Kenmore 41790802992, 41790812992, 41791702001, 41793702200, 41793702201 Installation Guide

...Page 1

Before you begin ..................................................... 2

Location ................................................................... 2

Recommended grounding instructions .................... 2

Electrical requirements ............................................ 2

Exhaust requirements ............................................. 3

Water supply and drain requirements ...................... 3

I

I

stalla

st ct

[]

Please begin ............................................................ 3

|

Alternate installations .............................................. 5

Alternate methods of securing drain hose ............... 5

Alternate exhaust methods ...................................... 6

Alternate electrical connection ................................ 6

Rough-in dimensions ............................................... 8

Laundry Center

washer/dryer 240 volts

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

P/N 131639100D (0503)

Page 2

Before you begin...

Please read these instructions all the

way through.

'_ screwdriver screwdriver

j 5ocket Level

A You need these tools to

install your Kenmore Laundry

® Center. Getthem together in

one place to keep track of

them.

spot

B Check the where are

State code/law requirements: Some

Codes keep from or limit installation of

clothes dryers in residential garages,

closets, mobile homes and sleeping

quarters. (Check with your local building

inspector.)

Important: Observe all governing

codes and ordinances.

going to install the Laundry

®Center. Proper installation is

your responsibility. Make

sure you have everything

necessary for proper

installation.

You will need to meet

you

Location

Size: Must be large enough to fully open

dryer door. For recessed or closet

installations see Page 5 for spacing; for

product dimensions see the last page of these

instructions.

Support: The floor must be able to support

the appliance loaded weight of 500 pounds.

Level Floor: Maximum floor slope under

Laundry Center is 1 inch.

Protection from the weather:

Proper operation of dryer cycles requires

temperatures above 45°F. As some water

remains in the washer, do not store or

operate the washer below 32°R For

storage below 32°F. see Use and Care

Guide for "Winterizing."

_ It is the personal responsibility of

the customer to ensure that gasoline,

paint, thinners and other flammable

materials are not used or stored near the

Laundry Center. Fumes from these

materials could result in fire, explosion

or personal injury.

_Never install the Laundry Center up

against draperies or curtains and be sure

to keep any and all items from failing or

collecting behind the Laundry Center.

_ Replace all access or service panels

before operating Laundry Center.

Recommended

grounding instructions

Electrical ground is required

on this appliance.

This appliance must be grounded. In the

event of malfunction or breakdown,

grounding will reduce the risk of electric

shock by providing a path of least

resistance for electric current.

Improper connection of

the equipment-grounding conductor

can result in a risk of electric shock. Check

with a qualified electrician or serviceman

if you are in doubt as to whether the

appliance is properly grounded.

Electrical requirements

1. A S-wire single phase 120/240 volt

60Hz AC only electrical supply (or 3-

wire 120/208 volt if specified on

nameplate) is required on a separate

30 ampere circuit, fused on both

sides of the line (time-delay fuse or

circuit breaker is recommended). Do

not have a fuse in the neutral or

ground circuit.

Ifa power supply cord is used, it must

be a 30 amp rated flexible type with

three open end spade lug connectors

with upturned ends or closed loop

terminal connectors. A U.h

recognized strain relief (U.L mark on

it or Sears Part No. 687000) to fit a

one inch hole must be used. When

local codes permit, it must be plugged

into a mating 30 amp receptacle

(NEMA) type 10-30R. See Figure 1.

Figure 1

3-wire receptacle

(10-30R)

The appliance may be connected

directly to the fused disconnect (or

circuit breaker) box through flexible

armored or nonmetallic sheathed 10

gauge COPPER cable, DO NOT USE

ALUMINUM WIRE. It is the personal

responsibility and obligation of the

customer to contact a qualified

installer to assure that the electrical

installation is adequate and is in

conformance with the National

Electrical Code and local codes and

ordinances. A U.L recognized strain

relief must be provided at each end

of the power supply cable (at the

appliance and at the junction box).

Wire sizes (10 gauge COPPER WIRE

ONLY) and connection must conform

with the rating of the appliance (30

amperes).

DO NOT USE AN EXTENSION CORD.

4.

For mobile home

installation, the appliance frame must

not be connected to the neutral

terminal, but must be connected to

the ground cord (see Page 6,

Alternate Electrical Connection, for

detailed instructions).

Figure 2

4-wire receptacle

(14-30R)

Typical 30 Amp receptacle use:

Use where local codes permit flexible

type supply cord (pigtail).

If a 4-wire single phase 120/240 volt

60Hz AC receptacle of NEMA type 14-

30R (see Figure 2) is available, a matching

power supply cord (pigtail) must be used.

This cord contains 4 No. 10 gauge copper

conductors with spade or ring terminals

on the Laundry Center end and

terminating in a NEMA type 14-30P plug

on supply end. The fourth (grounding)

conductor must be identified by a green

cover and the neutral conductor by a

white cover. Cord should be type SRD or

SRDT, with a U.L. recognized strain relief,

and be at least 3 feet and no more than

6 feet long. The 4-wire power supply

cord and strain relief are not provided

with the Laundry Center.

NOTE: Laundry Center dryers operating

on 208 volt power supply will have longer

drying times than dryers operating on

240 volt power supply.

Exhaust requirements

Use only 4 inch (10.16 cm) diameter

(minimum) rigid or flexible metal duct

and approved vent hood which has a

swing-out damper(s) that opens when

the dryer is in operation. When the dryer

stops, the damper(s) automatically closes

to prevent drafts and the entrance of

insects and rodents. To avoid restricting

the outlet, maintain a minimum of 12

inches (38.5 cm) clearance between the

vent hood and the ground or any other

obstruction.

The following are

specific requirements for proper and

safe operation of your laundry center.

Failure to follow these instructions can

create excessive drying times and fire

hazards.

Page 2

Page 3

r,'_ Do not use plastic flexible

duct to exhaust the dryer. Excessive lint can

build up inside the exhaust system and create

a fire hazard and restrict air flow. Restricted

air flow will increase drying times, if your

present system is made up of plastic duct or

metal foil duct, re_lace it with a rigid or

flexible metal duct. Ensure the present duct

is free of any lint prior to installing laundry

center dryer duct.

_!_[[_ If the dryer is not

exhausted outdoors, some fine lint will be

expelled into the laundry area. An

accumulation of lint in any area of the home

can create a health and fire hazard. The

dryer exhaust system MUST be

exhausted to the outside of the

dwelling!

_v'__ Do not allow

combustible materials (for example:

clothing,draperies/curtains, paper) to come

in contact with the exhaust system. The dryer

MUST NOT be exhausted into a chimney, a

wall, a ceiling, or any concealed space of a

building which can accumulate lint, resulting

in a fire hazard.

Do not exceed the

length of duct pipe or number of elbows

allowed in the" EXHAUST DUCT LENGTHS"

chart. Lint can accumulate in the system,

plugging the system and creating a fire

hazard, as well as increasing drying times.

Do not screen the

exhaust ends of the vent system, nor use

any screws or rivets to assemble the exhaust

_stem. Lint can become caught inthe screen,

on the screws or rivets, clogging the exhaust

system and creating a fire hazard as well as

increasing drying times. Use an approved vent

hood to terminate the duct outdoors, and

seal all joints with duct tape. All male duct

pipe fittings MUST be installed downstream

with the flow of air.

Explosion hazard. Do

not install the laundry center where gasoline

or other flammables are kept or stored.If

the laundry center is installed in a garage, it

must be a minimum of 18 inches (45.7 cm)

above the floor. Failure to do so can result in

death, explosion, fire or burns.The exhaust

system back pressure MUST not exceed 0.6

inches (1.52 cm) of water column, measured

with an inclined manometer at the point

the exhaust connects to the dryer. The

exhaust system should be inspected and

cleaned a minimum of every two years with

normal usage. The more the dryer is used,

the more often you should check the

exhaust system and vent hood for proper

operation.

The Maximum Length of the exhaust

system depends upon the type of duct

used, number of elbows and type of

exhaust hood. The maximum length for

both rigid and flexible duct is shown in

chart.

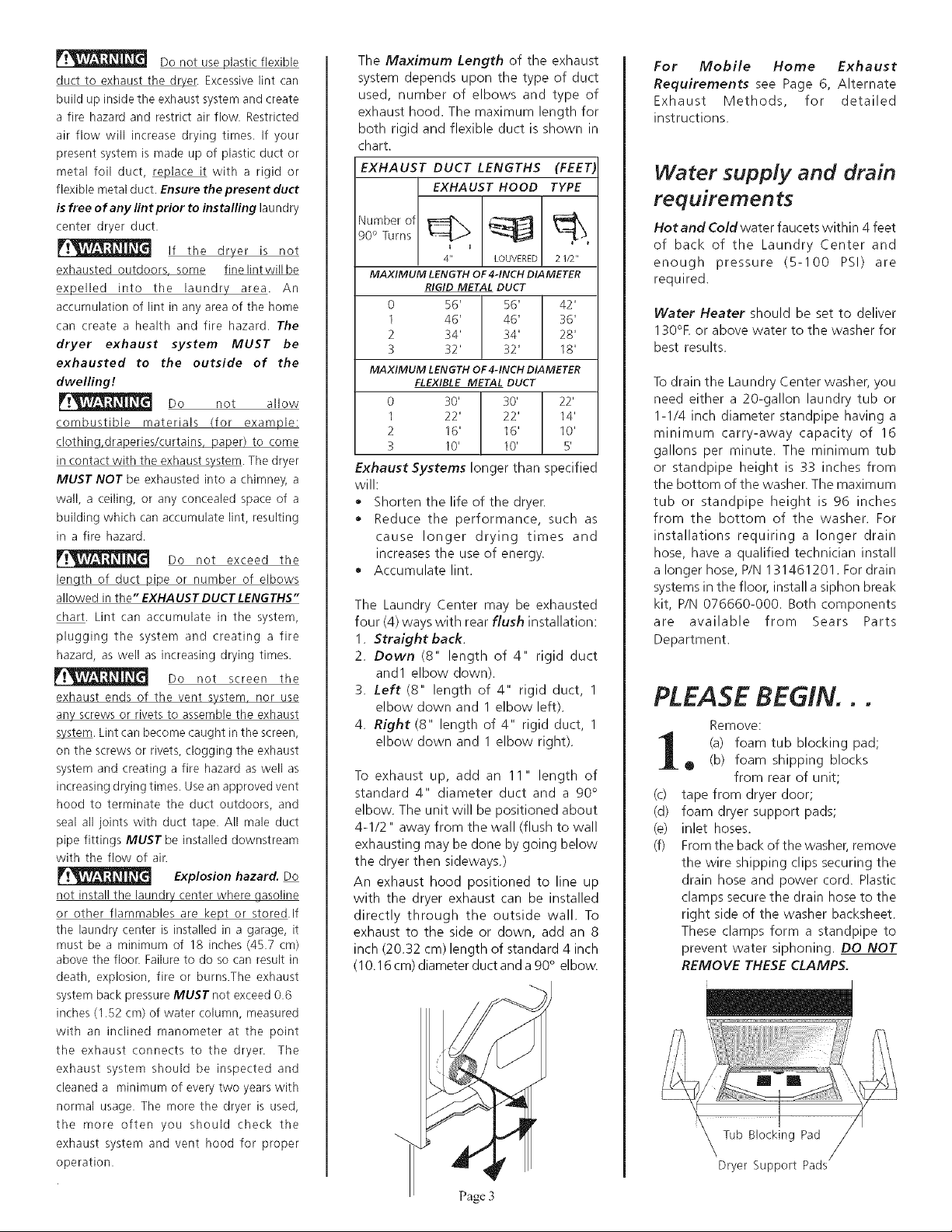

EXHAUST DUCT LENGTHS (FEET)

EXHAUST HOOD TYPE

Numberof _ _ _

go° Turns

MAXIMUM LENGTH OF 4-INCH DIAMETER

0 56' 56' 42'

1 46' 46' 36'

2 34' 34' 28'

3 32' 32' 18'

MAXIMUM LENGTH OF 4-INCH DIAMETER

0 30' 30' 22'

1 22' 22' 14'

2 16' 16' 10'

3 10' 10' 5'

Exhaust Systems longer than specified

will:

• Shorten the life of the dryer.

• Reduce the performance, such as

cause longer drying times and

increases the use of energy.

• Accumulate lint.

I I

4" LOUVERED 21/2"

RIGID METAL DUCT

FLEXIBLE METAL DUCT

The Laundry Center may be exhausted

four (4) ways with rear flush installation:

1. Straight back.

2. Down (8" length of 4" rigid duct

and1 elbow down).

3. Left (8" length of 4" rigid duct, 1

elbow down and 1 elbow left).

4. Right (8" length of 4" rigid duct, 1

elbow down and 1 elbow right).

To exhaust up, add an 11 " length of

standard 4" diameter duct and a 90°

elbow. The unit will be positioned about

4-1/2" away from the wall (flush to wall

exhausting may be done by going below

the dryer then sideways.)

An exhaust hood positioned to line up

with the dryer exhaust can be installed

directly through the outside wall. To

exhaust to the side or down, add an 8

inch (20.32 cm) length of standard 4 inch

(10.16 cm) diameter duct and a90° elbow.

For Mobile Home Exhaust

Requirements see Page 6, Alternate

Exhaust Methods, for detailed

instructions.

Water supply and drain

requirements

Hot and Coldwater faucets within 4 feet

of back of the Laundry Center and

enough pressure (5-100 PSI) are

required.

Water Heater should be set to deliver

130°F. or above water to the washer for

best results.

Todrain the Laundry Center washer, you

need either a 20-gallon laundry tub or

1-1/4 inch diameter standpipe having a

minimum carry-away capacity of 16

gallons per minute. The minimum tub

or standpipe height is 33 inches from

the bottom of the washer. The maximum

tub or standpipe height is 96 inches

from the bottom of the washer. For

installations requiring a longer drain

hose, have a qualified technician install

a longer hose, P/N 131461201. For drain

systems in the floor, install a siphon break

kit, P/N 076660-000. Both components

are available from Sears Parts

Department.

PLEASE BEGIN...

Remove:

(a) foam tub blocking pad;

® (b) foam shipping blocks

(c)

tape from dryer door;

(d)

foam dryer support pads;

inlet hoses.

(e)

(f)

From the back of the washer, remove

the wire shipping clips securing the

drain hose and power cord. Plastic

clamps secure the drain hose to the

right side of the washer backsheet.

These clamps form a standpipe to

prevent water siphoning. DO NOT

REMOVE THESE CLAMPS.

from rear of unit;

Page 3

Page 4

Usingthe four shipping cartoncorner posts (two on each

• side), carefully lay the

Laundry Center on its left side and

remove the foam shipping base.

Plastic Spacer Block Shipping Clips

Mechanisrn']_4_ _" _/

Shipping

h,pping1

Shipping_g_ _

Pad _ __-'_

Shipping Carton

Corner Posts

socket, remove mechanism

Usingtile ratchetwith 3/8 inch

• shipping bolt. Removeplastic

spacer block from centerof baseusing

adjustable pliers.

NOTE: If the Laundry Center isto be

transported at a later date, the tub

blocking pad,shipping bolt and plastic

spacer block should be retained.

__"_"_ Tub

_ _ _ _BJocking

Plastic_

Spacer _ Shipping

Block-_ b B°lt

Hose

and cold faucets to flush the

Runsome water from tile hot

• water lines and remove

particles that might clog up the water

valve screens. Check inlet hoses to

ensurethe rubberwashersare installed

in eachend. Carefully connect the inlet

hosesto the watervalve(onthe left side

of the washercabinet),tighten byhand,

then tighten another 2/3 turn with

pliers.

DO NOT CROSS

THREAD OR OVERTIGHTEN

THESE CONNECTIONS.

istile HOTwater faucet and

Determinewhich water faucet

® carefullyconnectthe bottom

inlet hose to the HOT water faucet,

tighten by hand, then tighten another

2/3 turn with pliers.Carefully connect

the top inlet hose to the COLD water

faucet, tighten byhand, then tighten

another 2/3 turn with pliers.

DO NOT CROSS

THREAD OR OVERTIGHTEN

THESE CONNECTIONS.

Turntile water on and check for leaks

at both connections.

__"X

Center is solid and level, tilt

0 To make sure the Laundry

• the machine Ibrward so the

rear legs are offthe ground. Gently set

the machine back down to allow the

rear legs to self adjust. Place a level on

top of the washer. Check it side to side,

then front to back. Screw the front

leveling legs up or down to make sure

the unit is solid on all four legs (no

rocking of the appliance should exist).

i

1 Remove two (2) screws

securing front access panel

o to dryer cabinet. Lower

panel until bottom tabs can be

disengaged from cabinet, remove

panel, and set aside.

Access

Screws

Return Laundry Center to

• upright position.

cord.

Install 3-wire power supply

® a. Removethe terminal block

cover located at the rear of the dryer.

b. Install U.L approved strain relief

(Figure11)in one inchhole ondryer

back below terminal block opening.

c. Thread U.L approved 30 amp

power cord through strain relief.

d. Connectthe centerwire of the power

cord to the center silver colored

terminal screwof the terminal block

and tighten securely.

e. Connectthe other wiresto the outer

terminals and tighten securely

(Figure 12).

f. Replacethe terminal block cover.

Form a "U" shapeonthe end

of the drainhosewith the hose

• pointed toward the drain.

Placethe formed end in a laundry tub

or astandpipe and securewith a cable

tie provided inthe enclosure package.

WATER COIJLD

SIPHON FROM THE LAUNDRY

CENTER IF THE ABOVE

INSTRUCTIONS ARE NOT

FOLLOWED,

laundry center to

• its final location.

Plug the power cord into a

grounded outlet.

Carefully move the

Page 4

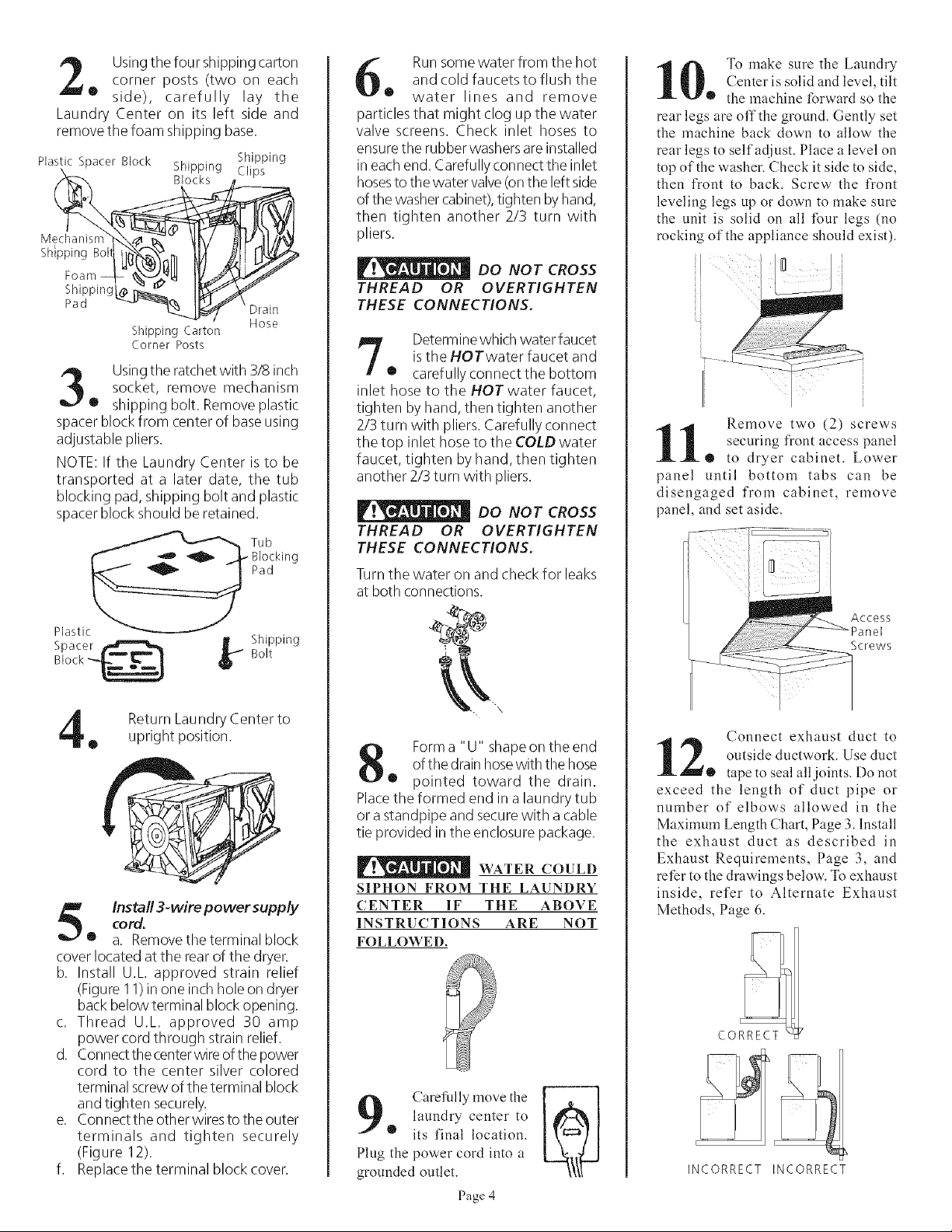

Connect exhaust duct to

2 outside ductwork. Use duct

• tape to seal all.joints. Do not

exceed the length of duct pipe or

number of elbows allowed in the

Maximum Length Chart, Page 3. Install

the exhaust duct as described in

Exhaust Requirements, Page 3, and

refer to the drawings below. To exhaust

inside, refer to Alternate Exhaust

Methods, Page 6.

CORRECT

INCORRECT INCORRECT

Page 5

INCORRECT

L

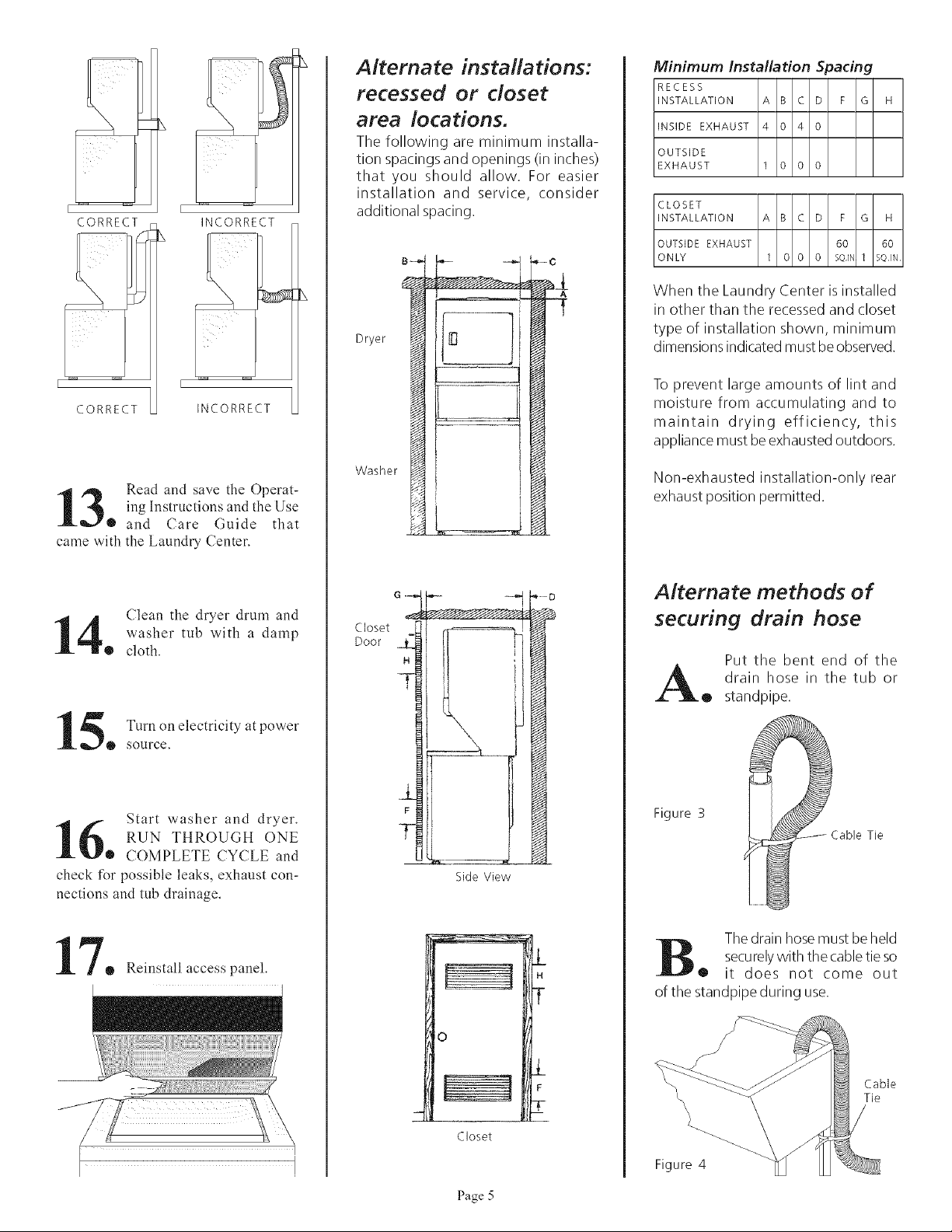

Alternate installations:

recessed or closet

area locations.

The following are minimum installa-

tion spacings and openings (in inches)

that you should allow. For easier

installation and service, consider

additional spacing.

Dryer

Minimum Installation Spacing

RECESS

INSTALLATION A B C D F G H

INSIDE EXHAUST 4 0 4 0

OUTSIDE

EXHAUST 1 0 0 0

CLOSET

INSTALLATION A B C D F G H

OUTSIDE EXHAUST 60 60

ONLY I O 0 0 SQIR I SQIN

When the Laundry Center isinstalled

in other than the recessed and closet

type of installation shown, minimum

dimensionsindicatedmust beobserved.

h

CORRECT

ing Instructions and the Use

3 Read and save the Operat-

• and Care Guide that

INCORRECT

came with the Laundry Center.

4 Clean the dryer drum and

washer tub with a damp

• cloth.

5 Turn on electricity at power

• source.

Start washer and dryer.

16 RUN THROUGH ONE

• COMPLETE CYCLE and

check for possible leaks, exhaust con-

nections and tub drainage.

Wastner

Closet

Door

To prevent large amounts of lint and

moisture from accumulating and to

maintain drying efficiency, this

appliance mustbeexhausted outdoors.

Non-exhausted installation-only rear

exhaust position permitted.

Alternate methods of

securing drain hose

H

F

Side View

Figure 3

Put the bent end of the

drain hose in the tub or

standpipe.

__able Tie

7® Reinstall access panel.

0

_ r

Closet

Page 5

L

T

t_

F

Thedrain hosemust beheld

securelywith the cabletie so

• it does not come out

of the standpipe during use.

Cable

Tie

Figure 4

Page 6

C ecure the hose as shown

in Figures 3 Standpipe, 4

® Tub, 5 In wall standpipe.

Alternate electrical

connection

Disconnect power supply cord from

electric supply before making these

changes.

Electrical ground is required on this

appliance.

Figure 9 Clam

Metal

Pipe

No. 4 Copper Wire

FigUreCable5Tie _ ..........

BE SURE THE HOSE IS NOT

TWISTED OR KINKED AND IS

SECURELY IN PLACE.

Alternate Exhaust

Methods

There are exhaust kits

a available that allow you to

o direct filtered exhaust

air inside to conserve energy during

winter months. You may use these

deviceswith the Laundry Center dryer

providing their use does not violate

national or localcodes, and the device

does not restrictexhaust airflow. Ifyou

use one of these kits, be aware that

excessive moisture in the home can

causemanyproblemsand that you may

seean increase in the time required to

drya load. Also,you must maintain the

kit installation properly to avoid

excessivelint buildup, which can affect

the dryer's performance.

This appliance is manufactured with the

neutral terminal connected to the frame.

A If local codes permit the use

DO NOT permit connection of the

frame grounding conductor to the

neutral wire of the power supply

cord:

a. Remove terminal block cover.

b. Remove the ground wire from the

Ground wire _ ] Green

#10 mirfimurn f l jground

(not supplied)_[[

of a flexible-type power

® supply cord (pigtail) and:

green ground screw and f_sten

under center silver-colored

terminal block screw. See Figure

8.

_-_€'I _ Ground clamp

"'"_)_T'_ attach to metal

cold water pipe

gmund_'_ \q V/ colored

wire ] ]

d. Connecttheneutralwireofthe

flexiblearmoredornonmetallic

sheathedcopperpowersupply

cabletothecentersilver-colored

terminalscrewoftheterminal

blockandconnecttheotherwires

totheouterterminals.SeeFigure

12.Forconnectingplain-end

fieldwire,seeFigure15.

e.

Replacetheterminalblockcover.

Green

ground screw

\

ground

wire

Neutral

Grounded neutral

Figure 12

DO NOT permit connection of"the

frame grounding conductor to the

neutral wire of the power supply

cord:

a. Remove terminal block cover.

b. Install U.L. approved strain relief"

(Figure 11) in one inch hole on

dryer back below terminal block

opening.

c. Install copper power supply

cable.

d. Remove the ground wire from the

green ground screw and f_sten

under center silver-colored

terminal block screw.

e. Connect the neutral wire of the

power supply cable to the center

silver-colored terminal of the

terminal block and connect the

other wires to the outer terminals.

See Figure 13. For connecting

plain-end wire see Figure 15.

Green Ground Green Conductor

Screw , Silver Terminal

Terminal Block

Ground

Wire

Connect ,,round wire

from externalground connector to

approved ground.

Ungrounded neutral

Figure 13

fi Connect a separate copper

ground wire (No. 10 minimum)

to a grounded cold water pipe*

by means of a clamp and then to

the frame of the appliance at the

green ground screw. Use Part

No. 685463 ground wire and

clamp assembly. Do not ground

to a gas supply pipe. Do not

connect the power supply cord

to electric power supply until

appliance is permanently

grounded.

g. Replace the terminal block

cover.

*Grounded cold water pipe must have

metal continuity to electrical ground and

not be interrupted by plastic, rubber or

other electrical insulating connectors

(such as hoses, fittings, washers or

gaskets, including water meter or pump).

Any electrical insulating connector

should bejumped as shown in Figure 9

with a length of" No. 4 wire securely

clamped to bare metal at both ends.

If connecting to a four-

wire electrical system

® (mobile home):

1. Remove the terminal block cover.

2. Install U.L. approved strain relief

(Figure 11) in one inch hole on duer

back below terminal block opening.

3, Install copper 4-wire power supply

cord.

Remove the ground wire from the

green ground screw and fasten

under center silver-colored terminal

block screw.

5. Connect the ground wire (green) of"

the copper 4-wire power supply cord

to the green ground screw.

Connect the neutral wire (white) of

the power supply cord to the center

silver-colored terminal screw of the

terminal block and connect the other

wires to the outer terminals. See

Figure 14. For connecting plain-end

field wire, see Figure 15.

7, Replace the terminal block cover.

Page 7

Green Ground

Screw Green

€Conductor

Ground

Wire

Red White Black

4-wire ungrounded neutral

Figure 14

IF YOUR POWER SUPPLY CORD

OR DIRECT WIRING HAS PLAIN

WIRE ENDS, SEE FIGURE 15 AND

FOLLOW THESE STEPS:

Silver Terminal

Terminal

Block

1. Strip outer covering back 3 inches

from the end exposing the 3 wires.

2. Strip the insulation back 1inch from

the end of each wire. Form the bare

wire into a U-shaped hook.

3. Loosen, do not remove, the center,

silver-colored screw of the terminal

block.

4. Slide the end of the neutral (white

or center) wire under the screw head

with the open side of"the hook on

the right. Squeeze the wire together

to form a loop.

5. Tighten the screw firmly.

6. Connect the remaining 2 wires to the

outer screws the same way. Tighten

the screws firmly.

Green Ground Screw

)

Ground

Wire "_ "Neutral

Plain-end field wiring

Figure 15

Page 8

ROUGH-IN D_MENSIONS

75 112"

54 5116"

0

WATER INLETS

(REAR)

"b

"i_''_ 41 114"

29 7116"

16 1/4"

25 1/4"

2 W2_

T

4 13!16"

I

_ 3 3/4_

27"

tl 7116"

...............30 13/16 ..... "_

Sears, Roebuck and Co.

Hoffman Estates, IL 60179 U°S.A.

Made in U.S.A.

Page 9

Antes de comenzar ............................................................ 2

Lugar de instalacion ........................................................... 2

Instrucciones recomendadas para la puesta a tierra ......... 2

Requerimientos electricos .................................................. 2

I strucc

pa la

l stal

Requerimientos del sistema de escape ............................. 3

Requerimientos para el agua y el desagOe ........................ 3

[]

f

Para comenzar ................................................................... 3

|

Instalaciones alternas ........................................................ 5

Metodos alternos para sujetar la manguera de desagOe... 5

Metodos de escape alternos .............................................. 6

ConexiOn electrica alterna .................................................. 6

Dimensiones para la instalacion ........................................ 8

Lavadora y Secadora Superpuestas

lavadora/secadora 240 voltios

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

P/N 131639100D (0503)

Page 10

Antes de comenzar...

Le regames leer atentamenle tedas estas

instrucciones.

_ador Zdor

de Punta Plana Phillips

_ _cates

A sted necesita estas herra-

puestas Kenmore. MantOngalas todasjuntas

para facilitar el uso.

es responsable de efectuar una instalacidn

adecuada. AsegOrese de que tiene todo Io

necesario para una instalacion correcta.

_ Usted deberfi cumplir los

requerimientos estatales del c6digo y

legales: Algunos cbdigos prohiben o limitan

la instalacidn de secadoras de ropa en garrties

residenciales, armarios, casas m6viles y

dormitorios. ((onsulte con su inspector local

de construccidn.)

Importante: Observe tedos los

reglamentos y codigos vigentes.

Lugar de insta#acidn

Tama_o: Debe ser Io sufidentemente grande

para que [a puerta de la secadora pueda

abrirse completamente. Paralas instalaciones

en nichos o armarios, vea [apagina 5 para [as

dimensiones del espacio; para lasdimensiones

de los artefactos vea la Oltima pagina de estas

instrucciones.

Soporte; Elpiso debe ser capaz de soportar

el peso de 500 libras del artefacto cargado.

Piso Nivelado: El desnivel maximo bajo [a

Lavadora/Secadora Superpuestas es de 1

pulgada.

Proteccidn contra las inclernencias del

tiernpo: Elfuncionamiento adecuado de los

ciclos de la secadora exigen temperaturas

superioresa45 °R Debidoaquequedaun

poco de agua en la lavadora, no guarde o

haga funcionar la lavadora a temperaturas

inferiores a 32 ° R Para almacenamiento a

temperatura inferior a 32° F,vea en la Gu[a

de Uso y Cuidado [aseccion sobre "Proteccion

para el invierno".

DEs responsabiNdad del cNente asegurarse

de que no se users o almacenen gasolina,

pintura, diluyentes y otros materiales

inflamables cerca de la Lavadora/Secadora

Superpuestas. Los vapores de estos productos

pueden causar un incendio, una explosion o

lesiones personales.

_2_ Nunca instale [a Lavadora/Secadora

de tubo Nive[

mientas para instalar su

O Lavadora/Secadora Super-

Verifique el lugar don de

desea instalar la Lavadora/

D Secadora Superpuestas. Usted

Superpuestas cerca de cortinas o cortinajes y

evite que caigan o seguarden articulos detras

de la Lavadora/Secadora.

_ Vuelva a colocar todos los paneles de

acceso o de servicio antes de poner en

funcionamiento la Lavadora/Secadora

Superpuestas.

lnstrucciones

recomendadas para #a

puesta a tierra

Este artefacto debe set puesto a

tierra.

En caso de malfuncionamiento o faNa, la

puesta a tierra reducir_i el riesgo de choque

electrico al proveer un trayecto de menor

resistencia a la corriente electrica.

Laconexi6n

incorrecta del conductor de puesta a tierra

del equipo puede resultar en un riesgo de

choque elOctrico. Consulte con un electricista

o t(_cnico de servicio calificado si usted tiene

dudas respecto a la puesta a tierra correcta

del artefacto.

Requerimientos electricos

1. Se requiere corriente elOctrica CA de 60

Hz, 120/240 voltios, monof_isica, trifilar (o

trifilar, 120/208 voltios si est.1especificado

en [a plata de nombre) en un circuito

separado de 30 amperes, con fusibles en

ambos lados de la Ifnea (se recomienda

fusible de retardo o disyuntor). No tenga

un fusible en el circuito neutro o de puesta

a tierra.

2. Si se usa un corddn elOctrico debe ser

para 30 amperes, flexible con tres

conectores de horquilla con terminales

abiertos y extremos dirigidos hacia arriba

o coneclores de anillos cerrados. Sedebe

usar un anclaje de cable aprobado por el

U.L (marcado U.L o el repuesto Sears

No. 687000) que ajuste en un agujero de

una pulgada. Cuando los cddigos locales

Io permitan debe ser enchufado en un

tomacorriente de 30 amperes (NEMA) del

tipo 10-30R. Ver Figura 1.

3. El artefacto puede ser conectado

directamente a la caja de desconexiOn

con fusibles (o disyuntor) mediante un

cable de COBRE de calibre 10 flexible, no

metNico y forrado. NO USEALAMBRE

DE ALUMINIO. Es la responsabilidad

personal y obligaciOn del cliente consultar

con un instalador calificado para

asegurarse de que la instalacidn elOctrica

sea adecuada yen conformidad cors el

COdigo Eledrico National y con loscodigos

y reglamentos locales. Un anclaje de cable

aprobado por U.L debe ser colocado en

cada extremo del cable de suministro

elOctrico (en el artefacto yen la caja de

empalme). Los tamaf_os de los alambres

y de la conexion (cobre solamente, calibre

10 deben cumplir con el rOgimen nominal

Tomacorriente de 3 tomas

Figura 1

(IO-SOR)

de[ artefacto (30) amperes).NO USE UN

CORDON DEEXTENSION.

4. _ Para la instalacion

en casas mdviles, el bastidor del arlefacto

no debe ser conectado al terminal neutro,

sino que ser conectado al cordon de

puesta a tierra (ver Pagina 6, Conexion

ElOctrica Alterna, para instrucciones

detalladas).

Uso tipico del tomacorriente de 30 amperes:

Usese donde los codigos locales permitan el

uso de cordon elOctrico del tipo flexible.

Sisedispone de un tomacorriente de 4 tomas

monofasico, 120/240 voltios, 60Hz CA tipo

14-30R NEMA (ver Figura 2), se debe usar un

cord6n electrico que tenga la misma potencia

(flexible). Estecordon contiene 4 condudores

de cobre, calibre 10 con terminales de

horquilla o anillo cerrado ene[ extremo de

conexion a la Lavadora/Secadora

Superpuestas y termina en un enchufe tipo

14-30P NEMA en el extremo de la

alimentacidn. Elcuarto conductor (de puesta

atierra) debe ser identificado por su cubierta

verde y el conductor neutro por su cubierta

blanca. El cordon debe ser del tipo SRD o

SRDT,con un anclaje de cable aprobado por

el U.L y debe ser por Io menos de 3 pies de

largo y no mas de 6 pies de largo. El cordon

Figura 2

Tomacorriente de 4 tomas

(14-30R)

electrico de de 4 conductores y el andaje del

cable no son suministrados con [a Lavadora/

Secadora Superpuestas.

NOTA: Las secadoras que funcionan cors un

suministro elOctrico de 208 voltios tendran

tiempo de secado m_s largo que las secadoras

que funcionan con un suministro elOctrico de

240 voltios.

Requerimientos del

sistema de escape

UtiNcesolamente ductos met_licos, r[gidos

ofiexiblesde4" (10,2 cm)dediametro

(minimo) y una caperuza de saNdade uso

aprobado, con registros que giren hacia

afuera que se abren cuando [a secadora se

encuentra en funcionamiento. Cuando la

secadora se detiene, los registros secierran

automaticamente para evitar [as corrientes

de aire y [aentrada de insectos y roedores.

Para evitar obstruir la salida, mantenga una

altura Nbremfnima de 12"(30,5 cm) entre la

caperuza de salida yel piso o entre cualqu ier

otra obstruccidn.

FI_[_ LOS siguientes

requerimientos son especificos para el

funcionamiento correcto y seguro de su

secadora. El incumplimiento de estas

instrucciones puede causarprolongacion

excesiva del tiempo de secado y riesgos de

incendio.

Pfigina 2

Page 11

]No use ductos flexibles de pBstico para el

escape de la secadora.

Sepuede acumular un exceso de pelusas en el

sistema de escape, treat un riesgo y obstruir el

flujo de aire. La restriction del flujo del aire

prolongara el tiempo de secado. Si su sistema

de escape actual tiene ductos de pBstico o de

laminas metalicas delgadas, _lacelo con

un ducto met_ilico rigido o flexible. AsegOrese

de que los ductos existentes no tengan

pelusas antes de instalar el ducto de la

secadoFa.

[]Si el escape de la secadora no se dirige al

exterior, algunas pelusas finas seran sopladas

hacia el recinto don@ se efect0a el lavado. La

acumulaciOn de pelusas en cualquier lugar de

la casa, puede crear un peligro para la salud y

un riesgo de incendio, iEIsistema de escape

de la secadora DEBE estar dirigido hacia el

exterior de la vivienda!

] No permita que los materiales

combustibles (por ejemplo: la ropa, cortinas/

cortinajes, papel) tenqan contacto con los

ductos. El escape de la secadora NO DEBE

dirigirse hacia el interior de una chimenea, hacia

una pared, hacia el cielo raso o hacia cualquier

otro espacio reducido deledificio, donde puede

ocumr acumulaci6n de pelusas y constituir un

peligro de incendio.

] Exceder la Ionqitud deJconducto riqido o

los n0meros de codos permitidos en los

diagramas "LARGO Mi_XlMO" puede

disminuir la capacidad de exhaustaci6n del

sistema. Obstruir el conducto puede provocar

peligro de incendio, asi como aumentar el

tiempo de secado.

]No coloque un filtro en el extremo del

escape del sistema ni emplee tornillos o

remaches para ensamblar el sistema de escape.

Las pelusas podrian quedar atrapadas en los

filtros, en los tornillos o en los remaches, Iocual

obstruina el sistema de escape y creana un

riesgo de incendio, asl como tambien

prolongaria el tiempo de secado. Use una

caperuza de salida adecuada para el extremo

del ducto que salga al exterior de la vivienda y

selle todas las juntas con cinta adhesiva para

ductos. Todos losaccesorios detuberia machos,

DEBEN ser instalados aguas abajo del flujo de

aire.

Riesgo de

explosi6n. No instale la secadora donde se

guarda gasolina uotros materiales infiamables.

Si lasecadora se instala en un garage, ella debe

estar por Io menos 18 pulgadas (45,7 cm) por

encima del suelo. El incumplimiento puede

resultar en la muerte, explosion, incendio, o

quemaduras.

1. La constrapresion del sistema de escape

NO DEBE exceder 0,6 pulgadas (1,52 cm)

de columna de agua, medida con un

manometro inclinado en la conexion del

ducto de escape a la secadora.

2.El sistema de escape debe ser

inspeccionado y limpiado cada 2 anos como

minimo, bajo condiciones de uso normal.

Mientras masse use la secadora, con mayor

frecuencia deben inspeccionarse el sistema

de escape y la caperuza de salida para

verificar su buen funcionamiento

El Largo M&ximo del sistema de escape

depende del tipo de ducto que se usa, del

nOmero de codos y del tipo de caperuza de

salida. En la tabla se muestra el [argo m_iximo

tanto para ductos flexibles como rigidos.

LARGOS DE DUCTOS DE ESCAPE (PIES)

TIPO DE CAPERUZA DE SALIDA

N0mero I_,decodos _ _

a 90° _ =

LARGO MAXIMO DE DUCTO DE METAL

RIGIDO DE 4 PULGADAS DE DIAMETRO

0 56' 56' 42'

1 46' 46' 36'

2 34' 34' 28'

3 32' 32' 18'

LARGO MAXIMO DE DUCTO DE METAL

FLEXIBLE DE 4 PULGADAS DE DIAMETRO

0 30' 30' 22'

1 22' 22' 14'

2 16' 16' 10

3 10' 10' 5'

Los Sistemas de Escape m_s [argos que los

especificados:

• Acortar_in la vida 0til de la secadora.

Reduciran el rendimiento, resultando en

prolongaci6n del tiempo de secado y

aumento del uso de energia.

• Acumular_in pelusas.

Se puede colocar el ducto de escape por

cuatro (4) maneras distintas cuando el

artefacto est_ instalado con elfondo paralelo

con la pared.

1. Derecho hacia atras.

2. Hacia abajo - ducto rigido, 8" (20,5 cm)

de Iongitud y4" (11,25cm) de di_metro &

1 ducto acodado hacia abajo.

3. Hacia la izquierda - ducto rigido, 8"

(20,5cm) de Iongitud y 4" (I 1,25cm) de

dkimetro, 1ducto acodado hada abajo y

un ducto acodado hacia la izquierda.

4. Hada la derecha - ducto r[gido, 8"

(20,5cm) de Iongitud y 4" (11,25cm) de

dkimetro, I ducto acodado hada abajo y

un ducto acodado hada la derecha.

Para colocar el ducto de escape hacia arriba,

aflada un ducto 11 " (28,2 cm) de Iongitud y

4" (11,25cm) de di_imetro y un ducto acodado

de 90 °, Elartefacto _"

debe estar a aproxi I //

-madamente41/2" I /_ /

(11,50cm)de la pared J/_ /--

(Se puede co[ocar el "/_ / /

ducto de escape k _

paraMo con la pared _k_.-_ I

por posicionarlo _ "'_

debajo de la secadora _ _,_

ydirigirlohacia _ _ _- r

un lado). _,f f

4" APERSIANADA 2 I/2"

Para permitir el escape lateral o inferior,

agregue un ducto de 8 pu[gadas (20,32 cm)

de largo y 4 pulgadas (10,I 6 era)de

diametro estandar y un codo de 90 °.

Para los Requerimientos del Sistema de

Escape en (asas M6viles, vea M6todos

Alternos de Escape en In P;_gina 6, para

instrucciones detalladas.

Requerimientos para el

agua y el desagSe

Serequieren [laves de agua caliente y fria a

una distancia de 4 pies de la parte trasera de

[a Lavadora/Secadora Superpuestas y

suficiente presion (5-100 Ibs/pulg.2).

Paraobtener mejores resultados elCalefactor

delAgua debe estar regulado de modo que

la temperatura del agua usada sea pot Io

menos de 130° F.

Para drenar [a Lavadora de la Lavadora/

Secadora Superpuestas, necesitara ya sea

un lavadero con capacidad para 75,7 litros

(20 galones) o una tuberia vertical de 3,17

cm (1 pulgada y 1/4) de di_metro con una

capacidad minima de vaciado de 60,5 litros

(16 galones) por minuto. La altura minima del

[avadero o de la tuberia vertical sera de 83,8

cm (33 pulgadas) desde el fondo de la

lavadora. Laaltura m_ixima del lavadero o de

la tuber[a vertical ser_ide 244 cm (96 pulgadas)

desde el fondo de la lavadora. Para las

instalaciones que requieran un tubo de drenaje

m_is largo, pida a un tOcnico capacitado que

insta[e un tubo m_is largo, P/N 131461201.

Para los sistemas de drenaje en elpiso, instale

un juego para detener la accion de sifon, N°

de pieza 076660-000. Ambos componentes

est_in disponibles en el Departamento de

Piezas de Repuesto de Sears.

PAPA COMENZAR...

(a) la pieza de espuma que

Saque:

® bloquea la cavidad;

(b) los bloques de espuma del embalaje de

la parte posterior del aparato;

(c) la cinta de la puerta de la secadora;

(d) las piezas de espuma para apoyar [a

secadora;

(e) Iostubosde entrada deagua.

(f) Saque las pinzas met_[icas del embalaje

de la parte posterior de la lavadora, que

sujetan el tubo de drenaje y el cable

e[ectrico. Hay abrazaderas de plZistico

que sujetan el tubo de drenaje en el

lado derecho del respaldo de la lavadora.

Estas abrazaderas forman una tuberia

vertical para prevenir el sifonaje de agua.

NO SA QUE E5 TASABRAZADERAS.

de [a Secadora

Page 12

la c_tiade cartdn (2 en cada lado),

Utilizando las cuatro esquineras de

® haga descansar cuidadosamente la

LavadoraiSecadora Superpuestas sobre el lado

izquierdo y saque la base de espuma de

embarque.

Bloque Espaciador

de Plkstico Bloquede

Sujetadoresde

Embarque

11 /

Espurna ---4- k'_."ZJ_ [_ IV_

Embarque

Esquineras de Embarque Desagt]e

de la Caja de Cart6n

3/8 de pnlgada, saqne el perno

Utilizando la llave de tnbo de

• de embarque. Saqne el bloqne

espaciador de plfistico del centro de la base

usando unos alicates ajustables.

NOTA: Si la Lavadora/Secadora

Superpuestas va a ser transporlada a otto

lugar posteriormente, conserve la espuma

de bloqueo de la tina, el perno de

embarque y el espaciador de plfistico.

Manguerade

Espumade

Bloqueode

los llaves de agna caliente y fria

Deje correr nn poco de agna de

• para vaciar las lineas y eliminar

las particulas que pueden obstruir las

rejillas de las vfilvulas de agna. Examine

los tubos de entrada de agua para

asegurarse de que las amndelas de caucho

est_n instaladas encada extremo. Conecte

con cuidado los tubos de entrada a la

vfilvula de agua (en el lado izquierdo de la

lavadora), apriete a mano y luego apriete

2/3 de vuelta con unos alicates.

NO ESTROPEE

LAS ROSCAS NI APRIETE ESTAS

CONEXIONES EXCESIVAM[ENTE.

agna es la de agna CALIENTE

Determine cufil de las llaves de

® y conecte con cuidado el tubo

inferior de entrada a la llave de agua

CALIENTE, apriete a mano y luego

apriete 2/3 de vuelta con unos alicates.

Conecte con cuidado el tubo superior de

entrada a la llave de agua FRIA, apriete a

mano y luego apriete 2/3 de vuelta con

unos alicates.

_NO ESTROPEE LAS

ROSCAS NI APRIETE ESTAS

CONEXIONES EXCESIVAMENTE.

l0 ara verificar si la Lavadorai

asentada, incline la mfiquina hacia adelante

de modo que los patas posteriores queden

en el aire. Luego vuelva a depositor

cuidadosamente la mfiquina para permitir

que los patas posteriores se ajusten.

Coloque un nivel de carpintero encima de

la lavadora. Revisela de lado a lado y luego

del fi'ente hacia Orris para asegurarse de

que el arte*hcto quede fim_emente asentado

sobre sus cuatro patas (no debe haber

movimiento de vaiv6n.

secadora. Haga descender el panel hasta

que las lengtietas inferiores puedan

desengancharse del gabinete, saque el

panel y coldquelo a un lado.

Secadora Superpuestas estfi

® nivelada y firmemente

aseguran el panel de acceso

1 Saque los dos (2) tornillos que

® delantero al gabinete de la

la Tina

Bloque Pernode

Espaciador

de Pl_stico_

Secadora Snperpnestas en la

Vnelva a colocar la Lavadora/

• posicidn vertical.

3 cenductores.

lnstale el corddn e|{ctrice de

• a. Saqne la tapa del tablero de

bornes situada en la parle trasera de la

secadora.

b. lnstale un anclaie de cable aprobado

pot el U.L. (Figura 11) en un agujero

de una pulgada en la parle trasera

debajo de la cavidad del tablero de

bornes.

c. Pase el cable de 3(1amperes aprobado

pot el U.L. a tray,s del anclaie.

d. Conecte el conductor central del

cord6n el_ctrico al tornillo de borne

plateado del tablero de bornes y apriete

firmemente.

e. Conecte los otros conductores a los

bornes externos y apriete firmemente

(Figura 12).

1. Vuelva a colocar la tapa del tablero de

bornes.

Abra la llave del agna y compmebe qne

no haya fllgas en ningnna de los dos

conexiones.

"-\

del tnbo de drenaje con el tnbo

Forn]e nna <<U>}en el extren]o

@ sefialando hacia el drenaie.

Coloque el extremo formado del tubo de

drenaje en un lavadero o una tuberia

vertical y fijelo con un sujetacables

incluido en el paquete.

ES POSIBLE QUE

EL AGUA SE SAOUE DESDE LA

LAVADORA/SECADORA

SUPERPUESTAS SI NO SE SIGUEN

LAS INSTRUCCIONES DE ARRIBA.

la LavadoraiSecadora

® Superpuestas hasta sn

nbicacidn definitiva.

Con cuidado, nmeva

Pfigina 4

Tornillos de[

de

Acceso

12 Conecte el dncto de escape

todas las uniones. No exceda el largo de

la tuberia del ducto o el numero de codos

permitido en la Tabla de Largo Mfiximo,

Pfigina 3. lnstale el ducto de escape como

se describe en la seccidn Requerimientos

del Sistema de Escape, Pfigina 3 y consulte

los dibujos que se incluyen a continuacidn.

Para conectar el escape hacia el interior,

consulte M4todos de Escape Alternos,

Pfigina 6.

hacia en sn lngar en el exterior.

® Utilice cinta para obtnrar

INCORRECTO INCORRECTO

Page 13

Instalaciones alternas:

Espacio de Instalacidn Minimo

instMacidn en un nicho o

en un armario.

A continuacidn se indican los espacios y

aberturas minimas necesarias para la

instalaci6n (en pulgadas}. Para facilitar

la instalaci6n y el servicio, se recomienda

I

I

INCORRECTO

agregar un poco milsde espacio.

INSTALACION

EN NICHO A B C D F G H

ESCAPE AL

INTERIOR 4 0 4 0

ESCAPE AL

EXTERIOR 1 0 0 0

INSTALACION

EN ARMARIO A B C D F G H

ESCAPE HACIA 60 60

EL EXTERIOR PULG PULG

SOLAMENTE 1 0 0 0 CUAD I CUAD

L

CORRECTO

3 Lea y conserve las

@ amiento y la Guia de Uso y

I

INCORRECTO

lnstrucciones de Funcion-

Cuidado incluida junto con la Lavadora

Secadora Superpuestas.

Limpie el tambor de la

4 secadora y la tina de la lava-

® dora con un patio hfimedo.

Conecte la corriente en el

® disyuntor/caiade fflsibles.

Secadora

Lavadora

Puerta del

Armario

Cuando la Lavadora/Secadora Super-

puestas es instalada en otro lugar que no

sea en un nicho o amlario como se muestra

en la ilustraci6n, se deben respetar las

dimensiones minimas indicadas.

Para evitar que se acmnulen grandes

cantidades de pelusas y hmnedad y

mantener la eficiencia del secado, este

artel:acto debe tener el escape hacia el

exterior.

Para las instalaciones sin escape, la Onica

posicidn de escape pennitida es en la parte

trasera.

G

Metodos altemos para

sujetar la manguera de

H

desagiJe

A Coloque el extremo doblado

de la manguera de desag0e en

® la tina o toma de agua.

y secadora, hfigala FUN-

6 Ponga en marcha la lavadora

• CIONAR DURANTE UN

CICLO COMPLETO y verifique si hay

escapes, revise las conexiones eRctricas

y el desagtie de la tina.

7 Vuelva a instalar el panel de

® acceso.

F

Vista Lateral

o

Armario

Pfigina 5

L

T

L

F

zr

Figura 3

Atadura

B a manguera de desagtie debe

sujetarse firmemente con la

® atadura de modo que no se

salga de la toma de agua durante el uso.

Atadura

Figura 4

Page 14

C njete la mangnera como se

yen la Figura 5 - toma de agua mural.

Figura 5

ASEGURESE DE QUE LA MAN-

GUERA NO ESTE TORC1DA O

DOBLADA Y QUE ESTE FIRME-

MENTE SUJETA EN SU LUGAR.

mnestra en la Fignra 3 - Tnbo

@ de Toma: en la Fignra 4- Tina:

Atadura

Metodos de escape

alternos

A Existen jnegos de escape qne

interior para conservar energia durante

los meses de invierno. Usted puede usar

estos dispositivos con la Lavadora/

Secadora Supeq_uestas siempre que el uso

noinfiinja losc6digos locales o nacionales

y que el dispositivo no restrinja el fit[in

del aire de escape. Si usa uno de estos

juegos, debe in*_rmarse de que el exceso

de humedad en el hogar puede causar

ranchos problemas y que notarfi un

aumento enel tiempo requerido para secar

una carga. Ademfis, la instalaci6n del

juego debe sermantenida en *bmladebida

para evitar acumulaci6n excesiva de

pelusas, que pueden afectar el rendimiento

de la secadora.

permiten dirigir el aire del

@ escape filtrado hacia el

Conexidn electrica a/tema

Desconecte el corddn e|_ctrico del

lomacnrriente antes de hacer estos

cambios.

Este artefacto debe ser puesto a tierra.

Este artefacto estfi fabricado con el

conductor neutro conectado al bastidor.

Si los cddigos locales

permiten el nso de nn corddn

a eRctrico tipo flexible y:

®

1. NO permiten conexidn del conductor

de pnesta a tierra de bastidor al

alambre neutro del corddn eRctrico:

a. Saque la tapa del tablero de

bornes.

b. Saque el cable de puesta a tierra

del tornillo de puesta a tierra vente

y coldquelo bajo el tornillo central

plateado del tablero de bornes.

Vet Figura 8.

_. _ puesta a tierra

--_. _ instalada en una

"_7/_ tuberia de metal

Alambte de / I

puesta--atierra _" I Torni[Io verde de

#10 minimo (no ] /puesta a tierra

suministrado) j__

Alambre de....-_,'-"'_'_47/7 -_-centra[

puesta a-tielTia- '_// plateado

Neutro no puesto atierra

Figura 8

Abrazadera de

de agua fria

Figura 9

Alambrede cobre N° 4

tablero de bornes.

*La tuberia del agua fria puesta a tierra

debe poseer continuidad metfilica a la

tierra eRctrica y no estar interrumpida

por conectores aisladores eldctricos de

plfistico o de goma o de otra clase (tales

como mangueras, accesorios, arandelas

o juntas, incluyendo un medidor de agua

o bomba). Cualquier conector aislador

eRctrico debe set conectado en puente

como se muestra en la Figura 9 con un

trozo de alambre de cobre N ° 4,

firmemente sujeto en ambos extremos al

metal desnudo mediante una abrazadera.

® eRctrico y:

1. Permiten conexidn del conductor de

puesta a tierra del bastidor al alambre

neutro del corddn eRctrico:

a. Saque la tapa del tablero de

bornes.

Tablero

de

Bornes

Abrazadera

Tuberia de

Metal del

Si los cddigos locales NO

permiten el uso de un corddn

B Para instalaci6n en casas

exterior. Si el tubo de escape de la

secadora corre a trav_s del piso y el firea

debajo de la casa mdvil es cermda, el ducto

de escape debe terminar mils allfi del firea

cerrada. AI alejar el ducto de escape se

evita la acumulacidn de pelusas y

humedad debajo de la casa mdvil. Vet

Figura 7.

m6viles, la secadora debe

@ tener el escape hacia el

Instalacidn en Casa Movil

h

Figura 7 [7

Conecte el alambre de puesta a tierra de

cobre separado del tornillo de puesta a

tierra verde auna tierra aprobada.

Conecte un alambre de puesta a

tierra de cobre separado (No. i0

minimo a una tuberia de agua fria

puesta a tierra* mediante una

abrazadera y luego al bastidor del

artefacto en el tornillo de puesta

a tierra verde. Use el con junto de

abrazadera y alambre de pnesta a

tierra Pieza No. 685463. No use

una tuberia de gas para la puesta

a tierra. No enchufe el corddn

el_ctrico en el tomacorriente

hasta que el artefacto no est_

perma-nentemente puesto a

tierra.

d. Vuelva a colocar la tapa del

Pfigina 6

Figura 10

b. lnstale un anclaje de cable

aprobado por el U.L. (Figura 11)

en un agujero de una pulgada en

la parte trasera de la secadora

debajo de la abertura del tablero

de bornes.

Figura 11

c. lnstale un corddn elSctrico de

cobre.

Page 15

d, Conecte el alambre neutro del

cable el_ctrico flexible de cobreo

no metfilico al tomillo de borne

central plateado del tablero de

bornes y conecte los otros

alambres a los bornes externos.

Vet Figura 12. Para conectar el

alambre de campo de extremo

sencillo, vet Figura 15.

Vuelva a colocar la tapa del

tablero de bomes.

de puesta a tierra verde

Alambre

de puesta.

a tierra

Conductor

Conductor Neutro puesto a tierra

Figura 12

NO se permite conexidn del

conductor de puesta a tierra del

bastidor al conductor neutro del

cord6n el_ctrico:

a. Saque la tapa del tablero de

bornes.

b. lnstale un anclaje de cable

aprobado pot el U.L. (Figura 11)

en un agujero de una pulgada en

la parte trasera de la secadora

debajo de la abertura del tablero

de bornes.

c. lnstale el corddn el_ctrico de

cobre.

d. Saque el alambre de puesta a

tierra del tornillo de puesta a tierra

verde e instfilelo bajo el tornillo

central plateado del tablero de

bornes.

e. Conecte el conductor neutro del

corddn el_ctrico al borne central

plateado del tablero de bornes y

conecte los otros alambres a los

Tornillo de

Puesta a Conductor Borne

Tierra Verde Verde Plateado TabJero

Borne:

Cenecte el alambre separade de puesta

a tierra de cebre del conector de puesta

a tierra externo a una fierra aprebada.

Conductor neutro no puesto a tierra

Figura 13

fl Conecte un alambre de puesta a

tierra de cobre separado (No. i0

minimo a una tuberia de agua fria

puesta a tierra* mediante una

abrazadera y luego al bastidor del

artefacto en el tomillo de puesta

a tierra verde. Use el conjunto de

abrazadera y alambre de puesta a

tierra Pieza No. 685463. No use

un tuberia de gas para la pnesta a

tierra. No enchufe el corddn

el&ctrico en el tomacorriente

hasta que el artefacto no est_

permanentemente pnesto a tierra.

g. Vuelva a colocar la tapa del

tablero de bomes.

*La tuberia del agua fria puesta a tierra

debe poseer continuidad metfilica a la

tierra elSctrica y no estar interrumpida

pot conectores aisladores elSctricos de

plfistico o de goma o de otra close (tales

como mangueras, accesorios, arandelas

o juntas, incluyendo un medidor de agua

o bomba). Cualquier conector aislador

elSctrico debe set conectado en puente

como se muestra en la Figura 9 con un

trozo de alambre de cobre N ° 4,

firmemente sujeto en ambos extremos al

metal desnudo mediante una abrazadera.

C i se conecta a un sistema

el_ctrico tetrafilar (casa

O mdvil):

1. Saque la tapa del tablero de bomes.

lnstale un anclaje de cable aprobado

por U.L. (Figura 11) en un agujero

de una pulgada en la porte trasera

de la secadora debajo del abertnra

del tablero de bornes.

3. lnstale un corddn el_ctrico de cuatro

conductores.

Saque el alambre de puesta a tierra

del tornillo de pnesta a tierra verde e

instfilelo en el tornillo central

plateado del tablero de bornes.

Tornillo Verde

de Puesta a

Ti,

Conductor

Borne Hateado

Tablero de

Bornes

Alambre

de Puesta

a Tierra

Rojo B[anco Negro

7. Vuelva a colocar la tapa del tablero

de bornes. Conector neutro no puesto

a tierra tetrafilar.

Figura 14

SI SU CORDON ELECTRICO 0 EL

CABLEADO DIRECTO TIENE

EXTREMOS DE ALAMBRE

SENClLLOS, VEA LA FIGURA 15 Y

SIGA ESTOS PASOS:

1. Saque la envoltura exterior del

alambre aproximadamente 3 pulgadas

desde el extremo, dejando al

descubierto tres alambres.

2. Tire hacia atrfis el aislamiento

aproximadamente una pulgada desde

el extremo de coda cable. Forme un

gancho en fbrma de U con el alambre

desnudo.

3. Afloie, sin sacar, el tomillo central

plateado del tablero de bomes.

4. Deslice el extremo del conductor

neutro (blanco o central)bajo la cabeza

del tornillo con el lado abierto del

gancho a la derecha. Apriete el

alambre para *bnnar un anillo.

5. Apriete el tomillo firmemente.

6. Conecte los dos alambres restantes a

los tornillos extemos de la misma

manera. Apriete firmemente los

tornillos.

Tornillo de puesta a tierra verde

Alambre

de Pluesta

a Ti6rra

bornes externos. Vet Figura 13.

Para la conexidn de alambre de

extremo sencillo ver Figura 15.

Conecte el alambre de puesta a tierra

(verde) del corddn de 4 conectores

de cobre al tomillo de puesta a tierra

verde.

Conecte el alambre neutro (blanco)

del corddn el&ctrico al tomillo central

plateado del tablero de bornes y

conecte los otros alambres a los

bomes externos. Vet Figura 14. Para

conectar el alambre de campo de

extremo sencillo, vet Figura 15.

Pfigina 7

Alambre de

puesta a tierra Neutro

Cableado de campo de extremo sencillo

Figura 15

Page 16

D_MENS+ONES PARA LA +NSTALACJON

2 tl2"

I

75 t/2"

54 /!6"

+

8

ESCAPE .......

EN]+RADA DEL AGUA

(PARTE TRASERA)

+

3 314"

-- 41 1!4"

29 71!6"

16 114"

36 It!6"

/

/ 519

_J

T

4 13116"

q

11 7t16"

Sears, Roebuck and Co,

Hoffman Estates+ +L60179 U°S,A,

30 !3116 ....... -=--_

Fabricado en Jos EE.UU.

Loading...

Loading...