TECH SHEET - DO NOT DISCARD PAGE 1

Models:

665.61682101

Electrical Shock Hazard

Disconnect power before servicing.

665.61683101

665.61684101

665.61689101

Replace all panels before operating.

Failure todo so can result in death orelectrical shock.

PRECAUTIONS TO BE OBSERVED BEFORE

AND DURING SERVICING TO AVOID POSSIBLE

EXPOSURE TO EXCESSIVE MICROWAVE ENERGY

a. Do not operate or allow the oven to be operated with the

door open.

b.

Make the following safety checks on all ovens to be

serviced before activating the magnetron or other

microwave source, and make repairs as necessary:

1. Interlock Operation

2. Proper Door Closing

3. Seal and Sealing Surfaces (Arcing,Wear & Other

Damage)

4. Damage to or Loosening ofHinges &Latches

5. Evidence of Dropping or Abuse

c. Before turning on microwave power for any service

test or inspection within the microwave generating

compartments, check the magnetron, waveguide or

POWER OUTPUT MEASUREMENT

The power output of the magnetron can be measured by

the following tap water temperature rise test:

✔

Be sure oven cavity is clean and cool (not used recently).

✔

Check the line voltage during this test. Low voltage will

lower the magnetron output.

1. Fill a glass beaker with 1000 ml (32 oz.) of tap water. Stir

the water with a thermometer (digital recommended) and

record the temperature. This starting temperature should

be between 10°C (50°F) to 24°C (75°F).

transmission line and cavity for proper alignment,

integrity and connections.

d. Any defective or misadjusted components in the

interlock, monitor, door seal, and microwave

generation, and transmission systems shall be

repaired, replaced, or adjusted by procedures

described in service manual before the oven is

released to the owner.

e. A microwave leakage check to verify compliance

with the Federal performance standard should

be performed on each oven prior to release to

the owner.

f. Do not attempt to operate the oven if the window

area of the door is broken.

2. Place the beaker in the center of the oven. Operate on

HIGH power level for 60 seconds.

3. When done, stir the thermometer through the water and

record the temperature.

4. Subtract the cold water temperature from the warm water

temperature to get the temperature rise. Normal range is

as shown in the following table:

Voltage

(VACunder load)

120V 11 - 14 19.8 - 25.2

108V 9.5 - 12.5 17.1 - 22.5

TemperatureRise

°C °F

FAILURE CODES/INDICATIONS

Display

Flashing

colon “:”

NOTE: If lights work, but cooling fan does not, 40W inverter may have failed. See “Checking Inverters” on page 11.

Likely Failure

Condition

Power Failure

-F2-

Keyboard Failure Replace membrane switch. If problem persists, replace control system assembly.

Humidity Sensor

-F3H-

-F3T-

-F7-

Failure

Temperature

Sensor Failure

1100W Inverter

Failure

After a power failure, the colon “:” will be flashing. Press any key to end this indication.

The colon will then be steady when in standby.

Connect a new sensor to the board (at P5). If no failure code appears when starting sensor

function, replace old sensor. Otherwise, replace control system assembly.

1. Check that the oven temperature is not below 5°C (41°F) or above 60°C (140°F).

2. If problem persists, replace the control system assembly.

1. Unplug the oven for at least 40 seconds. Check to see if this solves the problem.

(Possible reason: Over temperature protection for the magnetron operated earlier.)

2. Check the resistance of the magnetron thermostat. It should be close to 0 ohms.

3. Check wiring to the 1100W inverter and control system.

4. Replace 1100W inverter.

5. If problem persists, replace control system assembly.

Recommended Repair Procedure

FOR SERVICE TECHNICIAN'S USE ONLY PART NO. 4619-651-97964/8184640

PAGE 2 TECH SHEET - DO NOT DISCARD

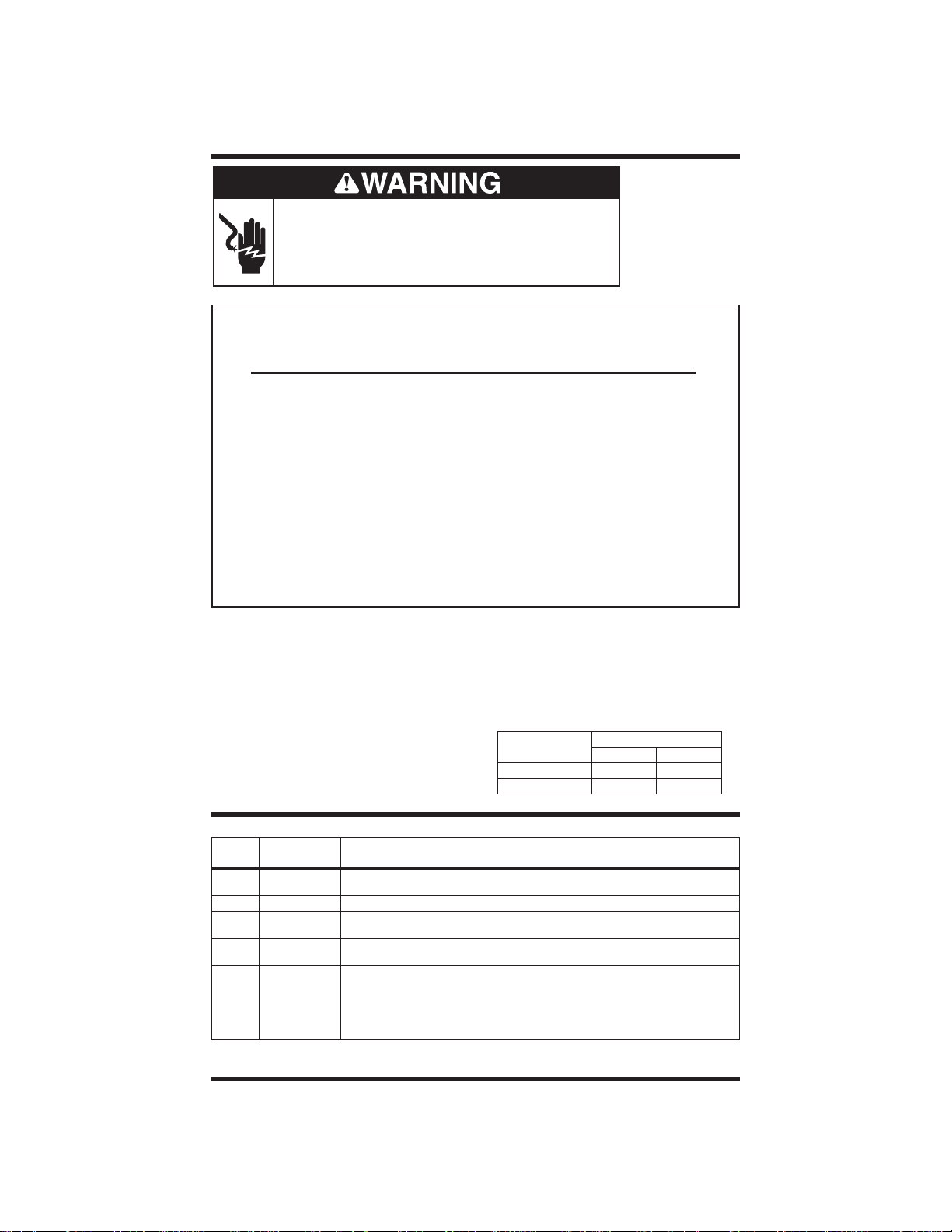

SCHEMATIC

DIAGRAM

37 R16

Filter Capacitor

TT

26 BL22

25 BL22

5P11

29 R16

28 W22

27 B22

External

Keyboard

Interlock

Secondary

8 OR16

FUSE

1 BR16

9 Y16

20 Amp.

Sensor

Humidity

43 Y/G18

38 R22

31 BL22

6P11

SM

7 R22

49 GR22

30 OR22

FUSE

53 OR22

34 R22

35 GR22

P7

1

B

120V / 60Hz

L

0.25 Amp.

47 26AWG/4C

BRW

2P0

50 GR16

P14

1

1

1

G

E

Door

NFS

TT

SM

CL

P7

P5

1P0

W

N

CN702

12

TR1-5101

19 BL22

2 BL16

1100W

4903

4906

4901

L.V.T.

INVERTER

1

46 26AWG/3C

MW Relay

DISPLAY PCB

7103

Sec.

Prim.

40W

1

CN1

Cavity

Thermostat-1

CN701

P2

& POWER PCB

1

45 26AWG/4C

1

INVERTER

1

P3

CN151

CN152

CN153

3 BL16

E701

CN703

GND

HF

HL

L1

1

N1

P12

1

1

41 Y/G18

40 W18

39 W18

42 Y/G18

11 BR22

4 Amp.

FUSE

52 BR22

FUSE

51 G22

17 B22

CL

P22

P22

21 W22

22 Y22

R24

B24

Cavity

Thermostat-2

MAGNETRON

Exhaust Fan

Thermostat

10 BR22

12 Y22

13 W22

14 W22

4 Amp.

16 G22

1P10

W20

B20

TR22

TR22

23 W22

4 BL16

31 BL22

15 R22

3P10

2P10

R20

HF

HL

Y22

HL

Y22

24 W22

2P11

1P11

CF

Cavity

Thermostat-3

Magnetron

Thermostat

Interlock

Motor Capacitor

9 Y16

WIRE SIZE - AWG16

WIRE COLOR - BROWN

WIRE NO. - 1

50 GR16

1 BR16

PINK

BROWN

ORANGE

GRAY

P:

BR:

OR:

GR:

32 BL16

WHITE

GREEN

YELLOW

Y:

G:

W:

TRANSPARENT

BLACK

BLUE

RED

B:

Monitor

33 W16

Primary

Interlock

18 BL16

R:

BL:

TR:

P0/P10/P11:

P2/P3/P5/P7/P12/P14/CN1/CN151/

HOOD EXHAUST

SYMBOL NOTES

WIRE TO WIRE CONNECTORS

CN152/CN153/CN701/CN702/CN703:

WIRE TO PCB CONNECTORS

FAN MOTOR

TURNTABLE

MOTOR

TT

HF

HOOD LAMP

(COOKTOP LAMP)

CAVITY LAMP

HL

CL

CONDITION:

DOOR OPEN

DWG. NO. MU-062 Rev.B

26AWG/3C(4C): RIBBON CABLE/3C(4C)

D.C. COOLING

FAN MOTOR

CF

STIRRER MOTOR

SM

PART NO. 4619-651-97964/8184640 FOR SERVICE TECHNICIAN'S USE ONLY

TECH SHEET - DO NOT DISCARD PAGE 3

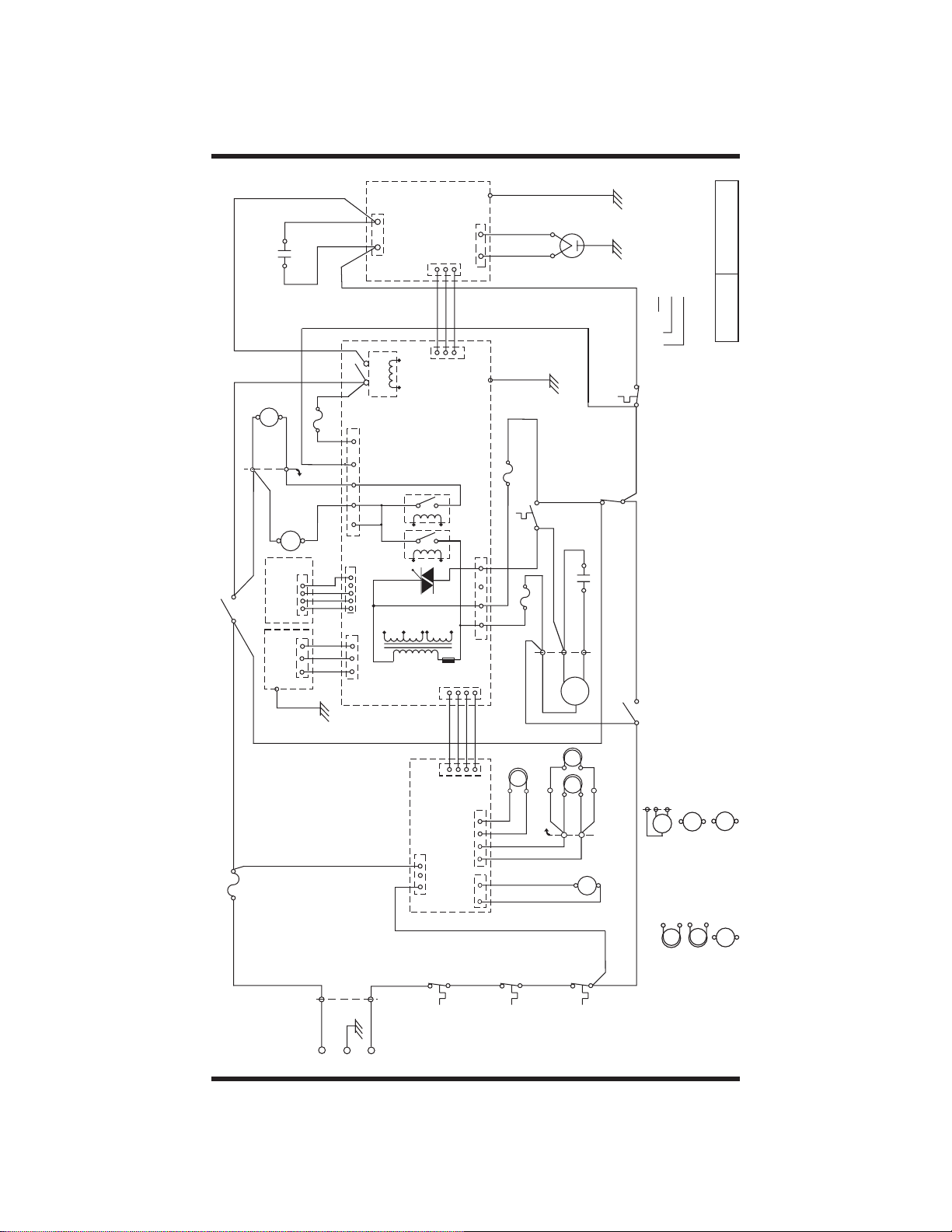

PICTORIAL DIAGRAM

GRAY

1

CN701

INVERTER

CN702

BLUE

BLACK

1100W

RED

MAGNETRON

CN703

WHITE

WHITE

Y/G

BLUE

INTERLOCK

PRIMARY SWITCH

INTERLOCK

MONITOR SWITCH

BLACK

ORANGE

WHITE

BLUE

RED

MAGNETRON

THERMOSTAT

BLUE BLUE

BROWN

YELLOW

ORANGE

INTERLOCK

SUPPORT

RED

BLUE

FILTER

CAPACITOR

INTERLOCK

SECONDARY

SWITCH

RED

WHITE

GRAY

RED

BLACK

BROWN

BLUE

RED

BLUE

BLUE

BLUE

BLUE

WHITE

FUSE & FUSE SADDLE

BLACK

BROWN

CAVITY

THERMOSTAT-3

CAVITY

THERMOSTAT-2

CAVITY

TWO POLES

GREEN

BROWN

THERMOSTAT-1

CONNECTOR

POWER CORD

BLUE

DC COOLING

EXTERNAL KEYBOARD

P7

40W INVERTER

1

CN153

FAN MOTOR

1

RED

CN152

1

PINK

WHITE

PINK

YELLOW

BLACK

CAVITY LAMP

CAVITY LAMP &

1

P2

MCU

DISPLAY PCB

RIBBON CABLE/4C

P7

CN1

CN151

1

HOLDER

RIBBON CABLE/4C

1

RIBBON CABLE/3C

L.V.T.

MW

4903

TR1 -5101

4901

4906

RELAY

RED

RED

BROWN

BROWN

FUSE &

FUSE SADDLE

2

RED

BLACK

1

BLACK

1

1

GREEN

FUSE &

FUSE SADDLE

GREEN

1

P14

ORANGE

WHITE

2

2

WHITE

WHITE

BROWN

BROWN

1

RED

3

3

RED

P12

ORANGE

HOOD EXHAUST

THREE POLES

CONNECTOR

YELLOW

FAN MOTOR

MOTOR

WHITE

GRAY

CAPACITOR

THERMOSTAT

EXHAUST FAN

GRAY

RED

BLUE

FUSE &

FUSE SADDLE

RED

BLUE

RED

RED

1

GRAY

P3

BLACK

WHITE

YELLOW

WHITE

Y/G

HUMIDITY

SENSOR

1

P5

P21

BLACK

RED

6

5

4

123

SIX POLES

CONNECTOR

BLACK

RED

WHITE

6

5

4

123

BLUE

BLUE

TRANSPARENT

STIRRER

TURNTABLE

WHITE

WHITE

YELLOW

TRANSPARENT

HOLDERS

HOOD LAMP

HOOD LAMPS &

RIBBON CABLE/3C

P21

MOTOR

MOTOR

YELLOW

POWER PCB

P11

1

P11

DWG. NO. L-M1-052 Rev. A

FOR SERVICE TECHNICIAN'S USE ONLY PART NO. 4619-651-97964/8184640

PAGE 4 TECH SHEET - DO NOT DISCARD

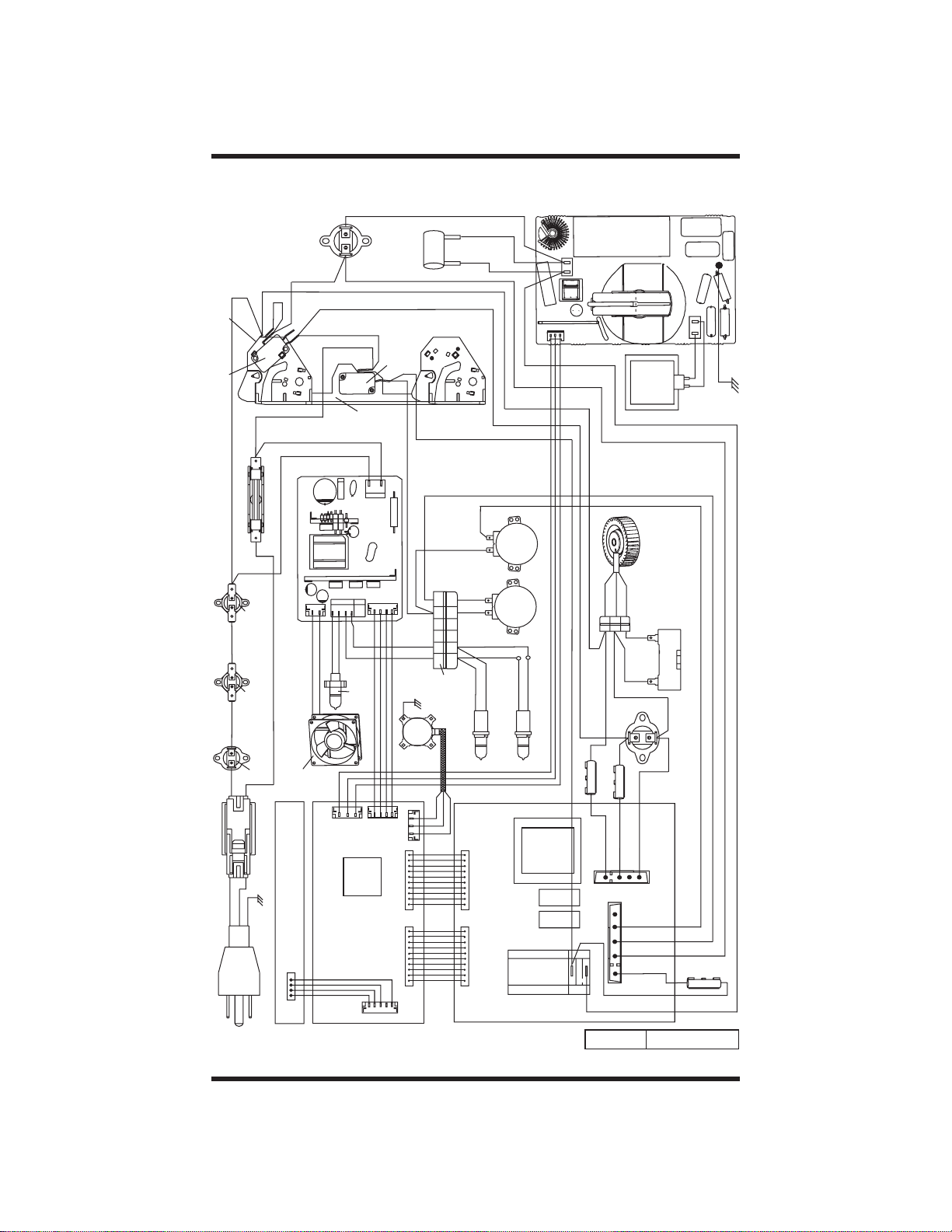

PICTORIAL DIAGRAM

Touch Panel

(Membrane

Switch)

Ribbon

Cable/4C

P7

External

Keyboard

Interlock

Secondary

Switch

1100W

Inverter

DISPLAY PCB

P6

1

MCU

P7

1

1

P11 P21

P5

P11 P21

Ribbon

Cable/3C

1

P2

1

P3

1

1

Ribbon

Cable/4C

Red

Black

White

CN701

1

CN151

Humidity

1100W

Inverter

40W

Inverter

Sensor

POWER PCB

Red

Red

4903

MW

RELAY

1

4906

4901

2

1

1

P14

P12

L.V.T.

TR1 -5101

Blue

Red

TT Motor

Magnetron

Thermostat

Gray

Stirrer Motor

Yellow

Thermostat

Exhaust fan

Brown

Fuse

4Amp.

Green

Fuse

4Amp.

Orange

Fuse

Orange

0.25 Amp.

DWG. No. L-M1-054 Rev. A

PART NO. 4619-651-97964/8184640 FOR SERVICE TECHNICIAN'S USE ONLY

TECH SHEET - DO NOT DISCARD PAGE 5

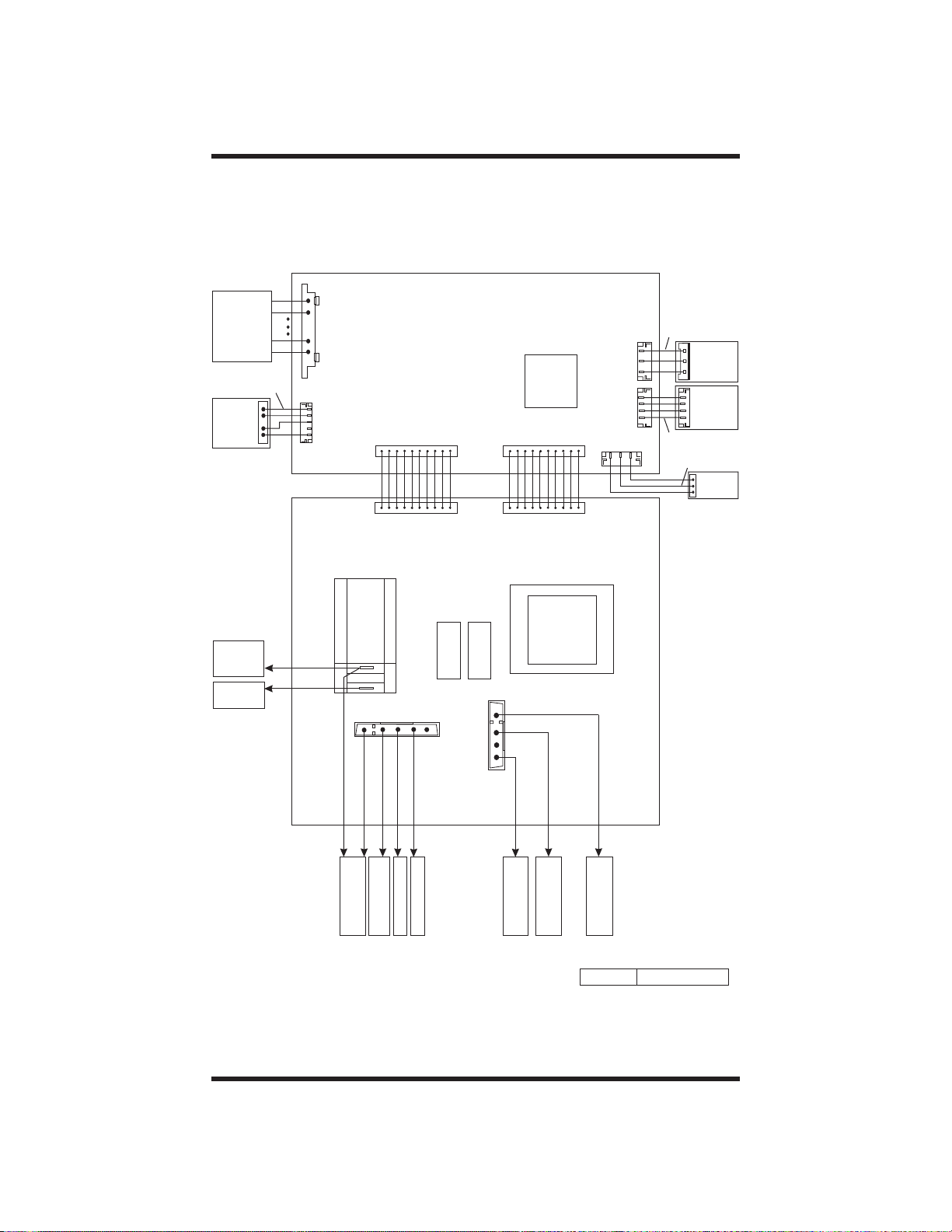

PART S LAYOUT

Not to Scale

Cavity

Thermostat 1

Opens at 165°C (329°F)

Closes at-35°C (-31°F)

(8183999)

Cavity Lamp

(8169418)

Turntable Motor

(4393755)

Hood (Cooktop)

Lamp

(8169418)

Primary Interlock

Switch

(4393599)

Monitor Interlock Switch

(4393697)

Secondary Interlock Switch

(4393599)

Control System Assembly

(Microcomputer)

(8184030)

Membrane Switch/

Control Panel/

Display Lens

(WT 8184228)

(BK 8184231)

(BI 8184230)

(SS 8184229)

Humidity Sensor

(4393808)

Hood (Cooktop)

Stirrer Fan Motor

Lamp

(8169418)

Fuse (0.25 Amp.)

(4393746)

(8184580)

Cavity Thermostat 2

Assembly

Opens at 125°C (257°F)

Closes at-35°C (-31°F)

(8184585)

Filter Capacitor

Fuse (4 Amp.)

(8184579)

Exhaust Fan Thermostat

(8184093)

Opens at 40°C (104°F)

Closes at60°C(140°F)

Hood (Exhaust)

Fan Motor (8183992)

Motor Capacitor

(8184092)

Cavity Thermostat 3

Assembly

Opens at 125°C (257°F)

Closes at -35°C (-31°F)

(8184586)

Magnetron

(8183990)

Magnetron

Thermostat

Opens at 145°C (293°F)

Closes at 105°C (221°F)

(8183994)

Fuse Holder

(4393538)

Line Fuse

(4393308)

110 0W I nverter

(8183997)

40W Inverter

(8184090)

12V Cooling Fan

Motor (8183995)

(8183998)

PRIMARY, MONITOR, AND SECONDARY SWITCH CHECKOUT PROCEDURE

Switch Check By

Primary

Interlock

Secondary

Interlock

1. Disconnect the wires at the Primary Interlock Switch.

2. Check from the common terminal (Blue/Black wires)

to the normally open terminal (White wire).

1. Disconnect the wires at the Secondary Interlock Switch.

2. Check from the common terminal (Orange/Yellow wires)

to the normally open terminal (White/Red wires).

Door

Open

−

−

Door

Closed

+

+

1. Disconnect the wires at the Monitor Switch.

Monitor

2. Check from the common terminal (White/Blue wires)

+

−

to the normally closed terminal (Yellow/Brown wires).

(+) Continuity (–) No Continuity

NOTE: These diagrams are not intended to show a complete circuit; they represent the position

of switches during “DOOR OPEN” and “DOOR CLOSED” (continuity checks only).

DOOR CLOSED

LN

(NC) (NO) (NC)

(NO) (NC) (NO)

SECONDARY

INTERLOCK

SWITCH

MONITOR

SWITCH

PRIMARY

INTERLOCK

SWITCH

FOR SERVICE TECHNICIAN'S USE ONLY PART NO. 4619-651-97964/8184640

DOOR OPEN

LN

(NC) (NO) (NC)

(NO) (NC) (NO)

SECONDARY

INTERLOCK

SWITCH

MONITOR

SWITCH

PRIMARY

INTERLOCK

SWITCH

PAGE 6 TECH SHEET - DO NOT DISCARD

TOUCH PANEL CONTINUITY

DIAGRAM

Example of use: When BEVERAGE is

selected, a resistance of less than 200 ohms

will be observed between 10 and 3 on the flex

circuit connector. See diagram below.

PIN #

7

8

9

10

11

12

13

14

15

16

17

18

1

2

3456

AUTO

DINNER

PLATE

BEVERAGE

FRESH

VEGETABLE

HOLD

WARM

ADD ONE

MINUTE

1

4

COOK

AUTO

REHEAT

FROZEN

VEGETABLE

BREAD

DEFROST

SOFTEN

CLOCK

KITCHEN

2

7

POPCORN

SOUP

MELT

TIMER

5

8

0

TURNTABLE

COOK

TIME

ESD GROUND PLANE

ON/OFF

START

ENTER

ULTRA

DEFROST

FROZEN

ENTREE

BAKED

POTATO

SURE

SIMMER

POWER

OFF

CANCEL

3

6

9

TOUCH PANEL AND

MICROCOMPUTER BOARD TEST

The microwave hood combination is

provided with a self-diagnostic routine that

can be accessed through the touch key

pad. To initiate this routine:

1. Depress the OFF/CANCEL button while

opening the door, and while still

depressing the OFF/CANCEL button,

unplug the microwave oven for two

seconds and plug it back in.

2. Release the OFF/CANCEL button and

then close the door.

3. Now, by pressing each button on the

control panel, “8” will appear in the

display to indicate that the circuits are

complete and all relays are working.

Refer to “Key Table for Test Mode” at

right.

NOTE: If the OFF/CANCEL button is

pressed during this diagnostic routine, you

will exit the test mode.

18 PIN FLEX CIRCUIT CONNECTOR

15 16

18

17 18

1

1234 56 78

91

11 12 13 14

0

KEY TABLE FOR TEST MODE

NOTE: Display position 1 is farthest to the right;

display position 5 is farthest to the left.

Key Name Function

Display

Position*

DINNER PLATE – 5

AUTO REHEAT – 4

AUTO COOK Humidity Sensor ♦

POPCORN – 1

BEVERAGE – 5

ULTRA DEFROST – 4

BREAD DEFROST – 2

SOUP – 1

FROZEN ENTREE – 5

FROZEN VEGETABLE – 4

FRESH VEGETABLE – 2

BAKED POTATO – 1

HOLD WARM – 5

SOFTEN – 4

MELT – 2

SURE SIMMER – 1

ADD ONE MINUTE – 5

(CLOCK) Buzzer 3

KITCHEN TIMER – 1

1 Relay 4901 5

2–3

3 Relay 4903 1

4–5

5–3

6 Relay 4906 1

7–5

8–3

9 Hood Fan Triac 1

COOK TIME – 5

0–3

POWER – 1

TURNTABLE ON/OFF – 5

START/ENTER – 3

(FAN) ON/OFF – 5

(FAN) 5 SPEEDS – 3

(LIGHT)

HIGH/MED/NIGHT/OFF

–1

OFF/CANCEL Exit Test Mode –

* “8” will appear in the display position indicated

in the table.

♦ Eight seconds after pressing AUTO COOK,

“Hmxxx” will appear in the display.

PART NO. 4619-651-97964/8184640 FOR SERVICE TECHNICIAN'S USE ONLY

TECH SHEET - DO NOT DISCARD PAGE 7

TROUBLESHOOTING GUIDE

Complete the following steps before checking

microwave circuitry:

1. Check the line voltage, household fuses or

circuit breakers.

2. Check for loose wiring or miswiring within

microwave.

3. Disconnect white wire from power

transformer and discharge high-voltage

capacitor.

4. All testing must be done with an

ohmmeter having a sensitivity of 20,000

ohms per volt or greater, and powered by

at least a 9-volt battery.

5. All operational checks using microwave

energy must be done with the microwave

oven loaded with a minimum of 300 ml

(10 oz.) of water in a microwave safe

container.

MICROWAVE COOKING

MICROCOMPUTER BOARD

LOW VOLTA GE

TRANSFORMER

BR

BL

P

P

GR

OR

OR

2P12

R

4P14

1P14

TTM RELAY

3P14

DOOR RELAY

MW RELAY

2

1

2

P3

3

DISPLAY PCB

4

POWER PCB

CAVITY LAMP

TR1-5101

4906

4901

4903

&

1P12

2P14

CAPACITOR

R

1

3

1

2

2

P2

3

1

RIBBON CABLE/3C

BL

G

BL

FILTER

RGR

CN702

1100W

INVERTER

CN701

FUSE

4 Amp.

MAGNETRON

THERMOSTAT

GR

CN703

G

BL

W

W

MAGNETRON

B

W

INTERLOCK

PRIMARY

SWITCH

CAVITY

THERMOSTAT

3

BL

BL

CAVITY

THERMOSTAT

BL BL

CAVITY

THERMOSTAT

1

BL

2

W

L1

INTERLOCK

SECONDARY

BR

B

SWITCH

FUSE

20 Amp.

BL

R

Y

OR

1

2

INVERTER

FUSE

4 Amp.

BR

BR

TURNTABLE MOTOR

2.7-3.8K

BL

STIRRER MOTOR

3.3-4.2K

B

FUSE

0.25 Amp.

W

R

1

2

3

4

CN1

1

2

40W

CN153 CN151

1

2

CN152

RIBBON

CABLE/4C

R

D.C. COOLING

FAN MOTOR

B

N

BLOWER FAN TURNS ON AUTOMATICALLY

L1

FUSE

20 Amp.

BBR BROR

EXHAUST FAN

THERMOSTAT

Y

CAPACITOR

WW

W

R

MOTOR

HOOD EXHAUST

FAN MOTOR

R

BB

CAVITY

THERMOSTAT

BL

3

BL

CAVITY

THERMOSTAT

2

CAVITY

THERMOSTAT

1

BL

BL

BLOWER FAN ON (VARIABLE SPEED)

MICROCOMPUTER BOARD

POWER PCB

LOW VOLTAGE

TRANSFORMER

TR1-5101

FUSE

L1

20 Amp.

B

OR

BR

FUSE

4Amp.

Y

BR

BR

BR

2P12

1P12

TRIAC

4P12

7103

B: Black W: White BR: Brown

BL: Blue G: Green OR: Orange

R: Red Y: Yellow GR: Gray

TR: Transparent P: Pink

FOR SERVICE TECHNICIAN'S USE ONLY PART NO. 4619-651-97964/8184640

G

YW

W

R

MOTOR

CAPACITOR

FUSE

4 Amp.

HOOD EXHAUST

FAN M OTOR

W

R

G

CAVITY

THERMOSTAT

3

BL

B

B

BL

THERMOSTAT

CAVITY

2

CAVITY

THERMOSTAT

1

BL

BL

W

N

W

N

PAGE 8 TECH SHEET - DO NOT DISCARD

MICROWAVE PLUGGED IN - TIME OF DAY DISPLAYED

MICROCOMPUTER BOARD

L1

BBR

FUSE

20 Amp.

OR

FUSE

4 Amp.

Y

BR

BR

BR

2P12

DOOR OPEN - CAVITY LAMP IS ON

MICROCOMPUTER BOARD

FUSE

L1

20 Amp.

BBR BR

OR

R

FUSE

4 Amp.

Y

BR

BR

2P12

TRANSFORMER

DISPLAY PCB

&POWER PCB

POWER PCB

LOW VOLTAGE

TRANSFORMER

TR1-5101

LOW VOLTAGE

TR1-5101

CAVITY

LAMP

1P12

1P12

P3

CABLE/4C

1

2

3

4

RIBBON

P

P

R

G

G

1

2

3

4

1

2

FUSE

4 Amp.

FUSE

4 Amp.

G

G

CN151

40W

INVERTER

CN152

CN1

2

1

B

B

CAVITY

THERMOSTAT

3

BL

CAVITY

THERMOSTAT

BL

BL

BL

3

CAVITY

THERMOSTAT

2

BL

CAVITY

THERMOSTAT

2

CAVITY

THERMOSTAT

1

BL

CAVITY

THERMOSTAT

1

BL

N

W

BL

N

BL

W

COOKTOP LAMP ON (VARIABLE LIGHT)

L1

FUSE

20 Amp.

OR

BBR BR

Y

R

BR

FUSE

4 Amp.

BR

2P12

HOOD LAMPS

(COOKTOP LAMPS)

MICROCOMPUTER BOARD

LOW VOLTAGE

TRANSFORMER

TR1-5101

DISPLAY PCB

&POWER PCB

TR

Y

1P12

W

TR

Y

W

1

2

P3

3

4

RIBBON

CABLE/4C

W

Y

G

1

2

3

4

3

4

R

FUSE

4 Amp.

CN151

40W

INVERTER

CN152

CN1

1

G

2

B

BL

CAVITY

THERMOSTAT

3

BL

BL

THERMOSTAT

B: Black W: White BR: Brown

BL: Blue G: Green OR: Orange

R: Red Y: Yellow GR: Gray

TR: Transparent P: Pink

PART NO. 4619-651-97964/8184640 FOR SERVICE TECHNICIAN'S USE ONLY

CAVITY

2

CAVITY

THERMOSTAT

1

BL

BL

N

W

TECH SHEET - DO NOT DISCARD PAGE 9

COMPONENT TESTS

Remove the lead wires from the related

component before conducting any of the

following tests.

All operational checks using microwave

energy must be done with the microwave

oven loaded with a minimum of 300 ml

(10 oz.) of water in a microwave safe

Conduct a microwave energy test after

performing any tests or repairs to the

microwave.

Check that all wire leads are in the

correct position before operating the

microwave oven.

Grasp wire connectors when removing

the wire leads from microwave parts.

container.

COMPONENT / TEST RESULTS

Magnetron

1. Remove wire leads. Check

that the seal is in good

condition.

2. Measure resistance

(ohmmeter scale: Rx1):

Filament terminal - - Normal: Less than 1 ohm

3. Measure resistance

(ohmmeter scale: Rx1000):

Filament to chassis - - Normal: Infinite

D.C. Cooling Fan Motor

1. Remove wire leads.

2. Using an external 9 or

12 DC voltage source,

connect to fan wires:

red wire to ‘+’ and black

Black

Red

wire to ‘–’.

- Fan should work. If not,

replace fan.

Turntable Motor/

Stirrer Motor

1. Remove wire leads.

2. Measure resistance

Digital

Meter

(ohmmeter scale:

Rx1000): Turntable Motor

- Normal: 2700-3800 ohms

(approx.)

COM

- Abnormal: Infinite

Stirrer Motor

- Normal: 3300-4200 ohms

(approx.)

- Abnormal: Infinite

Hood Exhaust Fan

Motor

1. Remove wire leads.

2. Measure resistance

(ohmmeter scale: Rx1): - Normal:

Black - White: 30 - 60 ohms

(approx.)

White

Red

Black - Red: 40 - 80 ohms

(approx.)

- Abnormal: Infinite

Black

FOR SERVICE TECHNICIAN'S USE ONLY PART NO. 4619-651-97964/8184640

PAGE 10 TECH SHEET - DO NOT DISCARD

COMPONENT / TEST RESULTS

Humidity Sensor

White

Red

Black

Resistor

3

2

1

1. Remove the 3-pin connector from PCBA (P5).

Note: Do not remove the attached resistor which is used

for internal resistance calibration.

2. Measure resistance across pins1&3

(ohmmeter scale:Rx1K): - Normal: 2.8K ohms (approx.)

at 25°±10°C (77°±18°F)

- Abnormal: Infinite

3. Measure resistance across pins2&3

(ohmmeter scale:Rx1K): - Normal: 2.8K ohms (approx.)

at 25°±10°C (77°±18°F)

- Abnormal: Infinite

Thermostats

Note: Refer to Parts Layout on page 5 for opening and

closing temperatures.

Cavity

Thermostat

1. Remove wire leads.

2. Cavity and Magnetron

Thermostats:

Measure continuity

(ohmmeter scale: Rx1): - Normal: Continuity

Magnetron

Thermostat

- Abnormal: Infinite

3. Exhaust Fan Thermostat:

Exhaust Fan

Thermostat

Measure continuity

(ohmmeter scale: Rx1): - Normal: Infinite

- Abnormal: Continuity

PART NO. 4619-651-97964/8184640 FOR SERVICE TECHNICIAN'S USE ONLY

TECH SHEET - DO NOT DISCARD PAGE 11

CHECKING INVERTERS

Measure Oven Input Current

Connect an ampmeter to measure the input

current of microwave oven when the power

level is set to Level 10 at the touch panel:

If more than 0.5A, the 1100W inverter

■

is probably okay. Check the magnetron

using test on page 9, and wiring.

If less than 0.5A, there is no input to the 1100W inverter.

■

Check for the following:

No AC voltage supply. Check Control System Assembly PCB and wiring.

–

No control signal. Check Control System Assembly PCB and wiring.

–

15A

Amps

Checking the 1100W Inverter

Note: Do not try to repair the

inverter board, nor try to make

any adjustments to the board.

Check wiring to 1100W

inverter:

120V AC

1. Unplug the oven’s main

power supply.

2. Visually inspect 4 connectors

CN701

on the 1100W inverter board:

CN701, CN702, CN703, E701

to see whether there are any

signs of failure due to loose

wires, bad crimping, signs of

overheating, etc.

Checking the 40W Inverter

Note: Do not try to repair the inverter

board, nor try to make any adjustments

to the board.

Check wiring to 40W

inverter:

1. Unplug the oven’s

main power supply.

2. Visually inspect 4

120V Mains

Input

connectors on the

40W inverter board:

CN1, CN151, CN152,

CN153 to see whether

there are any signs of

failure due to loose wires,

bad crimping, signs of overheating, etc.

CN702

Heat Sink

Control Signal

In/Out

CN1 CN152 CN151

Heat Sink

CN153

CN703

Control Signal Input

12V Halogen Lamps

and Cavity Lamps Output

12V Cooling Fan Output

E701

High Voltage

Output to

Magnetron

FOR SERVICE TECHNICIAN'S USE ONLY PART NO. 4619-651-97964/8184640

PAGE 12 TECH SHEET - DO NOT DISCARD

This page is intentionally blank.

PART NO. 4619-651-97964/8184640 FOR SERVICE TECHNICIAN'S USE ONLY

Loading...

Loading...