Kenmore 665.61682101, 665.61683101, 665.61684101, 665.61689101 Instruction Sheet

TECH SHEET - DO NOT DISCARD PAGE 1

Models:

665.61682101

Electrical Shock Hazard

Disconnect power before servicing.

665.61683101

665.61684101

665.61689101

Replace all panels before operating.

Failure todo so can result in death orelectrical shock.

PRECAUTIONS TO BE OBSERVED BEFORE

AND DURING SERVICING TO AVOID POSSIBLE

EXPOSURE TO EXCESSIVE MICROWAVE ENERGY

a. Do not operate or allow the oven to be operated with the

door open.

b.

Make the following safety checks on all ovens to be

serviced before activating the magnetron or other

microwave source, and make repairs as necessary:

1. Interlock Operation

2. Proper Door Closing

3. Seal and Sealing Surfaces (Arcing,Wear & Other

Damage)

4. Damage to or Loosening ofHinges &Latches

5. Evidence of Dropping or Abuse

c. Before turning on microwave power for any service

test or inspection within the microwave generating

compartments, check the magnetron, waveguide or

POWER OUTPUT MEASUREMENT

The power output of the magnetron can be measured by

the following tap water temperature rise test:

✔

Be sure oven cavity is clean and cool (not used recently).

✔

Check the line voltage during this test. Low voltage will

lower the magnetron output.

1. Fill a glass beaker with 1000 ml (32 oz.) of tap water. Stir

the water with a thermometer (digital recommended) and

record the temperature. This starting temperature should

be between 10°C (50°F) to 24°C (75°F).

transmission line and cavity for proper alignment,

integrity and connections.

d. Any defective or misadjusted components in the

interlock, monitor, door seal, and microwave

generation, and transmission systems shall be

repaired, replaced, or adjusted by procedures

described in service manual before the oven is

released to the owner.

e. A microwave leakage check to verify compliance

with the Federal performance standard should

be performed on each oven prior to release to

the owner.

f. Do not attempt to operate the oven if the window

area of the door is broken.

2. Place the beaker in the center of the oven. Operate on

HIGH power level for 60 seconds.

3. When done, stir the thermometer through the water and

record the temperature.

4. Subtract the cold water temperature from the warm water

temperature to get the temperature rise. Normal range is

as shown in the following table:

Voltage

(VACunder load)

120V 11 - 14 19.8 - 25.2

108V 9.5 - 12.5 17.1 - 22.5

TemperatureRise

°C °F

FAILURE CODES/INDICATIONS

Display

Flashing

colon “:”

NOTE: If lights work, but cooling fan does not, 40W inverter may have failed. See “Checking Inverters” on page 11.

Likely Failure

Condition

Power Failure

-F2-

Keyboard Failure Replace membrane switch. If problem persists, replace control system assembly.

Humidity Sensor

-F3H-

-F3T-

-F7-

Failure

Temperature

Sensor Failure

1100W Inverter

Failure

After a power failure, the colon “:” will be flashing. Press any key to end this indication.

The colon will then be steady when in standby.

Connect a new sensor to the board (at P5). If no failure code appears when starting sensor

function, replace old sensor. Otherwise, replace control system assembly.

1. Check that the oven temperature is not below 5°C (41°F) or above 60°C (140°F).

2. If problem persists, replace the control system assembly.

1. Unplug the oven for at least 40 seconds. Check to see if this solves the problem.

(Possible reason: Over temperature protection for the magnetron operated earlier.)

2. Check the resistance of the magnetron thermostat. It should be close to 0 ohms.

3. Check wiring to the 1100W inverter and control system.

4. Replace 1100W inverter.

5. If problem persists, replace control system assembly.

Recommended Repair Procedure

FOR SERVICE TECHNICIAN'S USE ONLY PART NO. 4619-651-97964/8184640

PAGE 2 TECH SHEET - DO NOT DISCARD

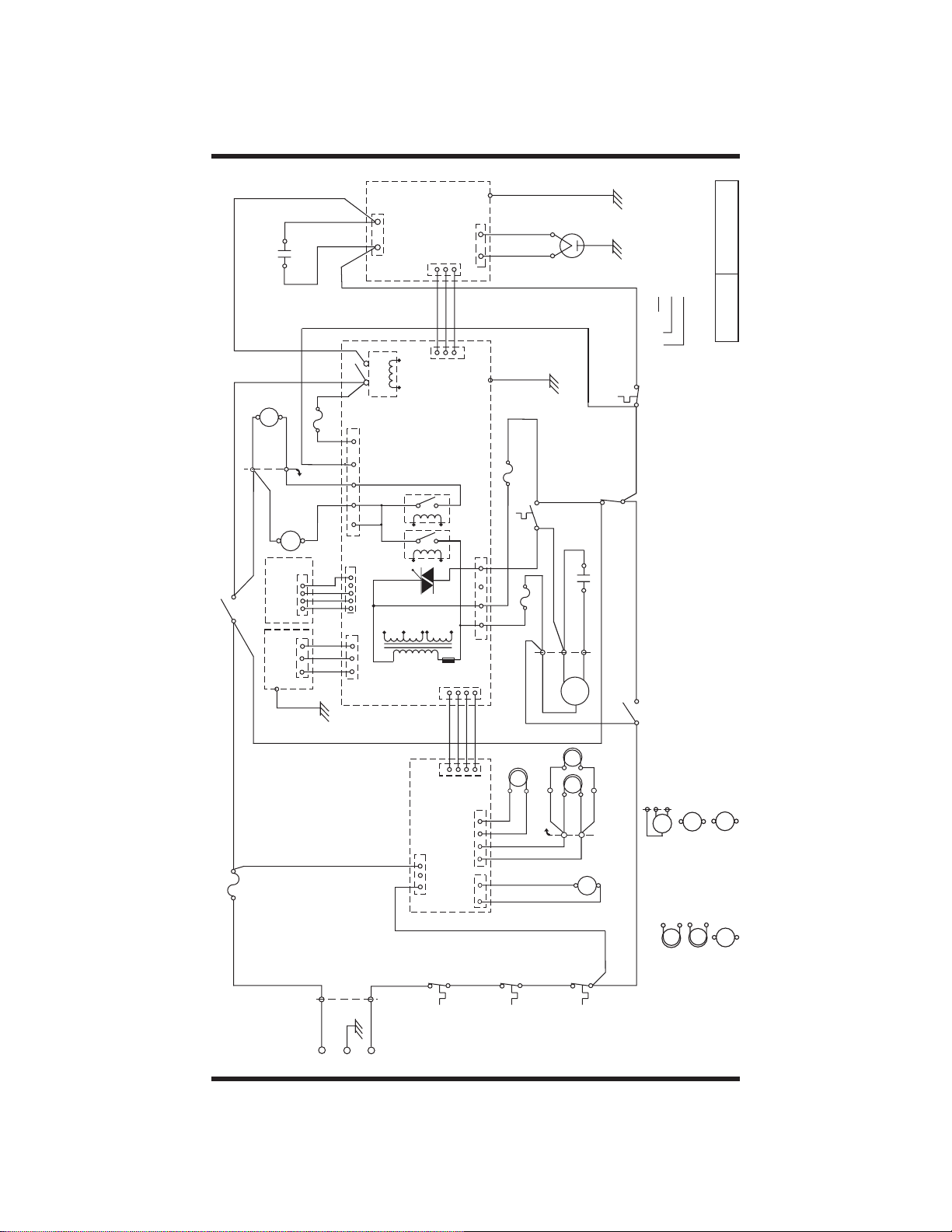

SCHEMATIC

DIAGRAM

37 R16

Filter Capacitor

TT

26 BL22

25 BL22

5P11

29 R16

28 W22

27 B22

External

Keyboard

Interlock

Secondary

8 OR16

FUSE

1 BR16

9 Y16

20 Amp.

Sensor

Humidity

43 Y/G18

38 R22

31 BL22

6P11

SM

7 R22

49 GR22

30 OR22

FUSE

53 OR22

34 R22

35 GR22

P7

1

B

120V / 60Hz

L

0.25 Amp.

47 26AWG/4C

BRW

2P0

50 GR16

P14

1

1

1

G

E

Door

NFS

TT

SM

CL

P7

P5

1P0

W

N

CN702

12

TR1-5101

19 BL22

2 BL16

1100W

4903

4906

4901

L.V.T.

INVERTER

1

46 26AWG/3C

MW Relay

DISPLAY PCB

7103

Sec.

Prim.

40W

1

CN1

Cavity

Thermostat-1

CN701

P2

& POWER PCB

1

45 26AWG/4C

1

INVERTER

1

P3

CN151

CN152

CN153

3 BL16

E701

CN703

GND

HF

HL

L1

1

N1

P12

1

1

41 Y/G18

40 W18

39 W18

42 Y/G18

11 BR22

4 Amp.

FUSE

52 BR22

FUSE

51 G22

17 B22

CL

P22

P22

21 W22

22 Y22

R24

B24

Cavity

Thermostat-2

MAGNETRON

Exhaust Fan

Thermostat

10 BR22

12 Y22

13 W22

14 W22

4 Amp.

16 G22

1P10

W20

B20

TR22

TR22

23 W22

4 BL16

31 BL22

15 R22

3P10

2P10

R20

HF

HL

Y22

HL

Y22

24 W22

2P11

1P11

CF

Cavity

Thermostat-3

Magnetron

Thermostat

Interlock

Motor Capacitor

9 Y16

WIRE SIZE - AWG16

WIRE COLOR - BROWN

WIRE NO. - 1

50 GR16

1 BR16

PINK

BROWN

ORANGE

GRAY

P:

BR:

OR:

GR:

32 BL16

WHITE

GREEN

YELLOW

Y:

G:

W:

TRANSPARENT

BLACK

BLUE

RED

B:

Monitor

33 W16

Primary

Interlock

18 BL16

R:

BL:

TR:

P0/P10/P11:

P2/P3/P5/P7/P12/P14/CN1/CN151/

HOOD EXHAUST

SYMBOL NOTES

WIRE TO WIRE CONNECTORS

CN152/CN153/CN701/CN702/CN703:

WIRE TO PCB CONNECTORS

FAN MOTOR

TURNTABLE

MOTOR

TT

HF

HOOD LAMP

(COOKTOP LAMP)

CAVITY LAMP

HL

CL

CONDITION:

DOOR OPEN

DWG. NO. MU-062 Rev.B

26AWG/3C(4C): RIBBON CABLE/3C(4C)

D.C. COOLING

FAN MOTOR

CF

STIRRER MOTOR

SM

PART NO. 4619-651-97964/8184640 FOR SERVICE TECHNICIAN'S USE ONLY

TECH SHEET - DO NOT DISCARD PAGE 3

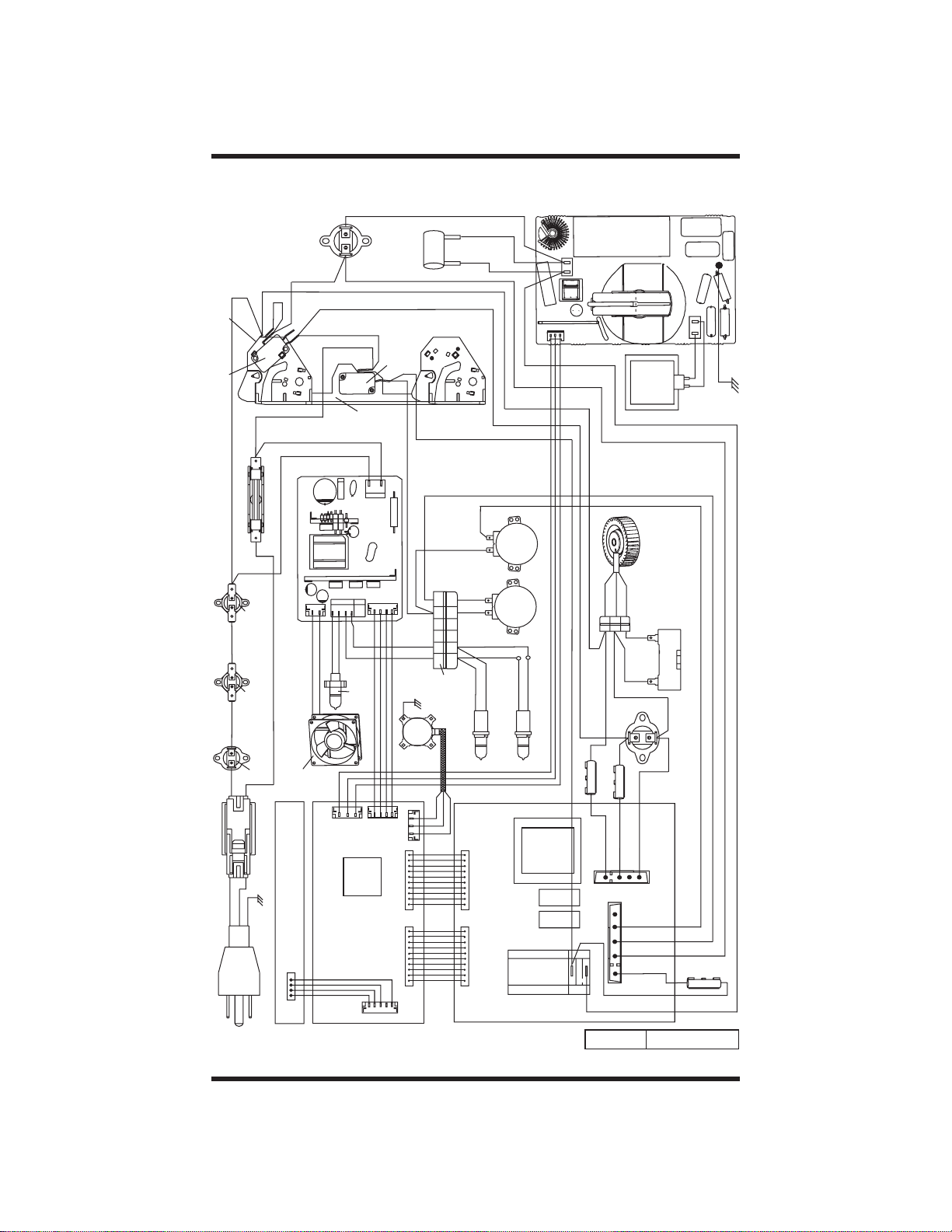

PICTORIAL DIAGRAM

GRAY

1

CN701

INVERTER

CN702

BLUE

BLACK

1100W

RED

MAGNETRON

CN703

WHITE

WHITE

Y/G

BLUE

INTERLOCK

PRIMARY SWITCH

INTERLOCK

MONITOR SWITCH

BLACK

ORANGE

WHITE

BLUE

RED

MAGNETRON

THERMOSTAT

BLUE BLUE

BROWN

YELLOW

ORANGE

INTERLOCK

SUPPORT

RED

BLUE

FILTER

CAPACITOR

INTERLOCK

SECONDARY

SWITCH

RED

WHITE

GRAY

RED

BLACK

BROWN

BLUE

RED

BLUE

BLUE

BLUE

BLUE

WHITE

FUSE & FUSE SADDLE

BLACK

BROWN

CAVITY

THERMOSTAT-3

CAVITY

THERMOSTAT-2

CAVITY

TWO POLES

GREEN

BROWN

THERMOSTAT-1

CONNECTOR

POWER CORD

BLUE

DC COOLING

EXTERNAL KEYBOARD

P7

40W INVERTER

1

CN153

FAN MOTOR

1

RED

CN152

1

PINK

WHITE

PINK

YELLOW

BLACK

CAVITY LAMP

CAVITY LAMP &

1

P2

MCU

DISPLAY PCB

RIBBON CABLE/4C

P7

CN1

CN151

1

HOLDER

RIBBON CABLE/4C

1

RIBBON CABLE/3C

L.V.T.

MW

4903

TR1 -5101

4901

4906

RELAY

RED

RED

BROWN

BROWN

FUSE &

FUSE SADDLE

2

RED

BLACK

1

BLACK

1

1

GREEN

FUSE &

FUSE SADDLE

GREEN

1

P14

ORANGE

WHITE

2

2

WHITE

WHITE

BROWN

BROWN

1

RED

3

3

RED

P12

ORANGE

HOOD EXHAUST

THREE POLES

CONNECTOR

YELLOW

FAN MOTOR

MOTOR

WHITE

GRAY

CAPACITOR

THERMOSTAT

EXHAUST FAN

GRAY

RED

BLUE

FUSE &

FUSE SADDLE

RED

BLUE

RED

RED

1

GRAY

P3

BLACK

WHITE

YELLOW

WHITE

Y/G

HUMIDITY

SENSOR

1

P5

P21

BLACK

RED

6

5

4

123

SIX POLES

CONNECTOR

BLACK

RED

WHITE

6

5

4

123

BLUE

BLUE

TRANSPARENT

STIRRER

TURNTABLE

WHITE

WHITE

YELLOW

TRANSPARENT

HOLDERS

HOOD LAMP

HOOD LAMPS &

RIBBON CABLE/3C

P21

MOTOR

MOTOR

YELLOW

POWER PCB

P11

1

P11

DWG. NO. L-M1-052 Rev. A

FOR SERVICE TECHNICIAN'S USE ONLY PART NO. 4619-651-97964/8184640

PAGE 4 TECH SHEET - DO NOT DISCARD

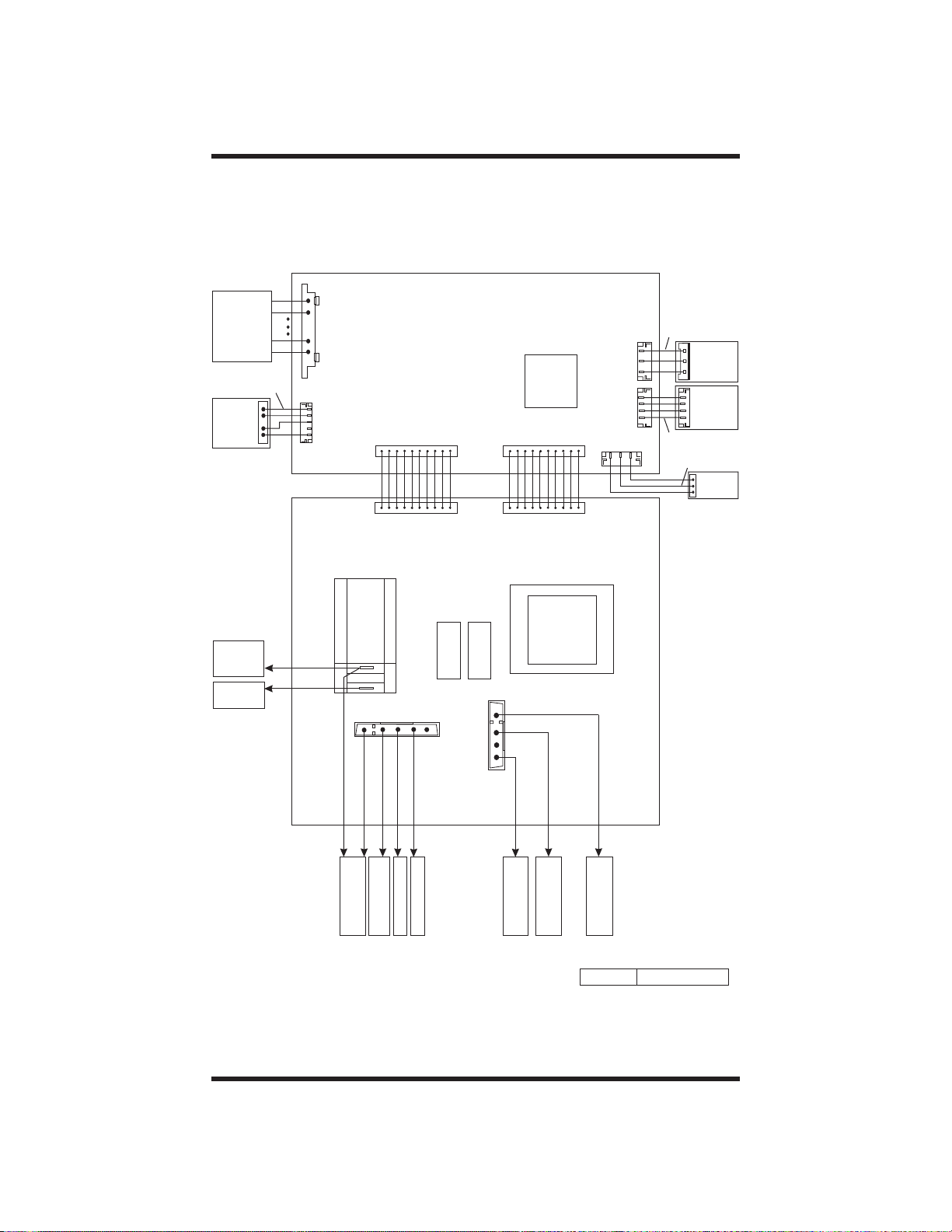

PICTORIAL DIAGRAM

Touch Panel

(Membrane

Switch)

Ribbon

Cable/4C

P7

External

Keyboard

Interlock

Secondary

Switch

1100W

Inverter

DISPLAY PCB

P6

1

MCU

P7

1

1

P11 P21

P5

P11 P21

Ribbon

Cable/3C

1

P2

1

P3

1

1

Ribbon

Cable/4C

Red

Black

White

CN701

1

CN151

Humidity

1100W

Inverter

40W

Inverter

Sensor

POWER PCB

Red

Red

4903

MW

RELAY

1

4906

4901

2

1

1

P14

P12

L.V.T.

TR1 -5101

Blue

Red

TT Motor

Magnetron

Thermostat

Gray

Stirrer Motor

Yellow

Thermostat

Exhaust fan

Brown

Fuse

4Amp.

Green

Fuse

4Amp.

Orange

Fuse

Orange

0.25 Amp.

DWG. No. L-M1-054 Rev. A

PART NO. 4619-651-97964/8184640 FOR SERVICE TECHNICIAN'S USE ONLY

Loading...

Loading...