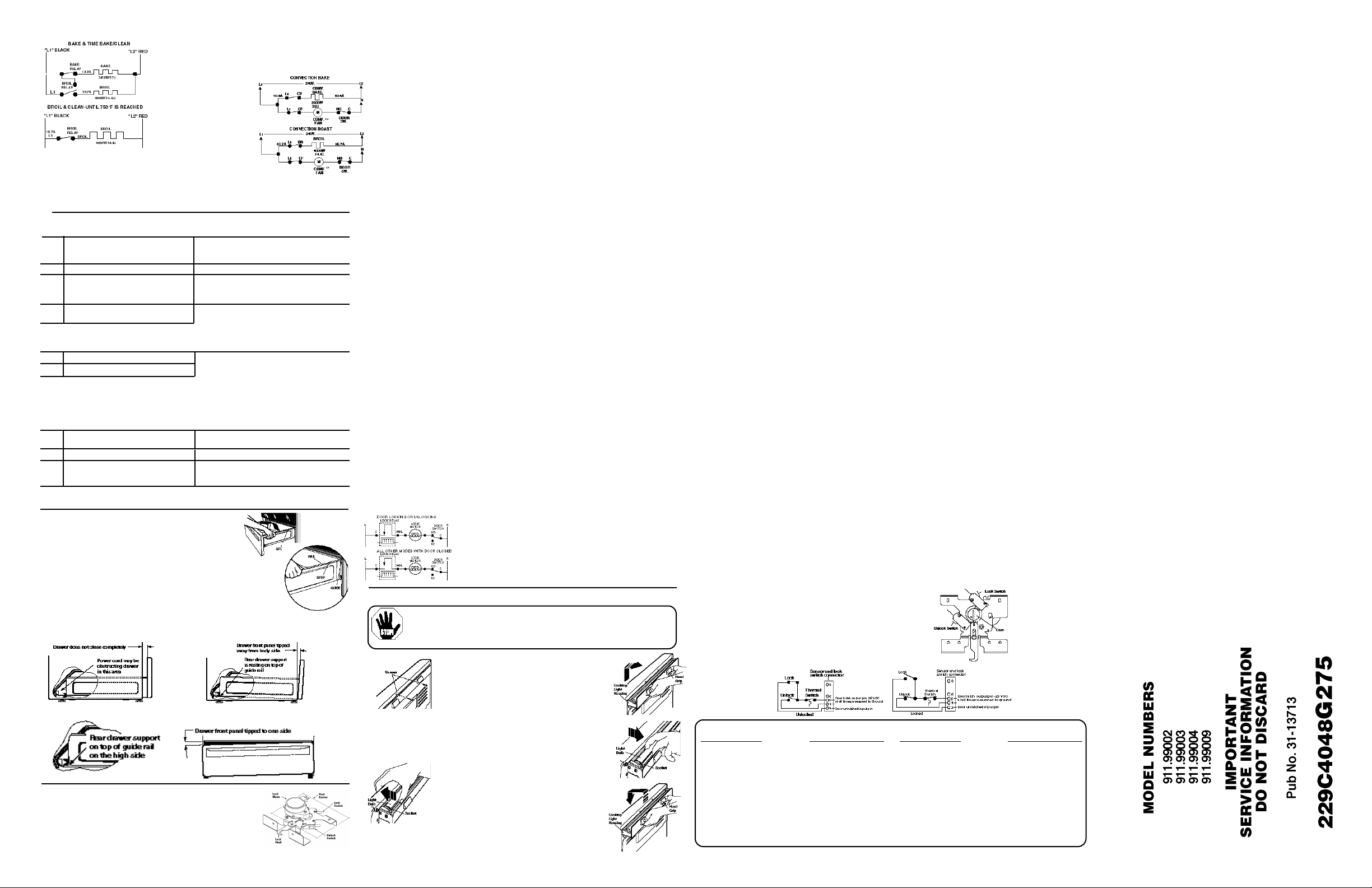

Kenmore 911.99002, 911.99003, 911.99009, 911.99004 Technical Data Sheet

NOTE:

• BAKE/TIME BAKE — Bake and broil units cycle during

preheat and balance of operation, one unit is on at a time.

• CLEAN — Broil unit only on

during 1st 30 minutes or

until oven reaches 750°F.

During balance of clean

oven will cycle between

bake and broil units.

Convection fan running make the following checks:

• Check the voltage from terminal CF to N on control - should read

120V in convection bake or roast mode.

• If voltage is OK, check convection fan motor. It reads approximately 15-20Ω’s at room

temperature. Check to make sure fan shaft is not rubbing on oven liner.

ERC FAILURE CODES

CODE

• Look for high resistance in the sensor circuit due to high contact resistance (poor terminal crimp, deformed

• Electrical noise interference in the sensor circuit ( Ham radio, cordless phone, etc.)

• Measure each sensor lead from connector block to ground. If shorted, look for pinched or cut wire in sensor

• Check connector terminals- Look for deformed or corrosion on terminals. Repair or replace.

• Check connector at sensor (remove sensor and carefully pull leads with connector into oven).

• If all above is ok, replace control.

NOTE: Connections can be intermittent due to a corrosive buildup between the connection to the terminals, or

by being bent by the insertion of a probe, etc.

MEANING

Clear/Off pad is shorted or touch board fault

F0

(after approx. 100 secs).

Loss of element redundant driver protection.

F1

Any key (other than Start of Clear/OFF pad)

F7

shorted (after approx. 40 secs).

F6

F2

Over-temperature-915°F if lock circuit is

made, 615°F otherwise.

terminals, loose connection inside sensor tube) or intermittent solder joint.

Sensor circuits open (2900 Ohms or greater).

F3

Sensor circuits shorted (950 Ohms or less).

F4

to damage terminals in block)-Should read 1100Ω at room ambient (approx.72°F).

circuit.

Both lock and unlock circuits are activated at

F9

FC

the same time (after approx. 60 secs.)

Loss of door motor redundant driver protection.

FF

FA

Surface warmer on indicator light supervisor

error

FE

CORRECTION

If code cannot be cancelled, unplug keypad and

power up. If 0) ceases, replace keypad/ glass

asm., If 0) is still present, replace main control.

If code cannot be cancelled, replace control.

If code cannot be cancelled, unplug keypad and

power up. If code ceases, replace keypad/glass

asm. If code is still present, replace main control.

• Look for welded relay contacts. (Heating elements on

in off mode.)

• Disconnect power to range.

• Disconnect sensor connector at control. Measure

sensor resistance at control connector (take care not

Check wiring and test operation of switches.

Perform resistance check.

Replace control

Replace control

• T E C H N I C A L D A T A S H E E T •

STORAGE DRAWER REMOVAL

To Remove:

1. Pull the drawer out until it stops.

2. Lift the front of the drawer until the stops clear the guides.

3. Remove the drawer.

To Replace:

1. Place the drawer rail on the guides.

2. Push the drawer in until it stops.

3. Lift the front of the drawer and push in until the stops clear the guides.

4. Lower the front of the drawer and push in until it closes.

——— If Drawer Won’t Close ———

——— If Drawer is Crooked ———

MOTORIZED DOOR LOCK

The motorized door lock assembly is located above the oven. The

assembly consists of a lock motor cam and switch assembly, lock

hook, heat barrier, and mounting plate.

229C4059P244

Motorized Door Lock Operation:

The lock motor is energized when the control is set for Clean

and Clean Time selected. The K1 relay contact will close and

complete the circuit that supplies the voltage to the lock motor.

REPLACING THE COOKTOP LIGHT BULB

CAUTION: Disconnect electrical power to the range at the main circuit

breaker or fuse box before attempting to replace the cooktop light bulb. Do

not touch a hot light bulb with wet hands or a wet cloth. Wait until the bulb

has cooled and use a dry cloth.

To Remove Old Bulb:

1. Pull the range away from the wall.

2. Remove the two screws from the top on the

back of the range.

3. Pull up on the hand grips on the back of the range

until the tabs at the bottom of the cooktop light

housing separate from the back of the range.

4. Pull out the cooktop light housing as far as possible, about 2 inches.

5. Remove the light bulb by unplugging it from both sockets with one motion.

To Install New Bulb:

1. Install the new light bulb by plugging it into

both sockets with one motion.

2. Using the hand grips on the cooktop light

housing, lift up and push the housing back into

the rear wall of the range. Then lower the

housing until the bottom tabs are inserted back

into the range.

3. Reattach the screws along the top edge on the back of the range.

Then push the range back against the wall.

NOTE: Display of Control will flash “LOCK DOOR” if the door switch is in the “C” to “NC” position.

(Door open)

• The word “LOCKED DOOR” will flash on and off in the display while the

lock motor is in motion. When the door is locked the word “LOCKED

DOOR” remains illuminated in the display.

• CAM - The cam on the motor performs two functions:

1. Positions the lock hook in the door to prevent opening during clean

operation.

2. Operates the lock switches which tell the control if the door is unlocked or

locked and ready for clean operation.

NOTE: When door is either being locked or unlocked both lock switches will

be in the open position.

Kenmore ELITE Radiant Free-Standing

Part Description Repair Part Number

6" Haliant Element WB30K5033

Bridge Element WB30T10088

9"Haliant Element WB30T10035

6"Haliant Element (Warmer) WB30T10042

Infinite Switch (Warmer) WB24T10012

Infinite Switch (Dual) WB24T10015

Infinite Switch-2600W WB24T10032

Infinite Switch-1500W WB24T10028

Oven Control WB27T10137

Oven Control-Stainless WB27T10144

Sensor WB23T10002

Glass Panel Asm-Black WB27T10160

Part Description Repair Part Number

Glass Panel Asm-White WB27T10155

Glass Panel Asm-Bisque WB27T10159

Glass Panel Asm-GPH/ SS WB27T10157

Glass MT ASM-Black WB62T10040

Glass MT ASM-Bisque WB62T10039

Glass MT ASM-White WB62T10038

Glass MT ASM-GPH WB62T10037

Bake Element -Hidden WB44T10015

Convection Element WB44T10001

Broil Element WB44T10008

Halogen Lamp WB08T10007

30" RADIANT FREE-STANDING CONVECTION RANGE

IMPORTANT SAFETY NOTICE: This information is intended for use by individuals

possessing adequate backgrounds of electrical, electronic and mechanical experience.

Any attempt to repair a major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the interpretation of this

information, nor can it assume any liability in connection with its use.

DISCONNECT POWER BEFORE SERVICING

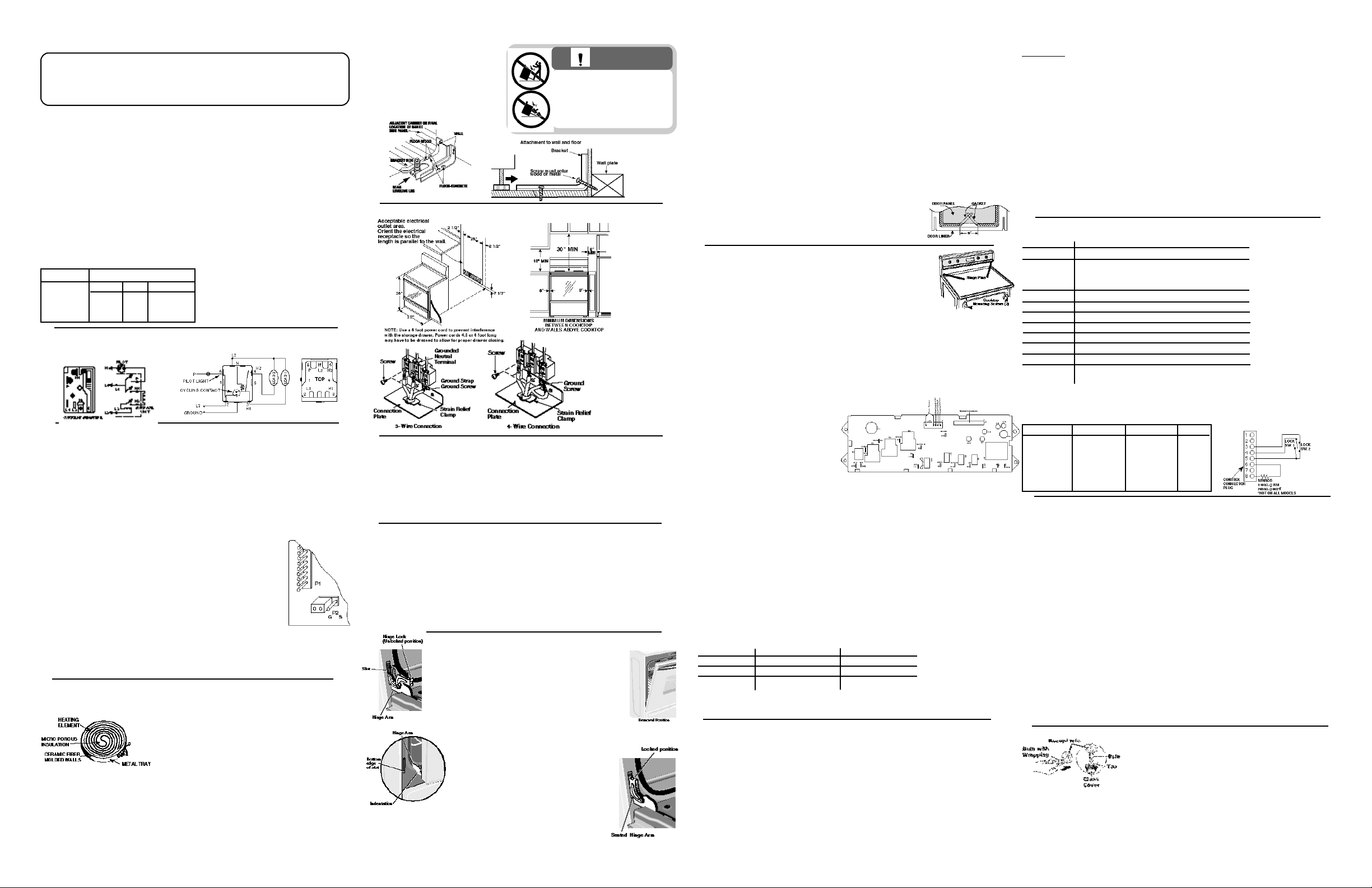

NOTE: Installation information for reference

only. See Installation Instructions shipped

with product for complete details and before

attempting to install.

Brackets should be attached to the floor or wall

to hold either right or left rear leg

leveler. Make sure leg leveler

reengages the bracket when range is moved

for any reason.

IMPORTANT: RECONNECT ALL GROUNDING DEVICES. All parts of this appliance capable

of conducting electrical current are grounded. If grounding wires, screws, straps, clips,

nuts, or washers used to complete a path to ground are removed for service, they must be

returned to their original position and properly fastened.

GROUNDING SPECIFICATIONS

Ground Path Resistance 0.10Ω Max.

Insulation Resistance 250KΩ Min.

INSTALLATION REQUIREMENTS

Power Supply: This appliance must be supplied with proper voltage and frequency, and

connected to an individual, properly grounded branch circuit, protected by a circuit

breaker or time delay fuse, as noted on rating plate. Wiring must conform to the National

Electrical Codes. The rating plate is located on the lower front frame behind the storage drawer.

Overcurrent Protection Ranges

NEC Rating Maximum Kilowatt Rating

35 Amp

40 Amp

50 Amp

208V

-

12.4

17.4

236V

12.4

15.4

21.4

240V

12.4

16.0

22.0

SURFACE UNIT SWITCHES

CURRENT SENSITIVE

CAUTION: This range connector block is

recognized for copper wire only, NOT

ALUMINUM WIRE. Refer to the installation

instructions for additional details.

SURFACE UNIT SWITCHES & CONTROLS

CONTROL TYPES:

Aluminum Wire

VOLTAGE SENSITIVE

GLASS CONTROL PANEL ASSEMBLY

The glass crystal assembly should only be removed when it needs to be replaced. All other

components, except infinite switches, are accessed from the back of the control panel assembly. The

infinite switches can be unscrewed from the front without removing the glass crystal assembly and

then removed from the back of the control panel assembly.

Replacing Infinite Switches

1. Turn the power off to the unit.

The Temperature Limit/Hot Light Switch performs two functions:

1. Keeps the Hot Light on until the glass surface above the heating unit has cooled below

2. Detects when glass temperature above a unit has exceeded its limit of approximately 1031°F

2. Remove knobs.

3. Unscrew 4 crystal retainer nuts. These must be hand tightened only.

4. Remove the two screws holding the infinite switch.

5. Remove control panel per instructions. ( ref. Section on Control Panel

Removal).

6. From the rear of the control panel assembly, unplug wires and remove

infinite switch.

7. Repeat steps in reverse order to reassemble the unit.

Removing Glass Crystal Assmbly

1. Turn the power off to the unit.

2. Remove all knobs.

3. Unscrew all crystal retainers while holding the glass crystal against the

control trim. The retainers must only be hand tightened.

Verify proper

location of jumper

P2 (on G)

The temperature limit/hot light switch cannot be calibrated.

The left front and right front element have two cooking zones:

• To use the large 9" cooking area or bridge, push to turn the control knob clockwise to desired

• To use the small 6" cooking area, push to turn the control knob counter clockwise to desired

When a cooking zone is activated, coils beneath the zone radiate heat through the glass cooktop

to the utensil. The red glow of the coils will be visible through the glass. It will take the cooking

zone on the glass surface a few moments to heat up. The coil cycles on and off to maintain your

selected control setting.

4. Move the glass crystal about 3 inches away from the control panel and unplug the harness

from the panel.

5. Repeat steps in reverse order to reassemble the unit.

NOTE: When the glass crystal assembly is removed for any reason, the crystal gaskets must be

replaced with new ones.

RADIANT HEATING ELEMENT SYSTEMS

Heating Elements: The radiant heating element consists of a spiral wound resistance wire attached

to micro porous insulation with molded ceramic fiber walls in a corrosion protected metal tray.

The Heating Elements come in 4 sizes:

• 6" - 240 Volt 1500 Watts

• 6"- 120 Volt 120 Watts (Note: The warmer will not glow

red like the cooking elements.)

• 9" - 240 Volt 2500 Watts (Dual Unit 6" & 9")

• Bridge - 240 Volt 2600 Watts

TEMPERATURE LIMIT/HOT LIGHT SWITCH

150°F. (After the heating element has been turned off.)

and disconnects power to that unit. When glass temperature cools below 1031°F, the unit will

turn back on.

setting.

setting.

To Remove:

1. Fully open the door.

2. Push the hinge locks down toward the door frame, to the

unlocked position. This may require a flat blade screwdriver.

3. Firmly grasp both sides of the door at the top.

4. Close door to the door removal position.

5. Lift door up until the hinge arm is clear of the slot.

HOT SURFACE INDICATOR LIGHT

The hot surface indicators are on turned by contacts within the heating element temperature

limiters. When glass temperature over a cooking element reaches 150°F, its hot surface indicator

light is activated to alert consumers that glass surface is too hot to touch. When the warmer element

is turned on, the hot surface indicator display is activated to alert consumers that the glass surface

may be hot. The surface indicators will remain activated until the glass surface temperature has

cooled below 150°F.

2. Fully open the door.

3. Push the hinge locks up against the front frame of the oven cavity, to

the locked position.

4. Close the oven door.

229C4059P244

• T E C H N I C A L D A T A S H E E T •

WARNING

• All ranges can tip

• Injury to persons could result

• Install anti-tip

device packed with range

• See Installation Instructions

MINIMUM CLEARANCES

*

*

NOTE: Effective

January 1, 1996, the

National Electrical

Code requires that new

or rewired

construction utilize a

4-conductor

connection to an

electric range.

DUAL CIRCUIT CONTROL

REMOVABLE OVEN DOOR

To Replace:

1. Firmly grasp both sides of the door at

the top, with the door at the same angle

as the removal position, seat the

indentation of the hinge arm into the

bottom edge of the hinge slot.

* RECOMMENDED

SPACING TO HEAT

SENSITIVE

SURFACES.

Cooling Air Flow Air enters the door assembly through large slots in the bottom and

flows upward between the inner and outer assemblies, exhausting through slots in the

top of the door. DO NOT INSULATE THIS AIR CHANNEL.

To Service Full Glass Door

1. Complete door assembly:

• Remove three screws from the bottom

door frame.

• Remove two screws at the top of the

door on the liner.

• The liner assembly and outer glass

panel assembly can now be separated.

2. Outer glass panel assembly:

• Remove four screws from the side posts at the bottom.

• Remove four screws from the side posts at the top

near the door vent trim.

• Slide the bottom trim and top vent trim out to free the

outer door glass. Note: On some doors the bottom

trim is sealed to the outer door glass and cannot be

separated.

3. Liner assembly:

• Remove three screws on each side of the door liner to remove the door hinge assembly.

• Remove four screws from the insulation retainer.

• Remove insulation retainer and then the insulation.

• The window pack and window gasket are now accessible, on units with a window door.

Door Gasket

The door gasket is clipped into the liner of the door panel.

To Service Gasket A 6" gap must be left in the gasket at bottom of door.

The gap is required to provide air flow in the oven for proper baking results.

COOKTOP REMOVAL

The cooktop is fastened to the front frame by two (2) screws. Remove the

2 screws and lift the back edge of cooktop upward (no more than 1 to 2

inches) to unhook the cooktop hinge from the backguard pins. Pull

forward. Unplug harness and unscrew ground wire located at rear of

cooktop. Lift cooktop off. NOTE: Raising cooktop too high can break the

glass.

Ceramic Glass Cooktop-

The ceramic glass is sealed into the COOKTOP and will

be supplied as a complete assembly.

CONTROL PANEL REMOVAL

The control panel contains the ERC, infinite heat switches and key pad/ glass assembly.

To Service:

1. Remove 2 screws (from bottom) securing control panel to the backguard.

2. Loosen 2 outside screws at the top, in the back of the range.

3. Pull bottom of panel out while lifting panel up.

4. Lay panel on cooking surface.

CAUTION: Place protective covering (such

as towel) between control panel and cooking

surface to avoid damage to control panel.

ERC

To Remove:

1. Turn the power off to the unit.

2. Slide the unit out so that the left side of the unit can be accessed freely.(When facing the range).

3. Remove cooktop per instructions in Cooktop Removal Section.

4. Remove three screws from the radiant brace.

5. Remove three screws from the back of the unit that attaches the side panel.

6. Remove one screw from the front of the unit that attaches the side panel.(Remove drawer to access.)

7. Lift the panel up and then out to remove.

8. Unplug the bake element.

9. Note the screw with the ground wire. Remove four screws attaching the side insulation retainer. Lift

the oven insulation up and push it under the radiant brace to hold out of the

10. Remove two screws and side to the element heater box.

11. Slide the hidden bake assembly out from the side.

To Replace:

1. Make sure you plug the wires back into the element and leads are placed back into the

tab in the retainer.

2.Reverse steps 1 through 11 above.

CONTROL VOLTAGE

Terminals

L1-N

L1A-BAKE

L1A-BROIL

L1A-CONV

L1-L2 *

L1A-N

IN-WM-N

COM-MDL

N- LIGHT

L1-OUT WM

L1 SURFACE

** L1-CF

OVEN SENSOR AND DOOR SWITCH OHMMETER TEST

Remove power from oven. Make resistance measurement from side of sensor & lock

switch connector with exposed terminals, disconnected from control.

CIRCUIT CONDITION TERMINALS OHMS

Oven Sensor Room Temp 6 to 8 1100Ω

Clean Temp 6 to 8 2650Ω

Unlatch Unlatched 3 to 5 0Ω

The Electronic Range Control system

consists of the control assembly, keypad/

Latch Latched 3 to 5 Open

glass assembly, oven sensor, door latch/ switch assembly.

Key Panel

The key panel is an electronic ( field disturbance) method using no moving parts. The circuit

board is conformally coated. It receives DC power from the ERC main control. It cannot be tested

separately from the control.

Voltage checks at the connector:

12 VDC from J1 pins 1 to 4.

12 VDC from J1 pins 1 to pins 16, 17, 18 when no keys are touched.

Key Panel Test

The keypad must have the designed minimum air clearance behind it to operate properly. A warped or

bent steel control panel could prevent some keys from operating. Depress each pad. The following

should occur:

• Bake, Broil, Convection Roast, Convection Bake, Clean, Kitchen Timer, Clock, Delay Start , Favorite

Recipe and Cook Time - Audible beep and display shows response corresponding to the key.

• Multi Stage- Press Bake, Cook Time, Up Min, Multi Stage. Display shows MULTI word.

• Warmer On/Off: Audible beep and display shows response.

• Warmer Power Level: Must press Warmer On/Off first. Select levels 1-3 as shown in display.

Power Level

1

2

3

•

Control Lockout- Audible beep. Hold 2 keys 5 seconds to activate. Hold 2 keys 5 seconds to deactivate.

Element off-time

4.6 sec

10.6 sec

7.2 sec

Element on-time

19 sec

13 sec

16.4 sec

• Clear/Off - Audible beep, display clears to time of day except for Kitchen Timer and Warming Zone.

The control has a section that can be entered to change how the control will work. To enter this

section: Press and hold BAKE and BROIL pads for 3 seconds and “SF” appears in display.

Select the area to change. When the change has been made, press START to return to Time of

Day.

• End of Cycle Tone - Press TIMER pad. *Display shows Con Beep when control is set for

Continuous End of Cycle Tone or Beep when set for Non-Continuous.

• °F or °C - Press Broil pad. *Display will show either F° or C°. Press Broil pad again to change.

• 12 hour, 24 hour, or blank out Time of Day Clock - Press Clock pad. *Display will show 12 hr,

24 hr, OFF for blank clock. Press again to change.

• Cook & Hold - used only with Time Bake or Delay Bake functions - Press Cooking Time pad.

*Display will show either HLd ON or HLd OFF. Press again to change.

• Child Lockout - Press CLEAN. *Display will show LOC ON (when any heating functions are

tried display will show OFF), press CLEAN again for LOC OFF, control unlocked.

• 12 hour shutdown comes set to shut down after 12 hours of continuous operations; this can be

eliminated - Press Delay Start pad. *Display will show no shdn. To turn back on, press Delay

Start pad again and display will show 12 shdn.

• Sales Mode, special feature added for sales floor demonstration - Press Clock & Timer pads at

the same time. *Display will start to cycle through the different modes of operation.

• Slew Rate- Press up or down to change slew.

• Use Temperature Offset- Press Bake Pad to change temperature offset.

• Surface warmer Shut Down Override- Press the Surface Warmer ON/OFF. Display shows No or

3:00 for three hour shut down.

BACKGUARD COMPONENT ACCESS

To access backguard component remove backguard assembly

1. Remove 2 screws (from bottom) securing control panel to the backguard.

2. Remove 2 screws at the top, in the back of the range.

3. Pull bottom of panel out while lifting panel up.

4. Lay panel on cooking surface.

CAUTION: Place protective covering (such as towel) between control panel and

cooking surface to avoid damage to control panel.

To replace Backguard assembly

1.Make sure 2 green ground leads are connecting outer infinite switches to mainback.

2. Reverse step 1 through 4 above.

To Replace

1. Wrap the bulb first. Push straight in, all the way. (Do not touch the bulb with fingers.)

2. Reverse steps 1 through 2 above.

3. Use only 120 volt and 35 watt Halogen Bulb.

HIDDEN BAKE HEATER ELEMENT

way.

VOLTAGE

120 VAC ALL THE TIME

240 VAC when oven is not calling for heat

(BAKE, CONV. & BROIL relay contacts open)

240 VAC all the time

120 VAC all the time

120 VAC when warmer is greater than 150°F

120 VAC when door is locking

120 VAC when oven light is not on

120 VAC when warmer is off

120 VAC when top light is off

120 VAC when oven door is closed and convection mode is

not operating

Oven Sensor/Lock Sw. Connector

4 to 5 Open

4 to 5 0Ω

NOTE: Temperature/

Mode Selection

Necessary for

operation of relay

contacts.

NOTE: Voltage must

be present across

terminals L1 to N for

control to operate.

* Voltage must be

present across

L1-L2 terminals

for warming zone

to operate.

SPECIAL FUNCTIONS

OVEN LIGHT REMOVAL

To Remove

1. Disconnect electrical power to the oven at the main circuit

breaker or fuse box.

2. Turn the glass cover counterclockwise 1/4 turn until the tabs

of the glass cover clear the grooves of the socket.

3. Pull straight out to remove the bulb.

Loading...

Loading...