Page 1

Installation Instructions

Instrucciones de Instalación

English / Español

Models/Modelos: 417.6173*, 417.7173*

Kenmore

®

Laundry Center

Centro de lavado

* = Color number, número de color

P/N: A13415001 (1801)

Sears Brands Management Corporation

Homan Estates, IL 60179 U.S.A.

www.kenmore.com

www.sears.com

Page 2

Important Safety Instructions

Table of Contents

WARNING

Important Safety Instructions ............... 2-3

Installation Requirements ................. 3-14

Unpacking Laundry Center .................... 15

Installation Instructions .................. 16-21

Accessories and Replacement Parts ........ 22

For your safety the information in this

manual must be followed to minimize

the risk of re or explosion or to prevent

property damage, personal injury or loss

of life. Save these instructions.

WARNING-RISK OF FIRE

Read all of the following instructions before installing and using this appliance:

• Destroy the carton and plastic bags after the laundry center is unpacked.

Children might use them for play. Cartons covered with rugs, bedspreads, or plastic sheets can become airtight chambers causing suffocation. Place all materials in a garbage container or make materials

inaccessible to children.

• Clothes dryer installation and service must be performed by a qualied

installer, service agency or the gas supplier.

• Install the appliance according to the manufacturer’s instructions and

local codes.

• The electrical service to the appliance must conform with local codes

and ordinances and the latest edition of the National Electrical Code,

ANSI/NFPA 70, or in Canada, the Canadian electrical code C22.1 part 1.

• The gas service to the dryer must conform with local codes and ordinances and the latest edition of the National Fuel Gas Code ANSI

Z223.1, or in Canada, CAN/ACG B149.1-2000. An individual manual

shut-o valve must be installed within 6 ft (1.83 m) of the dryer in accordance with the National Fuel Gas Code, ANSI Z223.1/NFPA 54.

• The laundry center is designed under ANSI Z 21.5.1 or ANSI/UL 2158 CAN/CSA C22.2 No. 112 (latest editions) for HOME USE only. This dryer

is not recommended for commercial applications such as restaurants,

beauty salons, etc.

• Do not install a clothes dryer with exible plastic or exible foil venting material. Flexible venting materials are known to collapse, be easily

crushed and trap lint. These conditions will obstruct clothes dryer airow

and increase the risk of re.

• The instructions in this manual and all other literature included with this

appliance are not meant to cover every possible condition and situation

that may occur. Good safe practice and caution MUST be applied when

installing, operating and maintaining any appliance.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

2

Page 3

Important Safety

Instructions

Installation Requirements

WARNING

Please read all instructions before using

this appliance.

Denitions

This is the safety alert symbol. It is used

to alert the user of potential personal

injury hazards. Obey all safety messages

that follow this symbol to avoid possible

injury or death.

Safety items throughout this manual are

labeled with a WARNING or CAUTION

based on the risk type as described

below:

DANGER

DANGER indicates an imminently

hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING

WARNING indicates a potentially

hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

CAUTION indicates a potentially

hazardous situation which, if not avoided,

may result in minor or moderate injury.

IMPORTANT

CAUTION

EXCESSIVE WEIGHT HAZARD

To avoid back or other injury, have

more than one person move or lift the

appliance.

Pre-Installation Requirements

Tools and materials needed for

installation:

• Adjustable pliers

• Phillips, straight, & square bit

screwdrivers

• Adjustable wrench

• Pipe wrench for gas supply (gas dryer)

• LP-resistant thread tape (for natural gas

or LP supply, gas dryer)

• Carpenter’s level

• External vent hood

• 4-inch (102 mm), rigid metal or semi-

rigid metal exhaust duct work

• 3-wire or 4-wire 240 volt cord kit

(electric dryer)

• 4 in. (102 mm) clamp

• Gas line shuto valve (gas dryer)

• ½ NPT union are adapters (x2) and

exible gas supply line (gas dryer)

• Metal foil tape (not duct tape)

• Inlet hoses (x2)

NOTE

Hoses are not included with washer

purchase. See “Accessories” section for

various inlet hose kits to t your specic

installation.

Indicates installation, operation, or

maintenance information which is

important but not hazard-related.

NOTE

Because of potentially inconsistent voltage capabilities, the use of this dryer

with power created by gas powered

generators, solar powered generators,

wind powered generators or any other

generator other than the local utility

company is not recommended.

3

Page 4

Installation Requirements

INSTALLATION CHECKLIST

Shipping Hardware

Foam shipping restraint (inside wash

tub) removed and stored

Foam shipping support (underneath

appliance) removed and stored

Leveling

Laundry center is level, side-to-side

and front-to-back

Cabinet is setting solid on all

corners

Water Supply

Use only new hoses and verify

rubber sealing washers are installed

HOT supply is connected to HOT

inlet and COLD supply is connected

to COLD inlet

HOT and COLD water supply

turned on

No leaks present at water supply

connections or appliance inlet

connections -recheck in 24 hours

Drain

Stand pipe or wall drain height min.

33”

Drain hose secured in place with

cable tie (shipped in drum)

Exhaust Venting

Free-owing, clear of lint buildup

4 inch (102 mm) rigid or semi-rigid

ducting of minimal length and turns

NO foil or plastic venting material

Approved vent hood exhausted to

outdoors

Gas Supply (Gas Dryer)

Manual shuto valve present in

supply

All connections sealed with

approved sealer and wrench tight

Conversion kit for LP system

Gas supply turned on

No leaks present at all connections

check with soapy water, NEVER

check with ame

240v Electric Supply

(Electric Dryer)

Approved NEMA 10-30R or 14-30R

service cord with all screws tight on

terminal block

Approved strain relief installed

Terminal access cover installed

before initial operation

Electrical Power

House power turned on

Laundry Center plugged in

Final Checks

Installation Instructions and Use and

Care Guide read thoroughly

Water enters drum when cycle

starts with lid lowered. Dryer door

latches and drum tumbles when

cycle starts

Registration card sent in

4

Page 5

Installation Requirements

Electrical requirements for

Laundry Center with electric dryer

CIRCUIT - Individual 30 amp. branch

circuit fused with 30 amp. time delay

fuses or circuit breakers.

POWER SUPPLY - 3-wire or 4-wire, 240

volt, single phase, 60 Hz, Alternating

Current.

IMPORTANT

This laundry center is internally grounded to neutral unless it was manufactured

for sale in Canada.

Only a 4-conductor cord shall be used

when the appliance is installed in a

location where grounding through the

neutral conductor is prohibited. Grounding through the neutral link is prohibited

for: (1) new branch circuit installations,

(2) mobile homes, (3) recreational vehicles, and (4) areas where local codes

DO NOT permit grounding through the

neutral.

OUTLET RECEPTACLE - NEMA 10-30R or

NEMA 14-30R receptacle to be located so

the power supply cord is accessible when

the dryer is in the installed position.

GROUNDING CONNECTION - See

“Grounding requirements” in Electrical

Installation section.

WARNING

Improper grounding of the laundry

center may cause serious injury or

death. Check with a licensed electrician if you are in doubt as to whether

the appliance is properly grounded.

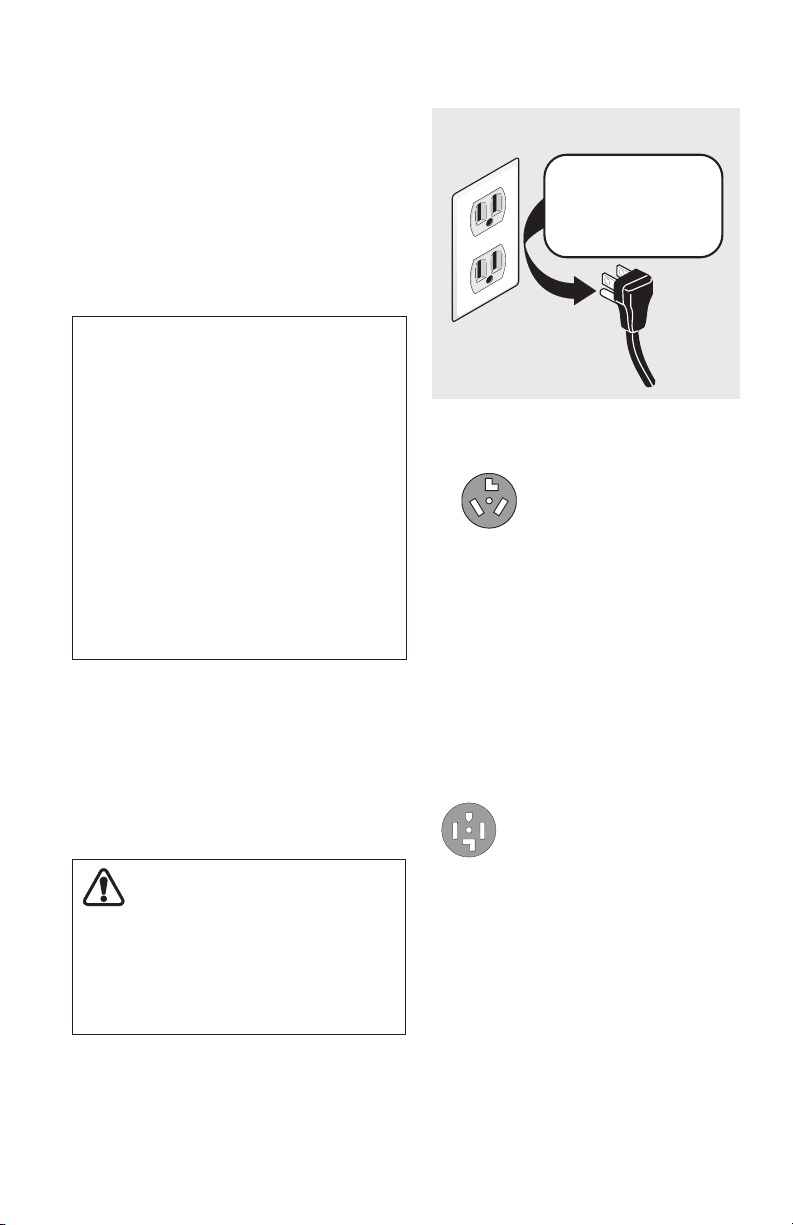

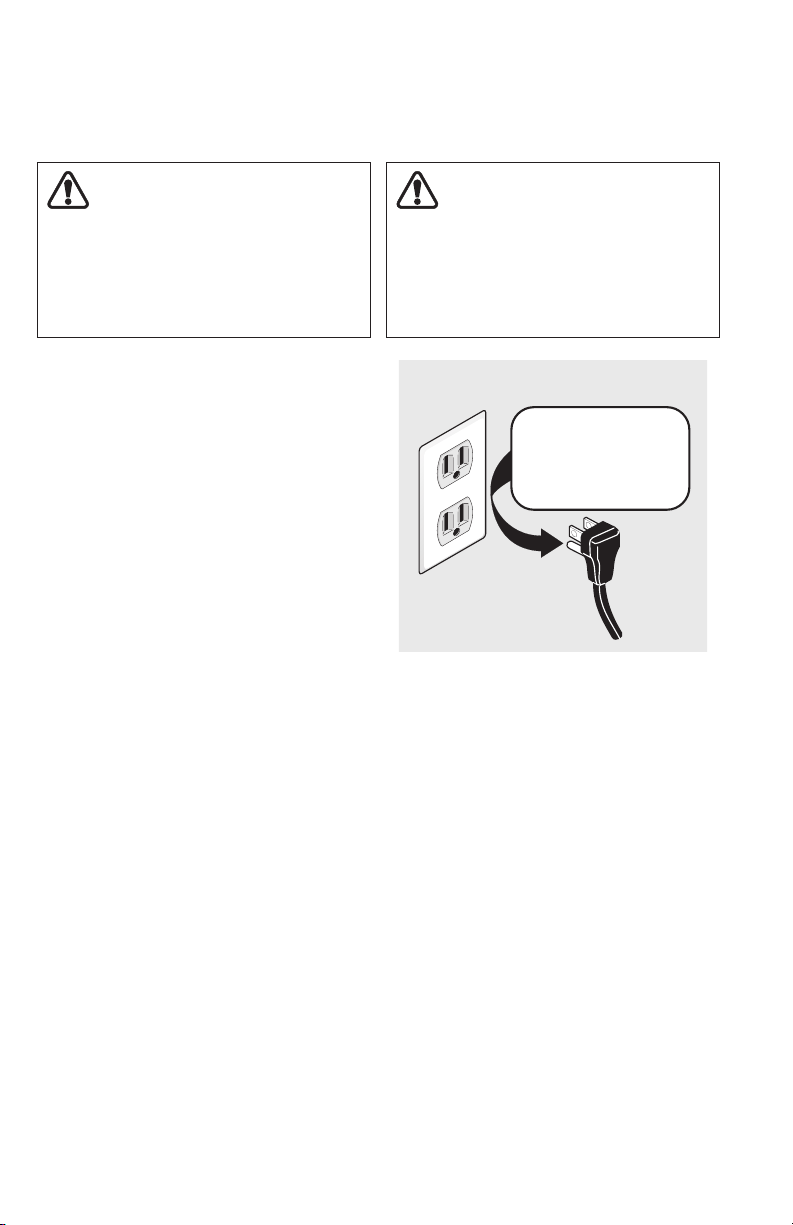

Grounding type wall receptacle

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

Power cord with

3-prong grounded plug

3-WIRE POWER SUPPLY CORD KIT

(not supplied)

3-wire receptacle

(NEMA type 10-30R)

The dryer MUST employ a 3-conductor

power supply cord NEMA 10-30 type

SRDT rated at 240 volt AC minimum,

30 amp, with 3 open end spade lug

connectors with upturned ends or closed

loop connectors and marked for use

with clothes dryers. For 3-wire cord

connection instructions see ELECTRICAL

CONNECTIONS FOR A 3-WIRE SYSTEM.

4-WIRE POWER SUPPLY CORD KIT

(not supplied)

4-wire receptacle

(NEMA type 14-30R)

The dryer MUST employ a 4-conductor

power supply cord NEMA 14-30 type

SRDT or DRT (as required) rated at 240

volt AC minimum, 30 amp, with 4 open

end spade lug connectors with upturned

ends or closed loop connectors and

marked for use with clothes dryers. For

4-wire cord connection instructions see

ELECTRICAL CONNECTIONS FOR A

4-WIRE SYSTEM.

5

Page 6

Installation Requirements

NOTE

Laundry centers manufactured for sale

in Canada have factory-installed, 4-wire

power supply cord (NEMA 14-30R).

Electrical requirements for

Laundry Center with gas dryer

WARNING

Improper grounding of the laundry

center.may cause serious injury or

death. Check with a licensed electrician if you are in doubt as to whether

the appliance is properly grounded.

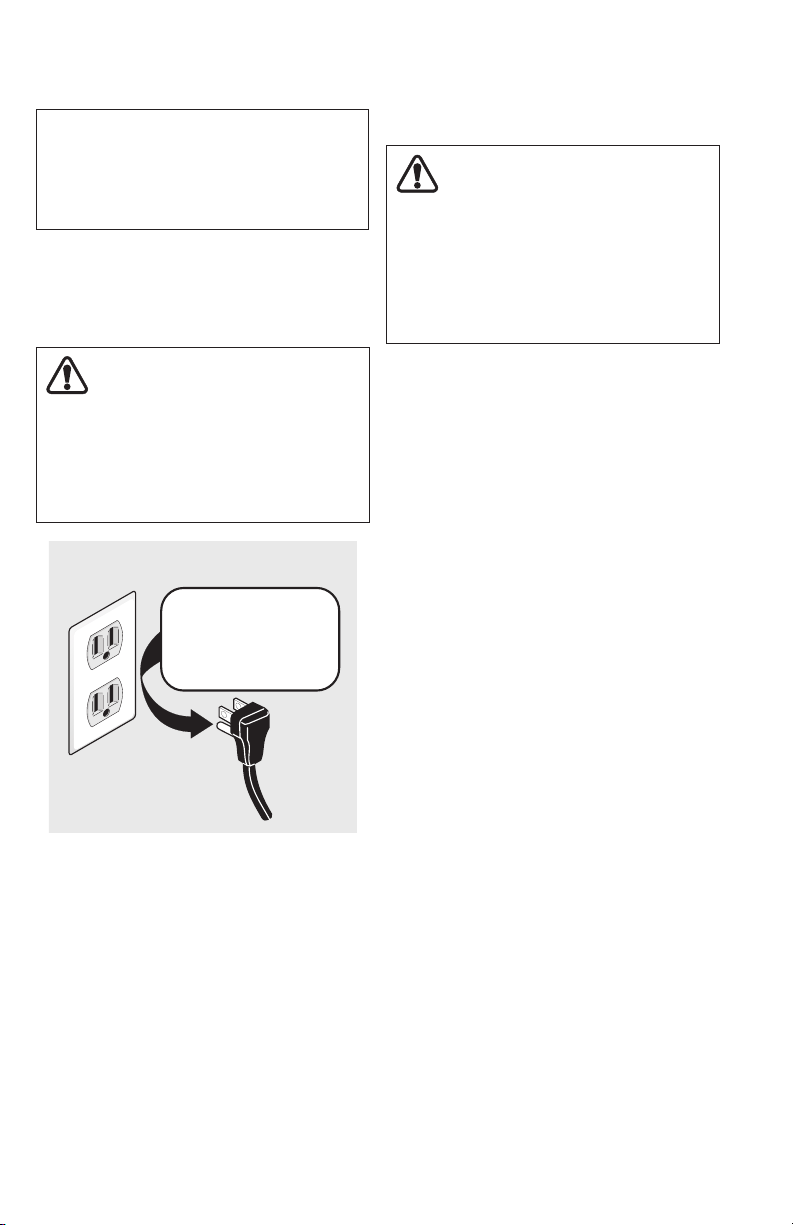

Grounding type wall receptacle

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

Power cord with

3-prong grounded plug

CIRCUIT - Individual, properly polarized

and grounded 15 amp. branch circuit

fused with 15 amp. time delay fuse or

circuit breaker.

POWER SUPPLY - 2-wire, with ground,

120 volt, single phase, 60 Hz, Alternating

Current.

POWER SUPPLY CORD - The dryer is

equipped with a 120 volt 3-wire power

cord.

GROUNDING CONNECTION - See

“Grounding requirements” in Electrical

Installation section.

Gas supply requirements

WARNING

EXPLOSION HAZARD

Uncoated copper tubing will corrode

when subjected to natural gas, causing gas leaks. Use ONLY black iron,

stainless steel, or plastic-coated brass

piping for gas supply.

1. Installation MUST conform with local

codes, or in the absence of local

codes, with the National Fuel Gas

Code, ANSI Z223.1 (latest edition).

2. The gas supply line should be 1/2 inch

(1.27 cm) pipe.

3. If codes allow, exible metal tubing

may be used to connect your dryer to

the gas supply line. The tubing MUST

be constructed of stainless steel or

plastic-coated brass.

4. The gas supply line MUST have an

individual shuto valve installed in

accordance with the B149.1, Natural

Gas and Propane Installation Code.

5. A 1/8 inch (0.32 cm) N.P.T. plugged

tapping, accessible for test gauge

connection, MUST be installed

immediately upstream of the gas

supply connection to the dryer.

6. The dryer MUST be disconnected

from the gas supply piping system

during any pressure testing of the gas

supply piping system at test pressures

in excess of 1/2 psig (3.45 kPa).

7. The dryer MUST be isolated from the

gas supply piping system during any

pressure testing of the gas supply

piping system at test pressures equal

to or less than 1/2 psig (3.45 kPa).

8. Connections for the gas supply

must comply with the Standard for

Connectors for Gas Appliances, ANSI

Z21.24 - CSA 6.10.

6

Page 7

Installation Requirements

Water supply requirements

Hot and cold water faucets MUST be

installed within 42 inches (107 cm) of your

washer’s water inlet. The faucets MUST

be 3/4 inch (1.9 cm) with threading for

laundry hose connection. Water pressure

MUST be between 10 psi (0.69 bars) and

120 psi (8.27 bars). Pressure dierence

between hot and cold cannot be more

than 10 psi. Your water department can

advise you of your water pressure.

NOTE

Washers connected to water supplies

with lower inlet pressure will experi-

ence longer lling times and may not

complete cycles as quickly.

Drain system requirements

1. Drain capable of eliminating 17 gals

(64.3 L) per minute.

2. A standpipe diameter of 1-1/4 in.

(3.18 cm) minimum.

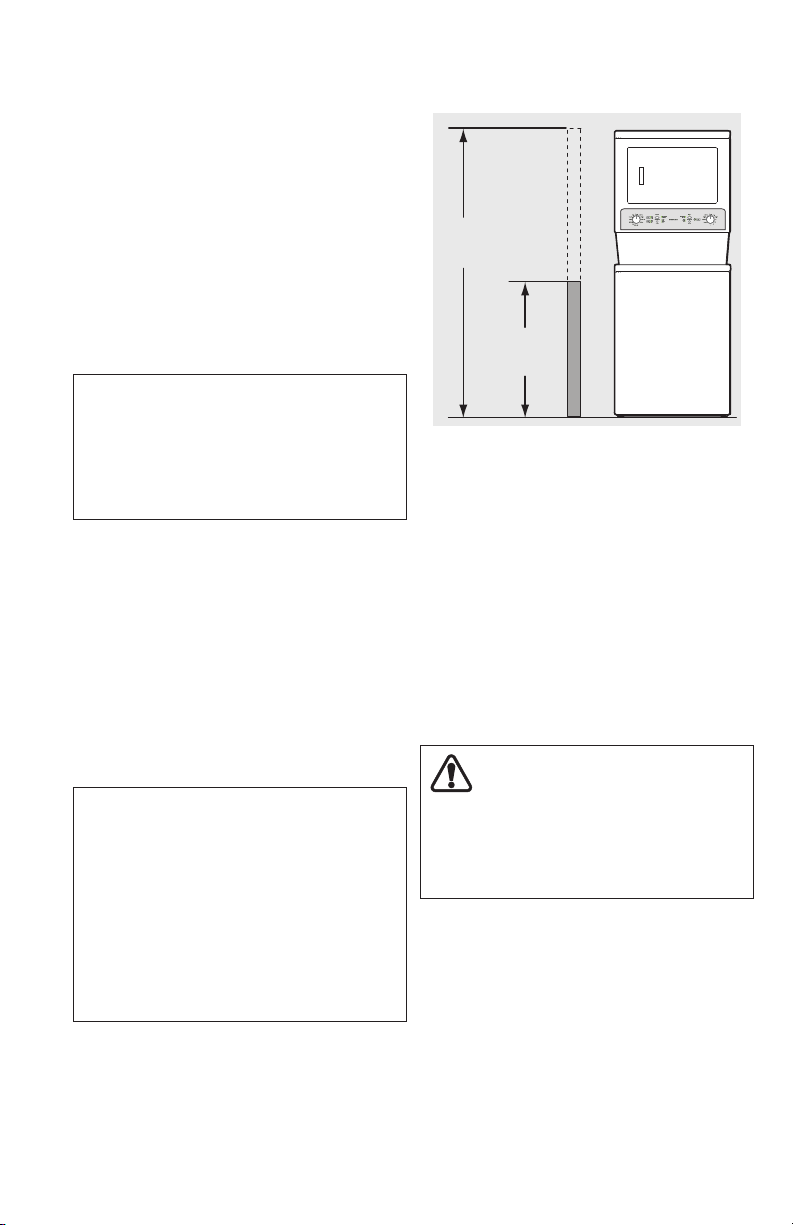

3. Standpipe height above the oor

should be:

Minimum height: 33 in. (84 cm)

Maximum height: 96 in. (244 cm)

96"

(244cm)

max.

33"

(84cm)

min.

Exhaust system requirements

Use only 4 inch (102 mm) diameter rigid

or exible metal duct and approved vent

hood which has a swing-out damper(s)

that open when the dryer is in operation.

When the dryer stops, the dampers

automatically close to prevent drafts and

the entrance of insects and rodents. To

avoid restricting the outlet, maintain a

minimum of 12 inches (30.5 cm) clearance

between the vent hood and the ground or

any other obstruction.

WARNING

NOTE

For installations requiring a longer

drain hose, have a qualied technician

install a longer drain hose (according to

your model number) available from an

authorized parts distributor. For drain

systems in the oor, install a syphon

break kit available from your local

hardware store.

FIRE HAZARD

Failure to follow these instructions can

create excessive drying times and re

hazards.

The following are specic requirements

for proper and safe operation of your

dryer.

7

Page 8

Installation Requirements

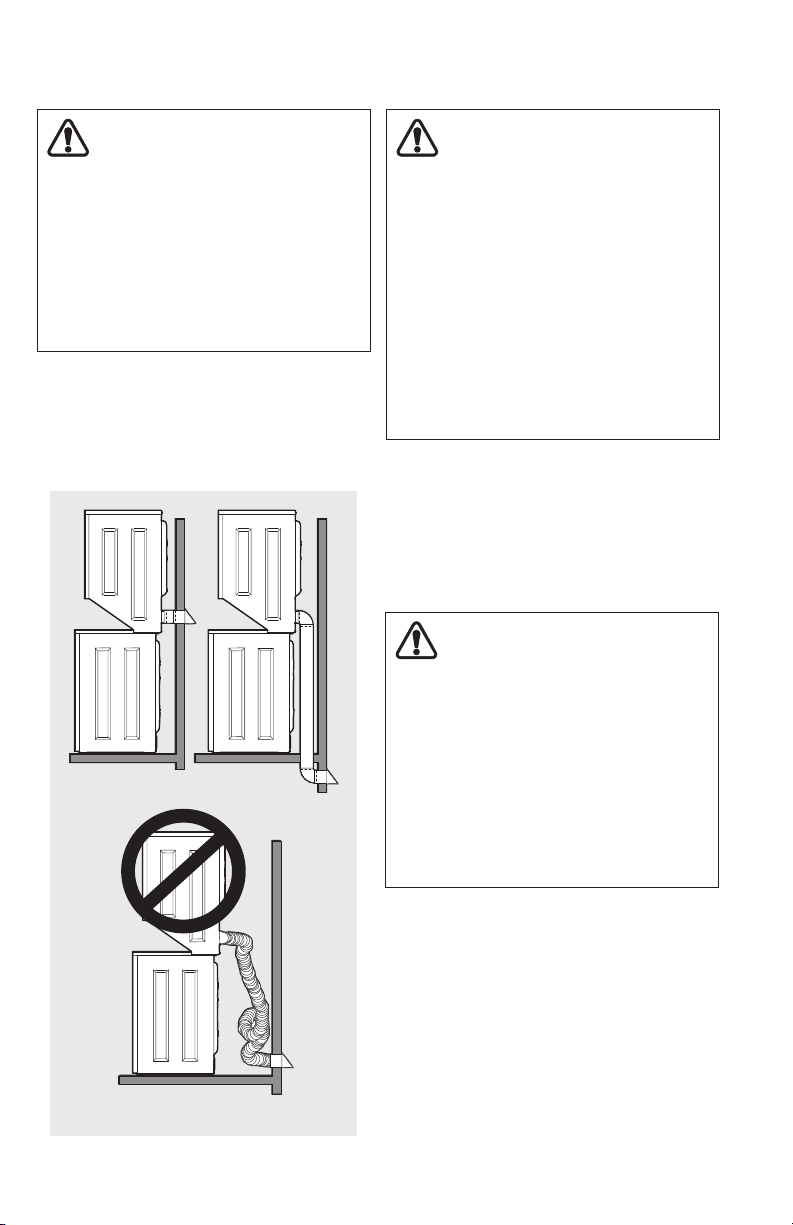

WARNING

FIRE HAZARD

DO NOT install a clothes dryer with

exible plastic or metal foil venting

materials. Flexible venting materials are known to collapse, be easily

crushed and trap lint. These conditions

will obstruct clothes dryer airow and

increase the risk of re.

If your present system is made up of

plastic duct or metal foil duct, replace it

with a rigid or semi-rigid metal duct. Also,

ensure the present duct is free of any lint

prior to installing dryer duct.

Correct

WARNING

FIRE HAZARD

A clothes dryer must be exhausted

outdoors. DO NOT exhaust dryer into

a chimney, a wall, a ceiling, an attic,

a crawl space or any concealed space

of a building. A clothes dryer produces

combustible lint. If the dryer is not

exhausted outdoors, some ne lint will

be expelled into the laundry area. An

accumulation of lint in any area of

the home can create a health and re

hazard.

The dryer must be connected to an

exhaust outdoors. Prior to installing your

new dryer, inspect the outdoor exhaust

opening and remove any accumulation of

lint around the outdoor exhaust opening

and in the surrounding area.

WARNING

FIRE HAZARD

Failure to follow safety warnings

exactly could result in serious injury,

death, or property damage.

DO NOT install a booster fan in the

exhaust duct.

Install all clothes dryers in accordance

with the installation instructions in this

manual.

Incorrect

8

Page 9

Installation Requirements

WARNING

FIRE HAZARD

• DO NOT allow combustible materi-

als (for example: clothing, draperies/

curtains, paper) to come in contact

with exhaust system. The dryer

MUST NOT be exhausted into a

chimney, a wall, a ceiling, or any

concealed space of a building which

can accumulate lint, resulting in a

re hazard.

• DO NOT screen the exhaust ends of

the vent system, or use any screws,

rivets or other fasteners that extend

into the duct to assemble the exhaust

system. Lint can become caught in

the screen, on the screws or rivets,

clogging the duct work and creating

a re hazard as well as increasing

drying times. Use an approved vent

hood to terminate the duct outdoors,

and seal all joints with metal foil

duct tape. All male duct pipe ttings

MUST be installed downstream with

the ow of air.

WARNING

FIRE HAZARD

Exceeding the length of duct pipe

or number of elbows allowed in the

“MAXIMUM LENGTH” charts can

cause an accumulation of lint in the

exhaust system. Plugging the system

could create a re hazard, as well as

increase drying times.

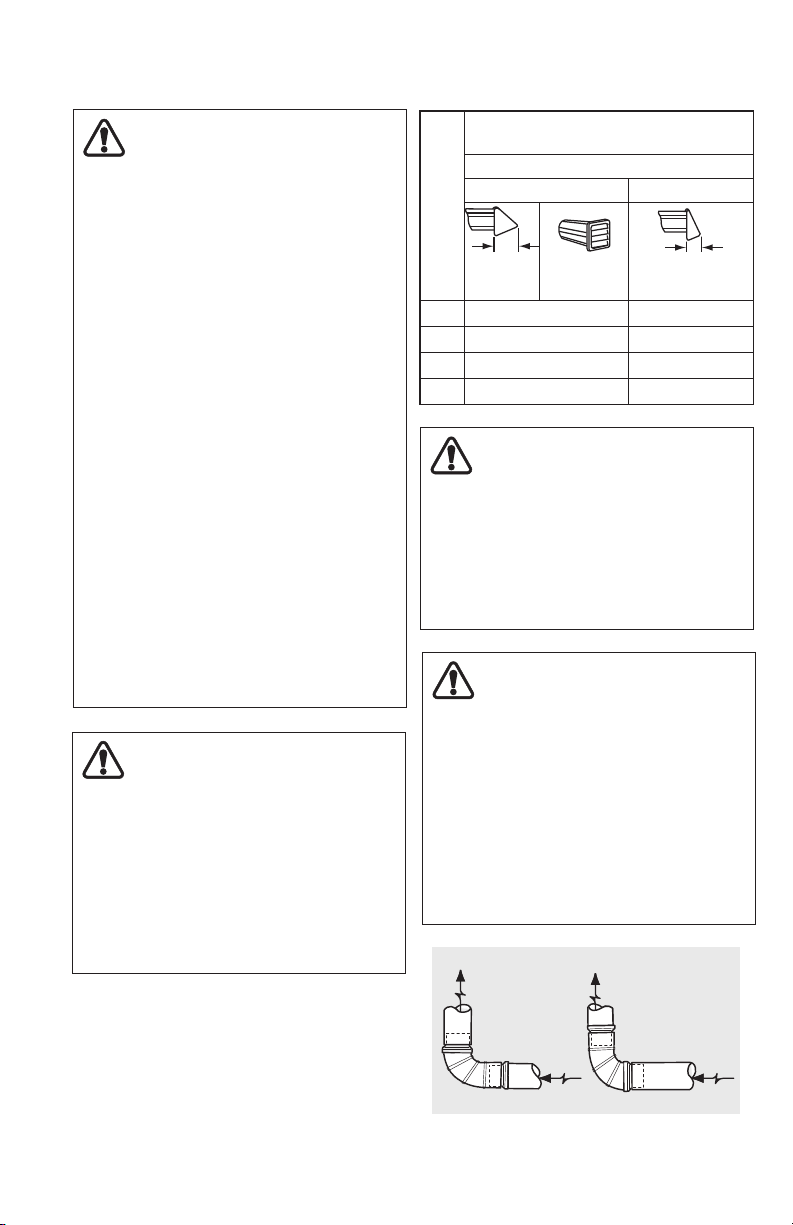

Number of 90° turns

0

1

2

3

MAXIMUM LENGTH

of 4” (102 mm) Rigid Metal Duct

VENT HOOD TYPE

(Preferred)

4”

(10.2 cm) louvered

56 ft. (17 m) 42 ft. (13 m)

48 ft. (14.5 m) 34 ft. (10.5 m)

40 ft. (12 m) 26 ft. (8 m)

32 ft. (9.5 m) 18 ft. (5.5 m)

2.5”

(6.35 cm)

WARNING

FIRE HAZARD

• DO NOT install exible plastic or

exible foil venting material.

• If installing semi-rigid venting,

DO NOT exceed 8 ft. (2.4 m) duct

length.

WARNING

FIRE HAZARD

• Failure to follow safety warnings

exactly could result in serious injury,

death, or property damage.

• DO NOT install a booster fan in

dryer exhaust duct.

• Install all clothes dryers in accordance with the installation instruc-

tions in this manual.

Install male fittings in correct direction:

Correct Incorrect

9

Page 10

Installation Requirements

In installations where the exhaust system is

not described in the charts, the following

method must be used to determine if the

exhaust system is acceptable:

1. Connect an inclined or digital

manometer between the dryer and

the point the exhaust connects to the

dryer.

2. Set the dryer timer and temperature

to air u (cool down) and start the

dryer.

3. Read the measurement on the

manometer.

4. The system backpressure MUST NOT

be higher than 0.6 inches of water

column. If the system back pressure

is less than 0.6 inches of water

column, the system is acceptable.

If the manometer reading is higher

than 0.6 inches of water column,

the system is too restrictive and the

installation is unacceptable.

Although vertical orientation of the

exhaust system is acceptable, certain

extenuating circumstances could aect

the performance of the dryer:

• Only rigid metal duct work should be

used.

• Venting vertically through a roof may

expose the exhaust system to down

drafts causing an increase in vent

restriction.

• Running the exhaust system through an

uninsulated area may cause condensa-

tion and faster accumulation of lint.

• Compression or crimping of the exhaust

system will cause an increase in vent

restriction.

• The exhaust system should be inspected

and cleaned a minimum of every 18

months with normal usage. The more

the dryer is used, the more often you

should check the exhaust system and

vent hood for proper operation.

Exhaust direction

The laundry center may be exhausted four

(4) ways with rear ush installation:

1. Straight back

2. Down (8 inch [20.3 cm] length of 4

inch diameter [102 mm] rigid duct and

1 elbow down)

3. Left (8 inch [20.3 cm] length of 4 inch

diameter [102 mm] rigid duct, 1 elbow

down and 1 elbow left)

4. Right (8 inch [20.3 cm] length of 4

inch diameter [102 mm] rigid duct, 1

elbow down and 1 elbow right)

An exhaust hood positioned to line up with

the dryer exhaust can be installed directly

through the outside wall. To exhaust to

the side or down, add an 8 inch (20.3

cm) length of standard 4 inch (102 mm)

diameter duct and a 90° elbow.

To exhaust up, add an 11 inch (28 cm)

length of standard 4 inch (102 mm)

diameter duct and a 90° elbow. The unit

will be positioned about 4.5 inches (11.5

cm) away from the wall (ush to wall

exhausting may be done by going below

the dryer then sideways).

See also

instruction.

Clearance Requirements

in this

10

Page 11

Installation Requirements

Manufactured or mobile home

installation

1. Installation MUST conform to current

Manufactured Home Construction &

Safety Standard, Title 24 CFR Part

3280 (formerly the Federal Standard

for Mobile Home Construction and

Safety, Title 24, HUD Part 280) or

Standard CAN/CSA-Z240 MH.

2. Dryer MUST be exhausted outside

(outdoors, not beneath the mobile

home) using metal ducting that

will not support combustion. Metal

ducting must be 4 inches (10.16 cm)

in diameter with no obstructions.

Rigid metal duct is preferred. Exhaust

ducts must be securely fastened to a

noncombustible portion of the mobile

home structure.

3. If dryer is exhausted through the oor

and area beneath the mobile home

is enclosed, the exhaust system MUST

terminate outside the enclosure with

the termination securely fastened to

the mobile home structure.

4. Refer to previous sections in this guide

for other important exhaust venting

system requirements.

5. When installing a gas dryer into a

mobile home, a provision must be

made for outside make up air. This

provision is to be not less than twice

the area of the dryer exhaust outlet.

6. Installer MUST anchor this laundry

center to the oor with approved

Mobile Home Installation Kit - P/N

137067200.

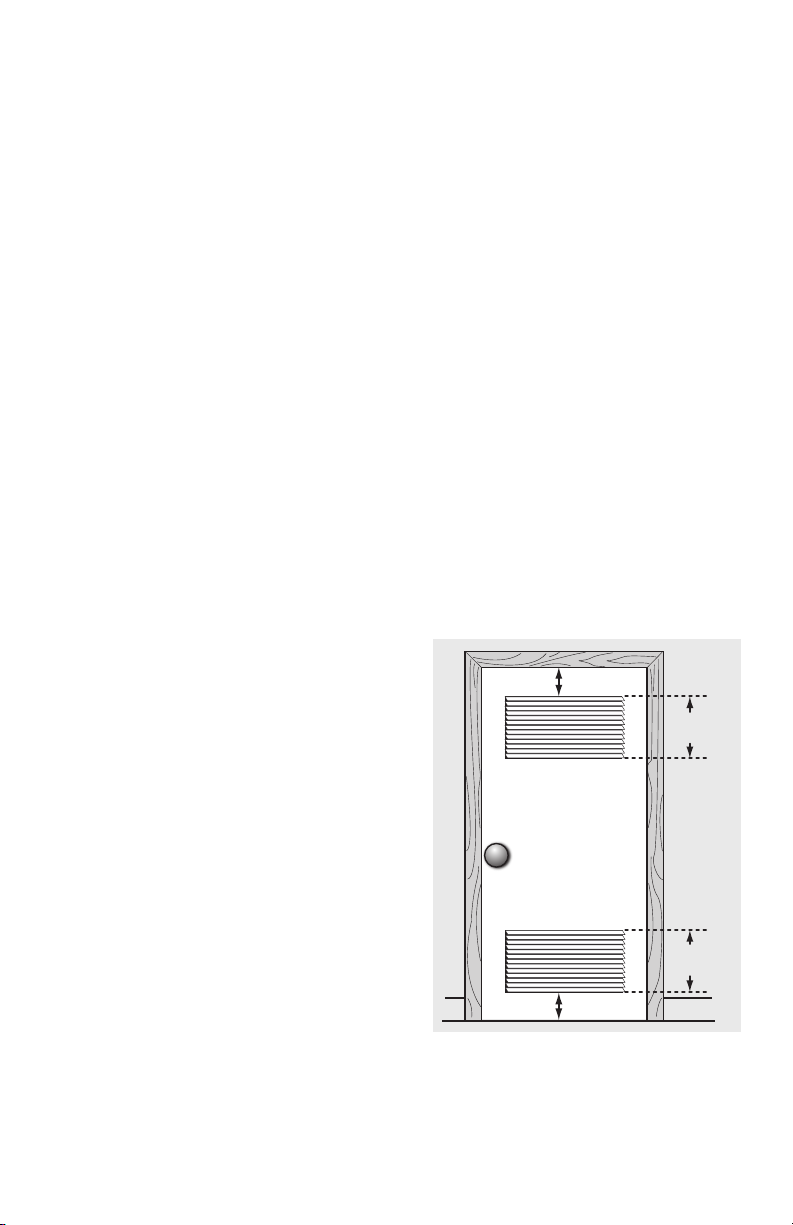

Installation in a Recess or Closet

1. A dryer installed in a bedroom,

bathroom, recess or closet, MUST be

exhausted outdoors.

2. No other fuel burning appliance shall

be installed in the same closet as the

gas dryer.

3. Your dryer needs the space around it

for proper ventilation.

4. DO NOT install your dryer in a closet

with a solid door.

5. Closet door ventilation required: A

minimum of 120 square inches (774.2

cm²) of opening, equally divided at

the top and bottom of the door, is

required. Openings should be located

3 inches (7.6 cm) from bottom and top

of door. Openings are required to be

unobstructed when a door is installed.

A louvered door with equivalent air

openings for the full length of the

door is acceptable.

3"

(7.6cm)

60 sq. in.

(387.1cm²)

60 sq. in.

(387.1cm²)

3"

(7.6cm)

11

Page 12

Installation Requirements

1” 0”

0”

31.5" (80 cm)

cm)

Clearance requirements

MINIMUM INSTALLATION CLEARANCES

- Inches (cm)

SIDES REAR TOP FRONT

Alcove

Closet

0”

(0 cm)0”(0 cm)1”(2.5 cm)

n/a

0”

(0 cm)0”(0 cm)1”(2.5 cm)1”(2.5 cm)

WARNING

EXPLOSION HAZARD

DO NOT install the laundry center

where gasoline or other ammables

are kept or stored. If the laundry

center is installed in a garage, the

dryer portion must be a minimum of

18 inches (45.7 cm) above the oor.

Failure to do so can result in death,

explosion, re or burns.

IMPORTANT

DO NOT INSTALL YOUR LAUNDRY

CENTER:

• In an area exposed to dripping water

or outside weather conditions. The

ambient temperature should never be

below 60° F (15.6° C) to maximize de-

tergent eectiveness.

• In an area where it will come in contact

with curtains, drapes, or anything that

will obstruct the ow of combustion

and ventilation air.

• On carpet. Floor MUST be solid with

a maximum slope of 1 inch (2.5 cm).

To minimize vibration or movement,

reinforcement of the oor may be necessary.

(2.5 cm)

Front view

17.6"

(45 cm)

77"

(196.5 cm)

drain

hose-

retention

clips on

rear of

washer

Side view

55.75"

(141.5 cm)

(96.5 cm)

(0 cm)

power cord

attachment

location on

rear of unit

(58.5 cm)

2

(33 mm)

27" (68.5 cm)

47.5" (120.5 cm)

38"

27”

(68.5 cm

23"

13"

(0 cm)

)

(24 cm)

(14 cm)

1

gas supply

pipe on rear

of gas unit

9.4"

5.5"

4 in. (102 mm)

exhaust vent

on rear of unit

water supply

connection on

rear of washer

31.5" (80 cm)

center line height

for 4 in. (102 mm)

exhaust outlet

41.5"

(105.5 cm)

(2.5 cm)

43.5"

(110.5

(1”)

1

Power supply cord length on gas unit

approximately 60 inches (152.5 cm).

2

Loose drain hose length beyond clamp

approximately 51.5 inches (131 cm).

12

Page 13

Installation Requirements

Electrical installation

The following are specic requirements

for proper and safe electrical installation

of your dryer. Failure to follow these

instructions can create electrical shock

and/or a re hazard

WARNING

ELECTRICAL SHOCK HAZARD

• This appliance MUST be properly

grounded. Electrical shock can result

if the dryer is not properly grounded.

Follow the instructions in this manual

for proper grounding.

• DO NOT use an extension cord with

this dryer. Some extension cords

are not designed to withstand the

amounts of electrical current this

dryer utilizes and can melt, creating

electrical shock and/or re hazard.

Locate the dryer within reach of

the receptacle for the length power

cord to be purchased, allowing

some slack in the cord. Refer to the

pre-installation requirements in this

manual for the proper power cord to

be purchased.

WARNING

ELECTRICAL SHOCK HAZARD

• A U.L.-approved strain relief must

be installed onto power cord. If the

strain relief is not attached, the cord

can be pulled out of the dryer and

can be cut by any movement of the

cord, resulting in electrical shock.

• DO NOT use an aluminum wired

receptacle with a copper wired

power cord and plug (or vice versa).

A chemical reaction occurs between

copper and aluminum and can cause

electrical shorts. The proper wiring

and receptacle is a copper wired

power cord with a copper wired

receptacle.

NOTE

Dryers operating on 208 volt power

supply will have longer drying times

than dryers operating on 240 volt

power supply.

Grounding requirements -

Electric dryer (USA)

WARNING

Improper grounding of the laundry

center may cause serious injury or

death. Check with a licensed electrician if you are in doubt as to whether

the appliance is properly grounded.

For a grounded, cord-connected dryer:

1. The dryer MUST be grounded. In the

event of a malfunction or breakdown,

grounding will reduce the risk of

electrical shock by a path of least

resistance for electrical current.

2. After you purchase and install a 3 wire

or 4 wire power supply cord having

an equipment-grounding conductor

and a grounding plug that matches

you wiring system, the plug MUST be

plugged into an appropriate, copper

wired receptacle that is properly

installed and grounded in accordance

with all local codes and ordinances. If

in doubt, call a licensed electrician.

3. DO NOT modify the plug you’ve

installed on this appliance. If it will

not t the outlet, have a proper outlet

installed by a qualied electrician.

For a permanently connected dryer:

The dryer MUST be connected to a

grounded metal, permanent wiring

system; or an equipment grounding

conductor must be run with the circuit

conductors and connected to the

equipment-grounding terminal or lead on

the appliance.

13

Page 14

Installation Requirements

Grounding requirements -

Electric dryer (Canada)

WARNING

Improper grounding of the laundry

center may cause serious injury or

death. Check with a licensed electrician if you are in doubt as to whether

the appliance is properly grounded.

For a grounded, cord-connected dryer:

1. The laundry center MUST be

grounded. In the event of a

malfunction or breakdown, grounding

will reduce the risk of electrical shock

by a path of least resistance for

electrical current.

2. Since your laundry center is equipped

with a power supply cord having

an equipment-grounding conductor

and a grounding plug, the plug must

be plugged into an appropriate

outlet that is properly installed and

grounded in accordance with all local

codes and ordinances. If in doubt, call

a licensed electrician.

3. DO NOT modify the plug provided

with this appliance. If it will not t the

outlet, have a proper outlet installed

by a qualied electrician.

Grounding requirements -

Gas dryer (USA and Canada)

WARNING

Improper grounding of the laundry

center may cause serious injury or

death. Check with a licensed electrician if you are in doubt as to whether

the appliance is properly grounded.

Grounding type wall receptacle

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

Power cord with

3-prong grounded plug

1. The laundry center is equipped with

a three-prong (grounding) plug for

your protection against shock hazard

and should be plugged directly into

a properly grounded three-prong

receptacle.

2. The plug must be plugged into an

appropriate outlet that is properly

installed and grounded in accordance

with all local codes and ordinances. If

in doubt, call a licensed electrician.

3. DO NOT modify the plug provided

with this appliance. If it will not t the

outlet, have a proper outlet installed

by a qualied electrician.

14

Page 15

Unpacking Laundry Center

Unpacking Instructions

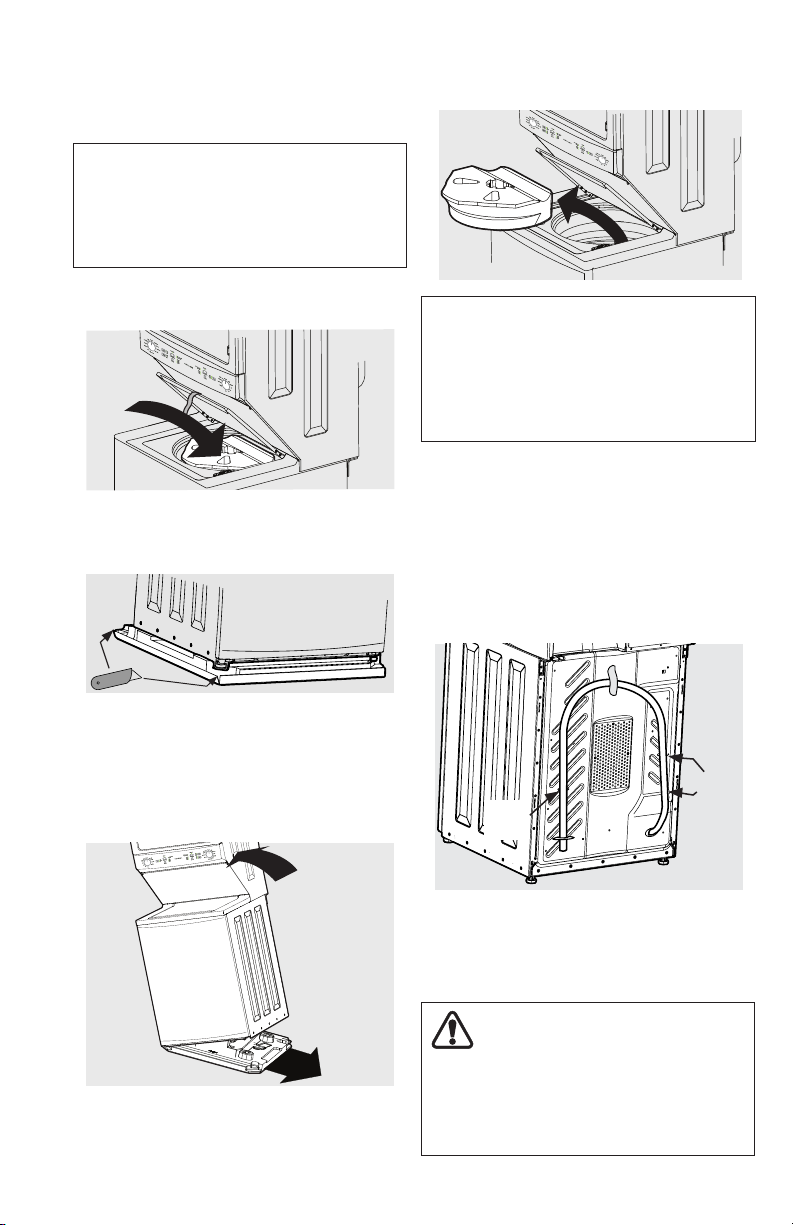

IMPORTANT

To prevent vibration, possible machine

damage and maximize performance,

the following steps must be completed.

1. If foam tub block has been removed,

reinsert it now and tape the lid securely.

2. Carefully cut the front and back

corners of the left side of the

remaining cardboard.

Front

NOTE

If the laundry center is to be trans-

ported at a later date, the tub blocking

pad, foam base and tub support should

be retained.

5. From the back of the washer, remove

the wire shipping clips securing the

drain hose.

6. DO NOT remove the PLASTIC CLIPS

which secure the drain hose to the right

side of the washer back sheet. It helps

form a standpipe to prevent water

siphoning.

3. With help from a second person,

carefully tip the laundry center slightly

to the left as shown in the picture be-

low. Remove the foam shipping support from the base of the unit. Save

packaging foam for future use.

1

2

4. Carefully lower laundry center to an

upright position and remove the tape

holding the lid shut. Remove the foam

tub block and other tub contents.

Wire

Clip

7. Carefully move the laundry center

to within four (4) feet of the

nal location for the start of the

installation.

CAUTION

EXCESSIVE WEIGHT HAZARD

To avoid back or other injury, have

more than one person move or lift the

appliance.

15

Plastic

Clips

Page 16

Installation Instructions

Gas connection

1. Remove the shipping cap from gas

pipe at the rear of the dryer.

IMPORTANT

DO NOT connect the dryer to L.P. gas

service without converting the gas valve.

An L.P. conversion kit must be installed

by a qualied gas technician.

2. Connect a 1/2 inch (1.27 cm) I.D.

semi-rigid or approved pipe from

gas supply line to the 3/8 inch (0.96

cm) pipe located on the back of the

dryer. Use a 1/2 inch to 3/8 inch

(1.27 cm to 0.96 cm) reducer for the

connection. Apply an approved thread

sealer that is resistant to the corrosive

action of liqueed gases on all pipe

connections.

Manual

Shutoff

Valve

Open

All connections must be wrench-tightened

Closed

Flare

Union

Nipple

GAS FLOW

Flexible

Connector

Flare

Union

Inlet Pipe on

Back of Dryer

to dryer

from gas supply

Shutoff Valve - Open position

4. Check for gas system leaks with a

manometer. If a manometer is not

available, test all connections by

brushing on a soapy water solution.

WARNING

EXOLOSION HAZARD

NEVER test for gas leaks with an open

ame.

IMPORTANT

The supply line must be equipped with

an approved manual shuto valve. This

valve should be located in the same

room as the dryer and should be in a

location that allows ease of opening

and closing. DO NOT block access to

the gas shuto valve.

3. Open the shuto valve in the gas

supply line to allow gas to ow

through the pipe. Wait a few minutes

for gas to move through the gas line.

16

Page 17

Installation Instructions

Electrical connection

(non-Canada) - 3 wire cord

3-wire receptacle

(NEMA type 10-30R)

WARNING

ELECTRICAL SHOCK HAZARD

Failure to disconnect power source before servicing could result in personal

injury or even death.

1. Turn o power supply to outlet.

2. Remove the screw securing the

terminal block access cover on the

back of the dryer.

3. Install a UL-approved strain relief

according to the power cord/strain

relief manufacturer’s instructions in

the power cord entry hole below the

access panel. At this time, the strain

relief should be loosely in place.

4. Thread an UNPLUGGED, ULapproved, 30 amp. power cord,

NEMA 10-30 type SRDT, through the

strain relief.

DO NOT remove

internal ground in

a 3-wire system!!

Neutral

terminal

WARNING

ELECTRICAL SHOCK HAZARD

DO NOT make a sharp bend or crimp

wiring/conductor at connections.

7. Follow manufacturer’s guidelines for

rmly securing the strain relief and

power cord.

8. Reinstall the terminal block cover.

IMPORTANT

30 AMP

NEMA 10-30

Neutral

(center wire)

5. Attach the power cord neutral (center

wire) conductor to the SILVER colored

center terminal on the terminal block.

Tighten the screw securely.

6. Attach the remaining two power cord

outer conductors to the outer, BRASS

colored terminals on the terminal

block. Tighten both screws securely.

If moving dryer from a 4-wire system

and installing it in a 3-wire system,

move the internal ground from the cen-

ter terminal back to the GREEN screw

next to the terminal block.

17

Page 18

Installation Instructions

Electrical connection

(non-Canada) - 4 wire cord

4-wire receptacle

(NEMA type 14-30R)

WARNING

ELECTRICAL SHOCK HAZARD

Failure to disconnect power source before servicing could result in personal

injury or even death.

1. Turn o power supply to outlet.

2. Remove the screw securing the

terminal block access cover on the

back of the dryer.

3. Install a UL-approved strain relief

according to the power cord/strain

relief manufacturer’s instructions in

the power cord entry hole below the

access panel. At this time, the strain

relief should be loosely in place.

4. Thread an UNPLUGGED, ULapproved, 30 amp. power cord,

NEMA 14-30 type DRT or SRDT,

through the strain relief.

Neutral

(WHITE

wire)

30 AMP

NEMA 14-30

Ground

(GREEN

wire)

8. Attach the RED and BLACK power

cord conductors to the outer, BRASS

colored terminals on the terminal

block. Tighten both screws securely.

Move internal ground (WHITE)

wire to neutral (SILVER)

terminal for 4-wire system.

GREEN

ground screw

GREEN

ground wire

BLACK or

RED power wire

Neutral

terminal

WHITE

neutral wire

BLACK

or RED

power wire

WARNING

ELECTRICAL SHOCK HAZARD

DO NOT make a sharp bend or crimp

wiring/conductor at connections.

9. Follow manufacturer’s guidelines for

rmly securing the strain relief and

power cord.

10. Reinstall the terminal block.

5. Disconnect the internal (WHITE) dryer

harness ground wire from the (GREEN)

ground screw next to the terminal

block.

6. Attach the ground (GREEN) power

cord wire to the cabinet with the

ground (GREEN) screw. Tighten the

screw securely.

7. Move the internal dryer harness

ground (WHITE) wire to the terminal

block and attach it along with the

neutral (WHITE) power cord wire

conductor to the center, SILVER

colored terminal on the terminal

block. Tighten the screw securely.

18

Page 19

Installation Instructions

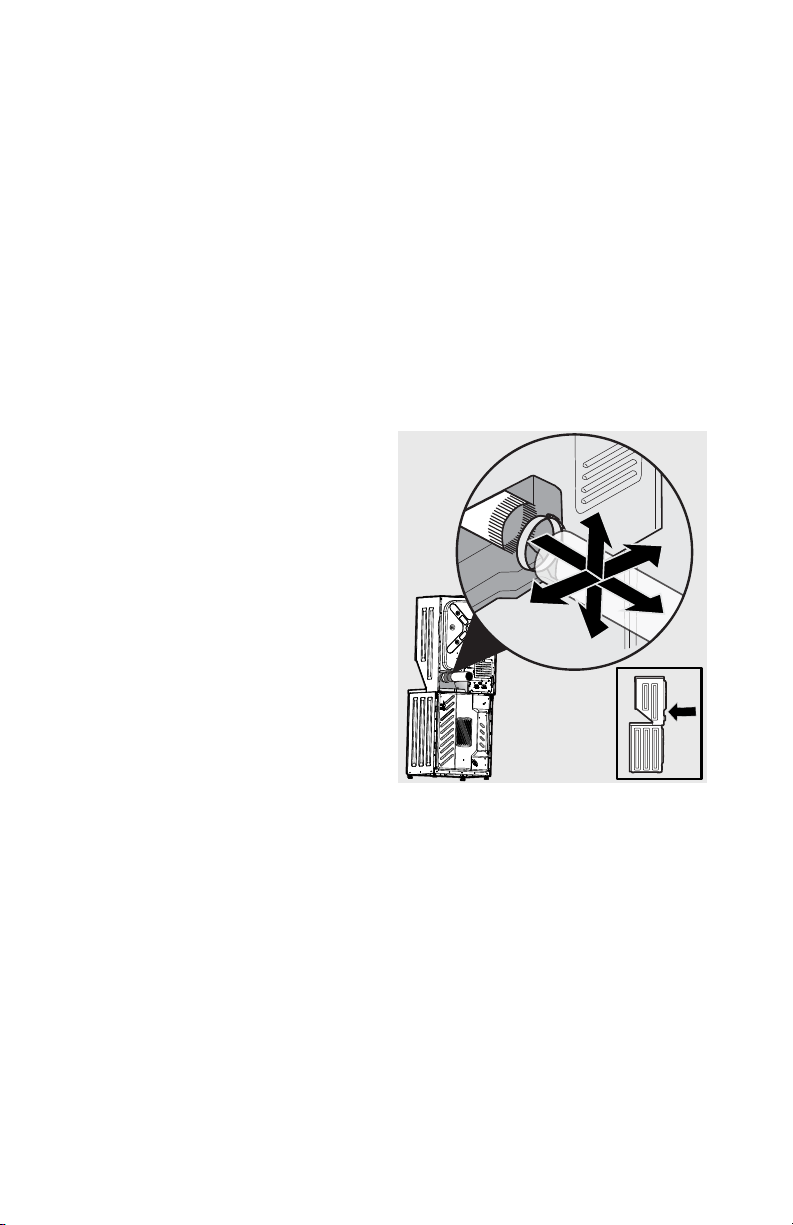

Leveling your laundry center

Excessive noise and vibration can be

prevented by properly leveling the laundry

center.

1. With the

laundry center

within 4 feet (1

m) of its nal

location, place

a level on top

of the washer lid.

2. Use adjustable

pliers to adjust

the leveling

legs so the

laundry center

is level frontto-rear and

side-to-side,

and stable corner-to-corner.

3. Press down

on alternate

corners and

sides and feel

for the slight-

est movement.

Adjust the

leg(s) so the laundry center sits solidly

on the oor on ALL four legs. Keep the

leveling leg extension at a minimum

for best performance of the washer.

Connecting inlet water

1. Run some water

from the hot and

cold faucets to ush

the water lines and

remove particles that

might clog the water

valve screens and

to determine which

faucet is hot and

which is cold supply

2. Check to ensure that

the inlet hoses have

the rubber washer

rmly in place.

raise

lower

Rubber Washers

Must Be Present

USE ONLY

NEW HOSES

NOTE

Hoses are not included with laundry

center purchase. See “Accessories” section for various inlet hose kits to t your

specic installation.

3. Connect the

HOT inlet

hose to the

HOT inlet

connection on

the washer

and the COLD

inlet hose

to the COLD inlet connection on the

washer. Tighten by hand until snug.

Then tighten each supply connection

another 2/3 turn with pliers. DO NOT

cross thread or over-tighten these

connections.

4. Connect the

HOT inlet hose

to the HOT

water supply

and the COLD

inlet hose to

the COLD

water supply.

Tighten by hand until snug.

5. Tighten

each supply

connection

another 2/3

turn with

pliers. DO

NOT bend,

kink, or pinch

water inlet hoses.

6. Turn on the water and check for leaks.

19

Page 20

Installation Instructions

Connecting vent

1. Remove the two screws securing the

dryer front access panel to the dryer

cabinet. Lift the panel until the tabs

can be disengaged from the cabinet,

remove the panel and set aside.

Screws

2. Connect the exhaust duct to the

outside exhaust system. Use of a 4”

(10.2 cm) clamp is recommended to

connect the dryer to the exhaust vent

system. Use metal foil tape to seal all

other joints.

Connecting drain and electrical

1. Form a “U” shape on the end of the

drain hose with the hose pointed

toward the drain. Place the formed

end in a laundry tub or a standpipe

and secure the drain hose with the

cable tie (provided in the enclosure

package) to the standpipe, inlet hose,

laundry tub, etc. so the hose does not

pull out from the force of the water.

Insert Less

Than 8.5"

(21.5 cm)

Clamp

3. Reinstall the dryer front access panel.

4. Carefully slide the laundry center to

its nal position. Recheck for level and

rock corners for stability.

Cable Tie

NOTE

The standpipe inside diameter must be

1-1/4” (3.2 cm) minimum. There must be

an air gap around the drain hose in the

standpipe. A snug hose t can cause a

siphoning action.

20

Page 21

Installation Instructions

IMPORTANT

Check to ensure the power is o at a

circuit breaker/fuse box before plugging the power cord into an outlet.

2. Plug the power cord into a grounded

outlet.

WARNING

6. If you have any questions during initial

operation, please review the “

Service Checklist

Guide

before calling for service.

7. Place these instructions in a location

near the appliance for future

reference.

” in your

Avoid

Use & Care

Improper grounding of the laundry

center may cause serious injury or

death. Check with a licensed electrician if you are in doubt as to whether

the appliance is properly grounded.

Grounding type wall receptacle

Do not, under

any circumstances,

cut, remove,

or bypass the

grounding prong.

Power cord with

3-prong grounded plug

3. Turn on the power at the circuit

breaker/fuse box.

4. Read the Use & Care Guide provided

with the laundry center. It contains

valuable and helpful information that

will save you time and money.

5. Run the washer through a complete

cycle, checking for water leaks and

proper operation.

NOTE

A wiring diagram and technical data

sheet are located behind the dryer

access panel.

WARNING

When discarding or storing your old

laundry center, ALWAYS remove the

washer and dryer doors.

21

Page 22

Accessories and Replacement Parts

Accessories

LP CONVERSION KIT

P/N PCK3100

Gas dryers intended for use in a

location supplied with LP must use a

conversion kit prior to installation.

MOBILE HOME INSTALLATION KIT

P/N 137067200

Installation in a mobile home requires

the use of a Mobile Home Installation

Kit.

INLET HOSE KITS

Please call 866-233-8353 (in Canada,

800-265-8352) to explore hose kit

options that will meet your specic

installation needs.

UNIVERSAL APPLIANCE WRENCH

P/N 137019200

A Universal Appliance Wrench is

available to aid in dryer/washer feet

adjustment.

Replacement parts:

If replacements parts are needed for

your laundry center, contact the source

where you purchased your laundry center

or refer to your Use and Care Guide for

more information.

Universal Appliance Wrench

TOUCH UP PAINT PENS*

Classic White Touch Up Pen -

P/N 5304468812

Classic Slate Touch Up Pen -

P/N 5304475700

*Other colors may be available.

Contact the source where you

purchased your laundry center.

CAUTION

Failure to use accessories manufactured by (or approved by) the manufacturer could result in personal injury,

property damage or damage to the

washer.

22

Page 23

23

Page 24

Kenmore

®

®

Customer Care Hotline

To schedule repair service or order parts

Para pedir servicio o ordenar piezas

1-844-553-6667

www. kenmore.com.

Page 25

Installation Instructions

Instrucciones de Instalación

English / Español

Models/Modelos: 417.6173*, 417.7173*

Kenmore

®

Laundry Center

Centro de lavado

* = Color number, número de color

P/N: A13415001 (1801)

Sears Brands Management Corporation

Homan Estates, IL 60179 U.S.A.

www.kenmore.com

www.sears.com

Page 26

Instrucciones de seguridad importantes

Índice

ADVERTENCIA

Instrucciones de seguridad importantes . 2-3

Requisitos para la instalación ............ 3-14

Desembalaje del centro de lavado .......... 15

Instrucciones de instalación ............. 16-21

Accesorios y piezas de repuesto ............. 22

Por su seguridad siga la información

contenida en este manual para minimizar el riesgo de incendio o explosión

y evitar daños en las propiedades,

lesiones personales o incluso pérdida

de vidas. Conserve estas instrucciones.

ADVERTENCIA

PELIGRO DE INCENDIO

Lea todas las instrucciones antes de instalar y utilizar este aparato.

• Destruya la caja de cartón y las bolsas de plástico una vez desembalado

el centro delavado. Losniños podrían utilizarlas para jugar. Las cajas

de cartón cubiertas con esterillas, colchas oláminas de plástico pueden

convertirse en cámaras herméticas y provocar asxia. Coloquetodos los

materiales en un contenedor de basuras o fuera del alcance de los niños.

• La instalación y revisión del centro de lavado debe ser realizada por un insta-

lador cualicado, unservicio de reparación o la empresa proveedora de gas.

• Instale el aparato de conformidad con las instrucciones del fabricante y

los códigos locales.

• El servicio eléctrico del aparato deberá cumplir los códigos y ordenanzas

locales y la última edición del National Electrical Code, ANSI/NFPA 70, o

en Canadá, el Canadian Electrical Code CSA C22.1.

• El servicio de gas de la secadora deberá cumplir los códigos y ordenanzas

locales y la última edición del National Fuel Gas Code NFPA 54/ANSI

Z223.1 o, en Canadá, el Natural Gas and Propane Installation Code CSA

B149.1. Deberá instalarse una válvula de desconexión manual individual

a un máximo de 1,83 m (6 pies) de la secadora, deconformidad con el

National FuelGas Code, NFPA 54/ANSI Z223.1.

• El centro de lavado está diseñado de conformidad con las normas ANSI

Z21.5.1 o UL 2158 - CAN/CSA C22.2 No. 112 y UL 2157 - CSA C22.2 No.

169 (últimas ediciones) solo para USODOMÉSTICO. Este centro de lavado

no está recomendado para aplicaciones comercialescomorestaurantes,

salones de belleza, etc.

• NO instale una secadora de ropa con material de ventilación de lámina

de aluminio exible o de plástico exible. Es sabido que los materiales

de ventilación exibles sedesmoronan, se aplastan fácilmente y atrapan

pelusa. Estas condiciones obstruyen elujo de aire en la secadora de ropa

y aumentan el riesgo de incendio.

• Las instrucciones de este manual y cualquier otra publicación incluida con

este aparato no están previstas para cubrir todas las posibles condiciones

y situaciones que puedan darse. Es NECESARIO aplicar la precaución y

las buenas prácticasde seguridad al instalar, poner enfuncionamiento y

realizar el mantenimiento de cualquier aparato.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

2

Page 27

Instrucciones de

seguridad importantes

Requisitos para la

instalación

ADVERTENCIA

Lea todas las instrucciones antes de utilizar este centro de lavado.

Deniciones

Este es el símbolo de alerta de

seguridad. Seutiliza para alertarle de

potenciales peligros de lesiones personales.

Obedezca todos los mensajes deseguridad

que aparezcan después de este símbolo

para evitar posibles lesiones oincluso la

muerte.

PELIGRO

PELIGRO indica una situación inmi-

nente ypeligrosa que, de no evitarse,

producirá lamuerte o lesiones graves.

ADVERTENCIA

ADVERTENCIA indica una situación

potencialmente peligrosa que, de no

evitarse, puede llegar a producir la

muerteolesiones graves.

PRECAUCIÓN

PRECAUCIÓN indica una situación

potencialmente peligrosa que, de no

evitarse, puede producir lesiones menos

graves o moderadas.

IMPORTANTE

IMPORTANTE indica información sobre

instalación, funcionamiento o mantenimiento que es importante pero no está

relacionada con peligros.

PRECAUCIÓN

PELIGRO DE PESO EXCESIVO

Para evitar lesiones en la espalda o de

otro tipo, el aparato debe ser levantado

otrasladado por más de una persona.

Requisitos previos a la instalación

Herramientas y materiales necesarios

para la instalación:

• Alicates ajustables

• Destornilladores Phillips, recto y cuadrado

• Llave inglesa

• Llave de tubo para el suministro de gas

(Secadora de gas)

• Cinta de hilo resistente al LP (secado-

radegas natural o LP)

• Nivel de carpintero

• Campana de ventilación exterior

• Conducto de salida de metal rígido

o semirrígido de 102 mm (4 pulgadas)

• Kit de cable de 3 o 4 hilos 240 voltios

(secadora eléctrica)

• Abrazadera de 102 mm(4”)

• Válvula de cierre de la tubería de gas

(secadora de gas)

• Adaptadores de unión abocinada NPT

½ (x2) y tubo exible de suministro de

gas (secadora de gas)

• Cinta de aluminio (no cinta de embalar)

• Tubos de entrada de agua (x2)

NOTA

El precio de la lavadora no incluye

mangueras. Consulte la sección “Accesorios” para ver los distintos kits de

mangueras de entrada adecuados a su

instalación concreta.

NOTA

GUARDE ESTAS INSTRUCCIONES

PARA CONSULTAS FUTURAS

Debido a la posible falta de voltaje

constante, no se recomienda el uso

de esta secadora con alimentación

mediante generadores de gas, solares,

eólicos u otro tipo de generador distinto

del suministrado por su empresa de

electricidad local.

3

Page 28

Requisitos para la instalación

LISTA DE COMPROBACIÓN PARA LA INSTALACIÓN

Materiales de embalaje y envío

qSujeción de espuma para envío (en

el interior del tambor) retirada y

guardada

qSujeción de espuma para envío

(bajoelaparato) retirada y guardada

Nivelado

qEl centro de lavado está nivelado,

delado a lado y de frontal a

trasera

qEl mueble se apoya bien en todas

las esquinas

Suministro de agua

qUtilice solo mangueras nuevas

ycompruebe que estén colocadas

lasarandelas de goma de sellado

qEl suministro de agua CALIENTE

está conectado a la entrada de

agua CALIENTE y la de agua FRÍA,

a la entrada de agua FRÍA

qSuministro de agua CALIENTE y

FRÍA conectados

qLas conexiones del suministro de

agua y las conexiones de entrada

del aparato no presentan pérdidas;

volver a comprobar en 24 horas

Desagüe

qTubería vertical o desagüe de

pared, altura mínima 33”

qManguera dedesagüe jado con

brida para cables (se entrega en el

tambor)

Salida de ventilación

qCon ujo libre, sin acumulación de

pelusa

qConducto rígido o semirrígido de

102mm (4 pulgadas) con mínima

longitud y curvas

qSIN material de plástico o papel

dealuminio

qCampana de extracción autorizada

con salida al exterior

Suministro de gas

(Secadora de gas)

qVálvula de cierre manual presente

enelsuministro

qTodas las conexiones selladas con

sellador aprobado y apretadas con

llave

qKit de conversión para sistema de

LP

qSuministro de gas abierto

qNo hay fugas en ninguna conexión

(comprobar con agua jabonosa,

NUNCAcon llama)

Fuente de alimentación de

240v (secadora eléctrica)

qCable de servicio homologado

NEMA 10-30R o 14-30R con todos

los tornillos apretados en la regleta

de bornas

qAprietacable homologado instalado

qCubierta de acceso al terminal in-

stalada antes de la operación inicial

Alimentación eléctrica

qCorriente eléctrica de la vivienda

encendida

qCentro de lavado conectado

Comprobaciones nales

q Instrucciones de instalación y Guía

de uso y mantenimiento: leer at-

entamente

q El agua entra en el tambor al iniciar

elciclo con la tapa bajada

q La puerta de la secadora queda

bien cer rada y el tambor gira al

comenzar elciclo

q Tarjeta de registro enviada

4

Page 29

Requisitos para la instalación

Requisitos eléctricos del centro

delavado con secadora eléctrica

CIRCUITO - Circuito de derivación

individual de 30amperios con fusibles o

disyuntor de 30amperios con retardo.

FUENTE DE ALIMENTACIÓN - 3 o 4 hilos,

240voltios, monofase, 60 Hz, corriente

alterna.

IMPORTANTE

Este centro de lavado tiene conexión interna neutra a tierra salvo unidades para

venta en Canadá.

Solo se utilizará cable de 4 conductores

cuando el aparato se instale en un lugar

en el que esté prohibido realizar la conexión a tierra a través del conductor neutro.

Está prohibido realizar la conexión a tierra

a través del enlace neutro para: (1) nuevas

instalaciones con circuito de derivación, (2)

viviendas móviles, (3) vehículos de recreo

y (4) áreas en las que los códigos locales

NO permitan la conexión atierra através

del conductor neutro.

TOMA DE CORRIENTE - NEMA 10-30R

o NEMA 14-30R situado de modo que el

cable de alimentación quede accesible

cuando la secadora quede instalada en su

posición.

CONEXIÓN A TIERRA - Ver “Requisitos de

conexión a tierra” en la sección Instalación

eléctrica.

Tomacorriente de pared con

conexión a tierra

Bajo ninguna

circunstancia corte,

extraiga o desvíe

las patas de

conexión a tierra.

Cable de alimentación

con enchufe de tres patas

con conexión a tierra

KIT DE CABLE DE ALIMENTACIÓN

DE3HILOS (no suministrado)

Toma de 3 hilos

(NEMA tipo 10-30R)

La secadora DEBERÁ utilizar un cable de

alimentación de 3 conductores NEMA

10-30 tipo SRDT para corriente alterna

de 240 voltios y 30 amperios nominales

como mínimo, con3 conectores de

pala con extremo abierto con extremos

girados hacia arriba o conectores de

bucle cerrado y marcados para uso con

secadoras de ropa. Para instrucciones de

conexión con cable de 3 hilos, consulte

CONEXIONES ELÉCTRICAS PARA UN

SISTEMA DE 3 HILOS.

KIT DE CABLE DE ALIMENTACIÓN

DE4HILOS (no suministrado)

ADVERTENCIA

Una inadecuada conexión a tierra en el

centro de lavado puede provocar lesiones graves o la muerte. Consulte a un

electricista cualicado en caso de duda

sobre si el aparato está adecuadamente

conectado a tierra.

Toma de 4 hilos

(NEMA tipo 14-30R)

La secadora DEBERÁ utilizar un cable de

alimentación de 4 conductores NEMA

14-30 tipo SRDT o DRT (según se precise)

para corriente alterna de 240 voltios y 30

amperios nominales como mínimo, con 4

conectores de pala con extremo abierto

con extremos girados hacia arriba o

conectores de bucle cerrado ymarcados

para uso con secadoras de ropa. Para

instrucciones de conexión con cable de 4

hilos, consulte CONEXIONES ELÉCTRICAS

PARA UN SISTEMA DE 4 HILOS.

5

Page 30

Requisitos para la instalación

NOTA

Los centros de lavado fabricados para

venta en Canadá tienen instalado de fábrica un cable de alimentación de 4 hilos

(NEMA 14-30R).

Requisitos eléctricos del centro

delavado con secadora de gas

ADVERTENCIA

Una inadecuada conexión a tierra en

el centro de lavado puede provocar

lesiones graves o la muerte. Consulte

a un electricista cualicado en caso de

duda sobre si el aparato está adecuadamente conectado a tierra.

Tomacorriente de pared con

conexión a tierra

Bajo ninguna

circunstancia corte,

extraiga o desvíe

las patas de

conexión a tierra.

Cable de alimentación

con enchufe de tres patas

con conexión a tierra

CIRCUITO - Circuito de derivación

individual de 15 amperios

adecuadamente polarizado yconectado

a tierra con fusible o disyuntor

de15amperios con retardo.

FUENTE DE ALIMENTACIÓN - 2 hilos,

conconexión a tierra 120 voltios,

monofase, 60Hz, corriente alterna.

CABLE DE ALIMENTACIÓN - La

secadora está equipada con un cable de

alimentación de 3hilosy 120 voltios.

CONEXIÓN A TIERRA - Ver “Requisitos

de conexión a tierra” en la sección

Instalación eléctrica.

Requisitos del suministro de gas

ADVERTENCIA

PELIGRO DE EXPLOSIÓN

Los tubos de cobre sin recubrir se

corroen al exponerse a gas natural,

provocando pérdidas de gas. Utilice

SOLO tubería de hierro negro, acero

inoxidable o latón con recubrimiento

deplástico para suministro de gas.

1. La instalación DEBERÁ cumplir las

normas locales o, de no haberlas,

con el Código Nacional de Gas

Combustible, ANSIZ223.1 (última

edición).

2. La entrada de gas deberá ser una

tubería de1,27 cm (1/2 pulgada).

3. Si los códigos lo permiten, puede

utilizarse tubería de metal exible para

conectar la secadora al suministro

de gas. La tubería DEBERÁ estar

fabricada de acero inoxidable olatón

con recubrimiento plástico.

4. La tubería de suministro de gas

DEBERÁ tener una válvula de cierre

individual instalada de conformidad

con el Código de Instalación de Gas

Natural y Propano, B149.1.

5. DEBERÁ instalarse una conexión

roscada con enchufe N.P.T. de 0,32cm

(1/8 de pulgada), accesible para

pruebas inmediatamente después dela

conexión de suministro degasa la

secadora.

6. La secadora DEBERÁ desconectarse del

sistema de tubería de suministro de gas

durante las comprobaciones de presión

del sistema de tubería de suministro de

gas a presiones de prueba superiores a

3,45 kPa (1/2 psig).

7. La secadora DEBERÁ aislarse del

sistema de tubería de suministro de gas

durante las comprobaciones de presión

del sistema de tubería de suministro de

gas a presiones de prueba iguales o

inferiores a 3,45 kPa (1/2 psig).

8. Las conexiones para el suministro de

gas deberán cumplir la Norma para

Conectores deAparatos de Gas, ANSI

Z21.24 - CSA 6.10.

6

Page 31

Requisitos para la instalación

Requisitos de suministro de agua

Las llaves de agua fría y caliente

DEBERÁN instalarse a menos de 107 cm

(42 pulgadas) de la entrada de agua de

la lavadora. Las llaves DEBERÁN ser de

1,9cm (3/4 de pulgada) con roscado

para conexión a manguera de lavado.

Lapresión de agua DEBERÁ ser entre 10

psi (0,69 bares) y 120 psi (8,27 bares).

Ladiferencia de presión entre caliente

y fría no puede ser de más de 10 psi. El

servicio de aguas podrá asesorarle sobre

su presión de agua.

NOTA

244cm

(96")

max.

84cm

(33")

min.

Las lavadoras conectadas a suministros

de agua con presión de entrada baja

tendrán tiempos de llenado más pro-

longados y es posible que no completen

los ciclos con la misma rapidez.

Requisitos del sistema de desagüe

1. Desagüe capaz de eliminar 64,3 l

(17galones) por minuto.

2. Tubería de subida con un diámetro

mínimo de 3,18 cm(1-1/4”).

3. La altura de la tubería de subida

porencima del suelo deberá ser:

-Altura mínima: 84 cm(33”)

-Altura máxima: 244 cm(96”)

NOTA

Para instalaciones que precisen una

manguera de desagüe más larga,

recurra a un técnico cualicado para

instalar una manguera de desagüe más

larga (según su número de modelo) disponible en distribuidores de recambios

autorizados. Para sistemas de desagüe

en el suelo, instale un kit de interruptor de sifón disponible en su ferretería

local.

Requisitos del sistema de

extracción

Utilice solo conducto metálico rígido

o exible de 102 mm (4 pulgadas) de

diámetro y campana de ventilación

aprobada con registro(es) giratorios que

se abren cuando la secadora está en

funcionamiento. Al detenerse la secadora,

los registros se cierran automáticamente

para evitar corrientes y la entrada de

insectos y roedores. Para evitar limitar

el ujo de salida, mantenga un espacio

mínimo de 30,5 cm (12 pulgadas) entre

la campana de ventilación y el suelo

ocualquier otra obstrucción.

ADVERTENCIA

PELIGRO DE INCENDIO

No seguir estas instrucciones puede

aumentar los tiempos de secado y

producir riesgo de incendio.

A continuación se detallan los requisitos

especícos para el funcionamiento

correcto yseguro de su secadora.

7

Page 32

Requisitos para la instalación

ADVERTENCIA

PELIGRO DE INCENDIO

NO instale una secadora de ropa con

materiales de ventilación de lámina de

metal o de plástico exible. Es sabido

que los materiales de ventilación

exibles se desmoronan, se aplastan

fácilmente y atrapan pelusa. Estas

condiciones obstruyen el ujo de aire

en la secadora de ropa y aumentan el

riesgo de incendio.

Si su sistema actual está realizado con

conducto de plástico o de hoja metálica,

sustitúyalo por conducto metálico rígido

o semirrígido. Compruebe también que

el conducto actual estélibre de pelusas

antes deinstalar elconductode la

secadora.

Correcto

ADVERTENCIA

PELIGRO DE INCENDIO

La secadora de ropa debe tener

extracción al exterior. NO evacue la

secadora a una chimenea, pared, techo, ático, cámara inferior u otro espa-

cio oculto de un edicio. Una secadora

de ropa produce pelusa combustible.

Si la secadora no evacua al exterior,

algo de pelusa na pasará al área

de lavado. La acumulación de pelusa

en cualquier área del hogar puede

constituir unriesgo para la salud y de

incendio.

La secadora deberá estar conectada a

una extracción exterior. Antes de instalar

su secadora nueva, inspeccione la

abertura de la extracción exterior y retire

cualquier posible acumulación de pelusa

alrededor delaabertura yen el área

cercana.

ADVERTENCIA

PELIGRO DE INCENDIO

No respetar estrictamente las advertencias de seguridad puede provocar

lesiones graves, muerte o daños en la

propiedad.

NO instale un ventilador de refuerzo

en el conducto de extracción.

Instale la secadora de ropa de conformidad con las instrucciones de

instalación de este manual.

Incorrecto

8

Page 33

Requisitos para la instalación

Correcto Incorrecto

Instale los accesorios macho en la

ADVERTENCIA

PELIGRO DE INCENDIO

• NO permita que materiales combustibles

(por ejemplo: prendas, visillos/cortinas,

papel) entren en contacto con el sistema

de extracción. La extracción de la secadora NO DEBERÁ ser a una chimenea,

pared, techo u otro espacio oculto de un

edicio, ya que puede acumularse pelusa

con el consiguiente riesgo de incendio.

• NO proteja los extremos de extracción

del sistema de ventilación ni utilice torni-

llos, remaches u otros cierres que lleguen

al interior del conducto para montar el

sistema de extracción. Es posible que

quede pelusa atrapada en la protec-

ción, tornillos o remaches, atascando el

conducto y creando peligro de incendio,

además de prolongar los tiempos de secado. Utilice una campana de ventilación

autorizada como terminación exterior del

conducto y selle todas las juntas con cinta

metálica. Todos los equipos con tubería

macho DEBERÁN instalarse hacia la

descarga del ujo de aire.

ADVERTENCIA

ADVERTENCIA

PELIGRO DE INCENDIO

• NO instale material de ventilación

de lámina de aluminio exible o de

plástico exible.

• Si instala un conducto de ventilación

semirrígido, NO supere los 8 pies

(2,4 m) de longitud.

ADVERTENCIA

PELIGRO DE INCENDIO

• No respetar estrictamente las advertencias de seguridad puede provocar

lesiones graves, muerte o daños en

las propiedades.

• NO instale un ventilador de refuerzo

en el conducto de extracción de la

secadora.

• Instale la secadora de ropa de

conformidad con las instrucciones de

instalación de este manual.

dirección correcta:

Superar la longitud de la tubería o

el número de codos permitido en las

tablas “LONGITUD MÁXIMA” puede

provocar acumulación de pelusa en

el sistema de extracción. Taponar el

sistema puede crear riesgo de incendio

yaumentar los tiempos de secado.

Número de vueltas de 90°

0 17 m (56 pies) 13 m (42 pies)

1 14,5 m (48 pies) 10,5 m (34 pies)

2 12 m (40 pies) 8 m (26 pies)

3 9,5 m (32 pies) 5,5 m (18 pies)

PELIGRO DE INCENDIO

de 102 mm (4”) conducto metálico rígido

TIPO DE CAMPANA DE VENTILACIÓN

10,2 cm (4”)

LONGITUD MÁXIMA

(Preferido)

de

listones 6,35 cm (2,5”)

En instalaciones en las que los grácos

no describan el sistema de extracción,

deberá utilizarse el siguiente método para

determinar siel sistema de extracción es

aceptable:

1. Conecte un manómetro inclinado o

digital entre la secadora y el punto en

el que la extracción se conecta a la

secadora.

2. Ajuste el temporizador y temperatura

de lasecadora a secado por aire

(enfriado) yponga la secadora en

funcionamiento.

3. Lea la medición en el manómetro.

9

Page 34

Requisitos para la instalación

4. La contrapresión del sistema NO

DEBERÁ ser superior a 0,6 pulgadas

de la columna de agua. Si la

contrapresión del sistema es inferior

a 0,6 pulgadas de la columna de

agua, el sistema es aceptable. Si la

lectura del manómetro es superior a

0,6 pulgadas de la columna de agua,

elsistema es demasiado restrictivo

ylainstalación es inaceptable.

Aunque es aceptable una orientación

vertical del sistema de extracción,

determinadas circunstancias podrían

llegar a afectar el rendimiento de la

secadora.

• Debería utilizarse solamente conducto

metálico rígido.

• Ventilar verticalmente a través de un

tejado puede exponer el sistema de

extracción a corrientes hacia abajo,

lo que aumentaría larestricción de la

ventilación.

• Hacer funcionar el sistema de extracción a través de un área sin aislamiento

puede provocar condensación y una

acumulación más rápida de pelusa.

• La compresión o apretado del sistema

deextracción provocará un aumento

enlarestricción de la ventilación.

• El sistema de extracción deberá ins-

peccionarse y limpiarse al menos cada

18meses de uso normal. Cuanto más se

utilice la secadora, mayor deberá ser la

frecuencia de inspección del funcio-

namiento del sistema de extracción y

delacampana de ventilación.

Dirección de la extracción

La extracción del centro de lavado puede

ser de cuatro (4) maneras con instalación

a ras posterior:

1. Recto atrás.

2. Abajo (20,3 cm [8 pulgadas] de longitud

dediámetro de 102 mm [4 pulgadas] de

conducto rígido y 1 codo abajo).

3. Izquierda (20,3 cm [8 pulgadas] de

longitud de diámetro de 102 mm [4

pulgadas] de conducto rígido, 1 codo

abajo y 1 codo izquierda).

4. Derecha ( 20,3 cm [8 pulgadas] de

longitud de diámetro de 102 mm [4

pulgadas] de conducto rígido, 1 codo

abajo y 1 codo derecha).

Es posible instalar una campana de

extracción alineada con la extracción de

la secadora directamente al otro lado de

la pared exterior. Para que la extracción

sea a un lado o abajo, añada un tramo

de 20,3 cm (8 pulgadas) de conducto

estándar de 102 mm (4 pulgadas)

dediámetro y un codo de 90°.

Para que la extracción sea hacia arriba,

añada un tramo de 28 cm (11 pulgadas)

de conducto estándar de 102 mm (4

pulgadas) de diámetro y un codo de

90°. La unidad se colocará a alrededor

de 11,5 cm (4,5 pulgadas) de la pared

(la extracción puede realizarse al ras de

la pared yendo debajo de la secadora

ydespués a un lado).

Véase también

estas instrucciones.

Requisitos de holgura

en

10

Page 35

Requisitos para la instalación

Instalación en viviendas

prefabricadas o móviles

1. La instalación DEBERÁ cumplir la

actual norma Manufactured Home

Construction & Safety Standard,

Título 24 CFR Parte 3280 (antes

Federal Standard for Mobile Home

Construction and Safety, Título 24,

HUD Parte 280) o la norma Standard

CAN/CSA-Z240 MH.

2. La secadora DEBERÁ tener extracción

alexterior (fuera, no debajo de la

vivienda móvil) utilizando conductos

de metal resistentes a la combustión.

El conducto metálico deberá tener

10,16cm (4pulgadas) de diámetro

sin obstrucciones. Es preferible

un conducto de metal rígido. Los

conductos de extracción deberán

estar bien sujetos a una parte no

combustible dela estructura de la

vivienda móvil.

3. Si la secadora realiza la extracción

a través del suelo y el área bajo la

vivienda móvil es cerrada, el sistema

de extracción DEBERÁ terminar fuera

del área cerrada con la terminación

rmemente jada alaestructurade

la vivienda móvil.

4. Consulte las secciones anteriores

de esta guía para conocer otros

requisitos importantes del sistema de

ventilación de extracción.

5. Al instalar una secadora de gas en

una vivienda móvil, debe hacerse

provisión deentrada de aire exterior.

Esta provisión no deberá ser inferior

al doble del área de lasalida de

extracción de la secadora.

6. El instalador DEBERÁ anclar el centro

de lavado al suelo con el Kit de

instalación paraviviendas móviles

N/P 137067200.

Instalación en nicho o armario

1. Una secadora instalada en un

dormitorio, baño, nicho o armario

DEBERÁ tener salida al exterior.

2. No se instalará ningún otro aparato

quemador de combustible en el

mismo armario que la secadora de

gas.

3. Su secadora necesita el espacio

alrededor para una adecuada

ventilación.

4. NO instale su secadora en un armario

con puerta maciza.

5. Ventilación necesaria para la puerta

del armario: Se precisa una abertura

mínima de 774,2 cm² (120 pulgadas

cuadradas), dividida por igual en la

parte superior e inferior de la puerta.

Las aberturas estarán situadas a 7,6

cm (3 pulgadas) dela parte inferior

y superior de la puerta. Si se instala

una puerta, deberá tener aberturas

sin obstrucciones. Es aceptable una

puerta de listones con aberturas

de aire equivalentes para toda la

longitud dela puerta.

7.6cm

(3")

387.1cm²

(60 sq. in.)

387.1cm²

(60 sq. in.)

7.6cm

(3")

11

Page 36

Requisitos para la instalación

80 cm (31,5")

Vista lateral

68,5 cm (27")

cm

Vista frontal

Requisitos de holgura

HOLGURAS MÍNIMAS PARA

LA INSTALACIÓN - Pulgadas (cm)

LATERALES POSTERIOR SUPERIOR FRONTAL

Hueco

Armario

0”

(0 cm)0”(0 cm)1”(2.5 cm)

0”

(0 cm)0”(0 cm)1”(2.5 cm)1”(2.5 cm)

ADVERTENCIA

PELIGRO DE EXPLOSIÓN

NO instale el centro de lavado en un

lugar donde se almacene o guarde

gasolina uotros productos inamables.

Si el centro de lavado se instala en un

garaje, la parte de secadora deberá

estar a un mínimo de 45,7 cm (18

pulgadas) sobre el suelo. Lo contrario

puede provocar la muerte, explosión,

incendio o quemaduras.

IMPORTANTE

NO INSTALE SU CENTRO DE LAVADO:

• En un área expuesta a goteo de agua o

alas condiciones atmosféricas del exterior. La temperatura ambiente

nunca deberá serinferior a 15,6° C

(60° F) para maximizar la efectividad

del detergente.

• En un área en la que entre en contacto

con cortinas, visillos o cualquier cosa

que obstruya el ujo del aire de combustión yventilación.

• Sobre moqueta o alfombra. El suelo

DEBERÁser sólido con una pendiente máxima de a 2,5 cm (1 pulgad).

Paraminimizar la vibración o movimiento puedeser necesario reforzar el suelo.

n/a

2.5 cm 0 cm

(1”)

45 cm

(17,6")

196,5 cm

(77")

Clips de

sujeción de

la manguera

de desagüe

en la parte

trasera de la

2

lavadora

120,5 cm (47,5")

141,5 cm

(55,75")

96,5 cm

(38")

(0”)

68.5 cm

(27”

power cord

attachment

location on

rear of unit

58,5 cm

(23")

33 mm

(13")

0 cm

(0”)

)

tubería de suministro

de gas en la parte

trasera de la unidad

de gas

24 cm

(9,4")

14 cm

(5,5")

1

2.5 cm

Salida de 102 mm

(4 pulgadas) para

extracción en la

parte trasera de

la unidad

conexión del

suministro de

agua en la

parte trasera

de la unidad

110.5

(43.5")

80 cm (31,5")

altura central de la

tubería para salida

de extracción de

102 mm (4 pulgadas)

105,5 cm

(41,5")

(1”)

1

Longitud del cable de alimentación de la unidad

de gas de aproximadamente 152,5 cm (60pul-

gadas).

2

Longitud de la manguera de desagüe suelta más

allá de la abrazadera aproximadamente 131 cm

(51,5 pulgadas).

12

Page 37

Requisitos para la instalación

Instalación eléctrica

A continuación se detallan los requisitos

especícos para la instalación eléctrica

correcta y segura de su secadora. No

seguir estas instrucciones puede crear

riesgos de descarga eléctrica y/o incendio.

ADVERTENCIA

PELIGRO DE DESCARGA ELÉCTRICA

• Este aparato DEBERÁ estar adecuadamente conectado a tierra. La falta de

una adecuada conexión a tierra puede