Kenmore 3851695180 Owner’s Manual

Kenmope

SEWING MACHINE 16951

OWNER'S MANU

Seal Canada Inc.

Dear" Homemaker:

You have just invested in a very fine zigzag sewing machine.

Before using your new Kenmore machine, please pause for a

momenl and carefully read this booklet which contains

instructtons on how to operate and care for your machine.

Specific instructions are given on threading, tension

adjustments, cleaning, oiling, etc. This will help you obtain

the best sewing results and avoid unnecessary service expense

for conditions beyond our control.

Advice on the operation and care of your machine is always

available at your nearest Sears Retail Store. Please remember,

if you have questions about your machine, always mention the

model number and serial number when you inquire.

Kenmore Sewing Machine

Record in space provided below the model

number and serial number of this appliance.

The model number and serial number are

located on the nomenclature plate, as identified

on Page 2 of this booklet.

Model No,385, Serial No.

Retain these numbers for future reference.

• k

KNOWING YOUR SEWING MACHINE

Machine identification ..................... 2

Accessories ............................ 4

Setting spool pins ....................... 5

Converting to free-arm sewing ............... 5

Pressure regulator, Presser feet lever ........... 6

Presser feet, Speed control plug .............. 7

Light and power switch, Sewing light .......... 8

Foot control, Seam guides, Darning plate ....... 9

Needle, thread and fabric chart .............. 10

Needles, Placement of needle ............... 11

Winding the bobbin ...................... t 2

Threading the bobbin thread ................ 13

Threading top thread ..................... 14

Picking up bobbin thread .................. 15

Adjusting top thread tensions ............... 16

STARTING TO SEW ....................... t 7

SIMPLE SEWING

Straight stitching ....................... 18

Fastening a seam, Turning a square corner

Zigzag stitching .......................... 20

Checking tensions, Overcasting, Interfacing darts

UTILITY AND STRETCH STITCH SEWING

Buttonhole making ...................... 22

Blind hemming .......................... 24

Shell stitching ......................... 25

Box stitching .......................... 26

Fagoting, Two-point shell stitching ........... 27

Satin stitching, Appliqueing ................ 28

Zipper application ...................... 29

Mending, Darning ....................... 30

Button sewing, Bar tacking .................. 31

Stretch stitching ........................ 32

Adjusting stretch stitch balance,

Straight stretch, Rick-rack stretch,

Overcast stretch, Smocking stretch, Serging or

pine leaf stretch, Elastic stretch, Stretch

patching, Herring bone stretch

Free-arm sewing .......................... 40

CHECKING PERFORMANCE PROBLEMS ...... 41

CARING FOR THE MACHINE

Cleaning feed dogs and shuttle .............. 43

Oiling under arm cover plate ................ 44

Oiling underside ........................ 45

Oiling in face cover plate .................. 46

Parts list ............................. 47

USING PORTABLE CASE OR CABINET ........ 49

KNOW NG YOUR .: =, EWUNG

MACHUNE IDENTtFICAT!ON

Arm Cover Plate

Upper Thread Guide '\\,.

Face Cover Plate

*&

"\

Bobbin Winder

\Pressure Regulato¢ X,

Extension Table/

Presser Foot Thumb Screw

Thread Spool Pins

Stretch Stitch Adjuster_4_

Light and Power Switch_ ._

Electric Cord Receptacle_ ! >'4_':

Thread Guide

Thread Guide

Needle

Clamp Screw

Needle Plate

Bobbin Cover

Plate

Presser Foot Lever

Free Arm

Nomenclature Plate

2

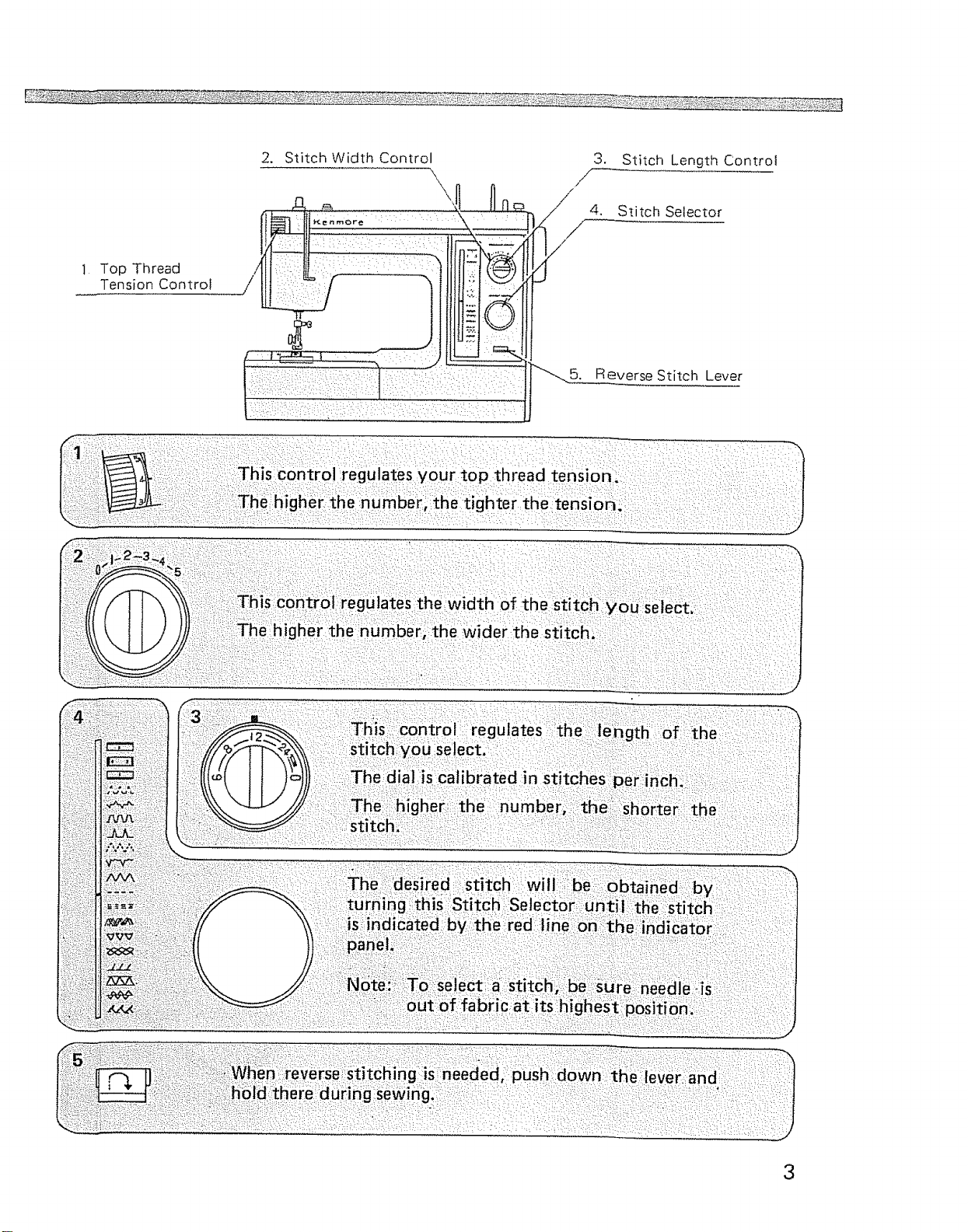

i Top Thread

Tension Control

2. Stitch Width Control

3. Stitch Length Control

\

,\

4, Stitch Selector

5. Reverse Stitch Lever

"i,_!_i!:_II!I!!_:I__!II!I:I:III!:_ii_,ii:_i:_il,i_:ii_!i;__!_iiii_II_i,iiiii_i:_iil_I!

3

_ACCESSOR_£S .... _

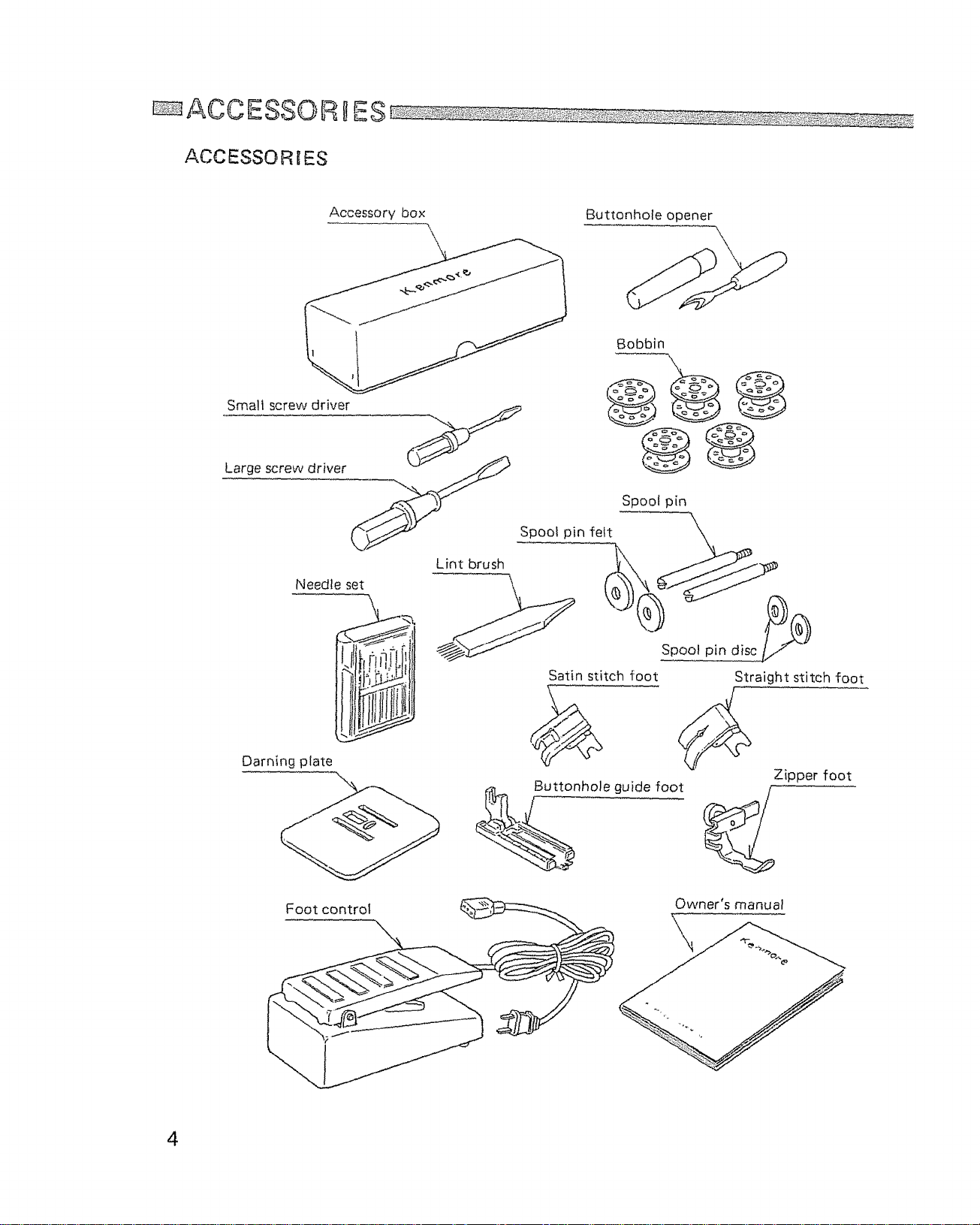

ACC ESSO R l ES

Accessory box Buttonhole opener

Large screw driver ,.._/

Darning plate

Foot control

Satin stitch foot

_- Buttonhole guide foot

Straight stitch foot

Zipper foot

%

Owner's manual

\

\

4

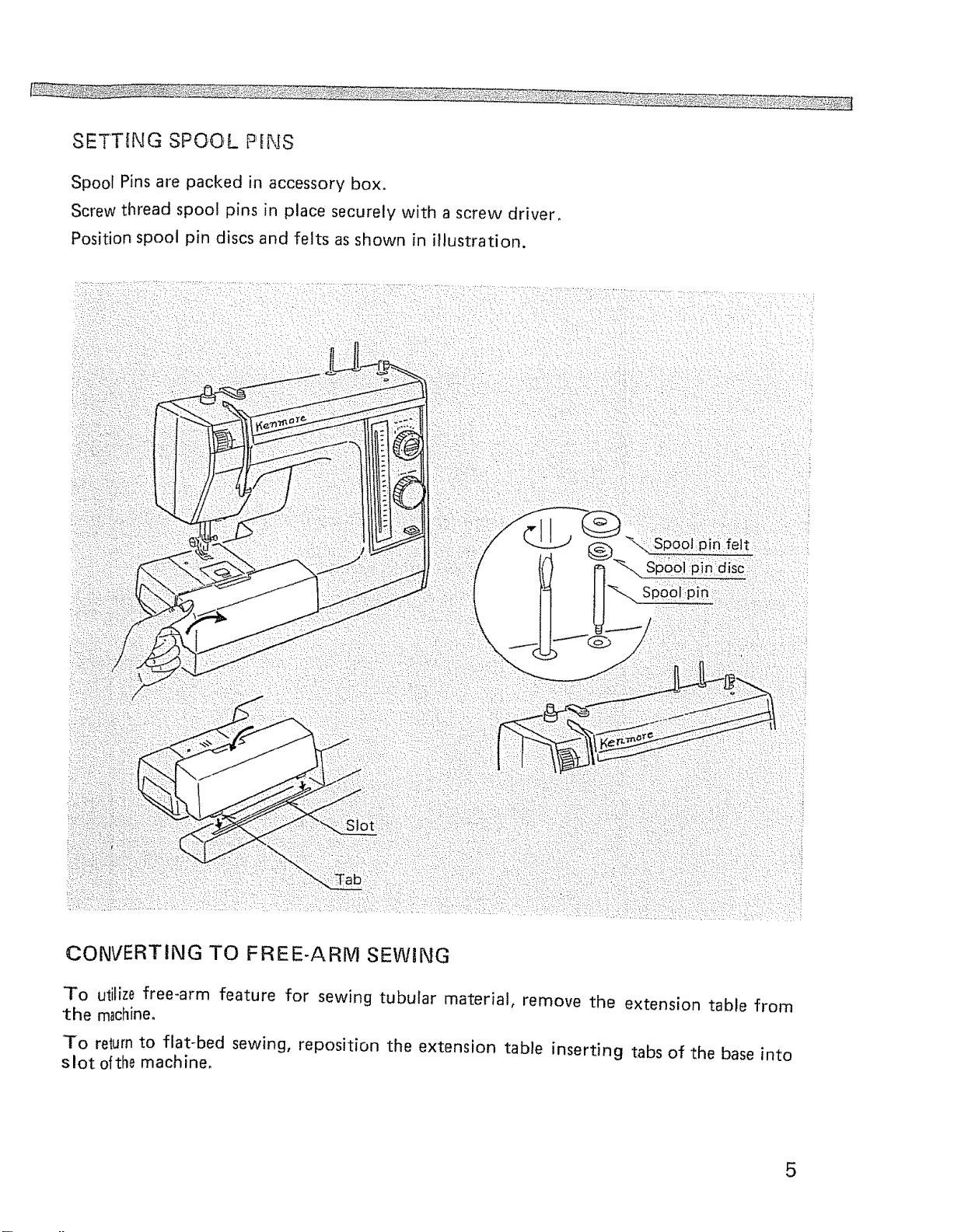

SETTING SPOOL PINS

Spool Pins are packed in accessory box.

Screw thread spoo! pins in place securely with a screw driver.

Position spool pin discs and felts as shown in illustration.

Spool Pin:;fett

isc

_, Spoo!:.pin

CONVERTING TO FREE-ARM SEWING

To utilize free-arm feature for sewing tubular material, remove the extension table from

the machine.

To return to flat-bed sewing, reposition the extension table inserting tabs of the base into

slot of the machine,

5

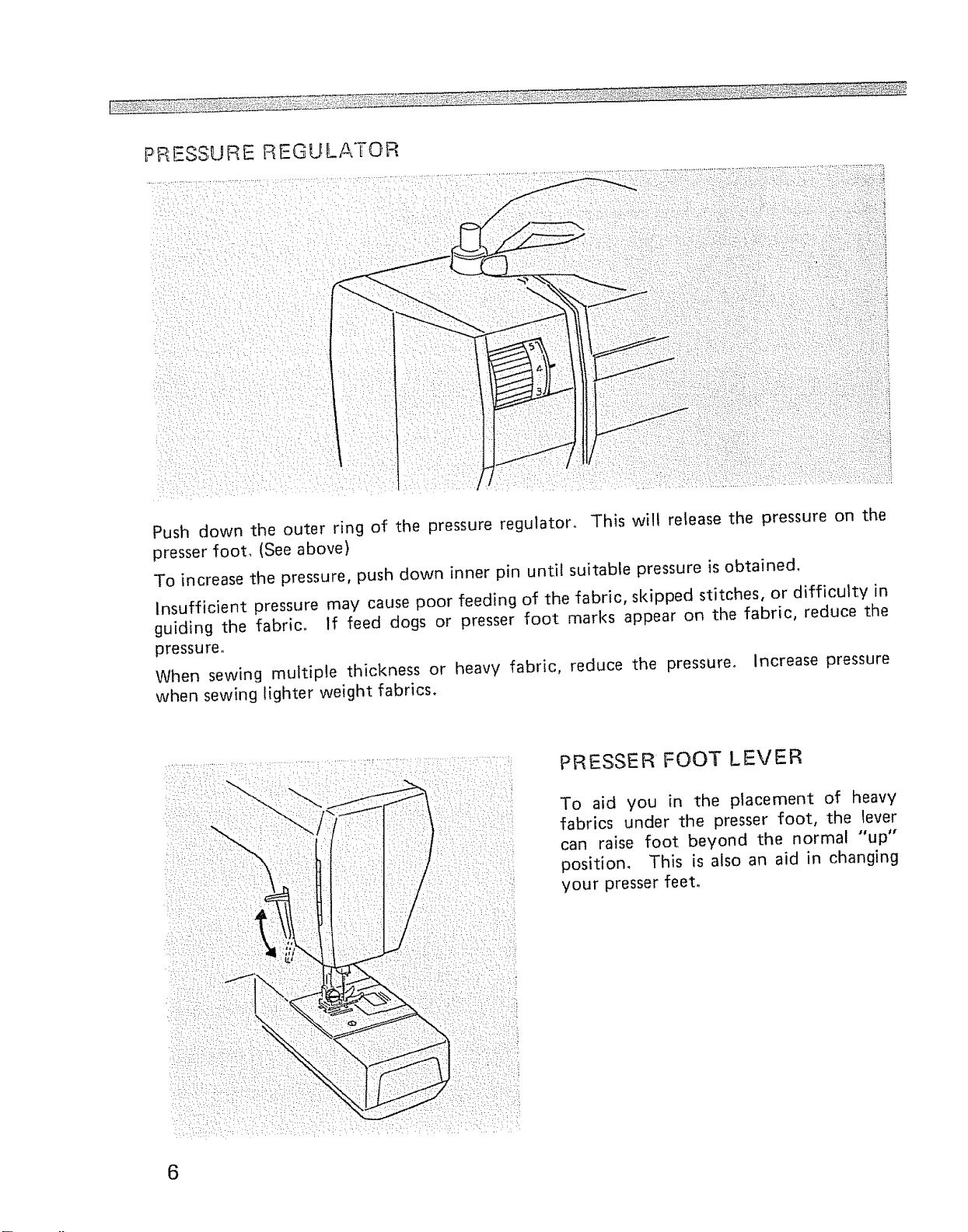

PRESSURE REGULATOR

Push down the outer ring of the pressure regulator° This will release the pressure on the

presser foot. (See above)

To increase the pressure, push down inner pin until suitable pressure is obtained.

Insufficient pressure may cause poor feeding of the fabric, skipped stitches, or difficulty in

guiding the fabric, if feed dogs or presser foot marks appear on the fabric, reduce the

pressure.

When sewing multiple thickness or heavy fabric, reduce the pressure, increase pressure

when sewing lighter weight fabrics.

PRESSER FOOT LEVER

To aid you in the placement of heavy

fabrics under the presser foot, the lever

can raise foot beyond the normal "up'"

position, This is also an aid in changing

your presser feet,

6

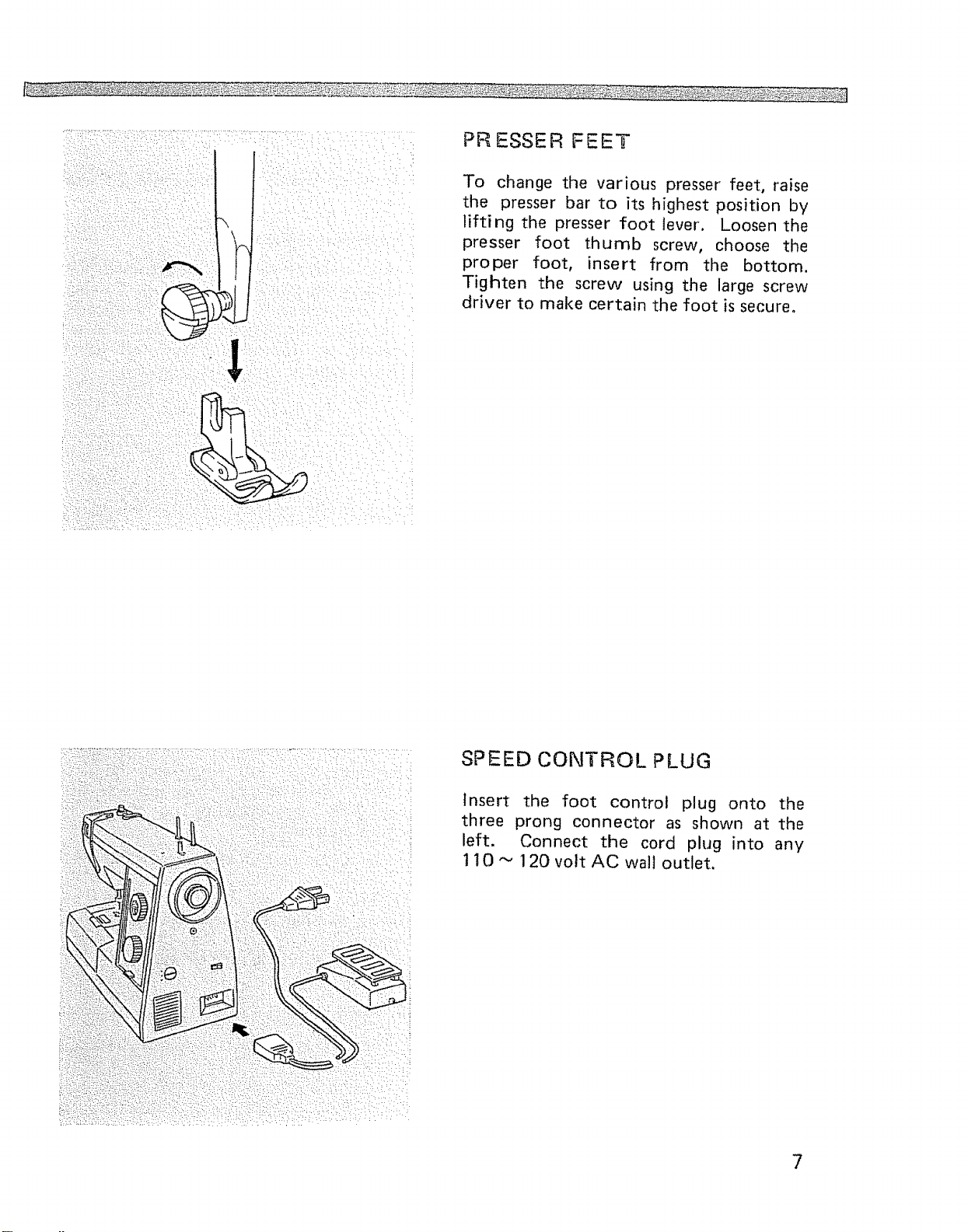

PR ESSER FEET

To change the various presser feet, raise

the presser bar to its highest position by

lifting the presser foot lever. Loosen the

presser foot thumb screw, choose the

proper foot, insert from the bottom.

Tighten the screw using the large screw

driver to make certain the foot is secure.

SPEED CONTROL PLUG

insert the foot control plug onto the

three prong connector as shown at the

left. Connect the cord plug into any

1 !0 "" 120 volt AC wall outlet.

7

L_GHT AND POWER SW_TCH

Turn on power by pushing light and

power switch,

important safety featu re

Your machine will not operate unless the

:] :;

light/power switch is turned on, Turning

on the power automatically illuminates

the whole stitching area. If you're inter-

rupted or stop sewing, turn off light/

power switch.

SEWING LIGHT

The sewing light is located in the face

cover as shown, To replace the bulb,

turn the light off and open the face

cover. Push the bulb up and turn the

bulb counter-clockwise and remove it

from the socket.

Push a new bulb in and turn it clockwise.

NOTE:

First, unplug the machine prior to re-

moving and replacing the bulb, Be aware

that the light bulb may be warm.

8

FOOT CONTROL

Step on this control to start to sew. The

harder you press on the control, the

faster the machine will sew. Slow down

by reducing pressure on the control,

You may want to practice your speed at

different levels when you first use the

machine,

SEAM GUIDES

Seam guides are printed on either side of

the needle plate to aid you in guiding

your fabric. THE GUIDE LINE EXTEND-

ING ALONG THE RIGHTSIDE OF THE

NEEDLE PLATE 1S THE "ALL IM-

PORTANT" 5/8" SEAM LINE,

The cornering guides are convenient when

turning a square corner 5/8" from the

fabric edge. See next section of this book

for directions°

DARNING PLATE

There are a few times when you want to

control the feeding of the fabric yourself,

Raise needle to its highest position and

raise presser foot. Place darning plate

over needle plate aligning two pins of

darning plate with holes of needle plate.

You may then determine the movement

of the fabric yourself. See page 31 for

button sewing application,

9

_ii¸ii,iiiiiil;!i!_i_ii!i_!i:ii_¸i_ii_:i:i_i:i:_i_¸i_i!::!_i_!_iii_i_ii_!_:_;:i¸!:_I:,!:_¸ii_i¸::_;_i_!_:_;:____,_i ;¸¸!=,::_,_i_i_=ii:il¸i¸ii:ii_i!ili!i:i_ii,_,i:_!_¸_i_!::_:_=_i:_!:_!_=_:!i!i=;i:_:!!_:i!i_!::i!_;_i_!:_!_:ii_i!ii;_!i_:_;:ii1:!!_ii_¸_I_

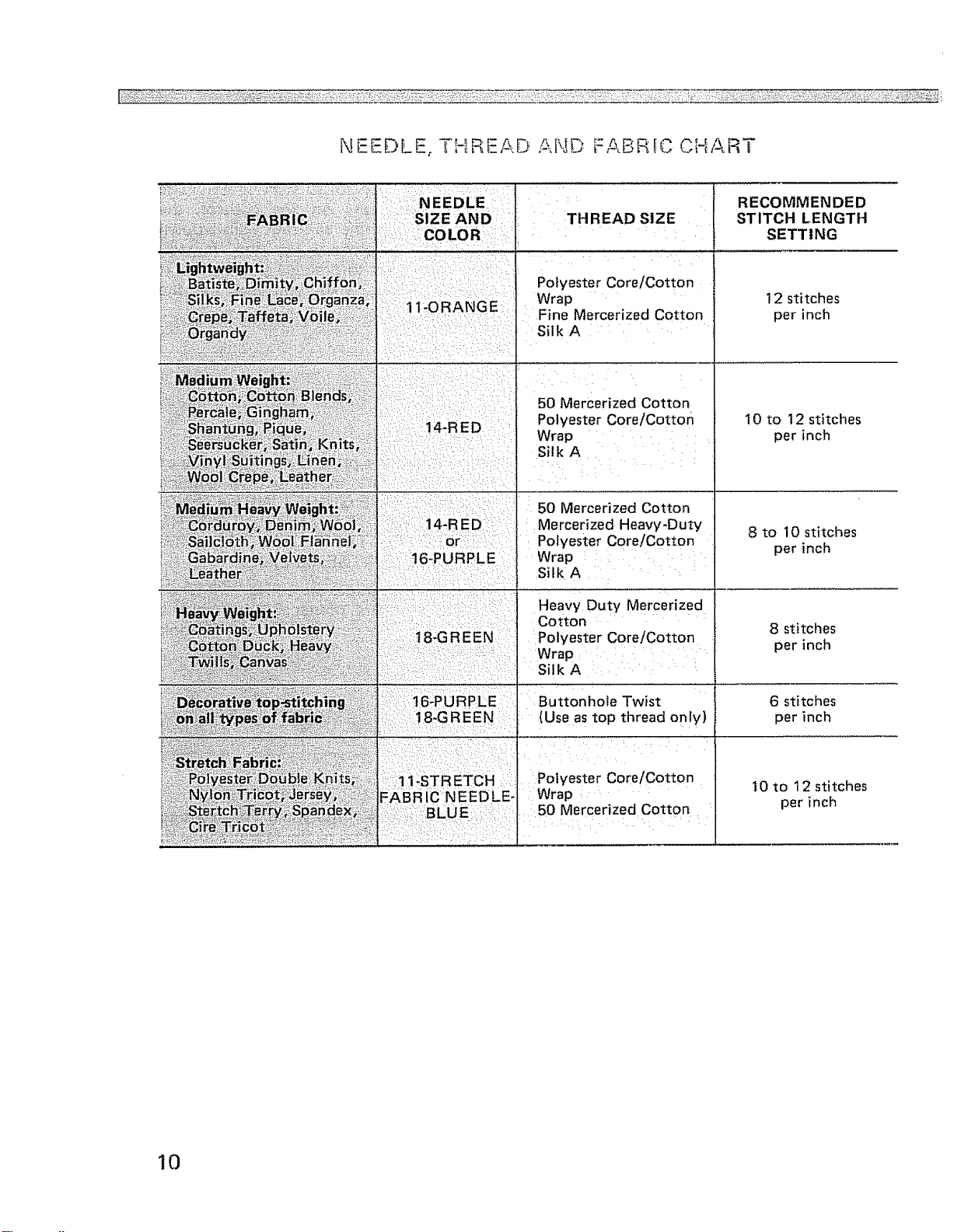

NEEDLE, THREAD !::_l',,tDFABRIC CHART

:::::=::::SIZE AND THREAD SIZE

li)ii ii!i i?iiii!ii:!iii i: i!i!!ii!:ii!;i!i!:!:ii i!!ii,ii!i

Polyester Core/Cotton

Wrap

: Fine Mercerized Cotton

i Silk A

50 MerCerized Cotton

Polyester Core/Cotton

Wrap

Silk A

RECOMMENDED

STITCH LENGTH

SETTING

12 stitches

per inch

10 to 12 stitches

per inch

:::::::::::::::::::::::: Buttonhole Twist

l_i!_:ii_i_i_!_!_:_}_!_!i(_:;i!i_iii!:!: :::::::::::::::::::::8:GREEN :::::1 :(Use as top thread only}

FABR iC::NEED LE-

6 stitches

per inch

10 to 12 stitches

per inch

10

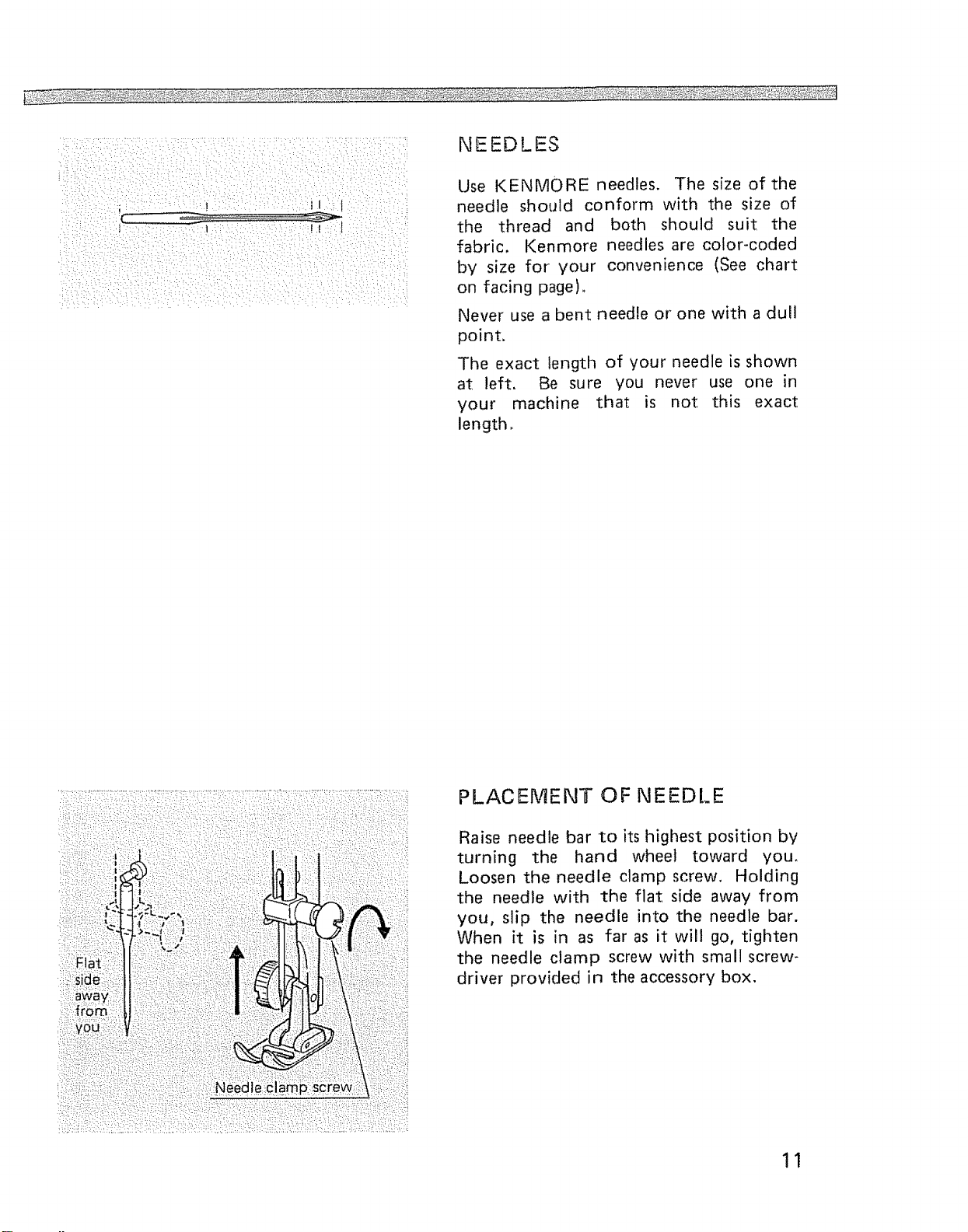

NEEDLES

Use KENMORE needles. The size of the

C

! il 1

needle should conform with the size of

the thread and both should suit the

fabric. Kenmore needles are color-coded

by size for your convenience (See chart

on facing page).

Never use a bent needle or one with a dull

point,

The exact length of your needle is shown

at left, Be sure you never use one in

your machine that is not this exact

length,

PLACEMENT OF NEEDLE

Raise needle bar to its highest position by

turning the hand wheel toward you°

Loosen the needle clamp screw. Holding

the needle with the flat side away from

you, slip the needle into the needle bar.

When it is in as far as it will go, tighten

the needle clamp screw with small screw-

driver provided in the accessory box.

11

WGND_NG THE BOBBIN

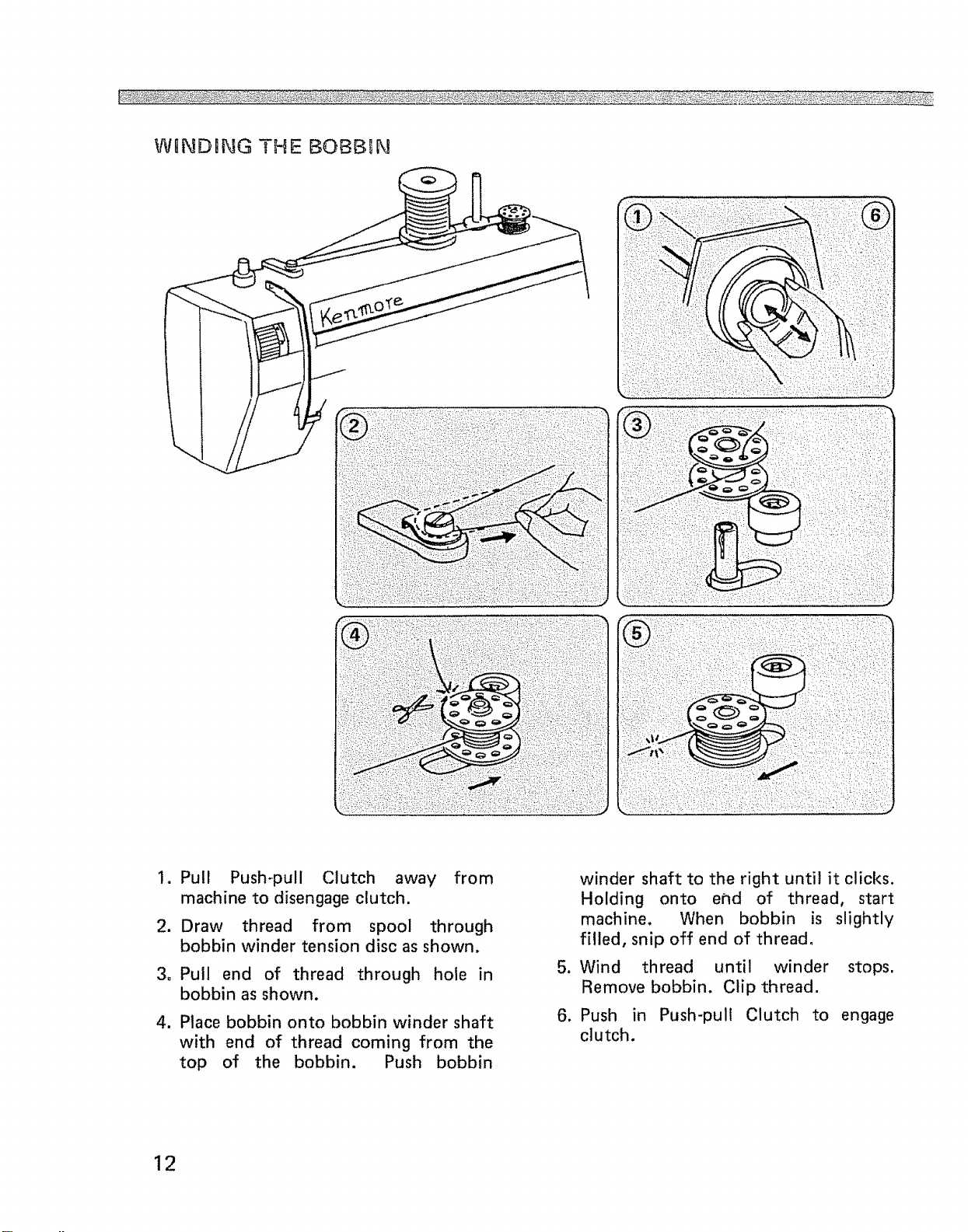

1. Pull Push-pull Clutch away from

machine to disengage clutch.

2, Draw thread from spool through

bobbin winder tension disc as shown.

30 Pull end of thread through hole in

bobbin as shown.

4. Place bobbin onto bobbin winder shaft

with end of thread coming from the

top of the bobbin. Push bobbin

12

winder shaft to the right until it clicks.

Holding onto et_d of thread, start

machine. When bobbin is slightly

filled, snip off end of thread.

5. Wind thread until winder stops.

Remove bobbin. Clip thread.

6. Push in Push-pull Clutch to engage

clutch.

THREADING "THE BOBBIN THREi-_,D

t_ Remove the extension table.

2. Remove the bobbin cover plate by

pulling it toward you while pushing it

down slightly.

3. Insert bobbin into shuttle making sure

bobbin rotates counter clockwise.

4. Pull 4-inches of thread through tension

slot of bobbin case and toward back of

machine as shown.

5. Close the bobbin cover plate allowing

thread to emerge through slot in

needle plate.

13

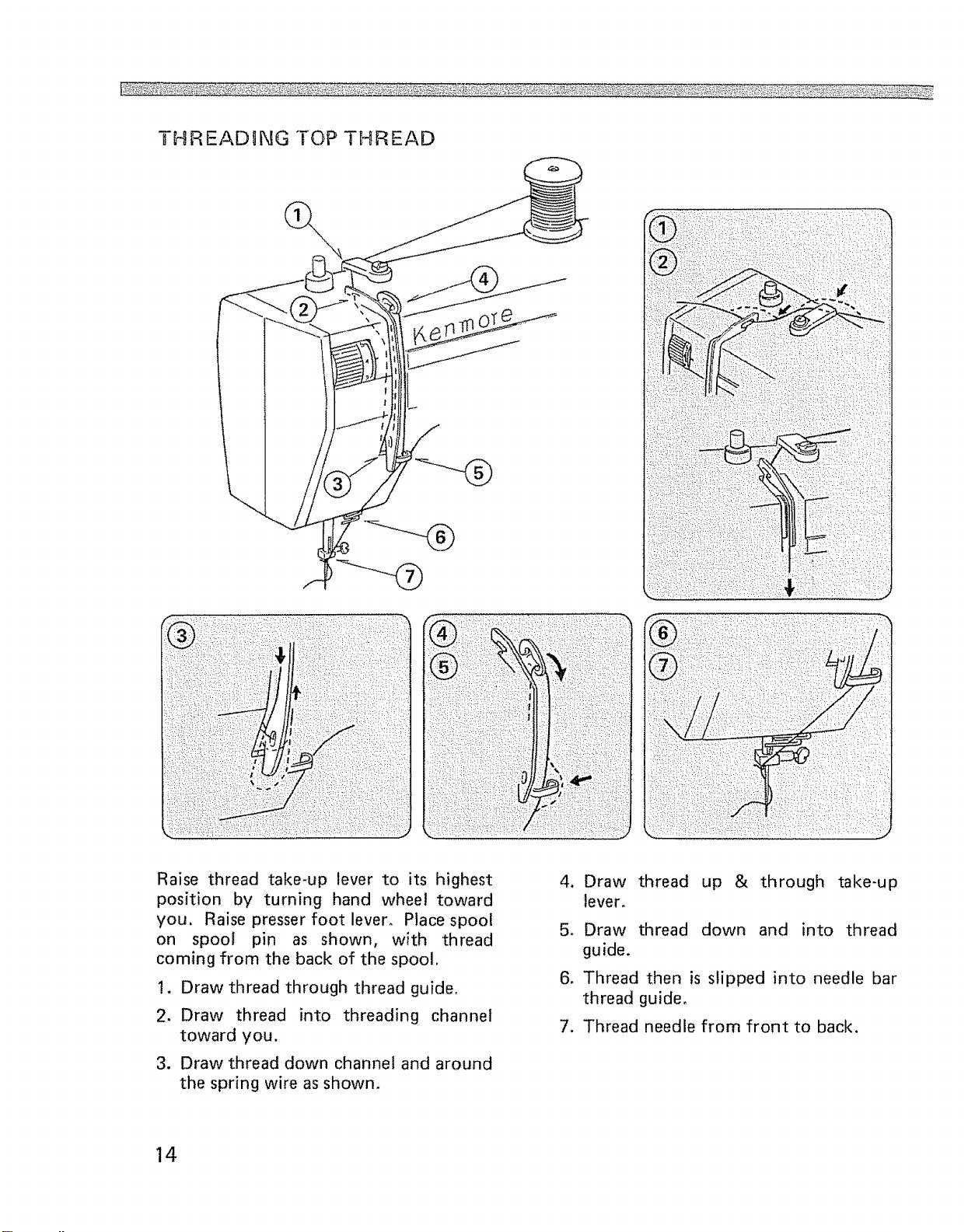

THREADING TOP THREAD

Raise thread take-up lever to its highest

position by turning hand wheel toward

you. Raise presser foot lever, Place spool

on spool pin as shown, with thread

coming from the back of the spool,

!. Draw thread through thread guide,

2, Draw thread into threading channel

toward you.

3. Draw thread down channel and around

the spring wire as shown,

14

4. Draw thread up & through take-up

lever.

5o Draw thread down and into thread

guide.

6. Thread then is slipped into needle bar

thread guide.

7. Thread needle from front to back.

@

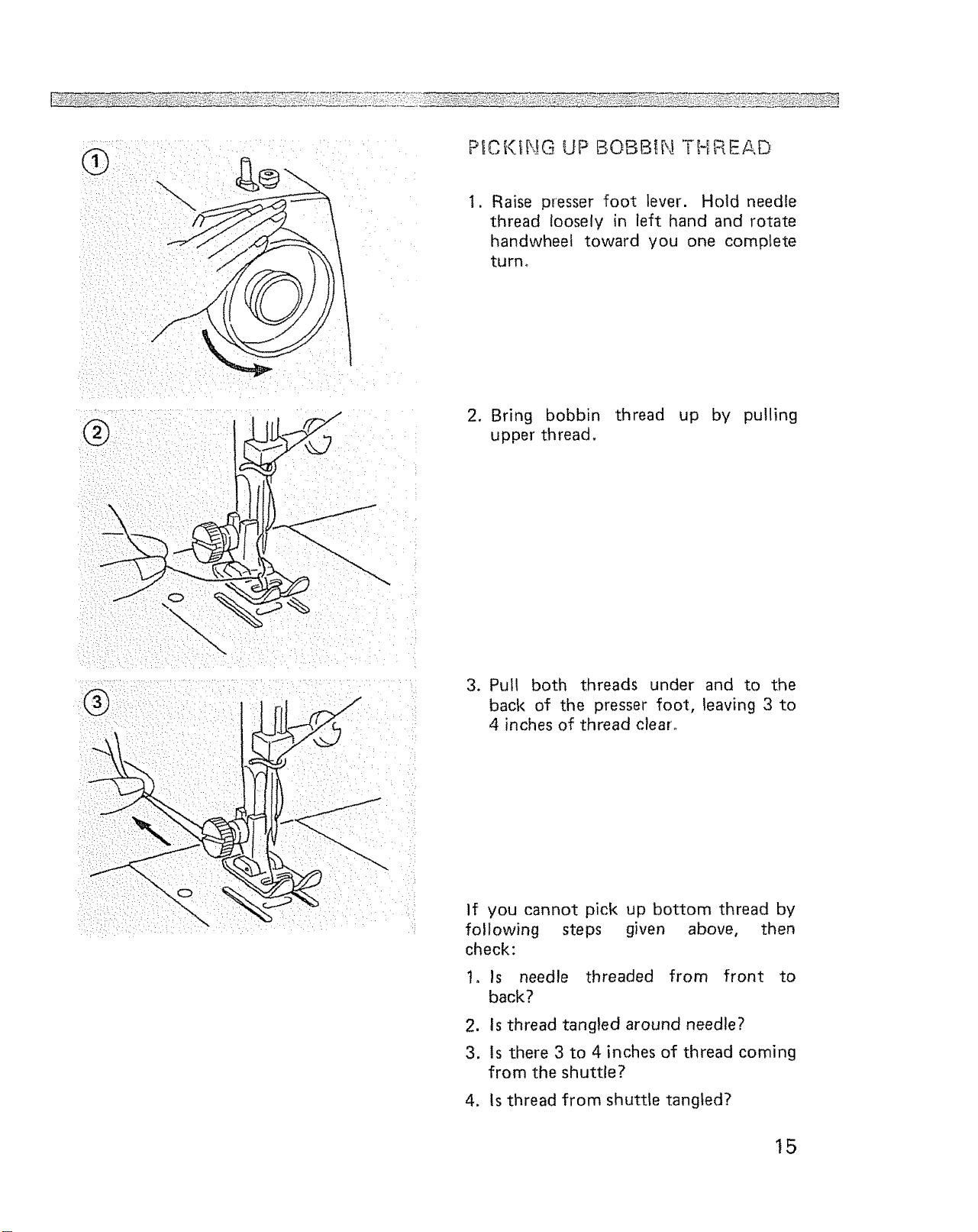

P_CKfNG UP BOBBIH THREAD

1. Raise presser foot lever. Hold needle

thread loosely in left hand and rotate

handwheel toward you one complete

turn,

2, Bring bobbin thread up by pulling

upper thread,

\

\

3, Pull both threads under and to the

back of the presser foot, leaving 3 to

4 inches of thread clear°

If you cannot pick up bottom thread by

following steps given above, then

check:

1, is needle threaded from front to

back?

2. Is thread tangled around needle?

3. Is there 3 to 4 inches of thread coming

from the shuttle?

4. Is thread from shuttle tangled?

15

Loading...

Loading...