole length at both

ends and also the center" line SeeFig, 1

Set Stitch Width Control to Green

Zone,, Stitch forward on left side of

buttonhole until desired length is ob-

tained, Stop with needle in fabric on

right side of stitching, (Point A). See

Fig, 2

Raise Presser Foot with needle in

fabric and turn fabric around 180

degrees using needle as a pivot, See

Fig 3

Fig; 3

Page 29

Fig, 4

]

Fig. 5

Lower Presser Foot and stitch one

stitch to left by turning Hand Wheel

toward you and raise needle, See Fig 4,

Set Stitch Width Control to 5 and

make bartack with a few stitches and

raise needle See Fig, 5

Set Stitch Width Control to Green

Zone and sew other side of buttonhole

stopping a few stitches before desired

length and raise needle, See Fig 6

Fig. 6

Fig. 7

Set Stitch Width Control to 5 and

make bartack a few stitches See Fig 7

Remove fabric from machine,

Depending upon the fabrics on which you are sewing, or your own preference in

buttonholes, you may slightly decrease the width of the sides and the spaces in

the center by varying the stitch width settings.

Page 30

ZIPPER APPLICATION

SETTINGS

Stretch Stitch Control .... Horizontal

Stitch Width Control ........... 0

Stitch Lengfl_ ControI ......... 12

Zipper Foot

foot

adjusting

Y

(right)

Fig, 1

/"

Fig, 2

Fig, 3

REGULAR ZIPPER

Pin or baste zipper to fabric and place

the work in position under the presser

foot.. Loosen the zipper foot adjusting

screw to set the foot on the left side of

the needle, and sew the left side zipper

as shown.. (Fig. 1) To sew the right-

side zipper, loosen the screw and bring

the foot to the right side of the needle.

INVISIBLE ZIPPER

Adjust the foot so the needle is sewing

through the center hole of the foot

and one groove of the foot is riding on

the teeth of the zipper', See Fig, 2, Fol-

low the zipper manufacturer's instruc-

tions,

After zipper has been inserted, finish

sewing seam by shifting foot to side

position sewing through side notch

CORDING

Foot can also be used to make cording

for slipcovers etc, Cover a cord with a

strip of bias fabric and sew asshown in

Fig,,3

NOTE:

Use "Law Bar Sewing Machine ZIP-

PER FOOT" (6757) for "invisible

zipper" and "cording", which will be

obtained at any stores of Sears Roe-

buck and Co, and Simpsons-Sears

Limited

Page 31

BUTTON SEWING

SETTINGS

StretchStitchControl...... Horizontal

StitchWidthControl..........Mustbe

adjusted

StitchLengthControl....... :_i_

ZigzagPresserFoot

1,

,,

3.

4 k

5.

Align two holes of button with slot

of presser foot and lower foot to

hold the button securely,

Turn hand wheel manually until

needle point isjust above button,

Adjust stitch width control so

needle will enter left hole of the

button,

Turn hand wheel again by hand so

needle enters second hole,, Readjust

stitch width if necessary° Stitch a

number of times.

Finish sewing with an extra two

inches of thread remaining, Draw

these threads to reverse Side of gar-

ment and tie,

BAR TACKgNG

SETTINGS

Stretch Stitch Control ......... Horizontal

Stitch Width Control ..............1 to 5

Stitch Length Control ..........Green Zone

Zigzag Presser Foot

This stitch is similar to a very short

satin stitch and is used to reinforce

points of strain such as corners of

pockets and straps on lingerie.

Sew 4 to 6 zigzag stitches,

Page 32

DARNBPJG

SETTINGS

StretchStitchControl........Horizon[al

StitchWidthControl ,_

.............. _H

Stitch Length Control .......... _i#

No Presser Foot

Remove presser foot, stretch fabric be-

tween embroidery hoops with hole

centered Draw the bobbin thread up

through the fabric by holding the top

thread and taking one stitch at the

spot where you wish to start darning_

Lowering the presser bar, start sewing

at a slow to medium speed, Move the

fabric back and forth with a steady

rhythm to cover the darning area.

When it is covered, turn the fabric and

sew another layer of stitching across

the first layer of stitching.

Page 33

This sewing machine can be used like a

flat bed machine, but easily converts

to free arm machine by removing the

extension table

The free arm enables you to sew

tubular types of pieces more easily

Just slip the sleeve or pants leg on the

free arm as shown above..

You will find many uses for this free

arm feature such as:

1 Mend elbows and knees of garments

more easily

2. Sew in sleeves more easily This is

especially true when sewing smaller

garments

3 Applique, embroider or hem

around edges of cuffs or pants legs

4. Sewing in elastic casings 'n skirts or

_3ants at the waistline

Page 34

0

a

0

p-

t--

"1-

E

m

0

E

6

0

.g

0

0

2

o

w

t_

o

rr p- 0 _ OC O: O_ O=

5

=b

0

o_

_3

x_N

ilo

mt,-

_0

,.or_

m o

_C

_ _._

rll _ -i:I

_ -,=_ :3

Page 35

Page 36

Ca ing

iVlachine !i

Fig 1

Fig 1 Cleaning the feed dogs with a

brush,,

To insure the best possible operation

of your machine, it is necessary to

keep the essential parts clean at all

times, Using a small brush, remove the

lint that accumulates in the shuttle

area and around the feed dogs,

Fig,.2 Parts of the Shuttle Assembly

Lever-_

4_Lever

Shuttle Assembly

ShuttIe Race Cover

Pointed --_

hook Shuttle

Shuttle driver

!

Shuttle Race

To

,

Clean the Shuttle Area:

This area must be kept free of dust,

lint and occasional tangled thread,

Raise the needle bar to its highest

point and remove the bobbin case_

Push levers of shuttle race aside and

lift shuttle race cover and shuttle

out,

3, Clean the shuttle race with small

brush,

4., Put a drop of oil on the center pin

of the shuttle and shuttle race, (see

arrows)

To Replace Shuttle Assembly:

1, Position shuttle race as illustrated

so that race is forming half moon

on the left side of the machine

2, Hold shuttle by center- pin and posi-

tion shuttle so as to form a half

moon on the right side Pointed

hook will be on the bottom,

3. Place shuttle race cover into place

over shuttle assembly.

4, Snap the levers into position

Fig. 2

Page 37

Remove arm cover plate to oil points indicated in top of machine head. To re-

move cover plate, loosen up two top screws and lift the cover plate as illustrated

below,,

Page 38

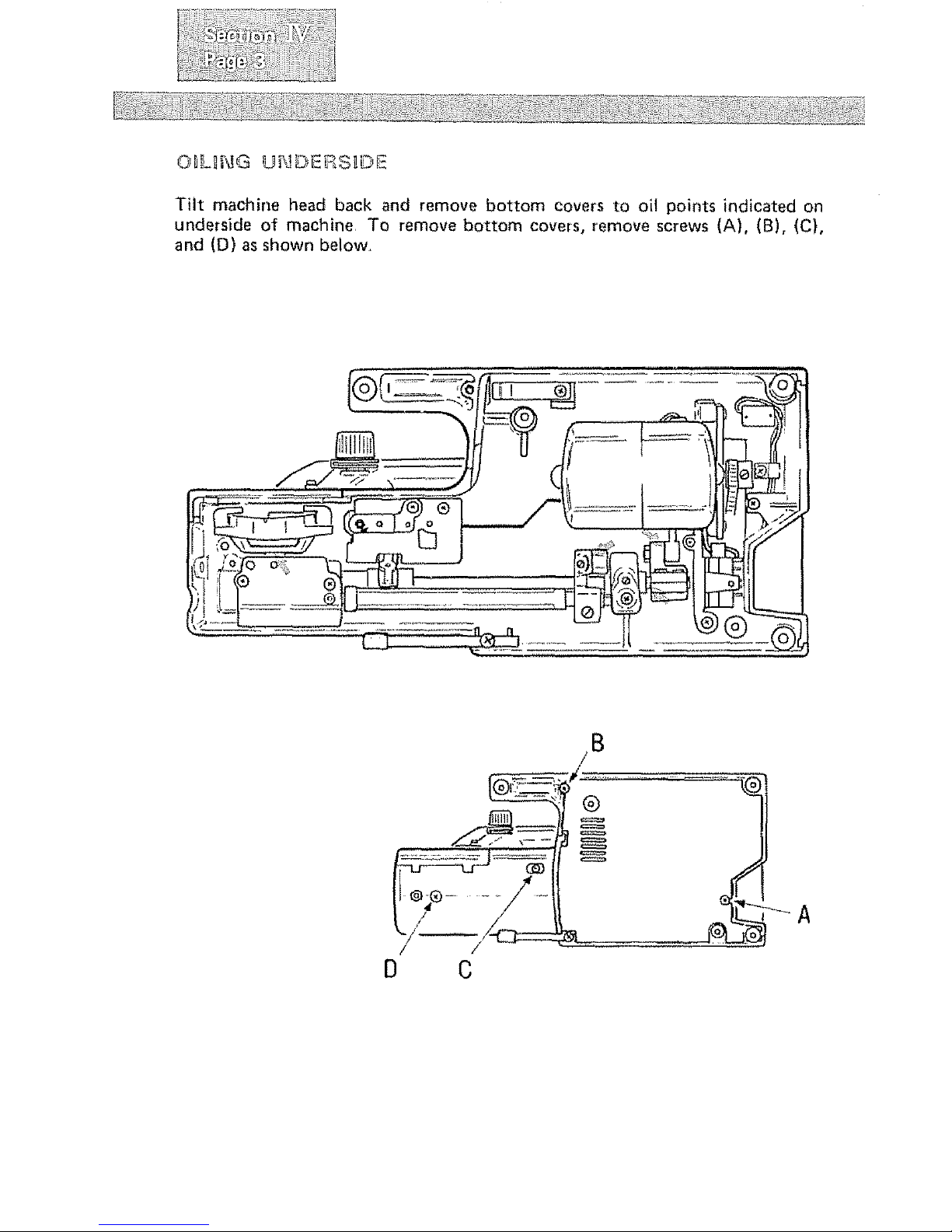

ODLI[_G Uf'_JDERSI_©E

Tilt machine head back and remove bottom covers to oil points indicated on

underside of machine, To remove bottom covers, remove screws (A), (B}, (C},

and (D) as shown below,

®

D C

®

--- A

Page 39

Open face cover plate and oil points in illustration

Page 40

PARTS LIST

5

4

6

9 I0 lI

I4 15 16 17 t8 19

Page 41

iPAR3TSL!S_

All partslistedhereinmaybeorderedfromanySears,RoebuckandCo,or

Simpsons-SearsLimitedstoreorservicecenter.

WHENORDERINGREPAIRPARTS,ALWAYSGIVETHEFOLLOWING

INFORMATION:

1,PARTNUMBER 2,PARTDESCRIPTION

3, MODELNUMBER 4..NAMEOFITEM

If thepartsyouneedarenotstockedlocally,yourorderwil!beelectronically

transmittedtoaSearsRepairPartsDistributionCenterforexpeditedhandling,

Re[.No., PartNo,, Description

1

2

3

4

5

6

7

8

9

10

11

t2

13

14

15

16

17

18

19

47

6510

*6862

t939

8286

2273

6550

6551

6552

6553

6554

*6746

36353

40390

6870

593401008

*6757

*6864

6797

40164

33379

6830

41670

41669

*6889

Shuttle

Bobbin case

Bobbin box with 10 bobbins

Bobbin winder rubber ring

Thread spool pin

Nylon disc

Noo 9 Single needles (BRN)

No, 11 Single needles (ORG)

No,, 14 Single needles (RED)

No, 16 Single needles (PUR)

No, 18 Single needles (GRN)

"Q NEEDLES'%

Needle clamp with screw

Standard zigzag foot

Satin stitch foot

Zipper foot

Zipper foot

Needle threader

Light bulb

Motor belt

Motor belt

Buttonhole opener

Large screw driver

Small screw driver

Oil and lint brush

*These items are not furnished with the machine, but may be ordered per

instructions above,

Page 42

Page 43

WARRANTY

FULL 25-YEAR WARRANTY ON SEWING MACHINE HEAD

For 25 years from the first day of use in your home. Sears wilt,

free of charge, repair defects in roateriai or workmanship which

appear in the sewing machine head

FULL TWO YEAR WARRANTY ON ELECTRICAL EQUIPMENT

OF SEWING MACHINE

For two years from the first day of use in your home. Sears will.

free of charge, repair defects in material or workmanship which

appear in the electrical equipment of the sewing machine, includ-

ing motor, wiring, switch and speed control

FULL 90- DAY WARRANTY ON ALL PARTS AND MECHANICAL

ADJUSTMENTS

For 90 days from the first day of use in your ilome. Sears will

free of charge, replace any parts and provide mechanical service

necessary for proper operation o! the sewing machine, except for

normal maintenance

To obtain warranty service described above, simply contact the nearest

Sears store or Service Center throughout the United States..

This warranty gives you specific legat rights and you may atso have

other rights which very from state to state

SEARS, ROEBUCK AND CO. • Sears Tower, BSC 41_3,Chicago, IL 60684

Page 44

SEWING MACHINE

ii: Now that you have purchased your Sewing Machine, should a

need ever exist for repair parts or service, simply contact any

Sears Service Center and most Sears, Roebuck and Co.o

i:i:::: Be sure to provide all pertinent facts when you call or visit.

The model number of your Sewing Machine will be shown on

your nomenclature plate on the back of your Sewing Machine.

See Section 1, page 3 for location.,

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION :

i *MODEL NUMBER *NAME OF ITEM "PART DESCRIPTION

if the parts you need are not stocked locally, your order will be li:::::

electronically transmitted to a Sears Repair Parts Distribution

Center for handling.

SEARS, ROEBUCK AND COo, Chicago, IL 60_:_4U.S.A.

S - 385 Printed in Taiwan Part No. 647800104 (_

Loading...

Loading...