Page 1

OWNER’S

MANUAL

MODEL NOS.

625.3485400

Super Capacity Genius

625.3485500

Super Capacity Genius

Caution:

Read and Follow

All Safety Rules and

Operating Instructions

Before First Use of

This Product.

W ater Softeners

u Warranty

u Start Up / Setting Timer

If you have questions when

installing, operatingor maintaining your softener, and

when setting the timer, call

this toll--free number...

1--800--426--9345

SAVE THIS MANUAL

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

PRINTED IN U.S.A.

u How It Works

u Care Of

u Specifications

u Repair Parts

Use plastic bag and tie provided, to hang manuals nearby

the softener for future reference.

Page 2

WARRANTY

SEARS RESIDENTIAL WATER SOFTENER

FULL TEN YEAR WARRANTY AGAINST LEAKS

Fortenyearsfromthedate ofpurchase,Searswillfurnishand installanewcurrentmodelwater

softener tank or salt storage drum, free of charge, if either the tank or drum develop a leak.

FULL THREE YEAR ELECTRONICS W ARRANTY

For a period of three years from date of purchase, Sears will replace the BRINE TANK LIGHT,

ELECTRONICBOARD, SENSOR HOUSING,WIRING HARNESS, TRANSFORMER,MICRO

SWITCH, DRIVE MOTOR, OR POWER CABLE, should they be defective in material or workmanship.

FULL ONE YEAR WARRANTY ON WATER SOFTENER

For one year from the date of purchase, when this water softener is installed and maintained

in accordance with our instructions, Sears will repair, free of charge, all other parts which may

be defective in material or workmanship.

TO OBTAIN W ARRANTY SERVICE, SIMPLY CONTACT THE NEAREST SEARS SERVICE

CENTERTHROUGHOUTTHEUNITEDSTATES.Thiswarrantyappliesonlywhilethisproduct

is in use in the United States.

This warranty gives you specific legal rights, and you may have other rights which vary from

state to state.

Sears, Roebuck and Co., D/817 WA, Hoffman Estates, IL 60179

Ifyou want yourwater softener professionallyinstalled,talk to yourSears Salesman. Hewillarrange

for a prompt, quality installation by Sears Authorized Installers.

SEARS INSTALLATION POLICY

All installation labor arranged by Sears shall be

performed in a neat, workmanlike manner in

accordance with generally accepted trade practices. Further,all installations shall comply with

all local laws, codes, regulations, and ordinances.Customershall alsobeprotected,during

installation, by insurance relating to Property

Damage, Workman’s Compensation and Public

SEARS INSTALLATION WARRANTY

In addition to any warranty extended to you on

the Sears merchandiseinvolved, which warrantybecomes effective the datethe merchandise in

installed, should the workmanship of any Sears

arranged installation prove faulty within one

year, Sears will, upon notice from you, cause

suchfaultstobecorrectedatnoadditionalcostto

you.

Liability.

FACTS AND FIGURES TO KEEP

Fill in the blanks below and keep this book in a safe

place so you always have these facts.

Water Softener Model No.†

Serial Number

Date Installed

Water Hardness Grains Per Gallon

Iron Content Parts Per Million

*pH Taste And/Or Odor

Water Pressure Pounds/Square Inch

Water Flow Rate Gallons Per Minute

† The model number is on the rating decal, located

on the rim, under the salt hole cover.

2

Page 3

TABLE OF CONTENTS

PAGE

NO.

SECTION 1 SOFTENER START UP

A. SAFETY GUIDES 4

B. CHECK LIST OF STEP-BY-STEP GUIDES TO INSTALL 5

C. PROGRAM THE TIMER 6-7

D. SANITIZING THE WATER SOFTENER 8

E. FILL THE STORAGE TANK WITH SALT 9

SECTION 2 HOW YOUR WATER SOFTENER WORKS

A. FACE PLATE TIMER FEATURES 10-11

B. SOFT WATER SERVICE AND REGENERA TION 12-14

SECTION 3 CARE OF YOUR SOFTENER

A. SALT: REFILLING STORAGE TANK, SALT BRIDGE 15

B. KEEPING THE WATER SOFTENER CLEAN 16

C. KEEP THE SOFTENER FROM FREEZING 17

D. HELPFUL HINTS CHECKLIST 18

SECTION 4 OTHER THINGS TO KNOW

A. DIMENSIONS/SPECIFICATIONS 19

SECTION 5 SERVICE TECH INFORMATION

A. TROUBLESHOOTING 20-23

D. ROTARY V ALVE SERVICE 24

E. WATER FLOW THROUGH THE SOFTENER VALVE 25-27

SECTION 6 REPAIR PARTS 28-31

3

Page 4

SECTION 1

1A. SAFETY GUIDES

WATER SOFTENER START-UP

s Read all steps, guides and rules carefully before installing and using yournew water softener.

Follow all steps exactly to correctly install. Failure to follow them could cause personal injury or

property damage. Reading this book will also

help you to get all of the benefits from your water

softener .

s Your water softener will remove hardness minerals and “clear water” iron from water, up to the

limits shown on page 19. It will not remove other

types of iron, acids, tastes and odors, etc. It will

not purify polluted water or make it safe to drink.

s Protect the softener and piping from freezing.

Damage from freezing voids the softener warran ty. See page 17.

CAUTIONS

PLEASEREADANDCOMPLYWITH THE FOLLOWING GUIDES TO PREVENT DAMAGE TO

THE SOFTENER OR OTHER PROPERTY,

PERSONAL INJURY, OR POSSIBLE FATAL

SHOCK.

s THIS SOFTENER WORKS ON 24 VOLTS

ONLY.BESURE TOUSE THETRANSFORMER

INCLUDED, AND PLUG IT INTO A 120V OUT LET.

s Unplug the transformer right away if the

power cable sould become damaged or

frayed. Make repairs before plugging back

into the power outlet.

s Always unplug the softener from electrical

power before removing outer valve covers.

4

Page 5

SECTION 1

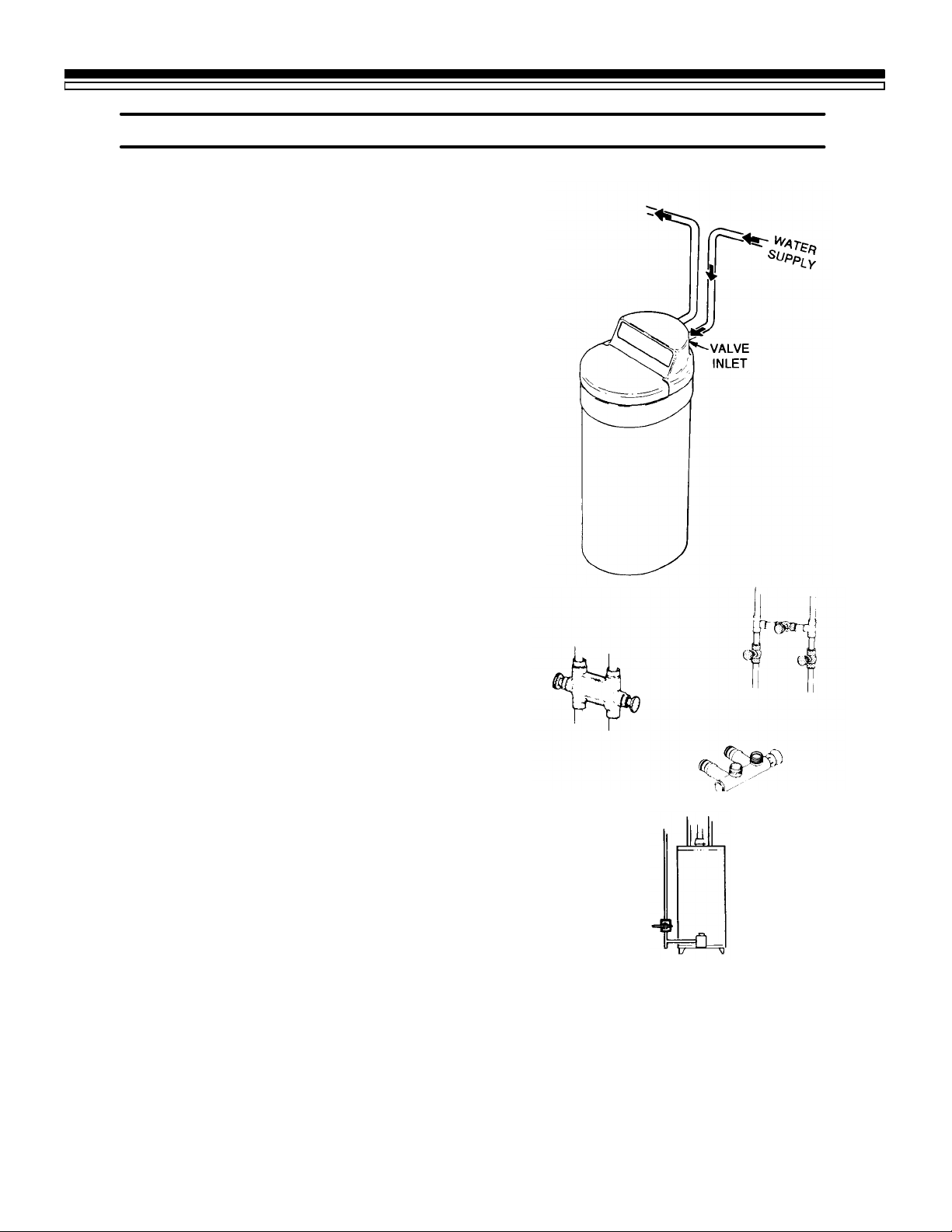

1B. CHECK LIST OF ALL STEP-BY-STEP GUIDES TO INSTALL

Refer to the Installation Manual, part no.

7141417, for step-by-step guides.

To be sure you have done all the steps to install

the softener, read the following list. Page numbers referred to are in the Installation Manual.

4 Is the house water flow going INTO the soft-

ener valve INLET? Trace piping to be sure.

See pages 10 and 11.

4 Is the plumbing bypassvalve(or3valves)set

for SERVICE? See FIG. 12, page 19 of this

manual.

WATER SOFTENER START-UP

4 Is the valve drain hose connected the right

way, and without sharp bends or kinks that

couldstoporreducewaterflow?Seepage16.

4 Is the softener power cable connected to the

transformer?Is the transformer pluggedinto

an inside, 120V-60Hz electrical outlet? See

page 20.

4 Be sure to restart the water heater. See page

20.

3--valve

brass

plastic

5

Page 6

SECTION 1

1C. PROGRAM THE TIMER

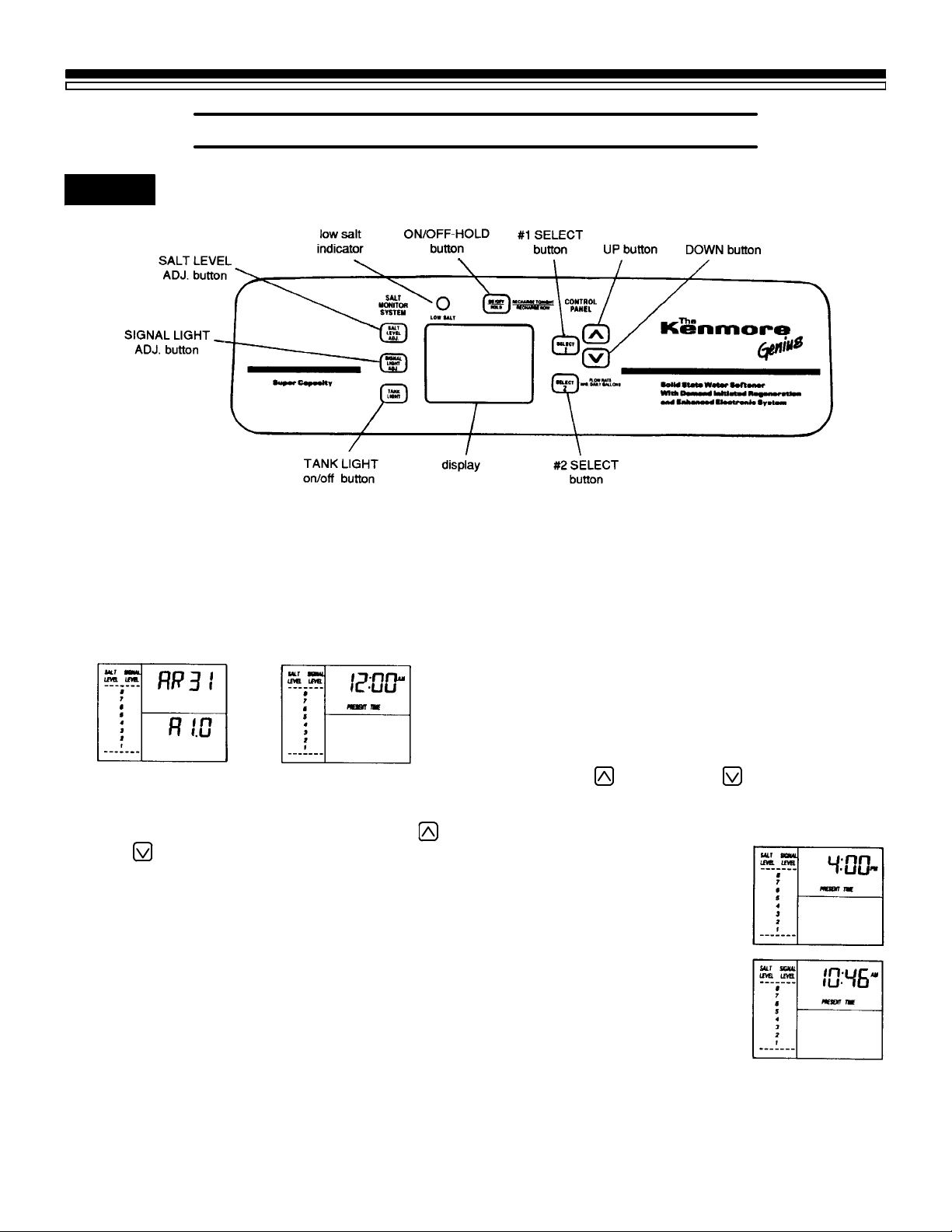

FIG. 1

WATER SOFTENER START-UP

When the transformer is plugged in, the model

code AR31, and a test number (example: A1.0)

show in the face plate display for 4 seconds.

Then, 12:00 AM and PRESENT TIME begin to

flash.

NOTE:

If AR-- shows in the display, press the UP or

DOWN button until AR31 shows. Then, press

the #1 SELECT button to set, and change to the

flashing PRESENT TIME display.

Tocheckthemodelcode,unplugthetransformer

atthewalloutletandpluginagain.ifotherthan

AR31 shows, see page 18 to reset.

repeatedlywhen the display reaches 1 using the

DOWN button, or the highest hardness setting

using the UP button.

1. SET PRESENT TIME OF DAY:

NOTE:

If the words¼PRESENT TIME do not show

in the display, press the #1 SELECT button

(FIG. 1) until they do, or see the notes above.

n Press the UP/DOWN buttons to set the

present time. Press UP to move the display

ahead;pressDOWNtomovethetimebackward.

If the present time is between

noonandmidnight,besurePM

shows.

If the present time is between

midnight and noon, be sure

AM shows.

SOUND “BEEPER”: A “beeper” sounds while

pressing buttons for timer set-up. One beep

signals a change in the face plate display.

Repeated beeps mean the timer will not accept a

changefromthebuttonyouhavepressed,telling

you to use another button. For example, while

setting the hardness (step 2), the beeper sounds

NOTE:

Each press of the UP/DOWN

buttons changes the time by 1

minute.Holding the buttonsin

changes the time 32 minutes

each second.

6

Page 7

SECTION 1

1C. PROGRAM THE TIMER

WATER SOFTENER START-UP

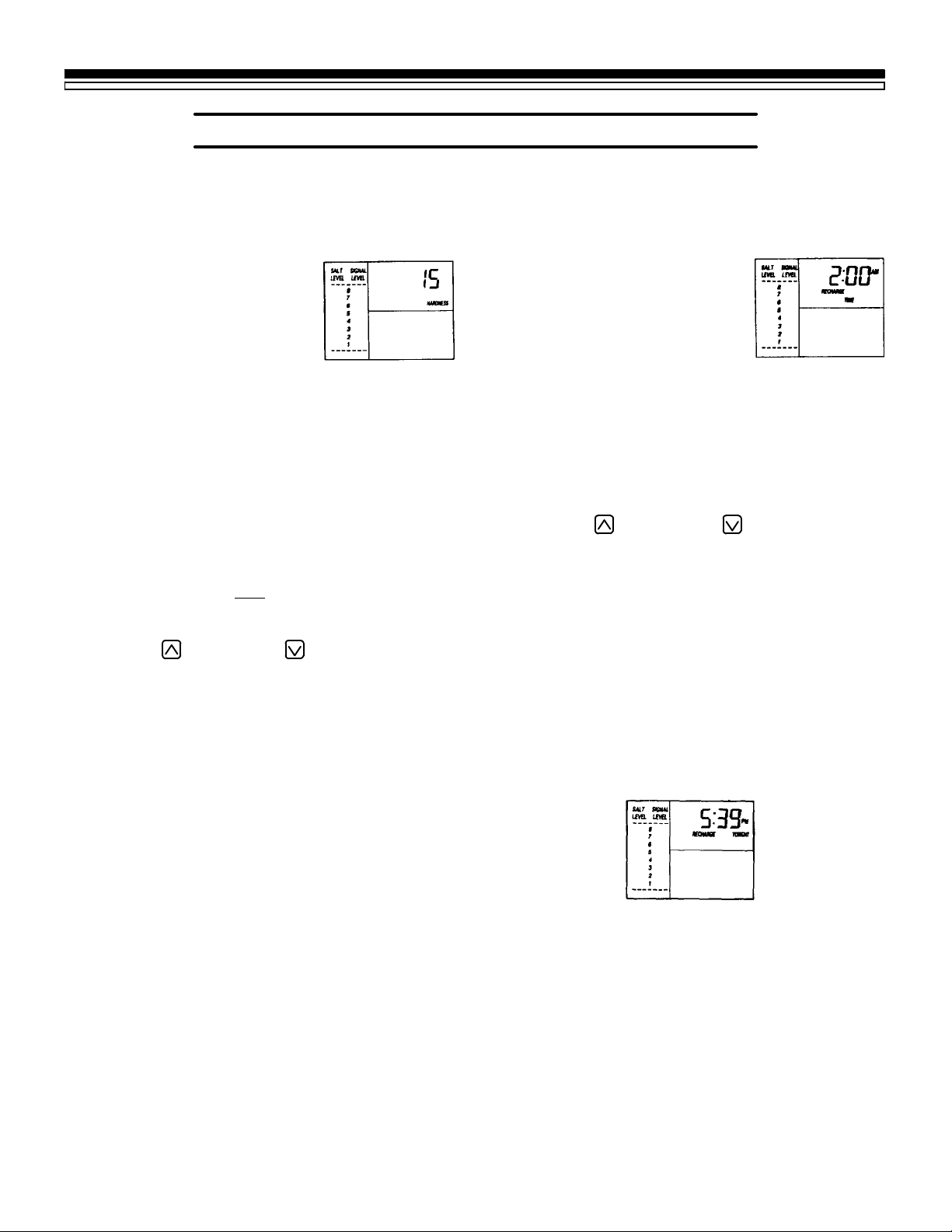

2. SET WATER HARDNESS NUMBER:

n Press the #1 SELECT button once to

display 15 (flashing) and HARDNESS.

The grains per gallon (gpg)

hardness of your water supply is on your water analysis

report. Be sure to enter water

test results on page 2, for

future reference.

NOTE:

If your water supply contains iron, compensate

for it by adding to the water hardness number.

For example, assume your water is 15 gpg hard and

contains2ppmiron.Add5tothehardnessnumberfor

each1 ppm ofiron.In this example,youwould use 25

for your hardness number.

15 gpg hardness

2 ppm iron x 5 = 10 +10

(times) 25 HARDNESS NUMBER

n Press the UP/DOWN buttons to set your

water hardness number in the display. The

DOWN button moves the display to 1. The UP

button moves the display to the highest setting

(see maximum setting for your model in the

specifications).

NOTE:

3. SETRECHARGE(REGENERATION)TIME:

n Pressthe #1 SELECT button to display 2:00

AM (flashing) and RECHARGE TIME.

At the 2:00 AM RECHARGE

TIME setting, the softener begins regeneration (see pages

12 and 13) at 2:00 AM, ending

nolaterthan4:00AM.Thisisa

goodtimein mosthouseholds

because water is not being

used (see AUTOMATIC BYPASS, page 14). If a different

RECHARGE TIME setting

would be better for your

household, do the following.

n Press the UP/DOWN buttons to set the

desired RECHARGE starting hour. Be sure to

observethe AM-PMasyou did whensetting the

present time of day.

NOTE:

Each press of the UP/DOWN buttons changes

the display 1 hour. Holding the buttons in

changes the display twice each second.

n Press the #1 SELECT button once again, to

return the present time, and RECHARGE TONIGHT in the display.

EachpressoftheUP/DOWNbuttonchangesthe

display by 1 between 1 and 25. Between 25 and

the highest number, the display changes 5 at a

time¼25, 30, 35, etc. Holding the UP or DOWN

buttoninchangesthedisplaytwiceeachsecond.

IF YOU NEED HELP PROGRAMMING THE TIMER, CALL TOLL FREE, NUMBER

1-800-426-9345.

SEE PAGES 10 AND 11 FOR OTHER FACE PLATE TIMER FEATURES.

7

Page 8

SECTION 1

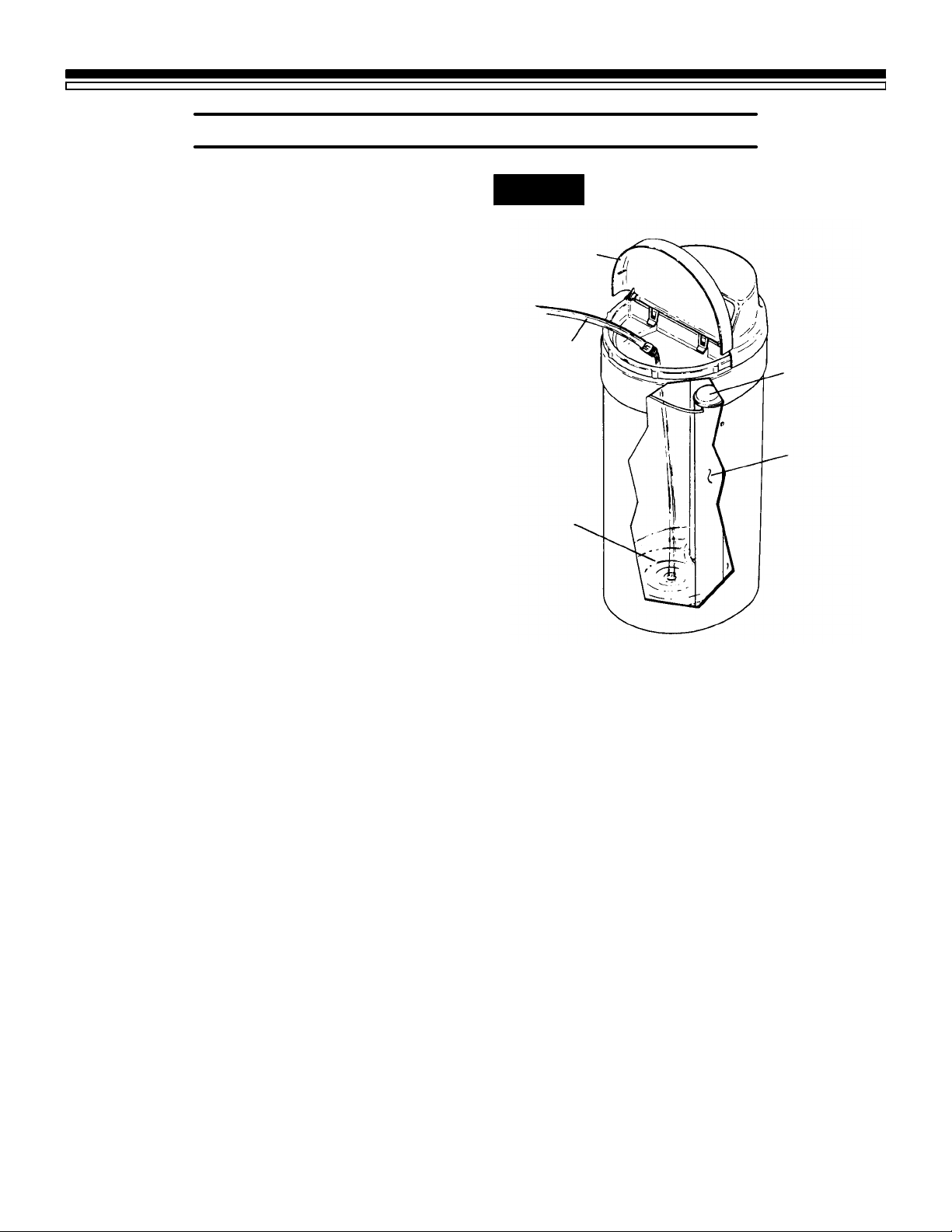

1D. SANITIZING THE WATER SOFTENER

WATER SOFTENER START-UP

Care is taken at the factory to keep your water

softener clean and sanitary. Materials used to

make the softener will not infect or contaminate

yourwatersupply, and will notcausebacteriato

form or grow. However, during shipping, storage, installing and operating, bacteria could get

into the softener. For this reason, sanitizing as

follows is suggested¬when installing.

1. Lift the salt hole cover and use a pail or hose

to fill the salt storage tank with at least 3

gallons of water.

2. Remove the brinewell cover (FIG. 3) and

pour about 3/4 ounce of common 5.25%

household bleach (Clorox, Linco, BoPeep,

White Sail, Eagle, etc.) in the softener brinewell.

3. PresstheON/OFF-HOLDbuttonand holdfor

3 seconds to start a recharge. This first re-

charge does several things.

FIG. 2 ADD WATER

Salt Hole

Cover

hose

Water,

About 3 Gallons

Brinewell

Cover

(remove and add

about 3/4 oz. bleach)

Brinewell

— It draws the bleach into and through the

softener to sanitize it.

— Itfillsthesalttanktothewaterlevelneed-

ed.

— It gets all the air out of the resin tank.

— Itmakes the resinbed (seepage 11)ready

for service.

NOTES:

This recharge takes about 2 hours.

You can sanitize the softener with or without salt in the storage tank.

¬

Recommended by the Water Quality Association. On

somewater supplies, thewater softener may needperiodic disinfecting.

8

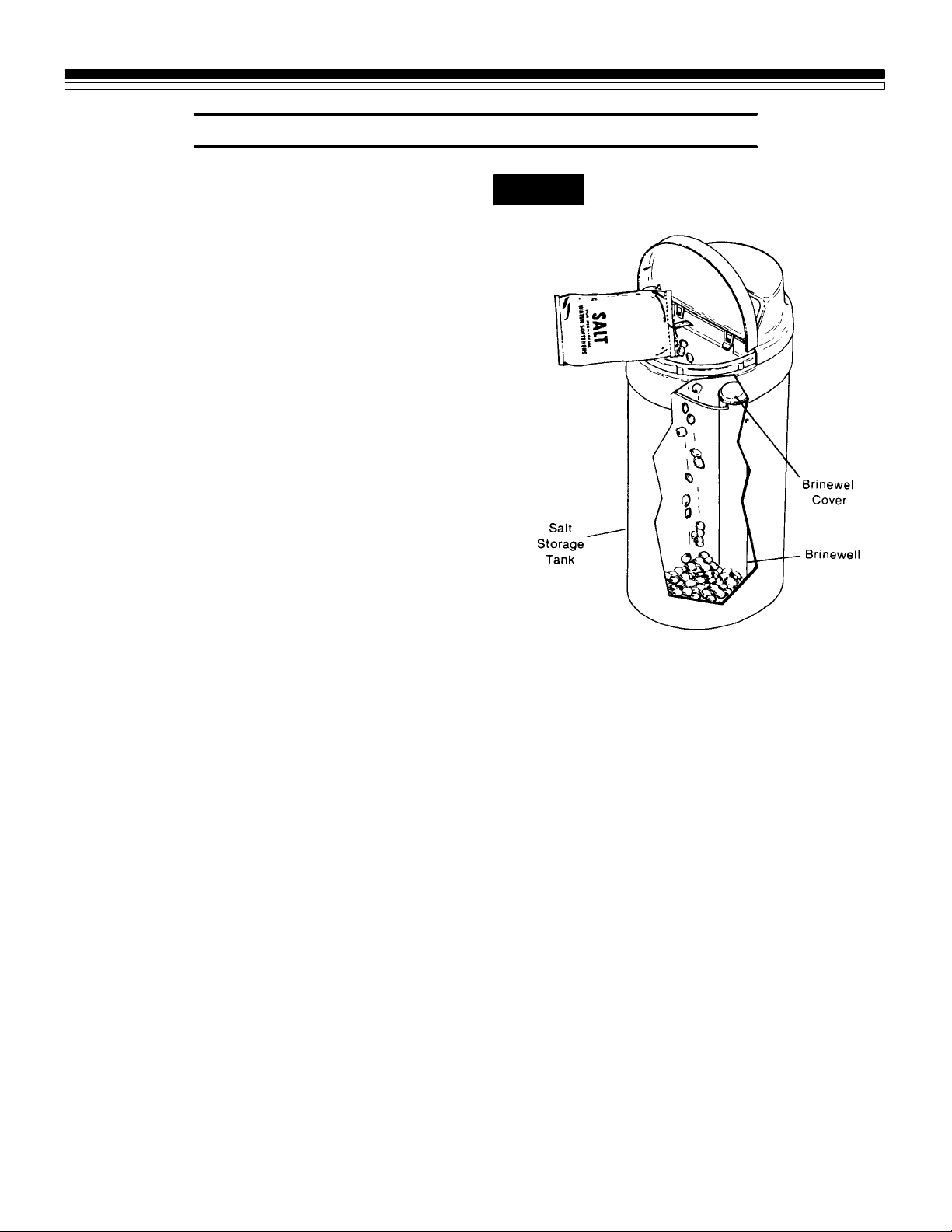

Page 9

SECTION 1

1E. FILL THE STORAGE TANK WITH SALT

WATER SOFTENER START-UP

Brine(saltdissolvedinwater)isneeded for each

and every regeneration. The water for making

brine is metered into the salt storage tank by the

softener.However,youmustkeepthetankfilled

with salt.

Fill the tank with NUGGET or PELLET water

softener salt. DO NOT use rock salts, as they

have dirt and sediments that will stop the

softener from working.

Before filling, be sure the brinewell cover is in

place on the top of the brinewell. Salt storage

capacity is shown on page 19. Be sure to set the

salt monitor system (see page 10).

NOTES:

The salt monitor system page 10, is calibrated to

the density of nugget or pellet water softener

salt. The monitor will not work as accurately

withother types ofsalt including rockand solar.

FIG. 3 ADD SALT

In humid areas, it is best to fill the storage tank

half-full,and to refillitmoreoften.Saltbridging

(seepage15)occurs moreoften when conditions

are humid.

W ATER SOFTENING SALT WITH IRON REMOVING ADDITIVES — Some salts have an

additive to help the softener handle iron in the

water supply. Although this additive may help

to keep the softener resin clean, it may also

release corrosive fumes that will weaken and

shorten the life of some softener parts.

Sodium information: Water softeners using sodium chloride for regeneration add sodium to

the water.Persons who are on sodium restricted

diets should consider the added sodium as part

of their overall sodium intake.

For example, if your water supply is 15 grains

hard, you would have to drink 3 quarts of

softened water to consume 335 milligrams of

sodium. That is equivalent to eating 2-1/2slices

of white bread.

Personswho are concerned abouttheir drinking

water should consider a Sears Drinking Water

System that will remove or reduce in excess of

90% of the sodium and other drinking water

contaminants.

You have now finished the water softener start up. After the sanitizing recharge, on

page 8, the softener will be giving you soft water.

9

Page 10

SECTION 2

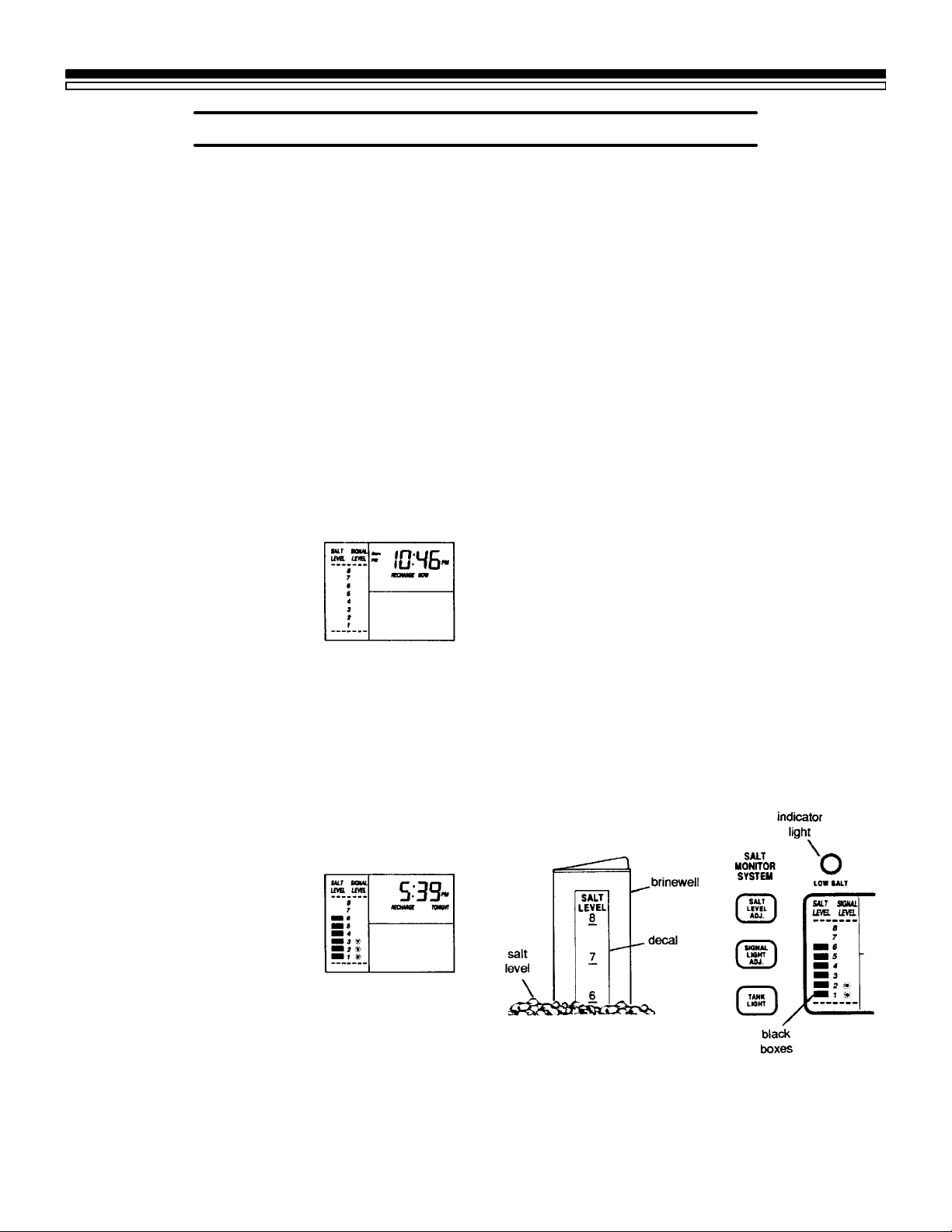

2A. FACE PLATE TIMER FEATURES

HOW YOUR WATER SOFTENER WORKS

EXTRA RECHARGE

Sometimes, a manually started regeneration

(recharge) may be desired, or needed. Two

examples are:

--You have used more water than usual (guests

visiting) and you may run out of soft water

before the next timer started regeneration.

--Youdidnotrefillthesoftenerwithsaltbeforeit

was gone.

You can start aregenerationrightaway,oryou

canset the timertoregenerate at the next2:00

AM (or other preset recharge time). Do the

following.

RECHARGE NOW

n Press the ON/OFF-

HOLDbuttonandholduntil

RECHARGE NOW, SERV

and FILL begin to flash in

the display. Upon reaching

fill, the first cycle of regeneration, the flashing SERV

goes off and FILL is on

steady. RECHARGE NOW

continues to flash. This regeneration will last for

about 2 hours. After the 2

hours, you will have soft

water again.

SALT MONITOR SYSTEM

The face plate timer has a low salt monitor with

an indicator light to remind you to refill the

storagetankwithsalt.Tosetthismonitorsystem:

1. Liftthesaltholecover andlevelthesaltinthe

storage tank.

2. The salt level decal, on the brinewell inside

the tank, has numbers from 0 to 8 (see

drawing on page 9 and below). Observe the

number the leveled salt is at or closest to.

NOTE: To light the salt storage area, press the

TANK LIGHT button on the face plate.

3. Now,pressthe SALTLEVELADJUSTbutton

until black bars display up to the salt level

number. For example, the pictures below

show the salt level at 6.

4. Finally, set the level you want the low salt

indicatorlight to come on.PresstheSIGNAL

LIGHT ADJUST button until a (T) shows

opposite this number. In the example below,

the light will come one when the stored salt

dropstolevel 2. Atlevel 2, thestoragetankis

about 1/3 full. This is the lowest you should

allow the stored salt level to drop to. To turn

the salt monitor off, press the button until

OFF shows.

RECHARGE TONIGHT

n Press and release (do not

hold) the ON/OFF-HOLD

button. RECHARGE TONIGHT flashes in the display, and the softener begins regeneration at the

next preset recharge time.

Press and release the ON/

OFF-HOLD button once

moreif you decide tocancel

the regeneration, and RECHARGE TONIGHT.

NOTE:

For accurate salt monitor operation, always use

nugget or pellet water softener salt. See page 9.

10

Page 11

SECTION 2

2A. FACE PLATE TIMER FEATURES

HOW YOUR WATER SOFTENER WORKS

TANK LIGHT

To light the inside of the salt

storage tank, press the TANK

LIGHT button on the face

plate. Press the same button

againto turn thelight off, or it

will go off automatically in 4

minutes.

WATER FLOW RATE THROUGH THE SOFTENER

To view the gallon per minute water flow rate

through the softener, if not already displayed,

press the #2 SELECT button.

Ifsoft water is being used,the

flow rate to the closest 1/10

gallon shows. If all faucets

and water using appliances

areoff,thedisplaywillshow0

flow.

AVERAGE DAILY GALLONS

Press the #2 SELECT button

again to show the average

number of gallons of soft water the household uses each

day.Thiswaterusage figureis

adjusted daily by the face

plate timer. To turn this display off, press the #2 SELECT

button once more.

PROGRAM MEMORY

If electrical power to the softener goes off, the

time display is blank but the face plate timer

keeps the correct time for about 72 hours. When

electrical power comes on again, you have to

reset the present time only if the display is

flashing. The HARDNESS and RECHARGE

TIME never require resetting unless a change is

desired.

Even if the timer is incorrect after a long power

outage, the softener works as it should to keep

your water soft. However, regenerations may

occuratthe wrongtimeofday untilyouresetthe

timer to the correct time of day.

ERROR CODE

Anerrorcodecouldappearin

the face plate display if a

problemoccursinthesoftener

electronics.If yousee anerror

code instead of the present

time of day, please call you

local Sears Service Department for service.

11

Page 12

SECTION 2

2B. SOFT WATER SERVICE AND REGENERATION

HOW YOUR WATER SOFTENER WORKS

SERVICE

When the softener is giving you soft water, it is

called “Service”. During service, hard water

comes from the house main water pipe into the

softener. Inside the softener resin tank is a bed

madeupofthousandsoftiny,plastic resinbeads

(FIG. 4). As hard water passes through the bed,

each bead attracts and holds the hardness

minerals. This is called ion-exchanging. It is

much like a magnet attracting and holding

metals. Water without the hardness minerals

(softwater)flowsoutofthesoftenerandintothe

house soft water pipes.

After a period of time, the resin beads become

coated with hardnessminerals and they have to

be cleaned. This cleaning is called regeneration

or recharge. Regeneration is started at 2:00 a.m.

by the electronic timer (see page 14). It takes

place in 5 stages or cycles. These are:

FILL

1

BRINING

2

3

BRINE RINSE

BACKWASH

4

5

FAST RINSE

REGENERATION

¡ FILL: Salt, dissolved in water, is called

brine. Brine is needed to clean the hardness

mineralsfromtheresinbeads.Tomakethebrine,

water flows into the salt storage area during the

fill stage as shown in FIG. 5. Fill cycle length

depends on how much soft water making

capacity you have used since the last regeneration.Asyouusemorewater,filltimeincreasesso

morebrineis made. The greateramount ofbrine

cleans more hardness minerals from the resin

bed.

FIG. 5 WATER FLOW THROUGH THE

SOFTENER IN FILL

FIG. 4 WATER FLOW THROUGH THE

SOFTENER IN SERVICE

12

Page 13

SECTION 2

2B. SOFT WATER SERVICE AND REGENERATION

HOW YOUR WATER SOFTENER WORKS

©BRINING:Duringbrining,thebrineismoved

from the salt storage area, into the resin tank.

Inside the resin tank, brine cleans hardness

minerals from the resin beads and they are

discharged out the drain. How much brine is

needed to clean the resin depends on:

--the amount of resin in the softener,

--how fast the brine goes through the bed.

The nozzle and venturi (FIG. 6) make suction to

take brine from the salt tank and put it into the

resin tank. They keep the brine flow down to a

very slow rate to get the best resin cleaningwith

the least salt.

¢BRINE RINSE: After all of the brine goes into

the resin tank, the brine valve closes. Water

keeps flowing the same way it did during

brining except the brine flow has stopped.

Hardness minerals and brine flush from the

resin tank to the drain. Brining and brine rinse

together vary in the length of time they take,

relative to the fill cycle length.

FIG. 6 WATER FLOW THROUGH THE

SOFTENER IN BRINING AND

BRINE RINSE

FIG. 7 WATER FLOW THROUGH THE

SOFTENER IN BACKWASH

¤FAST RINSE: Backwash is followed by a fast

flow of water down through the resin tank. The

fastflowpackstheresinbed and gets it readyfor

return to service (FIG. 8).

After fast rinse, the softener returns to service.

Hard water goes into the resin tank where the

resinbed again takes out the hardness minerals.

Soft water goes to the house soft water pipes.

£BACKWASH:During backwash, water flows

UPthroughthe resintank(FIG.7)at a fast rateto

flush iron minerals, dirt and sediments fromthe

bed and to the drain. The bed lifts and expands

for good cleaning.

FIG. 8 WATER FLOW THROUGH THE

SOFTENER IN FAST RINSE

13

Page 14

SECTION 2

2B. SOFT WATER SERVICE AND REGENERATION

HOW YOUR WATER SOFTENER WORKS

AUTOMATIC BYP ASS

During the brining, brine rinse and backwash

cycles of regeneration, HARD water goes

through the softener valve and to the house

pipes. If a faucet is opened, hard water is there

for your needs. However, you should not use

HOTwater, if possible,because the waterheater

willrefillwith hard water.The softenerregeneratesfrom2:00 AM to about 4:00 AM, (you canset

anytime), a time when not much water is used.

If you get up early in the morning and you can

hear the softener regenerating, change the time

setting.Set the rechargetime to12:00AM or 1:00

AM (page 7). Then regeneration will start and

endthatmuchearlierandyourwaterheaterwill

not refill with hard water if a hot faucet is

opened.

Two main parts of the softener’s electronics are

¡ a WATER METER, and © a COMPUTER.

¡ WATER METER — The water meter is in the

softenervalveoutlet.Aswaterflowsthroughthe

meter, it sends electric pulses to the computer.

Thecomputerchangesthepulsestoa measurein

gallons of water.

© COMPUTER — The computer is part of the

circuit board. It is programmed to know the

softener’s capacity (how many grains of hardnessmineralsitwilltakeoutofthewaterbeforea

regeneration is needed). When starting the

softener, page 7, you set it for the grains per

gallon (gpg) hardness of the water.

To find a regeneration pattern best for your

needs, the computer uses: (1) water usage from

the meter, (2) hardness setting, (3) softener

capacity, and(4) time sincethelastregeneration.

Thecomputeralwaysadjuststhispatterntoyour

water using habits. It works toward providing

you with soft water for the longest time and the

most efficient salt usage.

Softening capacity is used as hard water goes

through the softener and hardness minerals are

removed, capacity is used. When the computer

determinesthatonlyenoughcapacityremainsto

provide soft water up to the next regeneration

startingtime(2:00AM,orasotherwiseset)itwill

schedulearegeneration.RECHARGETONIGHT

displaysuntiltheregenerationbegins.Whenthe

regeneration begins, TONIGHT goes off and

RECHARGE NOW flashes during the 2 hour

regeneration.

14

Page 15

SECTION 3

3A. SALT¼REFILLING STORAGE TANK/BREAKING A SALT BRIDGE

CARE OF YOUR SOFTENER

WHEN TO REFILL WITH SALT: The Salt

Monitor System (see page 10) will turn on the

lowsaltlighttowarnyouwhentorefillwithsalt.

Check for a low salt light a few weeks after you

install the softener, and every week after that.

Always refill at about the #2 salt monitor level.

Atthis level, the tank is about 1/3 full. Never let

the softener use all the salt before refilling.

Without salt, you will soon have hard water.

PLEASE SEE PAGE 9 FOR SALT FILLING DIRECTIONS.

BE SURE TO RESET THE SALT MONITOR, PAGE 10.

SALT BRIDGE

NOTE:

You will have a loss in softening capacity and

may get partly hard water if less than 10 inches

(saltmonitorlevel2)ofsaltisinthestoragetank.

Sometimes, a hard crust or salt bridge forms in

thesalt storage tank.It is usuallycaused by high

humidityorthewrongkindofsalt.Whenthesalt

bridges, an empty space forms between the

water and salt. Thensalt willnot dissolve(melt)

in the water to make brine. Without brine, the

resinbed does not regenerate and you will have

hard water.

Ifthe storage tankis full ofsalt,itis hardto tell if

youhaveasaltbridge.Saltislooseontop,butthe

bridge is under it. The following is the best way

to check for a salt bridge.

Salt should be loose all the way to the bottom of

thetank.Holdabroomhandle, or like tool, up to

the softener as shown in FIG. 9. Make a pencil

markonthe handle,1²or2²belowthe topheight

of the rim. Then,carefully push it straight down

into the salt. If a hard object is felt before the

pencil mark gets to the top of the tank, it’s most

likely a salt bridge. Carefully push into the

bridge in a few places to break it. Do not try to

break the salt bridge by pounding on the

outside of the salt tank. You may damage it.

Ifthe wrong kind of salt made the bridge, take it

out. Then fill the tank with nugget or pellet salt

only.

FIG. 9 SALT BRIDGE

push tool into salt

bridge to break

1” -- 2”

Pencil

Mark

Broom Handle

Salt

Salt Bridge

Water Level

15

Page 16

SECTION 3

3B. KEEPING THE WATER SOFTENER CLEAN

CARE OF YOUR SOFTENER

COVERS

To keep your new Sears water softener looking

nice,apply a coatof paste wax and repeatonce a

year. When dusty, wipe it with a damp cloth to

keep it sparkling.

NOZZLE & VENTURI

Acleannozzleandventuri(FIG.10)isamustfor

thesoftenertoworkright.Thissmallunitmoves

brine from the salt storage tank to the resintank

duringregeneration.If itbecomes pluggedwith

sand, silt, dirt, etc., the softener will not work

and you will get hard water.

To get to the nozzle and venturi, remove the

softener top cover. Be sure the softener is in

service cycle (no water pressure at nozzle and

venturi), then turn off the cap from the nozzle

and venturi housing. Do not lose the large o-ring

seal. Lift out the screen support and screen, then

thenozzle and venturi.Wash and rinse the parts

inwarm water until clean.Ifneeded,use a small

brush to remove iron or dirt. Also check and

clean the gasket.

NOTE:

Never use cleaners having ammonia or abrasives. They may scratch and dull the surface.

FIG. 10 CLEANING THE NOZZLE &

VENTURI

Carefully replace all parts in the correct order.

Lubricatetheo-ringsealwithsiliconegreaseor

Vaseline and place in position. Install and

tightenthecap,byhandonly.Do notovertigh-

ten and break the cap or housing.

IRON FROM THE RESIN BED

Your water softener takes hardness minerals

(calciumandmagnesium)outofthewater.Also,

it can control some “clear water” iron. See

maximum allowed in the specifications on page

19. With clear water iron, water from a faucet is

clear when first put into a glass. After 15 to 30

minutes, the water begins to cloud or turn rust

colored. A water softener WILL NOT remove

any iron which makes the water cloudy or rusty

as it comes from the faucet (called red water

iron).Totake redwater ironout ofwater,orover

themaximum ofclearwateriron,anironfilteror

*INSTALL WITH

NUMBERED SIDE UP

CONCAVE SIDE DOWN. BE

SURE THE FLOW PLUG WITH

THE LARGEST CENTER HOLE

IS LOCATED IN THE NOZZLE

& VENTURI HOUSING.

other equipment is needed. Your local Sears

store has trained people to help you with iron

water problems.

If your water supply has clear water iron, even

thoughless than the maximum allowed, regular

resinbedcleaning is needed.Sears has resinbed

cleaner, Stock No. 42-34426 for this. Clean the

bed at least every 6 months. If iron shows up in

thesoftwater before6 months, clean moreoften.

Printed instructions are on the resin bed cleaner

bottle.

16

Page 17

SECTION 3

3C. KEEP THE SOFTENER FROM FREEZING

CARE OF YOUR SOFTENER

If the softener is installed where it could freeze

(summercabin, lake home,etc.), you mustdrain

all water from it to stop possible freezedamage.

To drain the softener —

1. Close the shut-off valve on the house main

water pipe, near the water meter or pressure

tank.

2. Open a faucet in the soft water pipes to vent

pressure in the softener.

3. Refer to FIG.12 on page19. Move thestemin

a single bypass valve to bypass. Close the

inlet and outlet valve in a 3-valve bypass

system, and open the bypass valve. If you

want water in the house pipes again, reopen

the shut-off valve on the main water pipe.

4. Unplug the transformer at the wall outlet.

Remove the salt hole cover and the main

cover. Take off both drain hoses.

5. Carefully remove the large holding clips at

the softener inlet and outlet (see Key No. 61,

on page 30). Separate the softener from the

adaptors or bypass valve.

6. Remove the brinewell cover and disconnect

the brine valve tubing at the nozzle and

venturiassembly (see page30). Lift the brine

valveoutofthebrinewell.Tipthebrinevalve

upside down to drain out water.

FIG. 11 DRAIN WATER FROM THE

SOFTENER

7. Looking at FIG.11,lay apiece of 2 inch thick

boardnearthefloor drain. Move thesoftener

close to the drain. SLOWLY and CAREFULLY tip it over until the rim rests on the wood

blockwiththeinletandoutletoverthedrain.

Donotallow thesoftener’sweightto reston

the inlet and outlet fittings or they will

break.

8. Tipthebottomofthesoftener upafewinches

and hold until all water has drained. Leave

the softener laying like this until you are

readyto use it. Plug the inlet and outlet with

rags to keep dirt, bugs, etc. out.

17

Page 18

SECTION 3

CARE OF YOUR SOFTENER

3D. HELPFUL HINTS CHECKLIST

... TO HELP YOU SAVE MONEY

Ifyourwatersoftenerfailstowork,makethefollowingeasychecks.Often,youwillfindwhat’swrong

yourselfandyouwon’thave to call andwaitforservice. If, after makingthechecks,your softener still

does not work right, call your Sears Service Department.

NOTE:

1. Also read ERROR CODE, page 11.

2.Ifanerrorcode is not dispIayed, pressandholdthe#1SELECTbuttonuntil(example:000- -)shows

in the display. Then, press the #1 SELECT again and hold until a flashing AR code appears. It must

show AR31. If AR 17, 22, 39 or 60 shows, the face plate computer is working on incorrect input and

would probably be the cause of the problem. To set AR31, press either the UP or DOWN button.

WhenAR31shows,pressthe #1 SELECT to returnaflashing12:00AMdisplay.Reset the presenttime,

hardness number and recharge time, pages 6 and 7.

PROBLEM CAUSE CORRECTION

NO SOFT WATER No salt (or salt bridged) in the storage tank Refill with salt, or break the salt bridge

(page 15). Press ON/OFF-HOLD

(RECHARGE NOW) button and hold for 3

seconds to start a regeneration (see page

10).

WATER HARD

SOMETIMES

Transfomer unplugged at the wall outlet, or

power cable leads loose, fuse blown, circuit

breaker popped, or circuit switched off.

Manual bypass valve(s) in bypass position Look at FIG. 12 on page 19. Move the

Dirty, plugged or damaged nozzle & venturi Take apart and clean or replace damaged

Valve drain hose plugged The drain hose must not have kinks, sharp

Hardness number setting too low Press and release the SELECT button

Using hot water when softener is

regenerating

Increase in the grains of hardness in your

water supply

Check for loss of power due to any of

these and correct. With the power back

on, look at the time display and read

PROGRAM MEMORY, page 11.

stem in a single valve to service. In a

3-valve bypass, open the inlet and outlet

valves, and be sure to fully close the

bypass valve.

parts (see page 16).

bends, or be raised too high above the

softener (see page 16 in your installation

manual).

until HARDNESS shows in the display.

Read the hardness number in the display

and be sure the same grains per gallon

number is shown on your water analysis

report. See page 7 to reset. Press and

release the SELECT button until the

present time shows in the display.

Avoid using hot water during this time

because the water heater refills with hard

water (see Automatic Bypass, page 14).

Ask your Sears retail or catalog store for a

new water analysis. Then make a new

hardness number setting (page 7).

18

Page 19

SECTION 4

4A. DIMENSIONS/SPECIFICATIONS

FIG. 12 BYPASS VALVES

OTHER THINGS TO KNOW

INCHES CM

A Salt Tank Height 40-1/4 102.2

B Resin Tank Diameter (nominal) 9 22.7

C Resin Tank Height (nominal) 40 101.6

D Inlet-Outlet Height 41-1/2 105.4

E Overall Height 46 116.8

F1Length 19-1/2 49.5

F2Width 16-1/2 41.9

— Distance between inlet-outlet

center lines

3-3/8 8.6

MODEL NO. 625.3485400 AND 625.3485500 TIMER AR CODE AR31

NOTE: Please see the rating decal for water softener operating capacity, salt usage and service flow

rate/pressureloss performance specifications. Performance specifications are validatedby theWater

QualityAssociation (WQA). Therating decal islocated on the rim,underthesalt hole cover (seepage

28).

W ATER SUPPLY TO WATER SOFTENER

MINIMUM WATER SYSTEM FLOW (gpm) 3

MINIMUM-MAXIMUM WATER PRESSURE (psi) 20-120

MAXIMUM WATER TEMPERATURE (°F) 120

MAXIMUM WATER HARDNESS (gpg) 110

MAXMUM “CLEAR WATER” IRON (ppm) 8

SALT FOR WA TER SOFTENER

TYPE OF SALT NEEDED Nugget/Pellet

ALTERNATE TYPE OF SALT Pure, evaporated, compacted

water softener salt

STORAGE CAPACITY (pounds) 200

OTHERS

TYPE OF ION EXCHANGE MATERIAL (resin) High Capacity

AMOUNT OF RESIN (cu.ft.) 1.0

REGENERATION (RECHARGE) CYCLE TIME (min.)

FILL 2.7-10.3

BRINING/BRINE RINSE 97-106

BACKWASH 7

FAST RINSE 3

TOTAL REGENERATION TIME 109.7-126.3

gpm = gallons per minute psi = pounds per square inch

gpg = grains per gallon ppm = parts per million

19

Page 20

SERVICE TECH. INFORMATION

SECTION

5

TROUBLESHOOTING

Keep this manual with your water softener. If repairs are needed, the service technician must have the

information on the following 8 pages. For telephone assistance, call toll free, 1--800--426--9345.

ALWAYS MAKE THESE INITIAL CHECKS FIRST

1. Does the time display show the correct time of day?

----If display is blank, check power source to the softener.

----If timeis flashing,power wasoff forover 24hours. The

softener resumes normal operation but regenerations

occur at the wrong time.

----If an errorcode (Example:Err3) showsin theface plate

display, go to AUTOMATIC ELECTRONIC DIAGNOS-

TICS.

2. Plumbing bypass valve(s) must be in Full Service

position.

3. The inlet and outlet pipes must connect to the softener

inlet and outlet respectively.

4. Is the transformer plugged into a “live”, grounded wall

outlet, and the power cable fastened securely?

5. The valve drain hose must be free of kinks and sharp

bends, and not elevated over 8 ft. above the floor.

REMOVE THE TOP COVER AND SALT TANK COVER

6. Is there salt in the storage tank?

7. Is the brine tubing connected? (See water flow

diagrams).

8. Is the brine valve float set right? (See page 23).

9. Press the #1 SELECT button 2 times to display the

hardness setting. Be sure it is the correct setting for the

household’s water supply. (Make a hardness test of the

raw water and compare with the hardness setting. Also

test a soft water sample to verify if a problem exists.)

Press the #1 SELECT button twice more to return to

present time in the display.

If you do not find the problem after making initial checks,

do the MANUAL INITIATED ELECTRONIC DIAGNOSTICS,

and the MANUAL ADVANCE REGENERATION CHECK.

Page 21

SERVICE TECH INFORMATION

SECTION

5

Seefaceplatereplacementon

5A. TROUBLESHOOTING

AUTOMATIC ELECTRONIC DIAGNOSTICS

The face plate computer has a self-diagnostic

function for the electrical system (except input

power and water meter). The

computer monitors the electronic components and circuits

for correct operation. If a

malfunction occurs, an error

code appears in the face plate

display.

POSSIBLE DEFECT

CODE

Err1 motor inop. / wiring harness or connection to switch / position switch / face plate

Err2 face plate

Err3 motor / face plate See face plate replacement on

Err4 face plate / position switch

Err5 face plate

PROCEDUREFORREMOVING ERROR CODE FROM FACEPLA TE:1. Unplug transformer 2. Correct defect

3. Plug in transformer 4. W ait for 6 minutes. The error code will return if the defect was not corrected.

MOST LIKELY LESS LIKELY

page 22.

The chart below shows the error codes that could

appear, and the possible defects for each code.

Whilean error codeappears in thedisplay,allface

plate buttons are inoperable except the SELECT

button.SELECT remains operationalso the service

person can make the MANUAL INITIATED

ELECTRONIC DIAGNOSTICS (below) to further

isolate the defect, and check the water meter.

MANUAL INITIATED ELECTRONICS DIAGNOSTICS

1. To enter diagnostics¼

----from a error code display, press the #1

SELECT button.

----from a time display, press and hold the #1

SELECT button for 3 seconds.

You will see 1 of the following displays.

All of the preceeding displays show what position

the valve is in, if the turbine is operating, and the

position switch open or closed status.

2. Press the ON/OFF-HOLD button to advance

the valve to the next position. To verify

component operation, or to possibly isolate a

defect, observe the following.

POSITION SWITCH STATUS: WIth the valve in

service, or any of the recharge cycles, the switch

indicator will show open . While the valve is

rotating from 1 position to another, the indicator

will show the switch closed . A defect is

probable if indications vary from this pattern.

Page 22

SERVICE TECH. INFORMATION

SECTION

5

5A. TROUBLESHOOTING

WATER METER TURBINE: With soft water in use,

the turbine flow rate display continually repeats a

000 to 199 count for each gallon of water passing

through the turbine. The display will remain a

steady¼000 if soft water is not in use (open a

nearby soft water faucet to check).

If you don’t get a reading in the display, with

facuet open, pull the sensor from the valve outlet

port.Passa small magnet backandforthin front of

thesensor.Youshouldgetareadingin the display.

If you get a reading, unhook the in and out

plumbing and check the turbine for binding.

OTHER INFORMAT ION: While in this diagnostic

screen,thefollowinginformationisavailableandmay

be beneficial for various reasons. This information is

retainedby thecomputer from the first time electrical

power is applied to the face plate.

¼Press to display the number of days this face

plate has had electrical power applied.

¼Press to display the number of regenerations

initiated by this face plate since the AR code

number was entered.

3. Press the #1 SELECT button and hold 3

seconds until¼

This code identifies the softener nominal capacity

size. If the wrong number shows, the softener will

operate on incorrect programming. Do the

following as needed.

AR31 does show — Press the #1 SELECT button

to return the present time display.

VALVEPOSITION INDICATORS:Depending on the

valve position, the following indicators show in

the display:

INDICA TOR VALVE POSITION

Serv service

Fill fill

Brine brining/brine rinse

Bkwash backwash

Rinse fast rinse

When the valve is rotating from 1cycle to another,

bothindicatorsflash.Forexample,if the valve isin

transition between fill and brining, both Fill and

Brine flash. Upon reaching brining position, Fill

goes off and Brine is on steady. The time display

shows the minutes of the cycle remaining.

NOTE: If the face plate is left in a diagnostic display

(or a flashing display when setting times or

hardness), present time automatically returns if a

button is not pressed within 4 minutes. To return to

the diagnositc display, repeat step 2.

Tochange AR number — press the or button

until AR31 shows. The, press the #1 SELECT

button and reset the timer¼page 6.

F ACE PLATE REPLACEMENT: BE SURE

THE VALVE IS IN SERVICE POSITION (OBSERVE VALVE CYCLE INDICATOR) WHEN

REPLACING THE FACE PLA TE.

If, after installing and

programming the replacement face place,

the valve is not in service position, do the following to assure correct

cycle orientation, or timing, between the face

plate and valve.

Use the MANUAL ADVANCE procedures,

page 23. With the RECHARGE NOW button,

advance through the recharge cycles until the

valve stops in service position, and RECHARGE no longer flashes in the timer.

NOTE: The valve motor may automatically

drive through several valve positions while

searching for service. If an error code occurs,

unplug the transformer, then plug in again.

Page 23

SERVICE TECH INFORMATION

SECTION

5

(flowtodrain)

5A. TROUBLESHOOTING

MANUAL ADVANCE REGE NERATION CHECK

This check verifies proper operation of the valve

motor, brine tank fill, brine draw, regeneration

flow rates, and other controller functions. Always

make the initial checks, and the manual

initiated diagnostics.

NOTES:The face plate display mustshowasteady

time (not flashing). If an Error code shows, first

press the #1SELECT button to enter the diagnostic

display.

1. Press the ON/OFF-HOLD button and hold in

for 3 seconds. RECHARGE NOW and FILL

begin to flash as the softener enters the fill

cycle of regeneration. When FILL is on steady,

remove the brinewell cover and, using a

flashlight, observe fill water entering the tank.

a. If water does not enter the tank, look for an

obstructed nozzle, venturi, fill flow plug, brine

tubing, or brine valve riser pipe.

NOTE: If water system pressure is low, an

elevated drain hose may cause back pressure,

stopping brine draw.

3. Again press ON/OFF-HOLD to move the

softener into backwash. Look for a fast flow of

water from the drain hose.

a. An obstructed flow indicates a plugged top

distributor, backwash flowplug, or drainhose.

4. Press ON/OFF-HOLD to move the softener

into fast rinse. Again look for a fast drain flow.

Allowthe softener to rinse for a few minutes to

flushoutanybrine that may remainintheresin

tank from the brining cycle test.

5. To return the softener to service, press

ON/OFF-HOLD.

CYCLE FLOW RATES (GALLONS PER MIN.)

FILL (flow to salt storage tank) 0.3 (1.1 liters)

BRINING .19 (.7 liters)

BRINE RINSE

BACKWASH

F AST RINSE

(flow to drain)

.12 (.45 liters)

2.0 (7.6 liters)

2.0 (7.6 liters)

2. After observing fill, press the ON/OFF-HOLD

button to move the softener into brining. A

slow flow of water to the drain will begin.

Verify brine draw from the brine tank by

shining a flashlight into the brinewell and

observing a noticeable drop in the liquid level.

NOTE: Be sure a salt bridge is not preventing

water with salt contact.

a. If the softener does not draw brine¼

¼nozzle and/or venturi dirty or defective.

¼nozzle and venturi not seated properly on

gasket.

¼restricted drain (check drain fitting and

hose).

¼defective nozzle and venturi seal.

¼other inner valve defect (rotor seal, rotor &

disc, wave washer, etc.).

Page 24

SERVICE TECH. INFORMATION

SECTION

5

5B. ROTARY VALVE SERVICE

Before working on the valve, turn off the water

supply and disconnect from electrical power.

TO RELIEVE PRESSURE:

----3VALVEBYPASS:Closethe inlet valve andopen

asoft water faucet.Then close theoutlet valve and

open the bypass valve.

----SEARS SPECIAL BYPASS: Slide the bypass valve

stem to bypass position. Loosen the 3 hex head

screws (see A in drawing) toward the back side of

the valve to allow pressure water to bleed out

Catch water with a rag.

DISASSEMBLY

To remove a part or group of parts, refer to the

valve drawing. A common screwdriver or nut

driver, Phillips screwdriver and pliers are the only

tools needed to completely disassemble.

SERVICING THE VALVE

Inspect all o-rings, seals and gaskets for wear or

defects.

Lower the cover onto the valve body and rotor

shaft. Then install the cover holding screws.

Before tightening the screws, install the valve

cam and gear. Then, turn the rotor (clockwise

only) to service position. Tighten the screws using

a criss-cross pattern. If a torque wrench is

available, torque to 30-40 inch pounds.

Inspectthebottomsurface oftherotorand disc for

scratches, chips or wear.

NOTE:Ifreplacementisneeded,besuretousethe

current replacement part.

ASSEMBLY

Be sure all parts are in place and in the proper

position.Lubricate ALL o-ringsand seals withFDA

approved silicone grease. To install the rotor seal,

first place the seal into the valve groove, rounded

side down (see cross-section). Apply a light

coating of silicone grease to the seal’s crossing

ribs. Then, carefully center the wear strip on the

seal, and push it downward onto the seal.

Install the nozzle and venturi seal and drain seal.

Assemble 2 o-rings and the wave washer onto the

rotor and disc. Then center the rotor and disc, in

the valve body, on the rotor seal.

Lubricatethe gear onthe motor,andthevalvecam

gear with Molykote grease, or other high quality

gear lubricant.

Be sure to orient switch as shown, with lever

toward the cam.

Page 25

SERVICE TECH INFORMATION

SECTION

5

5C .. WATER FLOW THROUGH THE SOFTENER VALVE

SERVICE CYCLE

Hard water enters the valve inlet port. Internal valve portingroutes the water

down and out the top distributor, into the resin tank. Hard water is softened

as it passes through the resin bed, then enters the bottom distributor. Soft

water flows back into the valve and out the valve outlet, to the house soft

water pipes.

FILL CYCLE

To begin a regeneration, the electroic timer energizes the circuit to the valve

motor. The valve motor rotates the rotor and disc and the valve cam until the

position switch lever drops, to open the motor circuit and position the valve in

FILL.Astherotoranddiscrotates,theportopensforSOFT water fill through the

venturi. Fill flow continues to the brine valve, and into the salt storage tank.Soft

water is still available to the house lines.

Page 26

SERVICE TECH. INFORMATION

SECTION

5

5C. WATER FLOW THROUGH THE SOFTENER VALVE

BRINING AND BRINE RINSE CYCLES

After fill, timer/switch action allows the motor to turn the rotor and disc into

BRINING position. Water flow is directed to the nozzle. Suction, created by the

nozzleandventuri,drawsbrinefrom the salt storage tank andinjects it into the resin

bed via the bottom distributor. Flow continues out the top distributor and to the

drain. Hard water is available at the valve outlet.

When the brine valve closes to end brine draw, water flow continues in the same

directions to slowly RINSE brine from the resin bed and to the drain.

BACKW ASH CYCLE

Timer/switch action again allows the motor to turn the

rotor & disc to place the valve in BACKWASH, stopping

water flow to the nozzle. W ateris routed down and out

the bottom distributor,up through the bed, and out the

top distributor to the drain. The fast flow (controlled by

a flow plug in the drain fitting) flushes dirt, sediments,

iron deposits, remaining brine and hardness to the

drain.

Page 27

SERVICE TECH INFORMATION

SECTION

5

5C. WATER FLOW THROUGH THE SOFTENER VALVE

FAST RINSE CYCLE

During FAST RINSE, the rotor & disc is positioned so water flow enters the

resin tank through the top distributor, and exits through the bottom

distributor, to the drain.

The electronic timer again energizes the motor to return thevalve to service.

As the valve rotates, the position switch lever drops to open the circuit. The

valve remains positioned in service until the electronic timer initiates the

next regeneration.

Page 28

SECTION 6

REPAIR PARTS

SEARS WATER SOFTENERS

MODEL NOS. 625.3485400

AND 625.3485500

KEY

NO.

10 7100819 Brinewell

11 7144619 Salt Storage Tank

12 7143956 Plastic Screw, 1/4² x 5/8²

13 0900431 Hose Clamp FY

14 1103200 Hose Adaptor FY

15 9003500 Grommet FY

16 7123689 Brine Valve Assy. (also see pg. 29)

17 7105047 Replacement Distributor

18 0502272 Resin

19 7144952 Resin Tank (incl. Key No. 18)

20 7096183 O-Ring, 2-3/4² x 3²

21 7077870 Top Distributor

22 0900215 O-Ring, 13/16² x 1-1/16²

23 7079092 O-Ring, 2--7/8² x 3-1/4²

24 7141001 Vapor Barrier

25 7088041 Clamp Section (2 req.)

26 7088033 Clamp Retainer (2 req.)

27 7084550 Transformer, 24V-25VA FY

28 7137939 Light, Salt Level

29 7137913 Decal, Salt Level¬

u

u

FY Included in parts bags¼see page 31.

¬ Aligns with top of brinwell.

P ART

NUMBER

1 7137604 Cover (main)

2 7137612 Salt Hole Cover

3 7118333 Wire Harness (switch)

4 7084330 Power Cord (transformer)

5 7144986 Timer Repl. (PWA)

6 7137638

7137688

7141483

7 7139486 Rim

8 7137727 Brinewell Cover

9 7143964 Wing Nut, 1/4²

7141417 Installation Manual

7137573 Owners Manual

u not illustrated

Face Plate (order req’d decal)

Face Plate Decal, Mod 625.3485400

Face Plate Decal, Mod 625.3485500

DESCRIPTION

28

Page 29

SECTION 6

REPAIR PARTS

SEARS WATER SOFTENERS

MODEL NOS. 625.3485400

AND 625.3485500

KEY

NO.

30 0505957 Lead Washer

31 0513860 Float Stop

32 7092317 Float

33 0516947 Float Seal

34 7093216 Float Rod & Stem

35 7092278 Guide Cap

36 0900535 O-Ring 15/16 x 1-3/16

37 0516211 Seal

38 0516924 Retainer, Bottom Seal

39 7116713 Clip

40 7092252 Brine Valve Body

41 7080653 Clip

42 7131365 Screen

43 7094979 Insert

44 7092294 Retaining Ring

45 7092286 O-Ring, 5/16 x 9/16

46 7095470 Brine Tube

47 7113016 Tubing Assy. (incl Key Nos. 43, 44 & 45)

48 7112997 Ground Clamp Kit FY

FY Included in parts bags¼see page 31.

P ART

NUMBER

DESCRIPTION

29

Page 30

SECTION 6

SEARSWATERSOFTENERS

REPAIR PARTS

MODEL NOS. 625.3485400

AND 625.3485500

49

30

Page 31

SECTION 6

SEARS WATER SOFTENERS

MODEL NOS. 625.3485400 AND 625.3485500

PARTS LIST

KEY

NO.

50 7131755 Screw, #6-20 x 7/8 (2 req.)

51 7133008 Motor (incl. 2 ea. of Key No. 50)

52 0900857 Screw, #6-20 x 3/8 (2 req.)

53 7117808 Motor Plate

54 0503288 Bearing

55 7113927 Cam and Gear

56 7142942 Clip (Drain)

57 0501228 Flow Plug

58 0900041 O-Ring, 5/8 x 13/16

59 7024160 Drain Hose Adaptor

60 0900431 Hose Clamp FY

61 7116713 Clip (2 req.) FY

62 0507369 Installation Nut (2 req.) Y

63 0507615 Installation Tube (2 req.) Y

64 0900570 Washer (2 req.) Y

u 42-3441 Install. Kit (incl. Key Nos. 62, 63 & 64) ¡

65 0507371 Installation Adaptor (2 req.) F©

66 0900535 O-Ring, 15/16 x 1-3/16 (2 req.) F©

67 7134224 Rotor Seal

68 7092634 O-ARing, 3/8 x 9/16

69 7092642 Plug (Drain Seal)

70 1219600 Spring

71 7081764 Seal (Nozzle & Venturi)

72 7082053 Valve Body

73 0900064 O-Ring, 1/4 x 3/8 (2 req.)

74 7081201 Retainer (Nozzle & Venturi)

75 7081104 Nozzle & Venturi Housing

76 1202600 Nut — Ferrule

77 7089267 Tubing

78 1148800 Flow Plug, .3 gpm

© PARTS INCLUDED WITH MODEL NO. 625.3484400 ONLY.

P ART

NUMBER

DESCRIPTION

REPAIR PARTS

KEY

NO.

79 7113032 Nozzle and Venturi — Gasket Kit

80 7090705 Screen

81 7089893 Screen Support

82 7039068 O-Ring, 3/8 x 1-3/8

83 7081188 Cap

84 7084607 Flow Plug, .15 gpm

85 9001006 O-Ring, 3-3/8 x 3-5/8

86 7103964 Rotor & Disc

87 7082087 Wave Washer

88 7064372 O-Ring, 3/4 x 15/16

89 7064380 O-Ring, 7/16 x 5/8

90 7085263 Valve Cover

91 7074123 Screw, #10-14 x 2 (5 req.)

92 7077472 Expansion Pin

93 7030713 Switch

94 7117816 Spacer

95 7070412 Screw, #4-24 x 1-1/8 (flat head)

96 7097171 Sensor Housing

97 2204101 Turbine Support and Shaft

98 7117858 Turbine

99 9000803 O-Ring

u 7137507 Nozzle & Venturi Assy. (incl. Key

u 7144813 Parts Bag, Model No. 625.3485400

u 7144821 Parts Bag, Model No. 625.3483500

u 7129716 Seal Kit (incl. Key Nos. 67, 68, 71,

u 42--3433 Drain Hose, 3/8² I.D. x 20¢ ¡

u not illustrated

¡ PARTS INCLUDED WITH MODEL NO. 625.3484500 ONLY.

P ART

NUMBER

DESCRIPTION

Nos. 75, and 78 through 84)

(incl. parts marked with a l, pages

28, 29 & 31) — order manuals separately, if needed.

(incl. parts marked with a s, pages

28, 29 & 31) — order manuals separately, if needed.

85, 88 and 89).

BYPASS INSTALLATION VALVE

MODEL NO. 625.34372

KEY

NO.

100 0502206 Retainer Ring

101 7129863 Bypass Body

102 7105013 O-Ring, 13/16 x 1 (4 req.)

103 7130911 Stem

104 0900535 O-Ring, 15/16 x 1-3/16 (2 req.)

u 42--3437 Bypass Valve (Complete) Y¡

P ART

NUMBER

DESCRIPTION

31

Page 32

OWNER’S

MANUAL

Demand Water Softeners

MODEL NOS.

625.3483400

625.3483500

The model number of

your water softener is

found on the rating decal. This decal is on the

rim, underthe salt cover.

Whenrequestingservice

or ordering parts, always

provide the following information:

For the repair or replacement parts you need

delivered directly to your home

Call 7 am -- 7 pm, 7 days a week

1 -- 800 -- 366 -- PART

(1 -- 800 -- 366 -- 7278)

For in--home major brand repair service

Call 24 hours a day, 7 days a week

1 -- 800 -- 4 -- REPAIR

(1 -- 800 -- 473 -- 7247)

For the location of a

Sears Parts and Repair Center in your area

Call 24 hours a day, 7 days a week

1 -- 800 -- 488 -- 1222

REPAIR SERVICES

REPAIR SERVICES

z Product Type

z Model Number

z Part Number

z Part Description

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

For information on purchasing a Sears

Maintenance Agreement, or to inquire

about an existing Agreement

Call 9 am -- 5 pm, Monday -- Saturday

1 -- 800 -- 827 -- 6655

America’s Repair Specialists

7137573 (4/94)

Loading...

Loading...