Kenmore 3851584180 Owner’s Manual

OWNER'S MANUAL

: SEWING MACHINE

MODEL 385. 1584180

: :: :: :: i::::!:::ii::_:i!:::::::::!_!:i::!:::i_I:Iii:!:i:!i_:!_:!i:i::i_

SEARS, ROEBUCK AND CO.

Dear Customer:

You have just invested in a very fine zigzag sewing machine. Before using your new Kenmore machine,

please pause for a moment and carefully read this booklet which contains instructions on how to operate

and care for your machine.

Specific instructions are glven on threading, tension adiustments0 cleaning, oiting, etc. This will help you

obtain the best sewing results and avoid unnecessary service expense for conditions beyond our control.

Advice on the operation and care of your machine is always available at your nearest Sears Retail Store.

Please remember, if you have questions about your machine or need parts and service, always mention

the model number and serial number when you inquire.

Kenmore Sewing Machine

Record m space provided below the model number and seriai

number of this appliance. The modei number and serta! number

are Located on the nomenclature prate, as identified on Page 3 of

this booklet.

Model No. 385, Serial No.

Retain these numbers for future reference.

THIS MODEL tS A CENTER NEEDLE, LOW BAR SEWING MACHINE,

TABLE OF CONTENTS

SECTION

SECTION

SECTION

I. KNOW YOUR MACHINE

A Portable case or Cabinet is Available ............. 2

Locate and Identify the parts .................. 2_3

Indentify the Accessories .......................... 4

2, PREPARE YOUR MACHINE FOR SEWING

Set Up the Machine ......................... 5_9

o Plut in the machine and Switch on the Power ......... 5

o Foot Control Use ....................... 5

o Set the Pressure Dial ..................... 6

o Setting Spool Pins .................... 7

o Adiust the Presser Foot Lever .................. 7

- Thread Cutter ............................ 7

a Accessory Storage Box ...................... 8

o Free Arm Sewing: the Removable Extension Table 8_9

Know What the Presser Feet Will Do .......... 10_12

o Check Your Presser Foot ..................... 10

Change the Presser Foot .................... 10

o Presser Foot Types ..................... 11_12

Choose Your Needle and Thread .............. 13_t4

o Check Your Needle ......................... t3

o Fabrtc, Needle, Thread and Stitch Length Chart .... 14

o To Change Your Needle ..................... 14

Prepare the Bobbin .......................... 15_16

6 To Remove the Bobbin from the Machine ........ 15

a Wind the Bobbin ....................... 15

e Insert the Bobbin into the Bobbin Holder ......... 16

Prepare Your Top Thread .................. 17"20

o Thread Your Needle ......................... 17

o Pick Up Your Bobbin Thread ................. 18

o Adjust the Top Thread Tension .............. 19_20

Stitch Selector ............................. 20

Stitch Width Control ........................ 21

Stitch Length Control ...................... 21

Adjusting Stretch Stitch Balance ................ 21

Reverse Stitch Control ................... 22

Starting To Sew ............................. 22

3° LEARN THE STITCHES

Practica] Stitch Chart ...................... 23"_26

Straight Stitches .......................... 27_29

o Straight Stitch ........................... 27

a Use the Seam Gutdes ...................... 27

o Turn a Square Corner ...................... 27

o Use the Darning Plate .................... 28

o Topstitchmg ............................ 28

Darning ............................... 29

Straight Stretch ............................. 29

Zigzag Stitches .................... 30_37

• Basic Zigzag ............................. 30

o Satin Stitch ......................... 31

o Applique ............................. 32

o Bar Tacking ......................... 32

o Monogramming ......................... 33

o Embroidery ........................... 33

o Sew a Button ............................ 34

o Overcasting Stitch ....................... 35

o Rick-Rack Stretch ....................... 35

e Three-Step Zigzag ....................... 36

o Overcast Stretch Stitching ................... 37

e Serging or Pine Leaf Stretch Stitching ............ 37

Blind Hemming ............................ 38

Lace Work ................................. 39

Buttonhole Making ........................ 40"_41

Sew in a Zipper ........................ 42"43

Shell Stitching ............................. 44

Two-Point Shell Stitching ..................... 44

Smocking ................................. 45

Stretch Patching ............................ 45

Fagoting Stitch ............................ 46

Herring Bone Stretch ........................ 46

Elastic Stretch Stitch ......................... 47

Box Stitching .............................. 47

SECTION 4. PERFORMANCE PROBLEMS CHART

What to Do When ......................... 48"--49

SECTION 5. CARE FOR YOUR MACHINE

Replace the Light Bulb ....................... 50

Clean the Bobbin Holder ...................... 50

Clean the Hook Race and Feed Dogs ............. 51

Oiling the Machines .......................... 51

PARTS LIST ...................................... 52_53

INDEX ............................................ 54_55

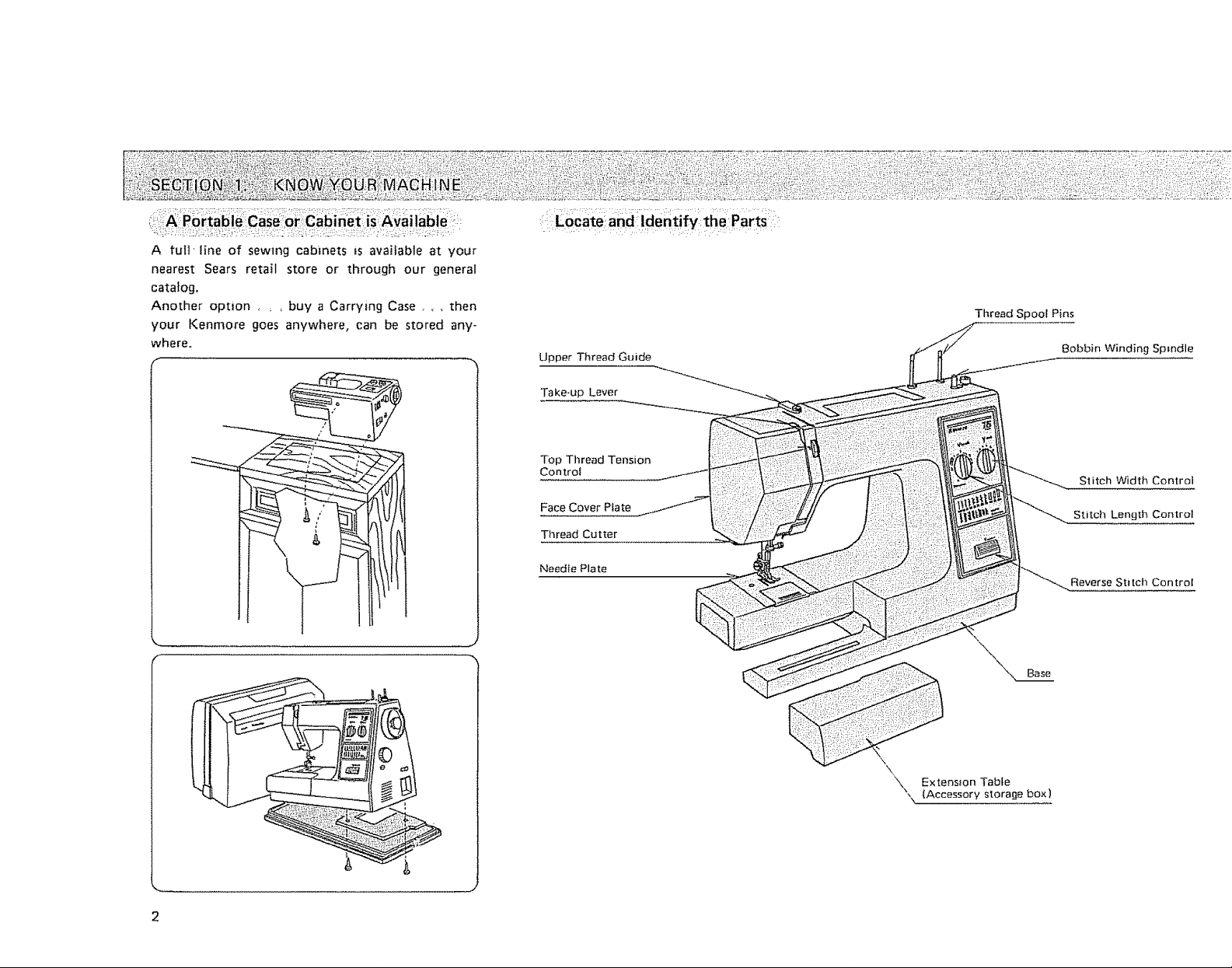

A fuN-line of sewing cabinets is available at your

nearest Sears retail store or through our general

catalog.

Another option • , _ buy a Carrying Case . _ , then

your Kenmore goes anywhere, can be stored any-

where.

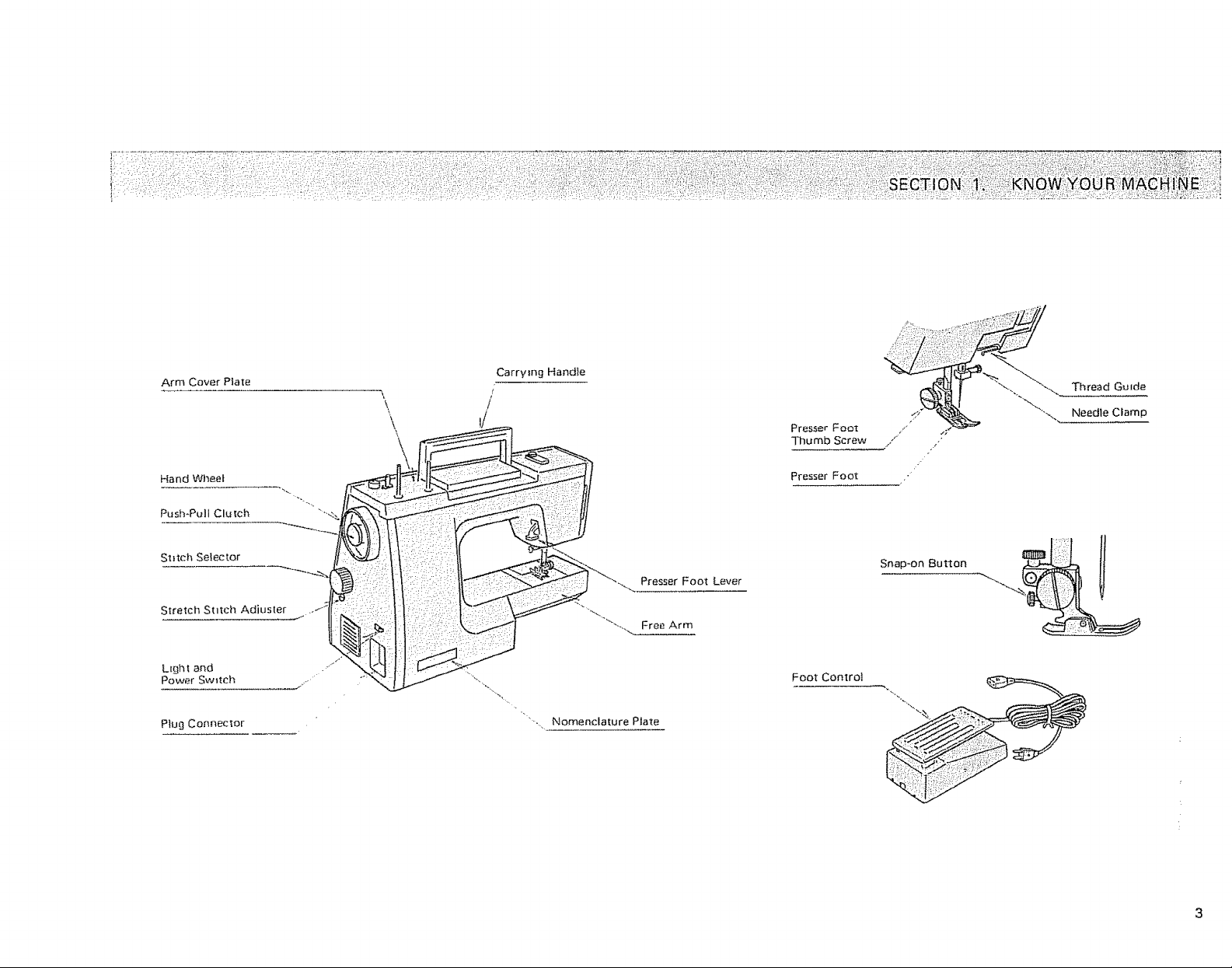

: ::locate: anaiiaentify: ttle Parts::i

Upper Thread Guide

Take-up Lever

Top Thread Tension

Control

Thread Spool Pins

Bobbin Winding Spindle

Width Control

Face Cover Piate

Thread Cutter

Needie Plate

J

\

Stitch Length Control

Reverse Stitch Con trol

\\

\

\

\ Extension Tabte

\,\ (Accessory storage box)

J

2

Arm Cover Plate

Carrying Handle

\

\

\

/

i

!/

Hand Wheel

Push*Pull Clutch

Stitch Selector /_

Stretch Stitch Adiuster .t .JSll

L_ght and . j

Power Sw_tch _-,

Plug Connector

Presser Foot ,.

Snap-on Button

Free Arm

Foot Control

-., Nomenclature Plate

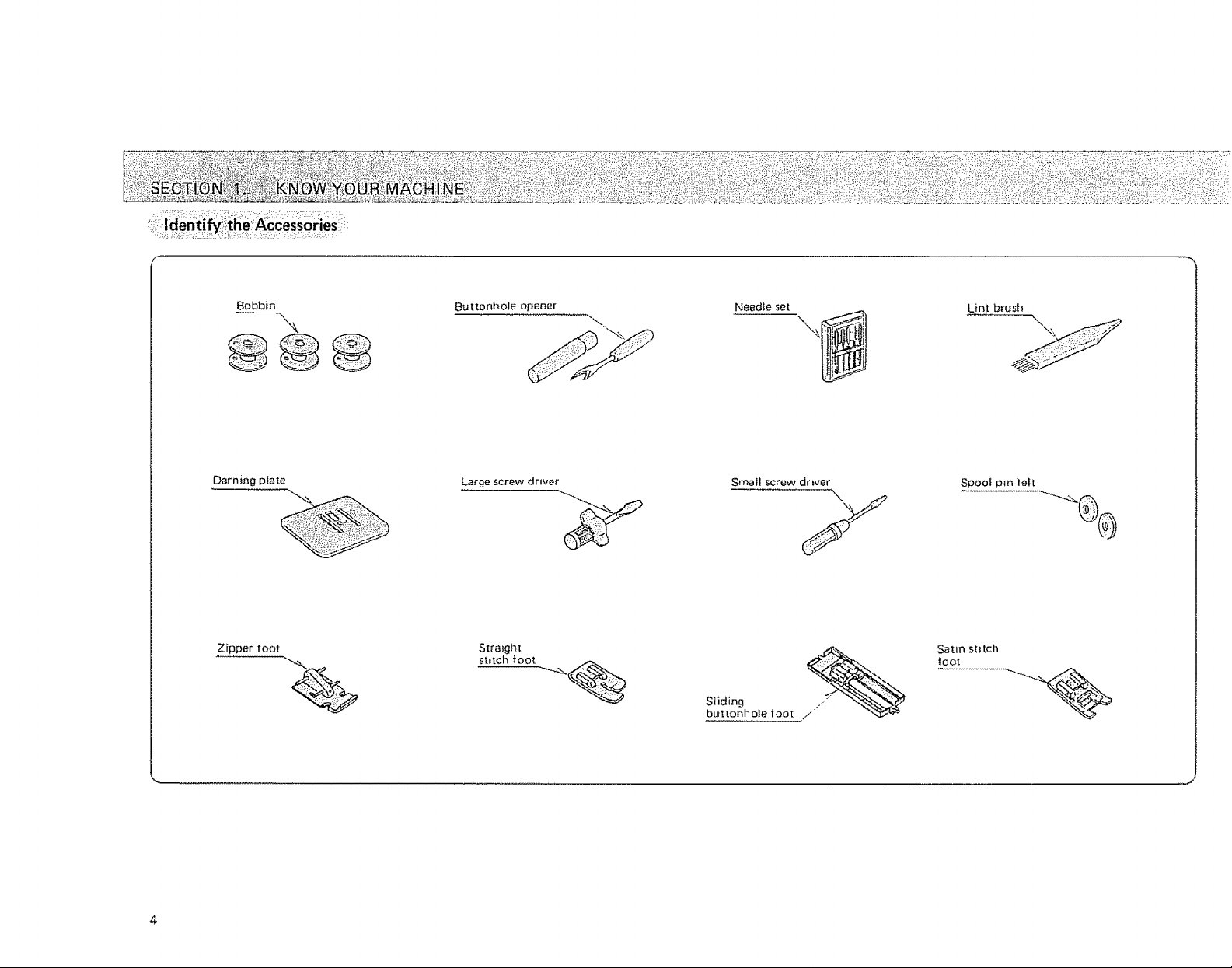

Bobbin

Buttonhole opener Needle set

Lint brush

Darning plate

Zipper foot Stra3ght

Large screw driver

stitch foot

--%

Small screw drwer

J

Sliding /"

buttonhole toot /

\

Spool pin teft

Set Up the Machine

Plug in the Machine and Switch on the Power

Power supply plug

Power

swlIch

\

PIug

connector

NOTE.

I, Check your outlet to be sureitis a 110to !20

2, Insert the machine plug into the three-prong

3. Insert the power supply plug into the outlet.

Before inserting the plug into your

machine, be sure the power sw_tch is

OFF

Volt AC outlet.

outlet, as shown. It will only fit one way.

Machine

plug

Sewmg ligh!

Power swltch %

4. Push the light and power switch to turn

on the power and sewing light.

SAFETY FEATUR E:

Your machine wil! not operate unless the

lighttpower switch is turned on. If you are

interrupted or stop sewing, turn off the

light/power switch to prevent injury to

children.

o Foot Control Use

Fool c/ontro!

The foot control regulates the speed at

which you sew.

To increase speed, gently press down with

the ball of your toot.

To decrease speed, release your foot pres-

sure slightly,

NOTE:

The foot control is sensitive and

win increase or decrease your

sewing speed immediately.

Practice on a scrap of fabric to

regulate your sewmg speed to

your taste and needs,

J

SetUp the MaChine:i:I(Continued)

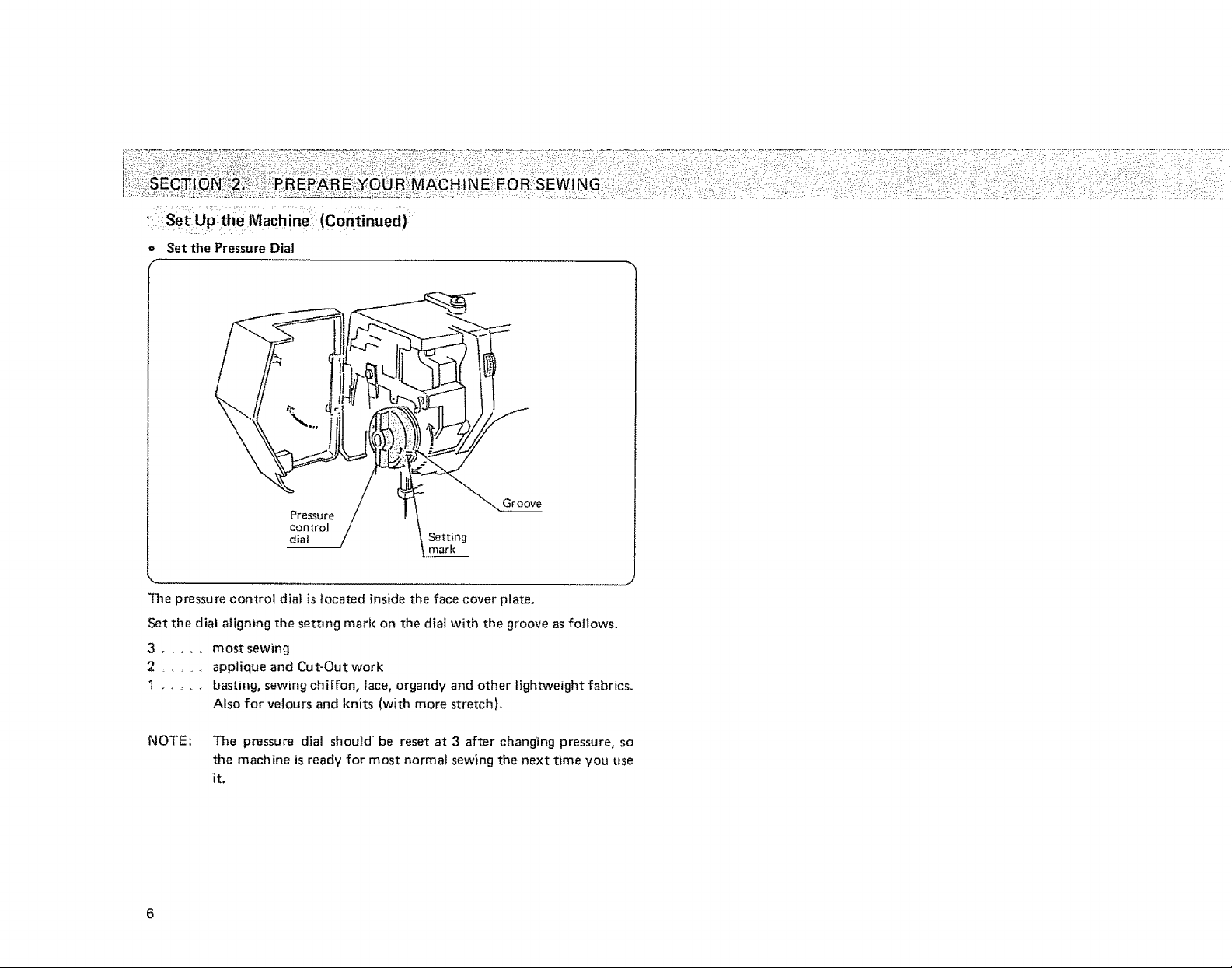

= Set the Pressure Dial

f

Pressure

control

dial Setting

mark

Groove

The pressure control dial is located inside the face cover plate.

Set the dial aligning the setting marl{ on the dial with the groove as follows.

3 ..... most sewing

2 ..... applique and Cut-Outwork

1 ..... basting, sewing chiffon, lace, organdy and other lightweight fabrics.

Also for velours and knits (with more stretch).

NOTE: The pressure dial should be reset at 3 after changing pressure, so

the machine is ready for most normal sewing the next time you use

it.

J

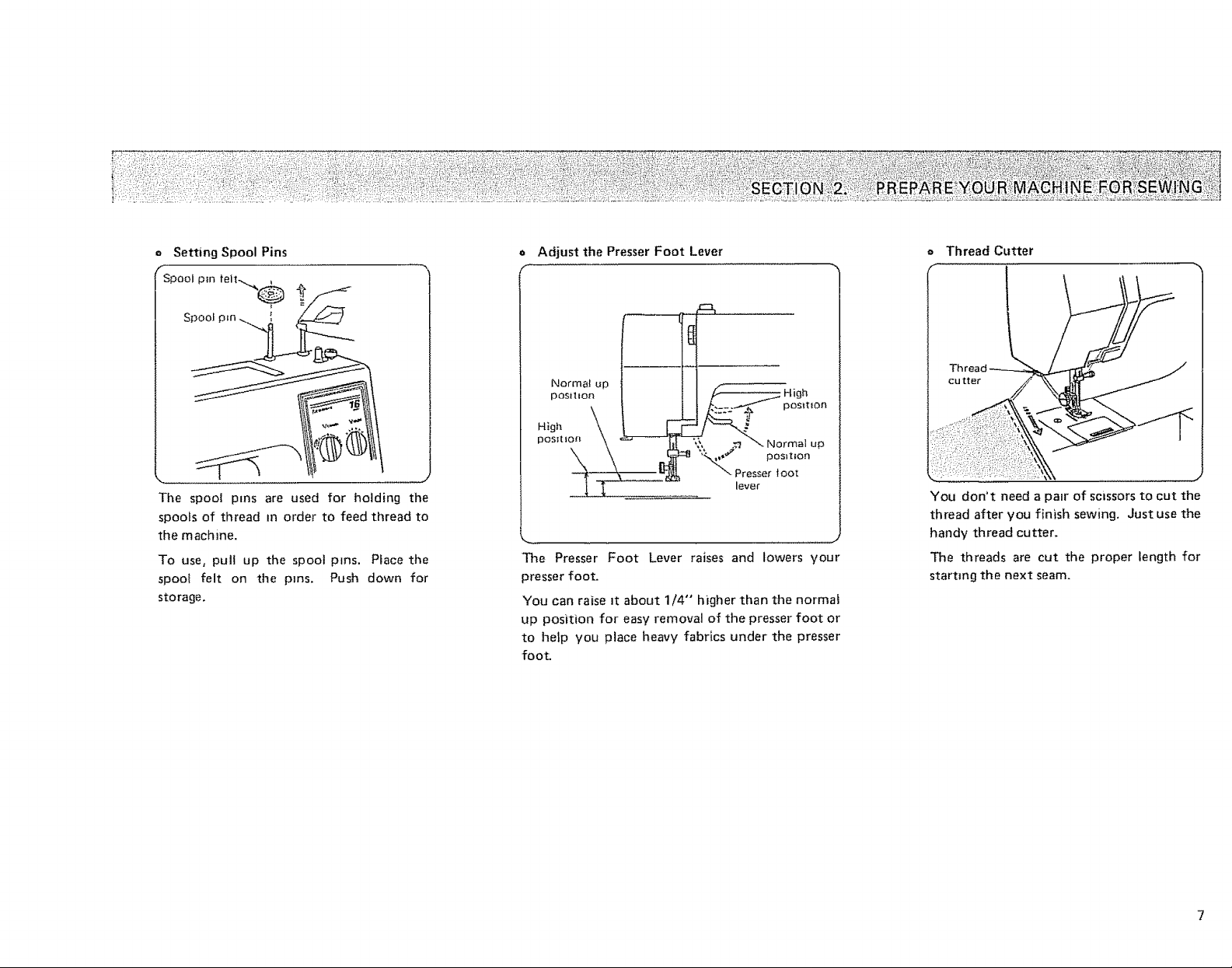

o Setting Spool Pins

Spool pln felt-_._O

Spool pin

o Adjust the Presser Foot Lever

f

= Thread Cutter

The spool pins are used for holding the

spools of thread in order to feed thread to

the machine.

To use, pull up the spool pros. Place the

spool felt on the pros. Push down for

storage.

Normal up _--

pos_llon l

Hi l,\i (

"'- Presser toot

The Presser Foot Lever raises and lowers your

presse r foot.

You can raise it about 1/4" higher than the normal

up position for easy removal of the presser foot or

to help you place heavy fabrics under the presser

foot

positron

lever

Tuh[rteeard

You don't need a pair of scissors to cut the

thread after you finish sewing. Just use the

handy thread cutter.

The threads are cut the proper length for

starttng the next seam.

7

= Accessory Storage Box

The lid of the accessory storage box lifts

open toward you,

Sewing accessories are conveniently located

m the box,

o Free-Arm Sewing: the Removable Extension Table

To remove:

To Remove the Extension TabLe

(for free-arm sewing)

1.

Grip the table with your index finger and thumb,

as shown.

2_

Pull gently toward you,

The extension table will snap out.

To Attach:

Extension table

Your sewing machine can do free arm sewing.

This feature makes sewing easy for:

J

Bar tacking to reinforce pockets, plackets

and waistlines on ready-made or home-

made garments to avoid fabric bunching

around the needle.

To Attach the Extension TabJe

(for flat-bed sewing)

t. Fit the tabs into the slot, as shown.

2. With your thumb and index finger, gently snap in.

8

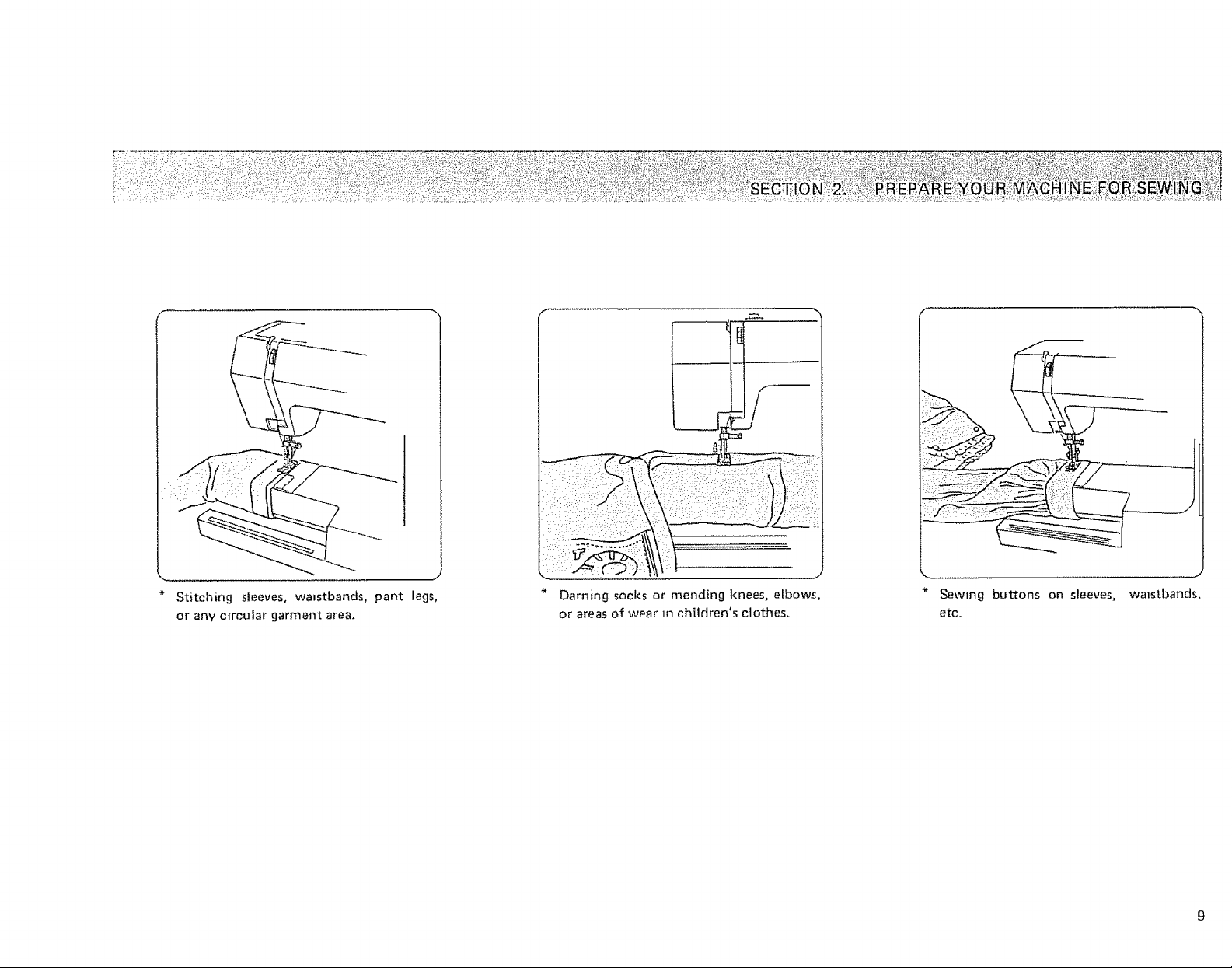

* Stitchingsleeves,wmstbands,pant

oranycirculargarmentarea.

_egs,

J

Darning socks or mending knees, e_bows,

or areas of wear in children's clothes.

* Sawing buttons on sleeves, waistbands,

etc.

__o : c:,:.::_::_:-i _:/ :::: ::=,,--:-:::::!_,:_:;:_>: ¸, .::_:-: :_ _ :_: :_:.

;i::iKnow What the Presser Feet Will Do

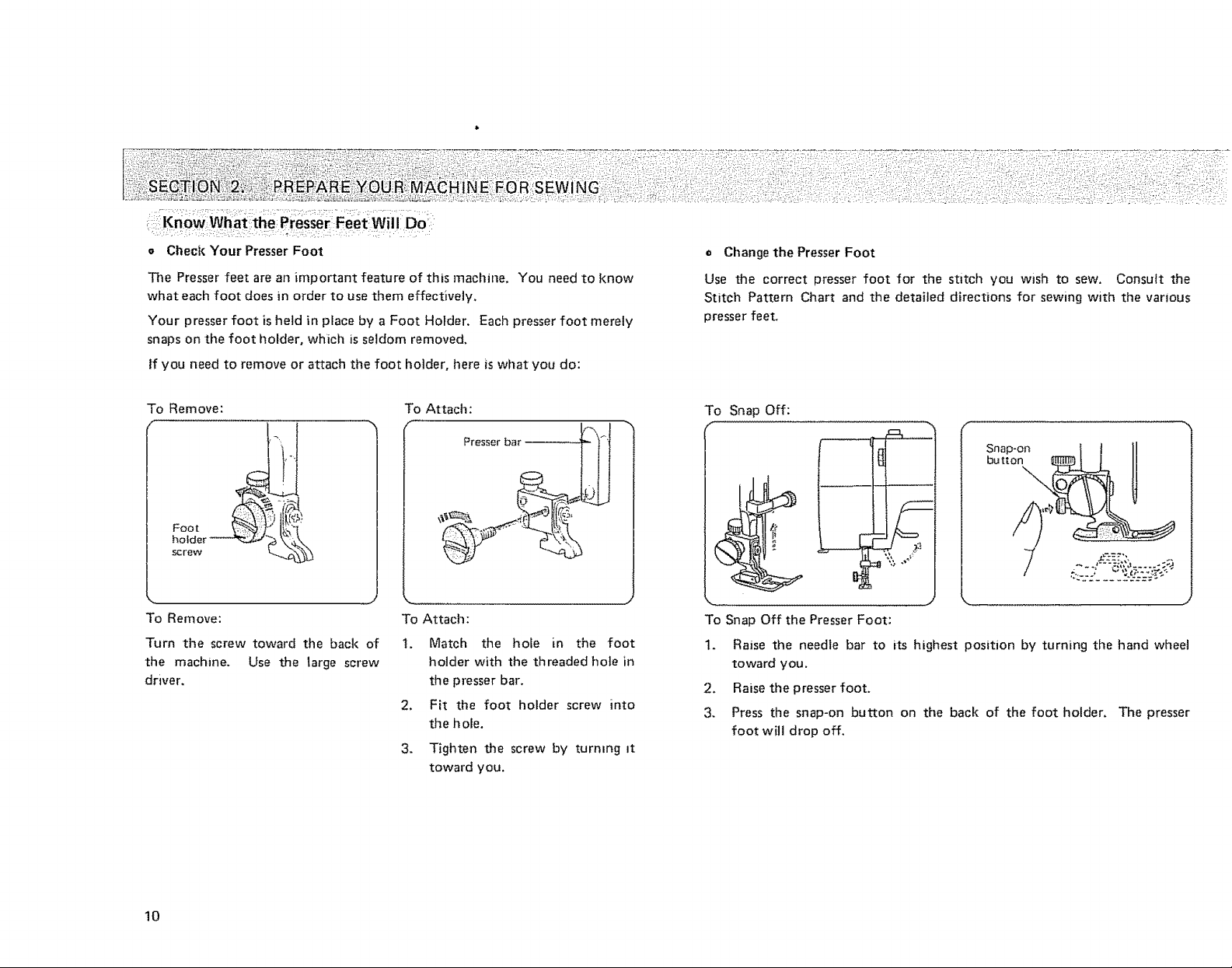

o Check Your Presser Foot

The Presser feet are an important feature of this machine, You need to know

what each foot does in order to use them effectively.

Your presser foot is held in place by a Foot Holder, Each presser foot merely

snaps on the foot holder, which is seldom removed.

tf you need to remove or attach the foot holder, here is what you do:

o Change the Presser Foot

Use the correct presser foot for the stitch you wish to sew. Consult the

Stitch Pattern Chart and the detailed directions for sewing with the various

presser feet.

To Remove:

holder

screw

To Remove:

Turn the screw toward the back of

the machine. Use the large screw

driver.

To Attach:

To Attach:

1. Match the hole in the foot

holder with the threaded hole in

the presser bar.

2. Fit the foot holder screw into

the hole.

3. Tighten the screw by turning it

toward you.

To Snap Off:

f

Snap-on

button

\

k__.

, J

To Snap Off the Presser Foot:

1. Raise the needle bar to its highest position by turning the hand wheel

toward you.

2, Raise the presser foot.

3. Press the snap-on button on the back of the foot holder. The presser

foot will drop off.

10

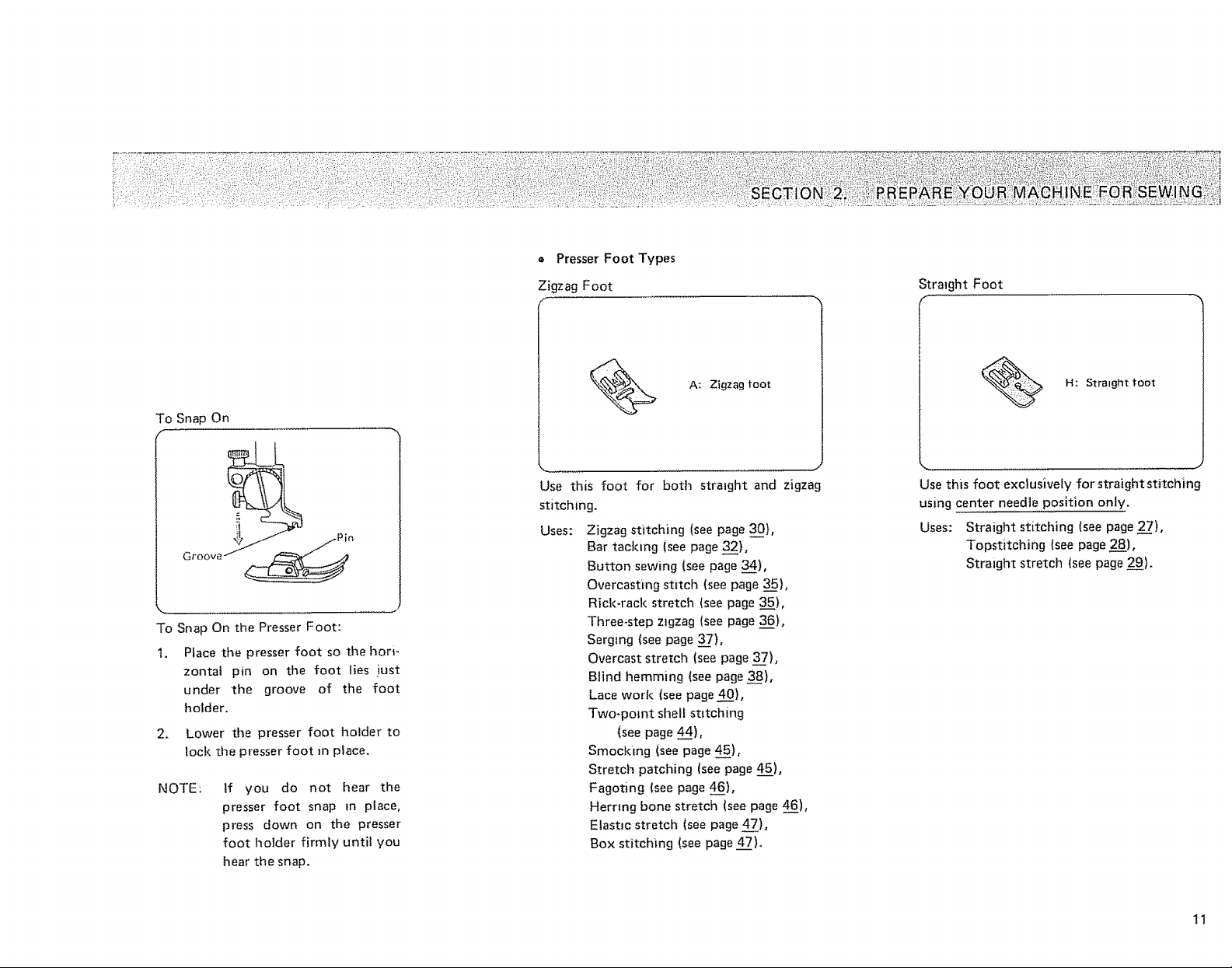

• Presser Foot Types

Zigzag Foot

Strmght Foot

f

To Snap On the Presser Foot:

t. Place the presser foot so the hori-

zontal pin on the foot lies iust

under the groove of the foot

holder,

2. Lower the presser foot holder to

lock the presser foot in place.

NOTE:

If you do not hear the

presser foot snap m place,

press down on the presser

foot holder firmly until you

hear the snap.

Use this foot for

stitching.

Uses:

Zigzag stitching (see page 3_0),

Bar tacking (see page 32),

Button sewing (see page 3_44),

Overcasting stitch (see page 3__5),

Rick-rack stretch (see page 35),

Three-step zigzag {see page 36),

Serging (see page 37),

Overcast stretch (see page 3__7),

Blind hemming (see page 38),

Lace work (see page 40),

Two-point shell stitching

(see page 44),

Smocking (see page 455),

Stretch patching (see page 45__),

Fagoting (see page 46),

Herring bone stretch (see page 4_6),

Elastic stretch (see page 47),

Box stitching (see page 47).

A: Zigzag toot

both straight and zigzag

H: Straight toot

Use this foot exclusively for straight stitching

using center needle position only.

Uses: Straight stitching (see page 2__7),

Topstitching {see page 2_88),

Straight stretch (see page 29).

11

_/:KnowWilatthe Preset Feet Will: Do (Continued)

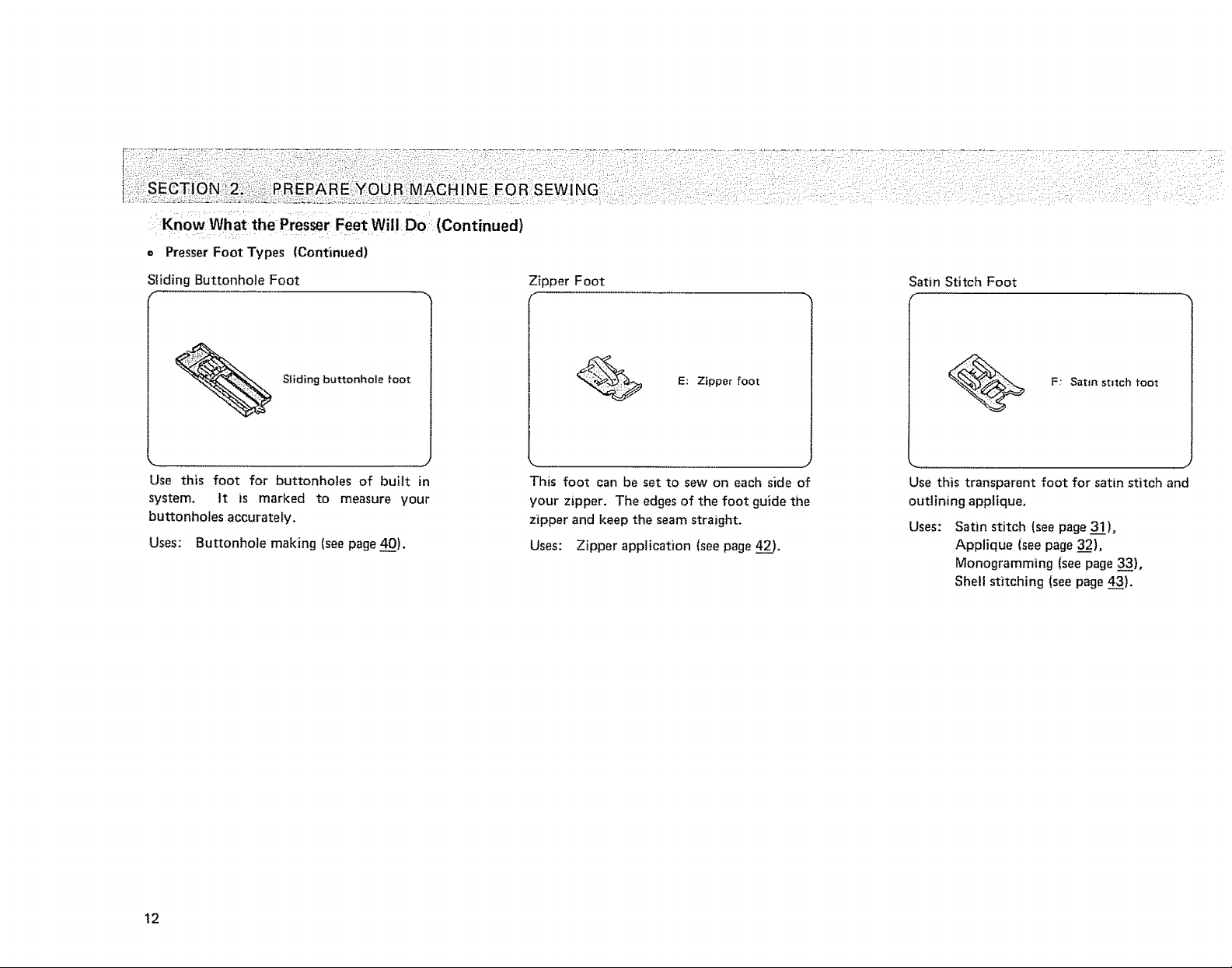

o Presser Foot Types (Continued)

i!ii¸ililiiii!i!i!il!iiiii!!iiiiiiiiiiiiii¸,¸iilillii!ilili!iiiiiiiii!

Sliding ButtonhoJe Foot

Sliding buttonhole toot

_ J

Use this foot for buttonholes of built in

system, It is marked to measure your

buttonholes accurately.

Uses: Buttonhole making (see page 40).

Zipper Foot

(-

E: Zipper foot

This foot can be set to sew on each side of

your zipper. The edges of the foot guide the

zipper and keep the seam straight.

Uses: Zipper application {see page 4_2_2),

Satin Stitch Foot

F: Satin stitch foot

Use this transparent foot for satin stitch and

outlining applique,

Usesz

Satin stitch (see page 31),

Applique (see page 32),

Monogramming (see page 33),

Shell stitching (see page 43).

12

_,_----dfm===_

,M--,

_t ......

Your choice of needle and thread depends on the fabric you are sewing.

In your needle case, you will find the following color-coded needles:

Blue {11) .......... for stretch fabrics

Orange {11) ..........

Red {14) ...........

Purple (16) .........

for lightweight fabrics

for medium or medium-heavy weight tabrics

for medium-heavy weight and decorative

topstitchmg on these fabrics

(This needle has a larger thread hole for

thicker topstltching thread,)

Green {18) .......... for heavy weight fabrics and decorative top-

stitching on these fabrics

o Check Your Needle

1, Look for barbed or blunt point.

2. A damaged needle can cause permanent snags or runs in knits, fine silks

and silk-Like fabrics.

Always buy a good quality thread. It should resist tangling and be strong,

smooth and consistent in thickness.

13

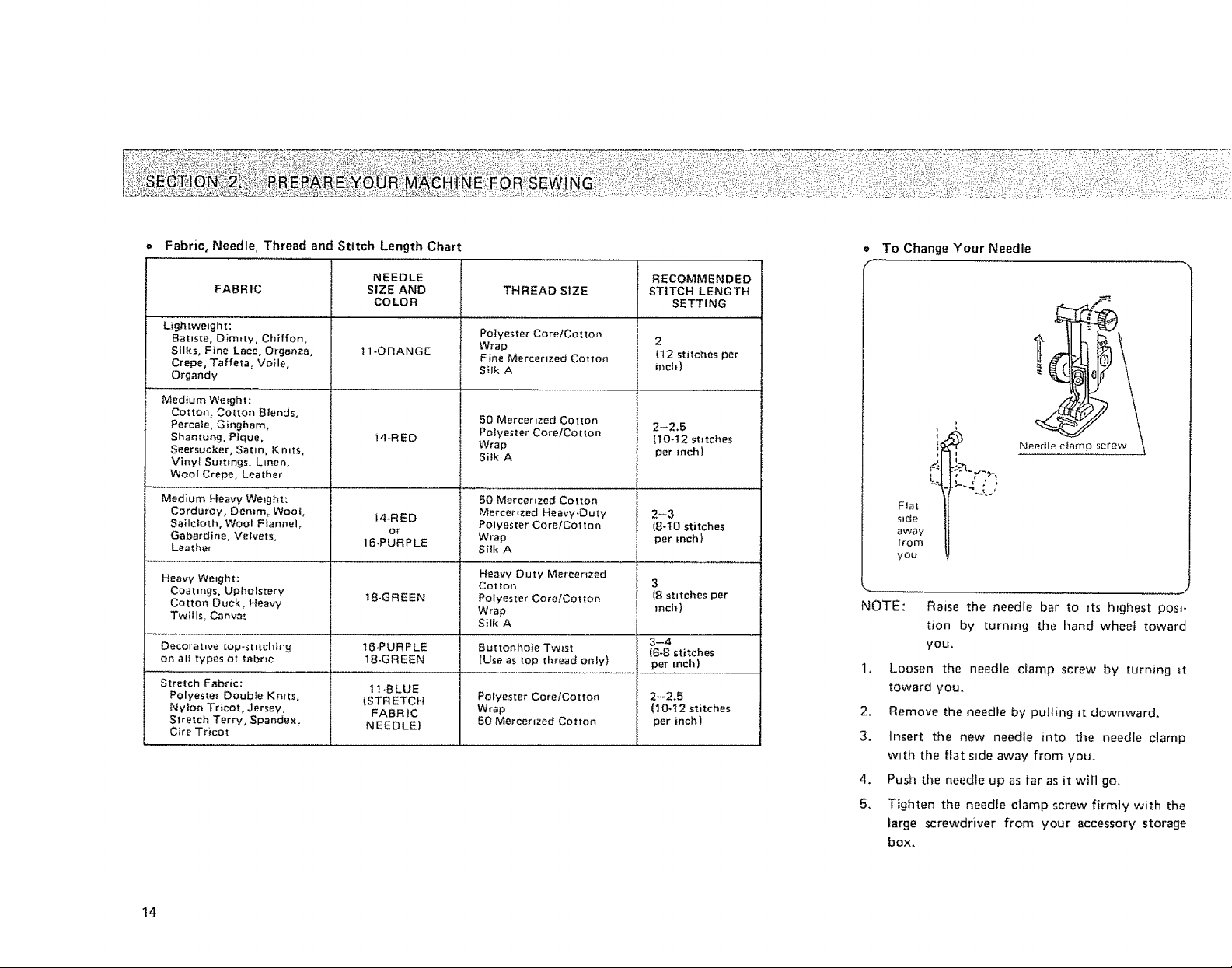

o Fabric, Needle, Thread and Stitch Length Chart

To Change Your Needle

FABRIC

Lightwmght:

Batiste0 Dimttyo Chiffon,

Silks, Fine Lace. Organza,

Crepe, Taffeta° Voile,

Organdy

Medium Weight:

Cotton, Cotton Blends,

Percate, Gingham,

Shantung, Pique,

Seersucker, Satin, Kmts.

Vinyl Su_tmgs= Lmen,

Wool Crepe, Leather

Medium Heavy Weight:

Corduroy, Demm_ Woot,

Sailcloth, Wool Flannel=

Gabardine, Velvets,

Lea ther

Heavy Weight:

Coatings, Upholstery

Cotton Ducks Heavy

Twills, Canvas

Decorat=ve top-stitching

on all types of fabr=c

Stretch Fabric:

Polyester Double Kmts,

Nyton Tricot, Jersey,

Stretch Terry, Spandex,

Cite Tricot

NEEDLE

SIZE AND

COLOR

11-ORANGE

14-RED

14-RED

or

16*PURPLE

18-GREEN

,6-PURPLE!

18-GREEN !

t t -B LUE

(STRETCH

FABRIC

NEEDLE)

THREAD SIZE

Polyester Core/Cotton

Wrap

Fine Mercerized Cotton

Silk A

50 Mercerized Cotton

Polyester Core/Cotton

Wrap

Silk A

50 Mercerized CottOn

Mercerized Heavy-Duty

Polyester Core/Cotton

Wrap

Silk A

Heavy Duty Mercerized

Cotton

Polyester Core/Cotton

Wrap

Silk A

Buttonhole Twist 3--4

[Use as top thread on_y) per inch)

Polyester Core/Cotton 2--2.5

Wrap (10-12 stitches

50 Mercerized Cotton per inch)

RECOMMENDED

STITCH LENGTH

SETTING

2

(12 stitches per

inch)

2--2.5

(10-12 stitches

per *rich )

2--3

(8-!0 stitches

per Lnch)

3

(8 stretches per

mch)

(6-8 stitches

Needle clamp screw

Flat

stale

away

from

you

NOTE :

Raise the needle bar to its highest posi-

tion by turning the hand wheel toward

you,

t. Loosen the needle cfamp screw by turning tt

toward you.

2. Remove the needle by pulling tt downward.

3. insert the new needle into the needle clamp

with the flat side away from you.

4. Push the needle up as tar as it will go.

5. Tighten the needle clamp screw firmly with the

large screwdriver from your accessory storage

box.

t4

Prepare the Bobbin

o To Remove the Bobbin from the Machine

o Wind the Bobbin

!. Gently push down on the bobbin cover plate and slide

it towards you.

2. Set aside.

3. Lift out the bobbin, as shown.

Bobbin winding spindle

Clutch

1. Put your spool of thread onto spool pin, with the thread winding in the direction

sh own.

2. Pull the clutch away from the machine to stop the needle from moving while you

wtnding the bobbin.

3o Draw thread from spool through bobbin winder tension disc as shown.

4. Place the threaded bobbin on the bobbin winding spindle so that the thread comes

out on top.

5. Push the bobbin winder spindle to the right until it elicks_

6. Holding onto end of thread, depress the foot control.

7. When the bobbin is slightly filled, stop the machine and clip the thread coming from

the bobbim

8. Slowly start the machine again and wind the thread until the bobbtn stops.

9. Push the bobbin wlnder spindle to the left and clip the thread.

10. Remove the bobbin.

11. Push in the clutch for normal sewing operation.

15

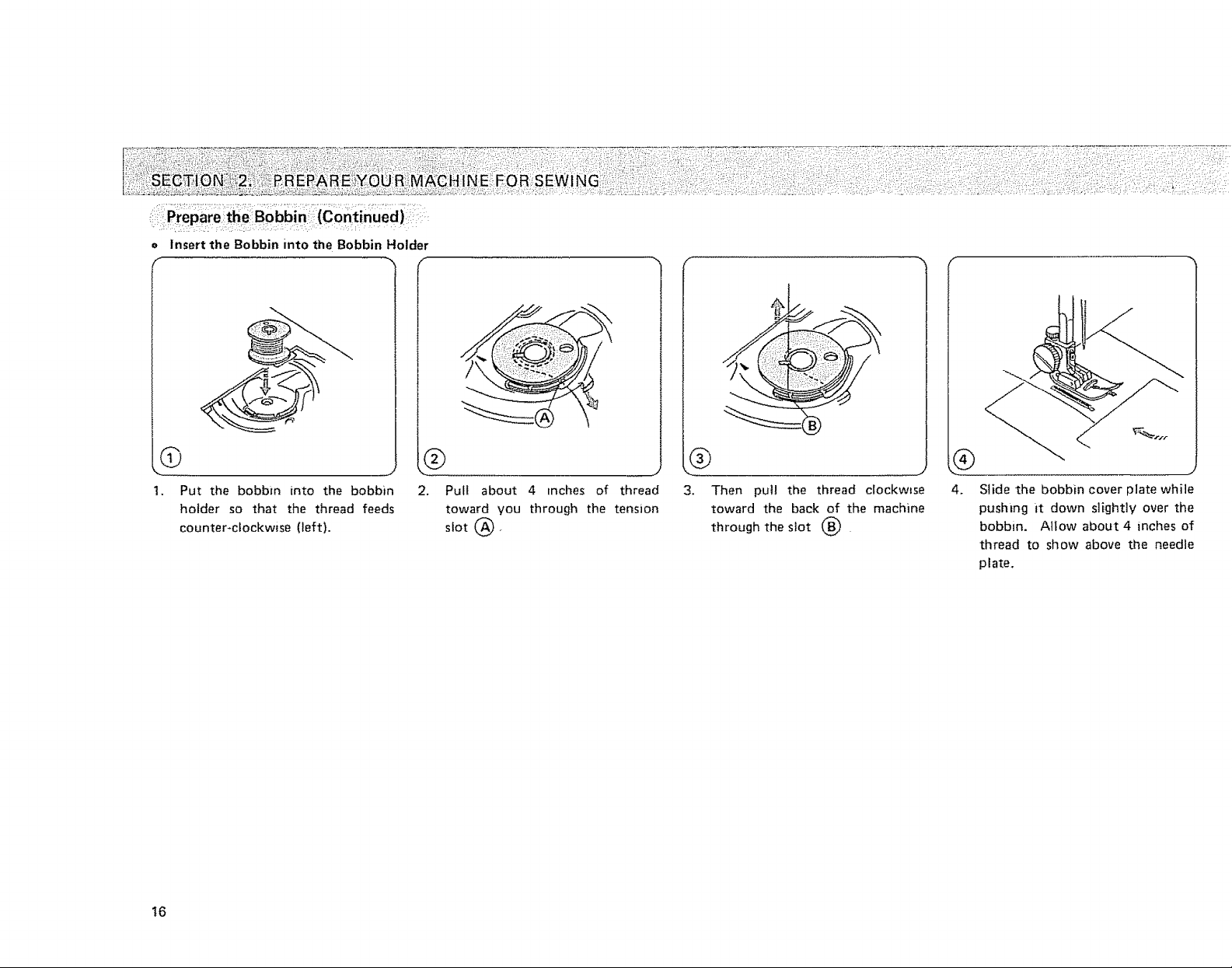

= Insert the Bobbin into the Bobbin Holder

f _ F

"x F

®

........................ J

1, Put the bobbin into the bobbin

holder so that the thread feeds

counter-cfockwJse (left).

16

®

2. Pu_l about 4 inches of thread

toward you through the tension

slot _.

®

3. Then pull the thread clockwise

toward the back of the machine

through the slot

4. Slide the bobbin cover plate while

pushing it down slightly over the

bobbin. Atlow about 4 inches of

thread to show above the needle

plate.

Loading...

Loading...