Kenmore 38519001890 Owner’s Manual

SERVICE MANUAL

SEWING MACHINE MODEL

385.19001890

NOVEMBER,1998

CONTENTS

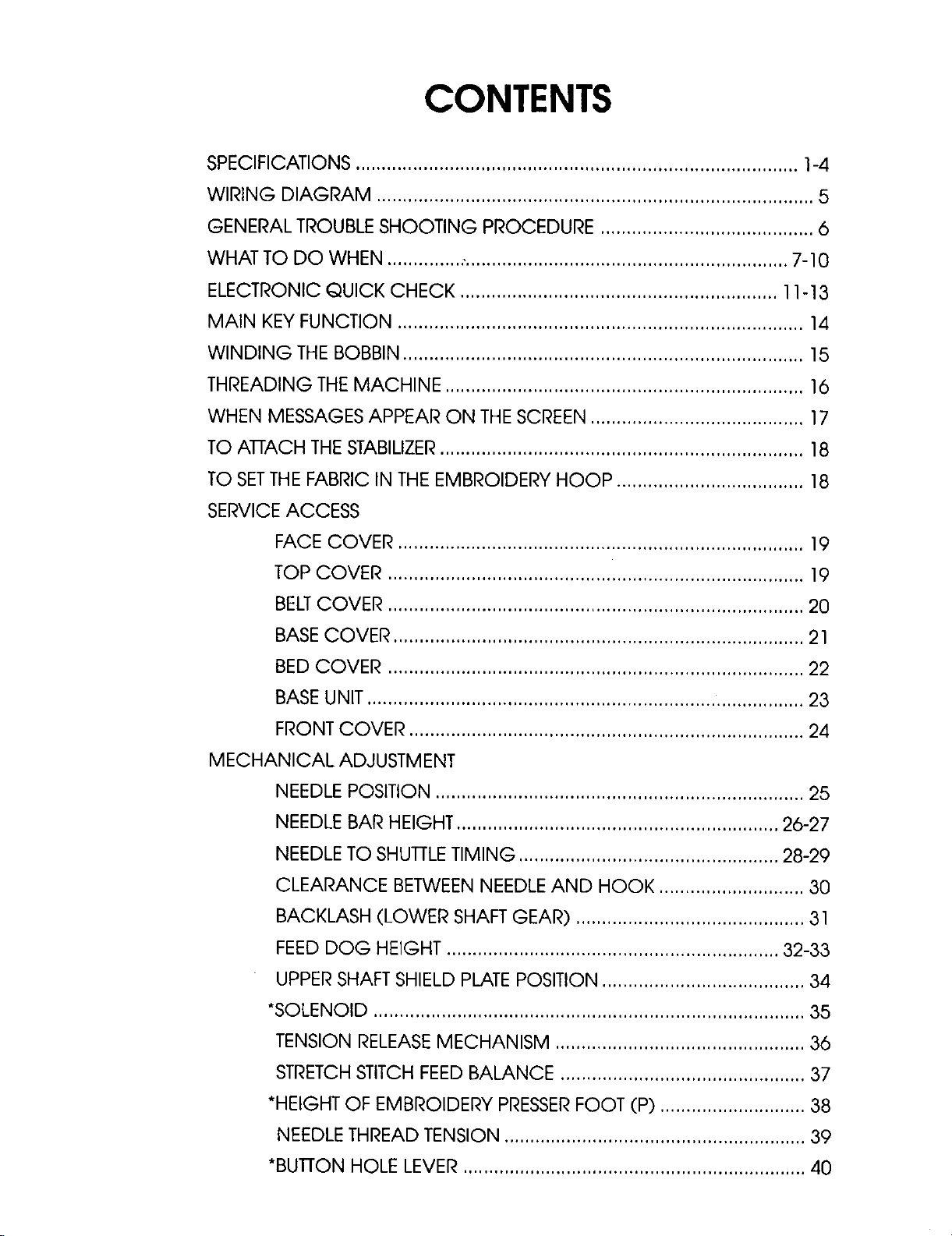

SPECIFICATIONS .....................................................................................I-4

WIRING DIAGRAM ....................................................................................5

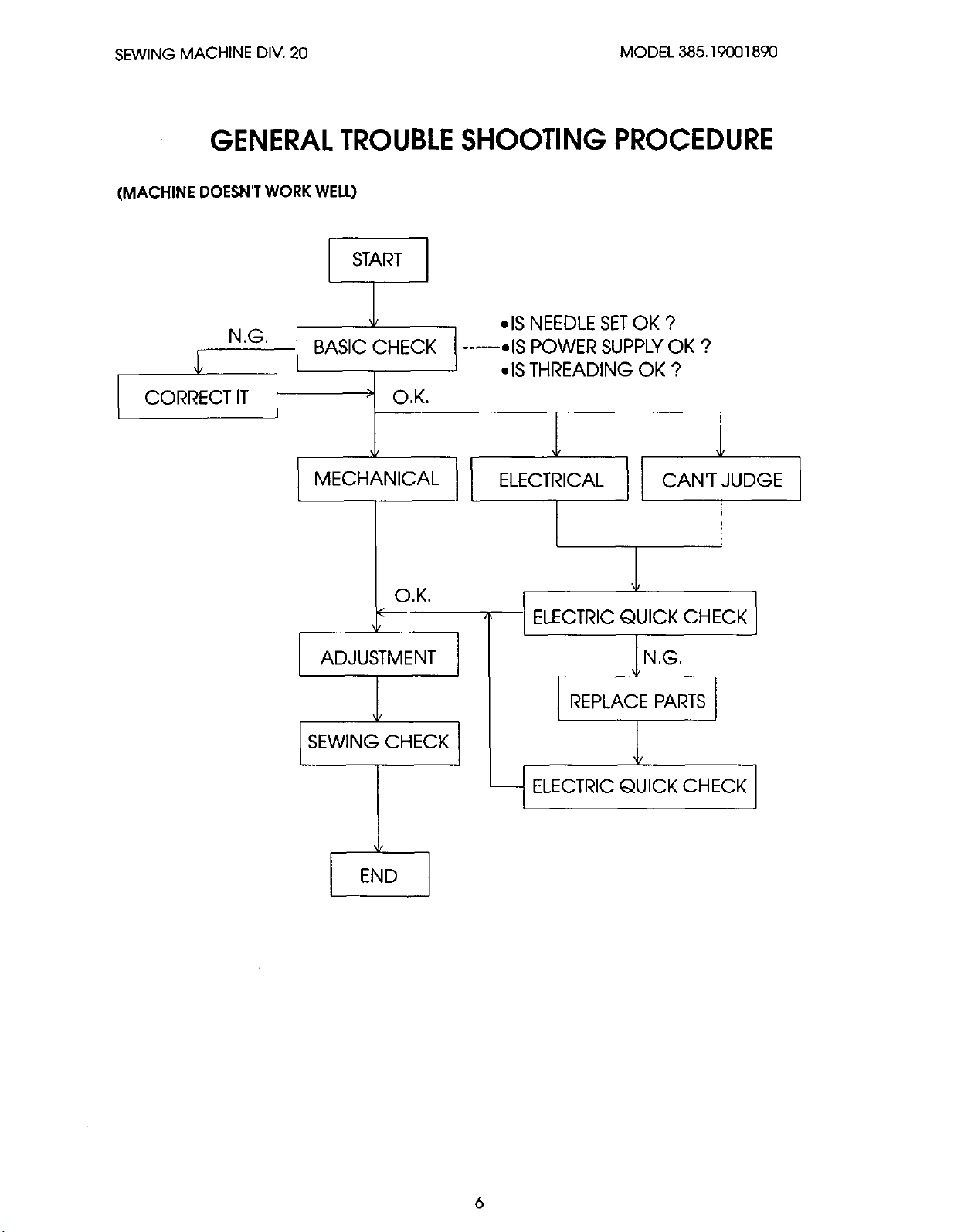

GENERAL TROUBLE SHOOTING PROCEDURE .........................................6

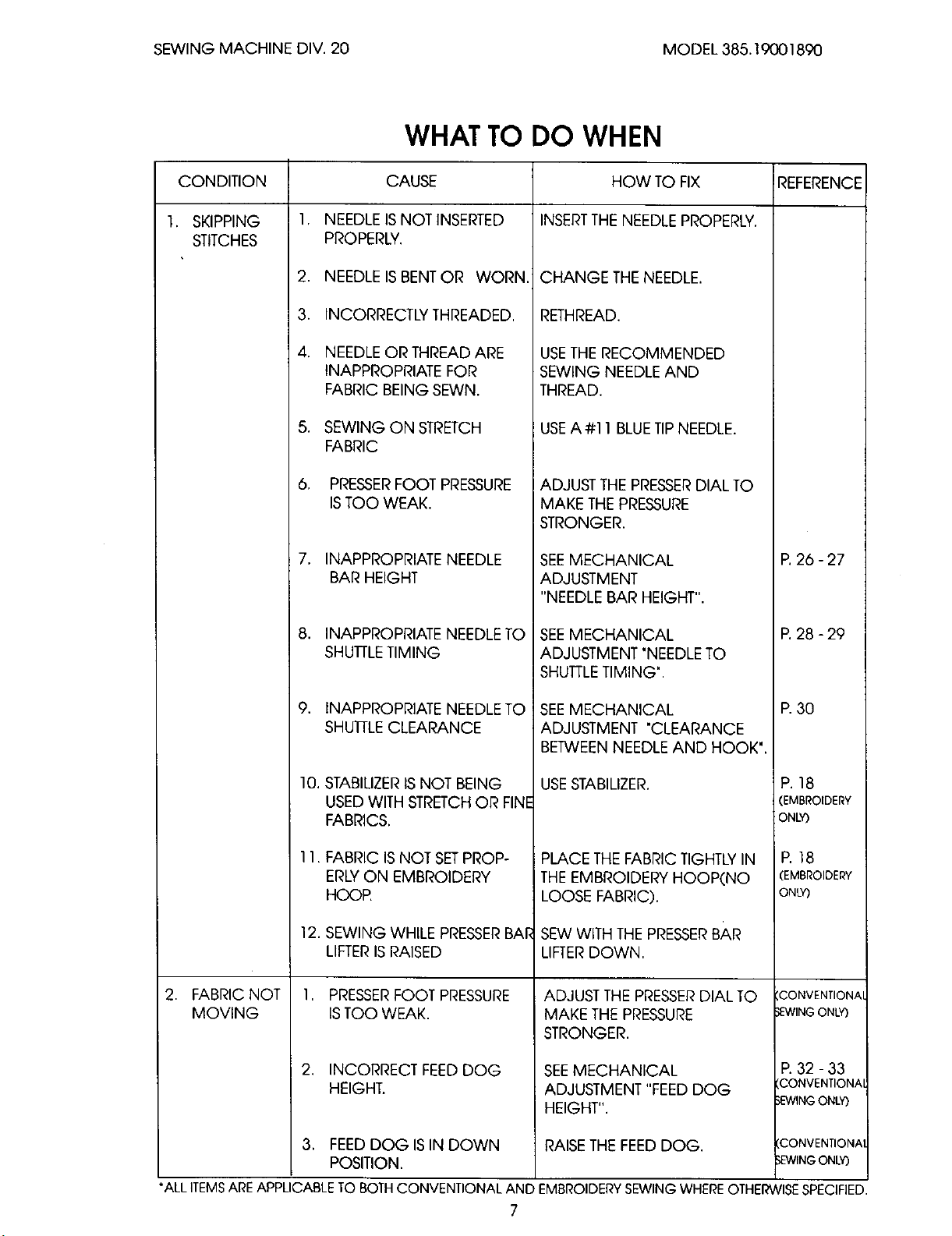

WHAT TO DO WHEN ...............,..............................................................7-10

ELECTRONIC QUICK CHECK .............................................................11-13

MAIN KEY FUNCTION ..............................................................................14

WINDING THE BOBBIN .............................................................................15

THREADING THE MACHINE .....................................................................16

WHEN MESSAGES APPEAR ON THE SCREEN .........................................17

TO ATrACH THE STABILIZER......................................................................18

TO SETTHE FABRIC INTHE EMBROIDERY HOOP ....................................18

SERVICE ACCESS

FACE COVER ..............................................................................19

TOP COVER ................................................................................19

BELTCOVER ................................................................................20

BASE COVER ...............................................................................21

BED COVER ................................................................................22

BASE UNIT....................................................................................23

FRONT COVER ............................................................................24

MECHANICAL ADJUSTMENT

NEEDLE POSITION .......................................................................25

NEEDLE BAR HEIGHT ..............................................................26-27

NEEDLE TO SHUTTLETIMING ..................................................28-29

CLEARANCE BETWEEN NEEDLE AND HOOK ............................30

BACKLASH (LOWER SHAFT GEAR) ............................................31

FEED DOG HEIGHT ................................................................32-33

UPPER SHAFT SHIELD PLATE POSITION .......................................34

*SOLENOID ...................................................................................35

TENSION RELEASE MECHANISM ................................................36

STRETCH STITCHFEED BALANCE ...............................................37

*HEIGHT OF EMBROIDERY PRESSER FOOT (P)............................38

NEEDLE THREAD TENSION ..........................................................39

*BUI-rONHOLE LEVER ..................................................................40

PRESSER BAR HEIGHT AND ALIGNMENT ................................... 41

OVER LOAD (1), (2) ............................................................... 42-43

*ADJUSTMENT OF TOUCH PANEL ............... ............................................ 44

*BOBBIN THREAD TENSION (1),(2) ..................................................... 45-46

PART REMOVAL AND REPLACEMENT

NEEDLE THREAD TENSION UNIT .................................................. 47

FEED DOG ................................................................................... 48

THREADER PLATE ......................................................................... 49

C-BOARD UNIT AND FUSE.......................................................... 50

TRANSFORMER ........................................................................... 51

MACHINE SOCKET UNIT ............................................................. 52

A-BOARD UNIT ............................................................................ 53

LCD UNIT ..................................................................................... 54

F-BOARD UNIT ............................................................................. 55

SLIDE VOLUME UNIT .................................................................... 56

DC MOTOR UNIT AND BELTTENSION ........................................ 57

*CARRIAGE PLATE COVER UNIT .................................................. 58

*BUI-IONHOLE SENSOR ................................................................ 59

*UPPER SHAFT SENSOR ................................................................. 60

*ZIGZAG STEPPING MOTOR ........................................................ 61

*FEED STEPPING MOTOR ............................................................. 62

*HOW 1O FIXA THREAD JAMMING ON THETHREAD TAKE-UPLEVER............. 63

CHECKING ELECTRONIC PARTS

*MACHINE SOCKET ...................................................................... 64

*C-BOARD .................................................................................... 65

*F-BOARD UNIT ............................................................................. 66

*DC MOTOR ................................................................................. 67

*FOOT CONTROL ........... : ............................................................. 68

*STEPPING MOTORS ..................................................................... 69

CARE ..................................................................................................... 69

OILING .................................................................................................... 70

SPECIAL TOOLS REQUIRED ................................................................... 71

*NEW ITEM

SEWING MACHIN EDIV. 20 MODEL 385.19001890

SPECIFICATIONS

MODEL 385.19001890

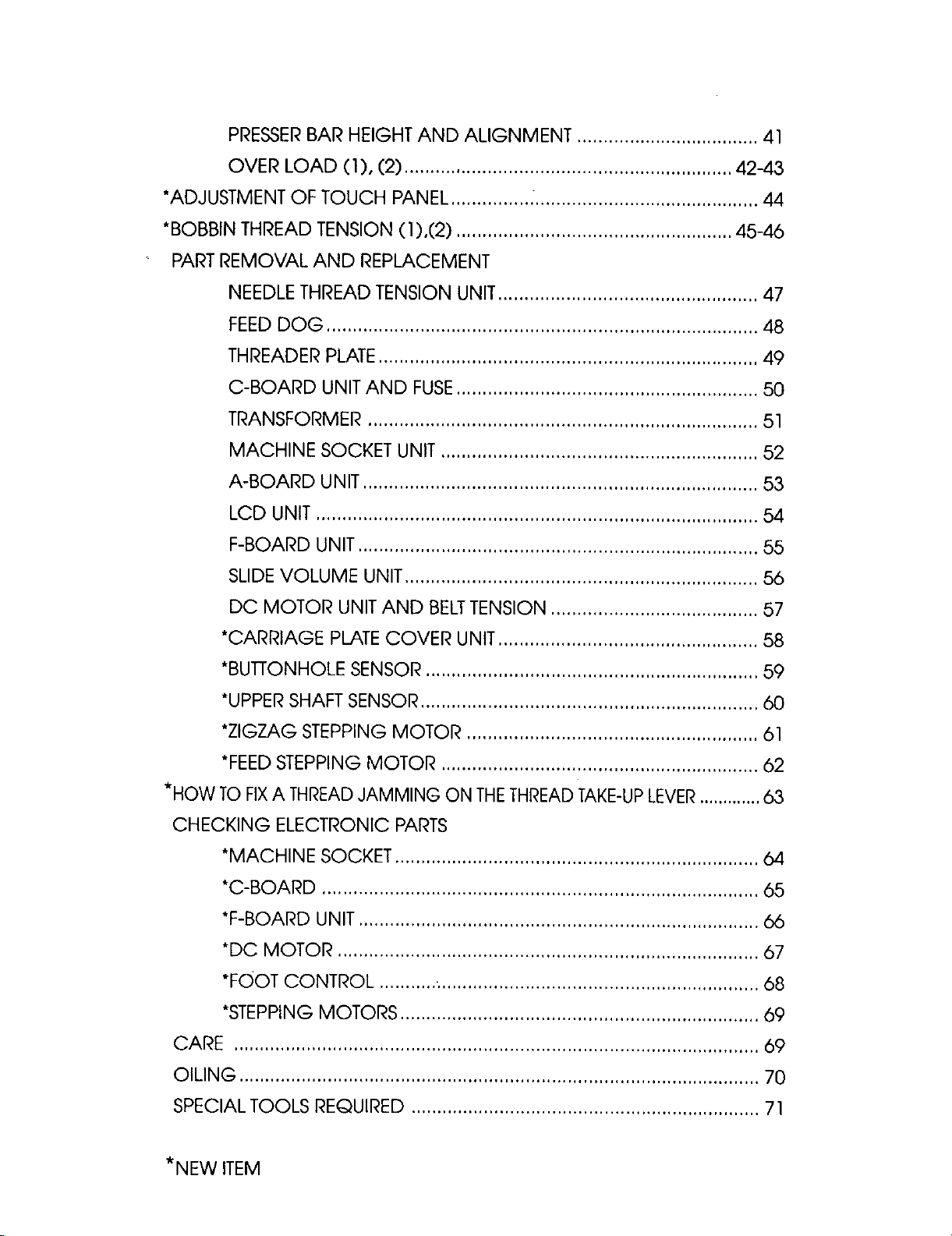

(A) GENERAL SPECIFICATIONS

I. TYPE:

2. CONVERTIBILITY:

3. SHUTTLESYSTEM:

4. STITCHPACKAGE:

BUILT-INSTITCH:

5. ELECTRONIC AUTOMATIC

BUI-rONHOLER:

6. BOBBIN WINDING SYSTEM:

7. THREADING SYSTEM:

8. PRESSERFOOT SYSTEM:

9. MACHINE COLOR:

10. NEEDLE POSITION:

11. EMBROIDERY SIZE:

12. DROP FEED DOG:

13. THREAD TENSION MECHANISM:

14. FEED BALANCE DIAL:

15. FOOT FIXING SYSTEM:

16. CONTROL:

16-1. STITCHWIDTH:

16-2. STITCHLENGTH:

16-3. PAl-tERN SELECTION:

16-4. MEMORY:

16-5. CLEAR:

17. FUNCTION KEY:

17-t. STARTSTOP KEY:

FREEARM, TWO IN ONE

(CONVENTIONAL AND EMBROIDERY)

EXTENSION TABLE

HORIZONTAL FULLROTARYSHU_LE

65 PLUS 840 BUILT-INMONOGRAMS

65

10 (UTILITY)

33 (STRETCH)

21 (DECORATIVE)

1 (DARNING)

840 (MONOGRAMS)

5 STYLES

REGULAR (SQUARE) X 3

ROUND

KEY HOLE

AUTOMATLC CLUTCH

(AUTO DECLUTCH TYPE)

SLITTAKE-UP LEVER

HIGH BAR

WHITE (J-N47)

7MM / MULTIPLENEEDLE POSITIONS

126 MM (5") X 90 MM (3.5")

DROP FEED SYSTEM

CONCEALED

BUILT-IN

SNAP-ON/OFF SYSTEM

ELECTRONIC TOUCH CONTROL PANEL AND

ADJUSTMENT

TOUCH SCREEN SYSTEM

PRE-PROGRAMMED,

ALSO MANUALLY ADJUSTABLE

TOUCH SCREEN SYSTEM

PRE-PROGRAMMED,

ALSO MANUALLY ADJUSTABLE

TOUCH SCREEN SYSTEM

TOUCH SCREEN SYSTEM

(EMBROIDERY ONLY)

TOUCH SCREEN SYSTEM

(EMBROIDERY ONLY)

PUSH BU_ON SYSTEM

(EMBROIDERY ONLY)

SE'WlNGMACHINEDIV.20 MODEL385.19001890

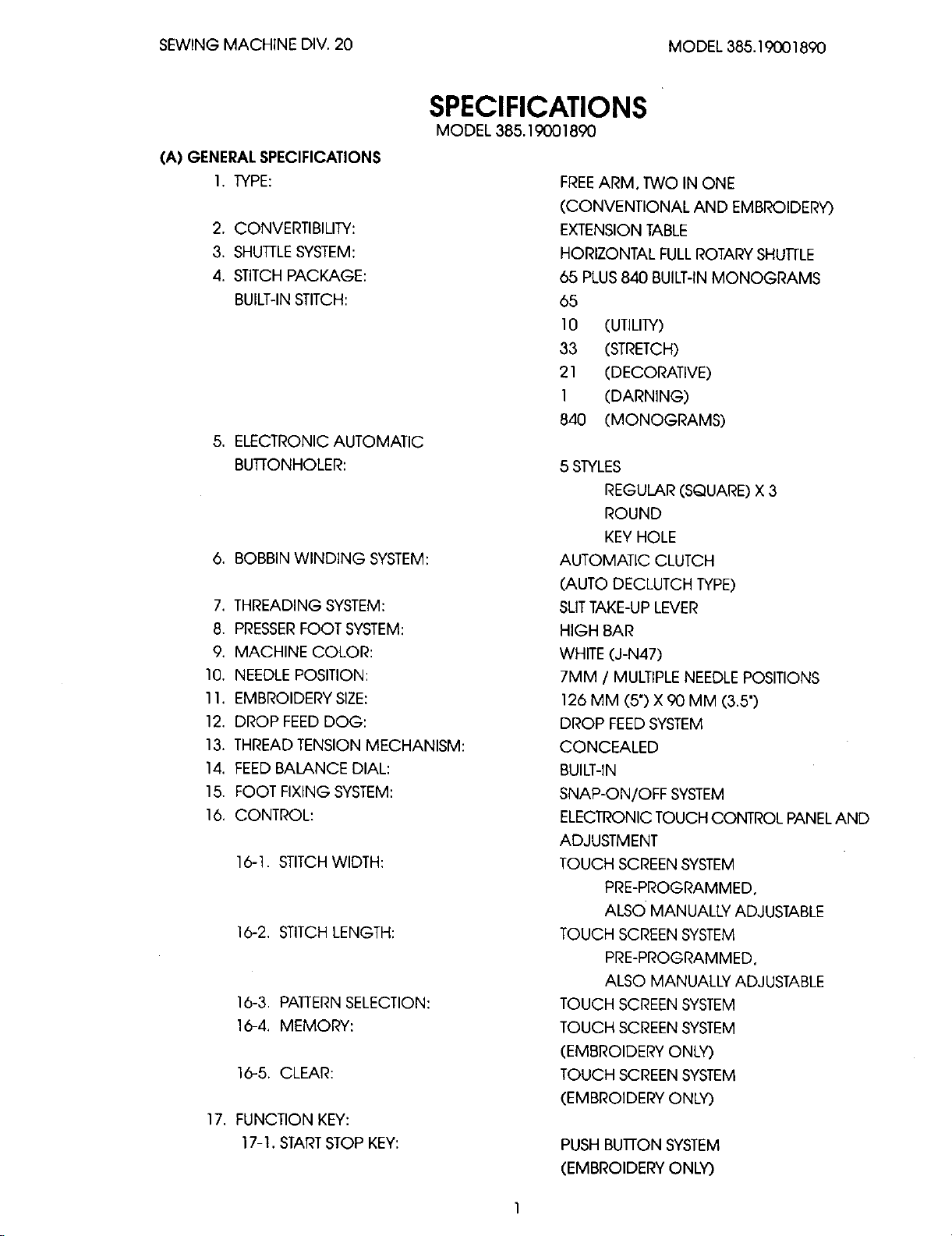

18. NEEDLE UP & DOWN:

19. REVERSESTITCH:

20. LCD (LIQUID CRYSTAL DISPLAY):

21. HORIZONTAL SPOOL PIN:

22. CARRY HANDLE:

23. BOBBIN COVER PLATE:

24. ADJUSTABLE PRESSERFOOT TENSION:

25. ACCESSORIES:

SEAM RIPPER/BUTTONHOLE OPENER

LARGE SCREW DRIVER

PLASTIC BOBBIN

STRAIGHT STITCHFOOT (H)

SATIN STITCHFOOT (F)

ZIPPERFOOT (E)

BLIND HEM FOOT (G)

OVEREDGE FOOT (C)

SPOOL PIN FELT

QUILTER

SPOOL STAND

NEEDLE SET

ADDITIONAL SPOOL PIN

SPOOL HOLDER (LARGE)

SPOOL HOLDER (SMALL)

LINT BRUSH

AUTOMATIC BH FOOT (R)

EMBROIDERY FOOT (P)

EMBROIDERY SCISSORS

EMBROIDERY HOOP (ROUND)

STARTERKIT

MEMORY CARD: SMALL FLOWER SERIES

26. OPTIONAL MEMORY CARDS:

*FLOWER SERIES

*HOLIDAY SERIES

*LITTLEGREY RABBIT

*CHILDREN'S SERIES

*MOTOR SPORTSSERIES

*WILD ANIMAL SERIES

*SPECIAL OCCASION SERIES

*FRUITAND VEGETABLE SERIES

*DOG SERIES

*BIG FLORAL SERIES

*FLORAL SCRIPTSERIES

PUSH BUTTONSYSTEM

PUSH BUTTONSYSTEM

YES

YES

YES

POP UP TYPE

DIAL TYPE(3 POSITIONS)

56O4O61O4

820832005

102261103

823801015

822804118

829801002

820817015

822801001

102403109

802422002

829803004

650807008

625031500

822020503

822019509

802424004

753801004

830810031

822814007

834809006

834812002

834811001

K-1 (834401004)

K-2 (834402005)

K-3 (834403006)

K-4 (834404007)

K-5 (834405008)

K-6 (834406009)

K-7 (834407000)

K-8 (834411007)

K-9 (834412008)

K-10 (834448003)

K-11 (834449004)

SEWINGMACHINEDIV.20 MODEL385.19001890

*MUSICAL INSTRUMENTSERIES

*FLORAL ART AND QUILTING DESIGNS

*SEWING-RELATED DESIGNS

*OCEAN LIFEDESIGNS

*CHRISTMAS DESIGNS I

*CHRISTMAS DESIGNS 1I

*CUIWORK DESIGNS

*FARM DESIGNS

*WILD LIFE& FISHING DESIGNS

*ANGEL DESIGNS

*BIRD DESIGNS

*THREE-LETTERMONOGRAM DESIGNS

*BORDER DESIGNS

*FLORAL DESIGNS ]

*GOBELIN STITCHFLORAL DESIGNS

*NOAH'S ARK DESIGNS ], 11"

27.

SPECIFICATION OF

MICRO-COMPUTER:

28. DRIVING MOTOR:

29. FOOT CONTROL:

30. STEPPING MOTOR:

31. MAXIMUM SPEED:

32. NEEDLETHREADING:

33. THREAD TENSION:

34, HARD COVER:

K-12 (8344500O8

K-101 (834408001

K-102 (834409002

K-103 (834410006

K-104 (834451009

K-105 (834520000

K-106 (834471005

K-107 (834472006

K-108 (834473007

K-109 (834474008

K-110 (834475009

K-111 (834476000

K-112 (834481008

K-113 (834482009

K-114 (834483000

K-115 (834484001

CPU:

ROM 8M BITS

RAM 256K BITS

VRAM 64K BITS

DC MOTOR

ELECTRONIC FOOT CONTROL

ZlG-ZAG WIDTH CONTROL

FEEDING CONTROL

EMBROIDERY HOOP CONTROL (X-AXIS)

EMBROIDERY HOOP CONTROL (Y-AXIS)

820 RPM (STRAIGHT STITCH)

500 RPM (AUTOMATIC BUI-rONHOLE)

700 RPM (OTHER STITCHES)

400 PRM (EMBROIDERY)

INTEGRATED NEEDLE THREADER

SEMI-AUTO TENSION CONTROL

(ROLLER TYPE)

YES

3

SEWING MACHINE DIV. 20 MODEL 385.19001890

(B) STITCH PACKAGE DETAIL

1. TOTAL STITCHES: 65

2. BUILT-INSTITCHES: 60

UTILITY: 10

STRETCH: 33

DECORATIVE: 21

DARNING 1

3. BUILT-INMONOGRAM 840

UTILITY STRETCH DECORATIVE

' I 4

O

L7

HI

Hi

HI

Ill

) l

E )

El

I

BUTi'ONHOLE

_:) n

i !, l

I T

)1

3

0 0

g

DARNING

I

III

lU

:>

X

X

4

SEWING MACHINE DIV. 20 MODEL 385.19001890

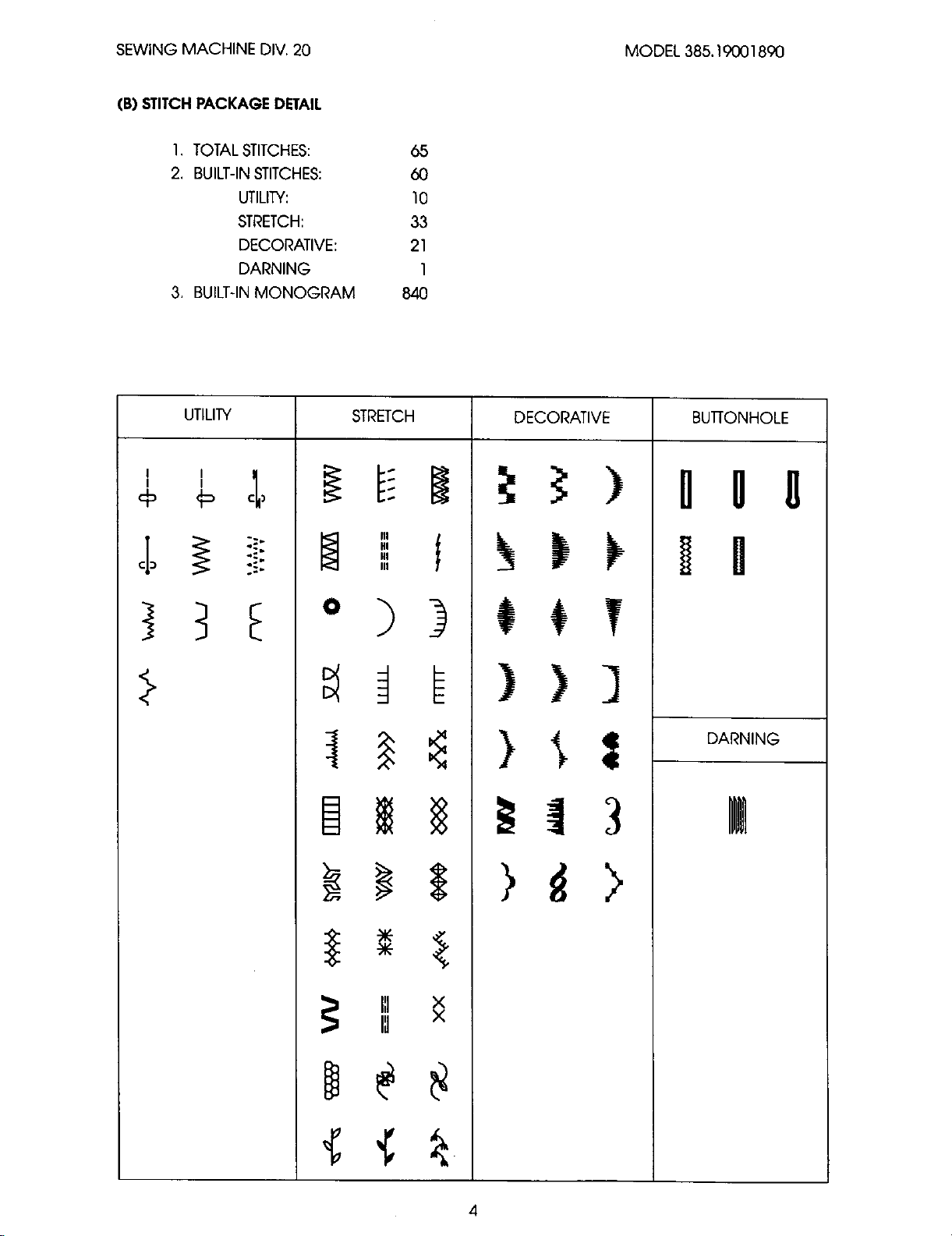

WIRING DIAGRAM

NAME OF ELECTRONIC PARTSAND WIRING

NOTE:

(A): UPPERSHAFT SENSOR

(B): MACHINE SOCKET UNIT (SECONDARY)

(C): DC MOTOR

(D): ZIGZAG WIDTH STEPPING MOTOR

(E): FEEDSTEPPING MOTOR

(F): X-AXIS EMBROIDERY STEPPING MOTOR

(G):Y-AXIS EMBROIDERY STEPPING MOTOR

(H): LCD MODULE

(I): F-BOARD

(J): BuYrONHOLE SENSOR

EACH CONNECTOR SHOULD BE CONNECTED AS FOLLOWS;

(A)-(A),(B)-(B),(C)-(C),(D)-(D),(E)-(E),(F)-(F),(G)-(G),(H)-(H),(J)-(J),(K)-(K)

(L)-(L),(M)-(M),(N)-(N),(O)-(O),(P)-(P).

(K): LAMP

(L): TENSION RELEASESOLENOID

(M): C-BOARD

(N): MACHINE SOCKET UNIT(PRIMARY)

(O): TRANSFORMER (SECONDARY)

(P): TRANSFORMER (PRIMARY)

(Q): INVERTER

(R): SLIDEVOLUME

(S): THREAD TENSION SENSOR

(T): LCD (BACK LIGHT)

(N)

5

SEWING MACHINE DIV. 20 MODEL 385. ] 9001890

GENERALTROUBLESHOOTING PROCEDURE

(MACHINE OOESN"TWORK WELL)

START

*IS NEEDLESETOK ?

BASIC CHECK

CORRECT IT

>10'K'

...... *IS POWER SUPPLY OK ?

*IS THREADING OK ?

MECHANICAL

O,K.

(

_t

ADJUSTMENT

SEWING CHECK I

l END

} } ELECTRICAL } } CAN'TJUDGE

ELECTRIC QUICK CHECK

_N.G,

REPLACE PARTS

ELECTRIC QUICK CHECK

6

SEWING MACHINE DIV. 20 MODEL 385.19001890

WHATTO DO WHEN

CONDITION HOW TO FIX REFERENCE

1, INSERTTHE NEEDLE PROPERLY.

1. SKIPPING

STITCHES

NEEDLE IS NOT INSERTED

PROPERLY.

2. NEEDLE ISBENTOR WORN.

3. INCORRECTLY THREADED,

4. NEEDLEORTHREAD ARE

INAPPROPRIATE FOR

FABRIC BEING SEWN.

5, SEWING ON STRETCH

CAUSE

CHANGE THENEEDLE.

RETHREAD.

USETHE RECOMMENDED

SEWING NEEDLE AND

THREAD,

USEA#11 BLUETIPNEEDLE.

FABRIC

6, PRESSERFOOT PRESSURE

ISTOO WEAK.

ADJUST THE PRESSERDIAL TO

MAKE THE PRESSURE

STRONGER.

7. INAPPROPRIATE NEEDLE

BAR HEIGHT

SEEMECHANICAL

ADJUSTMENT

P.26 - 27

"NEEDLE BAR HEIGHT".

8. INAPPROPRIATE NEEDLE TO

SHUI-rLETIMING

SEEMECHANICAL

ADJUSTMENT "NEEDLETO

P.28 - 29

SHUTTLETIMING".

9. INAPPROPRIATE NEEDLE TO

SHUYi-LECLEARANCE

10. STABILIZERISNOT BEING

USED WITH STRETCHOR FINE

FABRICS.

11. FABRIC IS NOT SETPROP-

ERLYON EMBROIDERY

HOOP.

12. SEWING WHILE PRESSERBAr,

LIFTERISRAISED

2. FABRIC NOT

MOVING

,

PRESSERFOOT PRESSURE

ISTOO WEAK.

.

INCORRECT FEEDDOG

HEIGHT.

3. FEEDDOG ISIN DOWN

POSITION.

*ALLITEMSAREAPPLICABLETOBOTHCONVENTIONALAND

7

SEEMECHANICAL

R 30

ADJUSTMENT "CLEARANCE

BETWEENNEEDLE AND HOOK".

USESTABILIZER.

P. 18

(EMBROIDERY

ONLY)

PLACE THEFABRIC TIGHTLYIN

THE EMBROIDERY HOOP(NO

LOOSE FABRIC),

E18

[EMBROIDERY

ONLY)

SEWWITH THE PRESSERBAR

LIFTERDOWN,

ADJUST THE PRESSERDIAL TO

MAKE THE PRESSURE

CONVENTIONA

_'_VINGONLY)

STRONGER.

SEEMECHANICAL

ADJUSTMENT "FEED DOG

HEIGHT".

RAISE THE FEED DOG.

EMBROIDERY SEWING WHERE OTHERWISE SPECIFIED.

P.32 - 33

CONVENTIONA

•"_/ING ONLY)

CONVENTIONA

EWING ONLY)

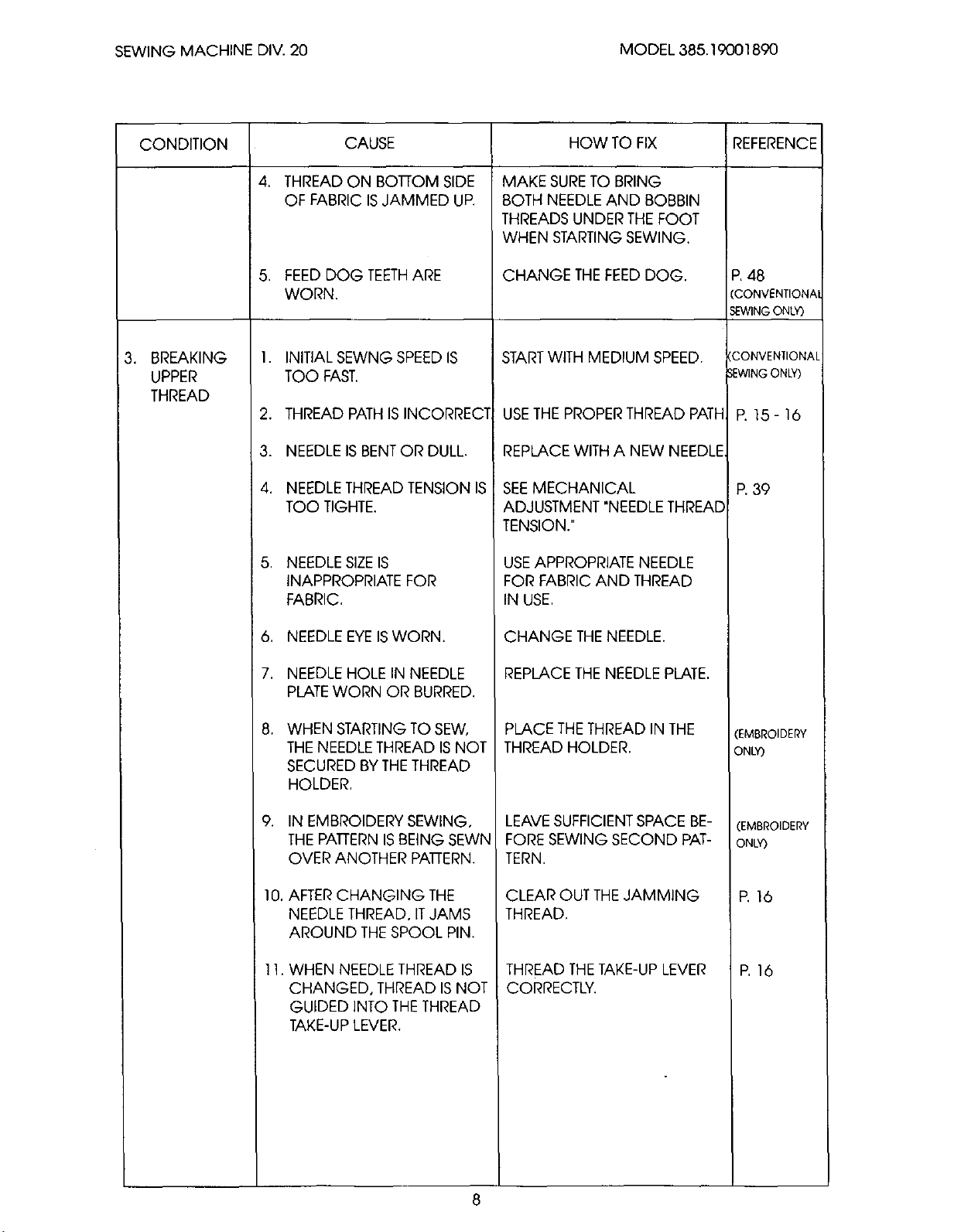

SEWING MACHINE DIV. 20 MODEL 385.19001890

CONDITION HOW TO FIX REFERENCE

4. THREAD ON BO1-POMSIDE

OF FABRIC ISJAMMED UP.

CAUSE

MAKE SURETO BRING

BOTH NEEDLE AND BOBBIN

THREADS UNDER THE FOOT

WHEN STARTING SEWING.

3. BREAKING

UPPER

5. FEEDDOG TEETHARE

WORN.

1. INITIAL SEWNG SPEEDIS

TOO FAST.

CHANGE THEFEED DOG.

STARTWITH MEDIUM SPEED.

P.48

(CONVENTIONAl

SEWING ONLY)

CONVENTIONAL

IEWlNG ONLY)

THREAD

2. THREAD PATHIS INCORRECT

3. NEEDLEISBENTOR DULL.

4. NEEDLETHREAD TENSION IS

TOO TIGHTE.

USETHE PROPER THREAD PATH

REPLACE WITH A NEW NEEDLE

SEEMECHANICAL

ADJUSTMENT "NEEDLETHREAD

R 15-16

R 39

TENSION."

5, NEEDLESIZEIS

INAPPROPRIATE FOR

FABRIC,

USEAPPROPRIATE NEEDLE

FOR FABRIC AND THREAD

IN USE,

6, NEEDLE EYEISWORN.

7. NEEDLE HOLE IN NEEDLE

PLATEWORN OR BURRED.

+

WHEN STARTINGTO SEW,

THE NEEDLE THREAD IS NOT

SECURED BY THE THREAD

HOLDER,

9. IN EMBROIDERY SEWING,

THEPATrERN ISBEING SEWN

OVER ANOTHER PAl-FERN.

10, AFTERCHANGING THE

NEEDLE THREAD, ITJAMS

AROUND THESPOOL PIN.

11. WHEN NEEDLE THREAD IS

CHANGED, THREAD ISNOT

GUIDED INTO THETHREAD

TAKE-UP LEVER.

CHANGE THE NEEDLE.

REPLACE THE NEEDLE PLATE.

PLACE THETHREAD IN THE

THREAD HOLDER.

LEAVE SUFFICIENTSPACE BE-

FORE SEWING SECOND PAT-

TERN.

CLEAR OUT THEJAMMING

THREAD,

THREAD THETAKE-UP LEVER

CORRECTLY.

(EMBROIDERY

ONLY)

EMBROIDERY

ONLY)

R16

P, 16

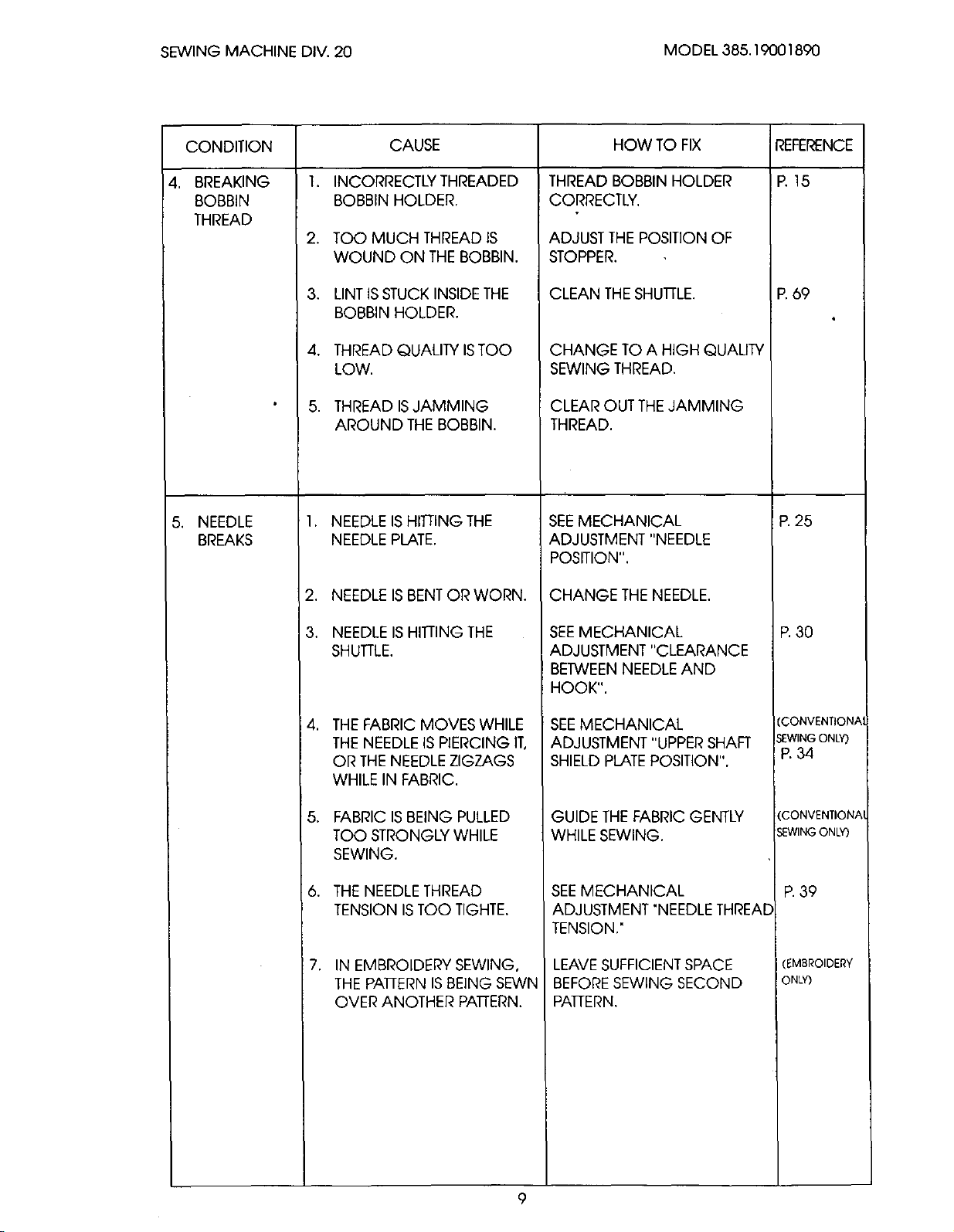

SEWINGMACHINEDIV.20 MODEL385.19001890

CONDITION

4, BREAKING

BOBBIN

THREAD

5. NEEDLE

BREAKS

CAUSE

1. INCORRECTLYTHREADED

BOBBINHOLDER,

2. TOOMUCHTHREADIS

WOUNDONTHEBOBBIN.

3. LINTISSTUCKINSIDETHE

BOBBINHOLDER.

4. THREADQUALITYISTOO

LOW.

5. THREADISJAMMING

AROUNDTHEBOBBIN.

1. NEEDLEISHITTINGTHE

NEEDLEPLATE.

HOW TO FIX

THREAD BOBBIN HOLDER

CORRECTLY.

ADJUST THE POSITION OF

STOPPER.

CLEAN THE SHUTTLE.

CHANGE TO A HIGH QUALITY

SEWING THREAD.

CLEAR OUT THEJAMMING

THREAD.

SEEMECHANICAL

ADJUSTMENT "NEEDLE

POSITION".

REFERENCE

P. 15

E 69

P.25

2. NEEDLEISBENTORWORN.

3. NEEDLEISHITTINGTHE

SHUTTLE.

.

THE FABRIC MOVES WHILE

THE NEEDLE IS PIERCING IT,

OR THE NEEDLE ZIGZAGS

WHILE IN FABRIC.

,

FABRIC ISBEING PULLED

TOO STRONGLY WHILE

SEWING.

.

THE NEEDLE THREAD

TENSION ISTOO TIGHTE.

17.

IN EMBROIDERY SEWING,

THE PATTERNIS BEING SEWN

OVER ANOTHER PATTERN.

CHANGE THE NEEDLE.

SEEMECHANICAL

ADJUSTMENT "CLEARANCE

BETWEENNEEDLE AND

HOOK".

' SEEMECHANICAL

ADJUSTMENT "UPPER SHAFT

SHIELD PLATEPOSITION".

GUIDE THE FABRIC GENTLY

WHILE SEWING.

SEEMECHANICAL

ADJUSTMENT "NEEDLE THREAD

TENSION,'

LEAVE SUFFICIENTSPACE

BEFORE SEWING SECOND

PAI_ERN.

P.30

:CONVENTIONA

_'WING ONLY)

P.34

CONVENTIONA

EWINGONLY)

P.39

(EMBROIDERY

ONLY)

9

SEWING MACHINE DIV. 20 MODEL 385.19001890

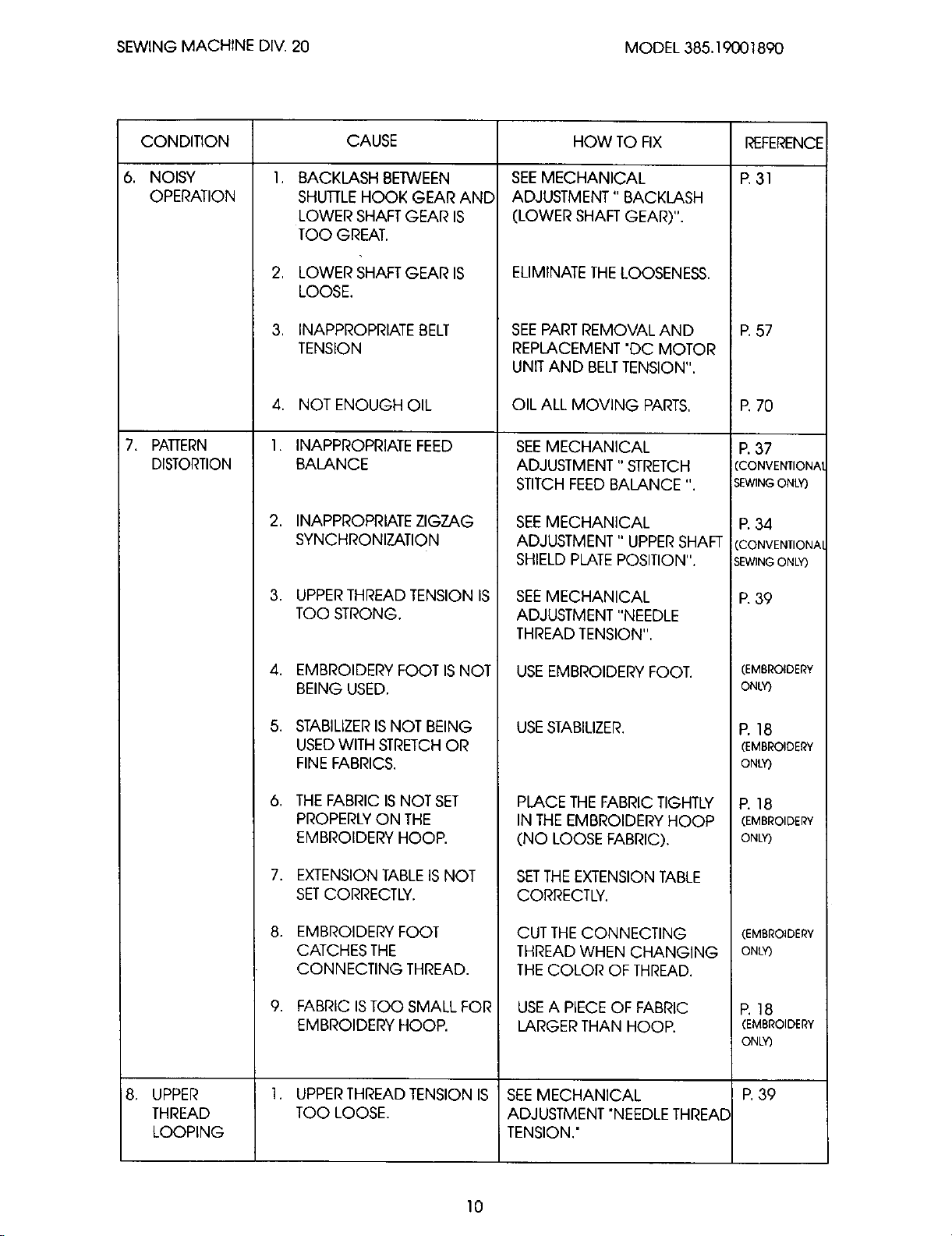

CONDITION

6. NOISY

OPERATION

7. PAI"[ERN

DISTORTION

CAUSE HOW TO FIX REFERENCE

1. E 31

BACKLASH BE[WEEN

SHUI_LE HOOK GEAR AND

LOWER SHAFTGEAR IS

SEEMECHANICAL

ADJUSTMENT '" BACKLASH

(LOWER SHAFT GEAR)".

TOO GREAT.

,

LOWER SHAFTGEAR IS

ELIMINATE THE LOOSENESS.

LOOSE.

3,

INAPPROPRIATE BELT

TENSION

SEEPART REMOVAL AND

REPLACEMENT "DC MOTOR

P.57

UNIT AND BELTTENSION'".

4. NOT ENOUGH OIL

1. INAPPROPRIATE FEED

BALANCE

.

INAPPROPRIATE ZIGZAG

SYNCHRONIZATION

OIL ALL MOVING PARTS.

SEEMECHANICAL

ADJUSTMENT " STRETCH

STITCHFEED BALANCE ".

SEEMECHANICAL

ADJUSTMENT " UPPERSHAFT

SHIELD PLATEPOSITION'".

P.7O

P.37

[CONVENTIONA

SEWINGONLY)

R 34

(CONVENTIONA

BEING ONLY)

,

UPPERTHREAD TENSION IS

TOO STRONG.

.

EMBROIDERY FOOT IS NOT

BEING USED.

5.

STABILIZERISNOT BEING

USED WITH STRETCHOR

FINE FABRICS.

.

THE FABRIC ISNOT SET

PROPERLYON THE

EMBROIDERY HOOP.

.

EXTENSION TABLEISNOT

SETCORRECTLY.

8.

EMBROIDERY FOOT

CATCHES THE

CONNECTING THREAD.

.

FABRIC ISTOO SMALL FOR

EMBROIDERY HOOP.

SEEMECHANICAL

ADJUSTMENT "NEEDLE

THREAD TENSION",

USEEMBROIDERY FOOT.

USESTABILIZER.

PLACE THE FABRIC TIGHTLY

IN THE EMBROIDERY HOOP

(NO LOOSE FABRIC).

SETTHEEXTENSION TABLE

CORRECTLY.

CUT THECONNECTING

THREAD WHEN CHANGING

THE COLOR OF THREAD.

USEA PIECE OF FABRIC

LARGER THAN HOOP.

R 39

(EMBROIDERY

ONlY)

R18

(EMBROIDERY

ONLY)

R18

(EMBROIDERY

ONLY)

(EMBROIDERY

ON{Y)

R18

(EMBROIDERY

ONLY)

8. UPPER

THREAD

LOOPING

.

UPPERTHREAD TENSION IS

TOO LOOSE.

SEEMECHANICAL

ADJUSTMENT "NEEDLETHREAE

TENSION."

10

P,39

SEWING MACHINE DIV. 20 MODEL 385.19001890

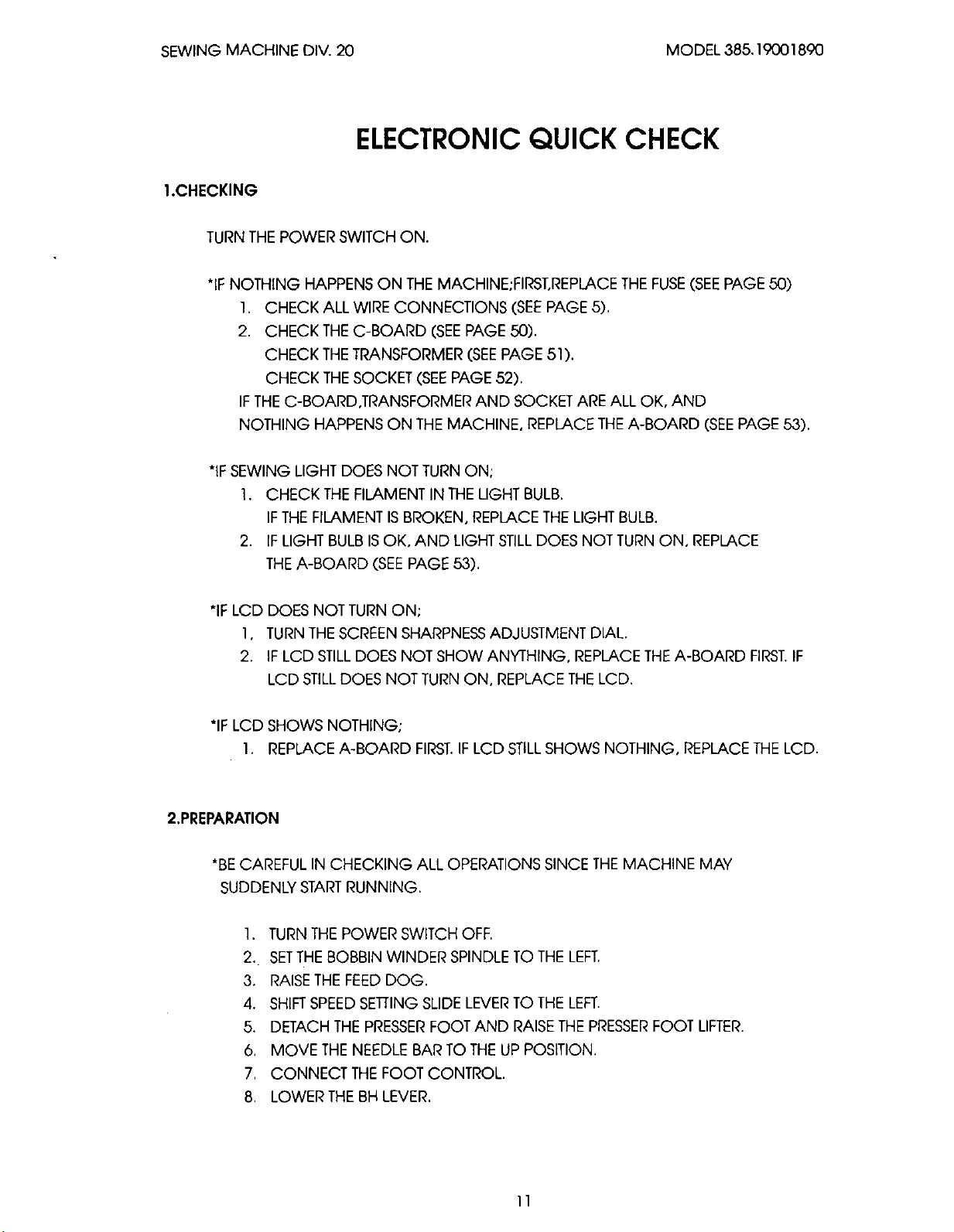

ELECTRONICQUICK CHECK

I.CHECKING

TURN THE POWER SWITCH ON.

*IF NOTHING HAPPENS ON THE MACHINE;FIRST,REPLACE THE FUSE(SEE PAGE 50)

1. CHECK ALL WIRE CONNECTIONS (SEE PAGE 5),

2. CHECK THE C-BOARD (SEEPAGE 50).

CHECK THETRANSFORMER (SEEPAGE 51).

CHECK THE SOCKET (SEEPAGE 52),

IF THEC-BOARD,TRANSFORMER AND SOCKET ARE ALL OK, AND

NOTHING HAPPENS ON THE MACHINE, REPLACE THEA-BOARD (SEEPAGE 53).

*IF SEWING LIGHT DOES NOT TURN ON;

1. CHECK THEFILAMENT IN THE LIGHT BULB.

IFTHE FILAMENT ISBROKEN, REPLACE THELIGHT BULB.

2. IFLIGHT BULBISOK, AND LIGHT STILLDOES NOT TURN ON, REPLACE

THEA-BOARD (SEE PAGE 53).

*IF LCD DOES NOT TURN ON;

1, TURN THESCREEN SHARPNESSADJUSTMENT DIAL.

2. IFLCD STILLDOES NOT SHOW ANYTHING, REPLACE THEA-BOARD FIRST.IF

LCD STILLDOES NOT TURN ON, REPLACE THELCD.

*IF LCD SHOWS NOTHING;

1. REPLACE A-BOARD FIRST.IFLCD STILLSHOWS NOTHING, REPLACE THELCD.

2.PREPARATION

_BECAREFUL IN CHECKING ALL OPERATIONS SINCE THEMACHINE MAY

SUDDENLY STARTRUNNING,

1. TURNTHE POWER SWITCH OFF,

2. SETTHEBOBBIN WINDER SPINDLE TO THE LEFT,

3. RAISETHE FEED DOG.

4. SHIFTSPEEDSETTINGSLIDE LEVER TO THE LEFT.

5. DETACH THE PRESSERFOOTAND RAISE THE PRESSERFOOT LIFTER.

6. MOVE THE NEEDLE BAR TO THE UP POSITION.

7, CONNECT THEFOOT CONTROL.

8. LOWERTHE BH LEVER,

11

SEWING MACHINE DIV. 20 MODEL 385.19001890

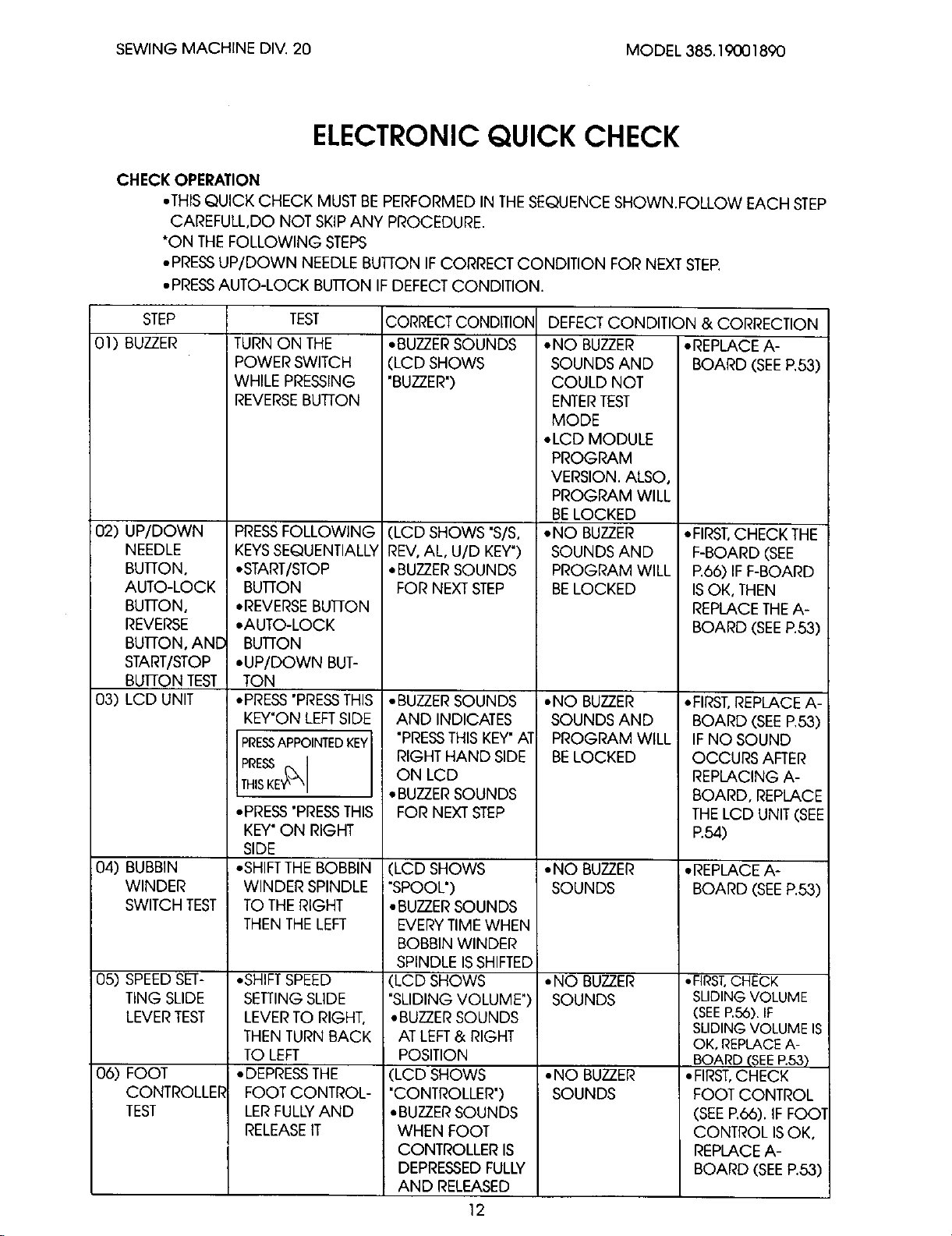

ELECTRONICQUICK CHECK

CHECK OPERATION

*THIS QUICK CHECK MUST BE PERFORMED IN THESEQUENCE SHOWN.FOLLOW EACH STEP

CAREFULL,DO NOT SKIP ANY PROCEDURE.

*ON THE FOLLOWING STEPS

.PRESS UP/DOWN NEEDLE BuYroN IF CORRECT CONDITION FOR NEXTSTEP.

.PRESS AUTO-LOCK BUTTON IF DEFECT CONDITION.

STEP

01) BUZZER

02) UP/DOWN

NEEDLE

BuYroN,

AUTO-LOCK

BUTTON,

REVERSE

BuYroN, AND

START/STOP

BUI_ON TEST

03) LCD UNIT

04) BUBBIN

WINDER

SWITCH TEST

05) SPEEDSET-

TiNG SLIDE

LEVERTEST

06) FOOT

CONTROLLEi_

TEST

TEST

TURN ON THE

POWER SWITCH

WHILE PRESSING

REVERSEBU_ON

PRESSFOLLOWING

KEYSSEQUENTIALLY

•START/STOP

BuYroN

•REVERSEBUYTON

•AUTO-LOCK

BUTTON

•UP/DOWN BUT-

TON

•PRESS"PRESSTHIS

KEY"ON LEFTSIDE

PRESSAPPOINTEDKEY

PRESS

THISKEY_'_

• PRESS*PRESSTHIS

KEY"ON RIGHT

SIDE

•SHIFTTHE BOBBIN

WINDER SPINDLE

TO THERIGHT

THEN THE LEFT

*SHIFT SPEED

SETTINGSLIDE

LEVERTO RIGHT,

THEN TURN BACK

TO LEFT

• DEPRESSTHE

FOOT CONTROL-

LERFULLYAND

RELEASEtT

CORRECTCONDITION

•BUZZERSOUNDS

(LCD SHOWS

"BUZZER")

(LCD SHOWS "S/S,

REV, AL, U/D KEY")

• BUZZERSOUNDS

FOR NEXTSTEP

• BUZZERSOUN DS

AND INDICATES

"PRESSTHIS KEY"AT

RIGHT HAND SIDE

ON LCD

• BUZZERSOUNDS

FOR NEXT STEP

(LCD SHOWS

"SPOOL')

*BUZZER SOUNDS

EVERYTIME WHEN

BOBBIN WINDER

SPINDLE ISSHIFTED

(LCD SHOWS

"SLIDING VOLUME")

*BUZZER SOUNDS

AT LEFT& RIGHT

POSITION

(LCD SHOWS

"CONTROLLER")

•BUZZERSOUNDS

WHEN FOOT

CONTROLLER IS

DEPRESSEDFULLY

AND RELEASED

12

DEFECT CONDITION & CORRECTION

• NO BUZZER

SOUNDS AND

• REPLACE A-

BOARD (SEEP.53)

COULD NOT

ENTERTEST

MODE

oLCD MODULE

PROGRAM

VERSION. ALSO,

PROGRAM WILL

BELOCKED

• NO BUZZER

SOUNDS AND

PROGRAM WILL

BELOCKED

• FIRST,CHECK THE

F-BOARD (SEE

P.66) IFF-BOARD

ISOK, THEN

REPLACE THE A-

BOARD (SEEP.53)

•NO BUZZER

SOUNDS AND

PROGRAM WILL

BELOCKED

• FIRST,REPLACE A-

BOARD (SEEP.53)

IF NO SOUND

OCCURS AFTER

REPLACING A-

BOARD, REPLACE

THE LCD UNIT (SEE

P.54)

• NO BUZZER

SOUNDS

• NO BUZZER

SOUNDS

• NO BUZZER

SOUNDS

•REPLACE A-

BOARD (SEEP.53)

• FIRST,CHECK

SLIDING VOLUME

(SEEP.56). IF

SLIDING VOLUME IS

OK, REPLACE A-

BOARD (SEEP.53)

• FIRST,CHECK

FOOT CONTROL

(SEE P.66). IF FOOT

CONTROL IS OK,

REPLACE A-

BOARD (SEE P.53)

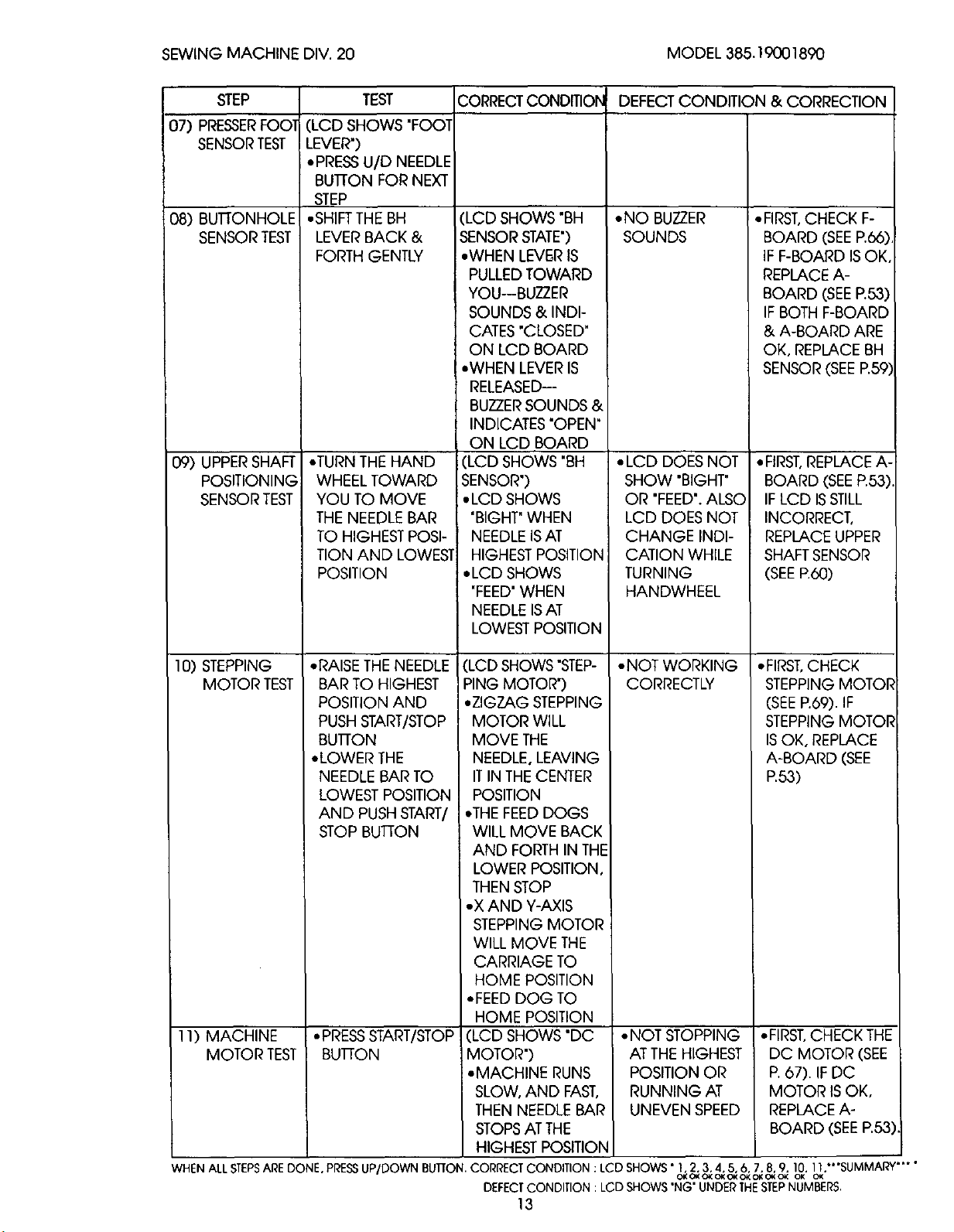

SEWING MACHINE DIV. 20 MODEL 385.19001890

STEP

07) PRESSER F-OO"

SENSOR TEST

08) BUITONHOLE

SENSOR TEST

09) UPPERSHAFT

POSITIONING

SENSOR TEST

TEST

(LCD SHOWS "FOOl

LEVER')

• PRESSU/D NEEDLE

BUTTON FOR NEXT

STEP

•SHIFTTHE BH

LEVERBACK &

FORTH GENTLY

•TURN THEHAND

WHEEL TOWARD

YOU TO MOVE

THE NEEDLE BAR

TO HIGHEST POSI-

TION AND LOWEST

POSITION

CORRECTCONDmOB DEFECT CONDITION & CORRECTION

(LCD SHOWS "BH

SENSOR STATE')

•WHEN LEVBR IS

PULLEDTOWARD

YOU--BUZZER

SOUNDS & INDI-

CATES "CLOSED"

ON LCD BOARD

•WHEN LEVERIS

•NO BUZZER

SOUNDS

• FIRST,CHECK F-

BOARD (SEEP.66)

IF F-BOARD ISOK,

REPLACE A-

BOARD (SEEP.53)

IF BOTH F-BOARD

& A-BOARD ARE

OK, REPLACE BH

SENSOR (SEEP.59]

RELEASED--

BUZZERSOUNDS &

INDICATES "OPEN"

ON LCD BOARD

(LCD SHOWS "BH

SENSOR")

•LCD SHOWS

"BIGHT" WHEN

NEEDLE IS AT

HIGHEST POSITION

•LCD SHOWS

"FEED"WHEN

• LCD DOES NOT

SHOW "BIGHT"

OR "FEED". ALSO

LCD DOES NOT

CHANGE INDI-

CATION WHILE

TURNING

HANDWHEEL

• FIRST,REPLACE A-

BOARD (SEEP.53)

IF LCD ISSTILL

INCORRECT,

REPLACE UPPER

SHAFTSENSOR

(SEEP.60)

NEEDLE ISAT

LOWEST POSITION

10) STEPPING

MOTOR TEST

•RAISE THENEEDLE

BAR TO HIGHEST

POSITION AND

PUSH START/STOP

BUTrON

•LOWER THE

NEEDLE BAR TO

LOWEST POSITION

AND PUSH START/

STOP BUTTON

(LCD SHOWS "STEP-

PING MOTOR')

•ZIGZAG STEPPING

MOTOR WILL

MOVE THE

NEEDLE, LEAVING

IT IN THECENTER

POSITION

•THE FEEDDOGS

WILL MOVE BACK

• NOT WORKING

CORRECTLY

• FIRST,CHECK

STEPPING MOTOR

(SEEP.69). IF

STEPPING MOTOR

ISOK, REPLACE

A-BOARD (SEE

P.53)

AND FORTH INTHE

LOWER POSITION,

THENSTOP

•X AND Y-AXIS

STEPPINGMOTOR

WILL MOVE THE

CARRIAGE TO

HOME POSITION

• FEED DOG TO

HOME POSITION

11) MACHINE

MOTOR TEST

• PRESSSTART/STOP

BU1-FON

(LCD SHOWS "DC

MOTOR")

•MACHINE RUNS

SLOW, AND FAST,

THEN NEEDLE BAR

STOPSAT THE

• NOT STOPPING

AT THE HIGHEST

POSITION OR

RUNNING AT

UNEVEN SPEED

• FIRST,CHECK THE

DC MOTOR (SEE

P.67). IF DC

MOTOR IS OK,

REPLACE A-

BOARD (SEEP.53)

HIGHEST POSITION

WHEN ALL STEPSARE DONE. PRESS UP/DOWN BUTTON. CORRECT CONDITION :LCD SHOWS" 1,2,3,4,5,6,7.8,9.10._.*""SUMMARY ....

DEFECT CONDITION : LCD SHOWS "NG" UNDER THESTEP NUMBEr_.

OK OK OK OKOK OK O_ OK OK OK

13

SEWING MACHINE DIV. 20 MODEL 385.19001890

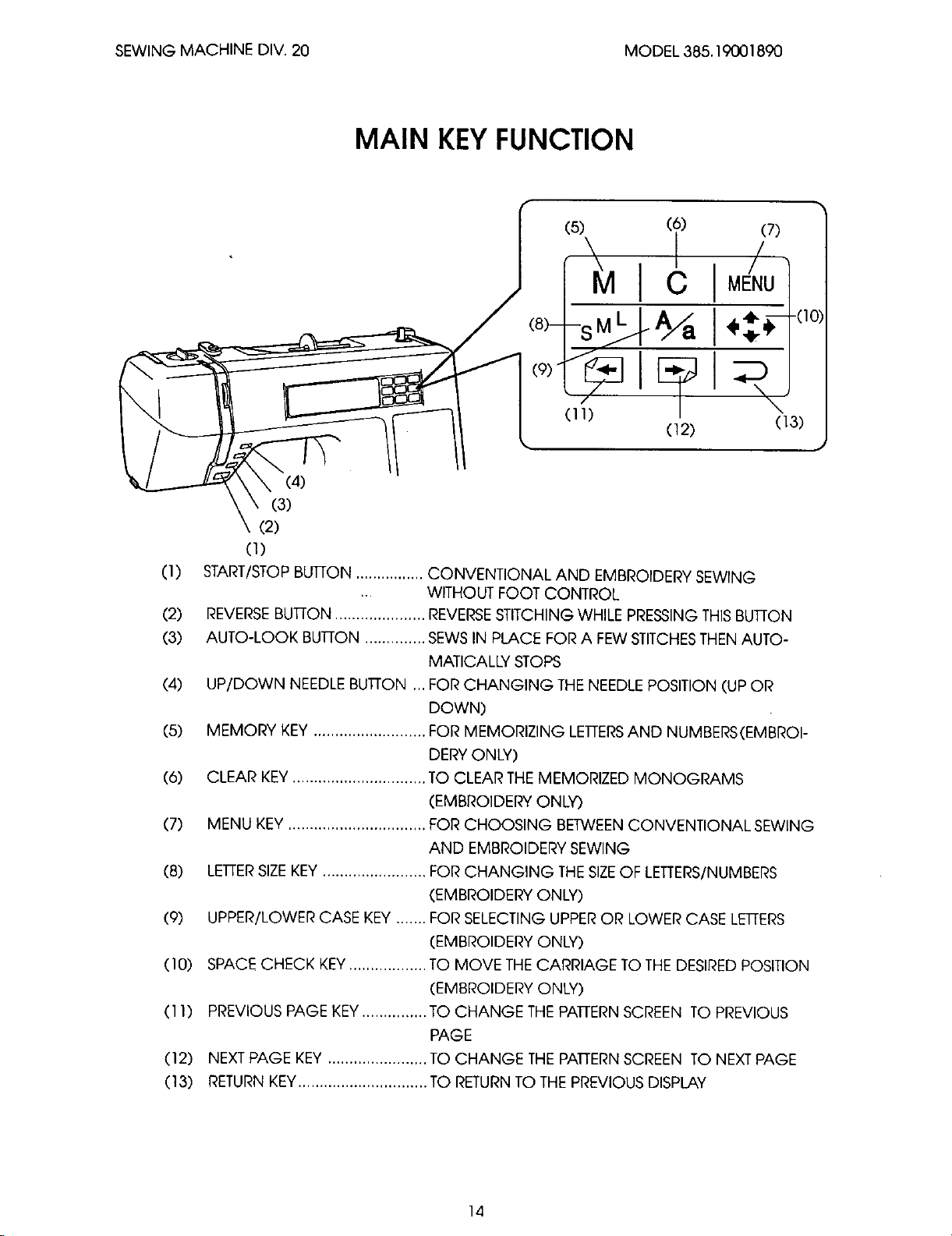

MAIN KEYFUNCTION

1c I. u

/_ (5) (6) (7)

(1)

(1) START/STOP BUTTON ................ CONVENTIONAL AND EMBROIDERY SEWrNG

.. WITHOUT FOOT CONTROL

(2) REVERSEBU_QN ..................... REVERSESTITCHING WHILE PREYING THISBUI_QN

(3) AUTO-LOOK BUNON .............. SEWS IN PLACE FOR A FEW STITCHESTHEN AUTO-

MATICALLY STOPS

(4) UP/DOWN NEEDLEBUTrON .,. FOR CHANGING THE NEEDLE POSITION (UP OR

DOWN)

(5) MEMORY KEY .......................... FOR MEMORIZING LETFERSAND NUMBERS(EMBROI-

DERY ONLY)

(6) CLEAR KEY ............................... TO CLEAR THE MEMORIZED MONOGRAMS

(EMBROIDERY ONLY)

(7) MENU KEY ................................ FOR CHOOSING BETWEENCONVENTIONAL SEWING

AND EMBROIDERY SEWING

(8) LEI-FERSIZEKEY ........................ FOR CHANGING THESIZEOF LETTERS/NUMBERS

(EMBROIDERY ONLY)

(9) UPPER/LOWER CASE KEY ....... FOR SELECTING UPPEROR LOWER CASE LETTERS

(EMBROIDERY ONLY)

(10) SPACE CHECK KEY .................. TO MOVE THE CARRIAGE TO THEDESIRED POSITION

(EMBROIDERY ONLY)

(11) PREVIOUS PAGE KEY............... TO CHANGE THE PATrERNSCREEN TO PREVIOUS

PAGE

(12) NEXT PAGE KEY ....................... TO CHANGE THE PATTERNSCREEN TO NEXTPAGE

(13) RETURNKEY.............................. TO RETURNTO THE PREVIOUS DISPLAY

14

SEWINGMACHINEDIV.20 MODEL385.19001890

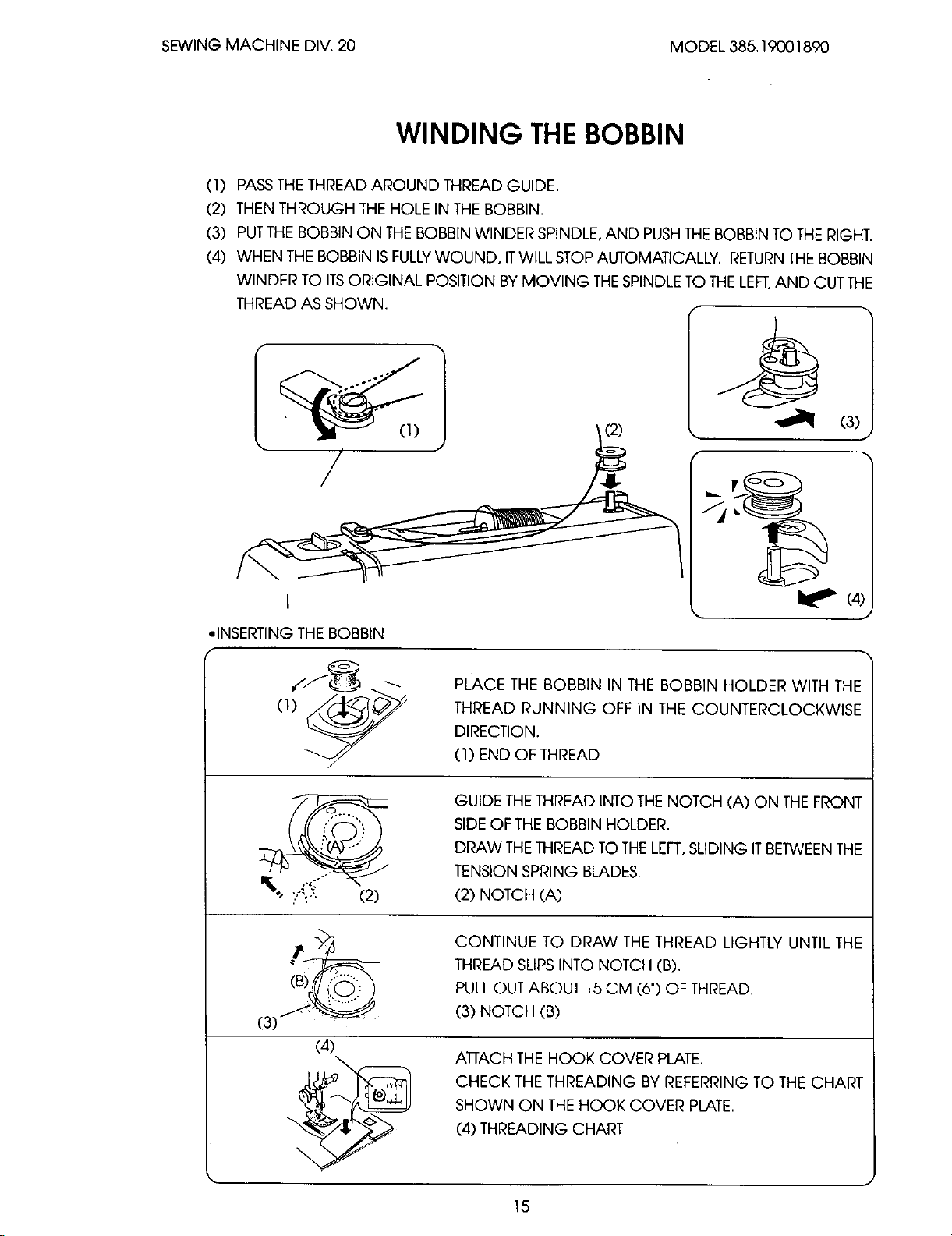

WINDING THEBOBBIN

(1) PASSTHE THREAD AROUND THREAD GUIDE.

(2) THEN THROUGH THE HOLE IN THE BOBBIN.

(3) PUTTHE BOBBIN ON THE BOBBIN WINDER SPINDLE, AND PUSHTHE BOBBIN TO THE RIGHT.

(4) WHEN THE BOBBIN IS FULLYWOUND, ITWILL STOP AUTOMATICALLY. RETURNTHEBOBBIN

WINDER TO ITSORIGINAL POSITION BY MOVING THESPINDLE TO THELEFT,AND CUT THE

THREAD AS SHOWN.

(2)

/

I

• INSERTING THE BOBBIN

(1)

• (2)

(4)

PLACE THE BOBBIN IN THE BOBBIN HOLDER WITH THE

THREAD RUNNING OFF IN THE COUNTERCLOCKWISE

DIRECTION.

(1) END OF THREAD

GUIDE THETHREAD INTO THE NOTCH (A) ON THE FRONT

SIDE OF THE BOBBIN HOLDER.

DRAW THETHREAD TO THELEFT,SLIDING ITBEIWEEN THE

TENSION SPRING BLADES,

(2) NOTCH (A)

CONTINUE TO DRAW THE THREAD LIGHTLY UNTIL THE

THREAD SLIPSINTO NOTCH (B).

PULLOUT ABOUT 15 CM (6") OF THREAD.

(3) NOTCH (B)

ATTACH THE HOOK COVER PLATE.

CHECK THE THREADING BY REFERRING TO THE CHART

SHOWN ON THE HOOK COVER PLATE,

(4) THREADING CHART

15

SEWING MACHINE DIV. 20 MODEL 385.19001890

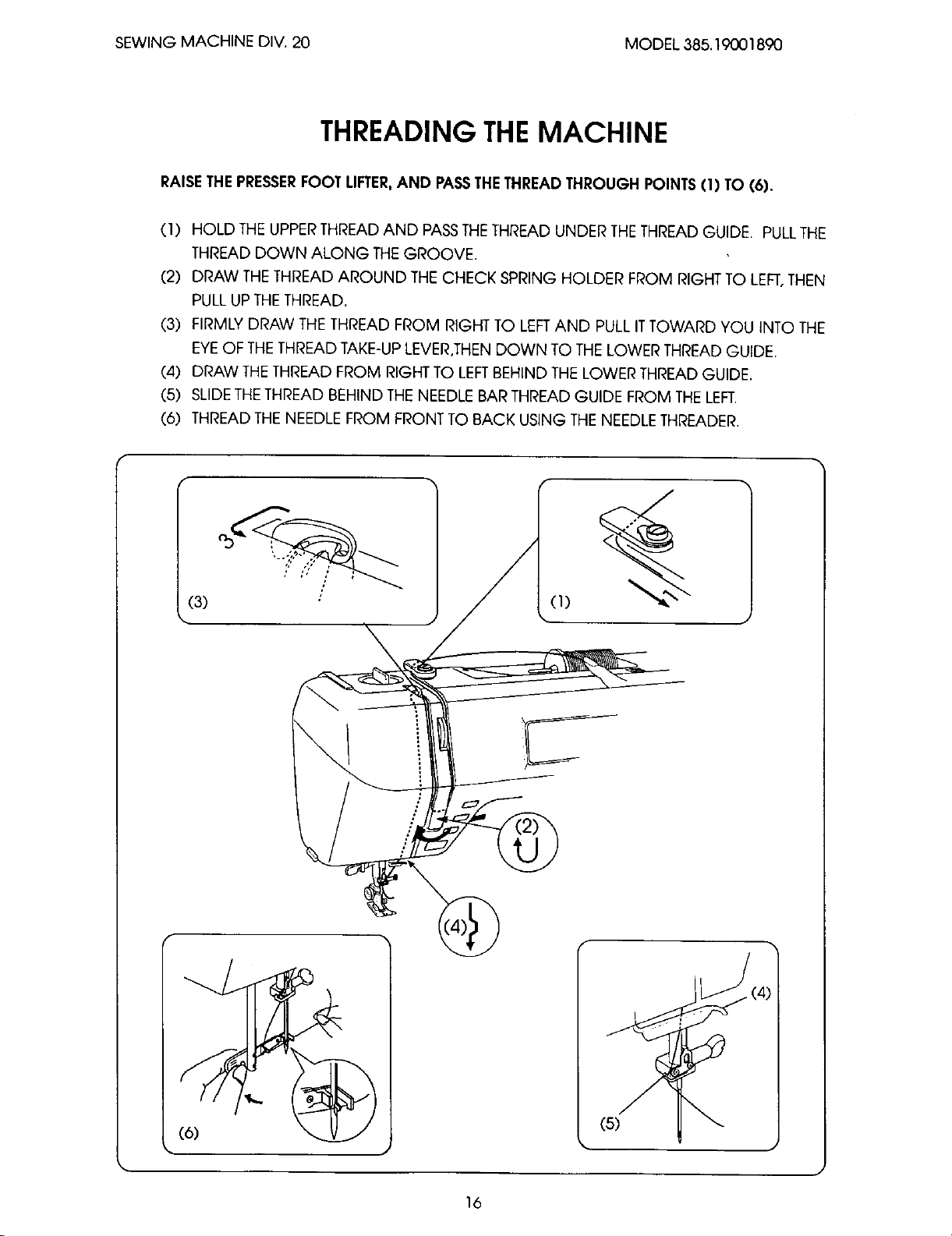

THREADINGTHEMACHINE

RAISETHEPRESSERFOOT LIFTER,AND PASSTHETHREADTHROUGH POINTS (I) TO (6).

(1) HOLD THE UPPERTHREAD AND PASSTHETHREAD UNDER THETHREAD GUIDE. PULLTHE

THREAD DOWN ALONG THEGROOVE.

(2) DRAW THE THREAD AROUND THE CHECK SPRING HOLDER FROM RIGHT TO LEFT,THEN

PULL UPTHE THREAD.

(3) FIRMLY DRAW THE THREAD FROM RIGHT TO LEFTAND PULL ITTOWARD YOU INTO THE

EYEOF THE THREAD TAKE-UP LEVER,THEN DOWN TO THE LOWER THREAD GUIDE.

(4) DRAW THETHREAD FROM RIGHT TO LEFTBEHIND THE LOWER THREAD GUIDE.

(5) SLIDETHETHREAD BEHIND THE NEEDLEBAR THREAD GUIDE FROM THELEFT.

(6) THREAD THE NEEDLE FROM FRONT TO BACK USING THE NEEDLE THREADER.

(3) ; (1)

(4)

(6)

(5)

J

J

16

SEWING MACHINE DIV. 20 MODEL 385.19001890

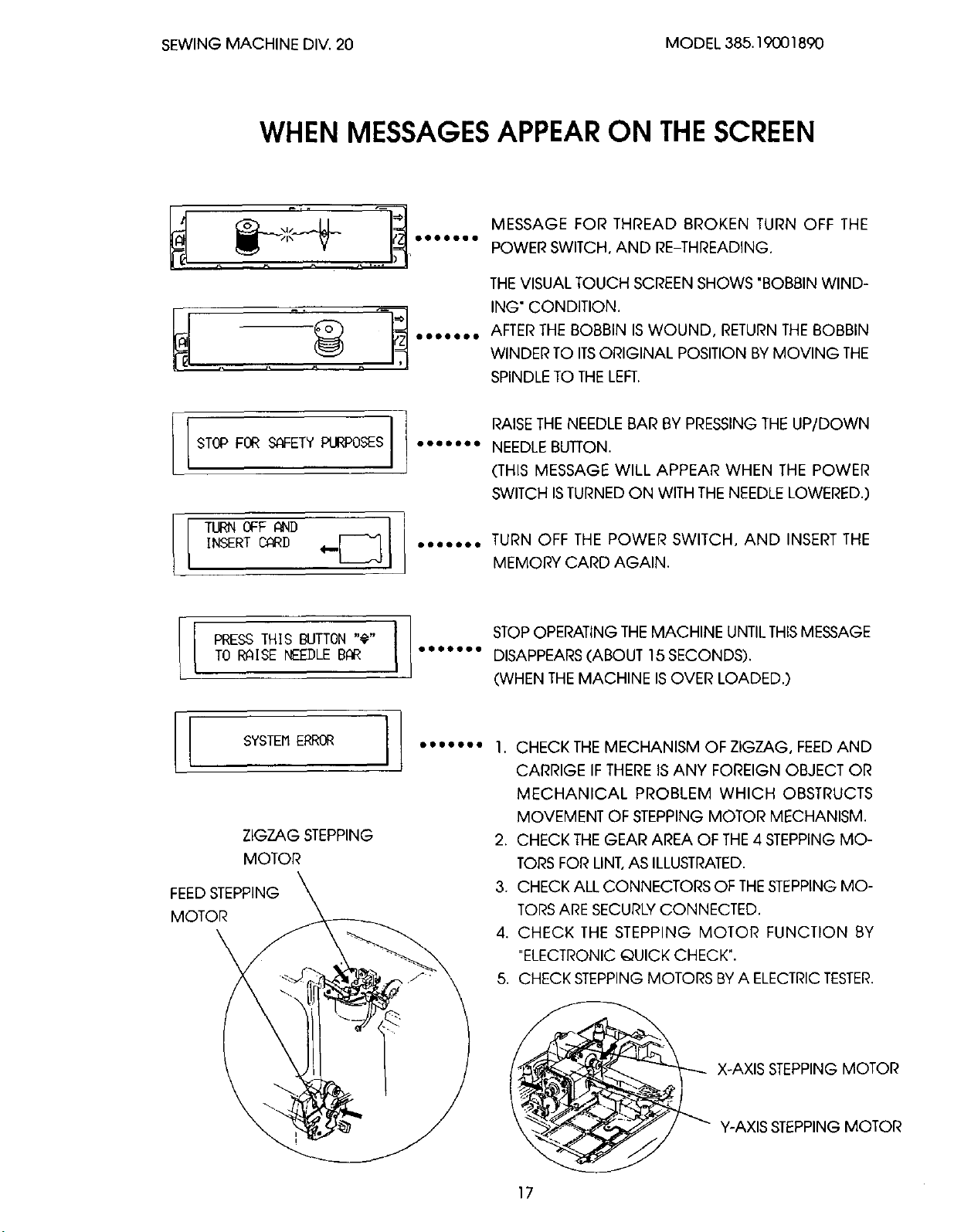

WHEN MESSAGESAPPEARON THESCREEN

MESSAGE FOR THREAD BROKEN TURN OFF THE

POWER SWITCH, AND RE-THREADING.

THEVISUAL TOUCH SCREEN SHOWS 'BOBBIN WIND-

ING" CONDITION.

AFTER THE BOBBIN ISWOUND, RETURNTHE BOBBIN

WINDER TO ITSORIGINAL POSITION BY MOVING THE

SPINDLETO THELEFT.

RAISE THE NEEDLE BAR BY PRESSING THEUP/DOWN

STOPFOR SAFETYPURPOSES

OOOOOOO

NEEDLE BUTTON.

(THIS MESSAGE WILL APPEAR WHEN THE POWER

SWITCH ISTURNED ON WITH THENEEDLE LOWERED.)

INSERTCPRD €..=

PRESS THIS BUTTON "@"

TO RAISE NEEDLE BPR

SYSTEM ERROR

ZIGZAG STEPPING

MOTOR

FEED STEPPING

MOTOR

\

0000000

•" "•" •" DISAPPEARS(ABOUT 15 SECONDS).

I STOP OPERATING THEMACHINE UNTILTHISMESSAGE

I *°'**°° 1.

TURN OFF THE POWER SWITCH, AND INSERT THE

MEMORY CARD AGAIN.

(WHEN THE MACHINE IS OVER LOADED.)

CHECK THE MECHANISM OF ZIGZAG, FEED AND

CARRIGE IF THERE ISANY FOREIGN OBJECT OR

MECHANICAL PROBLEM WHICH OBSTRUCTS

MOVEMENT OF STEPPING MOTOR MECHANISM.

.

CHECK THE GEAR AREA OF THE4 STEPPING MO-

TORS FOR LINT,AS ILLUSTRATED.

3.

CHECK ALL CONNECTORS OF THESTEPPINGMO-

TORSARE SECURLYCONNECTED.

4.

CHECK THE STEPPING MOTOR FUNCTION BY

"ELECTRONIC QUICK CHECK".

5.

CHECK STEPPINGMOTORS BYA ELECTRICTESTER.

@ -AXIS STEPPING MOTOR

17

Y-AXIS STEPPING MOTOR

SEWINGMACHINEDIV.20 MODEL385.19001890

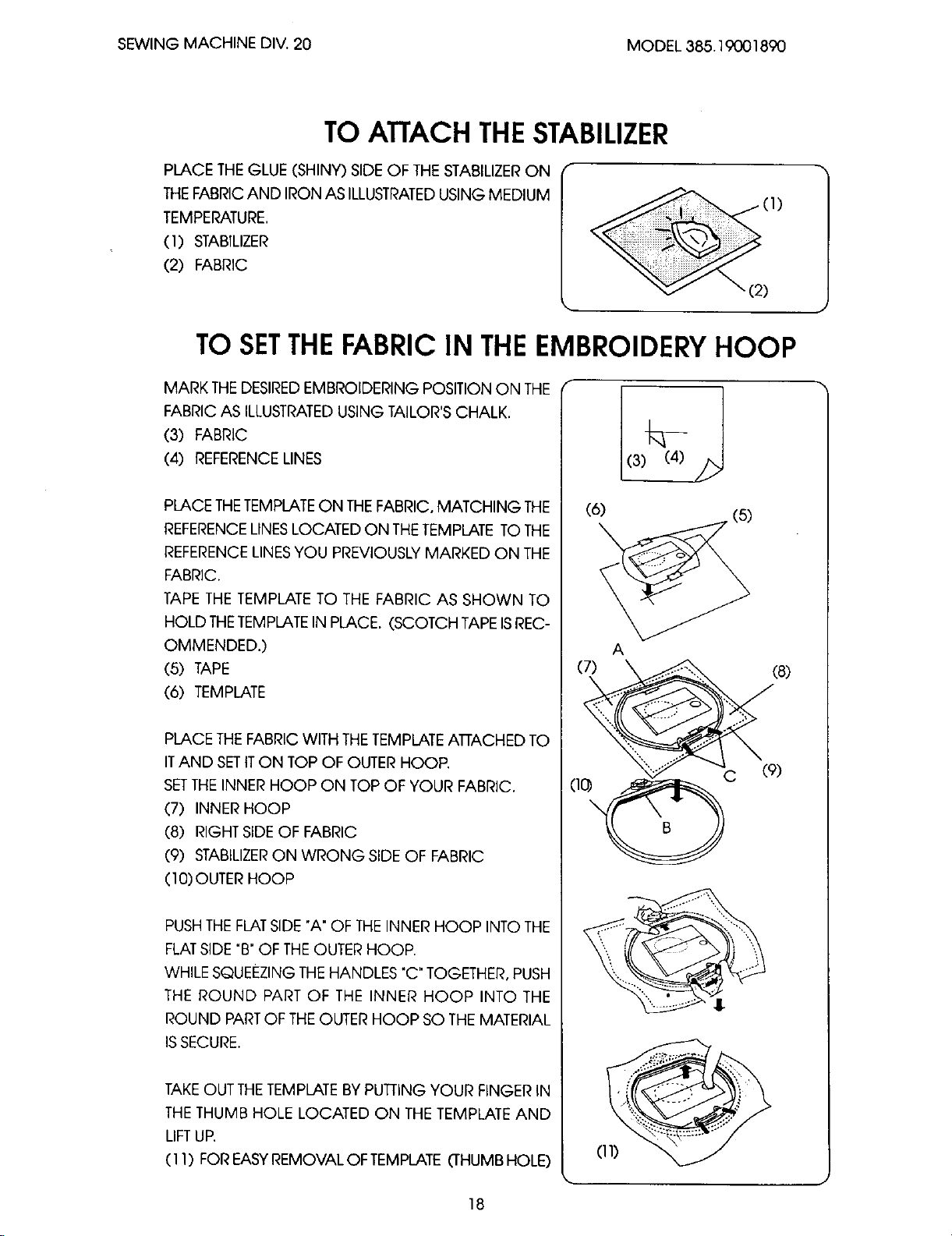

TO ATTACH THESTABILIZER

PLACE THE GLUE (SHINY) SIDE OF THE STABILIZERON

THEFABRIC AND IRON AS ILLUSTRATEDUSING MEDIUM

TEMPERATURE,

(1) STABILIZER

(2) FABRIC

I

TO SETTHEFABRICIN THEEMBROIDERYHOOP

MARK THEDESIREDEMBROIDERING POSITION ON THE

FABRIC AS ILLUSTRATEDUSING TAILOR'S CHALK.

(3) FABRIC

(4) REFERENCELINES

PLACE THETEMPLATEON THEFABRIC, MATCHING THE

REFERENCELINESLOCATED ON THETEMPLATE TO THE

REFERENCELINESYOU PREVIOUSLYMARKED ON THE

FABRIC.

TAPE THE TEMPLATE TO THE FABRIC AS SHOWN TO

HOLD THETEMPLATEIN PLACE. (SCOTCH TAPE ISREC-

OMMENDED.)

(5) TAPE

(6) TEMPLATE

PLACE THEFABRIC WITHTHETEMPLATEATTACHED TO

ITAND SETITON TOP OF OUTER HOOP.

SETTHEINNER HOOP ON TOP OF YOUR FABRIC.

(7) INNER HOOP

(8) RIGHT SIDE OF FABRIC

(9) STABILIZERON WRONG SIDE OF FABRIC

(10) OUTER HOOP

PUSHTHEFLATSIDE "A" OF THEINNER HOOP INTO THE

FLATSIDE "B" OF THE OUTER HOOP.

WHILE SQUEEZING THE HANDLES "C" TOGETHER, PUSH

THE ROUND PART OF THE INNER HOOP INTO THE

ROUND PARTOF THEOUTER HOOP SO THEMATERIAL

ISSECURE.

(6) (5)

A

(_(8)

(10)_C (9)

TAKEOUT THETEMPLATEBY PU_ING YOUR FINGER IN

THE THUMB HOLE LOCATED ON THE TEMPLATE AND

LIFTUP.

(11) FOR EASYREMOVAL OF TEMPLATE (THUMBHOLE)

18

(11)

SDA/ING MACHINE DIV. 20 MODEL 385.19001890

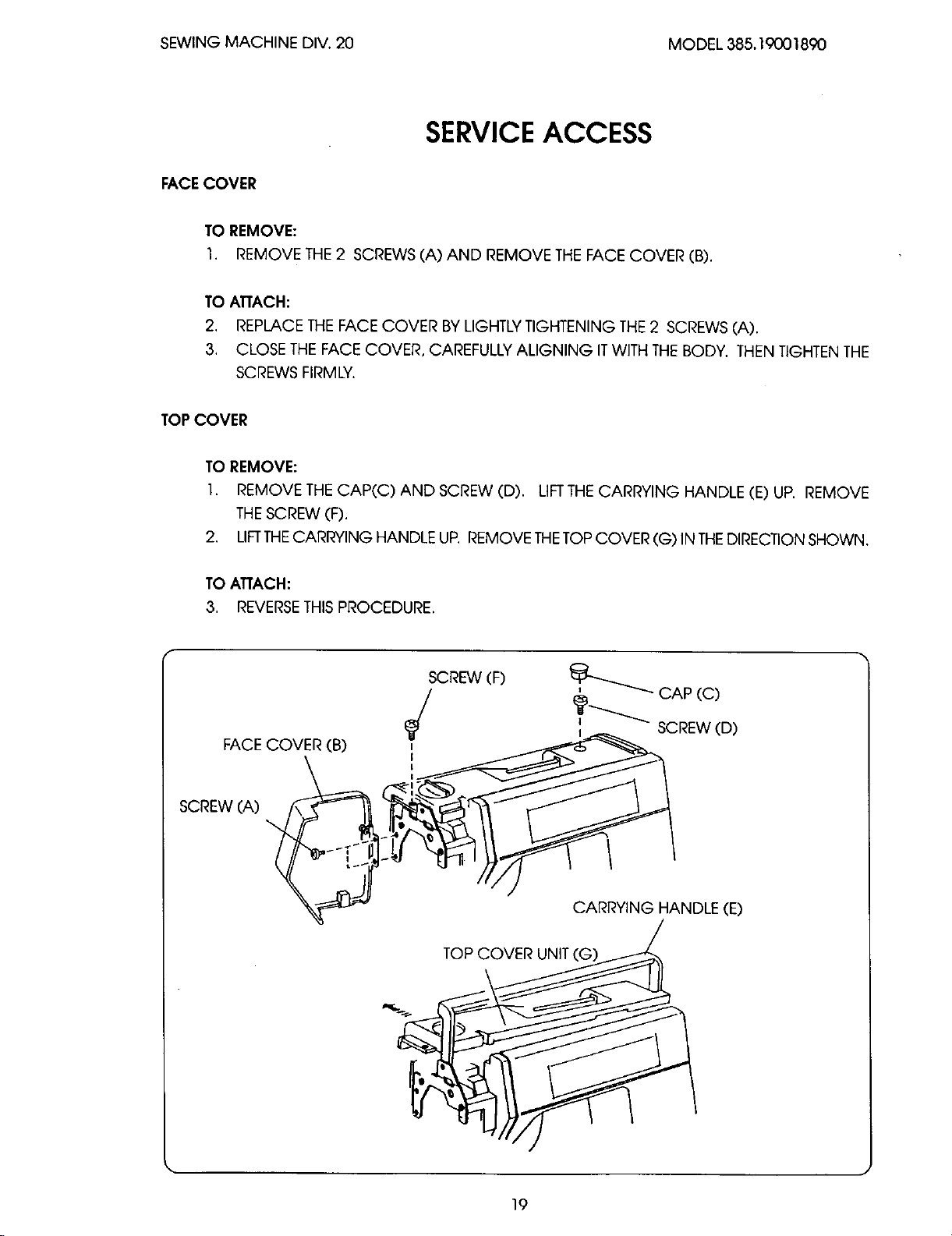

SERVICEACCESS

FACE COVER

TO REMOVE:

1. REMOVE THE 2 SCRE"WS(A) AND REMOVE THE FACE COVER (B).

TO ATTACH:

2. REPLACE THE FACE COVER BY LIGHTLYTIGHTENING THE2 SCREWS (A).

3. CLOSE THE FACE COVER, CAREFULLY ALIGNING ITWITH THEBODY. THEN TIGHTEN THE

SCREWS FIRMLY.

TOP COVER

TO REMOVE:

1. REMOVE THE CAP(C) AND SCREW (D). LIFTTHE CARRYING HANDLE (E) UP. REMOVE

THE SCREW (F).

2. LIFTTHECARRYING HANDLE UP. REMOVE THETOP COVER (G) IN THEDIRECTION SHOWN.

TO ATTACH:

3, REVERSETHIS PROCEDURE.

FACE COVER (B)

SCREW (A)

SCREW (F)

CARRYING HANDLE (E)

TOP COVER UNIT (G)

19

SEWING MACHINE DIV. 20 MODEL 385. ] 900 ]890

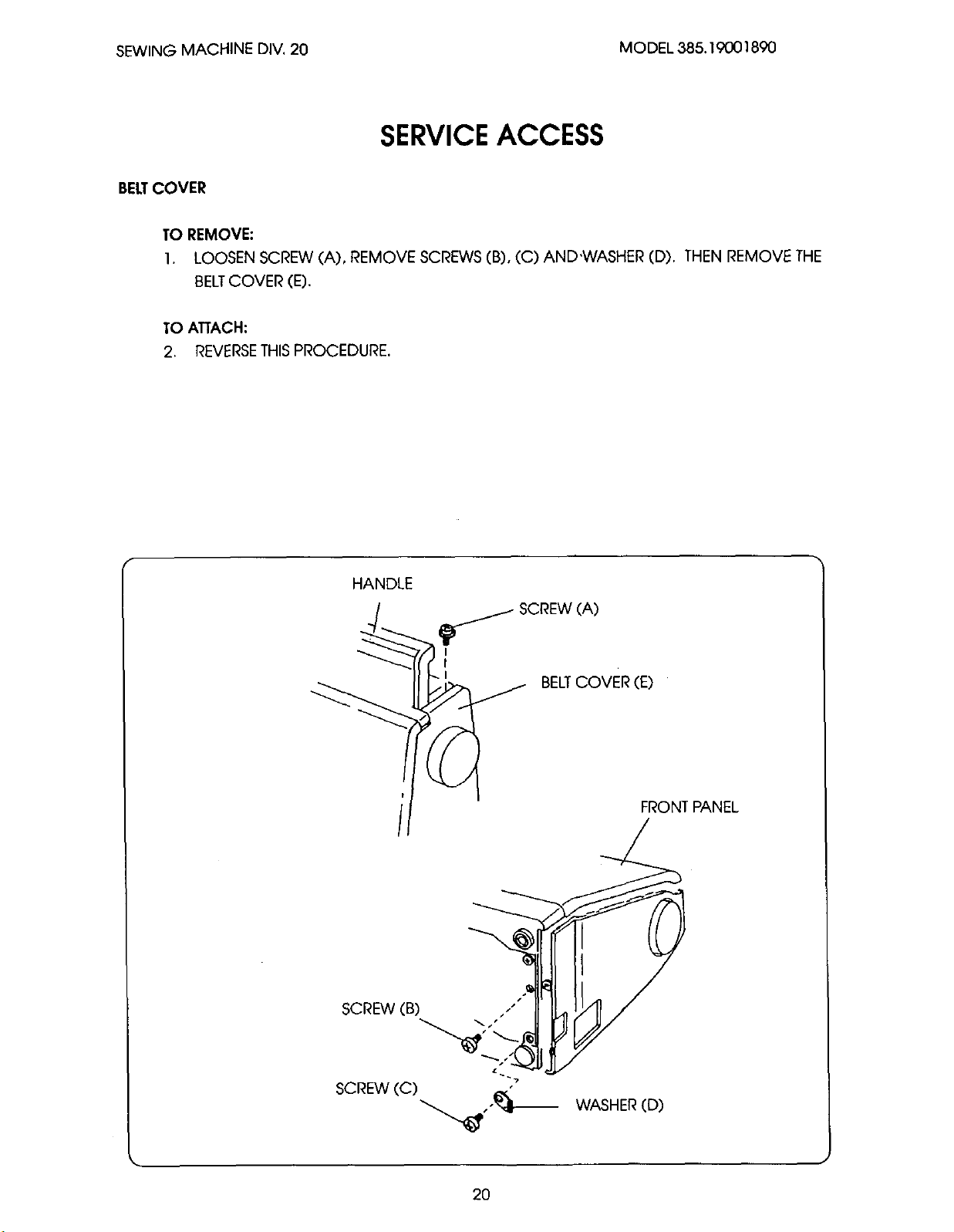

SERVICEACCESS

BELTCOVER

TO REMOVE:

1. LOOSEN SCREW (A), REMOVE SCREWS (B), (C) AND'WASHER (D). THEN REMOVE THE

BELTCOVER (E).

TO ATTACH:

2. REVERSETHISPROCEDURE.

HANDLE

_._- SCREW (A)

SCREW (B) ..

BELTcovER (E)

FRONT PANEL

SCREW (C) ;"

2O

WASHER(D)

Loading...

Loading...